BRANT RADIANT SS User Manual

DX2 Series

!

Insert Manual

For complete installation instructions, reference the Tube Heater General Manual that

accompanies this insert manual.

The DX2 Series Infra-Red Tube Heater is a positive pressure, single-stage radiant heater system. This

insert manual is a supplement to the Tube Heater General Manual and provides specic information

related to the DX2 Series model. All persons involved with the installation, operation and maintenance of

the heater system must read and understand the information in this insert manual and the accompanying

Tube Heater General Manual.

For Your Safety

If you smell gas:

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operation and maintenance

instructions thoroughly before installing or servicing this equipment.

This heater must be installed and serviced by trained gas installation and service

personnel only. Failure to comply could result in personal injury, asphyxiation, death,

re or property damage.

In locations used for the storage of combustible materials, signs must be posted to

specify the maximum permissible stacking height to maintain the required clearances

from the heater to the combustibles. Signs must either be posted adjacent to the

heater thermostats or in the absence of such thermostats, in a conspicuous location.

Not for residential use! Do not use this heater in the home, sleeping quarters,

attached garages, etc. Installation of a commercial tube heater system in residential

indoor spaces may result in property damage, serious injury, asphyxiation or death.

• Do not try to light any appliance. • Immediately call your gas supplier from a neighbor’s phone.

• Do not touch any electrical switch. • Follow the gas supplier’s instructions.

• Do not use any phone in your building. • If you cannot reach your gas supplier, call the re department.

Keep these instructions for future reference.

LIODX2a- Rev. 18111

2M-9/09_r3-5/14(DRP)

Replaces: LIODX2a-1M-3/09(CDS)

DX2 Series

Contents

1.0 Safety...................................................................3

Safety Labels and Locations ............................................3

Clearance to Combustibles .............................................4

2.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Requirements....................................................6

Electrical Requirements................................................6

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Specications ......................................................10

Tube Installation Sequence ............................................11

3.0 Operation ..............................................................12

Sequence of Operation ...............................................12

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operational Indicator Lights............................................13

4.0 Troubleshooting Guide ...................................................14

5.0 Parts ..................................................................18

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Parts List ..........................................................18

Kit Contents Check List ...............................................20

Approvals..........................................................20

Limited Warranty ....................................................20

NOTE: See page 10 for a list of available models and specications.

2

Air Metering Orifice

DO NOT REMOVE

TP-114

TP-3014

3”

DX2 Series

SAMPLE

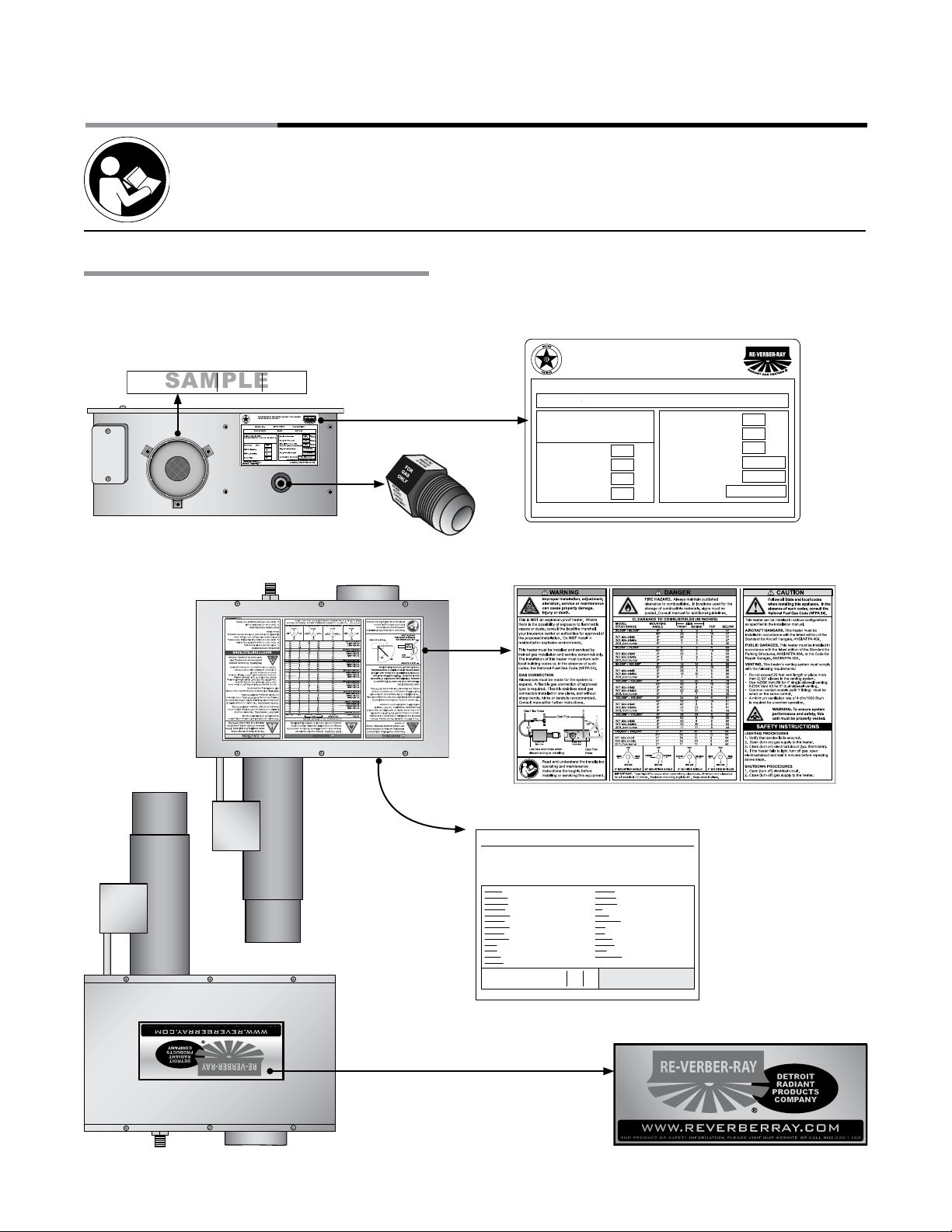

1.0 Safety • Safety Labels and Locations

1.0 Safety

Read and understand all safety information and warnings in this insert manual and the

Tube Heater General Manual before installation, operation and maintenance of the

radiant tube heater system.

Safety Labels and Their Locations

Product safety signs or labels should be replaced by the product user when they no longer are legible.

Contact either your local distributor or the product manufacturer for obtaining replacement signs or labels.

Back Panel

Top Panel

F/N: LLAC

Air Metering Orice

F/N: LLTB018 (Natural Gas)

F/N: LLTB019 (LP Gas)

RE-VERBER-RAY INFRA-RED RADIANT TUBE HEATER

FOR INDOOR INSTALLATION ONLY

MODEL NO.

DX

HL2 - 40 - 125N

DESIGN COMPLIES WITH:

ANS Z83.20b-2003-GAS FIRED LOW INTENSITY INFRA-RED HTR.

VOLTS AC 60Hz

AMPS - Starting

AMPS - Running

Heater Type:

DETROIT RADIANT PRODUCTS CO.

21400 HOOVER ROAD - WARREN, MI 48089

(586) 756-0950 www.reverberray.com

INPUT BTU/H

125,000 / 95,000

125,000

Manifold Pressure

Max. Inlet Pressure

120V

4.8

1.1

C1

Min. Inlet Pressure for

SAMPLE

Purpose of Input Adjustment

Min. Mounting Angle

Max. Mounting Angle

Combustion Chamber

F/N: LLTCL001 Clearance to

DX240125N

DX2-125

Production Code:

5.05

Version:

Data on this label is for the model shown on this label. If your heater has been converted,

this information is not accurate. Please contact the factory for assistance.

BURNER COMPONENTS:

Gas Valve:

Circuit Board:

Wire Harness:

N.O. Switch:

N.O. VL Orice:

N.C. Switch:

N.C. VL Orice:

Di Switch:

Di VL Orice:

Igniter:

Burner:

16” Tube:

Ind. Lights:

HEATER

TYPE:

C1

For parts replacement information, contact factory at 586-756-0950 or visit www.drp-co.com/parts.

(Specify TP-#’s)

VR4205-1324

240

MARK10DX-117

351A

3 PCS Harness

352A

None

N/A

None

None

N/A

None

IS22010051F5166

264E

Grey (+ / -)

SAMPLE

Norton

50

Mid

201B

4” Gen.

380

Yellow - 120V

328

C1 C2 C3

Orice Type:

Gas:

19

TP-204#

Air:

1 5/16”

TP-44#191 7/16”

Serial No.: 0804XXXXXXXXXX 0001

Stock:

Add-On:

Diag. Light:

Term. Block:

Transformer:

Fan:

Alt. Fan:

Alt. Fan Usage:

Relay:

Filter:

24 Volt In:

120 Volt In:

Gas In:

Extra VL Orice:

Internal Use Only:

Electric:

19

LLWT038

Tag:

1 5/16”

None

None

N/A

On Circuit Board

None

40 VA

Fasco Lg.

50Hz - 120V

When Specified

None

None

3 T-plug

2 x 4 Box

7/8” FC Flare

None

Special 1:

Special 2:

FOR USE WITH

NAT GAS

3.5in.

W.C.P.

W.C.P.

14.0in.

W.C.P.5.0in.

0 DEGREES

45 DEGREES

4” BC Aluminized

For Stainless Steel Upgrades the Combustion Table is upgraded to 409 Stainless Steel

Serial No. 0603DETR12345 0001

Combustibles Label.

N/A

N/A

55A

55B

N/A

N/A

832

66

Burner Control Box

83

Component Label

(located under the top

17

1 7/16”

panel)

Rating

Plate

F/N: LLLOGO1

Bottom Panel

3

!

1.0 Safety • Safety Labels and Locations • Clearance to Combustibles

DX2 Series

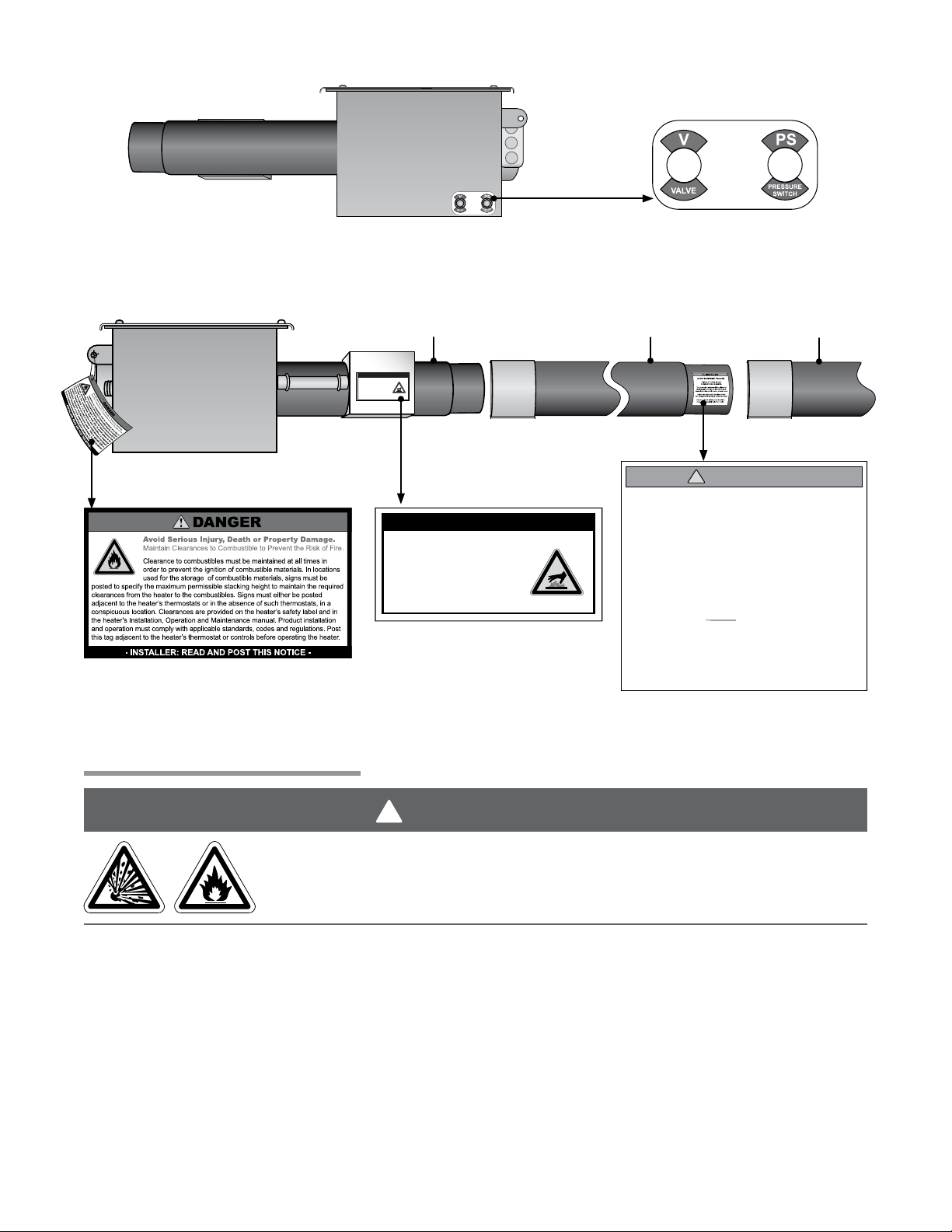

Right Panel

(Valve Compartment)

F/N: LL01 - Clearance Safety Tag

(Afx adjacent to heater’s thermostat)

Left Panel

(Fan Compartment)

16” Burner Tube

SERVICE ACCESS PANEL

IGNITER & FLAME SENSE COMPARTMENT

1. Turn off gas & electricity.

2. Remove cover by lifting top

cover upward and outward.

CAUTION: HOT SURFACE.

KEEP COVER IN PLACE. REMOVE FOR SERVICE ONLY.

SERVICE ACCESS PANEL

IGNITER & FLAME SENSE COMPARTMENT

1. Turn off gas & electricity.

2. Remove cover by lifting top

cover upward and outward.

CAUTION: HOT SURFACE.

KEEP COVER IN PLACE. REMOVE FOR SERVICE ONLY.

F/ N: L LTB 0 26

F/ N: LLV3 EP6

Primary Combustion

Chamber

!

INSTALLER

AVOID EQUIPMENT FAILURE

THIS 10 FT. TUBE IS THE

COMBUSTION CHAMBER.

The combustion chamber utilizes either 409

stainless, titanium alloy or aluminized steel -

depending on the model number of your heater.

THIS TUBE MUST BE THE FIRST TUBE

FOLLOWING THE BURNER CONTROL BOX.

Rotate the tube’s welded seam to bottom.

Consult the manual(s) for further details.

F/N: LLTB004 (orange)

Radiant

Tube(s)

Clearance to Combustibles

WARNING

Placement of explosive objects, ammable objects, liquids and vapors close to

the heater may result in explosion, re, property damage, serious injury or death.

Do not store or use explosive objects, liquids or vapor in the vicinity of the heater.

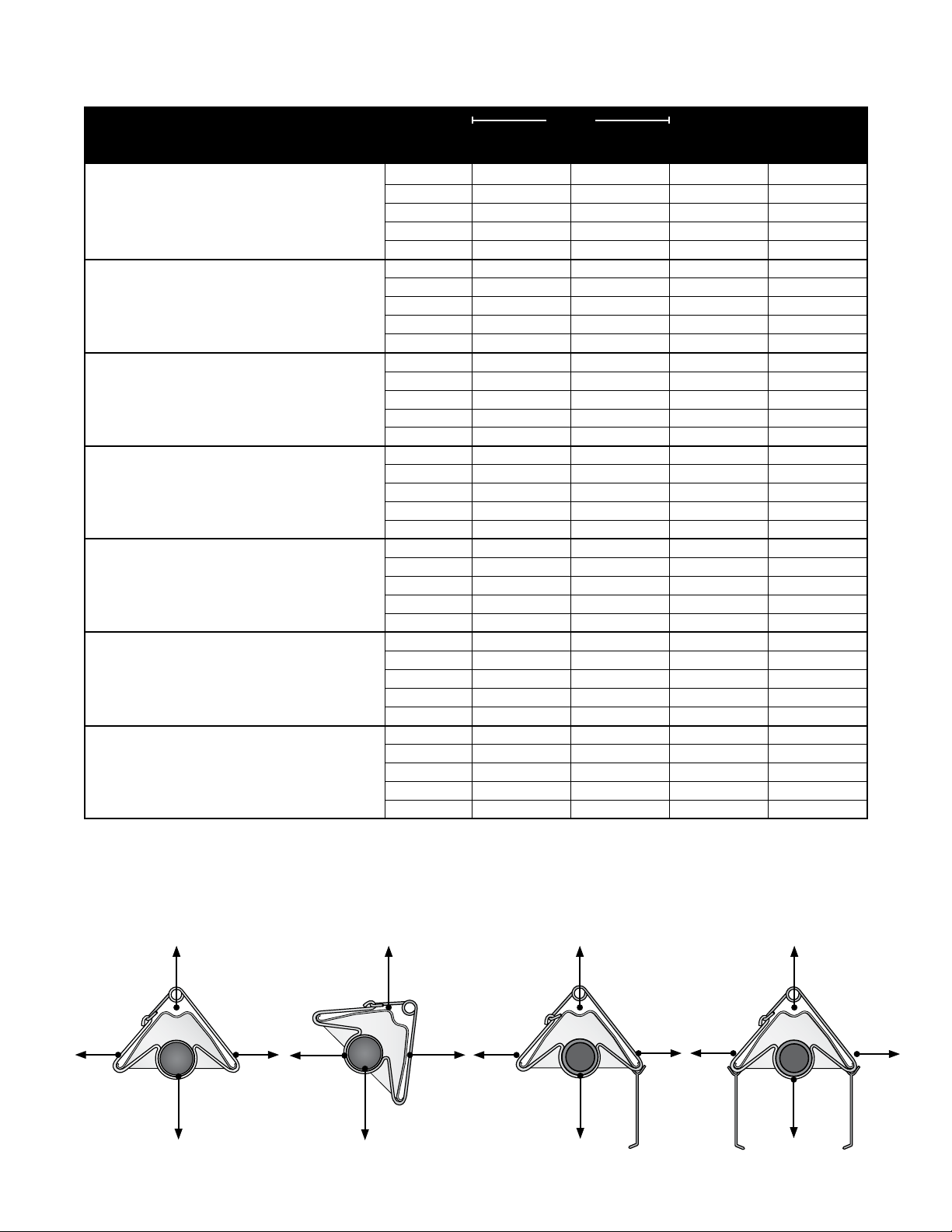

Clearance to combustibles is dened as the minimum distance that must exist between the tube surface,

or reector, and any combustible items (see Figure 1.1). It also pertains to the distance that must be

maintained from moving objects around the tube heater.

When installing the tube heater system, clearances to combustibles for your series tube heater and

conguration must be maintained. Refer to Chart 1.1 on the following page to determine the required

distances for your model.

The stated clearance to combustibles represents a surface temperature of 90ºF (32ºC) above room

temperature. Building materials with a low heat tolerance (such as plastics, vinyl siding, canvas,

tri-ply, etc.) may be subject to degradation at lower temperatures. It is the installer’s responsibility to

assure that adjacent materials are protected from degradation.

4

DX2 Series

1.0 Safety • Clearance to Combustibles

Chart 1.1 • Clearance to Combustibles in Inches (see Figure 1.1 for Mounting Angles)

Mounting

Model Number

DX2 (20, 30, 40) - 50, 60 [N, P]

with 1 side shield

with 2 side shields 0° 9 9 6 47

20 ft. from burner 0° 7 7 6 30

DX2 (20, 30, 40) - 75 [N, P] 0° 9 9 6 60

with 1 side shield 0° 29 8 6 60

with 2 side shields 0° 9 9 6 60

20 ft. from burner

DX2 (20, 30, 40, 50) - (80, 96, 100) [N, P] 0° 14 14 6 66

with 1 side shield 0° 29 8 6 66

with 2 side shields 0° 16 16 6 66

20 ft. from burner 0° 7 7 6 30

DX2 (30, 40, 50, 60) - 125 [N, P] 0° 20 20 6 76

with 1 side shield 0° 42 8 6 76

with 2 side shields 0° 20 20 6 76

20 ft. from burner 0° 7 7 6 30

DX2 (40, 50, 60) - 150 [N, P] 0° 24 24 6 81

with 1 side shield 0° 42 8 6 81

with 2 side shields 0° 23 23 6 81

20 ft. from burner 0° 11 11 6 44

DX2 (40, 50, 60, 70) - 175 [N, P]

with 1 side shield 0° 50 8 6 92

with 2 side shields 0° 30 30 6 92

20 ft. from burner 0° 11 11 6 44

DX2 (50, 60, 70, 80) - 200 [N, P] 0° 41 41 6 94

with 1 side shield 0° 54 8 6 94

with 2 side shields 0° 30 30 6 94

20 ft. from burner 0° 11 11 6 44

Angle*

0° 9 9 6 47

45° 39 8 10 47

0° 29 8 6 47

45° 39 8 10 60

0° 7 7 6 30

45° 39 8 10 66

45° 58 8 10 76

45° 58 8 10 81

0° 34 34 6 92

45° 63 8 10 92

45° 63 8 10 94

Side

Top BelowFront Behind

Heaters mounted on an angle between 0° to 45° must maintain clearances posted for 0° or 45°; whichever is greater.

*

Figure 1.1 • Mounting Angles

0° Mounting Angle 45° Mounting Angle

Top

Side

Side

Below

Front

Below

Top

Behind

0° Mounting Angle

with 1 Side Shield

(P/N: SSE)

Top

Front Behind

Below

0° Mounting Angle

with 2 Side Shields

(P/N: SSE)

Top

Side Side

Below

5

2.0 Installation • Gas Requirements • Electrical Requirements

!

2.0 Installation

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, serious injury or death. Read and understand, the installation, operating and

maintenance instructions thoroughly before installing or servicing this equipment. Only

trained, qualied gas installation and service personnel may install or service this equipment.

Not for residential use! Do not use this heater in the home, sleeping quarters, attached

garages, etc. Installation of a commercial tube heater system in residential indoor spaces

may result in property damage, serious injury or death.

Instructions for the following are detailed in the Tube Heater General Manual:

• Design considerations

• Hanger suspension and placement

• Tube layout and assembly

• Burner control box suspension

• Reectors (and accessories)

• Venting and combustion air intake

• Gas requirements

• Bafe assembly

DX2 Series

Note: Electronic versions of all manuals are available at www.detroitradiant.com

Gas Requirements

Type of Gas

Natural 3.5 Inches W.C. 5.0 Inches W.C. 14.0 Inches W.C.

Liqueed Petroleum 10.0 Inches W.C. 11. 0 Inches W.C. 14.0 Inches W.C.

IMPORTANT: Consult the Tube Heater General Manual for gas connection requirements.

Required Manifold

Pressure

Minimum Inlet

Pressure

Maximum Inlet

Pressure

Electrical Requirements

NOTICE

The DX2 Series comes standard requiring a 120VAC connection to the thermostat. An optional 24VAC

internal relay (24VAO) may be factory installed if the heater is to be controlled via a 24VAC thermostat.

A 40VA transformer is necessary when using the 24VAO option.

NOTE: A relay transformer may be used in lieu of the factory installed 24VAO option.

• 120VAC - 60 Hz GRD, 3-wire.

• 120VAC thermostat connection.

• Starting current 4.8 amps

• Running current 1.1 amps

6

Loading...

Loading...