Page 1

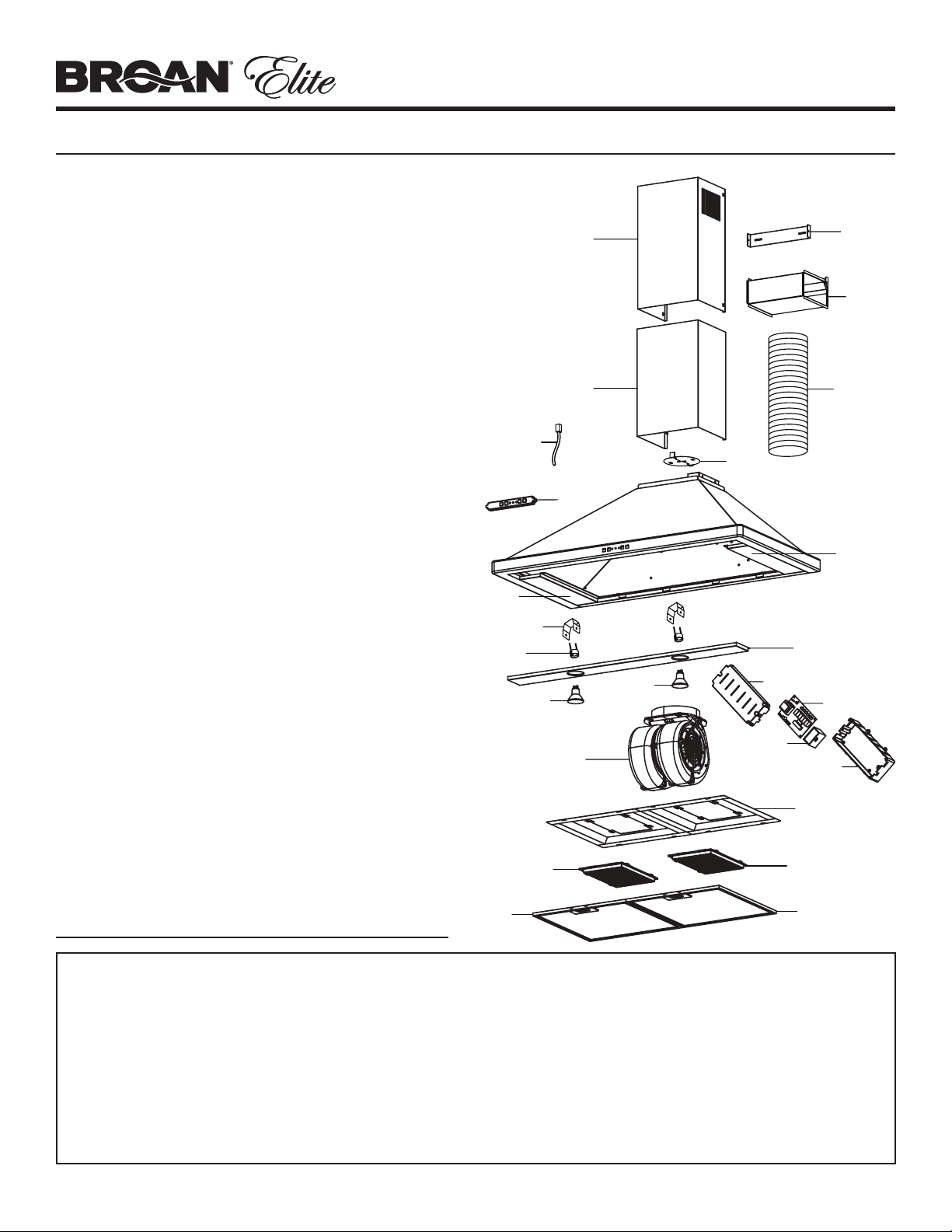

Chimney

Range Hood

READ AND SAVE THESE INSTRUCTIONS

FOR DOMESTIC COOKING ONLY

MODELS EW5830SS • EW5836SS

Page 1

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSON(S) OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If

you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel

and lock service disconnecting means to prevent power from being

switch on accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by qualified

personnel in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment to

prevent back drafting. Follow the heating equipment manufacturer’s

guideline and safety standards such as those published by the

National Fire Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. This product may have sharp edges. Be careful to avoid cuts and

abrasions during installation and cleaning.

6. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

7. Ducted fans must a

8. Use only metal ductwork.

9. Do not use this unit with any other solid-state speed control device.

10. Do not operate any fan with a damaged cord or plug. Discard fan or

return to an authorized service facility for examination and/or repair.

11. GROUNDING INSTRUCTION: The appliance must be grounded.

In the event of an electrical short circuit, grounding reduces the risk

of electric shock by providing an escape wire for the electric current.

The appliance is equipped with a cord having a grounding wire with

a grounding plug. The plug must be plugged into an outlet that is

properly installed and grounded. WARNING: Improper grounding

can result in a risk of electric shock. Consult a qualified electrician

if the grounding instructions are not completely understood, or if

doubt exists as to whether the appliance is properly grounded. Do

not use an extension cord. If the power supply cord is too short,

have a qualified electrician install an outlet near the appliance.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when flambéing

food (i.e. Crêpes Suzette, Cherries Jubilee, Peppercorn Beef

Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filters.

d) Use proper pan size. Always use cookware appropriate for the size

of the surface element.

lways be vented to the outdoors.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSON(S) IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

IF THE FLAMES DO NOT GO OUT IM MEDI ATELY, EVACUATE

AND CALL THE FIRE DEPART MENT.

2. NEVER PICK UP A FLAMING PAN – You may be burned.

3. DO NOT USE WATER , including wet dishcloths or towels – a violent

steam explosion will result.

4. Use an extinguisher ON LY if:

A. You know you have a Class ABC extinguisher, and you

know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust hazardous

or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced

impeller, keep drywall spray, construction dust, etc. off power unit.

4. Your hood motor has a thermal overload which will automatically

shut off the motor if it becomes overheated. The motor will restart

when it will cool down. If the motor continues to shut off and

restart, have the hood serviced.

5. The bottom of the hood MUST NOT BE LESS than 24” and

recommended at a maximum of 36” above cooktop for best

capture of cooking impurities.

6. Two installers are recommended because of the size of this

hood.

7. To reduce risk of fire and to properly exhaust air, be sure to duct

air outside. Do not exhaust air into spaces within walls or ceilings

or into attics, crawl spaces, or garages.

hood,

8. Be careful when installing the decorative flue and

have sharp edges.

9. This hood is not intended to be used as a shelf.

10. Please read specification label on product for further information

and requirements.

Register your product online at: www.broan.com

Installer: Leave this manual

with the homeowner.

Homeowner: Operation and Maintenance

instructions on pages 7 & 8.

they may

Page 2

MODELS EW5830SS • EW5836SS

Page 2

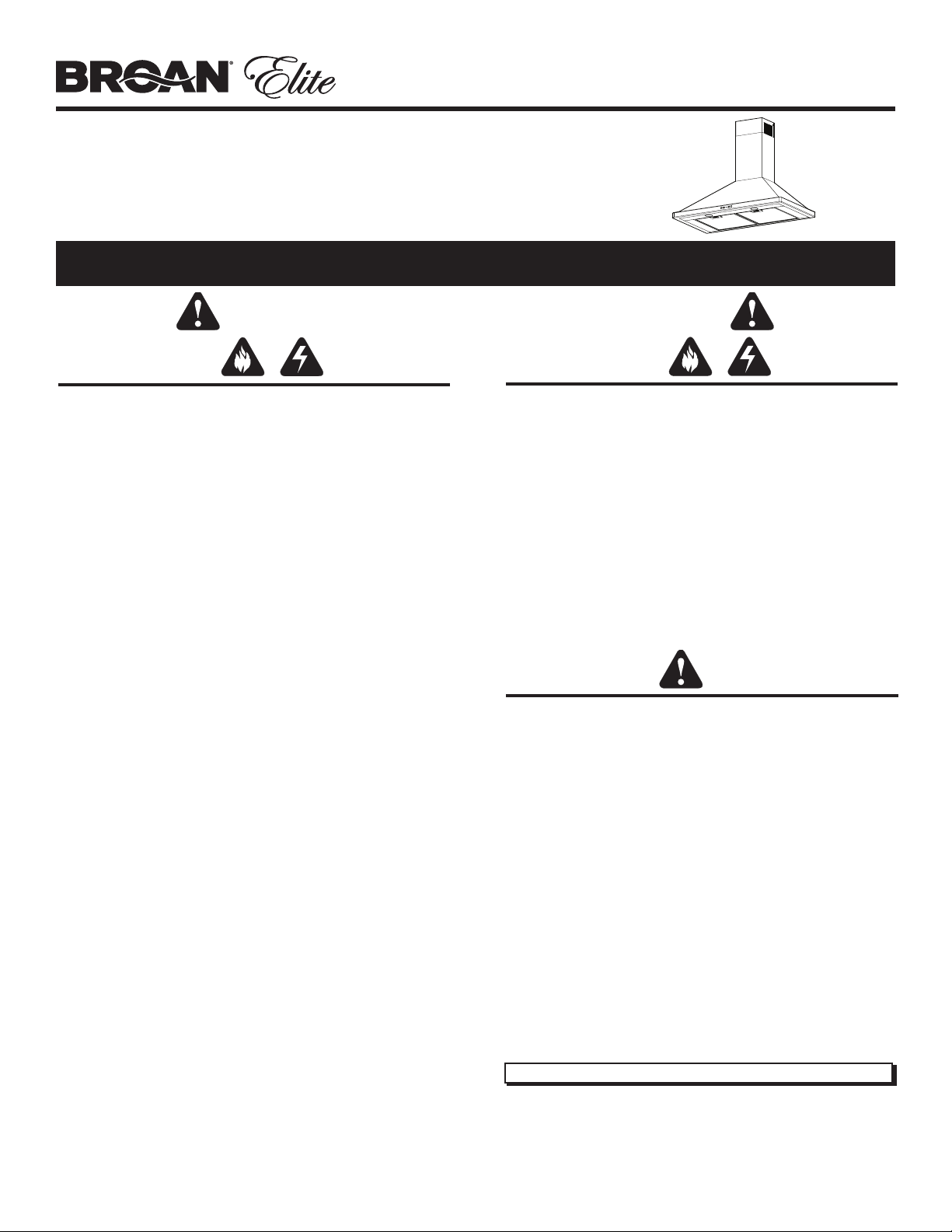

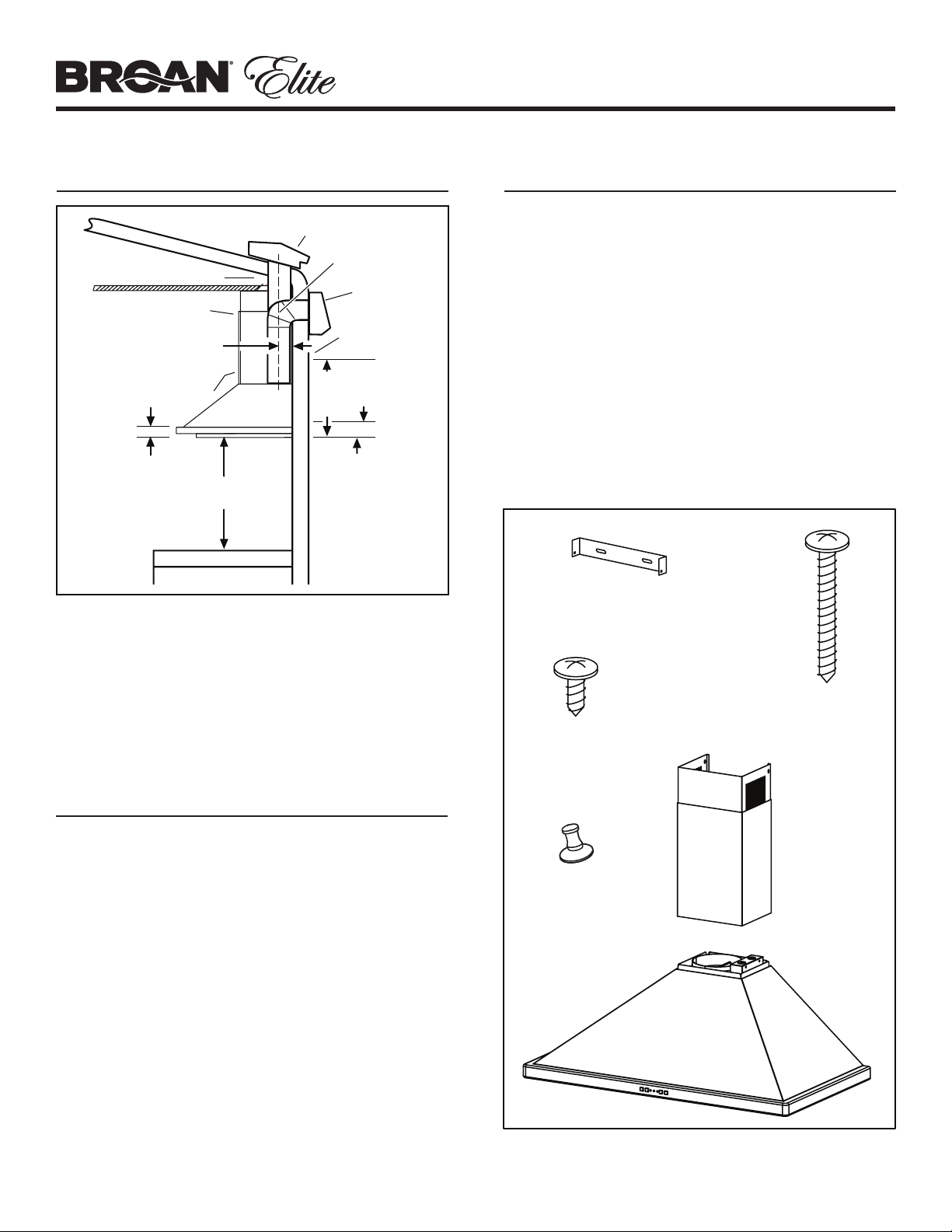

MEASURE THE INSTALLATION

CAP

ROOF

ROUND

ELBOW

6” ROUND DUCT

DECORATIVE FLUE

3½” FROM WALL TO

CENTER

LINE OF DUCT

(NOTE: CENTERLINE OF

IS ¾” LEFT OF

BLOWER

CENTERLINE

OF HOOD.)

DECORATIVE FLUE

HOOD

1 5/8”

24” TO 36” ABOVE

COOKING

SURFACE

The minimum hood distance above cooktop MUST NOT BE

LESS than 24”.

A maximum of 36” above cooktop is highly recommended for

best capture of cooking impurities.

Distances over 36” are at the installer and users discretion;

providing that the ceiling height permits.

WALL CAP

MOUNTING

HOOD

BRACKET

12 3/8” TO CENTER

OF

UPPER BRACKET

HOLES

2” TO CENTER

OF

LOWER HOOD

CHASIS

HOLES

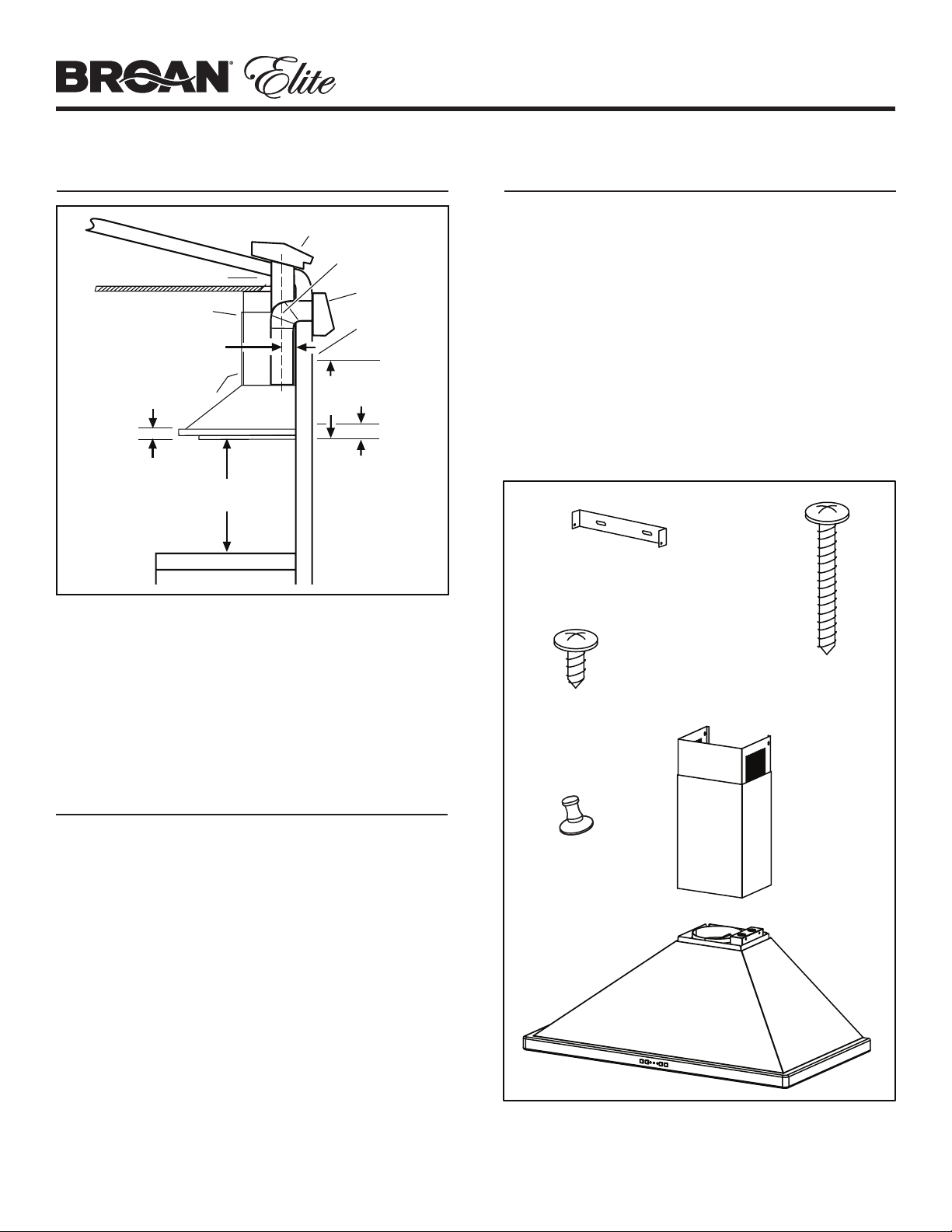

PREPARE THE HOOD

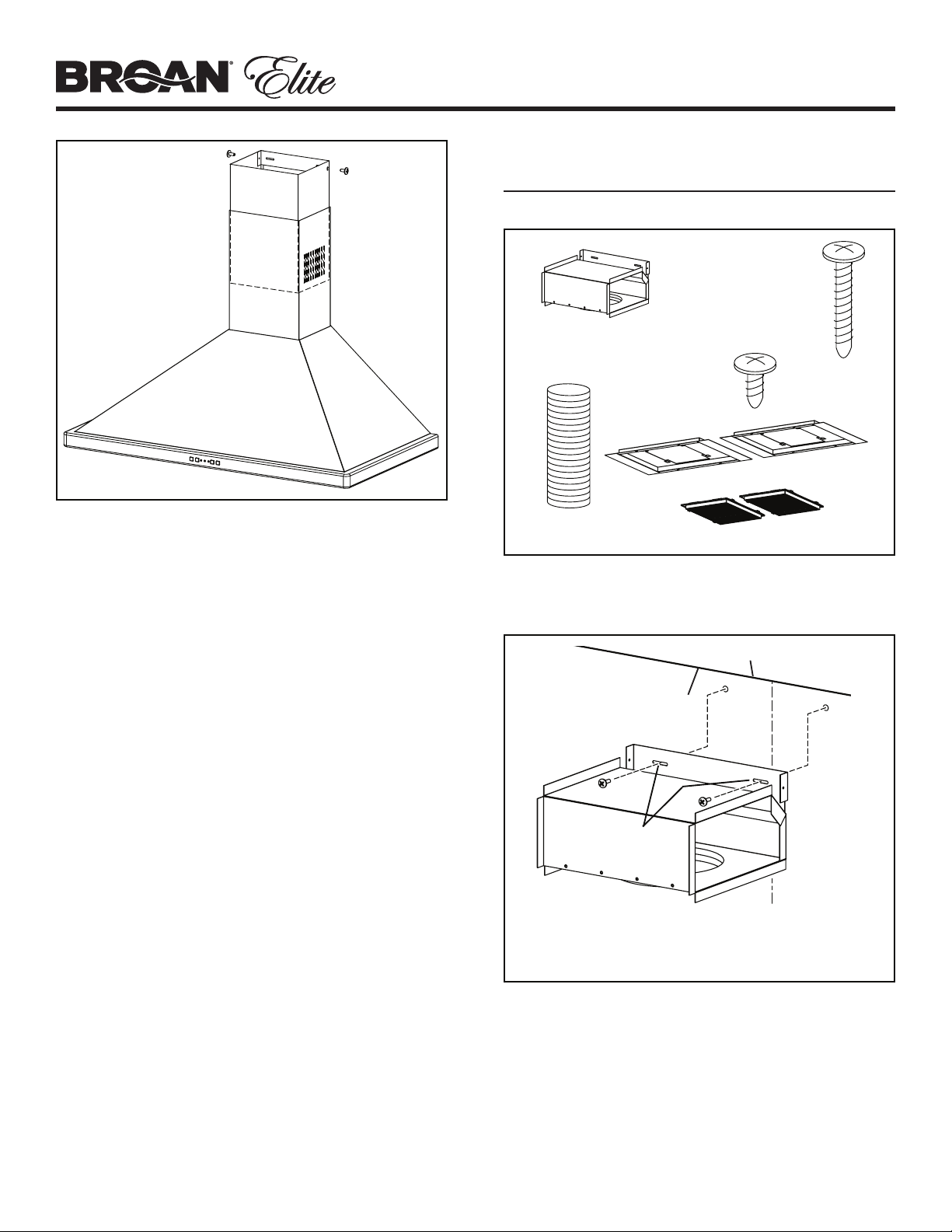

Unpack hood and check contents. Yo u should receive:

1 - Hood Assembly

1 - Decorative Flue Assembly (consisting of upper and lower

flue)

1 - Upper Flue Mounting Bracket

2 - Aluminum Grease Filters (installed on hood)

2 - 35W MR16 GU10 Halogen Lamps (installed on hood)

1 - Parts Bag containing:

6 - Mounting Screws (4mm x 38mm Cross Recessed Pan Head)

2 - Mounting Screws (4mm x 12mm Cross Recessed Pan Head)

1 - Suction Cup Tool

1 - Installation Manual

UPPER

FLUE MOUNTING

BRACKET

2 MOUNTING

SCREWS

(4mm x 12mm

Cross Recessed

Pan Head)

6 MOUNTING

SCREWS

(4mm x 38mm

Cross Recessed

Pan Head)

INSTALL THE DUCTWORK

(Ducted Hoods Only)

1. Decide where the ductwork will run between the hood and

the outside.

2. A straight, short duct run will allow the hood to perform most

efficiently.

3. Long duct runs, elbows and transitions will reduce the

performance of the hood. Use as few of them as possible.

Larger ducting may be required for best performance with

longer duct runs.

4. Install wall cap or roof cap. Connect round metal ductwork

to cap and work back towards the hood location. Use duct

tape to seal the joints between ductwork sections.

NOTE

Centerline of duct connector on hood is ¾” to the left of the

centerline of the hood – plan duct rough-in accordingly.

BULB

SUCTION

CUP TOOL

DECORATIVE

FLUE

ASSEMBLY

HOOD

ASSEMBLY

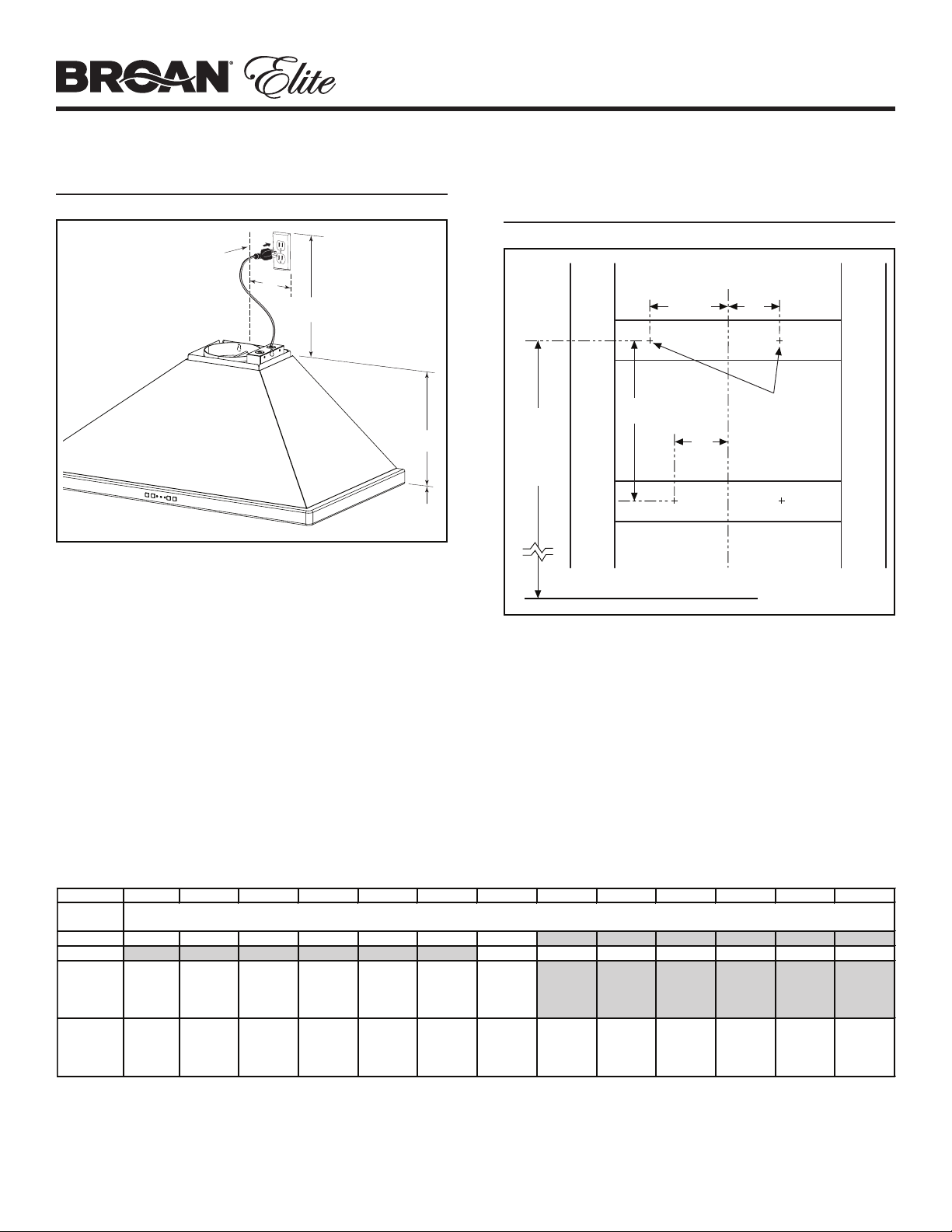

Page 3

MODELS EW5830SS • EW5836SS

Ceiling

Height

Desired Hood Distance (Above 36" High Cooktop)

Page 3

INSTALL THE WIRING INSTALL THE HOOD MOUNTING

SUPPORT

HOOD

CENTERLINE

3 1/2 ”

C

L

2 ”

4¼”

MAX.

24”

MAX.

12”

24” TO 36”

ABOVE

COOKTOP

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This appliance

is equipped with a cord having a grounding wire with a grounding

plug. The plug must be plugged into an outlet that is properly

installed and grounded.

Position the electrical outlet within the space covered by the

decorative flue and where it will not interfere with the round

duct. Make sure the outlet is no further than 24” from the top

of the hood chassis, and that the outlet does not interfere with

a mounting bracket fastening area or where the decorative flue

touches the wall.

4mm x 38mm

SCREWS

HERE

36” HIGH COOKTOP

A

SEE

CHART

BELOW

10 3/8 ”

3 ”

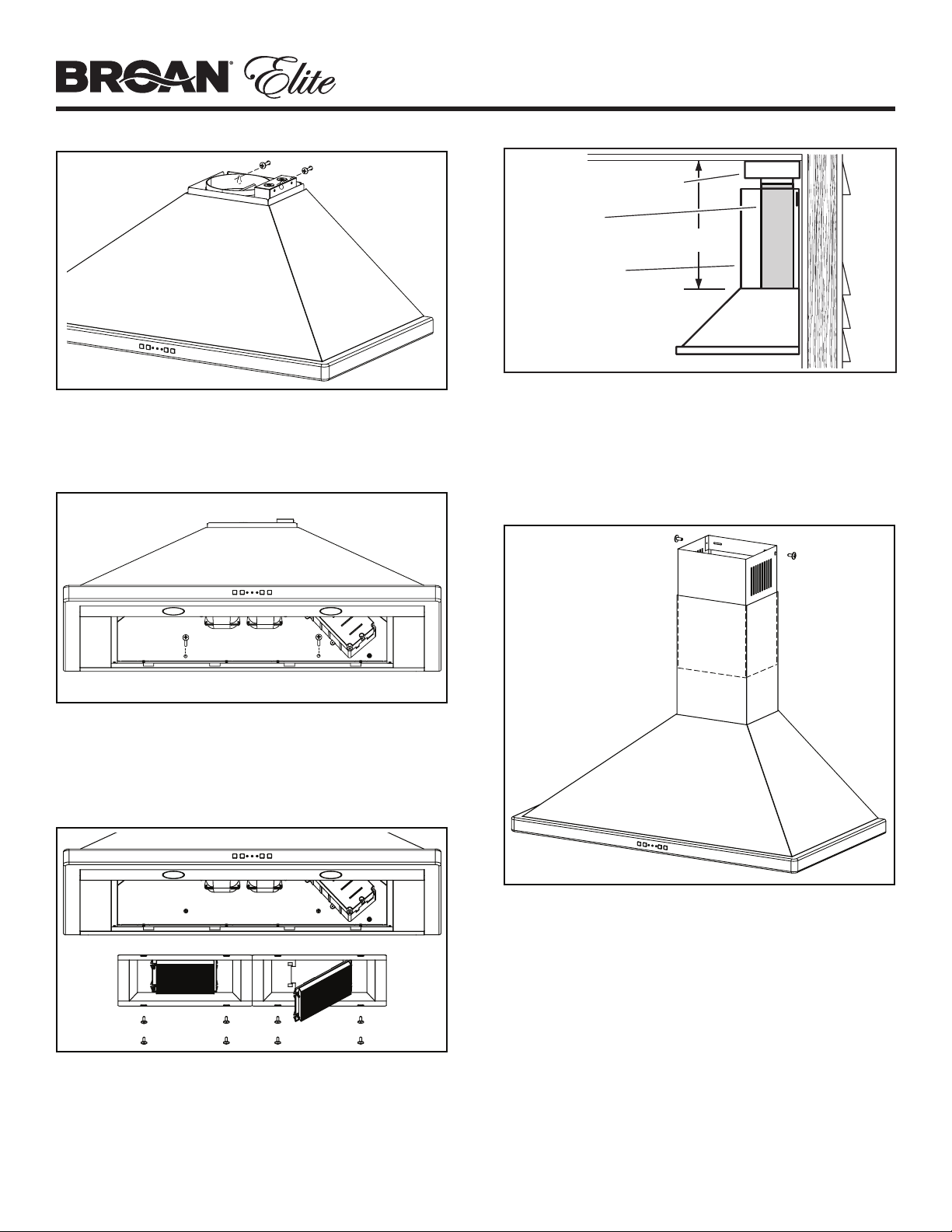

1. Construct wood wall framing that is flush with interior

surface of wall studs. Make sure the framing is centered over

installation location.

NOTE

Hood distance above cooktop is: Minimum 24”, Maximum 36”.

9-ft. and 10-ft. ceilings may require Flue Extension, Model

FXNE58SS, depending on installation height (purchase

separately). See chart below for additional installation height

information.

2. After wall surface is finished, fasten (2) 4mm x 38mm screws

at the locations shown above. DO NOT TIGHTEN screws all

the way.

24" 25"26" 27" 28"29" 30" 31" 32" 33" 34" 35" 36"

Upper Mounting Screws Location (Distance above 36" High Cooktop)

8 Feet 36-3/8" 37-3/8" 38-3/8" 39-3/8"40-3/8"41-3/8" 42-3/8"

9 Feet

9 Feet

with

FXNE58SS

10 Feet

with

FXNE58SS

* Non-duct recirculation louvers will be exposed in ducted configuration

36-3/8" 37-3/8" 38-3/8" 39-3/8"40-3/8"41-3/8" 42-3/8"

36-3/8" 37-3/8" 38-3/8" 39-3/8"40-3/8"41-3/8" 42-3/8"

*42-3/8"

*43-3/8" *44-3/8" *45-3/8" *46-3/8" *47-3/8" *48-3/8"

43-3/8" 44-3/8" 45-3/8" 46-3/8" 47-3/8" 48-3/8"

(Dimension “A”)

Page 4

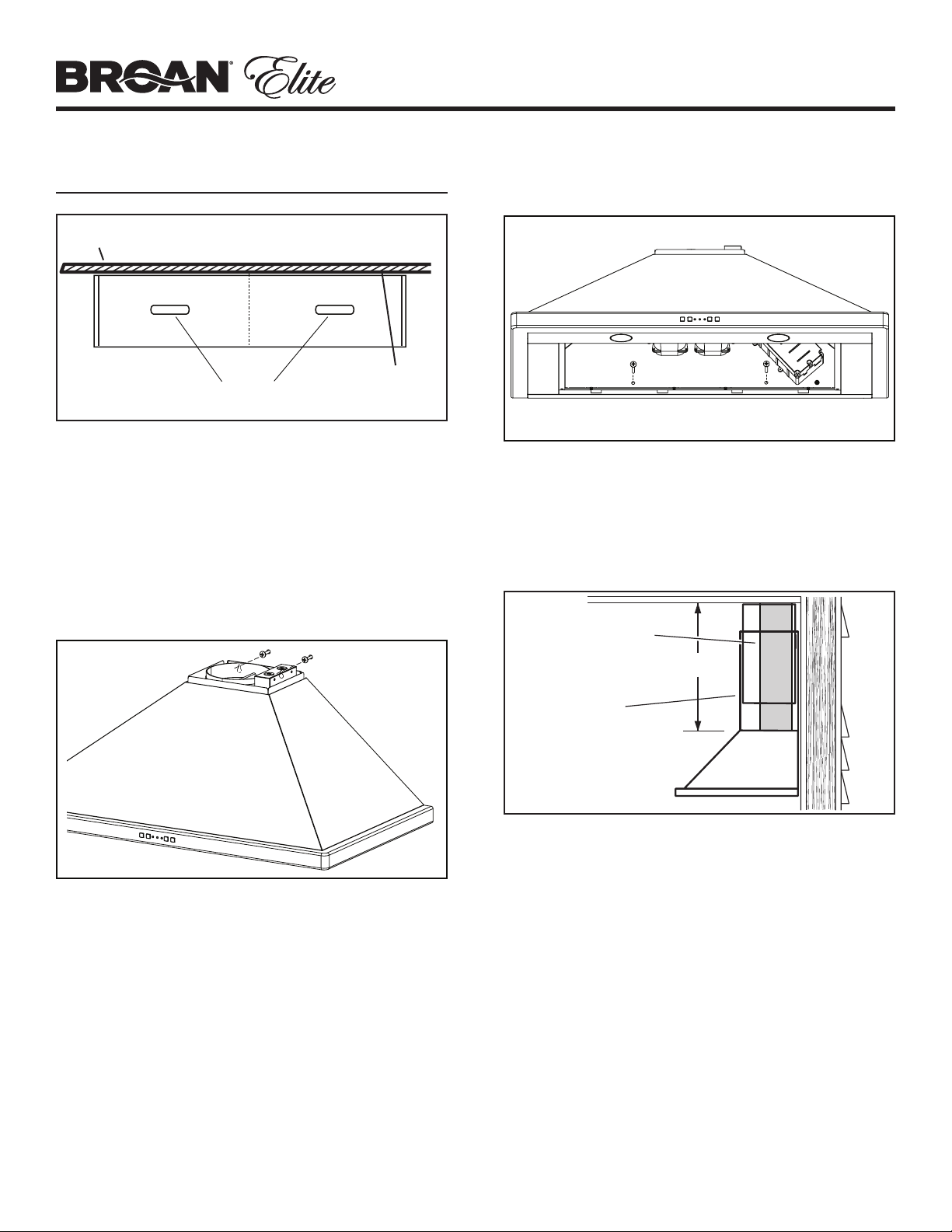

INSTALL THE HOOD

(Ducted Hoods Only)

MODELS EW5830SS • EW5836SS

Page 4

Ceiling

1. Center the flue mounting bracket over the hood location and

flush with the ceiling. Secure the upper flue bracket to the

wall using (2) 4mm x 38mm mounting screws. Note: Drywall

anchors may be required (not included).

2. Tighten the screws completely. Make sure that the bracket is

tight against the wall and ceiling.

3. Remove the protective plastic film covering the decorative

flue and the hood at this time.

4. Remove the grease filters by pulling down the metal latch tab

and tilting filters downward to remove.

Center of

installation

C

L

Upper flue mounting

bracket slots

Flush with

the ceiling

6. Install (2) 4mm x 38mm long screws into the holes inside the

hood and tighten them securely.

7. Reinstall grease filters by aligning rear filter tabs with slots

in the hood. Pull down the metal latch tab, push filters into

position and release. Make sure filters are securely engaged

after installation.

6” ROUND

STEEL DUCT

DUCT LENGTH

5. Align the two outer keyhole slots on the hood with the

mounting screws that were partially tightened into the wall

framing. Ensure that hood is seated entirely on mounting

screws and that hood is level. Then tighten screws completely.

DECORATIVE

FLUE

8. Measure and install steel ductwork to hood duct connector

and ductwork rough-in on ceiling or wall. Use duct tape to

make all joints secure and air tight.

9. Plug power cord

into wall outlet.

Page 5

MODELS EW5830SS • EW5836SS

INSTALL THE HOOD

(Non-Ducted Hoods Only)

NON-DUCT KIT MODEL RKE58 CONTENTS

2 MOUNTING

SCREWS

(4mm x 38mm

Cross Recessed

NON-DUCT PLENUM

ASSEMBLY

8 MOUNTING

SCREWS

(.188” x .375”

Cross Recessed

Flat Head)

Pan Head)

FILTER TRAYS

Page 5

10. Slide the upper decorative flue section into the lower

decorative flue section.

NOTE

For ducted applications, the louvers on the upper flue should

be hidden by positioning the louvers down, inside of the

lower flue.

11. Carefully place the upper/lower flue assembly into the

recessed area of the hood.

12. Slide the upper flue upward until it is aligned with its mounting

bracket. The bracket should be inside the flue. Secure the

upper flue to the upper flue mounting bracket using (2) 4mm

x 12mm mounting screws.

NOTE

9-10 ft. ceilings may require Flue Extension Model FXNE58SS

depending on installation height (purchase separately).

Discard the upper and lower flues supplied with your hood

and replace them with Flue Extension Model FXNE58SS.

FLEXIBLE DUCT

NON-DUCTED RECIRCULATION FILTERS

NOTE

Non-ducted installations require Non-Duct Kit, Model RKE58

(purchase separately).

Ceiling

Flush with

the ceiling

Upper flue mounting

bracket slots

C

L

Center of

installation

1. Center the non-duct plenum over the hood location and flush

with the ceiling. Secure the non-duct plenum to the wall using

(2) 4mm x 38mm mounting screws. Note: Drywall anchors

may be needed (not included).

2. Tighten the screws completely. Make sure that the non-duct

plenum is tight against the wall and ceiling.

3. Remove damper flaps from damper / duct connector and

discard flaps.

4. Remove the protective plastic film covering the decorative

flue and the hood

Remove the grease filters by pulling down the metal latch tab

5.

and tilting filters downward to remove.

at this time.

Page 6

6. Align the two outer keyhole slots on the hood with the

mounting screws that were partially tightened into the wall

framing. Ensure that hood is seated entirely on mounting

screws and that hood is level. Then tighten screws completely.

MODELS EW5830SS • EW5836SS

Page 6

NON-DUCT

6” ROUND

FLEXIBLE

METAL DUCT

DECORATIVE

FLUE

11. Measure and install section of flexible metal ductwork

(included with RKE58) to hood duct connector and bottom

of non-duct plenum. Use duct tape to make all joints secure

and air tight.

CAUTION

Do not use plastic duct.

12. Plug power cord into wall outlet.

PLENUM

DUCT LENGTH

7. Install (2) 4mm x 38mm long screws into the holes inside the

hood and tighten them securely.

8. Attach (2) filter trays to bottom of hood using (8) .188” x .375”

mounting screws.

9. Snap in 2-non-duct filters into filter trays by engaging filter

tab on side, rotating upward, and pressing firmly on (2) filter

clips.

10. Reinstall grease filters by aligning rear filter tab with slots

in the hood. Pull down the metal latch tab, push filters into

position and release. Make sure filters are securely engaged

after installation.

13. Slide the upper decorative flue section into the lower

decorative flue section.

NOTE

For non-ducted applications, the upper flue should be

oriented so the louvers are towards the ceiling.

14. Carefully place the upper/lower flue assembly into the

recessed area of the hood.

15. Slide the upper flue upward until it is aligned with the nonduct plenum. The non-duct plenum should be inside the flue.

Secure the upper flue to the non-duct plenum using (2) 4mm

x 12mm mounting screws.

NOTE

9-10 ft. ceilings may require Flue Extension Model

FXNE58SS depending on installation height (purchase

separately). Discard the upper and lower flues supplied with

your hood and replace them with Flue Extension Model

FXNE58SS.

Page 7

OPERATION

MAKE UP DAMPER CONNECTION

MODELS EW5830SS • EW5836SS

Page 7

Always turn the hood ON before cooking in order to establish an air

flow in the kitchen. After turning off the range, let the hood run for a

few minutes to clear the air.

Operate the hood as follows:

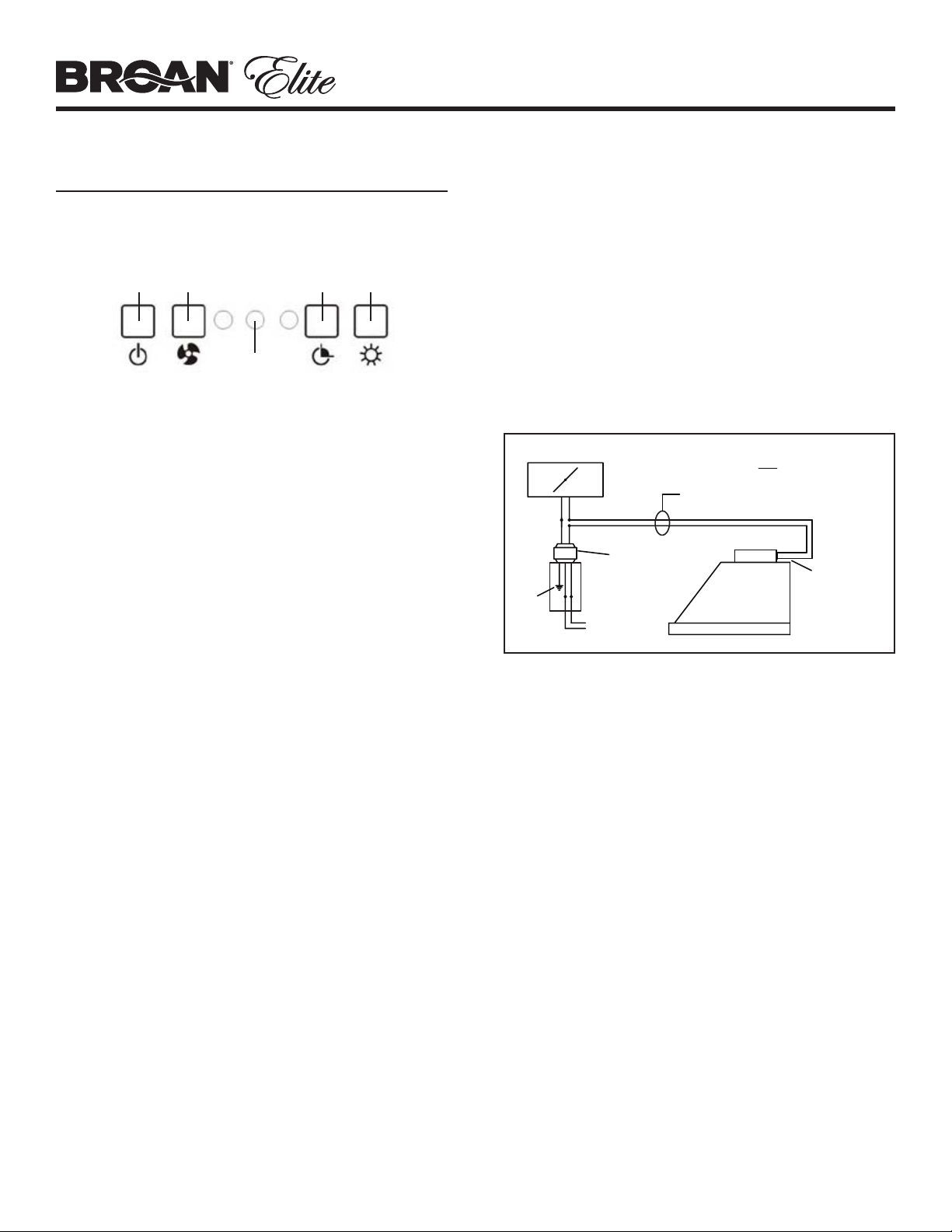

OFF FAN

DELAY

OFF

LIGHT

FAN SPEED

OFF

LED INDICATORS

Turns the fan OFF

FAN (1-Pushbutton Switch, 3-Fan Speeds)

Turns the fan ON to the last selected speed, and activates a blue LED

indicating the fan speed setting. Pressing the FAN button a second

time will index the fan speed and LED indicator to the next highest

setting. Pressing the FAN button when the fan is at the highest speed

setting will index the fan and LED indicator to the lowest setting.

DELAY-OFF (10 Minute Delay-OFF)

Activates the 10 minute delay off feature when the fan is ON (any

speed). When activated, the blue LED indicator above the selected

speed setting will blink. The hood fan will automatically turn OFF after

10 minutes has elapsed. The DELAY-OFF button can be pressed at

any time during the 10 minute countdown to turn off the feature.

LIGHT (1-Pushbutton Switch, 3-Light Intensities)

Turns the lights ON to the lowest intensity. Pressing the LIGHT button

a second time will index the light intensity to the next highest level.

are at

Pressing the LIGHT button when the lights

the highest intensity

will turn the lights off.

FILTER CHANGE INDICATION

After 30 hours of fan operation, the three blue LED indicators will blink

simultaneously, indicating that it is time to clean the grease filters.

To reset the filter clean timer, press and hold the OFF button for 3

seconds. The blinking LED indicators will turn off.

HEAT SENTRY SYSTEM

This range hood is equipped with a standard Heat Sentry system

that monitors excessive temperature and automatically turns the fan

speed on HIGH.

1) If the fan is ON, the Heat Sentry system will increase the fan

setting to its highest speed when the temperature is elevated.

The blue indicator for fan speed (3) will illuminate and blink at

a high rate, indicating that the heat sentry function is activated.

Once the temperature has reduced, the Heat Sentry system will

change the fan speed to the original setting.

2) If the fan is OFF, the Heat Sentry system will automatically turn

the fan on to its highest speed when the temperature is above

normal. The blue indicator for fan speed (3) will illuminate and

blink at a high rate, indicating that the heat sentry function is

activated. After the temperature has lowered to normal, the fan

tur

n off.

will

FUSES

The Range Hood Control Board contains a Main Fuse to protect the

controls from power surges. New fuses can be purchased at a local

electronic supply store. Use 5A, 120V, 5 mm diameter, 20 mm long,

fast-acting, cartridge-type fuses.

To replace a fuse (by qualified person(s):

1. Disconnect power at service entrance.

2. Remove filters

3. Remove control cover

4. Remove and inspect fuse.

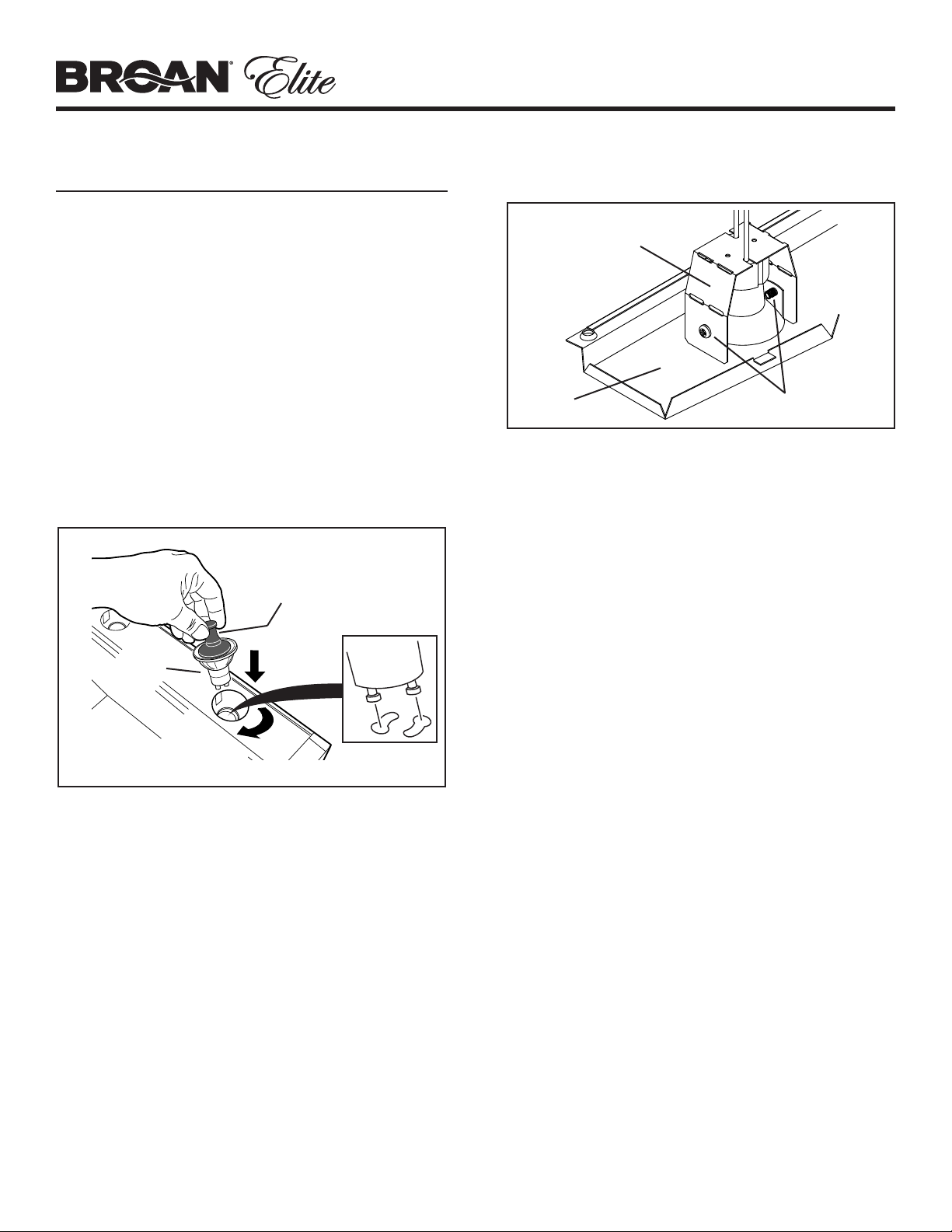

MAKE-UP AIR DAMPER

The hood is compatible with Broan Make-Up Air Damper Model

MD6T or Model MD8T (optional). Purchase separately.

MAKE-UP AIR DAMPER

GRD

120 VAC

60 HZ

24V

TRANSFORMER

(INCLUDED)

(switched low voltage)

20 GAUGE BELL WIRE FOR LOW

VOLTAGE CONNECTION ON

TOP OF HOOD

DRY CONTACT

TERMINAL

HOOD

BUSHING

FOR LOW

VOLTAGE

CONNECTION

Make the connection to the Make-Up Air Damper with low voltage

wiring, as shown. See Make-Up Air Damper instructions for additional

information.

REMOTE CONTROL

The hood is compatible with Broan Radio Frequency (RF) Remote

Control Model BCR1 (optional). Purchase separately.

To link the BCR1 remote control with the hood, press and hold the

LIGH T button for 3-seconds.

The blue LED indicators will turn on and off in succession to indicate

the hood is in RF linking mode. When in the linking mode, press any

key on the RF remote. An audible beep will be heard at the hood, and

the hood LED’s will stop blinking if a successful link is accomplished.

If the remote control did not successfully link with the

hood, the

linking

mode will be deactivated after 12 seconds, and the LED’s will stop

the sequential blinking. Refer to the BCR1 instructions for additional

information.

Page 8

CLEANING & MAINTENANCE

For performance, appearance, and health reasons, clean filter, fan

and grease-laden surfaces. Use only a clean cloth and mild detergent

solution on stainless and painted surfaces.

Clean all-metal filters in the dishwasher using a non-phosphate

detergent. Discoloration of the filter may occur if using phosphate

detergents, or as a result of local water conditions - but this will not

affect filter performance. This discoloration is not covered by the

warranty.

Clean the non-duct recirculating filter surfaces frequently with a damp

cloth and a mild detergent. DO NOT immerse filters in water or put in

dishwasher. Change the non-duct recirculating filters every 6 months.

For replacement non-duct recirculating filters - purchase S99010365

or Model FILTERE56.

The motor is permanently lubricated and never needs oiling. If the

motor bearings make excessive or unusual noise, replace the blower

assembly with an exact service replacement.

LIGHT BULBS

MODELS EW5830SS • EW5836SS

Page 8

LAMP SOCKET

BRACKET

LIGHT

PANEL

To change the depth of bulb sockets:

- Remove 2 screws on light panel – set screws aside

- Remove Light Panel.

- Loosen 2 Screws holding Lamp Socket Bracket to Light Panel.

- Adjust socket/bracket to desired depth.

- Re-tighten screws securely.

- Re-attach light panel with 2 screws that were previously set aside.

SCREWS

SUCTION

CUP TOOL

HALOGEN

BULB

(2)

ROTAT E

CLOCKWISE

WARNING

Bulbs may be hot. Always allow bulbs to cool down before removing

them.

Use (2) Halogen Bulbs (included with hood) - 120 V, 35 W, shielded

halogen bulbs - MR16 with GU10 base.

NOTE

Suction Cup Tool (included with hood) can be used to install and

remove light bulbs. Align pins on bulb with large diameter opening

on socket, then push bulb in towards hood and rotate clockwise

until firmly seated. The position of the bulb socket (depth) is

adjustable and may require adjustment when: a) certain brands of

bulbs are difficult to install. b) the bulb protrudes too far below the

light panel.

(1)

PUSH IN

Page 9

MODELS EW5830SS • EW5836SS

SERVICE PARTS

KEY PART NO. DESCRIPTION QTY.

1 S99527475 Decorative Upper and Lower Flues 1

2 S99527443 Motor / Blower Assembly 1

3 S99527444 Light Socket 2

(includes mounting hardware)

4 S99527445 Light Socket Bracket 2

(includes mounting hardware)

5 S99527446 User Interface Assembly 1

6 S99527448 User Interface Cable 1

7 S99527449 Control Board 1

8 S99527450 Control Enclosure 1

9 S99527452 Light Panel for EW5830SS 1

S99527453 Light Panel for EW5836SS 1

10 S99010368 Aluminum Grease Filter (pair) 2

11 S99010365 Non-Duct Recirculation Filters (pair) 1

12 S99527458 Non-Duct Filter Tr ay 2

13 S99527461 Damper Assembly 1

14 S99527462 6” Dia. Expandable Flexible 1

Aluminum Duct

15 S99527464 Non-Duct Plenum Assembly 1

16 S99527467 Upper Flue Mounting Bracket 1

17 S99526798 35W MR16 GU10 Halogen Lamp 2

18 S99527469 Capacitor 1

19 S99527480 Side Panels (pair) (EW5836SS only) 2

* S99527470 Heat Sensor 1

* S99527471 Fuse 1

* S99527481 User Interface Button (4-pack) 4

* S99527473 Parts Bag 1

* Not shown.

Order service parts by Part No. - not by Key No.

19

3

6

4

17

Page 9

1

16

15

1

13

5

17

8

14

19

9

7

Replacement parts can be ordered on our website:

www.broan.com

2

18

8

12

11

WARRANTY

Broan-NuTone warrants to the original consumer purchaser of its products that such products will be free from defects in materials or workmanship for a period of one year from the date of original

purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENT BULBS, FUSES, FILTERS, DUCTS, ROOF CAPS, WALL CAPS AND OTHER

ACCESSORIES FOR DUCTING. This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence, accident, improper

maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not allow limitation on how long an implied warranty lasts, so the above

limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROANNUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number below, (b) give the model number and part identification and (c) describe the nature of any defect

in the product or part. At the time of requesting warranty service, you must present evidence of the original purchase date.

BROAN-NUTONE ONE YEAR LIMITED WARRANTY

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, Ontario L5T 1H9 www.broan.ca 877-896-1119

10

Broan-NuTone LLC, 926 W. State Street, Hartford, Wisconsin 53027 www.broan.com 800-558-1711

11

10

Page 10

MODÈLES EW5830SS • EW5836SS

Hotte de cuisine

à cheminée

LIRE CES DIRECTIVES ET LES CONSERVER

POUR USAGE DOMESTIQUE SEULEMENT

Page 10

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, DE DÉCHARGES ÉLECTRIQUES

OU DE BLESSURES CORPORELLES, VEUILLEZ OBSERVER LES DIRECTIVES

SUIVANTES :

1. N’utilisez cet appareil que de la manière prévue par le fabricant. Si vous avez

des questions, communiquez avec le fabricant à l’adresse ou au numéro de

téléphone indiqués dans la garantie.

2. Avant de procéder à l’entretien ou au nettoyage de l’appareil, coupez

l’alimentation du panneau électrique et verrouillez l’interrupteur principal

afin d’empêcher que le courant ne soit accidentellement rétabli. S’il est

impossible de verrouiller l’interrupteur principal, fixez solidement un message

d’avertissement, par exemple une étiquette, sur le panneau électrique.

3. L’installation et les branchements électriques doivent être effectués par un

personnel compétent, conformément aux normes et aux codes en vigueur, y

compris les normes et les codes du bâtiment relatifs à la résistance au feu.

4. Pour éviter les refoulements, l’apport d’air doit être suffisant pour brûler les gaz

produits par les appareils à combustion et les évacuer dans le conduit de fumée

(cheminée). Respectez les directives du fabricant de l’appareil de chauffage

et les normes de sécurité, notamment celles publiées par la National Fire

Protection Association (NFPA), l’American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) et les codes des autorités locales.

5. Ce produit peut comporter des arêtes tranchantes. Prenez garde aux coupures

et aux éraflures lors de l’installation et du nettoyage.

6. Veillez à ne pas endommager le câblage électrique ou d’autres équipements non

apparents lors de la découpe ou du perçage du mur ou du plafond.

7. Les ventilateurs canalisés doivent toujours rejeter l’air à l’extérieur.

8. N’utilisez que des conduits métalliques.

9. N’utilisez pas de commande de régime à semi-conducteurs avec cet appareil.

10. Ne faites pas fonctionner le ventilateur si le cordon électrique ou la fiche est

endommagé. Jetez le ventilateur ou rapportez-le chez un réparateur agréé pour

le faire examiner et/ou réparer.

11. DIRECTIVES DE MISE À LA TERRE : Cet appareil doit être mis à la terre. Dans

l’éventualité d’un court-circuit, la mise à la terre réduit les risques de décharge

électrique en permettant au courant de s’échapper dans un fil. Cet appareil

comporte un cordon électrique muni d’un fil et d’une fiche de mise à la terre.

Cette fiche doit être branchée dans une prise de courant correctement installée

et mise à la terre. AVERTISSEMENT : Une mise à la terre incorrecte peut

entraîner un risque de choc électrique. Consultez un électricien qualifié si vous

ne comprenez pas complètement les directives de mise à la terre ou si vous

n’êtes pas sûr que l’appareil comporte une mise à la terre adéquate. N’utilisez

pas de rallonge électrique. Si le cordon électrique est trop court, demandez à un

électricien qualifié d’installer une prise de courant près de l’appareil.

POUR RÉDUIRE LES RISQUES D’INCENDIE CAUSÉS PAR DE LA GRAISSE SUR LE

PLAN DE CUISSON :

a) Ne laissez jamais les éléments de surface allumés à haute température. Les

débordements peuvent causer de la fumée et occasionner des écoulements

de graisse inflammables. L’huile doit être chauffée graduellement à basse ou à

moyenne température.

b) Mettez toujours la hotte en MARCHE lors d’une cuisson à feu vif ou lors de la

cuisson d’aliments à flamber (par ex., crêpes Suzette, cerises jubilé, bœuf au

poivre flambé).

c) Nettoyez souve nt la hot te. N e lais se z pas la grais se s’accumuler sur le ventilateur

ou les filtres.

d) Utilisez des casseroles de dimension appropriée. Utilisez toujours une batterie

de cuisine adaptée à la dimension de la surface chauffante.

AVERTISSEMENT

OBSERVEZ LES CONSIGNES SUIVANTES AFIN DE RÉDUIRE LES RISQUES DE

BLESSURES CORPORELLES EN CAS D’INCENDIE CAUSÉ PAR DE LA GRAISSE SUR

LE PLAN DE CUISSON :*

1. ÉTOUFFEZ LES FLAMMES à l’aide d’un couvercle étanche, d’une tôle à biscuits

ou d’un plateau en métal puis éteignez le brûleur. FAITES ATTENTION DE NE PAS

VOUS BRÛLER. SI LES FLAMMES NE S’ÉTEIGNENT PAS IMMÉDIATEMENT,

QUITTEZ LES LIEUX ET APPELEZ LE SERVICE DES INCENDIES.

2. NE SOULEVEZ JAMAIS UNE CASSEROLE EN FLAMMES – vous pourriez vous

brûler.

3. N’UTILISEZ PAS D’EAU, ni de serviettes ou de linges mouillés – une violente

explosion de vapeur pourrait survenir.

4. Utilisez un extincteur SEULEMENT si :

A) Vous savez qu’il est de classe ABC et que vous connaissez déjà son mode de

fonctionnement.

B) L’incendie n’est pas très important et ne se propage pas.

C) Les pompiers ont été avisés.

D) Vous pouvez combattre l’incendie en faisant dos à une sortie.

* Conseils tirés de la publication de la NFPA « Kitchen Fire Safety Tips ».

ATTENTION

1. Pour usage intérieur seulement.

2. Pour ventilation générale uniquement. Ne pas utiliser cet appareil pour évacuer des

matières ou des vapeurs dangereuses ou explosives.

3. Pour ne pas endommager les roulements du moteur, déséquilibrer les pales ou les

rendre bruyantes, protégez l’appareil de la poussière de plâtre, de construction, etc.

4. Le moteur de la hotte est muni d’un dispositif de protection de surcharge électrique

qui coupe automatiquement le moteur en cas de surchauffe. Il se remet en marche

lorsqu’il a refroidi. Faites réparer la hotte si le moteur continue à fonctionner par

intermittence.

5. Pour mieux capter les vapeurs de cuisson, le bas de la hotte DOIT ÊTRE AU

MINIMUM à 61 cm (24 po) et a recommandé au maximum à 91 cm (36 po) audessus de la surface de cuisson.

6. Il est recommandé que les installateurs soient deux, compte tenu de la taille de

cette hotte.

7. Pour réduire les risques d’incendie et évacuer l’air correctement, assurez-vous qu’il

est canalisé à l’extérieur. Ne pas évacuer l’air dans des espaces enfermés par des

murs ou un plafond ou dans un grenier, un vide sanitaire ou un garage.

8. Prenez garde en installant la cheminée décorative et la hotte, car elles peuvent

comporter des bords tranchants.

9. Cette hotte n’est pas conçue pour servir d’étagère.

10. Veuillez lire l’étiquette de spécifications du produit pour obtenir plus de

renseignements, notamment sur les exigences.

Enregistrez votre produit en ligne à : www.broan.com

Installateur : Veuillez remettre ce

manuel au propriétaire.

Propriétaire : Directives d’entretien et

d’utilisation à la pages 16 et 17.

Page 11

MODÈLES EW5830SS • EW5836SS

Page 11

MESURES DE L’INSTALLATION

CAPUCHON DE TOIT

CONDUIT ROND

DE 15 CM (6 PO)

CONDUIT DÉCORATIF

9

(3 ½ PO)

CM

ET LA LIGNE CENTRALE DU CONDUIT

(REMARQUE : LA LIGNE CENTRALE DU

VENTILATEUR SE TROUVE À

À GAUCHE DE LA LIGNE CENTRALE

DE LA HOTTE.)

ENTRE LE MUR

CONDUIT DÉCORATIF

4 CM

(1

5/8 PO)

2 CM (¾ PO)

HOTTE

61 À 91 CM (24 À 36 PO)

AU-DESSUS DE LA SURFACE

DE CUISSON

La distance minimale de la hotte au-dessus de la surface de cuisson

NE DOIT PAS ÊTRE INFÉRIEURE à 61 cm (24 po).

Un maximum de 91 cm (36 po) est également fortement recommandé

pour mieux capter les vapeurs de cuisson.

Une distance de plus de 91 cm (36 po) est laissée à la discrétion de

l’installateur et des utilisateurs si la hauteur du plafond le permet.

COUDE ROND

CAPUCHON MURAL

BRIDE

DE MONTAGE

DE HOTTE

32 CM (12 3/8 PO)

32 CM (12 3/8 PO)

AU CENTRE DES TROUS

AU CENTRE DES TROUS

SUPÉRIEURS DE LA BRIDE

SUPÉRIEURS DE LA BRIDE

5 CM (2 PO) AU CENTRE

DES TROUS INFÉRIEURS

DU CHÂSSIS DE LA HOTTE

PRÉPARATION DE LA HOTTE

Déballez la hotte et vérifiez le contenu de la boîte. Celle-ci doit

contenir les éléments suivants :

1 – Hotte assemblée en usine

1 – Conduits décoratifs de cheminée (conduit supérieur et

conduit inférieur)

1 – Bride de montage de conduit décoratif supérieur

2 – Filtres à graisse en aluminium (installés dans la hotte)

2 – Lampes halogènes MR16 GU10 de 35 W (installées dans la hotte)

1 – Sac de pièces contenant :

6 – Vis de montage (4 x 38 mm à tête cylindrique cruciforme)

2 – Vis de montage (4 x 12 mm à tête cylindrique cruciforme)

1 – Ventouse

1 – Manuel d’installation

BRIDE DE

MONTAGE DE CONDUIT

DÉCORATIF SUPÉRIEUR

2 VIS DE MONTAGE

(4 x 12 mm

à tête cylindrique

cruciforme)

6 VIS DE

MONTAGE

(4 x 38 mm

à tête cylindrique

cruciforme)

INSTALLATION DES CONDUITS

(hottes avec conduits seulement)

1. Planifiez la pose du conduit en déterminant son tracé entre la

hotte et l’extérieur de la maison.

2. Un tracé droit et court permet à la hotte d’être plus efficace.

3. Des conduits longs, des coudes et des transitions réduisent

l’efficacité de la hotte. N’en utilisez que le moins possible. Pour

plus d’efficacité, des conduits plus gros peuvent être nécessaires

si le parcours est trop long.

4. Installez le capuchon mural ou de toit. Connectez un conduit rond

en métal au capuchon en progressant vers la hotte. Scellez les

joints avec du ruban à conduit à chaque section.

REMARQUE :

la ligne centrale du raccord de conduit de la hotte se trouve à 2 cm

(¾ po) à gauche de la ligne centrale de la hotte. Planifiez la pose du

conduit en fonction de cette information.

VENTOUSE

POUR

AMPOULE

CONDUIT

DÉCORATIF

DE CHEMINÉE

HOTTE

ASSEMBLÉE

EN USINE

Page 12

MODÈLES EW5830SS • EW5836SS

Page 12

INSTALLATION DU CÂBLAGE INSTALLATION DU SUPPORT

DE MONTAGE DE LA HOTTE

LIGNE CENTRALE

DE LA HOTTE

9 cm

C

L

5 cm

(2 po)

MAX.

10,8 cm

(4 ¼ po)

MAX.

61 cm

(24 po)

(3,5 po)

30 cm

(12 po)

61 à 91 cm

(24 À 36 po)

AU-DESSUS

DE LA SURFACE

DE CUISSON

INSTRUCTIONS DE MISE À LA TERRE

Cet appareil doit être correctement mis à la terre. Dans l’éventualité

d’un court-circuit, la mise à la terre réduit les risques de décharge

électrique en permettant au courant de s’échapper dans un fil. Cet

appareil comporte un cordon électrique muni d’un fil et d’une fiche

de mise à la terre. Cette fiche doit être branchée dans une prise de

courant correctement installée et mise à la terre.

Placez la prise de courant dans l’espace recouvert par le conduit

décoratif de cheminée et à un endroit où elle ne nuira pas au passage

du conduit rond. Elle ne doit pas être à plus de 61 cm (24 po) du haut

du châssis de la hotte et ne pas empiéter sur la zone de fixation d’un

support de montage et de l’endroit où le conduit décoratif touche

au mur.

A

VOIR LE

TABLEAU

CI-DESSOUS

26,4 cm

3

(10

/8 po)

7,6 cm

(3 po)

VIS DE

4 x 38 mm ICI

91 cm (36 po) AU-DESSUS

DE LA SURFACE DE CUISSON

1. Construisez une charpente de bois qui affleure la surface

intérieure des montants du mur. Assurez-vous de centrer cette

charpente avec l’emplacement d’installation.

REMARQUE

La distance de la hotte au-dessus de la surface de cuisson est

: au minimum de 61 cm (24 po) et au maximum de 91 cm (36

po). Les plafonds de 2,7 m (9 pi) et 3 m (10 pi) peut nécessitent

la rallonge de conduit décoratif, modèle FXNE58SS selon la

taille de l’installation (vendue séparément). Voir le tableau cidessous pour de plus amples renseignements sur la hauteur

d’installation.

2. Une fois la surface du mur finie, fixez deux (2) vis de 4 x 38 mm

aux emplacements illustrés ci-dessus. NE SERREZ PAS les vis

jusqu’au bout.

Distance de hotte requise [91,4 cm (36 po) au-dessus de la surface de cuisson]

61 cm

(24 po)

Hauteur du

plafond

2,4 m

(8 pi)

2,7 m

(9 pi)

2,7 m (9 pi)

avec

FXNE58SS

3 m (10 pi)

avec

FXNE58SS

* Les évents de recirculation sans conduits sont exposés lors d’une installation avec conduits

92,4 cm

(36-3/8 po)

92,4 cm

(36-3/8 po)

92,4 cm

(36-3/8 po)

63,5 cm

(25 po)

Emplacement des vis de montage supérieures (à plus de 91,4 cm (36 po) au-dessus de la surface de cuisson) -

95 cm

(37-3/8 po)

95 cm

(37-3/8 po)

95 cm

(37-3/8 po)

66 cm

(26 po)

97,5 cm

(38-3/8 po)

97,5 cm

(38-3/8 po)

97,5 cm

(38-3/8 po)

68,6 cm

(27 po)

100 cm

(39-3/8 po)

100 cm

(39-3/8 po)

100 cm

(39-3/8 po)

71,1 cm

(28 po)

102,6 cm

(40-3/8 po)

102,6 cm

(40-3/8 po)

102,6 cm

(40-3/8 po)

73,7 cm

(29 po)

105,1 cm

(41-3/8 po)

105,1 cm

(41-3/8 po)

105,1 cm

(41-3/8 po)

76,2 cm

(30 po)

107,4 cm

(42-3/8 po)

*107,4 cm

(42-3/8 po)

107,4 cm

(42-3/8 po)

107,4 cm

(42-3/8 po)

78,8 cm

(31 po)

*110,2 cm

(43-3/8 po)

110,2 cm

(43-3/8 po)

81,3 cm

(32 po)

*112,7 cm

(44-3/8 po)

112,7 cm

(44-3/8 po)

83,9 cm

(33 po)

86,4 cm

(34 po)

(Dimension « A »)

*115,3 cm

(45-3/8 po)

115,3 cm

(45-3/8 po)

*117,8 cm

(46-3/8 po)

117,8 cm

(46-3/8 po)

88,9 cm

(35 po)

*120,3 cm

(47-3/8 po)

120,3 cm

(47-3/8 po)

91,4 cm

(36 po)

*122,9 cm

(48-3/8 po)

122,9 cm

(48-3/8 po)

Page 13

INSTALLATION DE LA HOTTE

(hottes avec conduits seulement)

MODÈLES EW5830SS • EW5836SS

Page 13

Plafond

Fentes de la bride de montage

de conduit décoratif supérieur

1. Centrez la bride de montage du conduit décoratif à l’emplacement

de la hotte au ras avec le plafond. Fixez la bride de montage

du conduit décoratif au mur avec deux (2) vis de montage de

4 x 38 mm. Remarque : Des chevilles d’ancrage peuvent être

nécessaires (non comprises).

2. Serrez complètement les vis. Assurez-vous que la bride est

fermement appuyée contre le mur et le plafond.

3. Enlevez la pellicule protectrice en plastique recouvrant la hotte

et le conduit décoratif.

4. Enlevez les filtres à graisse en tirant vers le bas sur la languette

métallique de retenue et en basculant les filtres vers le bas.

Centre de

l’installation

C

L

Au ras du plafond

6. Installez deux (2) longues vis de 4 x 38 mm dans les trous situés

à l’intérieur de la hotte et serrez-les fermement.

7. Pour remettre les filtres à graisse, alignez les ergots arrière des

filtres dans les fentes de la hotte. Tirez la languette métallique

vers le bas,

relâchez la languette. Vérifiez si les filtres sont bien fixés une fois

replacés.

CONDUIT ROND

DE 15 cm (6 po)

CONDUIT

DÉCORATIF

poussez les

LONGUEUR

DU CONDUIT

filtres pour les mettre en place et

5. Alignez les deux trous de serrure extérieurs de la hotte avec les

vis de montage que vous avez partiellement serrées dans la

charpente murale. Assurez-vous que la hotte est complètement

appuyée sur les vis de montage et qu’elle est bien de niveau.

Ensuite, serrez complètement les vis.

8. Mesurez et fixez le conduit en acier sur le raccord de conduit de

la hotte et les conduits du plafond ou du mur. Utilisez du ruban

pour conduit afin de fixer solidement tous les joints et assurer

leur étanchéité.

9. Branchez le cordon électrique dans la prise de courant.

Page 14

10. Glissez la section supérieure du conduit décoratif dans sa

section inférieure.

REMARQUE

Pour les applications avec conduits, vous devez dissimuler les

évents à lames du conduit supérieur en les faisant glisser à

l’intérieur du conduit inférieur.

11. Placez avec précaution les conduits décoratifs inférieur et

supérieur dans la partie de la hotte en retrait.

12. Glissez le conduit décoratif supérieur vers le haut jusqu’à ce

qu’il soit aligné avec sa bride de montage. La bride doit être à

l’intérieur du conduit décoratif. Fixez le conduit supérieur à la

bride de montage de conduit décoratif supérieur avec deux (2)

vis de montage de 4 x 12 mm.

REMARQUE

Les plafonds de 2,7 à 3 m (9 pi à 10 pi) peut nécessitent la

rallonge de conduit décoratif modèle FXNE58SS selon la taille de

l’installation (vendue séparément). Jetez les conduits décoratifs

supérieur et inférieur fournis avec votre hotte et remplacez-les

par la rallonge de conduit décoratif, modèle FXNE58SS.

MODÈLES EW5830SS • EW5836SS

Page 14

INSTALLATION DE LA HOTTE

(hotte sans conduits seulement)

CONTENU DE L’ENSEMBLE MODÈLE RKE58

POUR HOTTE SANS CONDUITS

2 VIS DE

MONTAGE

(4 x 38 mm

à tête cylindrique

ENSEMBLE DE CAISSON

NON CANALISÉ

8 VIS DE MONTAGE

(0,47 x 0,95 cm

(0,188 x 0,375 po) à

tête plate cruciforme)

CONDUIT

FLEXIBLE

FILTRES DE RECIRCULATION POUR

INSTALLATION SANS CONDUITS

REMARQUE

Les installations sans conduits nécessitent l’ensemble sans conduits,

modèle RKE58 (vendu séparément).

Au ras

du plafond

cruciforme)

PLATEAUX DE FILTRES

Plafond

Fentes de la bride de

montage de conduit

décoratif supérieur

C

L

Centre de

l’installation

1. Centrez le caisson non canalisé à l’emplacement de la hotte au

ras avec le plafond. Fixez le caisson non canalisé au mur avec

deux (2) vis de montage de 4 x 38 mm. Remarque : Des

d’ancrage peuvent être nécessaires (non comprises).

Serrez complètement les vis. Assurez-vous que le caisson non

2.

canalisé est fermement appuyé contre le mur et le plafond.

3. Enlevez les clapets de l’ensemble clapet / raccord de conduit et

jetez-les.

4. Enlevez la pellicule protectrice en plastique recouvrant la hotte

et le conduit décoratif.

5. Enlevez les filtres à graisse en tirant vers le bas sur la languette

métallique de retenue et en basculant les filtres vers le bas.

chevilles

Page 15

MODÈLES EW5830SS • EW5836SS

CAISSON NON

CANALISÉ

CONDUIT ROND

DE MÉTAL

DE 15 cm (6 po)

CONDUIT

DÉCORATIF

Page 15

LONGUEUR

DU CONDUIT

6. Alignez les deux trous de serrure extérieurs de la hotte avec les

vis de montage que vous avez partiellement serrées dans la

charpente murale. Assurez-vous que la hotte est complètement

appuyée sur les vis de montage et qu’elle est bien de niveau.

Ensuite, serrez complètement les vis.

7. Installez deux (2) longues vis de 4 x 38 mm dans les trous situés

à l’intérieur de la hotte et serrez-les fermement.

8. Fixez deux (2) plateaux de filtres au bas de la hotte avec huit (8)

vis de montage de 0,47 x 0,95 cm (0,188 x 0,375 po).

11. Mesurez et fixez le conduit en métal flexible (fourni avec le

modèle RKE58) sur le raccord de conduit de la hotte et au

du caisson non canalisé. Utilisez du ruban pour conduit afin de

fixer solidement tous les joints et assurer leur étanchéité.

bas

ATTENTION

N’utilisez pas de conduits en plastique.

12. Branchez le cordon électrique dans la prise de courant.

9. Enclenchez deux (2) filtres sans conduits dans les plateaux de

filtres. Pour ce faire, engagez et faites pivoter vers le haut la

languette latérale respective des filtres, puis appuyez fermement

sur les deux (2) attaches de filtre.

10. Pour remettre les filtres à graisse, alignez les languettes

arrière des filtres dans les fentes de la hotte. Tirez la languette

métallique vers le bas, poussez les filtres pour les mettre en

place et relâchez la languette. Vérifiez si les filtres sont bien

fixés une fois replacés.

13. Glissez la section supérieure du conduit décoratif dans sa

section inférieure.

REMARQUE

Pour les applications sans conduits, le conduit décoratif

supérieur doit être placé de façon que les évents à lames soient

vers le plafond.

14. Placez avec précaution les conduits décoratifs inférieur et

supérieur dans la partie de la hotte en retrait.

15. Glissez le conduit décoratif supérieur vers le haut jusqu’à ce

qu’il soit aligné avec le caisson non canalisé. Le caisson non

canalisé doit être à l’intérieur du conduit décoratif. Fixez le

conduit décoratif supérieur au caisson non canalisé avec deux

(2) vis de montage de 4 x 12 mm.

REMARQUE

Les plafonds de 2,7 à 3 m (9 pi à 10 pi) peut nécessitent la

rallonge de conduit décoratif modèle FXNE58SS selon la

taille de l’installation (vendue séparément). Jetez les conduits

décoratifs supérieur et inférieur fournis avec votre hotte et

remplacez-les par la rallonge de conduit décoratif, modèle

FXNE58SS.

Page 16

FONCTIONNEMENT

CONNEXION DU CLAPET D’AIR

MODÈLES EW5830SS • EW5836SS

Page 16

Mettez toujours la hotte en MARCHE avant de cuisiner afin d’établir

une circulation d’air dans la cuisine. Laissez la hotte fonctionner

quelques minutes après l’arrêt de la cuisinière afin de nettoyer l’air.

Pour utiliser la hotte, faites comme suit :

ARRÊT VENTILATEUR

VOYANTS DEL

INDIQUANT LE RÉGIME

ARRÊT

DU VENTILATEUR

ARRÊT

DIFFÉRÉ

ÉCLAIRAGE

ARRÊTE le ventilateur

VENTILATEUR (1 bouton-poussoir, 3 régimes de ventilateur)

Actionne le ventilateur au dernier régime sélectionné et active un

voyant DEL bleu indiquant le réglage du régime du ventilateur. Si

vous appuyez une deuxième fois sur le bouton VENTILATEUR,

le ventilateur et le voyant DEL passent au régime suivant. Si vous

appuyez sur le bouton VENTILATEUR alors que son régime est à

son plus haut niveau, le ventilateur et le voyant DEL passent au

régime le plus bas.

ARRÊT DIFFÉRÉ (arrêt différé de 10 minutes)

Active la fonction d’arrêt différé de 10 minutes lorsque le ventilateur

est en MARCHE (tous régimes). Lorsque cette fonction est

activée, le voyant DEL bleu situé au-dessus du réglage de régime

sélectionné se met à clignoter. Le ventilateur de la hotte S’ARRÊTE

automatiquement après un délai de 10 minutes. Vous pouvez

appuyer à tout moment sur le bouton ARRÊT DIFFÉRÉ durant les

10 minutes pour désactiver la fonction.

FUSIBLES

Le panneau de commande de hotte contient un fusible principal

pour le protéger contre les surtensions. Vous pouvez vous procurer

un nouveau fusible dans un magasin d’électronique local. Utilisez

des fusibles de 5 A, 120 V, 5 mm de diamètre, 20 mm de long, à

action rapide, de type cartouche.

Pour remplacer un fusible (le remplacement doit être effectué par

une ou des personnes qualifiées) :

1. Coupez le courant au panneau électrique.

2. Enlevez les filtres

3. Enlevez le couvercle de commandes

4. Enlevez et inspectez le fusible.

CLAPET D’AIR DE COMPENSATION

La hotte est compatible avec le Clapet d’air de compensation Broan

modèle MD6T ou modèle MD8T (en option). Vendu séparément.

CLAPET D’AIR

DE COMPENSATION

TERRE

TRANSFORMATEUR

24V (INCLUS)

120 VCA

60 HZ

DE COMPENSATION

(basse tension)

FIL DE SONNETTE DE CALIBRE

20 POUR UNE CONNEXION BASSE

TENSION AU-DESSUS DE LA HOTTE

MANCHON

DE BORNE

HOTTE

DE CONTACT

SEC POUR

CONNEXION

BASSE TENSION

ÉCLAIRAGE (1 bouton-poussoir, 3 intensités d’éclairage)

Allume la lumière et la règle à l’intensité la plus faible. Si vous appuyez

une deuxième

fois sur le bouton ÉCLAIRAGE, l’éclairage passe à

l’intensité suivante. Si vous appuyez sur le bouton ÉCLAIRAGE

alors que l’intensité est à son plus haut niveau, la lumière s’éteint.

INDICATEUR DE CHANGEMENT DE FILTRE

Après 30 heures de fonctionnement du ventilateur, les trois voyants

DEL bleus clignotent simultanément pour indiquer qu’il est temps de

nettoyer les filtres à graisse. Pour remettre le compteur de nettoyage

des filtres à zéro, maintenez le bouton ARRÊT enfoncé pendant

trois secondes. Les voyants DEL clignotants s’éteignent alors.

SYSTÈME DE DÉTECTEUR DE CHALEUR

Cette hotte de cuisine est équipée d’un système de détecteur de

chaleur standard capable de détecter une température excessive et

de régler automatiquement le ventilateur au régime ÉLEVÉ.

1) Si le ventilateur est en MARCHE, le système de détecteur de

chaleur augmente le régime du ventilateur à son niveau le plus

élevé au fur et à mesure que la température s’élève. Les voyants

bleus des trois (3) régimes du ventilateur s’allument et se

mettent à clignoter très rapidement pour indiquer que la fonction

de détection de chaleur est activée. Une fois la température

abaissée, le système de détecteur de chaleur rétablit le réglage

original du régime du ventilateur.

2) Si le ventilateur est ARRÊTÉ, le système de détecteur de

chaleur règle automatiquement le

ventilateur au

régime le plus

élevé lorsque la température est au-dessus de la normale. Les

voyants bleus des trois (3) régimes du ventilateur s’allument et se

mettent à clignoter très rapidement pour indiquer que la fonction

de détection de chaleur est activée. Une fois la température

revenue à la normale, le ventilateur s’arrête.

Connectez le clapet d’air de compensation avec des fils de basse

tension, tel qu’illustré. Pour de plus amples renseignements,

consultez les directives du clapet d’air de compensation.

TÉLÉCOMMANDE

La hotte est compatible avec la Télécommande Radiofréquence

(RF) Broan modèle BCR1 (en option). Vendue séparément.

Pour établir la liaison entre la télécommande BCR1 et la hotte,

maintenez le bouton ÉCLAIRAGE enfoncé pendant trois secondes.

Les voyants DEL bleus s’allument et s’éteignent successivement

pour indiquer que la hotte est en mode de liaison avec la

télécommande RF. Une fois le mode de liaison activé, appuyez

la

sur une touche quelconque de

alors un signal sonore et son voyant DEL s’arrête de clignoter

la liaison est réussie. Si la liaison entre la télécommande et la

télécommande R F. La hotte émet

si

hotte

échoue, le mode de liaison se désactive après 12 secondes et

les clignotements successifs des voyants s’arrêtent. Consultez les

directives relatives à la télécommande BCR1 pour de plus amples

renseignements.

Page 17

NETTOYAGE ET ENTRETIEN

Pour des raisons de santé, de performance et d’apparence, nettoyez

le filtre, le ventilateur et les surfaces graisseuses. Utilisez seulement

un chiffon propre et une solution de détergent doux sur l’acier

inoxydable et les surfaces peintes.

Nettoyez les filtres entièrement métalliques au lave-vaisselle avec

un détergent sans phosphate. Une décoloration du filtre peut se

produire si des détergents phosphatés sont utilisés et selon les

conditions locales de l’eau, sans toutefois affecter le rendement du

filtre. Cette décoloration n’est pas couverte par la garantie.

Nettoyez souvent les surfaces des filtres de recirculation avec un

linge humide et un détergent doux. NE PLONGEZ PAS les filtres

dans l’eau et ne les mettez pas au lave-vaisselle. Remplacez les

filtres de recirculation sans conduit tous les six mois. Pour remplacer

les filtres de recirculation sans conduits - veuillez acheter les filtres

S99010365 ou Modèle FILTERE56.

Le moteur est lubrifié en permanence et n’a pas besoin d’être huilé. Si

les roulements du moteur sont anormalement bruyants, remplacez

l’ensemble du ventilateur exactement par le même modèle.

AMPOULES

VENTOUSE

MODÈLES EW5830SS • EW5836SS

Page 17

SUPPORT DU

SOCLE D’AMPOULE

PANNEAU

D’ÉCLAIRAGE

Pour changer la profondeur des socles d’ampoule :

- Enlevez les deux vis du panneau d’éclairage et mettez-les de côté

- Enlevez le panneau d’éclairage.

- Desserrez les 2 vis retenant le support du socle d’ampoule au

panneau d’éclairage.

- Réglez le support / socle à la profondeur voulue.

- Resserrez les vis fermement.

- Fixez à nouveau le panneau d’éclairage avec les deux vis que

vous avez mises de côté.

VIS

(1)

ENFONCER

AMPOULE

HALOGÈNE

(2)

TOURNER

DANS LE SENS

HORAIRE

AVERTISSEMENT

Les ampoules peuvent être très chaudes. Laissez toujours les

ampoules refroidir avant de les enlever.

Utilisez deux (2) ampoules halogènes (fournies avec la hotte)

(ampoules halogènes avec écran de 120 V, 35 W - MR16 à culot

GU10.

REMARQUE

Vous pouvez utiliser la ventouse (fournie avec la hotte) pour

installer ou enlever les ampoules. Alignez les bornes de l’ampoule

sur la grande ouverture du socle, puis poussez l’ampoule vers

la hotte et tournez-la dans le sens horaire jusqu’à ce qu’elle soit

bien appuyée. La position du socle de l’ampoule (sa profondeur)

est réglable et peut exiger un ajustement lorsque : a) certaines

marques d’ampoule sont difficiles à installer. b) l’ampoule dépasse

trop sous le panneau d’éclairage.

Page 18

MODÈLES EW5830SS • EW5836SS

PIÈCES DE RECHANGE

N° DE N° DE PIÈCE DESCRIPTION QTÉ

REPÈRE

1 S99527475 Conduits décoratifs supérieur 1

et inférieur

2 S99527443 Ensemble moteur / ventilateur 1

3 S99527444 Socle d’ampoule 2

(comprend la quincaillerie

de montage)

4 S99527445 Support de socle d’ampoule 2

(comprend la quincaillerie

de montage)

5 S99527446 Ensemble d’interface utilisateur 1

6 S99527448 Câble d’interface utilisateur 1

7 S99527449 Panneau de commande 1

8 S99527450 Boîtier de commande 1

9 S99527452 Panneau d’éclairage pour 1

EW5830SS

S99527453 Panneau d’éclairage pour 1

EW5836SS

10 S99010368 Filtre à graisse en aluminium (paire) 2

11 S99010365 Filtres de recirculation pour 1

installation sans conduits (paire)

12 S99527458 Plateau de filtre sans conduits 2

13 S99527461 Ensemble de clapet 1

14 S99527462 Conduit d’aluminium flexible/ 1

extensible de 15 cm (6 po)

de diamètre

15 S99527464 Ensemble de caisson non canalisé 1

16 S99527467 Bride de montage de conduit 1

décoratif supérieur

17 S99526798 Lampe halogène MR16 GU10 2

de 35 W

18 S99527469 Condensateur 1

19 S99527480 Panneaux latéraux (paire) 2

(EW5836SS seulement)

* S99527470 Détecteur de chaleur 1

* S99527471 Fusible 1

* S99527481 Bouton d’interface utilisateur 4

(paquet de 4)

* S99527473 Sac de pièces 1

19

Page 18

1

16

15

1

14

6

13

5

19

4

3

17

17

2

9

8

7

18

8

* Non illustré.

Veuillez commander les pièces par n° de pièce et non par n° de repère.

Les pièces de rechange peuvent être commandées sur notre site :

www.broan.com

GARANTIE

Broan-NuTone garantit à l’acheteur consommateur original de ses produits qu’ils sont exempts de vice de matériaux ou de fabrication pour une période d’un an à compter de la date d’achat original. IL N’Y

A PAS D’AUTRES GARANTIES, EXPRIMÉES OU IMPLICITES, INCLUANT MAIS NON LIMITÉES AUX GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET DE CONVENANCE DANS UN BUT PARTICULIER.

Durant cette période d’un an, Broan-NuTone, à sa discrétion, réparera ou remplacera gratuitement tout produit ou pièce qui s’avèrera défectueux et ayant été utilisé normalement et d’une manière non abusive.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS, NI AUX AMPOULES HALOGÈNES OU INCANDESCENTES, FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE TOIT,

CAPUCHONS MURAUX ET AUTRES ACCESSOIRES POUR CONDUITS. Cette garantie ne couvre pas (a) l’entretien et le service normal ou (b) tout produit ou pièce endommagé à la suite d’un mauvais usage,

d’une négligence, d’un accident, d’un entretien inadéquat ou d’une réparation (autre que par Broan-NuTone), d’une mauvaise installation ou d’une installation non conforme au mode d’installation recommandé.

La durée de toute garantie implicite est limitée à une période de un an tel que spécifié pour la garantie exprimée. Certains États ou provinces ne permettent pas de limitation de la durée d’une garantie implicite.

Cette condition ne s’applique donc peut-être pas dans votre cas.

L’ENGAGEMENT DE BROAN-NUTONE À RÉPARER OU À REMPLACER, AU CHOIX DE BROAN-NUTONE, SERA LA SEULE OBLIGATION EXCLUSIVE SOUS CETTE GARANTIE. BROAN-NUTONE NE SE TIENDRA

PAS RESPONSABLE DES DOMMAGES DIRECTS, INDIRECTS OU SPÉCIAUX AYANT UN LIEN DIRECT OU INDIRECT AVEC L’UTILISATION OU LA PERFORMANCE DE SES PRODUITS. Certains États ou provinces

ne permettent pas l’exclusion ou la limitation de dommages directs ou indirects. Cette condition ne s’applique donc peut-être pas dans votre cas.

Cette garantie vous donne des droits spécifiques et il se peut que vous ayez d’autres droits qui varient d’une province à l’autre ou d’un État à l’autre. Cette garantie annule toutes les garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan-NuTone à l’adresse ou numéro de téléphone mentionnée ci-dessous, (b) donner le numéro de modèle et l’identification de la pièce et (c) décrire la

nature de tout défaut dans le produit ou la pièce. Au moment de la demande de service sous garantie, vous devez présenter une preuve de la date d’achat original du produit en question.

GARANTIE LIMITÉE DE UN AN DE BROAN-NUTONE

Broan-NuTone LLC, 926 W. State Street, Hartford, Wisconsin 53027 www.broan.com 800-558-1711

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, Ontario L5T 1H9 www.broan.ca 877-896-1119

11

10

12

11

10

Page 19

MODELOS EW5830SS • EW5836SS

Campana

para chimenea

LEA Y CONSERVE ESTAS INSTRUCCIONES

SOLAMENTE PARA COCINAR EN CASA

Página 19

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS ELÉCTRICAS O LESIONES

PERSONALES, SIGA LAS SIGUIENTES PRECAUCIONES:

1. Use la unidad sólo de la manera indicada por el fabricante. Si tiene preguntas,

comuníquese con el fabricante a la dirección o al número telefónico que se incluye

en la garantía.

2. Antes de dar servicio o limpiar la unidad, interrumpa el suministro eléctrico en el

panel de servicio y bloquee los medios de desconexión del servicio para evitar que

la electricidad sea reanudada accidentalmente. Cuando no sea posible bloquear los

medios de desconexión del servicio, fije firmemente una señal de advertencia (como

una etiqueta) en un lugar visible del panel de servicio.

3. Sólo personal cualificado debe realizar el trabajo de instalación y el cableado

eléctrico, de acuerdo con todos los códigos y normas correspondientes, incluidos

los códigos y las normas de construcción específicos sobre protección contra

incendios.

4. Con el fin de evitar la contracorriente se necesita suficiente aire para que se lleve

a cabo una combustión adecuada y la extracción de los gases a través del tubo

de humos (chimenea) del equipo quemador de combustible. Siga las directrices

y las normas de seguridad del fabricante del equipo de calentamiento, como las

publicadas por la Asociación Nacional de Protección contra Incendios (National Fire

Protection Association, NFPA), la Sociedad Americana de Ingenieros de Calefacción,

Refrigeración y Aire Acondicionado (American Society for Heating, Refrigeration

and Air Conditioning Engineers, ASHRAE) y las autoridades de los códigos locales.

5. Este producto podría tener bordes afilados. Trabaje con cuidado para evitar cortes y

abrasiones durante la instalación y la limpieza.

6. Al cortar o perforar a través de la pared o del cielo raso, tenga cuidado de no dañar

el cableado eléctrico ni otros servicios ocultos.

7. Los ventiladores en conductos siempre deben ventearse hacia el exterior.

8. Utilice únicamente conductos metálicos.

9. No use esta unidad junto con ningún otro dispositivo de control de velocidad de

estado sólido.

10. No haga a funcionar ningún ventilador con el enchufe o el cable dañado. Deseche el

ventilador o regréselo a una instalación de servicio autorizada para que lo examinen

o lo reparen.

11. INSTRUCCIONES PARA LA PUESTA A TIERRA: Este aparato debe estar conectado

a tierra. En caso de un corto circuito eléctrico, la puesta a tierra reduce el riesgo de

una descarga eléctrica al suministrar un cable de escape para la corriente eléctrica.

El aparato está equipado con un cordón que tiene un cable con una clavija a tierra.

La clavija debe conectarse a una toma eléctrica que esté instalada y conectada a

tierra adecuadamente. ADVERTENCIA: Una puesta inadecuada a tierra puede tener

el riesgo de una descarga eléctrica. Consulte a un electricista calificado si no se

entienden totalmente las instrucciones de puesta a tierra, o si tiene alguna duda

en cuanto a la conexión a tierra apropiada del aparato. No utilice una extensión

eléctrica. Si el cordón de la fuente de alimentación es demasiado corto, solicite a un

electricista calificado que instale una toma eléctrica cerca del aparato.

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO POR GRASA PRESENTE EN

LA ESTUFA:

a) Nunca deje desatendidas las unidades de la superficie cuando estén en ajustes altos

de calor. Los alimentos en ebullición provocan derrames grasosos y con humo que

se pueden incendiar. Caliente el aceite lentamente en ajustes de calor bajo o medio.

b) Siempre ENCIENDA la campana cuando esté cocinando a altas temperaturas o

flamee alimentos (por ejemplo crepas Suzette, cerezas Jubilee, bistec con pimienta

flameado).

c) Limpie frecuentemente los ventiladores. No permita la acumulación de grasa en el

ventilador ni en los filtros.

ADVERTENCIA

d) Use una cacerola del tamaño adecuado. Siempre use utensilios de cocina que sean

apropiados para el tamaño del elemento de la superficie.

PARA REDUCIR EL RIESGO DE LESIONES PERSONALES EN EL CASO DE QUE LA

GRASA DE LA ESTUFA SE INCENDIE, SIGA LAS SIGUIENTES PRECAUCIONES*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una charola para galletas o

una bandeja de metal, y después apague el quemador. PROCEDA CON CUIDADO

PARA EVITAR QUEMADURAS. SI LAS LLAMAS NO SE APAGAN INMEDIATAMENTE,

EVACÚE EL ÁREA Y LLAME AL DEPARTAMENTO DE BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA, se puede quemar.

3. NO USE AGUA, incluidos trapos o toallas de cocina mojados; puede producirse una

explosión violenta de vapor.

4. Use un extintor SÓLO si:

A) El extintor es de clase ABC y usted sabe cómo usarlo.

B) El incendio es pequeño y está confinado al área en la que se inició.

C) Se está llamando al Departamento de Bomberos.

D) Puede combatir el incendio teniendo la espalda orientada hacia una salida.

* Basado en “Kitchen Fire Safety Tips” (Sugerencias para la seguridad contra incendios

en la cocina) publicado por la NFPA.

PRECAUCIÓN

1. Sólo debe usarse bajo techo.

2. Sólo para usarse como medio de ventilación general. No debe usarse para la

extracción de materiales ni vapores peligrosos o explosivos.

3. Para evitar daños a los cojinetes del motor y rotores ruidosos o desbalanceados,

mantenga la unidad de potencia protegida contra rociados de yeso, polvos de

construcción, etc.

4. Este motor de campana tiene una protección contra sobrecargas térmicas que

automáticamente apagará el motor en caso de sobrecalentamiento. El motor

reanudará su funcionamiento cuando se enfríe. Si el motor continúa apagándose y

encendiéndose, solicite servicio para la campana.

5. La parte inferior de la campana NO DEBE ESTAR A MENOS de 24 pulg. (61 cm)

y recomendado en un máximo de 36 pulg. (91 cm) por encima de la estufa, para

captar mejor las impurezas que surgen al cocinar.

6. Se recomienda que dos personas hagan la instalación debido al gran tamaño de

esta campana.

7. Para reducir el riesgo de incendio y para descargar adecuadamente el aire, asegúrese

de dirigir el aire hacia el exterior. No descargue el aire en espacios contenidos entre

paredes o cielos rasos, ni en áticos, sótanos bajos ni en la cochera.

8. Tenga cuidado al instalar el tubo de humos decorativo y la campana; pueden tener

bordes afilados.

9. Esta campana no está diseñada para usarse como repisa.

10. Lea la etiqueta de especificaciones que tiene el producto para ver información y

requisitos adicionales.

Registre su producto en Internet en: www.broan.com

Aviso al instalador: Deje este manual con

el dueño de la casa. Aviso al dueño de la

casa: Instrucciones de funcionamiento y

mantenimiento en la páginas 25 y 26.

Page 20

MODELOS EW5830SS • EW5836SS

Página 20

MIDA LA INSTALACIÓN

TAPA DE TECHO

REDONDO

CONDUCTO

DE 6 PULG. (15 CM)

TUBO DE HUMOS DECORATIVO

3 ½ PULG. (9 CM) DE LA PARED

A LA LÍNEA CENTRAL DEL CONDUCTO

(NOTA: LA LÍNEA CENTRAL DEL

VENTILADOR ESTÁ A

(2

CM) DE LA LÍNEA CENTRAL

DE LA CAMPANA.)

TUBO DE HUMOS DECORATIVO

1 5/8

(4.13

3

/4 PULG.

PULG

.

CM)

DE 24 A 36 PULG. (61 A 91 CM)

POR ENCIMA DE LA SUPERFICIE

DE COCINADO

CAMPANA

La distancia mínima de la campana sobre la superficie de la estufa

NO DEBE SER MENOR de 24 pulg. (61 cm).

Se recomienda enfáticamente una distancia máxima de 36 pulg. (91 cm)

sobre la superficie de la estufa para la mejor captura de las impurezas

resultantes del cocinado.

Utilizar distancias superiores a las 36 pulg. (91 cm) queda a discreción

del usuario y del instalador, siempre y cuando lo permita la altura del

cielo raso.

CODO REDONDO

MONTAR LA CAMPANA

12 3/8 PULG. (32 CM)

AL CENTRO DE LOS

ORIFICIOS DEL SOPORTE

SUPERIOR

2 PULG. (5 CM)

AL CENTRO DE LOS

ORIFICIOS DEL

CHASIS INFERIOR

DE LA CAMPANA

TAPA

DE PARED

SOPORTE

PARA

PREPARE LA CAMPANA

Desempaque la campana y revise el contenido del paquete.

Debe contener lo siguiente:

1 – Conjunto de campana

1 – Conjunto de tubo de humos decorativo (contiene el tubo

superior e inferior)

1 – Soporte de montaje del tubo de humos superior

2 – Filtros de aluminio para grasa (instalados en la campana)

2 – Lámparas halógenas MR16 GU10 de 35 W (instaladas

en la campana)

1 – Bolsa de piezas con:

6 – Tornillos de montaje (4 x 38 mm de cabeza troncocónica

ahuecada)

2 – Tornillos de montaje (4 x 12 mm de cabeza troncocónica

ahuecada)

1 – Herramienta de ventosa

1 – Manual de instalación

SOPORTE DE

MONTAJE DEL TUBO

DE HUMOS SUPERIOR

2 – TORNILLOS

DE MONTAJE

(4 x 12 mm de cabeza

troncocónica ahuecada)

6 – TORNILLOS

DE MONTAJE

(4 x 38 mm de cabeza

troncocónica ahuecada)

INSTALE LOS CONDUCTOS

(sólo en campanas con conductos)

1. Decida dónde instalará el conducto entre

la campana y

el exterior.

2. Un conducto recto y corto permitirá que la campana funcione

más eficientemente.

3. Los tramos largos

de conductos, codos y transiciones reducirán el desempeño

de la campana. Use tan pocos de ellos como sea posible. Es

posible que se requieran conductos más grandes para un mejor

funcionamiento con tramos más largos de conductos.

4. Instale la tapa para pared o para techo. Conecte un conducto

metálico redondo en la tapa y trabaje hacia atrás, hacia la

ubicación de la campana. Use cinta para conductos para sellar

las uniones entre las secciones de conductos.

NOTA

La línea central del conector de conducto en la campana está a

3/4 pulg. (2 cm) de la línea central de la campana. Planee el empalme

del conducto según corresponda.

HERRAMIENTA DE

VENTOSA PARA

BOMBILLAS

CONJUNTO DEL

TUBO DE HUMOS

DECORATIVO

CONJUNTO

DE LA CAMPANA

Page 21

MODELOS EW5830SS • EW5836SS

INSTALE EL CABLEADO INSTALE EL SOPORTE

DE MONTAJE DE LA CAMPANA

LÍNEA CENTRAL

DE LA CAMPANA

4 ¼

pulg.

(10.8 cm)

MÁX.

24 pulg.

(61 cm) MÁX.

3 ½ pulg.

(8.9 cm)

C

L

2 pulg.

(5 cm)

Página 21

12 pulg.

(30 cm)

DE 24 A

36 PULG.

(61 A 91 CM)

POR ENCIMA

DE LA ESTUFA

INSTRUCCIONES PARA LA PUESTA A TIERRA

Este aparato debe estar conectado a tierra. En caso de un

cortocircuito eléctrico, la puesta a tierra reduce el riesgo de una

descarga eléctrica al suministrar un cable de escape para la corriente

eléctrica. Este aparato está equipado con un cordón que tiene un

cable con una clavija a tierra. La clavija debe conectarse a una toma

eléctrica que esté instalada y conectada a tierra adecuadamente.

Coloque el tomacorriente eléctrico dentro del espacio cubierto por

el tubo de humos decorativo y donde no interfiera con el conducto

redondo. Asegúrese de que el tomacorriente no esté a más de

24 pulg. (61 cm) de la parte superior del chasis de la campana y que

el tomacorriente no interfiera con un área de sujeción de soportes o

donde el tubo de humos toque la pared.

AQUÍ LOS

TORNILLOS

de 4 x 38 mm

ESTUFA DE 36 pulg. (91 cm)

DE ALTO

A

VEA EL

CUADRO

ABAJO

10 3/8 pulg.

(26.4 cm)

3 pulg.

(7.6 cm)

1. Construya un bastidor de madera en la pared que quede al ras

de la superficie interior de los montantes de la pared. Asegúrese

de que el bastidor esté centrado en el lugar de la instalación.

NOTA

La distancia de la campana por encima de la estufa es: Mínima

de 24 pulg. (61 cm) y máxima de 36 pulg. (91 cm). Los cielos

rasos de 9 y 10 pies (2.7 y 3 m) peude requieren una extensión

del tubo de humos, modelo FXN5E58SS dependiendo de la

altura de la instalación (se compra por separado). Consulte

información adicional sobre la altura de la instalación en el

cuadro siguiente.

2. Después de terminar con la superficie de la pared, sujete (2)

tornillos de 4 x 38 mm en los lugares mostrados arriba. NO

APRIETE totalmente los tornillos.

Distancia deseada de la campana (por encima de la estufa de 36 pulg. (91 cm) de alto)

Altura del

cielo raso

8 pies (2.4 m)

9 pies (2.7 m)

9 pies

(2.7 m) con

FXNE58SS

10 pies

(3 m) con

FXNE58SS

* El alistonado de recirculación sin conductos quedará expuesto en una configuración con conductos

24"25" 26" 27" 28"29" 30" 31" 32" 33" 34" 35" 36"

Ubicación de los tornillos de montaje superiores (distancia por encima de la estufa de 36 pulg. (91 cm) de alto) –

36-3/8" 37-3/8" 38-3/8" 39-3/8" 40-3/8"41-3/8" 42-3/8"

*42-3/8"

36-3/8" 37-3/8" 38-3/8" 39-3/8" 40-3/8" 41-3/8" 42-3/8"

36-3/8" 37-3/8" 38-3/8" 39-3/8" 40-3/8" 41-3/8" 42-3/8"

(Dimensión “A”)

*43-3/8" *44-3/8" *45-3/8" *46-3/8" *47-3/8" *48-3/8"

43-3/8" 44-3/8" 45-3/8" 46-3/8" 47-3/8" 48-3/8"

Page 22

INSTALE LA CAMPANA

(sólo en campanas con conductos)

MODELOS EW5830SS • EW5836SS

Página 22

Cielo raso

Ranuras del soporte de montaje

1. Centre el soporte de montaje del tubo de humos sobre la

ubicación de la campana y a nivel con el cielo raso. Fije el

soporte del tubo de humos superior a la pared utilizando dos

(2) tornillos de montaje de 4 x 38 mm. Nota: Podría necesitar

anclajes para paneles de yeso (no se incluyen).

2. Apriete totalmente los tornillos. Asegúrese de que el soporte

esté apretado contra la pared y el cielo raso.

3. En este momento quite la película de plástico protector que

cubre el tubo de humos decorativo y la campana.

4. Retire los filtros de grasa estirando hacia abajo la pestaña

metálica e inclinando los filtros hacia abajo para quitarlos.