Branson TRACTOR Service manual

Service Manual

(00 series - Chassis)

KUKJE MACHINERY CO., LTD

KUKJE MACHINERY CO., LTD

GENERAL

CONTENTS 1. (GENERAL)

1. ABOUT WARRANTY ………………………………………………………………………………………………… |

002 |

||

2. OVERVIEW OF THE TRACTOR |

|

|

|

<1> OVERVIEW ……………………………………………………………………………………………............. |

003 |

||

<2> OPERATION PART |

|

|

|

1) MANUAL TRANSMISSION ……………………………………………………………………............ |

004 |

||

2) HST TRANSMISSION …………………………………………………………………………………….. |

005 |

||

3. LOCATION OF SAFETY DECALS …………………………………………………………………………………. |

006 |

||

4. SPECIFICATIONS |

|

|

|

<1> SPECIFICATION ………………………………………………………………………………………............ |

008 |

||

<2> TRAVELING SPEED …………………………………………………………………………………............. |

010 |

||

5. PERIODIC MAINTENANCE SCHEDULE ………………………………………………………………............ |

011 |

||

6. OIL, GREASE, ANTI-FREEZE, FUEL AND COOLANT CHART |

|

||

<1> OIL, GREASE AND ANTI FREEZE ………………………………………………………………............ |

012 |

||

<2> FUEL, OIL AND COOLANT ………………………………………………………………………............. |

012 |

||

7. CHECK AND MAINTENANCE |

|

|

|

<1> DAILY CHECK …………………………………………………………………………………………............ |

013 |

||

<2> CHECK POINTS OF INITIAL 50 HOURS |

………………………………………………………………. |

014 |

|

<3> CHECK POINTS OF EVERY 50 HOURS |

………………………………………………………............. |

019 |

|

<4> CHECK POINTS OF EVERY 100 HOURS |

……………………………………………………………… |

021 |

|

<5> CHECK POINTS OF EVERY 200 HOURS |

……………………………………………………………… |

028 |

|

<6> CHECK POINTS OF EVERY 300 HOURS |

……………………………………………………………… |

029 |

|

<7> CHECK POINTS OF EVERY 400 HOURS |

……………………………………………………………… |

030 |

|

<8> CHECK POINTS OF EVERY 800 HOURS |

……………………………………………………………… |

030 |

|

<9> CHECK POINTS OF EVERY 1500 HOURS |

…………………………………………………………….. |

030 |

|

<10> CHECK POINTS OF EVERY 3000 HOURS |

…………………………………………………............. |

030 |

|

<11> CHECK POINTS OF EVERY 1 YEAR …………………………………………………………………… |

030 |

||

<12> CHECK POINTS OF EVERY 2 YEARS |

…………………………………………………………………. |

031 |

|

<13> OTHERS ……………………………………………………………………………………………………….. |

034 |

||

1KUKJE MACHINERY CO., LTD.

GENERAL

1. ABOUT WARRANTY

*. WARRANTY

You will need the “Warranty Registration” when your tractor requires warranty service. Read it and keep in a safe place.

< Information you will need when contacting the dealer for service >

xType of model and machine s/n number.

xIn case of engine, the engine s/n number.

xCircumstances of breakdown.

(What kind of work, gear position, etc)

xAmount of work done.

(Square footage or number of hours)

xOther information in as much detail as possible surrounding the circumstanced of the breakdown.

Chassis S/N |

Engine S/N |

2KUKJE MACHINERY CO., LTD.

2. OVERVIEW OF THE TRACTOR

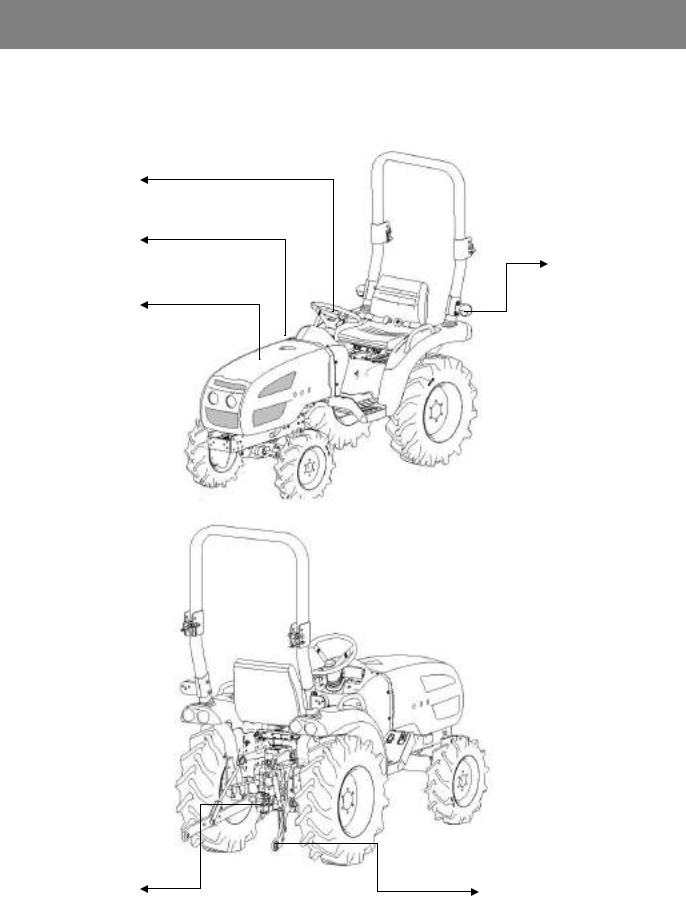

<1> OVERVIEW

Steering

Steering Wheel

Wheel

Fuel

Fuel Tank

Tank

Hood

Hood

Head

Head Lamp

Lamp

Front

Front Tire

Tire

Combination

Combination Lamp

Lamp

Drawbar

Drawbar

GENERAL

ROPS

ROPS

Direction

Direction Lamp

Lamp

Seat

Seat

Rear

Rear Tire

Tire

Lower

Lower Link

Link

3KUKJE MACHINERY CO., LTD.

GENERAL

2. OVERVIEW OF THE TRACTOR

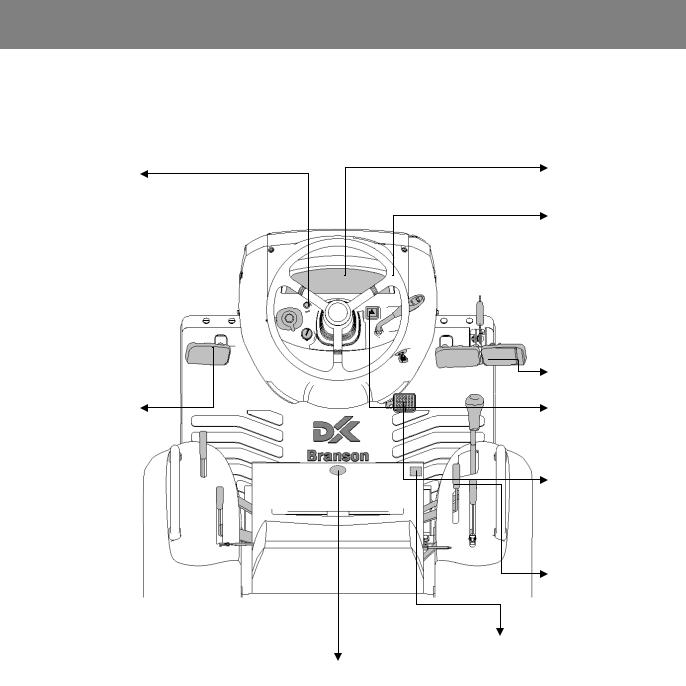

<2> OPERATION PART

1) Manual transmission

Emergency

Emergency Stop

Stop S/W

S/W

Combination

Combination S/W

S/W

Side

Side Lamp

Lamp S/W

S/W

Clutch

Clutch Pedal

Pedal

Range

Range Shift

Shift Lever

Lever

PTO

PTO Shift

Shift Lever

Lever

Instrument

Instrument Panel

Panel

Steering

Steering Wheel

Wheel

Accelerator

Accelerator Lever

Lever

Key

Key Switch

Switch

Brake

Brake Pedal

Pedal

Emergency

Emergency Lamp

Lamp S/W

S/W

Main

Main Shift

Shift Lever

Lever

Accelerator

Accelerator Pedal

Pedal

Position

Position Lever

Lever

MFWD

MFWD Lever

Lever

Differential

Differential Lock

Lock Pedal

Pedal

Slow

Slow Return

Return Valve

Valve

4KUKJE MACHINERY CO., LTD.

GENERAL

2.OVERVIEW OF THE TRACTOR

2)HST transmission

Emergency

Emergency Stop

Stop S/W

S/W

Instrument

Instrument Panel

Panel

Cruise

Cruise S/W

S/W

Combination S/W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering Wheel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Accelerator Lever |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brake Pedal |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

Clutch Pedal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Forward Pedal |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key Switch |

||||

Side Lamp S/W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Emergency Lamp S/W |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Parking Lever |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Backward Pedal |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Range Shift Lever |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MFWD Lever |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Differential Lock Pedal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PTO Shift Lever |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Position Lever |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

Slow Return Valve |

||||||||||||||

5KUKJE MACHINERY CO., LTD.

GENERAL

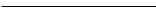

3. LOCATION OF SAFETY DECALS

LOCATION OF SAFETY DECALS

Safety decals are provided to ensure safe operation.

Keep the safety decals clean at all times and protect them from damage.

In case of loss or damage, replace with a new decal.

12. TZE5170000B4

10. TA00016518A |

11.TA00016517A |

9. NTE5150000C4

6. NTE5270000A4

4.TZE4190000B4

8. NTE5210000C4

5. TZE5130000B4

7. TZE5110000B4

6KUKJE MACHINERY CO., LTD.

GENERAL

3. LOCATION OF SAFETY DECALS

LOCATION OF SAFETY DECALS

Safety decals are provided to ensure safe operation.

Keep the safety decals clean at all times and protect them from damage.

In case of loss or damage, replace with a new decal.

3. NTE6220000C4

1. TZE5180000B4

2. TZE4300000B4

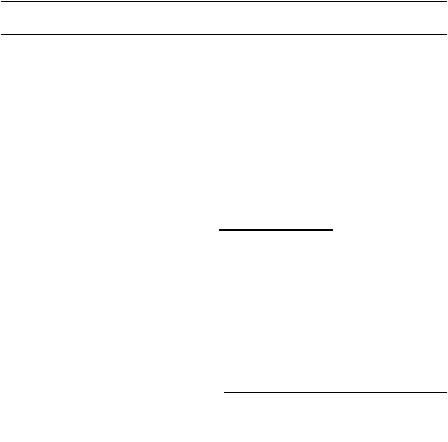

No |

Part code |

Part description |

|

|

|

|

|

LABEL, FAN |

1 |

TZE5180000B4 |

WARNING |

|

|

|

2 |

TZE4300000B4 |

LABEL, PTO CAUTION |

|

|

|

3 |

NTE5220000C4 |

LABEL, SAFETY |

|

|

|

|

|

LABEL, FILLER |

4 |

TZE4190000B4 |

CAUTION |

|

|

|

No |

Part code |

Part description |

|

|

|

7 |

TZE5110000B4 |

LABEL, START CAUTION |

|

|

|

8 |

NTE5210000C4 |

LABEL, PTO |

|

|

|

9 |

NTE5150000C4 |

LABEL, DRAWBAR |

|

|

|

10 |

TA00016518A |

LABEL, SAFETY |

|

|

|

7KUKJE MACHINERY CO., LTD.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GENERAL |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

TZE5130000B4 |

|

LABEL, MUFFLER |

|

|

|

11 |

|

TA0016517A |

|

LABEL, SAFETY |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LABEL, START |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

NTE5270000A4 |

|

CAUTION |

|

|

|

12 |

|

TZE5170000B4 |

LABEL, ROPS WARNING |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

<1> SPECIFICATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

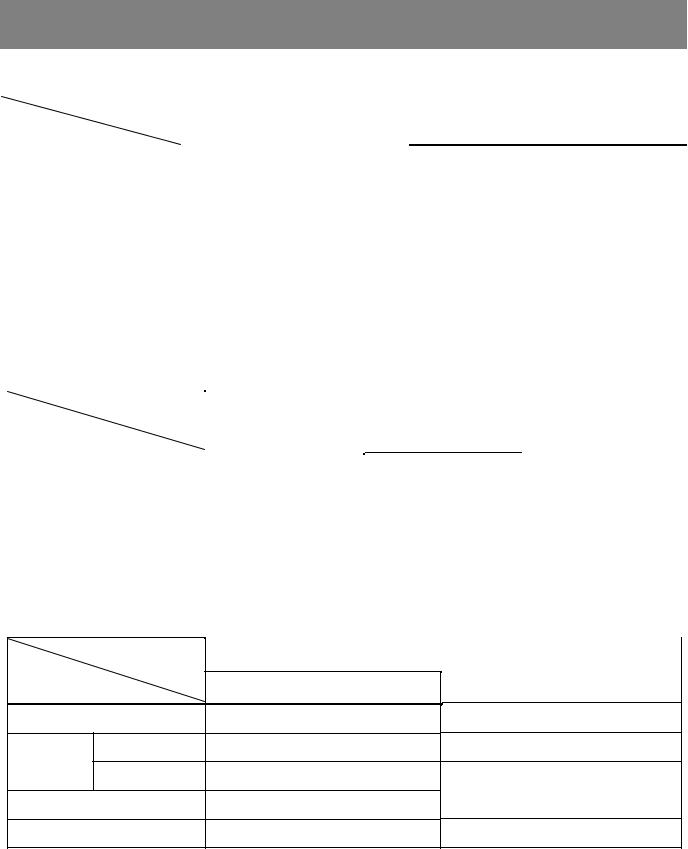

Items |

|

Unit |

|

Manual transmission |

|

HST transmission |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

2100 |

|

|

2400 |

|

2800 |

|

2400h |

|

2800h |

||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Drive System |

|

|

|

|

|

|

|

|

|

|

4 Wheel Drive |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Main Dimensions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Overall Length |

|

in |

|

|

|

|

|

|

|

|

106 (2692mm) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Overall Width |

|

in |

|

|

|

|

|

|

|

|

44.3 (1124mm) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Overall Height |

|

in |

|

|

|

|

|

|

|

|

87.2 (2216mm) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Wheel Base |

|

in |

|

|

|

|

|

|

|

|

59.1 (1502mm) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Front Tread |

|

in |

|

|

|

|

|

|

|

|

33.6 (853mm) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Rear Tread |

|

in |

|

|

|

|

|

|

|

|

34.6 (880mm) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Ground Clearance |

|

in |

|

|

|

|

|

|

|

|

12.4 (315mm) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Weight |

|

lbs. |

1785 |

|

|

|

|

1805 |

|

1807 |

|

1805 |

|

1807 |

|

||||

|

|

(810kg) |

|

|

(819kg) |

|

(820kg) |

|

(819kg) |

|

(820kg) |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Engine |

|

|

|

|

|

|

|

|

Vertical 4 cycle. Water cooled, Diesel |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Combustion System |

|

|

|

|

|

|

|

|

|

|

Swirl Chamber |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Aspiration |

|

|

|

|

N/A |

|

|

|

Turbo |

|

N/A |

|

Turbo |

||||||

|

|

|

|

|

|

|

|

Charger |

|

|

Charger |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Engine Horsepower |

|

HP |

20.5 |

|

|

|

|

24.0 |

|

28.0 |

|

24.0 |

|

28.0 |

|

||||

|

(2600 rpm) |

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

No. of Cylinders |

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Bore x Stroke |

|

mm |

74 X 82 |

|

|

78 X 82 |

|

78 X 82 |

|

78 X 82 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Displacement |

|

cc |

1058 |

|

|

|

|

1175 |

|

1175 |

|

1175 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Compression Ratio |

|

|

21.5:1 |

|

|

|

|

|

|

21:1 |

|

21:1 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Fuel Consumption |

|

gal/hp.hr |

|

|

|

|

|

|

|

|

0.067 (210 g/hp.hr) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8KUKJE MACHINERY CO., LTD.

|

|

|

|

|

|

|

|

|

|

|

|

GENERAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type of Air Cleaner |

|

|

|

|

|

|

|

Dry, element |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel Tank Capacity |

|

gal |

|

|

|

|

6.08 (23L) |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. SPECIFICATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

Items |

|

Unit |

|

Manual transmission |

|

|

HST transmission |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

2100 |

|

2400 |

|

2800 |

|

|

2400h |

2800h |

|

|||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Battery |

|

Volt |

|

|

|

12 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering |

|

|

|

|

|

|

|

Hydrostatic |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

Clutch |

|

|

|

|

|

|

|

Dry, single stage |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brake |

|

|

|

|

|

|

|

Wet disc |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transmission |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gear Shifting |

|

|

|

|

|

6F x 2R |

|

Hydrostatic, high low gear shift |

|

||||

(F x R) |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Tires (Agricultural) |

|

|

|

|

|

Turf and Industrial tires Available |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

Front |

|

|

|

|

|

|

6 - 12 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

Rear |

|

|

|

|

|

|

9.5 - 16 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

Rear PTO |

|

|

|

|

|

|

|

6 spline shaft |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

Type |

|

|

|

|

|

|

|

Live |

|

|

|

||

|

|

|

|

|

|

|

|||||||

Speed |

|

|

|

|

540 rpm, 960 rpm, 2500rpm(mid) @2600 engine rpm |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||

MID PTO |

|

|

|

|

|

|

|

14 spline shaft |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

Type |

|

|

|

|

|

|

|

Live |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||

Speed |

|

|

|

|

|

|

2500 rpm @ 2600 engine rpm |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||

Hydraulic System |

|

|

|

|

|

|

|

Control / Position |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

3 point hitch |

|

|

|

|

|

|

|

Category I |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lift capacity at lift |

|

lbs |

|

|

|

|

|

1433 (650kg) |

|

|

|||

point |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Pump Capacity |

gal/min |

|

|

|

|

|

7.7 (29.0L/min) |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9KUKJE MACHINERY CO., LTD.

GENERAL

4. SPECIFICATIONS

<2> TRAVELING SPEED

|

|

|

|

SHIFTING |

MODEL |

|

||

LEVEL |

|

|

|

|

|

|

|

|

|

|

|

|

Manual transmission |

|

HST transmission |

||

|

|

|

MAIN |

|

RANGE |

|

|

|

|

|

|

2100, 2400, 2800 |

|

2400h,2800h |

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

L |

0.7(1.1Km/h) |

|

|

|

|

|

|

|

|

|

|

3.9(6.2Km/h) |

|

|

2 |

2 |

|

L |

1.1(1.8Km/h) |

|

|

|

|

|

|

|

|

|

|

|

Forward |

|

3 |

3 |

|

L |

2.1(3.3Km/h) |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

1 |

|

H |

2.7(4.4Km/h) |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

9.6(15.5Km/h) |

|

|

5 |

2 |

|

H |

4.8(7.8Km/h) |

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

3 |

|

H |

8.8(14.1Km/h) |

|

|

|

|

|

|

|

|

|

|

|

Reverse |

|

1 |

R |

|

L |

0.8(1.3Km/h) |

|

2.3(3.7Km/h) |

|

|

|

|

|

|

|

|

|

|

2 |

R |

|

H |

3.4(5.5Km/h) |

|

5.8(9.3Km/h) |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

Rated Engine rpm: 2600 rpm Tire: agri 9.5-16 (423mm)

This specification will be changed without prior notice for improvement of quality

Theory speeds figured by rated engine rpm (mile/hr)

10 |

KUKJE MACHINERY CO., LTD. |

GENERAL

5. PERIODIC MAINTENANCE SCHEDULE

< SCHEDULE >

Running hours |

50 |

100 |

150 |

200 |

|

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Check items |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine oil |

R |

R |

|

R |

|

|

R |

|

R |

|

R |

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transmission fluid |

R |

○ |

○ |

○ |

|

○ |

R |

○ |

○ |

○ |

○ |

○ |

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Front axle fluid |

R |

○ |

○ |

○ |

|

○ |

R |

○ |

○ |

○ |

○ |

○ |

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine oil filter |

R |

|

|

|

|

|

R |

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transmission fluid filter |

R |

|

|

|

|

|

R |

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Radiator cleaning |

|

|

|

At the time the coolant is replaced |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel oil filter and element |

|

○ |

|

○ |

|

|

R |

|

○ |

|

○ |

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Coolant |

|

|

Check before every use (Replace every year) |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Air cleaner element |

○ |

○ |

○ |

○ |

|

○ |

○ |

○ |

○ |

○ |

R |

○ |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fan and radiator cleaning |

○ |

○ |

○ |

○ |

|

○ |

○ |

○ |

○ |

○ |

○ |

○ |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Battery solution |

Replace every two years |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Battery (specific gravity) |

|

○ |

|

○ |

|

|

○ |

|

○ |

|

○ |

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel pipe and connection |

○ |

○ |

○ |

○ |

|

○ |

○ |

○ |

○ |

○ |

○ |

○ |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering wheel hose |

○ |

○ |

○ |

○ |

|

○ |

○ |

○ |

○ |

○ |

○ |

○ |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Radiator hose |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hydraulic fluid hose |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel hose, electric cables |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric cables |

○ |

○ |

○ |

○ |

|

○ |

○ |

○ |

○ |

○ |

○ |

○ |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Greasing |

○ |

○ |

○ |

○ |

|

○ |

○ |

○ |

○ |

○ |

○ |

○ |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tightening handles |

|

○ |

|

○ |

|

|

○ |

|

○ |

|

○ |

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tightening bolts |

○ |

○ |

|

○ |

|

|

○ |

|

○ |

|

○ |

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling fan belt |

○ |

○ |

|

○ |

|

|

○ |

|

○ |

|

○ |

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine breed pipe |

○ |

○ |

|

○ |

|

|

○ |

|

○ |

|

○ |

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine crankcase cleaning |

|

|

|

|

|

|

○ |

|

|

|

|

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Intake/Exhaust gas valves |

|

|

|

|

|

|

|

|

|

|

|

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel injection valve |

|

|

|

|

|

|

|

|

|

|

|

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Generator motor |

○ |

○ |

|

|

|

|

○ |

|

|

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hydraulic system |

○ |

○ |

|

|

|

|

○ |

|

|

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

KUKJE MACHINERY CO., LTD. |

||||||

GENERAL

Inspection should be done every 50 hours. If the tractor is not used much, inspect every year.

Replace parts every two years regardless of running hours.

Replace the steering wheel hose every two years.

6. OIL, GREASE, ANTI-FREEZE, FUEL AND COOLANT CHART

<1> OIL, GREASE AND ANTI-FREEZE

Type |

Type |

Remarks |

|

Item |

|||

|

|

||

|

|

|

|

Fuel |

Diesel(KS # 2) |

Summer: S Winter W |

|

|

|

|

|

Engine oil |

SAE 10W-40 |

CG Above |

|

|

|

|

|

Grease |

NO.2 of KSM2130 |

Multi purpose |

|

|

|

|

|

Anti - Freeze |

International genuine product |

No.2 of KSM 2142,permanent type |

|

|

|

|

|

Transmission, Steering, |

Branson origin oil |

-Texaco TDH oil, 1893 |

|

Front axle fluid |

|

-Chevron Tractor HYD Fluid |

Note) Use winter diesel when temperature is below 50’F.

<2> FUEL, OIL AND COOLANT

|

|

Model |

|

|

|

Manual Transmission |

|

|

|

Type |

|

|

|

|

|

|

|

|

|

|

|

|

2100 |

|

|

2400 |

|

2800 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

Fuel |

6.08 gal (23L) |

|

6.08 gal (23L) |

6.08 gal (23L) |

|||

|

|

|

|

|

|

|

|

|

|

Coolant |

|

Radiator |

1.00 |

gal (3.8L) |

1.00 |

gal (3.8L) |

1.00 |

gal (3.8L) |

|

|

|

|

|

|

|

|

|

|

|

|

Sub tank |

0.21 |

gal (0.8L) |

0.21 |

gal (0.8L) |

0.21 |

gal (0.8L) |

||

|

|

||||||||

|

|

|

|

|

|

|

|||

|

Engine oil |

0.79 gal (3L) |

|

0.79 gal (3L) |

0.79 gal (3L) |

||||

|

|

|

|

|

|||||

Transmission oil |

3.43 gal (13L) |

|

3.43 gal (13L) |

3.43 gal (13L) |

|||||

|

|

|

|

|

|

|

|||

Front axle oil |

0.79 |

gal (3.0L) |

0.79 |

gal (3.0L) |

0.79 |

gal (3.0L) |

|||

|

|

|

|

|

|

|

|

|

|

Model |

|

|

HST Transmission |

|

Type |

2400h |

2800h |

||

|

||||

Fuel |

6.08 |

gal (23L) |

6.08 gal (23L) |

|

Radiator |

1.00 |

gal (3.8L) |

1.00 |

gal (3.8L) |

Coolant |

|

|

|

|

Sub tank |

0.21 |

gal (0.8L) |

0.21 |

gal (0.8L) |

Engine oil |

0.79 gal (3L) |

0.79 gal (3L) |

||

Transmission oil |

3.96 |

gal (15L) |

3.96 gal (15L) |

|

12 |

KUKJE MACHINERY CO., LTD. |

GENERAL

Front axle oil |

0.79 gal (3.0L) |

0.79 gal (3.0L) |

|

|

|

7.CHECK AND MAINTENANCE

Be sure to check and service the tractor on a flat place with the engine shut off, the parking brake on and chock the wheels.

<1> DAILY CHECK

To prevent trouble from occurring, it is important to know the condition of the tractor, Check the following items before starting.

13 |

KUKJE MACHINERY CO., LTD. |

GENERAL

<Checking >

Check areas where previous trouble was experienced.

Walk around the tractor.

1.Check the tire pressure, and check for wear and damage.

2.Check for oil and water leaks.

3.Check the engine oil level.

4.Check the transmission fluid level.

5.Check the coolant level.

6.Check the condition of seat belt and ROPS attaching hardware.

7.Check and clean the radiator screen and grill.

8.Check that the bolts and nuts of the tires are tight.

9.Check the number plate or SMV emblem for damage and clean, replace as necessary of equipped.

10.Care of danger, warning, and caution labels.

11.Clean around the exhaust manifold and the muffler of the engine.

While sitting in the operator’s seat.

1.Check the HST pedal, brake pedal and clutch pedal.

2.Check the parking brake.

3.Check the steering wheel.

Turning the key switch.

1.Check the performance of the instrument panel lights.

2.Check the head lights, tail lights and hazard lights. Clean if necessary.

3.Check the performance of the meters and gauges.

Starting the engine.

1.Check to see that the lights on the easy checker go off.

2.Check the color of the exhaust gas.

3.Check the brakes for proper operation.

7.DISASSEMBLING AND SERVICING

<2> CHECK POINTS OF INITIAL 50 HOURS

14 |

KUKJE MACHINERY CO., LTD. |

<Changing engine oil >

Be sure to stop the engine.

Allow engine to cool down sufficiently, oil can be hot and can burn.

1.Place an oil pan underneath the engine.

2.To drain the used oil, remove the drain plug(1) at the bottom of the engine and drain the oil completely.

3.Screw in the drain plug(1).

4.Fill with the new oil up to the upper notch on the dipstick.

Important

¾Never mix two different types of oil.

Engine oil |

2100 |

3.0 L |

|

|

2400(h) |

3.17 |

U.S.qts |

||

capacity |

||||

2800(h) |

0.79 |

gal |

||

|

||||

|

|

|

|

*. PART NAME |

|

|

1) |

Drain plug |

2) Oil inlet |

3) |

Dipstick |

|

GENERAL

(3)

7. DISASSEMBLING AND SERVICING

15 |

KUKJE MACHINERY CO., LTD. |

GENERAL

<Replacing engine oil filter cartridge >

Be sure to stop the engine before changing oil filter cartridge.

1.Remove the oil filter cartridge with the filter wrench.

2.Apply a slight coat of oil onto the cartridge gasket.

3.To install the new cartridge, screw it in by hand. Over tightening may cause deformation of rubber gasket.

4.After the new cartridge has been replaced, the engine oil normally decrease a little. Thus see

that the engine oil does not leak through the seal and be sure to read the oil level on the dipstick. Then, replenish the engine oil up to the specified level.

Important

¾To prevent serious damage to the engine, replacement element must be highly efficient. Use only a Branson genuine filter.

*. PART NAME

1) Engine oil filter

7. DISASSEMBLING AND SERVICING

16 |

KUKJE MACHINERY CO., LTD. |

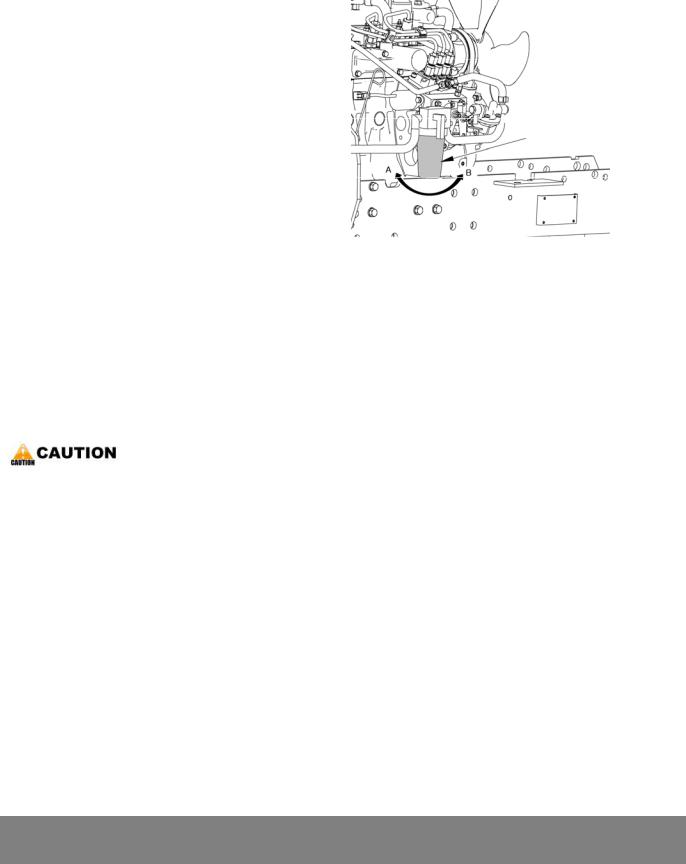

<Changing transmission fluid >

Be sure to stop the engine before checking and changing the transmission fluid.

1.Place an oil pan under the tractor.

2.Remove the drain plugs(1) at the bottom of the rear axle cases, transmission case and front transmission case.

3.Drain the transmission fluid.

4.After draining, screw in the four drain plugs.

5.Fill new oil from filling port after removing the filling plug(2), up to the upper notch on the dipstick.

6.After running the engine for a few minuets, stop it and check the oil level again, if low, add oil to proper level.

Important

¾Use only multi-grade transmission oil. Use of other oils may damage the transmission of hydraulic system.

¾Never work the tractor immediately after changing the transmission oil. Keep the engine at medium speed for a few minutes to prevents damage to the transmission.

|

2100 |

Front case |

3L (0.79gal) |

|

|

|

|||

Transmission |

2400 |

|

|

|

Rear case |

13L (3.43gal) |

|||

2800 |

||||

|

||||

fluid capacity |

|

|

||

|

|

|

||

2400h |

Front case |

3L (0.79gal) |

||

|

||||

|

2800h |

|

|

|

|

Rear case |

15L (3.96gal) |

||

|

|

|

|

*. PART NAME |

|

1) Drain plug |

2) Filling plug |

3)Dipstick

7.DISASSEMBLING AND SERVICING

GENERAL

(1)

(1)

(1)

(3)

17 |

KUKJE MACHINERY CO., LTD. |

<Replacing hydraulic oil filter cartridge >

Be sure to stop the engine before changing the oil filters.

1.Drain the transmission fluid.

2.Remove the oil filter cartridge by using a filter wrench.

3.Apply a slight coat of oil onto the cartridge gasket.

4.To install the new cartridge, screw it in by hand. Over tightening may cause deformation of rubber gasket.

5.After the new cartridge has been replaced, the transmission fluid level will normally decrease slightly. Make sure that the transmission fluid does not leak through the seal. Check the fluid level.

Important

¾To prevent serious damage to the hydraulic system. Use only a genuine Branson filter.

<Cleaning transmission oil strainer (HST) >

1.Clean the strainer with nonflammable solvent.

NOTE

1) When changing the transmission fluid, disassemble and rinse the strainer with nonflammable solvent to completely clean off filings. When reassembling, be careful not to damage the parts.

2) Since the fine filings in the oil could impair the component parts of the hydraulic system which is precision built to withstand high pressure, the suction line end is provided with an oil strainer.

3) Please do the replacing, of the oil filter cartridge and the cleaning oil strainer at the same time. And when replacing, reinstall the oil strainer first.

7. DISASSEMBLING AND SERVICING

GENERAL

(1)

(2)

*. PART NAME

1) Hydraulic oil filter (HST) 2) Hydraulic oil filter

18 |

KUKJE MACHINERY CO., LTD. |

<Checking clutch pedal free travel >

When checking, park the tractor on flat ground, apply the parking brake, stop the engine and remove the key.

1.Slightly depress the clutch pedal and measure stroke “A” at top of stopper bolt(1).

2.If the measurement is not within the factory specifications, loosen the lock nut and adjust the clutch pedal rod(2) length.

3.After adjusting it, measure total stroke “B” between stopper bolt(1) and clutch housing(4).

4.If the measurement is not within the factory specifications, adjust it with the clutch pedal stopper bolt(1).

5.And at the same time, adjust the clearance “C”

between safety switch(5) and clutch rod(6).

NOTE

1)After adjustment, secure the stopper bolt with the lock nut(3).

Clutch pedal free travel on |

Factory |

7.0 to 9.0 mm |

|

stopper bolt stroke “A” |

spec. |

0.28 to 0.35 in. |

|

|

|

|

|

Reference : |

|

25.0 to 35.0 mm |

|

Clutch pedal free travel “L” |

|

||

|

0.98 to 1.38 in. |

||

on top of clutch pedal. |

|

||

|

|

||

|

|

|

|

Clearance “B” |

Factory |

1.5 to 2.0 mm |

|

spec. |

0.06 to 0.08 in. |

||

|

|||

|

|

|

GENERAL

L

*. PART NAME |

|

|

|

1) |

Stopper bolt |

2) |

Clutch pedal rod |

3) |

Lock nut for stopper bolt |

4) |

Clutch housing |

5) |

Satety switch |

6) |

Clutch rod |

7. DISASSEMBLING AND SERVICING

<3> CHECK POINTS OF EVERY 50 HOURS

19 |

KUKJE MACHINERY CO., LTD. |

GENERAL

< Checking engine start system >

Do not allow anyone near the tractor while testing.

If the tractor does not pass the test do not operate the tractor.

Preparation before testing

1.Sit on operator’s seat.

2.Set the parking brake and stop the engine.

3.HST type

-. Shift the range gear shift lever to “Neutral” position.

-. Place the speed control pedal in “Neutral” position.

Manual transmission type

-. Shift the main gear shift lever in “Neutral” position.

4.Shift the PTO gear shift lever to “Neutral” position.

5. |

Fully depress the clutch pedal. |

*. PART NAME |

|

|

|

Test 1 : Safety switch for clutch pedal |

1) |

Clutch pedal |

2) |

Range shift |

|

1. |

Place the speed control pedal in “Neutral” |

3) |

PTO gear shift |

4) |

Speed control pedal |

|

position for a HST type or shift the main gear |

5) |

Main gear shift |

|

|

|

shift lever for a Manual transmission type to |

|

|

|

|

|

“Neutral” position. |

|

|

|

|

2.Release the clutch pedal.

3.Turn the key to “Start” position.

4.The engine must not crank.

7.DISASSEMBLING AND SERVICING

20 |

KUKJE MACHINERY CO., LTD. |

Test 2 : Safety switch for HST of main gear

1.Fully depress the clutch pedal.

2.Depress the speed control pedal HST type or shift the main gear shift lever Manual transmission type to “Desired” position.

3.Turn the key to “Start” position.

4.The engine must not crank.

Test 3 : Safety switch for PTO

1.Fully depress the clutch pedal.

2.Place the speed control pedal in “Neutral” position HST type or shift the main gear shift lever Manual transmission type to “Neutral” position.

3.Shift the PTO gear shift lever to “On”(Engaged) position.

4.Turn the key to “Start” position.

5.The engine must mot crank.

Test 4 : Seat switch

1.Sit on operator’s seat.

2.Start the engine.

3.Fully depress the clutch pedal.

4.Shift the PTO gear shift lever to “On”(Engaged) position.

5.Stand up. (Do not get off the machine.)

6.The engine must shut off after approximately 1 second.

7.If it does not stop, consult your local Branson

Dealer for this service.

NOTE

1)If the engine cranks during nay of these tests, adjust or replace the required safety switch.

<Greasing >

1.Apply the grease to the following position as figures.

GENERAL

(1)

(2)

(4)

(3)

(5)

*. PART NAME |

|

1) Grease fitting(HST pedal) |

2) Battery terminals |

3)Grease fitting (Lifting rod RH)

4)Grease fitting (Top link)

5)Front axle tie rod

7. DISASSEMBLING AND SERVICING

21 |

KUKJE MACHINERY CO., LTD. |

GENERAL

< Checking wheel mounting screws and nuts tightening torque >

Never operate tractor with a loose rim, wheel, or axle.

Any time bolts and nuts are loosened, retighten to specified torque.

Check all bolts and nuts frequently and keep them tight.

1.Check wheel bolts and nuts regularly especially when new. If there are loosened, tighten as follows.

|

Front wheel |

mounting |

77 to 90 Nm |

|

7.9 to 9.2 kgfm |

||

|

bolt |

|

|

Tightening |

|

57.2 to 66.5 ft-lbs |

|

|

|

||

torque |

|

|

|

Rear wheel mounting |

108 to 125 Nm |

||

|

11.0 to 12.8 kgfm |

||

|

Nut / bolt |

|

|

|

|

80 to 93 ft-lbs |

|

|

|

|

|

|

|

|

|

<4> CHECK POINTS OF EVERY 100 HOURS

<Changing engine oil >

-. Reference the page. 14.

<Checking clutch pedal free travel >

-. Reference the page. 18.

<Checking battery condition >

Never remove the vent plugs while the engine is running.

(2)

(3)

*. PART NAME

1)Front wheel mounting bolt

2)Rear wheel mounting bolt

3)Rear wheel mounting nut

7. DISASSEMBLING AND SERVICING

22 |

KUKJE MACHINERY CO., LTD. |

GENERAL

Keep electrolyte away from eyes, hands and clothes. If you are spattered with it, wash it away completely with water immediately and get medical attention.

Wear eye protection and rubber gloves when working around battery.

1.Mishandling the battery shortens the service life and adds to maintenance costs.

2.The original battery is a maintenance free type, but stills needs some servicing. If the battery is weak, the engine is difficult to start and the

lights become dim. It is important check the |

*. PART NAME |

|

|

battery periodically. |

1) |

Good |

2) Charge |

|

3) |

Change |

|

< Battery charging >

When the battery is being activated, hydrogen and oxygen gases in the battery are extremely explosive. Keep open sparks and flames away from the battery at all times, especially when charging the battery.

When charging battery, remove battery vent plugs.

When disconnecting the cable from the battery, start with the negative terminal first. When connecting the cable to the battery, start with the positive terminal first.

Never check battery charge by placing a metal object across the posts. Use a voltmeter or hydrometer.

7. DISASSEMBLING AND SERVICING

23 |

KUKJE MACHINERY CO., LTD. |

GENERAL

1.Make sure each electrolyte level is to the bottom of vent wells, if necessary add distilled water in a well-ventilated area.

2.The water in the electrolyte evaporates during recharging. Liquid shortage damages the battery. Excessive liquid spills over and damages the tractor body.

3.To slow charge the battery, connect the battery positive terminal to the charger positive terminal and the negative to the negative, then recharge in the standard fashion.

4.A boost charge is only for emergencies. It will partially charges the battery at a high rate and in a short time. When using a boost-charged battery, it is necessary to recharge the battery as early as possible. Failure to do this will shorten the battery’s service life.

5.When the specific gravity of electrolyte become between 1.27 and 1.29 charge has completed.

6.When exchanging an old battery for a new one, use battery of equal specification.

Direction for storage

1.When storing the tractor for long periods of time, remove the battery from tractor, adjust the electrolyte to the proper level and store in a dry place out of direct sunlight.

2.The battery self-discharges while it is stored. Recharge it once every three months in hot seasons and once every six months in cold seasons.

Battery |

Volts |

Capacity |

Reserve |

Cold |

Normal |

Type |

(V) |

at 5H.R |

Capacity |

Cranking |

Charging |

|

|

(A.H.) |

(min.) |

Amps |

Rate(A) |

|

|

|

|

|

|

BX50S |

12 |

40 |

90 |

480 |

4.5 |

|

|

|

|

|

|

7. DISASSEMBLING AND SERVICING

24 |

KUKJE MACHINERY CO., LTD. |

GENERAL

<Cleaning air cleaner element >

1.Remove the air cleaner cover(1) and primary element(2).

2.Cleaning the primary element :

When dry dust adheres to the element, blow compressed air from the inside turning the element. Pressure of compressed air must be under 205kPa (2.1 kgf/ , 30 psi).

When carbon or oil adheres to the element,

soak the element in detergent for 15 minutes |

|

|

|||||

then wash it several times in water, rinse with |

|

|

|||||

clean water and dry it naturally. After the |

|

|

|||||

element |

is fully dried, |

inspect inside |

of the |

*. PART NAME |

|

||

element with a light and check if it is damaged |

1) Cover |

2) Primary element |

|||||

or not. |

|

|

|

|

3) Evacuator valve |

|

|

3. When |

to |

replace |

the |

air cleaner |

primary |

|

|

element(2) : Once a year or after every six times |

|

|

|||||

of cleaning, whichever comes first. |

|

|

|

||||

Important |

|

|

|

|

|

|

|

¾ The air cleaner uses a dry element, never apply |

|

|

|||||

oil. |

|

|

|

|

|

|

|

¾ Do not run the engine with the filter element |

|

|

|||||

removed. |

|

|

|

|

|

|

|

¾ Be sure to refit the dust cup with the arrow↑(on |

|

|

|||||

the rear of cup) upright. If the dust cup is |

|

|

|||||

improperly fitted, evacuator valve will not |

|

|

|||||

function and dust will adhere to the element. |

|

|

|||||

¾ Do not touch the secondary element except in |

|

|

|||||

cases where replacing is required. |

|

|

|

||||

Evacuator valve |

|

|

|

|

|

||

Open |

the |

evacuator |

valve |

once a week under |

|

|

|

ordinary conditions or daily when used in a dusty place to get rid of large particles of dust and dirt.

7. DISASSEMBLING AND SERVICING

25 |

KUKJE MACHINERY CO., LTD. |

GENERAL

< Cleaning fuel filter >

This job should not be done in the field, but in a clean place.

1.Loosen and remove the fuel filter bowl(2), and rinse the inside with kerosene.

2.Take out the filter element(4) and dip it in the kerosene to rinse.

3.After cleaning, reassemble the fuel filter, keeping out dust and dirt.

4.Bleed the fuel system.

NOTE

1)When the fuel filter bowl has been removed, fuel stops flowing from the fuel tank. If the fuel tank is almost full, however, the fuel will flow back from the fuel return pipe to the fuel filter. Before checking the above, mark sure the fuel tank is less than half-full.

<Checking fan belt tension >

Be sure to stop engine before checking belt tension.

1.Stop the engine and remove the key.

2.Apply moderate thumb pressure to the belt between pulleys.

3.If the tension is incorrect, loosen the alternator mounting bolts and, using a lever placed between the alternator and the engine block, pull the alternator out until the deflection of the belt falls within acceptable limits.

4.Replace fan belt if it is damaged.

Fan belt |

Factory |

A deflection of between 7 to 9mm |

|

(0.28 to 0.34 in.) when the belt is |

|||

tension |

spec. |

||

pressed in the middle of the span. |

|||

|

|

||

|

|

|

7. DISASSEMBLING AND SERVICING

(2)

*. PART NAME

1) Filter bracket

2) Fuel filter bowl

3) O-ring

4) Filter element

5) O-ring

A) Loosen

B) Tighten

*. PART NAME |

|

1) Adjusting screw |

2) Tension bolt |

A) Check the belt tension |

B) To tighten |

26 |

KUKJE MACHINERY CO., LTD. |

GENERAL

< Adjusting brake pedal free travel >

Stop the engine and chock the wheels before checking the brake pedal.

The difference between the right and left pedal free travel must be less than 4.0 mm (0.16 in.).

1.Release the parking brake.

2.Slightly depress the brake pedals and measure the free travel at the top of the pedal stroke.

3.If the measurement is not within the factory *. PART NAME

specifications, loosen the lock nut and turn the |

1) |

Brake pedal |

2) Turnbuckle |

turnbuckle to adjust the brake rod length. |

3) |

Lock nut |

L : Free travel |

4.Retighten the lock nut securely.

5.Keep the free travel in the right and left brake

pedals equal.

Brake pedal |

Factory spec. |

30 to 40 mm |

|

free travel (L) |

1.18 to 1.57 in. |

||

|

|||

|

|

|

NOTE

1)After checking brake pedal free travel, be sure to engage the parking brake lever fully and check to see that the brake pedals are securely locked.

7. DISASSEMBLING AND SERVICING

27 |

KUKJE MACHINERY CO., LTD. |

GENERAL

< Checking fuel line >

Stop the engine when attempting the check and change prescribed below.

Remember to check the fuel line periodically. The fuel line is subject to wear and aging, fuel may leak out onto the running engine, causing a fire.

1.Check to see that all line and hose clamps are tight and not damaged.

2.If hoses and clamps are found worn or damaged, replace or repair them at once.

3.The fuel line is made of rubber and ages

regardless of period of service. Replace the fuel |

|

|

pipe together with the clamp every two years |

*. PART NAME |

|

and securely tighten. |

1) Fuel hoses |

2) Hose clamps |

4.However if the fuel pipe and clamp are found damaged or deteriorated earlier than two years, then change or repair.

5.After the fuel line and clamp have been changed, bleed the fuel system.

Important

¾When the fuel line is disconnected for change, close both ends of the fuel line with a piece of clean cloth of paper to prevent dust and dirt from entering. Entrance of dust and dirt causes malfunction of the fuel injection pump. In addition, particular care must be taken not to admit dust and dirt into the fuel pump.

7. DISASSEMBLING AND SERVICING

<5> CHECK POINTS OF EVERY 200 HOURS

28 |

KUKJE MACHINERY CO., LTD. |

GENERAL

<Replacing engine oil filter cartridge >

-. Reference the page 15.

<Checking intake air line >

1.Check to see that hoses and hose clamps are tight and not damaged.

2.If hoses and clamps are found worn or damaged, replace or repair them at once.

<Checking radiator hose and hose clamp >

Check to see if radiator hoses are properly fixed |

|

|

every 200 hours of operation or six months, |

*. PART NAME |

|

whichever comes first. |

1) Hose |

2) Hose clamps |

1.If hose clamps are loose or water leaks, tighten bands securely.

2.Replace hoses and tighten hose clamps securely, if the radiator hoses are swollen, hardened or cracked. Replace hoses and hose clamps every 2 years or earlier if checked and found that hoses are swollen, hardened or cracked.

Precaution at overheating

Take the following actions in the event the coolant |

|

|

temperature is near or more than the boiling point, |

|

|

which is called “Overheating”. |

*. PART NAME |

|

1. Stop the machine operation in a safe place and |

1) Hose |

2) Clamp |

keep the engine unloaded idling. |

|

|

2.Don’t stop the engine suddenly, but stop it after about 5 minutes of unloaded idling.

3.Keep yourself well away from the machine for another 10 minutes or while the steam has blown out.

4.Checking that there gets on danger such as burn, get rid of the causes of overheating according to the manual and start again the engine.

7.DISASSEMBLING AND SERVICING

<6> CHECK POINTS OF EVERY 300 HOURS

29 |

KUKJE MACHINERY CO., LTD. |

Loading...

Loading...