Page 1

33

3

33

at brooksinstrument.com/documentation

For these product’s complete instruction manual, please download it

instruction manuals with product shipments to reduce our paper consumption.

In an effort to be more eco-friendly, Brooks is no longer supplying printed

• GT1600 Series

22

2

22

Global HeadquartersGlobal Headquarters

Global Headquarters

Global HeadquartersGlobal Headquarters

Brooks InstrumentBrooks Instrument

Brooks Instrument

Brooks InstrumentBrooks Instrument

407 West Vine Street

Hatfield, PA 19440-0903 USA

Toll-Free (USA): 888-554-FLOW

Tel (215) 362 3700

Fax (215) 362 3745

BrooksAm@BrooksInstrument.com

A list of all Brooks Instrument locations and contact details can be found at

www.BrooksInstrument.com

This Quick Start Guide applies to the following Brooks product(s):

Brooks Instrument

Sincerely,

back cover of this guide.

services, please contact your local Brooks Sales and Service office listed on the

Should you require any additional information concerning Brooks’ products and

application problems just like yours.

your flow measurement or control needs and offer years of experience solving

They have been extensively trained to help you select the optimal solutions for

local Brooks product and application specialist is truly your “partner in flow”.

unsurpassed local technical expertise in virtually every corner of the planet. Your

But Brooks’ products are only half of the story. You are backed by Brooks’

that matters - real users of flow instrumentation, like you.

category for accuracy, reliability and user preference, as judged by the audience

award-winning meters and controllers consistently rank at the top of their

measurement and control needs with a Brooks Instrument device. Brooks’

Thank you for your purchase. We appreciate this opportunity to service your flow

Dear Customer,

QuicQuic

k Start Guidek Start Guide

Quic

k Start Guide

QuicQuic

k Start Guidek Start Guide

High Flow Glass High Flow Glass

High Flow Glass

High Flow Glass High Flow Glass

Flow MetersFlow Meters

Flow Meters

Flow MetersFlow Meters

TT

ube ube

T

ube

TT

ube ube

CAUTION

WARNING

VV

ariable ariable

V

ariable

VV

ariable ariable

!

!

X-VA-GT1600-QS-eng

PN:541B221AAG/A

February

ArAr

eaea

Ar

ea

ArAr

eaea

Read this page before proceeding!

, 2019

Brooks is a trademark of Brooks Instrument, LLC.

All other marks are property of their respective owners.

PN: 541B221AAG/A

Reference: 834z986

© Copyright 2019, Brooks Instrument, LLC,

All rights reserved. Printed in USA.

www.BrooksInstrument.com

www.BrooksInstrument.com

www.BrooksInstrument.com

VV

V

VV

GT1600 Series

ariable ariable

ariable

ariable ariable

ArAr

ea Flowmetersea Flowmeters

Ar

ea Flowmeters

ArAr

ea Flowmetersea Flowmeters

Page 2

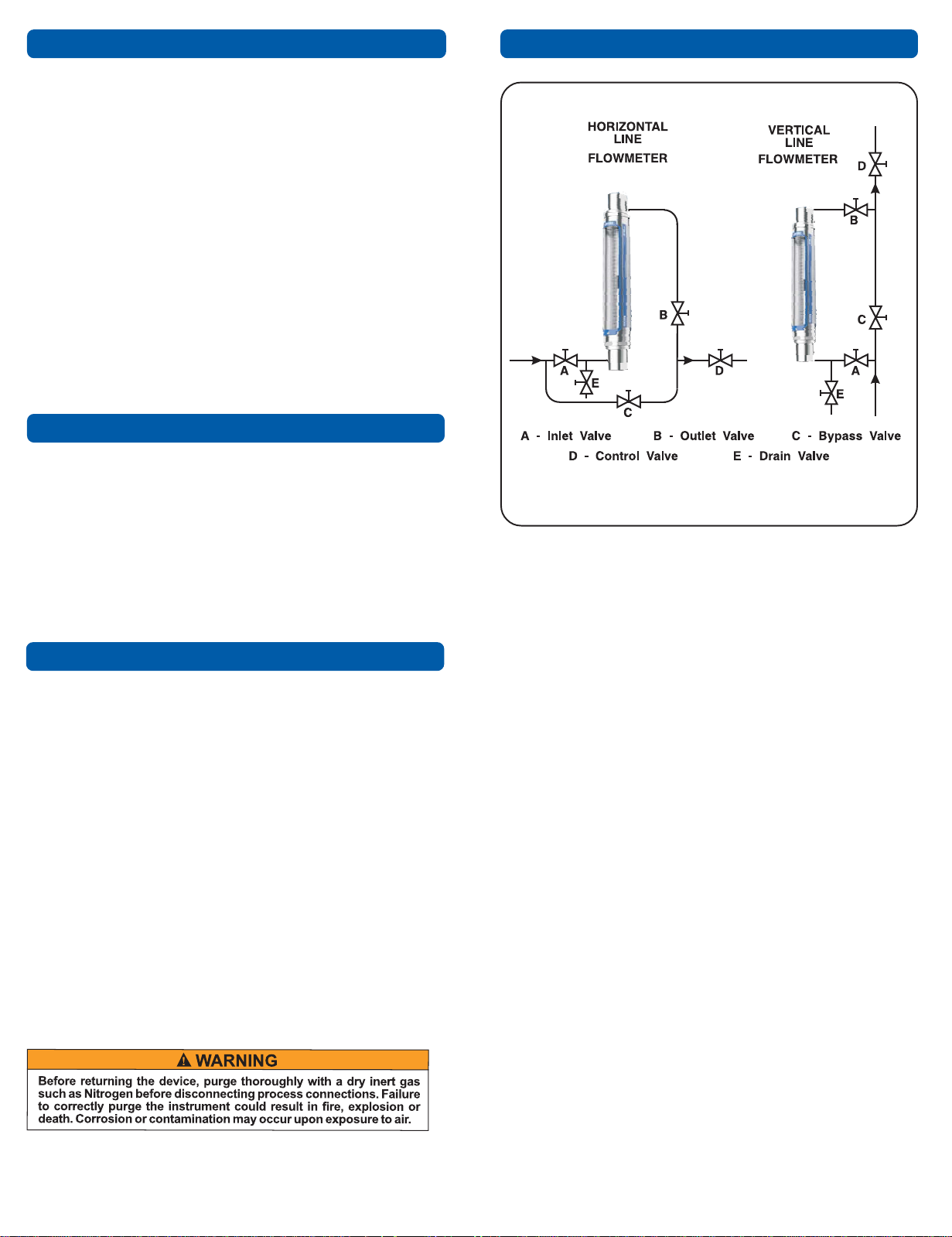

Installation (See Figure 1)Installation (See Figure 1)

Installation (See Figure 1)

Installation (See Figure 1)Installation (See Figure 1)

a. Carefully remove the covers from each end of the flowmeter.

b. Install the flowmeter with the inlet at the bottom and the outlet at

the top.

c. When installing the flowmeter in the process line, follow accepted

plumbing practices for flanged or threaded fittings.

d. Install the flowmeter within 5o of true vertical. Use of a level is

recommended to determine the proper alignment.

e. Installation of a bypass piping arrangement is recommended, see

Figure 1, Typical Flowmeter Installations. Bypass piping permits

the meter to be isolated from the flow for servicing and cleaning.

Pressure Equipment Directive (2014/34/EU)Pressure Equipment Directive (2014/34/EU)

Pressure Equipment Directive (2014/34/EU)

Pressure Equipment Directive (2014/34/EU)Pressure Equipment Directive (2014/34/EU)

Note: Equipment falls under Sound Engineering Practice (SEP)

according to the directive.

It is recommended that a final leak test of the system plumbing and

the meter be performed before subjecting it to the process fluid.

NONO

TE: If the device includes an TE: If the device includes an

NO

TE: If the device includes an

NONO

TE: If the device includes an TE: If the device includes an

instruction manual for prinstruction manual for pr

instruction manual for pr

instruction manual for prinstruction manual for pr

OperationOperation

Operation

OperationOperation

Alarm, please rAlarm, please r

Alarm, please r

Alarm, please rAlarm, please r

oper installation instructions.oper installation instructions.

oper installation instructions.

oper installation instructions.oper installation instructions.

eferefer

ence the completeence the complete

efer

ence the complete

eferefer

ence the completeence the complete

After the flowmeter has been installed in the flow system, it is ready

for operation. An optional built-in needle control valve may be

provided to control the flow through the flowmeter. These control

valves are designed for control. Excessive tightening may damage the

valve seat and limit its effectiveness as a control valve. If tight shut-off

is required, it is recommended that a separate shut-off valve is

installed in the process line immediately before the flowmeter.

InstallationInstallation

Installation

InstallationInstallation

Figure 1 Typical Flowmeter Installation

44

4

44

55

5

55

EquipmenEquipmen

Equipmen

EquipmenEquipmen

Receipt of EquipmenReceipt of Equipmen

Receipt of Equipmen

Receipt of EquipmenReceipt of Equipmen

t Receipt and Return Prt Receipt and Return Pr

t Receipt and Return Pr

t Receipt and Return Prt Receipt and Return Pr

tt

t

tt

ocedurocedur

ocedur

ocedurocedur

eses

es

eses

When the equipment is received, the outside packing case should be

chec

ked for damage incurred during shipment. If the packing case is

damaged, the local carrier should be notified at once regarding his

liability. A report should be submitted to the nearest Brooks Instrument

location listed on the Global Service Network page on our website:

brooksinstrument.com/service-support

Remove the envelope containing the packing list. Carefully remove the

instrumen

t from the packing case. Make sure spare parts are not discarded

with the packing materials. Inspect for damaged or missing parts.

Return ShipmenReturn Shipmen

Return Shipmen

Return ShipmenReturn Shipmen

tt

t

tt

Prior to returning any instrument to the factory for any reason, visit our

website for instructions on how to obtain a Return Materials

Authorization Number (RMA #) and complete a Decontamination Statement to

accompany it: brooksinstrument.com/service-support All instruments

returned to Br

ooks also require a Material Safety Data Sheet (MSDS) for

the fluid(s) used in the instrument. Failure to provide this information

will delay processing of the instrument.

Instrument must have been purged in accordance with the following:

66

6

66

77

7

77

Loading...

Loading...