Bradley Corporation S59-2005 Installation Manual

ASSE 1016 & UPC Certified

For use with shower heads rated

at 9.5 L/min (2.5 gpm) or higher.

Inlet Connections: 1/2" NPT

Outlet Connections: 1/2" NPT

Temperature Range: Cold - 110°F

Maximum Pressure: 125 PSIG

Inlet Temperature, Hot: 120° - 180°F

Inlet Temperature, Cold: 33° - 85°F

Minimum Temp. Differential

(From valve set point): 20°F

Raccords d’arrivée : 1/2" NPT

Raccords de sortie : 1/2" NPT

Plage de température : Eau froide à 43 °C (110 °F)

Pression maximum : 860 kPA (125 PSIG)

Température d’arrivée,

eau chaude : 49 °C à 82 °C (120 °F à 180 °F)

Température d’arrivée,

eau froide : 0,6 °C à 27 °C (33 °F à 85 °F)

Différence de température

minimum (à partir de valeur

de consigne de robinet) : -6,7 °C (20 °F)

Installation

S59-2005

Thermostatic Mixing Valve for

Individual Showers

Table of Contents

Supplies Required ............................................................2

Dimensions ....................................................................... 3

Installation Instructions ..................................................... 4

Troubleshooting ................................................................5

Table des matières

Fournitures requises ......................................................... 6

Dimensions ....................................................................... 7

Instructions relatives à l'installation ..................................8

Dépannage ....................................................................... 9

Contenido

Materiales necesarios ....................................................11

Dimensiones ................................................................... 12

Instrucciones de instalación ...........................................13

Solución de problemas ...................................................14

Conexiones de entrada: 1/2" NPT / tubería

Conexiones de salida: 1/2" NPT

Rango de temperatura: Agua fría a 43° C (110° F)

Presión máxima: 860 kPA (125 PSIG)

Temperatura de entrada

de agua caliente: 49° C a 82° C (120° F a 180° F)

Temperatura de entrada

de agua fría: 0,6° C a 27° C (33° F a 85° F)

Diferencial mínimo de

temperatura (desde elpunto

de referencia de la válvula): 20°F

215-1501 Rev. F EN 12-03-009

© 2012 Bradley

Page 1 of 15 10/10/2012

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

S59-2005T1 Installation

Installation

THIS

SIDE

UP

Packing List

•

•

•

•

IMPORTANT!

Read this entire installation manual to ensure proper installation. When finished with the installation,

file this manual with the owner or maintenance department. Compliance and conformity to local

codes and ordinances is the responsibility of the installer. Rough in the shower according to the

instructions provided with your shower.

The maximum temperature for this valve has been set to approximately 110°F (43°C) with an

incoming hot water temperature of 140°F (60°C). This maximum temperature may need to be adjusted

based on the installation conditions or application. The maximum inlet temperature of the valve is

180°F (82°C), with a recommended inlet temperature of 120°F - 180°F (49°C-82°C). The valve has a

maximum operating pressure of 125 PSI (860 kPA). Water temperature over 110° may result in serious

scalding. Excessive heat to the valve may cause damage to internal parts.

Separate parts from packaging and make sure all parts are accounted for before discarding

packaging material. If any parts are missing, do not begin installation until you obtain the missing

parts.

Make sure that all water supply lines have been flushed and then completely turned off before

beginning installation. Debris in supply lines can cause valves to malfunction.

Product warranties may be found under “Products” on our web site at www.bradleycorp.com.

Supplies Required

• Teflon Tape

• 3/32" and 1/8" Allen Key Wrenches

• Screwdriver

• 1/2" NPT Brass Pipe Plug

• Adjustable Wrench

2 10/10/2012 Bradley • 215-1501 Rev. F; EN 12-03-009

Installation S59-2005T1

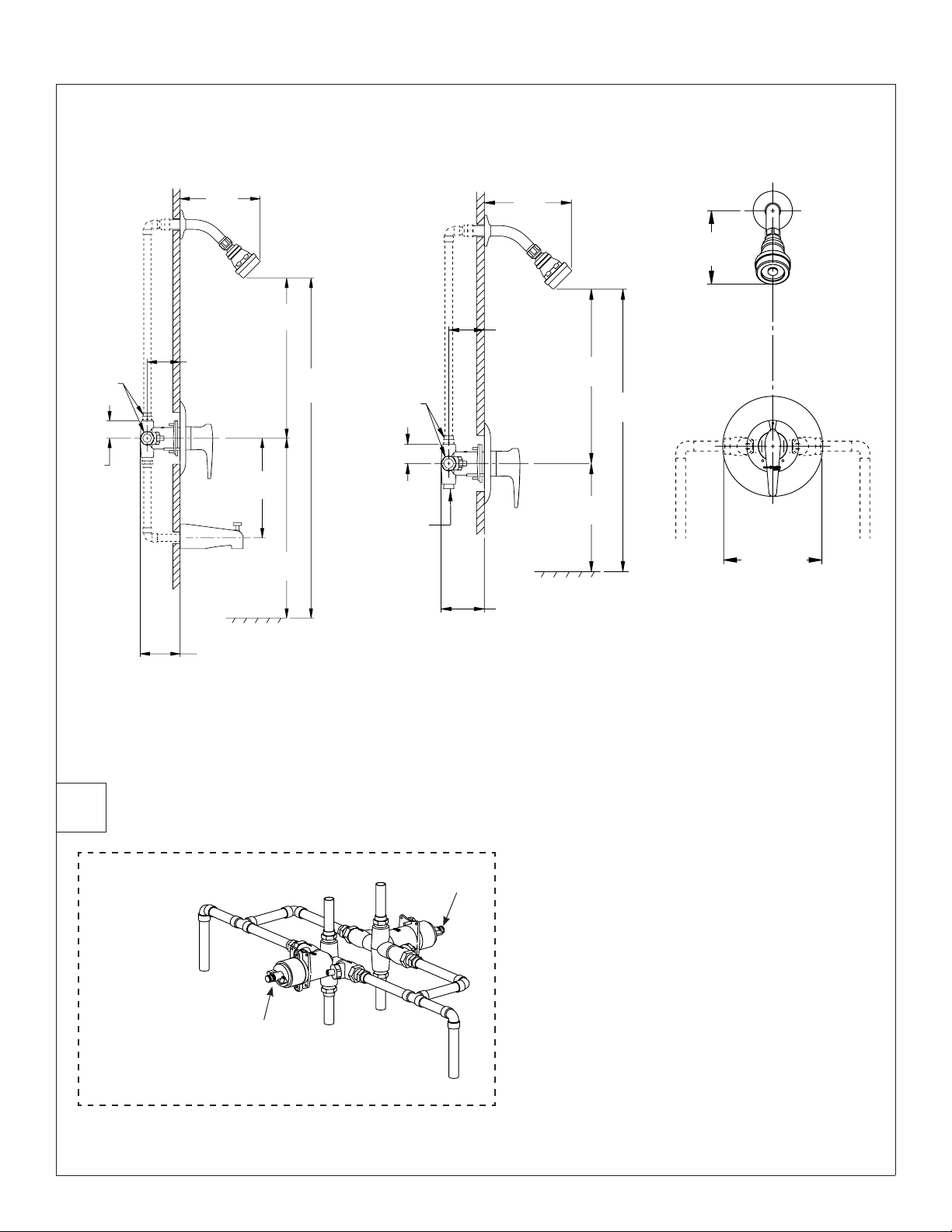

Dimensional Information

Tub/Shower Installation

7"

(178)

40"

(1016)

1/2" (13)

NPT

1-1/2"

(38)

3-1/4" (83) Max.

2-1/2" (64) Min.

12"

(305)

72"

(1829)

32"

(813)

1/2" (13)

NPT

1-1/2"

(38)

1/2" NPT Plug

(not supplied)

Shower Only Installation

7"

(178)

3-1/4" (83) Max.

2-1/2" (64) Min.

(mm)

Front View

5"

(127)

24"

(610)

72"

(1829)

Hot Cold

48"

(1219)

6-1/2" (165)

w/ Stops

2-1/2" (64)

w/o Stops

3-7/8" (98) Max. Depth

3-1/8" (79) Min. Depth

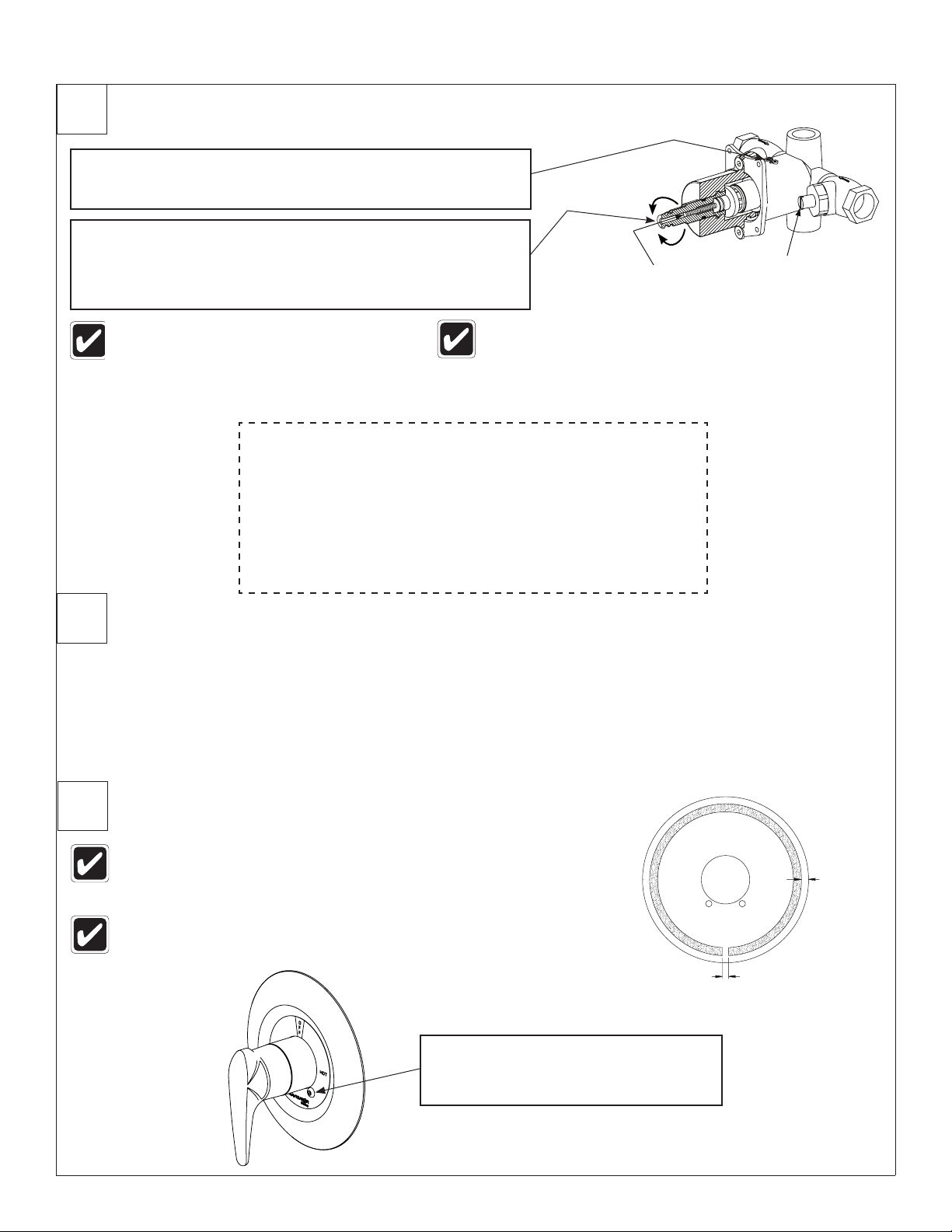

Installation Instructions

1

Rough-in

"Back-to-Back" Installation

See Step 2 for

required valve

adjustment and

"Back-to-Back"

installation.

Hot

Standard

Install

Supplies

Reversed

Cold

3-7/8" (98) Max. Depth

3-1/8" (79) Min. Depth

• Rough-in 1/2" NPT hot and cold water supply

(supplied by installer).

• For finished wall, make a 4-1/2" hole in the wall

where the shower handle is desired.

• For unfinished wall, use the rough-in shield as

a guide. Keep rough-in shield over valve when

finishing wall. The face of the rough-in shield

should fit flush with the finished wall. The rough-in

shield can either be secured to the valve using

the escutcheon screws or press-fit into place.

Bradley • 215-1501 Rev. F; EN 12-03-009 10/10/2012 3

S59-2005T1 Installation

2

Connect Valve and Adjust Valve Temperature

Position valve with port labeled “UP” towards showerhead.

Connect valve to hot and cold supplies and showerhead or tub

A

spout supplies.

Turn on hot and cold supplies to pressurize valve and check for

leaks. (Valve will not operate unless both hot and cold supplies are

turned on.) Adjust maximum temperature using a 3/32" hex-head

B

Allen key. The range of the thermostat is 95° F to 115° F (35° C to

46° C).

Check the temperature when

approximately 2.5-4 GPM water

flow is reached (equivalent to

one shower).

"Back-to-Back" Installation

On the valve that is "backwards":

• Turn off hot and cold supplies.

• Remove (2) screws that hold down cap.

• Remove entire valve assembly from the valve body and

rotate 180°. Arrow on cap must point to HOT side. Re-install

screws.

H

C

Set Screw

This device must be checked for final temperature and

adjusted as necessary. The standard preset factory

temperature setting is 110°F (43°C). Consult proper

medical and/or safety authorities for the optimum

temperature recommended for your particular application.

Stop/Check Screws

3

Shut the hot water supply off by closing hot water inlet valve or supply check valve. While the hot water supply is turned off, check

to make sure the cold water is reduced to .5 GPM or less. If the cold water is reduced properly, reopen the hot water supply.

Shut the cold water supply off by closing the cold water inlet valve or supply check valve. While the cold water supply is off, check

to make sure that the hot water flow has shut down. If hot water is shut down, reopen cold water supply. Test unit weekly for proper

function and desired set temperature.

4

Test Unit

Attach Escutcheon and Handle

The included foam rim seal may be applied to the back of

the escutcheon 1/4" from the outer edge, with the seam

at the bottom.

If the Rough-in Shield is used, remove the shield before

installing the escutcheon and handle.

DO NOT SKIP THIS STEP!!!

Place the escutcheon and handle on the

wall over the valve and secure with the

A

screws provided.

UP

1/4"

1/4"

4 10/10/2012 Bradley • 215-1501 Rev. F; EN 12-03-009

Installation S59-2005T1

Troubleshooting Thermostatic Mixing Shower Valve

Before attempting to troubleshoot the valve or disassemble the components, check for the following:

• Stop/check valves are fully open and that all inlet and outlet shut-off valves are open

• Hot and cold inlet pipes are connected properly, and that there are no cross-connectio ns or leaking

stop/check valves

• Water heater output is at least 15° F above the set temperature.

Be sure to close the appropriate shut-off valves prior to disassembly of the valve and reopen the valves

after inspection and repair is complete.

Problem Cause Solution

External leaks in

the system

Limited water flow Dirt and debris have collected on the stop/check

Temperature

fluctuation

or improper

Temperature

Either the NPT joints or the o-rings have been

damaged.

valve seat, limiting the movement of the stop/

checks.

Thermostat is slowly failing. Inspect Thermostat:

Inlet supply line to the mixing valve is being

shared by other pieces of equipment that are

used only periodically, such as laundry appliances

or washdown stations. It may reduce the inlet

pressure to the mixing valve to less than 3 PSI.

The supply line size may not be large enough to

supply both the valve and the other appliances.

Valve temperature is not properly set. Adjust the temperature as described on page 4.

Piston does not move freely and must be cleaned. Clean the piston as described below.

Replace the NPT joints and/or o-rings where necessary. For

replacement of o-rings, order the o-ring/seat kit as specified

in the included Service Guide.

Clean Stop and Check Valves:

Remove the stop and checks, clean the screen and seat

and reassemble the valve. Do not remove the seat. The

components may be brushed with a small wire brush to

remove debris. If the stop/check valves need to be replaced,

contact your Bradley representative and ask for Stop/Check

Valve (S27-102).

1. At room temperature (80°F or less), remove the valve

assembly from the valve body as described below.

2. Place the thermostat into a small container filled with

115°F water. The thermostat's pushrod should pop

out of the thermostat approximately 1/10".

3. If the pushrod does not pop out, the thermostat must

be replaced (it cannot be repaired). Order a new

thermostat kit as specified in the Service Guide.

Enlarge the supply line size, reconfigure the supply line or

regulate the supply usage.

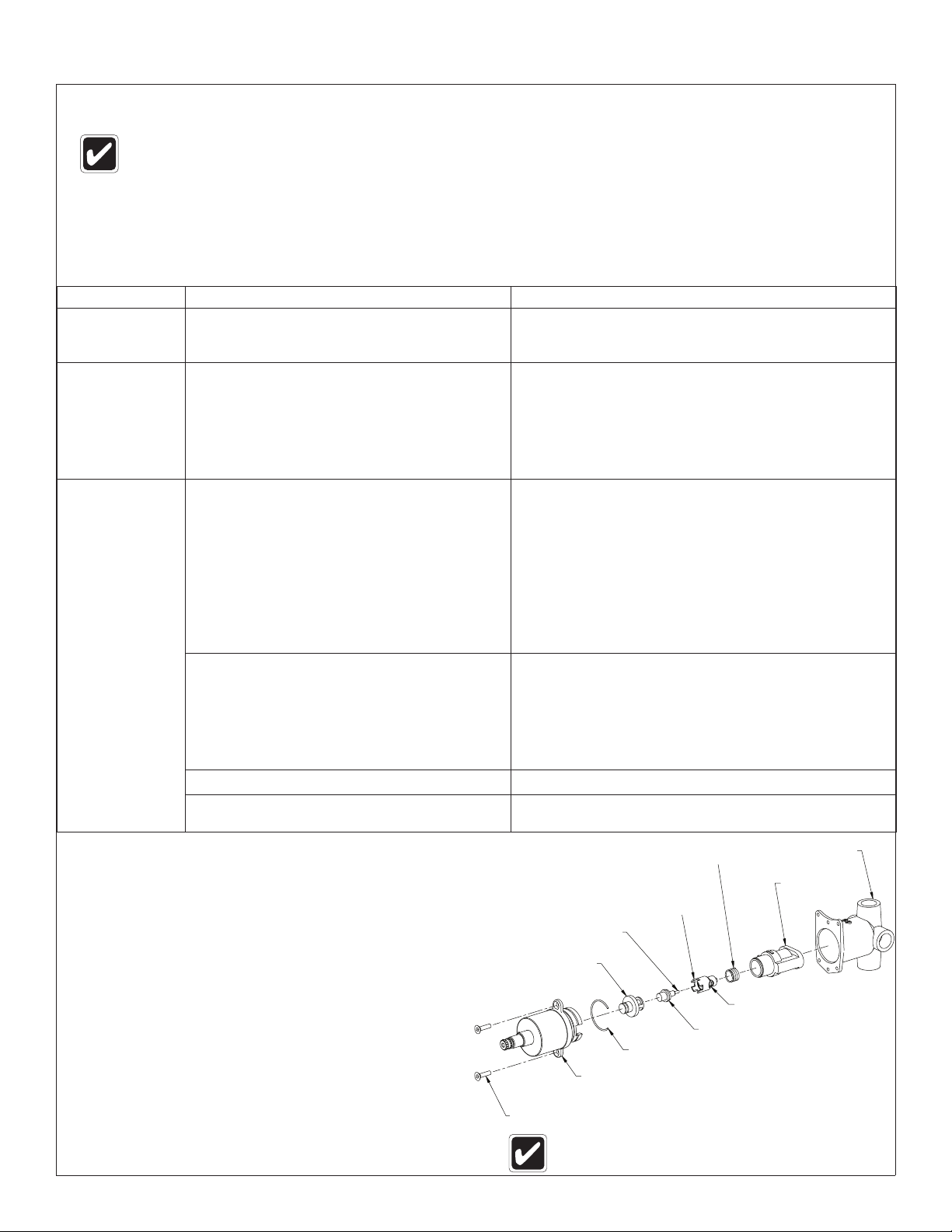

Troubleshooting: Piston Disassembly and Cleaning

Check the piston for free and smooth movement

Remove the handle and escutcheon to expose the valve

assembly. Loosen the two screws that hold the valve

assembly in the valve body. Remove the valve assembly.

Gently pry the retainer off the valve assembly. This will

separate the cap and liner exposing other components.

Disassemble components.

Push in on the piston with your finger (the piston should

move freely). If not, the piston and liner assembly needs

to be cleaned.

Clean the piston and liner assembly with any cleaner

suitable for brass and stainless steel (400-grit sandpaper

may be used to polish and hone the piston and liner). If

the piston does not move freely after a thorough cleaning,

the piston/liner assembly must be replaced.

Thermostat Pushrod

Seat Assembly

Screws

Piston (Push in, then

release to check for

smooth movement)

Retainer

Cap with Stem

Arrow on cap must point to HOT side.

Spring

Piston Assembly

Thermostat

Valve Body

Liner

Bradley • 215-1501 Rev. F; EN 12-03-009 10/10/2012 5

Loading...

Loading...