Page 1

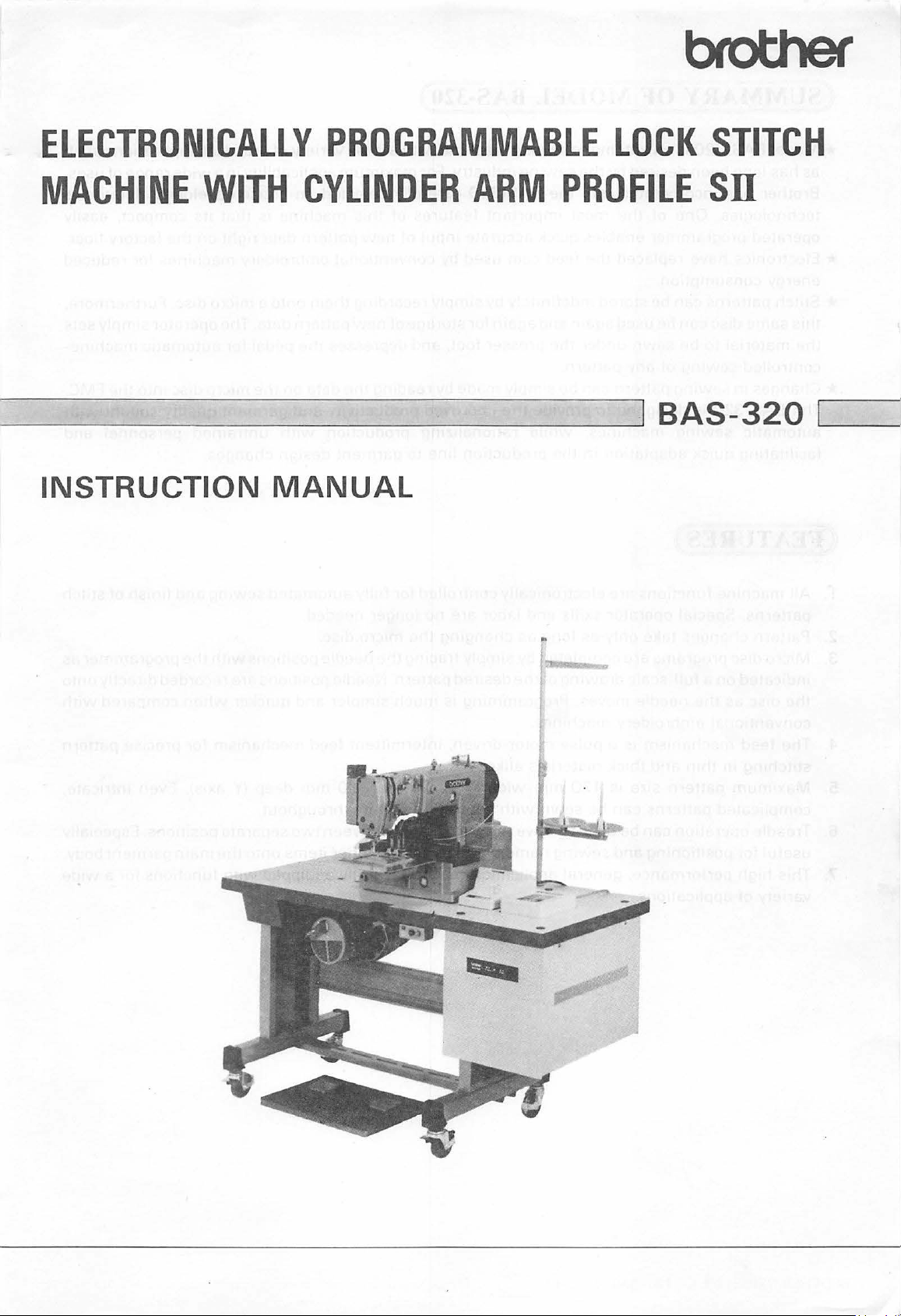

ELECTRONICALLY

PROGRAMMABLE

LOCK

STITCH

MACHINE

___________

INSTRUCTION

WITH

CYLINDER

MANUAL

ARM

PROFILE

____]

BAS-3201

Sll

.___

_

Page 2

(SU,MMARY OF MODEL ·BAS-320)

* Model

as

Brother has incorporated into

technologies. One of

operated programmer enables quick accurate input

* Electronics have replaced

energy consumption.

*Stitch

this

the

controlled sewing of any pattern.

* Changes in sewing pattern can be simply made by reading

The

automatic

facilitating quick adaptation

1.

2.

3.

4. The feed mechanism is a pulse motor-driven,

5.

6.

7. This high performance, general application machine is

BAS-320

has long been desired by

patterns can be stored indefinitely by simply recording them onto a micro disc. Furthermore,

same disc can

material to be sewn under

BAS-320

All

machine functions are electronically controlled for

patterns.

Pattern changes take only

Micro

indicated on a full-scale

the disc as

conventional embroidery machines.

stitching

Maximum

complicated patterns can be sewn

Treadle operation can be used

useful for positioning and sewing name tags, labels, and other items onto

variety

disc programs are completed by simply tracing

of

is an automatic

the

be

used again and again for storage

is designed to provide

sewing

Special operator skills and labor are no longer needed.

the

in

thin

pattern size is

applications.

machines,

drawing

needle moves. Programming is much simpler and quicker

and

thick

sewing

the

sewing industry. For maximum applicability

the

most important features

the

feed cam used by conventional embroidery machines for reduced

the

while

in

the production line to garment design changes.

as

long as changing the micro disc.

of

materials alike.

120

mm

to

move

machine

BAS-320

presser foot, and depresses

the

improved productivity and garment

rationalizing production

the

desired pattern. Needle positions are recorded directly onto

wide

with

consistent

the

with a wide

carefully selected, in-house developed electronics

of

of

new

of

the

intermittent

(X

asxis) and

quality

presser foot between

variety

this

machine is

pattern data right on

new

patte~n

the

the

data on

with

fully

automated sewing and finish

needle positions

feed mechanism

100

mm

throughout.

two

fully

equipped

of

practical applications such

ina

wide

range

that

its

compact, easily

the

data. The operator simply sets

pedal

for

automatic machine-

the

micro disc into

quality

untrained personnel and

with

the

programmer as

when

deep

(Y

separate positions. Especially

the

with

compared

for

precise pattern

axis). Even intricate,

main

garment

functions

of

uses,

factory floor.

the

FMC.

sought

with

of

stitch

with

body.

for a wide

Page 3

CONTENTS

(MAIN

PART

NAMES]

....................

(SPECIFICATIONS}. .....................

(INSTALLATION)....

ITl

Pos1t1on1ng

[I]

Installation

[}]Co

rd

connections

01ns

tallation

[I]

Machine

[]]Ins

tallati

(LUBRICATION

[I]

Lubrication

[I]

Oil

draining

{

CORRECT

[I]

Needle

[I]

Upper

[}]Bobbin

0 Bobbin case

[}]Th

read

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

of

spool stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

of

eye

head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

on

of

V-be!t

AND

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OPERATION}.

installation

thread thr

thread

tension

ead ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

winding

installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

.

................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

guard

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

OIL

DRAINING}........

..

..............................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

and

threading

.

.............................

.......................

.

.................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

... ....

.

..............

..

..

....

.

.....

......

.

.

2

3

. 3

(HOW

[I] Data

[I]

[}]Test swi

0 Emer

(

SEWING)

[I]

[I]

[}]Sewing

0 Rotary hook clea

TO

USE

switch

Step back swit

tch

gency stop switch use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

.........................

Mic

ro disc

Sewing

insertion

speed adjustme

.....................

(STANDARD

[I] Needle

[I]

Needle

[}]Need

0Shuttle

[I]

Shuttle

[]]Presser

II]

Movable

[!]

Presser

[I]

Thread

[!Q]

Needle and feed

[TI]

Origin

[ill2-Step

@]

Timing

bar

bar lift

le t o

shuttle hoo.k poi

driver

hook

plate

knife adju

foot adju

wiper adjustm

adjustment

presser

belt

THE

FMC]........................

use

.......

ch

use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ning

·. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

.

............................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

nt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.........

ADJUSTMENTS}_...................

height

tension adju

adju

stme

nt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stroke

needle

thread

lift

adju

stment.......

nt

gap

adjustment.......

contact

guide

stroke

stme

stmen

t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ent

timing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

foot

operation

adjustment......

adjustment

adju

stment

nt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.......

adjustment

stment

....

adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.....

............

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

......

: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

..

.......................

.

.. ..

....

.....................

.......

..

...........................

....

. . .

.................

...............................

.........

....

.................

.........

........

. .

....... 1.3

7

10

10

10

11

11

12

12

12

12

13

13

14

15

15

16

16

18

(

OPERATION

FLOW

CHART).

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

Page 4

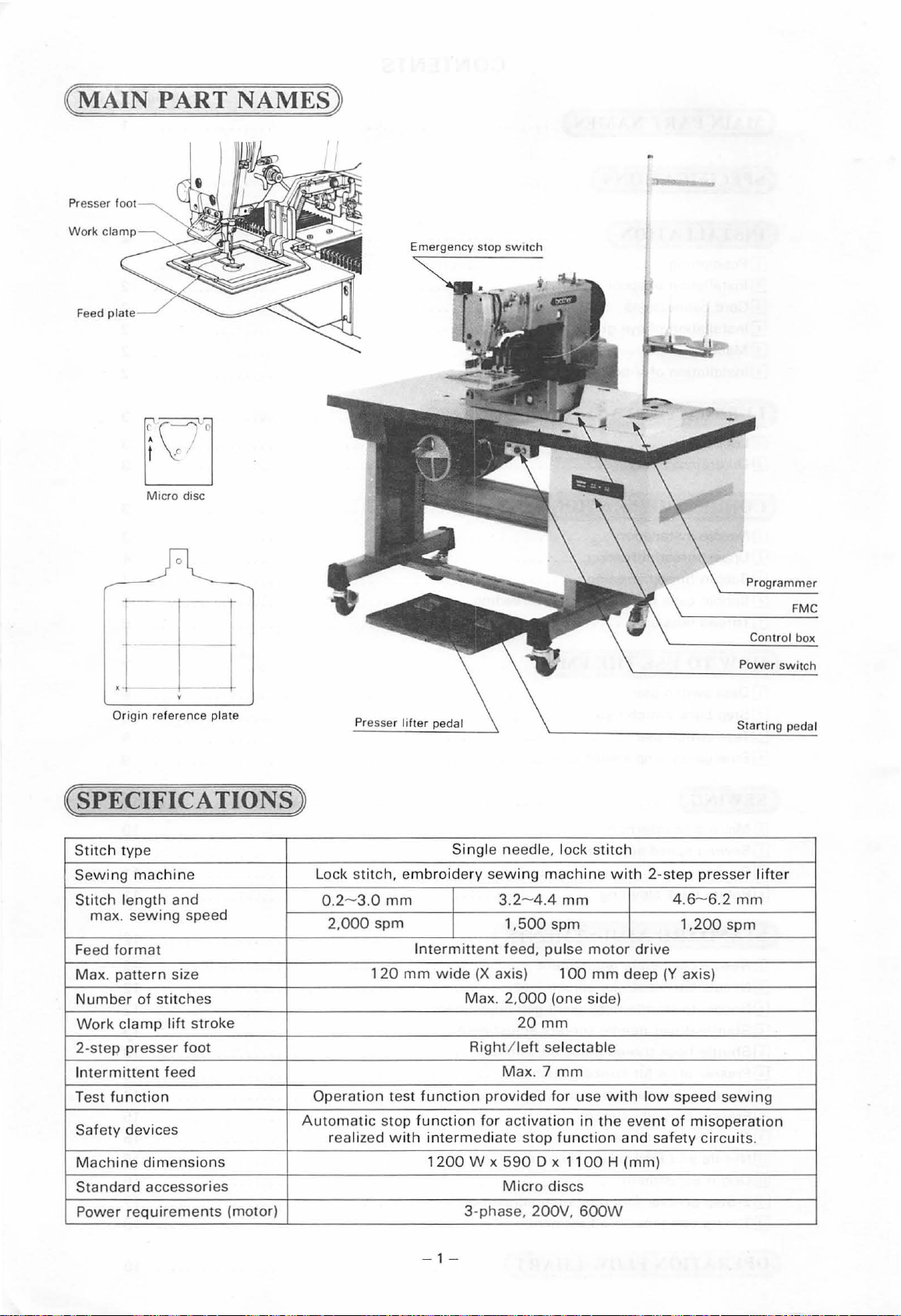

( MAIN PART NAMES)

Presser foot

Work

cia

Feed pia

Micro disc

Emergency stop

switch

r--

_l

[

_j_

Origin

reference plate

(SPECIFICATIONS)

Stitch

type

Sewing mac

Stitch

max. sew

format

Feed

Max.

pattern

Numb

Work

2-step presser

ntermittent

I

Test

function

Safety

Machine dimen

Standard

Power

hin

e

length

er of

clamp

and

ing speed

size

sti

tches

lift

stroke

foot

feed

devices

sion s

accessories

requirements

Automat

(motor)

sti

Lock

0.2-3.0

Operation

tch,

2,000

120

ic stop

realized

embroidery

mm

spm

Int

mm

test

function

with

Sing le

sew

ermittent

wide

(X

Max. 2,000

Right /

function

intermediate

1200

prov

for activation

W x

3-

phase

need

le, lock

ing

machine with 2-s

3.2-

4.4

mm

1,

500

spm

feed,

pulse

axis)

Max

590

Micro

100

(one side)

20

mm

left

selectable

. 7

mm

ided for

stop

function

D x 1100 H (mm)

discs

, 200V,

stitch

motor

mm

use

in

the

600W

deep

with

and

drive

low

event

safety

tep

4

.6-6.2

1,200

(Y

axis)

speed

of

misoperati

Programmer

Power

Starting

presser l

mm

spm

sewing

circuits.

FMC

Control box

switch

pedal

ifter

on

-1-

Page 5

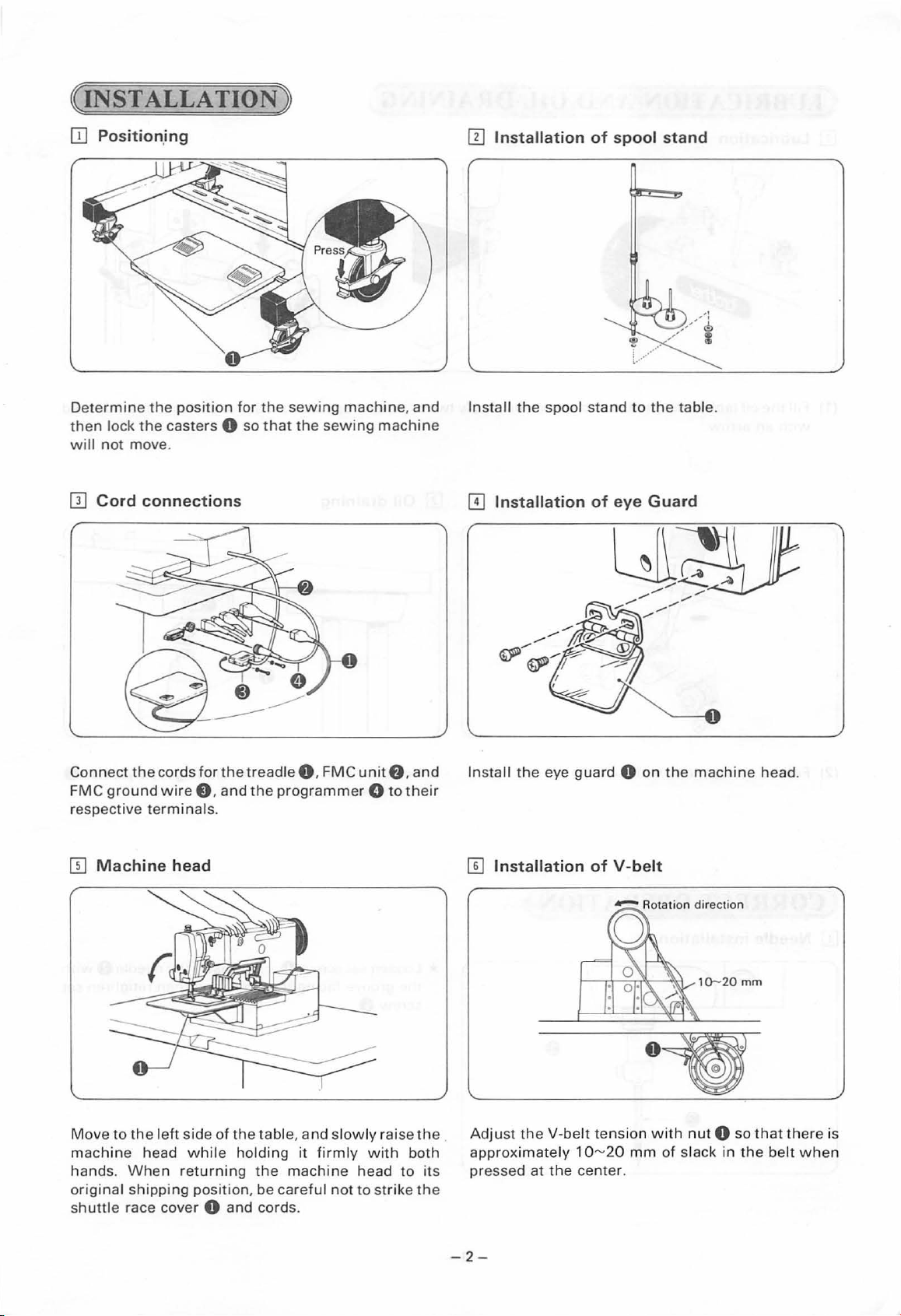

(INSTALLATION)

[I]

Position.ing

llJ

Installation

of

spool

stand

Determine

then

lock

will

not

move.

[1]

Cord

Connect

FMC

ground

respective

the

position

the

casters 0

connections

the

cords

for

wire

8,

terminals

the

and

.

for

the

sewing

so

that

the

treadle

the

0,

programmer 0 to

machine, and

sewing

FMC

machine

unit

f),

and

their

Install

[I]

Install

the

Installation

the

spool

stand

eye

guard 0 on

of

to

eye

the

table.

Guard

the

machine

head

.

IT]

Machine

Move

to

machine

hands. When

original

shuttle

race cover 0

head

the

left

head

shipping

side

of

the

while

returning

position,

and

tab

holding

the

be

careful

cords.

le,

and slowly

it

firm

machine

not

ly

head

to

raise

with

strike

both

to

the

its

the

[I]

Installation

Adjust

.

approximately 1

pressed

the

V-belt

at

the

-2-

of

V-belt

tension with

0"-'20

mm

cente

r.

of

1D--20

nut

slack

mm

0 so

in

the belt

that

there

whe

is

n

Page 6

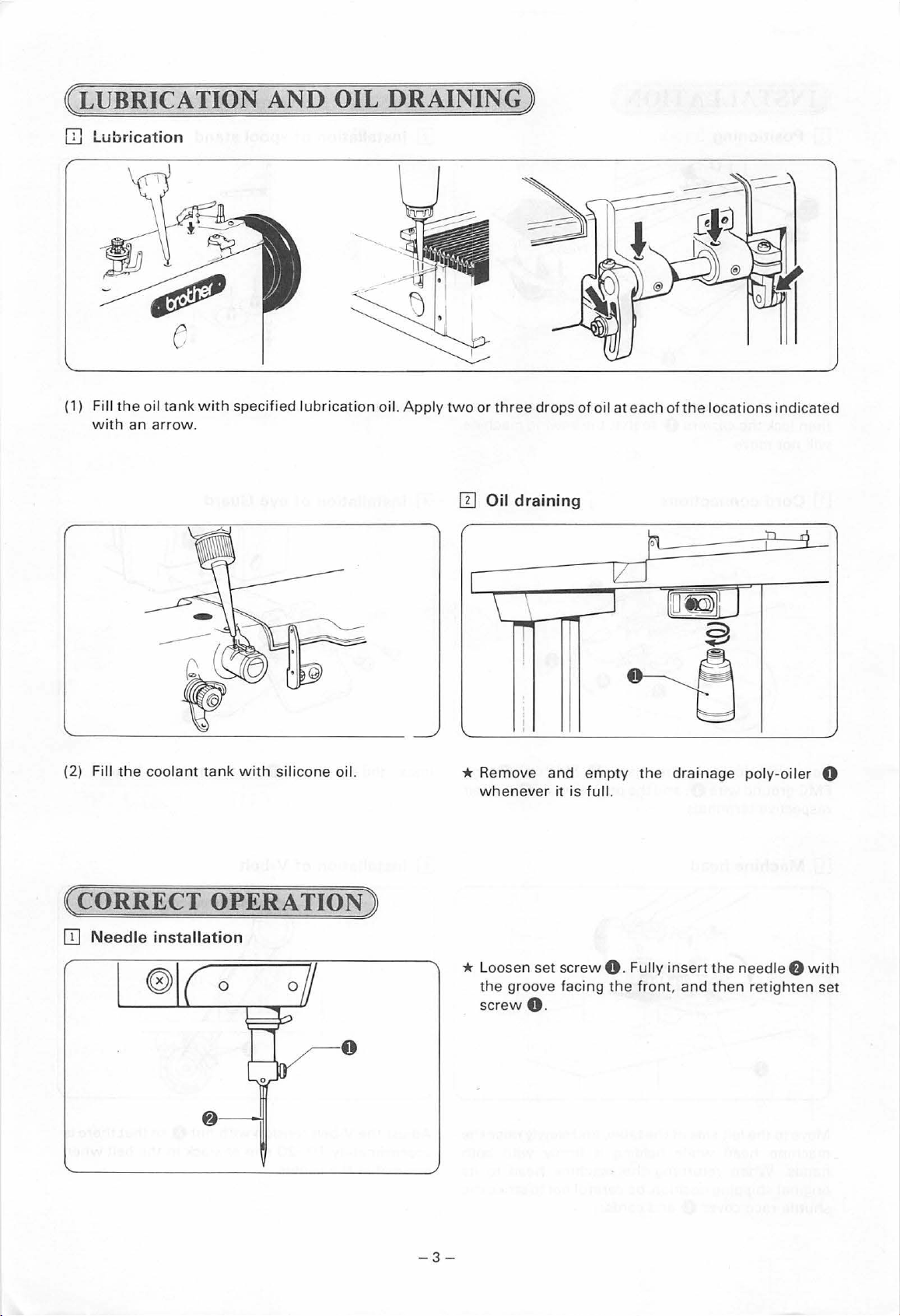

( LUBRICATION

IIl Lubrication

AND

OIL

DRAINING)

(1) Fill

with

Fi

(2)

ll

the

an

the

oil

tank

arrow

coolant

with

specified

.

tank

with silicone oil.

lubrication

oil.

Apply

two or

three

[I]

Oil draining

r

\ \

*

Remov

whenever

drops

rr

I

I

I

e and

it

of

empty

is

full.

oil

_j

at

each o

fthe

~

lL_j

l[L@J

0

~

the

drainage poly-oile

locations

t J

~

indicated

'rl

M

r 0

( CORRECT OPERATION)

OJ

Needle

installation

* Loo

sen

set sc

the

groov

e facing the

s

cr

ew O.

-

3-

rew

0 . Fully i

front

ns

ert the need

, and then retighten set

le

f)

wit

h

Page 7

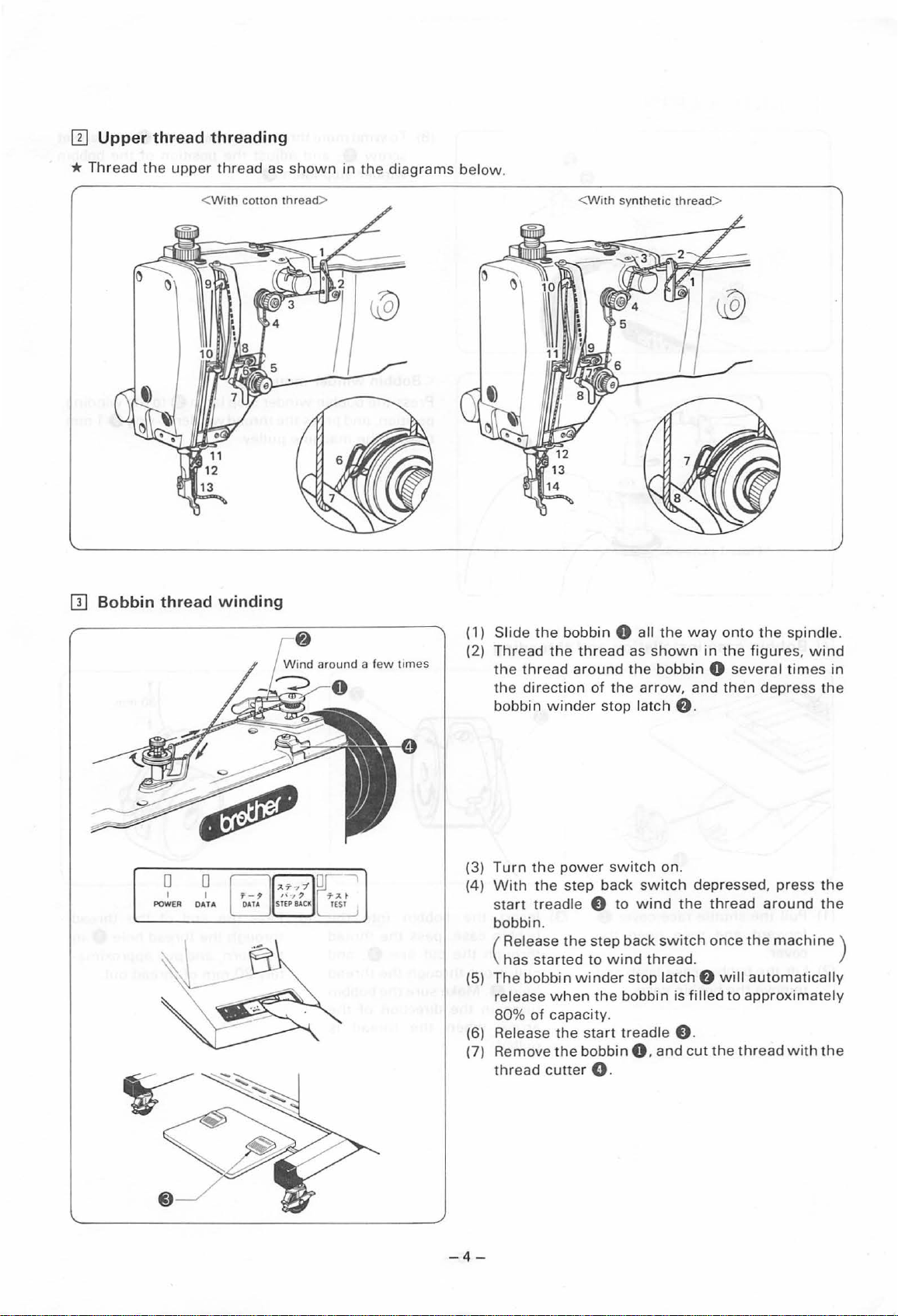

ITl

*

Thread

Upper

thread threading

the

upper

thread

<

With

cotton

as

thread>

shown

in

the

diagrams

below

.

<With

syn th

etic

thread

>

[}]

Bobbin thread

0

I

POWER

winding

(1)

Sl

ide

the

(2)

Thread

the

thread

the

direction

bobbin winder

(3)

Turn the

(4)

With

the

s

tart

tr

bobbin.

Release

(

has

started

(5)

The

bobbin

release

80%

of

(6) Release

(7)

Remove

thread

bobbin

the

thread

around

of

pow

er swit

step

ea dle e

the

step

to

winder

when

the

capacity.

the

start

the

bobbin

cutte

r 0 .

0 all

the

as

shown

the

bobbin

the

arrow

stop l

atch

f).

ch

on.

back switch

to

wind

back

switch

wind

thread.

stop l

atch

bobbin

treadle

0 .

is filled

8.

and

way

onto

the

in

the

figure

0 several

, and

then

depress

depressed, press

the

f)

cut

thread

once

the

around

the

machine

will

automatica

to

approximately

thread

spindle.

s,

wind

times

in

the

the

the

lly

with

the

)

-4

-

Page 8

(8) To

wind

screw

winder

<

Bobbin

Press

the bobbin

position,

towa

rd

more

0.

stop latch

winder

and

the

mach

thr

ead

and

adjust

mounting

winder

press the

ine pulley.

onto

the

f)

.

stop

thread

the

position

>

latch

winder

bobbin

f)

to

0-ring

0,

of

the

loosen

the

bobbin

winding

G 1

set

mm

[I]

Bobbin

(1) Pull

forward and

cover.

(2)

Lift

the

remove

case

installation

the shuttle

bobbin case latch

the

race cover 0

then

bobbin

open

case.

and

the

and

threading

In

sert

(3)

bobbin

through

pull

hol

e 0 .

turns in

arrow

pulled

the

case, pass

the

it

out

through

Make sure

the

when the

.

bobbin

cut line

direct

into the

the

thr

f)

,

the

thread

the

bobbin

ion

of

thread

ead

and

the

is

(4) Pass

through the

the

tely

the

horn,

30

mm

end

thread

and

of

of the

pull

approxima-

thr

ead

thread

hole 0 in

out.

- 5 -

Page 9

IT]

Thread

1.

Bobbin

tension

thread

tension

* The bobbin thread

that

the

bobbin

when

the

adjustment

will

suspended by

screw

tension

not descend

should be adjusted so

the

bobbin thread. Turn

0 to adjust.

of

its

own

weight

2.

Upper

Turn

upper

Adjust

th~ead

thread

the

thread

thread

thread tension control

remainder is between

tension

tension

tension to

control

the

nut

f)

to

material being sewn.

nut

0 so

30

to

40

mm.

adjust

that

the

the

3. Thread

To

adjust

loosen set

unit.

Also, slide

stitch.

5.

Upper

take-up

the

height

screw

the

thread

spring

of

the

8 and

adjustment

tension

turn

release

height

thread take-up spring,

the

entire

adjustment

unit

in

or

out

so

that

timing

4.

Thread

Adjust

the

the

tension disc opens approximately

Loosen set

upper thread

tension on the upper thread is released

thread take-up lever 0 is completely

end

take-up

the

thread take-up spring tension by

tension stud 0

screw

tension

of

a stitch.

spring

with

0 and adjust the position

tension

a screwdriver.

1.5

mm

after

release lever 8 so

lowered

turning

the

ot'the

that

when

at

final

the

the

the

-6-

Page 10

DATA LAMP

Press the data switch and

the data lamp

nate, and data

in. When the operation is

completed, the lamp

go out.

The lamp

twice

when

on to the micro disc.

POWER

Illuminates

wer

switch is turned on.

DATA

SWITCH

Initiates storage

a micro disc or reading out

of data from a micro disc.

will

will

will

illuminate

data is stored

LAMP

when

of

illumi-

be

read

will

the po-

data on

EJECT

LEVER

Press

this

lever

to

micro disc in or

TEST

LAMP

Illuminates when the test switch is turned

on.

TEST

SWITCH

Press this switch to confirm program

contents. The machine

stitch increments when the treadle is

depressed after this switch is turned on.

• Speed

STEP

The machine

is depressed when the step back switch is

pressed.

(This function is used to confirm the direction

of machine pulley rotation,

bobbin, or

position.)

foot

will

lifter

BACK

to

open the lid. Slide the

out

gently. ·

will

increase when

pedal' is pressed.

SWITCH

will

run

while

return

to

the machine stop

move in single

the

presser

the start treadle

to

wind

the

*A

previously programmed pattern can be moved vertically

r-----------,

I I

CD

I : ®

+-nl

I I

I I

._

___________

I I

ln....:

""'"?""'

J

Note:

Be

sure to stop the machine quickly

checking the direction of pulley

switch

depressed, and

Make

sure

illuminated,

(1) Hold

the

lamps have

when

rotation.

or

horizontally.

the

test

data

switch.

switches.

CD

Press.the data

one pulse (0.2

@ Press

one

pulse (0.2

® Press

the

data

(0.2 mm)

@)

Press

step back

(0.2 mm)

Press

the

mode once

the

the

the

test

the

switch

mm)

step

switch

mm)

step back

switch

to

the

data

switch

switch

to

the

switch

twice

to

twice

to

switch

to

move

back.

to

move

forward.

to

cancel

pattern has been moved to

location as described above.

both

and

then

to

move

the

left.

to

move

the

right.

once, and

the

pattern

once, and

the

pattern one pulse

the

then

the

test

release

the

the

then

then

pattern

the

press

and

pattern

pattern

press

one

pulse

press

transfer

desired

data

the

the

Page 11

OJ

[I]

Data

Step

switch

0

I

POWER

back

use

Data lamp

svVitch use

*This

(1)

(2) Press

switch

on a micro disc

programmed pattern data

Insert a micro disc on

been recorded

illuminate

being read out. The data

when

is being stored onto a disc. The emergency stop

lamp

will

data cannot be read

is used

the

data switch. The data lamp

to

data is being read out, and

illuminate

to

into

into

the FMC.

indicate

if

read pattern data recorded

the

machine, or

onto a micro

which

stitch pattern data has

that

stitch pattern data is

lamp

will

the

disc has bad sectors and

or

stored.

disc.

illuminate

twice

when

to

store

will

once

data

0 0

I I

POWER

DATA

* This switch is used

at a time

resewing in

bobbin thread runs

switch

broke

large patterns.

(1) Press

machine is running.

the emergency

(2) Press

The emergency stop

(3) Press

reverse one stitch at a

switch

(4)

When

position,

presser foot is stopped too soon, simply press

step back

foot movement.

(5) The machine

treadle 0 is pressed.

* Turn

0

forward. The presser foot

stitch

time.

in

to

or

ran out. This is especially useful

the

the

the

is depressed.

the

release the step back switch. If

switch

the

test

to

move

units

the

return

emergency stop

emergency stop

step back switch. The presser foot

presser foot has returned

the

ifthe

to

move

reverse

the

stop·lamp

will

switch

presser foot one

sewing

event

the

out

to

the point

All

lamp

time

again

to

start

on and press

step back

in

operations

sewing

the

machine one stitch

direction

thread breaks or

mid-pattern. Use

where

switch 0 while

will

will

illuminate.

switch

will

as long as

resume reverse presser

switch

0 once again.

go out.

when

the

stitch

will

advance in

is pressed at

the

to

to

enable

the

this

the

thread

with

the

stop and

will

step back

the

desired

the

the

the

start

start treadle

at a

time

·1

00

this

-8-

Page 12

[I]

Test

switch

use

D D

I I

POWDI

DATA

*This

(1)

(2) Press

(3) Press

(4) Press the test switch. The test lamp

(5) Press

(6)

(7) Press

* The presser foot

switch is used to recommence sewing from

the

any position in

breaks or

pattern.

Press

machine is running. All operations

the

emergency stop lamp

The emergency stop lamp

automatically

move

stitch at a

lifter

When

position, press

foot

will

presser foot was stopped too soon, simply press

the

test

advancing again.

the step back

switch

the

test

will

foot

step back

increas

the

the

emergency stop switch 0

the

emergency stop switch 0 once again.

the

start treadle

the

start treadle

but

the presser foot

time

pedal 8

the

presser foot has reached

stop, and

switch

the

start treadle 8

is on. If

switch

reverse one stitch at a

switch

if

the presser foot

pattern in

bobbin thread runs

return

to

f).

at

low

speed. Press

to

increase

the

test

the

test lamp

again;

switch

the

the

will

advance in

step back switch is pressed after

has been

is depressed. The speed

the

event

out

will

will

illuminate.

will

go out.

f).

The presser foot

the

sewing start position.

will

illuminate.

The

work

clamp

will

begin advancing one

the

presser foot

the

speed.

the

switch

is pressed

again. The presser

will

go out. If

presseer foot

to

begin sewing again.

100

stitch

while

turned

lifter

off,

time

as long

pedal8

the

is pressed.

th·e

while

thread

in

mid-

the

stop and

will

will

not

desired

the

will

start

units

the

test

presser

as

the

will

if

[I)

Emergency

(Also serves

(2)

If

the

emergency stop

All machine functions

again

to

(3) Abnormal machine operation

The emergency stop

emergency lamp

oper~tion.

stop

switch

__

____,

as

lamp)

cancel

the

emergency stop mode.

will

The emergency stop mode

use

switch

will

stop and

function

illuminate

* The machine

pressed

(1

) If

the

during

All machine functions

gency stop

problem has been solved, press

switch

stop

operate,

cancelled, and

* Neither treadle

stop lamp is on.

0 is turned

will

if

an abnormal load is applied or a malfucntion is detected during machine

ON

during test switct) operation

the

emergency lamp

automatically engage, all machine operations

will

be cancelled

will

go on. Press

when

the emergency stop

will

stop immediately

while

sewing or test

emergency stop

sewing.

switch

lamp

0 again;

the

emergency stop

the

lamp

will

work

the

if

this

switch

switch

will

stop, and

will

the

thread cutter

will

go out.

while

emergency stop

will

switch

operation.

0 is

go on. Once

the

function

the

stop, and

is pressed.

turned

the

emergency

emergency

switch

switch

emer-

will

will

the

is

ON

the

be

0

-9-

Page 13

( SEWING)

ITl

Micro

disc

insertion

Press the lever

¢

Turn

the p

ower on

(1) Two patterns. one per side, can be recorded

Ea

Note: Micr

IT]

Sewing

ch patte

rn

can

o discs

producing

Also

be

speed

(

t

;J~

POWER

be

up

shou

a magne

carefu

l of

adjustment

~~

SPEED

<®

to

a max

imum

ld be stored

tic

field. Magnetic

dust

, oil,

4 I 6

' .

,.

2 0 8

,.

....

0

10

L...--

2000

away

from

and

other foreign

0

Slide the micro disc in ge

w ith t

he

on

each

mic

stitches

fields may

.

magnets,

radios, televis

erase or

matter

(1)

Turn

se

(2)

Sewing

for

Stitch length

(mm)

Sewi

(spm)

indents facing f

ro

disc

.

damage di

.

the

stepless speed

wing

speed .

speeds

different stit

ng speed

ntl

y

orwa

rd

ion

s, and

sc conte

vary

as

show

ch len

gths

0.2- 3.0 3.

850- 2,000

Close

the

other

electronic products

nts

.

cont

rol 0

to

n in the

.

2-4.4

550-

1,500 400- 1,200

lid.

any

des

below

4.6- 6.2

ired

table

*

Before

Sewing

0 0

I I

POWER DATA

(1)

(2)

With

the

step back

f)

a

nd start

Th

e mac

released,

desc

end

presser

swi

bar

lifter

tch depressed, press

sewing.

hine wi

and

ll s

the

top

when

presser

.

plate

the

foot

0 raised,

the

start trea

start

treadle

lift

er plate 0

hold

f)

the

dle

is

will

- 10 -

Page 14

[}]

Sewing

Data lamp

(1) Turn

(2)

(3) Press the data switch. The data

(4) Press

(5) Press

(6) Press

the

power on.

Insert a micro disc.

illuminate, data

will

go

out

the

work

clamp, insert material under

and

then

press

lower

the

the

will

return

start position.

the

machine

will

will

be read in, and

when

completed.

presser foot

the

presser foot

work

clamp.

start treadle

to

the

origin, and move

start treadle 0 once again, and

begin sewing.

the

lifter

treadle 8

the

lifter

0.

The feed mechanism

to

lamp

data lamp

to

raise

work

clamp,

treadle 8

the

sewing

will

the

to

the

[I]

Rotary

Open

remove

the

the

shuttle

hook

cleaning

race cover, and

bobbin case.

Slide

the

shuttle

0

in

the

direction

to

open the

and then remove the

race body 8 and

race body latch

of

shuttle

race body,

shuttle

••

the

shuttle

arrow

body

Use a screwdriver 8

ly pointed object

thread or other foreign matter

from

the

rotary hook thread

guide and

drop

cleaning is completed.

of

shuttle

oil

to

or

to

remove any

race.

the

race

similar-

Apply

when

a

-11-

Page 15

(

STANDARD

*

Turn

the

machine

[I]

Needle

Turn

the

needle bar so

needle

*

Align

II]

Needle

bar

height

pulley

to

that

bar

bushing

the

second reference

bar

lift

ADJUSTMENTS)

pulley

comp

reference line@.

0.

stroke

by

hand when

adjustment

lete

ly lower

line,@,

adjustment

the

needle

the top

with

making

reference line

the

any

bar. Remove cap

bottom

adjustments

f),

loose n

on

the

needle bar, is a

of

the

needle

bar

set

busing

screwO. and

lign

ed

with

when

using

vertically adju

the

bottom

needle

DP x 17

st

of

the

the

.

Turn

top,

the

* A

(I]

the

pulley

with

the

shuttle

lign

the

Needle

to

bottom

hook

bottom

to

shuttle

raise

of

point

reference

----;t---0

the

need le bar

the

needle

is ali

hook

-----

bar

gned

with the needle

line,@, with

point

.01-0.08

from

the

bushing

the

gap

adjustment

mm

'0

0.

needle

Now

center

bottom

lowest

, loosen A llen sc

of

.

the

position

need le bar

and

rew

bushing

align

reference line®.

f)

and

turn

when

the

using

shuttle

needle

second fr

driver

so

DP x 17

om

that

.

Turn

the pulley

connecting

link

and

stud

align

f)

the

to

shuttle

adjust

the

hook

needle

point

to

with

needle

shuttle

-12

hook ·

-

center

point

. Loosen set

gap

screw

to

0.01-D.OB

0 and

mm

.

turn

the

ecce

ntric

Page 16

0

Shuttle

Turn

the

pulley

connecting

will

result

point

will

II]

Shuttle

driver needle

and

align

link

stud

f)

in

skipped

interrupt

hook

stitches.

the

thread

contact

the

rotary

so

that

needle,

guide

hook

the

needle

Also,

if

resulting

adjustment

adjustment

point

with

meets

the

needle

in

abnormal abrasion

the

needle center. Loosen set

the

shuttle

does

not

driver.

sufficient

.

Note

ly

that

contact

screw 0 and

excessive

the

shuttle

needle

driver,

turn

the

to

driver cont

the

eccen

rotary

tric

act

hook

[I]

Presser plate

lift

stroke

adjustment

Adjust

thread guide

width, slide

retighten

so

that

the

the needle

0 is

at

the

thread

screws.

groove

the

middle of

guide light

of

the shutt

the

nee dle zigzag

ly

in, and

le

hook

then

The

presser

machine

presser

presser

plate l

ift

stroke

is stopped. To adjsut, l

arm

stoppe

plate lift

r

f)

stroke,

so

increase

is a

maximum

ower the

that the

presser

the

presser

20

work

plate 0 to

mm

from the needle plate

cia mp,

loosen

pre

plate 0 to

set

sser arm

presser

screw

arm

8,

stoppe

stopper

-13-

top

and

to

presser plate

vert

ically

r

f)

gap is 1

f)

gap.

bottom

adjust the

mm.

To decrea se

when

position

of

the

the

the

Page 17

[I]

Movable

0

knife

adjustment

Loosen set

groove

<Movable

(1) Open the

(2) Remove

(3) Remove set screws 8 and

remove the needle plate.

of

screw

the

shuttle

and

shuttle

the

8 and adjust

hook thread guide 8

fixed

knife

replacement>

race cover.

thread

cutter

the

thread cutter lever 0 so

when

connecting

flat

rod.O.

screws

8.

and

that

the

movable knife 8

the

machine is stopped.

(4) Remove the movable knife

new

movable knife.

tip

aligns

with

0 and replace

the

needle

with

a

Set

the

(5) Remove the fixed knife

new

fixed knife.

fixed knife 8 gap is

of

the

fixed knife 8 does not extend beyond

left

side

of

Adjust

the

needle plate.

0.5

8,

and replace

so

the

mm.

Be

with

needle plate 8

sure

the

left

a

to

side

the

(6)

the

connecting rod O.

* Make sure

after

-14-

thread

movable

installing

cutter

knife

the

connecting rod 8 pin

link

8 and thread

movable knife is properly aligned

the

needle plate.

into

cutter

Page 18

[!]

Presser

foot

adjustment

~

3.5

mm---r----

1

*Turn

(1) Loosen set screw

(2)

(3) Standard vertical presser foot stroke is 3.5 mm. If

(4)

the

pulley and

down

position before making

ment.

the

presser foot

material.

* The material

foot is too low, and stitches may skip

presser foot is too high.

Turn

the pulley by hand and make sure

the

screw

link

center

8.

Lower the feed

screw

feed shaft

enters

If it does not come

loosen

adjust.

the

stroke is excessive, loosen

feed

stroke.

If vertical presser foot movement is not necessary,

loosen step

intermittent

lower

0,

and

f)

bottom lightly touches

will

be improperly fed

of

the

hole

to

the center, remove cap

e.

and move

8,

and secure

8.

the

presser

the

then

retighten it so

in

the

the

nut

link

foot

to

below

presser foot

presser foot

if

the

the

adjsut-

presser

if

needle

0 and raise

to

decrease

link

L 0 to

the

that

the

the

8.

0.

to

the

the

the

·

[!]

(1)

(2)

Thread

Adjust

Work

that

footO.

wiper

the solenoid lever 8 so

the

the

wiper 0 to

thread

adjustment

wiper

0 so

needle

that

point

that

the

thread

it is aligned

gap is

approximately2

with

-15-

wiper

the

0 is level

center

mm.

oft

Be

when

he needle bar. Slide

sure

the

the

machine is stopped.

the

wiper

0 does

not

wiper

strike

0 in

the

or

out so

presser

Page 19

liQ]

Needle

Need le

(1)

Adjust element

pos

ition

(2)

Adjust

needle

the

mater

* The feed

movement

[ill Origin

and feed

up

position

0 so

.

the

needle and feed

has

been

removed

ial.

timing

and

adjustment

timing

o~"'"

The

should be ali

the

the

that

from

shou

ld be increased

improve

adjustment

element

needle

up

the

timing

sewing

and

gned

crank

position.

needle

with

the

mater

effic

magnet

when

is

in

tip

is

19

element

ial,

and

when

iency.

mm

f)

so

sewin

Rotation

k -

above

so

that the

that

the

g heavy

direction

the

needle

feed

feed

materials. This

plate

mechanism

mec

hanism

when

stops

will

23

The

should

the needle

above

position.

the

begins

before

decr

ease need le

,~~V";'"

-

t~

element

and

aligned

tip

is

needle

needle

magnet

2 mm

down

after

sidewise

be

the

needle is in

to

operate

the

when

the

enters

up

the

*The

Pl

~

/

X

'"\_

Y

""-

orig

in (X-

0,

Y-0)

< X

(1) Remove

(2) Loosen set

origin

plate w

the origin

axis

f)

0

ith

>

.

latera

is

at

the

the

orig

.

swatooth

screw

lly

to

adjust.

middle

in

reference

presser

0 .

and

fro

nt. Replace

plate 0

fo

ot L 0

move

X-axis

and

the

feed

to

adjust

sawtooth

origin

dog

L

-1

6-

Page 20

1m

2-Step

presser

foot

operation

adjustment

<Y

axis>

( 1 ) Remove

(2) Loosen Allen bolt

8 forward or back

Turn

the

(1) Presser foot motion can

the

bottom left

the

power

settings

rear cover

f),

and

to

adjust.

off

and then open

of

dip switches 1, 2, and 3 0 on

of

the

control circuit board.

0.

.move

Y-axis origin dog

the

control box.

be

adjusted by adjusting

the

•

OFF

1~:

2

3

OFF

,..-·-

'

~

__

-c,.""

ON

ON

:Ill

The presser foot

The presser foot

sewing is completed.

First

switch

Second

switch

will

will

ON: Presser left 8 descends.

ON:---Presser

rise automatically

rise

when

the

presser bar

When the presser foot lifter treadle 8 is pressed, presser

right

8.

simultaneously. The work clamp (pressers right and left)

and the presser foot

descend. (The presser foot

switch.)

presser left

right

when

sewing is completed.

lifter

treadle is pressed

8.

and the presser foot 8

will

appear

lifter treadle is a

as

below

will

when

two

all rise

position

8 and presser foot 8 descend.

when

they

First

switch

Second

switch

First

Second

ON:----Presser

switch

switch

ON: Presser

ON: Presser right 8 and presser

ON:---Presser

right 8 descends.

left

8 and presser foot 8 descend.

foot 8 descends.

-17-

left

8 descend.

Page 21

liT!

Timing

belt tension

adjustment

(1)

(2) L

Remove

presser

oosen

adj

ustment

The

timing

no

give

sawtooth

L

f).

nut

8

screw 9 to

belt 0 shoul

when

pressed

presser

and scr

d be

firm

R 0

ew

adjust.

adjusted

ly by

0.

hand.

and

sawtooth

and

turn

so

that there is

the

- 18 -

Page 22

(()lfERATION

;FLOW

CHART)

Power

switch

Data switch on - - Micro disc reading

Depress presser foot

treadle

Depress presser foot

treadle

Test

switch

Depress start treadle -

on -

lifter-

lifter-

on -

START

-Work

-Work

-Test

-Presser

clamp rises; set

material.

clamp descends.

lamp illuminates.

foot stops at sewing

start position.

Power switch on -

Data switch on - - Micro disc reading

Depress presser foot

threadle.

Depress presser foot

treadle.

To

change pattern

lifter-

lifter-

- Work clamp rises.

*

Replace presser foot, feed

plate; confirm needle

descent.

*Set

material

in

place.

Depress start

Test

switch

Depress start

treadle-

off-

treadle-

-Feed

-Feed

- Test lamp goes out.

- Machine, feed operate.

-Stop--thread

drive (pulse motor)

(confirm

presser foot and work

operation.)

} Max. 2,000

needle descent,

stop

spm.

cutting

I

Work clamp rises

clamp

When thread breaks

bobbin

Press emergency stop swtich.

Press emergency stop switch.

Press step back switch. -

thread

-Lamp

-IE

-Lamp

- Presser foot moves one

or

runs

out

illuminates.

Remove problem

goes out.

at

stitch

direction.

a time in reverse

Press step back switch. -

One machine cycle

pleted

com-

I

-19-

-Presser

foot stops.

Loading...

Loading...