Page 1

HANDBOOK FOR COMPACT

OVERLOCK MACHINE

MANUAL DE INSTRUCCIONES DE LA

MAQUINA COMPACTA OVERLOCK

English

Product Code: 884-B01

Español

Please visit us at http://solutions.brother.com

where you can get product support and answers to

frequently asked questions (FAQs).

Visítenos en

donde hallará consejos para la solución de problemas

así como la lista de preguntas y respuestas más

frecuentes.

http://solutions.brother.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using the sewing machine, basic safety precautions should always be followed, including the following.

Read all instructions before using.

DANGER

To reduce the risk of electric shock.

The sewing machine should never be left unattended when plugged in. Always unplug this sewing machine from the

electrical outlet immediately after using and before cleaning.

WARNING

To reduce the risk of burns, fire, electric shock, or injury to persons.

1. Do not allow to be used as a toy. Close attention is necessary when the sewing machine is used by or near children.

2. Use this sewing machine only for its intended use as described in this manual. Use only accessories recommended by

the manufacturer as contained in this manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped

or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer or service center for

examination, repair, electrical or mechanical adjustment.

4. Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing machine and

foot controller free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any openings.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn the main switch to the symbol "O" position which represents off, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch the sewing machine to the symbol "O" position when making any adjustments in the needle area, such as

threading needle, changing needle, or changing presser foot, etc.

15. Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when making any

other user servicing adjustments mentioned in the instruction manual.

16.This sewing machine is not intended for use by young children or infirm persons without supervision.

17.Young children should be supervised to ensure that they do not play with this sewing machine.

18. Do not disassenble the machine.

19. If the LED light unit (light-emitting diode) is damaged, it must be replaced by authorized dealer.

CAUTION

To use the machine safely

1. (For U.S.A. only)

This appliance has a polarized plug (one blade wider than the other) to reduce the risk of electric shock, this plug is

intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the

proper outlet.

Do not modify the plug in any way.

2. Make sure you watch the needles carefully while you are sewing. Do not touch the hand wheel, needles, knives, or

other moving parts.

3. Turn off the main power and unplug the cord in the following circumstances:

- When you have stopped using the machine

- When you are replacing or removing the needle or any other part

- If there is a power failure while you are using the machine

- If you are checking or cleaning the machine

- Leaving the machine unattended

4. Do not store anything on the foot controller.

5. Fully plug the machine directly into the wall. Do not use extension cords.

6. If water is dropped on the machine, unplug the machine immediately, and contact your local authorized dealer.

7. Do not put furniture on the cord.

8. Do not bend the cord, or pull on the cord to unplug.

9. Do not touch the cord with wet hands.

10. Place the machine near to the wall outlet.

11. Do not place the machine on an unstable surface.

12. Do not put on the soft cover.

13. If you notice any abnormal sound or condition, consult your local authorized dealer.

II

I

II

Page 3

To give your machine a longer life

1. Do not store this machine in direct sunlight or in high humidity conditions. Do not use or store the machine near a

heater, iron, halogen lamp or other hot object.

2. Use only mild soaps or detergents to clean the case. Benzene, thinner, and scouring powders can damage the

case and machine, and should never be used.

3. Do not drop or hit the machine.

4. Always consult this manual before you replace or fit the presser foot, needle, or any other parts to make sure you fit

them correctly.

To repair or adjust the machine

If the machine breaks down or needs adjustment, first follow the troubleshooting table to inspect and adjust

the machine yourself. If the problem persists, consult your local authorized dealer.

"SAVE THESE INSTRUCTIONS"

"This sewing machine is intended for household

use."

CAUTION

When leaving this sewing machine unattended, the main power and light switch of the machine must be

switched off or the plug must be removed from the socket-outlet.

When servicing the sewing machine, or when removing covers, the machine or the electrical set must be

disconnected from the supply by removing the plug from the socket-outlet.

English

FOR USERS IN THE UK, EIRE,

MALTA AND CYPRUS ONLY

IMPORTANT

- In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying the mark, rating

as marked on plug.

- Always replace the fuse cover. Never use plugs with the fuse cover omitted.

- If the available electrical outlet is not suitable for the plug supplied with this equipment, you should contact your

authorized dealer to obtain the correct lead.

FOR USERS IN AC INPUT 220-240V

COUNTRIES AND MEXICO

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do not

play with the appliance.

IIII

II

IIII

Page 4

CONGRATULATIONS ON CHOOSING THIS COMPACT

OVERLOCK MACHINE

Your machine is a high quality, easy-to-use product. To fully enjoy all the features, we suggest that you

study this booklet.

If you need more information regarding the use of your machine, your nearest authorized dealer is always

happy to be of service.

Enjoy yourself!

CAUTION

When threading or replacing needle, the main power and light switch of the machine must be switched off

or the plug must be removed from the socket-outlet.

When the machine is not in use, it is recommended that the electric supply plug is disconnected from the

wall socket to avoid any possible hazards.

Notes on the motor

- The maximum operating speed of this sewing machine is 1,300 stitches per minute, which is quite fast compared to

the normal operating speed of 300 to 800 stitches per minute for the ordinary sewing machine.

- The bearings in the motor are made of a special sintered, oil-impregnated alloy mounted in oilsoaked felt to withstand

long hours of continuous operation.

- Continuous operation of the sewing machine can cause heat to build in the motor area, but not enough to adversely

affect its performance.

It is important to keep fabric and paper away from the air openings on the back and sides of the machine so air can

get to these openings.

- When the motor is running, sparks can be seen through the air openings in the motor bracket on the side opposite the

hand wheel. These sparks are produced by the carbon brushes and the commutator, and are part of the machines

normal operation.

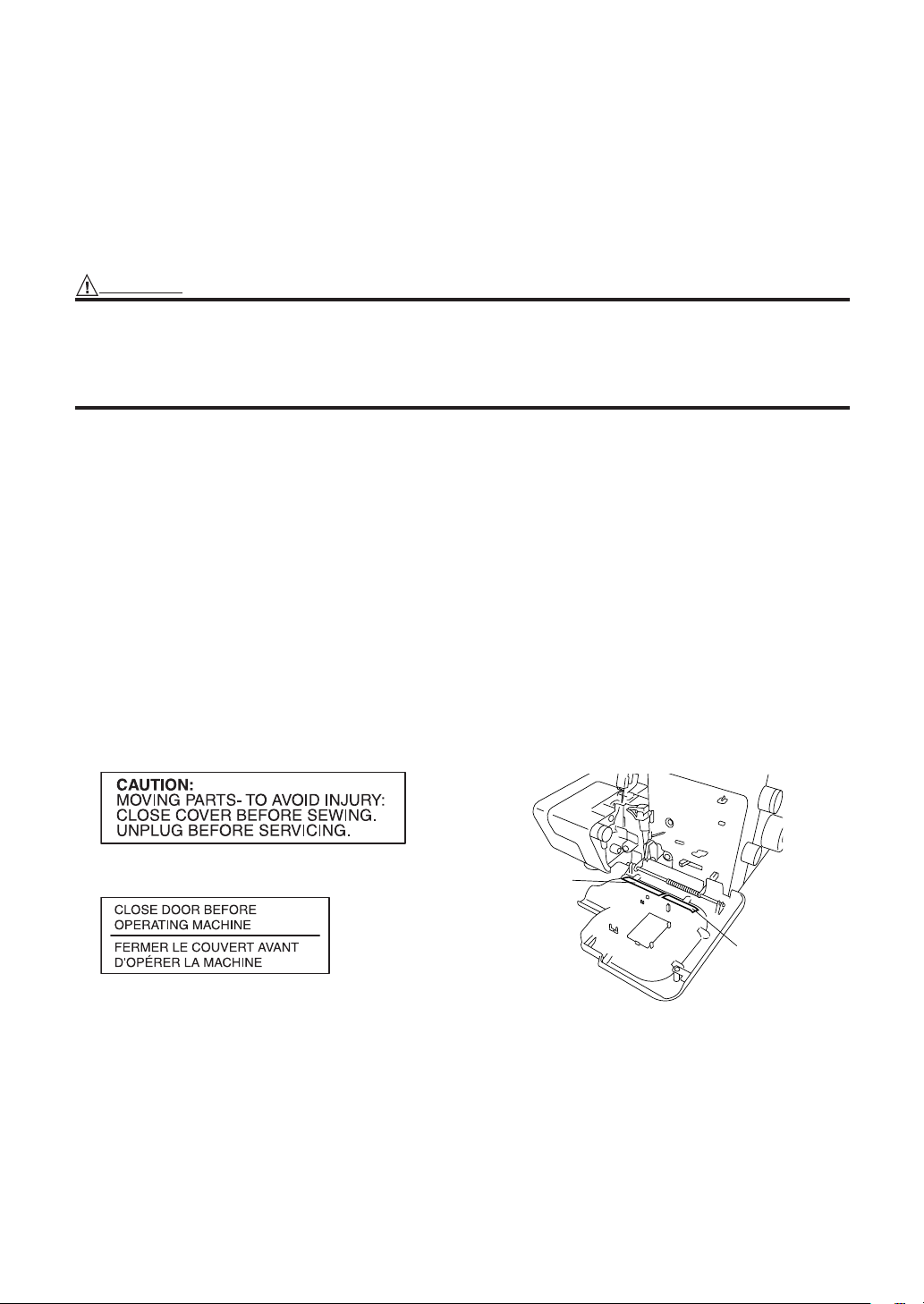

WARNING LABELS (for complying with UL and CSA requirements)

The following warning labels are on the machine.

Be sure to observe the precautions described in the labels.

1 Caution (U.S.A. and CANADA only)

2 Face plate sticker (U.S.A. and CANADA only)

Label locations

1

2

IIIIII

III

IIIIII

Page 5

Contents

IMPORTANT SAFETY INSTRUCTIONS ...................................................................................

WARNING LABELS ...................................................................................................................

Contents .................................................................................................................................... 1

Chapter 1: Names of parts and their functions ...................................................................... 2

Accessories ......................................................................................................................... 3

Powering the machine ........................................................................................................ 4

Turning direction of hand wheel ......................................................................................... 4

Opening/ Closing front cover .............................................................................................. 4

Attaching/ Removing presser foot ...................................................................................... 4

Trim trap ...............................................................................................................................5

Free-arm sewing (removing bed extension) ...................................................................... 5

Wide table ............................................................................................................................5

Retracting knife ...................................................................................................................6

Stitch length ......................................................................................................................... 6

Stitch width ..........................................................................................................................6

Differential feed ................................................................................................................... 7

Adjusting the presser foot pressure....................................................................................7

Tension adjustment dial......................................................................................................8

Chart of thread tension adjustment, Two needle (Four-thread) ........................................ 9

Chart of thread tension adjustment, One needle (Three-thread) ......................................10

Chart of thread tension adjustment, One needle (Two-thread) ........................................10

Needle ................................................................................................................................. 11

Removing/Installing the needle .......................................................................................... 11

Chapter 2 : Preparation before threading ............................................................................... 12

Thread tree .......................................................................................................................... 12

How to use the thread spool cap ........................................................................................ 12

How to use the thread net ................................................................................................... 12

Before threading..................................................................................................................12

Chapter 3: Threading ................................................................................................................13

Thread for two-needle four-thread overlock stitch ............................................................. 13

Thread for one-needle three-thread overlock stitch (right needle) ................................... 13

Thread for one-needle three-thread overlock stitch (left needle) .....................................13

Thread for one-needle two-thread overlock stitch (right needle) ...................................... 14

Thread for one-needle two-thread overlock stitch (left needle) ........................................ 14

Threading the lower looper ................................................................................................ 14

Threading the upper looper ................................................................................................ 16

Threading the left needle .................................................................................................... 17

Threading the right needle ................................................................................................. 17

Threading the needle (using the needle threader) ...........................................................18

Chapter 4: Sewing materials, threads and needles comparison chart ................................. 19

Chapter 5: Sewing .................................................................................................................... 20

Stitch selection .................................................................................................................... 20

Test sewing .........................................................................................................................20

Chaining-off ......................................................................................................................... 21

To start sewing .................................................................................................................... 21

To remove work ................................................................................................................... 21

To secure chain ................................................................................................................... 22

If threads break during sewing ........................................................................................... 23

To sew fine materials ..........................................................................................................23

To use the stitch finger W .................................................................................................... 23

Two-thread sewing.............................................................................................................. 24

Narrow overlock/Rolled hemming stitch ............................................................................ 25

Chart of narrow overlock/ Rolled hemming stitch .............................................................. 26

Chapter 6: Troubleshooting ..................................................................................................... 27

Chapter 7: Maintenance ............................................................................................................28

Cleaning ..............................................................................................................................28

Oiling.................................................................................................................................... 28

Chapter 8: Introduction of optional feet ..................................................................................29

Blind stitch foot ....................................................................................................................29

Taping foot ........................................................................................................................... 31

Pearl sequence foot ............................................................................................................ 32

Piping foot ............................................................................................................................ 33

Gathering foot ...................................................................................................................... 34

Specifications ........................................................................................................................... 35

Specifications ...................................................................................................................... 35

Setting record ...................................................................................... Inside of the back cover

II

I

II

IIIIII

III

IIIIII

English

1

Page 6

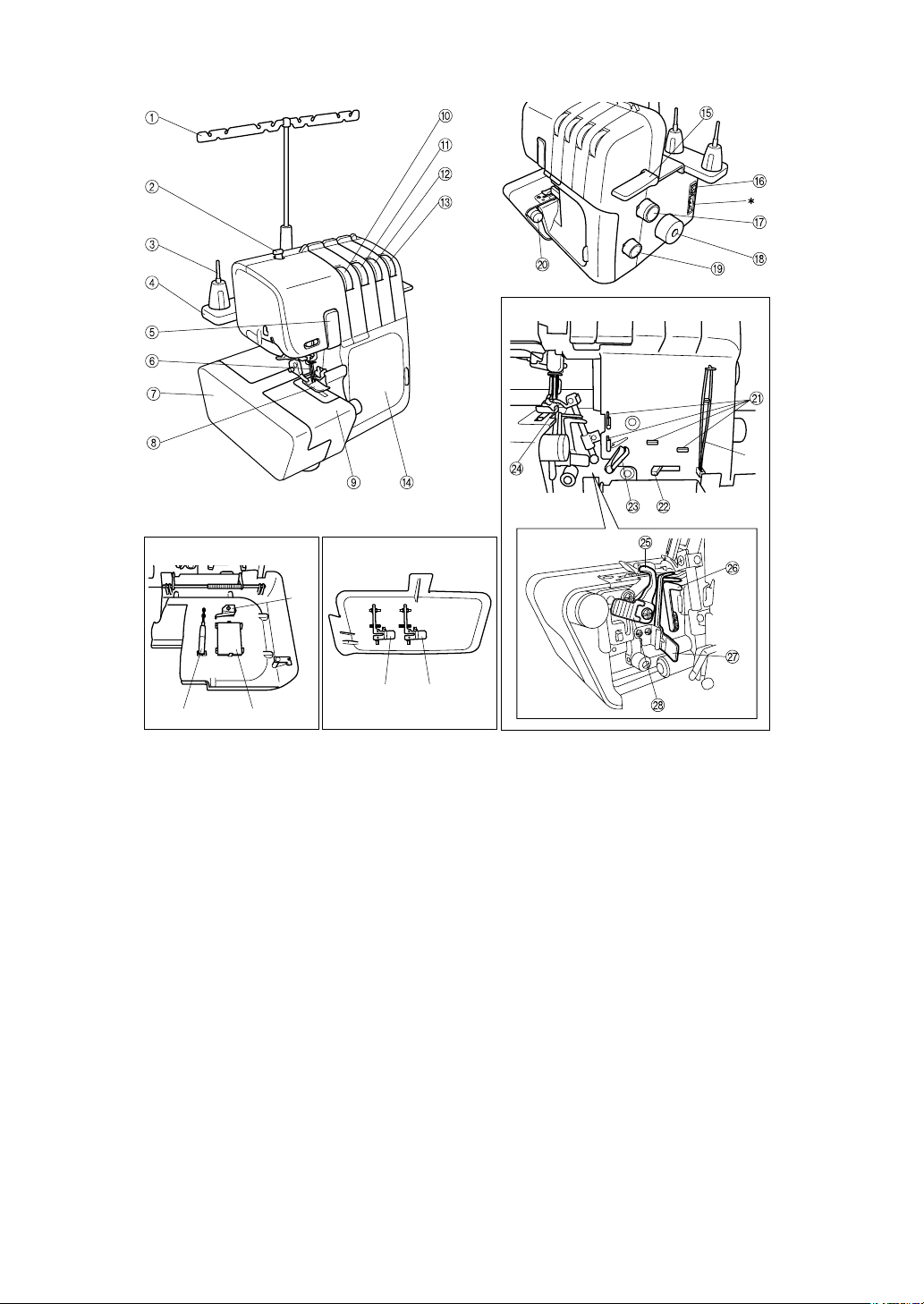

CHAPTER 1

NAMES OF PARTS AND THEIR FUNCTIONS

12

<A>

<B>

<C><D>

1 Thread tree

2 Presser foot pressure adjustment screw

3 Spool pin

4 Spool support

5 Thread take-up cover

6 Needles

7 Bed extension

8 Presser foot

9 Material plate cover

0 Left needle thread tension dial

A Right needle thread tension dial

B Upper looper thread tension dial

C Lower looper thread tension dial

D Front cover

E Presser foot lifting lever

F Main power and light switch

G Stitch length adjustment dial

H Hand wheel

I Differential feed ratio adjustment dial

J Stitch width dial

K Thread guide

<F><E>

Inside of the front cover

<A> Tweezers (accessory)

L Lower looper threading lever

M Thread take-up for loopers

N Upper looper

O Upper knife

P Lower looper

Q Stitch finger

R Knife lever

1 Front cover compartment

Accessories can be stored in this compartment.

<B> Thread change assembly, <C> Needle set,

<D> Hexagonal driver

2 Bed extension compartment

The removed stitch fingers can be stored in this

compartment. (See CHAPTER 5 "Narrow overlock/Rolled

hemming stitch".

<E> Stitch finger, <F> Stitch finger W

* Air openings (on the back)

2

Page 7

Accessories

Included accessory

1 Soft cover: X77871000

2 Accessory bag: 122991052

3 Tweezers: XB1618001

4 Thread net (4): X75904000

5 Thread spool cap (4): X77260000

6 Cleaning brush: X75906001

7 Hexagonal driver: XB0393001

8 Needle set (SCHMETZ 130/705H): X75917001

#80: 2 pcs., #90: 2 pcs.

9 Foot controller:

XC7359021 (120V Area)

XC7438321 (230V Area)

XC7456321 (U.K.)

XD0112121 (Argentina)

XD0852021 (Korea)

XD0105021 (China)

XE0629001 (Australia, New Zealand)

XE3414001 (Brazil)

0 Instruction DVD: XB2007001 (NTSC)

A Thread change assembly: XB1991001

B Trim trap: XB1958001

C Stitch finger W: XB1902001

1

XB2014001 (PAL)

8

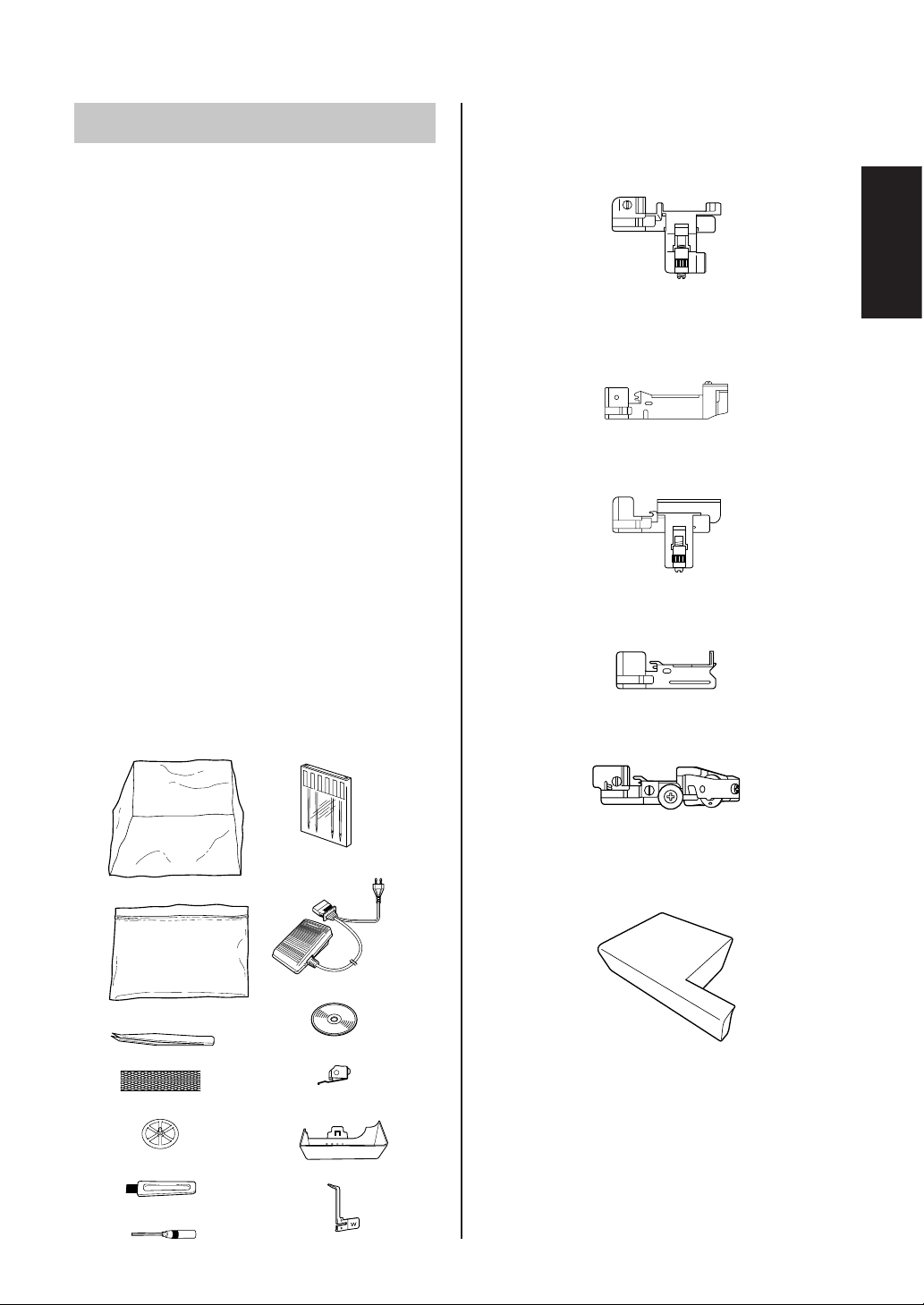

Optional accessory

For further information about the following items,

see CHAPTER 8.

D Blind stitch foot: X76590002

English

E Gathering foot:

SA213 (U.S.A., CANADA)

X77459001 (OTHERS)

LG

F Pearl sequence foot:

SA211 (U.S.A., CANADA)

X76670002 (OTHERS)

LS

G Piping foot:

SA210 (U.S.A., CANADA)

XB0241101 (OTHERS)

LP

H Taping (Elastic) foot:

SA212 (U.S.A., CANADA)

X76663001 (OTHERS)

2

3

4

5

6

7

9

0

A

B

C

I Wide table assembly:

XB2023001

* In some regions, the wide table is an

included accessory.

The wide table can also be used as an

accessory box.

Size:

35 cm (W) x 25.5 cm (D)

[Approx. 13-3/4 inches (W) x 10 inches (D) ]

3

Page 8

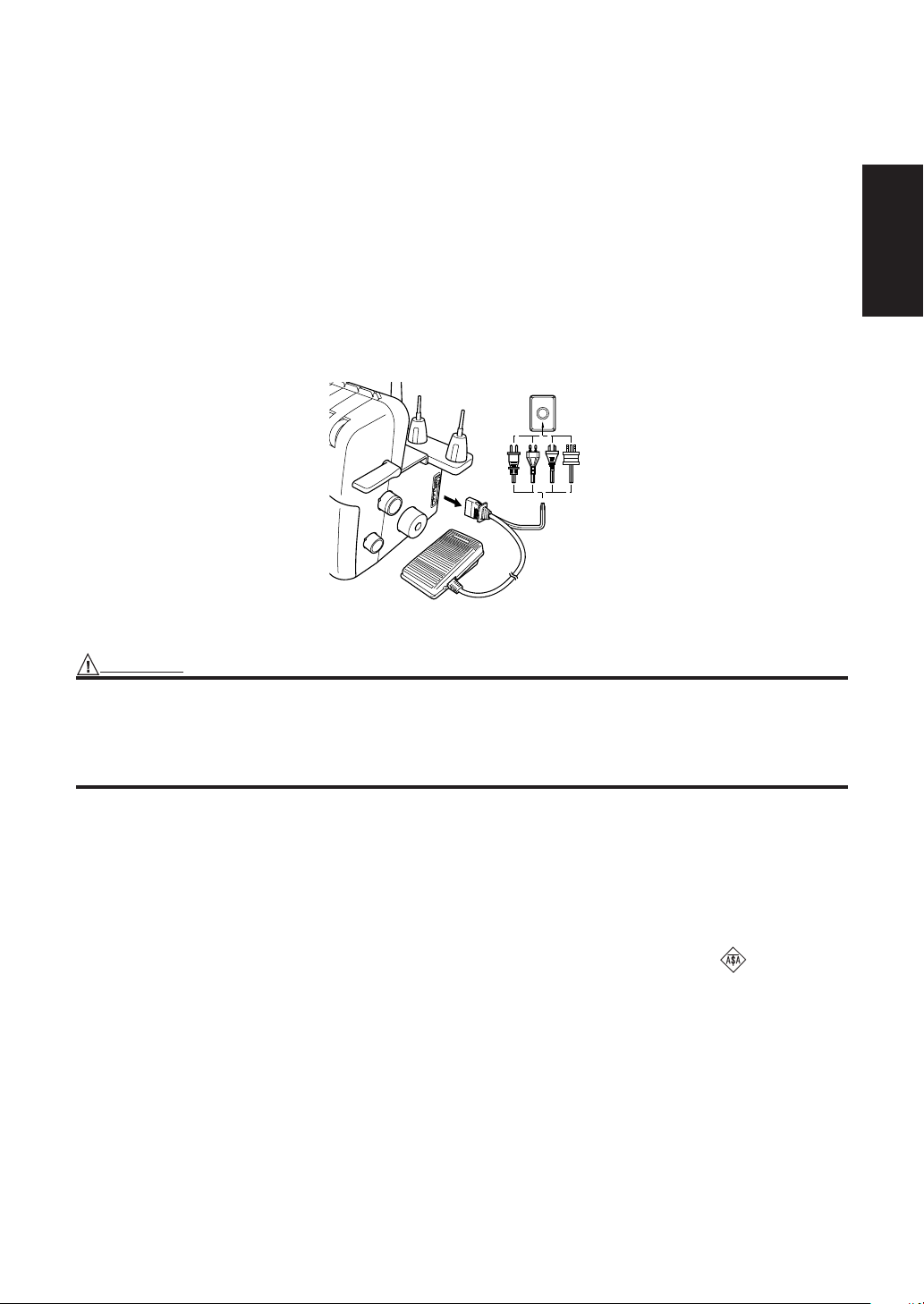

Powering the machine

Opening/ Closing front cover

Turning on the machine

1. Insert the three-pin plug into the socket on the

bottom right side of the machine. Insert the power

supply plug into a power outlet.

2. Turn the main power and light switch <A> to "I" mark

(to "O" mark to turn off).

<A>

Operation

When the foot controller is pressed lightly, the machine

runs at a low speed. As the foot controller is pressed

further, the machine will increase speed. When the foot

controller is released, the machine stops.

NOTE (For U.S.A. only):

Foot controller: Model KD-1902

This foot controller can be used on the machine with

product code 884-B01. The product code is mentioned

on the machine rating plate.

Turning direction of hand wheel

The hand wheel <A> turns in a counterclockwise

direction (direction of arrow). This is the same direction

as an ordinary home sewing machine.

The needles move to their highest positions by turning

the hand wheel so that the mark <B> on the hand wheel

is aligned to the line on the machine.

It is necessary to open the front cover when threading

this machine. Slide it to the right 1 and open 2, or

close it and slide it to the left.

CAUTION

For your safety, make sure that the front cover is

closed when operating the machine.

Always turn off the machine before opening the

front cover.

1

2

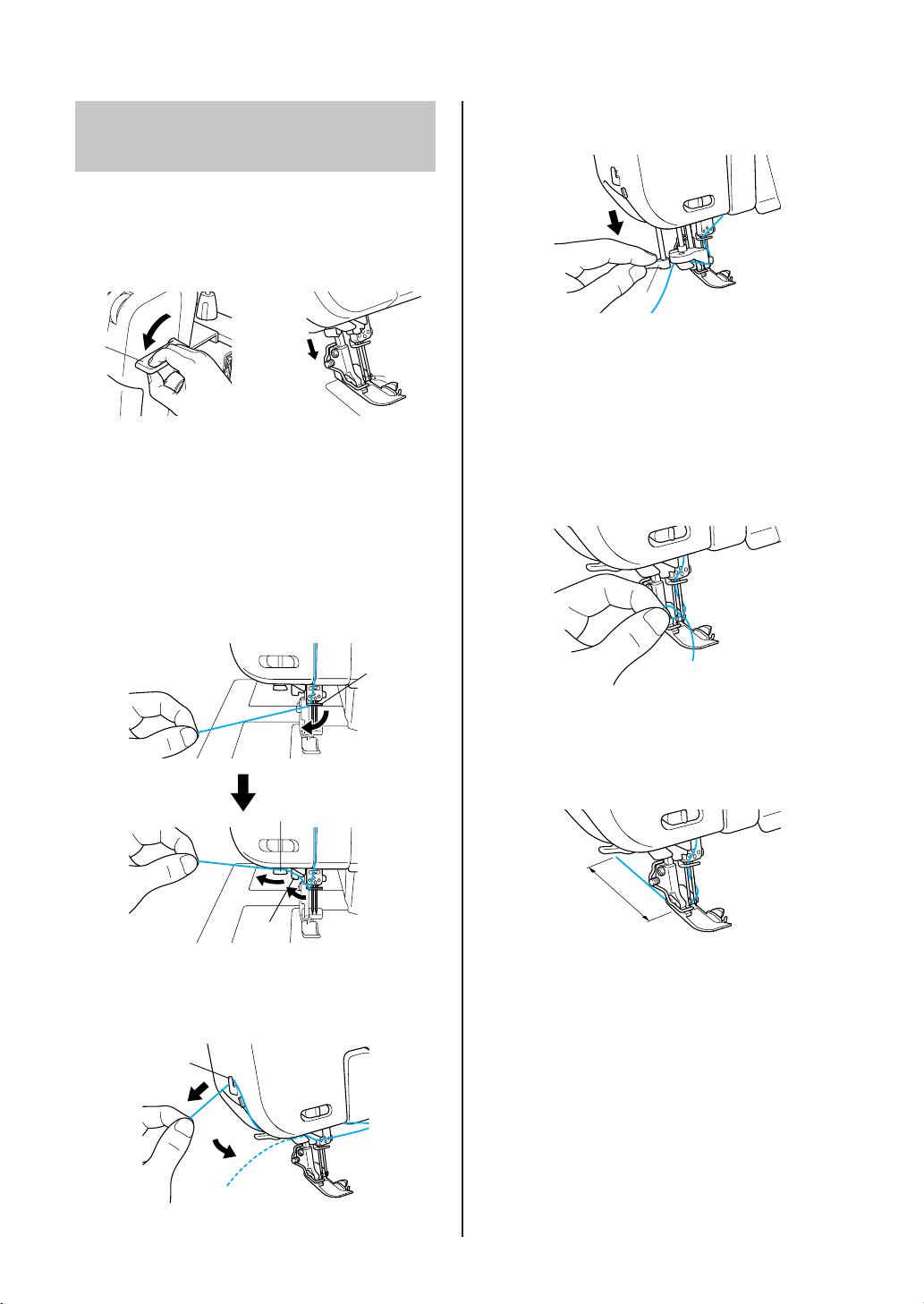

Attaching/ Removing presser foot

1. Turn off the main power and light switch or

disconnect the electric supply plug.

2. Raise the presser foot lever. 1

3. Turn the hand wheel 2 so that the mark on the hand

wheel is aligned to the line on the machine. (See

CHAPTER1 "Turning direction of hand wheel".)

4. Push the button on the presser foot holder and the

standard presser foot will be released. 3 4

5. Raise the presser foot farther by pushing the presser

foot lever upward. Then remove the presser foot and

store it in a safe location.

6. Again, raise the presser foot farther by pushing the

presser foot lever upward. Then place the presser

foot just under the presser foot holder <A> so that

the groove in the bottom of the presser foot holder

<B> is aligned and catches the bar on the top of the

foot <C>. Then lower the presser foot lever to

attatch the foot, pushing the button on the presser

foot.

<A>

<B>

4

<A>

1

2

3

1

2

<B>

4

<C>

4

Page 9

Trim trap

The optional trim trap <A> holds the trimmed

fabric and thread produced when sewing.

<B>

<A>

To install:

Insert the trim trap <A> until it contacts the front cover.

NOTE:

Be sure to position the positioning guide <B> to the one

on the machine.

To remove:

Slowly pull out the trim trap.

NOTE:

The optional trim trap can also be used as the foot

controller holder.

2. Position the fabric, and start sewing. (See CHAPTER

5.)

English

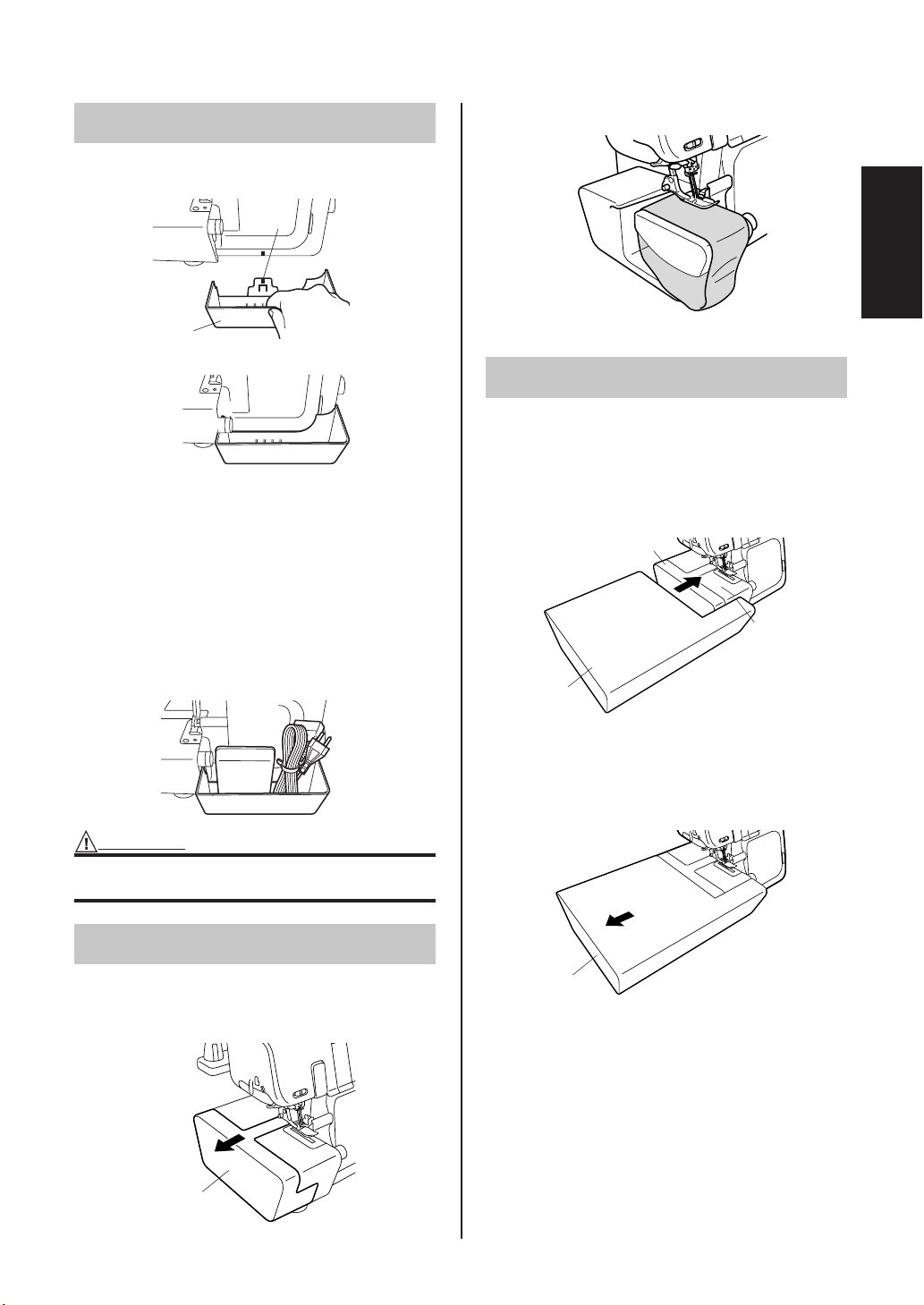

Wide table

Using the wide table <A> makes the large piece sewing

easy.

To install:

Attach the wide table <A> by pushing it in the direction

of the arrow until the edge line 1 is aligned to the line

2 of the bed extension <B>.

<B>

2

1

<A>

CAUTION

Always remove the foot controller from the trim

trap when carrying the machine.

Free-arm sewing (removing bed extension)

Free-arm sewing enables tubular pieces to be sewn

more easily.

1. Remove the bed extension <A>.

<A>

NOTE:

Be careful not to lose the removed bed extension.

To remove:

To remove the wide table <A>, lift up the machine a little

and then pull out the wide table <A> in the direction of

the arrow.

<A>

NOTE:

Do not move the machine while the wide table <A> is

attached, otherwise damage or injuries may occur.

5

Page 10

Retracting knife

1

2

<A>

Stitch length

To sew without cutting the fabric edge, you need to

retract the knife as follows.

CAUTION

Do not touch the knife.

Move the knife lever only while the needle is at its

lowest point.

Be sure to unplug the power supply cord from the

wall outlet before retracting the knife.

1. Pull up the knife lever <A>, then pull it to the right.

<A>

2. Bring down the knife.

The normal stitch length setting is 3 mm. To change the

stitch length, turn the stitch length adjustment dial on the

right side of the body.

<A>

1

2

1 Shorten the stitch length to a minimum of 2 mm (5/64

inch).

2 Lengthen the stitch to a maximum of 4 mm (5/32

inch).

<A> Selection mark

Stitch width

The normal stitch width setting for regular overlock stitch

is 5mm (13/64 inch). To change the stitch width, turn the

stitch width adjustment dial.

3. Retract the knife completely, then take your hand off

from the lever.

6

1 Increase the width to a maximum of 7 mm (9/32

inch).

2 Reduce the stitch width to a minimum of 5 mm

(3/16 inch).

<A> Selection mark

Page 11

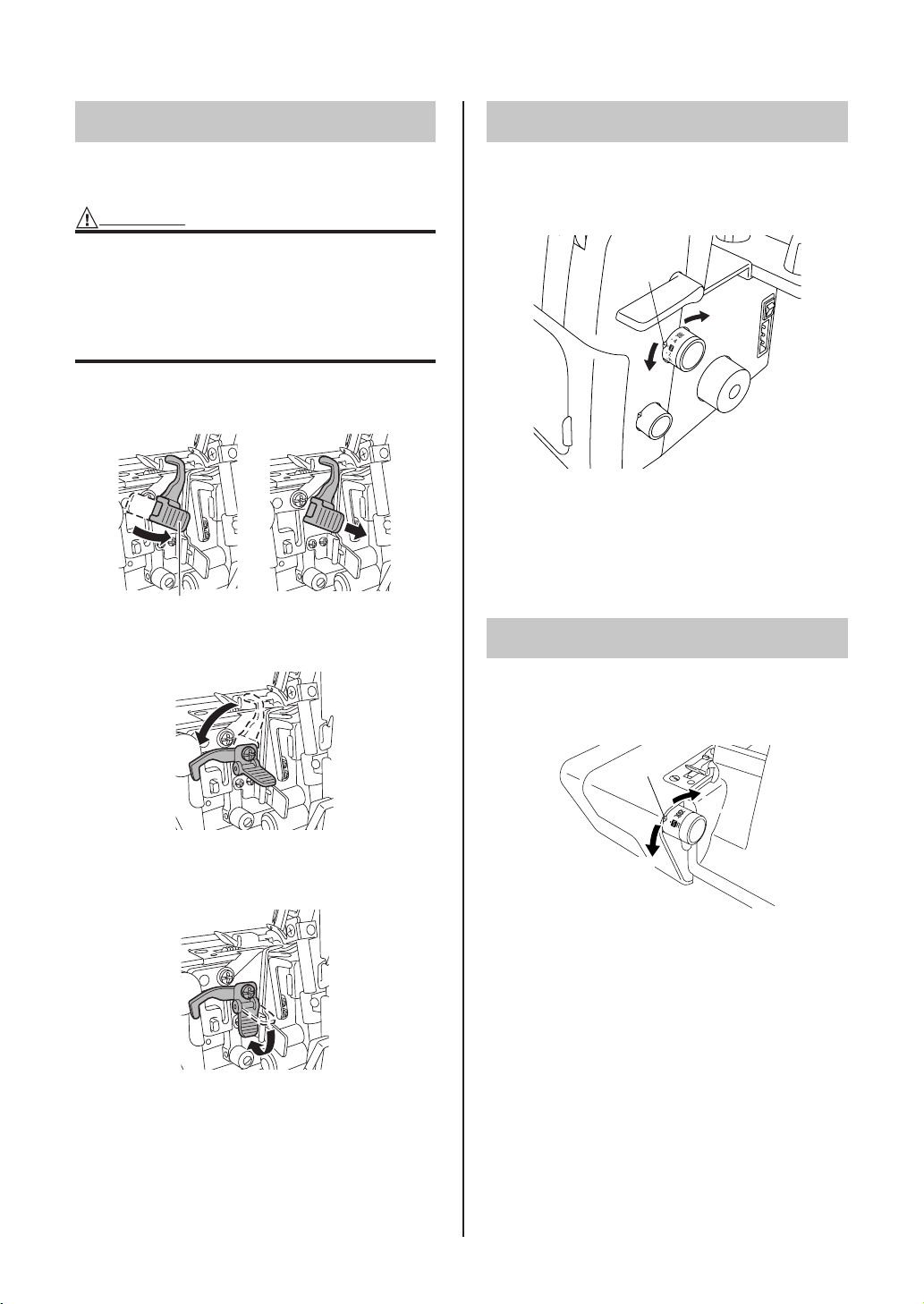

Differential feed

This serger is equipped with two sets of feed dogs under

the presser foot to move the fabric through the machine.

The differential feed controls the movement of both the

front and the rear feed dogs. When set at 1, the feed

dogs are moving at the same speed (ratio of 1). When

the differential feed ratio is set at less than 1, the front

feed dogs move slower than the rear feed dogs,

stretching the fabric as it is sewn. This is effective on

lightweight fabric that may pucker. When the differential

feed ratio is set at greater than 1, the front feed dogs

move faster than the rear feed dogs, gathering the fabric

as it is sewn. This function assists in removing the

rippling when serging stretch fabrics.

An example

When stretch material is sewn without using the

differential feed, the edge will be wavy.

English

Differential feed adjustment

Main

Feed

ratio

0.7 - 1.0

1.0

1.0 - 2.0

The normal setting is 1.0 on the differential feed

adjustment dial.

To adjust the diffrerential feed, turn the dial on the right

bottom of the body.

feed

(rear)

Differential

feed

(front)

Effect

Material is

pulled tight.

Without

differential

feed.

Material is

gathered or

pushed

together.

Application

Prevents thin

materials from

puckering

Normal

sewing

Prevents

stretch

materials from

stretching or

puckering

To get smooth finish, adjust the feed ratio from 1.0

toward 2.0.

(The feed ratio required depends on the elasticity of the

material.)

The more elastic the material, the further toward 2.0 the

differential feed ratio should be set. Test sew with a

scrap of the fabric to find the correct adjustment.

CAUTION

When sewing thick non-stretchable material such

as denim, do not use the differential feed as it may

damage the fabric.

Adjusting the presser foot pressure

Turn the pressure adjustment screw on the top left of the

machine. You can adjust by reffering the value on the

screw.

The normal setting is "2".

1

<A>

2

<A>

1

2

1 Less than 1.0 2 Greater than 1.0

<A> Selection mark

1 Less pressure

2 More pressure

<A> Selection mark

7

Page 12

Tension adjustment dial

There is a thread tension dial for each needle thread,

the lower looper thread and the upper looper thread.

The correct thread tension may vary according to the

type and thickness of the fabric and the type of thread

used. Thread tension adjustments may be necessary for

any change in sewing materials.

1234

1 Yellow marked tension disc is for left needle.

2 Green marked tension disc is for right needle.

3 Pink marked tension disc is for upper looper.

4 Blue marked tension disc is for lower looper.

Tension control

Sewing is possible at position "4" for most

circumstances. (Standard: SPAN 60/3Z)

If the stitch quality is insufficient, select a different

tension setting.

5

4

3

<A> Tension selection mark

1 For heavy tension: 4 to 7

2 For light tension: 4 to 2

3 For medium tension: 5 to 3

If you cannot find the correct tension, refer to the charts

on following pages.

CAUTION

Make sure that the thread is properly seated in the

tension discs.

!

8

Page 13

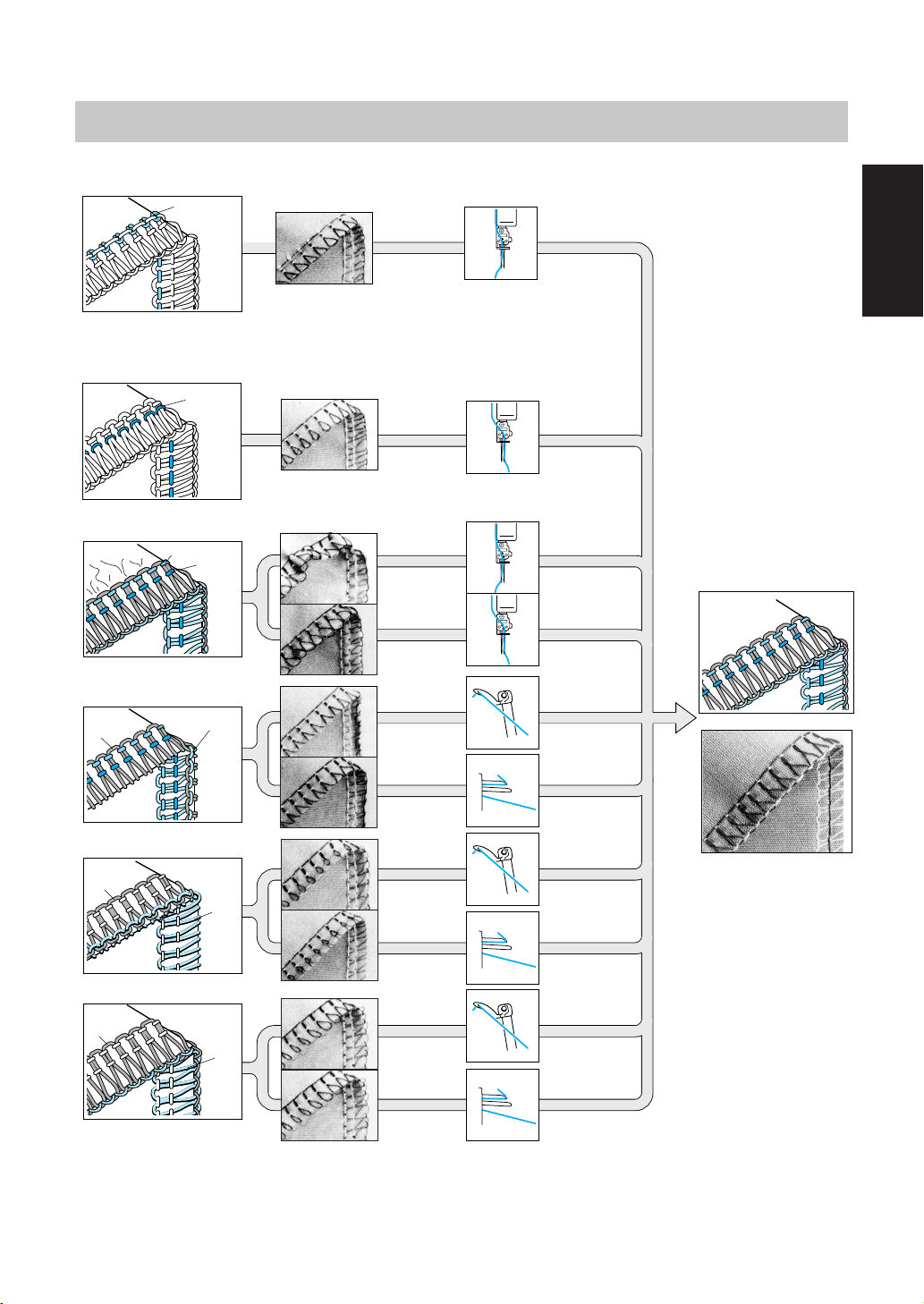

Chart of thread tension adjustment, Two-needle (Four-thread)

A: Reverse B: Surface C: Left needle thread D: Right needle thread E: Upper looper thread F: Lower looper thread

A

B

A

B

A

A

F

C

Left needle

thread is loose.

D

Right needle

thread is loose.

C

D

B

E

Left needle

thread is tight.

Right needle

thread is tight.

Upper looper

thread is tight.

Tighten left

needle thread.

(yellow)

Tighten right

needle thread.

(green)

Loosen left

needle thread.

(yellow)

Loosen right

needle thread

(green)

Loosen upper

looper thread

(pink)

English

B

A

F

E

B

A

F

E

B

Lower looper

thread is loose.

Upper looper

thread is loose.

Lower looper

thread is tight.

Upper looper

thread is loose.

Lower looper

thread is loose.

Tighten lower

looper thread

(blue)

Tighten upper

looper thread

(pink)

Loosen lower

looper thread

(blue)

Tighten upper

looper thread

(pink)

Tighten lower

looper thread

(blue)

When you adjust the

thread tension, do it in the

following order:

(1) Left needle thread

(2) Right needle thread

(3) Upper looper thread

(4) Lower looper thread

This is the easiest way to

obtain the correct thread

tension.

9

Page 14

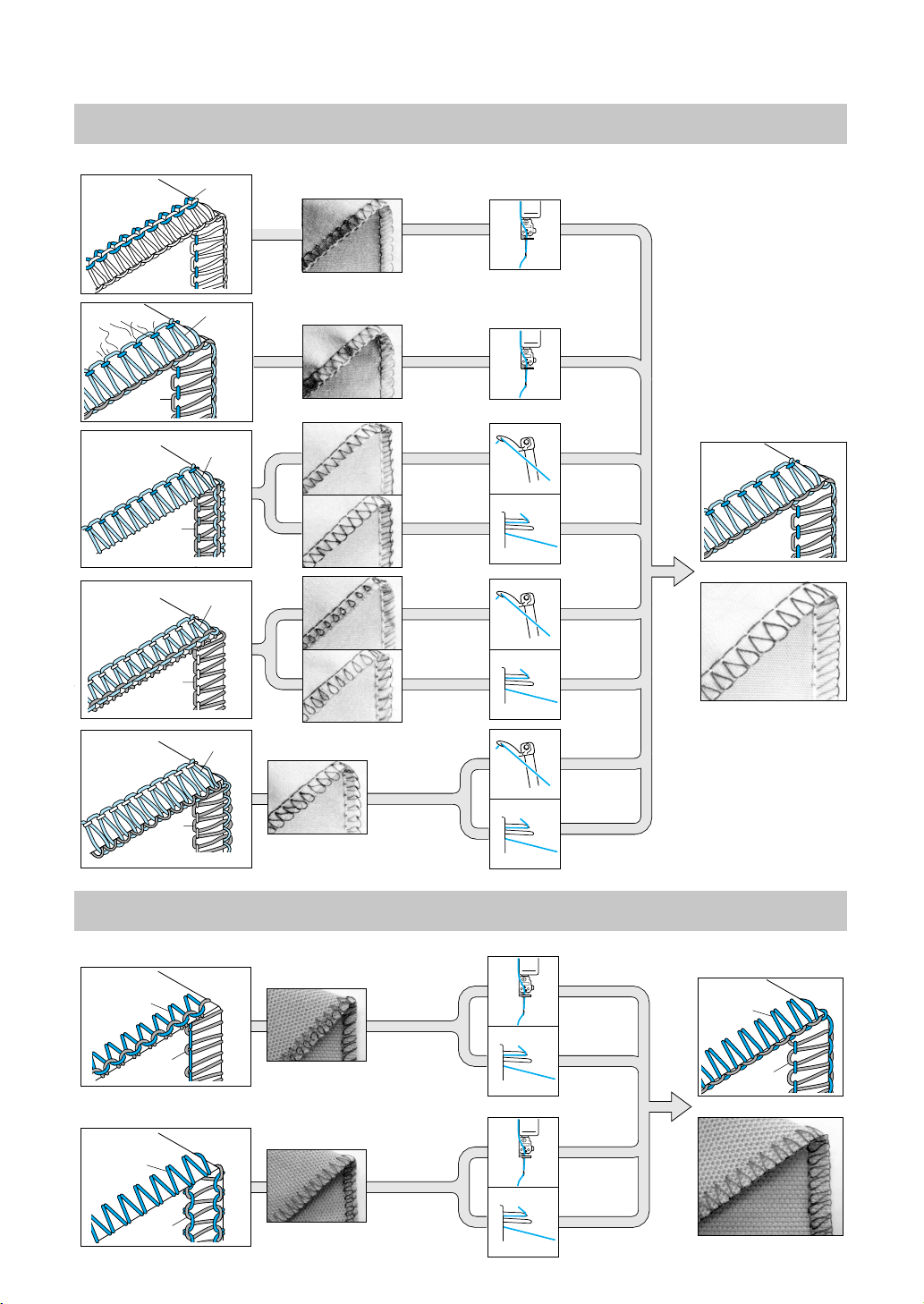

Chart of thread tension adjustment, One-needle (Three-thread)

A: Reverse B: Surface C: Needle thread D: Upper looper thread E: Lower looper thread

C

A

Needle thread is

B

C

A

D

B

A

B

A

B

A

B

E

E

D

E

D

E

D

loose.

Needle thread is

tight.

Upper looper

thread is tight.

Lower looper

thread is loose.

Upper looper

thread is loose.

Lower looper

thread is tight.

Upper looper

thread is loose.

Lower looper

thread is loose.

Tighten needle

thread.

(yellow or green)

Loosen needle

thread.

(yellow or green)

Loosen upper

looper thread

(pink)

Tighten lower

looper thread

(blue)

Tighten upper

looper thread

(pink)

Loosen lower

looper thread

(blue)

Tighten upper

looper thread

(pink)

Tighten lower

looper thread

(blue)

When you adjust the

thread tension, do it in the

following order:

(1) Needle thread

(2) Upper looper thread

(3) Lower looper thread

This is the easiest way to

obtain the correct thread

tension.

Chart of thread tension adjustment, One-needle (Two-thread)

A: Reverse B: Surface C: Needle thread D: Lower looper thread

C

A

D

B

C

A

D

B

Needle thread is

tight.

Lower looper

thread is loose.

Needle thread is

loose.

Lower looper

thread is tight.

10

Loosen needle

thread.

(yellow or green)

Tighten lower

looper thread

(blue)

Tighten needle

thread.

(yellow or green)

Loosen lower

looper thread

(blue)

C

A

D

B

Page 15

Needle

This machine uses a standard home sewing

machine needle.

The recommended needle is SCHMETZ 130/705H

(#80 or #90).

Needle description

1 Back (flat side) 2 Front 3 Groove

1

How to check the needle

4 Flat surface

5 Place the needle on its flat side and check to see if the

space is parallel.

NOTE:

Countermeasures for material breakage <A>.

2

3

5

4

To remove:

1. Turn the main power and light switch to the

OFF position.

2. Turn the hand wheel so that the mark on the

hand wheel is aligned to the line on the

machine. (See CHAPTER 1 "Turning direction

of hand wheel".)

3. Loosen the corresponding needle set screw

with turning the included hexagonal driver

toward 2 in the figure, and remove the needle.

To install:

1. Turn the main power and light switch to the

OFF position.

2. Turn the hand wheel so that the line on the

hand wheel is aligned to the line on the

machine.

3. Hold the needle with its flat side away from you

and insert it up as far as it will go.

4. Tighten the needle set screw securely with

turning the included hexagonal driver toward

1 in the figure.

NOTE:

Make sure to insert the needles to the highest point in

the needle chamber.

If the needles have been inserted correctly, the right

needle should be set slightly lower than the left one.

English

It can reduce the occurrence of material breakage by

using SCHIMETZ 130/705H SUK (#90) BALL POINT.

Removing/Installing the needle

<A> Removing/ installing the left needle

<B> Removing/ installing the right needle

<A> <B>

1

2

1 Tighten 2 Loosen

1

2

CAUTION

Always be sure to turn off the power before

removing/ inserting the needle.

Do not drop the needle and needle set screw in

the machine, otherwise it may be damaged.

11

Page 16

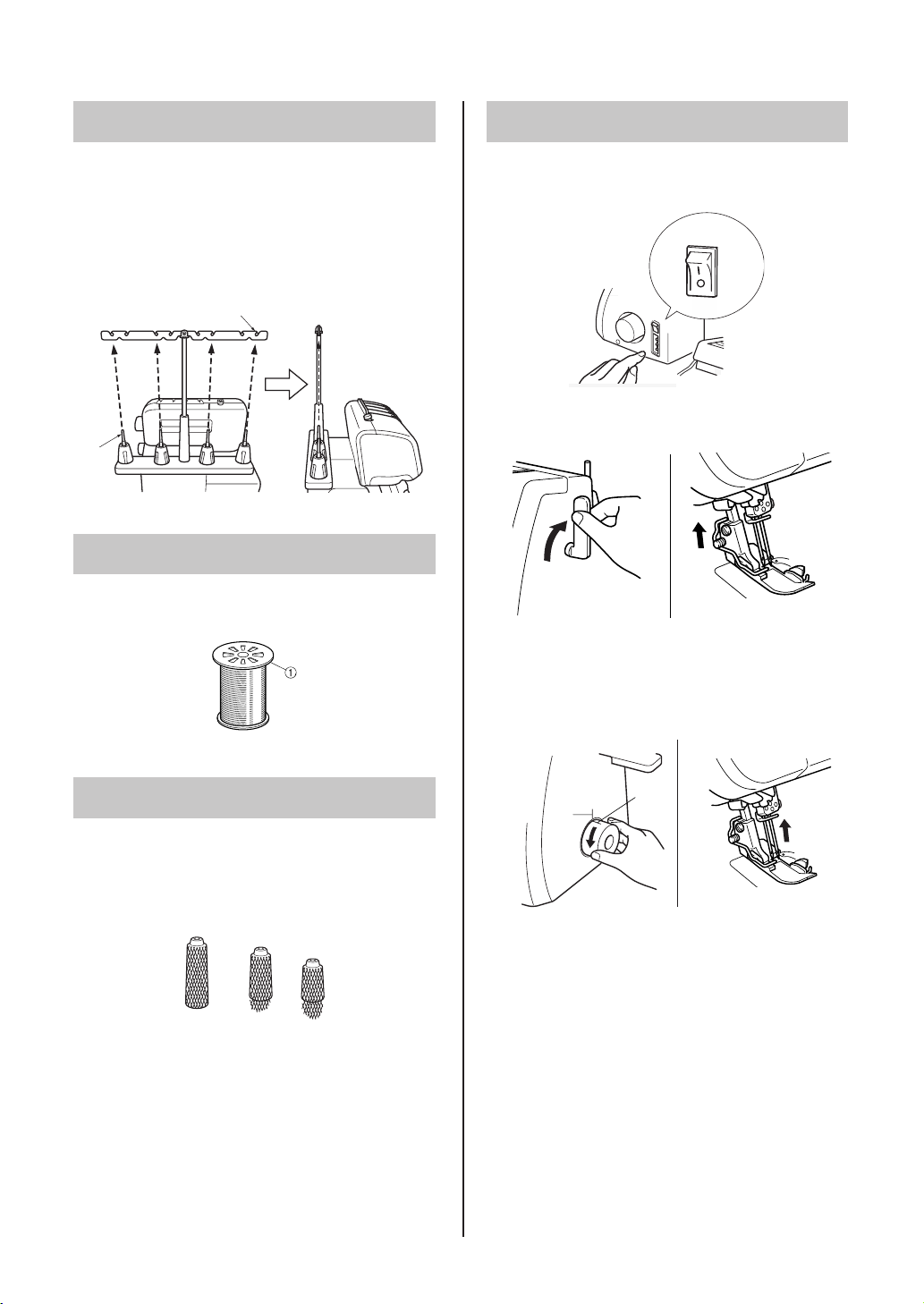

CHAPTER 2

PREPARATION BEFORE THREADING

Thread tree

Raise the telescoping thread tree to its highest

position. Make sure that the thread holders are in

alignment above the spool pins as illustrated

below.

1 Thread holder on thread tree

2 Spool pin

3 Correct position

1

2

3

How to use the thread spool cap

When using sewing thread spools, the thread

spool cap should be used as illustrated below.

Make sure that the spool notch is on the bottom.

Before threading

1. Turn off the main power and light switch for

safety.

2. Raise the presser foot using presser foot lever.

3. Turn the hand wheel so that the mark on the

hand wheel <A> is aligned to the line <B> on

the machine. (See CHAPTER 1 "Turning

direction of hand wheel".)

1 Thread spool cap

How to use the thread net

If you are sewing with loosely spun nylon thread,

we recommend that you cover the spool with the

net supplied to prevent the thread from slipping off

the spool.

Adapt the net to the shape of the spool.

<A>

<B>

12

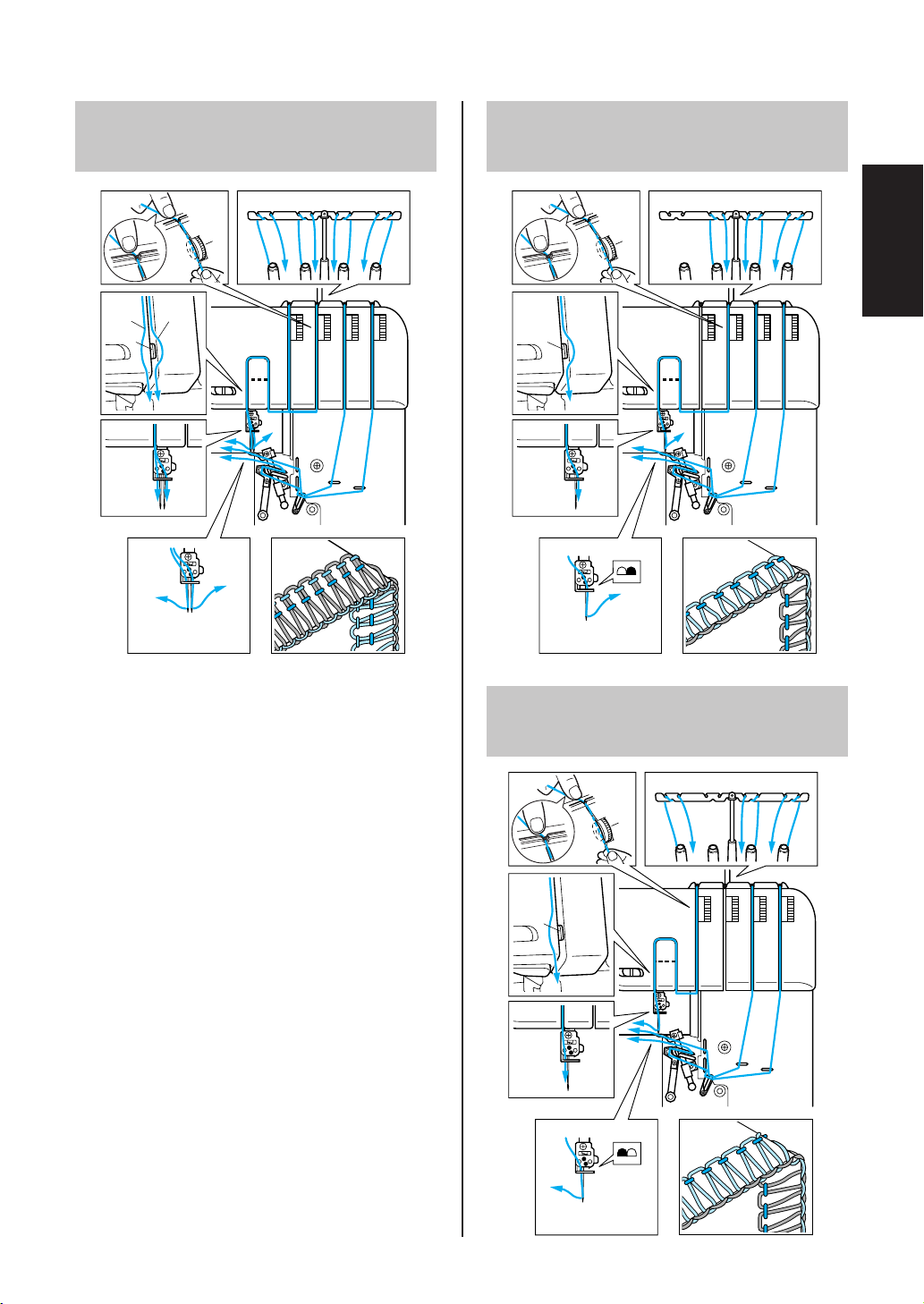

Page 17

CHAPTER 3

THREADING

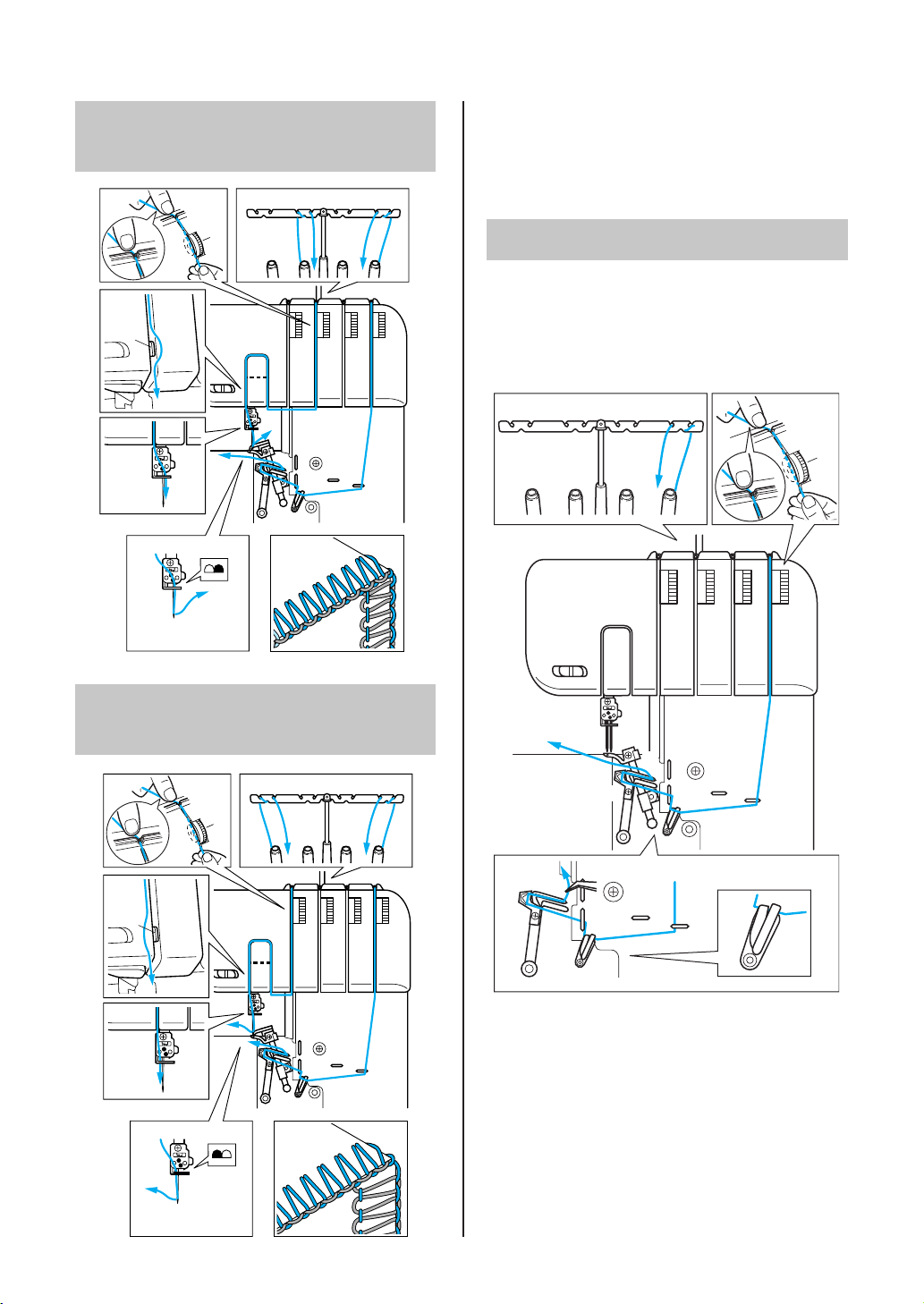

Thread for two-needle four-thread

overlock stitch

1

2

3

4

6

5

left

needle

<A>

3

4

right

needle

7

7

Thread for one-needle three-thread

overlock stitch (right needle)

3

4

<A>

7

7

1

2

3

4

6

5

English

Thread for one-needle three-thread

overlock stitch (left needle)

3

4

<A>

7

1

2

3

4

6

7

5

13

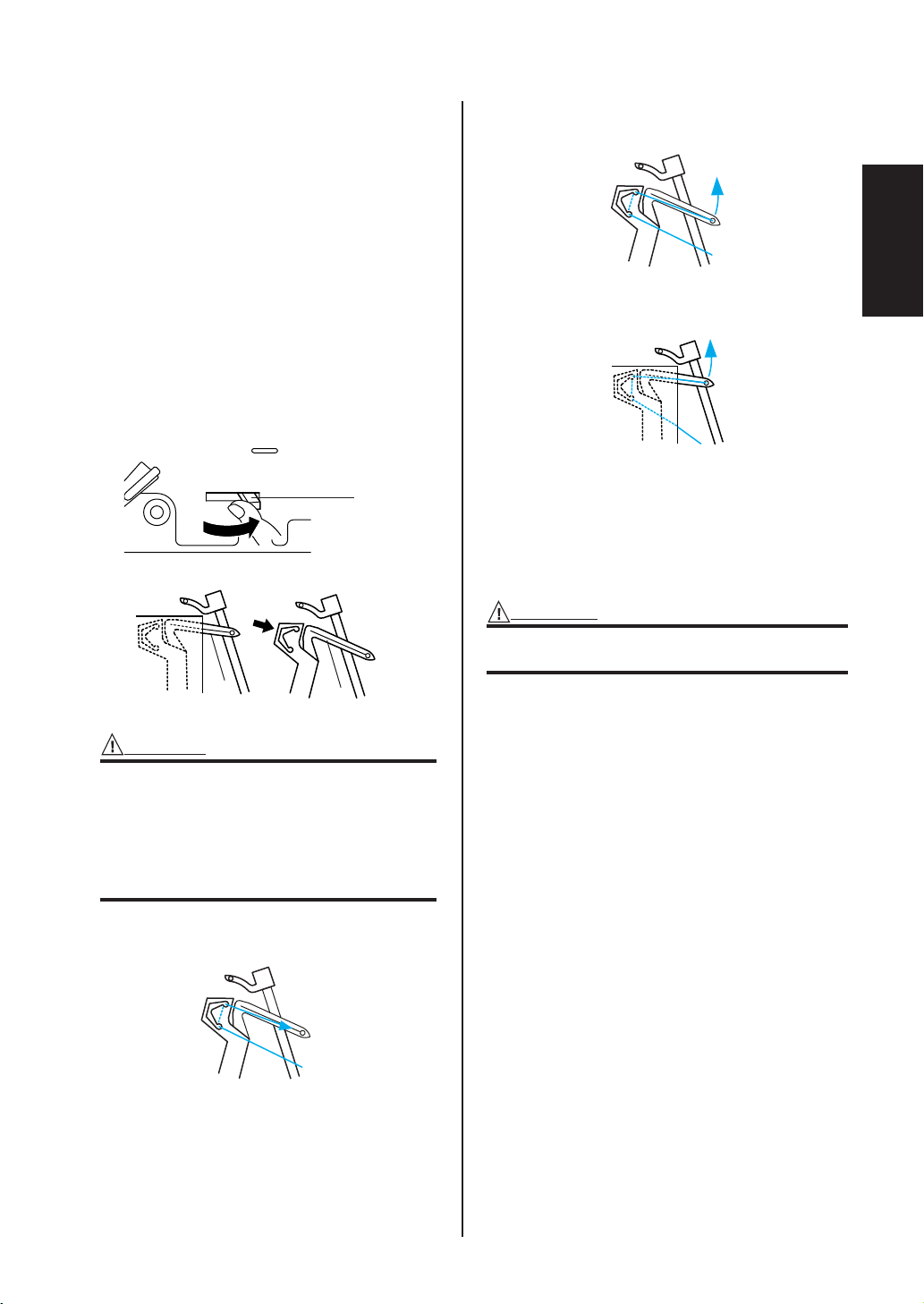

Page 18

Thread for one-needle two-thread

overlock stitch (right needle)

3

4

<A>

1

2

3

4

Threading has to be done in the following order.

1. Lower looper

2. Upper looper

3. Right needle

4. Left needle

Threading the lower looper

Run the thread in the sequence illustrated,

following the blue color and the numbers next to

each threading point.

6

7

7

5

Thread for one-needle two-thread

overlock stitch (left needle)

3

4

<A>

1

2

3

4

1

2

0

9

0

9

8

7

8

7

6

3

4

3

4

5

6

14

6

7

5

1. Open the front cover by sliding to the right and

guiding the top toward you.

7

2. Pull the thread off the spool and directly up

through the thread holder 1 and the thread

holder 2 on the thread tree from back to front.

3. Pass the thread through the thread guide 3 on

the top of machine.

4. Pass the thread through the tension disc 4

which is in the channel next to the blue tension

adjustment dial.

Page 19

5. Guide the thread down the channel and pass

the thread through the threading points

5678 next to the blue color marks following

the numerical order in the accompanying

illustration.

NOTE:

Make sure to thread both of the thread take-ups 7.

3. Pass the thread through the eye of the lower

looper.

Continue on "Lower looper easy threading

operation".

Lower looper easy threading

operation

1. Slide the lower looper threading lever <A> to

the right.

The lower looper <B> moves to the position

illustrated as below.

<A>

<B>

CAUTION

Slide the threading lever only in the directions

shown by the arrow. Forcefully moving the

threading lever in any other direction may

damage it.

<B>

English

4. Slowly turn the hand wheel, and make sure the

lower looper returns to the original position.

NOTE:

If the lower looper thread breaks during sewing, cut and

remove thread from both of the needles.

Before re-threading the lower looper, make sure that the

lower looper re-threading is done exactly as

diagrammed. The machine will not operate properly if the

threading is not done in the proper sequence.

CAUTION

Thread the needles after the lower looper and

upper looper have been threaded.

Before sliding the lower looper threading lever,

make sure the needle is at its highest position.

2. Pass the thread as illustrated.

15

Page 20

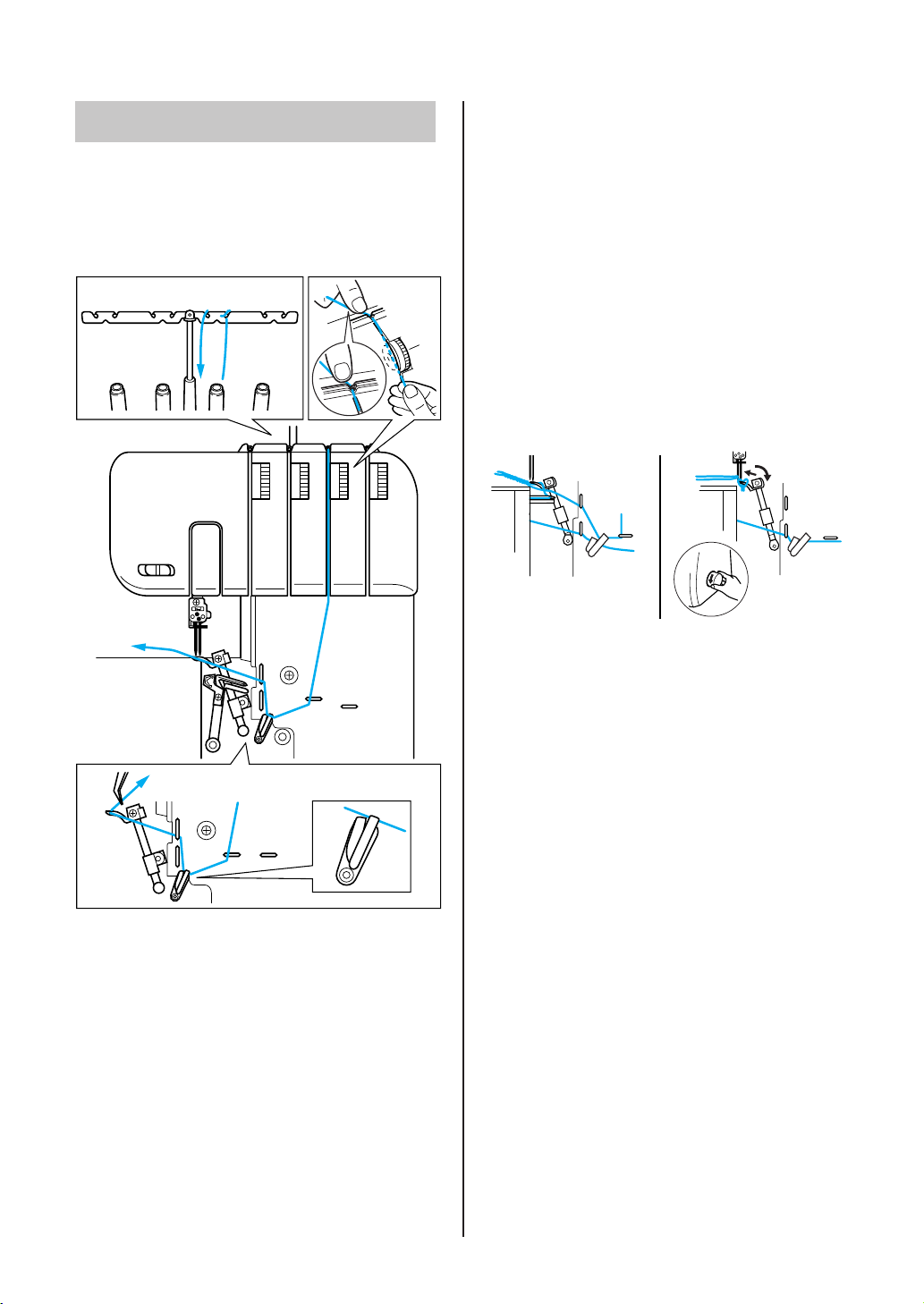

Threading the upper looper

Run the thread in the sequence illustrated,

following the pink color and the numbers next to

each threading point.

5. Guide the thread down the channel and pass

the thread through the threading points

5678 next to the pink color marks following

the numerical order in the accompanying

illustration.

NOTE:

Make sure to thread only through the upper thread

take up 7.

9

2

1

8

7

6

3

4

5

3

4

6. Pass the thread through the eye of the upper

looper 9.

NOTE:

If the upper looper thread breaks during sewing:

This may be caused by the lower looper thread getting

caught on the upper looper. If this happens, lower the

upperlooper by turning the hand wheel, remove the

lower looper thread from the upper looper, and re-thread

the upper looper from at least the tension disc.

9

8

7

6

1. Open the front cover by sliding to the right and

guiding the top toward you.

2. Pull the thread off the spool and directly up

through the thread holder 1 and the thread

holder 2 on the thread tree from back to front.

3. Pass the thread through the thread guide 3 on

the top of machine.

4. Pass the thread through the tension disc 4

which is in the channel next to the pink tension

adjustment dial.

16

Page 21

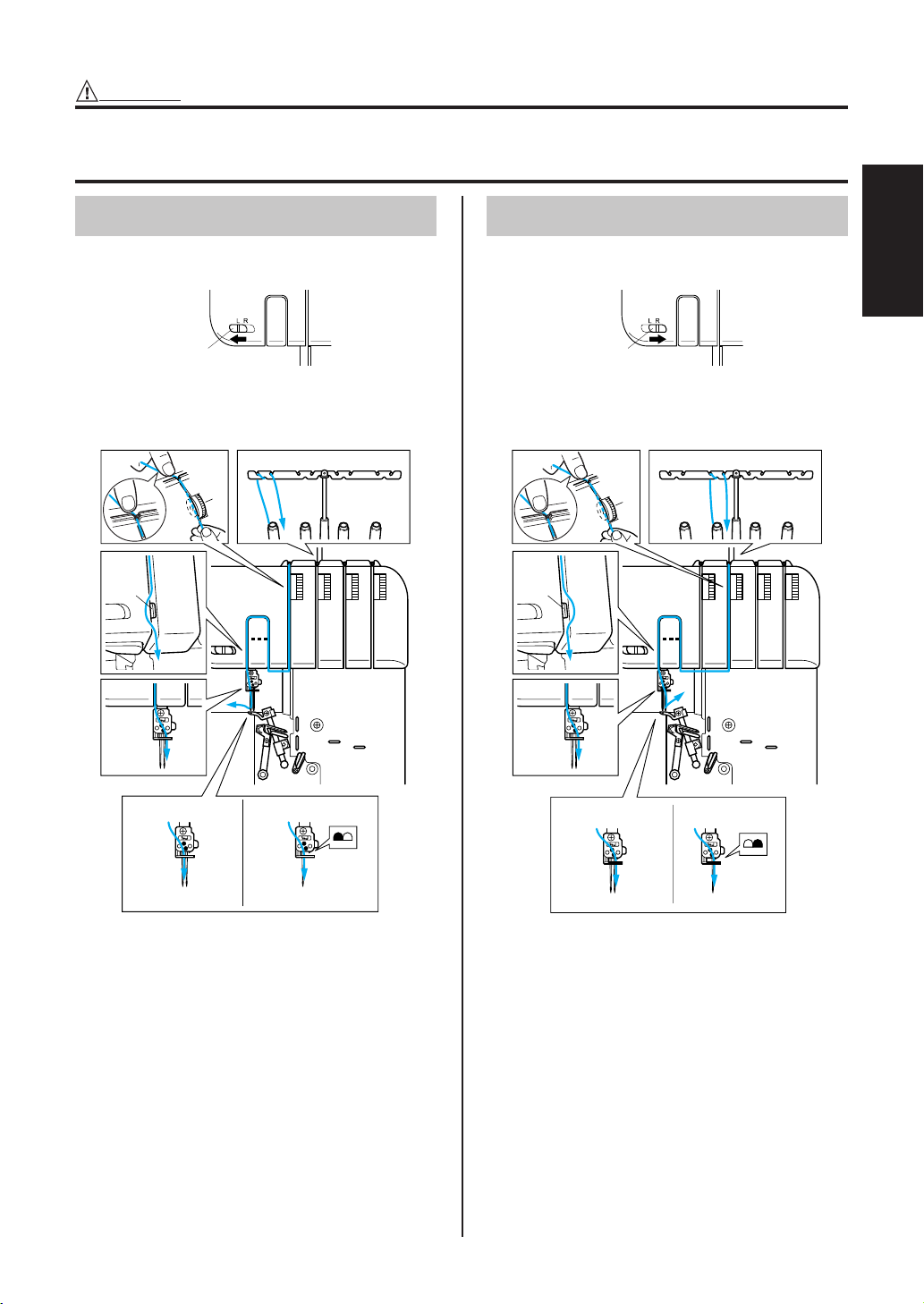

CAUTION

· Turn off the machine before threading for safety.

· Turn the hand wheel so that the mark on the hand wheel is aligned to the line on the machine (See

CHAPTER 1 "Turning direction of hand wheel").

Threading the left needle

1. Slide the change switch <A> to the left until it is

aligned to the "L" mark on the machine.

<A>

2. Run the thread in the sequence illustrated,

following the yellow color and the numbers

next to each threading point.

3

4

<B>

1

2

3

4

6

7

5

Threading the right needle

1. Slide the change switch <A> to the right until it

is aligned to the "R" mark on the machine.

<A>

2. Run the thread in the sequence illustrated

below, following the green color and the

numbers next to each threading point.

3

4

<B>

7

1

2

3

4

6

5

English

7

Two needles

One needle

a) Pull the thread off the spool and directly up

through the thread holder 1 and the thread

holder 2 on the thread tree from back to front.

b) Hold the thread with your left and right hands,

then pass the thread through the thread guide

3, and then pass the thread through the

tension disc 4 which is in the channel next to

the yellow tension adjustment dial.

c) Guide the thread down the channel and across

through the threading points 5 6 7 next to

the yellow color marks following the numerical

order in the accompanying illustration.

NOTE:

Make sure the thread is through the left of the

separater <B>.

7

Two needles One needle

a) Pull the thread off the spool and directly up

through the thread holder 1 and the thread

holder 2 on the thread tree from back to front.

b) Hold the thread with your left and right hands,

then pass the thread through the thread guide

3, and then pass the thread through the

tension disc 4 which is in the channel next to

the green tension adjustment dial.

c) Guide the thread down the channel and across

through the threading points 5 6 7 next to

the green color marks following the numerical

order in the accompanying illustration.

NOTE:

Make sure the thread is through the right of the

separater <B>.

17

Page 22

Threading the needle

(using the needle threader)

The needle can be threaded by one-touch

operation using the needle threader.

1. Lower the presser foot lever 1 to lower the

presser foot.

4. Lower the needle threader lever 6 on the left

side of the machine as much as possible.

6

1

2. Pull the end of the thread, which has been

passed through the needle bar thread guide

2, to the left, then pass the thread through the

notch of the thread guide 3, and then firmly

pull the thread from the front and insert it into

the slit of the thread guide disk 4 all the way.

NOTE:

Make sure that the thread passes the notch of the

thread guide 3.

2

4

The thread passes through the eye of the

needle.

5. Release the needle threader lever 6.

6. Carefully pull the loop of the thread through the

eye of the needle to pull out the end of the

thread.

7. Raise the presser foot lever 1, then pass the

end of the thread through the presser foot, and

then pull out about 5 cm (2 inches) of thread

toward the rear of the machine.

3

3. Cut the thread with the thread cutter 5 on the

left side of the machine.

5

18

5cm

Page 23

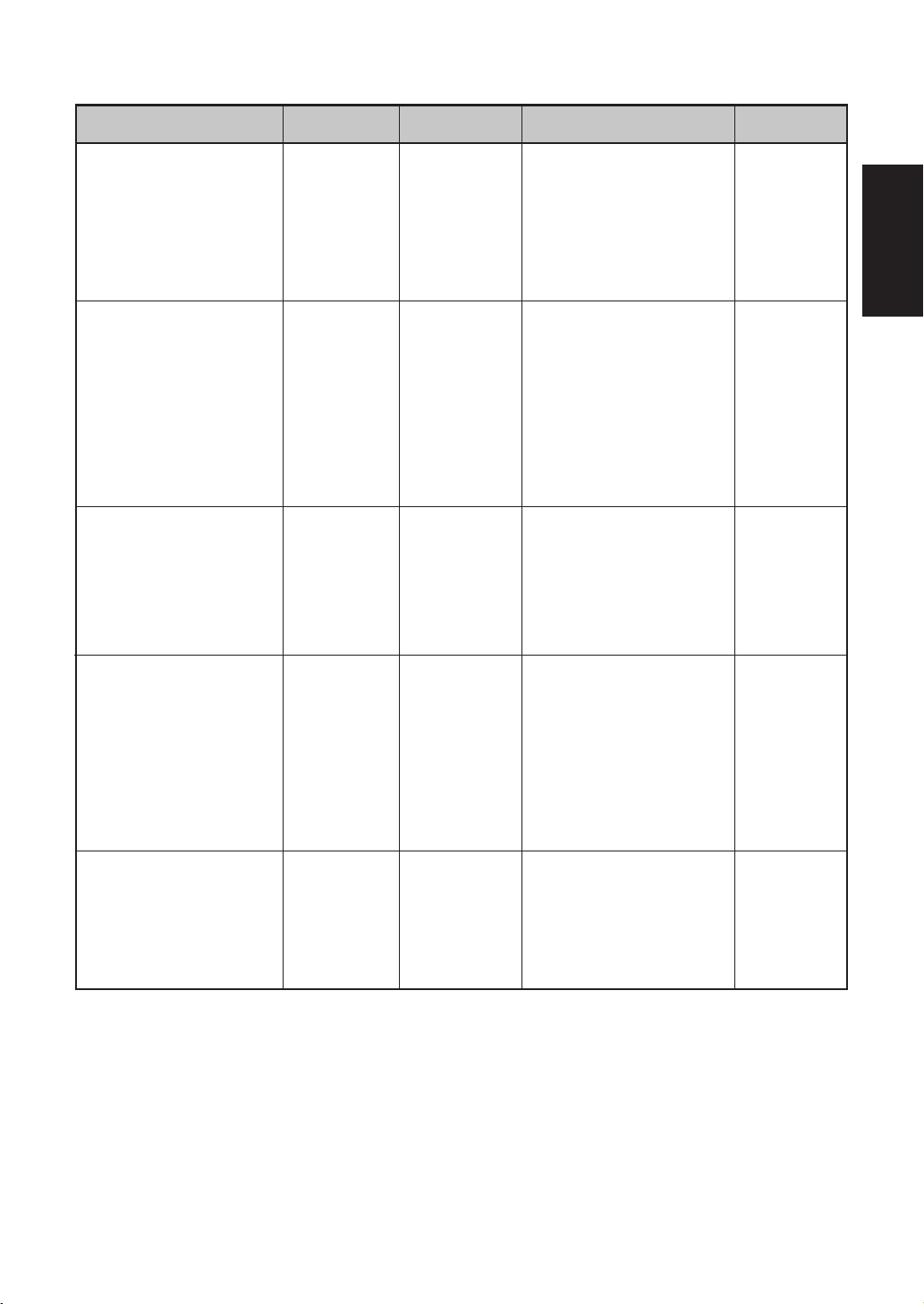

CHAPTER 4

SEWING MATERIALS,THREADS AND NEEDLES COMPARISON CHART

Material

Fine materials:

Georgette

Lawn

Organdy

Tricot

Fine materials:

Georgette

Lawn

Organdy

Tricot

Medium materials:

Broad cloth

Gabardine

Serge

Stitch

Overlock

stitch

Narrow over

lock/Rolled

hemming stitch

Overlock

stitch

Stitch Length

(mm)

2.0 - 3.0

R - 2.0

2.5 - 3.5

Thread

Spun #80 - 90

Cotton #100

Filament #80 - 100

Needle thread :

Spun #80 - 90

Filament #80 - 100

Looper thread :

Woolly nylon thread

Spun #80 - 90

Filament #80 - 100

Spun #60 - 80

Cotton #60 - 80

Filament #60 - 80

Needle

SCHMETZ

130/705H

#80

English

SCHMETZ

130/705H

#80

SCHMETZ

130/705H

#80

#90

Medium materials:

Broad cloth

Heavy materials:

Tweed

Denim

Knits

NOTE:

Decorative thread will work best in the upper looper for fashion sewing.

Narrow over

lock/Rolled

hemming

stitch

Overlock

stitch

R - 2.0

3.0 - 4.0

Needle thread :

Spun #60 - 80

Filament #60 - 80

Looper thread :

Woolly nylon thread

Spun #60 - 80

Filament #60 - 80

Cotton #50 - 60

Spun #60

Filament #50 - 60

SCHMETZ

130/705H

#80

#90

SCHMETZ

130/705H

#90

19

Page 24

CHAPTER 5

SEWING

Stitch selection

Select the stitch pattern before you start sewing.

This sewing machine can sew five different

stitches by following the simple steps below:

Four-thread overlock stitch

Use all four threads and two needles for

producing four-thread overlock stitches.

Use: Produces strong seam. Ideal for sewing

knits and wovens.

Three-thread overlock stitch

5 mm (3/16 inch)

Use three threads and the left needle, producing 5

mm (3/16 inch) seams.

Use: For overlock stitching on suits, blouses,

slacks, etc. Ideal for medium to heavy materials.

NOTE:

Remove the right needle when sewing this overlock

stitch.

Two-thread overlock stitch 2.8 mm

(7/64 inch)

Use two threads and the right needle, producing

2.8 mm (7/64 inch) seams.

Use: For overlock stitching on suits, blouses,

slacks, etc. Ideal for fine to medium materials.

NOTE:

Remove the left needle when sewing this overlock

stitch.

Narrow overlock stitch 2.0mm (5/64

inch) and

Rolled hemming stitch 2.0mm (5/64

inch)

Use as decorative or finishing stitch. See "Narrow

overlock/Rolled hemming stitch" in this chapter

for details.

NOTE:

You can use the optional accessory foot for even more

varieties of stitches. See CHAPTER 8 for details.

Three-thread overlock stitch 2.8 mm

(7/64 inch)

Use three threads and the right needle, producing

2.8 mm (7/64 inch) seams.

Use: For overlock stitching on suits, blouses,

slacks, etc. Ideal for fine to medium materials.

NOTE:

Remove the left needle when sewing this overlock

stitch.

Two-thread overlock stitch

5 mm (3/16 inch)

Use two threads and the left needle, producing 5

mm (3/16 inch) seams.

Use: For overlock stitching on suits, blouses,

slacks, etc. Ideal for fine to medium materials.

NOTE:

Remove the right needle when sewing this overlock

stitch.

Test sewing

Make the test sewing before you start sewing.

1. Set the thread tension as follows:

<For the four-thread overlock stitch and

three-thread overlock stitch>

· Set all the thread tension to "4".

<For the one-needle two-thread overlock

stitch>

· Set the needle thread tension to "2".

· Set the lower looper thread tension to "6".

(See "Chart of two-thread overlock stitch" in

this chapter for details.)

2. Thread the machine and pull all threads out

about 15 cm (6 inches) behind the presser

foot.

20

Page 25

3. Place a piece of scrap material under the

presser foot for test sewing.

NOTE:

Always lift the presser foot before placing the fabric

under it. You cannot start sewing by just running

the fabric under the foot without lifting the presser

foot.

4. Holding all threads with your left hand, turn the

hand wheel slowly a few times toward you,

and check to see that the threads entwine

themselves before using the foot controller to

sew.

To start sewing

1. Thread the machine and pull all threads out

about 15 cm (6 inches) behind the presser

foot.

English

2. Lift the presser foot and place the material well

underneath the presser foot before starting to

sew. Slowly sew a few stitches by turning the

hand wheel.

3. The fabric will be fed automatically. You need

only guide it in the required direction.

4. Check the stitch formation (stitch chain) to see

if it is uniform. If the stitch is not uniform, recheck that the threading has been done

properly and in sequence.

5. Follow the Seam Allowance Guide for

consistent cutting of the fabric seams. The

scale of Seam Allowance Guide shows 9.5,

12.7, 15.9, and 25.4mm (3/8, 1/2, 5/8, and 1

inches) when the stitch width dial is set to "5".

Chaining-off

After test-sewing, continue to depress the foot

controller slightly and chain-off 10cm (4 inches).

The threads will entwine themselves into a chain

automatically.

NOTE:

If the thread tension is not correctly balanced, the

chaining-off result will be uneven. If this happens, pull

the threads slightly. Check the threading order and

adjust the thread tension to create an even chain. (See

CHAPTER 1 "Tension adjustment dial".)

3

2

1

1 Presser foot 2 Upper knife 3 Seam Allowance Guide

To remove work

When the seam is finished, keep the machine

running at a low speed to obtain chaining-off.

Then cut the stitches 5 cm (2 inches) from the

work. If feeding for chaining-off is not enough, pull

the thread gently.

21

Page 26

To secure chain

There are two methods available to secure the

chain.

Method 1

Secure the chain of the beginning and the end of

a stitch with your machine.

At the beginning of a stitch

1. Sew a few stitches, after chaining-off for 5cm

(2 inches).

2. Stop the machine and raise the presser foot.

3. Put the chain under the presser foot, and serge

over it pulling toward you.

4. After sewing a few stitches, cut off the extra

chain with the knife as illustrated.

3. Lower the needles and the presser foot at the

same position.

4. Serge over the seam, taking care not to cut the

serged seam with a knife.

5. After sewing a few stitches, serge off the fabric

as illustrated.

6. Cut the threads with scissors.

Method 2

With this method, the chain at the beginning and

the end of a stitch can be secured in the same

manner.

1. Tie the thread unpicked from chain.

At the end of a stitch

1. At the end of the seam, sew one stitch out of

the fabric before stopping the machine.

2. Raise the presser foot and the needles, then

reverse the fabric.

2. Insert the chain into the end of the seam, using

a hand sewing needle with large eye.

3. Fix the chain with a drop of fabric glue, and cut

the extra stitches after drying.

22

Page 27

If threads break during sewing

To use the stitch finger W

Remove the material and re-thread in the correct

order, Lower looper, Upper looper, right needle

and then the left needle (to re-thread, see

CHAPTER 3 "Threading"). Replace the material

under the presser foot and sew 3-5 cm (1-1/8 to 2

inches) over the previous stitches.

CAUTION

Do not leave straight pins in the fabric when

sewing as they will damage the needles and

knives.

When sewing stretch fabrics, using the included

stitch finger W prevents the fabric from stretching

without adjusting the thread tension.

English

“W” mark

Stitch finger Stitch finger W

To sew fine materials

1. Adjust the presser foot pressure to prevent the

material from puckering and to allow sewing of

curves. (See CHAPTER 1 "Adjusting the

presser foot pressure".)

2. Loosen the thread tension, but remember that

if the tension is too loose, the thread may

break and stitches may be skipped.

23

Page 28

Two-thread sewing

How to set the thread change assembly

NOTE:

Be sure to set the thread change assembly to the

machine after completing the needle threading

using the needle threader. (You cannot use the

needle threader with the thread change assembly

set to the machine.)

1. Turn off the machine for safety.

5. Push the thread change assembly 2 fully

downward until the tip 3 of the thread change

assembly is put in the eye of the upper looper

4.

2. Turn the hand wheel so that the mark on the

hand wheel is aligned to the "

TC

" mark on the

machine.

TC

3. Hold the thread change assembly 1 with your

fingertips tightly so that the gap is closed as

shown below.

1

Make sure that the tip is in the

eye of the upper looper.

Setting of the looper has finished.

Chart of two-thread overlock stitch

Stitch length

Stitch width

Stitch finger

Thread tension

Left needle

thread

Lower looper

thread

Right needle

thread

For fine

materials

2 (1 - 3)

6 (5 - 7)

2 (1 - 3)

3

5 - 7

Install

For medium

materials

2 (1 - 3)

6 (5 - 7)

2 (1 - 3)

4. While holding the thread change assembly 1,

push the hole of the thread change assembly

onto the upper end of the OL shaft 2 so that

the OL shaft passes through the hole.

24

Lower looper

thread

6 (5 - 7)

6 (5 - 7)

Page 29

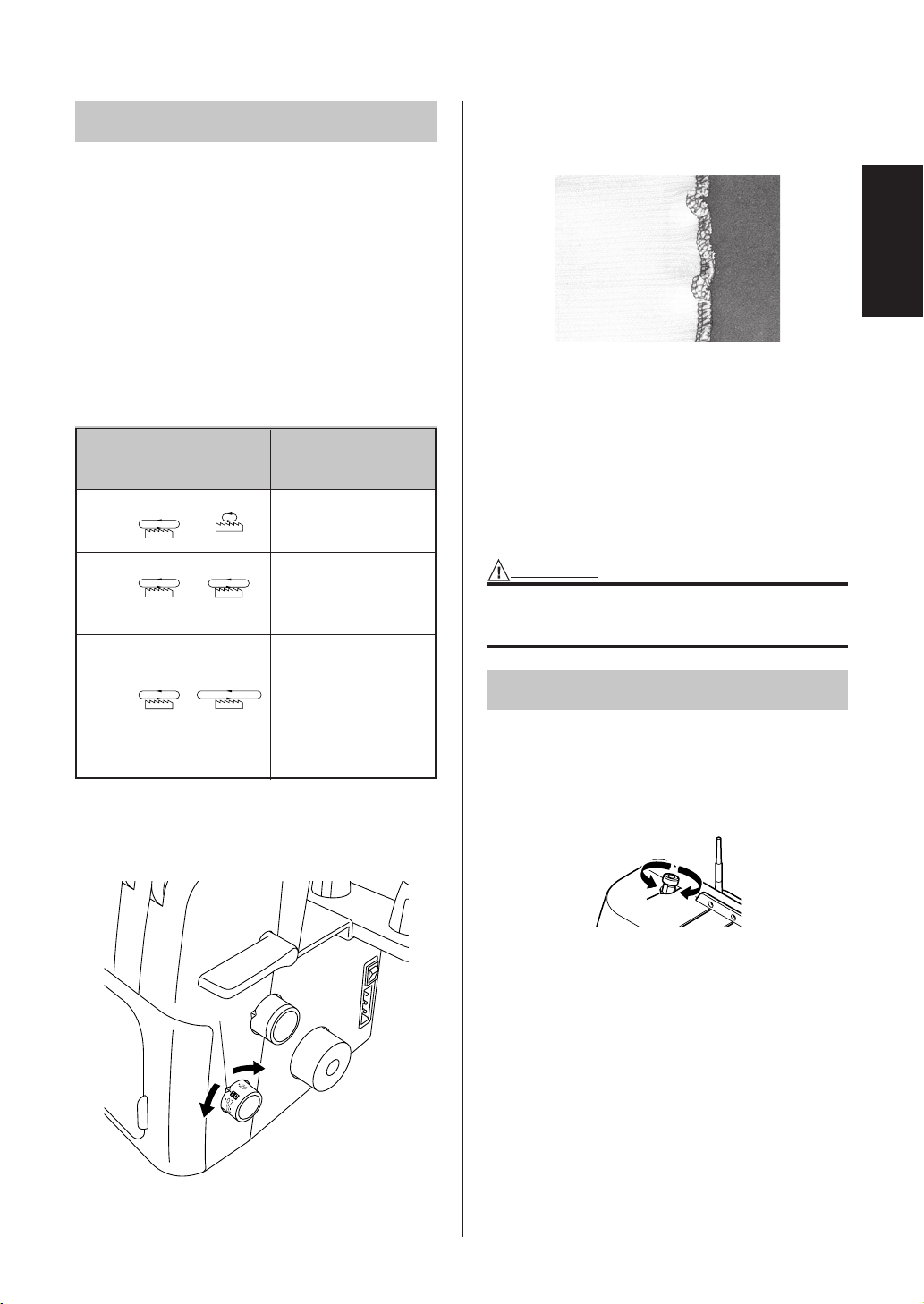

Narrow overlock/ Rolled hemming stitch

The Narrow overlock/Rolled hemming stitch is a

decorative finish for lightweight to midweight

fabrics. It is often used to complete the edge of a

fabric. This stitch is sewn by removing the left

needle and using the 3-thread overlock stitch.

4. Store the removed stitch finger <A> and/or

stitch finger W <B> inside of the bed

extension.

Instructions for both narrow overlock/

Rolled hemming stitches

CAUTION

Turn off the main power and light switch before

removing/ installing a needle.

1. Remove the left needle.

NOTE:

For the recommended thread and needle, see

CHAPTER 4 "Sewing materials, threads, and

needles comparison chart".

2. Thread the machine for a three thread

overlock, using the right needle.

3. Remove the stitch finger <A>.

1 Raise the presser foot lever.

2 Pull all threads toward the back of the

machine.

3 Check to make sure that the thread is no

longer wrapped around the stitch finger.

4 Open the front cover.

5 Turn the hand wheel until the upperlooper

is at its lowest position.

6 Pull the stitch finger to the right and remove

it.

English

<B><A>

NOTE:

Make sure to install a stitch finger when sewing

regular overlock stitches.

5. Adjust the stitch width adjustment dial up to the

"R" position.

<A>

<A> Selection mark

6. Adjust the stitch length.

Set the stitch length adjustment dial to "R to 2"

position (for narrow overlock stitch: R to 2, for

rolled hemming stitch: R).

3

<A>

<A> Selection mark

<A>

25

Page 30

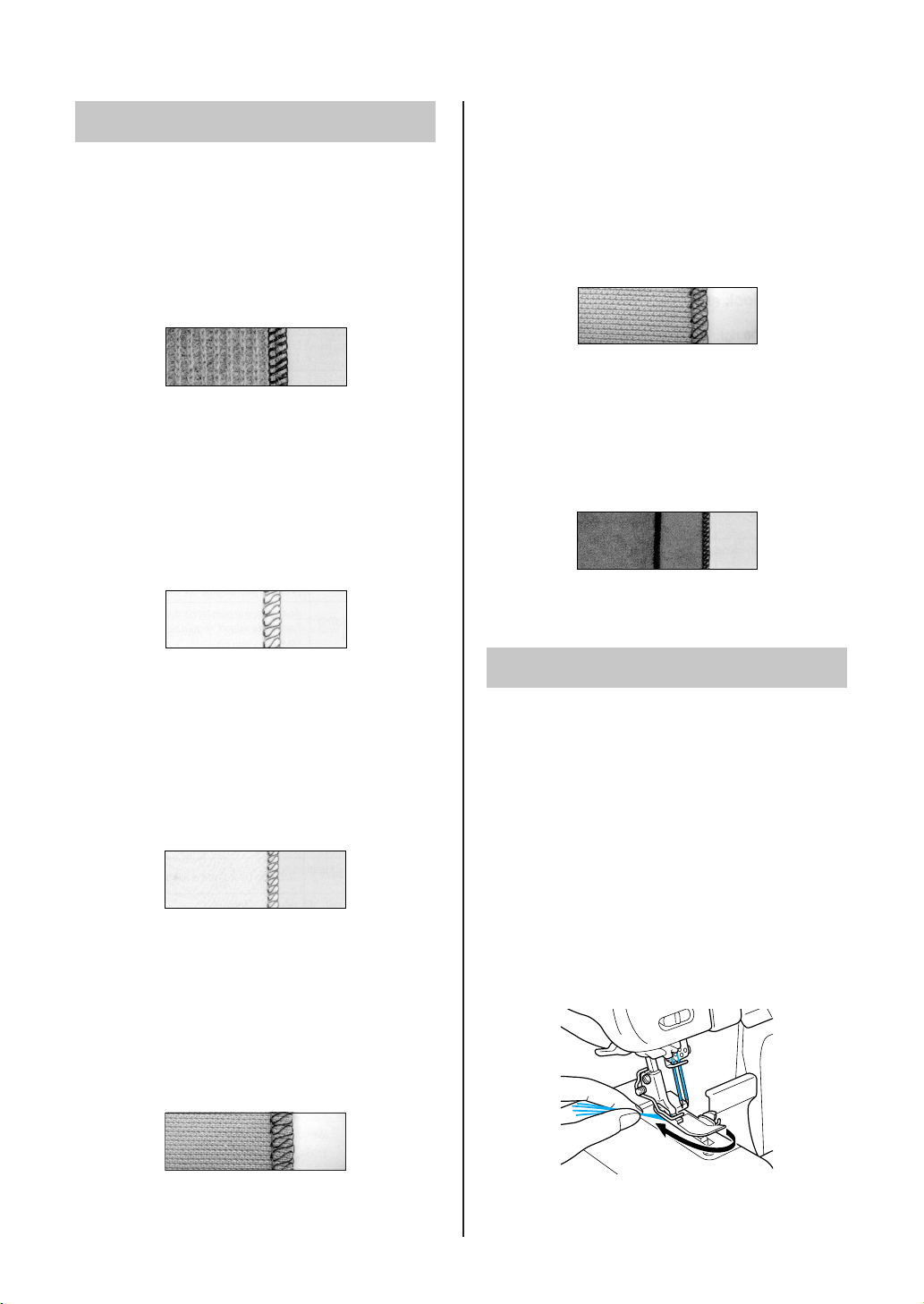

Chart of narrow overlock/ Rolled hemming stitch

Stitch Style

Materials

Needle thread

Upper looper thread

Rolled hemming stitch

Underside of material

Top of material

See CHAPTER 4 "Sewing

materials, threads, and needles

comparison chart".

See CHAPTER 4 "Sewing

materials, threads, and needles

comparison chart".

See CHAPTER 4 "Sewing

materials, threads, and needles

comparison chart".

Narrow overlock stitch

Underside of material

Top of material

See CHAPTER 4 "Sewing

materials, threads, and

needles comparison chart".

See CHAPTER 4 "Sewing

materials, threads, and

needles comparison chart".

See CHAPTER 4 "Sewing

materials, threads, and

needles comparison chart".

Lower looper thread

Stitch Length

Stitch Width

Stitch Finger

Thread Tension

Needle Thread

Upper looper Thread

Lower looper Thread

26

See CHAPTER 4 "Sewing

materials, threads, and needles

comparison chart".

R

R

Removed

For fine materials

4 (3 - 5)

5 (4 - 6)

7 (6 - 8)

For medium materials

5 (4 - 6)

5 (4 - 6)

7 (6 - 8)

See CHAPTER 4 "Sewing

materials, threads, and

needles comparison chart".

R - 2.0

R

Removed

For fine materials

4 (3 - 5)

5 (4 - 6)

5 (4 - 6)

For medium materials

5 (4 - 6)

6 (5 - 7)

6 (5 - 7)

Page 31

CHAPTER 6

TROUBLESHOOTING

This sewing machine is designed for trouble-free operation. However, the following chart indicates trouble

which may occur if basic adjustments are not made properly.

Trouble

1. Does not feed

2. Needles break

3. Threads break

4. Skipped stitches

Cause

Presser foot pressure too

loose

1. Needles bent, or needle

tip blunt

2. Needles incorrectly

installed

3. Material pulled forcibly

1. Improper threading

2. Thread tangled

3. Thread tension too tight

4. Needles incorrectly

installed

5. Wrong needle used

6. The tip of the thread

change assembly is not

in the eye of the upper

looper.

1. Needle bent, or needle

tip blunt

2. Needle incorrectly

installed

3. Wrong needle used

Remedy

Turn the pressure adjustment screw clockwise to

increase the presser foot pressure. (See page 7.)

Replace with new needle. (See page 11.)

English

Install needles correctly. (See page 11.)

Do not press or pull material too hard when

sewing.

Thread correctly. (See pages 13-18.)

Check spool pin, thread holders, etc. and

remove tangled thread.

Adjust the thread tension. (See pages 8-10.)

Install needles correctly. (See page 11.)

Use correct needle

Schmetz 130/705H - suggested (See page 11.)

Put the tip of the thread change assembly in

the eye of the upper looper. (See page 24.)

Replace with new needle. (See page 11.)

Install needle correctly. (See page 11.)

Use correct needle.

Schmetz 130/705H - suggested (See page 11.)

5. Stitches are not

uniform

6. Fabric is puckered

4. Improper threading

5. Presser foot pressure too

loose

6. The tip of the thread

change assembly is not

in the eye of the upper

looper.

Thread tensions are not

adjusted properly

1. Thread tension too tight

2. Improper threading or

thread tangled

Thread correctly. (See pages 13-18.)

Turn the pressure adjustment screw

clockwise to increase the presser foot

pressure. (See page 7.)

Put the tip of the thread change assembly in

the eye of the upper looper. (See page 24.)

Adjust the thread tension. (See pages 8-10.)

Decrease thread tension when sewing

lightweight or fine material.

(See pages 8-10.)

Thread correctly. (See pages 13-18.)

27

Page 32

CHAPTER 7

MAINTENANCE

Cleaning

CAUTION

Turn off the machine before cleaning.

Turn the hand wheel and move the needles down.

Periodically clean dust, trimmed fabric and thread

with the included cleaning brush.

Oiling

For smooth and silent operation, the moving parts

(indicated with arrows) of the machine should be

oiled periodically.

CAUTION

Turn off the machine before opening the front

cover and oiling.

NOTE:

Be sure to oil your sewing machine before use.

Always clean the lint off your machine before you apply

oil.

Oil the machine once or twice a month for normal use. If

the machine is used more often, oil it once a week.

28

Page 33

CHAPTER 8

INTRODUCTION OF OPTIONAL FEET

CAUTION

Turn off the machine while replacing the presser

foot.

Blind stitch foot

Features

When using the blind stitch presser foot (multi

purpose foot), you can sew blind stitches and

overlock at the same time. This is ideal when

sewing cuffs, trouser bottoms, pockets, and

hemming skirts etc.

The stitch guide on this foot is also useful when

sewing special stitches like flatlock, pin tuck and

other decorative stitches.

Blind stitching

The blind hem stitch is used for putting a near

invisible hem in garments or home decoration

projects. Use it to hem pants, skirts, or draperies.

6. Lower the presser foot lever, adjust the fabric

guide toward the folded edge.

7. Adjust the guide position of the presser foot

with the adjusting screw so that the needle is

lightly touching the crease in the fabric. In this

case, the thickness of the fabric is the

criterion.

By turning the screw forward (toward you) the

fabric guide will go to the right. By turning the

screw backward (away from you) the fabric

guide will go to the left.

!

English

"

Recommended settings

- Stitch Width: 5 mm

- Stitch Length: 3 - 4 mm

- Needle Thread Tension: Slightly Slackened (0-2)

- Upper Looper Thread Tension:

Slightly Tightened (5-7)

- Lower Looper Thread Tension:

Slightly Slackened (2-4)

Procedure

1. Attach the blind stitch foot (see CHAPTER 1

"Attaching/ Removing presser foot").

2. Set up the machine for 3 thread overlock stitch

with one needle in the left position.

The right needle should be removed.

3. Turn the wrong side of the fabric out, fold the

fabric once and then back to the required

width, as illustrated.

1 Reverse

2 Needle path

Sewing will be easier if a crease is ironed into

the folded fabric before sewing.

4. Turn the hand wheel so that the line on the

hand wheel is aligned to the line on the

machine (see CHAPTER 1 "Turning direction

of hand wheel").

5. Lift the presser foot lever and insert the fabric

with the folded edge on the left in such a way

that the needle pierces just the folded edge as

it sews.

3 Adjusting screw

4 Fabric guide

To adjust the position of the fabric guide, a

piece of the same fabric should be used to do

a sewing test.

8. While folding the fabric by hand, sew so that

the needle just catches the edge of the

crease.

9. Open the fabric as shown in the illustration.

For best results, use a fine thread in a color

that matches the fabric.

When done correctly, this stitch will be very

hard to see on the right side of the fabric.

Flatlock stitching

The Flatlock stitch is primarily used as a

decorative finish on a project. The finished stitch

can look like a ladder or small parallel lines when

the fabric is pulled flat.

Recommended settings

- Stitch Width: 5 mm

- Stitch Length: 2 - 4 mm

- Needle Thread Tension: 0-3

- Upper Looper Thread Tension: 2-5

- Lower Looper Thread Tension: 6-9

29

Page 34

Procedure

1. Attach the blind stitch foot (see CHAPTER 1

"Attaching/ Removing presser foot").

2. Set up the machine for 3 thread overlock with

one needle in the left position.

The right needle should be removed.

3. Fold the fabric as shown in the illustration.

9. When stiching is finished, pull the fabric open

(flat).

1 Surface

4. Turn the hand wheel so that the line on the

hand wheel is aligned to the line on the

machine (see CHAPTER 1 "Turning direction

of hand wheel").

5. Lift the presser foot lever and insert the fabric

with the folded edge in such a way that the

needle pierces just on the fold.

6. Lower the presser foot lever, adjust the fabric

guide toward the folded edge.

7. Adjust the guide position of the presser foot

with the adjusting screw so that the needle

moves down to a position 1/8 inch (2.5 to 3.0

mm) inside the folded edge of the fabric, so

that some of the stitching loops over the edge.

!

Either stitch finish can be used on the right

side of the fabric. If you sew with the wrong

sides together, the upper looper thread will

decorate the right side when pulled flat. If you

sew with the right sides together, the needle

thread ladder will decorate the right side when

pulled flat.

NOTE:

This method is not suitable for thin fabrics.

Pin tuck stitching

The Pin tuck stitch uses a rolled edge to add

shape and decoration to any sewing project.

Contrasting thread in the upper looper adds an

accent to your project.

For thin fabrics, it's a good idea to choose a fine

thread which will run smoothly.

Procedure

1. Attach the blind stitch foot (see CHAPTER 1

"Attaching/Removing presser foot").

2. Set up the machine for narrow overlock

stitching. (Refer to CHAPTER 5 "Narrow

overlock/Rolled hemming stitch".)

3. Draw equally spaced lines on the fabric with a

fabric pencil as guides for pin tuck placement.

Fold the fabric along one of the lines and

press in place lightly with an iron.

2 Adjusting screw

3 Fabric guide

By turning the screw forward the fabric guide

will go to the right. By turning the screw

backward the fabric guide will go to the left.

To adjust the position of the fabric guide, a

piece of the same fabric can be used to do a

sewing test.

8. While holding the fabric pieces together, sew

at a constant speed down the fold.

30

1 Making lines

2 Fold in two

4. Turn the hand wheel so that the line on the

hand wheel is aligned to the line on the

machine (see CHAPTER 1 "Turning direction

of hand wheel").

5. Lift the presser foot lever and insert the fabric

with the folded edge in such a way that the

needle pierces just the folded edge.

6. Lower the presser foot lever, adjust the fabric

guide toward the folded edge.

7. Align the blind stitch presser foot guide with the

line on the right side of the stitch finger.

By turning the screw forward the stitch guide

will go to the right. By turning the screw

backward the stitch guide will go to the left.

Page 35

8. Align the fold with the guide and insert the

5

fabric up to the needle position.

!

Machine setting (type of stitch):

- 2 needle 4 thread overlock

- 1 needle 3 thread overlock (Either needle can

be used.)

English

"

3 Adjusting screw

4 Fabric guide

9. Guide the fold in the fabric to sew half way

between the needle and the upper knife.

10. Continue sewing until all marked lines have

been sewn.

Correct minor contractions by hand.

Taping foot

Features

By using the tape presser foot, you can sew

tapes, as well as elastics and hem at the same

time beautifully.

- Tapes or elastics from 6mm up to 12mm width

can be sewn.

- Attatching tapes is very useful for reinforcement

on stretchable materials sucn as knitted garment

at shoulder. Also attaching elastics is suitable

for sewing cuffs, necklines, etc.

How to set the elastic / tape

1

4

5

2

3

1. Attach the taping foot (see CHAPTER 1

"Attaching/ Removing presser foot").

2. Lift the presser foot lever.

3. Turn the hand wheel so that the line on the

hand wheel is aligned to the line on the

machine (see CHAPTER 1 "Turning direction

of hand wheel").

4. Flip open the tape guide 1, then set the

presser adjusting dial 2 at "0".

5. Put the tape or the elastic 5 through the slot

3.

6. Insert the tape or the elastic 5 through the slot

3 so that the righthand side of tapes / elastics

will be set along the guide 4.

7. Flip shut the tape guide 1 so that it will be set

at the lefthand side of tapes / elastics.

Test sewing

<A> <B>

<A> Usage of the elastic

<B> Usage of the tape

1. Lift the presser foot lever.

2. Insert the materials, till the edge of the

materials will touch the blade.

3. Lower the presser foot lever.

4. Set the stitch width control dial at "5".

31

Page 36

5. Set the stitch length control lever.

- Tapes: between "3" and "4"

- Elastics: "4"

6. Adjust the presser adjusting dial 2

- at "0" when sewing with tapes.

- at desirable number for contraction when

sewing with elastics.

NOTE:

Contraction will be increased with larger number.

7. Make trial sewing and adjust thread tensions.

Example of proper sewing seam:

<A>

<B>

<A> Surface

<B> Tape

<C> Surface

<D> Elastic

NOTE:

Thread tensions are similar to normal overedging

when sewing with tapes.

It is recommendable to have a stronger tension for

under looper and over looper for beautiful finish.

It is advisable to make trial sewing on each material

/ thread due to different contraction.

<C>

<D>

How to adjust the machine

1. Adjust the stitch length according to the length

as <A> or <B>. For example, 4mm stitch

length means 4mm for <A> or <B>.

<A>

<B>

<A>

<B>

2. Adjust stitch width 3 to 5mm.

3. Adjust thread tension as follows:

Needle thread: slightly decrease

Over looper thread: slightly decrease

Under looper thread: slightly increase

How to set fabric and pearl

1 ~ 1.5mm

2

Pearl sequence foot

Features

By using the pearl sequence foot, you can bead

on fabric. It is useful for decorated edge of

curtains, table clothes, dresses, etc. From 3mm to

5mm sequins and pearls can be sewn with this

foot.

LS

Preparation

1. Retract the knife (see CHAPTER 1 "Retracting

knife").

2. Attach the pearl sequence foot (see CHAPTER

1 "Attaching/ Removing presser foot").

3. Set up the machine for 3 thread overlock stitch

with one needle in the left position.

The right needle should be removed.

1

3

1. Fold the fabric according to the line for pearl

fitting.

2. Place the fabric at needle dropping point

keeping the folded edge with guide 1.

3. Use the screw 2 and adjust the clearance

between folded edge needle so that it

becomes 1mm to 1.5mm.

4. Place the pearl through the guide just front of

guide tunnel 3.

Test sewing

1. Sew turning hand wheel by hand until the pearl

comes through the tunnel.

2. Sew at slow speed while guiding the strand of

pearls and fabric by hand.

3. Tie both ends of thread at the beginning and

end.

NOTE:

Thread tension is easy to loosen especially for small

size pearls. Retract movable stitch tongue for better

stitching.

32

Page 37

Piping foot

Features

By using the piping foot, you can attach piping at

the edge of material. Piping is used to decorate

the edge of fabric (pajamas, sports ware), cover

for furniture, cushion, bag, etc.

LP

Preparation

Attach the piping foot (see CHAPTER 1

"Attaching/ Removing presser foot").

Machine setting (type of stitch):

- 2 needle 4 thread overlock

- 1 needle 3 thread overlock (the right needle

should be removed)

How to adjust the machine

1. Set stitch length at 3mm. (standard position)

2. Set stitch width at 5 to 6mm

3. Adjust thread tension for ordinary overlock

stitching (refer to CHAPTER 5 "Stitch

selection").

How to set fabric and piping tape

3cm

2

<A>

1

1 Surface 2 Reverse

1. Put piping tape between the 2 pcs of fabric and

adjust both edges of the fabric as illustrated.

Keep 3cm piping tape over the edge of fabric

for steady sewing. (The surface of fabric

should be inside.)

2. Place fabric with piping tape under presser

foot and put the piping tape into the groove

<A> of piping foot and start sewing.

Start sewing

1. Carefully guide the fabric and piping tape by

hands during sewing.

2. Turn both sides of the fabric after sewing.

NOTE:

For easy sewing, bast the both fabric and piping tape

before sewing.

Piping sewing is difficult at sharp angles.

In case of wide piping tape, the tape should be attached

after trimming the excess tape.

English

3mm

5 ~ 6mm

3mm

5 ~ 6mm

33

Page 38

Gathering foot

Features

You can create beautiful gathers using the

gathering foot on various garment and home

decorating applications.

LG

Preparation

Attach the gathering foot (see CHAPTER 1

"Attaching/ Removing presser foot").

Machine setting (type of stitch):

- 2 needle 4 thread overlock

- 1 needle 3 thread overlock (Either needle can

be used.)

How to set fabric

4. Adjust the other settings to those used during

normal overlock sewing.

5. Sew while keeping the fabric aligned with the

fabric guide 3.

- Adjust the size of the gathers by setting the

sitich length between 2mm and 5mm.

- Adjust the amount of fabric that is gathered

by setting the differential feed ratio between

1.0 and 2.0.

NOTE:

Do not pull or stretch the fabric.

3

1

1 Surface 2 Reverse

1. Raise the presser foot lever.

2. Turn the hand wheel so that the mark on the

hand wheel is aligned to the line on the

machine (see CHAPTER 1 "Turning direction

of hand wheel").

3. Position the bottom piece of fabric (the fabric

that will be gathered 1 under the guide 3 just

below the needle).

4. Position the top piece of fabric 2 between the

gathering foot and the guide 3 on top of the

bottom fabric 1.

5. Lower the presser foot lever.

2

Test sewing

1. Set the stitch length to 3mm.

2. Set the differential feed ratio to 2.

3. Set the stitch width to 5mm.

34

Page 39

SPECIFICATIONS

Specifications

Use

Fine to heavy materials