Page 1

POWER

MODULE

REGISTER YOUR PRODUCT ONLINE AT www.broan.com/register

READ AND SAVE THESE INSTRUCTIONS

INTENDED FOR DOMESTIC COOKING ONLY

PM250 SERIES

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you

have questions, contact the manufacturer at the address or telephone

number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and

lock service panel to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment manufacturer’s guidelines

and safety standards such as those published by the National Fire

Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local

code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on low

or medium settings.

B. Always turn hood ON when cooking at high heat or when flambeing

food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filter.

D. Use proper pan size. Always use cookware appropriate for the size of

the surface element.

CAUTION

1. For indoor use only.

2. To reduce risk of fire and to properly exhaust air, be sure to duct air

outside. Do not vent exhaust air into spaces within walls or ceilings

or into attics, crawl spaces, or garages.

3. Take care when using cleaning agents or detergents.

4. Avoid using food products that produce flames under the Range Hood.

5. For general ventilating use only. Do not use to exhaust hazardous or

explosive materials and vapors.

6. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power unit.

7. Your hood motor has a thermal overload which will automatically shut

off the motor if it becomes overheated. The motor will restart when

it cools down. If the motor continues to shut off and restart, have the

hood serviced.

8. The bottom of the hood MUST NOT BE LESS than 24” and

recommended at a maximum of 30” above the cooktop for best capture

of cooking impurities.

9. Two installers are recommended.

10. Use with approved cord-connection kit only.

11. Please read specification label on product for further information and

requirements.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF

A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray,

then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the

flames do not go out immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent

steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already

know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

Page 2

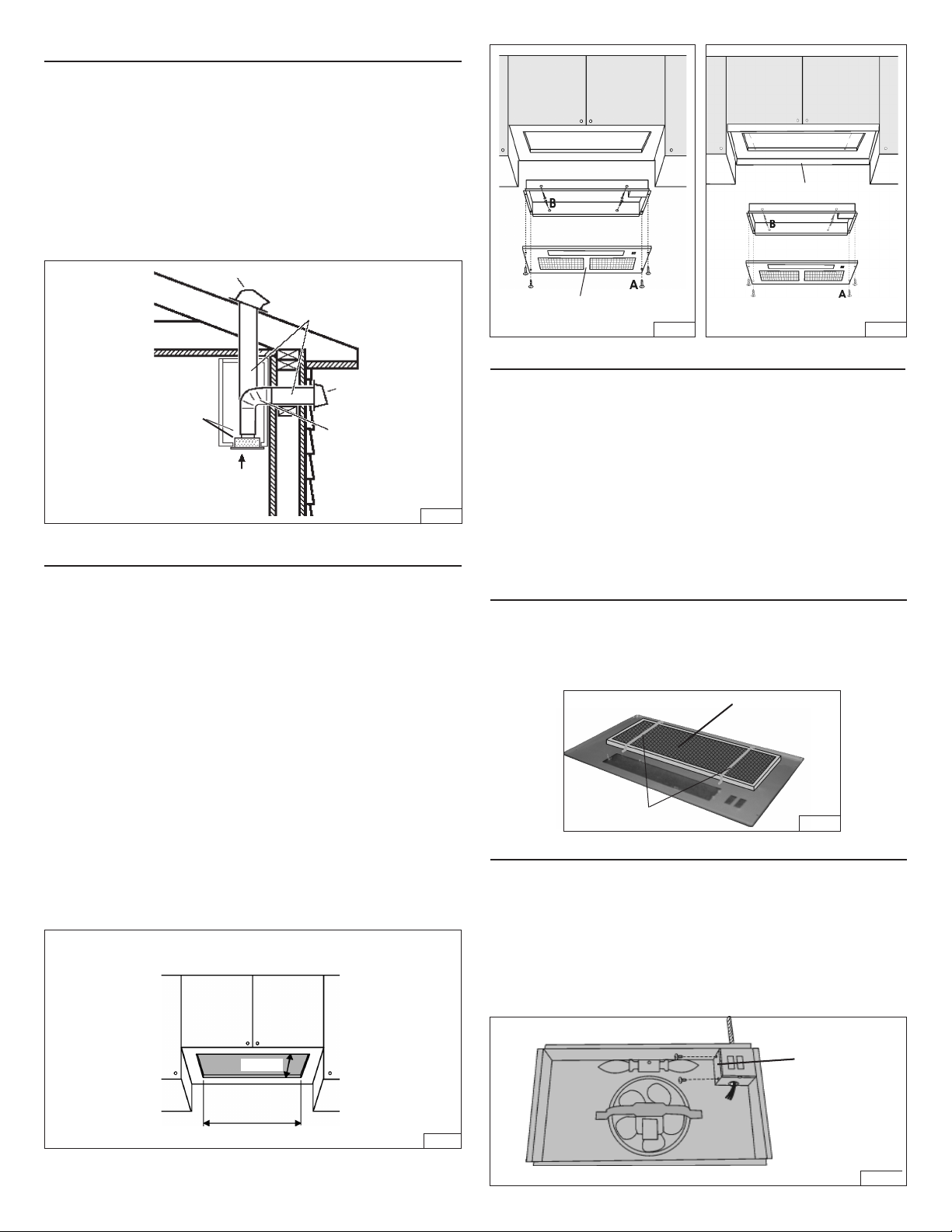

INSTALL THE DUCTWORK

NOTE: To reduce the risk of fire, use only metal ductwork.

1. Decide where the ductwork will run between the hood and the

outside (Refer to Figure 1).

2. A straight, short duct run will allow the hood to perform most

efficiently.

3. Long duct runs, elbows, and transitions will reduce the performance

of the hood. Use as few of them as possible. Larger ducting may

be required for best performance with longer duct runs.

4. Install a roof or wall cap. Connect round metal ductwork to cap and

work back towards hood location. Use duct tape to seal the joints

between ductwork sections.

ROOF CAP

ROUND

DUCT

WALL

CAP

POWER

MODULE

24” TO 30” ABOVE

COOKING SURFACE

7”

ROUND

ELBOW

FIG. 1

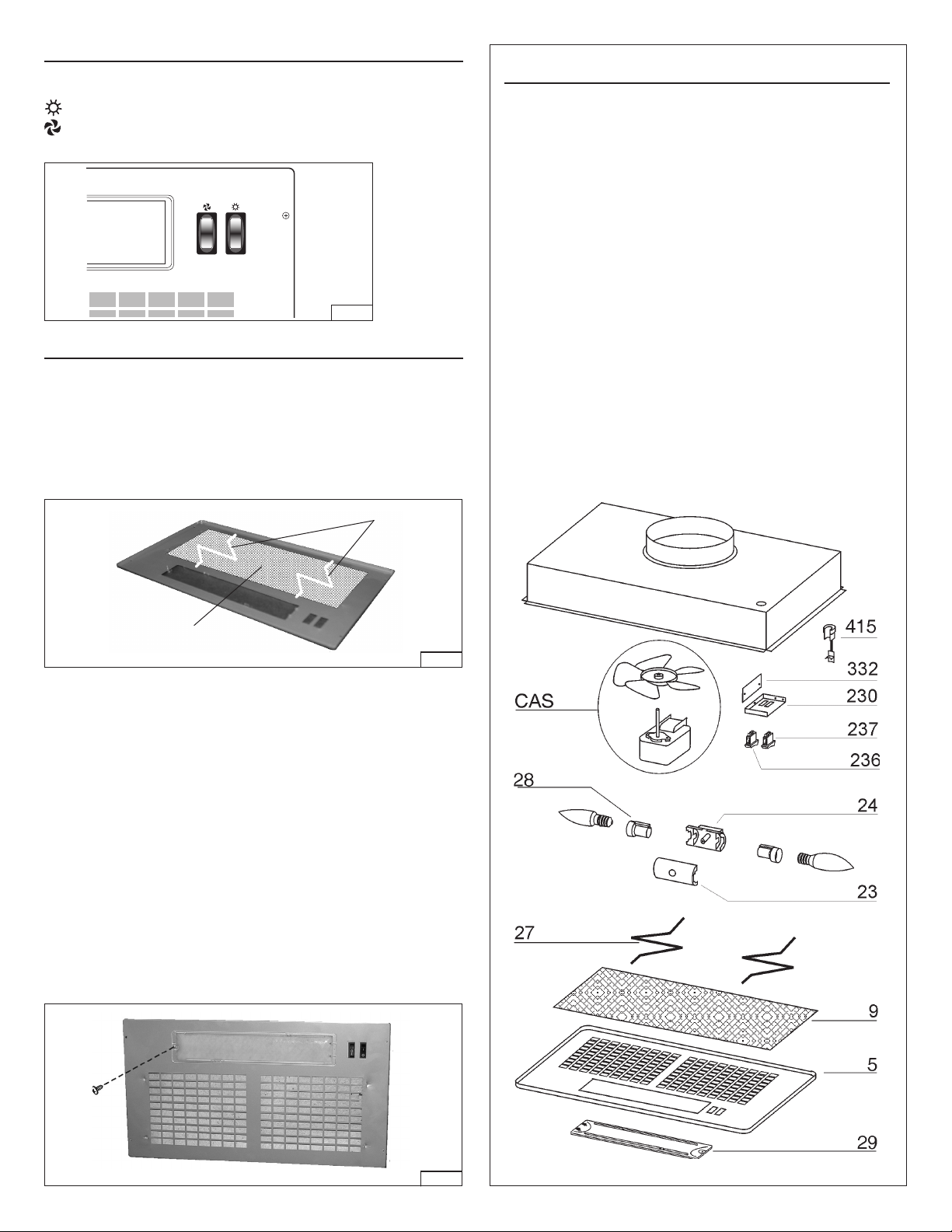

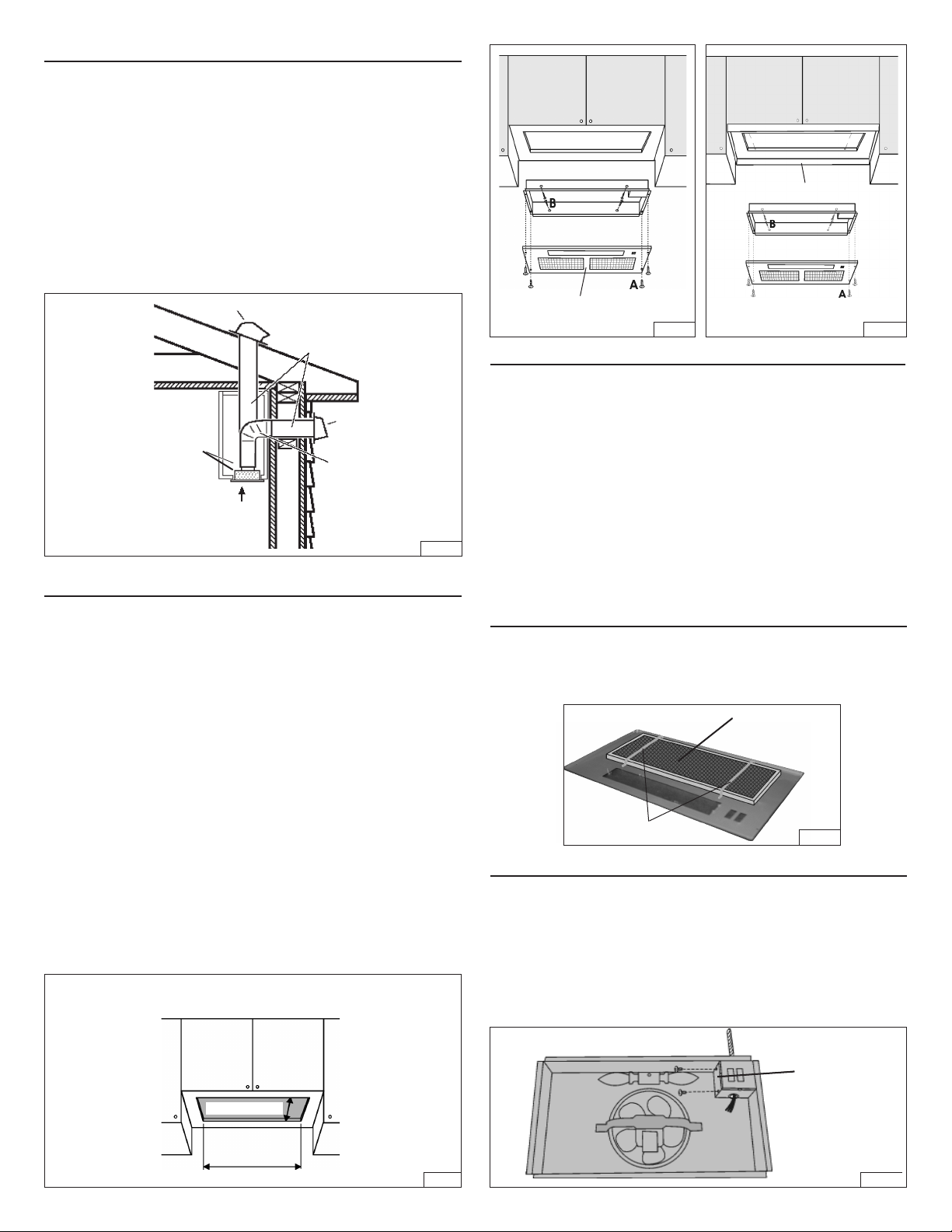

INSTALL THE HOOD

NOTE: the hood has to be installed, inside the cabinet, at minimum 1”

from the rear wall cabinet and at 3” from the front wall cabinet.

The internal height of cabinet has to be minimum 16”.

The hood should be mounted centered over the cook top burners.

1. Cut a hole in the bottom of the cabinet, using the dimensions shown

in Fig. 2.

2. Take off the (4) “A” screws and remove the metal grid (Fig. 3).

3. NOTE: For installations where the Power Pack is less than 30” above

cook top, it is recommended that the Power Pack be mounted into

a metal liner or non-combustible material. This will allow easier

cleaning and provide protection to the cabinetry (Fig.3A).

4. Insert the hood in the cabinet (Fig. 3) or metal liner (Fig. 3A) and

secure with the (4) “B” mounting sheet metal screws.

(Fig. 3 - wood bottom installation; recommended thickness 1/2”-

3/4”).

(For alternate mounting, use machine screws with washers and

nuts. This alternate mounting method needs to be done prior to

installation of metal liner).

5. In the Non-Ducted Recirculation Configuration, install the Nonducted recirculation Filter before replacing the grid (see section

“Non-ducted recirculation filter installation”).

6. Replace the grid after wiring is completed.

CUT A HOLE IN THE BOTTOM OF THE CABINET

METAL LINER

GRID

FIG. 3

FIG.3A

CONNECT DUCTWORK

Ducted Configuration

1. Use 7” round metal duct to connect the discharge collar on the

hood to the ductwork above. An optional 7” round damper may be

used (purchased seperately).

2. Use duct tape to make all joints secure and air tight.

Non-Ducted Recirculation Configuration

1. Connect a 7” round metal duct to the discharge opening so that

the air is sent outside the cabinet and sent back into the room.

2. Use duct tape to make all joints secure and air tight.

NON-DUCTED RECIRCULATION

FILTER INSTALLATION

1. Remove the metal wires (Fig. 7) and discard them.

2. Install the Non-ducted recirculation Filter over the grease filter

and secure it with the metal wires supplied with the Non-ducted

recirculation Filter (Fig. 4).

NON-DUCTED

RECIRCULATION

FILTER

METAL WIRES

FIG. 4

WIRING

Note: This range hood must be properly grounded.

The unit should be installed by a qualified electrician in

accordance with all applicable national and local electrical codes.

Secure the conduit to the upper wiring hole through a conduit

connector.

Remove the (2) screws of the lateral wiring field cover and make

electrical connections. Connect both white leads to white supply lead

using suitable connector, connect black to black and green to green.

10-1/4”

19-1/2”

LATERAL

WIRING FIELD

COVER

FIG. 2

FIG. 5

Page 3

OPERATION

ON

OFF

HI

LO

OFF

Controls

Light switch: turns the lamps on and off.

Blower switch: makes it possible to select the motor operating

speed.

FIG. 6

MAINTENANCE

ALWAYS SWITCH OFF THE ELECTRICITY SUPPLY BEFORE CARRYING

OUT ANY OPERATIONS ON THE APPLIANCE.

Grease Filter

The grease filter should be cleaned frequently. Use a warm detergent

solution. Grease filter is dishwasher safe.

To remove the grease filter: remove the (4) screws and take off the

metal grid. Take off the metal wires and remove the grease filter.

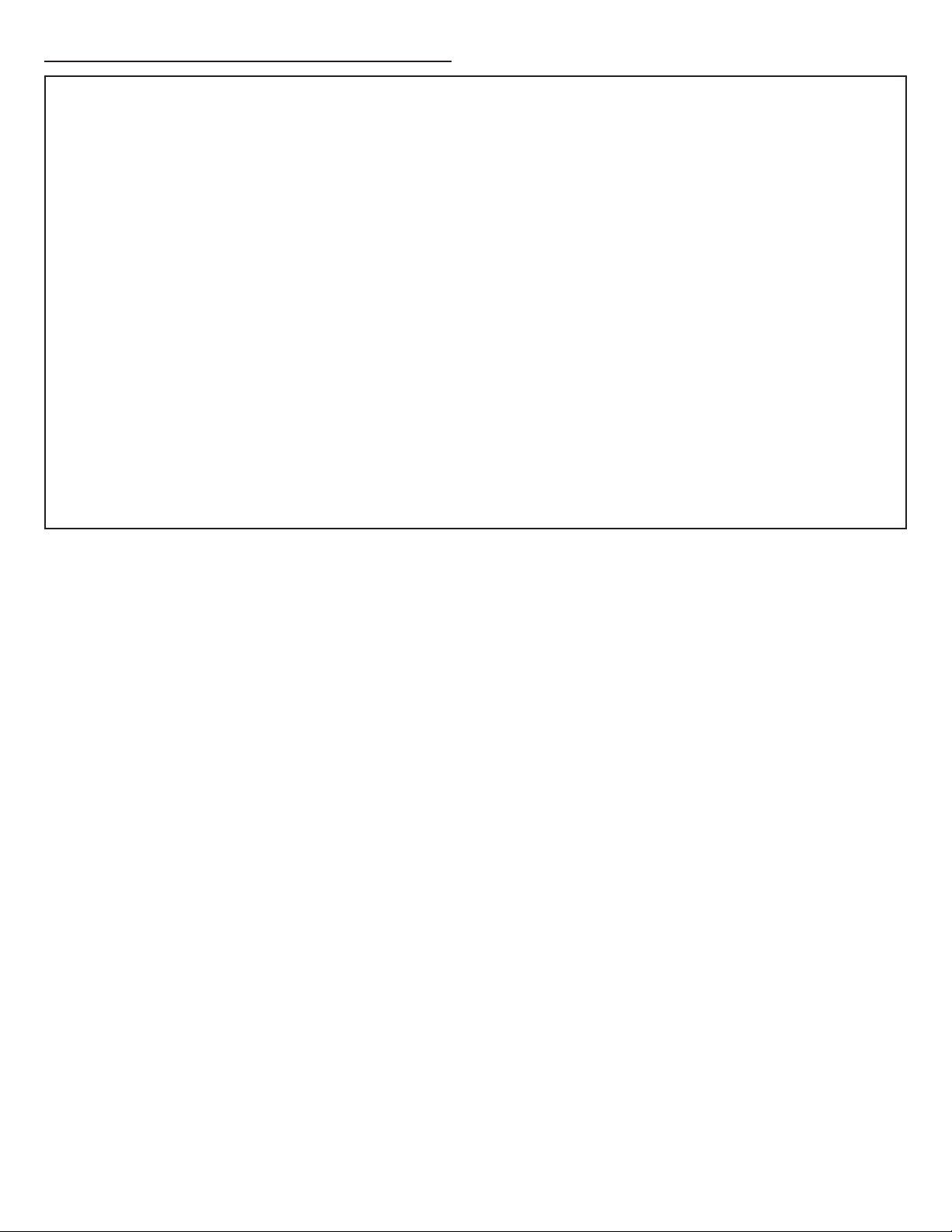

SERVICE PARTS

KEY NO. PART NO. DESCRIPTION

5 97018550 Grid (Silver)

9 99010370 Grease Filter

23 B03295095 Upper Lampholder

24 B03295094 Lower Lampholder

27 98010831 Metal Wire

28 B02300280 Lampholder

29 B03294757 Light Fitting

230 98010828 Controls Closing

236 99030347 Blower Switch (Black)

237 99030342 Light Switch (Black)

332 98010834 Cover Controls

415 99400048 Strain Relief Bushing

Not shown 97018559 Hardware Package

CAS R730090 Blower Assembly

- 97018557 Socket Assembly

(Includes key No.24, 23, 28)

- - “40 Watt Max.Candelabra

Bulbs not included”

- B08999040 Non-Ducted Filter Kit

(purchased separately)

METAL WIRES

GREASE

FILTER

FIG. 7

Non-Ducted Recirculation Filter

The Non-Ducted Recirculation filter should be changed every 6 months.

To remove the Non-Ducted Recirculation filter:

1. Remove the grid taking off the (4) “A” screws 3.9x6mm (Fig. 3).

2. Remove the metal wires (Fig. 4) and replace the Non-ducted

recirculation Filter.

Cleaning

Occasional care will help preserve its fine appearance.

• Clean with warm water and mild detergent only.

• Follow all cleaning by rinsing with clear water.

• Wipe dry with clean, soft cloth.

Light bulbs

This range hood requires two 40-Watt light bulbs (not included).

To change bulbs:

1. Remove the 2.9x9.5mm screw securing the light fitting.

2. Pull down lens to remove.

3. Replace with light bulbs of the same type (MAX 40W, 120V,

Candelabra Base Bulb). CAUTION: BULB MAY BE HOT!

FIG. 8

Page 4

WARRANTY

BROAN-NUTONE LLC ONE YEAR LIMITED WARRANTY

Broan-NuTone LLC (Broan-NuTone) warrants to the original consumer purchaser of Broan products that such products will be free from

defects in materials or workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS FOR

A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is found to be

defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENT BULBS,

FUSE, FILTERS, DUCTS, ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a)

normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not allow

limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE

AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty supersedes

all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address stated below or telephone number stated below, (b) give

the model number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty service, you must present evidence of the original purchase date.

In USA - Broan-NuTone LLC, 926 West State St., Hartford, WI, 53027 www.broan.com (800-558-1711)

In CANADA - Broan-NuTone Canada, 1140 Tristar Dr., Mississauga, ON, L5T 1H9 www.broan.ca (1-877-896-1119)

99044715C

Page 5

MODULE DE HOTTE

ENCASTRABLE

ENREGISTREZ VOS PRODUITS EN LIGNE À www.broan.com/register

LISEZ ET CONSERVEZ CES INSTRUCTIONS

POUR UTILISATION DOMESTIQUE SEULEMENT

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, D’ÉLECTROCUTION

OU DE BLESSURES CORPORELLES, OBSERVEZ LES INSTRUCTIONS

SUIVANTES :

1. N’utilisez cet appareil que de la façon prévue par le constructeur.

Si vous avez des problèmes, contactez le fabriquant à l’adresse ou au

numéro de téléphone indiqués dans la garantie.

2. Avant de nettoyer ou de réparer l’appareil, coupez le courant au

panneau d’alimentation et verrouillez-en l’accès afin d’éviter sa remise

en marche accidentelle. Si le panneau d’alimentation ne peut être

verrouillé, apposez un avertissement bien en évidence, par exemple

une étiquette de couleur vive.

3. Les travaux d’installation et de raccordement électrique doivent

être effectués par du personnel qualifié en respectant les normes et

règlements en vigueur, y compris les normes et codes de bâtiment en

matière de prévention d’incendie.

4. Une circulation d’air efficace est requise afin d’assurer la combustion

et l’évacuation complète des gaz par la cheminée des équipements à

combustion pour prévenir les retours de cheminée. Conformez-vous

aux instructions et aux standards de sécurité des manufacturiers

d’équipement de chauffage, tels qu’ils sont publiés par la National

Fire Protection Association (NFPA) et l’American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE) ainsi que les

responsables des codes locaux.

5. Lorsque vous coupez ou perforez un mur ou un plafond, prenez garde

de ne pas endommager les fils électriques ou autre installation qui

pourraient y être dissimulés.

6. Les conduits de l’installation doivent toujours évacuer l’air à l’extérieur.

7. N’utilisez pas cet appareil avec une autre commande de vitesse à

semi-conducteur.

8. Pour réduire les risques d’incendie, n’utilisez que des conduits en métal.

9. Cet appareil doit être relié à une mise à la terre.

POUR RÉDUIRE LES RISQUES DE FEU DE CUISINIÈRE :

A. Ne laissez jamais les appareils de cuisson sans surveillance lorsqu’ils

sont réglés à feu vif. Les débordements engendrent de la fumée et

des déversements graisseux pouvant s’enflammer. Chauffez l’huile

lentement, à feu doux ou moyen.

B. Mettez toujours le module en marche lorsque vous cuisinez à feu vif ou

que vous cuisinez des mets flambés (par ex. : crêpes Suzette, cerises

jubilé, steak au poivre flambé).

C. Nettoyez régulièrement les pales du ventilateur. Ne laissez pas la

graisse s’accumuler sur le ventilateur ou le filtre.

D. Utilisez le bon format de casserole. Servez-vous toujours d’ustensiles

de cuisson appropriés à la dimension de la surface chauffante.

4. Utilisez un extincteur SEULEMENT LORSQUE :

A. Vous savez qu’il s’agit d’un extincteur de classe ABC et que vous

en connaissez le fonctionnement.

B. L’incendie est petit et limité à l’endroit où il a débuté.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en ayant accès à une sortie

de secours.

* Tirées du Kitchen Fire Safety Tips publié par la NFPA.

ATTENTION

1. Pour usage intérieur seulement.

2. Afin de réduire les risques d’incendie et d’évacuer correctement l’air,

assurez-vous d’évacuer l’air à l’extérieur. N’évacuez pas l’air dans

des espaces clos comme l’intérieur des murs ou d’un plafond, dans

le grenier, faux-plafond ou garage.

3. Faites très attention lors de l’utilisation de produits nettoyants ou

de détergents.

4. Évitez d’utiliser sous le module des produits alimentaires pouvant

s’enflammer.

5. N’utilisez cet appareil que pour une ventilation générale. Ne l’utilisez

pas pour évacuer des matières ou des vapeurs dangereuses

ou explosives.

6. Pour éviter de causer des dommages au moteur et de rendre les

rotors bruyants et/ou déséquilibrés, gardez votre appareil à l’abri

poussières de gypse et de construction ou de rénovation, etc.

7. Le moteur de votre module possède une protection thermique

qui l’arrêtera automatiquement s’il surchauffe. Il redémarrera

automatiquement une fois refroidi. Si le moteur continue de s’éteindre

et de remettre en marche, faites vérifier votre module.

8. Le fond de la hotte DOIT PAS ÊTRE inférieure à 24 “et a recommandé

à un maximum de 30” au dessus de la table de cuisson pour mieux

capturer les impuretés de cuisine.

9. Il est recommandé de confier l’installation de ce module à deux

personnes.

10. Ce module ne doit être utilisé qu’avec un ensemble de cordon

d’alimentation approuvé.

11. Nous vous recommandons de lire l’étiquette indiquant les

caractéristiques de votre module pour de plus amples renseignements

et exigences.

SÉRIE PM250

des

AVERTISSEMENT

AFIN D’ÉVITER TOUS RISQUES DE BLESSURE LORS D’UN FEU DE

CUISINIÈRE, OBSERVEZ LES INSTRUCTIONS SUIVANTES* :

1. ÉTOUFFEZ LES FLAMMES à l’aide d’un couvercle le plus hermétique

possible, une plaque à biscuits ou un plateau en métal, puis éteignez

le brûleur. ATTENTION de NE PAS VOUS BRÛLER. Si les flammes

ne s’éteignent pas immédiatement, SORTEZ ET APPELEZ LES

POMPIERS.

2. NE PRENEZ JAMAIS EN MAIN UNE POÊLE OU UNE CASSEROLE

QUI A PRIS FEU - vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni de torchons ou de serviettes mouillés - vous

provoqueriez une violente explosion de vapeur.

Page 6

INSTALLATION DU SYSTÈME DE CONDUITS

NOTE : Pour réduire les risques d’incendie, n’utilisez que des

conduits en métal.

1. Déterminer par où passera le conduit, entre votre module et l’extérieur

(Réf. Figure 1).

2. Un conduit droit et court permettra à votre module de fonctionner

plus efficacement.

3. Un conduit long avec des coudes et des transitions réduira la

performance de votre module. En utiliser le moins possible. Pour

une grande distance, il faut un conduit d’évacuation d’air au diamètre

plus grand.

4. Installer un capuchon de toit ou de mur. Relier le conduit rond en

métal au capuchon, puis acheminer le conduit jusqu’à l’emplacement

de votre module. Sceller hermétiquement les raccords à l’aide de

ruban à conduits.

CAPUCHON DE TOIT

CONDUIT ROND

GAINE METALLIQUE

GRILLE

FIG. 3

RACCORDEMENT DES CONDUITS

FIG. 3A

CAPUCHON

DE MUR

MODULE

DE HOTTE

ENCASTRABLE

DE 24 PO (61 CM) À 30 PO

(76 CM) AU-DESSUS

DU PLAN DE CUISSON

COUDE ROND

DE 7 PO (25 CM)

FIG. 1

INSTALLATION DU MODULE

NOTE : le module doit être installé à l’intérieur de l’armoire à 1 po

(2,5 cm) minimum du mur arrière de l’armoire et à 3 po (7,5 cm) de

la partie avant de l’armoire.

La hauteur interne minimale de l’armoire doit être de 16 po (40 cm).

Le module doit être installé au centre, au-dessus de la surface de

cuisson.

1. Découper un trou au fond de l’armoire en utilisant les dimensions

indiquées à la Fig. 2.

2. Dévisser les quatre (4) vis « A » et retirer la grille en métal (Fig. 3).

3. NOTE : Pour les installations où le module se trouve à moins de

30 po (76 cm) au-dessus du plan de cuisson, il est recommandé

de le monter dans un revêtement d’armoire en métal ou dans un

matériau incombustible. Cette précaution facilitera le nettoyage et

protégera l’armoire (Fig. 3A).

4. Placer la hotte dans le meuble (Fig. 3) ou dans la gaine en métal

(Fig. 3A) et la fixer à l’aide des quatre (4) vis « B » de montage pour

tôle. (Fig. 3 – installation arrière en bois – épaisseur recommandée

1/2 - 3/4 po).

(Pour un autre type de montage, utiliser des vis d’assemblage avec

des rondelles et des écrous. Cette méthode de montage doit être

faite avant l’installation de la gaine métallique).

5. Pour une configuration à recirculation, installer le filtre à charbon

avant de réinstaller la grille (voir la section « Installation du filtre à

charbon »).

6. Réinstaller la grille après avoir effectué le raccordement électrique.

DÉCOUPER UN TROU À LA BASE DE L’ARMOIRE

Hottes à évacuation

1. À l’aide d’un conduit rond de 7 po (17,8 cm) en métal, relier le

collier d’évacuation du module au système d’évacuation. Un

clapet rond de 7 po (17,8 cm) peut être utilisé comme option (vendu

séparément).

2. Sceller hermétiquement les raccords à l’aide de ruban à conduits.

Hottes à recirculation

1. Relier un conduit rond de 7 po (17,8 cm) en

métal

à la bouche

d’évacuation pour que l’air soit évacué hors de l’armoire et retourné

dans la pièce.

2. Sceller hermétiquement les raccords à l’aide de ruban à conduits.

INSTALLATION DU FILTRE À CHARBON

1. Enlever les fils métalliques (Fig. 7) et s’en défaire.

2. Installer le filtre à charbon par-dessus le filtre à graisses et le tenir

en place au moyen de fils métalliques fournis avec le filtre à charbon

(Fig. 4).

FILTRE À CHARBON

FILS MÉTALLIQUES

FIG. 4

INSTALLATION ÉLECTRIQUE

NOTE : ce modèle de module doit être correctement relié à la terre.

Cet appareil devrait être installé par un électricien conformément

aux normes locales et nationales en matière d’électricité.

Faire passer le fil dans l’orifice pour câble supérieur à l’aide d’un

serre-fil.

Retirer les deux (2) vis du couvercle latéral de la boîte de jonction et

effectuer le raccordement électrique. Relier les deux fils blancs au fil

blanc d’alimentation à l’aide d’un connecteur approprié, puis relier le

fil noir au fil noir et le fil vert au fil vert.

10 ¼ po

19 ½ po

FIG. 2

COUVERCLE

LATÉRAL DE

LA BOÎTE DE

JONCTION

FIG. 5

Page 7

FONCTIONNEMENT

ON

OFF

HI

LO

OFF

Commandes

L’interrupteur d’élairage: allume et éteint les lampes.

L’interrupteur du ventilateur: permet de sélectionner la vitesse

de fonctionnement.

FIG. 6

ENTRETIEN

COUPER TOUJOURS L’ALIMENTATION ÉLECTRIQUE AVANT

D’EFFECTUER UNE QUELCONQUE OPÉRATION SUR L’APPAREIL.

Filtre à graisses

Le filtre à graisses doit être nettoyé fréquemment. Utiliser une solution

d’eau chaude additionnée de détergent. Le filtre à graisses peut être

lavé au lave-vaisselle.

Pour enlever le filtre à graisses, retirer les quatre (4) vis ainsi que la

grille en métal. Enlever les fils métalliques, puis retirer le filtre à graisses.

LISTE DES PIÈCES DE RECHANGE

REPÈRE N° DE PIÈCE DESCRIPTION

5 97018550 Grille (Argent)

9 99010370 Filtre à graisses

23 B03295095 Boîtier de douille supérieur

24 B03295094 Boîtier de douille inférieur

27 98010831 Fil métallique

28 B02300280 Douille

29 B03294757 Diffuseur

230 98010828 Boîtier de commandes

236 99030347 Interrupteur du ventilateur (Noir)

237 99030342 Interrupteur d’éclairage (Noir)

332 98010839 Couvercle de commandes

415 99400048 Bague anti-traction

Non

représenté 97018559 Accessoires de quincaillerie

CAS R730090 Bloc ventilateur

- 97018557 Assemblage douille

(repères nos 24, 23 et 28)

- - «Ampoules à petit culot de

40 W max non comprises»

- B08999040 Ensemble de recirculation

(à acheter séparément)

FILS MÉTALLIQUES

FILTRE À

GRAISSES

FIG. 7

Filtre à charbon

Le filtre à charbon devrait être changé tous les six mois.

Pour retirer le filtre à charbon:

1. Retirer la grille en enlevant les quatre (4) vis « A » de 3,9 mm x

6 mm (Fig. 3).

2. Enlever les fils métalliques (Fig. 4) et remplacer le filtre à charbon.

Nettoyage

Un entretien ponctuel contribuera à préserver l’apparence de la hotte.

• Nettoyer à l’eau chaude additionnée d’un détergent doux seulement.

• Procéder à un rinçage à l’eau claire après chaque nettoyage.

• Essuyer à l’aide d’un chiffon propre et doux.

Ampoules

Ce type de module requiert deux ampoules de 40 W (non comprises).

Pour changer les ampoules :

1. Retirer la vis de 2,9 mm x 9,5 mm retenant le diffuseur.

2. Tirer le diffuseur vers le bas pour l’enlever.

3. Remplacer par des ampoules de même type (ampoule à petit culot

de 40 W/120 V max).

ATTENTION : L’AMPOULE PEUT ÊTRE CHAUDE!

FIG. 8

Page 8

GARANTIE

GARANTIE LIMITÉE D’UN AN BROAN-NUTONE

Broan-NuTone garantit à l’acheteur original que les produits vendus en vertu de la présente sont libres de tout vice de matériau ou de

fabrication pour une période d’un an à compter de la date d’achat originale. CETTE GARANTIE NE COMPORTE AUCUNE AUTRE

GARANTIE, EXPRESSE OU TACITE, Y COMPRIS, MAIS SANS S’Y LIMITER, LES GARANTIES TACITES DE VALEUR MARCHANDE

OU D’ADAPTATION À UN USAGE PARTICULIER.

Durant cette période d’un an, Broan-NuTone réparera ou remplacera gratuitement, à sa discrétion, tout produit ou toute pièce jugés

défectueux dans des conditions normales d’utilisation.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS, NI AUX AMPOULES HALOGÈNES

OU INCANDESCENTES, FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE TOIT, CAPUCHONS MURAUX ET AUTRES

ACCESSOIRES POUR CONDUITS. Cette garantie ne couvre pas (a) les frais d’entretien ou de service normaux ni (b) tout produit ou

toute pièce soumis à un abus, une négligence, un accident, un entretien ou une réparation inadéquats (autres que ceux effectués par

Broan-NuTone), une mauvaise installation ou une installation contraire aux instructions recommandées.

La durée de toute garantie tacite est limitée à la période d’un an stipulée pour la garantie expresse. Certains territoires ou provinces

interdisant de limiter la durée d’une garantie tacite, la limitation ci-dessus peut ne pas s’appliquer à votre situation.

L’OBLIGATION POUR BROAN-NUTONE DE RÉPARER OU DE REMPLACER LE PRODUIT, À SA DISCRÉTION, CONSTITUE LE SEUL

RECOURS DE L’ACHETEUR EN VERTU DE LA PRÉSENTE GARANTIE. BROAN-NUTONE NE PEUT ÊTRE TENUE RESPONSABLE

DES DOMMAGES INDIRECTS OU CONSÉCUTIFS NI DES DOMMAGES-INTÉRÊTS PARTICULIERS DÉCOULANT DE L’UTILISATION

OU DU RENDEMENT DU PRODUIT. Certains territoires ou provinces ne permettant pas la limitation ou l’exclusion des dommages

indirects ou consécutifs, la limitation ci-dessus peut ne pas s’appliquer à votre situation.

La présente garantie vous confère des droits spécifiques reconnus par la loi. D’autres droits pourraient également vous être accordés

selon la législation locale en vigueur. La présente garantie remplace toutes les autres garanties précédentes.

Pour vous prévaloir de cette garantie, vous devez (a) aviser Broan-NuTone à l’adresse ou au numéro de téléphone indiqués ci-dessous,

(b) donner le numéro de modèle du produit et le numéro d’identification de la pièce et (c) décrire la nature de la défectuosité du produit

ou de la pièce. Lors de votre demande de garantie, vous devez présenter une preuve de la date d’achat originale.

Aux États-Unis - Broan-NuTone LLC, 926 West State St., Hartford, WI, 53027 www.broan.com (800-558-1711)

Aux Canada - Broan-NuTone Canada, 1140 Tristar Dr., Mississauga, ON, L5T 1H9 www.broan.ca (1-877-896-1119)

99044715C

Page 9

MÓDULO

DE POTENCIA

REGISTRE SU PRODUCTO EN LÍNEA EN www.broan.com/register

LEA Y CONSERVE ESTAS INSTRUCCIONES

INDICADO SOLAMENTE PARA COCINAR EN CASA

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS

ELÉCTRICAS O LESIONES PERSONALES, OBSERVE LAS SIGUIENTES

PRECAUCIONES:

1. Use la unidad sólo de la manera indicada por el fabricante. Si tiene

preguntas, comuníquese con el fabricante a la dirección o al número

telefónico que se incluye en la garantía.

2. Antes de dar servicio o limpiar la unidad, interrumpa el suministro

eléctrico en el panel de servicio y bloquee el panel de servicio para

evitar que se active accidentalmente la electricidad. Cuando no sea

posible bloquear los medios de desconexión del servicio, fije una señal

de advertencia prominente (como una etiqueta) en un lugar visible del

panel de servicio.

3. Una o más personas calificadas deben realizar el trabajo de instalación

y el cableado eléctrico, de acuerdo con todos los códigos y normas

correspondientes, incluidos los códigos y normas de construcción

específicos de protección contra incendios.

4. Se necesita suficiente aire para que se lleve a cabo una combustión

y una extracción adecuadas de los gases a través del tubo de humos

(chimenea) del equipo quemador de combustible, con el fin de evitar el

contratiro. Siga las directrices y las normas de seguridad del fabricante

del equipo de calefacción, como las publicadas por la Asociación

Nacional de Protección contra Incendios (National Fire Protection

Association, NFPA), y la Sociedad Americana de Ingenieros en

Calefacción, Refrigeración y Aire Acondicionado (American Society

for Heating, Refrigeration and Air Conditioning Engineers, ASHRAE),

y las autoridades de los códigos locales.

5. Al cortar o perforar a través de la pared o del cielo raso, tenga cuidado

de no dañar el cableado eléctrico ni otros servicios ocultos.

6. Los ventiladores en conductos siempre deben ventearse hacia

el exterior.

7. No use esta unidad junto con ningún dispositivo separado de estado

sólido para el control de la velocidad.

8. Para reducir el riesgo de incendio, use solamente conductos metálicos.

9. Esta unidad debe estar conectada a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO POR GRASA

PRESENTE EN LA ESTUFA:

A. Nunca deje desatendidas las unidades de la superficie cuando estén en

ajustes altos de calor. Los alimentos en ebullición provocan derrames

grasosos y con humo que se pueden incendiar. Caliente el aceite

lentamente en ajustes de calor bajo o medio.

B. Siempre ENCIENDA la campana cuando esté cocinando a altas

temperaturas o flamee alimentos (por ejemplo crepas Suzette, cerezas

Jubilee, bistec con pimienta flameado).

C. Limpie frecuentemente los ventiladores. No permita la acumulación de

grasa en el ventilador ni en el filtro.

D. Use una cacerola del tamaño adecuado. Siempre use utensilios

de cocina que sean apropiados para el tamaño del elemento

de la superficie.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES A LAS PERSONAS EN

CASO DE UN INCENDIO PRODUCIDO POR GRASA EN UNA ESTUFA,

OBSERVE LO SIGUIENTE*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una charola

para galletas o una bandeja de metal, y después apague el quemador.

PROCEDA CON CUIDADO PARA EVITAR QUEMADURAS. Si las

llamas no se apagan inmediatamente, EVACUE EL ÁREA Y LLAME

A LOS BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA porque podría

ocasionarse quemaduras.

3. NO TRATE DE APAGAR EL FUEGO CON AGUA ni con trapos o toallas

de cocina mojados, pues ocasionará una explosión violenta de vapor.

4. Use un extintor SÓLO si:

A. El extintor es de Clase ABC y usted sabe cómo hacerlo funcionar.

B. El incendio es pequeño y está confinado al área en la que se inició.

C. Se está llamando al Departamento de Bomberos.

D. Puede combatir el incendio teniendo la espalda orientada hacia

una salida.

* Basado en “Kitchen Fire Safety Tips” (Sugerencias para la seguridad

contra incendios en la cocina) publicado por NFPA.

PRECAUCIÓN

1. Sólo debe usarse bajo techo.

2. Para reducir el riesgo de incendio y para descargar adecuadamente

el aire, asegúrese de dirigir el aire hacia el exterior. No descargue

el aire en espacios contenidos entre paredes o cielos rasos, ni en

áticos, sótanos bajos ni en la cochera.

3. Tenga cuidado cuando use agentes de limpieza o detergentes.

4. Evite usar bajo la campana de la estufa productos alimenticios que

produzcan llamas.

5. Sólo para usarse como medio de ventilación general. No debe usarse

para la extracción de materiales ni vapores peligrosos o explosivos.

6. Para evitar daños a los cojinetes del motor y rotores ruidosos o

desbalanceados, mantenga la unidad de potencia protegida contra

rociados de yeso, polvos de construcción, etc.

7. Este motor de campana tiene una protección contra sobrecargas

térmicas que automáticamente apagará el motor en caso de

sobrecalentamiento. El motor reanudará su funcionamiento cuando

se enfríe. Si el motor continúa apagándose y encendiéndose, solicite

servicio para la campana.

8. La parte inferior de la campana NO DEBE SER inferior a 24 “y

recomendó a un máximo de 30” por encima de la estufa para mejor

las impurezas al cocinar.

9. Se recomienda instalar entre dos personas.

10. Use este producto solamente con el juego de cable de alimentación-

conexiones aprobado.

11. Lea la etiqueta de especificaciones que tiene el producto para ver

información y requisitos adicionales.

SERIE PM250

Page 10

INSTALACIÓN DEL SISTEMA DE CONDUCTOS

NOTA: Para reducir el riesgo de incendio, use solamente

conductos metálicos.

1. Decida dónde instalará el conducto entre la campana y el exterior

(consulte la Figura 1).

2. Un conducto recto y corto permitirá que la campana funcione más

eficientemente.

3. Los tramos largos de conductos, codos y transiciones reducirán el

rendimiento de la campana. Use tan pocos de ellos como sea posible.

Es posible que se requieran conductos más grandes para un mejor

funcionamiento con tramos más largos de conductos.

4. Instale una tapa de techo o una tapa de pared. Conecte un conducto

metálico redondo en la tapa y trabaje hacia atrás, hacia la ubicación

de la campana. Use cinta para conductos para sellar las uniones entre

las secciones de conductos.

RECUBRIMIENTO METÁLICO

TAPA DE TECHO

CONDUCTO

REDONDO

TAPA DE

PARED

MÓDULO DE

POTENCIA

DE 24 A 30 PULG.

(61 A 76 CM) POR ENCIMA

DE LA SUPERFICIE DE

COCINADO

CODO REDONDO

DE 7 PULG. (25 CM)

FIG. 1

INSTALE LA CAMPANA

NOTA: La campana se tiene que instalar dentro del gabinete, como

mínimo a 1 pulgada (2.5 cm) del gabinete de la pared posterior y a

3 pulgadas (7.5 cm) del gabinete de la pared delantera. La altura interior

del gabinete tiene que ser como mínimo de 16 pulg. (40 cm).

La campana debe montarse centrada sobre los quemadores superiores.

1. Corte un orificio en la parte inferior del gabinete, utilizando las

dimensiones mostradas en la Fig. 2.

2. Retire los cuatro (4) tornillos “A” y retire la rejilla metálica (Fig. 3).

3. NOTA: En instalaciones donde el paquete de potencia esté a menos

de 30 pulg. (76 cm) arriba de la cubierta, se recomienda que lo monte

sobre un recubrimiento metálico o un material no combustible. Esto

facilitará la limpieza y brindará protección a los gabinetes (Fig. 3A).

4. Inserte la campana en el gabinete (Fig. 3) o recubrimiento metálico

(Fig. 3A) y asegure con los cuatro (4) tornillos “B” de montaje para

chapa metálica. (Fig. 3: instalación con fondo de madera; espesor

recomendado de ½ a ¾ pulg.). (Para obtener un montaje alternativo,

utilice tornillos maquinados con arandelas y tuercas. Es necesario que

este método alternativo se realice antes de instalar el recubrimiento

metálico).

5. En la configuración de recirculación para sistemas sin conductos,

instale el filtro correspondiente antes de reemplazar la rejilla

(vea la sección “Instalación del filtro de recirculación para sistemas

sin conductos”).

6. Vuelva a colocar la rejilla después de completar el cableado.

RECORTE UN ORIFICIO EN LA PARTE INFERIOR DEL GABINETE

REJILLA

FIG. 3

FIG. 3A

CONECTE LOS CONDUCTOS

Configuración para sistemas con conductos

1. Utilice un conducto metálico redondo de 7 pulg. (17.8 cm) para

conectar el collarín de descarga en la campana con el conducto

superior. Se puede usar un regulador redondo de 7 pulg. (17.8 cm)

opcional (se compra por separado).

2. Use cinta para conductos para fijar y sellar herméticamente todas

las uniones.

Configuración de recirculación para sistemas sin conductos

1. Conecte un conducto metálico redondo de 7 pulg. (17.8 cm) a la

abertura de descarga, de tal manera que el aire se envíe fuera del

gabinete y de regreso hacia la habitación.

2. Use cinta para conductos para fijar y sellar herméticamente todas

las uniones.

INSTALACIÓN DEL FILTRO DE RECIRCULACIÓN

PARA SISTEMAS SIN CONDUCTOS

1. Retire los cables metálicos (Fig. 7) y deséchelos.

2. Instale el filtro de recirculación para sistemas sin conductos sobre el

filtro para grasa y asegúrelo con los alambres metálicos incluidos con

el filtro de recirculación (Fig. 4).

FILTRO DE

RECIRCULACIÓN

PARA SISTEMAS SIN

CONDUCTOS

ALAMBRES METÁLICOS

FIG. 4

CABLEADO

Nota: Esta campana debe estar adecuadamente conectada a tierra.

La unidad debe ser instalada por un electricista calificado de acuerdo

con todos los códigos eléctricos nacionales y locales aplicables.

Asegure el conducto al orificio de cableado superior con un conector

para conductos.

Retire los dos (2) tornillos de la cubierta lateral del cableado y haga

las conexiones eléctricas. Conecte ambos cables blancos al cable de

suministro blanco utilizando un conector adecuado; conecte negro con

negro y verde con verde.

10-1/4 pulg.

19-1/2 pulg.

FIG. 2

CUBIERTA

LATERAL DEL

CABLEADO

FIG. 5

Page 11

FUNCIONAMIENTO

ON

OFF

HI

LO

OFF

Controles

Interruptor de luz: enciende y apaga las lámparas.

Interruptor del ventilador: permite seleccionar la velocidad de

funcionamiento del motor.

FIG. 6

MANTENIMIENTO

SIEMPRE APAGUE EL SUMINISTRO ELÉCTRICO ANTES DE REALIZAR

CUALQUIER OPERACIÓN EN EL ELECTRODOMÉSTICO.

Filtro para grasa

El filtro para grasa se debe limpiar con frecuencia con una solución

tibia de detergente y agua. El filtro para grasa se puede lavar en el

lavaplatos.

Para quitar el filtro para grasa: Quite los cuatro (4) tornillos y retire la

rejilla metálica. Quite los alambres metálicos y quite el filtro para grasa.

ALAMBRES METÁLICOS

PIEZAS DE SERVICIO

CLAVE N.º PIEZA N.º DESCRIPCIÓN

5 97018550 Rejilla (plateada)

9 99010370 Filtro para grasa

23 B03295095 Soporte de lámpara superior

24 B03295094 Soporte de lámpara inferior

27 98010831 Alambre metálico

28 B02300280 Soporte de lámpara

29 B03294757 Portalámparas

230 98010828 Cierre de los controles

236 99030347 Interruptor del ventilador (negro)

237 99030342 Interruptor de la luz (negro)

332 98010834 Controles de la cubierta

415 99400048 Buje protector contra tirones

No se muestra 97018559 Paquete de herrajes

CAS R730090 Conjunto del ventilador

- 97018557 Conjunto del receptáculo

(incluye las claves 24, 23, 28)

- - “No se incluyen las bombillas

Candelabra de 40 watts máx.”

- B08999040 Juego de filtro para sistema

sin conductos (se compra por

separado)

FILTRO

PARA GRASA

FIG. 7

Filtro de recirculación para sistemas sin conductos

El filtro de recirculación para sistemas sin conductos se debe cambiar

cada 6 meses. Para quitar el filtro de recirculación para sistemas sin

conductos:

1. Retire la rejilla quitando los (4) tornillos “A” de 3.9 x 6 mm (Fig. 3).

2. Retire los alambres metálicos (Fig. 4) y reemplace el filtro de

recirculación para sistemas sin conductos.

Limpieza

Un cuidado ocasional ayudará a mantener su buen aspecto.

• Limpie solamente con agua tibia y un detergente suave.

• Enjuague bien con agua clara después de limpiar.

• Seque con un paño limpio y suave.

Bombillas

Esta campana requiere dos bombillas de 40 watts (no incluidas).

Para cambiar las bombillas:

1. Retire el tornillo de 2.9 x 9.5 mm que asegura el portalámparas.

2. Estire la lente hacia abajo para quitarla.

3. Reemplace con bombillas del mismo tipo (bombillas con base

Candelabra de 40 W, 120 V máx.). PRECAUCIÓN: ¡LA BOMBILLA

PUEDE ESTAR CALIENTE!

FIG. 8

Page 12

GARANTÍA

GARANTÍA BROAN-NUTONE LIMITADA POR UN AÑO

Broan-NuTone garantiza al consumidor comprador original de sus productos que dichos productos carecerán de defectos en materiales

o en mano de obra por un período de un año a partir de la fecha original de compra. NO EXISTEN OTRAS GARANTÍAS, EXPLICITAS O

IMPLÍCITAS, INCLUYENDO, ENTRE OTRAS, GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN O APTITUD PARA UN PROPÓSITO

PARTICULAR.

Durante el período de un año, y a su propio criterio, Broan-NuTone reparará o reemplazará, sin costo alguno, cualquier producto o pieza

que se encuentre defectuoso o bajo condiciones normales de servicio y uso.

LA PRESENTE GARANTÍA NO CUBRE LOS TUBOS FLUORESCENTES NI SUS ARRANCADORES, TUBOS, BOMBILLAS DE

HALÓGENO E INCANDESCENTES, FUSIBLES, FILTROS, CONDUCTOS, TAPONES DE TECHO O PAREDES Y DEMÁS ACCESORIOS

PARA CONDUCTOS. Esta garantía no cubre (a) mantenimiento y servicio normales o (b) cualesquiera productos o piezas que hayan sido

utilizados de forma errónea, negligente, que hayan causado un accidente, o que hayan sido reparados o mantenidos inapropiadamente

(por otras compañías que no sean Broan-NuTone), instalación defectuosa, o instalación contraria a las instrucciones de instalación

recomendadas.

La duración de cualquier garantía implícita se limita a un período de un año como se especifica en la garantía expresa. Algunos estados

no permiten limitaciones en cuanto al tiempo de vencimiento de una garantía implícita, por lo que la limitación antes mencionada puede

no aplicarse a usted.

LA OBLIGACIÓN DE BROAN-NUTONE DE REPARAR O REEMPLAZAR, SIGUIENDO EL CRITERIO DE BROAN-NUTONE, DEBERÁ SER

EL ÚNICO Y EXCLUSIVO RECURSO LEGAL DEL COMPRADOR BAJO ESTA GARANTÍA. BROAN-NUTONE NO SERÁ RESPONSABLE

POR DAÑOS INCIDENTALES, CONSECUENTES, O POR DAÑOS ESPECIALES QUE SURJAN A RAÍZ DEL USO O DESEMPEÑO

DEL PRODUCTO. Algunos estados no permiten la exclusión o limitación de daños incidentales o consecuentes, por lo que la limitación

antes mencionada puede no aplicarse a usted.

Esta garantía le proporciona derechos legales específicos, y usted puede también tener otros derechos, los cuales varían de estado a

estado. Esta garantía reemplaza todas las garantías anteriores.

Para calificar para la garantía de servicio, usted debe (a) notificar a Broan-NuTone al domicilio o al número de teléfono que se menciona

abajo, (b) dar el número del modelo y la identificación de la pieza, y (c) describir la naturaleza de cualquier defecto en el producto o la pieza.

En el momento de solicitar servicio cubierto por la garantía, usted debe de presentar un comprobante con la fecha original de compra.

En los EE.UU. - Broan-NuTone LLC, 926 West State St., Hartford, WI, 53027 www.broan.com (800-558-1711)

En Canadá - Broan-NuTone Canada, 1140 Tristar Dr., Mississauga, ON, L5T 1H9 www.broan.ca (1-877-896-1119)

99044715C

Loading...

Loading...