Page 1

POWER

MODULE

PM250 SERIES

READ AND SAVE THESE INSTRUCTIONS

!

INTENDED FOR DOMESTIC COOKING ONLY

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you

have questions, contact the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel

and lock service panel to prevent power from being switched on

accidentally. When the service disconnecting means cannot be

locked, securely fasten a prominent warning device, such as a tag,

to the service panel.

3. Installation work and electrical wiring must be done by a qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s

guidelines and safety standards such as those published by the National Fire Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on

low or medium settings.

B. Always turn hood ON when cooking at high heat or when flambeing

food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef

Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filter.

D. Use proper pan size. Always use cookware appropriate for the size

of the surface element.

!

!

CAUTION

1. To reduce risk of fire and to properly exhaust air, be sure to duct air

outside. Do not vent exhaust air into spaces within walls or ceilings

or into attics, crawl spaces, or garages.

2. Take care when using cleaning agents or detergents.

3. Avoid using food products that produce flames under the Range

Hood.

4. For general ventilating use only. Do not use to exhaust hazardous

or explosive materials and vapors.

5. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power unit.

6. Your hood motor has a thermal overload which will automatically

shut off the motor if it becomes overheated. The motor will restart

when it cools down. If the motor continues to shut off and restart,

have the hood serviced.

7. For best capture of cooking impurities, the bottom of the hood should

be a minimum of 24" and a maximum of 30" above the cooking

surface.

8. Two installers are recommended.

9. Use with approved cord-connection kit only.

10. Please read specification label on product for further information

and requirements.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent

steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already

know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

Page 2

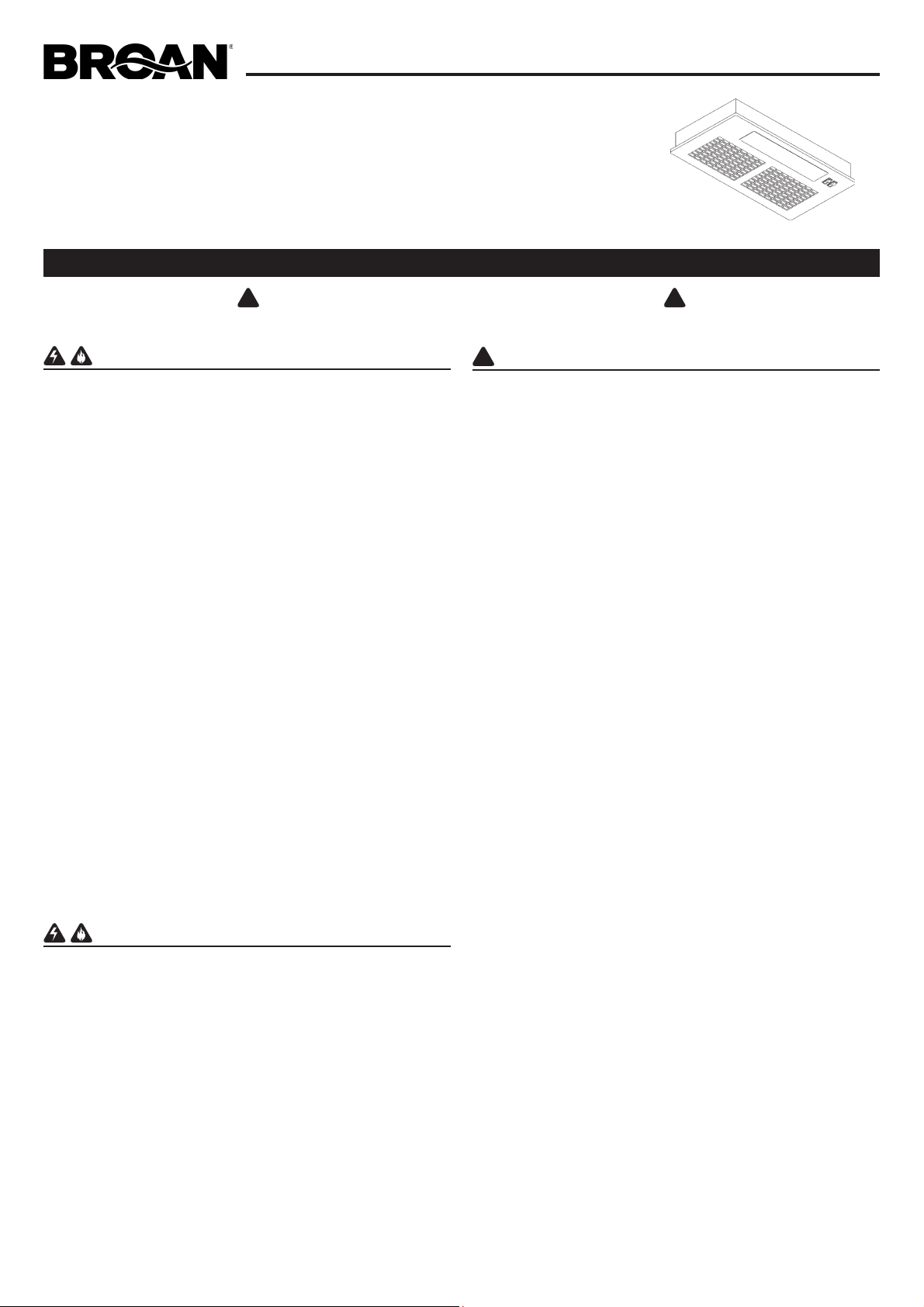

INSTALL THE DUCTWORK

CONNECT DUCTWORK

NOTE: To reduce the risk of fire, use only metal ductwork.

1. Decide where the ductwork will run between the hood and the

outside.

2. A straight, short duct run will allow the hood to perform most

efficiently.

3. Long duct runs, elbows, and transitions will reduce the performance

of the hood. Use as few of them as possible. Larger ducting may

be required for best performance with longer duct runs.

4. Install a roof or wall cap. Connect round metal ductwork to cap

and work back towards hood location. Use duct tape to seal the

joints between ductwork sections.

ROOF CAP

ROUND

DUCT

WALL

CAP

POWER

MODULE

24” TO 30” ABOVE

COOKING SURFACE

7”

ROUND

ELBOW

FIG. 1

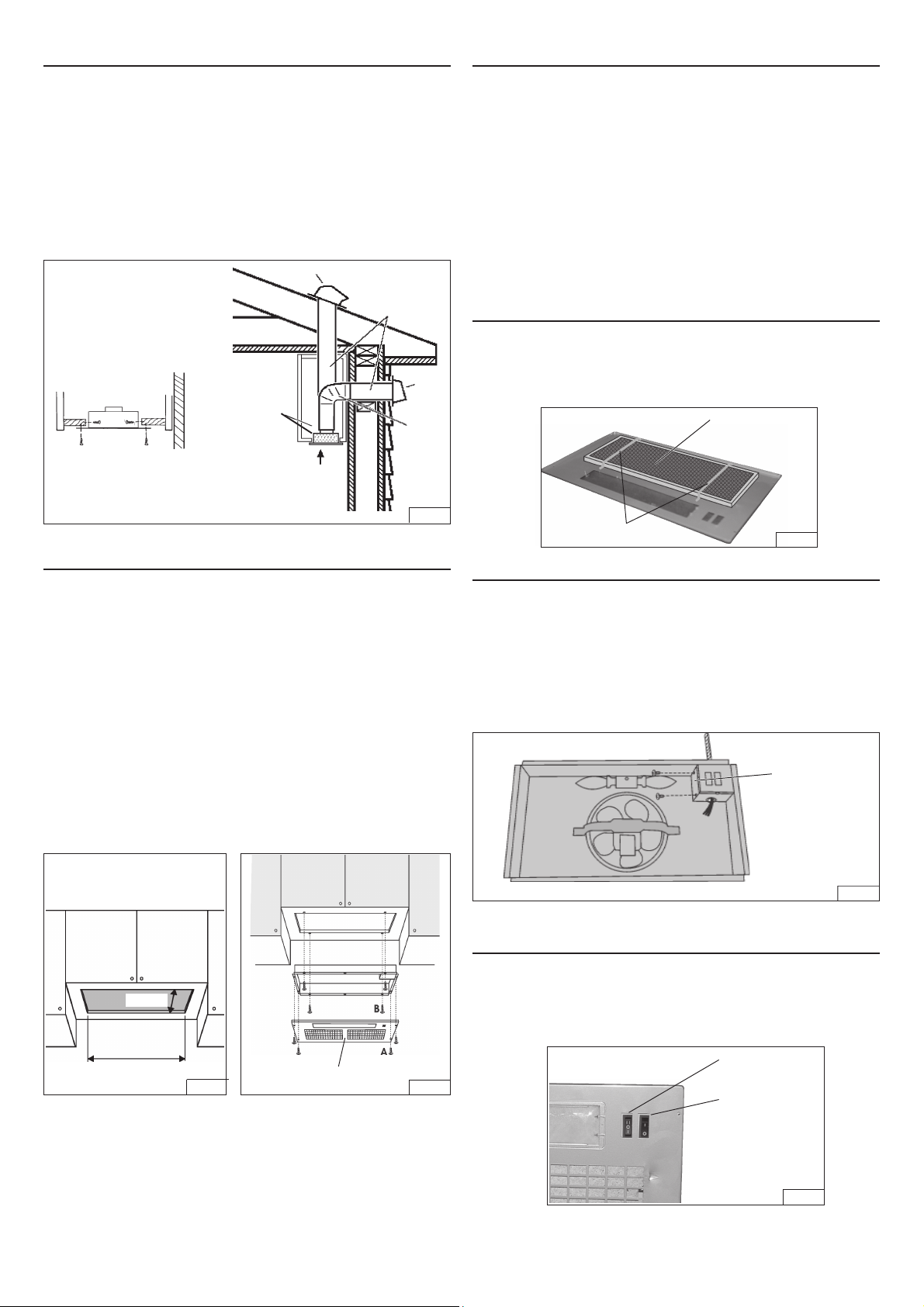

INSTALL THE HOOD

NOTE: the hood has to be installed, inside the cabinet, at minimum

1” from the rear wall cabinet and at 3” from the front wall cabinet.

The internal height of cabinet has to be minimum 16”.

The hood should be mounted centered over the cook top burners.

1. Cut a hole in the bottom of the cabinet, using the dimensions shown

in Fig. 2.

2. Take off the (4) “A” screws and remove the metal grid (Fig. 3).

3. NOTE: For installations where the Power Pack is less than 30”

above cook top, it is recommended that the Power Pack be

mounted into a metal liner or non-combustible material. This will

allow easier cleaning and provide protection to the cabinetry.

4. Insert the hood in the cabinet and secure with the (4) “B” mounting

screws 3.2x13mm (Fig. 3). For alternative side fixing use M4x15mm

screws with washers and nuts.

5. In the Non-Ducted Recirculation Configuration, install the Nonducted recirculation Filter before replacing the grid (see section

“Non-ducted recirculation filter installation”).

6. Replace the grid after wiring is completed.

CUT A HOLE IN THE BOTTOM OF

THE CABINET

Ducted Configuration

1. Use 7" round metal duct to connect the discharge collar on the

hood to the ductwork above. An optional 7” round damper may

be used (purchased seperately).

2. Use duct tape to make all joints secure and air tight.

Non-Ducted Recirculation Configuration

1. Connect a 7” round metal duct to the discharge opening so

that the air is sent outside the cabinet and sent back into the

room.

2. Use duct tape to make all joints secure and air tight.

NON-DUCTED RECIRCULATION FILTER

INSTALLATION

1. Remove the metal wires (Fig. 7) and discard them.

2. Install the Non-ducted recirculation Filter over the grease filter and

secure it with the metal wires supplied with the Non-ducted

recirculation Filter (Fig. 4).

NON-DUCTED

RECIRCULATION

FILTER

METAL WIRES

FIG. 4

WIRING

Note: This range hood must be properly grounded.

The unit should be installed by a qualified electrician in accor-

dance with all applicable national and local electrical codes.

Secure the conduit to the upper wiring hole through a conduit

connector.

Remove the (2) screws of the lateral wiring field cover and make

electrical connections. Connect both white leads to white supply lead

using suitable connector, connect black to black and green to green.

LATERAL

WIRING FIELD

COVER

FIG. 5

10-1/4”

19-1/2”

FIG. 2

GRID

OPERATION

Controls

Light switch: turns the lamps on and off.

Blower switch: makes it possible to select the motor operating speed.

Position 0: motor off; Position I: motor lower speed; Position II: motor

high speed.

BLOWER SWITCH

FIG. 3

LIGHT SWITCH

FIG. 6

Page 3

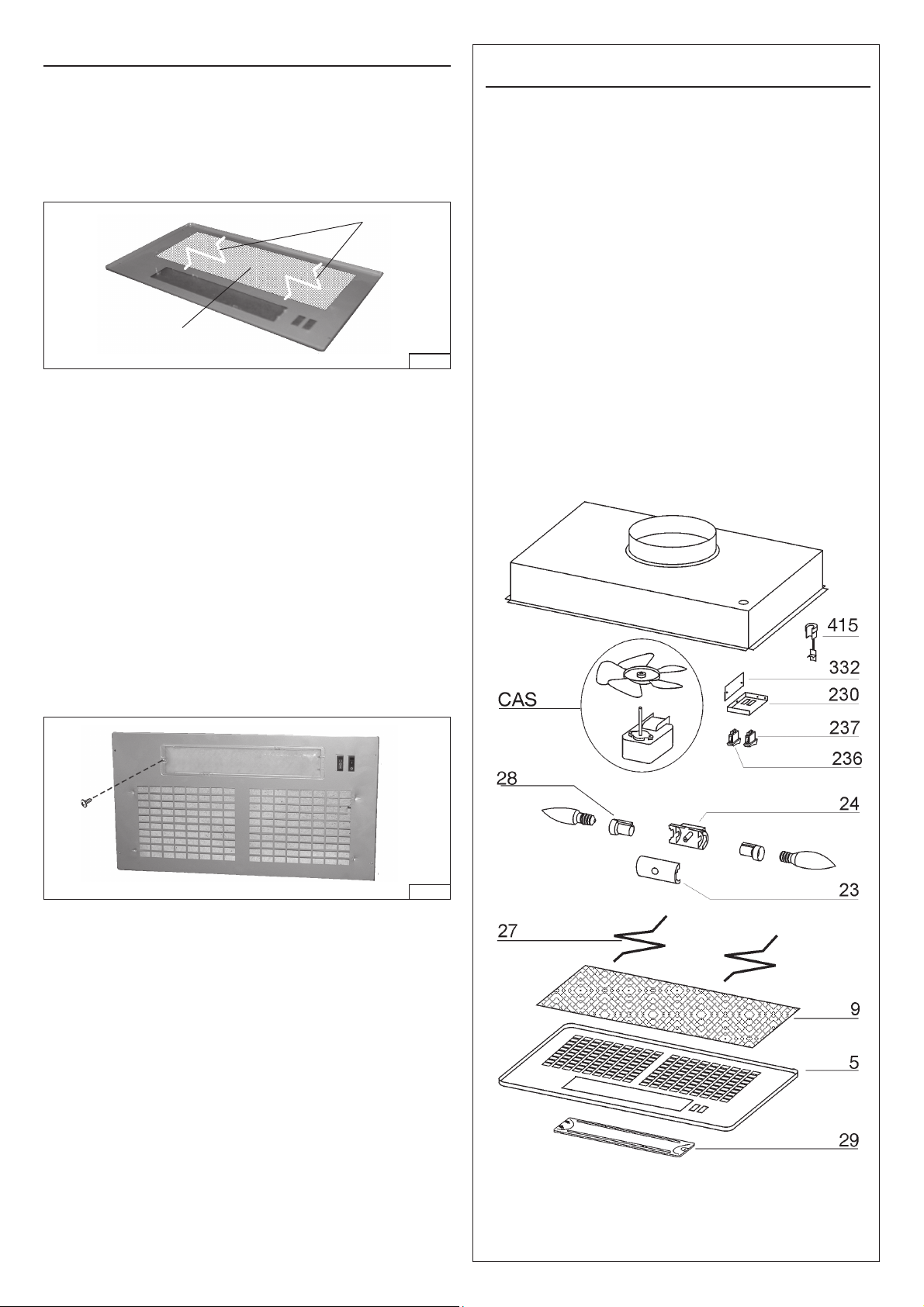

MAINTENANCE

ALWAYS SWITCH OFF THE ELECTRICITY SUPPLY BEFORE

CARRYING OUT ANY OPERATIONS ON THE APPLIANCE.

Grease Filter

The grease filter should be cleaned frequently. Use a warm detergent

solution. Grease filter is dishwasher safe.

To remove the grease filter: remove the (4) screws and take off the

metal grid. Take off the metal wires and remove the grease filter.

METAL WIRES

GREASE

FILTER

Non-Ducted Recirculation Filter

The Non-Ducted Recirculation filter should be changed every 6

months.

To remove the Non-Ducted Recirculation filter:

1. Remove the grid taking off the (4) “A” screws 3.9x6mm (Fig. 3).

2. Remove the metal wires (Fig. 4) and replace the Non-ducted

recirculation Filter.

Cleaning

Occasional care will help preserve its fine appearance.

• Clean with warm water and mild detergent only.

• Follow all cleaning by rinsing with clear water.

• Wipe dry with clean, soft cloth.

Light bulbs

This range hood requires two 40-Watt light bulbs (not included).

To change bulbs:

1. Remove the 2.9x9.5mm screw securing the light fitting.

2. Pull down lens to remove.

3. Replace with light bulbs of the same type (MAX 40W, 120V,

E12, Type B or Type T8 Bulb). CAUTION: BULB MAY BE HOT!

FIG. 7

SERVICE PARTS

KEY NO. PART NO. DESCRIPTION

5 B03118152 Grid (White)

5 B03127681 Grid (Silver)

9 B08087922 Grease Filter

23 B03295095 Upper Lampholder

24 B03295094 Lower Lampholder

27 B02011270 Metal Wire

28 B02300280 Lampholder

29 B03294794 Light Fitting

230 BE3348475 Controls Closing

236 B02300822 Blower Switch (White)

236 B02300826 Blower Switch (Black)

237 B02300823 Light Switch (White)

237 B02300827 Light Switch (Black)

332 BE3248476 Cover Controls

415 B03202454 Strain Relief Bushing

CAS R730090 Blower Assembly

- B06108604 Socket Assembly

(Includes key No.24, 23, 28)

- - “40 Watt Max.Candelabra

Bulbs not included”

- B08999040 Non-Ducted Filter Kit

(purchased separately)

FIG. 8

Page 4

WARRANTY

BROAN-NUTONE LLC ONE YEAR LIMITED WARRANTY

Broan-NuTone LLC warrants to the original consumer purchaser of its products that such products will be free from defects in

materials or workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone LLC will, at its option, repair or replace, without charge, any product or part which is

found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENDT

BULBS. This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject

to misuse, negligence, accident, improper maintenance or repair (other than by Broan-NuTone LLC), faulty installation or installation

contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not

allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE LLC’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE LLC’S OPTION, SHALL BE THE

PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE LLC SHALL NOT BE LIABLE

FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE

OR PERFORMANCE. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty

supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone LLC at the address stated below or telephone: 1-800-637-1453,

(b) give the model number and part identification and (c) describe the nature of any defect in the product or part. At the time of

requesting warranty service, you must present evidence of the original purchase date.

Broan-NuTone LLC. 926 West State Street, Hartford, WI 53027 (1-800-637-1453)

NuTone, Inc., 4820 Red Bank Road, Cincinnati, OH 45227 (1-800-543-8687)

Broan-NuTone Canada, Inc. 1140 Tristar Drive, Mississauga, Ontario, L5T 1H9 (1-888-882-7626)

Page 5

MODULE DE

PUISSANCE

LISEZ ET CONSERVEZ CES INSTRUCTIONS

SERIES PM250

!

SEULEMENT POUR UTILISATION DOMESTIQUE

AVERTISSEMENTS

POUR REDUIRE LES RISQUES D’INCENDIE, DE DECHARGES

ELECTRIQUES OU DE DOMMAGES AUX PERSONNES, OBSERVEZ

LES INSTRUCTIONS SUIVANTES:

1. N’utilisez cet appareil que comme cela est indiqué par le constructeur.

Si vous avez des problèmes, contactez le fabriquant à l’adresse ou

au numéro de téléphone indiqués dans la garantie.

2. Avant de pourvoir à l’entretien ou au nettoyage de votre appareil,

éteignez-le au tableau des commandes ou bloquez le tableau des

commandes afin d’éviter de le mettre en marche accidentellement. Si

vous ne pouvez pas bloquer le système permettant d’éteindre votre

appareil, appliquez un avertissement extérieur d’une façon sure,

comme par exemple un panneau, sur le tableau des commandes.

3. L’assemblage et la connexion électrique doivent être faits par des

personnes qualifiées en respectant les normes et règlements en

vigueur, y compris les normes et règlements concernant les possibilités

d’incendie.

4. Il est indispensable qu’il y ait suffisamment d’air pour que la combustion

et l’évacuation des gaz à travers le tuyau du brûleur du combustible

ait lieu sans retour de flamme. Suivez les indications données par le

fabricant du brûleur ainsi que les normes de sécurité comme celles

qui sont publiées par l’Association Nationale pour la Protection contre

les Incendies National Fire Protection Association (NFPA) et la

American Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), et les autorités locales en matière de normes.

5. Quand vous coupez ou percez des trous dans le mur ou le plafond,

n’abîmez pas les fils électriques ou autres.

6. Le ventilateur canalisé doit toujours évacuer l’air vers l’extérieur.

7. N’utilisez pas cet appareil avec un appareil contrôlant la vitesse à état

solide.

8. Afin de diminuer tout risque d’incendie n’utilisez que des conduits en

métal.

9. Votre appareil doit être relié à la terre.

ATTENTION - POUR REDUIRE LES RISQUES D’INCENDIE DES

MATIERES GRASSES QUI SONT EN TRAIN DE CUIRE:

A. Ne laissez jamais ni vos éléments chauffants, ni vos casseroles ou

poêles sur le feu sans les contrôler si vous réglez l’apport de chaleur

sur une position élevée. Si vos casseroles ou poêles débordent cela

provoque de la vapeur et des éclaboussures de graisse qui peuvent

prendre feu. Chauffez les huiles lentement à feu bas ou moyen.

B. Faites toujours fonctionner votre hotte quand vous cuisez à des

températures élevées ou quand vous cuisinez des plats flambés.

(par ex. crêpes Suzette, Cerises “Jubilé”, Steack au poivre flambé).

C. Nettoyez régulièrement les ailes de vos ventilateurs. Ne permettez

pas que la graisse s’accumule sur le ventilateur ou sur le filtre.

D. Utilisez des casseroles de taille appropriée. Utilisez toujours des

ustensiles de cuisson dont la taille est appropriée à la surface de

votre élément de cuisson.

!

connaissez déjà le mode d’emploi.

B. Ce n’est pas un très gros incendie et qu’il se limite à l’endroi où il

a explosé.

C. Vous êtes en train d’avertir les pompiers.

D. Vous avez la possibilité d’essayer d’éteindre l’incendie en ayant

le dos tourné vers une issue.

* D’après les “Suggestions concernant la Sécurité contre les incendies

des cuisines” publiées par NFPA.

!

ATTENTION

1. Pour réduire tout risque d’incendie et pour évacuer correctement

l’air, assurez-vous de prévoir un conduit de ventilation extérieur.

Ne videz pas l’air dans les espaces limités par des murs ou des

plafonds, les combles, les passages étroits ou les garages.

2. Faites très attention quand vous utilisez des produits de nettoyage

ou des détergents.

3. Évitez d’utiliser des aliments pouvant s’enflammer sous la Range

Hood.

4. N’utilisez cet appareil que pour une ventilation générale. Ne l’utilisez

pas pour évacuer des matières ou des vapeurs dangereuses ou qui

peuvent exploser.

5. Pour éviter de causer des dommages au moteur et de rendre les

rotors bruyants et/ou non équilibrés, évitez que les sprays pour murs

secs, la poussière de construction entrent en contact avec la partie

électrique.

6. Le moteur de votre hotte a un thermostat qui éteindra

automatiquement le moteur s’il est surchauffé. Le moteur se remettra

en marche lorsqu’il se sera refroidi. Si le moteur continue à s’éteindre

et à se remettre en marche, faites vérifier votre hotte.

7. Pour mieux capturer les impuretés de cuisine, le bas de votre hotte

devrait être à une distance minimum de 24” et à une distance

maximum de 30” au-dessus du plan de cuisson.

8. Vu que cette hotte est grande et lourde, il est recommandé de confier

l’installation de cette hotte à deux personnes.

9. Utiliser uniquement avec un kit de connexion pour alimentation

homologué.

10. Nous vous recommandons de lire l’étiquette indiquant les

caractéristiques de votre hotte pour de plus amples informations et

exigences.

AVERTISSEMENTS

POUR REDUIRE LES RISQUES DE DOMMAGES AUX PERSONNES

AU CAS OÙ VOTRE CUISINIERE PRENDRAIT FEU, OBSERVEZ LES

INSTRUCTIONS SUIVANTES:*

1. ETEINDRE LES FLAMMES à l’aide d’un couvercle le plus hermétique

possible, une plaque à gâteaux, ou un plateau en métal, puis éteindre

le brûleur. ATTENTION à NE PAS VOUS BRÛLER. Si les flammes

ne s’éteignent pas immédiatement, SORTEZ ET APPELEZ LES

POMPIERS.

2. NE PRENEZ JAMAIS EN MAIN UNE POÊLE OU UNE CASSEROLE

QUI A PRIS FEU - Vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni torchons ou serviettes mouillés - vous

provoqueriez une violente explosion de vapeur.

4. Utilisez un extincteur SEULEMENT si:

A. Vous savez que vous avez un extincteur Classe ABC, et vous en

Page 6

INSTALLATION DU SYSTEME

D’EVACUATION

REMARQUE: Pour réduire les risques d’incendie, n’utilisez que

des tuyaux en métal.

1. Décidez où le tuyau rond doit être installé, entre votre hotte et

l’extérieur.

2. Un tuyau droit et court permettra à votre hotte de fonctionner d’une

façon plus efficace.

3. Un tuyau long avec des coudes et des transitions réduira le bon

fonctionnement de votre hotte. En utiliser le moins possible. Pour

de longues utilisations, il faut un tuyau d’évacuation d’air ayant un

diamètre plus large.

4. Installez un couvercle sur le toit ou au mur. Reliez un tuyau en

métal rond au couvercle et faites-le aller jusqu’à l’emplacement

de votre hotte. Rendez les jonctions du tuyau hermétiques au

moyen d’un ruban pour tuyaux.

COUVERCLE DU TOIT

MODULE

DE

PUISSANCE

DE 24”(61cm) À 30”

(76cm) AU-DESSUS

DU PLAN DE CUISSON

TUYAU ROND

VERCLE

DU MUR

COUDE

ROND DE 7”

FIG. 1

COU-

INSTALLATION DE LA HOTTE

REMARQUE: la hotte doit être installée à l’intérieur du meuble à 1”

(25.4mm) minimum de la partie postérieur du meuble et à 3” (76.2mm)

de la partie antérieure.

L’hauteur intérieure du meuble doit être de 16” (406.4mm) minimum.

La hotte doit être montée au milieu sur les feues du plan de cuisson.

1. Découpez un trou au fond du meuble en utilisant les dimensions

reportées dans la Fig. 2.

2. Otez les (4) vis “A” et retirez la grille en métal (Fig. 3).

3. REMARQUE : Pour les installations où le module de puissance

se trouve à moins de 30'’ au-dessus du plan de cuisson, il est

recommandé de glisser ce dernier dans une enveloppe

métallique ou dans un corps incombustible. Cette précaution

facilitera le nettoyage et fournira une protection au meuble.

4. Encastrez la hotte dans le meuble et fixez en serrant les (4) vis

de montage “B” 3.2x13mm (Fig. 3). Pour un fixage lateral,

utiliser les vis M4x15mm avec rondelles et écrous.

5. Dans la configuration recyclant l’air, installez le filtre à charbon

avant de reposer la grille (cf. paragrapheInstallation du filtre à

charbon”).

6. Reposez la grille (depuis avoir effectué le raccordement

electrique).

DECOUPEZ UN TROU AU FOND

DU MEUBLE

CONNEXION DU SYSTEME D’EVACUATION

Modèle avec tuyau d’évacuation

1. Reliez le collier d’évacuation qui se trouve sur votre hotte au

système de conduction qui se trouve au-dessus au moyen d’un

tuyau rond en métal de 7”. On peut utiliser une clapêt rounde de

7” (achèté-la séparément).

2. Utilisez un ruban pour tuyauterie afin de rendre toutes les jonctions

sures et étanches.

Modèle recyclant l’air

1. Reliez la bouche d’évacuation de l’air à un tuyau rond en métal

de 7” de sorte que l'air soit convoyé en dehors du placard murale

et renvoyé dans la pièce.

2. Utilisez un ruban pour tuyauterie afin de rendre toutes les jonctions

sures et étanches.

INSTALLATION DU FILTRE A CHARBON

1. Otez les fils métalliques (Fig. 7) et jetez-les.

2. Installez le filtre à charbon sur le filtre à graisse et assujettissezle au moyen des fils métalliques fournis avec le filtre à charbon

(Fig. 4).

FILTRE A CHARBON

FILS METALLIQUES

FIG. 4

INSTALLATION ELECTRIQUE

Remarque: Ce modèle de hotte doit être relié à la terre

correctement.

Cet article devrait être installé par un électricien qualifié selon

les lois nationales et locales en matière d’électricité.

Faire passer le conduit dans l’orifice pour câble superieur à

l’aide d’un raccord de conduit.

Enlever les (2) vis du couvercle latéral de la boîte électrique et faire

le raccordement électrique. Relier ensemble les deux câbles blancs

et les-reliés au câble blanc d’alimentation, à l’aide d’un connecteur

approprié; relier le noir au noir et le vert au vert.

COUVERCLE

LATERAL DE LA

BOITE

ELECTRIQUE

FIG. 5

FONCTIONNEMENT

Commandes

L’interrupteur de la lumière allume et éteint les lampes.

L’interrupteur du moteur permet de sélectionner la vitesse de

marche du moteur. Position 0: moteur éteint; Position I: vitesse

ralentie du moteur; Position II: vitesse élevée du moteur.

10-1/4”

19-1/2”

FIG. 2

GRILLE

FIG. 3

INTERRUPETUR

DU MOTEUR

INTERRUPETUR

DE LA

LUMIERE

FIG. 6

Page 7

ENTRETIEN

TOUJOURS COUPER L’ALIMENTATION ELECTRIQUE AVANT

D’EFFECTUER UNE QUELCONQUE OPERATION SUR L’APPAREIL.

Filtre à graisse

Le filtre à graisse devra être fréquemment nettoyé. Utilisez une

solution détergente chaude. Le filtre à graisse peut être lavé en

machine.

Pour enlever le filtre à graisse retirez les (4) vis et ôtez la grille en

métal. Otez les fils métalliques et enlevez le filtre à graisse.

FILS METALLIQUES

FILTRE A

GRAISSE

Filtre à charbon

Le filtre à charbon sans conduit devra être changé tous les 6

mois.

Pour ôter le filtre à charbon:

1. Otez la grille en enlevant les (4) vis “A” 3.9x6mm (Fig. 3).

2. Otez les fils métalliques (Fig. 4) et remplacez le filtre à charbon.

FIG. 7

LISTE PIECES DE RECHANGE

N. PART N. DESCRIPTION

5 B03118152 Grille (Blanc)

5 B03127681 Grille (Gris)

9 B08087922 Filtre à graisse

23 B03295095 Couvercle supérieure

ampoule

24 B03295094 Couvercle inférieure ampoule

27 B02011270 Fil métallique

28 B02300280 Porte-ampoule

29 B03294794 Plafonnier

230 BE3348475 Fermeture commandes

236 B02300822 Interrupteur Moteur (Blanc)

236 B02300826 Interrupteur Moteur (Noir)

237 B02300823 Interrupteur lumière (Blanc)

237 B02300827 Interrupteur lumière (Noir)

332 BE3248476 Couvercle commandes

415 B03202454 Serre cable

CAS R730090 Ensemble moteur

- B06108604 Ensemble ampoules

(Comprenant N. 24, 23, 28)

- - “Culot 40 Watt Max.

Ampoules non comprises”

- B08999040 Kit pour modèles recyclant l’air

(peut etre achetéz

separemment)

Nettoyage

Un entretien ponctuel contribuera à préserver son aspect.

• Nettoyez à l’eau chaude en prenant soin d’utiliser un détergent

non agressif.

• Faites suivre le nettoyage d’un rinçage à l’eau claire.

• Essuyez avec un chiffon propre et doux.

Ampoules

Ce type de hotte nécessite deux ampoules à 40 watt (non

comprises).

Pour changer les ampoules:

1. Otez la vis 2.9x9.5mm qui retient le dispositif d’éclairage.

2. Retirez les lentilles avant d’enlever l’appareil.

3. Remplacez par des ampoules de même type (MAX 40W, 120V,

E12, Type B ou Type d’ampoule T8). ATTENTION :

L’AMPOULE PEUT ÊTRE CHAUDE.

FIG. 8

Page 8

GARANTIE

GARANTIE BROAN-NUTONE LLC LIMITÉE À UN AN

Broan-NuTone LLC garantit au consommateur-acheteur de ses produits que ces produits seront sans défauts concernant les

matières employées et concernant la fabrication pendant une période d’un an à partir de la date d’achat. IL N’Y A AUCUNE

AUTRE GARANTIE, EXPLICITE OU IMPLICITE, Y COMPRIS, MAIS NON PAS LIMITEE A, LES GARANTIES IMPLICITES OU

CONCERNANT LA CAPACITE COMMERCIALE OU LA CONVENANCE POUR TOUT BUT PARTICULIER. Pendant cette période

d’un an, Broan-NuTone LLC réparera ou remplacera, s’il le jugera nécessaire, gratuitement, tout article ou toute pièce qui

résulteront défectueux à condition qu’ils aient été utilisée et entretenu correctement.

CETTE GARANTIE NE S’ETEND PAS AUX INTERRUPTEURS DES NEON, NEON, LAMPES HALOGENES, AMPOULES

d”ILLUMINATION. Cette garantie ne couvre pas (a) l’entretien normal ni (b) tout article ou toute pièce qui aient subi une utilisation

erronée, une négligence, un accident, un entretien erroné ou une réparation (autre que de la part de Broan-NuTone LLC), une

installation défectueuse ou bien une installation ne respectant pas les instructions d’installation recommandées. La durée de

toute garantie implicite est limitée à un an comme cela est spécifié dans la garantie explicite. Quelques états ne permettent pas

de limites quant à la durée d’une garantie implicite, par conséquent la limitation indiquée ci-dessus peut ne pas vous concerner.

L’OBLIGATION DE REPARER OU DE REMPLACER DE LA PART DE BROAN-NUTONE LLC SERA LE SEUL ET EXCLUSIF

REMEDE DE L’ACHETEUR COUVERT PAR CETTE GARANTIE. BROAN-NUTONE LLC NE SERA PAS RESPONSABLE DES

DOMMAGES ACCIDENTELS, CONSEQUENTIELS OU SPECIAUX DUS A L’UTILISATION DU PRODUIT OU A SA

PERFORMANCE OU EN ETANT LA CONSEQUENCE. Quelques états ne permettent pas l’exclusion ou la limitation des dommages

accidentels ou conséquentiels, par conséquent la limitation indiquée ci-dessus peut ne pas vous concerner.

Cette garantie vous donne des droits légaux spécifiques, et vous pouvez aussi avoir d’autres droits, qui varient d’Etat à Etat.

Cette garantie dépasse toute garantie précédente. Pour avoir droit à la garantie, vous devez (a) avertir la Maison Broan-NuTone

LLC à l’adresse indiquée ci-dessous ou téléphoner : 1-800-637-1453, (b) donner le numéro du modèle et l’identification de la

pièce défectueuse et (c) décrire la nature de tout défaut de l’article ou de la pièce. Au moment où vous demandez le service de

garantie, vous devez présenter la preuve d’achat avec la date.

Broan-NuTone LLC. 926 West State Street, Hartford, WI 53027 (1-800-637-1453)

NuTone, Inc., 4820 Red Bank Road, Cincinnati, OH 45227 (1-800-543-8687)

Broan-NuTone Canada, Inc. 1140 Tristar Drive, Mississauga, Ontario, L5T 1H9 (1-888-882-7626)

99043829B

04307531/3

Loading...

Loading...