Page 1

Installation and Operation Manual

X-VA 2500 Series-eng

Part Number: 541B165AAG

May, 2011

Brooks® 2500 Series Flowmeters

Brooks® Models 2510, 2520, 2530

Acrylic block flowmeters are available in various sizes

and ranges, with direct reading scales in both SAE and

SI units for air and water. For other gases or liquids,

special scales can be provided. If you use this meter

with fluids other than air or water, please consult

chemical compatibility data for possible effects on the

meter. These meters are manufactured of durable

acrylic and if properly installed and maintained, will

provide long-term trouble-free operation.

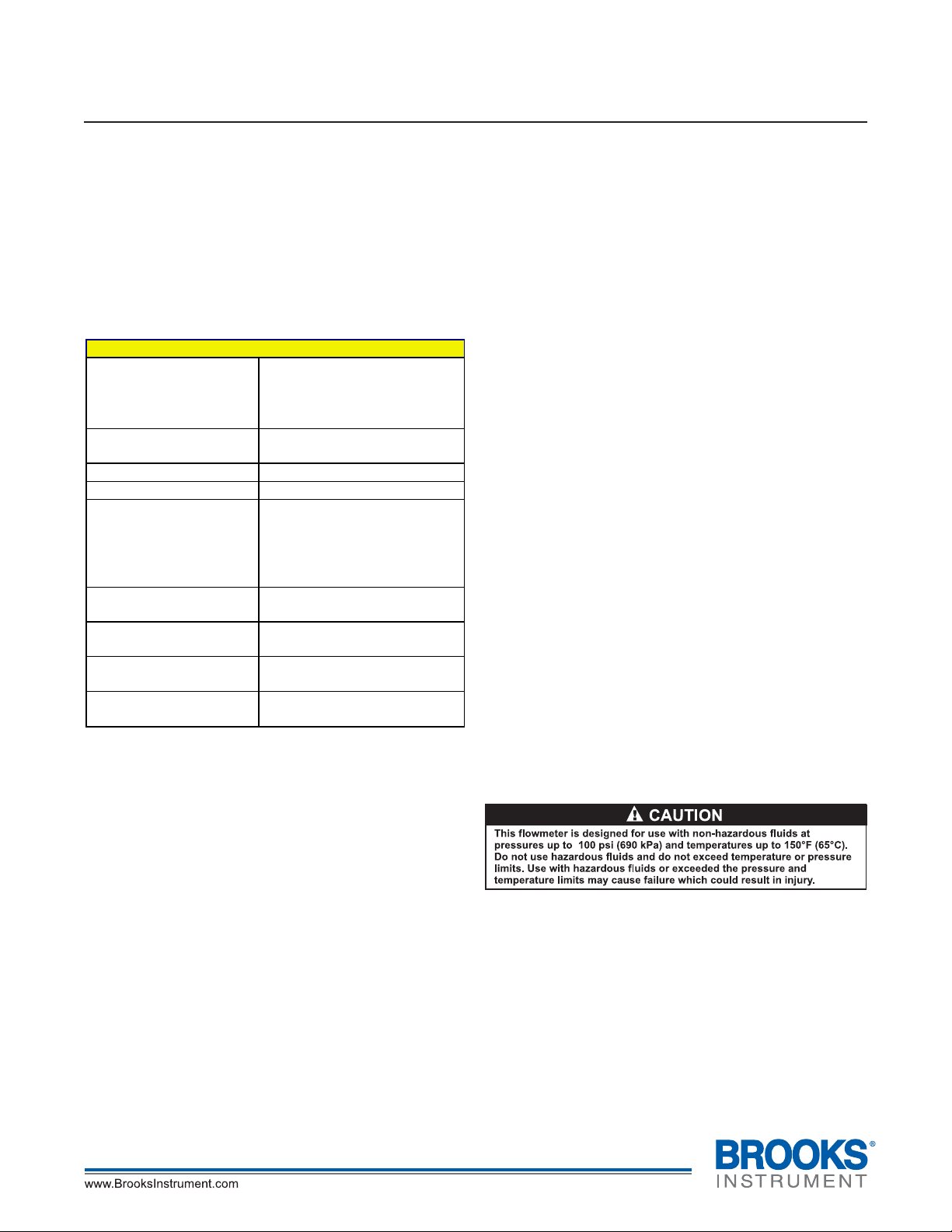

SPECIFICATIONS

2510 Series

ACCURACY:

FLOATS:

METER BODY:

FITTINGS:

ELASTOMERS:

VALVES:

MOUNTING

INSERTS:

MAXIMUM

TEMPERATURE:

MAXIMUM

PRESSURE:

± 5% Full Scale

2520 2530 Series

± 3% Full Scale

Black Glass, Stainless Steel,

Aluminum or Black Delri n

Clear Acrylic

Brass or Stainless Steel

Buna-N with Brass

Viton fluoroelastomers

Brass or Stainless Steel

Cartridge Type (Optional)

10-32 UNF

150°F (65 °C)

100 PSIG (690 kPa)

®

Fittings

O-rings with Stainless

Steel fittings

UNPACKING

Precautions have been taken to prevent any damage

from occurring during shipment. However, if the meter

is received damaged, report it to the carrier

immediately. Before installing, verify that you have the

model and flow range required.

INSTALLATION

These meters are supplied with 5/8" or 7/8" hex's on the

inlet and outlet fittings. When installing 1/8-27 MNPT or

¼-18 MNPT fittings into the meter, place the

appropriate size wrench on the hex to prevent the inlet/

outlet fitting from rotating. Torque only to 60 in-lbs.

Failure to do so will cause the fitting to rotate, and may

damage the meter body, causing leaks and/or meter

failure. Use pipe thread sealant or Teflon® tape to ease

installation and provide a better seal. This meter is

supplied with #10-32 threaded inserts for mounting.

When installing, use slotted screws and torque to a

maximum of 35 in-lbs. Mounting dimensions are shown

in Figure 1.

CLEANING AND DISASSEMBLY

Occasional cleaning may be required if dirt appears in

the flow tube or if float movement becomes restricted.

To clean, remove the top plug and remove the float.

Wash the tapered hole and top plug with a mild liquid

detergent and soft brush. Rinse all parts with clean

water and dry thoroughly with clean air or nitrogen. Do

not use solvents to clean this meter as they will attack

the acrylic and destroy the meter.

REASSEMBLY

Check to make sure that all parts are clean and dry. To

lubricate the O-rings, apply a small amount of

halocarbon grease prior to reassembly. If applicable,

reinstall the rod guide assembly into the flowmeter

body. Make sure the rod guide is seated firmly in the

body of the meter. Reinstall the top plug, making sure

that the rod guide is properly aligned. Tighten top plug

until it's flush with top of acrylic body. Exceeding this

may damage the meter body.

ACHIEVING ACCURATE FLOWRATES

To obtain an accurate flowrate, the float must be read at

the position indicated on the meter. If the meter uses a

ball float, the flowrate is determined by reading the

center of the ball. Additionally, the flowmeter should be

installed in a manner, which minimizes both external

vibrations and internal flow variations. Special care

should be taken so that the connections to the meter's

inlet and outlet fittings do not overly restrict the liquid or

gas flow being metered. This could result in a reduced

flow volume, preventing the meter from reaching its

maximum flowrate. Furthermore, internal pressures

could be affected, which can cause inaccurate flow

readings. On start-up, slowly purge any fluid trapped in

the meter.

Page 2

Brooks® 2500 Series Flowmeters

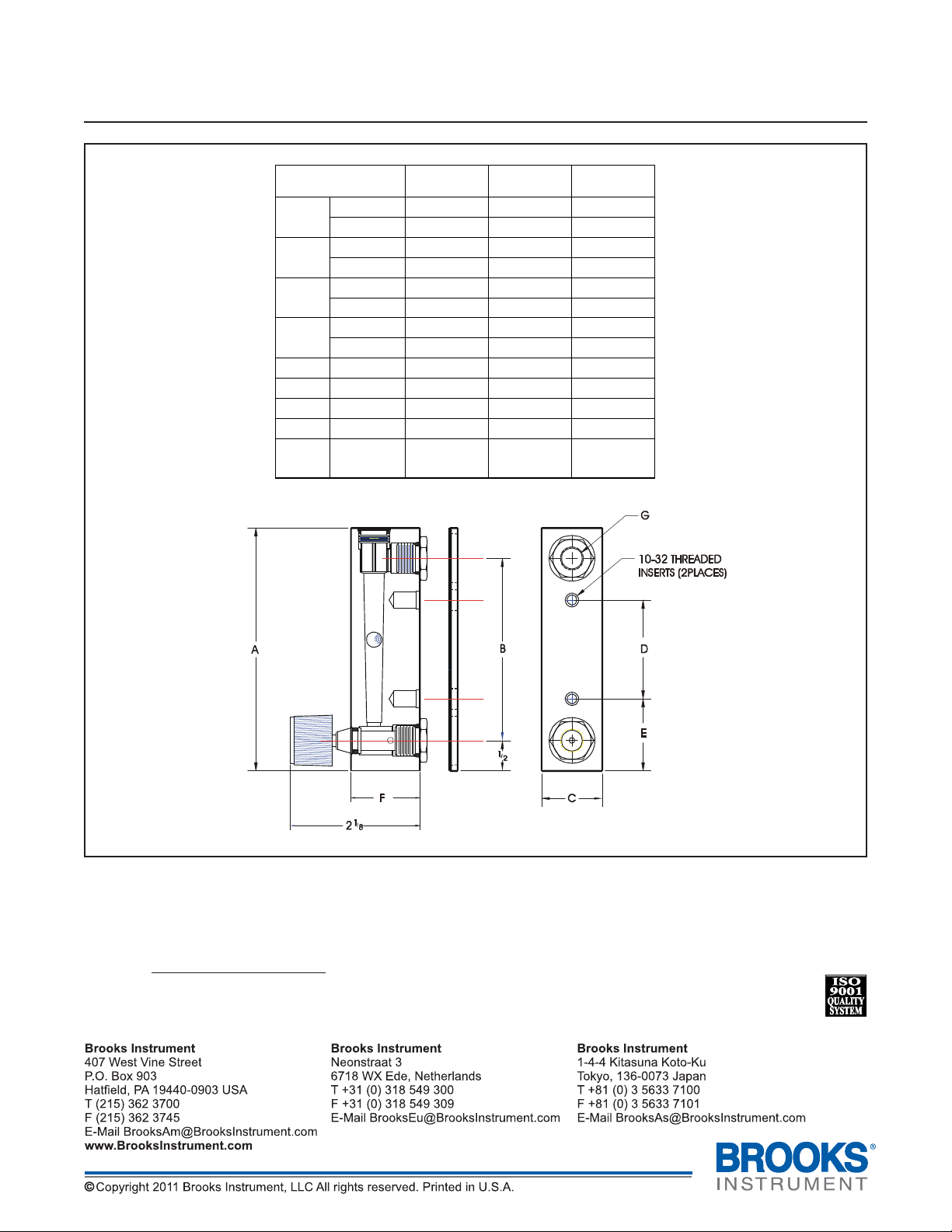

DIMENSIONS 2510 2520 2530

Installation and Operation Manual

X-VA-2500 Series-eng

Part Number: 541B165AAG

May, 2011

A

B

C

D

IN.

mm 102 165 168

IN. 3 5 ½ 5 1/2

mm 76.2 140 140

IN. 1 1 3/8 1 1/8

mm 25.4 34.9 28.6

IN.

mm

E IN.

mm

F IN.

mm

G IN.

4 6 ½ 6 5/8

1 5/8 3 ½ 3 ½

41.3 88.9 88.9

1 3/16 1 1/2 1 1/2

30.2 38.1 38.1

1 1/8 1 1/8 1 3/8

28.6 28.6 34.9

1/8-27

MNPT

1/8-27

MNPT

¼-18

MNPT

Figure 1 Dimensions for Brooks 2500 Series Flowmeters

Due to Brooks Instrument’s continuous improvement of our products, all specifications are subject to change without

notice.

If you have any questions regarding installation, maintenance, replacement or use of this flowmeter, please visit our

website at www.BrooksInstrument.com for Customer Service contact information.

Loading...

Loading...