Broan ECM SERIES, Nortron 21ECM10, Nortron 21ECM15, Nortron 21ECM18, Nortron 21ECM20 Installation And Operating Instructions Manual

...Page 1

ECM SERIES ELECTRIC FURNACE

TEL.: 905-670-2500

FAX: 905-795-8311

CUSTOMER SERVICE TEL.: 1-888-882-7626

MISSISSAUGA, ONTARIO L5T 1H9

30042458A

• Never tamper with the unit or its controls. User MUST contact

a specialized contractor when a failure occurs. DO NOT

ATTEMPT to repair.

• When using a humidifier make sure not to damage the heating

element bank.

• We recommend that your unit be inspected by a specialized

technician once a year.

• Poor maintenance of air filters OR an unbalanced static

pressure may result in a performance decrease.

• Always use genuine parts for maintenance or service call.

The use of unbranded parts will void the warranty.

• The use of this unit without an air distribution duct will void

the warranty.

• It is strictly forbidden to use jumpers to simulate heat demand.

• Risk of electrical shock. Disconnect power before installation,

servicing, maintenance or field wiring. Replace all panels

before operating. Failure to do so can result in electrical

shock causing severe injuries or death.

• When performing installation, servicing or cleaning the unit,

it is recommended to wear safety glasses and gloves.

• To assure a proper performance of your furnace, we recommend

that you use high quality name brand thermostats.

• When applicable local regulation comprises more restrictive

installation and/or certification requirements, the aforementioned

requirements prevail on those of this document and the

installer agrees to conform to these at his own expenses.

• For your safety, do not store or use gasoline or other flammable

liquids and vapors in the vicinity of this unit or any other

appliance.

• These instructions are intended to be use by qualified personnel

who have been trained in installing this type of furnace.

Installation of this furnace by an unqualified person may

lead to equipment damage and/or hazardous condition

which may lead to bodily harm.

• This furnace is not watertight and is not designed for outdoor

installation. This furnace shall be installed in such a manner

as to protect its electrical components from water. Outdoor

installation leads to a hazardous electrical condition and to

premature furnace failure, thus voiding the warranty.

• Do not block the combustion air openings in the furnace.

Any blockage will result in improper overheat situation and

may result in a fire hazard and/or cause bodily harm.

• The unit must have an uninterrupted or unbroken electrical

ground to minimize personal injury if an electrical fault

should occur. When performing electrical connection, the

ground conductor must be firmly attached to the ground lug

in the furnace.

• Do not use this furnace as a construction heater. Use of this

furnace as a construction heater exposes the furnace to

abnormal conditions, contaminated combustion air and the

lack of air filters. Failure to follow this warning can lead to

premature furnace failure and/or vent failure which could

result in a fire hazard and/or bodily harm.

• The owner and/or the user is responsible of the following:

Always maintain the immediate surrounding of the furnace

free from combustible and highly flammables materials.The

furnace ambient air should not have an excessive dust

concentration and humidity. Never operate this central heating

appliance without an air filter.

• Before performing any service functions, unless operations

specifically require the power to be on, make sure all utilities

are turned “OFF” upstream of the appliance. Failure to comply

with this warning will cause a fire hazard and/or bodily

harm.

• All questions regarding the operation, maintenance or warranty

of this unit should be addressed to the company where this

product has been sold from.

WARNING

!

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS.

CAUTION

• Never burn garbage or paper in the heating system and never leave rags or paper around the unit.

• Return air grilles and warm air registers must not be obstructed.

IMPORTANT: All local and national code requirements governing the electrical installation heating equipment, wiring and flue connections

must be followed. Some of the codes that may be applicable are:

ANSI/NFPA 70 NATIONAL ELECTRICAL CODE

CSA C22.1 CANADIAN ELECTRICAL CODE

Only the latest issues of the above codes should be used, and are available from either:

The National Fire Protection Agency

Batterymarch Park

Quincy, MA 02269

The Canadian Standards Association

178 Rexdale Blvd.

Rexdale, Ontario M9W 1R3

or

Page 2

2

This furnace has been designed and manufactured to give the

most reliable performance possible. Each unit has been given a

running inspection before shipment to assure that every component

is operating efficiently.

The safe and dependable operation of the furnace depends upon

proper installation and compliance with all national and local

codes and standards.

INSTALLATION AND OPERATING INSTRUCTIONS

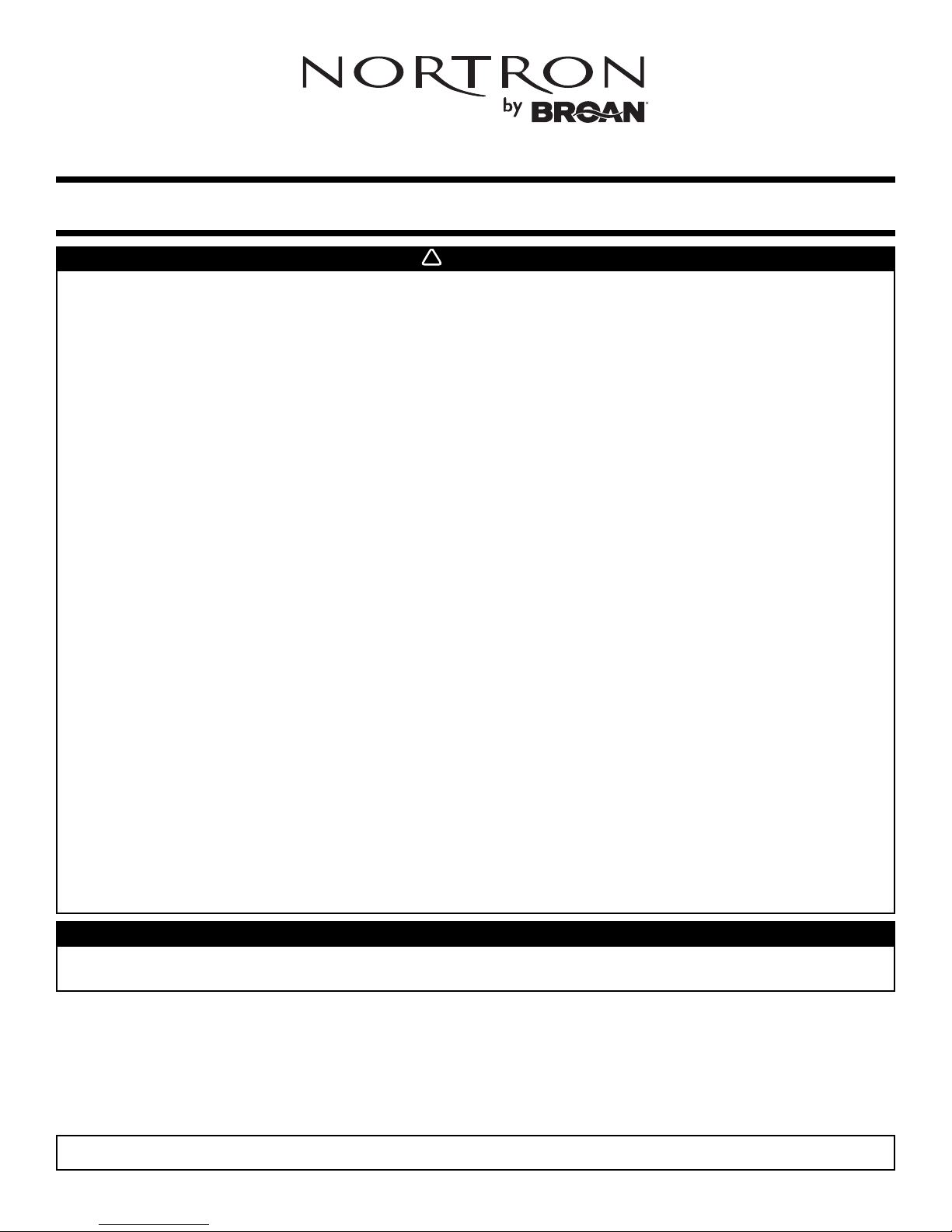

FRONT VIEW RIGHT SIDE VIEW REAR VIEW LEFT SIDE VIEW

TOP VIEW

1½”

(38 mm)

1½”

(38 mm)

20”

(508 mm)

20”

(508 mm)

1”

(25 mm)

39”

(991 mm)

FILTER FRAME

(EITHER SIDE, REAR

OR BOTTOM)

1½” x 1½” KO

(38 mm x 38 mm)

1½” x 1½” KO

(38 mm x 38 mm)

1½” x 1½” KO

(38 mm x 38 mm)

WIRING KO’S

A

B

C

WIRING KO’S

C

A = 1” (25 mm)

B = 1/4” (6 mm) & 1¼” (32 mm)

C = 1/2” (13 mm) & 1½” (38 mm)

WIRING KO’S VALUES

DISCHARGE

17” x 17”

(432 mm x 432 mm)

18” x 18”

(457 mm x 457 mm)

RETURN

18” x 18”

(457 mm x 457 mm)

RETURN

18” x 18”

(457 mm x 457 mm)

RETURN

1. LOCATION – The furnace should be centrally located to the

heating area.

2. POSITIONS – It can be installed for vertical, horizontal or

downflow operation. When installed horizontally, the furnace

should be positioned such as the door will not end up being on

the top. The door should be on the side of the furnace, to

ensure that the motor bearings are in their designed position.

In vertical downflow installations, use only “L”- or “T”-shaped

plenum with no openings or registers directly below furnace.

3. INSTALLATION CLEARANCES – As shipped from the factory,

each unit is approved for “zero inch” clearance. If additional

clearance is required, it will be indicated on the data label

attached to the furnace.

4. TEMPERATURE RISE – Furnaces are shipped to operate at

0.20” W.C. (50 Pa) external static pressure. They are certified

for operation up to 0.50” W.C. (125 Pa). Check the following

page for temperature rise table on specification chart and, if

necessary, adjust the unit to match.

5. SERVICE CLEARANCE – Units are serviced from the FRONT.

Leave at least 24” (610 mm) clearance in front of the door.

GENERAL REQUIREMENTS AND SPECIFICATIONS

CAUTION

This unit must be installed in a dry place, in a non-corrosive, well-ventilated environment, without excessive dust. The ambient

temperature must be over 10°C and under 27°C. If the ambient temperature is 10°C or less, the plenum must be insulated on

10 ft linear minimum length.

UNIT CERTIFICATION

This furnace is CSA certified.

®

Page 3

GENERAL REQUIREMENTS AND SPECIFICATIONS (CONT’D)

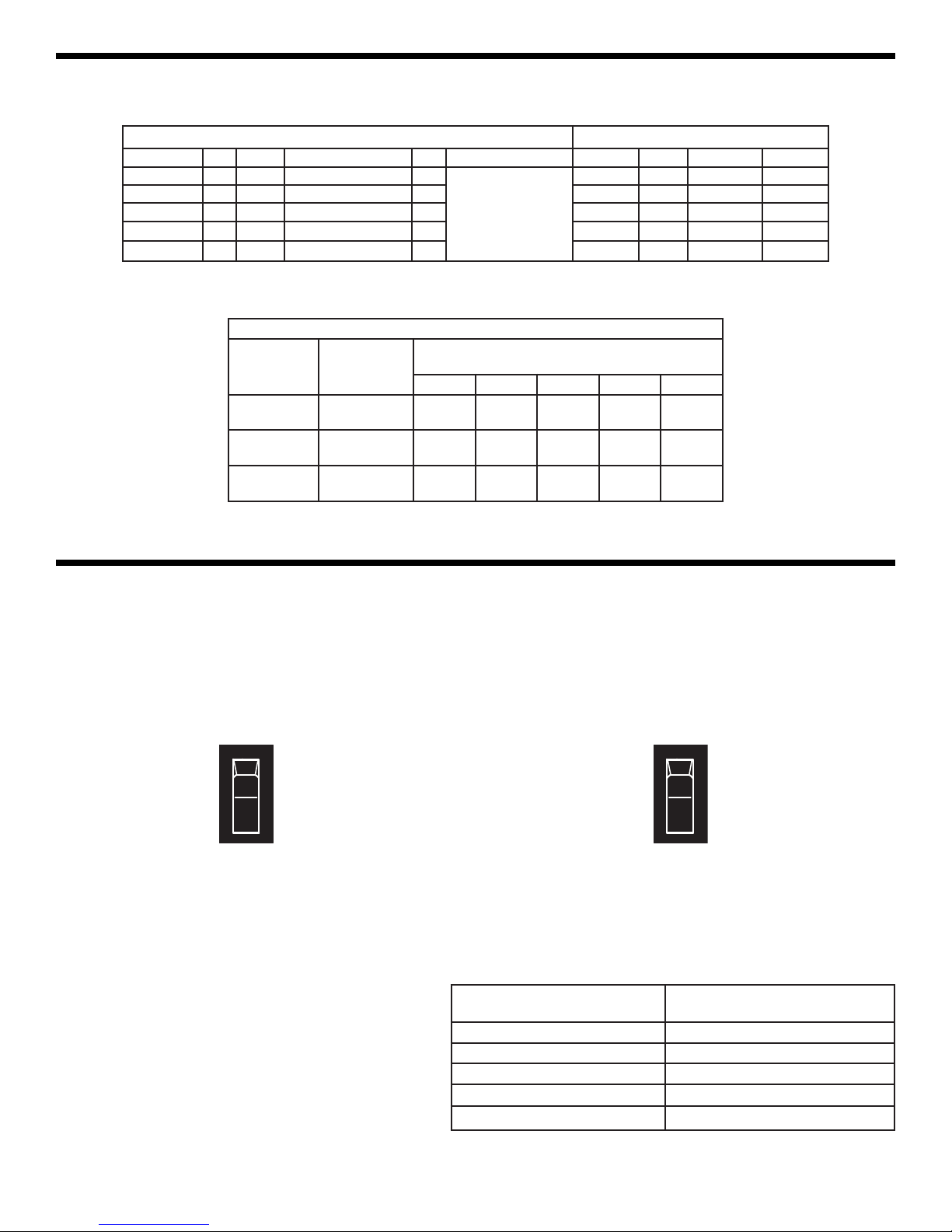

OPERATING OPTIONS

The furnace is shipped from the factory in a “Standard Heating

Mode” (both switches in the Down position). When the thermostat

calls for heat, the automatic controls will be activated and the

furnace turns “ON”.

The blower will run at low speed or higher speed (as selected by

SPEED SELECTOR switch).

As the furnace heats up, it automatically switches to a medium

speed when additional elements are activated by the electronic

control, if it was initially set to run at low speed. The timing of this

blower speed change will depend on whether C

OLD or MILD is

selected on the SEASON SELECT switch.

You may, however, change from the Standard Heating Mode by

using the controls built into your furnace.

SPEED SELECTOR SEASON SELECT

HIGH

MILD

COLD

The SPEED SELECTOR switch is used to control the fan speed

(ventilation). Even if there is no call for heat, the ventilation can be

controlled by the thermostat; the fan speed is determined by this

switch.

L

OW – The blower motor will operate at low speed.

H

IGH – The blower motor will operate at a higher speed.

During spring or fall, you may require less rapid response when

the thermostat calls for heat.

When M

ILD is selected, it takes more time to bring all the elements

online.

When C

OLD is selected, the heating elements come online faster.

3

L

OW

*FACTORY SETTINGS.

SUBJECT TO CHANGE WITHOUT NOTICE.

**This speed can only be run with heater off, for cooling/ventilation purposes only.

WARNING:

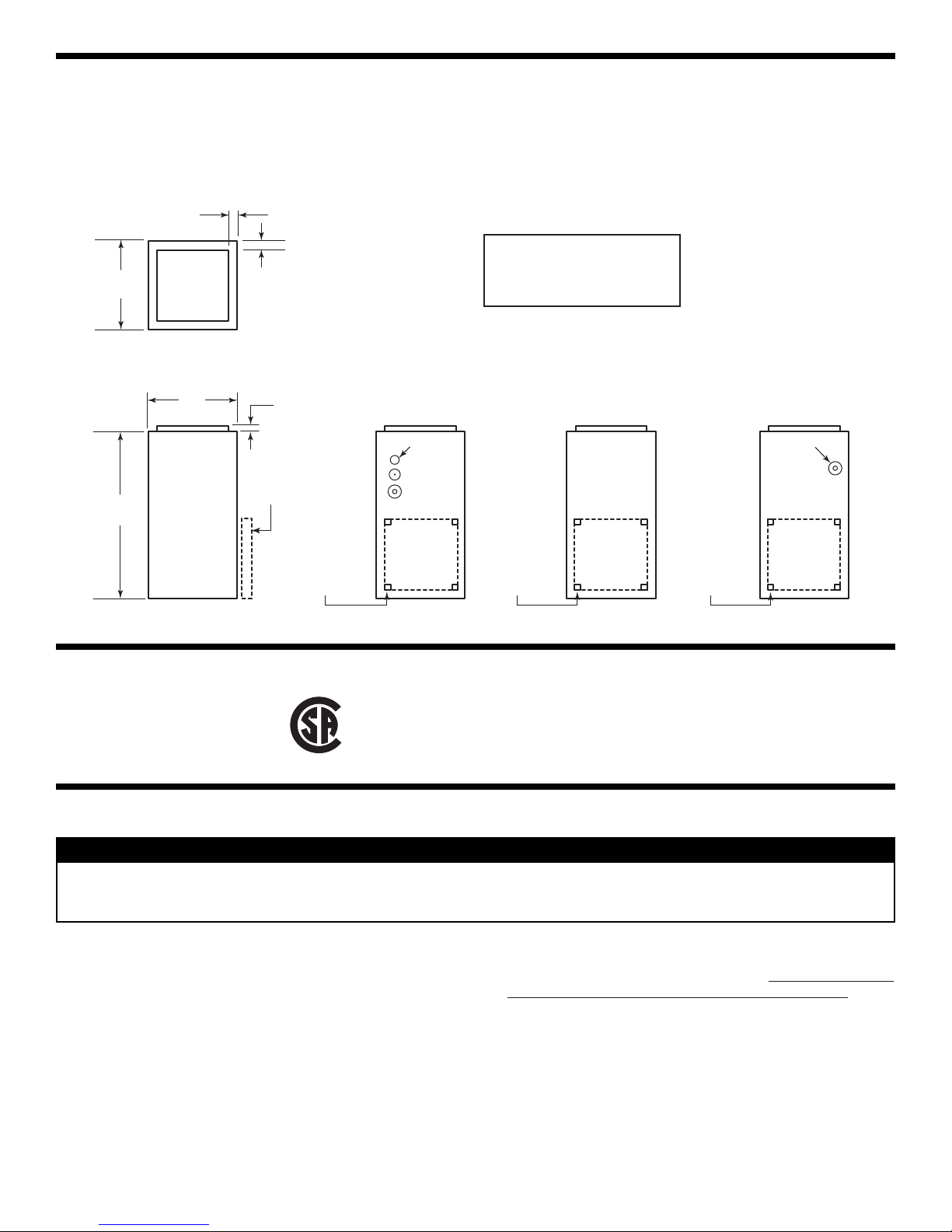

240 VOLTS – SINGLE PHASE TEMP. RISE @ 0.20 in. W.C.

MODEL NO. kW BTUH AMPS INCL. MOTOR HP BLOWER °C °F *SPEED RPM

21ECM10 10 34120 43 1/3

10” x 8”

(254 mm x 203 mm)

19 34 MEDIUM 903

21ECM15 15 51180 64 1/3 22 40 MEDIUM 903

21ECM18 18 61420 76 1/3 26 47 MEDIUM 903

21ECM20 20 68240 84 1/3 29 52 MEDIUM 903

21ECM23 22.5 76770 94 1/3 36 65 MEDIUM 903

10” x 8” (254 mm x 203 mm) BLOWER

SPEED FLOW RATE

STATIC PRESSURE

(INCHES OF WATER COLUMN)

0.2 0.3 0.4 0.5 0.6

LOW**

CFM

L/s

684

323

582

275

535

252

481

227

429

202

MEDIUM

CFM

L/s

1149

542

1104

521

1064

502

1016

479

977

461

HIGH

CFM

L/s

1238

584

1203

568

1174

554

1139

538

1106

522

MILD SEASON (First Stage)

Slow Response Sequence

COLD SEASON (Second Stage)

Rapid Response Sequence

Element 1 - Heat on instantly Element 1 - Heat on instantly

Blower on after 3 seconds delay Blower on after a 3 seconds delay

Elements 3 and 5 after 1 minute delay Elements 3 and 5 after 10 seconds delay

Element 2 after 2 minutes delay Element 2 after 20 seconds delay

Element 4 after 3-minute delay Element 4 after 30 seconds delay

NOTE: Elements 4 and 5 only where applicable.

Page 4

INSTALLATION NOTES

1. COLD AIR RETURN

The duct can be attached to either side, rear or the bottom of

the furnace.

For side return there are four 1½” (38 mm) knockouts which

can be removed and used as an outline for cutting a 18” x 18”

(457 mm x 457 mm) return air opening in the furnace left or

right side. Mount the filter frame to the furnace over the opening

with the open side of the frame facing front. Then attach the

19” x 19” (483 mm x 483 mm) air duct to the flanges on the

filter frame. For bottom mounting, remove the screws holding

the bottom plate to the furnace, discard the bottom plate and

attach the filter frame to the bottom flanges with the open side

of the frame facing front.

2. ELECTRICAL WIRING - POWER SUPPLY

The furnaces are completely factory wired. From a separate

breaker, a two-wire plus ground supply wire is required. The

ground conductor must be firmly attached to the ground lug in

the furnace and the supply wires to the terminal block in the

furnace.

NOTE: If a FK120 ECM kit will be used to supply an air cleaner

and/or humidifier, a third (neutral) conductor must be

brought into the furnace.

3. CONNECTING AND ADJUSTING

THE LOW VOLTAGE THERMOSTAT

(Use only class 1 wires inside furnace compartments.)

Attach thermostat wires to the low voltage terminal

connections located on the printed circuit board inside the

furnace. Follow the diagrams supplied with the thermostat. As

a general guide, remember that the R & W terminals control

single stage heating; the R & Y terminals control cooling. Single

stage cooling uses “Y/Y2” as first and only stage.

Two-stage cooling uses “Y1” as first stage and “Y/Y2” as

second stage. Make sure the thermostat is levelled on the wall

and in appropriate location as per instructions supplied with the

thermostat.

Because each installation is different an accurate reading of

the current draw should be made with an AC meter. Set the

meter at a 2 A range.

A. Set the anticipator at its highest setting.

B. Disconnect the “W1” thermostat wire from the furnace low

voltage terminal connections.

C. Connect the AC meter between the “W1” terminal on the

board and the loose “W1” wire.

D. Turn the thermostat up to start the furnace and allow it to

run, with all elements on, for three or four minutes.

E. Read the current draw on the meter and reset the anticipator

to match the meter reading.

FOR USE IN MOBILE HOMES

ECM Series furnaces models 21ECM10, 21ECM15, 21ECM18

and 21ECM20 are certified for “L” -shape and “T”-shape shallow duct

installation with model FSB-1 sub-base in downflow applications

when the supply air ducts pass through the floor of the structure.

Recommended size of a floor opening: 14¼” x 14¼” (362 mm x 362 mm).

The duct system must be designed so that the external static

pressure of the system does not exceed the maximum external

static pressure of 0.50” W.C. (125 Pa).

SHALLOW DUCT AREA REQUIREMENTS

Duct Depth Duct Width

4” (102 mm) 16” (406 mm)

5” (127 mm) 13” (330 mm)

6” (152 mm) 10” (254 mm)

4

CAUTION

Before turning the furnace on, the heat anticipator in the

thermostat must be properly set to prevent its failure and to

assure comfortable, economical heating.

WARNING

!

For all installations, we only recommend appropriate gauge

good quality copper wire(s). However, it is the electrician’s

responsibility to ensure that the wiring and connections are

compliant to the latest editions of the Canadian Electrical

Code and local codes.

Page 5

5

USING OPTIONAL EQUIPMENT

1. TWO-STAGE OR OUTDOOR THERMOSTAT

(The SEASON SELECT switch must be in the MILD position).

Follow the directions supplied with the two-stage or outdoor

thermostat in conjunction with the furnace wiring diagram.

2. AIR CONDITIONING

Your furnace is equipped with all the controls required for the

addition of air conditioning (except the heat-cool thermostat).

The evaporator coil may be installed by a local contractor in

sheet metal plenum of his own manufacture. The coil should be

located: Centered over the “chimney” of the furnace 4” (102 mm)

to 6” (152 mm) above the top of the furnace.

Make sure no air is allowed to bypass the cooling coil during

cooling operation. If the discharge opening is a great deal larger

than the coil, and the ductwork is correspondingly larger than

the coil, you may want to use a bypass damper for heating. The

damper would be closed in summer, directing all air flow

through the coil. In winter the damper would be open to allow

air to bypass the coil.

Typical air-conditioning field wiring connections are shown in

the following diagram:

3. ELECTRONIC AIR CLEANERS AND/OR POWERED

FURNACE HUMIDIFIERS

These units operate at 120 V. Your 240 V furnace is designed

so that Model FK120 ECM adaptor kit can be mounted inside

the furnace to supply the required 120 V. Instructions for

mounting and wiring are included with the kit.

4. INTERLOCK CONNECTION

When the electric furnace is used in combination with another

device (as for example, a wood burning furnace), it is

recommended to perform the connection by referring to the

wiring diagram below. The burning furnace thermostat will then

turn automatically on the blower in the electric furnace.

MAINTENANCE

MOTOR: The motor is lubricated for life and needs no oiling.

FILTERS: Size is 20” x 20” x 1” (508 mm x 508 mm x 25 mm).

Should be inspected and replaced when dirty.

Ordinarily replacement is required twice per heating

season and, perhaps, a third time if continuous

blower operation is used.

NOTE: Each element has an automatic reset thermal

cut-out which is set to open at 160°F (71°C). If it opens,

the element will be de-energized until the cut-out resets

itself. In addition to that, there are 2 manual reset thermal

cut-outs that

open at 200°F (93°C). If any of them open,

a front panel needs to be removed so the cut-out can be

manually reset.

The reason for the failure should be investigated before

re-starting the furnace. The limit usually opens when

airflow is reduced because of blocked ductwork or very

dirty filters.

WIRING COLOR CODES

C G R W1 W2 Y

COMMON GREEN RED WHITE

WHITE

(BLUE

OPTIONAL)

YELLOW

WARNING

!

Cut 240 V supply before removing the front panel!

R

G

24 VAC

Power Output

Call for FAN

Furnace

Furnace

Thermostat

G

R

Relay

NC

NO

COM

External Request

for Fan Activation

Electric Furnace

System

THERMOSTAT

FURNACE

FE0002A

CONDENSER

Page 6

6

SERVICE PARTS

1

3

5

8

9

10

11

12

13

2

4

67

14

REPLACEMENT PARTS

KEY NO. PART NO. DESCRIPTION

1 30270032 Automatic Limit

2 30030006 Season Select Switch

3 30030025 Speed Selector Switch

4 30280021 Thermostat Indicator Light

5

10941289 Motor 1/3 HP208/230 V for 21ECM10 and 21ECM15

10941290 Motor 1/3 HP208/230 V for 21ECM18/20/23

6 10940080 Element Assembly 5000 W, 240 V

7 10940081 Element Assembly 4500 W, 240 V

8 30274131 20 A Relay

9 30274132 30 A Relay

10 30280020 Manual Reset Limit

11 624665 Electronic Control (PC Board)

12 30300022 Transformer 240 V

13 30010010 Fiberglass Filter 20” x 20” x 1” (508 mm x 508 mm x 25 mm)

14

10941291 Service Blower Assembly for 21ECM10 and 21ECM15

10941292 Service Blower Assembly for 21ECM18/20/23

15* 624664 Daughterboard (21ECM23 only)

16* FK120 ECM 120 Volt Kit (optional, purchase separately)

* Item not shown.

REPLACEMENT PARTS AND REPAIR

In order to ensure your unit remains in good working condition, you must use Broan-NuTone genuine replacement parts only. The

Broan-NuTone genuine replacement parts are specially designed for each unit and are manufactured to comply with all the applicable

certification standards and maintain a high standard of safety. Any third party replacement part used may cause serious damage and

drastically reduce the performance level of your unit, which will result in premature failing. Also, Broan-NuTone recommends to

contact a certified service depot for all replacement parts and repair.

Page 7

WIRING DIAGRAMS

7

For the use of a two-stage heat thermostat or

an outdoor thermostat, connect between W1

and W2. Make sure that the Season Select

switch is set to the “Mild” Position.

HI BLACK

MED-HI BLUE

MED-LO YELLOW

LO RED

FAN MOTOR SPEED COLOR

WIRING COLOR CODE

BLK BLACK

BLU BLUE

BRN BROWN

GRN GREEN

GRY GREY

ORG ORANGE

PNK PINK

PPL PURPLE

RED RED

WHT WHITE

YEL YELLOW

LEGEND

F1 Fuse

E Heating Element

KC Heating Element

Relay

K Fan Relay

HTL Auto-Reset

Thermal Protector

MRHTL Manual Reset

Thermal Protector

M Fan Motor

TB Terminal Block

T Transformer Class 2

HEAT Heat

L1, L2 240 V Line Supply

N Neutral

KC3

HEAT 3

HEAT 1

HEAT 2

KC2

KC1

K7

24 VAC

24 VAC

COMMON OUT

FUSED 24 VAC

POWER OUT

CALL FOR FAN

CALL FOR COOL

REVERSING VALVE

CALL FOR HEAT 1

CALL FOR HEAT 2

CALL FOR COOL 1

BOARD POWER

SUPPLY

POWER

HEAT 1

HEAT 2

HEAT 3

HEAT 4

VOUT

GND

24VDC

24VDC

24VDC

E

HTL

E

HTL

E

HTL

G

L1

COM

NO

COMNO

COMNO

Class 2 Transformer

Pri: 240 V 60 Hz

Sec: 24 V 60 Hz 40 VA

YEL

YEL

RED

BLK

RED

BLK

BLK

BLK

RED

KLBDER

BLK

BLK

HEAT 3

HEAT 2

HEAT 1

PNK

BRN

GRY

WHT

YEL

WHT

WHT

BLK

PPL

VENTILATION SPEED

MED-LO

LO

24VDC

4

6

2

5

13

PNK

RED

YEL

BLU

BLU

ORG

WHT

P2

P1

GRY

PNK

TB

T

HEAT INDICATOR

SEASON SELECT

GRY

PPL

PPL

PPL

BLK

BLK

BLK

BLK

BLK

BLK

NC

YEL

X13 COM

X13 HEAT

X13 COOL

XFMR

L1

L1

L2COM

L2

L2

BLK (HI)

BLU (MED-HI)

RED (LO)

YEL (MED-LO)

WHT

5

4

3

2

1

N

G

L

C

M

BLK

BLK

RED RED

ORG BLK

P2-8

P2-4

P2-3

P2-2

P2-1

P2-5

P2-6

P2-7

NC

C=COM

L=LINE

G=GROUND

N=NEUTRAL

1=LO

2=MED HI

3=MED HI

4=HI

5=HI

M

15 kW 240 VAC

Single phase

N

L2

RED

RED

RED

Y1

W2

W1

O

Y/Y2G

R

C

F1

5 AMPS

P3

P3-1 P3-2 P3-3

P3-4 P3-5

P3-6

P3-7

GRY

BRN

PNK

Open: 93.3°C (200°F)

MRHTL2

WHTWHT

WHT

WHT

RED

RED

MRHTL1

WHTWHT

Line voltage wiring:

UL AWM 1015/1230, 600V, 105°C,

VW-1,12 AWG;

CSA TEW 600V, 105°C,

FT1, 12 AWG.

Low voltage wiring: same ratings

as high voltage except 18 AWG.

Critical Characteristics

1. If any of the original wire, as

supplied, must be replaced,

use the same equivalent wire.

Wiring must comply with

applicable codes, ordinances

and regulations.

2. Field wiring must comply

with applicable codes,

ordinances and regulations.

Use only Class 1 wiring

inside furnace compartments.

KC3

HEAT 3

HEAT 1

KC1

K7

24 VAC

24 VAC

COMMON OUT

FUSED 24VAC

POWER OUT

CALL FOR FAN

CALL FOR COOL

REVERSING VALVE

CALL FOR HEAT 1

CALL FOR HEAT 2

CALL FOR COOL 1

BOARD POWER

SUPPLY

POWER

HEAT 1

HEAT 2

HEAT 3

HEAT 4

VOUT

GND

24VDC

24VDC

E

HTL

E

HTL

G

L1

COM

NO

COMNO

Class 2 Transformer

Pri: 240 V 60Hz

Sec: 24 V 60Hz 40 VA

YEL

YEL

RED

BLK

BLK

BLK

RED

KLBDER

BLK

HEAT 3

HEAT 1

PNK

GRY

WHT

YEL

WHT

BLK

PPL

VENTILATION SPEED

MED-LO

LO

24VDC

4

6

2

5

13

PNK

RED

YEL

BLU

BLU

ORG

WHT

P2

P1

GRY

PNK

TB

T

HEAT INDICATOR

SEASON SELECT

GRY

PPL

PPL

PPL

BLK

BLK

BLK

BLK

BLK

NC

YEL

X13 COM

X13 HEAT

X13 COOL

XFMR

L1

L1

L2COM

L2

L2

BLK (HI)

BLU (MED-HI)

RED (LO)

YEL (MED-LO)

WHT

5

4

3

2

1

N

G

L

C

M

BLK

BLK

RED RED

ORG BLK

P2-8

P2-4

P2-3

P2-2

P2-1

P2-5

P2-6

P2-7

NC

C=COM

L=LINE

G=GROUND

N=NEUTRAL

1=LO

2=MED HI

3=MED HI

4=HI

5=HI

M

10 kW 240 VAC

Single phase

N

L2

RED

RED

RED

Y1

W2

W1O

Y/Y2GR

C

F1

5 AMPS

P3

P3-1 P3-2 P3 -3

P3-4 P3-5

P3-6

P3-7

GRY

PNK

Open: 93.3°C (200°F)

MRHTL2

WHTWHT

WHT

WHT

RED

MRHTL1

WHTWHT

WARNING

Risk of electric shock. Disconnect power before installation, servicing, maintenance or field wiring. Replace all panels before

operating. Failure to do so can result in electric shock causing severe injuries or death.

!

Page 8

8

WIRING DIAGRAMS (CONT’D)

Line voltage wiring:

UL AWM 1015/1230, 600V, 105°C, VW-1,12 AWG;

CSA TEW 600V, 105°C, FT1, 12 AWG.

Low voltage wiring: same ratings as high voltage

except 18 AWG.

Critical Characteristics

1. If any of the original wire, as supplied, must be

replaced, use the same equivalent wire. Wiring

must comply with applicable codes, ordinances

and regulations.

2. Field wiring must comply with applicable codes,

ordinances and regulations. Use only Class 1

wiring inside furnace compartments.

For the use of a two-stage heat thermostat or

an outdoor thermostat, connect between W1

and W2. Make sure that the Season Select

switch is set to the “Mild” Position.

HI BLACK

MED-HIGH BLUE

MED-LOW YELLOW

LOW RED

FAN MOTOR SPEED COLOR

WIRING COLOR CODE

BLK BLACK

BLU BLUE

BRN BROWN

GRN GREEN

GRY GREY

ORG ORANGE

PNK PINK

PPL PURPLE

RED RED

WHT WHITE

YEL YELLOW

LEGEND

F1 Fuse

E Heating Element

KC Heating Element

Relay

K Fan Relay

HTL Auto-Reset

Thermal Protector

MRHTL Manual Reset

Thermal Protector

M Fan Motor

TB Terminal Block

T Transformer Class 2

HEAT Heat

L1, L2 240 V Line Supply

N Neutral

HEAT 4

E

HTL

KC4

KC3

HEAT 3

HEAT 1

HEAT 2

KC2

KC1

K7

24 VAC

24 VAC

COMMON OUT

FUSED 24VAC

POWER OUT

CALL FOR FA

CALL FOR COOL

REVERSING VALVE

CALL FOR HEAT 1

CALL FOR HEAT 2

CALL FOR COOL 1

BOARD POWER

SUPPLY

POWER

HEAT 1

HEAT 2

HEAT 3

HEAT 4

VOUT

GND

24VDC

24VDC

24VDC

24VDC

E

HTL

E

HTL

E

HTL

G

L1

COM

NO

COM

NO

COMNO

COMNO

Class 2 Transformer

Pri: 240 V 60 Hz

Sec: 24 V 60 Hz 40 VA

YEL

YEL

RED

BLK

RED

BLK

BLK

BLK

BLK

RED

KLBDER

BLK

BLK

BLK

HEAT 4

HEAT 3

HEAT 2

HEAT 1

PNK

BRN

GRY

YEL

WHT

WHT

WHT

BLK

PPL

VENTILATION SPEED

MED-LO

LO

24VDC

4

6

2

5

13

PNK

RED

YEL

BLU

BLU

ORG

WHT

P2

P1

GRY

PNK

TB

T

HEAT INDICATOR

SEASON SELECT

GRY

PPL

PPL

PPL

BLK

BLK

BLK

BLK

BLK

BLK

BLK

RED

NC

YEL

PPL

X13 COM

X13 HEAT

X13 COOL

XFMR

L1

L1

L2COM

L2

L2

BLK (HI)

BLU (MED-HI)

RED (LO)

YEL (MED-LO)

WHT

5

4

3

2

1

N

G

L

C

M

BLK

BLK

RED RED

ORG BLK

P2-8

P2-4

P2-3

P2-2

P2-1

P2-5

P2-6

P2-7

NC

C=COM

L=LINE

G=GROUND

N=NEUTRAL

1=LO

2=MED HI

3=MED HI

4=HI

5=HI

M

18/20 kW 240 VAC

Single phase

N

L2

RED

RED

RED

RED

RED

RED

Y1

W2

W1O

Y/Y2G

R

C

BLK

F1

5 AMPS

P3

P3-1 P3-2 P3-3

P3-4 P3-5

P3-6

P3-7

WHT

GRY

BRN

PNK

PPL

Open: 93.3°C (200°F)

MRHTL2

WHTWHT

WHT

WHT

MRHTL1

WHTWHT

WARNING

Risk of electric shock. Disconnect power before installation, servicing, maintenance or field wiring. Replace all panels before

operating. Failure to do so can result in electric shock causing severe injuries or death.

!

Page 9

9

WIRING DIAGRAMS (CONT’D)

Line voltage wiring:

UL AWM 1015/1230, 600V, 105°C, VW-1,12 AWG;

CSA TEW 600V, 105°C, FT1, 12 AWG.

Low voltage wiring: same ratings as high voltage

except 18 AWG.

Critical Characteristics

1. If any of the original wire, as supplied, must be

replaced, use the same equivalent wire. Wiring

must comply with applicable codes, ordinances

and regulations.

2. Field wiring must comply with applicable codes,

ordinances and regulations. Use only Class 1

wiring inside furnace compartments.

For the use of a two-stage heat thermostat or

an outdoor thermostat, connect between W1

and W2. Make sure that the Season Select

switch is set to the “Mild” Position.

HI BLACK

MED-HIGH BLUE

MED-LOW YELLOW

LOW RED

FAN MOTOR SPEED COLOR

WIRING COLOR CODE

BLK BLACK

BLU BLUE

BRN BROWN

GRN GREEN

GRY GREY

ORG ORANGE

PNK PINK

PPL PURPLE

RED RED

WHT WHITE

YEL YELLOW

LEGEND

F1 Fuse

E Heating Element

KC Heating Element

Relay

K Fan Relay

HTL Auto-Reset

Thermal Protector

MRHTL Manual Reset

Thermal Protector

M Fan Motor

TB Terminal Block

T Transformer Class 2

HEAT Heat

L1, L2 240 V Line Supply

N Neutral

HEAT 4

E

HTL

KC4

KC3

HEAT 3

HEAT 1

HEAT 2

KC2

KC1

K7

24 VAC

24VAC

COMMON OUT

FUSED 24 VAC

POWER OUT

CALL FOR FAN

CALL FOR COOL.

REVERSING VALVE

CALL FOR HEAT 1

CALL FOR HEAT 2

CALL FOR COOL 1

BOARD POWER

SUPPLY

POWER

HEAT 1

HEAT 2

HEAT 3

HEAT 4

VOUT

GND

24VDC

24VDC

24VDC

24VDC

E

HTL

E

HTL

E

HTL

G

L1

COM

NO

COM

NO

COMNO

COMNO

Class 2 Transformer

Pri: 240 V 60 Hz

Sec: 24 V 60 Hz 40 VA

YEL

YEL

RED

BLK

RED

BLK

BLK

BLK

BLK

RED

KLBDER

BLK

BLK

BLK

BLK

PPL

HEAT 4

HEAT 3

HEAT 2

HEAT 1

PNK

BRN

GRY

WHT

YEL

WHT

WHT

WHT

BLK

PPL

VENTILATION SPEED

MED-LO

LO

24VDC

4

6

2

5

13

PNK

RED

YEL

BLU

BLU

ORG

WHT

P2

P1

GRY

PNK

TB

T

HEAT INDICATOR

SEASON SELECT

GRY

PPL

PPL

PPL

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

RED

NC

YEL

Open: 93.3°C (200°F)

MRHTL1

WHTWHT

PPL

PNK

X13 COM

X13 HEAT

X13 COOL

XFMR

L1

L1

L2COM

L2

L2

BLK (HI)

BLU (MED-HI)

RED (LO)

YEL (MED-LO)

WHT

5

4

3

2

1

N

G

L

C

M

BLK

BLK

RED RED

ORG BLK

P2-8

P2-4

P2-3

P2-2

P2-1

P2-5

P2-6

P2-7

COM

KC5

NO

HEAT 5

MRHTL2

NC

C=COM

L=LINE

G=GROUND

N=NEUTRAL

1=LO

2=MED HI

3=MED HI

4=HI

5=HI

M

23 kW 240 VAC

Single phase

N

L2

RED

RED

RED

RED

RED

RED

RED

Y1

W2

W1O

Y/Y2

G

R

C

BLK

24VDC

P2-3

P2-2

P2-1

P1-4

P1-3

P1-2

P1-1

24V

regulated

RLY PWR2

Heater

Logic

HEAT6 IN

HEAT5 IN

HEAT6

HEAT5

HEAT 5

RED

E

HTL

F1

5 AMPS

P3

P3-1 P3-2 P3-3

P3-4 P3-5

P3-6

P3-7

GRY

PNK

PNK

WHT

PNK

PNK

PPL

GRY

PPL

WHT

GRY

BRN

PNK

PNK

WHT

BLK

WHT

WHT

WARNING

Risk of electric shock. Disconnect power before installation, servicing, maintenance or field wiring. Replace all panels before

operating. Failure to do so can result in electric shock causing severe injuries or death.

!

Page 10

The first step in identifying an operational problem is to determine

whether the fault is in the furnace or in the thermostat and/or its

connecting wiring.

To help make this determination, the furnace is equipped with a

“Thermostat ON” diagnostic light. If the light is “ON”, it indicates

the thermostat has closed and is calling for heat; the blower

should be running. If the light is “OFF”, the furnace should not be

operating.

1. If the furnace will not start:

Turn the thermostat to its highest setting. If the light goes on,

the thermostat has closed, so the fault is in the furnace. If the

light does not go on, the thermostat or its connecting wiring is

the problem.

2. If the furnace will not turn off:

Turn the thermostat to its lowest setting. If the light goes off and

the furnace continues to run, the thermostat has opened properly

and the fault is in the furnace. If the light stays on, the fault is

in the thermostat or its connecting wiring.

After the fault area is isolated by use of the diagnostic light, a check

of the following components can be made more efficiently.

TROUBLESHOOTING

PROBLEM POSSIBLE DEFECTIVE PARTS OR COMPONENTS

1. The furnace will not turn on

• Thermostat

• Circuit breaker or fuse is open

• Motor

• S

PEED SELECTOR switch (open contact)

• Electronic control

• Transformer

2. Motor runs continuously • Thermostat wires incorrectly attached to furnace

3. Elements on, but motor does not run

• Motor

• SPEED SELECTOR switch (open contact)

• Electronic control

4. Motor going on and off in short cycles

(or in too long cycles)

• Heat anticipator in thermostat incorrectly set

or may be defective

5. Must set thermostat much higher (or lower)

than the desired house temperature

• Thermostat is not leveled or out of calibration

6. Not enough heat

• One or more defective elements or relays

• SEASON SELECT switch in MILD position

• Safety limits opening because duct obstruction

or dirty filters are restricting air flow

• Defective or incorrectly wired two-stage

or outdoor thermostat

• Lack of enough cold air returns in house

7. Two-stage or outdoor thermostat not operating properly • SEASON SELECT switch not in MILD position

10

SIXTY-MONTH LIMITED WARRANTY FOR NORTRON PRODUCTS

Broan-NuTone Canada (Broan-NuTone) warrants to the original consumer purchaser of Notron products that such products will be free from defects in

materials or workmanship for a period of sixty (60) months from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this sixty-month period, Broan-NuTone will, at its option, repair or replace without charge, any product or part which is found to be defective under

normal use and service. This product or part should be shipped prepaid by the customer to the company factory or the nearest authorized service center.

THIS WARRANTY DOES NOT EXTEND TO FILTERS, FURNACE KITS SOLD SEPARATELY, DUCTS, AND ACCESSORIES FOR DUCTING. This warranty

does not cover (a) normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence, accident, improper

maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions. Broan-NuTone

does not accept any responsibility for transportation of repaired part or replaced product mentioned above and for reinstallation costs.

The duration of any implied warranty is limited to the sixty-month period as specified for the express warranty. Some jurisdictions do not allow limitation

on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND

EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL

DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some jurisdictions do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from province to another. This warranty supersedes all prior

warranties, and applies only in Canada territorial limits.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number stated below, (b) give the model number and part

identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty service, you must present evidence of the

original purchase date.

Broan-NuTone Canada; 1140 Tristar Drive, Mississauga, ON L5T 1H9 www.broan.ca 877-896-1119

Loading...

Loading...