Page 1

BAS-300 Series

Programmable electronic pat ern

sewer with cylinder bed

......

BAS-304 • 311

BAS-326

• 340

APPLICATION

EXAMPLE

S

....

.~

, .

Page 2

Page 3

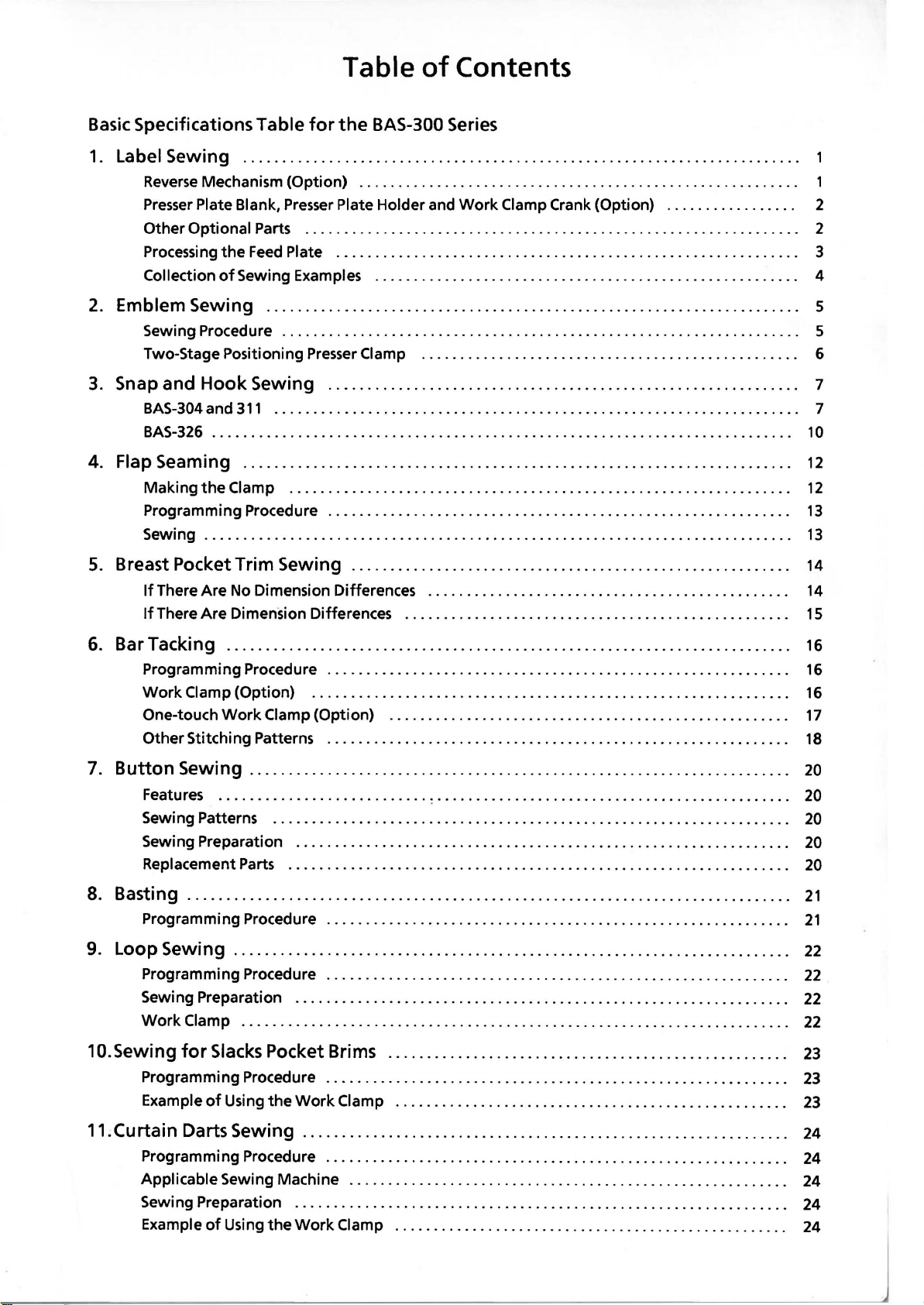

Table

Basic

Specifications Table

1.

Label Sewing ..

Reverse

Presser Plate Blank, Presser Plate Holder and

Other Optional Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Processing

Collection

2.

Emblem Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Sewing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Two-Stage Positioning Presser Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.

Snap and

BAS-304 and

BAS-326 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

Flap Seaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making

Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanism (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hook

the

........................

the

Feed

of

Sewing Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

311

Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

for

the

BAS-300 Series

Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

of

Contents

...

......

Work

.................

Clamp Crank (Option) . . . . . . . . . . . . . . . . . 2

.......

............

.

10

12

12

13

13

5.

Breast Pocket Trim Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

If

There

Are

No Dimension Differences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If

There

Are

Dimension Differences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.

Bar Tacking .

Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Work

Clamp (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

One-touch

Other

Stitching Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.

Button

8.

Basting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.

Loop Sewing

Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Features

Sewing

Sewing

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sewing Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Work

Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...

...

......

Work

Clamp (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.......

Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

......

.........

...

....................................

...........

......................

: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

....

.....................................

.........

...............

14

15

16

16

16

17

18

21

21

22

22

22

10.

Sewing

11.Curtain Darts Sewing

for

Slacks

Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Example

of

Pocket Brims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using

the

Work

Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

...............................................................

Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Applicable

Sewing Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Example

Sewing Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

of

Using

the

Work

Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

23

24

Page 4

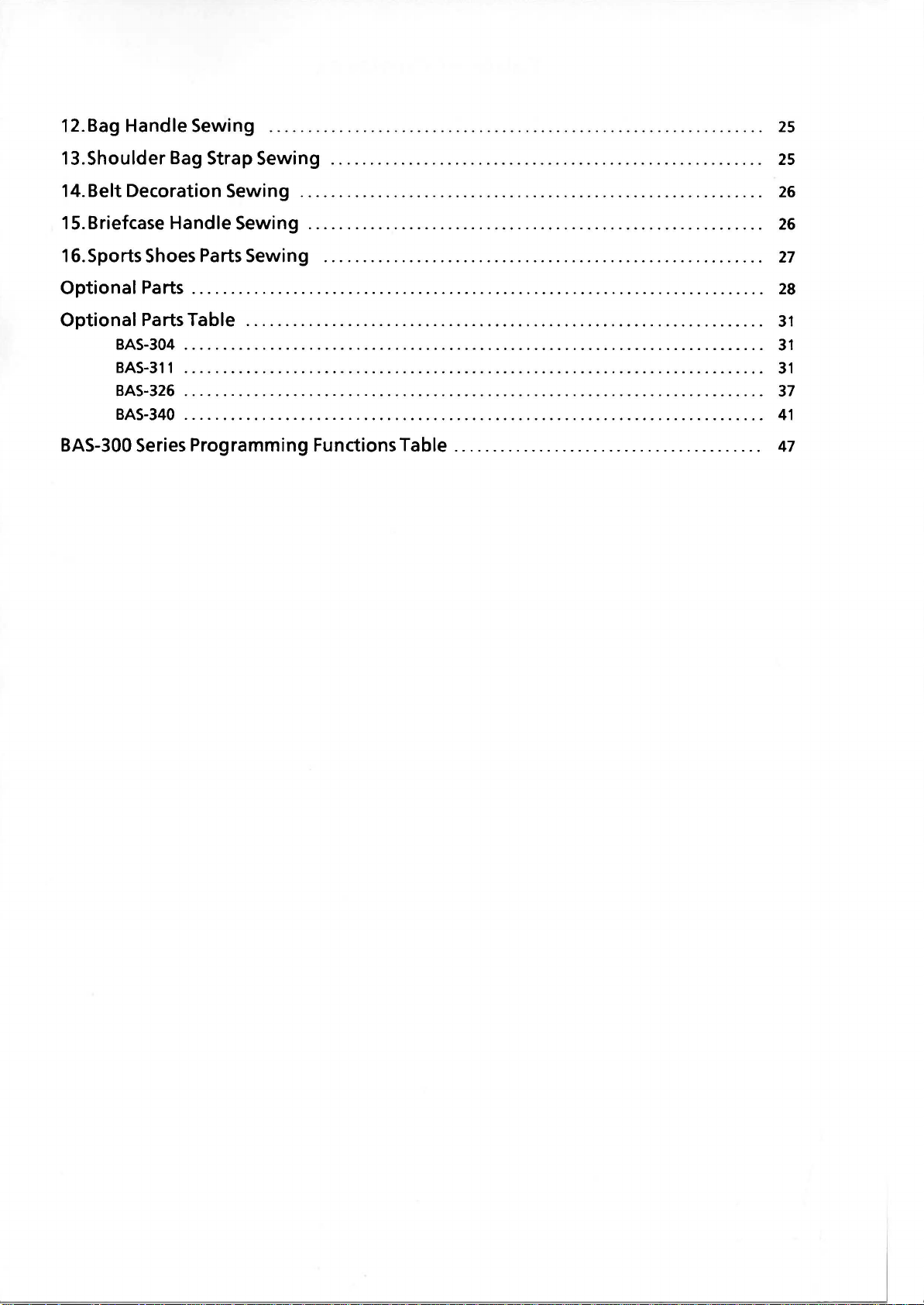

12.Bag Handle Sewing

................................................................

25

13.Shoulder Bag Strap Sewing

14.Belt Decoration Sewing

15.

Briefcase Handle Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

........................................................

............................................................

25

26

16.Sports Shoes Parts Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Optional

Optional

BAS-300 Series Programming Functions Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Parts Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BAS-304

BAS-311 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BAS-326

BAS-340

...........................................................................

...........................................................................

...........................................................................

31

31

31

37

41

47

Page 5

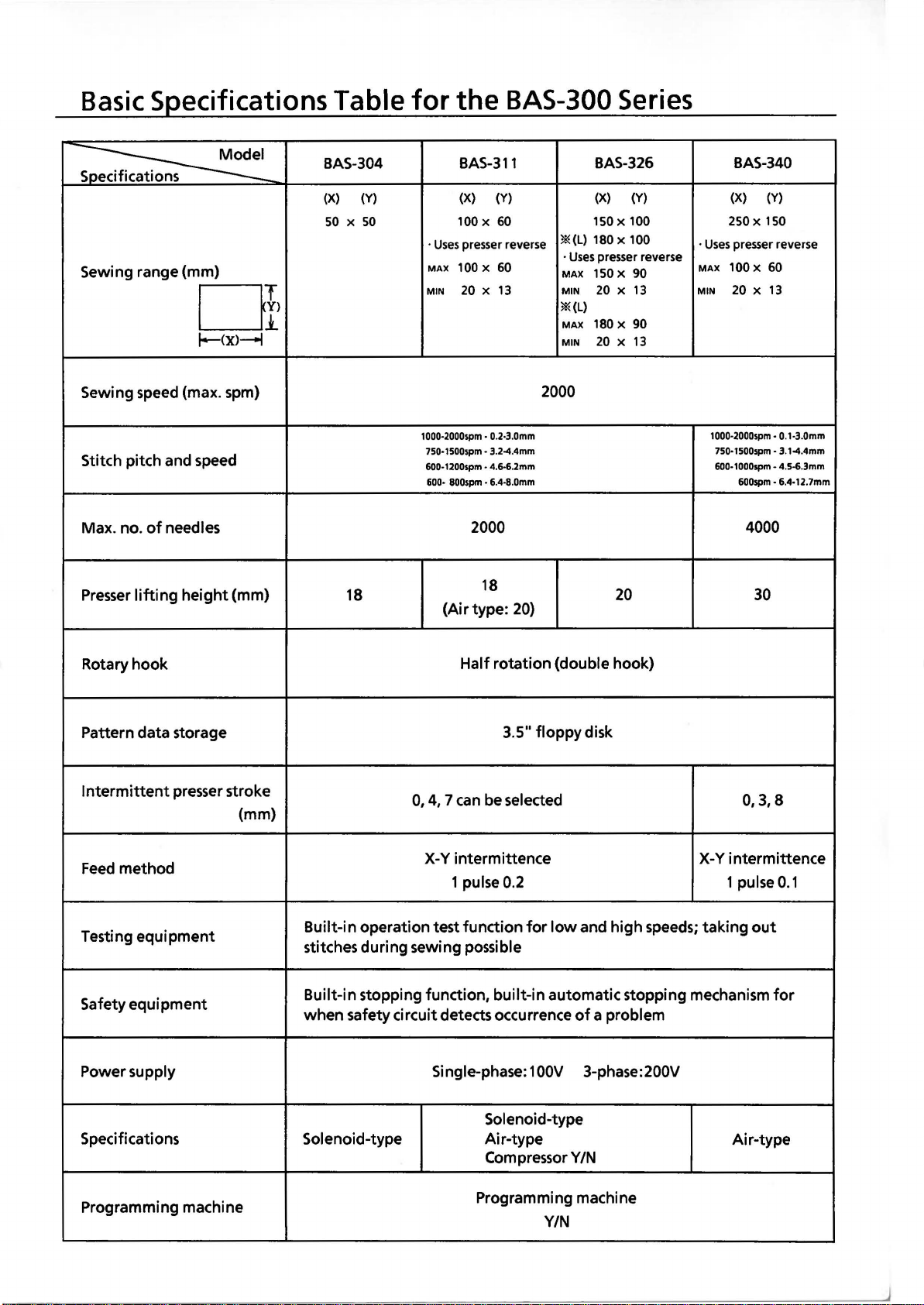

Basic

Specifications

Table

for

the

BAS-300 Series

;pi

~

Sewing range (mm)

or

1---<x>--l

Sewing speed (max. spm)

Stitch pitch and speed

Max. no.

Presser

of

needles

lifting

height

(mm) 18

BAS-304

(X) (Y)

SO X SO

BAS-311

(X)

(Y)

100 X 60 1S0 X 100

·

Uses

presser reverse

MAX

100 X 60

MIN

20 X

13

*

·

Uses

MAX

MIN

*(L)

MAX

MIN

2000

1000·2000spm • 0.2·3.

750·1500spm • 3.

600·1200spm • 4.

600· 800spm • 6.

0mm

2-'1.4mm

6·6.2mm

4·8

.0mm 600spm • 6.

2000 4000

18

(Airtype:

20)

BAS-326 BAS-340

(X) (Y)

(L)

180 X 100

presser reverse

1S0 X 90

20 X

180 X 90

20 X

13

13

(X)

2S0

•

Uses

presser reverse

100 X 60

MAX

MIN

20 X

1000·2000spm • 0.1·3.

750·1500spm • 3.1-'1.

600·1000spm • 4.

20 30

(Y)

X 1S0

13

0mm

4mm

5·6.3mm

4·12.7mm

Half

Rotary

Pattern

hook

data

Intermittent

storage

presser stroke

0,

4, 7 can be selected

rotation

3.5"

(mm)

X-Y

Feed

method

intermittence

1 pulse 0.2

Testing

Safety

equipment

equipment

Built-in

stitches

Built-in

when

operation

during

stopping

test

function

sewing possible

function,

built-in

for

safety circuit detects occurrence

Power supply Single-phase: 1

(double hook)

floppy

low

disk

and

automatic

of

a problem

OOV

3-phase:200V

X-Y

intermittence

1 pulse

high

speeds;

taking

stopping mechanism

0,3,8

0.1

out

for

Specifications Solenoid-type

Programming machine

Solenoid-type

Air-type

Compressor Y/N

Programming machine

Y/N

Air-type

Page 6

Page 7

1.

Label Sewing

To

perform label sewing, attach the inner clamp reverse device

device

is

available

as

an

option

for

each model

as

follows:

BAS-311·

to

the sewing machine.

326·

The

inner clamp

340

Reverse device

BAS-320

(Option)

and

BAS-325

BAS-340

type

types

BAS-310, BAS-311

*

For

BAS-31

For

BAS-311 s 12651-101

ForBAS-320

For

BAS-325

For

BAS-326

For

BAS-340

0

and

BAS-326

512651-001

505650-001

509569-001

515522-001

519994-001

types

-1-

Page 8

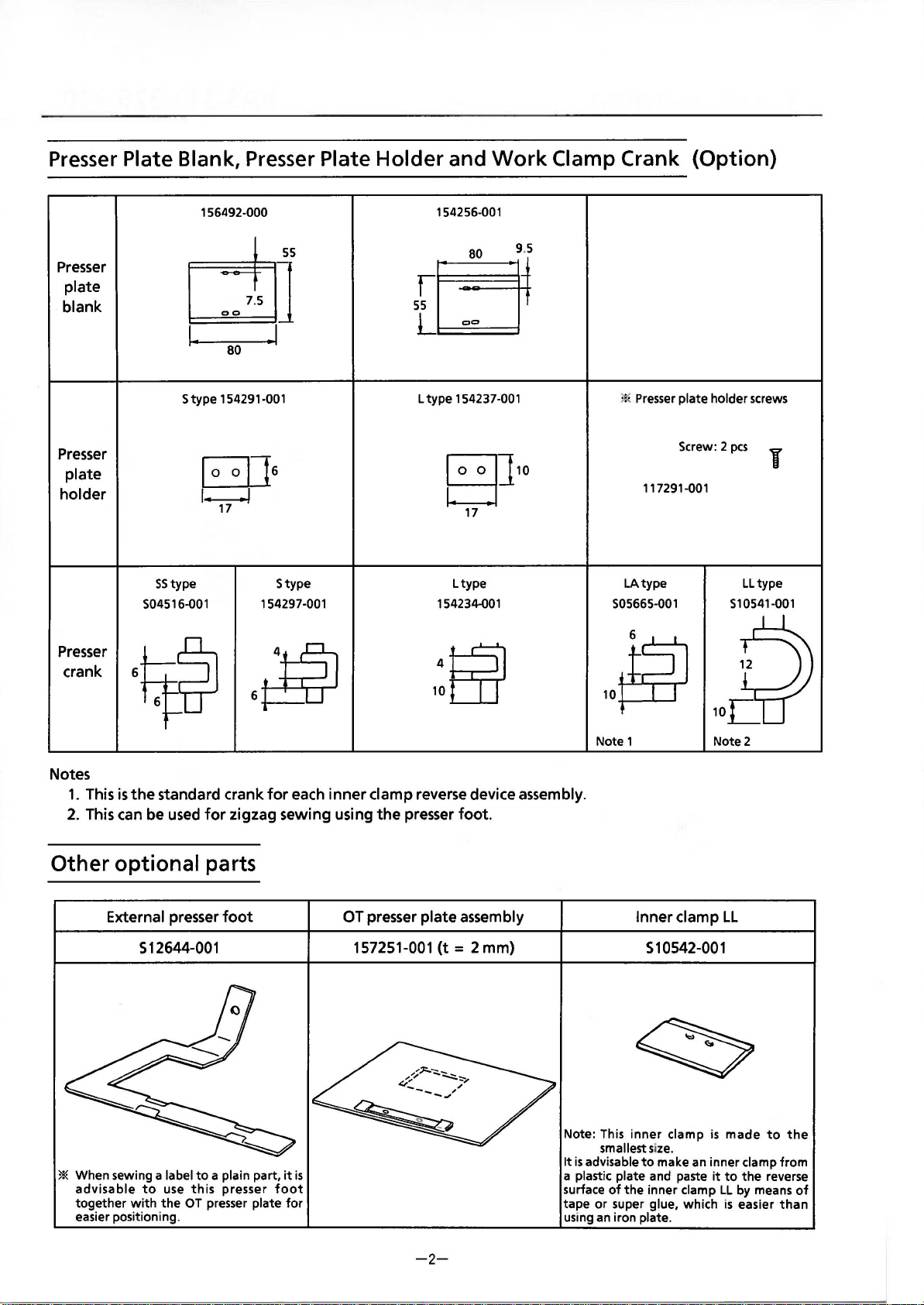

Presser

Presser

plate

blank

Plate Blank,

156492-000 154256-001

dJ1

1.

80

S

type 154291-001

Presser

.1

Plate Holder and

55

rc:Jl

L

oo

L type 154237-001

Work

Clamp Crank (Option)

~

:.

Presser

plate holder

screws

Presser

plate

holder

Presser

crank

Notes

1.

This

is

2.

This can be used

Other

optional parts

Rl

1----l

17

SS

type Stype

504516-001 154297-001

·~

the

standard crank

for

6

.tM

for

each

inner

zigzag sewing using

SJ'"

17

Ltype

154234-001

,:E§1

clamp reverse device assembly.

the

presser

foot.

Screw: 2

pes

T

117291-001

LA

type

505665-001 510541-001

,.~

Note 1

1{

10c

Note2

LL

t

type

I

External presser

512644-001

* When sewing a label

advisable

together

easier positioning.

to

with

use

the

foot

to

a plain part,

this

presser

OT

presser plate

it

foot

for

OT presser plate assembly

157251-001

is

(t

-2-

= 2 mm)

Inner clamp

510542-001

Note: This

It

is

a plastic plate and paste

surface

tape or super glue, which is easier

using

inner

smallest size.

advisable

of

the

an iron plate.

clamp

to

make an inner clamp from

inner clamp

is

it

LL

LL

made

to

the

by means

to

the

reverse

of

than

Page 9

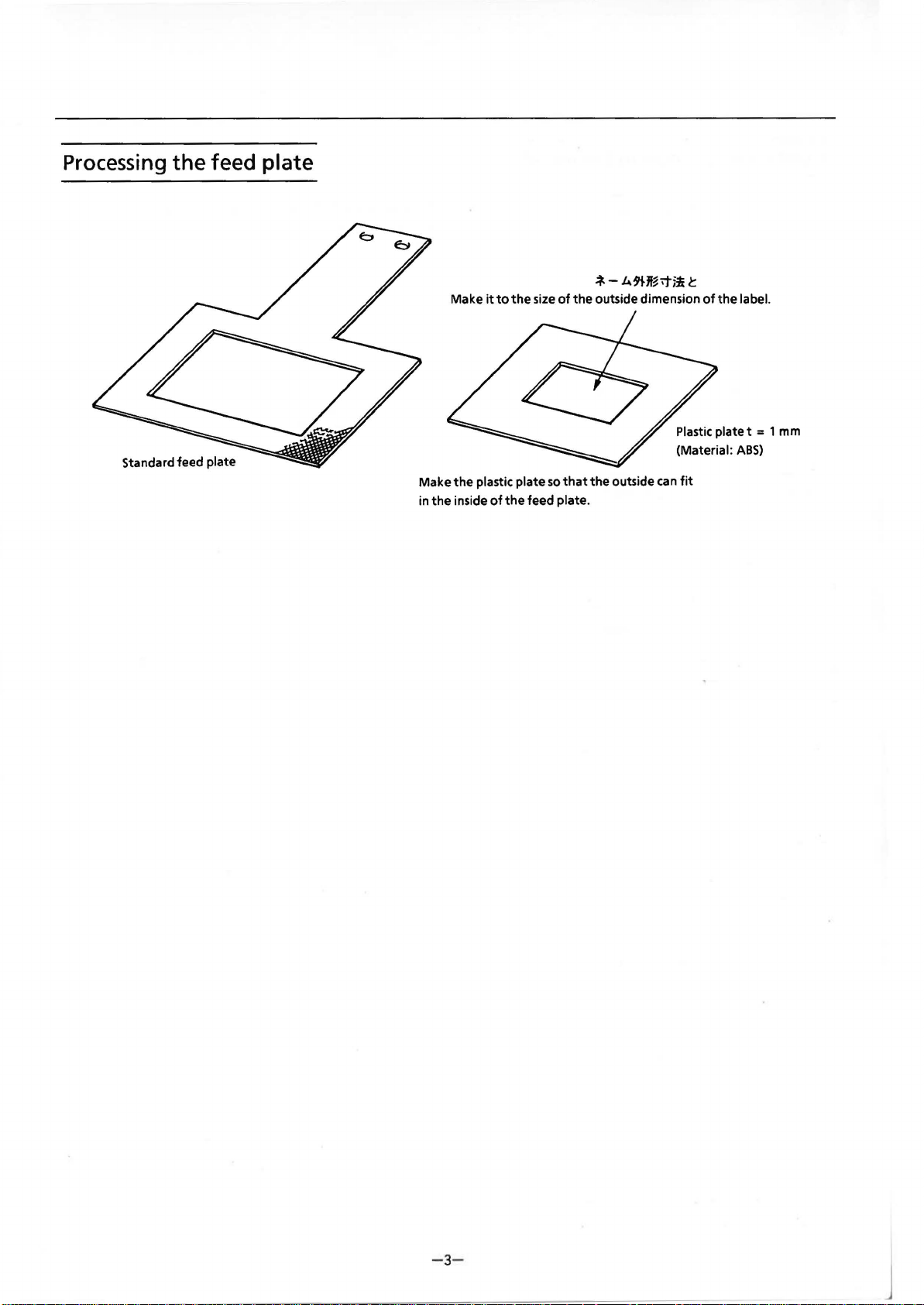

Processing

the

feed plate

Make

*-

it

to

the

size

of

the

.L.~Jf~>tit

outside dimension

t:

of

the

label.

Standard feed plate

Make

in

the

the

plastic plate

inside

of

the

feed plate.

so

that

the

outside

Plastic plate t

(Material:

can

fit

= 1 mm

ABS)

- 3-

Page 10

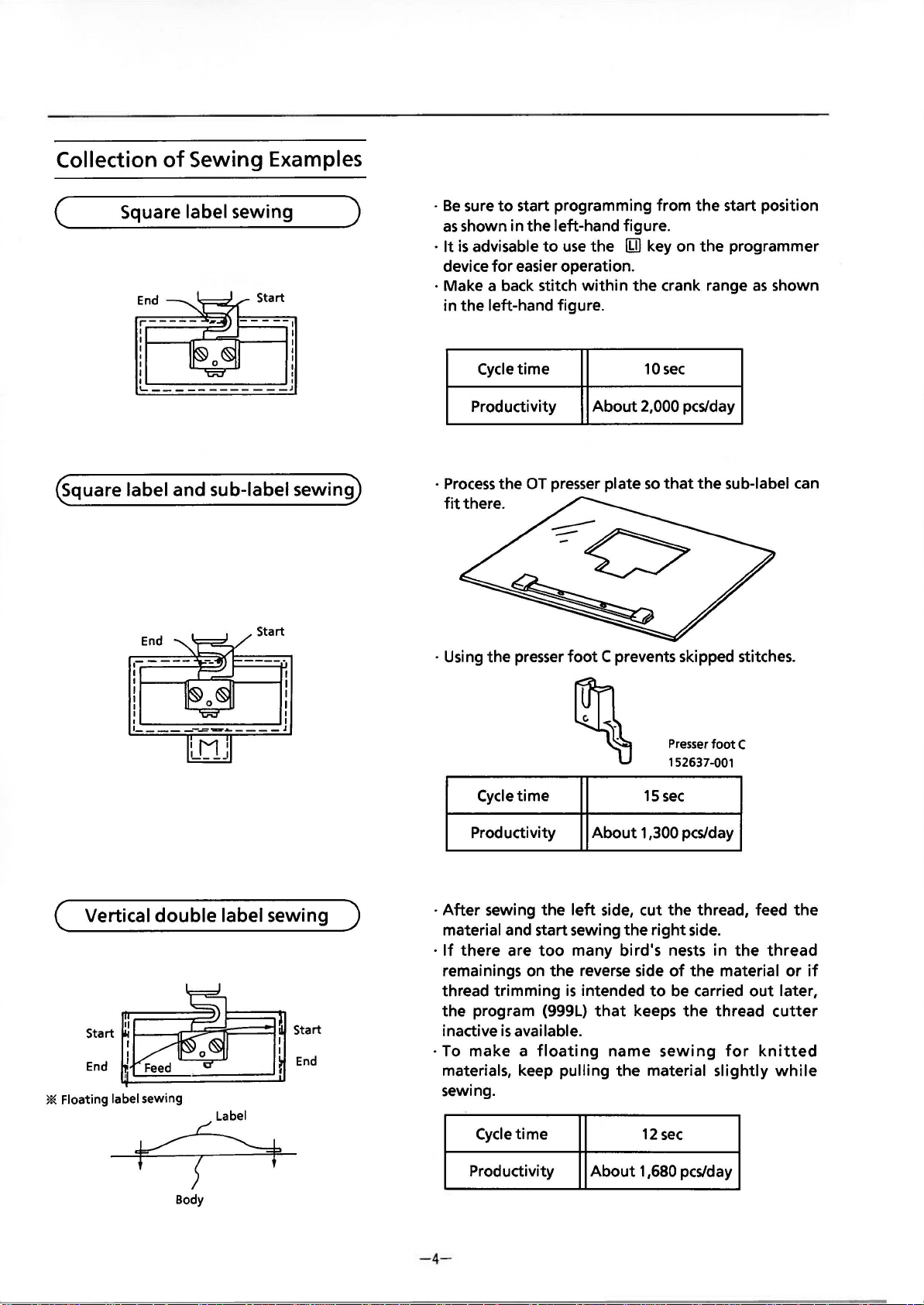

Collection

(

_____

s_q_u_a_r_e_l_a_be_l_s_e_w_i_n~g

of

Sewing Examples

____

~)

·

Be

sure

to

start programming from

as

shown in

·

It

is

advisable

device

· Make a back stitch

in the left-hand figure.

Cycle

the

left-hand figure.

to

use

for

easier operation.

time

the

within

[Y)

key on

the

crank range

10

sec

the

start position

the

programmer

as

shown

~quare

label and sub-label sewing)

Productivity

·

Process

fit

· Using the

the

there.

Cycle

Productivity

OT

presser

presser

time

About

foot

About

2,000

pes/day

plate

so

that

the

C prevents skipped stitches.

Presser foot C

152637-001

15

sec

1,300

pes/day

sub-label

can

(..__v

__

ert

__

ic_a_l

d_o_u_b_l_e_la_b_e_l_se_w

Start

End

* Floating label sewing

Body

__

i

n.....:g~)

Start

End

·After

material and start sewing

·

If

remainings on

thread trimming

the program (999L)

inactive

·To

materials, keep pulling

sewing.

-

4-

sewing the

there

are

is

available.

make a

Cycle

time

Productivity

left

side, cut the thread, feed

the

too

many bird's nests in

the

reverse side

is

intended

that

floating

About

keeps

name

the

12

1,680

to

material

right

of

be

the

sewing

sec

pes/day

side.

the

material

carried

thread

slightly

the

for

thread

out

later,

cutter

knitted

while

the

or

if

Page 11

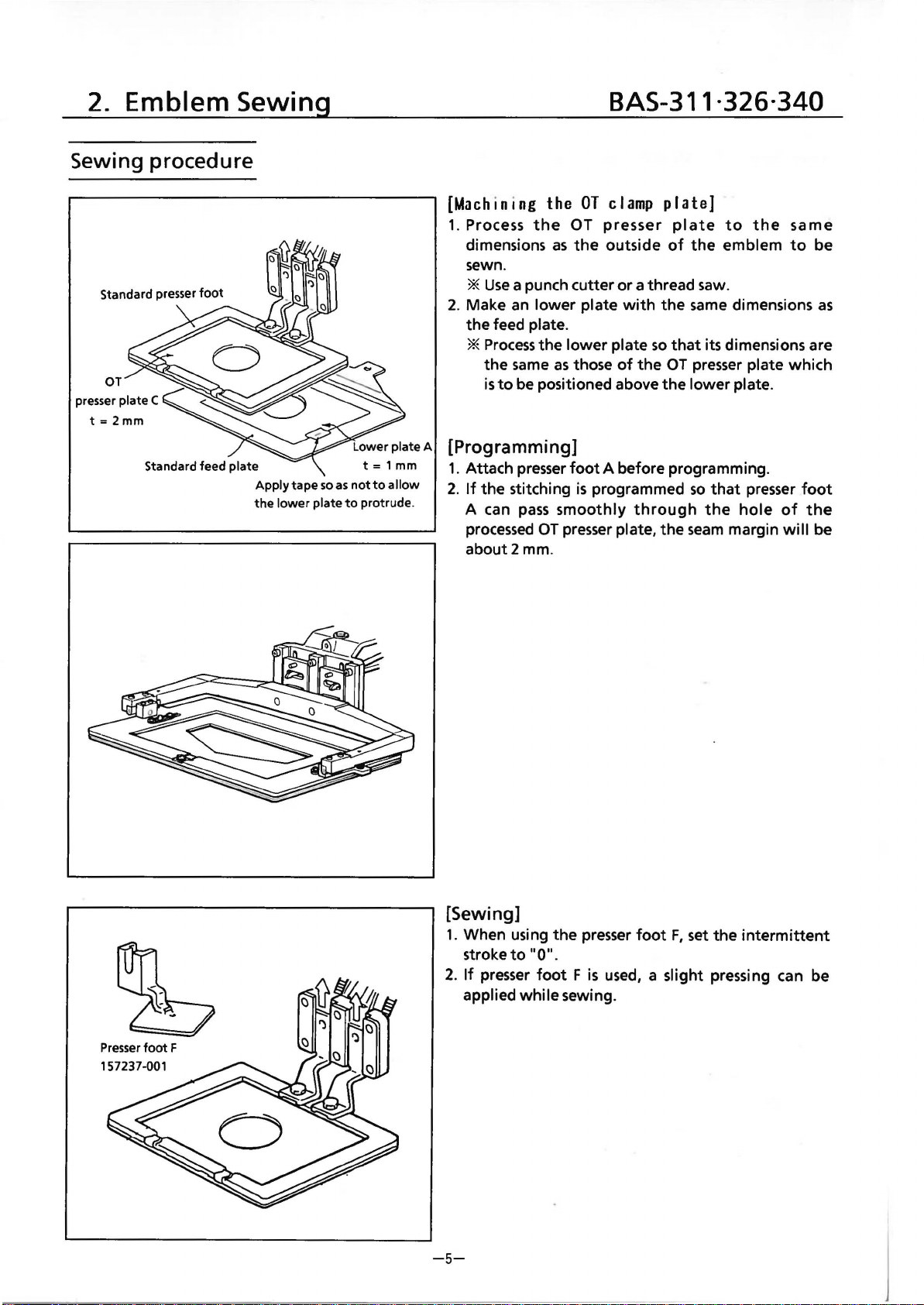

2. Emblem Sewing

Sewing procedure

BAS-311·

326·

340

OT

t=2mm

Standard feed plate t = 1 mm

Apply

tape

so

as

not

to

allow

the

lower plate

to

protrude.

[Machining

1.

Process

dimensions

sewn.

*

Use

2.

Make

the feed plate.

*Process

the

is

to

the

the

as

a punch cutter

an

lower plate

the

lower plate

same

as

be positioned above

[Programming]

1.

Attach

2.

If

A can

processed

about2

the

presser

stitching

pass

smoothly

OT

presser plate, the

mm.

OT

clamp

OT

presser

the

outside

those

foot

A before programming.

is

programmed

or

a thread

with

so

of

the

through

plate]

plate

of

the

the

same

that

OT

presser plate which

the

lower plate.

so

seam

to

the

same

emblem

saw.

dimensions

its dimensions are

that

the

hole

margin

presser

of

will

to

foot

the

be

as

be

[Sewing]

1.

2.

Presser

foot

F

157237-001

-5-

When using

stroke

If

presser

applied while sewing.

to

"0".

foot F is

the

presser

used,

foot

F,

set the

a slight pressing can be

intermittent

Page 12

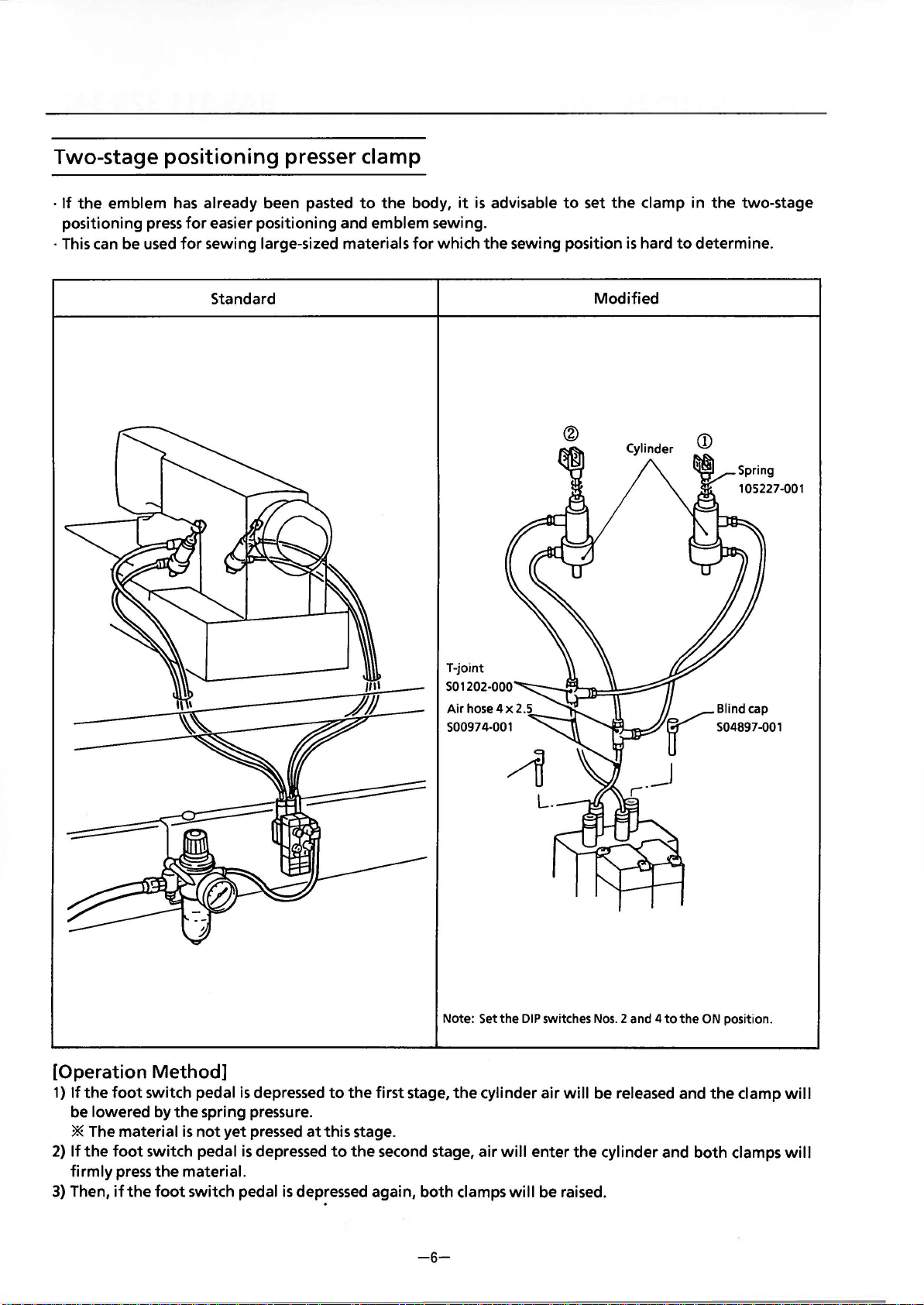

Two-stage

·

If

the

emblem

be

press

used

positioning

·This

can

positioning

has

already been pasted

for

easier positioning and emblem sewing.

for

sewing large-sized materials

presser clamp

to

the

body,

for

which

it

is

advisable

the

sewing position

to

set

the

is

clamp in

hard

to

determine.

the

two-stage

Standard

Airhose4x2.5

500974-001

Modified

'"""---..:..~

Note: Set

[Operation

1)

If

the

be lowered by

* The material

2)

lfthe

firmly

3)

Then,

Method]

foot

switch pedal

foot

switch pedal

press

the

if

the

foot

is

the

spring pressure.

is

not

yet

is

material.

switch pedal

depressed

pressed

depressed

to

the

first stage,

at

this stage.

to

the

second stage, air

is

depressed again, both clamps

-6-

the

cylinder air

the

DIP

switches

will

enter the cylinder and both clamps

will

be raised.

Nos.

2 and 4

will

be released and

to

the

ON

position.

the

clamp

will

will

Page 13

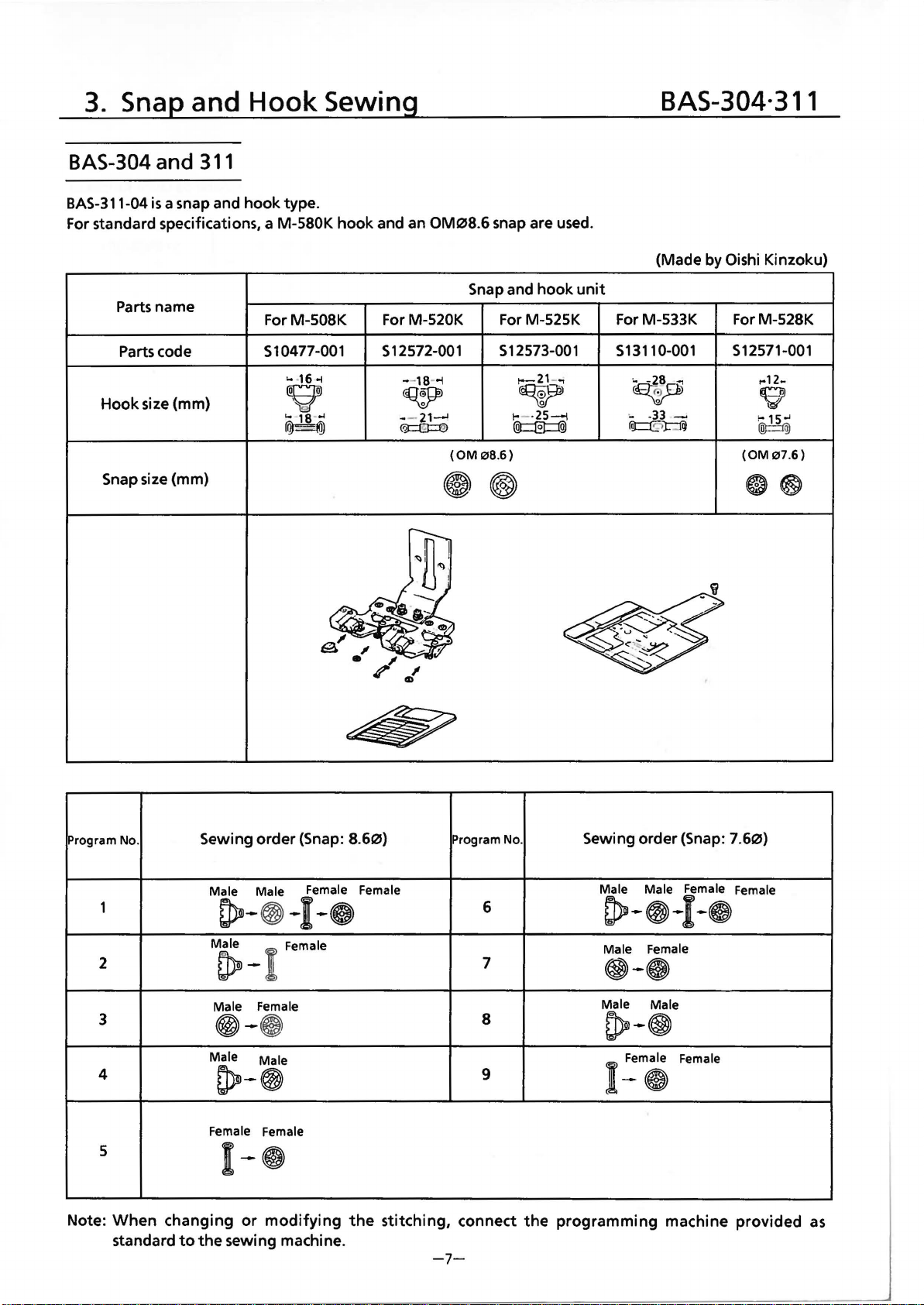

3.

Snap and Hook Sewing

BAS-304 and 311

BAS-304·

311

BAS-311-04

For standard specifications, a

Hook size (mm)

Snap size (mm)

is

a snap and

Parts name

Parts code

hook

For

S10477-001 S12572-001

type.

M-580K

M-508K

.. 16-1

~

...

18·

""

~

hook

and an

For M-520K

OM08

-- 18-

-1

~

- - 21.-J

@::@=@

~

.6 snap are used.

Snap and

For

M-525K

S12573-001

~21-..,

~

l- - -

~

{OM

1218.6)

@

hook

25-1

(Made by

unit

For M-533K ForM-528K

S13110-

001

...

-28

._,

Oishi Kinzoku)

~

'-

.

33-

~

S12571-001

.-12-

~

i- 15-'

@J:39)

{OMIZI7.

6)

@®

Program No.

1

2

3

4

5

Note:

When

standard

Sewing

Male

~-0-I-~

Male

Q)-

Male

@-

Male

~-0

Female Female

1-~

changing

to

the

order

(Snap:

Male

Female Female

Female

1

Female

~

Male

or

modifying

sewing machine.

8.60)

the

stitching,

-7-

Program

6

7

8

9

connect

No.

the

programming

Sewing order (Snap: 7.

Male Male Female Female

C})-0-I-o

Female

Male

@-G

Male

Male

Cj)-@

Female Female

-~

1

machine

60)

provided

as

Page 14

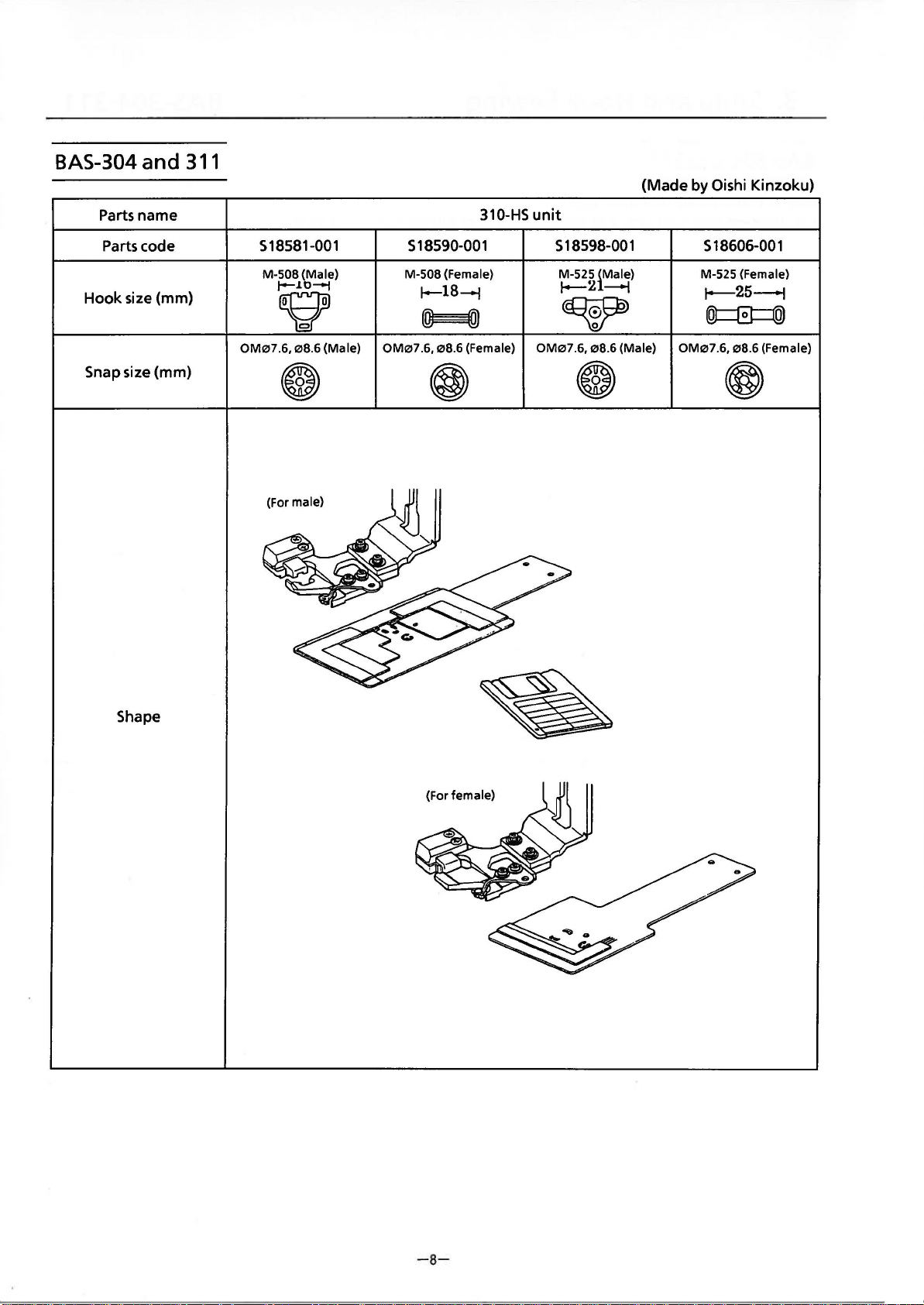

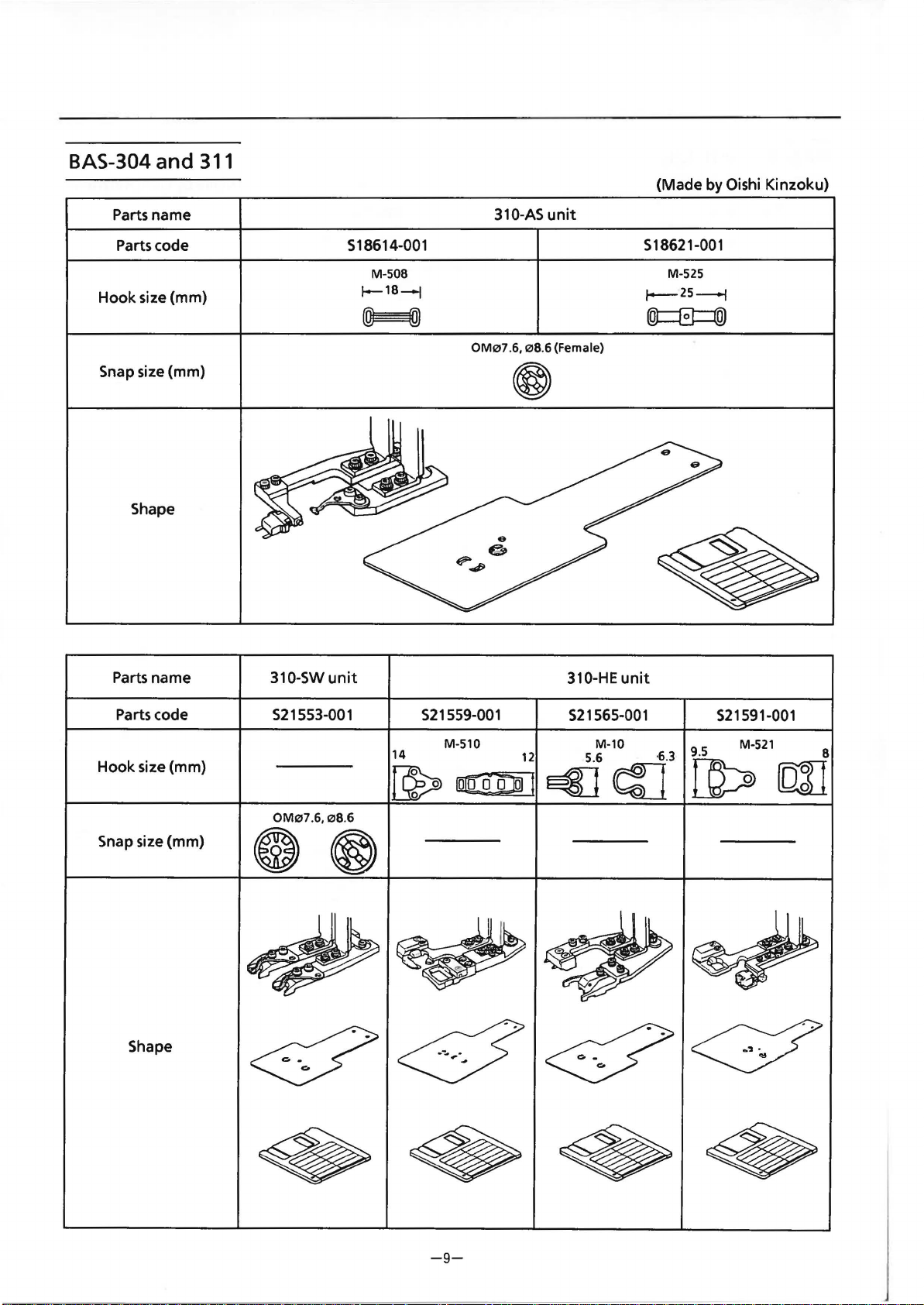

BAS-304 and 311

(Made

by

Oishi Kinzoku)

Parts name

Parts code

Hook

size (mm)

Snap size (mm)

310-HS

S18581-001 S18590-001 S18598-001 S18606-001

M-508 {Male) M-508 {Female)

OM07

l-~0-1

~

.6,

08.6

{Ma I

e)

1--18-1

~

OM07.6,

08.6

{Female) OM07.6,

~ ®

{For male)

unit

M-525

1--2

~

lMale)

---1

M-525 (Female)

t----25--1

@::::8::::@

08.6

{Male) OM07.6, 08.6 {Female)

~

@

Shape

{For female)

-8-

Page 15

BAS-304 and

311

(Made

by

Oishi Kinzoku)

Parts name

Parts code

Hook

size (mm)

Snap size (mm)

Shape

S18614-001

M-508

J.-18-J

~

310-AS

OM07

.6,

unit

1218.6

s 18621-001

M-525

t---25---i

@::::::8:=:@

(Female)

Parts name

Parts code

Hook

size (mm)

Snap size (mm)

Shape

310-SW

S21553-001

OM07.6,

unit

1218.6

e®

S21559-001

14

M-510 M-

~

12

IDfiT}JJilll

~

310-HE

S21565-001

5.6

unit

10

~

g

·6.3

1]fl

S21591-001

M-521

5

.

8

[0]]

-9-

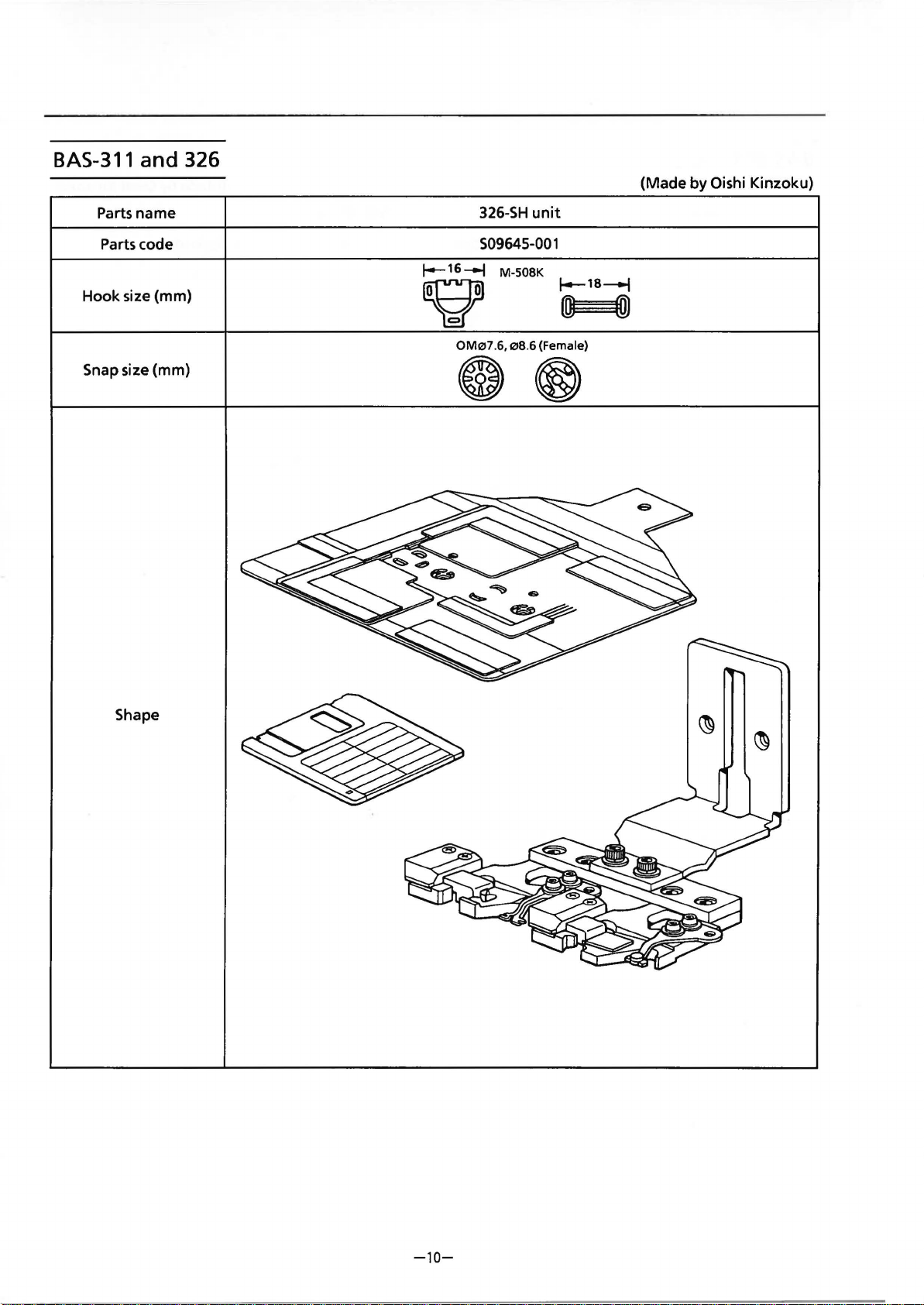

Page 16

BAS-311

and

326

(Made by Oishi Kinzoku)

Parts name

Parts code

Hook size (mm)

Snap size (mm)

326-SH

S09645-001

f--16

--1 M-508K

~

OM07.6,

e®

08.6

unit

(Female)

Shape

-10-

Page 17

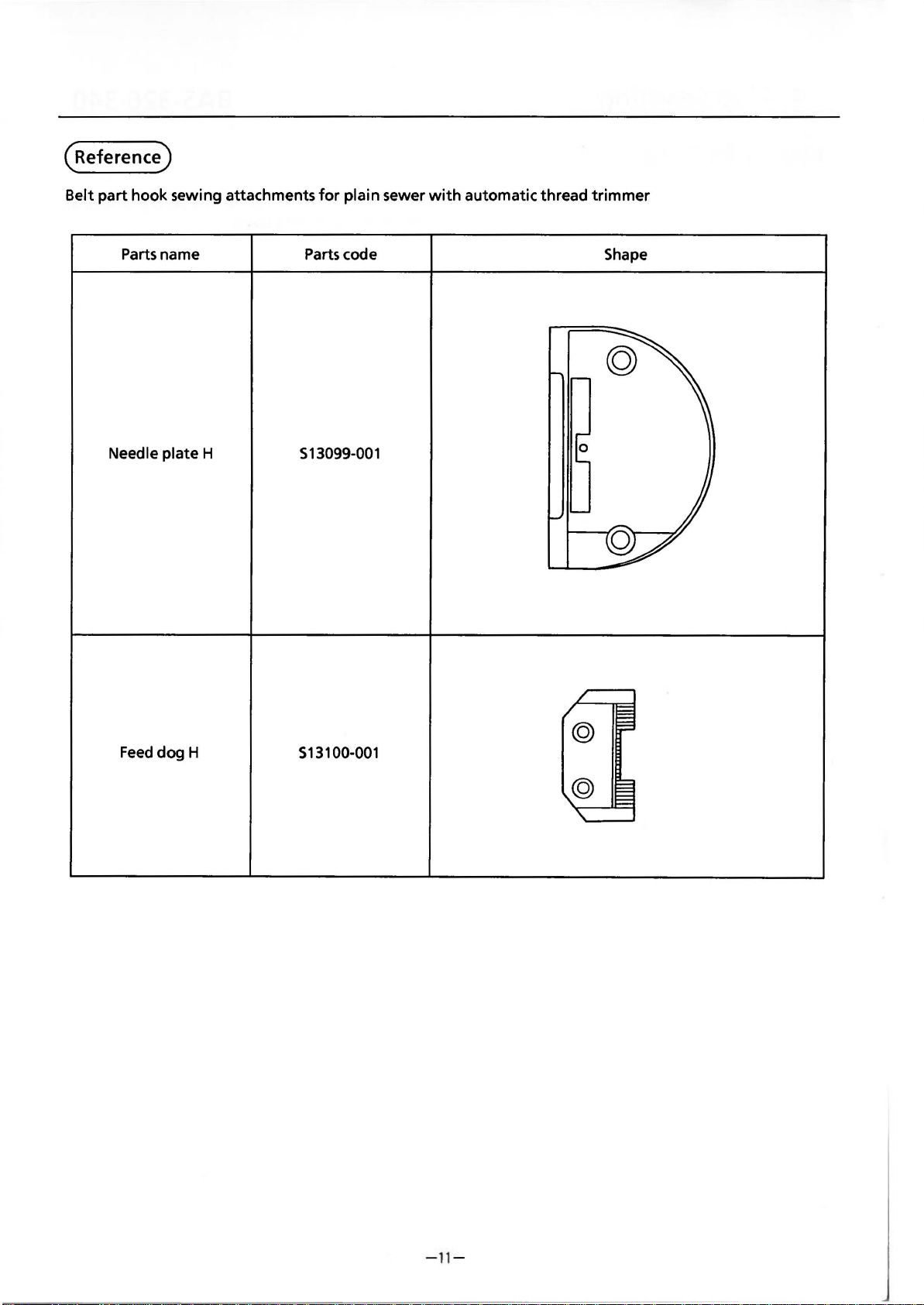

(Reference)

Belt

part

hook

sewing attachments

for

plain sewer

with

automatic thread

trimmer

Parts name Parts code

Needle plate H 513099-001

Shape

Feed

dog H

513100-001

-11

-

Page 18

4. Flap Seaming

BAS-326·

340

Making

the

Clamp

1)

When making

cassette-type optional parts.

Cassette

502968-001

Cassette

502971-001

Cassette

502966-001

2 Butterfly program (right)

152632-001

3 Butterfly program (left)

152633-001

the

clamp,

plate U-A

plate

U-B

plate

0-A

(t = 1)

(t = 2)

use

the

parts provided

as

2)

3)

Presser

foot

A

152283-

101

-12-

When using

outside diameter

the

width

NOTE:

If

the material being sewn slips

sewing

or

thin

cassette plate U and

cassette plate

presser

ofthe

cassette plate groove

Use

a punch

processing.

can

be

carried

rubber

is

D.

foot A for

of

presser

cutter

out

stuck

to

the

more easily

the lower surface

upper

sewing,

foot A is

or

a thread saw

during

surface

because

4mm,

to

be

5mm.

sewing,

if

sandpaper

the

process

for

of

the

of

the

Page 19

Programming Procedure

(Example)

1)

Set

a stitch diagram

between

NOTE:

2)

Use

program

the

cassette plates U and

Secure

that

it

does

the feed key on the programmer machine

so

that

stitch line.

At

this time, programming

key (

~)

is

smoothing function

NOTE:

3)

After

For

the

used

for

programming, attach

give a test run

that

presser

center

If

plate

of

any interference

or

foot A passes

the cassette plate groove.

the program

such

as

the

stitch diagram

not

move.

the end

used

BAS-325,

of

along

is

used

the trace function

programming.

to

the

sewing machine

is

found,

to

clear

the

ones shown

D.

with

tape, etc.,

the

needle follows

will

be

easier

if

the

straight

lines and

along curved lines.

the

presser

smoothly

adjust

the

interference.

foot

to

make sure

along

the

cassette

at

left

so

to

the

line

the

can

be

A, and

the

Sewing

Standard

work

clamp

Presser

foot

157237-001

1)

When sewing,

with

the standard

2)

When using

presser

the

stroke

press

the cassette plate from

work

clamp.

presser

at

foot

F,

"0",

and keep pressing

set the

the

top

intermittent

the

cassette plate during sewing.

F

-13-

Page 20

5. Breast Pocket Trim Sewing BAS-311 · 326·

340

Before programming, make sure

to

the specified dimensions.

If

There Are No Dimension Differences

that

the

length,

width

and angle

[Work

1)

Process

width

2)

If

the

positioned, sewing

of

Clamp]

the

OT

and angle

lower

the breast pocket have been finished

presser plate

of

the breast pocket.

surface

of

can

be carried

the

to

OT

match

presser

out

easily.

the

length,

plate

is

{Example)

Start

poi

[bJ

[Programming]

If

there

dimensions

sewn in a

To

program this single cycle sequence, program a

shunt feed

nt

is

no

difference

(size)

on

sides

single cycle.

(F)

between points A and

in

A and

the

B,

breast

both

B.

sides

pocket

can

be

-14-

Page 21

If

There

Are

Dimension Differences

{Example)

Start

point

[f]

Thin rubber

A

E~d

~

IEJ

End s

/

Shunting

Start

~

;/s

point

point

ss~

'Y

[Work

1)

2)

Clamp]

Process

dimensions

If thin rubber

surface

will

out

the

of

of

the

be

firmly clamped and sewing

easily.

work

clamp

the breast pocket.

or

sand

paper

work

clamp blank, then the material

[Programming]

Use

a split program. Enter a shunt feed

final stitch position

position in

point.

seam

in

seam A to

B,

and then enter

plate

is

stuck

666

to

can

the

~at

match

to

the lower

be

(F)

from

initial

that

the

carried

the

stitch

start

Thin rubber

[Sewing]

1)

This

program enables the

at B to

The sewing procedure

shunting point

Raise

then restart the machine.

after the machine returns

A,

2)

When setting the material, adjust the

located on the circuit board

so

positioning.

*Two-stage

reconfirm the position

at

B,

the clamp

it

will

stop and the clamp

that

the clamp

•

If

the clamp

first stage, air

cylinder,

spring force.

the material

mm), the

in the specified position.

·

If

the

foot

air enters the

the material firmly. (Refer

to

check the material position and

can

positioning

foot

will

and the clamp

Because

at

this

material

switch

cylinder, and the clamp

presser

ofthe

is

sew A, move

and stop the sewing machine.

Seam B will

to

the shunting

will

be

or

modify the air tube

be

provided

unit

switch

is

(SW)

be

released from the clamp

will

be

the clamp

time

(floating

can

be

moved freely and set

pressed

to

top.

foot

to

be

material.

to

be

sewn, and

point

raised.

DIP

switch

with

two-stage

is

pressed

lowered by the

does

the

second

6)

to

not

by 1

stage,

will

lifted

the

at

the

press

to

2

press

-15-

Page 22

6. Bar Tacking BAS-311· 326

~

Number

Stitch size: 7-16 x 1 -2

·The

bar

of

stitches: 42

tacking

as

shown

W~'·aWlvV/1

Number

St

itch size: 7-20 x

above can be

Programming Procedure

Because

programming

1.

2.

3.

4.

5.

After

6.

Save

7.

Although

disk.

the

Enlarge

After

the

will

be displayed

Press

the

Use

the

programming

the

number

easier.

the

stitching

[f)

key

1M1

key.

jog

key

program

the

is

for

to

set

on

stitch

of

cross stitches

pattern

pressed,

10

times

the

program

the

final

the

floppy

pattern

by

"905"

enlargement.

stitch, key

was enlarged,

of

five

will

for

disk.

stitches:

is

or

35

1.5-3

programmed

small,

ten

be displayed

each stitch.

in"

it

times

111

the

program

is

the

[§".

~

Number

Stitch size:

and sewn freely.

advisable

original

in

the

STEP

will

of

stitches:

6.5-

to

size.

space

be

written

use

W¥14

28

16

x 1 - 2

the

enlargement

for

5 times enlargement, and "91

in

Number ofstitches:

Stitch size: 3 - 7 x 1 -2

the

original

function

size

on

21

to

the

make

0"

floppy

Work

clamp (Option)

· OT presser

· Presser

· Presser

·

OT

feed plate bracket assembly

•

OTfeed

·Screw

foot

foot

plate

foot

D assembly

SL

SR

S14846-001

S14255-001

S14254-001

S14841-001

S14252-001

149168-001 2 2

-16-

Page 23

BAS-304·311·326

One-touch

A one-touch

easier.

BAS-311

BAS-326 . . . . . . . Max. sewing thickness

Note:

If

the

limited.

Work

work

. . . . . . . Max. sewing thickness

sewing thickness

Clamp (Option)

clamp

(option)

is

is

greater

provided

to

make conversion and positioning

is

Smm (sewing area

is

S.Smm

than

(sewing area

the

maximum,

* For

* For

at

the

BAS-311

BAS-326

this

time

at

this

time

range

is

100 x 60mm).

is

150 x 1

of

use

of

of

the

work

S20279-001

S20813-001

OOmm).

the

thread

clamp

wiper

blank

will

be

Items included

* Presser

* Jig

holder

Screw

<For

as

a set:

foot

holder

L,

R . . 1 each

setl,

R . . . . . . . . 2 each

holder

both

Parts name Jig

Parts code

set

BAS-311

and BAS-326 >

holder

S20822-001

L set

Presser

foot

holder

<L>

<R>

Jig holder R set

S20823-001

,,

Shape

-17-

,,

Page 24

BAS-304·311·326

One-touch

A

work

clamp

(For large bar tacking]

[For small bar tacking]

[For vertical bar tacking] (L)

Work

for

all

Work

types

Clamp

Clamp (Option)

of

bar

(L)

(L)

tacking

(R)

(R)

(R)

can be

attached

Stitch

f¥'

· Y "Y V Y V ·

1<1

~v

·¥~~

II

~~~

·tn~~

!'

as

the

one-touch

pattern

A/¢AAA!MA~

lo

...

U

v ·o

II

'If

~: ~

X

'V

V • V

14

l1

M •o

1

..

' I .' I t

ll

X

10

(reference)

Yl

-.

I

· ~

r~

't

t.

II

"

II

II U U 10

.,.

t

O,

OJ

Y r

10

o

~

I I

"

work

11

clamp

for

(R)

523818-001

(L) 523819-001

Feed

523820-001

(R)

523821-001

(L) 523822-001

Feed

the

BAS-311.

Parts

plate:

plate:

code

523823-001

(R)

523827-001

(For

triangular

(For half-moon bar tacking] (L)

bar tacking] (L)

(R)

(R)

(L) 523828-001

Feed

plate:

523829-001

(R)

523833-001

(L) 523834-001

Feed

plate:

523835-001

(R)

523824-001

(L) 523825-001

Feed

plate:

523826-001

[For

cross

bar tacking]

(L)

(R)

-18-

(R)

523830-001

(L) 523831-001

Feed

plate:

523832-001

Page 25

Other Stitching Patterns

Butterfly

pattern

stitch

v:J

Number ofstitches: B4/4 Number

Stitch size: 5 x 5

Label attaching stitch

:

I I

Number ofstitches: 70 Number ofstitches:

Stitch size:

Shoehorn stitch Pattern stitch

Number

Stitch size:

50

x 12

I

za7?

of

stitches:

60

56

x 3 Stitch size: 48 x 1 0 Stitch size: 92.5 x 55.5

Straight label stitch Trapezoidal zigzag stitch Half-moon tackstitch

::;:....

a$"

r:::J

of

stitches: 84/4 Number

Stitch size:

Label attaching stitch

20-

25

x 0 Stitch size:

of

stitches: 70 Number ofstitches:

16

x 6 Stitch

Trapezoidal pattern stitch

..

(

Stitch size: 86 x

\

c:

Number

of

stitches:

J

B4

2B

·~

35

(]?;

Numberofstitches:

Stitch size:

31

x 20.5

63

[

Numberofstitches:

Stitch size:

-

]

e_-

}

Number ofstitches : 98 Number ofstitches:

Stitch size:

~

size: 12

::-:

50-

u

x 7

60 x 20-

50 x 54

56

]

:

9B

30

112

Front hok attaching stitch Facing hem stitch Safety

v

Number

Stitch size: 20.5 x 15.9 Stitch size: 20 x

Hand loop stitch

Number

Stitch size: 6-14 x

Button attaching stitch

Number

Stitch size: 2.5-6.5 x 0-6.5

of

stitches: 112/2 Number

F+F?;

of

stitches: 42/2

l:

of

stitches: 9

or

18

u

of

stitches: 70 Number

29

kfbS

of

Number

Stitch size: 6-14 x

stitches: 28

s:

Number

Stitch size: 2.5-6.5 x 0-

of

stitches: 9

or

18

6.5

Stitch size: 35.1 x 40.3

kQ

Number

Stitch size:

Number

Stitch size:

belt

stitch

~

of

stitches: 112

El

t;

28

x

;

of

stitches:

14-25

X

of

stitches: 9

2.5-6.5 x 0-

or

18

6.5

_..

v

Number

Stitch size:

Numberofstitches: 18

Stitch size: 2.7 x 2.7

of

stitches:

45 x 21

56

-o

-19-

Page 26

7.

Button Sewing

If

a three-hole

be

used

as

button

lock stitch

button

Features

1.

Stitching

2.

Sewing

3.

Up

4.

If

the

can

be quickly changed, requiring no trouble

of

three-hole buttons and various

to

ten sewing patterns can be stored in

button

clamp

Sewing Patterns

clamp and a special-purpose

PROM

are attached

to

the

BAS-304

sewers.

to

is

removed,

the

machines

button

the

memory.

can

sewing

be

used

replace

as

as

the

feed

cam.

shown in

the

below figure

electronic sewing machines.

8©CD@@®®

BAS-304·

or

BAS-311,

can

they

be achieved.

311

can

Sewing Preparation

Attach

button

the

Before

the

clamp and

front.

turning

special-purpose

the

needle

on

the

power, be sure

Replacement Parts

PROM,

will

and

turn

the

not

touch each other

to

move the needle

DIP

switch

because

to

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

No.

5 located on

the

machine origin

the

the button position.

1.

BU

presserfoot

2.

BU

presser

3.

Presser

foot

OTfeed plate bracket assembly

OTfeed plate

Button

float

Float spring presser plate

PROM

for

PROM

for

Screw

Screw

Washer

Bolt 4.76

Washer 4.76

Button clamp

UL

foot

UR

D assembly

spring 153871-001

button sewing (304) Special order

button sewing (311)

circuit board

point

will

S14849-001

S14848-001

s 14846-001 2

S14841-001

S14069-001

S14073-001

S15167-001

149168-001 2

062670-512 2

102707-002 2

117363-001 2

025710-232 2

S03463-001

to

ON.

come be

The

at

-20-

Page 27

8.

Basting

Programming Procedure

(Example 1)

l.

999

. F

6

(Example 2)

2

1.

Press

the

If]

key. (The clamp

BAS-304·

will

move

311

to

the

machine origin point.)

2.

Use

the

jog key

to

move

the

clamp

to

the sewing

start position.

5

l.

999

. F

3. Program

In

4.

stitches

that

the

first stitch

the

same

way, program

by

pressing the

movement should

by

pressing the

the

[b)

key. Note, however,

be

made for

IQ

second

two

key.

and

or

third

more

pulses.

5.

After

position,

6.

7.

the

Program

In

l.

999. F

4

the fourth stitch

stitch

to

8.

Program

jog

9.

10

. Then,

After

[E)".

7

"999"

fourth stitch by pressing

the

same

to

is

press

the

by

pressing the

displayed

1El

key, and move the needle

IQ

in

the

key.

the

jog

key.

way, program the movement

to

the

fifth

stitch, from

the sixth stitch, and from the sixth stitch

the seventh stitch.

the

eight and ninth stitches

key and the

programming

the

clamp

IQ

key.

will

the

ninth stitch, key in "111

return

to

the sewing

third

by

using

stitch

the

to

from

fifth

the

start

position.

11. Press

12.

in

the

Press

the

READ/WRITE

floppy disk.

the

If]

key

switch

to

clear

to

the

store

display

the

program

of

the

programming machine.

11

12

6

-21-

Page 28

9. Loop Sewing

Programming procedure

(Example)

Sewing Preparation

BAS-304·

1.

Prepare a stitching pattern, and program

stitch.

For

the linear part,

programming.

2.

The

seam

part covered by

be 3.0

to

1.

Use

the

pitch

4.0 mm.

presser

press

the

for

the linear part and the zigzag

cross

stitching should preferably

foot

A.

[1!)

key

311

for

for

each

easier

Work

Work

513097-001

Clamp

clamp L

2.

Turn

the

DIP

board

stages

•

Feed

· Work Clamp L

· Work Clamp R

pi ate

to

ON,

for

easier working.

.....

Presser

foot

A

152283-101

switch

and the clamp

.

..

..

No.

513098-001

513097-001

513096-001

2 located on the circuit

will

operate in

two

-22-

Page 29

10. Seaming

for

Slacks Pocket Brims

BAS-326

When sewing

100mm)

Programming

Program curved lines easily by using

If

the

split program

efficiency.

seams

can

provide symmetric curved lines.

for

slacks

pocket brims, using

procedure

is

used,

the

left

the

BAS-326

Pocket

--~==/===;J;===;=k~;;Si~g

Facing

the

smoothing program.

start and

the

right

start

and

BAS-373

Y

Main

material

will

be made alternately, improving sewing

(width

interfacing

180mm x

length

Example

of

Using

the

Work

Clamp

-23-

Page 30

11. Curtain Darts Sewing

The

BAS-311

1

OOmm

can store

can

also be used.

up

to

10

patterns

Programming procedure

(Example)

(Example)

c

A

Start

~

T

\,

~

End

D

.

~

I

t

for

darts sewing, and a

1.

Patterns A and B are programmed by specifying

the

2.

Pattern C

pitch

3.

For pattern

sewing

adjuster plastic plate

machine speed

and protects

wide

range

seam

pitch and then pressing

is

provided

(6

to

7 mm)

at

both ends

D,

the

for

the

to

needle

program

low

BAS-311

of

darts lengths from 75-

the

1Y1

with

a part

passing

for

sewing

is

possible. This changes

speed

from

with

the

wire

can

be set

the

curtain

during

breakage.

hook.

lap

key.

wide

so

that

sewing

seam

lap

height

the

I

'

l

Applicable sewing machine

·

Use

a air specifications type

thick

· A 1

·The

materials

OOV

compressor can also be provided.

BAS-311

to

thin

lace.

is

of

horizontal head specifications.

Sewing Preparation

·

Set

the

intermittent

·

Use

the

presser

Example

of

stroke

foot

A ( 1 52283-101

Using

at

the

with

strong pressing pressure because

7 mm.

).

Work

75-1

OOmm

Clamp

the

materials

to

be sewed vary

from

0 0

0

0

0

0

.,

......

Plastic

Mater1a

....,...,,E-SCU-.J

plat

e

presser

c<

Cprt~m

-24-

Page 31

12. Bag

Handle

Work clamp and sewing pattern

Sewing

BAS-326

·Sewing speed:

·Thread:

Nylon upper thread

lower thread #30

·Needle:

·Programming time:

· Cycletime:

· Daily production output:

2,618

DPx 5

pieces

1,000spm

#21

11

sec.

10

#20

min.

13. Shoulder Bag Strap Sewing

Work

clamp and sewing pattern

flt-----7!

I'

I

I

I /

I / ' I

~----~lol

/I

' / I

' "' I

Y,

I

BAS-326

·Sewing speed:

·Thread:

Tetron upper thread

lower thread #30

1,649

DPx 5 #21

pieces

·Needle:

·Programming time:

·Cycle time:

· Daily production output:

1,500spm

17

sec.

10

#20

min.

-25-

Page 32

14. Belt Decoration Sewing

Work

clamp and sewing pattern

BAS-340

·Sewing

·Thread:

· Needle: 134KKD #1

· Programming

·

Cycle

· Daily production

speed: 1,250spm

Tetron upper thread

lower

thread

time:

900 pieces

32

#50

time:

sec.

output:

00

20

#30

min.

15. Briefcase

Work

Handle

clamp and sewing pattern

Sewing

BAS-340

·Sewing

·Thread:

·Needle:

• Programming

•

Cycle

• Daily production

speed: 800spm

Nylon upper thread

lower

thread

DPx

17

time:

time:

26

sec.

1,000 pieces

#30

#21

20

output:

#20

min.

-26-

Page 33

16. Sports Shoes Parts Sewing

Work

clamp and sewing pattern

BAS-340

·Sewing

·Thread:

·Needle:

· Material: Cushion

·Clamp

·

Presser

·Cycle

• Daily production

speed: 1,500spm

Tetron upper thread

lower

thread #30

DPx5#8-#21

method: Cassette

foot:

A-F

time:

14sec.

2,058 pieces (514

#20

type

output:

sets)

-27-

Page 34

Optional Parts

BAS-340

[Needle cooler assembly] 521110-009

~

I

*

When

set

the

needle cooler assembly

the

DIP

switch B-4

to

ON

as

shown above.

is

attached,

-28-

Page 35

Optional Parts

BAS-311·

[Light

transformer

AC200V

To

terminal

To

terminal

No. 20

326

No.

assembly] S 18465-000

For

SV

marking

21

light

I

: j

L---

__

( .

L .

.J

...,

LJ

I

' I

I

I

..

I

*Connect

------

the

following

Connector

Connectors

pin

parts

to

the

other

6V machine

MOLEX Female

MOLEX 3191-02R1

ends

of

the

light

pin

(143548-000) 2

(S

18466-000) 1

-29-

respective connectors.

SV

1381ATL MOLEX

(143549-000) 4

MOLEX 1545P

(SOSOOB-000)

marking

Male

pin 1380TL

light

2

Page 36

Optional

Parts

BAS-326

[Data Converter assembly] 518051-001

If this assembly is used.

can be interchanged .

data

in

the

BAS-320 and BAS-325 micro disk (2.

5")

and data in

the

BAS-326

floppy

disk (3.5")

Converter harness

*The

BAS-320

has a different

area size,

so

correct before making conversions.

-30-

Page 37

Optional Parts Table

BAS-304

Presser

~

A

02

.5 152283-101 c

B

04

0

-JIE~'

A : 510211-001 E: 510212-101 F: 510213-001

~

152636-001 D

·_r

I

13

~

02

03

Needle

0

-,_:I

foot

~

152637-001

154069-001

hole

plate

~

4

2.

60

°

t--

I

-.....I..

I

'r

12.8

~

b~

E 01 .6 154089-001

F

02

J

02

.5 513815-001

0

~

157237-001

3

BAS-311

~

A 02.5 152283-101

B

04

~

c

152636-001 D

Presser

~

02

03

foot

~

152637-001

154069-001

~b~

E 01 .6 154089-001

F

02

02

J

157237-001

.5 513815-001

-31-

Page 38

Optional Parts Table

BAS-311

Needle

hole

plate

-dE~·

·

~

I

A : 510211-001 E: 510212-101 F: 510213-001

13

Work

clamp

2.8

blank

<>i•·•

~

E-1: 153526-000

OT presser

E-3

: 154386-000

plate

assembly

E-4

: 510269-000

1

0.6

t=0.5

A:

157248-001 B: 157250-001

Feed

plate blank

A:

510265-000

t=1

C: 157251-001

B: 510266-000

t=2

1

,.

E: 513566-000

-32-

H : S 19659-000

Page 39

Optional Parts Table

BAS-311

OT

feed plate blank

(t

= 1.2)

1

(C)

514844-001 (D) 514845-001

<D

(G) 519666-001

(312) 514598-001 @

®

(DE)

514253-001 @ Frame assembly

For basting

(ST)

For

~0

(F)

514251-001

for

OT

feed plate bracket 514841-001

loop

sewing

.

5

514252-001

<D

Feed

plate

31

®

@

Work

Work

clamp

(R)

clamp (L)

0-2

513092-001

513090-001

513091-001

BAS-320/325 feed

<D

Feed

plate

attachment

bracket: 512586-001 ® Cassette supporter pin

Cassette supporter plate

@

3types

of

nut

-33-

plate

<D

Feed

®

Work

@

Work

attachment

513006·001

513007-001

021660-306

plate

clamp

clamp

31

<D

®

0-3

(R)

(L)

Work

Work

513098-001

513096-001

513097-001

clamp

(R)

clamp (L):

:

510411-001

510412-001

Page 40

Optional Parts Table

BAS-311

For cylinder bed

t=

1.2

Feed

plate

blank

E:

513566-001 513567-000

Feed

plate

lower

plate

(for

C,

D)

Home position reference plate assembly

513046-001

-34-

Page 41

Optional Parts Table

BAS-304·

311

Attachment

for

i-----7

~6

button

sewing

3 2

1

2

3

4

5

6

7

OT

presser

foot

D assembly 2

BU

presser

foot

U-R

BU

presser

foot

U-L 1

Screw4

.37 2 149168-001

Button

clamp assembly 1

Bolt4.76

Flat

washer

4. 76 2

* The

14~

$14846-001

1 $14848-001

$14849-001

$03463-001

2 117363-001

025710-232 14

PROM

for

button

OT

feed

plate

8

OT feed

9

Button

10

Float spring presser

11

Screw 357-40 x 5 2

12

13

Washer

PROM

sewing

bracket assembly 1 $14841 -

plate 7 flat

float

spring 1.2

for

button

sewing 1 $15167-001

in

the

BAS-304

plate

001

1 $14069-001

153871-001

1

1 $14073-001

062670-512

102707-002

2

is

available by special order.

-35-

Page 42

Optional Parts Table

BAS-311

Attachment

for

bar tacking

1 Presser

2 Presser

3-1

OT

feed

OT feed

3-2

Attachment

1 OT presser

foot

5R

foot

5L

plate

DE

plate

5T 1 514252-001

for

one-touch

work

2

foot

1

1 514254-001 4

1 514255-001

1 514253-001

clamp

514850-001

OT

feed

plate

bracket assembly

OT

presser

foot

5

5crew4

6

o assembly

.37

1 514841-001

2 514846-001

2 149168-001

OT

presser

foot

2

3

5crew4.37

o assembly

1

1

514846-001

149168-001

-36-

Page 43

Optional Parts Table

BAS-326

A

02.5

8

04

01.6

152283-101

152636-001

=d[cJ

04

Presser

c

02

D

03

Needle

plate

3.2

foot

152637-001

154069-001

hole

02.2

3.2

01.6

E

F

02

J

02

.5

154089-001

157237-001

513815-001

4.8

A:

502371-001

: 502441-001

5

502372-001

E :

M:

502288-001

Presser spring

Presser

foot

F : 502373-001

L: 502469-001

FH : 51

0690-00 1

MM

: 505667-001

Inner clamp

LL

1 : 502853-001

2 : 502854-001

-37-

3 : 502855-001

LL

: 510542-001

Page 44

Optional Parts Table

BAS-326

<D

Cassette

~

Cassette

work

work

cia m p 1 R

clamp 1 L

<D

~

~

41.5

502845-001

502846-001

Cassette

work

clamp

<D

Cassetteworkclamp2R

0

Cassetteworkclamp2L

~

----,~>~

~2

~~~

0

0

<D~

<D

--~

~

502847-001

502848-001

52

<D

Cassette

®

Cassetteworkclamp3L

1.

Cassette plate D-A

2.

Butterfly

3.

Butterfly

work

clamp

program (right)

program (left)

3R

502849-001

502850-001

~

502966-001

152632-001

152633-001

<D

Cassette

® Cassette

2

1.

Cassette plate U-A

2.

Cassette plate

2

work

work

clamp

clamp 4L

(t = 1)

U-B

(t = 2)

4R

502851-001

502852-001

502968-000

502971-001

1. Cassette supporter

1.

Cassette supporter plate assembly 180

2.

Cassette plate D-B180

3.

Cassette

lower

plate

late A 180

assembly

502963-001

514384-001

514388-001

514386-000

-38-

Work

clamp L

502470-001

Page 45

Optional Parts Table

BAS-326

Sub-plate

OT

OT

OT

presser

presser

presser

plate

A assembly

plate

B assembly

plate

C assembly

Work

Sub-plateS

S02442-001

503902-001

503903-001

503904-001 (t = 2)

clamp crank

(t=O.S)

(t=

1)

OT

OT

OT

presser

presser

presser

Foot

Sub-platel

S02443-001

OT

presser plate

plate

A assembly 1

plate

B assembly 150

plate

C assembly 150

operation

509378-001

SO

509379-001

509380-001 (t = 2)

pedal plate

(t = 0.5)

(t=

1)

OT

OT

OT

presser

presser

presser

plate

A assembly 180

plate

B assembly 180

plate

C assembly 180

Sub-plate 180

S10682-001

513695-001

513697-001

513698-001

(t=0.5)

(t=

1)

(t=2)

Work

clamp

plate

LL

S10541-001

Foot

operation

S02984-002

switch plate L assembly

-39-

Page 46

Optional Parts Table

BAS-326

Part names

Work

clamp

blank

Lozenge

~~"'~"'~

...

~~(

~~~~~~~~~

~~~~~~~~

Lozenge

"l/ "l/

~$$$$$~

~$$$$$~

~~~~~~~~~

~~~~~~~~~

s

Work

clamp

blank

Feed

plate

blank

$&$&$

Plate

thickness

B-1R

8-1L 153449.()00

8-3L

B-3R

1-3R

1-3L

1-4R

1-4L 502824.()00

1-SR

1-SL 502826.()00

2-3R

2-3L

2-4R 502829.()00

2-4L

2-SR

2-SL

150R-3

L

150L-3 509371.()00

1

SOR-5

1

SOL-S

L-180

3-3 3.2

3-4

3-5

4-3 3.2

3.2

3.2

3.2

3.2

4-4 4

4-5

5-3 3.2

S-4

S-5

5-3A

5-4 A 4

5-SA 5 502983.()00

150-3

150-5

180

1

2 2

3

4

5

150

180

3.2

3.2

3.2

Size(AxB)

39x80

4

3.2

4

5

4 75 X 135 L

5

5

4

5

5

4

5

5 L 509375.()00

1

2

39x80

50 X 110

sox

110 L

sox

110 L

7Sx

135

75x

135 L

90x

135

90x

135 L

123x135

100x80

125x110

150x

135

180x135

216x

135

170x

140

246x

148

200x

140

230x

140

Lozenge

5

L

5

5

5

5

5

L

5

L

5

L

5 509374.()00

5

Lozenge

Hole

Parts code

153448.()00

153470.()00

153471.()00

502821.()00

502822.()00

502823.()00

502825.()00

502827-000

502828.()00

502830.()00

502831-000

502832.()00

509370-000

509372.()00

509373.()00

513694.()00

502833.()00

502834.()00

50283 5.()00

502836.()00

502837.()00

502838.()00

502839.()00

502840.()00

502841.()00

502981.()00

502982.()00

13693.()00

5

502234-000

502843-000

502844.()00

502842.()01

503309.()01

509376-000

513692-000

-40-

Page 47

Optional Parts Table

BAS-340

A

02.5

8

04

152283-101

152636-001

01 .6

~3

Presser

c

02

D

03

Needle

foot

152637-001

154069-001

hole

plate

E 01 .6

F

02

J 02.5

154089-001

157237-001

513815-001

02.2

~3

..

Jt

'

·:·

This can also

A:

510211-001

Presser

foot U NS

~

·-~

~

be

..

"-··~

~~

used as

the

519620-009

Presserfoot

assembly

-

cassette work clamp for

(180x

100)

UNL assembly

E: 510212-101

the

8A5-326.

Presser

plate

UNS

519611-001 (180 X 1 00)

Work

clamp

F: 510213-001

assembly

519635-001

(250x

150)

-41-

519609-009 (250 X 150)

Page 48

Optional Parts Table

BAS-340

Work

clamp

SEU

S19637-001

E1

(180x

100) S19638-001 (150 X 1 00)

Work

clamp

blank

: S17979-001 E4: S17981-001

0.6

L: S19599-001

-42-

0.6

R: S19600-001

Page 49

Optional Parts Table

BAS-340

OT

work

clamp assembly

2 519594-001

3

4 517982-001

A-150 509378-001

B-150

C-150

519592-001

509379-001

509380-001

(T=2,

(T

(T=4,

250x

150)

= 3, 250 X 150)

250x150)

(T=0.5)

(T=

1)

(T = 2)

52

53

54

A-180 513695-001

B-180 513697-001

C-180

Presser spring

519618-001

519616-001 (T =

519614-001

513698-001

(T

(T=4,

= 2, 180 X 100)

3,

180 X 100)

180x

100)

(T=0.5)

(T=

1)

(T=2)

t=0.4

502853-001

2

t=0.6

502854-001

Screw4.37

107419-002

-43-

t=0.8

3 502855-001

J

Page 50

Optional Parts Table

BAS-340

Feed

plate

~.r

A 517894-001 c 518543-001

Feed

plate

blank

A 517976-001

·:· This can also be used

C-1

as

the

cassette

519634-001

work

clamp

for

the

Presser

BA5-326.

-44-

c 517978-001

plate

C-2

519914-001

Page 51

Optional Parts Table

BAS-340

Cassette supporter plate 326 assembly

·

~

The

519912-001

Cassette supporter plate assembly

cassette

for

the BA5-326/326L

can

be

used

.

<D

2

* The cassette

Cassette supporter plate 519627-001 Butterfly program (right) 152632-001

Cassette

Cassette

body 519630-001 Butterfly program (left) 152633-001

lower

plate 519631-001

Cassette

center

(T=

1.0) 519643-000

(T = 2.0) 519632-000

plate

Cassette

2

for

the

BAS-301/302

upper plate

(T

= 1 .0) 5 19644-000

(T

=2.0) 519633-000

can

be

used

.

-45-

Page 52

Optional Parts Table

BAS-340

Cassette

Cassette supporter

Cassette body 340L 520755-001

®

Cassette

lower

plate

plate

340L assembly 520753-001

supporter plate assembly

Butterfly

Butterfly

519631-001

Presser

foot

(SEU)

program (right) 152632-001

program (left)

152633-001

520756-001

-46-

*The

work

clamp

for

the

BAS-326

can

be used.

Page 53

BAS-300 series

·This

is

a guide list

when you are programming.

for

using during progr9mming .

programming

functions

Please

refer

to

table

this table

for

the correct instructions

Function Instruction code keys

Quit

Clear

data

Low speed conversion

Trace

Repeat

Point symmetry

X axis symmetry

Y axis symmetry

Return

Traced

Mirror

Traced

Mirror

drawing

drawing

K

K

111

(g)

222

[B)

666

[Q

555

[Q

333

[Q

440[Q

441[Q

442[Q

443[Q

001

~

011

~

BAS-304

BAS-311

BAS-326

0 0 0

0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0

0 0 0 0

0 0 0 0

0

0

0 0

0 0

0

0

0

BAS-340

0

0

0

0

0

0

Traced

drawing

Mirror

K

Smoothing

Smoothing end

Double-row sewing

Split_program

Setting enlargement and reduction modes

Setting X

ratio

modes (

DDOis000-199%)

Setting Y

ratio

modes

(OOOis000-199%)

Parallel

Split program wi

Cross

stitching

( 0 can be a numeral

Basting program

K

width

for

enlargement and reduction

for

enlargement and reduction

movement

during sewing

th

no thread trimming

setting For

from

0-9)

When pitch

When

not

Be

sure

to

width

is

3mm: 030M

set: 2mm

press

the

2mm

I I I

I

770

010

~

IOI3IOI

corner.

EEl

666 0

888

~

I~

I~

I I

~

777

EB

888 0

[!J

~

999

789

2[ll[l

~

[!J

~

0 0 0

0

0 0 0 0

0 0 0 0

0 0

0 0

0 0 0

0 0 0

0

0 0 0 0

0 0 0

0 0 0

0

0

0 0 0

0

0 0 0

0 0 0

0

Setting enlargement

For

instructions on operating the programming machine, refer

machine.

input

For

twofold

input

-47-

9[ill]~

to

the operating instructions

0

0 0 0

for

each

J

Page 54

Loading...

Loading...