Page 1

...

-;

...

,

~

...

----....-···

SERVICE MANUAL

{ELECTRICAL)

FOR

'

..

,·..

.

..

. ·

..

..._

..

·

BAS-300A

BAS-304A•311A•314A•315A

SERIES

.. /-·---

=

326A•326LA•341A•342A

,

Page 2

This service

can

be made into a book since electrical descriptions

for

the

BAS-300A series

manual

has

been compiled so

are

very similar.

that

it

Applicable models

are

BAS-304A, 311A, 314A,

315A, 326A, 326LA, 341A,

For some of them,

separated

for

the

air

the

electrical description

and

solenoid specifications.

and

342A.

is

Page 3

(ELECTRICAL

Warning

Never touch three large-sized capacitors on the power circuit

voltage residual charges stay

CHECK AND

for

a minimum

of

DIP

SWITCH)

1-2

minutes after the power is turned off.

Cautions

* During checking

* Check if the cooling

damaged due

with

dust, clean them

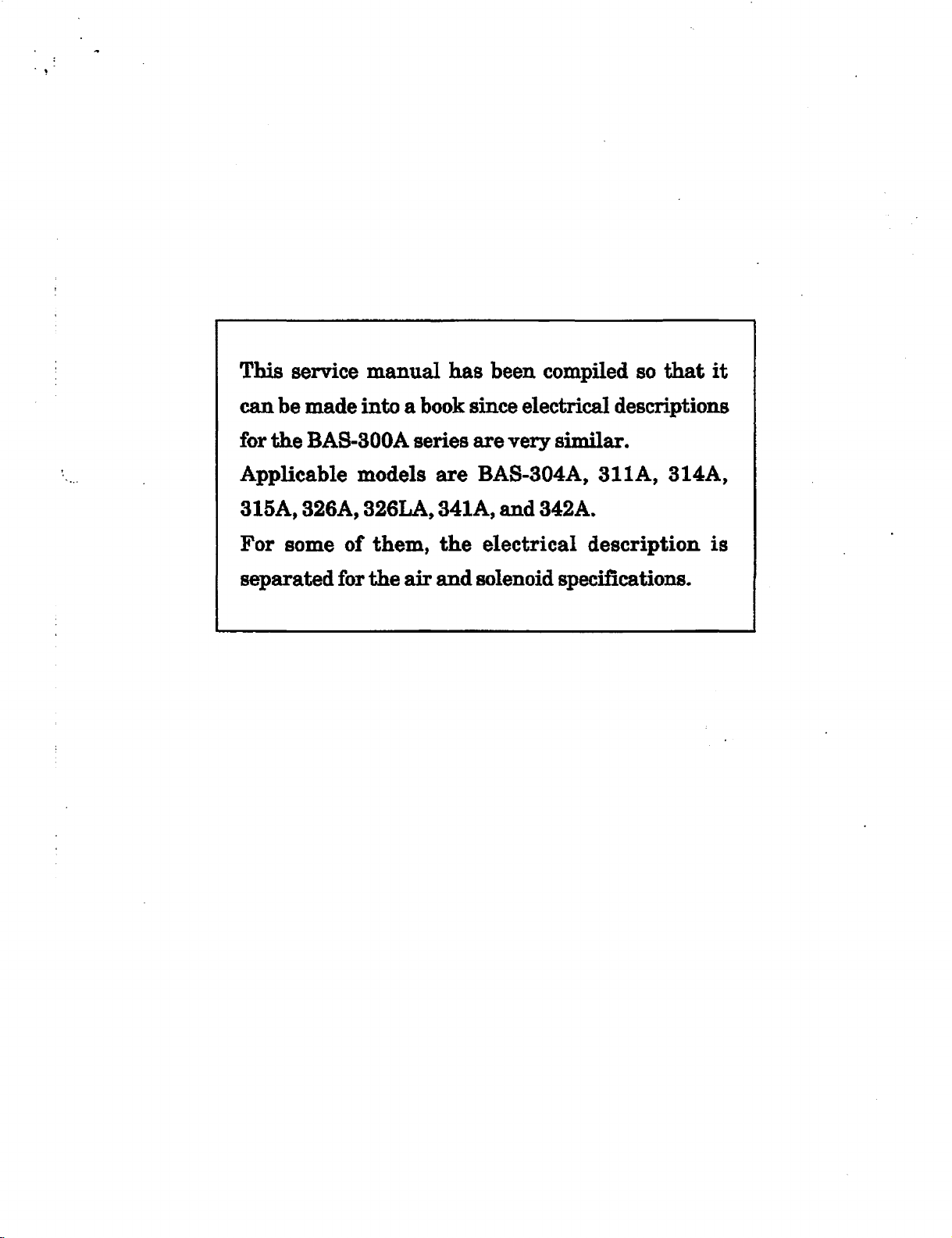

II1

Fuses

or

repair

work

when the power

fan

in

the

control box works correctly.

to

high temperature inside

at

regular intervals.

Fuse4

Fuse3

Fuse2

Fuse1

is

applied, take

the

control box. To prevent

-+-Bh

board

If

it

stops.

(see

the illustration below).

care

not

to

short -circuit terminals.

electronic parts and

the

air vents from being choked

The

devices

high-

may be

NOTE:

No.

1

2

3

4

NOTE:

When replactng

Part name

Fuse2A

(Glass tube

Fuse

(Glass tube

Fuse

(Glass

GfuseSAFB

(Quick melting

Prior

fuse,

SA

fuse,

15A

tube

fuse,

to

replacing fuse

the

fuses,

2A-125V)

SA·12SV)

15A-125V)

type,

SA-2SOV)

No.4.

be

sure

be

to

use

Part code

152566-000

152565-000

502887·000

508030-000

sure

to

check

the

specified

Fuji

Fuji

Fuji

Toyo

the

Measure

terminals.

ones

Manufacturer

Tansi

FUJI

Tansi

FUJI

Tansi

FUJI

Fuse

TOYOSA

TR

array

- If 20 -

works correctly.

-

If

0 Q or

pulse

listed below.

Company

2A

Company

SA

Company

15A

Company

assembly.

the

resistance

30

n:

Replace

co:

Replace

motor drive

Problem

The

work

clamp does

operate.

The power lamp does

on

and

no operation

The

feed plate

plate

The

machine

tum.

between

fuse

(by 1 oon

the

(PMD)

do

1.

range)

TR

PCB,

and

not operate.

motor

The

TR

array

assembly

instead

the

array

of

not

not

occurs.

presser

does

not

EB

and e

assembly

and the

fuse

come

1.

-1-

Page 4

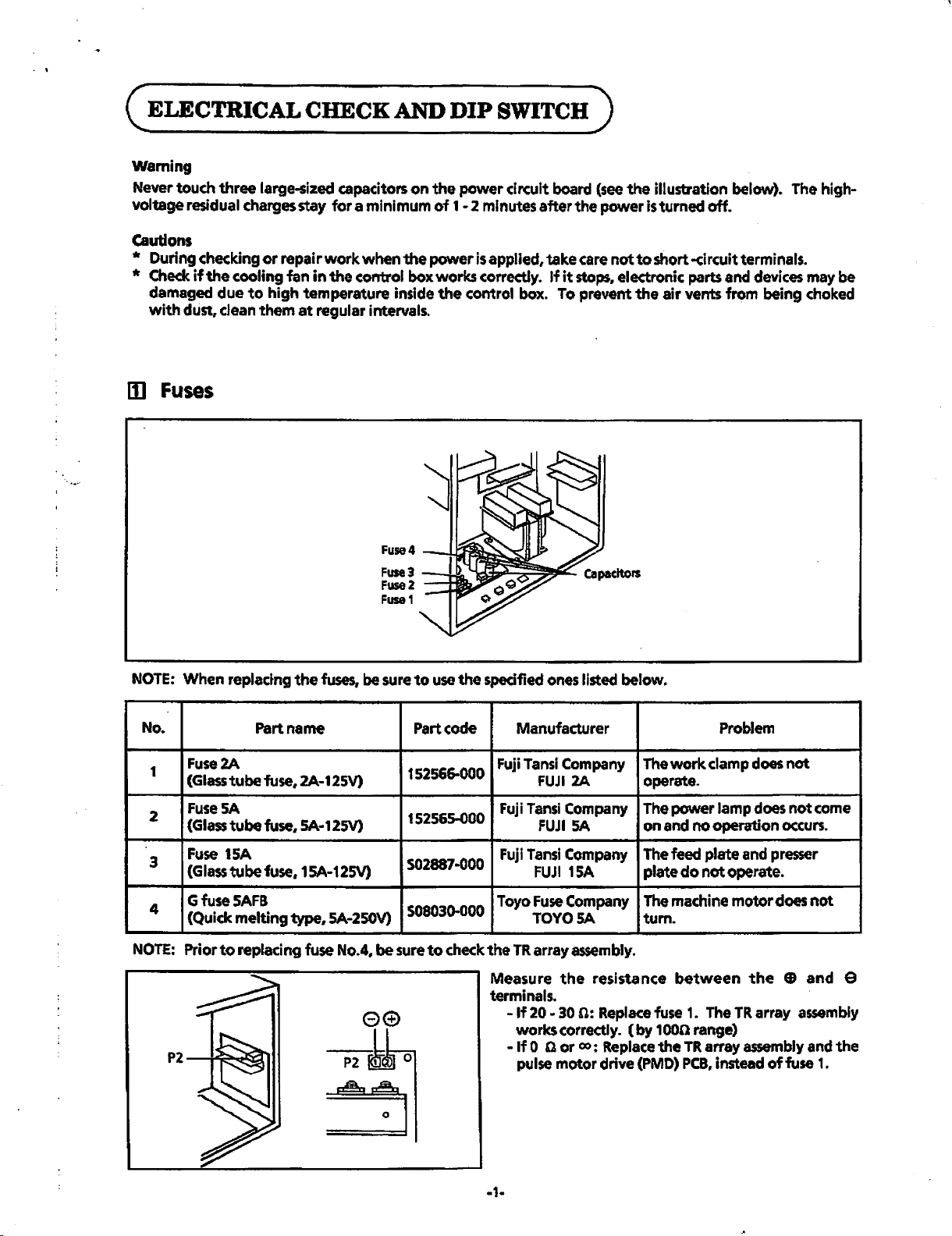

rzl

Voltage measurement

1. Checkng

ru·m

between

2. Checkng

Turn

pins 1 and 2

3.

Checkng solenoids' voltages

the

on

control

power

pins 1 and 2, 3

the

+

on

power

of

voltage

while

SV

source

while

connecting

connector P7.

connecting

and

4, and

the

the

connector

between

connector

5 and 6

P7

P8

to

the

of

connector P1.

to

the

control

(1) Turn

Remove

control

off

PCB,

the

P1

PCB,

Check

on

the

Between

Between

Between

then

Check

on

the

Between

power.

from

then

points of

control

pins 1 and

pins 3 and

pins

measure

points

control

pins

J1,

and

measure

P8

PCB

2

4

5 and 6

the

of

P7

PCB

1 and 2

measure each solenoid's

resistance.

Resistance values are different according

sewing machine model.

Check

points Solenoid Value

Between Intermittent

pins1

and2

presser foot

Proslerfoot(Oftly

forsolennl

Between

pins3and4

Between

pins5and6

Between

pins7and8

)&(

tpedfb11oct)

Tension

release

Thread

trimmer

Thread

wiper

Resistance and voltage values

Resistance

Voltage

Resistance

Voltage

Resistance

Voltage

Resistance

Voftege

Resistance

Voltage

:;?'

~

the

voltages

Acceptable value

Approx.

Approx.

Approx.

65

11

25

Vdc

Vdc

Vdc

voltage between

Acceptable value

Approx.

304A 326A 341A

311A

50

12V

50

10V

50

30V

60

30V

are

65

Vdc

to

the

342A

326LA

12n

~

_/"

20V

./'

~

./'

~

50

_/"

20V

~

100

sn

20V · 60V

110

20V

60

30V

approximate.

...

_.,.,.

P1

1

(2) lnsertP1

Insert

intoJ1,andturnonthe

the

measure the voltage.

•

As

for

the

foot

solenoids, measure

and

lowering

·As

for

tension

thread

measure

in

Since,

very

briefly,

measure.

Each

voltage value is

·2-

power.

test

probe

from

the

lead

wire

side,

presser foot and intermittent presser

the

voltage

while

them.

release,

wiper

solenoids,

the

voltage upon finishing

this

case,

the

the

value

as

in

thread

start

indicator

is

used as a

the

above

trimmer,

sewing,

of

sewing.

only

oscillates

table.

and

raising

and

then

rough

Page 5

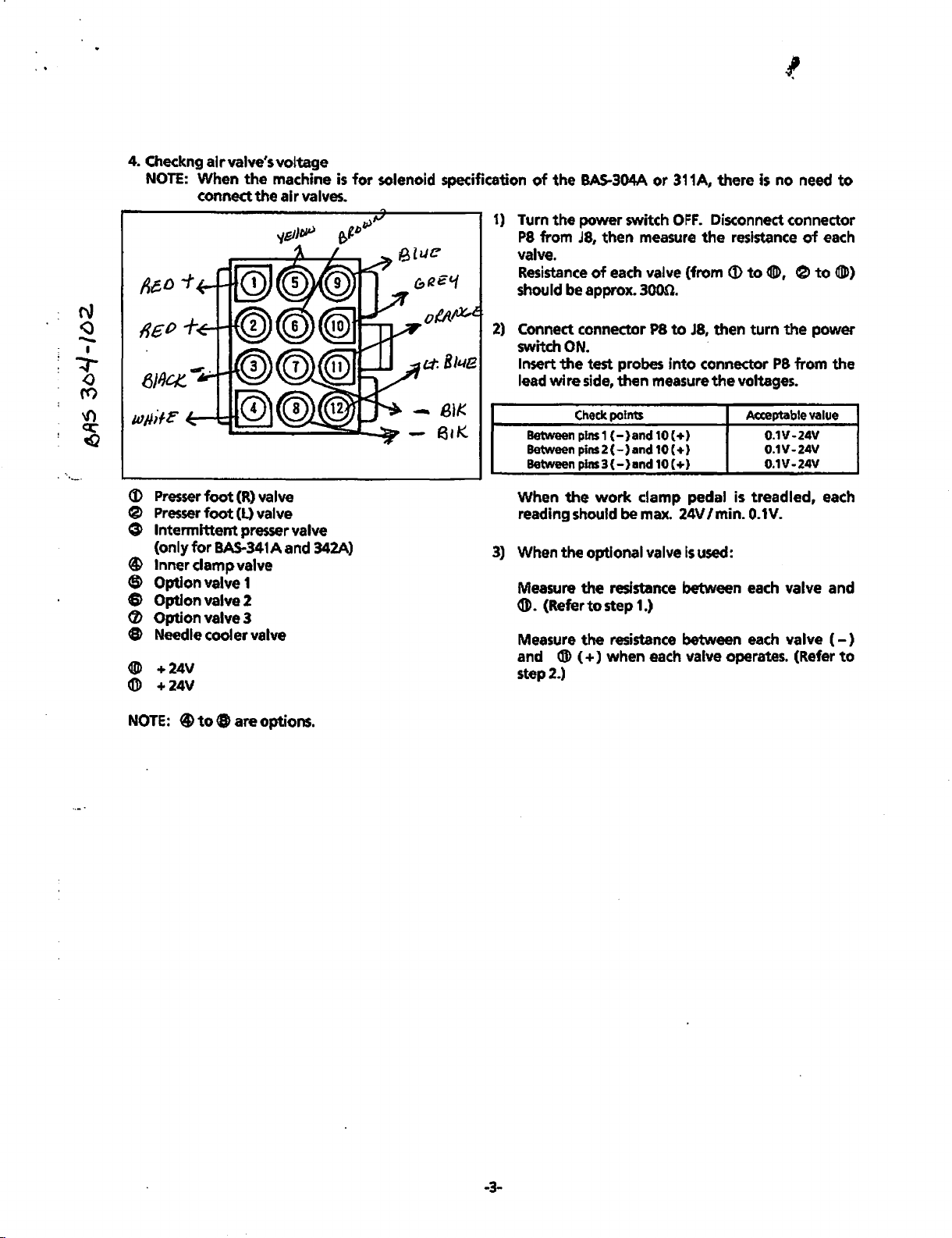

4. Checkng

NOTE:

(J)

Presser

e

Presser

air

valve's

When

the

connect the

foot

(R) valve

foot

(L) valve

voltage

machine

air

valves.

G Intermittent presser valve

(only

for

BAS-341A

and

342A)

® Inner clamp valve

$ Option valve 1

8 Option valve 2

(/) Option valve 3

8 Needle cooler valve

~

+24V

®

+24V

is

for

solenoid specification

of

the

BAS-304A

1)

Turn

the

power

P8

from

J8,

then measure

valve.

Resistance

of

each valve (from (t)

should be approx. 3000.

2)

Connect connector

switch

Insert

lead

When

reading

3)

When

Measure

®. (Refer

Measure

and ® (

ON.

the

test probes

wire

side, then measure

Check

points

Between pins 1

Between pins 2

Between pins 3

the

(-}and

(-)and

(-}and

the

work

should be max. 24V I min. 0.1V.

optional valve

the

resistance between each valve and

to

step 1.)

the

resistance between

+)

when

step2.)

or

switch

P8

10 C

10 C

10 (

clamp

311A, there

OFF.

Disconnect connector

the

to

J8,

into

connector

the

+)

+)

+)

pedal is

Is

used:

resistance

to$,

then

turn

voltages.

Acceptable

treadled,

is

no

P8

0.1V-24V

0.1V-24V

0.1V-24V

each

each valve operates. (Refer

need

of

each

e

to~)

the

power

from the

value

each

valve

to

(-)

to

NOTE:

@to

8 are options.

-3-

Page 6

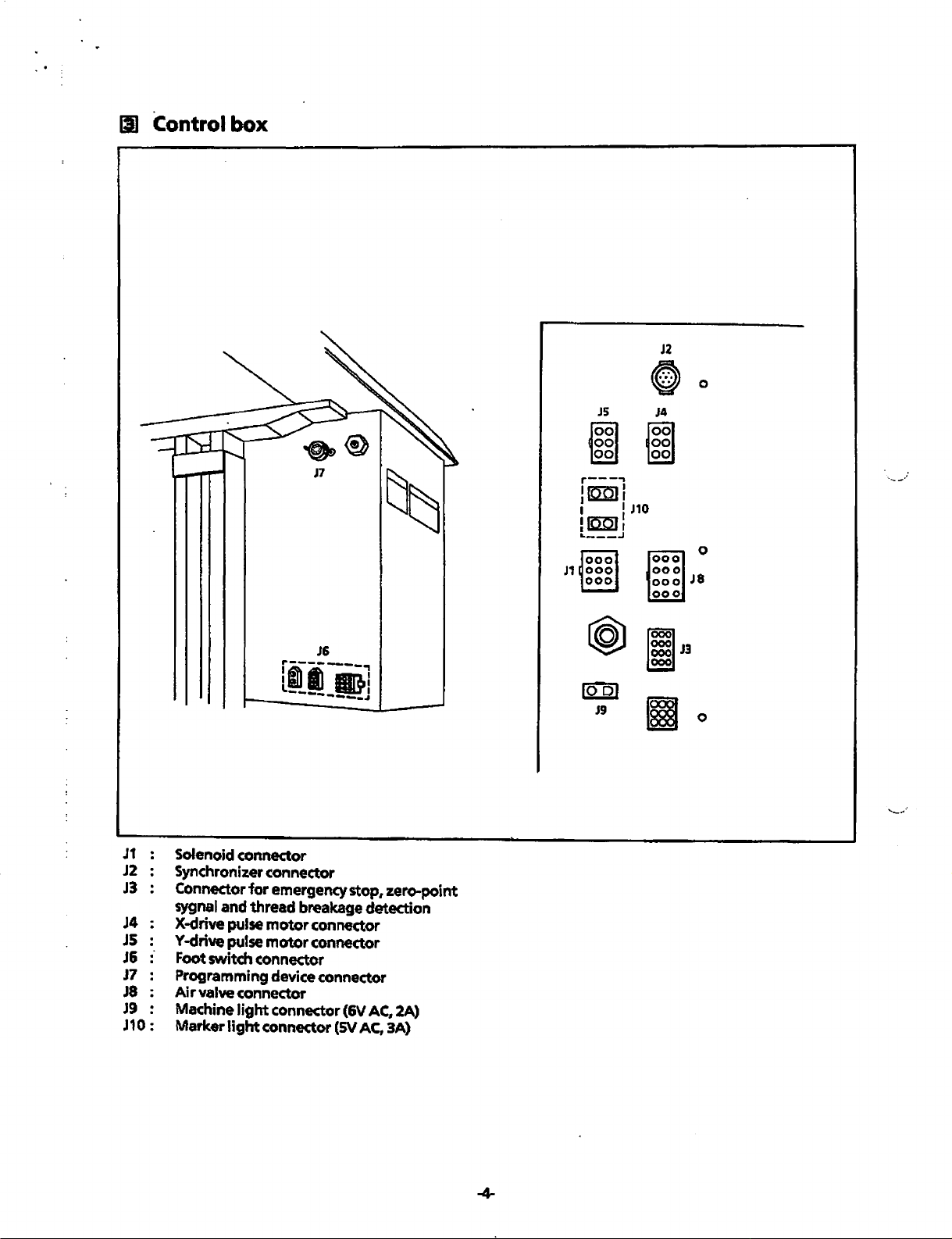

Ill Control box

~0

JS

J4

~~

r---.,

lra:QJI

: 1

~Kmlr

'"---.J

J1

s1o

J2

0

J8

J6

fi~---~

_____

"----

J1

J2

J3

J4 X-drive pulse

JS

J&

J7

J8

J9 Machine light connector (6V AC. 2A)

J 1 0 :

Solenoid connector

Synchronizer connector

Connector for emergency stop, zero-point

sygnal

and

thread

Y-drive pulse

Foot switch connector

Programming device connector

Air

valve connector

Marker

light

breakage

motor

connector

motor

connector

connector

,

•.

detection

(SV

AC,

3A)

lool

J9

Page 7

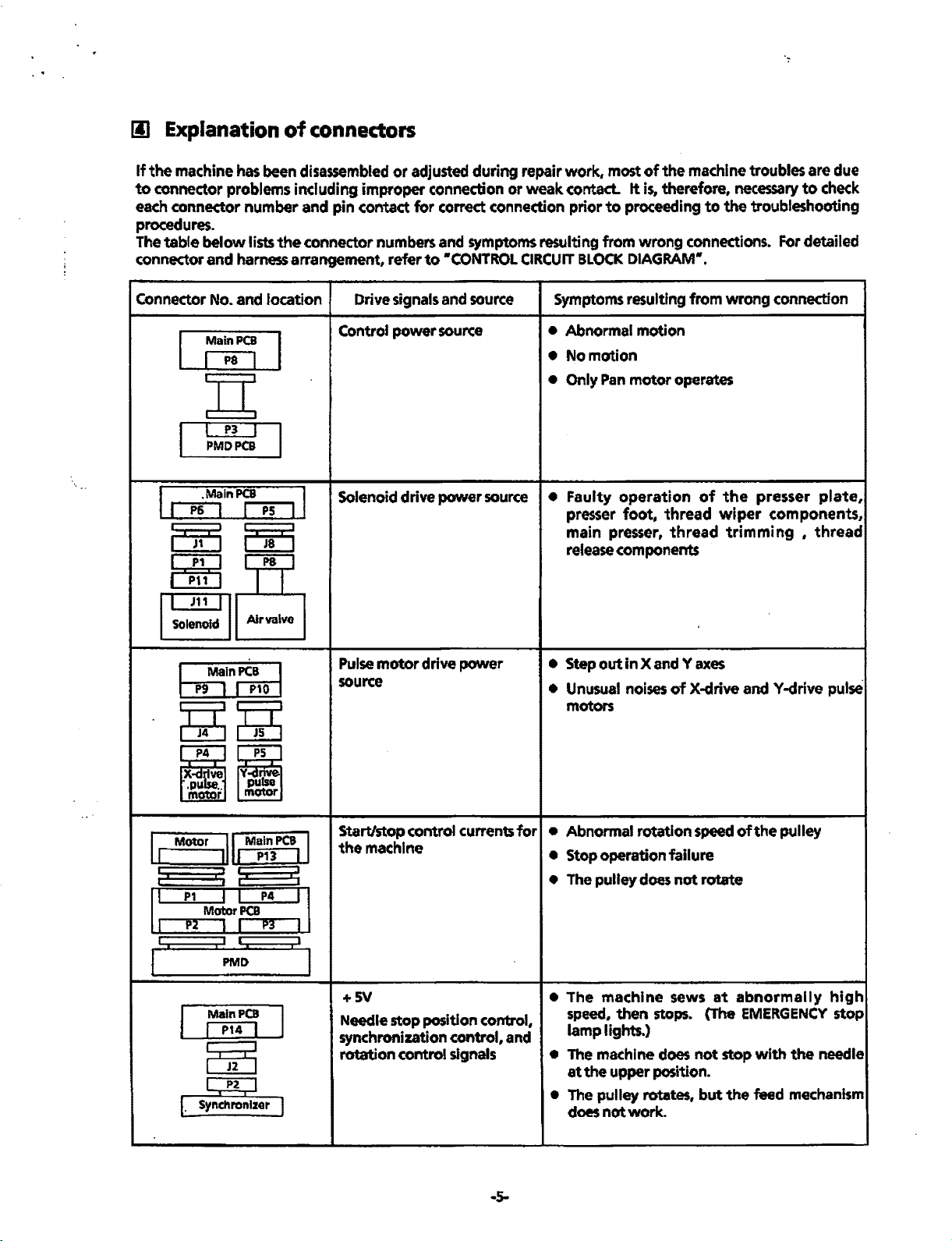

Ill

Explanation

If

the

machine

to

connector problems including improper connection

each connector number and pin contact

procedures.

The

table

connector and harness arrangement, refer

has

below

of

connectors

been disassembled

lists

the

connector numbers and symptoms resulting

or

adjusted during repair work, most

for

correct connection prior

to

•coNTROL

or

weak contact.

CIRCUIT

to

from

BLOCK

of

the

machine

It

is,

therefore,

proceeding

wrong

DIAGRAM•.

connections. For detailed

troubles

necessary

to

the troubleshooting

are

to

due

check

Connector No. and location

Main

PCB

I P8 I

I P3 I

PMDPCB

.MainPCB I

I

P6

I

I I

PS

Solenoid drive power

I

m [5[5

ElBg

I J11 I

Solenoid

~In~

~~

Air

PS

Y

nlsve.

pu

motor

valve

a

Drive signals and source

Control

Pulse

source

power

motor

source

drive

power

source

Symptoms resulting from wrong connection

• Abnormal motion

•

Nomotion

• Only Pan

•

Faulty

presser

main

release components

• Step out

• Unusual noises

motors

motor

operation

foot,

presser,

in

X and Y

operates

of

thread

thread

axes

of

X-drive

the

presser

wiper

components,

trimming ,

andY-drive

plate,

thread

pulse

Motor

-[ L

I

;.

1:

I I I

I

ll

Main

PCB

·I

P13

I:

:I

I:

:~M+r:

1

PMD

Main

PCB

I P14 I

I I

Start/stop

I

the

LJ

:1

I

I

+SV

Needle stop position control,

synchronization control, and

rotation control signals

control currents

machine

~

P2

I

Synchronizer

r.

I

l

..

s-

for

• Abnormal rotation speed

• Stop operation failure

• The pulley

• The

speed,

lamp

• The machine does

at

the

• The pulley rotates,

does

does

machine

then

stops. (The EMERGENCY

lights.)

upper position.

not

work

not

sews

.

rotate

at

not

stop with

but

the

of

the

pulley

abnormally

the

needle

feed mechanism

high

stop

Page 8

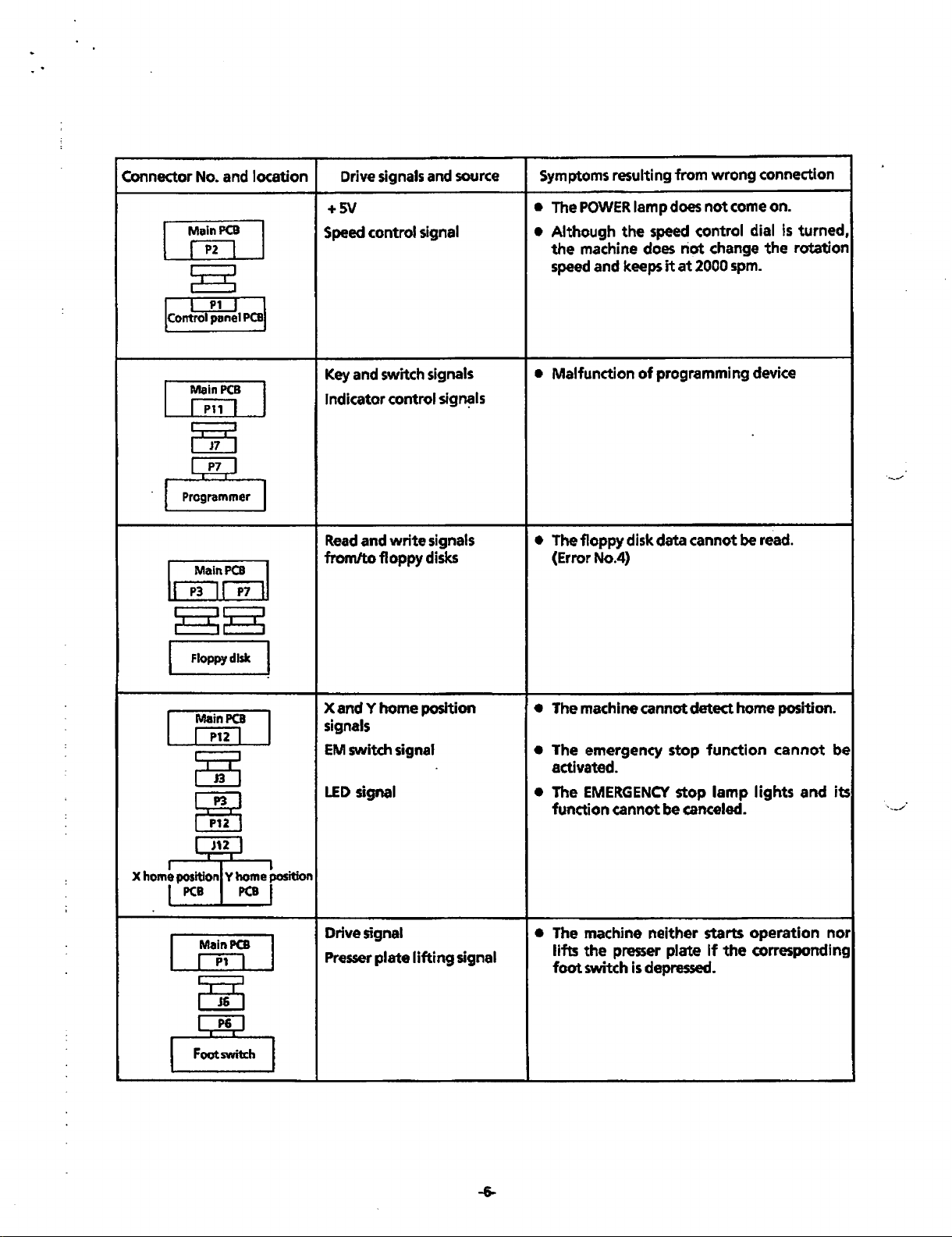

Connector No. and

Main

PCB

[PO

f I

P1

panel

Main

em]

l J

PCB

1control

location

PCBJ

Drive

signals and

+SV

Speed control signal

Key and switch signals

Indicator control

source

sig~ls

from

does

wrong

not

come on.

Symptoms resulting

• The

•

Although

POWER

lamp

the

speed <ontrol dial is

the machine does riot change the

speed and keeps

•

Malfunction

it

at

2000

of

programming

spm.

connection

turned,

rotation

device

· I Programmer

MainPCB

IIP31

I

86

I

Floppy

Main

Qifl

~

~

r

I . . h I

Xh

ome

position Y

I

PCB

Main

QCJ

,,2

T T

P7

disk

PCB

1

PCB

PCB

ome

~

.J

II

I

..

positiOn

i

Read

and

write

from/to

X

signals

EM

LED

Drive signal

Presser

floppy

andY

home

switch signal

signal

plate

signals

disks

position

lifting

signal

•

The

floppy

(Error No.4)

• The machine

• The emergency

activated.

• The

function

• The machine

lifts

foot

disk data

cannot

EMERGENCY

cannot

neither

the

presser

switch is depressed.

cannot

detect

home

stop

function

stop

lamp

be canceled.

starts

plate

If

the

be

read.

position.

cannot

lights

and

operation

corresponding

be

its

nor

Page 9

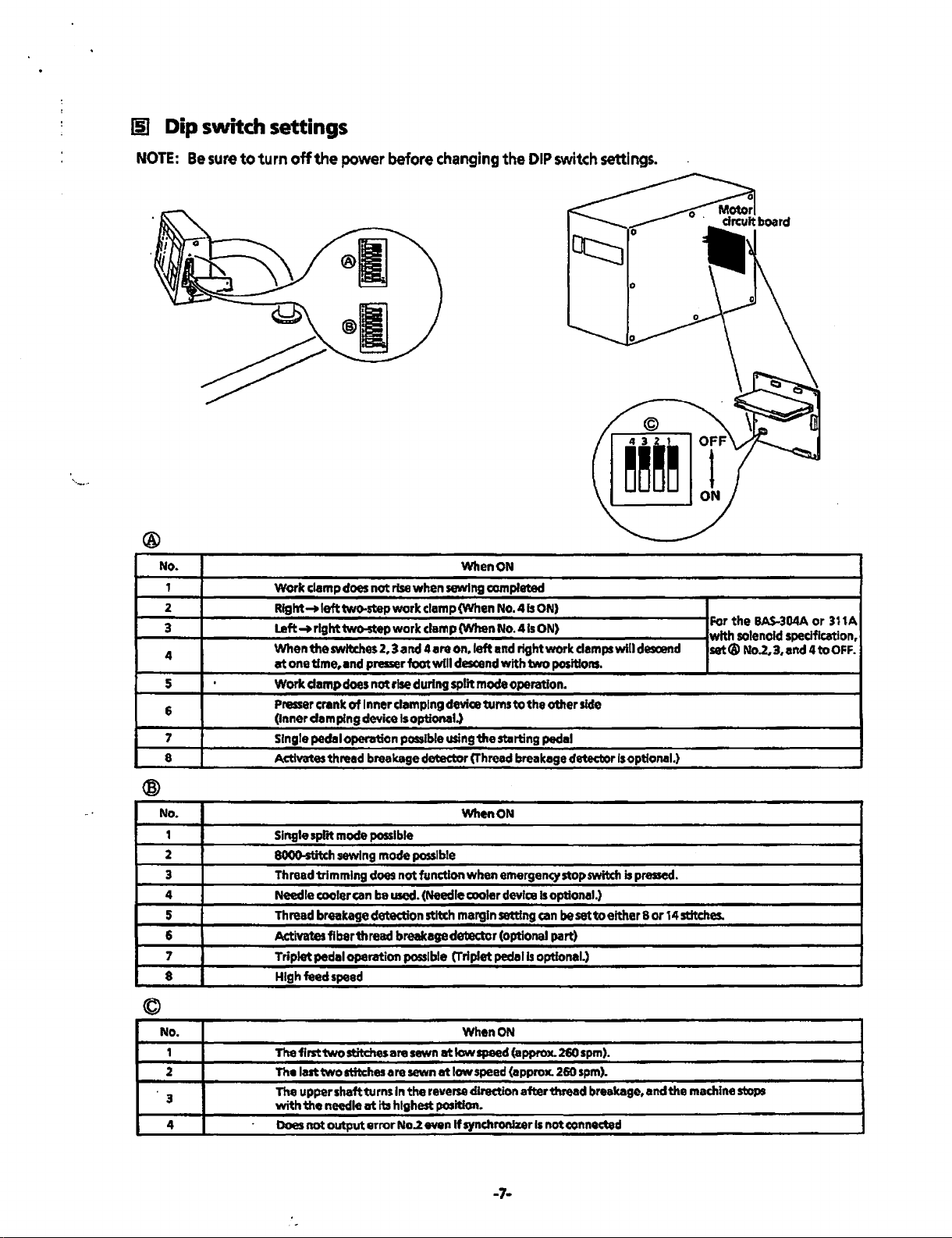

liJ

Dip switch settings

NOTE:

®

No.

1

2

3

4

5

6

7

8

Be

sure

to

turn

off

the

power

before

Work clamp

Rfght..,.lefttwo-stepwork clamp (When

Left~

When the

at

one timer and presser foot

Work clamp does

Presser

(Inner damping

Single pedal operation

Activates thread breakage detector

does

not

rise when sewing

right two-step work clamp (When No.

switches

crank

2, 3 and 4 are on. left

not

rise

during

of

Inner clamping

device

Is

optional.)

possible

changing

When

will

descend

split

mode

device

turns

using

the st.rting pedal

(Thread

the

DIP

ON

com

plated

No.4

fs

ON)

41s

ON)

and

right work

With

two

operation.

to

the other

breakage detector

switch

settings.

ct::::J.

clamps

side

will

Is

optional.)

positions.

0

descend

Fer

the

BAS-304A

or

311A

with solenoid spedfication,

set®

No.2~

3#

and 4

to

OFF.

No.

1

2

3 Thread trimming

4

5

6

7

8

Single split

8000-stitch sewing mode

Needle cooler

Thread breakage detection stitch margin setting

mode

Ad:ivates fiber thread breakage detector (optional part)

Triplet pedal operation

High

feed

speed

possible

possible

does

not function when

can

be

used. (Needle cooler

possible

When ON

{Triplet

©

No. When

,

2

3

4

The first two stitches are

Thelalttwo

The

with

Does

stitches are

upparshaftturns

the

needle

at

its highest position.

not

output

error

In

No.2 even

sewn

sewn

the

at

low

at

low

reverse

If

synchronizer

emergency

device

pedal

ON

speed

(approx.

speed

(approx.

direction afterttvead breakage, and the

stopswitd1

Is

optional.)

can

be

set

is

optional.}

260

260

Is

notconnocted

to

spm).

spm).

is

pressed.

either 8

or

14

-7-

stitches.

machine

stops

Page 10

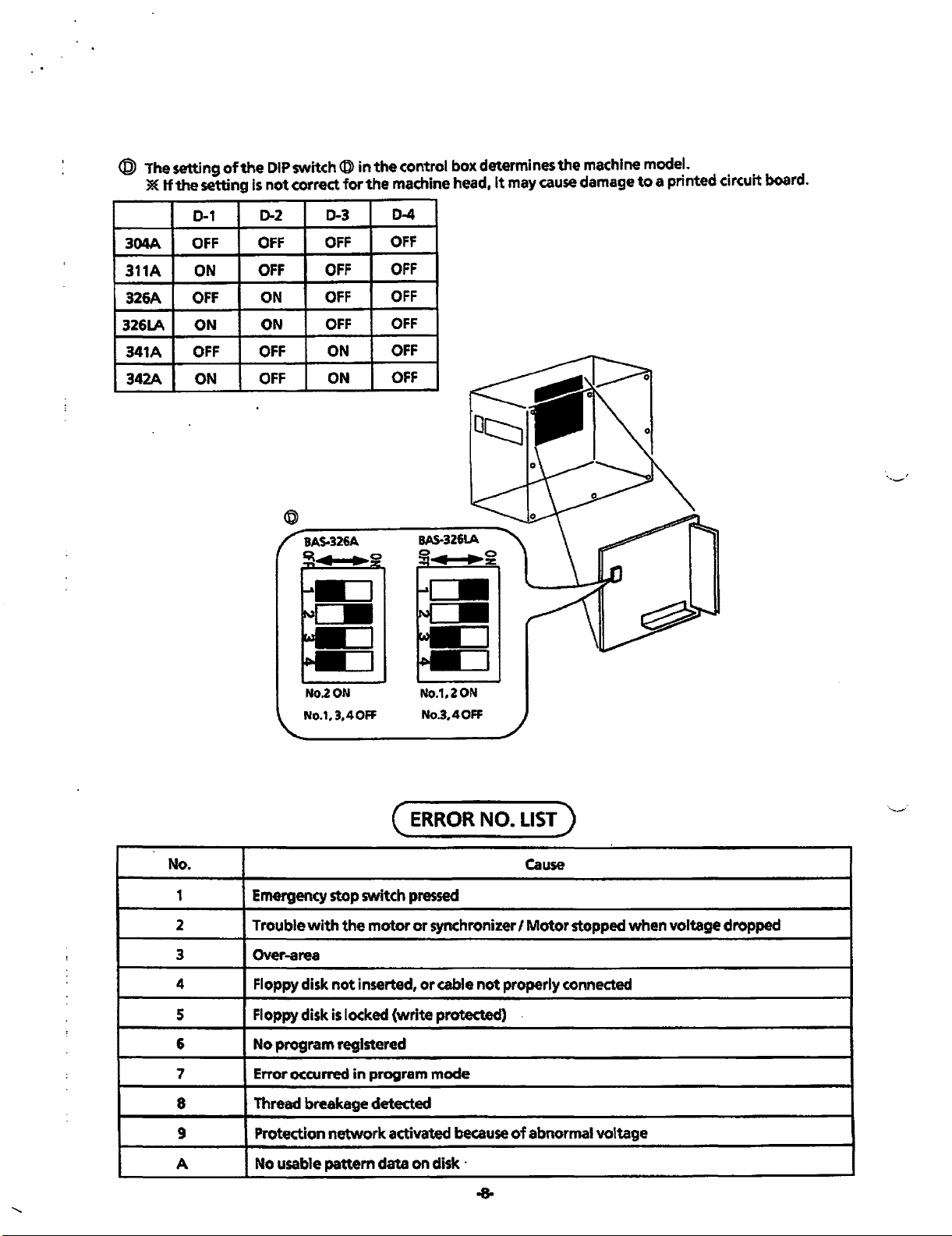

@

The

setting

*

If

the setting

of

the

is

DIP

switch@ in

not

correct

for

the

control box determines

the

machine head,

It

may

the

machine model.

cause

damage

to

a printed circuit board.

0-1

304A

311A

326A

326LA

341A

342A ON

OFF

ON

OFF

ON

OFF

D-2

OFF

OFF

ON

ON

OFF

D-3

OFF

OFF

OFF

OFF

ON

D-4

OFF

OFF

OFF

OFF

OFF

No.

1

2

3

4

5

6

7

8

9

No.2

0N

No.1,

3,4

OFF

Emergency

Trouble

Over-area

Floppy disk

Floppy disk

No program registered

Error occurred

Thread breakage detected

Protection network activated

stop switch

with

the motor

not

inserted,

is

locked (write protected)

in

program

No.1,20N

No.3,40FF

(

ERROR

pressed

or

synchronizer I

or

mode

cable

because

NO.

LIST)

Cause

Motor

not

properly connected

of

abnormal voltage

stopped when voltage dropped

A

No

usable pattem data on

di'k

·

Page 11

(TROUBLESHOOTING)

1

2

3

4

Indicates manual operation.

Indicates

\,_____,/

Selects

a

appears

determination and solution table".

the

yes-or-no

Indicates

swltch

in

operation.

course

of

dedsion-making

that

the

procedure

the

first column

action

to

follow, using

process.

to

follow

of

•problem

5

6

7

D

0

-9-

Indicates

Indicates

appears

Indicates turning-off

wtting-up

that

on

the next

the

operation.

procedure

page.

of

the

power switch.

to

follow

Page 12

Powering-up

sequence

L

Tum

Insert

on

POWER

switch.

the

floppy

disk.

No

.,

_

_...'

Floppy

disk

insertion

1+----------------\

Press

the

PRO

NO.

switch, then press

the

RNi switch.

No

Yes

TurnonPOWER

switch.

-10.

Page 13

Presser

and

presser

plate

operation

Set cassette or

material

to

~==-----------_1

TumonPOWER

No

be sewn.

No

switch.

Shifting

to

the

sewing

start

position

No

Yes

No

Input

sewing data.

Page 14

No

No

Input sewing data

and

shift

to

sewing start position.

the

·._...

Test

Yes

--·

No

No

-12-

Page 15

No

Yes

Input sewing data

and

shift

to

sewing start position.

the

Sewing

operation

No

No

No

No

-13-

Page 16

No

No

ln~t

sewing

and start

operation.

data

se'Ning

-~-·

Emergency

stop

and

restarting

operation

No

No

·14-

Page 17

.......

No

Programming

device

-15-

Page 18

c

PROBLEM

DETERMINATION AND SOLUTION )

Precautions

1.

Be

sure

to

tum

2.

the

power

When

replacing a fuse,

the power switch

cord.

be

sure

to

OFF

before opening

use a

new

Problem determination and solution table

• Prior

• l-etters marked

NO.

FLOWCHART

ERROR

#1

The

will

the

isturMd

to

proceeding

-no

fuse has

-each

those items should be checked

IN

CHAPTERS

STATUS

POWER

not

light

POWER

plug is correctly inserted.

AND

lamp

when

switch

ON.

to

the

following

blown

with

an asterisk (e.g. (a)*) in

PROBABLE

1.

Power cord

defective

d~2

__liiiRIII

[n:l®

~

table,

while

the

CAUSES

~

~

311

check

power

(a)* Measure voltage between taps 20 and

I I

2.

Fuse

3.

Power

defective

blown

PCB

.PI

Remove fuse No.2 and check

continuity.

the

(a)*Unplug connector

NOTE:

~

Main

4.

circuit board

defective

1

2

P7~

(a)*Unplug connector

the

one having

the

is

·CHECK/

21

Make sure

matches

fuse.

board,

the

that

ct·IECK

applied.·

ADJUSTMENT I REPAIR

on

transformer

that

the

If

there

turn

the' voltage.

the

contrOl

lnsertatesterprobe

connector

board, tum

the

voltage

the

control

control box cover

same

quality

I

ADJUSTMENT I REPAIR

in

control box.

the

measured voltage

specification.

is

no

continuity, replace

P8

~er

it

is not

is

defe

P7

power

the

PCB.

board

of

ON,

~rox.

the

lead

of

ON,

the

If

box

from

the

on

circuit

or

and capacity

it

for

the

main circuit Power

then

10

ve.

intothe

wire

the

main circuit

then

If

it

is

not + 5V,

Is

defective.

plugging

as

column indicate

measure

VDC,

side.

measure

in

I unplugging

the

old

one.

that

REPLACEMENT

PARTS

Power cord

Glass

tube

fuse

SA

PCB

Maindrcuit

board

··

...

~·

5.

Panel

drcuit

#2

If

the

RJW

pressed,

indicator

the

floppy

drive

(FDD)

not

light

FDD does

the

floppy

data.

switch is

the

lamp

disk

does

and the

not

read

disk

on

defective

1.

Connector contact

defective

2.

Main

circuit board

defective

board

Check

drcuit

circuit board.

Oleck

contacts between connector

circuit board and

between

circuit

(a)

Tum

switch

intermittent!~

~ain

bUzzer does

manner,

·defective.

(b)

St~

H e presser plate

normally,

defective.

the

connection between

board

and connector

the

connections, harnesses, and

the

connectors

board and

the

power

to

check

tochec

the

on

the

P3

the

ON, and press

If

Then press

if

the

not

operate

control

presser

the

control circuit board

P2

panel circuit board and

or

P7

FDD.

the

buzzer sounds

buzzerst~

drcuit

ce

not

-16-

the

panel Panel

of

the

main board

pin

P2

of

the

main

of

the

main

the

EM

the

button

If

in

sucn

a

board is

lifter switch.

work

Is

drcuit

Maindrcuit

board

the

Page 19

NO.

IN

CHAPTER

FLOWCHART

ERROR

STATUS

8

AND

PROBABLE

CAUSES

CHECK/

ADJUSTMENT I REPAIR

REPlACEMENT

PARTS

#2

If

the

RIW

switch is

pressed,

indicator lamp on

the

drive

not

FDD

the

data.

#3

After a few

seconds

R/W

pressed,

code appears

the

the

floppy disk

(FDD)

does

light

and

does

floppy disk

switch

ERROR

the

not

after

is

an error

display.

read

the

on

#4

The

presser

will

not

the

presser

lifter

stepped on.

rise when

plate

switch

plate

is

3.

Presser

switch defective

4. Floppy disk

(FDD)

1.

Floppy disk

defective

2.

Floppy disk drive

(FDD)

3.

Main

1.

Fuse

2.

Power

defective

plate

defective

defective

PCB

defective

blown

PCB

lifter

drive

(a)

If

the

presser

operates just

without

presser

Unplug connector

(b)

press

and

operates normally, the

lifter

switch

Replace

Chec:k

ERROR

disk.

normally read, t e old floppy

defective.

Check

ERROR

Replace

(a)

(a)*Turn the power

the

If

error code No.4 appears on

indicator.

If

the

if

error code No.4 appears on

indicator.

the main

Remove

continuity.

replace

of

the control

measure

65

VDC,

plate automatically

byturningthe

any other operator action, the

plate

lifter

switch

P6

of

the

RMI switch.

presser

is

defective.

FDD.

If

yes,

insert other floppy

newl~

inserted

If

PCB.

fuse

No.3

If

there

the

fuse.

PCB

the voltage.

the power supply

flo~y

yes,

replace the

and check

is

no continuity,

ON

while connector

is

plugged, then

If

power on

is

defective.

the

control box

If

the machine

plate

disk

tsk

is

it

for

it

is

not

Is

defective.

the

is

the

FDD.

P8

approx.

Presser

lifter switch

assembly (2-

stage switch)

FDD

Floppy disk

FDD

Main

Fuse

(1SA)

Power

plate

PCB

No.2

PCB

~

3.

Presser

switch and its cable

defective

7 1

r.::::;;::;;:;, : l Switch)

~

~/..:

For

342A)

4.

Main

I'T'\

~~

plate

lifter

.------,

(First

rt:=

1..:

,

~

I Presser

• : (Second

!l:J_;

P6

pneumatic specification

PCB

Switch)

"c.J

Start

defective

~-

@@l@

9

i©©>®

IQ)@@

©@lQI4

12

J8

{a)

UnplugconnectorP&ofthecontrol box,

then check

If

the

followl ng specified value,

plate

defective:

oa

lifter

released, respectively.

(BAS-304A,

(a) Refer

(b) Step on

while pressing

If

an error code appears on

indicator,

(c)* Unplug connector

tum

voltage

switch.

between pins 1 (-) and 1 0

between pins2 (·)and 10

is

defective.

it

for

measured

lifter

switch or its cable

or

oo 0 when the

switch

311A, 314A,

to

#2, 2(a).

the

presser

STEP

the

main

the

power

on

J8

while stepping on

If

it

is

not

continuity.

value

is

not

is

ON.

presser

stepped on

31

plate

BACK

PCB

is

P8

of

the

then measure

approx. 24

the

the

presser

is

or

SA,

326A,

lifter

switch

switch.

the

not

defective.

control box.

VDC

(+),and

(+),main

plate

326LA,

ERROR

the

the

start

PCB

Presser

lifter

assembly

cable

Main

plate

switch

341A, and

PCB

or

Its

-17-

Page 20

NO.

IN

FLOWCHART

ERROR

#4

The presser plate

will

the presser plate

lifter switch

stepped

CHAPTER

AND

STATUS

not rise when

is

on.

8

5.

PROBABLE

CAUSES

AJ

r valve defective

1(QJ@©

@©(QJ

(Q)@(Q]

9

[9

(a)

CHECK/

Unplug

then

If

it

is

ADJUSTMENT I REPAIR

connector

P1

of the control box,

measure the resistance.

not

approx.

400

0 between pins 1

and 10. and between pins 2 and 10,

air

valve

is

defective.

the

.

REPLACEMENt

PAR15

Air

valve

:1

··".

'·

·,

~

4[Q)©©

P1

For

solenoid specification

4.

Mafn

PCB

12

defectiv~

+

3 9

~00

00~

0

1

P1

S.

Air valve defective

9

7

-

3

000

[ooo

(BAS~304A

(a} Refer

(b) Step on the presser plate

while

If

. indicator,

(c)*

Unplug

tum

and 311A)

to

#2,

2(a).

pressing

an error code appears on

on

the

STEP

BACK

the

main

PCB

connector

P1

of

power, then measure

voltage of J 1 while stepping

switch.

between pins 3

circuit board

(a)

Unplug connector

If

It

is

not approx.

(+)and

Is

defective.

P1,

then measure

resistance.

If

it

is

not approx. s ohms between pins 3

and 4, the solenoid

is

defective.

lifter

switch

switch.

the

is

the

ERROR

not defective.

control box,

the

on

the

start

10

VDC

4 (·),the main

the

Main

Air

PCB

valve

000

7

1

-18-

Page 21

' .

;.

·~--

NO.

IN

CHAPTER

FLOWCHART

ERROR

STATUS

#5

The

presser

will

not lower

when the

plate lifter switch

is

stepped on. once lowered by stepping on the

#6

The

presser

will

not

return

its home position

when the start

foot switch

stepped on.

AND

plate

presser

plate

to

Is

8

PROBABLE

1.

Presser

plate lifter

switch defective

1.

Start

foot

and

its cab I e

defective

~1~

P6

CAUSES

switch

(First

: Presser

r

!(Second

J

Switch)

Start

CHECK/

If

the

presser

rises

when the power

respectively,

action

to

lifter

switch

plate

lifter

presser

(a)

plate lifter switch

If

nothing shifts

P1

of

connedorsJ&andP&oftheconttolbo~

(b) Unplug connector

then

measured

following specified

switch or its

when

ADJUSTMENT I REPAIR

plate automatically lowers

is

turned

without

the machine, the

is

switch

any

defective.

rises

by

other operator

presser

If

the

releasing

Is

at

all, reinsert connector

the main circuit board

P6

of

check

it

for

contl nuity.

value

Is

not both the

values,

cable

is

defective:

the

start foot switch

respectively.

OFF

or

ON,

plate

or

presser

plate

presser

it,

the

d~fective.

and

the control

If

box,

the

the start foot

co

0

or

00

is

off

or

on,

REPLACEMENT

PARTS

Presser

plate

lifter switch

assembly

(2-stage

switch)

Start

foot

switch

2.

Home position

signal error

3.

Fuse

blown

(a)

If

the

direction

home position

Reinsert

(b)

presser

plate

and

moves

its motion

signal

is

connector P12

incorrect.

of

circuit board, connectors

the control

P12

(c)

Press

of

box,

and

connectors J

the machine

head.

EMERGENCYSTOPswitchtwice,

then operate the feeding

hand.

If

the

LED

on the home position

PCB

does not flicker when the feeding

mechanism

approaches

the

position, the home position signal

incorrect.

Check

if

the

sensor

(d)

position

PCB

is

the

sensor

(e)

Oean

Remove

fuse

continuity.

the

fuse.

sensor)

subject

from the light.

X-axis

No.3,

If

there

(particularly,

on the home position

to

any light.

home position dog.

then

check

is

no continuity, replace

in the

is

reverse

erratic, the

the control

J3

and

P3

12

mechanism

home

Y-home

If

yes, protect

it

for

of

and

is

by

Home

PCB

Fuse

position

1SA

-19-

Page 22

••

olo•

• • • I

....

l ~ •

l\

• ·,

_.,-·~~~~-:~~-

.

. )

.J

/

~

.t.'+·

i

'\~·

\.

-~:

..

. •

Page 23

NO.

IN

CHAPTER

FLOWCHART

ERROR

:f/:6

The

presser

will

not

AND

STATUS

plate

return

to

its home position

when the start

foot

switch

stepped on.

is

8

PROBABLE

4.

PowerPCB

defective

5.

Pulse

cabl~ve

CAUSES

motor

or

1

fQJ@

4

©><QJl9

3

[Q)

(Q)

6

CHECK I ADJUSTMENT I REPAIR

Refer

to

#4, 2(a)*.

Unplug connector P4and

its

box,

then

measure

approx. 0.5 n between

between pins 1 and

and between pins 4 and 6, the pulse motor

or

its cable

is

defective.

PS

the

resistance.

pins

1 and

3,

between pins4and

from control

If

it

is

2,

not

5,

REPLACEMENT

PARTS

Power

PCB

Pulse

motor

assembly

#7

The

presser

shifts

to

its home

position,

error

appears on

ERROR

then

code

indicator.

#8

The

presser plate

will

not

shift

the

sewing start

position.

#9

The

TEST

lamp will

not

light

when

TEST

switch is

pressed.

plate

No.3

the

to

the

6.

Main

circuit board

defective

1.

Floppy disk

defective

1.

Floppy

defective

2.

Main circuit board

defective

1.

TEST

cable defective

A 1

I I

ld

II

II

Bl

disk

switch

r-,

It

1111111

lllll1llll

or

Replace

If

overloaded with sewing programs.

error

the

main circuit board.

code

No.3 appears,

Insert another floppy

functions normally

floppy

Replace

Its

Unplug connector

board, then

harness

measured

Al3

specified values,

defective;

Between pins

813

co 0

swings when

dis~

the old floppy disk

the

connector for continuity.

value

or

the moment the indicator needle

with

main circuit board. Main

P2

check

the

is

not

the

B1

(-)and

the

the

floppy disk

disk.

If

the machine

the

newly

inserted

Is

defective.

of

the

control

operation panel board

both

the following

drcult

If

the

panel circuit board

810

( + ): normally

TEST

switch

Is

on.

is

is

Main circuit

board

Floppy

disk

drcuit

board

Panel

circuit

2.

Test

#10

No

feeding

operation occurs

during

the

test.

lamp or its

cable defective

AI

le

~

IIIII

Bl

3.

Main circuit board

defective

1111111

Unplug connector

board, then

A7 ( + ) and A3

hamess connector.

indicate

magnified ohm range, the panel circuit

Al3

board

813

Replace

Refer

PROBABLE

check

(-)of

some

value

Is

defective.

the

main circuit board.

to

#6,

Nos.1,

CAUSES

-20.

P2

of

the control circuit

continuity between pins

the operation panel

If

the tester

with

3,

column •

the

maximum

4,

5,

does

and 6

not

in

the

Panel

circuit

board

Main circuit

board

Page 24

NO.

IN

CHAPTER

FLOWCHART

ERROR

STATUS

#11

Rapid feed can

be

used

during

test.

8

AND

not

the

PROBABLE

1.

Presser plate

switch and its cable

defective

CAUSES

lifter

Refer

CHECK/

to

#4,

ADJUSTMENT I REPAIR

3.

REPLACEMENT

PARTS

#12

The

machine does

not

operate

programmed

during

#13

The

machine will

not

sew.

#14

The machine

operates

speed and

stops

while

an error code.

as

the

test.

at

high

then

suddenly

displaying

Feeding mechanism

not

adjusted. smoothly by hand.

1.

Cable defective Check

2.

Main

circuit board

defective

3. Power module

short-drculted

1. Synchronizer

or

cable defective

Adjust

Refer

PROBABLE

the

circuit board.

If

ERROR

drcuit

If

indicator and

power

(a)

Its

(b) Replace

the

to

#6,

continuity

main circuit board and

error code No.2

indicator, check voltages on

board.

error

code No.2 appears

module is short-circuited.

Check

circuit board and connectors

the

control box are correctly connected.

If

not,

feeding mechanism

Nos.1, 3, 4, 5, and 6 in

CAUSES

if

connector P14

correct

the

column .

between connector

does

the

fuse No.4 is blown,

the

synchronizer.

P4

not

appear on

on

of

connections.

to

of

the

the

move

the

P13

the

PMD

the

the

ERROR

the

main

J2

and

of

main

P2

of

Main

circuit

board

PMDdrcuit

board

FuseSAFB

Synchronizer

assembly

#15

The

machine

operates

presser

but

the

plate does

not.

#16

The thread can

be

cut.

Synchronizer

cable defective

1. Synchronizer

not

cable defective

2.

Main

defective

5~0]

a

or

its

or

circuit

board

3

IOOO

lc

t.2_

o

I

Refer

to

NOTE:

Refer

Its

9

to

(a)*While inserting

let

the

trimming

voltages between pins 5 (

(for thread

between pins 3

release solenoid: BAS-326A and 326LA

only) from

tester does

board

1

-21-

#14.

If

the

machine

status,

the

normally performed.

#1

5.

machine perform thread

operation, and measure

trimmer

the

not

is

defective.

is

placed

test

operation

the

connector

solenoid), and

(+)and 4 (·)(for

lead

wire

oscillate,

In

+)and

side.

the

this

will

P1

tension

tfthe

main

error

be

Into

the

6 (·)

drcuit

Synchronizer

Synchronizer

Maindrcuit

J 1,

board

Page 25

NO.

IN

CHAPTER

FLOWCHART

ERROR

#16

The thread cannot

be

STATUS

cut.

8

AND

PROBABLE

3.

Threadtrimming

solenoid, main

presser solenoid

cable defective

9

5]

I 0 B

r

6 l C 0 Approx. 5 ohms

OGC

1 1

#17

The

machine does adjusted properly

not

stop

with

the

needle

at

the

upper position

after

thread

trimming. defective

#18

The machine

cannot sew

patterns as

programmed.

1.

Synchronizer

2.

Mal n circuit board

CAUSES

or

CHECK/

ADJUSTMENT I REPAIR

Unplug connector

resistance.

<Thread trimmer

P9,

then

measure

solenoid>

between pins

Sand&

Approx. Sohms 304A, 311A, 326A. 326LA

3 Approx. 10 ohms 341A, 342A

1

e....;...r.-

-----.3

<Tension release

solenoid>

only

between pins

3and4

BAS-326A. 326LA

4

not

needle stop position varies

each

time

complete, adjust

the ma<hine operation is

the

upper needle stop

at

random

If

the

signal issuing timing.

Refer

to

#12.

the

REPLACEMENT

PARTS

Thread

trimming

solenoid

assembly

Main

circuit

board

#19

The operation

not

stop if

switch is pressed.

#20

The thread cannot

be

cut

after

emergency stop

is

state

#21

The

cancelled.

STEP

the

the

BACK

will

EM

switch is

inoperative.

1.

EM

switch

cable defective

J12

1.

STEP

BACK

or

its cable

defective

Al

II

r-.

IIIIIIIIIJJ

hllllllllrlllll

~I

J Bl3

or

its

switch

Unplug connector

machine head, then

If

the

resistance is

specified values,

defective;

Between pins 1 and 3:

when

respectively.

Between pins 2 and 3: co Q

when

respectively.

Referto#16and

Unplug connector

board,

then

measured value is

specified resistances,

is

I

defective.

Between pins B 1

normally co 0

needle

switch is

Al3

the

EM

the

EM

check

swings

ON.

P12

check

not

the

EM

switch

switch

#17.

P2

it

for

not

the

(·) and

the

moment

when

from

J12

of

the

it

for

continuity. assembly

the

following

switch assembly

0

nor

co 0

is

OFF

or

ON,

oro

n

is

OFF

or

ON,

of

the

control

continuity.

the

following

panel circuit board

B9

(

+)

;

the

STEP

indicator

BACK

the

drcuit

If

the

is

EM

switch

Panel circuit

board

..._·

#22.

Sewing is

resumed.

not

Referto#12and

#13.

-22-

Page 26

NO.

IN

OIAPTER 8

FLOWCHART

ERROR

STATUS

#23

Programming

cannot be

made.

AND

PROBABLE

1.

Programmer

connector or its

cable

defective

2.

Programmer

defective

3.

Main

drcuit

CAUSES

board

CHECK/

Reattach

connector

Replace

Replace

the

the

ADJUSTMENT

I

REPAIR

REPLACEMENT

PARTS

connectors

P11

programmer. Programmer

main

P7

and

J7,

of

the control circuit

drcuit

board. Maindrcuit

and

board.

board

·23-

Page 27

(oPTIONs)

Using terminals

of

lamp and marker

(j)(Ac6V)

light

When

using

(AC4.5V).

Lamp

38E

The

lamp

(5·1

~01

*When

Marker

3!E

When

purchasing a

below.

Contact

Connector

light

purchasing a

desribed below.

Contact pin(s)

Connector(s)

the

lamp,

below is

ML651-01

pi

n(s)

use

the

connector

an

option.

lamp

P assembly)

lamp

on

the

MOLEX terminal pin (female) 1381ATL

(143548-000) 2

MOLEX3191·02R1

0 (AC&V).

market, replace

pes.

(518466-000) 1pc.

marker

light

on

the

MOLEXterminal

(143549-000)

MOLEX

4pcs.

154SP

market, replace

pin{male)

(505008-000) 2pcs.

When

the

connectors

the

1380n

using

the

of

connectors

marker

the

lamp

of

the

light,

with

marker

use

the

the

parts described

light

connector

with

the

@

parts

-24-

Page 28

The

PC

set

and

the

and switches can

PC

programmer assembly

PC

programmer

be

added

without

I······

assembly

replacing

525157-000

have

been introduced. By attaching the sequencer, the

the

control

P-ROM.

valves

.......

PCset

·I······

533257-009

Page 29

P12

J3

P3

Jt2

[it~

'

I

1------

PCB

)7

H

4P-S

P12

HEAD

-AA

t )

I)

tOP•

PU

PROGRAMMER

111

P10

121

'VPM

131

141

I

tl

P9

121

XPW

131

IGToiXB

HF-AII

foYA

-YA

PID

-YB

tXA

-XA

tW

'

-

.,

~

IUIP)

Hl5P-

Tl"T

~r

:r

,...

~UA":"::C~LO::r.1V...,-A,.......,I9l'"'l

I

:

J

... lJI.Y·B 5 P2

ca

g

AC

ll

i

lA[

....

P3

P4

lOV•A

?

iDY-ll

16

ov.;-c·

rt1

1

~==~

1:

tOY-N

1

ACtOV

~-

iHF-M.

rfr:l:rt

MAIN

MOTOR

529008

DCIN

Pt

~I""

~

~~

~,It

PCB

WYU

p:!j\j;

P5

AIR

P6

Soleaaid

POD

P?

power

r-

~

...

;:-

1

Page 30

Page 31

--r-

0

Loading...

Loading...