Page 1

INSTALLATION INSTRUCTIONS

HRV90H AND ERV90HC

RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

06010C rev. G

Model no.: HRV90HT

(HRV with ports on top)

Model no.: HRV90HS

(HRV with ports on sides)

Model no.: ERV90HCT

(ERV with ports on top)

Model no.: ERV90HCS

(ERV with ports on sides)

VB0082

VB0080 VB0079

VB0081

Page 2

ABOUT THIS MANUAL

Because of the large amount of models covered by this publication, the illustrations are typical ones. Some details of your unit may be

slightly different than the ones shown.

Please take note that this manual uses the following symbols to emphasize particular information:

NOTE: Indicates supplementary information needed to fully complete an instruction.

We welcome any suggestions you may have concerning this manual and/or the unit, and we would appreciate hearing your comments

on ways to better serve you. Please contact us by phone at 1-800-558-1711.

WARNING

Identifies an instruction which, if not followed, might cause serious personal injuries including possibility of death.

!

CAUTION

Denotes an instruction which, if not followed, may severely damage the unit and/or its components.

- 2 -

!

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSON(S) OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning the unit, disconnect power cord from electrical outlet.

3. This unit is not designed to provide combustion and/or dilution air for fuel-burning appliances.

4. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

5. Do not use this unit with any solid-state speed control device other than main optional wall control VT4W, and no other optional

auxiliary wall controls than 60-minute crank timer and/or 20-minute lighted push button and/or Humidity Control.

6. This unit must be grounded. The power supply cord has a 3-prong grounding plug for your personal safety. It must be plugged into a

mating 3-prong grounding receptacle, grounded in accordance with the national electrical code and local codes and ordinances. Do

not remove the ground prong. Do not use an extension cord.

7. Do not install this unit in a cooking area or connect directly to any appliances.

8. Do not use to exhaust hazardous or explosive materials and vapors.

9. When performing installation, servicing or cleaning these units, it is recommended to wear safety glasses and gloves.

10. Due to the weight of the unit, two installers are recommended to perform installation.

CAUTION

1. To avoid prematurate clogged filters, turn OFF the unit during construction or renovation.

2. Please read specification label on product for further information and requirements.

3. Be sure to duct air outside – Do not intake / exhaust air into spaces within walls or ceiling or into attics, crawl spaces, or garage.

4. Intended for residential installation only in accordance with the requirements of NFPA 90B.

5. Do not run any air ducts directly above or closer than 2 ft (0.61 m) to any furnace or its supply plenum, boiler, or other heat producing

appliance. If a duct has to be connected to the furnace return plenum, it must be connected not closer than 9’10” (3 m) from this

plenum connection to the furnace.

6. The ductwork is intended to be installed in compliance with all local and national codes that are applicable.

7. When leaving the house for a long period of time (more than two weeks), a responsible person should regularly check if the unit operates

adequately.

8. If the ductwork passes through an unconditioned space (e.g.: attic), the unit must operate continuously except when performing

maintenance and/or repair. Also, the ambient temperature of the house should never drop below 18°C (65°F).

WARNING

ABOUT THESE UNITS

LIMITATION

For residential (domestic) installation only. This unit must be installed in accordance with all national and local regulations, building codes

and safety codes.

Page 3

1. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

1.1 AIR DISTRIBUTION (NORMAL OPERATION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 A

IR DISTRIBUTION (RECIRCULATION OR DEFROST MODE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4 P

ERFORMANCE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.5 D

IMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.6 CONTROLS AND LINKAGE POSSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. TYPICAL INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

2.1 FULLY DUCTED SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..7

2.2 CENTRAL DRAW POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.3 S

IMPLIFIED INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.4 I

NSTALLATION FOR ERV UNITS ONLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-16

3.1 INSPECT THE CONTENT OF THE BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 LOCATING THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3 U

NIT PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4 HOW TO HANG THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.5 PLANNING OF THE DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.6 I

NSTALLING THE DUCTWORK AND REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12

3.7 CONNECTING THE DUCT TO THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.8 INSTALLING THE TANDEM® TRANSITION KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-15

3.9 INSTALLING 2 EXTERIOR HOODS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-19

4.1 INTEGRATED CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.2 ELECTRICAL CONNECTION TO OPTIONAL WALL CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-18

4.3 VT4W OPTIONAL MAIN WALL CONTROL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.4 O

PTIONAL AUXILIARY WALL CONTROLS OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5. ELECTRICAL CONNECTION TO THE FURNACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6. WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7. B

ALANCING THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8. CONNECTING THE DRAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

9. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23-24

9.1 BIANNUAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23-24

9.2 ANNUAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

10. SERVICE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

11. T

ROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

TABLE OF CONTENTS

- 3 -

Page 4

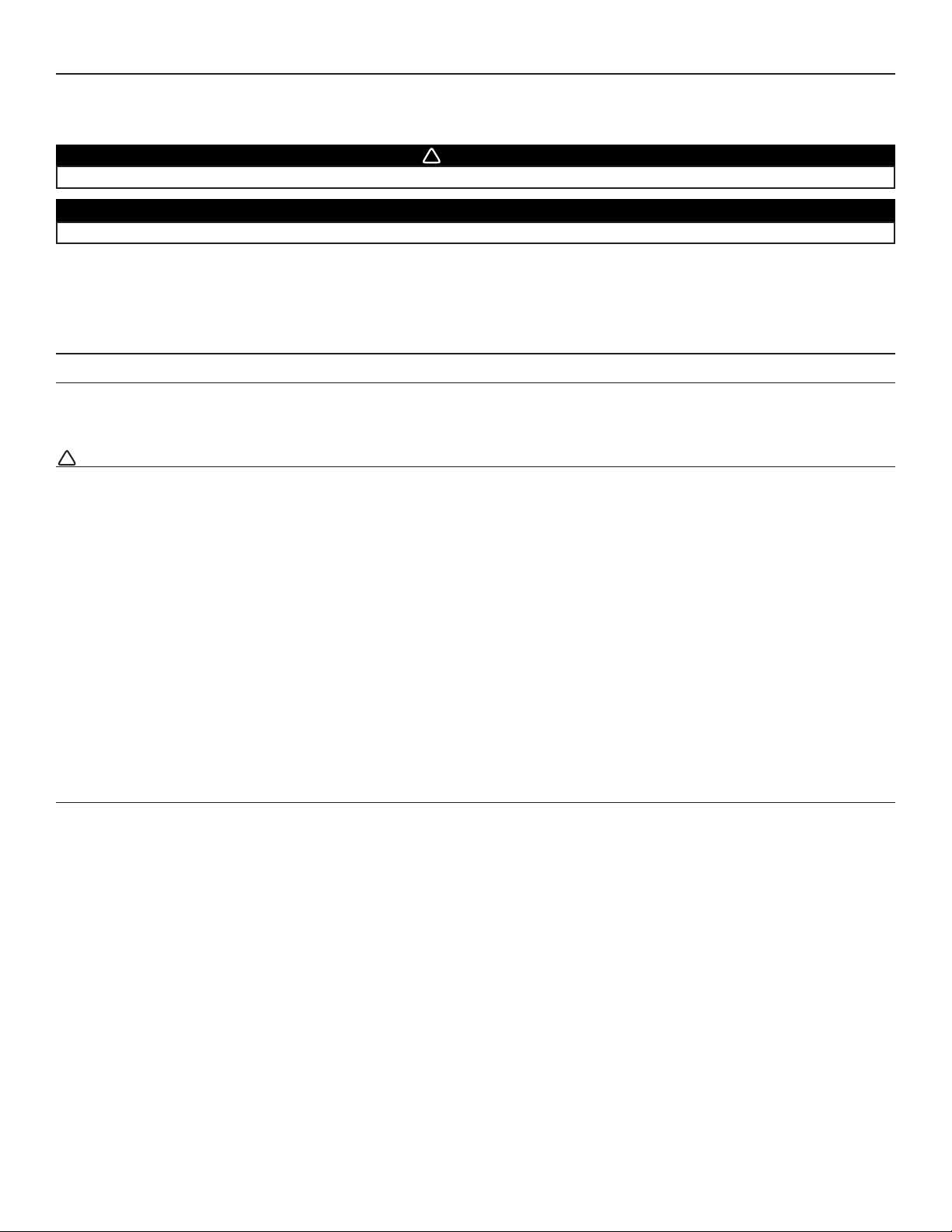

HRV ERV

1. TECHNICAL DATA

1.1 AIR DISTRIBUTION (NORMAL OPERATION)

HRV ERV

1.2 A

IR DISTRIBUTION (RECIRCULATION OR DEFROST MODE)

Celcius (°C)

-5 to -27

-27 and less

Fahrenheit (°F)

23 to -17

-17 and less

Defrosting (min.)

9

10

Operation time (min.)

between each defrost cycle

23

22

Outside Temperature HRV and ERV Defrost Cycles

- 4 -

EXHAUST AIR-

FROM BUILDING

FRESH AIR

TO BUILDING

EXHAUST AIR-

FROM BUILDING

FILTERED AIR

TO BUILDING

EXHAUST AIR-

FROM BUILDING

FILTERED AIR

TO BUILDING

EXHAUST AIR

FROM BUILDING

FRESH AIR

TO BUILDING

FRESH AIR

FROM OUTSIDE

EXHAUST AIR

TO OUTSIDE

FRESH AIR

FROM OUTSIDE

EXHAUST AIR

TO OUTSIDE

1.3 SPECIFICATIONS

Weight

Oval Ports

Drain Diameter

42 lb (19 kg)

Fit 5” (127 mm) ducts

1/2” (12 mm)

45 lb (20.4 kg)

Fit 5” (127 mm) ducts

N/A

Installation Chains, springs and hooks (provided with the unit).

Motor Speeds High and low speed

Electrical supply 120 V, 60 Hz 120 V, 60 Hz

Power Consumption 150 watts 160 watts

Model HRV ERV

VF0038

VF0036

VF0039

VF0037

Page 5

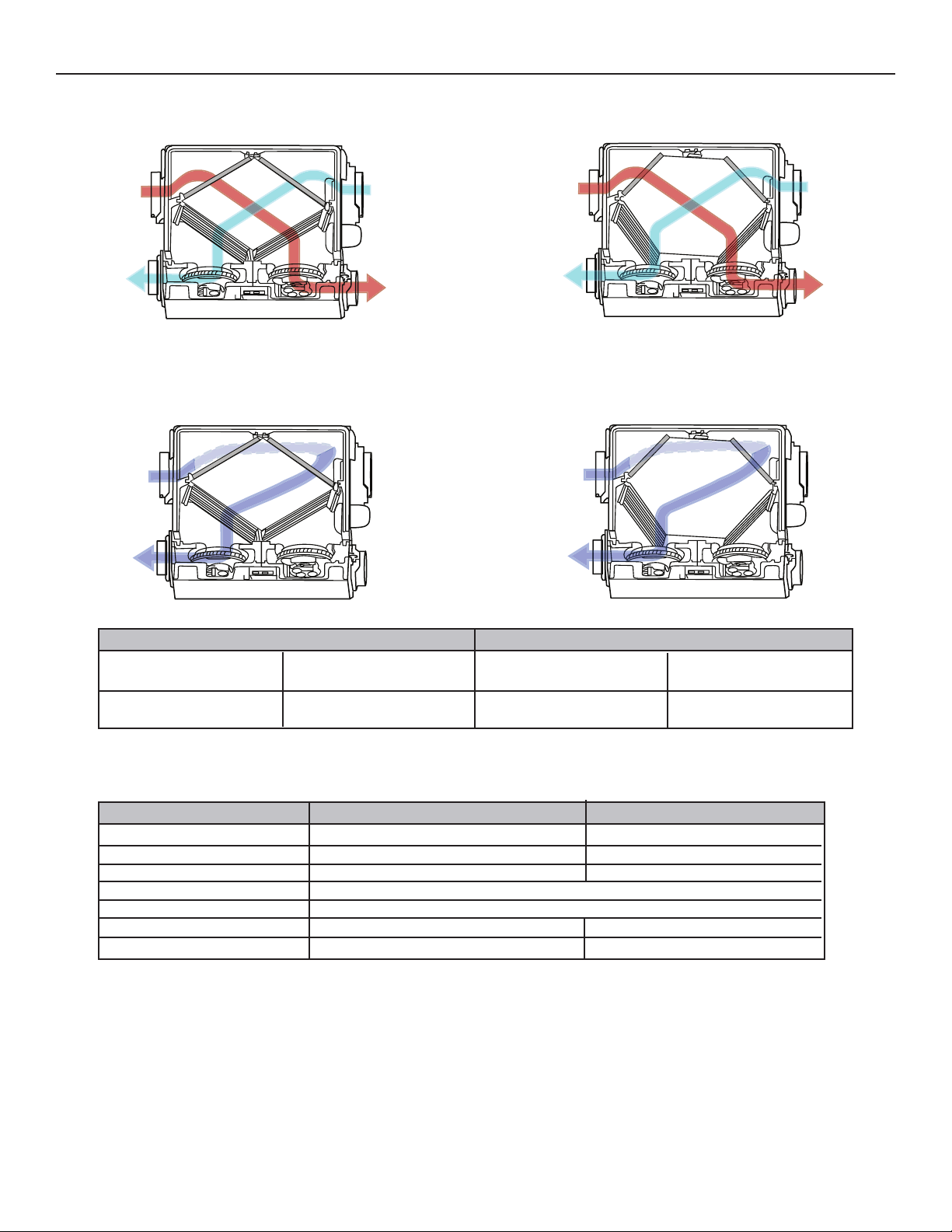

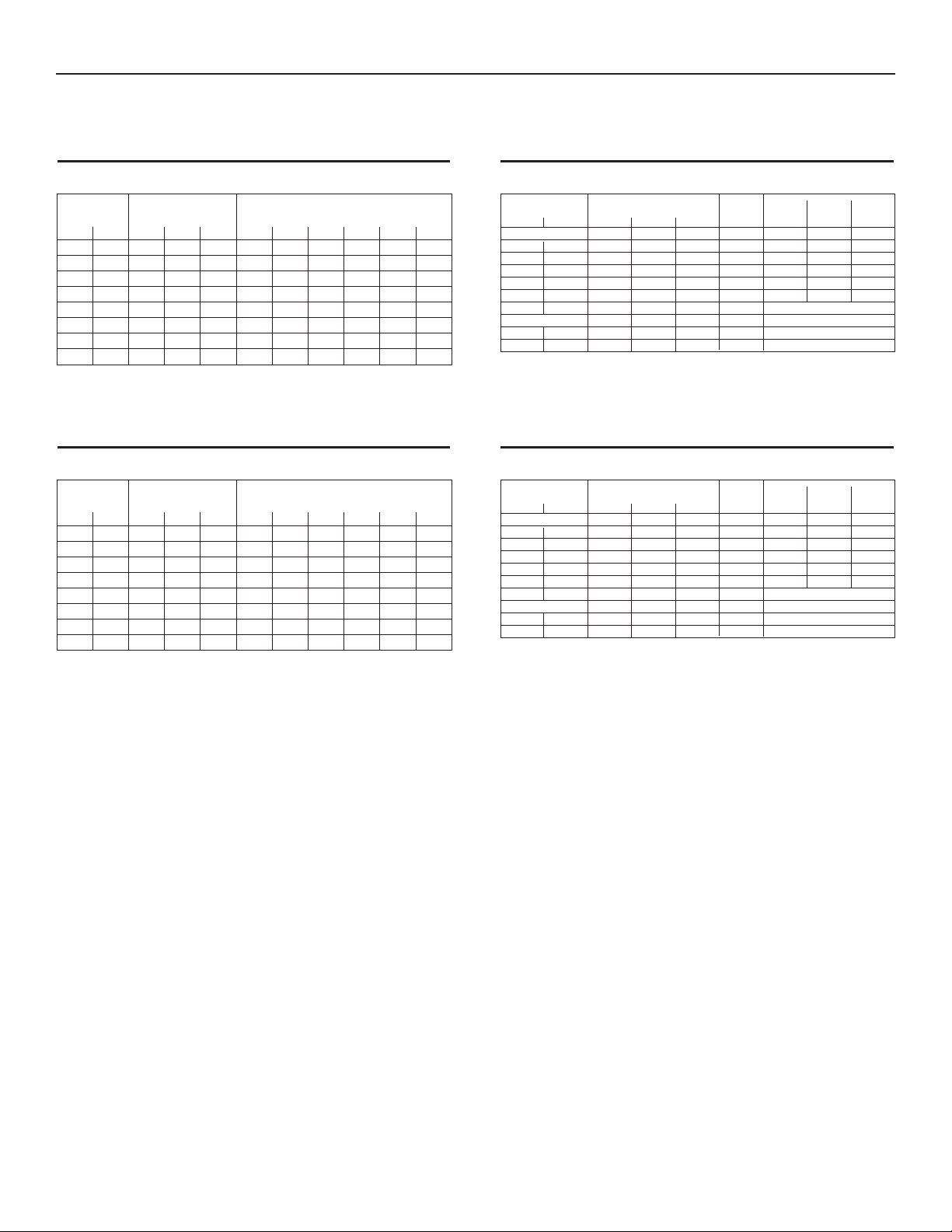

1.4.1 HRV UNITS

1. TECHNICAL DATA (CONT’D)

1.4 P

ERFORMANCE CHARTS

Ventilation Performance

NOTE: A

LL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

.

SUPPLY POWER SENSIBLE APPARENT

LATENT RECOVERY/

TEMPERATURE NET AIR FLOW CONSUMEDRECOVERY SENSIBLE MOISTURE

WATTS EFFICIENCY

EFFECTIVENESS

TRANS-

FER

68

82

116

110

66

65

59

55

78

76

68

81

0.07

0.04

0.04

0.08

Not tested

-

C°

0

0

0

-25

+35

F°

+32

+32

+32

-13

+95

l/s

23

30

44

30

-

-

cfm

48

63

93

63

-

-

m3/h

82

108

157

108

-

-

COOLING

HEATING

TOTAL RECOVERY EFFICIENCY

EXT STATIC NET SUPPLY GROSS AIR FLOW

PRESSURE AIR FLOW SUPPLY EXHAUST

Pa

25

50

75

100

125

150

175

200

in.w.g.

.1

.2

.3

.4

.5

.6

.7

.8

l/s

52

50

48

45

43

41

38

35

cfm

110

106

101

96

92

87

81

75

m

3

/h

187

180

173

162

155

148

137

126

l/s

52

50

48

46

43

41

38

36

cfm

110

106

102

97

92

87

81

76

m3/h

187

180

173

166

155

148

137

130

l/s

58

55

53

50

49

45

43

40

cfm

122

116

113

107

103

96

91

85

m3/h

205

198

191

180

173

162

155

144

Energy Performance

1.4.2 ERV UNITS

Ventilation Performance

NOTE: A

LL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

.

SUPPLY POWER SENSIBLE APPARENT

LATENT RECOVERY/

TEMPERATURE NET AIR FLOW CONSUMEDRECOVERY SENSIBLE MOISTURE

WATTS EFFICIENCY

EFFECTIVENESS

TRANSFER

70

85

127

102

67

65

61

56

82

77

73

78

0.60

0.54

0.49

0.50

49

68

C°

0

0

0

-25

+35

F°

+32

+32

+32

-13

+95

l/s

22

30

45

30

23

-

cfm

46

64

91

64

46

-

m

3

/h

79

108

155

108

166

-

COOLING

HEATING

TOTAL RECOVERY EFFICIENCY

EXT STATIC NET SUPPLY GROSS AIR FLOW

PRESSURE AIR FLOW SUPPLY EXHAUST

Pa

25

50

75

100

125

150

175

200

in.w.g.

.1

.2

.3

.4

.5

.6

.7

.8

l/s

55

53

50

49

46

44

42

39

cfm

116

113

107

104

98

94

88

82

m

3

/h

197

192

182

177

166

160

150

139

l/s

56

55

52

50

48

46

43

40

cfm

119

116

111

107

101

97

91

84

m3/h

202

197

189

182

172

165

155

143

l/s

59

57

54

53

50

47

45

42

cfm

125

121

115

112

105

100

95

90

m3/h

212

206

195

190

178

170

161

153

Energy Performance

- 5 -

Page 6

1. TECHNICAL DATA (CONT’D)

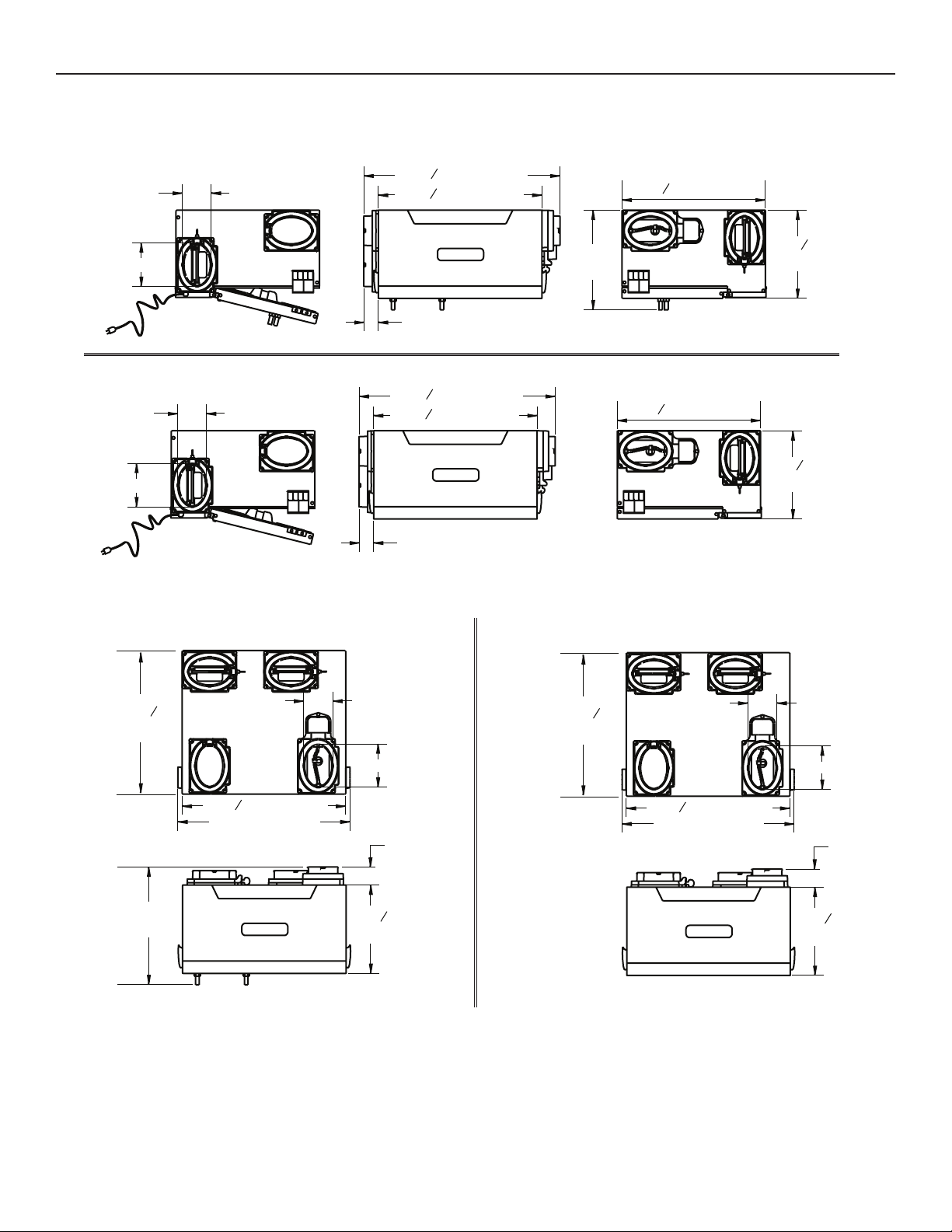

1.5 DIMENSIONS

1.5.1 DIMENSIONS FOR PORTS ON SIDES UNITS

HRV

ERV

1.5.2 DIMENSIONS FOR PORTS ON TOP UNITS

HRV ERV

1.6 C

ONTROLS AND LINKAGE POSSIBILITY

MAIN CONTROL

• VT4W

AUXILIARY CONTROLS

• 20-MINUTE PUSH BUTTON TIMER

• 60-MINUTE CRANK TIMER

• HUMIDITY CONTROL

LINKAGE POSSIBILITY

• AIR HANDLER INTERLOCK

(USED WITH FORCED AIR SYSTEM)

- 6 -

4’’ (102 mm)

6’’ (152 mm)

VK0055

4’’ (102 mm)

6’’ (152 mm)

1

27 16” (688 mm)

9

22

16” (574 mm)

2” (51 mm)

1

27 16” (688 mm)

9

16” (574 mm)

22

13¾”

(349 mm)

13

19 16” (503 mm)

13

19 16” (503 mm)

3

12 16”

(310 mm)

3

12 16”

(310 mm)

VK0057

13

19 16”

(503 mm)

9

22

16” (574 mm)

23 ¾” (603 mm)

16 ¼”

(413 mm)

VK0056

2” (51 mm)

4’’ (102 mm)

6’’ (152 mm)

2½”

(64 mm)

3

16”

12

(310 mm)

13

19 16”

(503 mm)

VK0058

9

22

16” (574 mm)

23 ¾” (603 mm)

4’’ (102 mm)

6’’ (152 mm)

2½”

(64 mm)

3

16”

12

(310 mm)

Page 7

2.3 SIMPLIFIED INSTALLATION (CONNECTION TO A FORCED AIR SYSTEM)

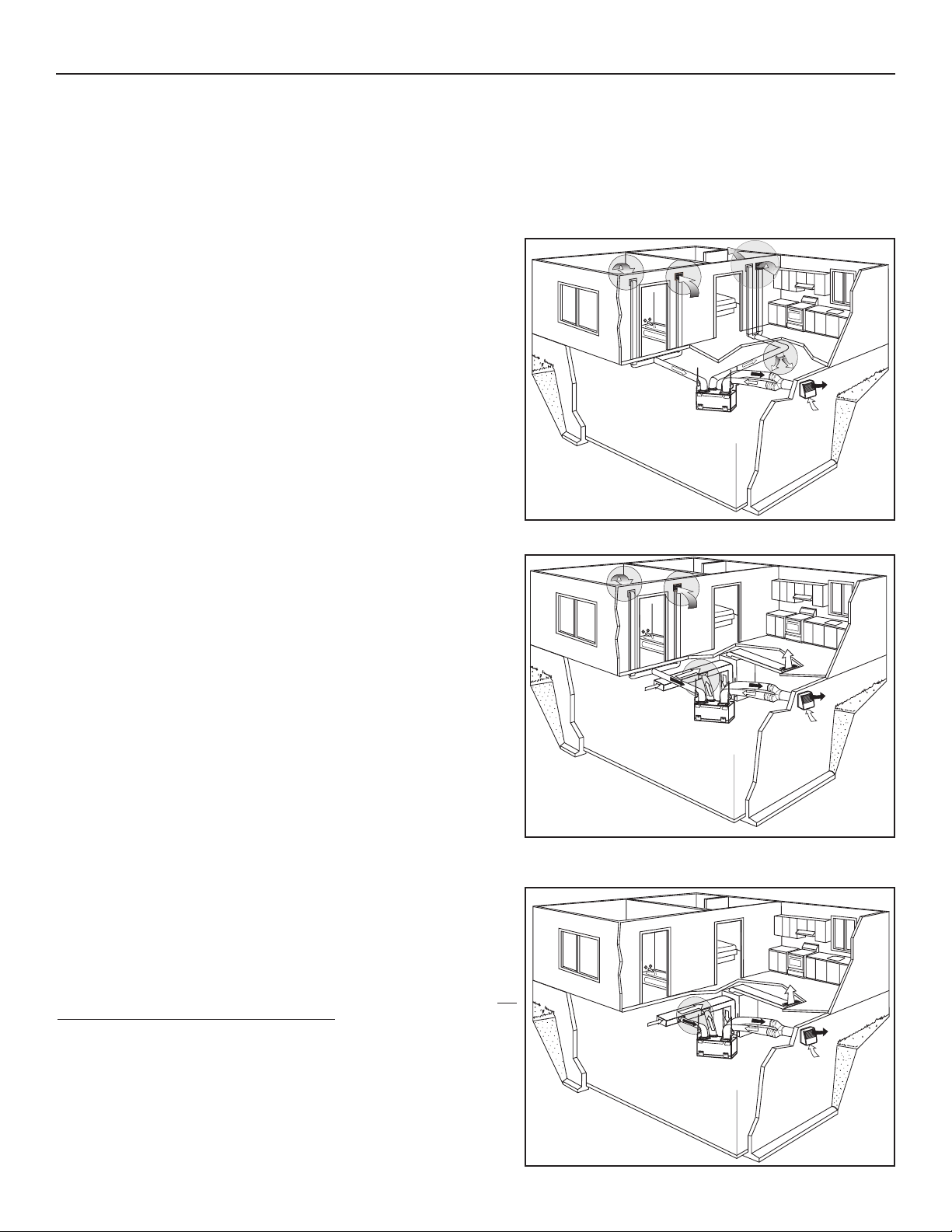

2. TYPICAL INSTALLATIONS

Installations may vary according to the type of unit and the ports configuration (top or sides). Use the following illustrations as guidelines

to help you decide on how the unit will be installed.

All the units should be hung from the joists.

In every case, bathroom fans and a range hood should be used to exhaust stale air. Also, for homes with more than one level, we

recommend one exhaust register at the highest level.

There are 3 installation methods: Fully ducted, Central Draw Point and Simplified Installation.

NOTE: An electrical outlet has to be available within 3 feet of the unit.

2.1 FULLY DUCTED SYSTEM (PRIMARILY FOR HOMES WITH RADIANT HOT WATER OR ELECTRIC BASEBOARD HEATING.)

2.2 CENTRAL DRAW POINT (CONNECTION TO A FORCED AIR SYSTEM.)

For this type of installation, it is not essential that the forced air system

blower runs when the unit is in operation, but we recommend it.

NOTE: Home with multiple forced air systems should have one unit on

each system.

Stale air coming from the registers located at the highest level of the house

is exhausted to the outside. Fresh air from outside is filtered and supplied

by the register located in the lowest liveable level.

Homes with more than one level require at least one exhaust register at the

highest level.

See figure at right.

Stale air coming from the registers located at the highest level of the house

is exhausted to the outside. Fresh air from outside is filtered and supplied

to the return (plenum) or the supply duct of the forced air unit. See figure

at right.

Stale air is exhausted to the outside. Fresh air from outside is filtered and

supplied to the return (plenum) or the supply duct of the forced air unit. See

figure at right.

To avoid cross-contamination and achieve the highest efficiencies, the

forced air system blower must always be ON.

NOTE: Home with multiple forced air systems should have one unit on

each system.

- 7 -

VH0055

VH0056

VH0057

Page 8

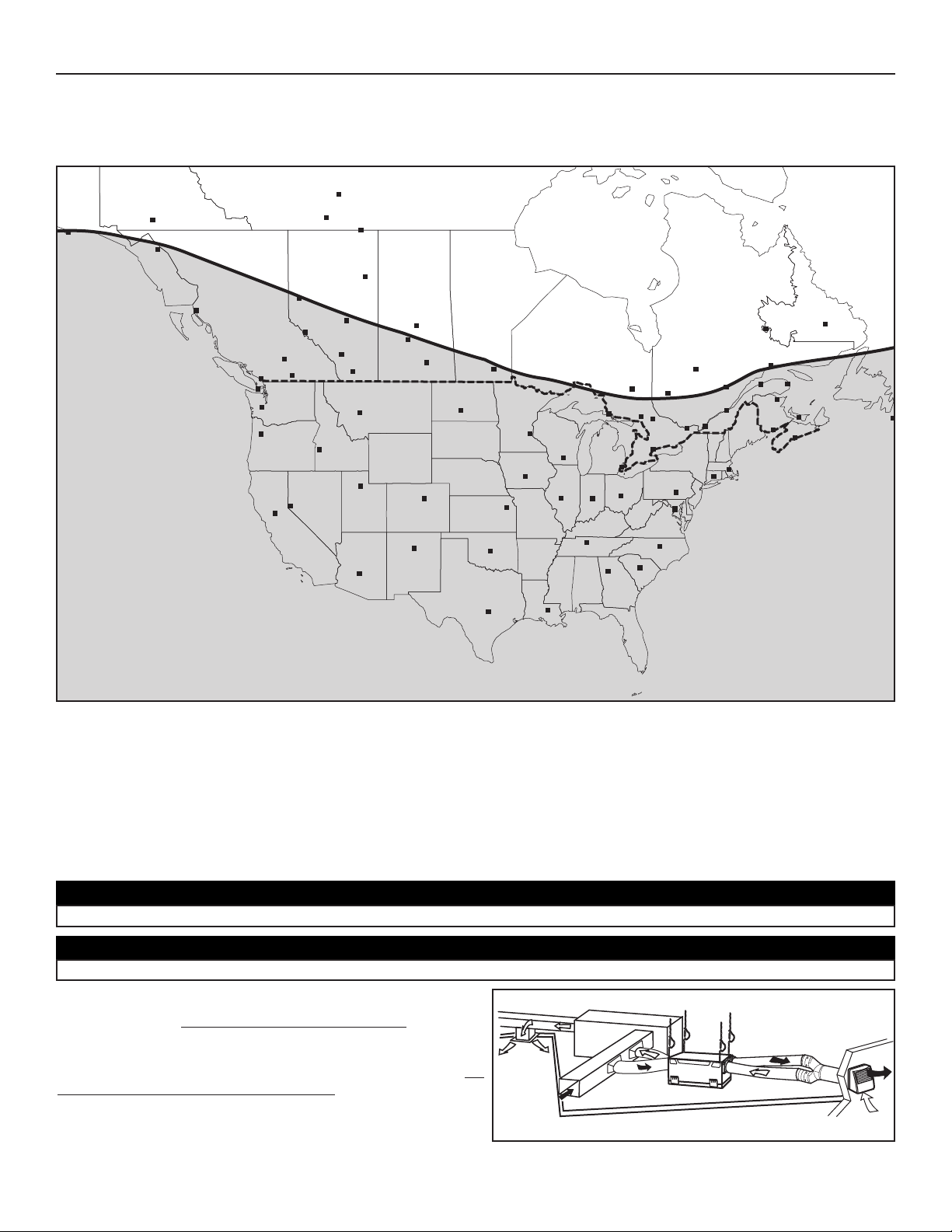

2. TYPICAL INSTALLATIONS (CONT’D)

The ERV units are created to meet specific requirements related to geographical locations. Take a look at the map below; the shaded

area shows the limits where the ERV unit can be installed. However, there is no geographical limitation for installing an HRV unit.

NOTE:The ERV unit is designed to assist in the management of humidity introduced into the home.

During cooling season, in extreme humidity conditions, the use of additional dehumidification unit may be required to quickly

remove all excess moisture. During heating season, in extreme dryness conditions, the use of a humidifier may be required if

the indoor air is still too dry.

ANCHORAGE

WHITEHORSE

JUNEAU

HAY RIVER

YELLOWKNIFE

Prince Rupert

GRANDE PRAIRIE

FORT MCMURRAY

FORT SMITH

EDMONTON

PRINCE ALBERT

SASKATOON

JASPER

KAMLOOPS

CALGARY

PENTICTON

REGINA

LETHBRIDGE

HELENA

VICTORIA

OLYMPIA

WINNIPEG

SALEM

BOISE

BISMARCK

SALT LAKE CITY

SAULT STE MARIE

ST. PAUL

DES MOINES

MADISON

TIMMINS

HARRISBURG

SACRAMENTO

DENVER

TOPEKA

SUDBURY

TORON TO

DETROIT

INDIANAPOLIS

SANTA FE

SPRINGFIELD

OKLAHOMA CITY

PHOENIX

COLUMBUS

NASHVILLE

ATLANTA

BATON ROUGE

AUSTIN

COLUMBIA

RALEIGH

WASHINGTON

OTTAWA

NORTH BAY

VAL-DOR

CHICOUTIMI

HARTFORD

CHIBOUGAMAU

MONTRÉAL

QUEBEC

BOSTON

GOOSE BAY

LABRADOR CITY

SEPT-ILES

MATANE

GASPÉ

BATHURST

ST-JOHN

HALIFAX

CHARLOTTETOWN

ST JOHN’S

RENO

2.4 INSTALLATION FOR ERV UNITS ONLY

2.4.1 GEOGRAPHICAL LOCATION

All 3 types of installations can be used in the attic (Fully ducted system, Central Draw Point or Simplified). The example shown below is

a Simplified installation (connection to a forced air system).

Stale air is exhausted to the outside. Fresh air from outside is filtered

and supplied to the return (plenum) of the forced air unit

.

See figure at right.

To avoid cross-contamination and achieve the highest efficiencies, the

forced air system blower must always be ON.

NOTE: Home with multiple forced air systems should have 1 unit on

each system.

Due to the potential temperature difference between the attic and the rest of the house, all unit ducts must be insulated.

CAUTION

The attic temperature must always be above 0°C (32°F).

CAUTION

2.4.2 ERV UNITS ATTIC INSTALLATION

- 8 -

VN0006

VH0058

Page 9

- 9 -

3. INSTALLATION

3

.1 INSPECT THE CONTENTS OF THE BOX

• Inspect the exterior of the unit for shipping damage. Ensure that there is no damage to the door, door latches, power cord, etc.

• Remove and discard the 2 transport brackets (A) and open the door. Discard the styrofoam

fillers (ERV units only) and remove the hardware kit from the unit. Inspect the interior of the unit

for damage. Ensure that heat or energy recovery core, core filters, insulation, dampers, etc. are

all intact.

3.2 LOCATING THE UNIT

Choose an appropriate location for the unit.

• Within an area of the house where the ambient temperature is between 10°C (50°F) and 65°C (149°F) (basement, furnace room,

closet, etc.).

• So as to provide easy access to the interior of the unit, for maintenance.

• Close to an exterior wall, so as to limit the length of the insulated flexible duct to and from the unit.

• Away from hot chimneys and other fire hazards.

• Allow for a power source (standard 3-prong grounding outlet).

• For HRV units ONLY: Close to a drain. If no drain is close by, use a pail to collect run-off.

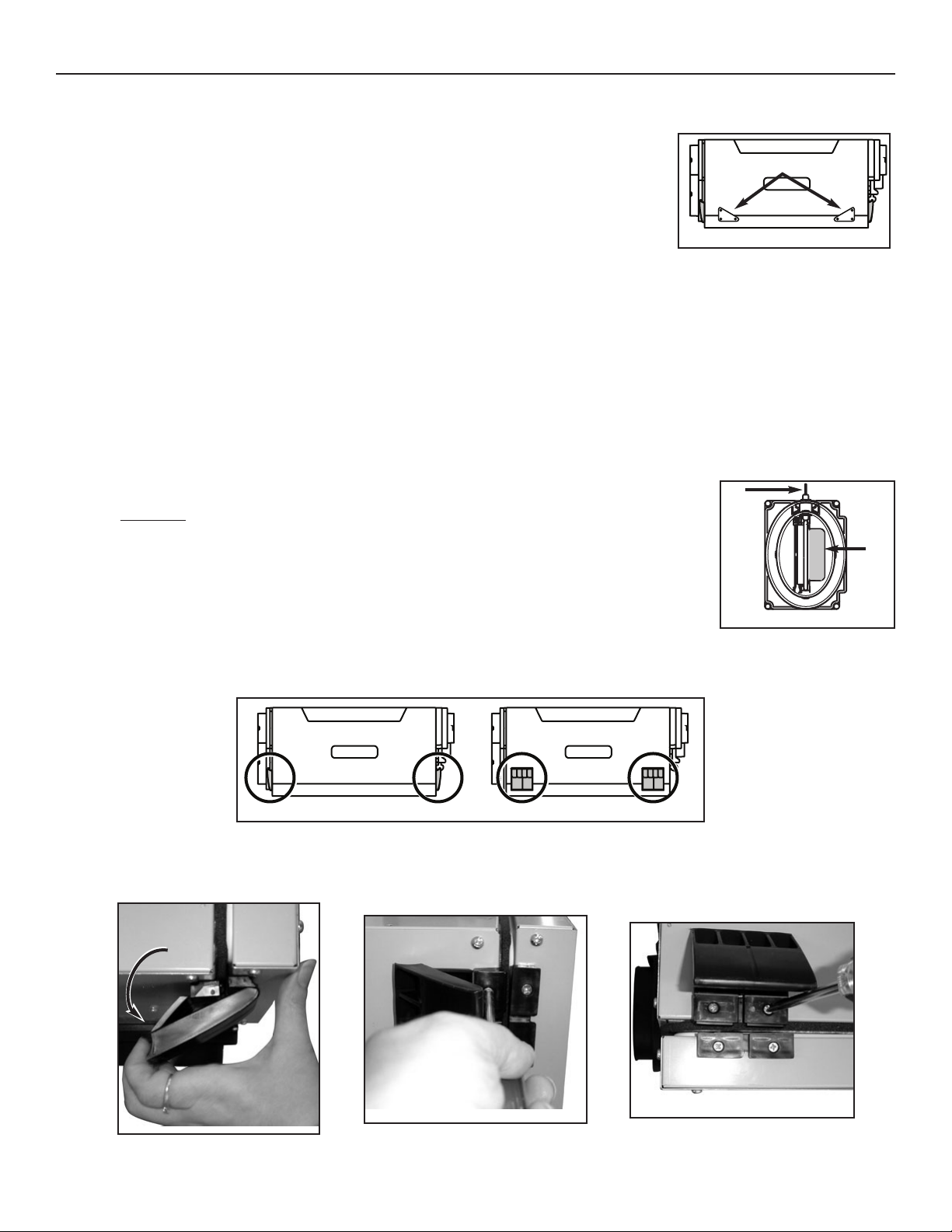

3.3 UNIT PREPARATION

Both HRV and ERV units are equipped with 2 ports having integrated balancing damper. Turn the thumb

screw (A) clockwise to manually open and adjust the damper (B).

HRV UNITS: Set the Fresh air to building port to wide open position, and adjust the Exhaust air to outside

port to 3rd notch.

NOTE: If the unit needs to be balanced, adjust the damper of the Exhaust air to outside port to wide open

position. See

Section 7

.

ERV UNITS: Set both Fresh air to building port and Exhaust air to outside port to wide open position.

The door latches location can be changed from sides to front of the unit, according to the installation needs.

To do so, turn the unit upside down. Open the latches and unscrew them from the unit. Install the latches on their new locations.

A

B

Port with integrated balancing

damper - Top view

Latches on sides of the unit

Latches in front of the unit

VO0089

VO0090

VO0094

A

VD0183

VJ0032

VD0176

Page 10

- 10 -

3. INSTALLATION (CONT’D)

3.5 P

LANNING OF THE DUCTWORK

• Keep it simple. Plan for a minimum of bends and joints.

• Keep the length of insulated ducts to a minimum.

• Do not ventilate crawl spaces or cold rooms. Do not attempt to recover the exhaust air from a dryer or a range hood. This would

cause clogging of the filters and recovery module.

• If the house has two floors or more, be sure to plan for at least one exhaust register on the highest lived-in level.

3.6 INSTALLING THE DUCTWORK AND REGISTERS

3.6.1 FULLY DUCTED SYSTEM (AS ILLUSTRATED IN SECTION 2.1)

Stale air exhaust ductwork

• Install the stale air exhaust registers where the contaminants are produced: kitchen, living room, etc. Position the registers as far

from the stairway as possible and in such a way that the air circulates in all the lived-in spaces in the house.

• If a register is installed in the kitchen, it must be located at least 4 feet (1.2 m) from the range.

• Install the registers 6 to 12 inches (152 to 305 mm) from the ceiling on an interior wall OR install them in the ceiling.

Fresh air distribution ductwork

• Install the fresh air distribution registers in bedrooms, dining rooms, living room and basement.

• Keep in mind that the fresh air registers must be located as far as possible from the stale air registers.

• Install the registers in the ceiling OR 6 to 12 inches (152 to 305 mm) from the ceiling on an interior wall. The duct lenght should be

at least 15’ (4.6 m). (The fresh air will then flow through the room and mix with room air, ensuring a continuous renewed airflow.)

• If a register must be floor installed, direct the airflow up the wall.

WARNING

Never install a stale air exhaust register in a closed room where a combustion device operates, such as a gas furnace, a gas

water heater or a fireplace.

!

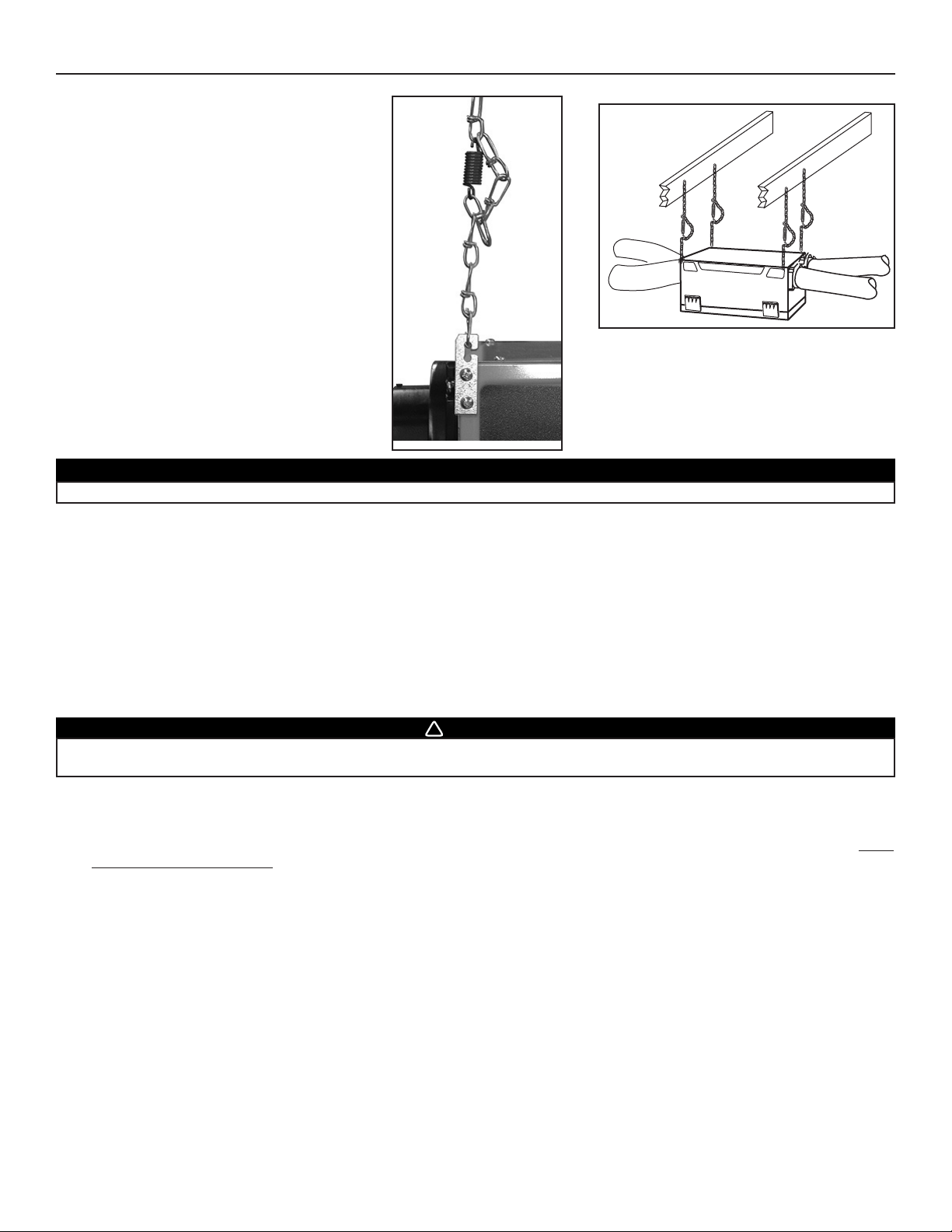

3.4 HOW TO HANG THE UNIT

Hang the unit with the 4 chains, hooks and springs

provided.

CAUTION

Make sure the unit is level.

VD0184

VD0185

Page 11

3. INSTALLATION (CONT’D)

3.6 INSTALLING THE DUCTWORK AND REGISTERS (CONT’D)

3.6.2 C

ENTRAL DRAW POINT SYSTEM (AS ILLUSTRATED IN SECTION 2.2)

Stale air exhaust ductwork

Same as for Fully Ducted System, described on point 3.6.1.

Fresh air distribution ductwork

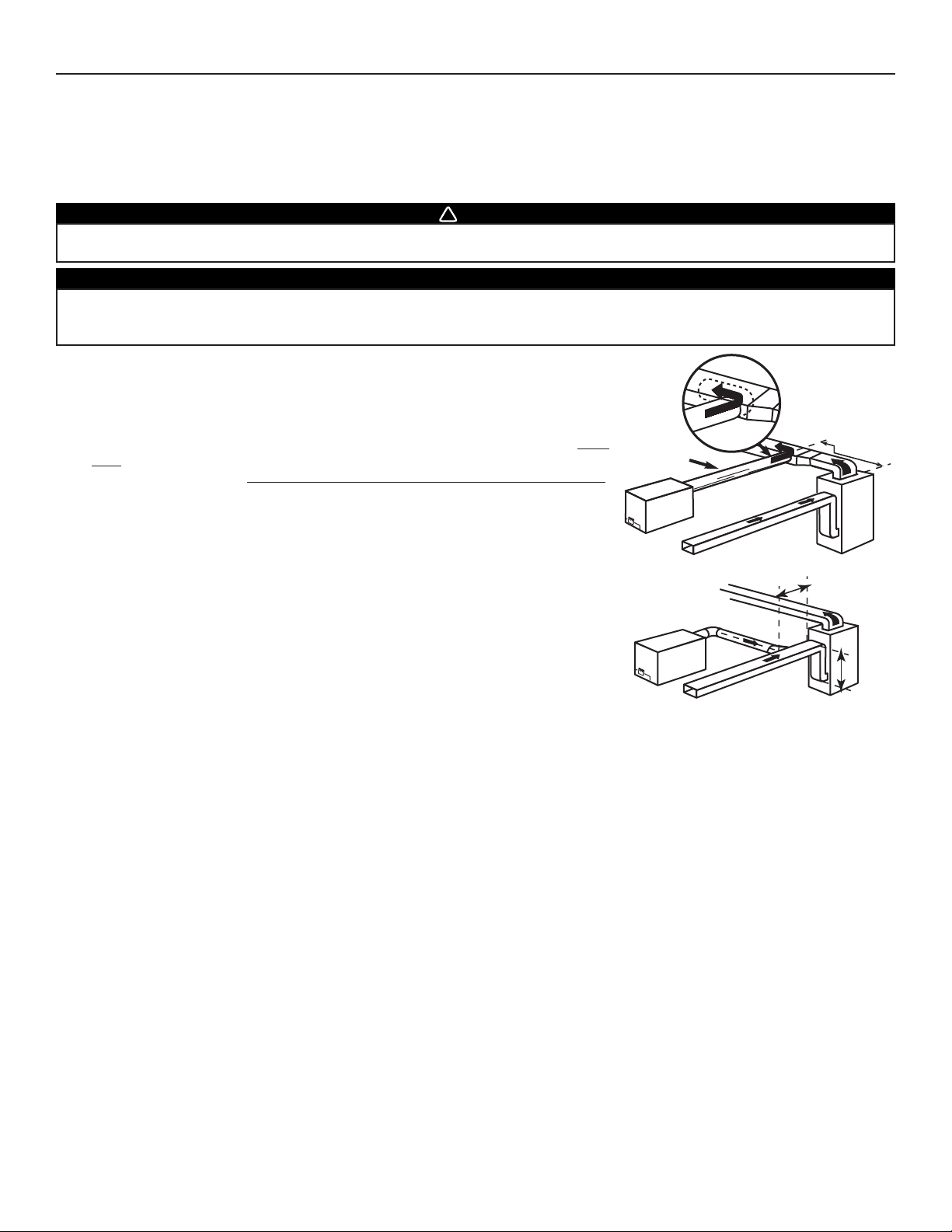

There are 2 methods for connecting the unit to the furnace/air handler:

Method 1: Supply side connection

• Cut an opening into the furnace supply duct at least 18 inches (0.5 m) from the

furnace/air handler.

• Connect this opening to the

Fresh air to building

port of the HRV/ERV (use steel

duct, see figure beside).

• Make sure the HRV/ERV duct form an elbow inside the furnace/air handler ductwork.

• If desired, interlock (synchronize) the furnace/air handler blower operation (see

Section 5).

Method 2: Return side connection

• Cut an opening into the furnace return duct not less than 10 feet (3.1 m) from the

furnace/air handler (A+B).

• Connect this opening to the

Fresh air to building

port of the HRV/ERV

(see figure beside).

NOTE: For Method 2, it is not essential that the furnace/air handler runs when the

unit is operation, but we recommend it. If desired, interlock (synchronize) the

furnace/air handler blower operation (see Section 5).

WARNING

When performing duct connections, always use approved tools and materials. Respect all corresponding laws and safety

regulations. Please refer to your local building code.

CAUTION

When performing duct connections to the furnace supply duct, this duct must be sized to support the additional airflow

produced by the HRV/ERV. Also, use a steel duct. It is recommended that the HRV/ERV is running when the furnace is in

operation to prevent backdrafting inside HRV/ERV.

!

MINIMUM 18”

(0.5 M)

A+B=

NOT LESS

THAN

10’ (3.1 M)

STEEL DUCT

- 11 -

VJ0036

VJ0035

A

B

Page 12

3.6 INSTALLING THE DUCTWORK AND REGISTERS (CONT’D)

3.6.3 S

IMPLIFIED INSTALLATION (AS ILLUSTRATED IN SECTION 2.3)

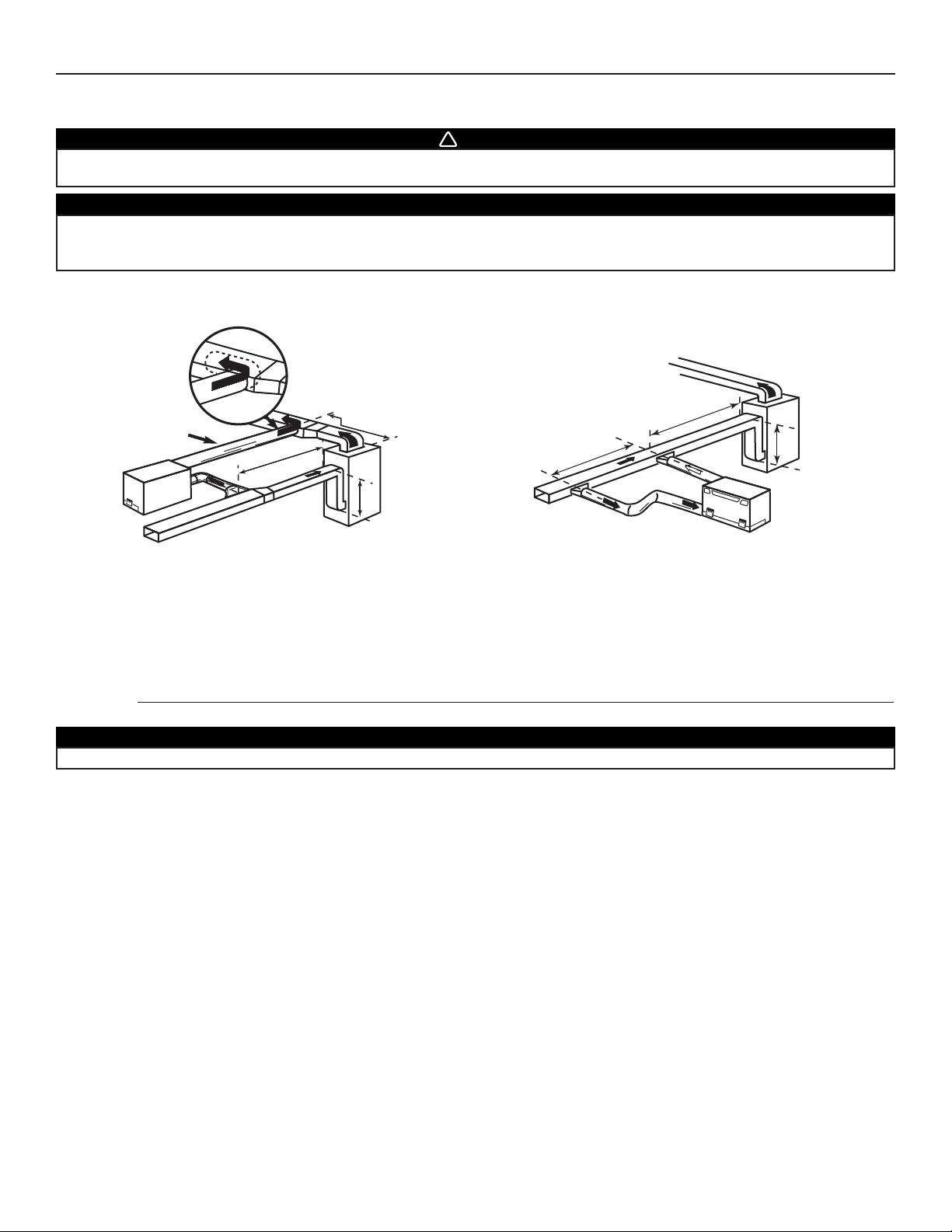

There are 2 methods for connecting the unit to the furnace/air handler:

Method 1: Supply-return connection Method 2: Return-return without

Stale air intake

• Cut an opening into the furnace/air handler return duct not less than 10 feet (3.1 m) from the furnace/air handler (A+B).

• Connect this opening to the

Exhaust air from building

port of the HRV/ERV.

Fresh air distribution

• Same instructions as for Method 1 or Method 2, Section 2.6.2.

For Method 2 (Return-return), make sure there is a distance of at least 3 feet (0.9 m) between the 2 connections to the furnace/air

handler.

NOTE: For Method 1, it is not essential to synchronize the furnace blower operation with the unit operation, but we recommend it.

3. INSTALLATION (CONT’D)

CAUTION

If using Method 2, make sure the furnace/air handler blower operation is synchronized with the unit operation! See Section 5

.

- 12 -

WARNING

When performing duct connections, always use approved tools and materials. Respect all corresponding laws and/or safety

regulations. Please refer to your local building code.

CAUTION

When performing duct connections to the furnace supply duct, this duct must be sized to support the additional airflow

produced by the HRV/ERV. Also, use a steel duct. For a Return-Return installation, the furnace blower must be in operation

when the HRV/ERV is in operation.

!

A+B= NOT LESS

THAN 10’ (3.1 M)

MINIMUM 18”

(0.5 M)

STEEL DUCT

A+B= NOT LESS

THAN 10’ (3.1 M)

MINIMUM 3’

(0.9 M)

A

A

B

B

VJ0037

VJ0038

Page 13

Rigid ducts

Use a small length of flexible duct to connect the rigid duct to the ports in order to avoid vibration transmissions. Use tie-wraps to

perform connections.

3.7 CONNECTING THE DUCTS TO THE UNIT

Insulated flexible ducts

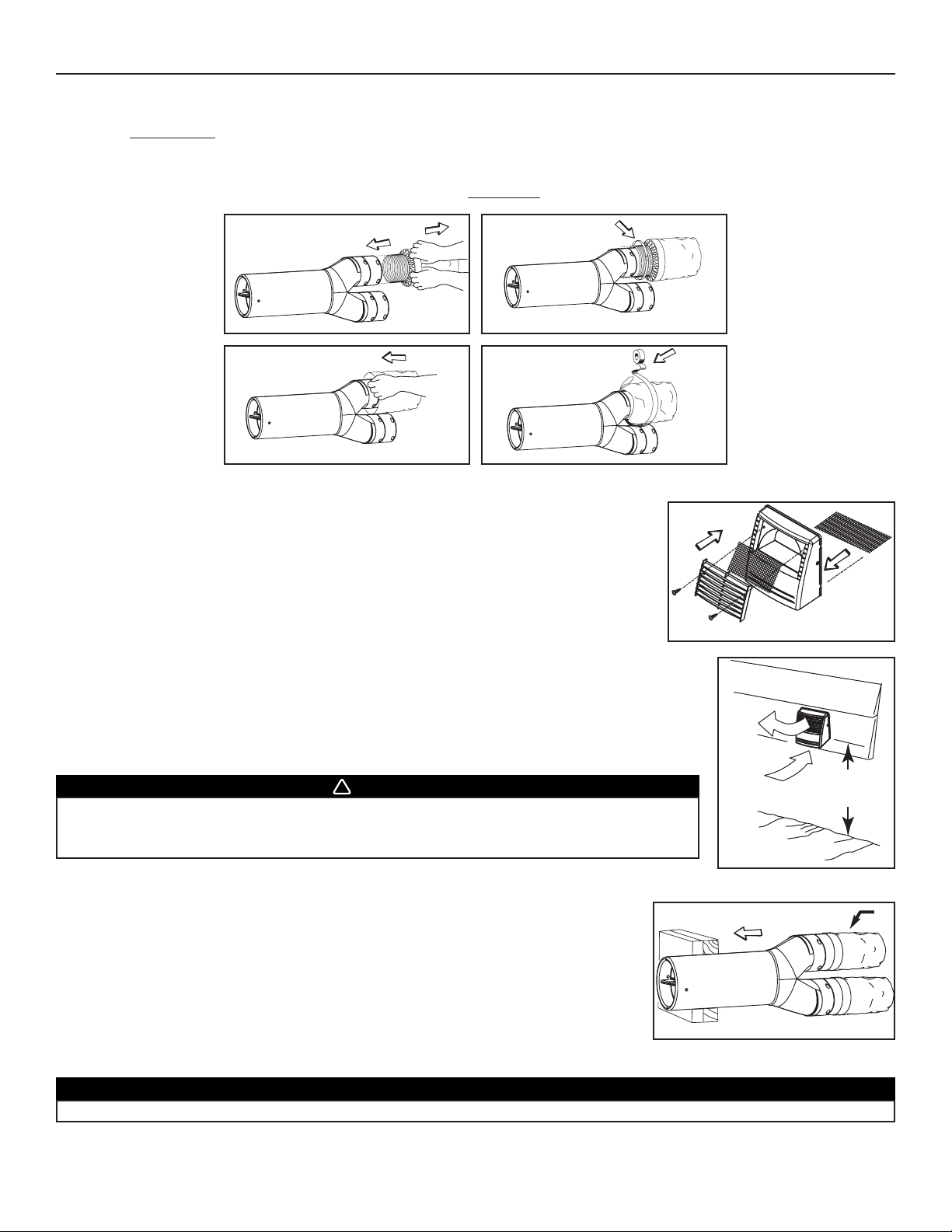

Use the following procedure for connecting the insulated flexible ducts to the port of the unit (

Exhaust air to outside

and

Fresh air from

outside

ports).

CAUTION

Make sure the vapor

barrier on the

insulated ducts

does not tear during

installation to avoid

condensation within

the ducts.

CAUTION

Do not use screws to connect the rigid ducts to the ports.

CAUTION

Make sure the balancing dampers are set to their appropriate position before connecting the ducts to the ports. See Section 3.3

.

VJ0040

VJ0041

Pull back the insulation to

expose the flexible duct.

Attach the flexible

duct to the port using

tie wrap.

Pull the vapor barrier

over the insulation

and over the outer

ring of the double collar.

Apply duct tape to the

joint making an airtight

seal. Avoid compressing

the insulation when

pulling the tape tightly

around the joint.

Compressed insulation

loses its R value and

causes water dripping

due to condensation

on the exterior surface

of the duct.

Pull the insulation

over the joint and

tuck in between the

inner and outer rings

of the double collar.

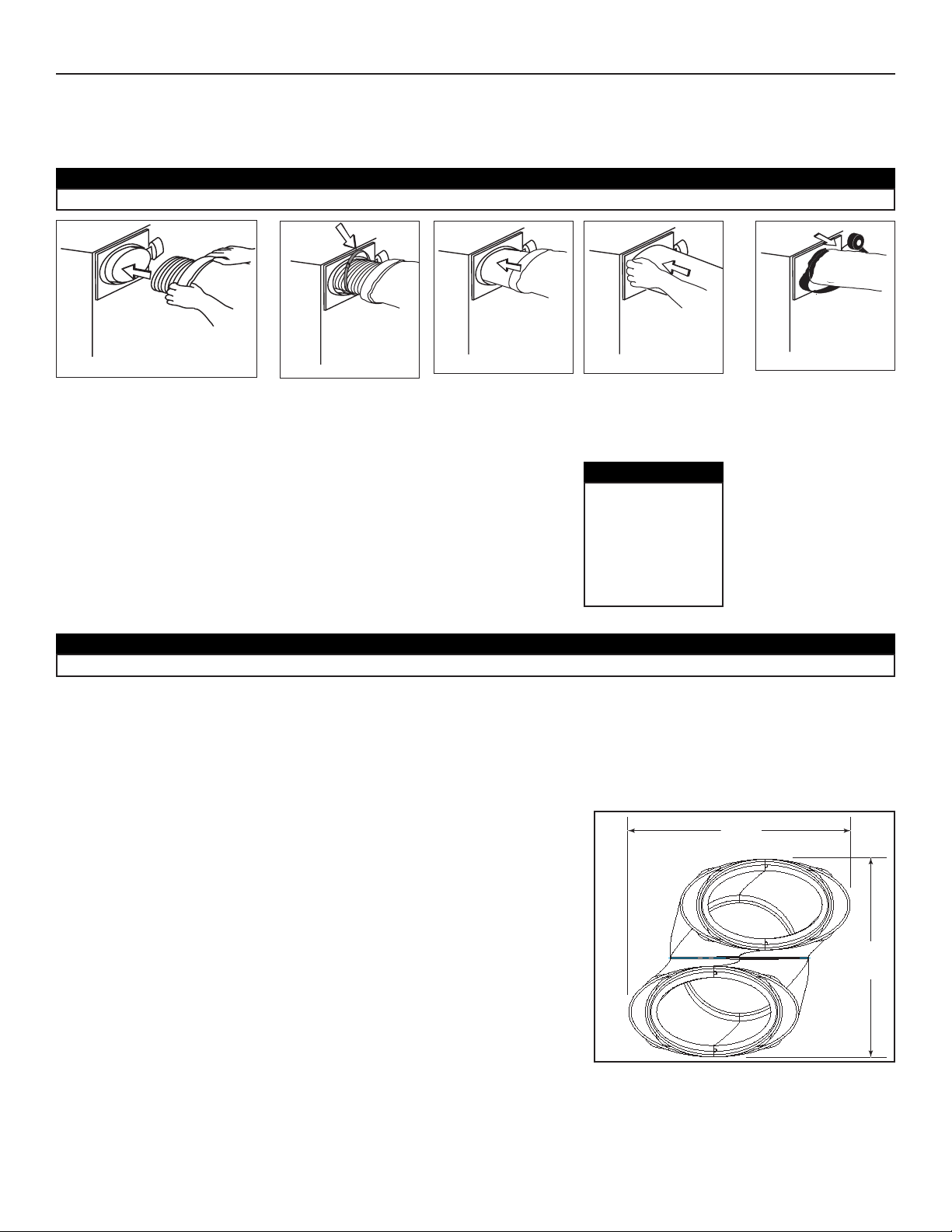

3.8 INSTALLING THE TANDEM® TRANSITION KIT

Use the following procedure for connecting the insulated flexible ducts to the Tandem® transition* (

Exhaust air to outside

and

Fresh air

from outside

).

NOTE: The joist opening needed to install the Tandem® tansition must be

9¾” (248 mm) minimum. Also, the maximum height of the Tandem®

transition is 8¾” (222 mm). See Tandem® transition end view beside.

If the joist are perpendicular to the ducts, or if the connection to the exterior

hood is in a limited area, your installation will need two exterior hoods

instead of one. In this case, do not use the Tandem® transition kit. See

next Section 3.9 I

NSTALLING 2 EXTERIOR HOODS.

*Patent pending.

- 13 -

3. INSTALLATION (CONT’D)

VJ0039

VJ0043

VJ0042

VD0118

9 3/4"

248 mm

8 3/4"

222 mm

Page 14

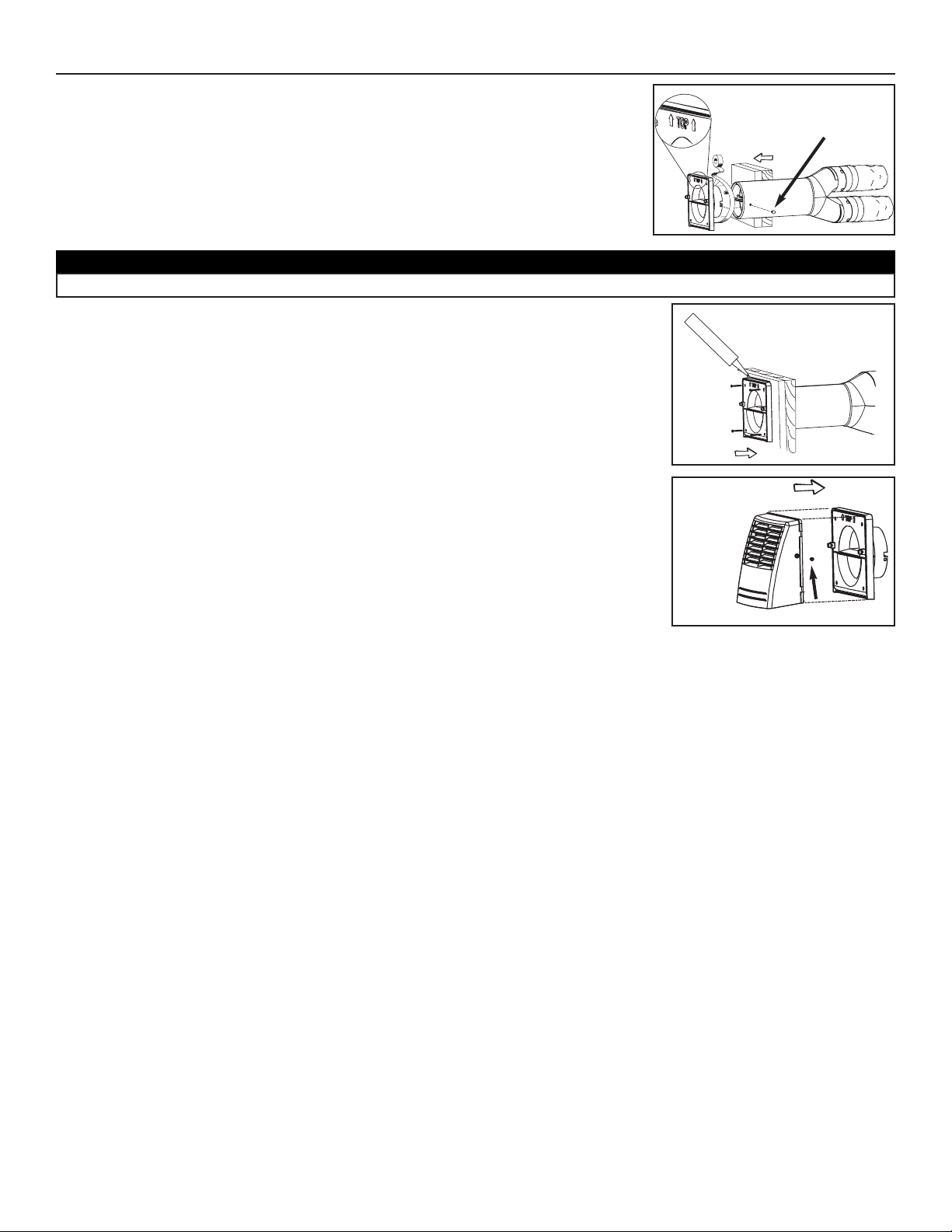

3.8 INSTALLING THE TANDEM® TRANSITION KIT (CONT’D)

3.8.1 C

ONNECTION TO TANDEM® TRANSITION

1. For each duct, pull back the insulation to expose the interior flexible duct.

2. Connect the interior flexible duct to the smaller part of the Tandem® transition (5’’ oval) using a tie wrap.

3. Pull the insulation over the joint. Pull the vapor barrier over the insulation.

4. Apply duct tape gently to the joint in order to make an airtight seal

. See figures below.

3.8.2 A

SSEMBLING DUAL EXTERIOR HOOD*

Exterior dual hood is coming in separate parts. Using 2 #8 x

3

¼4” screws, assemble the top

metal screen and the plastic grille to the dual exterior hood. Then, slide the bottom metal

screen to the dual exterior hood. See illustration beside.

*Patent pending

3.8.3 L

OCATING THE DUAL EXTERIOR HOOD

The dual exterior hood must be installed at a minimum distance of 18 inches (457 mm) from the

ground. See illustration beside.

3.8.4 C

ONNECTING TANDEM® TRANSITION TO THE DUAL EXTERIOR HOOD

1. Using a jig saw, cut a 6’’ diameter hole in the exterior wall and insert the Tandem®

transition through this hole.

1) Exhaust air to outside duct

3. INSTALLATION (CONT’D)

1

2

3

4

EXHAUST AIR TO OUTSIDE

DUCT ON TOP

WARNING

Make sure this hood is at least 3 feet (0.9 m) away from any of the following:

• High efficiency furnace vent. • Any exhaust from a combustion source.

• Gas meter exhaust, gas barbecue-grill. • Garbage bin and any other source of contamination.

!

1

CAUTION

The Tandem® transition must be inserted in such a way that the

Exhaust air to outside

duct will be located on the top.

- 14 -

VJ0025

VJ0023

VJ0022

VJ0024

VO0024

18''

(457 mm)

VD0083

VD0084

Page 15

3.8 INSTALLING THE TANDEM® TRANSITION KIT (CONT’D)

3.8.4 C

ONNECTING TANDEM® TRANSITION TO THE DUAL EXTERIOR HOOD (CONT’D)

2. Join the end of the Tandem® transition to the rear of the exterior backplate. Secure

with 2 Xmas tree pins and seal properly with duct tape.

3. Using 4 #8 x 1¼” screws, mount the the exterior backplate to the exterior wall. Seal the

outline with caulking.

4. Snap the assembled exterior hood on its backplate and secure with 2 provided screws

(#8 x 1¼” long).

3. INSTALLATION (CONT’D)

CAUTION

The exterior backplate must be installed with the word “TOP” pointing upward.

Xmas tree pin

screw

- 15 -

VD0085

VD0086

VD0087

Page 16

3. INSTALLATION (CONT’D)

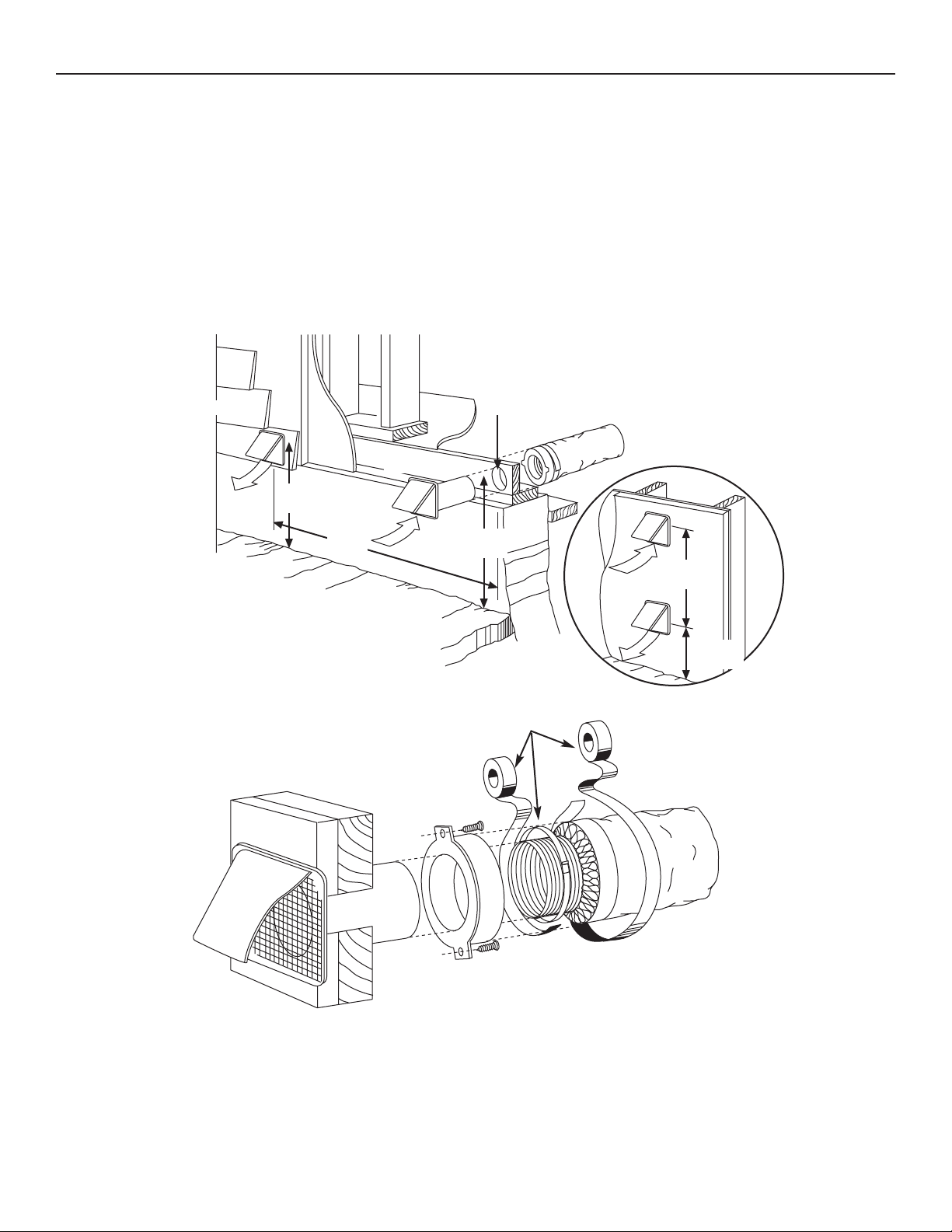

3.9 INSTALLING 2 EXTERIOR HOODS

Choose an appropriate location to install the exterior hoods:

• There must be a minimum distance of 6 feet (1.8 m) between the hoods to avoid cross-contamination

• There must be a minimum distance of 18 inches (457 mm) from the ground

Make sure the intake hood is at least 6 feet (1.8 m) away from the following:

• Dryer exhaust, high efficiency furnace vent, central vacuum vent

• Gas meter exhaust, gas barbecue grill

• Any exhaust from a combustion source

• Garbage bin and any other sources of contamination

Refer to figure below for connecting insulated ducts to the exterior hoods. An ‘’Anti-gust intake hood’’ should be installed in regions where

a lot of snow is expected to fall.

TAPE AND DUCT TIE

OPTIONAL

DUCT LOCATION

EXHAUST HOOD

INTAKE HOOD

18’’

(457 MM)

18’’

(457 MM)

6’’ Ø

(152 MM)

18’’

(457

MM)

6’

(1.8 M)

6’

(1.8

M)

- 16 -

VD0028

Page 17

4. CONTROLS

4.1 INTEGRATED CONTROL

All units are equipped with an integrated control, located under the unit, in front of the electrical

compartment. Use the push button (1) to control the unit. The LED (2) will then show which

mode the unit is in.

1

2

Refer to table below to see how to operate the unit using its integrated control.

PRESS ON PUSH BUTTON LED COLOR RESULTS

ONCE AMBER UNIT IS ON LOW SPEED

TWICE GREEN UNIT IS ON HIGH SPEED

THREE TIMES NO LIGHT UNIT IS OFF

If a problem occurs during the unit operation, its integrated control LED (2) will blink. The color of the blinking light depends on the type

of error detected. Refer to

Section 11 Troubleshooting

on last page for further details.

4.1.1 BOOT SEQUENCE

The unit boot sequence is similar to a personnal computer boot sequence. Each time the unit is plugged in after being unplugged, or

after a power failure, the unit will perform a 30-second booting sequence before starting to operate. During the booting sequence, the

integrated control LED will light GREEN or AMBER for 5 seconds, and then will shut off for 2 seconds. After that, the LED will light RED

for the rest of the booting sequence. During this RED light phase, the unit is checking and resetting the motorized damper position.

Once the motorized damper position is completely set, the RED light turns off and the booting sequence is done.

NOTE: No command will be taken until the unit is fully booted.

For more convenience, this unit can also be controlled using an optional main wall control.

NOTES: 1.The integrated control must be turned OFF to use an optional main control.

2. If an optional auxiliary control is used, if activated, this auxiliary control will override the optional main control.

4.2 ELECTRICAL CONNECTION TO OPTIONAL WALL CONTROLS

Use the terminal connector included in the installation kit to perform the electrical

connection for main and optional wall controls. Check if all wires are correctly inserted in

their corresponding holes in the terminal block. (A wire is correctly inserted when its

orange receptacle is lower than another one without wire. On picture beside, wire A is

correctly inserted, but not wire B.)

CAUTION

Never install more than one optional main wall control per unit. Make sure that the wires do not short-circuit between themselves

or by touching any other components on the wall control. Avoid poor wiring connections. To reduce electrical interference

(noise) potential, do not run wall control wiring next to control contactors or near light dimming circuits, electrical motors,

dwelling/building power or lighting wiring, or power distribution panel.

WARNING

Always disconnect the unit before making any connections. Failure in disconnecting power could result in electrical shock or

damage of the wall control or electronic module inside the unit.

!

A

B

VE0106

- 17 -

No li ght OFF or remote controled

Amber light LOW speed

Green ligh HIGH speed

Blinking light See User Manual

Sans lumière Arrêté ou contrôlé

par contrôle mural

Lumière ambre Basse vitesse

Lumière verte Haute vitesse

Clignotant Voir guide d’utilisation

VD0182

WARNING

Risk of electric shock. Before performing

any maintenance or servicing, always

disconnect the unit from its power source.

CAUTION

Unscrew both screws to open the electrical

compartment. To completely remove, detach

from its retention wire inside.

AVERTISSEMENT

Danger d’électrocution. Débranchez

toujours l’appareil avant d’entreprendre

des travaux d’entretien ou de réparation.

ATTENTION

Dévisser les deux vis pour ouvrir le compartiment

électrique. Pour retirer complètement, le

détacher de son fil de rétention intérieur.

Page 18

4. CONTROLS (CONT’D)

4.2.1 ELECTRICAL CONNECTION TO VT4W MAIN WALL CONTROL

MAIN WALL

CONTROL VT4W

REAR VIEW

4.2 ELECTRICAL CONNECTION TO OPTIONAL WALL CONTROLS (CONT’D)

4.2.2 ELECTRICAL CONNECTION TO OPTIONAL AUXILIARY WALL CONTROLS

NOTE: If an optional auxiliary wall control is

activated and then, the Humidity

Control is being activated, the

Humidity Control will override the

auxiliary wall control commands.

Once the wall control(s) connections have been made, insert the terminal connector in the bottom of the unit, on the electrical

compartment front face.

4.3 VT4W OPTIONAL MAIN WALL CONTROL OPERATION

TERMINAL

CONNECTOR

COLOR MODE SUGGESTED USE

GREEN INTERMITTENT SELECT THIS MODE WHEN YOU ARE AWAY FROM THE HOUSE

FOR A FEW DAYS. ALSO, WHEN YOU DEEM THE INSIDE AIR IS

TOO DRY IN HEATING SEASON, OR TOO HUMID DURING

COOLING SEASON

. IN THIS MODE, THE UNIT IS OFF FOR

40 MINUTES PER HOUR AND VENTILATES AT MINIMUM SPEED

THE REMAINING 20 MINUTES OF THE HOUR.

Y

ELLOW MIN SPEED FOR NORMAL DAILY OPERATION.

VENTILATION

RED MAX SPEED FOR EXCESS POLLUTANTS AND HUMIDITY

VENTILATION (PARTIES, ODORS, SMOKE, ETC.).

- 18 -

NO C NC I OC OL Y R G B

G

Y

VE0100A

NO C NC I OC OL Y R G B

B

MAIN WALL CONTROL

LITE-TOUCH CONSTRUCTO

and

SIMPLE-TOUCH CONSTRUCTO

REAR VIEW

B G

OC

HUMIDITY CONTROL

H

E

V

U

I

T

M

A

I

D

L

E

I

R

%

20%

HUMIDITY

25%

CONTROL

30%

C

O

N

O

M

Z

F

O

T

R

50%

40%

60-MINUTE

CRANK TIMER

T

Y

O

F

F

70%

60%

E

20-MINUTED LIGHTED PUSH BUTTON

(5 MAXIMUM)

VE0110A

No li ght OFF or remote controled

Amber light LOW speed

Green ligh HIGH speed

Blinking light See User Manual

Sans lumière Arrêté ou contrôlé

par contrôle mural

Lumière ambre Basse vitesse

Lumière verte Haute vitesse

Clignotant Voir guide d’utilisation

VD0182

WARNING

Risk of electric shock. Before performing

any maintenance or servicing, always

disconnect the unit from its power source.

CAUTION

Unscrew both screws to open the electrical

compartment. To completely remove, detach

from its retention wire inside.

AVERTISSEMENT

Danger d’électrocution. Débranchez

toujours l’appareil avant d’entreprendre

des travaux d’entretien ou de réparation.

ATTENTION

Dévisser les deux vis pour ouvrir le compartiment

électrique. Pour retirer complètement, le

détacher de son fil de rétention intérieur.

MAX

MIN

INTERMITTENT

VT4W

VC0070

Page 19

4. CONTROLS (CONT’D)

4.4 OPTIONAL AUXILIARY WALL CONTROLS OPERATION

4.4.1 20-MINUTE LIGHTED PUSH-BUTTON TIMER

Set the push-button timer to ON. The fan motors will then operate at high speed for 20 minutes and the indicator

will light up.

To stop activation, push one time; the unit will then get back to previous selection.

4.4.2 60-MINUTE CRANK TIMER

This control makes the system operate at high speed for periods varying from 10 to 60 minutes.

4.4.3 HUMIDITY CONTROL

Setting during the fall, winter and spring months:

Adjust knob to the desired maximum humidity level.

Setting during summer:

Adjust knob to the OFF positon.

CAUTION

Do not select a humidity level below 30%. This could lead to excessive dryness in the air

causing discomfort for the occupants.

5. ELECTRICAL CONNECTION TO THE FURNACE

For a furnace connected to a cooling system:

On some older thermostats, energizing the “R” and “G” terminals at the furnace has the effect of energizing “Y” at the thermostat and

thereby turning on the cooling system. If you identify this type of thermostat, you must use the ALTERNATE FURNACE INTERLOCK WIRING.

STANDARD FURNACE INTERLOCK WIRING ALTERNATE FURNACE INTERLOCK WIRING

WARNING

Never connect a 120-volt AC circuit to the terminals of the furnace interlock (standard wiring). Only use the low voltage class

2 circuit of the furnace blower control.

!

- 19 -

HUMIDITY

CONTROL

VC0084

VC0017

25%

ON

TURN

OFF

PAST

20

10

20

30

60

40

50

H

E

V

U

I

M

T

A

I

D

L

E

I

T

R

Y

%

20%

30%

O

F

F

70%

60%

C

E

O

N

O

M

Z

F

O

T

R

50%

40%

VC0085

NO C NC I OC OL Y R G B

UNIT TERMINAL CONNECTOR

COOLING SYSTEM

FOUR

WIRES

TWO WIRES

heating only

W

R

G

C

Y

FURNACE

24-VOLT

TERMINAL BLOCK

VE0108A

W R G

THERMOSTAT

Y

TERMINALS

TWO WIRES

NO C NC I OC OL Y R G B

COOLING SYSTEM

UNIT TERMINAL CONNECTOR

4 WIRES

2 WIRES

heating only

W

R

R

G

C

Y

Y

FURNACE

24-VOLT

TERMINAL BLOCK

W R G Y

wiring

nuts

THERMOSTAT

TERMINAL

NO

NC

C

2 WIRES

Page 20

6. WIRING DIAGRAM

WARNING

Risk of electrical shocks. Before performing any maintenance or servicing, always disconnect the unit from its power source.

!

- 20 -

Neutral

J10-1 J10-2

120V, 60Hz

J5-2

capacitor

Exhaust fan motor

Exhaust fan motor

J5-1

J5-3

J7-2

A1

K1

K1

JU1

LOGIC DIAGRAM

321

K2

K2

HI MED

F1

J9-1

J9-2

Line

J9-3

J7-1

J9-4

J4-2

capacitor

Supply fan motor

Supply fan motor

J4-1

J4-3

J6-2

J6-1

K3

A2

J2-4

J2-5

J12-5

J12-4

J12-3 J2-3

Damper motor

K4

J3-2

J3-1

J2-2

J2-1

J12-2

J12-1

Door interlock switch

J11-2

J11-1

Furnace

blower

J14-3

J14-1

K5

K2

K4

interlock

(optional; see

notes 3, 5)

J14-2

K5

K1

Override

J14-4

K3

switch

(optional; see

notes 3, 4)

Field wiring

J14-5

J14-6

J14-7

remote

J14-8

J14-9

control (see

notes 3, 4)

J14-10

CPU

J8-1

J8-2

J8-4

J8-5

120 V, 60Hz

9.5 V

class 2

24 V

class 2

90 V

68 V

120 V

neutral

Override

switch

notes 3 & 4)

9 8 7 6 5 4 3 2 1

10

J13

ICP

J11

J12

1 2

123

MED HI

JU1

1 2 3 1 2

BK

BK

C1

(optional; see

J14

1 2 3 4 5

1 2

1 2 3 4

J9

See note 1

1 2 1 2 3

J7

J6

BK

BK

C2

J14-1 : NO

J14-2 : COM

J14-3 : nc

(optional; see notes 3, 5)

Furnace blower interlock

A1

ASSEMBLY

ELECTRONIC

W

BK

J10

F1

J4

BN

BL

BK

G

M2

COLOR CODE

Critical characteristic.

G

W1

120 V, 60 Hz

NOTES

BK BLACK

BL BLUE

BN BROWN

G GREEN

R RED

W WHITE

Y YELLOW

nc no connection

ordinances and regulations.

use the same equivalent wire.

Certified line fuse.

1. For continued fire protection. Use specified UL listed/CSA

2. If any of the original wire, as supplied, must be replaced,

3. Field wiring must comply with applicable codes,

4. Remote controls (class 2 circuit) available,

see instruction manual.

5. Furnace fan circuit must be class 2 circuit only.

Y R G

R1

temperature sensor

t˚

reed switch)

(magnetically actuated

24 V

class 2

90 V

68 V

120 V

BL

BK

Field wiring

W W

9.5 V

R

Defrost

DAMPER

ELECTRONIC ASSEMBLY

J1

A2

Line voltage factory wiring

Class 2 low voltage factory wiring

Class 2 low voltage field wiring

WIRING DIAGRAM

123

123

JU1

1 2 3 4 5 1 2

J3

1 2

J2

S1

BK

BK

Door interlock switch

M3

JU1

T1

Damper motor

FAN MOTORS SPEED SELECTION

SETTING FAN SPEEDS

Factory shipped Low - High

Low-Med select Low- Med

B

remote control

(see notes 3 & 4)

BN

BN

Y

Y

class 2

neutral

W

G

12345

J8

J5

BN

BL

BK

M1

motor

capacitor

motor

capacitor

Supply fan

Supply fan

VE0130A

motor

Exhaust fan

Exhaust fan

motor

Page 21

7.1 WHAT YOU NEED TO BALANCE THE UNIT

• A magnehelic gauge capable of measuring 0 to 0.5 inch of water (0 to 125 Pa) and

2 plastic tubes.

• The balancing chart located on the unit door.

7.2 PRELIMINARY STA GE S TO BALANCE THE UNIT

• Seal all the unit ductwork with tape. Close all windows and doors.

• Turn off all exhaust devices such as range hood, dryer and bathroom fans.

• Make sure the integrated balancing dampers are fully open. Turn the thumb screw (A) clockwise

to manually open the dampers. Both are located on the Exhaust air to outside port and on Fresh

air to building port.

• Make sure all filters are clean (if it is not the first time you balance the unit).

7.3 BALANCING PROCEDURE

1. Set the unit to high speed.

Make sure that the furnace/air handler blower is ON if the installation is in any way connected to

the ductwork of the cold air return. If not, leave furnace/air handler blower OFF. If the outside

temperature is below 0°C / 32°F, make sure the unit is not running in defrost while balancing.

(By waiting 10 minutes after plugging the unit in, you are assured that the unit is not in a

defrost cycle.).

2. Place the magnehelic gauge on a level surface and adjust it to zero.

3. Connect tubing from gauge to EXHAUST air flow pressure taps (see diagram beside).

Be sure to connect the tubes to their appropriate

high/low

fittings. If the gauge drops below

zero, reverse the tubing connections.

NOTE: It is suggested to start with the exhaust air flow reading because the exhaust has

typically more restriction than the fresh air, especially in cases of fully ducted

installations or source point ventilation. Place the magnehelic gauge upright and

level. Record equivalent AIR FLOW of the reading according to the balancing chart.

4. Move tubing to FRESH air flow pressure taps (see diagram). Adjust the fresh air balancing damper until the fresh air flow is

approximately the same as the EXHAUST air flow. If fresh air flow is less than exhaust air flow, then go back and adjust the exhaust

balancing damper to equal the fresh air flow.

5. Secure both dampers thumb screw in place with tape.

6. Write the required air flow information on a label and stick it near the unit for future reference (date, maximum speed air flows, your

name, phone number and business address).

NOTE: The unit is considered balanced even if there is a difference of ±10 cfm (or ± 5 l/s or 17 m3/h) between the two air flows.

Fresh air flow

Balancing

Chart

Exhaust air flow

7. BALANCING THE UNIT

To avoid balancing, the difference between stale air ducts total length and fresh air ducts total length must not exceed 50 ft. However,

even if the stale air ducts and fresh air ducts lengths are almost equal, your local building codes may require balancing the unit.

If the unit does not need to be balanced, shut all the pressure taps (located on the unit door) with the small plastic plugs included in the

hardware kit.

A

Port with integrated balancing

damper - Top view

- 21 -

VP0009

VJ0032

VP0015

1 12 12 11

1 12 12 11

3 13 33 23

1 12 12 11

1 12 12 11

3 13 33 23

Page 22

8. CONNECTING THE DRAIN (HRV UNITS ONLY)

To drain

In order to keep the drain pan intact, hand

tighten the 2 plastic drain fittings to the unit

door using the gaskets and nuts as shown.

Cut 2 sections of plastic tubing, about 12”

(305 mm) long and attach them to each drain

fitting. Join the 2 short sections to the “T”

junction and main tube as shown.

Make a water trap loop in the tube to prevent

the unit from drawing unpleasant odors from

the drain source. Make sure this loop is

situated BELOW the “T” as shown. This will

prevent water from being drawn back up into

the unit in case of negative pressure. Run the

tube to the floor drain or to an alternative

drain pipe or pail. Be sure there is a slight

slope for the run-off.

Tie-wrap

From the inner side of the unit door, using the

provided drain tube, punch out both drain

holes (A).

VD0181

A

- 22 -

VO0091

VO0092

VO0093

Page 23

3. Lift both foam filters bracket (1) and remove the foam filters from the core. While holding

the core, rotate the 2 core retainers (2) and slide out the core from the unit.

2. Unlatch the door and open it. Clean the inner side of the door with a damp cloth, then wipe with a dry

one. Disengage the door from its hinge by sliding it from left to right and set aside.

9. MAINTENANCE

WARNING

Risk of electrical shocks. Before performing any maintenance or servicing, always disconnect the unit from its power source.

!

1. Unplug the unit.

9.1 SEMI-ANNUAL MAINTENANCE

Since this guide covers both HRV and ERV units, top and side ports, the illustrations shown in the maintenance procedures are typical.

The following procedures applies for both HRV and ERV units.

Refer to pictures below to identify the inner parts of your unit.

1

3

3

4

2

2

1

3

3

4

1) HRV core 3) Foam filter brackets

2) Core retainers 4) Foam core filters

1) ERV core 3) Foam filter brackets

2) Core retainers 4) Foam core filters

VB0078

VB0077

2

2

WARNING

Be careful before opening the door; water or small debris could fall out. For HRV unit, always wait one minute after

disconnecting the unit before opening the door in order to allow water to drain out from the unit.

!

VD0179

WARNING

Always hold the core when rotating the 2 core retainers; failure to do so will cause the core to fall out.

!

1

1

2

VD0177

- 23 -

VD0005

Page 24

9. MAINTENANCE (CONT’D)

9.1 S

EMI-ANNUAL MAINTENANCE (CONT’D)

4. Clean the inside walls of the unit with a clean damp cloth, then wipe with a clean dry one.

5. Wash the 2 core filters under hot water with mild soap. Rinse thoroughly and let dry completely before reinstalling on the core.

6. Remove the dust on the core using a vacuum cleaner and a soft brush attachment.

7. Slide the core in the unit. Secure the core by rotating both core retainers to their initial

positions.

NOTE: Once the core reinstalled in the unit, the arrows (A) on its sticker label must be

pointing towards the unit motors.

8. Reinstall both foam filters and secure them to the core by pulling down the 2 foam filter brackets. Reinstall the door.

9. Close the door and plug the unit.

NOTE: The unit will return to its previous setting after a 30-second delay for boot sequence.

9.2 ANNUAL MAINTENANCE

Do the same operations as the Semi-Annual Maintenance (

Section 9.1

).Then, clean the exterior hood(s).

WARNING

Once the core reinstalled in the unit, always rotate both core retainers to their initial position; failure to do so will cause the

core to fall out.

!

VD0178

VB0078

A

- 24 -

Page 25

- 25 -

10. SERVICE PARTS

ITEM DESCRIPTION PART NUMBER HRV90HS HRV90HT ERV90HCS ERV90HCT

(PORTS ON SIDES)(PORTS ON TOP)(PORTS ON SIDES)(PORTS ON TOP)

1OVAL PO RT (FITS 5” DIAMETER DUCTS) V16040 1 1 1 1

2DOOR LATCH WITH SCREWS V16035 2 2 2 2

3OVAL PORT WITH INTEGRATED BALANCING DAMPER V16041 2 2 2 2

4

M

OTOR & WHEEL ASSEMBLY

V16024 2 2 2 2

(MOTOR CAPACITOR AND INLET RING INCLUDED)

5CAPACITOR 3 µF V17024 2 2 2 2

6ELECTRONIC BOARD V16038 1 1 1 1

7ERV FOAM FILTER V16031 N/A N/A 2 2

8ERV CORE (WITH 2 FILTERS) V16037 N/A N/A 1 1

9DRAIN CONNECTOR KIT V03203 1 1 N/A N/A

10 DOOR ASS’Y V16096 1 1 1 1

11 HRV CORE (WITH 2 FILTERS) V16044 1 1 N/A N/A

12 HRV FOAM FILTER V16032 2 2 N/A N/A

13 MOTORIZED DAMPER PORT ASS’Y V16029 1 1 1 1

14* TRANSFORMER V16567 1 1 1 1

15* GREEN TERMINAL BLOCK V16416 1 1 1 1

1

2

3

3

12

11

13

4

7

8

9

4

5

6

10

* PART NOT SHOWN.

VL0019

Page 26

11. TROUBLESHOOTING

Problems Possible causes You should try this

1. Unit does not work. •The circuit board may be defective. •Unplug the unit. Disconnect the main

control and the auxiliary control(s)

(if need be). Jump G and B terminals.

Plug the unit back and wait about

10 seconds. If the motors run on

high speed and the damper opens,

the circuit board is not defective.

2. The damper actuator •The damper actuator or the integrated •Unplug the unit. Disconnect the main control and the optional control(s)

does not work. damper port mechanism may be defective. (if need be). Wait 10 seconds and plug the unit back. Check if the damper

opens. If not, use a multimeter and check for 24V AC on J12-1 and J12-2

(in electrical compartment). If there is 24V AC, replace the entire port assembly.

NOTE: It is normal to experience a small delay (7-8 seconds) before

detecting the 24V AC signal at starting-up. This signal will stay

during 17-18 seconds before disappearing.

•The circuit board may be defective. •If there is no 24V AC, replace the circuit board.

3. The wall control does not •The wires may be in reverse position. •Ensure that the color coded wires have been connected to their

work OR the indicators flash. appropriate places.

•The wires may be broken. •Inspect every wire and replace any that are damaged.

•The wire in the wall OR the wall • Remove the wall control and test it right beside the unit using another

control may be defective. shorter wire. If the wall control works there, change the wire. If it does

not, change the wall control.

4. The Humidity Control does • The wires may be in reverse position. •Ensure that the color coded wires have been connected to their

not work OR the 20-minute appropriate places.

push-button timer does not •The Humidity Control or push button •Jump the OL and OC terminals. If

work OR its indicator light may be defective. the unit switches to high speed, remove

does not stay on. the Humidity Control or push button

and test it right beside the unit using

beside the unit using another

shorter wire. If it works here, change the wire. If it doesn’t, change the

Humidity Control or the push button.

5. The supply and/or exhaust •The circuit board may be defective. •Press on the integrated control push button until the unit turn on low

motor do not work. speed (the LED will light AMBER). Using a multimeter, check the voltage

on J4-1 and J4-2 (for supply motor), and on J5-1 and J5-2 (for exhaust

motor). The reading must be ± 68 V AC. Then set the unit on high

speed by pressing on the integrated control 1 more time (the LED will

light GREEN). Using a multimeter, check the voltage on J4-1 and J4-2

(for supply motor), and on J5-1 and J5-2 (for exhaust motor). The

reading must be ± 120 V AC if the fan motor speed setting is

Low-High, or ± 90 V AC if the fan motor speed setting is Low-Medium.

If all the readings correspond to the right voltage values, the circuit

board is not defective. If one or both readings are different, change the

circuit board.

•The motor(s) may be defective. •Using a multimeter, check the ohms value on each motor connectors.

For BLUE and BLACK motor wires, the right value is ± 52 ohms. For

BLUE and BROWN motor wires, the right value is ± 72 ohms. For

BROWN and BLACK motor wires, the right value is ± 124 ohms. If the

ohm values are the same, the motor is not defective. Replace the

motor capacitor.

6. The defrost cycle does not work • Ice deposits may be hindering •Remove the ice.

(the fresh air duct is frozen OR the damper operation.

the fresh air distributed

is very cold. •The damper rod or the port •Inspect these parts and replace if necessary.

damper itself may be broken.

•The damper actuator or circuit board •See point 2.

may be defective.

7. The integrated control •The 30-second boot sequence • See

Section 4.1.1 Boot Sequence

push button does not work. is not completed.

- 26 -

If the integrated control LED of the unit is flashing, this means the unit sensors detected a problem. See the table below to know where on the unit the problem occurs.

LED flashes GREEN. • Thermistor error. Replace the entire port assembly (fresh air from outside port).

LED flashes AMBER. • Damper error. Go to Point 6.

LED flashes RED. • The door is open and the unit is not unplugged. Close the door and press once on the integrated control

push button to reset the unit.

• Exhaust motor error. Go to Point 5.

NO C NC I OC OL Y R G B

VE0097

NO C NC I OC OL Y R G B

VE0098

Page 27

MANUAL DE INSTALACIÓN

MODELOS HRV90H Y ERV90HC

SÓLO PARA USO RESIDENCIAL

LEA Y CONSERVE ESTAS INSTRUCCIONES

06010C rev. G

Modelo n.°: HRV90HT

(HRV con aberturas

en la parte superior)

Modelo n.°: HRV90HS

(HRV con aberturas laterales)

Modelo n.°: ERV90HCT

(ERV con aberturas

en la parte superior)

Modelo n.°: ERV90HCS

(ERV con aberturas laterales)

VB0082

VB0080 VB0079

VB0081

Page 28

ACERCA DE ESTE MANUAL

Dado el gran número de modelos de los que trata este manual, las ilustraciones son de carácter general. Algunos detalles de su aparato

pueden ser ligeramente distinos de los que se muestran aquí.

Tenga en cuenta que en este manual se emplean los siguientes símbolos cuando se quiere insistir en una información determinada:

NOTA: Da información complementaria para realizar una instrucción.

Con el fin de ofrecerle mejor servicio, no dude en enviarnos sus comentarios o sugerencias en relación con este manual o con el aparato.

Para ello, comunique con nosotros en el teléfono 1-800-558-1711.

ADVERTENCIA

Se refiere a una instrucción que, de no siguirse, podría causar heridas corporales graves e incluso la muerte.

!

CUIDADO

Se refiere a una instrucción que, si no seguirse, podría dañar gravemente el aparato o sus piezas.

- 2 -

!

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA O LESIÓN CORPORAL, RESPETE LAS SIGUIENTES

INDICACIONES:

1. Utilice este aparato únicamente de la forma en que indica el fabricante. Si tiene cualquier pregunta, comunique con el fabricante en

la dirección o el teléfono que aparacen en la garantía.

2. Antes de reparar o limpiar el aparato, desenchufe el cable de alimentación de la toma.

3. Este aparato no se ha concebido para proporcionar aire de combustión o de dilución a otros aparatos de combustión.

4. Al cortar o perforar la pared o el techo, procure no dañar el cableado eléctrico ni otras instalaciones de servicios públicos.

5. No utilice este aparato con un dispositivo de control de velocidad con semiconductores distinto al control de pared opcional principal

VT4W; ne emplee tempoco otros controles de pared auxiliares opcionales distintos a un temporizador mecánico de 60 minutos, un

botón pulsador luminoso de 20 minutos o un control Humidity.

6. Este aparato debe conectarse a tierra. El cable de alimentación tiene un enchufe de tres patillas para su seguridad personal. Este

enchufe debe enchufarse en una toma para tres patillas, conectada a tierra según el código nacional de electricidad y los códigos y

ordenanzas locales. No quite la patilla de tierra ni utilice un cable prolongador.

7. No instale este aparato en una zona donde se cocine ni lo conecte directamente a ningún tipo de aparato.

8. No utilice este aparato para extraer materiales y vapores peligrosos o explosivos.

9. Al instalar, reparar o limpiar estos aparatos, se aconseja llevar anteojos y guantes de seguridad.

10. Teniendo en cuenta el peso del aparato, se aconseja que lo instalen dos personas.

CUIDADO

1. Para evitar que los filtros se obstruyan prematuramente, APAGUE el aparato cuando realice obras de construcción o renovación.

2. Para mayor información y conocer mejor los requisitos del aparato, lea la etiqueta con las características técnicas del producto.

3. Compruebe que el aire va fuerta. No introduzca ni saque el aire de espacios situados entre paredes, techos o altillos, sótanos o

cocheras.

4. Aparato previsto únicamente para instalaciones residenciales con arreglo a los requisitos de NFPA 90B.

5. No ponga ningún tubo de aire directamente sobre (o a menos de 2 pies o 0,61 m) una caldera o de su cámara de alimentación, de

una cámara de combustión o de cualquier otro aparato que produzca calor. Si hay que conectar un tubo a la cámara de retorno de

una caldera, la conexión debe hacerce a 9’10” (3 m) o más de la conexión de dicha cámara con la caldera.

6. Los tubos deben instalarse con arreglo a los códigos locales y nacionales aplicables.

7. Si no va a estar en la casa durante un largo periodo (más de dos semanas), un responsable debería verificar regularmente que el

aparato funciona debidamente.

8. Si las tuberías pasa a través de un espacio do acondicionado (p. ej., un altillo), el aparato debería funcionar constantemente, menos

cuando se repare o se limpie. Asimismo, la temperatura ambiente de la casa nunca debería bajar de 18°C (65°F).

ADVERTANCIA

ACERCA DE ESTOS APARATOS

LIMITACIÓN

Estos aparatos son sólo para una instalación residencial (doméstico). La instalación ha de realizarse con arreglo a todos los reglamentos nacionales y locales, códigos de construcción y códigos de la seguridad.

Page 29

1. DATOS TÉCNICOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

1.1 DISTRIBUCIÓN DEL AIRE (FUNCIONAMIENTO NORMAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 D

ISTRIBUCIÓN DEL AIRE (MODO RECIRCULACIÓN O DESHIELO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3 CARACTERÍSTICAS TÉCNICAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4 D

IAGARMAS DE RENDIMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.5 D

IMENSIONES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.6 CONTROLES Y POSIBILIDADES DE CONEXIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. INSTALACIONES HABITUALES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

2.1 SISTEMA TOTALMENTE ENTUBADO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 VENTILACIÓN EN EL PUNTO DE ORIGEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.3 I

NSTALACIÓN SENCILLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.4 I

NSTALACIÓN PARA APARATOS ERV ÚNICAMENTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. INSTALACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-16

3.1 EXAMEN DEL CONTENIDO DE LA CAJA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 UBICACIÓN DEL APARATO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3 P

REPARACIÓN DEL APARATO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4 FORMA DE COLGAR EL APARATO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.5 PLANIFICACIÓN DE LOS TUBOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.6 I

NSTALACIÓN DE LOS TUBOS Y REGISTROS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12

3.7 CONEXIÓN DE LOS TUBOS AL APARATO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.8 INSTALACIÓN DEL CONJUNTO DE CAMBIO DE SECCIÓN TANDEM® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-15

3.9 INSTALACIÓN DE 2 BOCAS EXTERIORES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4. CONTROLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-19

4.1 CONTROL INTEGRADO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.2 CONEXIÓN ELÉCTRICA CON LOS CONTROLES DE PARED OPCIONALES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-18

4.3 FUNCIONAMIENTO DEL CONTROL DE PARED PRINCIPAL OPCIONAL VT4W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.4 F

UNCIONAMIENTO DE LOS CONTROLS DE PARED AUXILIARES OPCIONALES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5. CONEXIÓN ELÉCTRICA CON LA CALDERA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6. D

IAGRAMA DE CABLEADOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7. EQUILIBRADO DEL APARATO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

8. CONEXIÓN DEL DESAGÜE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

9. M

ANTENIMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23-24

9.1 MANTENIMIENTO SEMESTRAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23-24

9.2 MANTENIMIENTO ANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

10.0 PIEZAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

11.0 S

OLUCIÓN DE PROBLEMAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

ÍNDICE

- 3 -

Page 30

HRV ERV

1. DATOS TÉCNICOS

1.1 DISTRIBUCIÓN DEL AIRE (FUNCIONAMIENTO NORMAL)

HRV ERV

1.2 D

ISTRIBUCIÓN DEL AIRE (MODO RECIRCULACIÓN O DESHIELO)

Centígrado (°C)

-5 a -27

-27 y menos

Fahrenheit (°F)

23 a -17

-17 y menos

Deshielo (min.)

9

10

Tempo de funcionamiento (min.)

entre cada ciclo de deshielo

23

22

Temperatura exterior CICLOS DE DESHIELO DEL HRV y ERV

- 4 -

AIRE DE SALIDA

DEL EDIFICIO

AIRE PURO DE

ENTRADA EN

EL EDIFICIO

AIRE DE SALIDA

DEL EDIFICIO

AIRE FILTRO

DE ENTRADA

EN EL EDIFICIO

AIRE DE SALIDA

DEL EDIFICIO

AIRE FILTRO

DE ENTRADA

EN EL EDIFICIO

AIRE DE SALIDA

DEL EDIFICIO

AIRE PURO DE

ENTRADA EN

EL EDIFICIO

AIRE PURO

DEL EXTERIOR

AIRE DE SALIDA

HACIA EL EXTERIOR

AIRE PURO

DEL EXTERIOR

AIRE DE

SALIDA HACIA

EL EXTERIOR

1.3 CARACTERÍSTICAS TÉCNICAS

Peso

Aberuras ovales

Diámetro del desagüe

42 libras (19 kg)

Tubos de 5” (127 mm)

1/2” (12 mm)

45 libras (20.4 kg)

Tubos de 5” (127 mm)

No procede

Instalación Cadenas, resortes y ganchos (vienen con el aparato).

Velocidades de motores Velocidad alta y baja

Alimentación eléctrica 120 V, 60 Hz 120 V, 60 Hz

Consumo de energía 150 vatios 160 vatios

Modelo HRV ERV

VF0038

VF0036

VF0039

VF0037

Page 31

1.4.1 APA RAT O S HRV (VENTILADORES DE TERMOR RECUPERACIÓN)

1. DATOS TÉCNICOS (CONTINUACIÓN)

1.4 D

IAGRAMAS DE RENDIMIENTO

Rendimiento de ventilación

NOTA: T

ODAS LAS CARACTERÍSTICAS TÉCNICAS ESTÁN SUJETAS A CAMBIO SIN PREVIO AVISO

.

TE MPERAT URA VATI OS

EFICIENCA DE

EFICACIA

RECUPERACIÓN

DE ENTRADA CORRIENTE NETA DE AIRE

CONSUMIDOS RECUPERACIÓN

SENSIBLE L

ATENTE/TRANSF.

SENSIBLE

APARENTE

DE HUMEDAD

68

82

116

110

66

65

59

55

78

76

68

81

0,07

0,04

0,04

0,08

No comprobada

-

C°

0

0

0

-25

+35

F°

+32

+32

+32

-13

+95

l/s

23

30

44

30

-

-

pi3/m

48

63

93

63

-

-

m3/h

82

108

157

108

-

-

REFRIGERACIÓN

CALEFACCIÓN

EFFICIENCIA DE RECUPERACIÓN TOTAL

PRESIÓN CORRIENTE NETA DE CORRIENTE BRUTA DE AIRE

ESTÁTICA EXT. AIRE DE ENTRADA ENTRADA SALIDA

Pa

25

50

75

100

125

150

175

200

Pulg. agua

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

l/s

52

50

48

45

43

41

38

35

pi3/m

110

106

101

96

92

87

81

75

m3/h

187

180

173

162

155

148

137

126

l/s

52

50

48

46

43

41

38

36

pi3/m

110

106

102

97

92

87

81

76

m3/h

187

180

173

166

155

148

137

130

l/s

57

55

53

50

49

45

43

40

pi3/m

122

116

113

107

103

96

91

85

m3/h

205

198

191

180

173

162

155

144

Rendimiento energético

1.4.2 APA RAT O S ERV (VENTILADORES DE RECUPERACIÓN DE ENERGÍA)

Rendimiento de ventilación

NOTA: T

ODAS LAS CARACTERÍSTICAS TÉCNICAS ESTÁN SUJETAS A CAMBIO SIN PREVIO AVISO

.

TEMPERATURA VATIOS EFICIENCA DE EFICACIA

RECUPERACIÓN

DE ENTRADA CORRIENTE NETA DE AIRE

CONSUMIDOSRECUPERACIÓN

SENSIBLE

LATENTE/TRANSF.

SENSIBLE

APARENTE

DE HUMEDAD

73

137

102

69

62

54

94

74

83

0,68

0,48

0,58

54

70

C°

0

0

-25

+35

F°

+32

+32

-13

+95

l/s

13

45

25

14

-