Original Instructions

100-412-183 - REV. 13

DCX S

Power Supply

Operating Manual

Branson Ultrasonics Corporation

41 Eagle Road

Danbury, CT 06813-1961 USA

(203) 796-0400

http://www.bransonultrasonics.com

Manual Change Information

At Branson, we strive to maintain our position as the leader in ultrasonics plastics joining,

metal welding, cleaning and related technologies by continually improving our circuits and

components in our equipment. These improvements are incorporated as soon as they are

developed and thoroughly tested.

Information concerning any improvements will be added to the appropriate technical

documentation at its next revision and printing. Therefore, when requesting service

assistance for specific units, note the Revision information found on the cover of this

document, and refer to the printing date which appears at the bottom of this page.

Copyright and Trademark Notice

Copyright © 2017 Branson Ultrasonics Corporation. All rights reserved. Contents of this publication may not be

reproduced in any form without the written permission of Branson Ultrasonics Corporation.

Mylar is a registered trademark of DuPont Teijin Films.

Loctite is a registered trademark of Loctite Corporation.

WD-40 is a registered trademark of WD-40 Company.

Windows 7, Windows Vista, and Windows XP are registered trademarks of Microsoft Corporation

Other trademarks and service marks mentioned herein are held by their respective

owners.

ii 100-412-183 REV. 13

Foreword

Congratulations on your choice of a Branson Ultrasonics Corporation system!

The Branson DCX S Power Supply system is process equipment for the joining of plastic

parts using ultrasonic energy. It is the newest generation of product using this

sophisticated technology for a variety of customer applications. This Operating Manual is

part of the documentation set for this system, and should be kept with the equipment.

Thank you for choosing Branson!

Introduction

This manual is arranged into several structured chapters which will help you find the

information you may need to know to safely handle, install, set up, program, operate,

and/or maintain this product. Please refer to the Table Of Contents and/or the Index of

this manual to find the information you may be looking for. In the event you require

additional assistance or information, please contact our Product Support department (see

1.3 How to Contact Branson for information on how to contact them) or y our local Branson

representative.

100-412-183 REV. 13 iii

iv 100-412-183 REV. 13

Table Of Contents

Chapter 1:Safety and Support

1.1 Safety Requirements and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 How to Contact Branson. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2:Introduction

2.1 Models Covered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.2 Compatibility with other Branson Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.3 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.4 Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.5 Welding Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.6 Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Chapter 3:Delivery and Handling

3.1 Shipping and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.2 Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.3 Unpacking the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.4 Take Inventory of Small Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.5 Returning Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Chapter 4:Technical Specifications

4.1 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.2 Physical Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.3 Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.4 Standard Modules and Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Chapter 5:Installation and Setup

5.1 About Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

5.2 Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

5.3 Installation Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.4 Power Supply Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

5.5 Assembling the Acoustic Stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

5.6 Converter Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

5.7 Testing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

5.8 Still Need Help?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Chapter 6:Converters and Boosters

6.1 Converters and Boosters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Chapter 7:Operation

7.1 Activating Ultrasonic Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

7.2 Setting the Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

7.3 Resetting the Power Supply Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

7.4 Configuring the Power Supply Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

7.5 LCD Bar Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

7.6 Web Page Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.7 Ultrasonics Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

100-412-183 REV. 13 v

Chapter 8:Maintenance

8.1 General Maintenance Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.2 Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.3 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.4 Recommended Spare Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.5 Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8.7 Cold Start Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Appendix A:Timing Diagrams

A.1 Timing Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Appendix B:Signal Diagrams

B.1 Signal Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

vi 100-412-183 REV. 13

List Of Figures

Chapter 1:Safety and Support

Figure 1.1 Safety-related Labels Found on the DCX S Power Supply (Horizontal) . . . . . . . . . . . 3

Figure 1.2 Safety-related Labels found on the DCX S Power Supply (Vertical) . . . . . . . . . . . . . 4

Chapter 2:Introduction

Figure 2.1 The DCX S Power Supply (Horizontal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 2.2 The DCX S Power Supply (Vertical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

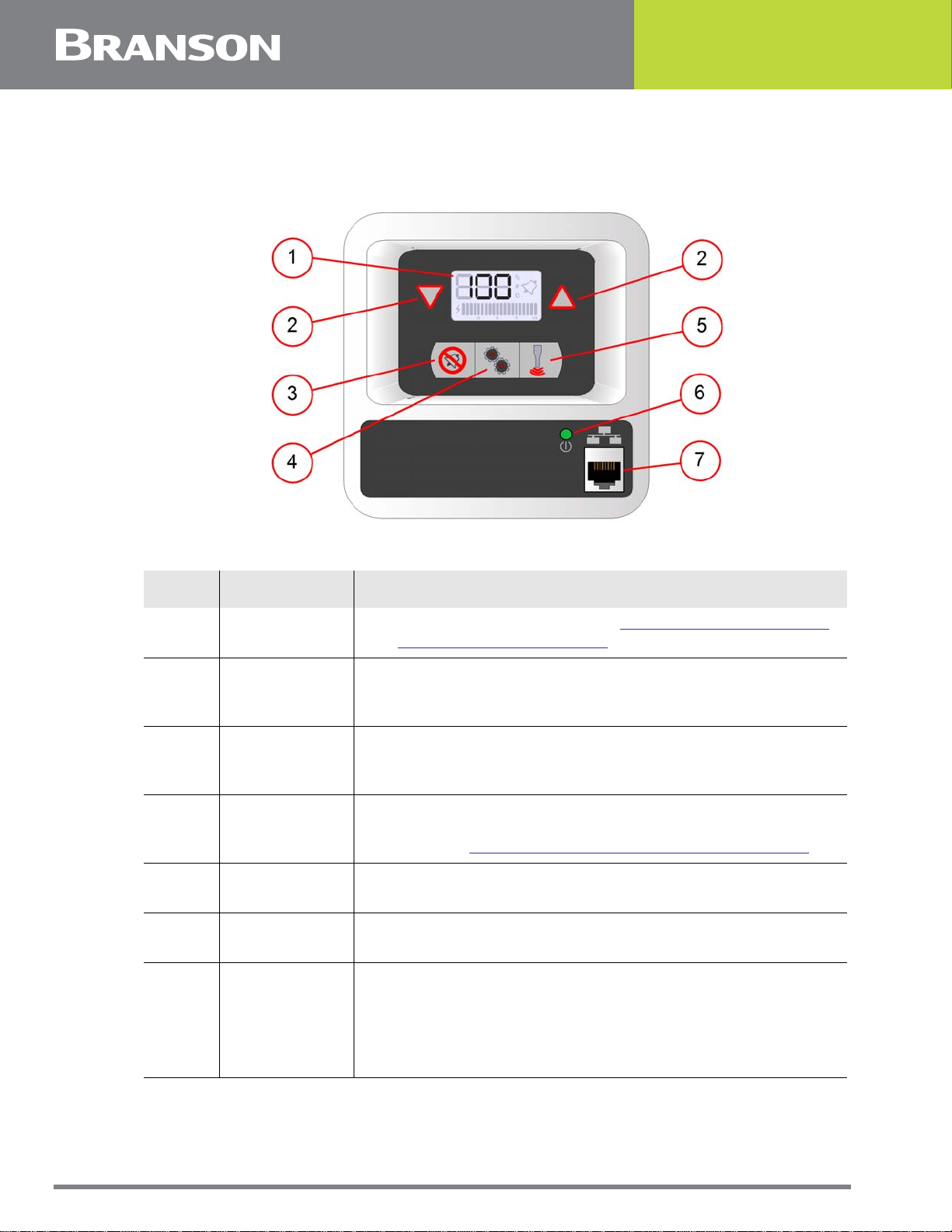

Figure 2.3 DCX S Power Supply Front Panel Controls and Indicators . . . . . . . . . . . . . . . . . . . .20

Figure 2.4 LCD Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 2.5 DCX S Power Supply Back Panel (Horizontal) . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 2.6 DCX S Power Supply Bottom Panel (Vertical) . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Chapter 3:Delivery and Handling

Chapter 4:Technical Specifications

Figure 4.1 Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 4.2 System Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Chapter 5:Installation and Setup

Figure 5.1 DCX S Power Supply Benchtop Dimensional Drawing . . . . . . . . . . . . . . . . . . . . . . .44

Figure 5.2 DCX S Power Supply Vertical Mount Dimensional Drawing (400 W, 750 W and 800 W)

45

Figure 5.3 DCX S Power Supply Vertical Mount Dimensional Drawing (1.25 kW and 1.5 kW) . . .46

Figure 5.4 DCX S Power Supply Vertical Mount Dimensional Drawing (2.5 kW and 4 kW) . . . . .47

Figure 5.5 LCD Viewing Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Figure 5.6 DCX S Power Supply Connections (Horizontal Model). . . . . . . . . . . . . . . . . . . . . . .52

Figure 5.7 DCX S Power Supply Connections (Vertical Model) . . . . . . . . . . . . . . . . . . . . . . . .53

Figure 5.8 User I/O Cable Identification and Wire Color Diagram . . . . . . . . . . . . . . . . . . . . . .55

Figure 5.9 Typical Digital I/O Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Figure 5.10 Typical Analog I/O Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Figure 5.11 RF Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Figure 5.12 Assembling the Acoustic Stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure 5.13 Connecting Tip to Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Chapter 6:Converters and Boosters

Figure 6.1 20 kHz CH-20S Converter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Figure 6.2 20 kHz Booster Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Figure 6.3 20 kHz Converter/Booster/Horn, Typical Dimensions . . . . . . . . . . . . . . . . . . . . . . .81

Figure 6.4 30 kHz Converter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Figure 6.5 30 kHz Booster Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Figure 6.6 30 kHz Converter/Booster/Horn, Typical Dimensions . . . . . . . . . . . . . . . . . . . . . . .84

Figure 6.7 40 kHz, 4TR Converter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Figure 6.8 40 kHz Booster Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Figure 6.9 40 kHz Converter/Booster/Horn, Typical Dimensions . . . . . . . . . . . . . . . . . . . . . . .87

Chapter 7:Operation

Figure 7.1 LCD at Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Figure 7.2 LCD when in External Amplitude Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Figure 7.3 Test Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

100-412-183 REV. 13 vii

Chapter 8:Maintenance

Figure 8.1 Reconditioning Stack Mating Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 8.2 Interconnect Diagram, Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Appendix A:Timing Diagrams

Figure A.1 Weld Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure A.2 Weld Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure A.3 Weld Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Appendix B:Signal Diagrams

Figure B.1 Continuous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

viii 100-412-183 REV. 13

List Of Tables

Chapter 1:Safety and Support

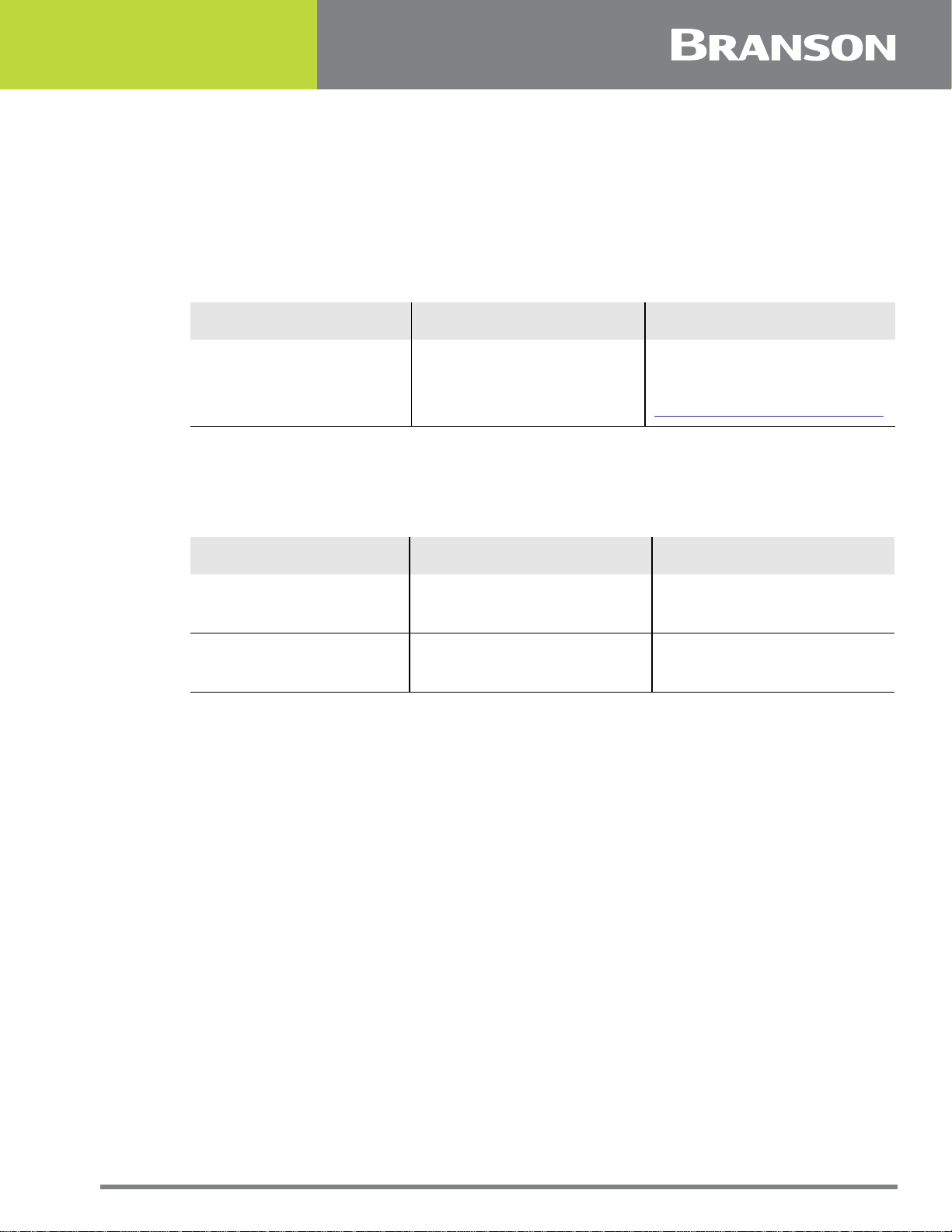

Table 1.1 Authorized Service Center (North America) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 1.2 Authorized Service Centers (South America). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 1.3 Authorized Service Centers (Asia) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 1.4 Authorized Service Centers (Europe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Chapter 2:Introduction

Table 2.1 Models Covered In This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 2.2 Power Supply Compatibility with Branson Converters. . . . . . . . . . . . . . . . . . . . . . .17

Table 2.3 DCX S Power Supply Front Panel Controls and Indicators . . . . . . . . . . . . . . . . . . . .20

Table 2.4 LCD Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Table 2.5 Connections to the DCX S Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Chapter 3:Delivery and Handling

Table 3.1 Shipping Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 3.2 Inspect the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Table 3.3 Unpacking the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Table 3.4 Small Parts included (=x): Power Supply Assemblies. . . . . . . . . . . . . . . . . . . . . . .31

Table 3.5 DCX S Power Supply System Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Chapter 4:Technical Specifications

Table 4.1 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 4.2 Electrical Input Operating Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 4.3 Input Current and Circuit Breaker Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 4.4 Continuous Duty Max. Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 4.5 Dimension and Weight of DCX S Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Chapter 5:Installation and Setup

Table 5.1 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Table 5.2 Input Current and Circuit Breaker Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .48

Table 5.3 DCX S Power Supply Connections (Horizontal Model). . . . . . . . . . . . . . . . . . . . . . .52

Table 5.4 DCX S Power Supply Connections (Vertical Model). . . . . . . . . . . . . . . . . . . . . . . . .53

Table 5.5 User I/O Cable Pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Table 5.6 Available Digital Input Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Table 5.7 Available Digital Output Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Table 5.8 Available Analog Input Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Table 5.9 Available Analog Output Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Table 5.10 Default User I/O Connector Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Table 5.11 RF Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Table 5.12 Input Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Table 5.13 Acoustic Stack Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Table 5.14 Stack Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Table 5.15 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Table 5.16 20 kHz System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Table 5.17 30 kHz System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Table 5.18 40 kHz System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Table 5.19 Tip to Horn Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Table 5.20 Continuous Duty Max. Power & Full Power Duty Cycle . . . . . . . . . . . . . . . . . . . . . .72

Table 5.21 Converter Cooling Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

100-412-183 REV. 13 ix

Chapter 6:Converters and Boosters

Table 6.1 20 kHz CH-20S Converter Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 6.2 20 kHz Booster Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 6.3 20 kHz Converter/Booster/Horn, Typical Dimensions. . . . . . . . . . . . . . . . . . . . . . . 81

Table 6.4 30 kHz Converter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 6.5 30 kHz Booster Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 6.6 30 kHz Converter/Booster/Horn, Typical Dimensions. . . . . . . . . . . . . . . . . . . . . . . 84

Table 6.7 40 kHz, 4TR Converter Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 6.8 40 kHz Booster Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 6.9 40 kHz Converter/Booster/Horn, Typical Dimensions. . . . . . . . . . . . . . . . . . . . . . . 87

Chapter 7:Operation

Table 7.1 Setting the Amplitude Using the Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . 91

Table 7.2 Resetting the DCX S Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 7.3 Steps to configure the Power Supply Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 7.4 Power Supply Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 7.5 Power Bar Graph Interpretation Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 7.6 Frequency Bar-Graph Interpretation - 20 kHz (50 Hz Segment) . . . . . . . . . . . . . . . 99

Table 7.7 Frequency Bar-Graph Interpretation - 30 kHz (76 Hz Segment) . . . . . . . . . . . . . . . 99

Table 7.8 Frequency Bar-Graph Interpretation - 40 kHz (100 Hz/Segment) . . . . . . . . . . . . . . 99

Table 7.9 Frequency Bar Graph Interpretation Examples . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 7.10 Power Supply Ultrasonic Test Procedure (Front Panel). . . . . . . . . . . . . . . . . . . . . 107

Table 7.11 Power Supply Ultrasonic Test Procedure (User I/O). . . . . . . . . . . . . . . . . . . . . . . 107

Table 7.12 Power Supply Ultrasonic Test Procedure (Web Page Interface) . . . . . . . . . . . . . . . 108

Chapter 8:Maintenance

Table 8.1 Stack Reconditioning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 8.2 Reconditioning Stack Mating Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 8.3 Stack Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 8.4 Stack Reassembly for a 20 kHz System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 8.5 Stack Reassembly for a 30 kHz System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 8.6 Stack Reassembly for a 40 kHz System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 8.7 Stud Torque Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 8.8 DCX S Power Supply System Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Table 8.9 Suggested Spares. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Table 8.10 Converters Compatible with the DCX S Power Supply . . . . . . . . . . . . . . . . . . . . . 123

Table 8.11 DCX S Power Supply Compatible Boosters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Table 8.12 Other Items used with the DCX S Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . 126

Table 8.13 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Table 8.14 Troubleshooting Common Electrical Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Table 8.15 Troubleshooting Fan/Power Switch Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Table 8.16 Troubleshooting Ultrasonic Power Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Table 8.17 Troubleshooting Weld Cycle Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Table 8.18 Steps to Perform a Cold Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Appendix A:Timing Diagrams

Appendix B:Signal Diagrams

x 100-412-183 REV. 13

Chapter 1: Safety and Support

1.1 Safety Requirements and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 How to Contact Branson. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

100-412-183 REV. 13 1

1.1 Safety Requirements and Warnings

This chapter contains an explanation of the different Safety Notice symbols and icons

found both in this manual and on the product itself and provides additional safety

information for ultrasonic welding. This chapter also describes how to contact Branson for

assistance.

1.1.1 Symbols Found in this Manual

These symbols used throughout this manual warrant special attention:

DANGER Indicates an immediate danger

If these risks are not avoided, death or severe injury will be the

result.

WARNING Indicates a possible danger

If these risks are not avoided, death or severe injury might result.

CAUTION Indicates a possible danger

If these risks are not avoided, slight or minor injury might result.

NOTICE Indicates a possible damaging situation

If this situation is not avoided, the system or something in its vicinity

might be damaged.

Application types and other important or useful information are

emphasized.

2 100-412-183 REV. 13

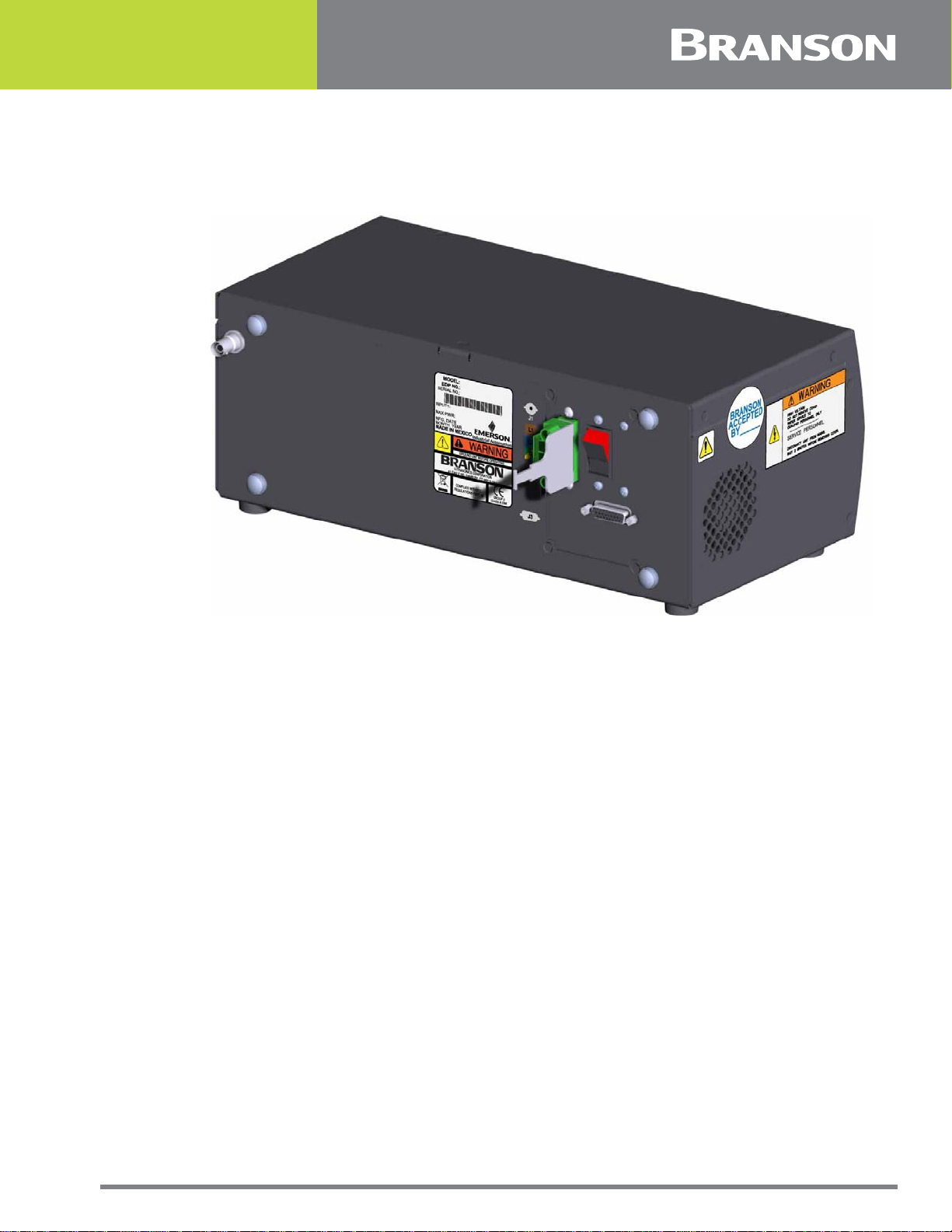

1.1.2 Symbols Found on the Product

The DCX S Power Supply has several safety -related labels on it to indicate the presence of

hazardous voltages inside the unit.

Figure 1.1 Safety-related Labels Found on the DCX S Power Supply (Horizontal)

100-412-183 REV. 13 3

Figure 1.2 Safety-related Labels found on the DCX S Power Supply (Vertical)

4 100-412-183 REV. 13

1.2 General Precautions

Take the following precautions before servicing the power supply:

• Be sure the power switch is in the off position before making any electrical connections

• To prevent the possibility of an electrical shock, always plug the power supply into a grounded

power source

• To prevent the possibility of an electrical shock, ground the power supply by securing an 8 gage

grounded conductor to the ground screw located next to the air outlet

• Power supplies produce high voltage. Before working on the power supply assembly, do the

following:

Turn off the power supply;

Unplug main power; and

Allow at least 2 minutes for capacitors to discharge

• High voltage is present in the power supply. Do not operate with the cover removed

• High line voltages exist in the ultrasonic power supply assembly. Common points are tied to

circuit reference, not chassis ground. Therefore, use only non-grounded, battery-powered

multimeters when testing the power supply assembly. Using other types of test equipment can

present a shock hazard

• Keep hands from under the horn. Down force (pressure) and ultrasonic vibrations can cause

injury

• Do not cycle the welding system if either the RF cable or converter is disconnected

• When using larger horns, avoid situations where fingers could be pinched between the horn and

the fixture

• Ensure power supply installation is performed by qualified personnel and in accordance with local

standards and regulations

CAUTION Loud Noise Hazard

Sound level and frequency of the noise emitted during the ultrasonic

assembly process may depend upon a. type of application, b. size,

shape and composition of the material being assembled, c. shape

and material of the holding fixture, d. welder setup parameters and

e. tool design.

Some parts vibrate at an audible frequency during the process. Some

or all of these factors may result in an uncomfortable noise being

emitted during the process.

In such cases operators may need to be provided with personal

protective equipment. See 29 CFR (Code of Federal Regulations)

1910.95 Occupational Noise Exposure.

100-412-183 REV. 13 5

1.2.1 Intended Use of the System

The DCX S Power Supply and components are designed to be used as part of an ultrasonic

welding system. These are designed for a wide variety of welding or processing

applications.

1.2.2 Emissions

When being processed, certain plastic materials can emit toxic fumes, gases or other

emissions that can be hazardous to the operator’s health. Where such materials are

processed, proper ventilation of the workstation is required. Check your materials

suppliers for recommended protection when processing their materials.

CAUTION Corrosive Material Hazard

Processing of many materials, such as PVC, can be hazardous to an

operator’s health and could cause corrosion/damage to the

equipment. Use proper ventilation and take protective measures.

1.2.3 Setting up the Workplace

Measures for setting up a workplace for safe operation of the ultrasonic welder are

outlined in Chapter 5: Installation and Setup

1.2.4 Regulatory Compliance

This product meets electrical safety requirements and EMC (Electromagnetic Compliance)

requirements for North America and the European Union.

6 100-412-183 REV. 13

1.3 How to Contact Branson

Branson is here to help you. We appreciate your business and are interested in helping

you successfully use our products. To contact Branson for help, use the following

telephone numbers, or contact the office nearest you.

1.3.1 Authorized Service Center (North America)

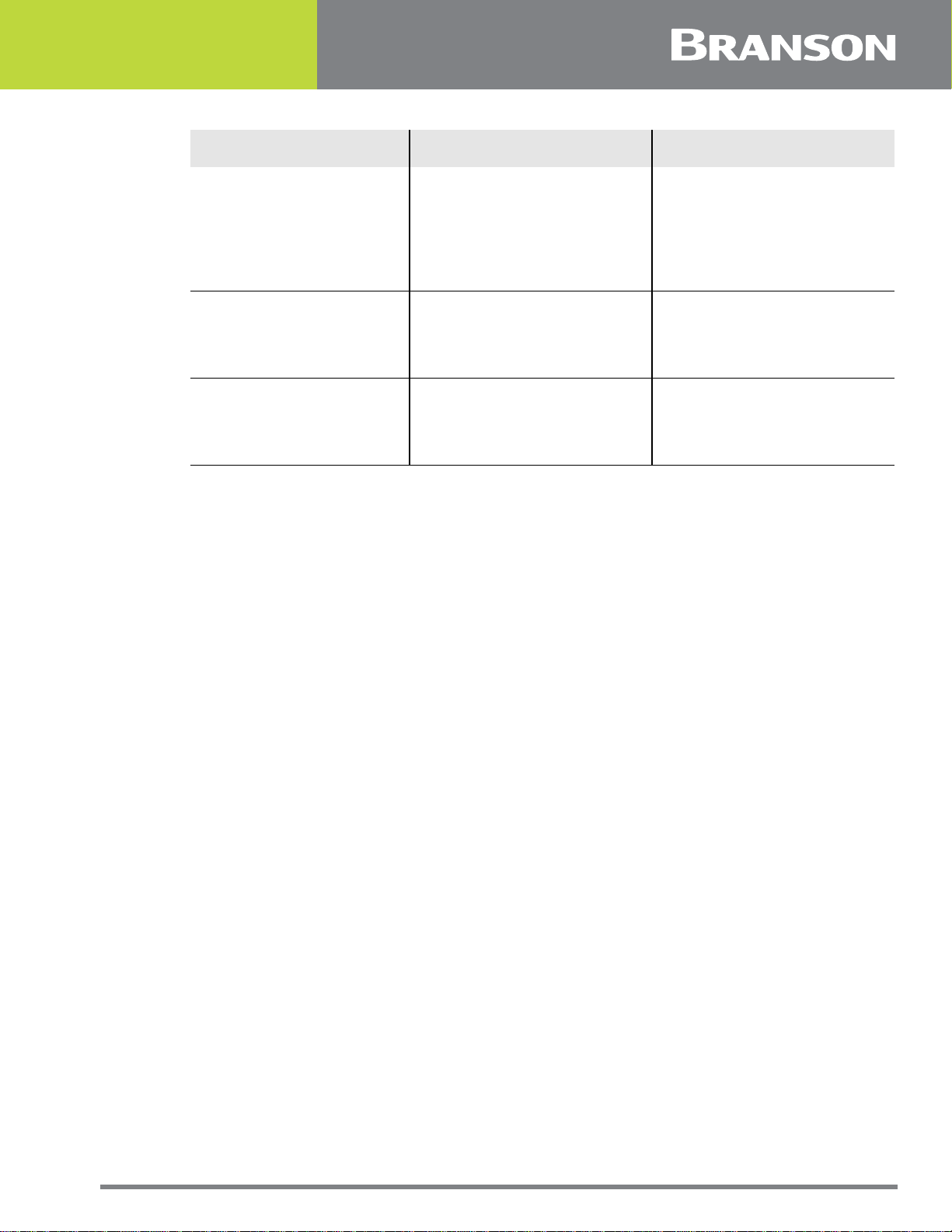

Table 1.1 Authorized Service Center (North America)

Name Address Tel/Fax Number

Branson Ultrasonics Corp.

Global Headquarters

United States

41 Eagle Road, Commerce

Park,

Danbury CT 06813-1961

1.3.2 Authorized Service Centers (South America)

Table 1.2 Authorized Service Centers (South America)

Name Address Tel/Fax Number

Intersonic

Argentina

Branson do Brasil

Brasil

Av. Cramer 2361 1C

Buenos Aires 1428

Rua Goiatuba, 81

06465-300 – Barueri / SP

Tel: 1-203-796-0400

Fax: 1-203-796-0593

info@bransonultrasonics.com

Tel: 011-54-11-4781-2327

Fax: 011-54-11-4782-2412

Tel: 55-11-4208-1652

100-412-183 REV. 13 7

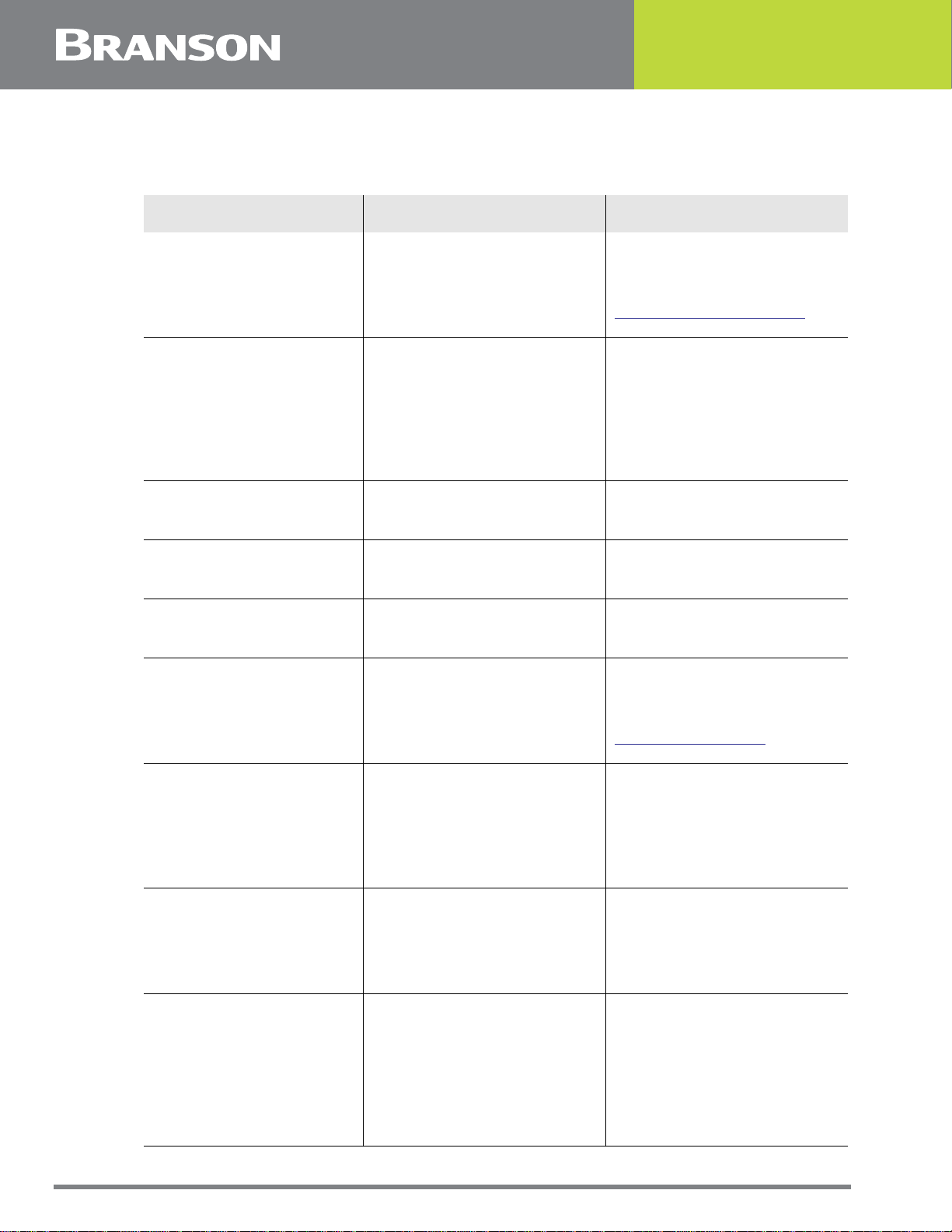

1.3.3 Authorized Service Centers (Asia)

Table 1.3 Authorized Service Centers (Asia)

Name Address Tel/Fax Number

Branson Ultrasonics

(Shanghai) Co. Ltd. –

China Headquarters

China

Branson Ultrasonics Co.

Ltd. Beijing Office

Branson Ultrasonics Co.

Ltd. Tianjin Office

Branson Ultrasonics Co.

Ltd. Dongguan Office

Branson Ultrasonics Co.

Ltd. Suzhou Office

Branson Ultrasonics Asia

Pacific Co. Ltd.

Hong Kong Office

528 Rong Le Dong Road,

Song Jiang

Song Jiang Industry Zone

CN-Shanghai, 201613 PRC

Room 216, Flat B, 12 Hong

Da North Road,

Chuangxin Technological

Mansion Beijing Department

Area.

Beijing 100176 PRC

Flat A, 5/F Pioneer Building

213 Wai Yip Street, Kwung

Tong

Kowloon, Hong Kong

Tel: 86-21-3781-0588

Fax: 86-21-5774-5100

c.service@emerson.com

Tel: 86-10-6787-7806

Fax: 86-10-6787-3378

Tel: 86-22-2732-5233

Fax: 86-22-2732-3581

Tel: 86-769-8541-0736

Fax: 86-769-8541-0735

Tel: 86-512-6295-3652

Fax: 86-512-6295-3651

Tel: 852-2790-3393

Fax: 852-2341-2716

info@emerson.com

Branson Ultrasonics

Div. of Emerson Electric

Co. P. Ltd. “Ajanta

House”

India

Branson Ultrasonics

Japan Headquarters

Division of Emerson

Japan Ltd.

Branson Korea Co., Ltd.

Korea

8 100-412-183 REV. 13

8/35, Marol Co-Op Industrial

Estate

M.V. Road, Andheri (East)

Mumbai 400 059, India

4-3-14 Okada, Atsugi-Shi

Kanagawa 243-0021

Japan

#803, 8F Dongil Techno

Town

823, Kwan Yang-2dong,

Dong An-gu

An Yang-si, Kyung Ki-do,

431-062 Korea

Tel: 91-22-2850-5570

Fax: 91-22-2850-8681

Tel: 81-46-228-2881

Fax: 81-46-288-8892

Tel: 82-1577-0631

Fax: 82-31-422-9572

Table 1.3 Authorized Service Centers (Asia)

Name Address Tel/Fax Number

No. 20, Jalan Rajawali 3,

Branson Ultrasonics

Div. of Emerson Elec (M)

Sdn Bhd.

Malaysia

Branson Ultrasonics

Philippines

Branson Ultrasonics

Singapore

Branson Ultraschall

Taiwan

Puchong Jaya Industrial

Park

Batu 8, Jalang Puchong

47170 Puchong, Selangor

Malaysia

Emerson Building

104 Laguna Blvd.

Laguna Technopark Inc.

Sta. Rosa, Laguna, 4026

Philippines

10 Pandan Crescent

#03-06 UE Tech Park LL3

Singapore 128466

Div. of Emerson Electric

(Taiwan) Co. Ltd.

5F-3, No. 1, Wu-Chiuan First

Road

Wu-Ku Ind Zone, Hsin-

Chuang City

Tel: 603-8076-8608

Fax: 603-8076-8302

Tel: 63-49-502-8860

Fax: 63-49-502-8860

Mobile: 63-917-5372072

Tel: 65-6891-7600

Fax: 65-6873-7882

Tel: 886-2-2298-0828

Fax: 886-2-2298-9985

Emerson Limited

Thailand

Taipei Hsien 24892, Taiwan

662/39-40 Rama 3 Road

Tel: 66-2-293-01217

Bangpongpang, Yannawa

Fax: 66-2-293-0129

Bangkok 10120, Thailand

100-412-183 REV. 13 9

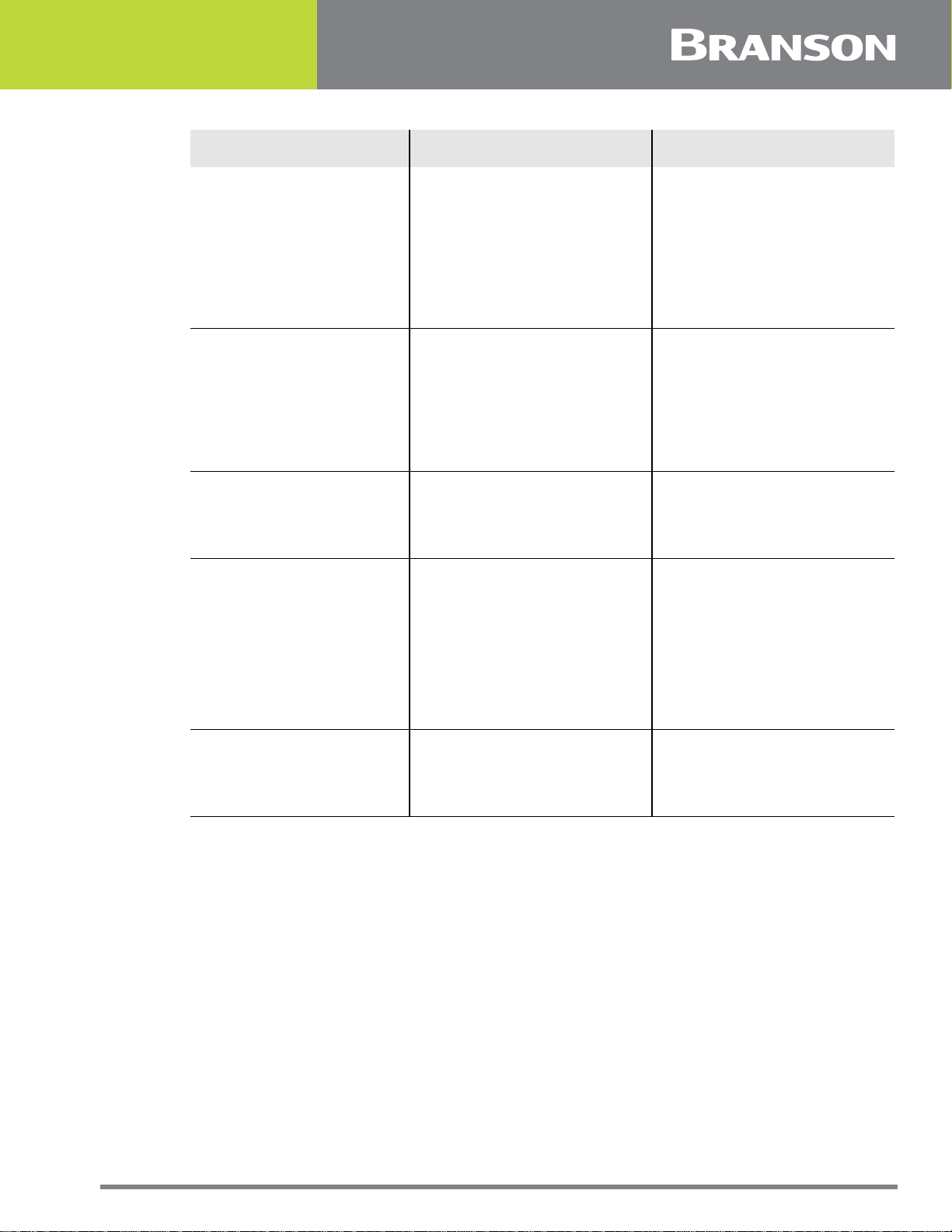

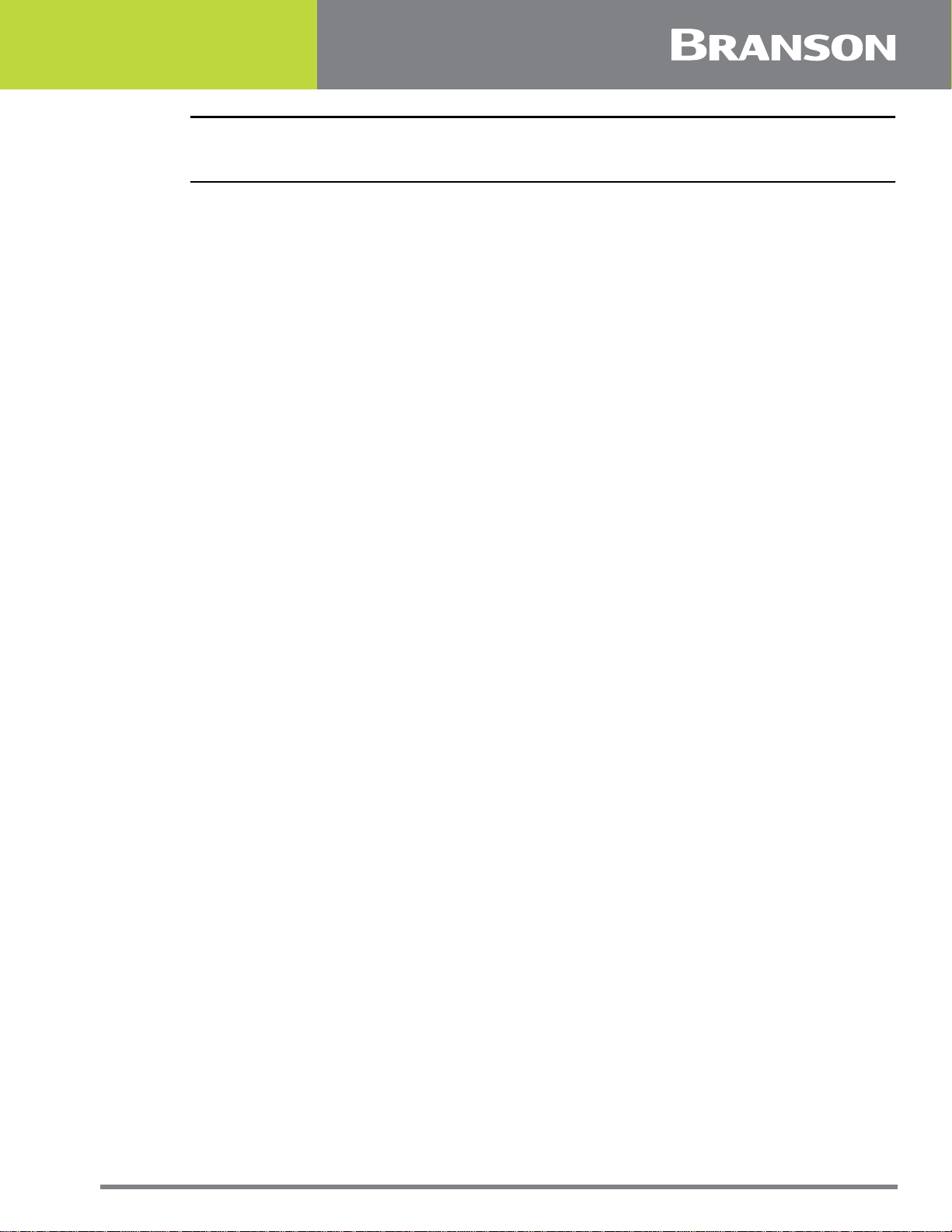

1.3.4 Authorized Service Centers (Europe)

Table 1.4 Authorized Service Centers (Europe)

Name Address Tel/Fax Number

Branson Ultraschall

Czech Republic

Branson Ultrasons

France

Branson Ultraschall

European Headquarters

Germany

Branson Ultrasuoni, S.r.l.

Italy

Branson Ultrasonics B.V.

Netherlands

Branson Ultrasonidos

S.A.E.

Portugal

1 Rue des Pyrenees Silic 404

94573 Rungis Cedex

France

Niederlassung der EMERSON

Technologies GmbH & Co.

OHG

Waldstraße 53-55

63128 Dietzenbach,

Germany

Via Dei Lavoratori, 25

20092 Cinisello Balsamo

Milano, Italy

P.O. Box 9, 3760 Soest

The Netherlands

Rua General Orlando

Barbosa 74, RC-NP

4490-640 Póvoa de Varzim

Portugal

Tel: 420-374-625-620

Fax: 420-374-625-617

Tel: 33-1-4180-2550

Fax: 33-1-4687-8729

Tel: 49 (0)6074/497-0

Tel: 49 (0)6074/497-784

Fax: 49 (0)6074/497-199

info@branson.de

Tel: 39-02-660-8171

Fax: 39-02-660-10480

Tel: 31-35-60-98101

Tel: 351-936-059-080

Mobil: 351-252-101-754

Emerson a.s., division

Branson

Slovakia

Branson Ultrasonidos

S.A.E.

Spain

10 100-412-183 REV. 13

Piestandska 1202/44

91528 Nove Mesto Nad

Vahom

Slovak Republic

Edificio Emerson

C/Can Pi, 15 1ª Planta

(Antigua Carretera del Prat)

Polígono Industrial Gran Vía

Sur

08908 HOSPITALET DE

LLOBREGAT (BARCELONA)

Spain

Tel: 421-32-7700-501

Fax: 421-32-7700-470

Tel: 34-93-586-0500

Fax: 34-93-588-2258

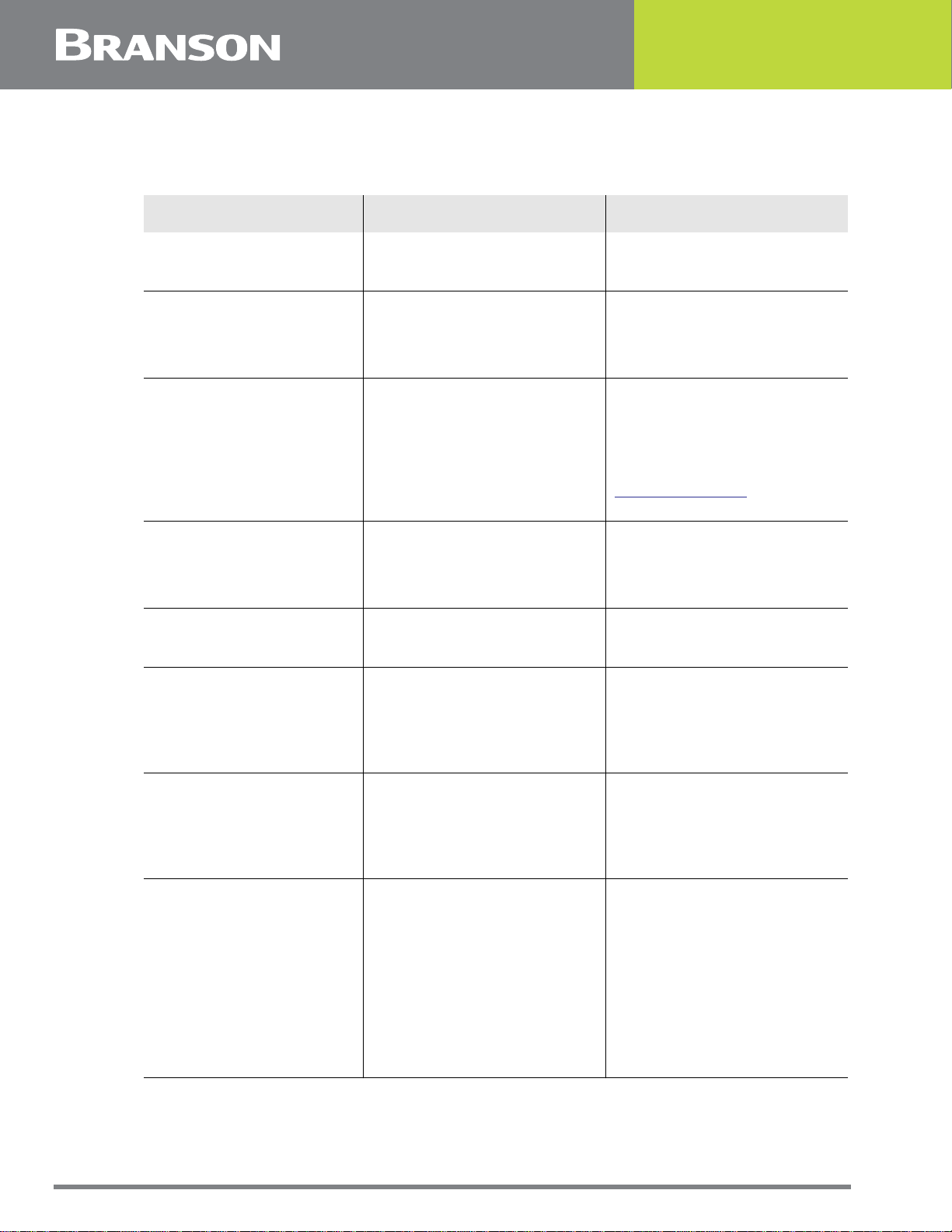

Table 1.4 Authorized Service Centers (Europe)

Name Address Tel/Fax Number

Sonifers: Case Postale 1031

Branson Ultrasonics S.A.

Bransonics: Chemin du

Faubourg-de-Cruseilles 9

Switzerland

CH 1227, Carouge,

Switzerland

Tel: 41-22-304-8340

Tel: 41-58-611-1222

Fax: 41-22-304-8359

Branson Ultrasonics

United Kingdom

Branson Ultraschall

Rusia

158 Edinburgh Avenue

Tel: 44-1753-756675

Slough, Berkshire

Fax: 44-1753-551270

England SL1 4UE

Torfyanaya road, 7F

Tel: 7-812-449-35-24

197374, Saint-Petersburg

Mobile: 7-962-693-77-12

Russia

100-412-183 REV. 13 11

12 100-412-183 REV. 13

Chapter 2: Introduction

2.1 Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Compatibility with other Branson Products . . . . . . . . . . . . . . . . . . . . 17

2.3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 Welding Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6 Glossary of Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

100-412-183 REV. 13 13

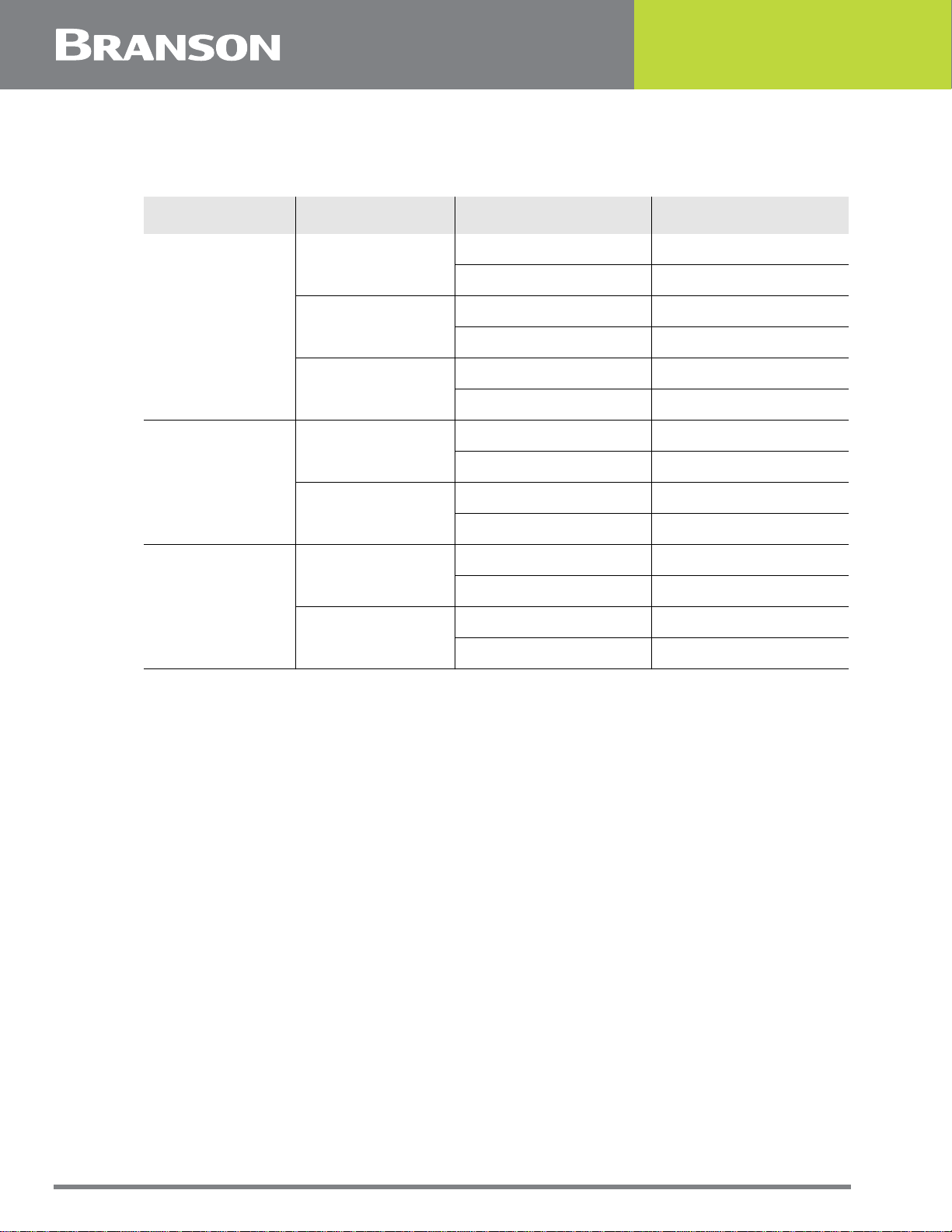

2.1 Models Covered

This manual covers all models of the DCX S Power Supply.

Table 2.1 Models Covered In This Manual

Frequency Power Model EDP

1250 W

20 kHz

30 kHz

40 kHz

2500 W

4000 W

750 W

1500 W

400 W

800 W

Horizontal 101-132-1792

Vertical 101-132-1801

Horizontal 101-132-1793

Vertical 101-132-1802

Horizontal 101-132-1795

Vertical 101-132-1803

Horizontal 101-132-1796

Vertical 101-132-1804

Horizontal 101-132-1797

Vertical 101-132-1805

Horizontal 101-132-1791

Vertical 101-132-1800

Horizontal 101-132-1798

Vertical 101-132-1806

14 100-412-183 REV. 13

2.1.1 Overview of these Models

Figure 2.1 The DCX S Power Supply (Horizontal)

Figure 2.2 The DCX S Power Supply (Vertical)

100-412-183 REV. 13 15

The DCX S Power Supply generates ultrasonic energy through an ultrasonic converter for

welding plastics. Several models are available, depending on the desired frequency (for

example, 20 kHz), the desired power range (for example, 2.5 kW), and the intended

mounting arrangement (horizontal or vertical). The power supply also contains a

microprocessor-based controller module that provides for control and monitoring of

welding operations.

The power supply provides the following features:

• End of Weld Store: Allows the power supply to track and store the frequency of the last weld

• Timed Seek: Tracks and starts the stack on the correct frequency. It does this by running the

horn at a low-level amplitude (10 %) to find and lock on to the stack operating frequency. Seeks

are timed from the moment sonics was last activated

• Line Regulation: Maintains converter amplitude by regulating for variances in the line voltages

• Load Regulation: Maintains converter amplitude over the full range of rated power

• System Protection: Protects the power supply by providing six levels of protection

Voltage

Current

Phase

Temperature

Power

Frequency

• Web Page Interface: Provides access, via Ethernet connection, to power supply information,

diagnostics, and configuration web pages

• Frequency Offset: Provides for applying an external frequency offset to the operating frequency

• Amplitude Control: Provides complete control of amplitude throughout the weld cycle:

programmable starting ramp, and digital setting of weld amplitude.

2.1.2 Power Supply Manual Set

The following documentation is available in electronic format for the DCX S Power Supply:

• DCX S Power Supply Instruction Manual (100-412-183)

• DCX S Power Supply Quick Start Guide (100-412-185)

• DCX S Power Supply Web Page Interface Instruction Manual (100-412-187)

16 100-412-183 REV. 13

2.2 Compatibility with other Branson Products

Table 2.2 Power Supply Compatibility with Branson Converters

DCX S Model Converter

CR-20

CR-20S

20 kHz / 1250 W

20 kHz / 2500 W

20 kHz / 4000 W

30 kHz / 750 W

30 kHz / 1500 W

40 kHz / 400 W

40 kHz / 800 W

NOTICE

CR-20C

CH-20S

CH-20C

CS-20S

CS-20C

CR-30S

CR-30C

CH-30S

CH-30C

CS-30S

CS-30C

CR-40S

CR-40C

4TP

4TR

Special adaptor cables are available to connect to MS-style

converters (CR20 and 4TR). See Table 8.8 DCX S Power Supply

System Cables.

100-412-183 REV. 13 17

2.3 Features

2.3.1 The Welding System

The welding system consists of a DCX S Power Supply and a converter-booster-horn stack.

The system can perform ultrasonic welding, inserting, staking, spot welding, swaging,

degating, and continuous ultrasonic operations. It is designed for automated,

semi-automated and/or manual production operations.

2.3.2 The Power Supply

The DCX S Power Supply consists of an ultrasonic power supply assembly with a system

controller and user interfaces. The ultrasonic power supply assembly converts

conventional 50/60 Hz line current to 20 kHz, 30 kHz or 40 kHz electrical energy. The

system controller controls the welding system.

Listed below are the control features of the DCX S Power Supply ultrasonic welding system.

• Autotuning: Branson power supply tuning ensures that the system is running at peak efficiency

• Digital Amplitude Setting: This feature allows you to set the exact amplitude necessary for

your application, allowing increased range and setting repeatability over analog systems

• Frequency Offset: This process feature allows a user to set a frequency value, for certain

specific applications, where the force imparted on the fixture or anvil causes a frequency shift in

the stack’s operation. You should only use this feature when advised to do so by Branson

• Horn Signature: Using the DCX S Power Supply Web Page Interface, you may scan your

ultrasonic stack to view its operating frequency on your computer, using digital readouts and bar

graphs to give you the best picture of the stack’s operation

• LCD (Liquid Crystal Display): Provides a clear visual interface to monitor and configure the

system

• Membrane Keys: For high reliability and immunity from factory dust and oils

• Login ID Numbers: Allows for keeping track of user access to the DCX S Power Supply Web

Page Interface

• Ramp Starting: The starting of the DCX S Power Supply and horn is done at a rate that helps

reduce electrical and mechanical stress on the system. The horn start rate may be adjusted for

some tough-to-start applications

• Seek: Ensures operation at resonance; minimizes tuning errors; and operates the stack at low

amplitude (approximately 10%), then provides a means of sensing and storing the resonant

operating frequency value

• Start-up Diagnostics: At start-up, the controls test the major internal components

• Timed Seek: When enabled, will do a Seek once every minute to update horn resonant

frequency to memory. This is especially useful when the welding process affects the actual

temperature of the horn, causing a resonant frequency shift

• True Wattmeter: The controls on the power supply include a true wattmeter for accurate

measurement of power and energy

• Web Page Interface: Provides access, via Ethernet connection, to power supply information,

diagnostics, and configuration web pages

18 100-412-183 REV. 13

2.3.3 The Actuator

The DCX S Power Supply does not provide actuator control functions, and does not interface

with actuator signals.

2.3.4 Converter/Booster/Horn Assembly

The Converter

The ultrasonic electrical energy from the power supply is applied to the converter

(sometimes called the transducer). This transforms the high frequency electrical

oscillations into mechanical vibrations at the same frequency as the electrical oscillations.

The heart of the converter is piezoelectric ceramic elements. When subjected to an

alternating voltage, these elements alternately expand and contract, resulting in better

than 90% conversion of electrical to mechanical energy.

The Booster

Success in ultrasonic assembly depends on the right amplitude of movement at the horn

face. Amplitude is a function of horn shape, which is largely determined by the size and

form of the parts to be assembled. The booster can be used as a mechanical transformer

to increase or decrease the amplitude of vibrations applied to the parts through the horn.

The booster is a resonant half-wave section of aluminum or titanium. It is mounted

between the converter and the horn, as part of the ultrasonic stack. It also provides a

clamping point for rigid stack mounting.

Boosters are designed to resonate at the same frequency as the converter with which they

are used. Boosters are usually mounted at a nodal (minimum vibration) point of axial

motion. This minimizes the loss of energy and prevents vibration from being transmitted

to the stack supporting structure.

The Horn

The horn is selected or designed for a specific application. Each horn is tuned typically as

a half-wave section that applies the necessary force and vibr ation uniformly to the parts to

be assembled. It transfers ultrasonic vibrations from the converter to the workpiece. The

horn is mounted to the booster as part of the ultrasonic stack.

Depending on their profile, horns are referred to as stepped, conical, exponential, bar, or

catenoidal. The shape of the horn determines the amplitude at the face of the horn.

Depending on the application, horns can be made from titanium alloys, aluminum, or

steel. Titanium alloys are the best materials for horn fabrication due to their high level of

strength and low loss. Aluminum horns are usually chrome- or nickel-plated or hardcoated to reduce wear. Steel horns are for low amplitude requiring hardness, such as

ultrasonic insertion applications.

100-412-183 REV. 13 19

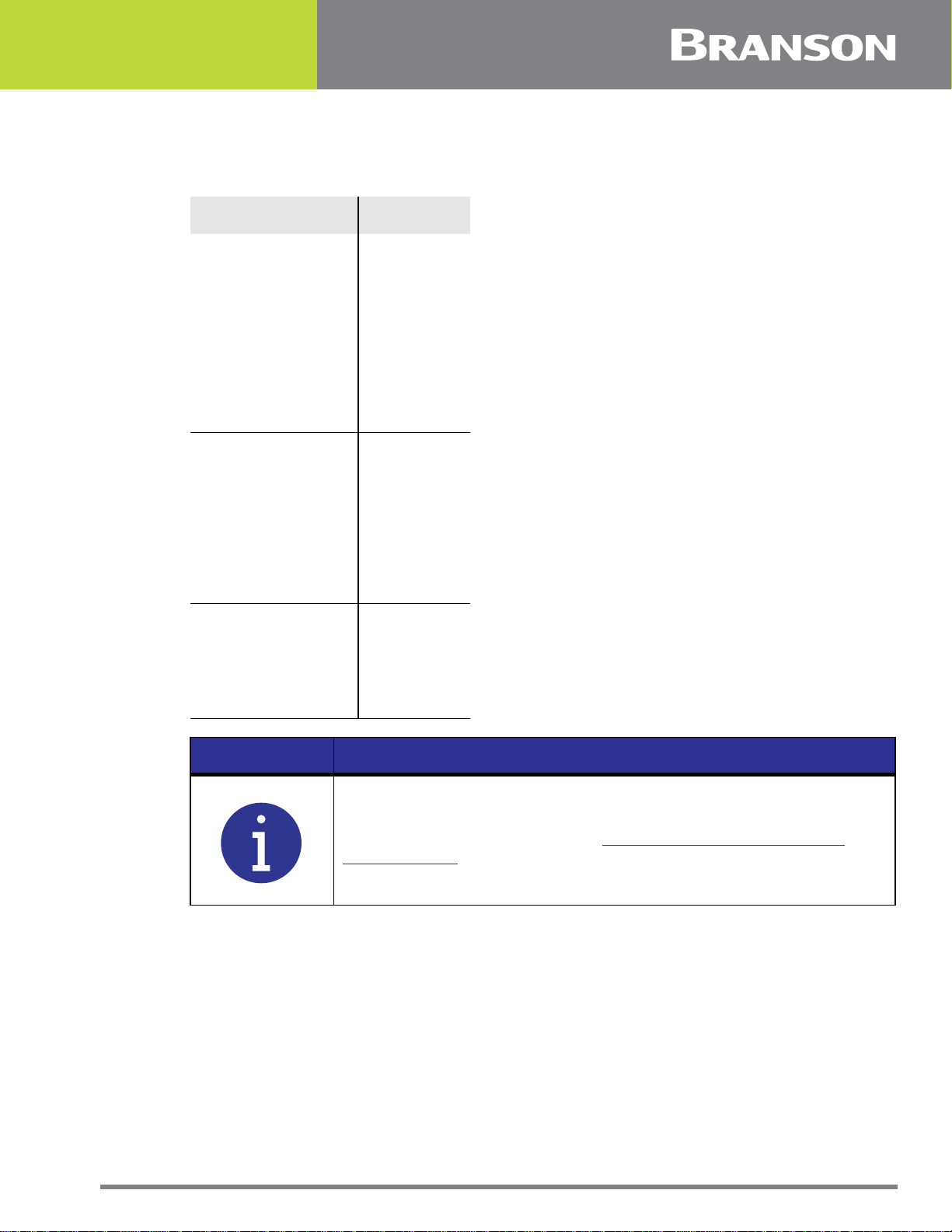

2.4 Controls and Indicators

2.4.1 DCX S Power Supply Front Panel

Figure 2.3 DCX S Power Supply Front Panel Controls and Indicators

Table 2.3 DCX S Power Supply Front Panel Controls and Indicators

Item Name Function

1LCD

2

3

4

5

6

7

Up/Down

Arrow Keys

Alarm Reset

Key

Configuration

Key

Ultrasonic T est

Key

Power-On

indicator

Ethernet

Service Port

For detailed information refer to Figure 2.4 LCD Description

and Figure 2.4 LCD Description.

Use to adjust the amplitude of ultrasonic vibrations (10% to

100%). Also used to select registers and edit register

values.

Use the Reset key to reset alarms. When changing system

registers, use the Reset key to set a register back to its

default value.

Use the Configuration key to change system registers. For

information on using the Configuration key to set system

registers see 7.4 Configuring the Power Supply Registers.

Use the Test key to turn on Sonics.

Lights when the power supply is connected to main power

and the power switch is on.

Use the Ethernet Service port to connect to the DCX S Power

Supply Web Page Interface.

For detailed information on using the web page interface

refer to the DCX S Power Supply Web Page Interface

Instruction Manual (100-412-187).

20 100-412-183 REV. 13

Loading...

Loading...