Page 1

KE-430B, 430C, 431B, 431C

KE-432B, 432C, 433B

KE-434B, 434C, 435B, 435C

KE-436B, 436C, 484C

SERVICE MANUAL

BE-438B, 438C

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

ELECTRONIC LOCKSTITCH BAR TACKER

ELECTRONIC LOCKSTITCH BELT LOOP BAR TACKER

ELECTRONIC LOCKSTITCH PATTERN TACKER

ELECTRONIC LOCKSTITCH BUTTON SEWER

Page 2

This service manual is intended for KE-430B series, KE-430C series, BE-438B, BE-438C, KE-484C; be sure to read the

KE-430B series, KE-430C series, BE-438B, BE-438C, KE-484C instruction manual before this manual.

Carefully read the “SAFETY INSTRUCTIONS” below and the whole of this manual to understand this product before you

start maintenance.

As a result of research and improvements regarding this product, some details of this manual may not be the same as those

for the product you purchased.

If you have any questions regarding this product, please contact a Brother dealer.

SAFETY INSTRUCTIONS

1. Safety indications and their meanings

This service manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

DANGER

The instructions which follow this term indicate situations where failure to follow the

instructions will almost certainly result in death or severe injury.

CAUTION

Symbols

・・・・・・

・・・・・・

・・・・・・

The instructions which follow this term indicate situations where failure to follow the

instructions could cause injury when using the machine or physical damage to equipment

and surroundings.

This symbol ( ) indicates something that you should be careful of. The picture inside the triangle

indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

This symbol ( ) indicates something that you must not do.

This symbol ( ) indicates something that you must do. The picture inside the circle indicates the

nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

i

KE-430B, 430C series

Page 3

2. Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before opening the face plate of the control box. Touching areas where high voltages are present can result in

severe injury.

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is free from

sources of strong electrical noise such as

high-frequency welders.

Sources of strong electrical noise may cause problems with correct operation.

Any fluctuations in the power supply voltage should

be within 10% of the rated voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

The power supply capacity should be greater than the

requirements for the sewing machine’s electrical

consumption.

Insufficient power supply capacity may cause problems with correct operation.

The pneumatic delivery capability should be greater

than the requirements for the sewing machine’s total

air consumption.

Insufficient pneumatic delivery capability may cause

problems with correct operation.

Installation

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be done.

The sewing machine weighs more than 52 kg. The

installation should be carried out by two or more

people.

Do not connect the power cord until installation is

complete, otherwise the machine may operate if the

foot switch is depressed by mistake, which could

result in injury.

Hold the machine head with both hands when tilting it

back or returning it to its original position.

Furthermore, after tilting back the machine head, do

not push the face plate side or the pulley side from

above, as this could cause the machine head to

topple over, which may result in personal injury or

damage to the machine.

Be sure to connect the ground. If the ground connec-

tion is not secure, you run a high risk of receiving a

serious electric shock, and problems with correct

operation may also occur.

The ambient temperature should be within the range

of 5C to 35C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation should

occur in any devices.

Excessively dry or humid environments and dew formation may cause problems with correct operation.

Avoid exposure to direct sunlight during use.

Exposure to direct sunlight may cause problems with

correct operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct operation.

All cords should be secured at least 25 mm away

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too firmly

with staples, otherwise there is the danger that fire or

electric shocks could occur.

Install the belt covers to the machine head and motor.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin, otherwise

inflammation can result.

Furthermore, do not drink the oil or eat the grease

under any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

KE-430B, 430C series

ii

Page 4

CAUTION

Sewing

This sewing machine should only be used by operators who have received the necessary training in safe

use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may enter

your eyes and injury may result.

Set the needle to the needle up stop position before

turning off the power.

If this is not done, the wiper may strike the needle,

which might cause the needle to break.

Turn off the power switch at the following times,

otherwise the machine may operate if the foot switch

is depressed by mistake, which could result in injury.

When threading the needle

When replacing the needle and bobbin

When not using the machine and when leaving the

machine unattended

Cleaning

Set the needle to the needle up stop position before

turning off the power.

If this is not done, the wiper may strike the needle,

which might cause the needle to break.

Turn off the power switch before carrying out

cleaning, otherwise the machine may operate if the

foot switch is depressed by mistake, which could

result in injury.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this

may result in personal injury or damage to the

machine.

If an error occurs in machine operation, or if abnormal

noises or smells are noticed, immediately turn off the

power switch. Then contact your nearest Brother

dealer or a qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin, otherwise

inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

Maintenance and inspection

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspection of the

electrical system.

Set the needle to the needle up stop position before

turning off the power.

If this is not done, the wiper may strike the needle,

which might cause the needle to break.

Turn off the power switch and disconnect the power

cord from the wall outlet at the following times,

otherwise the machine may operate if the foot switch

is depressed by mistake, which could result in injury.

When carrying out inspection, adjustment and main-

tenance

When replacing consumable parts such as the ro-

tary hook

Disconnect the air hoses from the air supply and wait

for the needle on the pressure gauge to drop to “0”

before carrying out inspection, adjustment and repair

of any parts which use the pneumatic equipment.

If the power switch and air need to be left on when

carrying out some adjustment, be extremely careful to

observe all safety precautions.

Hold the machine head with both hands when tilting it

back or returning it to its original position.

Furthermore, after tilting back the machine head, do

not push the face plate side or the pulley side from

above, as this could cause the machine head to

topple over, which may result in personal injury or

damage to the machine.

Use only the proper replacement parts as specified

by Brother.

If any safety devices have been removed, be absolutely sure to re-install them to their original positions

and check that they operate correctly before using

the machine.

Any problems in machine operation which result from

unauthorized modifications to the machine will not be

covered by the warranty.

iii

KE-430B, 430C series

Page 5

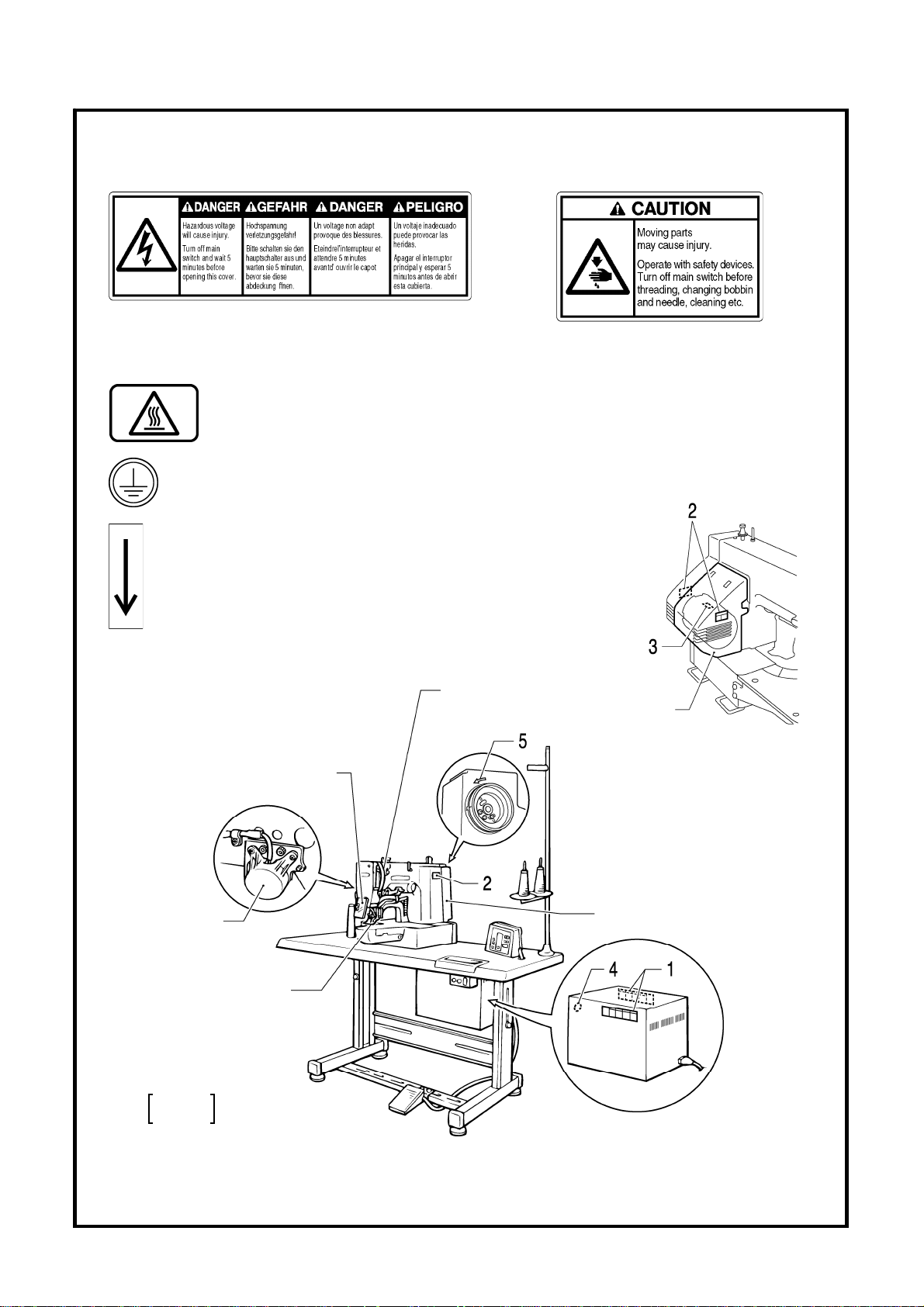

3. Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are

difficult to read, please contact your nearest Brother dealer.

1

2

3

High temperature warning display

Safety devices

Eye guard

Finger guard

Thread take-up cover

Thread take-up solenoid cover

Belt cover

Frame side cover, etc.

4

5

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a

serious electric shock, and problems with correct operation may also occur.

Direction of operation

Thread take-up cover

Frame

side

cover

e guard

Ey

Thread take-up

solenoid cover

Belt cover

2670Q

Finger guard

KE-430B

KE-430C

KE-430B, 430C series

2737Q

iv

Page 6

CONTENTS

1. SPECIFICATIONS ............................... 1

1-1. SPECIFICATIONS ........................................... 1

1-2. Standard thread tension................................... 5

2. MECHANICAL DESCRIPTIONS ......... 7

2-1. Needle b ar and thread take-up

mechanisms..................................................... 7

2-2. Lo wer shaft and shuttle race mechanisms....... 9

2-3. Work clamp lifter mechanism........................... 10

2-4. Work clamp open-close mechanism

(KE-432B, 432C).............................................. 12

2-5. Thread wiper mechanism................................. 13

2-6. Feed mechanism ............................................. 15

2-7. Thread trimmer mechanism............................. 17

2-8. Thread nipper mechanism ............................... 19

2-9. Thread take-up mechanism ............................. 21

3. DISASSEMBLY ................................... 22

3-1. Covers.............................................................. 22

3-2. Work clamp ar m mechanism

(KE-430B, 430C, 431B, 431C)......................... 24

3-3. Work clamp ar m mechanism

(KE-432B, 432C).............................................. 25

3-4. Work clamp arm mechanism (KE-433B).......... 26

Work clamp arm mechanism (KE-434B, 434C,

3-5.

435B, 435C, 436B, 436C, 484C)

Work clamp arm

3-6.

3-7. Shuttle hook mechanism.................................. 30

3-8. Needle bar mechanism.................................... 31

3-9. Stepping foot mechanism

(KE-435B, 435C, 436B, 436C)......................... 32

3-10. Upper shaft mechanism.................................... 33

3-11. Lower shaft mechanism.................................... 35

3-12. Feed mechanism (1)......................................... 37

3-13. Feed mechanism (2)......................................... 39

3-14. Work clamp lifter mechanism

(Solenoid specifications).................................. 41

3-15. Stepping foot lifter mechanism

(KE-435B, 435C, 436B, 436C)......................... 43

(BE-438B, 438C) ..................... 29

........................... 27

3-16. Thread wiper mechanism.................................. 44

3-17. Thread nipper mechanism ................................ 47

3-18. Thread take-up mechanism .............................. 49

3-19. Thread trimmer mechanism.............................. 51

4. ASSEMBLY......................................... 54

4-1. Thread trimmer mechanism (1)........................ 54

4-2. Thread nipper mechanism................................ 56

4-3. Thread wiper mechanism................................. 59

4-4. Thread take-up mechanism.............................. 62

4-5. Work clamp lifter mechanism

(Solenoid specifications)................................... 65

4-6. Feed mechanism (1)......................................... 70

4-7. Feed mechanism (2)......................................... 74

4-8. Upper shaft mechanism.................................... 76

4-9. Stepping foot lifter mechanism

(KE-435B, 435C, 436B, 436C)......................... 79

4-10. Stepping foot mecha nism

(KE-435B, 435C, 436B, 436C)......................... 80

4-11. Needle bar mechanism..................................... 82

4-12. Lower shaft mechanism.................................... 83

4-13. Thread trimmer mechanism (2) ........................ 86

4-14. Shuttle hook mechanism.................................. 87

4-15. Work clamp arm mechanism

(KE-430B, 430C, 431B, 431C)......................... 89

4-16. Work clamp arm mechanism

(KE-432B, 432C).............................................. 90

4-17. Work clamp arm mechanism (KE-433B)........... 91

4-18. Work

4-19. Work clamp arm mechanism

4-20. Work clamp arm mechanism

4-21. Covers.............................................................. 97

clamp arm mechanism (KE-434B, 434C,

435B, 435C, 436B, 436C, 484C)

(BE-438B, 438C).............................................. 94

(Applying grease) ............................................. 95

........................... 92

KE-430B, 430C series

Page 7

5. ADJUSTMENT..................................... 99

5-1. Adjusting the needle bar height........................ 99

5-2. Adjusting the needle bar lift amount................. 100

5-3. Adjusting the driver needle guard .................... 101

5-4. Adjusting the needle clearance........................ 101

5-5. Adjusting the shuttle race thread guide ............ 102

5-6. Adjusting the clearance between the shuttle

hook and bobbin case holder position bracket

(KE-484C)........................................................ 103

5-7. Adjusting the work clamp lift amount

(KE-430B, 430C, 431B, 431C, 433B) .............. 104

5-8. Adjusting the work clamp lift amount

(KE-432B, 432C).............................................. 104

5-9. Adjusting the work clamp lift amount (KE-434B,

434C, 435B, 435C, 436B, 436C, 484C)........... 105

5-10. Adjusting the button clamp lift amount

(BE-438B, 438C).............................................. 106

5-11. Work clamp pressure adjustment

(KE-432B, 432C).............................................. 107

5-12. Adjusting the holding pressure

(BE-438B, 438C).............................................. 107

5-13. Work clamp closing-distance adjustment

(KE-432B, 432C).............................................. 108

5-14. Adjusting the position of the button holder

(BE-438B, 438C).............................................. 109

5-15. Work clamp adjustment

(KE-435B, 435C, 436B, 436C)......................... 109

5-16. Changing the work clamp lift

(KE-435B, 435C, 436B, 436C)......................... 110

5-17. Adjusting the thread wiper................................ 111

5-18. Adjusting the thread take-up amount................ 114

5-19. Adjusting the movable knife.............................. 116

5-20. Adjusting the position of the thread trimming

link mechanism ................................................ 122

5-21. Adjusting the backlash...................................... 123

5-22. Adjusting the presser solenoid position

(Solenoid specifications) .................................. 124

5-23. Adjusting the sensor perceive plate position

(Solenoid specifications) .................................. 125

5-24. Adjusting the home position.............................. 126

5-25. Adjusting the needle up stop position ............... 129

5-26. Adjusting the tension of the upper shaft timing

belt ................................................................... 129

5-27. Checking the head position switch.................... 130

5-28. Work clamp interchangeability

(KE-433B)....................................................... 131

5-29. Work clamp interchangeability (KE-434B,

434C, 435B, 435C, 436B, 436C, 484C) ........... 131

5-30. Adjustment of air pressure (Pneumatic

specifications)................................................... 132

5-31. Adjustment of inner clamping device ................ 132

6. TROUBLESHOOTING ........................ 133

7. OPTIONAL PARTS............................. 136

8. ELECTRIC MECHANISM.................... 138

8-1. Precautions at the time of adjustment................. 138

8-2. Components inside the control box and

the operation panel........................................... 138

8-3. Fuse explanation ................................................ 139

8-4. Connectors ......................................................... 140

8-5. Explanation of the DIP switches ......................... 147

8-6. Explanation of the memory switches

(KE-430*, 431*, 432*, 433B, 434*, 435*,

484C, BE-438*) ................................................ 150

8-7. Explanation of the memory switches

(KE-436B, 436C).............................................. 155

8-8. Setting the work clamp mode.............................. 159

8-9. Checking the input sensor and DIP switch

input.................................................................. 161

8-10. Checking the input voltage................................ 163

8-11. Clearing all memory settings............................. 164

8-12. Confirming software version ............................. 165

8-13. Table of error codes.......................................... 167

8-14. Troubleshooting................................................ 171

8-15. Control circuit block diagram............................. 190

KE-430B, 430C series

Page 8

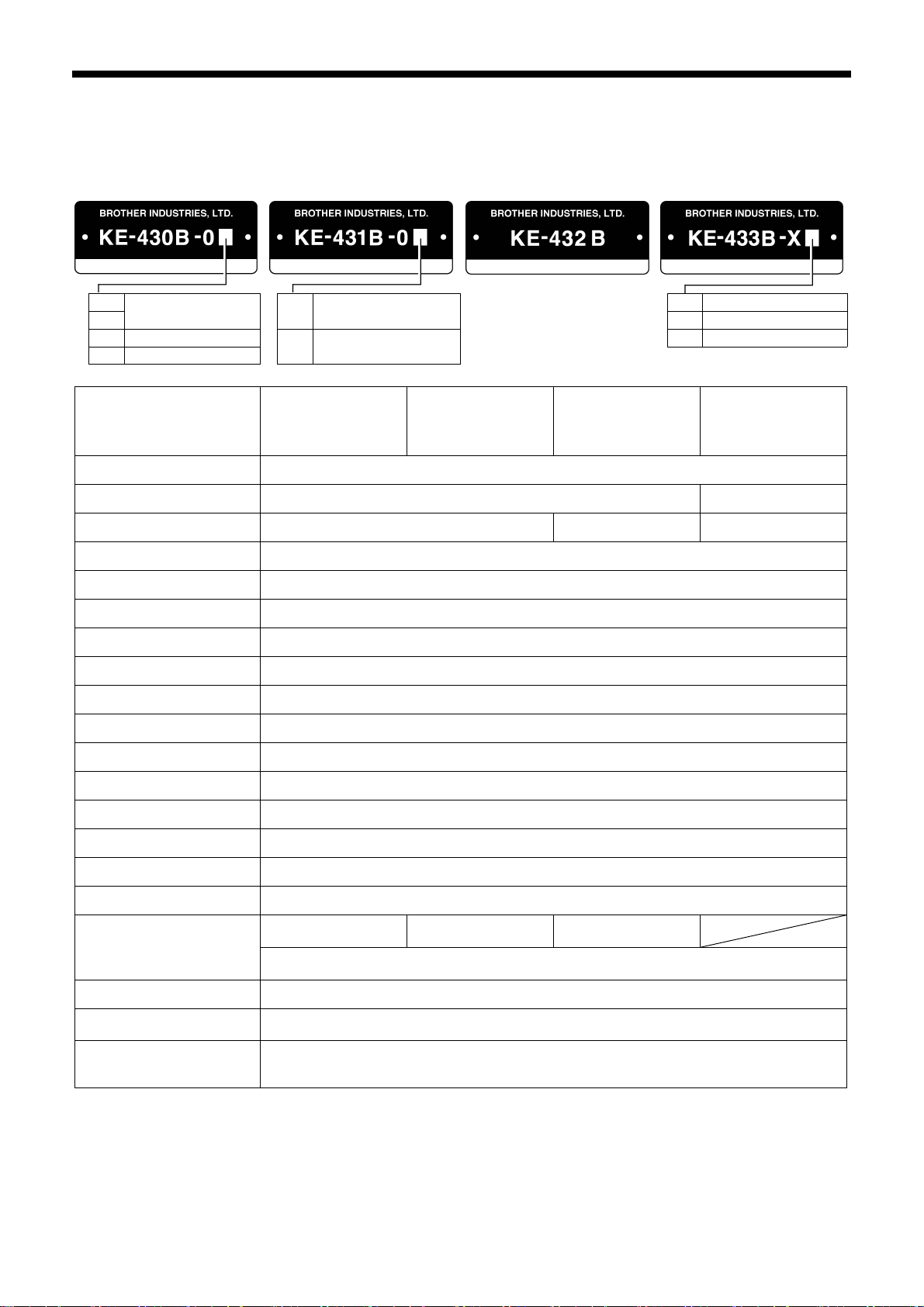

1. SPECIFICATIONS

1. SPECIFICATIONS

1-1. SPECIFICATIONS

1

Ordinary materials 2

5

2 Denim

7 Knitted materials

Stitch formation Single needle lock stitch

Maximum sewing speed

Maximum pattern size

Feed mechanism

Stitch length

Number of stitches

Maximum stitch number 20,000 stitches (including 10,000 stitches which can be added)

Work clamp lifter Solenoid type

Work clamp height

Rotary hook Shuttle hook (shuttle hook 2, optional)

Electronic lockstitch

Bar tacking length

Bar tacking length

3

KE-430B

bar tacker

6 -14 mm

14 - 25 mm

30 10 mm max. 12 3 mm max. 30 30 mm max.

R- intermittent feed mechanism (pulse-motor driven mechanism)

KE-431B

Electronic lockstitch

belt loop bar tacker

2,700 rpm 2,500 rpm

0.1 - 10.0 mm

17 mm max.

KE-432B

Electronic lockstitch

eyelet buttonhole

end bar tacker

Variable

1 Ordinary materials

2 Denim

7 Knitted materials

Electronic lockstitch

decorative pattern

KE-433B

tacker

Wiper device Standard equipment

Thread trimmer device Standard equipment

Thread take-up device Standard equipment

Data storage method P-ROM (Any sewing pattern can be added using PS-3000.)

Number of user programs

Number of cycle programs

35 sewing patterns are

Number of stored data

Motor Three-phase 400W induction motor

Weights

Power source

set already

(Up to 100 patterns can be added. Total number of stitches of stored data

6 sewing patterns are

set already

which can be added is within 10,000.)

Machine head: 52 kg, Operation panel: 0.6 kg,

Control box: 9 - 19 kg (depending on destination)

Single-phase 110, 220 - 230, 240V

3-phase 220-230, 380, 400V

Maximum electric power consumption; 600VA

16

4

3 sewing patterns are

set already

1

KE-430B, 430C series

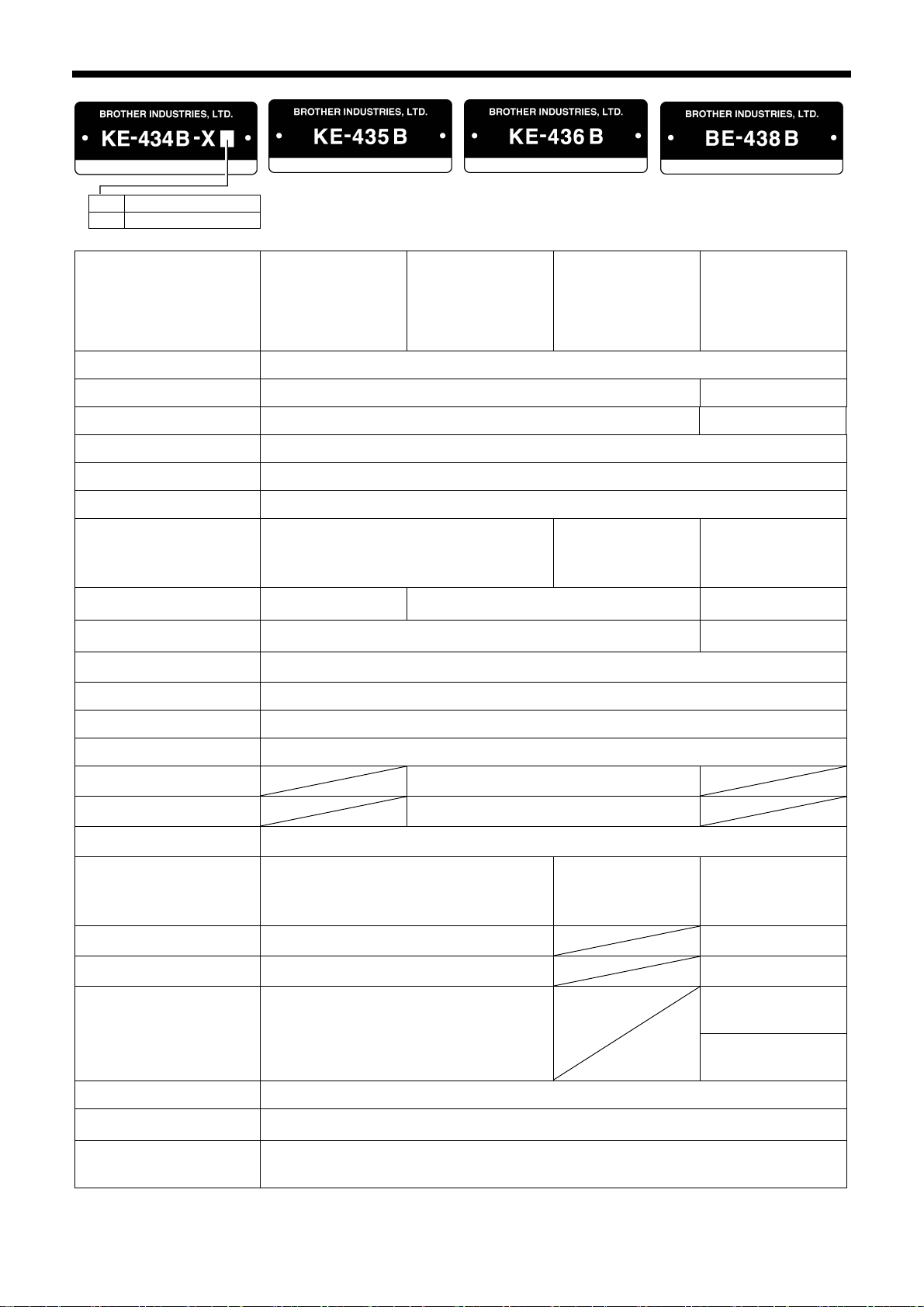

Page 9

1 Medium

materials

2 Heavy materials

KE-436B

KE-434B

Electronic lockstitch

pattern tacker

KE-435B

Electronic lockstitch

pattern tacker

with stepping foot

Electronic lockstitch

pattern tacker

with stepping foot

and programming

function

Stitch formation Single needle lock stitch

1. SPECIFICATIONS

BE-438B

Electronic lockstitch

button sewer

Maximum sewing speed

Maximum pattern size 100 60 mm max.

2,500 rpm (Pitch 3 mm) 2,500 rpm

0 - 6.4 0 - 6.4 mm

Feed mechanism R- intermittent feed mechanism (pulse-motor driven mechanism)

Stitch length

Number of stitches

0.1 - 10.0 mm

Variable

20,000 stitches

Maximum stitch number

20,000 stitches (including 10,000 stitches

which can be added)

20,000 stitches

(One pattern)

(including 10,000

stitches which can

be added)

Work clamp lifter

Work clamp height

Rotary hook

Solenoid type or

pneumatic type

Pneumatic type Solenoid type

17 mm max. (for solenoid)

25 mm max. (for pneumatic) (Max. 17 mm for inner clamping device)

Shuttle hook (shuttle hook 2, optional)

13 mm max.

Wiper device Standard equipment

Thread trimmer device Standard equipment

Thread take-up device Standard equipment

Stepping foot lift amount 18 mm

Stepping foot stroke 0 mm, 3 - 8 mm

Safety device

built-in stopping mechanism

P-ROM (Any sewing

Data storage method

P-ROM (Any sewing pattern can be added

using PS-3000.)

3.5 floppy disk

2HD/1.44MB, 2DD

pattern can be

added using

PS-3000.)

Number of user programs

Number of cycle programs

16

4

16

4

49 sewing patterns are

set already

Number of stored data

(*)

Motor Three-phase 400W induction motor

Weights

Machine head: 56 kg, Operation panel: 0.6 kg (2.8 kg: KE-436B),

Control box: 9 - 19 kg (depending on destination)

Single-phase 110, 220 - 230, 240V

Power source

3-phase 220-230, 380, 400V

Maximum electric power consumption; 600VA

* Up to 100 patterns can be added. Total number of stitches of stored data which can be added is within 10,000.

KE-430B, 430C series

(*)

2

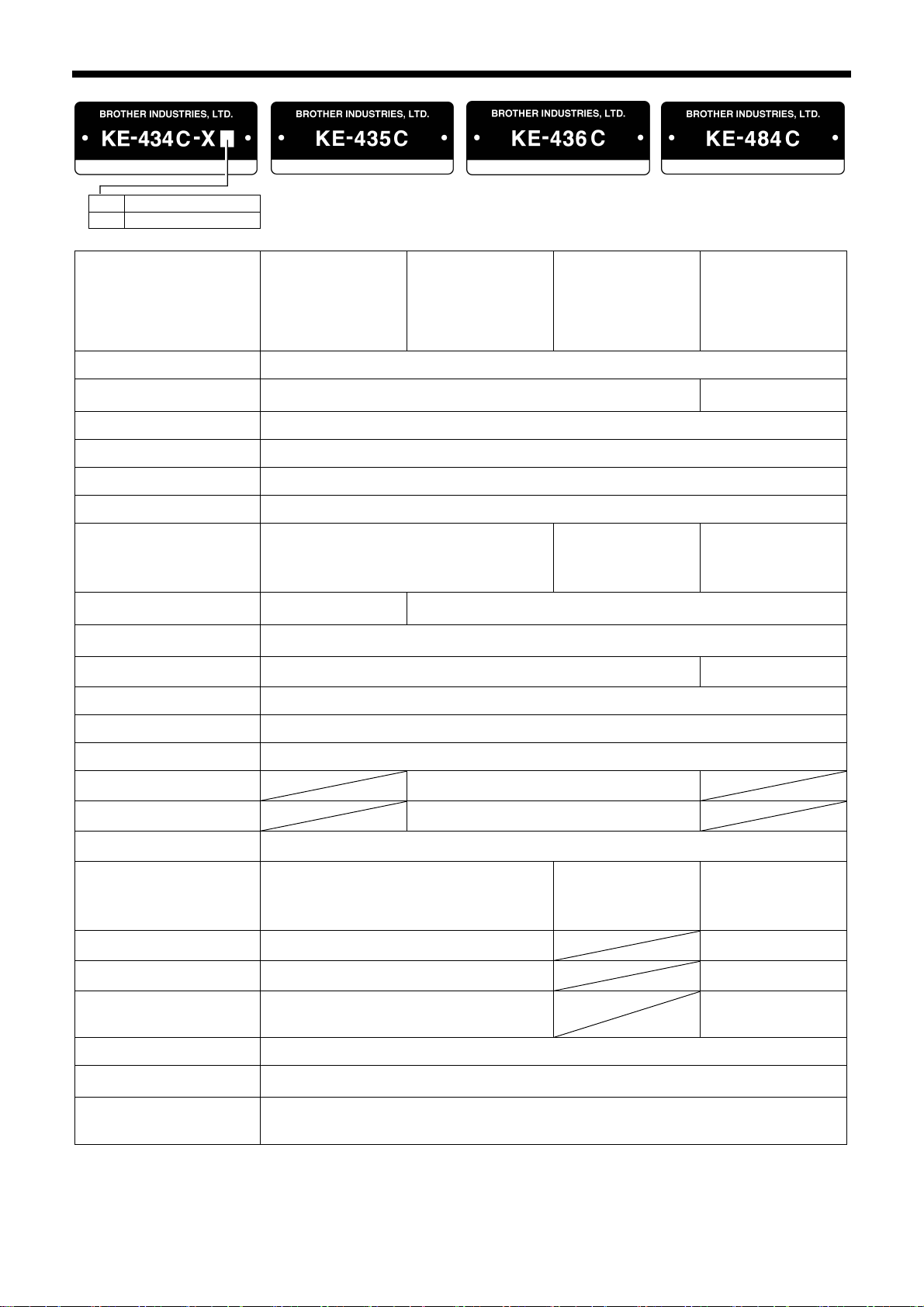

Page 10

1. SPECIFICATIONS

1 Ordinar

y materials

2 Denim

Knitted materials

7

Bar tacking length

2

Bar tacking length

3

6 -14 mm

14 -25 mm

KE-430C

Electronic lockstitch

bar tacker

KE-431C

Electronic lockstitch

belt loop bar tacker

KE-432C

Electronic lockstitch

eyelet buttonhole

end bar tacker

Electronic lockstitch

Stitch formation Single needle lock stitch

Maximum sewing speed

Maximum pattern size

Feed mechanism

Stitch length

Number of stitches

30 26 mm max. 30 10 mm max. 12 3 mm max. 0 - 6.4 0 - 6.4 mm

R- intermittent feed mechanism (pulse-motor driven mechanism)

2,700 rpm 2,500 rpm

0.1 - 10.0 mm

Variable

Maximum stitch number 20,000 stitches (including 10,000 stitches which can be added)

Work clamp lifter Solenoid type

Work clamp height

17 mm max. 13 mm max.

Rotary hook Shuttle hook (shuttle hook 2, optional)

BE-438C

button sewer

Wiper device Standard equipment

Thread trimmer device Standard equipment

Thread take-up device Standard equipment

Data storage method P-ROM (Any sewing pattern can be added using PS-3000.)

Number of user programs

Number of cycle programs

Number of stored data

61 sewing patterns are

set already

(Up to 100 patterns can be added. Total number of stitches of stored data

6 sewing patterns are

set already

16

4

3 sewing patterns are

set already

49 sewing patterns are

which can be added is within 10,000.)

Motor Three-phase 400W induction motor

Weights

Machine head: 52 kg, Operation panel: 0.6 kg,

Control box: 9 - 19 kg (depending on destination)

Single-phase 110, 220 - 230, 240V

Power source

3-phase 220-230, 380, 400V

Maximum electric power consumption; 600VA

set already

3

KE-430B, 430C series

Page 11

1. SPECIFICATIONS

1 Medium

2 Heavy materials

Stitch formation Single needle lock stitch

Maximum sewing speed

Maximum pattern size 100 60 mm max.

Feed mechanism R- intermittent feed mechanism (pulse-motor driven mechanism)

materials

KE-434C

Electronic lockstitch

pattern tacker

KE-435C

Electronic lockstitch

pattern tacker

with stepping foot

2,500 rpm (Pitch 3 mm)

KE-436C

Electronic lockstitch

pattern tacker

with stepping foot

and programming

function

Electronic lockstitch

pattern tacker

with treble hook

KE-484C

2,200 rpm

(Pitch 3 mm)

Stitch length

Number of stitches

0.1 - 10.0 mm

Variable

20,000 stitches

Maximum stitch number

20,000 stitches (including 10,000 stitches

which can be added)

20,000 stitches

(One pattern)

(including 10,000

stitches which can

be added)

Work clamp lifter

Work clamp height

Rotary hook Shuttle hook (shuttle hook 2, optional)

Solenoid type or

pneumatic type

Pneumatic type

17 mm max. (for solenoid), 25 mm max. (for pneumatic)

(Max. 17 mm for inner clamping device)

Treble hook

Wiper device Standard equipment

Thread trimmer device Standard equipment

Thread take-up device Standard equipment

Stepping foot lift amount 18 mm

Stepping foot stroke 0 mm, 3 - 8 mm

Safety device

built-in stopping mechanism

P-ROM (Any sewing

Data storage method

P-ROM (Any sewing pattern can be added

using PS-3000.)

3.5 floppy disk

2HD/1.44MB, 2DD

pattern can be

added using

PS-3000.)

Number of user programs

Number of cycle programs

16

4

16

4

Number of stored data (*)

Motor Three-phase 400W induction motor

Weights

Machine head: 56 kg, Operation panel: 0.6 kg (2.8 kg: KE-436C),

Control box: 9 - 19 kg (depending on destination)

Single-phase 110, 220 - 230, 240V

Power source

3-phase 220-230, 380, 400V

Maximum electric power consumption; 600VA

* Up to 100 patterns can be added. Total number of stitches of stored data which can be added is within 10,000.

KE-430B, 430C series

(*)

4

Page 12

1. SPECIFICATIONS

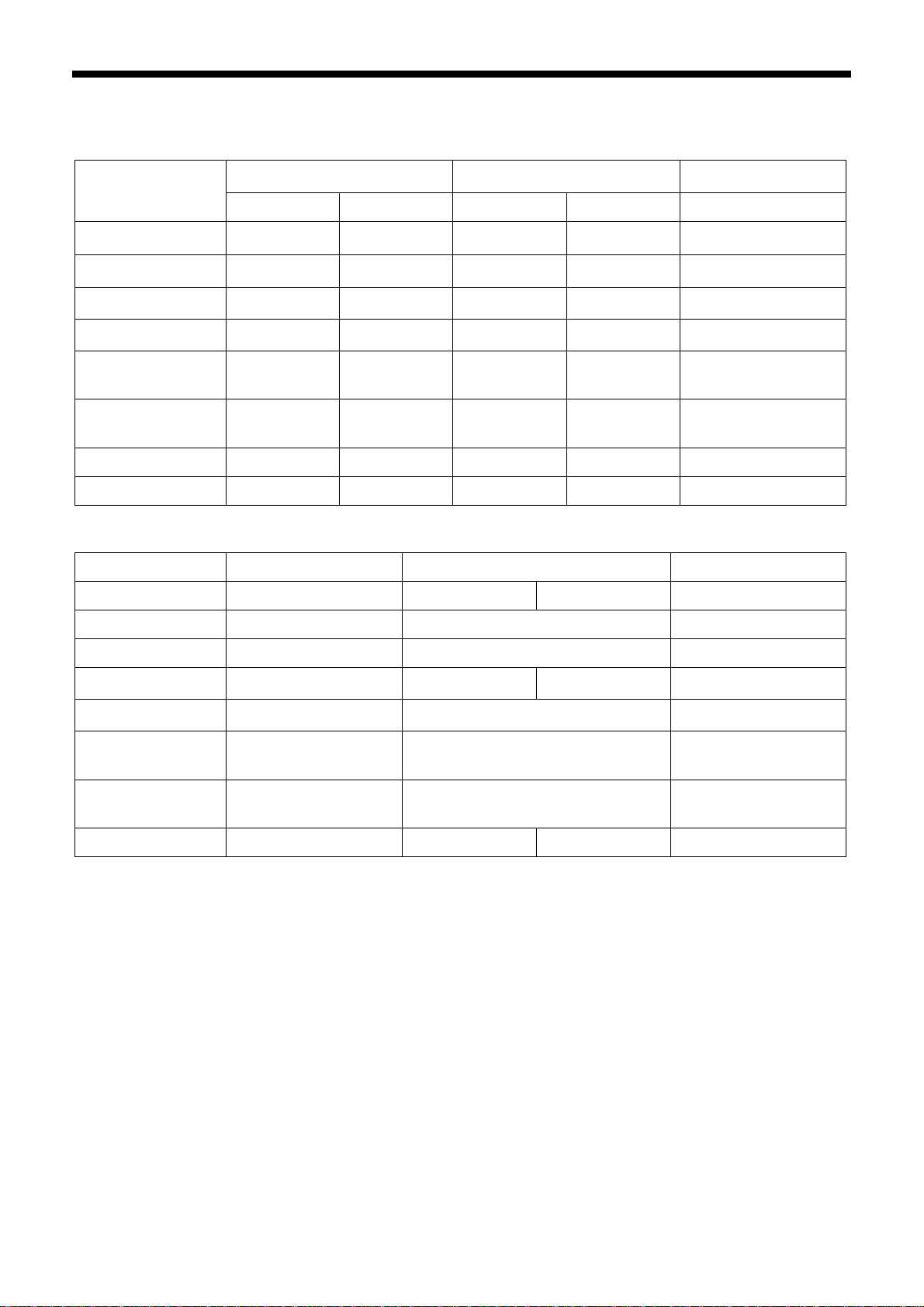

1-2. Standard thread tension

[KE-430B, 430C, 431B, 431C, 432B, 432C, 433B, 434B, 434C, 435B, 435C, 436B, 436C]

Use

Upper thread

Lower thread

Upper thread tension

(N)

Lower thread tension

(N)

T hread take-up

spring height

(mm)

Thread take-up

s pring tension

(N)

Pre-t (N) ension

Medium materials

(Ordinary materials)

Standard hook Large hook Standard hook Large hook Standard hook

#50 or

equivalent

#60 or

equivalent

0.8 - 1.2 1.0 - 1.3 1.2 - 1.6 1.4 - 1.8 0.8 - 1.2

0.2 - 0.3

6 - 8

0.3 - 0.4

0.5 - 0.8

←

←

←

←

←

←

Heavy materials (Denim) Knitted materials

#30 or

equivalent

#50 or

equivalent

0.2 - 0.3

6 - 8

0.5 - 0.6

0.3 - 0.5

← #60 or equivalent

← #80 or equivalent

←

←

←

←

0.25 - 0.3

6 - 8

0.3 - 0.4

0.5 - 0.8

Needle

[BE-438B, 438C, KE-484C]

Model BE-438B BE-438C KE-484C

Needle

Upper thread #60 or equivalent #60 or equivalent #4 or equivalen t

Lower thread

Upper thread tension

Lo n

T hread take-up

T

spring tension

Pre-tension (N)

(N)

wer thread tensio

(N)

spring height

(mm)

hread take-up

(N)

DP×5#14 ← DP×17NY#19 ← DP×5#9

TQ×1#12 TQ×1# NY#12 12 DP×17 DP×17#25

#60 or equivalent or equivale #4 or equivalent #60 nt

0.7 - 1.3 0.7 - 1.3 0.7 - 1.5 4.5 - 5.0

0 0 1

.3 - 0.4 .3 - 0.4 .0 - 1.2

6 - 8 6 - 8 0 - 5

0.4 - 0.6 0.4 - 0.6 2.0 - 2.5

0.1 - 0.3 0.1 - 0.3 0.05 - 0.3 0.3 - 0.5

5

KE-430B, 430C series

Page 13

1. SPECIFICATIONS

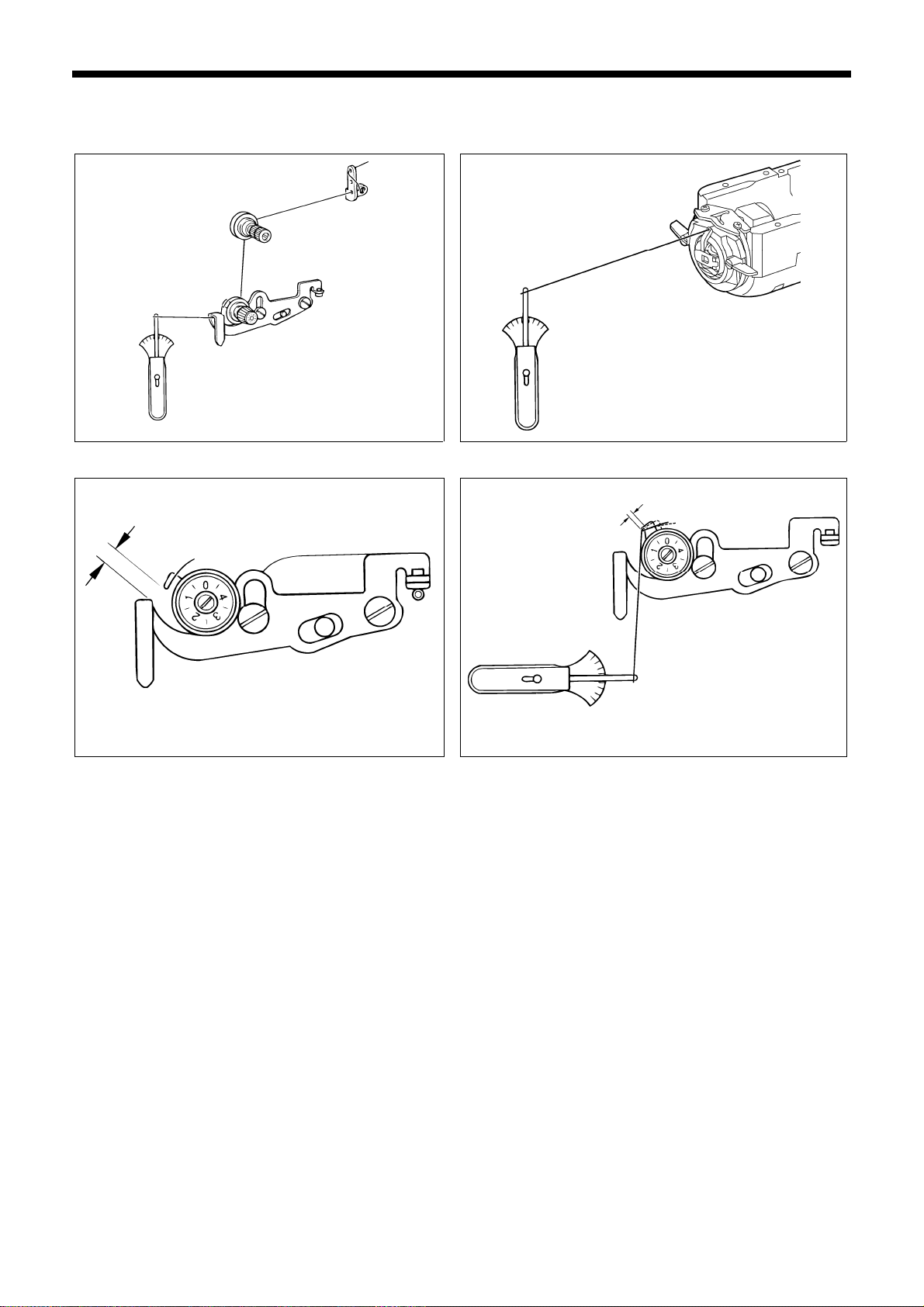

1-2-1. Measuring tension

Upper thread tension Lower thread tension

3564Q 3565Q

Thread take-up spring height Thread take-up spring tension

3566Q

1–2 mm

Measure the value when the thread take-up

spring starts to extend.

3567Q

* When the spring height (stroke) is great or the spring tension is insufficient, it may cause the thread end length to vary after

thread trimming.

KE-430B, 430C series

6

Page 14

2. MECHANICAL DESCRIPTIONS

2. MECHANICAL DESCRIPTIONS 2. MECHANICAL DESCRIPTIONS

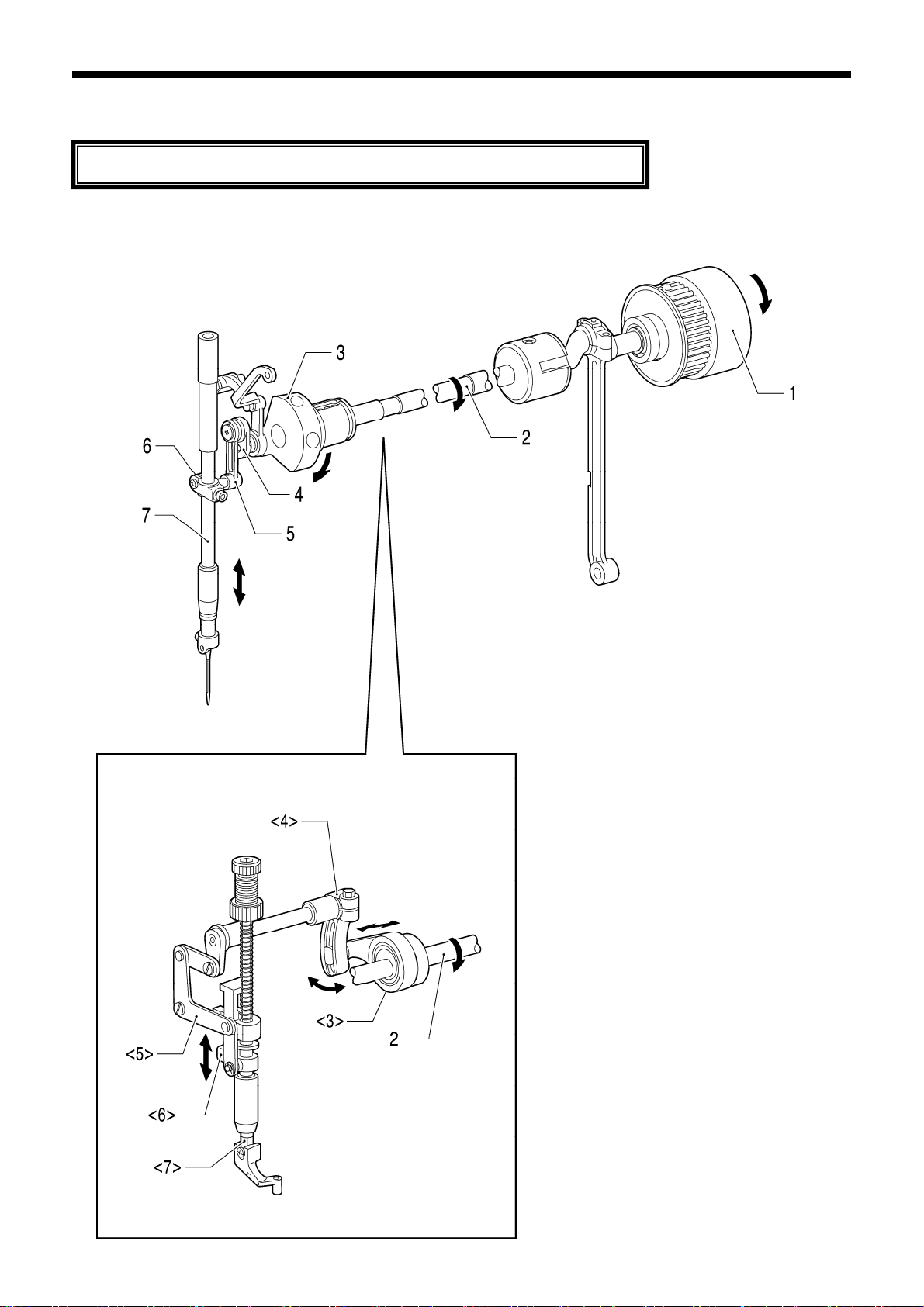

The mechanisms operate in the order of the numbers given in the illustrations.

2-1. Needle bar and thread take-up mechanisms 2-1. Needle bar and thread take-up mechanisms

With stepping foot

3240Q 40Q

7

<3> Stepping foot connecting rod

<4> Stepping foot arm

<5> Stepping link assy

<6> Presser bar lifter

<7> Stepping foot

KE-430B, 430C series

1. Pulley

2. Upper shaft

3. Thread take-up crank

4. Needle bar crank

5. Needle ba r conne cting ro d

6. Needle bar clamp

7. Needle bar

Page 15

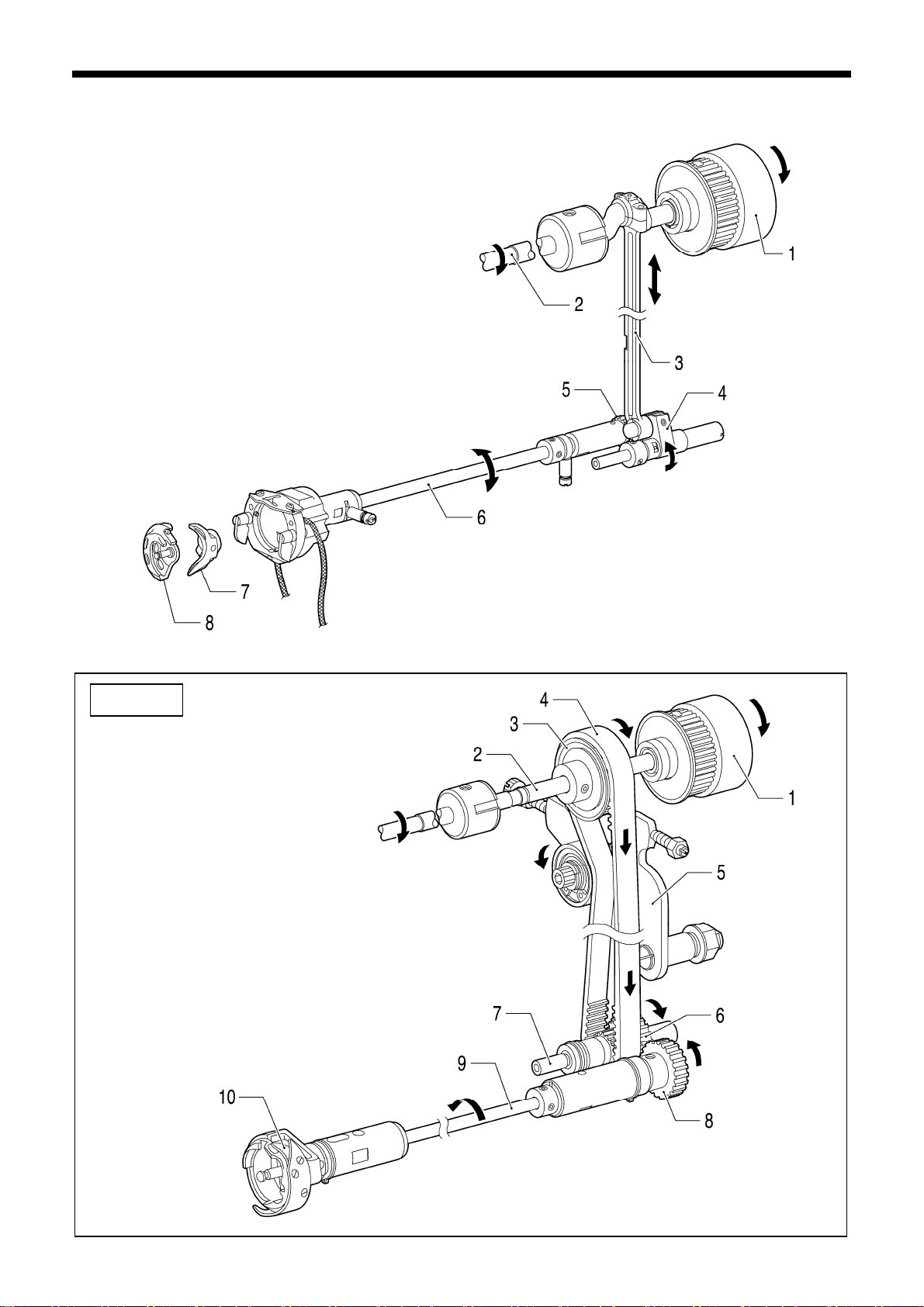

KE-484C

3241Q 41Q

2. MECHANICAL DESCRIPTIONS

1. Pulley

2. Upper shaft

3. Thread take-up crank

4. Ne

edle bar crank

5. Needle ba r conne cting ro d

6. Needle bar clamp

7. Needle bar

KE-430B, 430C series

8

Page 16

2. MECHANICAL DESCRIPTIONS

2-2. Lower shaft and shuttle race mechanisms 2-2. Lower shaft and shuttle race mechanisms

3242Q Q

KE-484C

1. Pulley

2. Upper shaft

3. Timing pulley

4. Timing belt

5. Tensi on pulley arm

6. Lower shaft timing pulley

7. Lower shaft

8. Lower gear

9. Rotary hook shaft

1

0.Treble hook assy

1. Pulley

2. Upper shaft

3. Cra

nk rod assy

4. Rock gear

5. Lower gear

6. Lower shaft

7. Driver

8. Shuttle hook

3243

Q3243Q

9

KE-430B, 430C series

Page 17

2. MECHANICAL DESCRIPTIONS

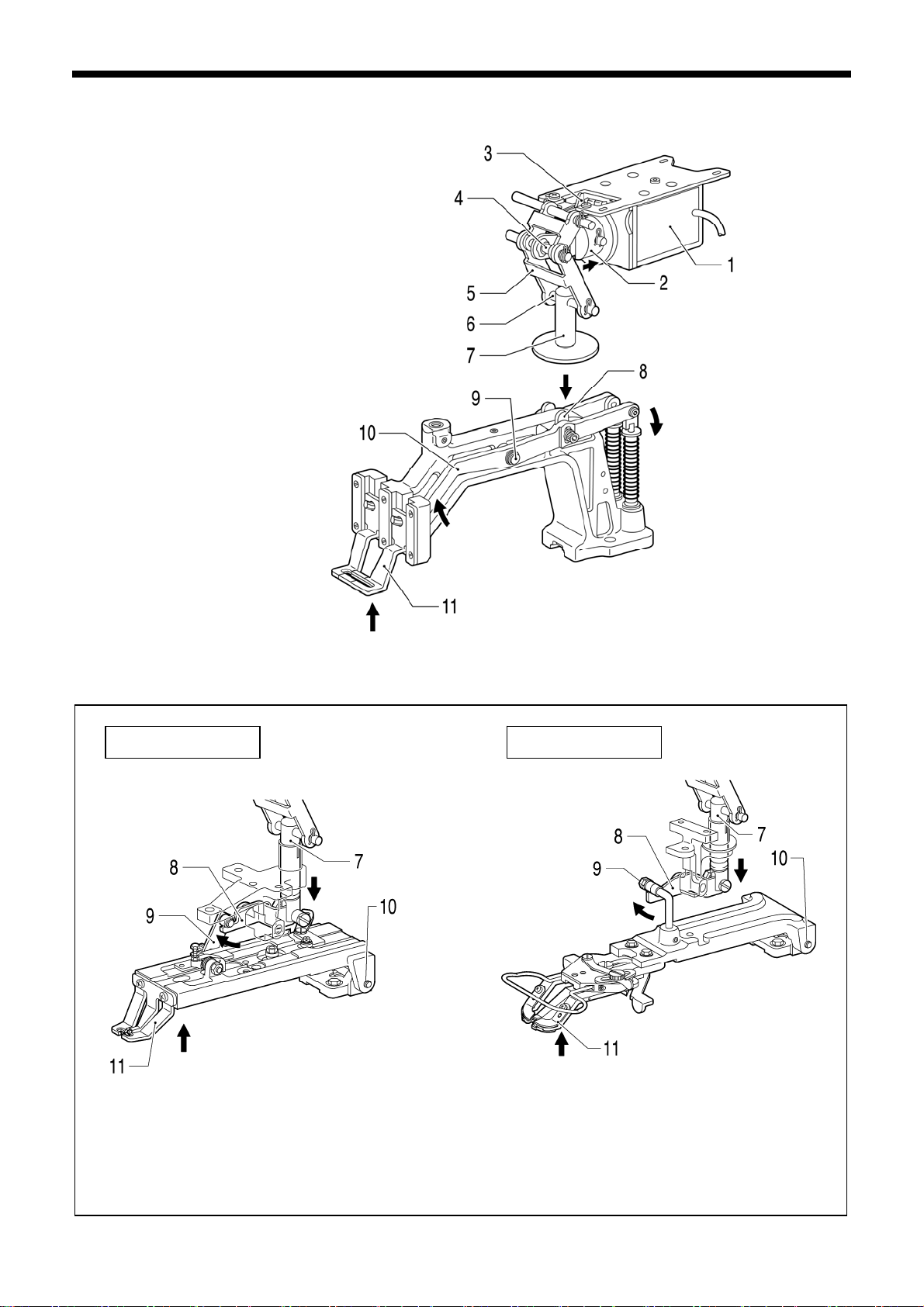

2-3. Work clamp lifter mechanism

1. Work clam p solenoi d

2. Plunger

3. Link assy, C

4. Link shaft, B

5. Link, B

6. Link shaft, C

7. Work clam p plate

8. Work clamp a rm lever plate

9. Work clamp a rm lever shaft

10.Work clamp arm lever

11.Work clamp

* When the presser solenoid is turned off, the

presser plate rises, and work clamp s lo wer.

KE-432B, 432C BE-438B, 438C

3266Q 3267Q

7. Work

clamp lifting rod

8. Work clamp lifter lever

9. Presser adjusting plate assy

10. Button clamp holder shaft

11. Work clamp

7. Work

clamp lifting rod

8. Button clamp lifting lever

9. Button clamp holder hook assy

10. Button clamp holder shaft

11. Button clamp

3244

Q

KE-430B, 430C series

10

Page 18

2. MECHANICAL DESCRIPTIONS

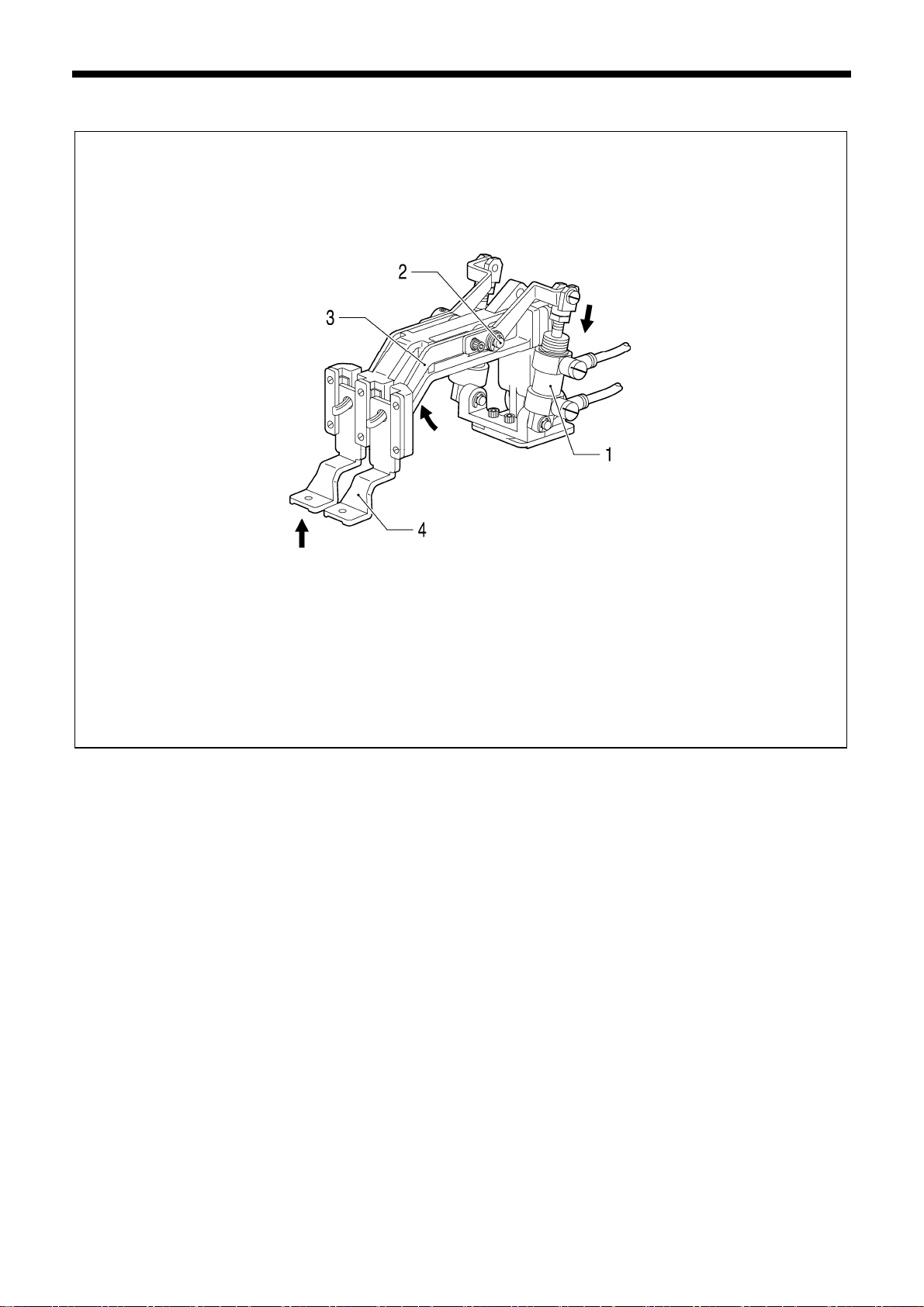

Pneumatic specifications

3245Q45Q

1. Air cylinder

2. Work clamp a rm lever shaft

3. Work clam p arm leve r

4. Work clamp

11

KE-430B, 430C series

Page 19

2. MECHANICAL DESCRIPTIONS

2-4. Work clamp open-close mechanism (KE-432B, 432C)

3262Q

1. Solenoid assy

2. OY solenoid pin

3. Sensor plate

4. Work cla mp c arri er ro d as sy

5. Lever

6. Roller

7. Work clam p carrier plat e

8. Work clam p guid e plate

9. Screw

10.Work clamp

KE-430B, 430C series

12

Page 20

2. MECHANICAL DESCRIPTIONS

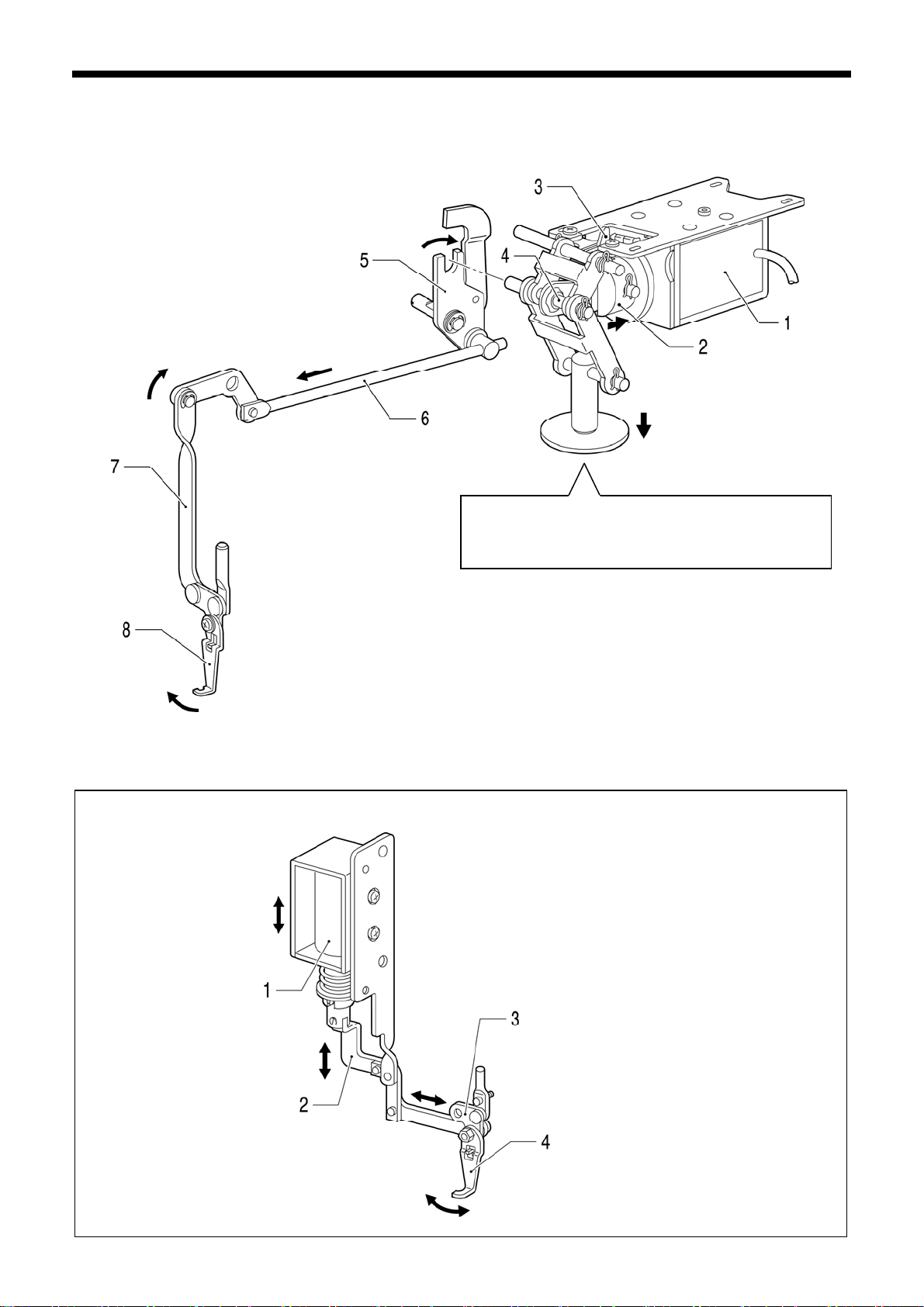

2-5. Thread wiper mechanism 2-5. Thread wiper mechanism

Solenoid type thread wiper

3246Q3246Q

When the presser solenoid is turned off, the

presser plate rises, and thread wiper operates in

the opposite direction.

1. Work clam p solenoi d

2. Plun

ger

3. Link assy, C

4. Link shaft, B

5. Thread wi pe r drivin g lever

6. Thread wi pe r ro d assy

7. Thread wi pe r arm assy

8. Thread wiper

3247QQ

1. Thread wi pe r so le noid

2. Thread wi pe r co nne cting rod as sy

3. Thread wi pe r arm assy

4. Thread wiper

13

KE-430B, 430C series

Page 21

Stepping foot specifications

3248Q Q

KE-484C

3249Q 3249Q

2. MECHANICAL DESCRIPTIONS

1. Thread wi pe r so le noid

2. Thread wi pe r co nne cting rod as sy

3. Thread wi pe r arm assy

4. Thread wiper

1. Thread wi pe r cyli nd er

2.

Thread wiper connecting rod lever

3. Thread wi pe r co nne cting rod

4. Thread wi pe r arm assy

5. Thread wiper

KE-430B, 430C series

14

Page 22

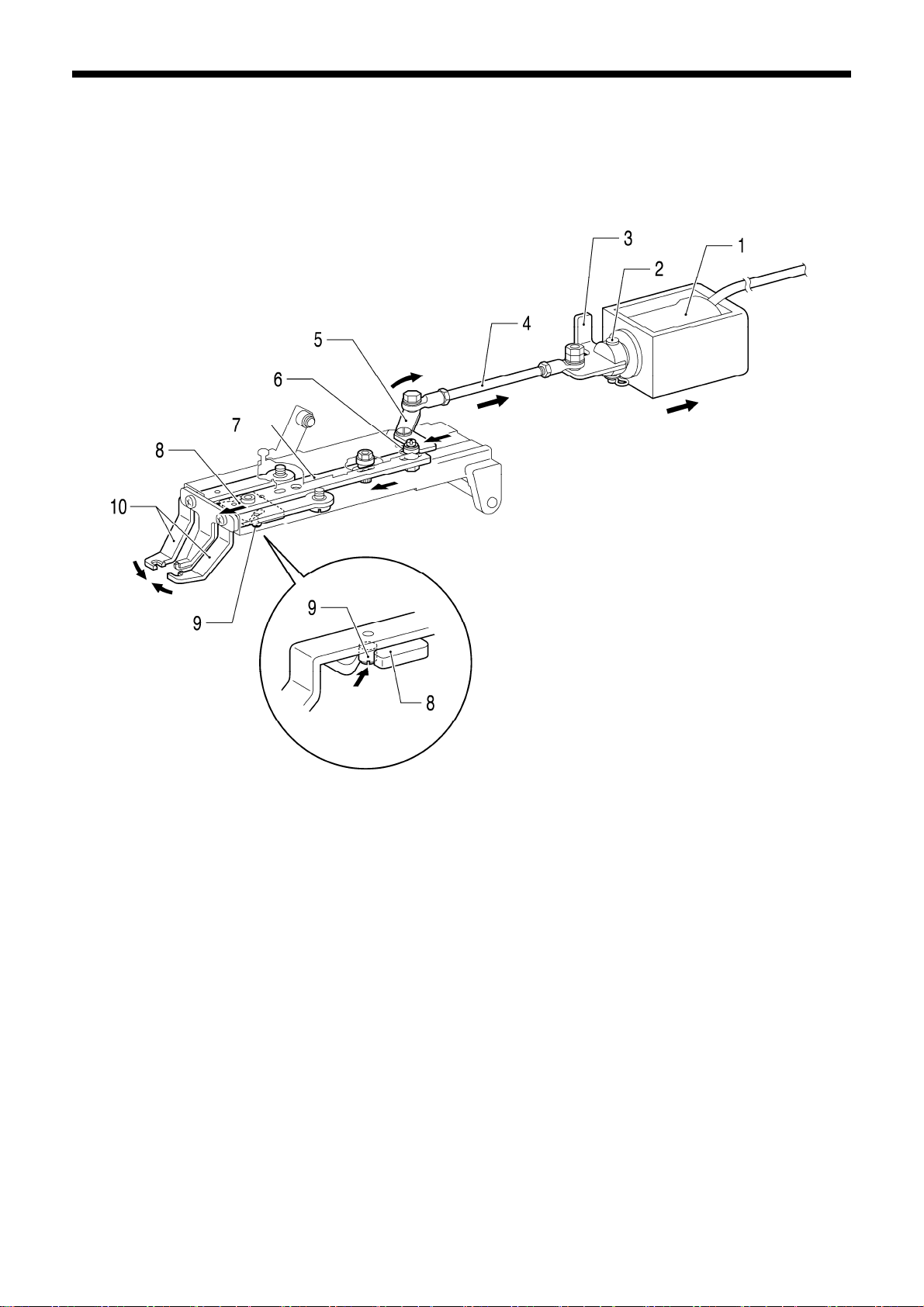

2. MECHANICAL DESCRIPTIONS

2-6. Feed mechanism

Sewing patterns are created through combination s of X and Y movements.

KE-430B, 431B, 432B, 433B, BE-438B

KE-430C, 431C, 432C, BE-438C

X direction

3250Q

Y direction

3251Q

1. Pulse motor, X

2. Coupling hub, 6.35

3. Coupling spacer

4. Coupling hub, 8

5. Feed cam, X

6. Feed cam roller

7. X-feed lever

8.

Tack length regulator block assy

9. Feed bracket

1. Pulse motor, Y

2. Coupling hub, 6.35

3. Coupling spacer

4. Coupling hub, 8

d cam, Y

5. Fee

6. Feed cam roller

7. Y-feed lever

8. Tack width feed shaft

9. Feed bracket

15

KE-430B, 430C series

Page 23

KE-434B, 435B, 436B

KE-434C, 435C, 436C, 484C

X direction

Y direction

2. MECHANICAL DESCRIPTIONS

1. Pulse motor, X

2. Coupling hub, 8

3. Coupling spacer

3252Q

4. Coupling hub, 8

5. Feed cam, X

6. Feed cam roller

7. X-feed lever

8. Tack length regulator block assy

. Feed bracket

9

1. Pulse motor, Y

2. Coupling hub, 8

3. Coupling spacer

4. Coupling hub, 8

3253

Q

5. Feed cam, Y

6. Fee

d cam roller

7. Y-feed lever

8. Tack width regulator block assy

9. Feed bracket

KE-430B, 430C series

16

Page 24

2. MECHANICAL DESCRIPTIONS

2-7. Thread trimmer mechanism

3254Q

1. Thread trimmer solenoid

2. Driving lev er push lever

3. Thread driving lever

4. Thread trimmer roller

5. Thread trimmer cam

6. Thread trimmer rod

7. Thread trimmer lever

8. Connecting rod lever assy

9. Thread trimmer connecting rod

10. Movable knife

11. Fixed knife

17

KE-430B, 430C series

Page 25

KE-484C

3255Q

2. MECHANICAL DESCRIPTIONS

1. Thread trimmer solenoid

2. Driving lev er push lever

3. Thread driving lever

4. Thread trimmer roller

5. Thread trimmer cam

6. Thread trimmer rod

7. Thread trimmer lever

8. Thread trimmer rod, L

9. Thread trimmer connecting rod

10. Movable knife

11. Thread trimmer cylinder

12. Extension rod

13. Fixed knife

KE-430B, 430C series

18

Page 26

2. MECHANICAL DESCRIPTIONS

2-8. Thread nipper mechanism

Manual operation

In thread trimming

3256Q

1. Thread trimmer solenoid

2. Driving lev er push lever

3. Thread driving lever

4. Tension release driving lever

5. Lower thread retainer collar

6. Thread trimmer cam

1. Lifting lever

2. Lifting crank

3. Tensi on release lever

4. Tension release stud

5. Tension release pin

3257Q

7. Tension release driving lever

8. Tension release lever, U

9. Tension release rod assy

10. Tension release lever

11. Tension release stud

12. Tension release pin

19

KE-430B, 430C series

Page 27

KE-484C

3258Q

2. MECHANICAL DESCRIPTIONS

1. Tension release cylinder

2. Tensio n release pin push leve r

3. Tensio n release pin, L

4. Ten

sion release pin

KE-430B, 430C series

20

Page 28

2. MECHANICAL DESCRIPTIONS

2-9. Thread take-up mechanism

Stepping foot specifications

KE-484C

3260

3259Q

1. Th

read take-up solenoid

2. Solenoid joint

3. Thread take-up lever crank

4. Thread take-up lever

Q

3261Q

1. Thread take-up cylinder

2. Thread take-up lever

21

KE-430B, 430C series

Page 29

3. DISASSEMBLY

3. DISASSEMBLY

Disassembly should only be carried out by a

qualified technician.

Turn off the power switch before disassembly,

otherwise the machine may operate if the foot

switch is depressed by mistake, which could

result in injury.

Be sure to wear protective goggles and gloves

when handling the lubricating oil and grease,

so that they do not get into your eyes or onto

your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the

grease under any circumstances, as they can

cause vomiting and diarrhea.

Keep the oil out of the reach of children.

Disassemble each part in order of the numbers.

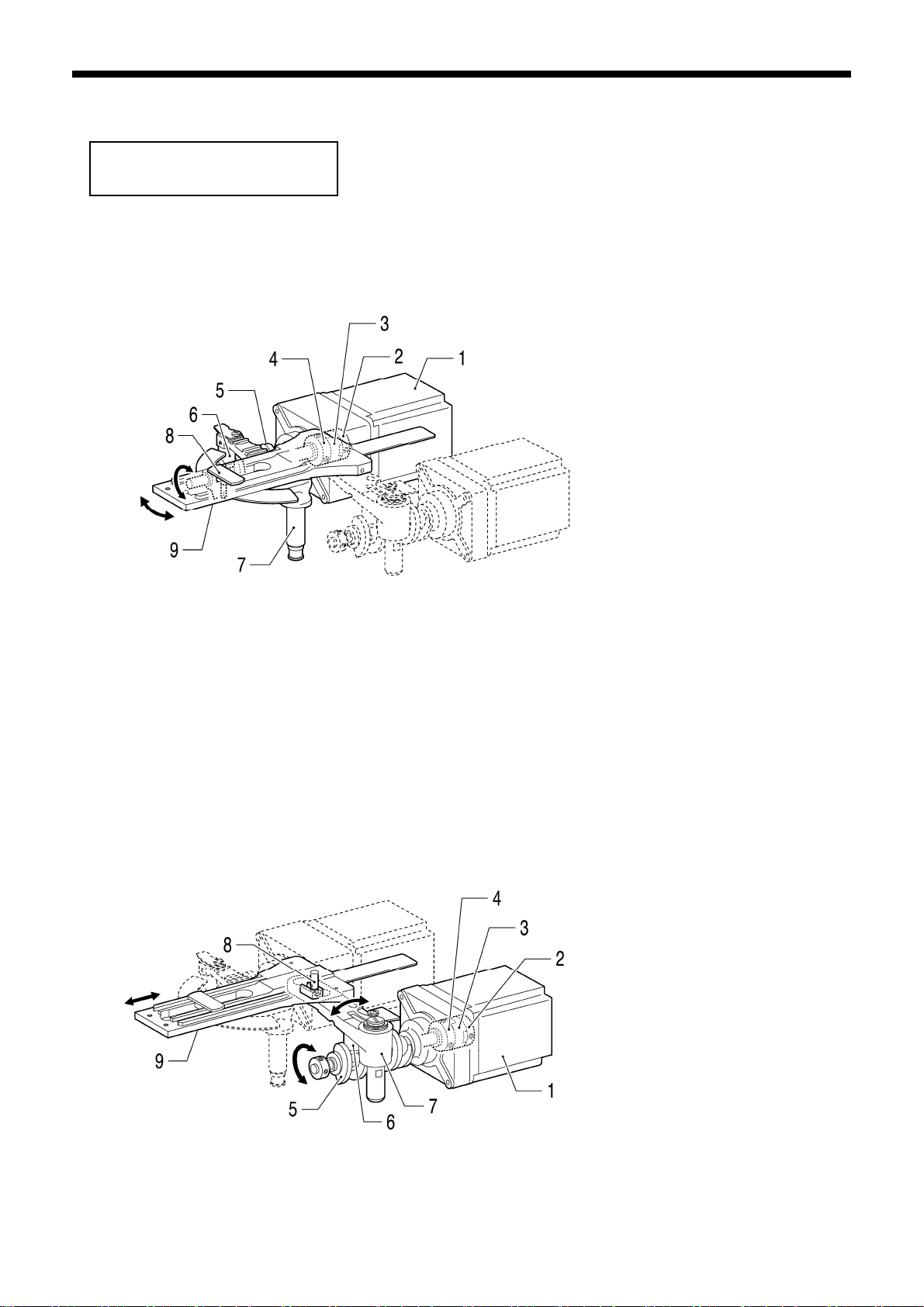

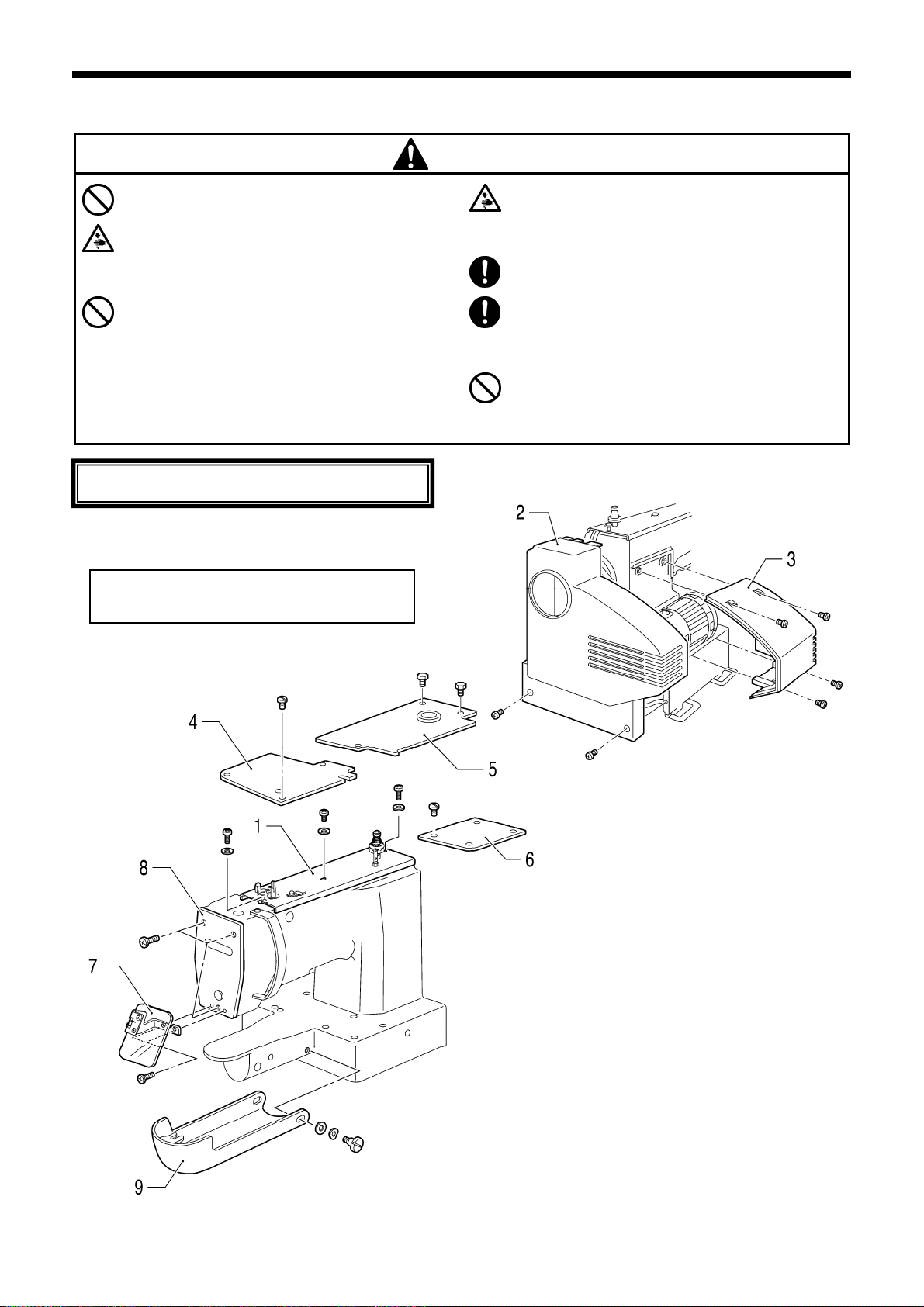

3-1. Covers

KE-430B, 431B, 432B, 433B, BE-438B

KE-430C, 431C, 432C, BE-438C

CAUTION

3268Q

Disconnect the air hoses from the air supply

and wait for the needle on the pressure gauge

to drop to “0” before disassembly of any parts

which use the pneumatic equipment.

Use only the proper replacement parts as

specified by Brother.

If any safety devices have been removed, be

absolutely sure to re-install them to their

original positions and check that they operate

correctly before using the machine.

Any problems in machine operation which

result from unauthorized modifications to the

machine will not be covered by the warranty.

3269

1. Top cover

2. Belt cover

3. Frame side cover

4. Bed cover, L F

5. Bed cover, L R

6. Bed cover, R

7. Eye guard assy

8. Face plate assy

9. Shuttle race cover assy

Q

KE-430B, 430C series

22

Page 30

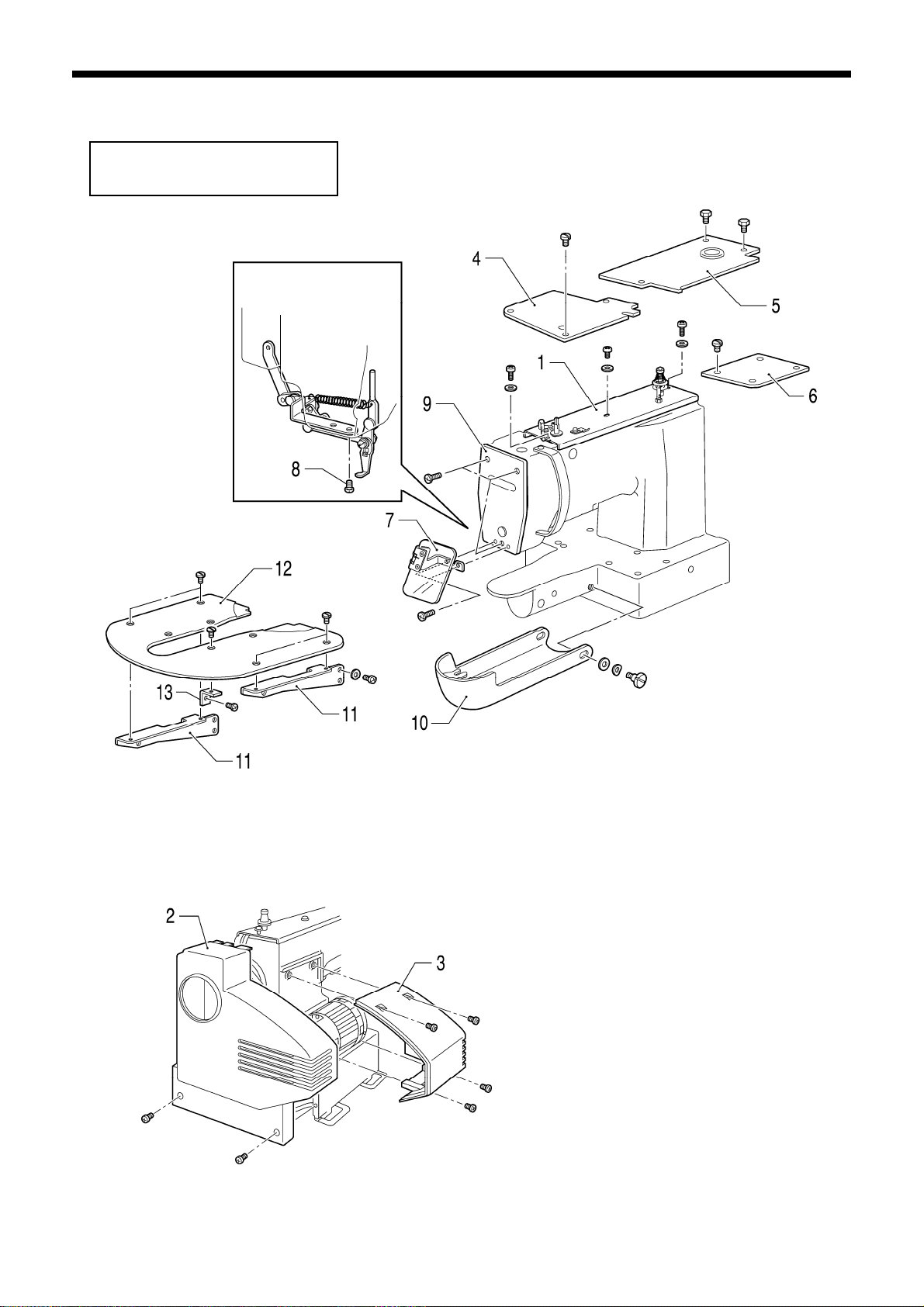

3. DISASSEMBLY

KE-434B, 435B, 436B

KE-434C, 435C, 436C, 484C

<KE-435B, 435C>

<KE-436B, 436C>

3269Q

1. Top

cover

3270Q

2. Belt cover

3. Frame side cover

4. Bed cover, L F

5. Bed cover, L R

6. Bed cover, R

7. Eye guard assy

8. B o lt s [2 pcs]

9. Face plate assy

10. Shuttle race cover assy

11. Auxiliary plate supports [2 pcs]

12. Needle plate auxiliary plate

13. Auxiliary plate supports [4 pcs]

23

KE-430B, 430C series

Page 31

3-2. Work clamp arm mechanism (KE-430B, 430C, 431B, 431C)

1. Set screw

2. Needle

3. Needle ba r thre ad gui de

4. B o lt s [2 pcs]

5. Work clamp arm assy

6. Work clamp felt

7. Screws [2 pcs]

8. Feed plate

Be careful not to drop these two bearing balls

when removing the feed bracket assembly.

9. Rubber cap

10. Set screw [Loosen]

11. Tack width feed shaft

12. Rod end

13. Screws [8 pcs]

14. Feed bracket guide plate

15. Feed bracket assy

16. Flat screws [2 pcs]

17. S

crews [2 pcs]

18. Ne

edle plate

Be careful not to drop these three bearing balls

when removing the work clamp arm assembly.

Remove the feed bracket guide

plate and the feed bracket

assembly together as a single unit.

3. DISASSEMBLY

3271Q

3272

Q

KE-430B, 430C series

24

Page 32

3. DISASSEMBLY

3-3. Work clamp arm mechanism (KE-432B, 432C)

Be careful not to drop these two bearing balls

en removing the feed bracket assembly.

wh

1. Set screw

2. Ne

edle

3. Needle ba r thre ad gui de

4. Bolt

5. Nuts [2 pcs]

Adjusting screw

Compression spring

[Push upward and remove horizontally]

6. Set screw s [2 pcs: Loosen]

7. Button c

lamp holder shaft

8. Work clamp arm assy

9. Bolts [2 pcs]

10. Button clamp holder support

11. Work clamp felt

12. Screws [2 pcs]

13. Feed plate

14. Rubber cap

15. Set screw [Loosen]

3273

Remove the feed bracket

guide plate and the feed

bracket assembly together

as a single unit.

3274Q

16. T

ack width feed shaft

17. Rod end

18. Screws [8 pcs]

19. Feed bracket guide plate

20. Feed bracket assy

21. Flat screws [2 pcs]

22. Screws [2 pcs]

23. Needle plate

Q

25

KE-430B, 430C series

Page 33

3-4. Work clamp arm mechanism (KE-433B)

Q

3275

9. Rubber cap

10. Set screw [Loosen]

11. Tack width feed shaft

12. Screws [8 pcs]

13. Feed bracket guide plate

[Pull upward]

14. Screw

15. Cover support stand

16. Feed bracket cover

17. Set

18. Tack length regulator block

19. Feed bracket guide shaft assy

20. Retainer assys [2 pcs]

21. Spacers [2 pcs]

22. Feed bracket assy

23. X fe

24. Y feed cover

25. Flat screws [2 pcs]

26. Screws [2 pcs]

27. Needle plate

screw [Loosen]

[Pull out]

ed cover

Be careful not to drop these three bearin g balls

when removing the work clamp arm assembly.

3. DISASSEMBLY

1. Set screw

edle

2. Ne

3. Needle ba r thre ad gui de

4. B o lt s [2 pcs]

5. Work clamp arm assy

6. Work clamp felt

7. B o lt s [2 pcs]

8. Feed plate

Remove the feed bracket guide plate as a single

assembly with the feed

bracket and other parts

still assembled.

Be careful not to drop the two bearing balls

wh

en removing the feed bracket guide shaft

assembly.

3276Q

KE-430B, 430C series

26

Page 34

3. DISASSEMBLY

3-5

. Work clamp arm mechanism (KE-434B, 434C, 435B, 435C, 436B, 436C, 484C)

KE-434B, 434C Solenoid specification

3277Q

1. Set screw

2. Ne

edle

3. Needle ba r thre ad gui de

4. Bolts [2 pcs: pneum ati c spec. only]

5. Cylinder support

[pneumatic spec. only]

6. B o lt s [2 pcs]

7. Work clam p arm assy

8. B o lt s [2 pcs]

9. Feed plate

10. Feed bracket cover

27

KE-430B, 430C series

Page 35

11. Rubber cap

12. Set

13. Tack length regulator block assy

14. Retainer assys [2 pcs]

15. Spacers [2 pcs]

16. Screws [2 pcs]

17. Flat screws [2 pcs]

18. Feed bracket guide plate, R

19. Feed bracket assy

20. X-feed lever cover

21. Flat screws [2 pcs]

22. Screws [2 pcs]

23. Needle plate

screw [Loosen]

3279Q

Tack width regulator

block assy

-feed lever

Y

3. DISASSEMBLY

3278Q

1) Turn the Y-feed lever forward as

far as it will go.

2)

Lift up feed bracket guide plate R

and the feed bracket assembly

together, remove the tack width

regulator block assembly from the

Y-feed lever, and pull all of them

forward to remove them.

KE-430B, 430C series

28

Page 36

3. DISASSEMBLY

3-6. Work clamp arm mechanism (BE-438B, 438C)

1. Set screw

2. Ne

3. Needle ba r thre ad gui de

4. Nuts [2 pcs]

Adjusting screw

Compression spring

[Push upward and remove horizontally]

5. Set screw s [2 pcs: Loosen]

6. Button clam p hol der sh aft

Be careful not to drop these two bearing balls

when removing the feed bracket assembly.

7. Butto

edle

8. Bolts [2 pcs]

9. Button clamp holder support

10. Work clamp felt

11. Screws [2 pcs]

12. F

13. Ru

14. Set screw [Loosen]

n clamp holder

eed plate

bber cap

3280Q

3281

Remove the feed bracket

de plate and the feed

gui

bracket assembly together

as a single unit.

15. Tack width feed shaft

16. Rod end

17. Screws [8 pcs]

18. Feed bracket guide plate

19. Feed bracket assy

20. Fl

at screws [2 pcs]

crews [2 pcs]

21. S

22. Needle plate

Q

29

KE-430B, 430C series

Page 37

3-7. Shuttle hook mechanism

KE-484C

3. DISASSEMBLY

3282Q

1. Bobbin case assy

2.

Shuttle race base setting claw

[Open to right and left]

3. Shuttle race base

4. Shuttle hook

1. Bobbin case assy

2. Screw

3. Hook stopper setting base

4. Set screw [Loosen]

5. Treble hook assy

3283

Q

KE-430B, 430C series

30

Page 38

3. DISASSEMBLY

3-8. Needle bar mechanism

Q

3286Q

Do not remove the needle bar guide if possible to

preve

bar rubbing.

3284

nt the machine from overheating due to needle

Q

3285

1. Rubber cap

2. Screw

3. Needle bar

4. Slide block

5. Needle bar clamp

[Pull out]

6. Rubber cap

7. Set screw [Loosen]

8. Wick

[Pull out from arm]

9. Thread take-up support

shaft

10. Thread take-up support

11. Oil cap

12. Set screw [Loosen]

13. Set screw [Loosen]

14. Ne

edle bar connect-

ing rod

edle bearing

15. Ne

hread take-up lever

16. T

17. Rubber caps [2 pcs]

18. Screws [2 pcs]

19. Needle bar guide

31

KE-430B, 430C series

Page 39

3-9. Stepping foot mechanism (KE-435B, 435C, 436B, 436C)

3287Q

Note:

Remove the presser adjusting screw gently, as the presser bar

spring guide and the presser bar spring may fly out at this time.

Remove the stepping link assembly and the

sser bar lifter together as a single u nit.

pre

1. Screw

2

. Finger guard

3. Presser foot

4. Presse r adj us ting screw

5. Presse r ba r spring gu id e

6. Presse r ba r spri ng

7. Wa

sher

8. Screw [Loosen]

9. Presse r ba r clam p

10. Cushion

11. Presser bar

12. Screws [2 pcs]

13. Stepping link assy

14. Presser bar lifter

15. Nut

16. Feed lifter lever shaft

17. Bolt [Loosen]

18. Stepping foot arm, R

19. Stepping foot arm, F [Pull out]

3. DISASSEMBLY

KE-430B, 430C series

32

Page 40

3. DISASSEMBLY

3-10. Upper shaft mechanism

<KE-435B, 435C>

<

KE-436B, 436C>

3289Q

3288

1. Screw [Loosen]

2.

Set screw [Loosen]

3. Th

read take-up crank

4. Screws [2 pcs]

5. Thread trimmer solenoid

6. Screw

7. Wick support

8. Screws [2 pcs]

9. Crank rod (Upper pa rt)

10. Cran

k rod (Lower part)

[Lower downward]

11. Set screws [2 pcs: Loosen]

<11> Set screws [2 pcs: Loosen]

12. Set screws [2 pcs: Loosen]

13. Motor connector

14. Nut [Loosen]

15. Bolt [Loosen]

16. Bolts [3 pcs]

17. Motor bracket

18. Upper shaft timing belt

19. Set screws [2 pcs: Loosen]

20. Timing pulley assy, U

21. Screws [2 pcs]

22. Syn

chronizer assy

23. Upper shaft

24. Thrust washer

25. Bobbin winder pulley

<25> Stepping foot connecting ro d

26. Thread trimmer cam

Q

33

KE-430B, 430C series

Page 41

KE-484C

1. Screw [Loosen]

2. Set screw [Loosen]

3. Thread take-up crank

4. Screws [2 pcs]

5. Thread trimmer solenoid

6. Belt cover support pillars [2 pcs]

7. Screws [4 pcs]

8. Blind plate

9. Frame side cover

10. Setting plate packing

11. Nut

12. Plain washer

13. Nuts [2 pcs: Loosen]

14. Adjusting screw [Loosen]

15. Adjusting screw [Loosen]

16. Tension pulley arm

17. Set screws [2 pcs: Loosen]

18. Set screws [2 pcs: Loosen]

19. Set screws [2 pcs: Loosen]

20. Motor connector

21. Nut [Loosen]

22. Bolt [Loosen]

23. Bolts [3 pcs]

24. Motor bracket

3. DISASSEMBLY

3290Q

3291Q

25. Upper shaft timing belt

26. Set screws [2 pcs: Loosen]

27. Timing pulley assy, U

28. Screws [2 pcs]

29. Synchronizer assy

30. Upper shaft

31. Thrust washer

32. Bobbin winder pulley

33. Thread trimmer cam

34. U-timing pulley, F

35. U-timing belt, F

KE-430B, 430C series

34

Page 42

3. DISASSEMBLY

3-11. Lower shaft mechanism

KE-430C series

BE-

438C

1.

Support [Turn in the direction of the arro w] 9. Set screws [2 pcs: Loosen]

2. Felt holder 10. Wick [Untie the knot]

3. Bolt [Loosen] 11. Set screws [2 pcs: Loosen]

4. Driver 12. Rock gear shaft

5. Retaining ring [Pull out from the rear of the machine]

6. Set screw s [2 pcs: Loosen] 13. Set scre w collar

7. Lower shaft assy 14. Rock gear

[Pull out from the rear of the machine]

8. Set screw collar

Tilt the machine head.

KE-430B series

BE-438B

Remove the rock gear and the

nk rod together as a single unit.

cra

15. Crank rod (Lower part)

3292Q

3293Q

35

KE-430B, 430C series

Page 43

KE-484C

Note:

This part consists of three smaller parts

which should not be disassembled.

3295Q

3. DISASSEMBLY

Tilt the machine head.

1. Set screw [Loosen]

wer gear

2. Lo

3. Set screw s [2 pcs: Loosen]

4. Rotary hook shaft

5. Set screw collar

6. Lower shaft gear spacer

7. Thrust bearing

8. Set screw [Loosen]

9. Wick [Untie the knot]

10. Lower shaft

[Pull out from the rear of the machine]

11. Lower shaft timing pulley

12. U-timing belt, F

3294

Q

KE-430B, 430C series

36

Page 44

3. DISASSEMBLY

3-12. Feed mechanism (1)

KE-430B, 431B, 432B, 433B, BE-438B

KE-430C, 431C, 432C, BE-438C

3296

Q

If the tack width feed lever shaft cannot

be rem

oved, remove the retaining ring.

Oil supply

hole

3298Q

Tilt the machine head.

Retaining

ring

1. Set screw s [2 pcs: Loosen]

screw collar

2. Set

3. Set screw [Loosen]

4. Tack width feed lever shaft (with retaining

ring) [Pull upward]

5. Thrust washer

6. Wicks [3 pcs: Pull out from oil supply hole]

7.

Y-feed lever assy [Pull upward]

Thrust washer

8.

9. X-feed lever assy [Pull upward]

10. Screw

11. Home sensor setting plate

12. Screw

13. Cord holder

14. Screw

15. Home sensor setting plate

16. Screw

17. Cord holder

Return the machine head to its

original position.

3297Q

37

KE-430B, 430C series

Page 45

KE-434B, 435B, 436B

KE-434C, 4

35C, 436C, 484C

3296

Q

If the tack width feed lever shaft cannot

be removed, remove the retaining ring.

Oil supply

hole

3300Q

3. DISASSEMBLY

Tilt the machine head.

Return the machine head to its

original position.

Retaining

ng

ri

3299Q

1. Set screw s [2 pcs: Loosen]

screw collar

2. Set

3

. Set screw [Loosen]

Tack width feed lever shaft (with retaining

4.

ring) [Pull upward]

5. Thrust washer

6. Wicks [3 pcs: Pull out from oil supply hole]

7. Y-feed lever assy [Pull upward]

8. Thrust washer

9. X-feed lever assy [Pull upward]

10. Screw

11. Y-sensor setting plate

12. Screw

13. X-sensor setting base

crews [3 pcs]

14. S

15. Cord clamps [3 pcs]

KE-430B, 430C series

38

Page 46

3. DISASSEMBLY

3-13. Feed mechanism (2)

KE-430B, 431B, 432B, 433B, BE-438B

KE-430C, 431C, 432C, BE-438C

Same for both

X and Y

3302Q

Q

3301

1. B o lt s [4 pcs]

2.

Pulse motor assy, X

[Disconnect the harness]

3. B o lt s [4 pcs]

4. Pulse m otor assy, Y

[Disconnect the harness]

5. Coupling spacer

6. Set screw s [2 pcs: Loosen]

7. Coupling hub, 6.35

8. Screws [2 pcs]

9. Feed cam bracket

10. Positioning pins [2 pcs]

11. Screw

12. Feed home position dog

13. Set screws [2 pcs: Loosen]

14. Coupling hub, 8

15. Set screws [2 pcs: Loosen]

16. Cam shaft

17. Ball bearings [2 pcs]

18. Feed cam

39

KE-430B, 430C series

Page 47

KE-434B, 435B, 436B

KE-434C, 4

35C, 436C, 484C

3. DISASSEMBLY

1.

Bolts [4 pcs] 13. Positioning pins [2 pcs]

3303

3304Q

Q

2. Pulse motor assy, X [Disconnect the harness] 14. Set screws [2 pcs: Loosen]

3. PM bracket, X 15. Coupling hub, 8

4. Ball bearing 16. Coupling spacer

5. Bolts [4 pcs] [3 pcs: KE-484C] 17. Set screws [2 pcs: Loosen]

6. Pulse motor assy, Y [Disconnect the harness] 18. Feed cam

7. Set screw s [2 pcs: Loosen] 19. Ball bearing [X side only]

8. Set screw collar 20. Ball bearing

9. PM bracket, Y 21. Cam shaft

10. Ball bearing 22. Set screws [2 pcs: Loosen]

11. Screws [2 pcs]

23. Coupling hub, 8

12. Y-feed cam bracket

KE-430B, 430C series

40

Page 48

3. DISASSEMBLY

3-14. Work clamp lifter mechanism (Solenoid specifications)

KE-430B, 431B, 433B, 434B

KE-430C, 431C, 434C

l cap

11. Oi

12. Snap pin

13. Link shaft, C [Pull out]

14. Work clamp plate

15. Work clamp lifter link-related parts

16. Rubber caps [2 pcs]

17. Screws [2 pcs]

18. Screws [4 pcs]

19. Presser solenoid assy

[Disconnect the harness]

3305Q

Note:

Hold the work clamp plate

when removing link shaft

C, otherwise the work

clamp plate may fall

down.

3307

Q

1. Springs [2 pcs]

Screws [2 pcs]

2.

3. Guide

4. Snap pins [2 pcs]

5. Rubber cap

6. Link shaft, D [Pull out]

7. Set screws [2 pcs: Loosen]

8. Snap pins [2 pcs]

9. Link shaft, A [Pull out]

10. Washers [2 pcs]

Be careful not to drop.

<KE-433B, 434B, 434C>

3306Q

Do not remove,

otherwise the work

clamp will not move

smoothly.

41

KE-430B, 430C series

Page 49

KE-432, 432C

BE-438, 4

38C

3308Q

11. Oil cap

12. Snap pin

13. Link shaft, C [Pull out]

14. Presser lifter link-related parts

15. Set screw [Loosen]

16. Button clamp lever shaft [Pull out]

17. Work clamp lifter lever

[KE-432B, 432C]

Button clamp lifting lever

[BE-438B, 438C]

18. Retaining ring [BE-438B, 438C]

19. Work clamp lifting rod

[Pull downward]

20. Rubber caps [2 pcs]

21. Screws [2 pcs]

22. Screws [4 pcs]

23. Presser solenoid assy

[Disconnect the harness]

Springs [2 pcs]

1.

2. Screws [2 pcs]

3. Guide

4. Snap pins [2 pcs]

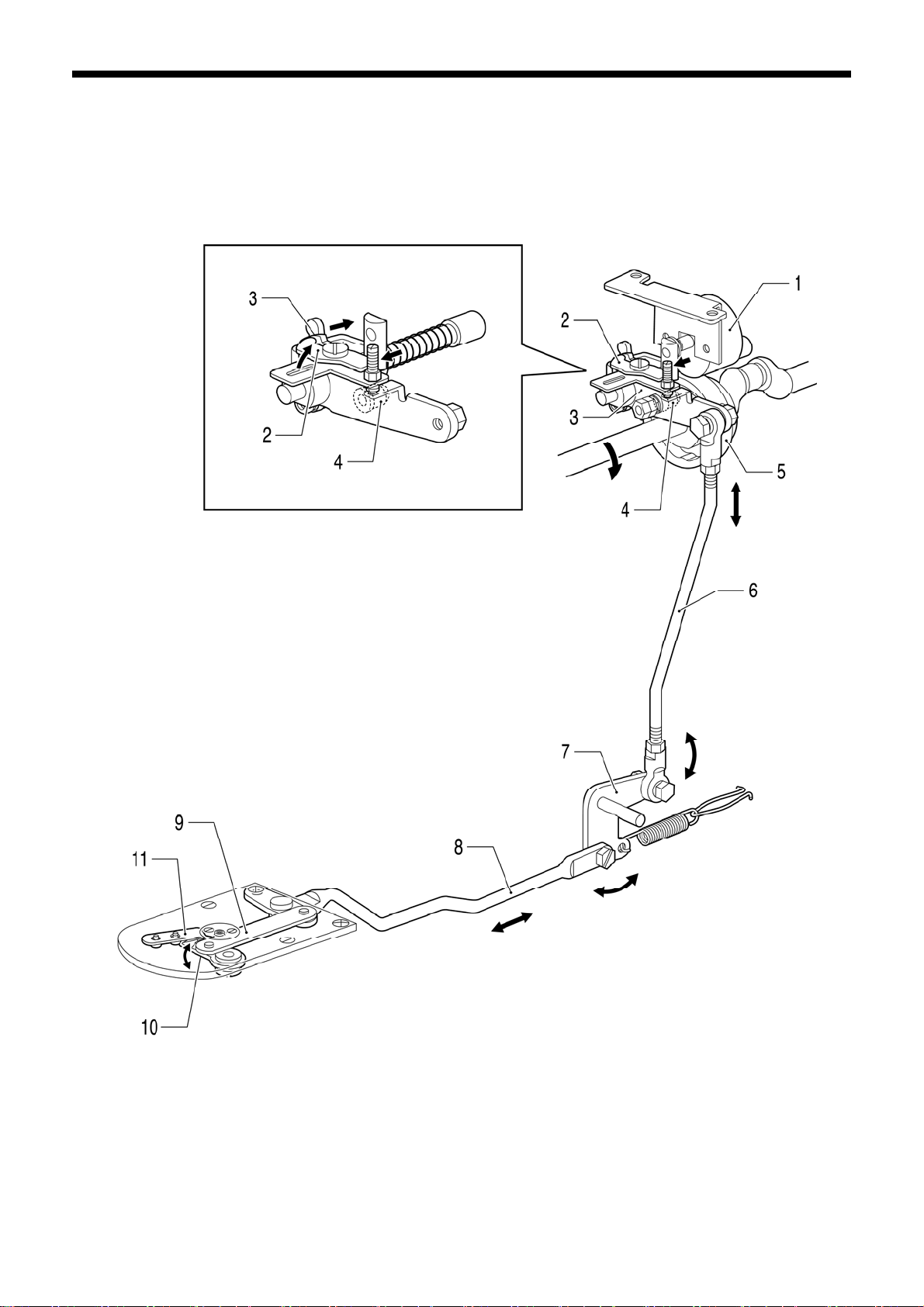

5. Rubber cap

6. Link shaft, D [Pull out]

7. Set screw s [2 pcs: Loosen]

8. Snap pins [2 pcs]

9. Link shaft, A [Pull out]

10. Washers [2 pcs]

Be careful not to drop.

<BE-438B, 438C>

3. DISASSEMBLY

Q

3309

KE-430B, 430C series

42

Page 50

3. DISASSEMBLY

3-15. Stepping foot lifter mechanism (KE-435B, 435C, 436B, 436C)

1. Ret

aining ring

2. Plain washer

3. Screws [4 pcs]

4. Air cylinder setting pl ate

[Pull upward after disconnecting the air tubes]

3310Q

43

KE-430B, 430C series

Page 51

3-16. Thread wiper mechanism

Solenoid specifications

3312

Q

R

emove the thread wiper rod assembly from the

work clamp lever lifter shaft, and then lift it up

together with the thread wiper driving lever to

remove them.

Work clamp lever

lifter shaft

3. DISASSEMBLY

3311Q

1. Screw

2. Plain

washer

3. Thread wiper

4. Retaining ring

5. Set screw [Loosen]

Thread wiper arm assy

6.

[Pull downward]

7. Set screw [Loosen]

8. Thread wi pe r sh aft

9. Retaining ring

10. Tension release lever spring

11. Retaining ring

12. Thread wiper rod assy

13. Thread wiper driving lever

KE-430B, 430C series

44

Page 52

3. DISASSEMBLY

Pneumatic specifications

3313Q

1. Screw with w ashe r

2. Liftin

g lever

3. Plunger pin

4. B o lt s [2 pcs]

5. Solenoid box assy

[Disconnect the harness]

6. Screws [2 pcs]

7. Thread wi pe r co nne cting rod as sy

8. Set screw [Loosen]

9. Thread wiper arm assy [Pull downward]

45

KE-430B, 430C series

Page 53

Stepping foot specifications

KE-484C

3. DISASSEMBLY

3314Q

1. Plunger pin

2.

Bolts [2 pcs]

3. Solenoid box assy

[Disconnect the harness]

4. Set screw [Loosen]

5. Thread wi pe r co nne cting rod as sy

Q

3315

1. Screw

2. B o lt s with washers [2 pcs]

3. B o lt s [2 pcs]

4. Cyli

nder box

[Disconnect the harness]

5. Set screw [Loosen]

6. Thread wi pe r co nne cting rod

KE-430B, 430C series

46

Page 54

3. DISASSEMBLY

3-17. Thread nipper mechanism

1. Set

screw

2. Thread tension assy [Pull out]

3. Tension release pin

4. Tension release stud

5. Shoulder screw

6. Shoulder screw

7. Tension release rod assy

8. Driving lev er push lever

9. Set screw [Loosen]

10. Work clamp lever lifter shaft

11. Collar

12. Tension release lever

13. Screw with washer

14. Lifting lever

15. Screw [KE-434B, 434C Pneumatic spec.]

16. Tension release rod [KE-434B, 434C Pneumatic spec.]

17. Presser bar lifter crank

3316Q

47

KE-430B, 430C series

Page 55

Stepping foot specifications

KE-484C

3. DISASSEMBLY

3317

1. Set screw

2. Thread tension assy [Pull out]

3. Tension release pin

4. Tensio n release pin, L

5. Shoulder screw

6. Shoulder screw

7. Tension release rod assy

8. Driving lev er push lever

9. Screw

10. Tension release bracket

3318Q

1. Set screw

2. Thread tension assy [Pull out]

3. Tension release pin

4. Tensio n release pin, L

5. Tensi on release cylinder assy

6. Rubber cap

7. Set screw [Loosen]

8. Lever shaft

9. Tensio n release pin push leve r

Q

KE-430B, 430C series

48

Page 56

3. DISASSEMBLY

3-18. Thread take-up mechanism

3319Q

Stepping foot specifications

1. Screws [2 pcs]

2. Solenoid setting plate

3. Spring

4. Set screw s [2 pcs: Loosen]

5. Solenoid joint

6. Screw

7. Spring washer

8. Plain washer

9. Nut

10. Shoulder screws [2 pcs]

11. Thread take-up lever

12. Retaining ring

13. Thread take-up lever crank

14. Plain washer

3320

Q

49

KE-430B, 430C series

Page 57

KE-484C

3. DISASSEMBLY

3321Q

1. Pin

2. Screws [2 pcs]

3. Setting plate

4. Shoulder screws [2 pcs]

5. Thread take-up lever

KE-430B, 430C series

50

Page 58

3. DISASSEMBLY

3-19. Thread trimmer mechanism

Return the machine head to its normal

sition, and then remove the

po

connecting rod lever assembly and the

thread driving lever assembly.

Tilt the machine head.

Be careful not to drop.

3323Q

Be careful not to drop.

3322Q

1. Rubber cap

2

. Set screw [Loosen]

3. Lever shaft

bber cap

4. Ru

5. Set screw [Loosen]

6. Retaining ring

7. Driving lever gui de shaft

[Pull out]

8. Cu

shion

9. Thread release driving lever

assy

10. Washer

11. Spring

12. Spring

13. Spring hook

14. Nuts [2 pcs]

15. Shoulder screws [2 pcs]

16. Washers [2 pcs]

17. Set screw [Loosen]

18. Thread trimmer lever shaft

19. Thread trimmer lever

20. Connecting rod lever assy

21. Thread driving lever assy

51

KE-430B, 430C series

Page 59

KE-484C

Be careful not to drop.

Return the machine head to

its normal position, and then

remove the thread trimmer

rod L and the thread driving

lever assembly.

Tilt the machine head.

3325Q

3. DISASSEMBLY

3324Q

1. Rubber cap

2. Set screw [Loosen]

3. Lever shaft

4. Rubber cap

5. Set screw [Loosen]

6. Ret aining rings [2 pcs]

7. Driving lever gui de shaft

[Pull out]

8. Cushion

9. Wa

sher

10. Spring

11. Spring

12. Bolts [2 pcs]

13. Thread trimmer cylinder

14. Nuts [2 pcs]

15. Shoulder screws [2 pcs]

16. Washers [2 pcs]

17. Set screw [Loosen]

18. Thread trimmer lever shaft

19. Thread trimmer lever

20. Thread trimmer rod, L

21. Thread driving lever assy

KE-430B, 430C series

52

Page 60

3. DISASSEMBLY

53

KE-430B, 430C series

Page 61

4. ASSEMBL Y

Assemble each part in order of the numbers.

grease to the required places when reassembling the parts and once ever y two years.

Apply

4-1. Thread trimmer mechanism (1)

Install the retaining ring between the thread

release driving lever assembly and the

washer.

Pla

ce the cushion against the edge of the

arm, set the various parts so that there is no

gap between them as shown in the

illustration, and then tighten the set screw as

far as the screw stop.

Adjust the position of the thread driving lever

assembly while referring to “5-20. Adjusting

the position of the thread trimming link

mechanism”.

3328Q

Tighten the set screw on the screw flat while

lightly pressing the lever shaft downward.

Apply grease.

Tilt the machine head.

Apply grease.

3330Q

Tighten the set screw on the screw flat while lightly

pressing the thread trimmer lever shaft upward.

Apply grease.

Apply grease.

Driving lever guide shaft

1.

2. Spri

3. Washer

4. Thread rel ea se driving lev er assy

5. Thread drivi n g lever assy

6. Cushion

7. Retaining ring

8. Set screw

9. Rubber cap

10. Connecting rod lever assy

11. Lever shaft

12. Set screw

13. Rubber cap

14. Thread trimmer lever

15. Thread trimmer lever shaft

(with washer and retaining ring)

16. Set screw

17. Thread trimmer rod assy

18. Shoulder screw

19. Nut

20. Washers [2 pcs]

21. Sh

22. Nut

23. Spring hook

24. Spring

4. ASSEMBL Y

3329Q

ng

oulder screw

KE-430B, 430C series

54

Page 62

4. ASSEMBL Y

KE-484C

Install the retaining ring between the thread

driving lever assembly and the washer.

ce the cushion against the edge of the

Pla

arm, set the various parts so that there is no

gap between them as shown in the

illustration, and then tighten the set screw as

far as the screw stop.

Adjust the position of the thread driving lever

assembly while referring to “5-20. Adjusting

the position of the thread trimming link

mechanism”.

3331Q

Tighten the set screw on the screw flat while

lightly pressing the lever shaft downward.

Apply grease.

Tilt the machine head.

Apply grease.

3333Q

Tighten the set screw on the screw flat while lightly

pressing the thread trimmer lever shaft upward.

3332Q

Apply grease.

Apply grease.

1. Driving lever gui de shaft

2. Spring

3. Washer

4. Thread drivi n g lever assy

5. Cushion

6. Ret aining rings [2 pcs]

7. Set screw

8. Rubber cap

9. Thread trimmer rod, L

10. Lever shaft

11. Set screw

12. Rubber cap

13. Thread trimmer lever

14. Thread trimmer lever shaft

(with washer and retaining ring)

15. Set screw

16. Thread trimmer rod assy

17. Shoulder screw

18. Nut

19. Washers [2 pcs]

20. Shoulder screw

21. Nut

22. Thread trimmer cylinder

23. Bolts [2 pcs]

24. Spring

55

KE-430B, 430C series

Page 63

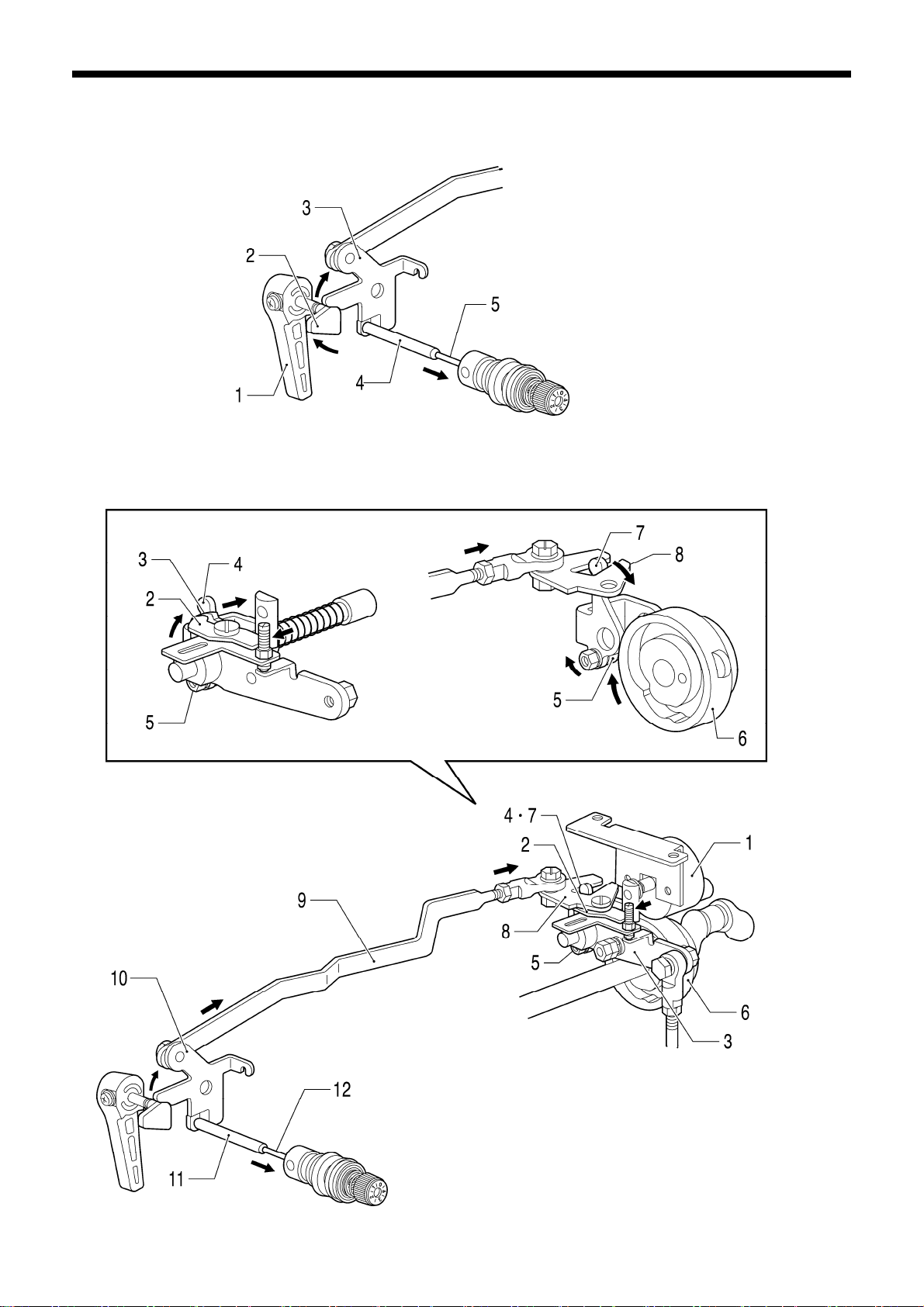

4-2. Thread nipper mechanism

Solenoid specifications

After installing the lifting lever,

check that it moves smoothly.

3334Q

Apply grease.

4. ASSEMBL Y

Apply grease.

Driving lever

stopper

Install the driving lever push lever

an

d the tension release lever U to

the driving lever stopper with the

shoulder screw.

1. Presse r ba r lifter cran k

2. Liftin

g lever

3. Screw with w ashe r

4. Work clamp lever lifter shaft

5. Tensi on release lever

6. Collar

7. Tension release rod assy

8. Shoulder screw

9. Driving lev er push lever

10. Tension release lever, U

11. Shoulder screw

KE-430B, 430C series

56

Page 64

4. ASSEMBL Y

Pneumatic specifications

After installing the lifting

lever

, check that it moves

smoothly.

3335Q

3336Q

Tighten the set screw while lightly

pressing the work clamp lever lifter

shaft.

Apply grease.

Install the driving lever push lever

and the tension release lever U to

the driving lever stopper with the

shoulder screw.

Apply grease.

Driving lever

stopper

Adjust the thread take-up spring height

while referring to “1-2. Standard thread

tension”.

1. Presse r ba r lifter cran k 12. Retaining ring

2. Tension release rod 13. Tension release rod assy

3. Screw 14. Shoulder screw

4. Lifting lever 15. Driving lever push lever

5. Screw with w ashe r 16. Tension release lever, U

6. Work clamp lever lifter shaft 17. Shoulder screw

7. Tensi on release lever 18. Tension release stud

8. Collar 19. Tension release pin

9. Retaining ring 20. Thread tension assy

10. Set screw

21. Set screw

11. Tension release lever spring

57

KE-430B, 430C series

Page 65

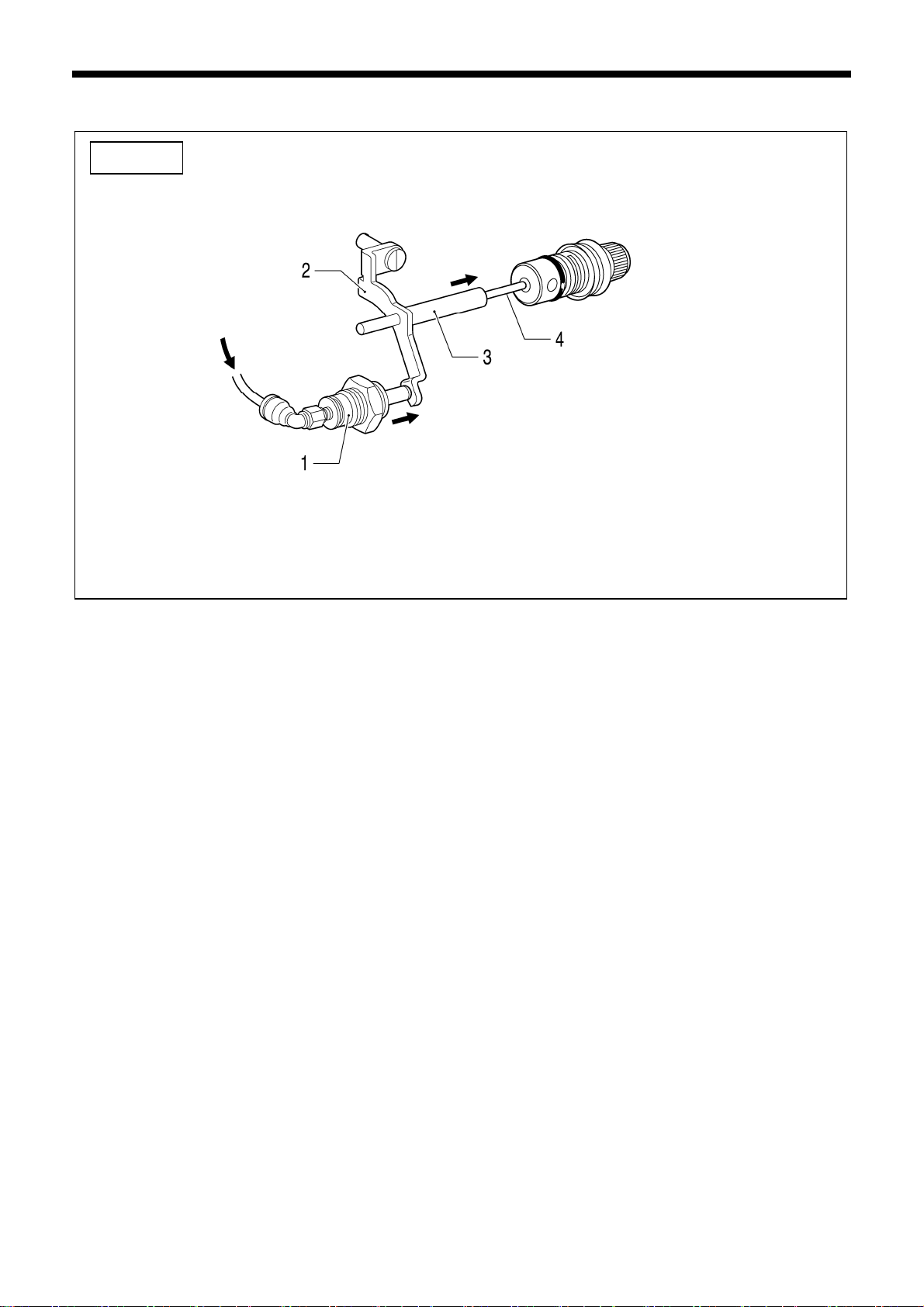

Stepping foot specifications

sion release bracket

1. Ten

2. Screw

3. Tension release rod assy

4. Shoulder screw

Driving lever push lever

5.

6. Tensi on release lever, U

. Shoulder screw

7

Tension release pin, L

8.

9. Tension release pin

10. Thread tension assy

11. Set screw

KE-484C

3338Q

Apply sealant (Threebond 1212 or similar) to the

thread sec

Apply grease.

tion.

Adjust the thread take-up spring height

wh

ile referring to “1-2. Standard thread

tension”.

1. Tensio n release pin push leve r

2. Leve

3. Set screw

4. Rubber cap

5. Tension release cylinder assy

6. Tensio n release pin, L

7. Tension release pin

8.

9. Set screw

4. ASSEMBL Y

Apply grease.

Driving lever stopper

Install the driving

lever

push lever

and the tension

release lever U to

the driving lever

stopper with the

shoulder screw.

r shaft

Thread tension assy

3337Q

KE-430B, 430C series

58

Page 66

4. ASSEMBL Y

4-3. Thread wiper mechanism

Solenoid specifications

hten the set screw while lightly

Tig

pressing the work clamp lever lifter

shaft.

3341Q

Adjust the thread take-up spring height while

referring to “1-2. Standard thread tension”.

After installing the thread wiper, moved the forked

part of the thread wiper driving lever and check

that the thread wiper unit moves smoothly.

Not

e:

If the thread wiper unit does not move smoothly,

error E-60 may be displayed.

3339Q

Adjust while referring to “5-17. Adjusting the

thread wiper”.

Thread wiper rod assy

1.

[Insert from above]

2. Thread wi pe r drivin g lever

3. Thread wiper shaft (with washer and

retaining ring)

4. Set screw

5.

Thread wiper rod assy

[Place onto the work clamp lever lifter

shaft]

6. Retaining ring

7. Work clamp lever lifter shaft

8. Set screw

9. Tension release lever spring

10. Retaining ring

11. Thread wiper arm assy

12. Retaining ring

13. Set screw [Temporarily tighten]

14. Thread wiper

15. Plain washer

16. Screw

17. Tension release stud

18. Tension release pin

19. Thread tension assy

20. Set screw

59

KE-430B, 430C series

Page 67

Pneumatic specifications

When installing the sole-

d box assembly, pass

noi

the tension release rod

through the hole.

3342Q

After i

nstalling the plunger pin, push

the thread wiper connecting rod

assembly up and check that the thread

wiper unit moves smoothly.

4. ASSEMBL Y

Adjust while referring to “5-17.

Adjusting the thread wiper”.

1.

Thread wiper arm assy

2. Set screw [Temporarily tighten]

3. Thread wi pe r co nne cting rod as sy

4. Screws [2 pcs]

5. Solenoid box assy

6. Washers [2 pcs]

7. B o lt s [2 pcs]

8. Plunger pin

9. Lifting lever

10. Screw with washer

KE-430B, 430C series

60

Page 68

4. ASSEMBL Y

Stepping foot specifications

After installing the face pl

install the bolts, and then push the thread wiper connecting

rod assembly up and check that the thread wiper unit moves

smoothly.

ate while referring to “4-21. Covers”,

KE-484C

3343Q

Adjust while referring to “5-17.

sting the thread wiper”.

Adju

1. Thread wi pe r co nne cting rod as sy

2.

Set screw [Temporarily tighten]

3. Solenoid box assy

4

. Washers [2 pcs]

Bolts [2 pcs]

5.

6. Plunger pin

7. Bolts [ 2 pcs: Install to face plate]

3344Q

1.

Thread wiper connecting rod

2. Set screw [Temporarily tighten]

3. Cylinder box

4. Washers [2 pcs]

5. B o lt s [2 pcs]

6. B o lt s with washers [2 pcs]

7. Screw

61

KE-430B, 430C series

Page 69

4-4. Thread take-up mechanism

3346Q

While pushing the solenoid joint

in the direction of the arrow, set

the solenoid setting plate and the

solenoid joint so that the gap

between them is 0.5 mm, and

then tighten the set screws.

* Move the solenoid joint and

check that the thread take-up

lever operates smoothly. If it

does not move smoothly, it

may damage the solenoid. If

the movement is not smooth,

make fine adjustments to the

position of the solenoid setting

plate until the thread take-up

lever operates smoothly.

Seen from the front

3345Q

Attach the spring to spring

ho

oks (A) and (B).

1) Provisionally install the solenoid

joint to the thread take-up solenoid

with the set screws.

2) Place the solenoid joint onto the

thread take-up lever crank so that

the flat surface is against the flat

part of the thread take-up crank,

and then install the solenoid setting

plate to the machine head.

Apply grease.

3347Q

Thread take-up lever crank

1.

2. Plain washer

3. Retaining ring

4. Thread take-up lever

5. Shoulder screws [2 pcs]

6. Set screw [Temporarily tighten]

7. Spring washer

8. Plain washer

9. Nut

10. Solenoid joint

11. Set screws [2 pcs]

12. Spring

13. Solenoid setting plate

14. Screws [2 pcs]

4. ASSEMBL Y

KE-430B, 430C series

62

Page 70

4. ASSEMBL Y

p

Stepping foot specifications

3346Q

While pushing the solenoid joint

in the direction of the arrow, set

the solenoid setting plate and the

solenoid joint so that the gap

between them is 0.5 mm, and

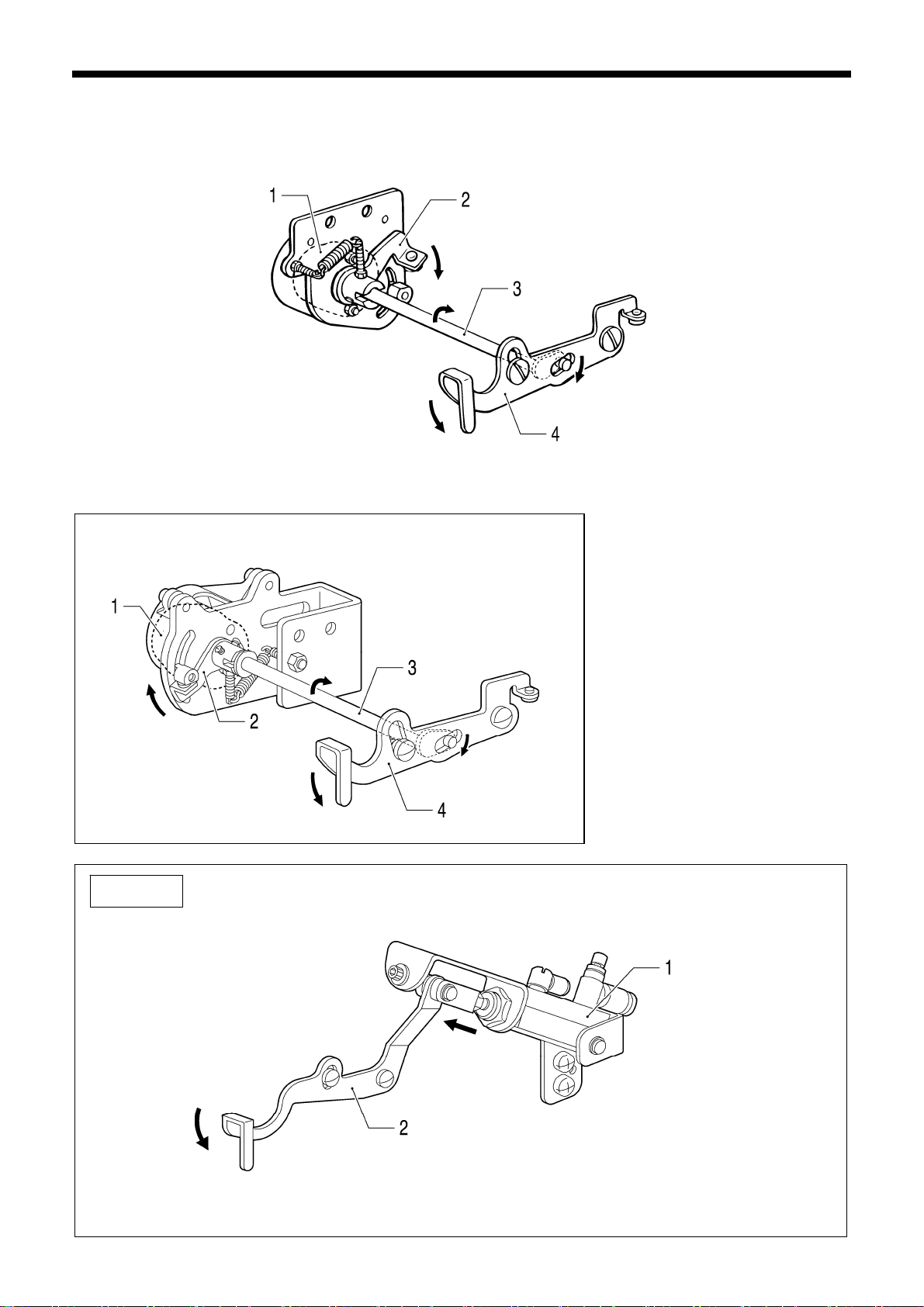

then tighten the set screws.