Page 1

Technical Data Sheet

BRADY B-7569 VINYL FILM WITH PERMANENT ADHESIVE

TDS No. B-7569

Effective Date: 10/20/2011

Description:

Brady B-7569 is a thermal transfer printable flexible vinyl film coated with a permanent pressure sensitive acrylic adhesive.

B-7569 is designed to be used with the MINIMARK

37 printers (per regional availability) as well as for pre-printed labeling and floor marking.

Details:

Use:

B-7569 is used for Pipe Markers, Arrow Tape, Warehouse Marking, Floor Marking, Warning Panels, Safety Signs and

Hazardous Substance Identification.

Special Properties:

Permanent acrylic adhesive

Substrate Type:

Vinyl film

Standard Material Colors:

White, red, yellow, green, blue, orange and black

Recommended ribbons

MINIMARK

Standard performance black and white (R-7968), red, green and blue (R-7969)

HIgh performance black (R-6000), white, red, green and blue (R-4400)

Globalmark®, Powermark®:

Standard Ribbons

BBP® 31:

R-10000

Thickness (PSTC-33):

Total: 0.105 mm (0.004 in.)

Adhesive Properties:

Adhesion to Stainless Steel (PSTC-1)

Ultimate Dwell (72 Hrs.) (Avg.) -- 130 N/100mm (120 oz/in)

Adhesion to Powder Coated Metal (PSTC-101)

Ultimate Dwell (72 Hrs.) -- 50 N/100mm (45 oz/in)

Adhesion to Polypropylene (PSTC-101)

Ultimate Dwell (72 Hrs.) (Avg.) -- 60 N/100mm (55 oz/in)

Adhesion to Textured ABS (PSTC-101)

Ultimate Dwell (72 Hrs.) (Avg.) -- 25 N/100mm (25 oz/in)

Tack (ASTM D 2979) (Avg.) -- 700 g (7 N)

Abrasion Resistance (Method 5306 of U.S. Federal Test Method Std. No. 191A):

CS-10 wheels, 250 g wts.

After 100 cycles the legend printed with R-7968 has a moderate fading

Print legible up to 300 cycles with R-10000 ribbon

Print legible up to 500 cycles with R-4400 ribbon

Print legible up to 1000 cycles with R-6000 ribbon

TM

:

TM

, Globalmark®, Powermark® and BBP® 31, BBP® 33, BBP® 35, BBP®

Page 2

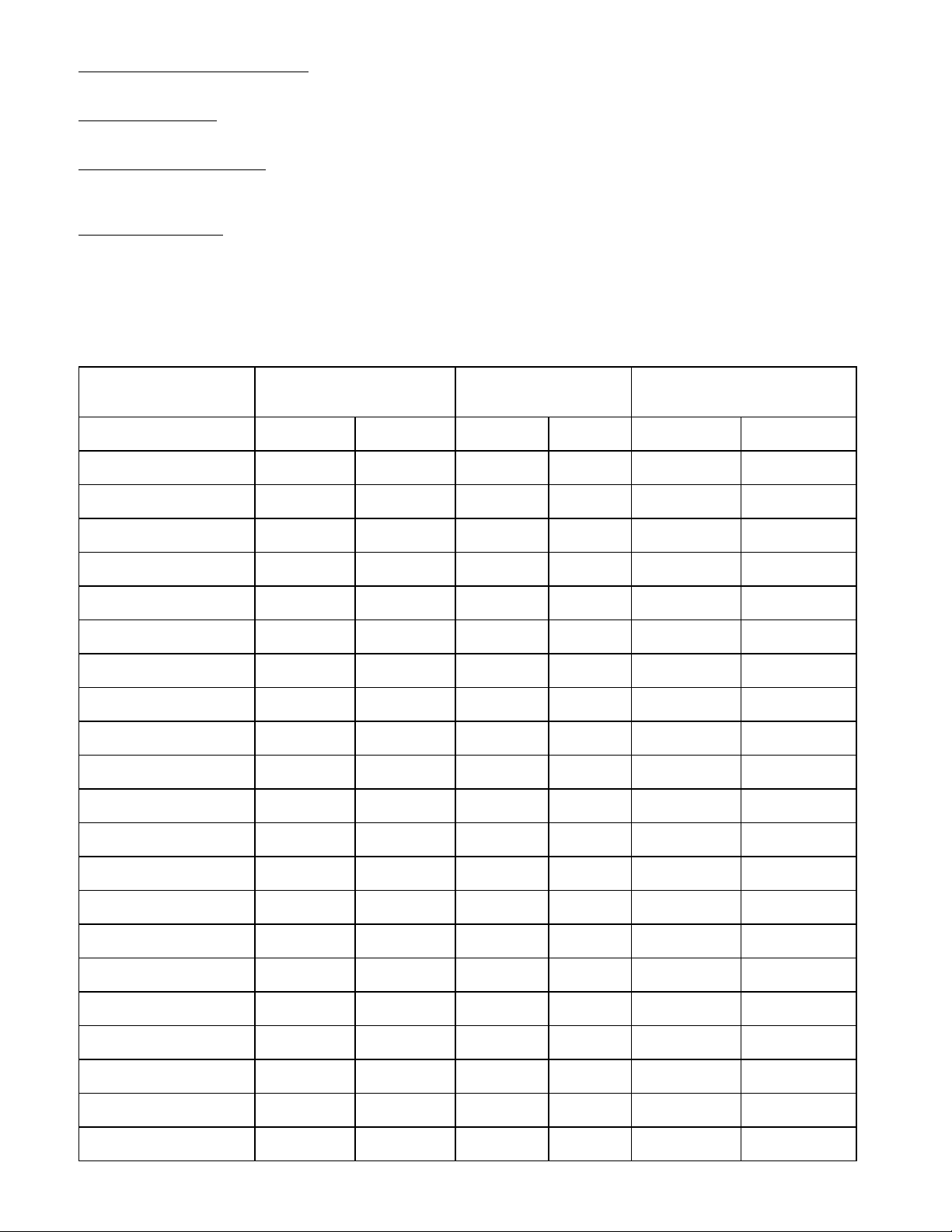

Minimum Application Temperature

Reagent

R-10000 Ribbons

Standard Performance

Ribbons

High Performance Ribbons

Dip Test

Rub Test

Dip Test

Rub Test

Dip Test

Rub Test

Acids

30% Sulfuric Acid

NE

NE

NE

NE

NE

NE

10% Sulfuric Acid

NE

NE

NE

NE

NE

NE

30% Hydrochloric Acid

NE

NE

NE

NE

NE

NE

10% Hydrochloric Acid

NE

NE

NE

NE

NE

NE

Glacial Acetic Acid

F F F F F

F

5% Acetic Acid

NE

NE

NE

NE

NE

NE

Bases

50% NaOH

NE

NE

NE F NE

NE

10% NaOH

NE

NE

NE

NE

NE

NE

10% Ammonia

NE

NE

NE

NE

NE

NE

5% Sodium Hypochlorite

NE

NE

NE

NE

NE

NE

10% Sodium Chloride

NE

NE

NE

NE

NE

NE

Cleaners and Solvents

MEK F F F F F F

Acetone F F F F F F

Toluene F F F F F F

Methanol

NE F NE F NE

NE

Isopropyl Alcohol

NE

NE

NE F NE

NE

Heptane

NE

NE

NE

NE

NE

NE

Mineral Spirits

F F NE

NE

NE

NE

10°C (50°F)

Service Temperature

-20°C to 75°C (-4°F to 167°F)

Average Outdoor Durability:

Up to 3 years (Average expected outdoor life of product will depend on user definition of failure, climatic conditions,

mounting techniques, and material color.)

Chemical Resistance:

Samples were printed with the standard performance ribbons R-7968/R-7969 and the high performance ribbons

R-6000/R-4400 using the MINIMARK

TM

thermal transfer printer. Additional samples were printed with the R-10000 ribbon

using the BBP® 31 thermal transfer printer. Printed samples were laminated to aluminum and allowed to dwell 24 hours prior

to testing. Testing conducted at room temperature. Testing consisted of 5 cycles of 10 minute immersions in the specified

test fluid followed by a 30 minute recovery period. After final immersion the samples were rubbed 10 times with a cotton

swab saturated with test fluid.

Page 3

Turpentine

F F NE F NE

F

Alconox®

NE

NE

NE

NE

NE

NE

DI Water

NE

NE

NE

NE

NE

NE

Ethanol

Not Tested

Not Tested

NE

NE

NE

NE

Formula 409®

Not Tested

Not Tested

NE

NE

NE

NE

Bioact® EC-7R

TM

Not Tested

Not Tested

F F F

F

Northwoods

TM

Buzz Saw

Not Tested

Not Tested

NE F NE

NE

Fuels, Oils &

Lubricants

Diesel Fuel

NE

NE

NE

NE

NE

NE

Gasoline F F F F F F

ASTM #3 Oil

NE

NE

NE

NE

NE

NE

SAE 20 Oil

NE

NE

NE

NE

NE

NE

NE = No Effect

F = Failed (affected sample)

Shelf Life and Fitness for Use: Product testing, customer feedback, and history of similar products, support a customer

performance expectation of one year from the date of receipt for this product as long as this product is stored in its original

packaging in an environment below 80°F (27°C) and 60% RH. However, it remains the responsibility of the user to assess the

risk of using such product. We encourage customers to develop functional testing protocols that will qualify a product's fitness

for use, in their actual applications.

Trademarks:

ASTM: American Society for Testing and Materials (U.S.A)

Alconox® is a registered trademark of Alconox Co.

BBP® 31 is a registered trademark of Brady Worldwide, Inc.

BIOACT® is a registered trademark of Brady Worldwide, Inc.

TM

EC-7R

is a trademark of Petroferm Inc.

Formula 409® is a registered trademark of the Chlorox Company

Globalmark® is a registered trademark of Brady Worldwide, Inc.

MINIMARK

Northwoods

TM

is trademark of Brady Worldwide, Inc.

TM

is a trademark of the Superior Chemical Corporation

PSTC: Pressure Sensitive Tape Council (U.S.A.)

Powermark® is a registered trademark of Brady Worldwide, Inc.

SAE: Society of Automotive Engineers (U.S.A.)

Note: All values shown are averages and should not be used for specification purposes.

Test data and test results contained in this document are for general information only and shall not be relied upon by Brady

customers for designs and specifications, or be relied on as meeting specified performance criteria. Customers desiring to

develop specifications or performance criteria for specific product applications should contact Brady for further information.

Product compliance information is based upon information provided by suppliers of the raw materials used by Brady to

manufacture this product or based on results of testing using recognized analytical methods performed by a third party,

independent laboratory. As such, Brady makes no independent representation or warranties, express or implied, and assumes

no liability in connection with the use of this information.

Page 4

Loading...

Loading...