Brother 1850, 1910, PT-1900 Service Manual

SERVICE MANUAL

MODEL: PT-1900/1910/1850

PREFACE

This publication is a service manual covering the specifications, general mechanisms,

disassembly/reassembly procedure, and troubleshooting and error message of the Brother PT1900/1910/1850. It is intended for service personnel and other concerned persons to accurately

and quickly provide after-sale service for our PT-1900/1910/1850.

To perform appropriate maintenance so that the machine is always in best condition for the

customer, the service personnel must adequately understand and apply this manual.

This manual is made up of four chapters and appendices.

CHAPTER I SPECIFICATIONS

CHAPTER II GENERAL MECHANISMS

CHAPTER III DISASSEMBLY & REASSEMBLY PROCEDURE

CHAPTER IV TROUBLESHOOTING AND ERROR MESSAGE

APPENDIX 1. CIRCUIT DIAGRAMS

© Copyright Brother 2002

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

CONTENTS

CHAPTER I SPECIFICATIONS......................................................................... I-1

1.1 MECHANICAL SPECIFICATIONS ........................................................................ I-1

1.1.1 External Appearance...................................................................................... I-1

1.1.2 Keyboard........................................................................................................ I-2

1.1.3 Display........................................................................................................... I-2

1.1.4 Printing Mechanism ........................................................................................ I-2

1.1.5 Tape Cassette................................................................................................ I-3

1.1.6 Tape Cutter.................................................................................................... I-3

1.2 ELECTRONICS SPECIFICATIONS ...................................................................... I-10

1.2.1 Character Generator....................................................................................... I-10

1.2.2 Power Supply................................................................................................. I-10

1.3 KEY COMMANDS FOR SPECIAL FUNCTIONS................................................... I-10

1.3.1 Initializing....................................................................................................... I-10

1.3.2 Demonstration Print........................................................................................ I-10

CHAPTER II GENERAL MECHANISMS............................................................ II-1

2.1 MAIN MECHANISM .............................................................................................. II-1

2.1.1 Print Mechanism ............................................................................................ II-1

2.1.2 Roller Holder ASSY Setting & Retracting Mechanism ..................................... II-3

2.1.3 Tape & Ribbon Feed Mechanism.................................................................... II-4

2.1.4 Automatic Tape Cutter Mechanism (PT-1900/1910) ....................................... II-6

2.1.5 Tape Cutter Mechanism (PT-1850)................................................................. II-7

2.1.6 Roller Holder ASSY & Cassette Cover Interlocking Mechanism...................... II-8

2.2 OUTLINE OF CONTROL ELECTRONICS ............................................................ II-10

2.2.1 Configuration of the Electronic Part................................................................ II-10

2.2.2 Main PCB ....................................................................................................... II-10

2.2.3 Power Supply PCB......................................................................................... II-10

2.2.4 Cassette Sensor............................................................................................. II-10

2.2.5 DC Motors...................................................................................................... II-10

2.2.6 Thermal Print Head........................................................................................ II-10

i

2.3 MAIN PCB............................................................................................................. II-11

2.3.1 Block Diagram................................................................................................ II-11

2.3.2 Solder Points .................................................................................................. II-12

2.4 POWER SUPPLY PCB......................................................................................... II-13

CHAPTER III DISASSEMBLY & REASSEMBLY .............................................. III-1

3.1 DISASSEMBLY PROCEDURE.............................................................................. III-1

[ 1 ] Removing the Battery Lid and Batteries....................................................... III-1

[ 2 ] Removing the Tape Cassette and Tape Separator Stick.............................. III-2

[ 3 ] Removing the Bottom Cover....................................................................... III-4

[ 4 ] Removing the Cassette Cover, Main Frame ASSY...................................... III-7

[ 5 ] Removing the Main PCB Unit and Rubber Key Pad..................................... III-16

[ 6 ] Removing the Switch ASSY........................................................................ III-18

[ 7 ] Removing the Blind Cover........................................................................... III-18

[ 8 ] Removing the Power Supply PCB............................................................... III-19

[ 9 ] Removing the Battery Terminals................................................................. III-20

3.2 REASSEMBLY PROCEDURE............................................................................... III-21

[ 1 ] Installing the Battery Terminals ................................................................... III-21

[ 2 ] Installing the Power Supply PCB................................................................. III-22

[ 3 ] Installing the Blind Cover............................................................................. III-24

[ 4 ] Installing the Switch ASSY.......................................................................... III-25

[ 5 ] Installing the Rubber Key Pad ..................................................................... III-26

[ 6 ] Installing the Main PCB Unit ........................................................................ III-27

[ 7 ] Installing the Main Frame ASSY.................................................................. III-29

[ 8 ] Installing the Bottom Cover......................................................................... III-37

[ 9 ] Installing the Cassette Cover ....................................................................... III-39

[ 10 ] Installing the Tape Cassette and Tape Separator Stick ................................ III-40

[ 11 ] Loading Batteries and Installing the Battery Lid ........................................... III-41

[ 12 ] Demonstration Print and Final Check .......................................................... III-42

ii

CHAPTER IV TROUBLESHOOTING AND ERROR MESSAGE ....................... IV-1

4.1 TROUBLESHOOTING.......................................................................................... IV-1

4.1.1 Precautions.................................................................................................... IV-1

4.1.2 After Repairing............................................................................................... IV-1

4.1.3 Troubleshooting Flows.................................................................................... IV-2

[ 1 ] Tape feeding failure..................................................................................... IV-2

[ 2 ] Printing failure............................................................................................. IV-4

[ 3 ] Powering failure (Nothing appears on the LCD.).......................................... IV-6

[ 4 ] No key entry possible.................................................................................. IV-8

[ 5 ] Tape cutting failure...................................................................................... IV-9

[ 6 ] Abnormal LCD indication............................................................................. IV-10

[ 7 ] Tape cassette type not identified................................................................. IV-11

4.2 ERROR MESSAGE............................................................................................... IV-12

4.2.1 Error Message List ......................................................................................... IV-12

Appendix 1. CIRCUIT DIAGRAMS

Appendix 1.A Main PCB CIR 1900 (PT-1900/1910)

Appendix 1.B Main PCB CIR 1850 (PT-1850)

Appendix 1.C Sub PCB

iii

CHAPTER I SPECIFICATIONS

1.1 MECHANICAL SPECIFICATIONS

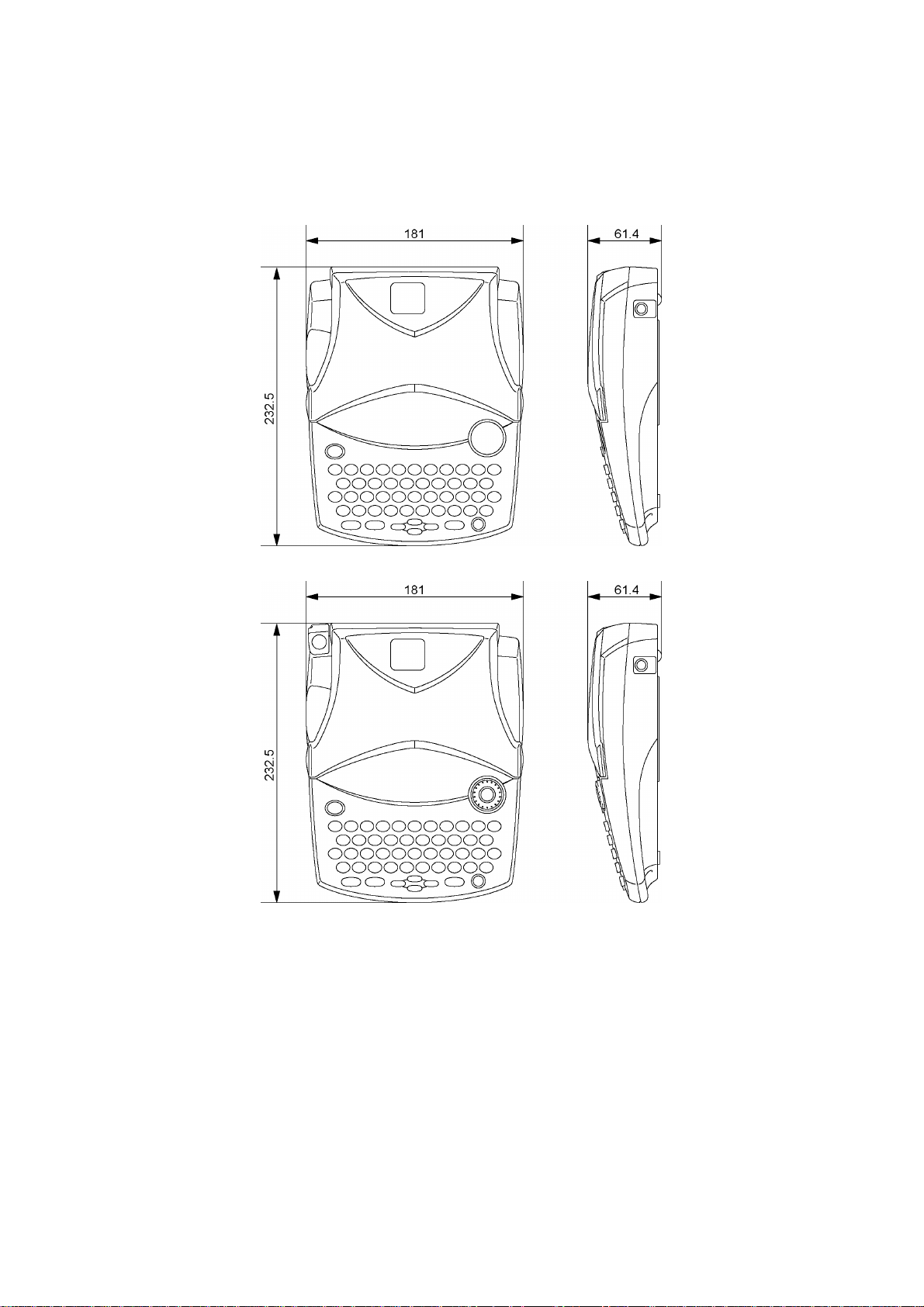

1.1.1 External Appearance

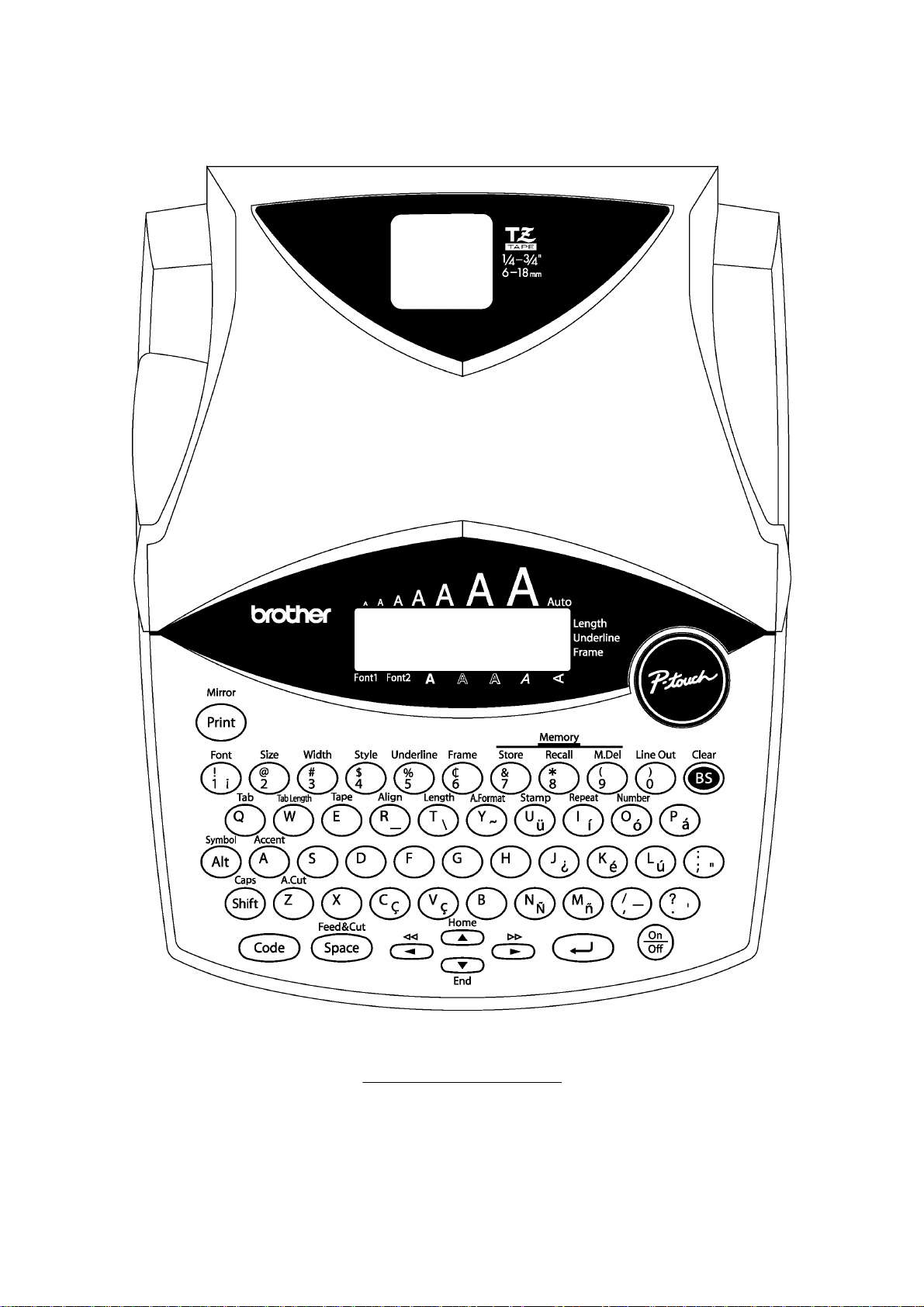

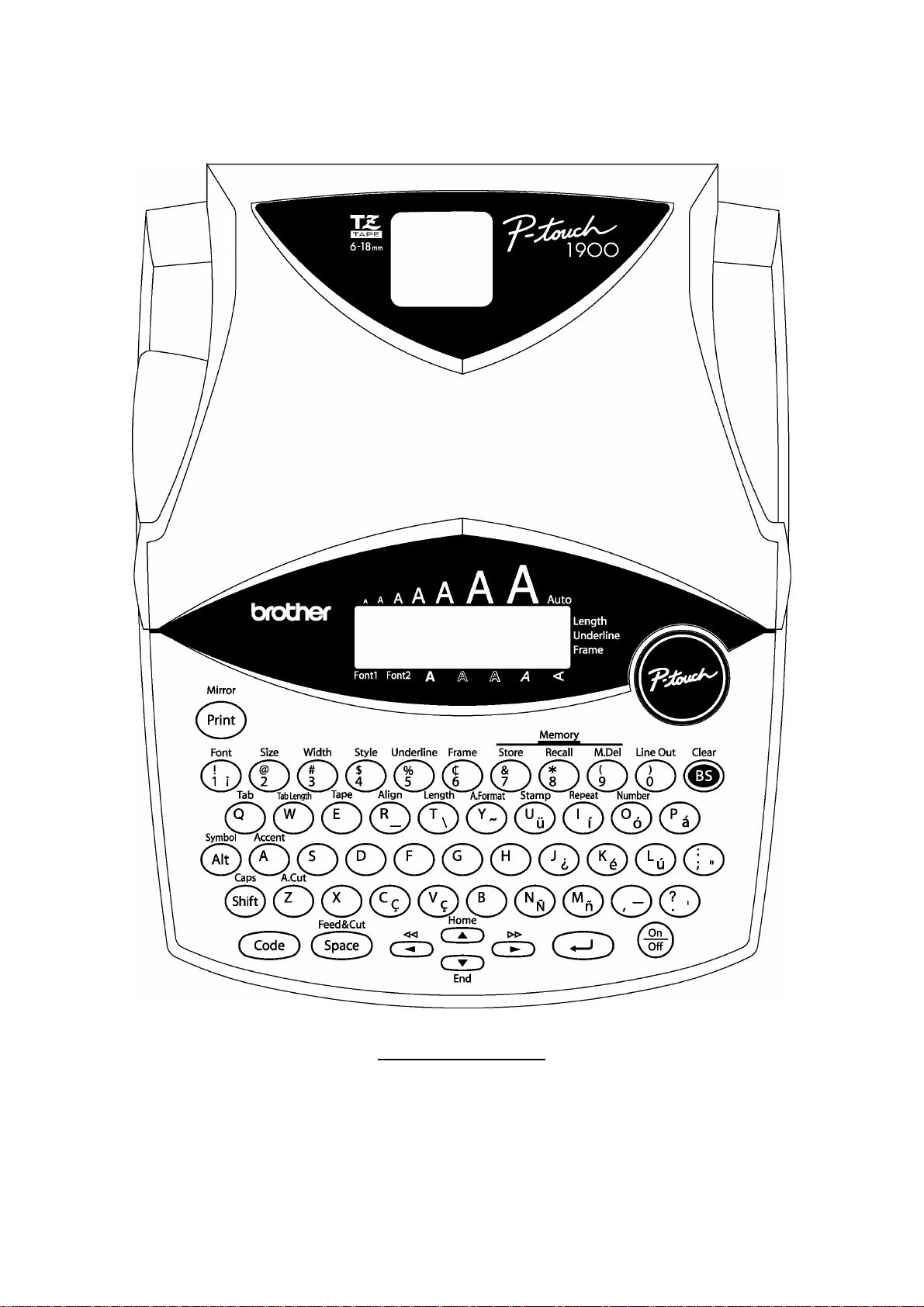

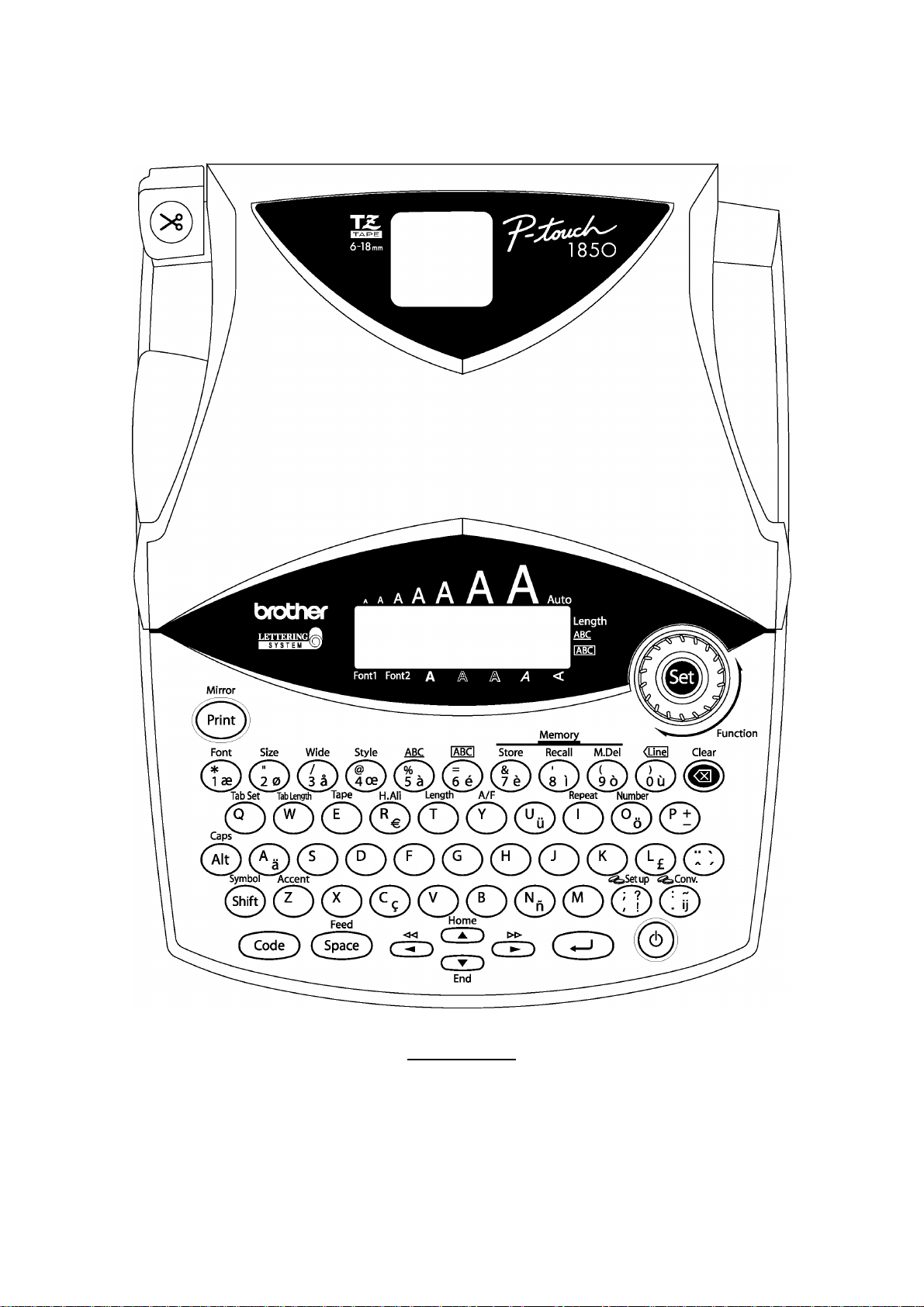

(PT-1900/1910)

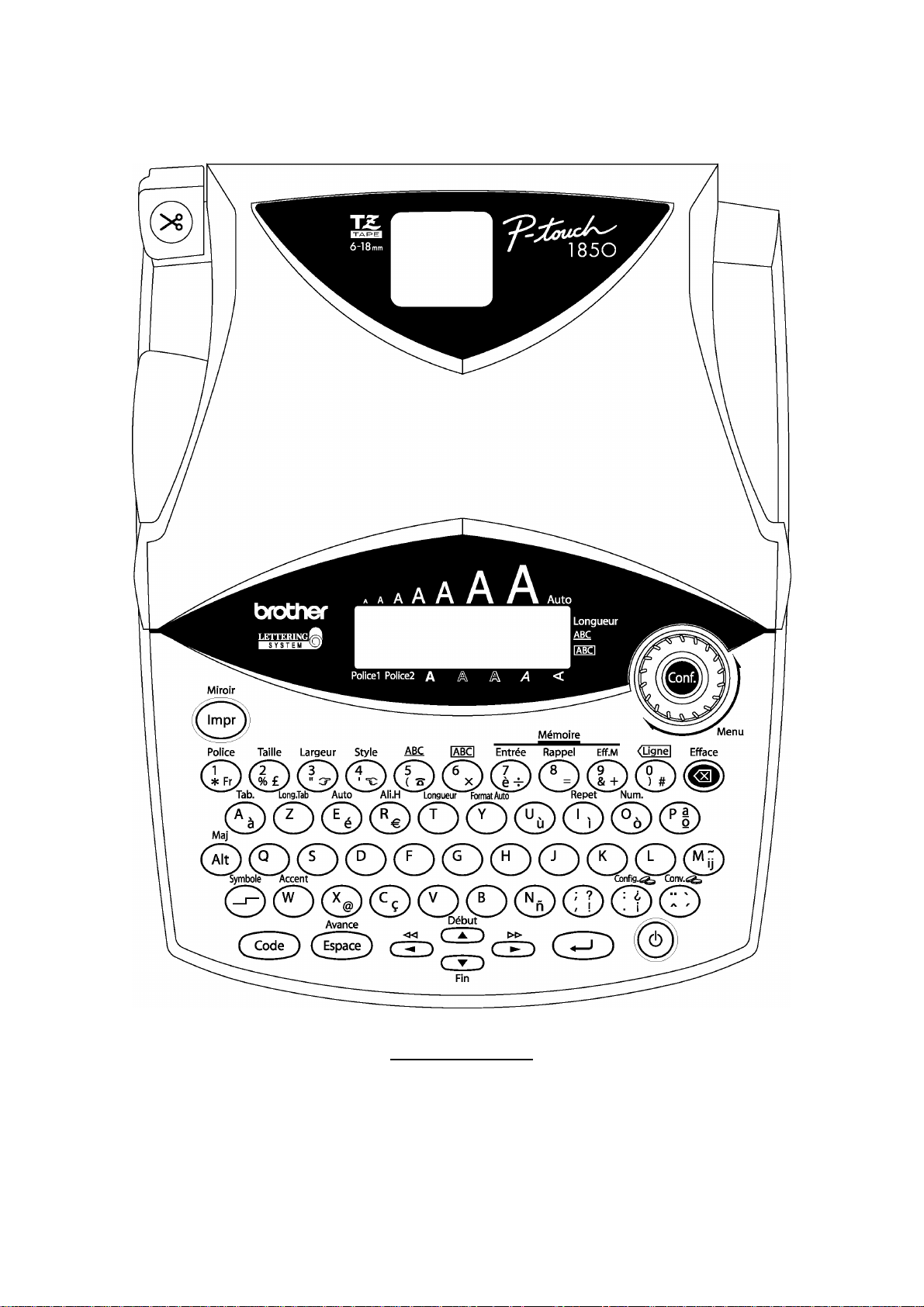

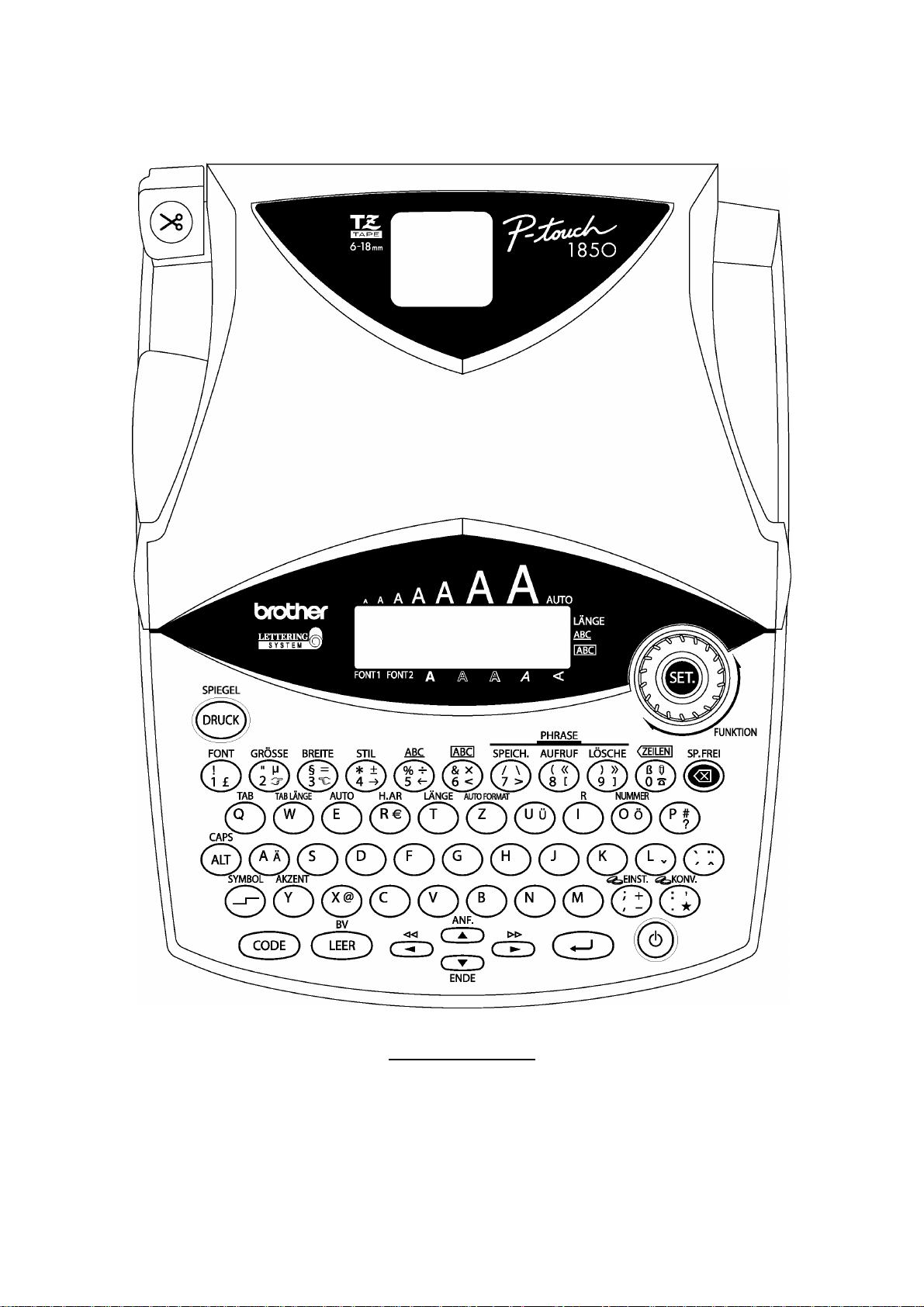

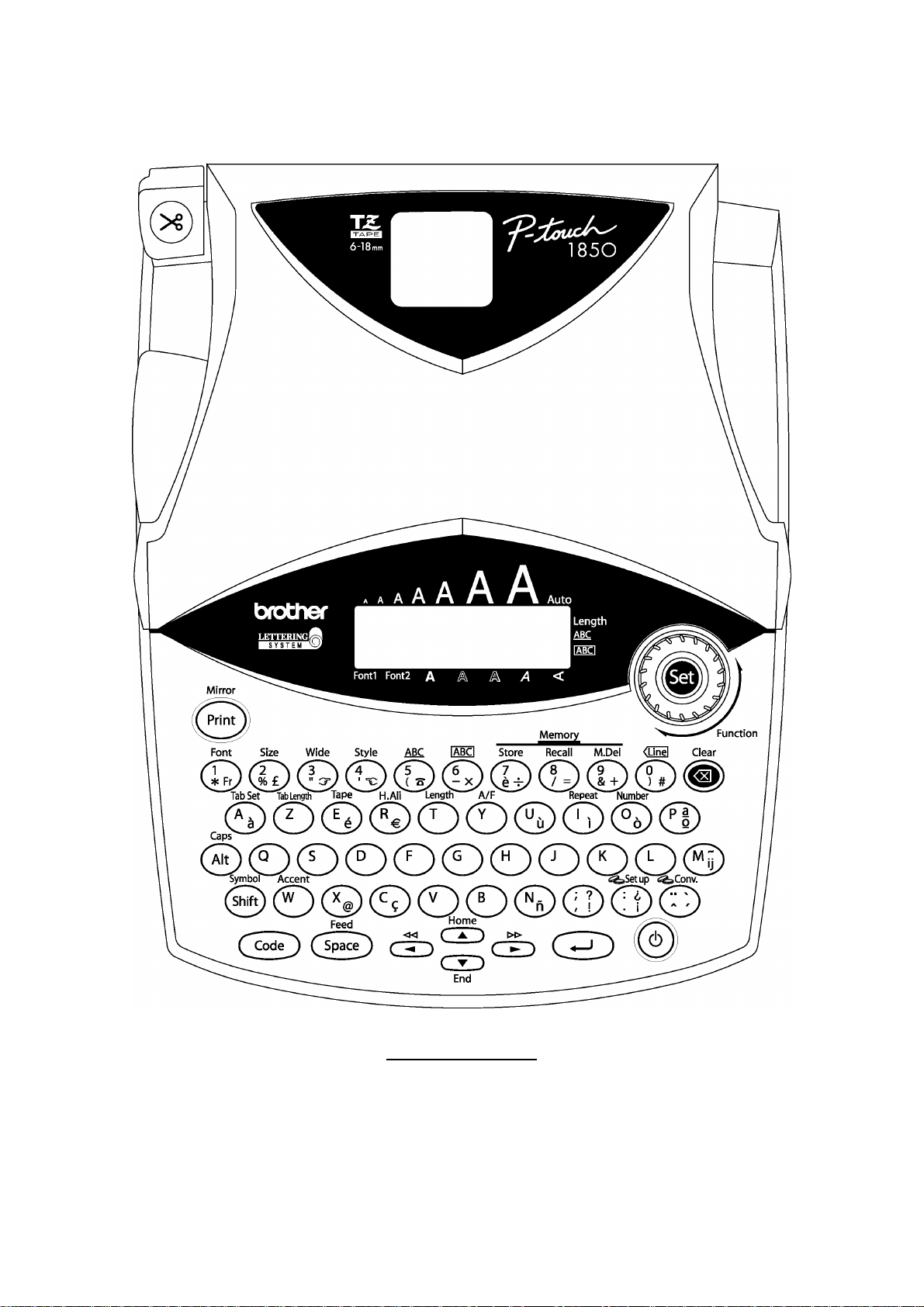

(PT-1850)

Fig. 1.1-1 PT-1900/1850

(1) Dimensions (W x D x H) 181 x 232.5 x 61.4 mm (7.13" x 9.15" x 2.42")

(2) Weight

Machine proper Approx. 800 g

In package Approx. 1.31 kg (PT-1900 (U.S.A./AUS))

Approx. 1.35 kg (PT-1900 (CANADA)/1850)

Approx. 2.7 kg (PT-1910/1850cc)

(including batteries, a tape cassette, and user's manual)

I-1

1.1.2 Keyboard

(1) Entry system Rubber key pad

(2) Number of alphanumeric and symbol keys 39

(3) Number of function keys 12 (including “On/Off ( ) ” key)

(4) Key arrangement See Fig. 1.1-2.

(5) Navigation dial (PT-1850) Rotary switch : 24 positions / cycle

1.1.3 Display

(1) Display type Liquid crystal display (LCD)

(2) Display composition 16 x 59 dots

(3) Number of indicators 20 (See Fig. 1.1-2.)

(4) Dot size 0.65 mm(25.6 mils) wide by 0.65 mm(25.6 mils) high

(5) Field-of-view angle adjustment Fixed by a resistor

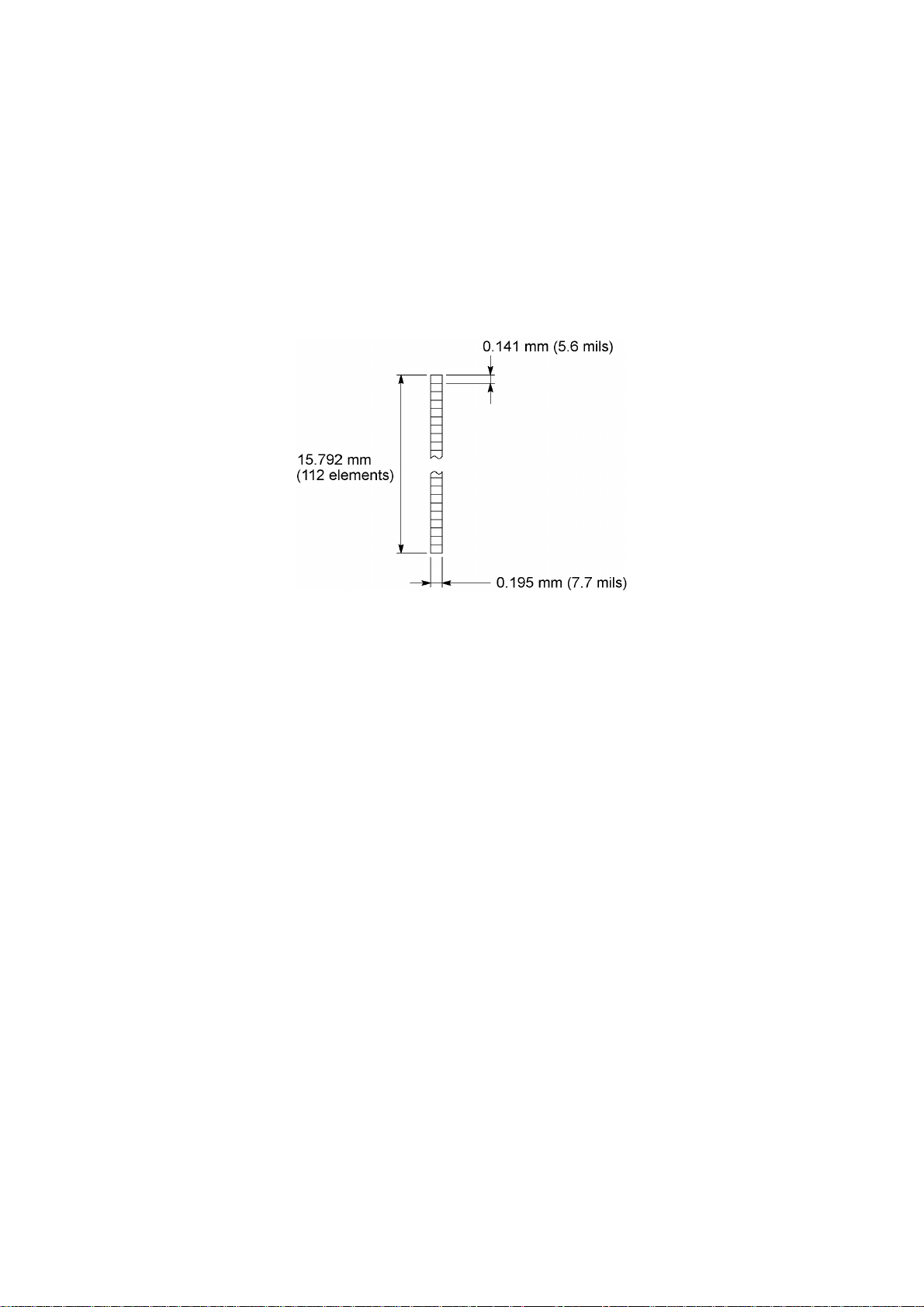

1.1.4 Printing Mechanism

(1) Print method Thermal transfer onto plastic tapes (laminate tape and

(2) Print speed 10 mm/second (Typical)

(3) Print head

Type Thermal print head

Heat generator Consists of 112 heating elements vertically aligned

Size of heating element 0.195 mm (7.7 mils) wide by 0.141 mm (5.6 mils) high

(4) Character size

Set key : 1

non-laminated tape) or special tapes (instant lettering tape,

non-laminated thermal film tape, iron-on transfer tape, and

porous-stamp tape)

(Fixed print head and tape feeding mechanism)

(PT-1850 : 128 heating elements)

Character size Height x Width (dots)

Size 6 1.55 mm x 1.13 mm (11 x 8)

Size 9 1.97 mm x 1.41 mm (14 x 10)

Size 12 2.82 mm x 2.12 mm (20 x 15)

Size 18 4.51 mm x 3.38 mm (32 x 24)

Size 24 5.92 mm x 4.37 mm (42 x 31)

Big <12 mm> 7.61 mm x 5.64 mm (54x 40)

Size 36 9.02 mm x 6.77 mm (64 x 48)

Size 42 10.72 mm x 8.04 mm (76 x 57)

Big <18 mm> 13.54 mm x 10.30 mm (96 x 73)

* The height and width of the printed character are different depending on characters.

The values in the above list refer to the values of ‘H’ of HELSINKI.

* The character size indicates the point size.

I-2

1.1.5 Tape Cassette

(1) Cassette Cartridge type

(2) Types of tape cassettes

• Laminated tape cassette Laminate tape, ink ribbon, and adhesive base tape

• Non-laminated tape cassette Non-laminate tape and ink ribbon

• Instant lettering tape cassette Instant lettering tape and ink ribbon

• Non-laminated thermal film Non-laminated thermal film tape

tape cassette

• Iron-on transfer tape cassette Iron-on transfer tape and ink ribbon

• Stamp tape cassette Porous-stamp tape and base paper

• Cloth tape cassette Cloth tape and ink ribbon

(3) Tape size

Laminate tape 6, 9, 12, 18 mm 8 m

Non-laminate tape 6, 9, 12, 18 mm 8 m

Iron-on transfer tape 18 mm 6 m

Porous-stamp tape 18 mm 3 m

Width Length

(5 m for the fluorescent coating tape)

Cloth tape 12 mm 4 m

Cleaning tape 18 mm

(4) Tape cassette packed with the machine

1.1.6 Tape Cutter

(1) Tape cutting Automatic cutter (scissors type) (PT-1900/PT1910)

(2) Cutter unit Not user-replaceable

Laminated tape cassette containing a 12-mm-wide black

ink ribbon, laminate tape, and adhesive base tape

Manual cutter (scissors type) (PT-1850)

I-3

PT-1900 U.S.A. / CANADA

PT-1910 U.S.A.

Fig. 1.1-2 Key Arrangement (1)

I-4

PT-1900 AUSTRALIA

Fig. 1.1-2 Key Arrangement (2)

I-5

PT-1850 FRENCH

Fig. 1.1-2 Key Arrangement (3)

I-6

PT-1850 GERMAN

Fig. 1.1-2 Key Arrangement (4)

I-7

PT-1850 U.K.

Fig. 1.1-2 Key Arrangement (5)

I-8

PT-1850 BELGIUM

Fig. 1.1-2 Key Arrangement (6)

I-9

1.2 ELECTRONICS SPECIFICATIONS

1.2.1 Character Generator

(1) Internal characters U.S.A./CAN (PT-1900/1910) 179 characters

U.K./ FRA/ BEL (PT-1850) 198 characters

GER (PT-1850) 211 characters

(2) Internal font HELSINKI, BRUSSELS

(3) Internal memory Text buffer 99 characters (PT-1900/1910/1850)

File memory 300 characters (PT-1900/1910/1850)

1.2.2 Power Supply

(1) Automatic power off Yes

Normal mode : 5 min. ± 30 sec.

1.3 KEY COMMANDS FOR SPECIAL FUNCTIONS

1.3.1 Initializing

Powering on the machine with both the Code and R keys held down will initialize the machine.

1.3.2 Demonstration Print

Pressing the D key with the Code key held down will start demonstration print. (This key

command takes effect only when no data is entered.)

I-10

CHAPTER II GENERAL MECHANISMS

2.1 MAIN MECHANISM

2.1.1 Print Mechanism

(1) Structure of Thermal Head

This machine uses thermal transfer printing. The thermal print head has a heat generator

consisting of 112 heating elements which are vertically aligned as shown in Fig. 2.1-1.

Each heating element is 0.195 mm wide by 0.141 mm high.

Fig. 2.1-1 Heat Generator of Thermal Head

(2) Printing Process

When the cylindrical rubber platen is pressed against the thermal print head with the tape*

and ink ribbon** sandwiched inbetween, the CPU applies electric power to the selected ones

of those 112 heating elements.

* Laminate tape when using laminated tape cassettes.

Non-laminated tape when using non-laminated tape cassettes.

Instant lettering tape when using instant lettering tape cassettes.

Non-laminated thermal film tape when using non-laminated thermal film tape cassettes.

Iron-on transfer tape when using iron-on transfer tape cassettes.

Cloth tape when using cloth tape cassettes.

** When using non-laminated thermal film tape cassettes or stamp tape cassettes, no ink

ribbon is sandwiched.

[For tape cassettes except non-laminated thermal film tape cassettes and stamp tape

cassettes]

If the selected heating element(s) generates heat, the ink on the sandwiched ribbon will be

melted and transferred to the tape, producing a dot(s) on the tape. The ink ribbon and the

tape are advanced and then the next heating cycle is repeated, thus forming a character on

the tape.

[For non-laminated thermal film tape cassettes]

If the selected heating element(s) generates heat, the thermal film tape develops itself to

produce a dot on the tape. The tape is advanced and the next heating cycle is repeated,

thus forming a character on the tape.

II-1

[For stamp tape cassettes]

If the selected heating element(s) generates heat, the porous-stamp tape will be melted so

that a pore (pores) will be formed in the tape. The tape is advanced and the next heating

cycle is repeated, thus forming a character of pores on the tape. The printed stamp tape

can be used as the face of a stamp. When the stamp is pressed against the ink-pad, it will

absorb ink through the pores.

For laminated tape cassettes, instant lettering tape cassettes, and iron-on transfer tape

cassettes, the CPU processes the print data to generate a mirror image so that the printed

character can be seen normally when viewed from the other side of the printed face of the

tape.

(3) Character Formation

While the DC motor feeds the tape and ink ribbon (only the tape when using non-laminated

thermal film tape cassettes or stamp tape cassettes) by 0.141 mm, the thermal head

generates heat once. The feed amount is decided by sending each five pulses of the signal

as one dot (0.141 mm) when the photo interrupter detects the encode gear assembled onto

the motor shaft. The feed amount of 0.141 mm is smaller than the width (0.195 mm) of the

heating elements so that the heat generated at one heating cycle will overlap with the next

heating cycle. This forms a character having no gap between adjacent printed dots.

II-2

2.1.2 Roller Holder ASSY Setting & Retracting Mechanism

This mechanism consists of the roller release lever, roller holder release rod, and roller holder

ASSY.

The roller holder ASSY supports the platen and the tape feed sub roller so that they can move

perpendicularly to the head ASSY and the tape feed roller, respectively, as well as rotating freely.

Loading a tape cassette and closing the cassette cover pushes down the roller release lever which

moves the roller holder release rod to the left (when viewed from the front of the machine). This

pivots the roller holder ASSY around the shaft provided on the chassis so as to press the roller

holder ASSY against the head ASSY side.

The platen is pressed perpendicularly against the head ASSY with the tape and ink ribbon (only

the tape when using non-laminated thermal film tape cassettes or stamp tape cassettes)

sandwiched inbetween under a uniform load by the platen (upper and lower) spring.

At the same time, the platen gear becomes engaged with the platen idle gear.

Also, the tape feed sub roller is pressed perpendicularly against the tape feed roller built in the

tape cassette with the tape (and base paper when using laminated tape cassettes or stamp tape

cassettes) sandwiched inbetween under a uniform load by the roller holder upper spring and roller

holder lower spring. At the same time, the sub roller gear becomes engaged with the tape idle

gear.

If you open the cassette cover, the roller release lever pops up, which shifts the roller holder

release rod so that the roller holder ASSY is retracted from the head ASSY, providing you with

enough space to replace the tape cassette.

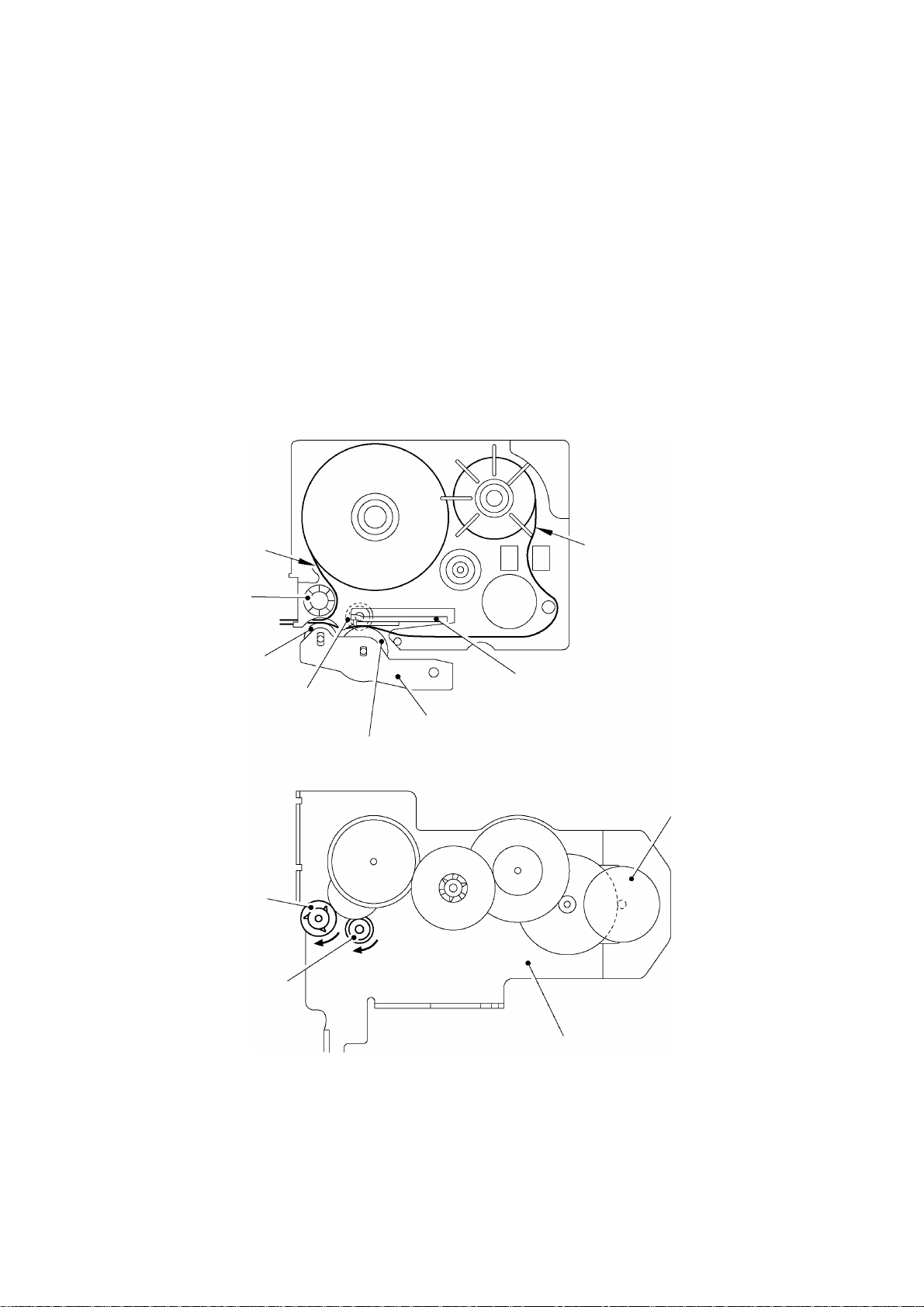

Adhesive base tape

Platen idle gear

Tape feed roller

Tape feed sub roller

(Tape feed) platen gear

(Tape feed) sub roller gear

Platen roller

Roller holder ASSY

Platen roller

Head ASSY

Shaft

Platen lower spring

Laminate tape

Tape cassette

Ink ribbon

Main frame ASSY

Roller release lever

Roller holder release rod

Platen upper spring

Tape feed sub roller

(Top)

Fig. 2.1-2 Roller Holder ASSY Setting & Retracting Mechanism

II-3

2.1.3 Tape & Ribbon Feed Mechanism

This mechanism consists of a DC motor, gear train, and roller holder ASSY.

(1) Tape Feeding

When you load a tape cassette and close the cassette cover, the tape feed roller inside the

cassette and the tape feed sub roller in the roller holder ASSY sandwich the tape (the

laminate tape and adhesive base tape when using laminated tape cassettes) inbetween, as

described in Subsection 2.1.2.

As the DC motor rotates, the rotation is transmitted via the gear train to the tape idle gear

(which rotates the tape feed sub roller gear) and the platen idle gear (which rotates the tape

feed platen gear). Accordingly, the sandwiched tape and ink ribbon will be advanced.

(When a laminated tape cassette is mounted, the sandwiched laminate tape and adhesive

base tape and ink ribbon will be advanced together.)

The feeding amount of the platen is slighty less than that of the tape feed sub roller.

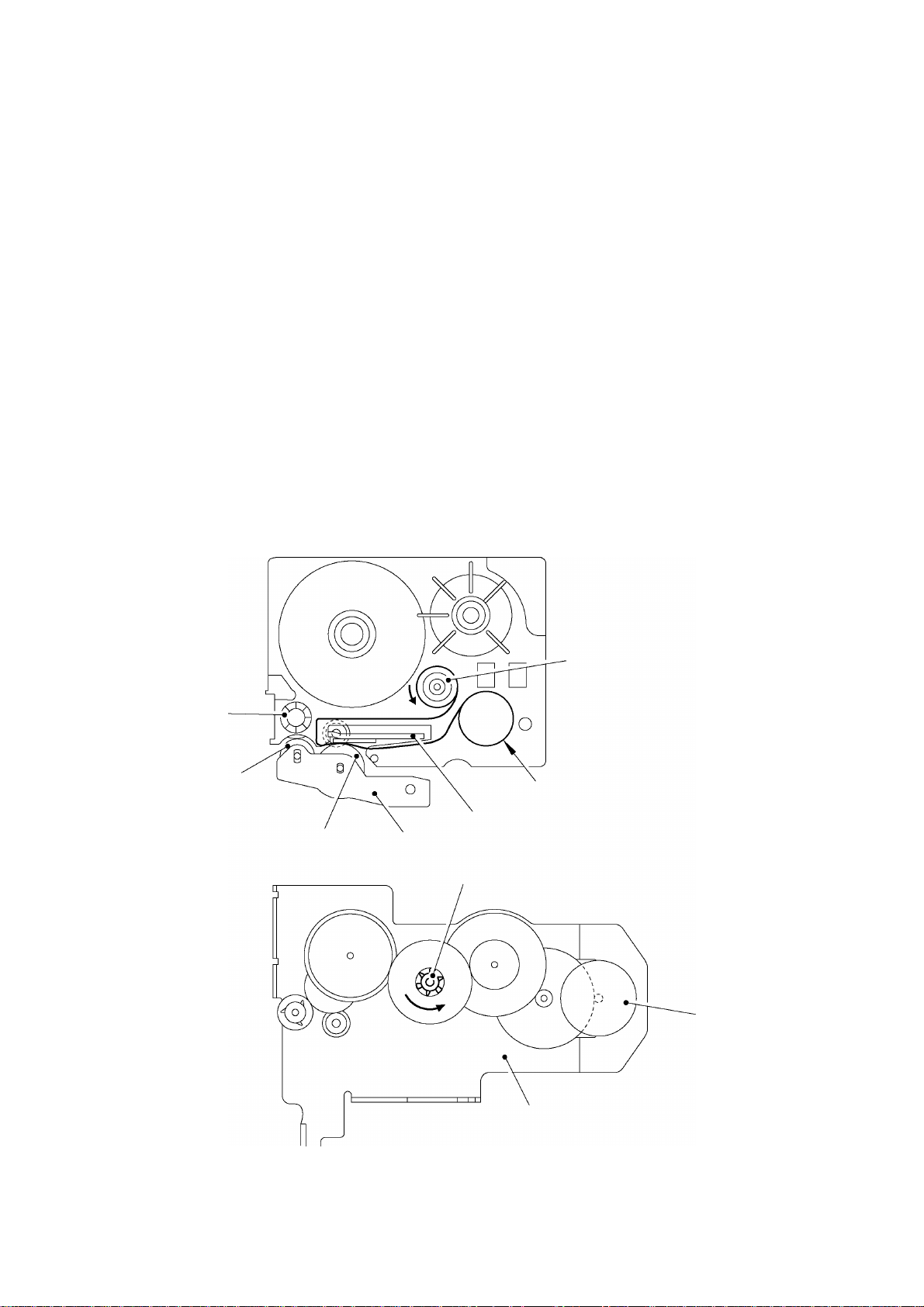

Adhesive

base tape

Tape feed

roller

(Tape feed)

sub roller gear

Tape idle gear

Platen idle gear

Transparent laminate tape

Head ASSY

Platen idle gear

Roller holder ASSY

Platen roller

DC motor

Main frame ASSY

Fig. 2.1-3 Tape Feeding Mechanism

II-4

(2) Adhesive Base Tape Feeding (only for laminated tape cassettes)

A laminated tape cassette contains both a transparent laminate tape roll and a separate

adhesive base tape roll.

When a transparent laminate tape and an adhesive base tape pass through the contact

point (between the tape feed roller and tape feed sub roller), they are then bonded together

into a single, printed tape. The ink printed on the laminate tape is, therefore, sealed up with

the adhesive base tape.

(3) Ink Ribbon Feeding (except for non-laminated thermal film tape cassettes and stamp tape

cassettes)

As the DC motor rotates, the ribbon drive cam located at the middle of the gear train rotates

counterclockwise. When fitted on the ribbon drive cam, the ribbon take-up roll in the tape

cassette also rotates to take up the ink ribbon.

To apply proper tension to the ink ribbon between the platen and the ribbon drive cam, the

feed amount of the ribbon drive cam is slightly greater than that of the tape feed gear. The

difference between the tape feed speeds at the platen and at the ribbon drive cam is

absorbed by the clutch spring which is integrated in the ribbon drive cam and allows the cam

to slip.

This way, the ink ribbon is kept tense, which enables the ribbon to clearly separate from the

tape at the stabilized angle after printing.

Tape feed roller

Tape feed sub roller

Platen roller

Ribbon take-up roll

Ink ribbon

Head ASSY

Roller holder ASSY

Ribbon drive cam

DC motor

Main frame ASSY

Fig. 2.1-4 Ribbon Feeding Mechanism

II-5

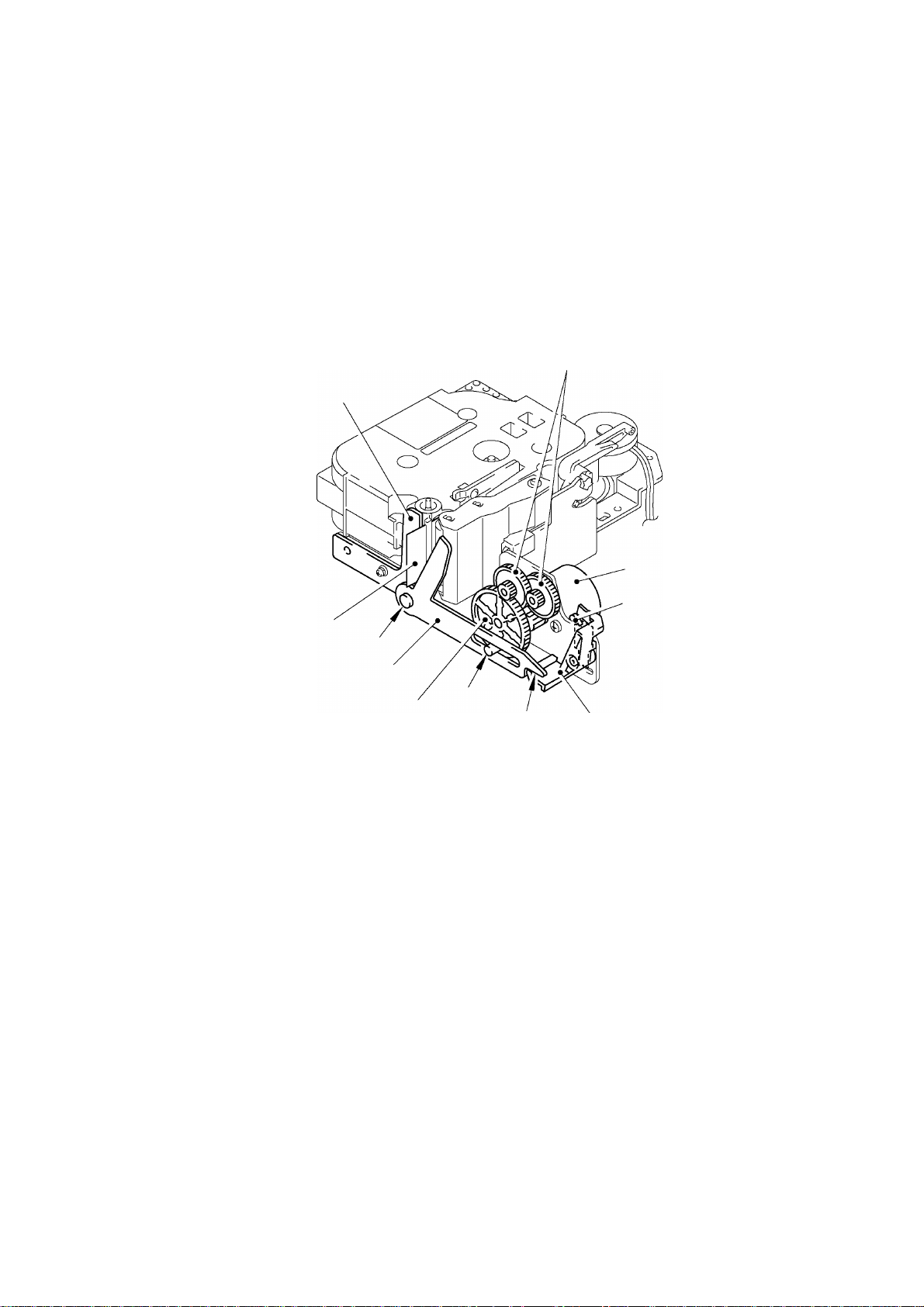

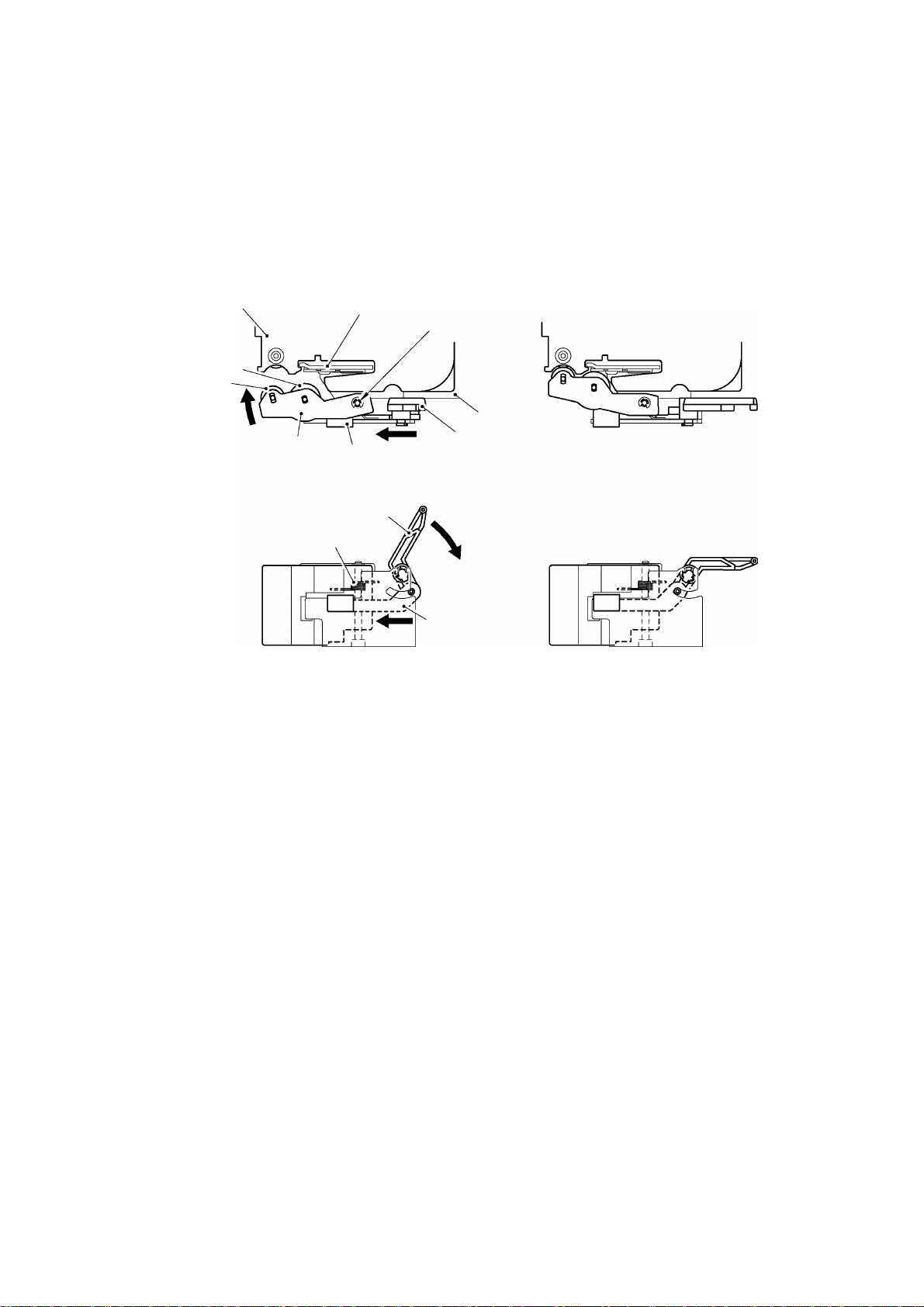

2.1.4 Automatic Tape Cutter Mechanism (PT-1900/1910)

The cutter ASSY consists of a stationary blade and a movable blade driven by the cutter motor.

Upon completion of printing and tape feeding, the CPU activates the cutter motor whose clockwise

rotation is transmitted via the idle gears to the cutter moving gear.

As the cutter moving gear rotates counterclockwise, its boss "X" (which is fitted in the opening of

the movable blade) actuates the movable blade to pivot it around shaft "Y." Consequently, the

cutter cuts the printed tape routing through the movable and stationary blades, just like a scissors.

After that, the CPU keeps the cutter motor on. When the movable blade comes back to the home

position, its end "Z" activates the cutter sensor actuator which presses the cutter sensor. The

moment the CPU receives the sensor signal, it stops the cutter motor.

Stationary blade

Cutter double gear

Cutter motor

Full cutter sensor PRO ASSY

Tape

Movable blade

“Y”

Cutter moving gear

“X”

“Z”

Actuator

Fig. 2.1-5 Automatic Tape Cutter Mechanism (PT-1900/1910)

II-6

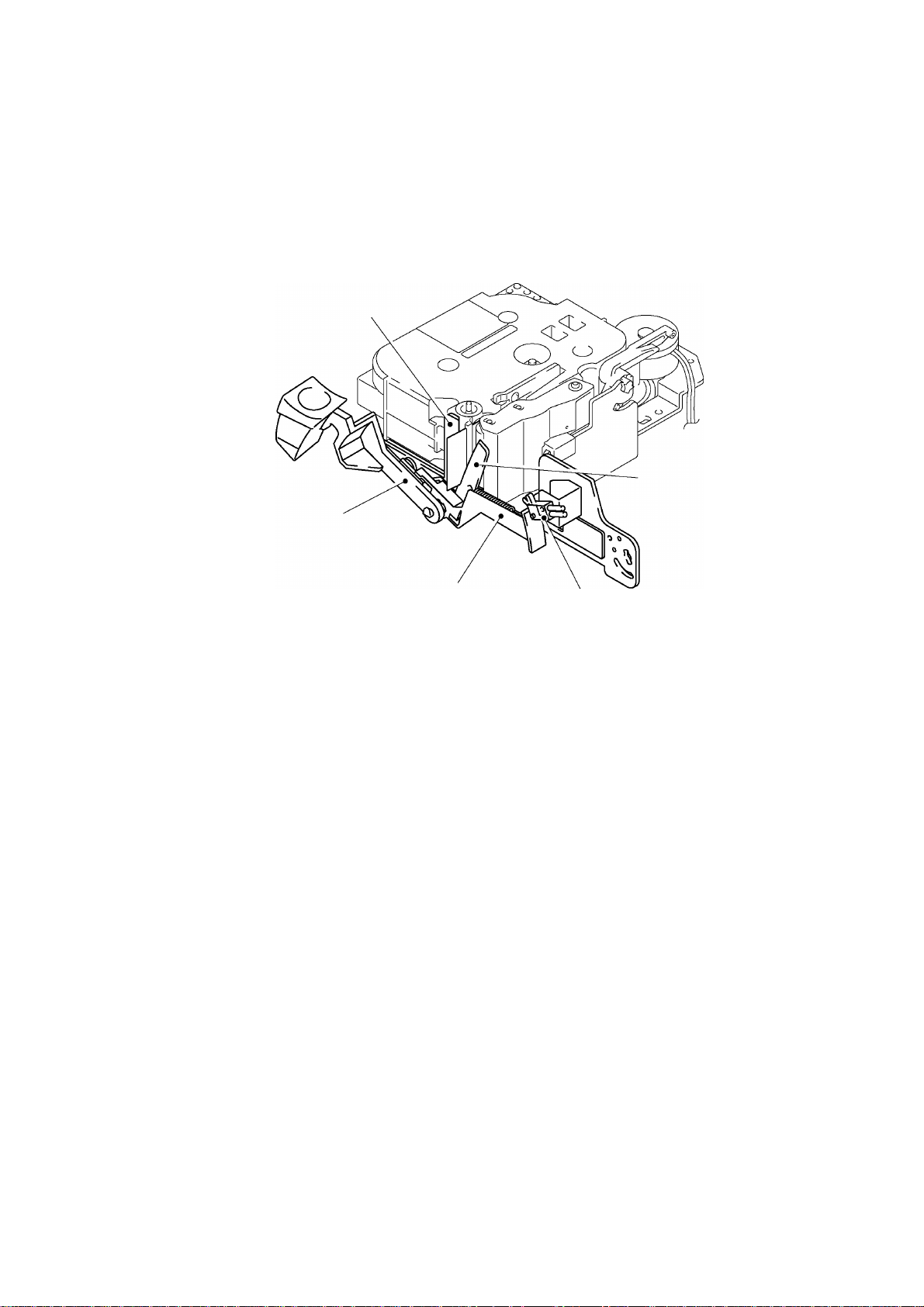

2.1.5 Tape Cutter Mechanism (PT-1850)

The cutter unit consists of a stationary cutter and a movable cutter.

Pressing the cutter lever actuates the movable cutter so that the cutter cuts the printed tape

routing through the movable and stationary cutters, just like a scissors. Attached to the cutter

lever, the cutter sensor arm turns up so that its tip comes into contact with the switch of the cutter

sensor circuit on the cutter sensor holder ASSY, stopping printing and tape feeding.

Stationary cutter

Cutter lever

Movable cutter

Cutter sensor arm

Fig. 2.1-6 Tape Cutter Mechanism (PT-1850)

Switch

II-7

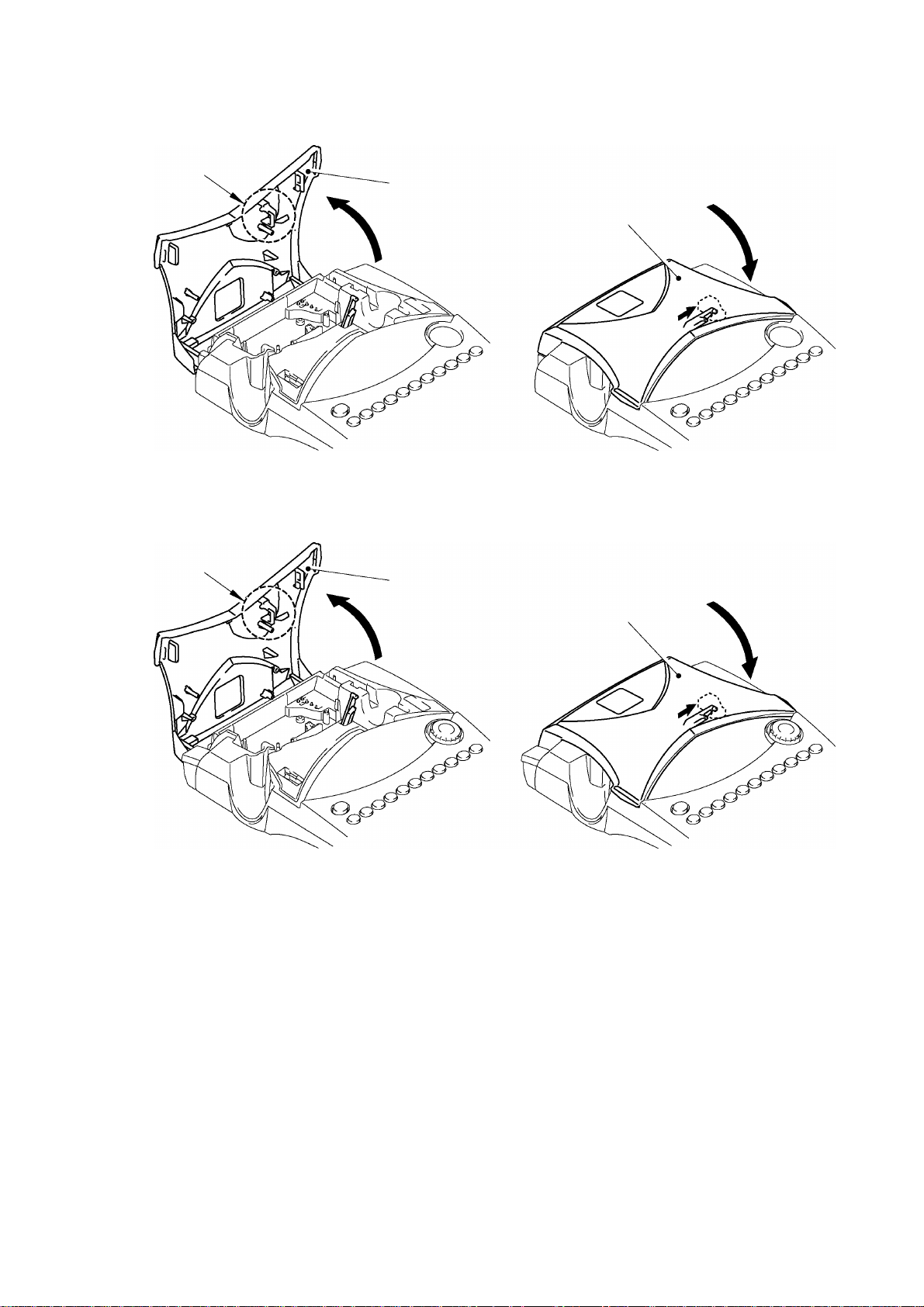

2.1.6 Roller Holder ASSY & Cassette Cover Interlocking Mechanism

Closing the cassette cover pushes down the roller release lever and brings the top of the lever into

the hooked section provided on the inside of the cassette cover.

As described in Subsection 2.1.2 “Roller Holder ASSY Setting & Retracting Mechanism”, the roller

release lever shifts the roller holder release rod so that the roller holder ASSY is pressed towards

the head ASSY side.

Tape cassette

Platen roller

Tape feed

sub roller

Roller holder ASSY

Roller holder release spring

Head ASSY

Shaft

Main frame ASSY

Roller release lever

Roller holder release rod

Roller release lever

Roller holder

release rod

(Roller Holder ASSY engaged)(Roller Holder ASSY retracted)

Fig. 2.1-7 Roller Release Lever and Roller Holder Release Rod

II-8

(PT-1900/1910)

Hooked section

(PT-1850)

Hooked section

Cassette cover

Cassette cover

Cassette cover

Cassette cover

Fig. 2.1-8 Roller Holder ASSY & Cassette Cover Interlocking Mechanism

Opening the cassette cover pulls up the roller release lever placed in the hooked section of the

cassette cover, which shifts the roller holder release rod so that the roller holder ASSY is retracted

from the head ASSY side by the roller holder release spring.

II-9

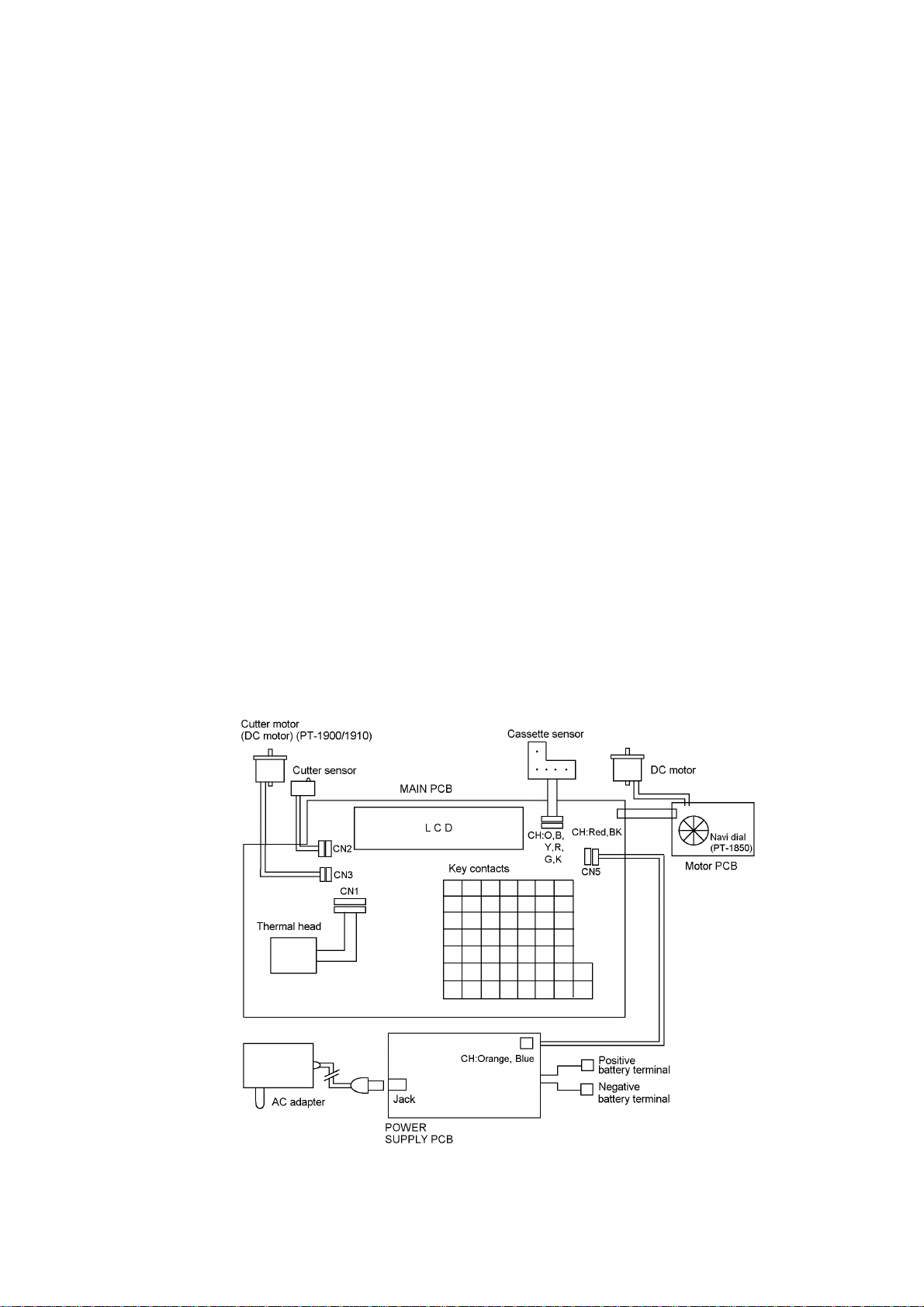

2.2 OUTLINE OF CONTROL ELECTRONICS

2.2.1 Configuration of the Electronic Part

Fig. 2.2-1 shows a block diagram of the control electronics of the PT-1900/1910/1850. The control

electronics consists of three printed circuit boards (main PCB, motor PCB, and power supply

PCB), a tape feed motor, a cutter motor (PT-1900/1910), and a thermal print head assembly.

2.2.2 Main PCB

This manages all the PT-1900/1910/1850 components including an LCD, key pad, two DC motors

(PT-1850: One DC motor), and thermal print head.

Note: When mounting the chips onto the PCB, use the lead-free solder.

2.2.3 Power Supply PCB

This has electrolytic capacitors (as filters for output lines), an AC adapter jack, battery terminal

plates, and other related electronic devices to feed power to the control electronics and the DC

motors from the AC adapter or batteries.

Note: When mounting the chips onto the PCB, use the lead-free solder.

2.2.4 Cassette Sensor

This supports the sensors that detect the tape width and ink ribbon type in the tape cassette.

2.2.5 DC Motors

This machine has two DC motors (PT-1850: One DC motor). One feeds tape and ink ribbon and

the other drives the cutter to cut (PT-1900/1910) the tape.

2.2.6 Thermal Print Head

This is a thick-film thermal print head which integrates a heat generator (consisting of 128 heating

elements vertically aligned) and driver circuitry.

Fig. 2.2-1 Control Electronics of PT-1900/1910/1850

II-10

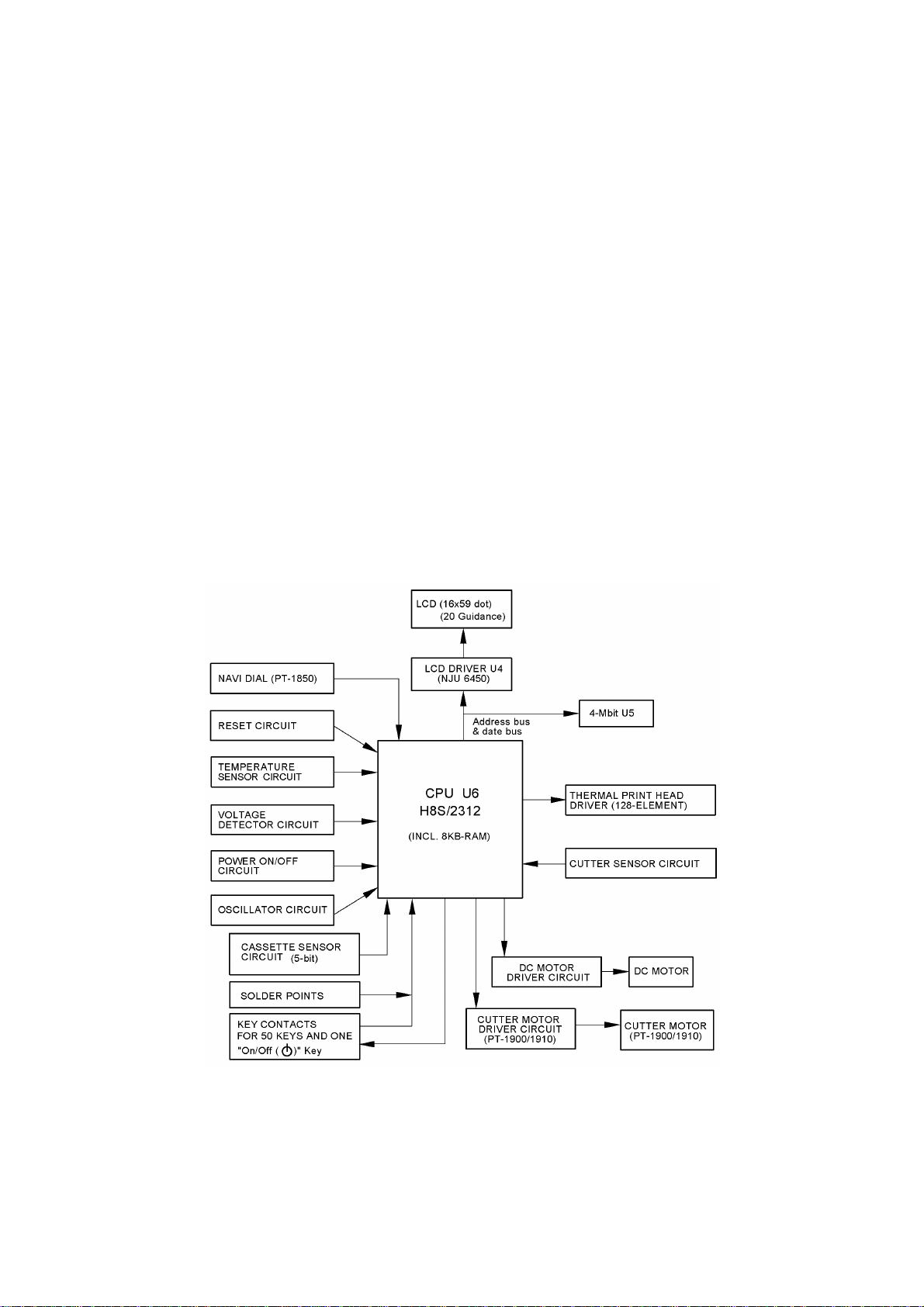

2.3 MAIN PCB

2.3.1 Block Diagram

Fig. 2.3-1 shows a block diagram of the main PCB. The main PCB consists of the following:

(1) CPU

(2) ROM (Masked)

(3) Key contacts matrix and solder points

(4) Power ON/OFF circuit and power saving circuit

(5) DC motor driver circuit

(6) Cutter motor driver circuit (PT-1900/1910)

(7) Thermal head drive circuit

(8) Voltage detector circuit and temperature sensor circuit

(9) Cassette sensor circuit

(10) Cutter sensor circuit

(11) Oscillator circuit

(12) Reset circuit

(13) LCD driver circuit

(14) Navi dial (PT-1850)

Fig. 2.3-1 Block Diagram of Main PCB

II-11

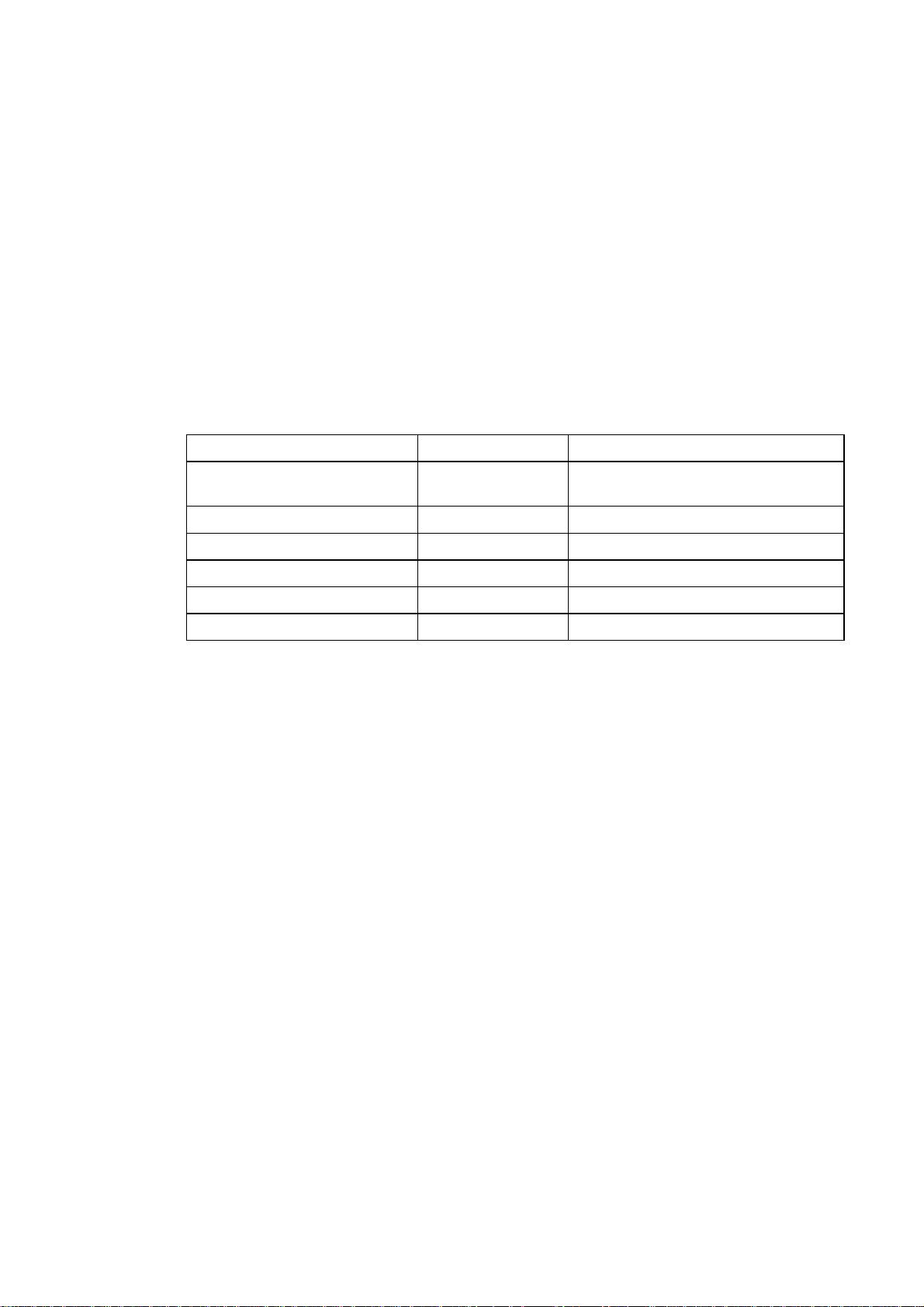

2.3.2 Solder Points

Solder points 1 through 5 customize the machine for the destination. Solder points A through C

are used for the individual thermal head properties.

The CPU reads the solder point status once in the powering-on sequence to recognize the

customization.

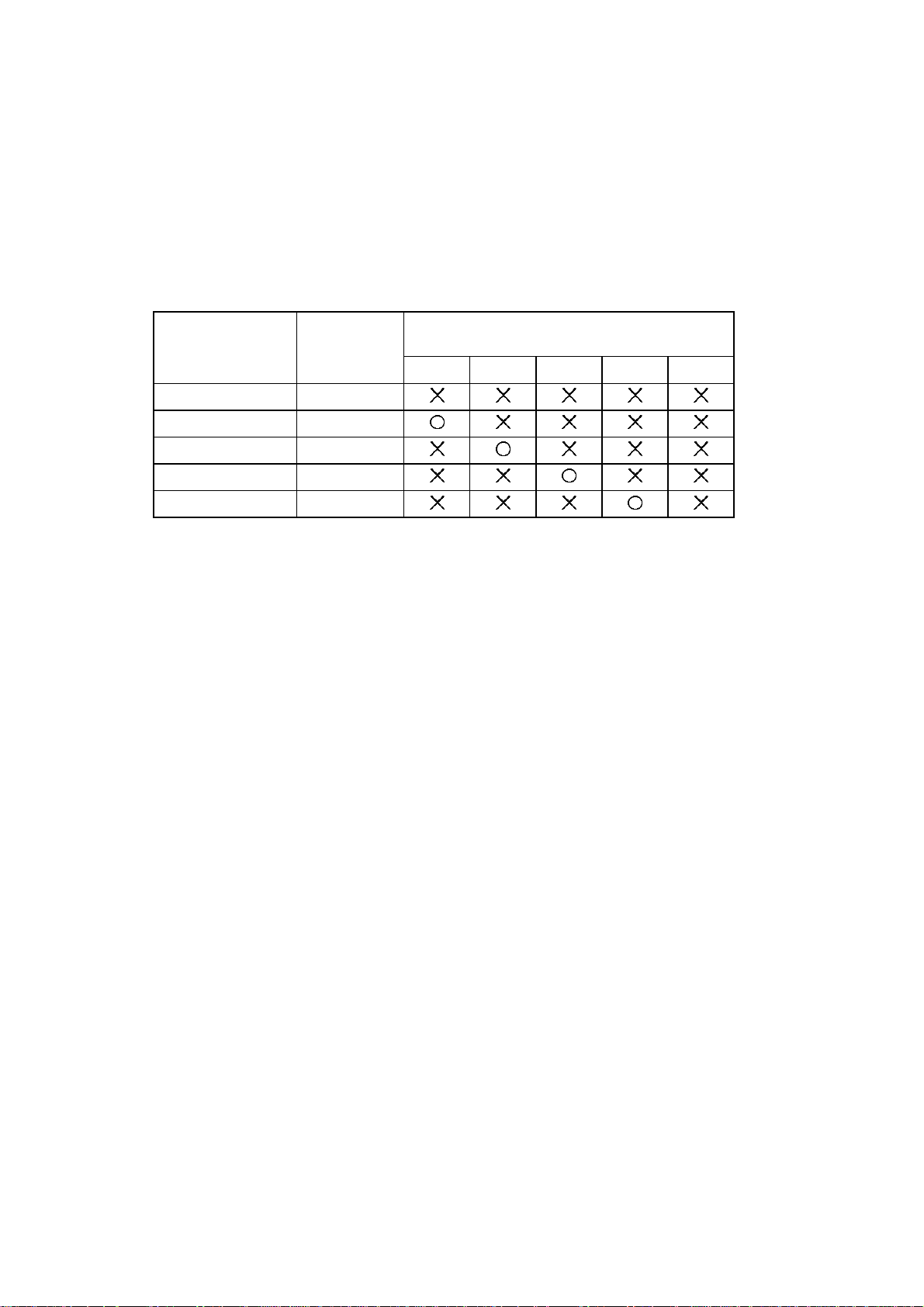

< Country Display >

The country display displays the country specifications as designated by the solder points (1 to 5.)

Country

Specification

U.S.A./CAN/AUS US

U.K. UK

GERMAN GE

FRENCH FR

BELGIUM BE

< Head Rank Display >

The head rank display displays the rank as designated by the solder points (A to C.)

The rank “B” is difined ad the setting for no soldering.

CAUTION: When soldering, use the lead-free solder.

LCD Display Solder Points

1 2 3 4 5

II-12

2.4 POWER SUPPLY PCB

C1 for the logic circuitry and the thermal print head and motor drive sources.

Connecting the AC adapter plug with the AC jack J1 cuts off the power fed from the batteries and

feeds power from the AC adapter.

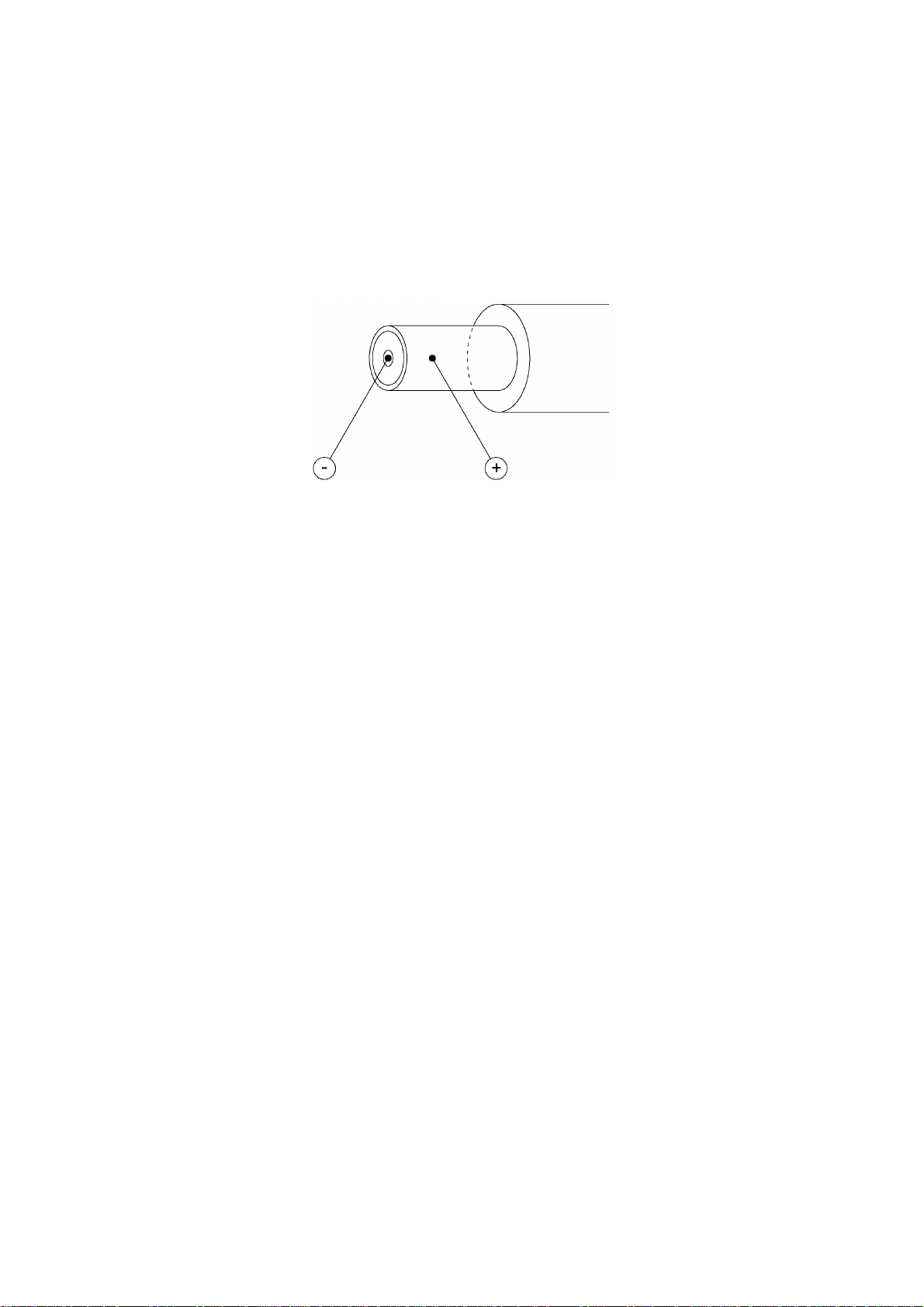

Fig. 2.4-1 hows the polarity of the AC adapter plug.

Fig. 2.4-1 AC Adapter Plug

II-13

CHAPTER III DISASSEMBLY & REASSEMBLY

3.1 DISASSEMBLY PROCEDURE

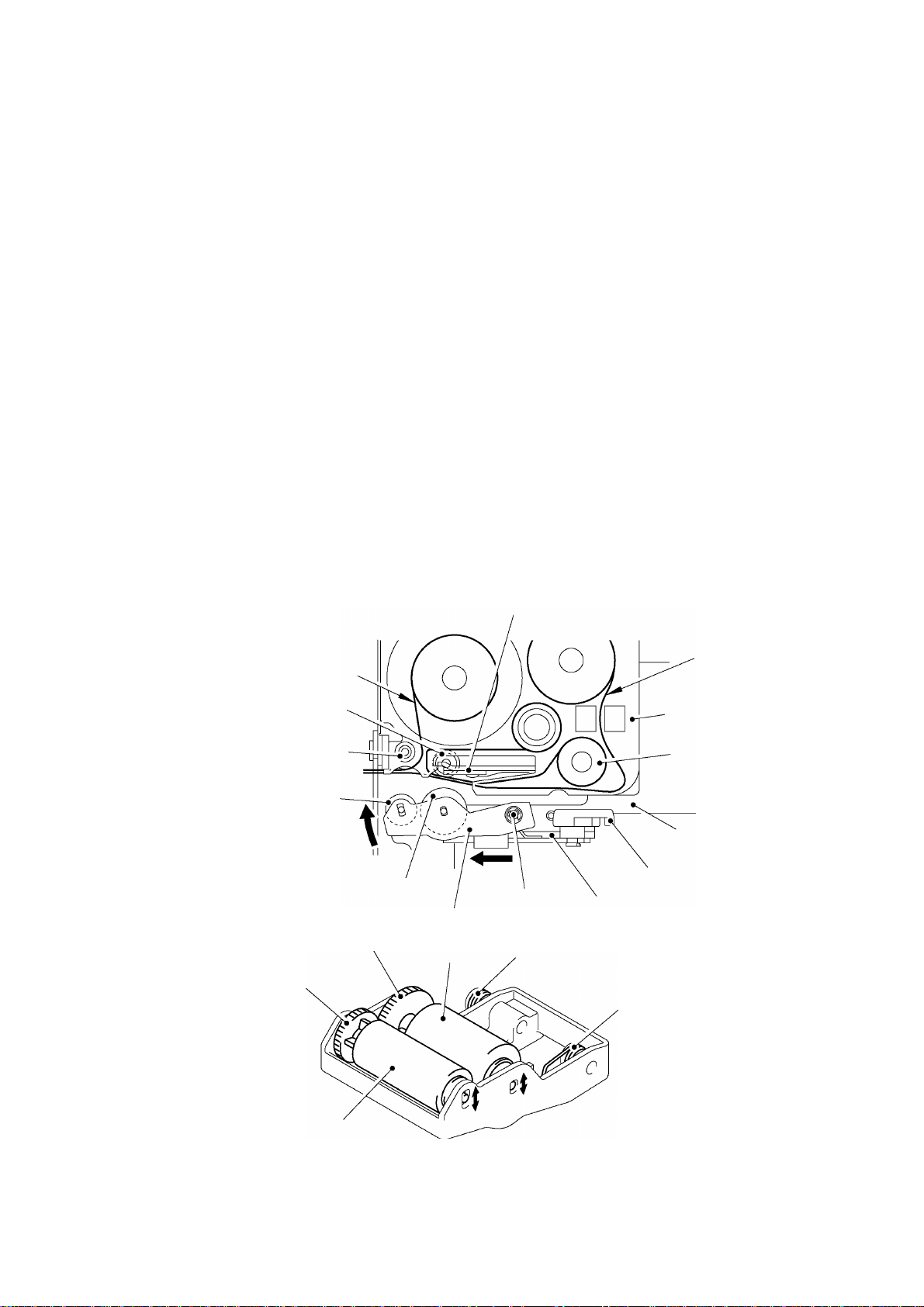

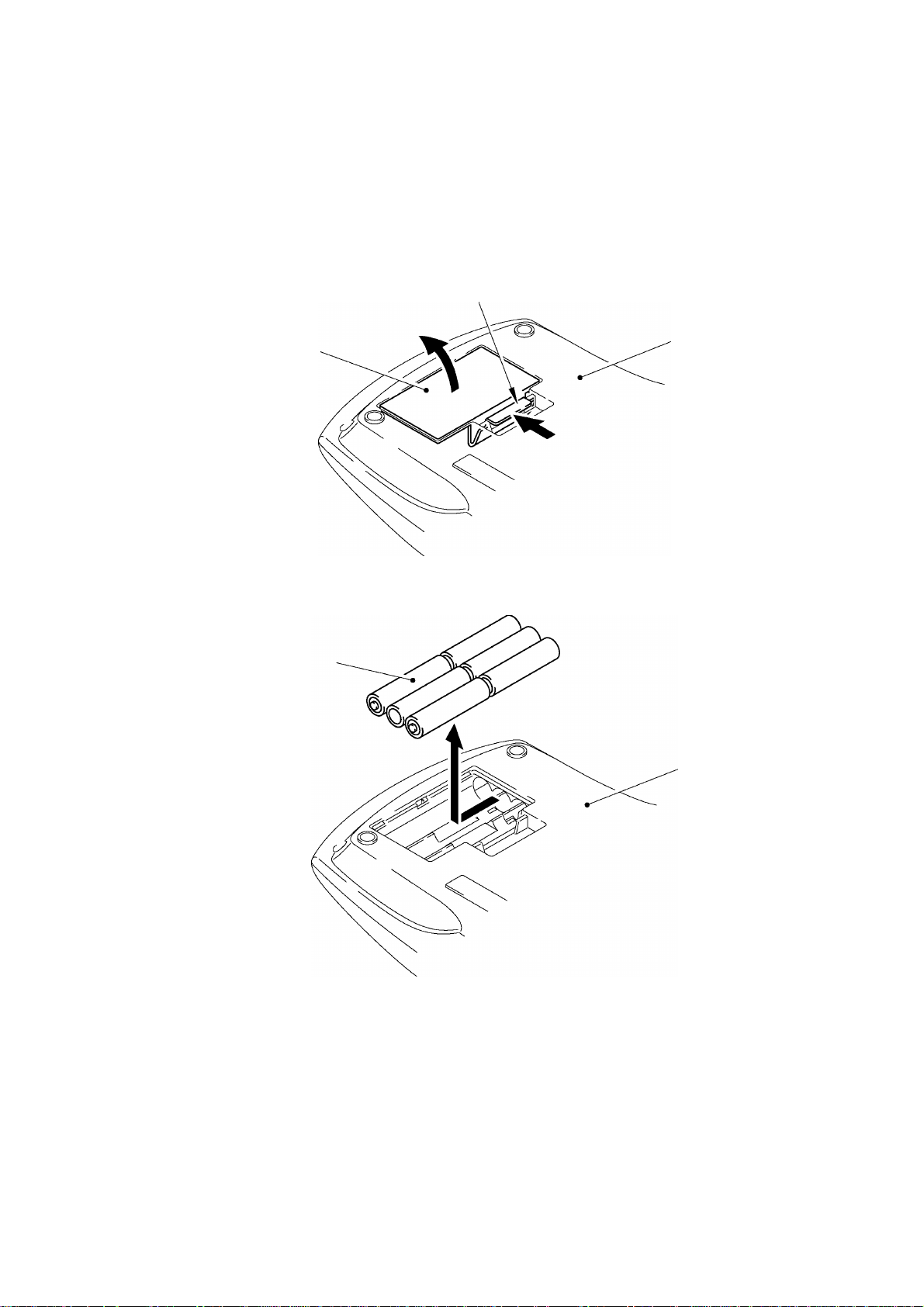

[ 1 ] Removing the Battery Lid and Batteries

(1) Turn the machine upside down.

(2) Press section “A” of the battery lid to remove, then take out batteries.

Section “A”

Battery lid

Batteries

Bottom cover

Bottom cover

Fig. 3.1-1 Removing the Battery Lid and Batteries

III-1

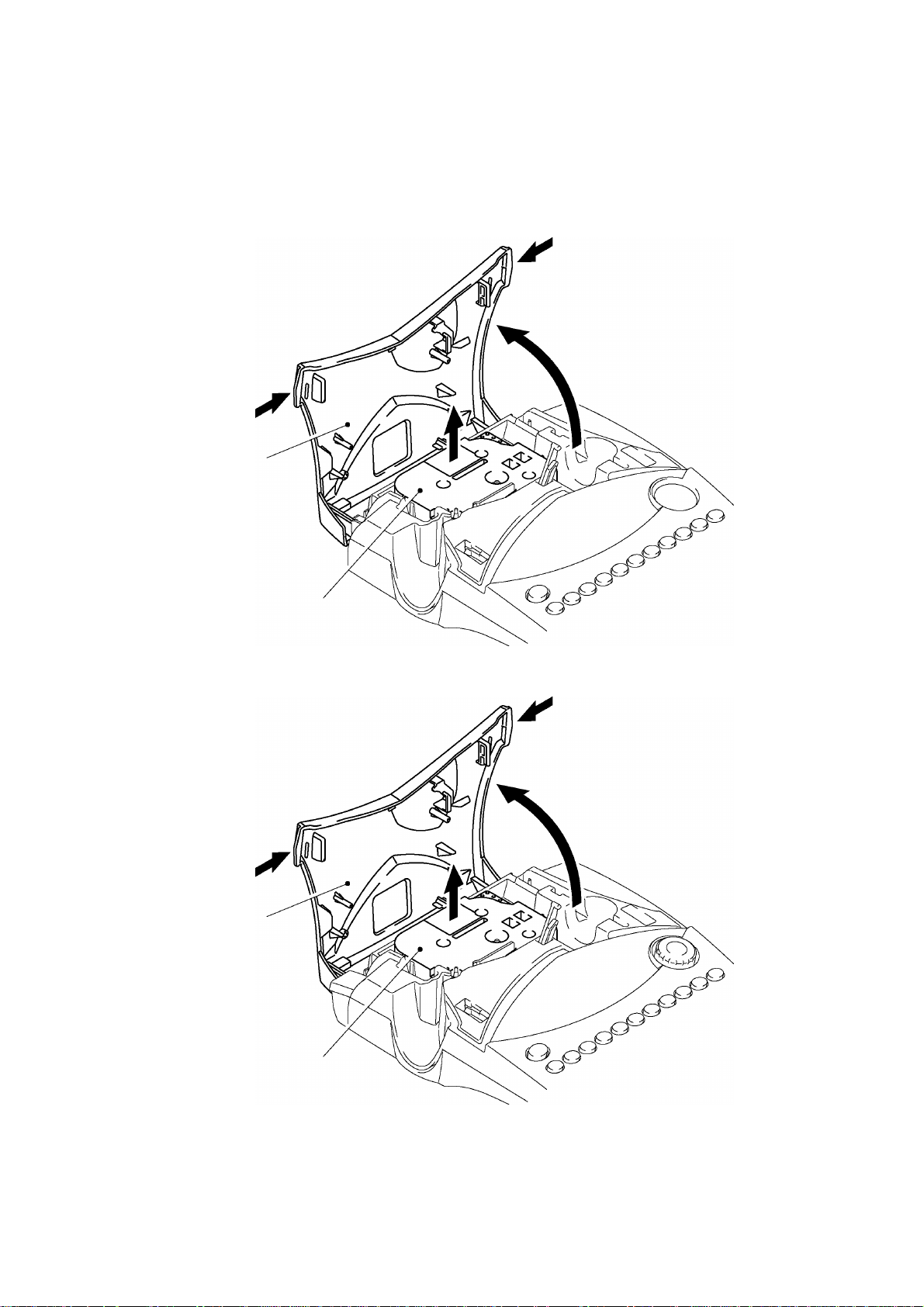

[ 2 ] Removing the Tape Cassette and Tape Separator Stick

(1) Place the machine rightside up and open the cassette cover fully.

(2) Pull the tape cassette up and out of the machine.

(PT-1900/1910)

Cassette cover

(PT-1850)

Cassette cover

Tape cassette

Tape cassette

Fig. 3.1-2 Removing the Tape Cassette

III-2

Loading...

Loading...