Page 1

Installation

S19-921H, S19-921HR

On-Site® Gravity-Fed Eyewash with Heater

Jacket

Douche oculaire On-Site à gravité avec

bande chauffante

Lavador de ojos On-Site de alimentación

por gravedad con camisa calentadora

Table of Contents

Pre-Installation Information ........................2

Components and Parts List........................3

Installation Instructions ........................... 4

Maintenance Information..........................6

Table des matières

Information avant installation....................... 7

Composantes et liste des pièces ...................8

Instructions d’installation ..........................9

Directives d’entretien............................11

Contenido

Watch the installation video!

Información previa a la instalación .................12

Componentes y lista de piezas .................... 13

Instrucciones de instalación ...................... 14

Instrucciones de mantenimiento ................... 16

PLEASE READ!

As of August 31, 2011, Bradley Corporation has discontinued the manufacturing and sale of Kleersight™ Ultra

Concentrate Water Preservative. Unfortunately, due to recent regulatory interpretations, it is no longer possible to

produce this product in a cost effective way.

As a result of this change, the Onsite Gravity Fed eyewash station no longer ships with preservative. Water

preservative may be purchased from various distributors, please contact your local distributor. Unfortunately, due to

the changing regulatory environment Bradley is unable to recommend a source for water preservative.

If you have additional questions or concerns please contact Bradley Customer Service at 800.BRADLEY

(800.272.3539).

We apologize for the inconvenience and appreciate your business.

Bradley Corporation

215-1714 Rev. F; ECN 16-05-066

© 2016 Bradley

Page 1 of 16 11/21/2016

Menomonee Falls, WI 53052 USA

P.O. Box 309

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

Page 2

S19-921H, S19-921HR Installation

F

IMPORTANT

Installation

P.O. Box 309, Menomonee F

UNIT EACH

TEST THIS

DIESES GERÄT 1ST

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

durch Untersc

60˚ F

Read this installation manual completely to ensure proper installation, then file it

with the owner or maintenance department. Compliance and conformity to drain

requirements and other local codes and ordinances is the responsibility of the

installer.

Packing List

•

•

•

THIS

SIDE

•

UP

Separate parts from packaging and make sure all parts are accounted for before

discarding any packaging material. If any parts are missing, do not begin installation

until you obtain the missing parts.

R

WI 53051

alls,

below.

PRÜFEN.

bestätigt

t melden.

y.

a pas fait

HENTLICH ZU

WEEK

WÖC

DAIRE

Testbetrieb prüfen,

he Störung sofor

alves chaque semaine et

e(s) each week and sign

Signed

e chose qui ne v

Signed

Date Signed

y malfunctions immediatel

hentlich im

hrift. Jeglic

Date

Date

t immédiatement.

Signed

Test le fonctionnement des v

Unterschrift

signe en bas. S'il y à quelqu

Signe

un rappor

Date

Datum

Date

Test the unit for leaks and adequate water flow. The inspection and testing results of

this equipment should be recorded weekly to verify proper operation. This equipment

should be inspected annually to ensure compliance with ANSI Z358.1.

Workers who may come in contact with potentially hazardous materials should be

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

trained regarding the placement and proper operation of emergency equipment per

ANSI Z358.1.

For questions regarding the operation or installation of this product, visit www.

bradleycorp.com or call 1-800-BRADLEY.

Product warranties and parts information may also be found under ”Products” on our

web site at www.bradleycorp.com.

100˚

This unit is to be used with tepid, potable water as defined by ANSI Z358.1. (Note: avoid

prolonged exposure to ambient heat sources above 100° F, or below 60° F).

2

11/21/2016 Bradley • 215-1714 Rev. F; ECN 16-05-066

Page 3

Installation S19-921H, S19-921HR

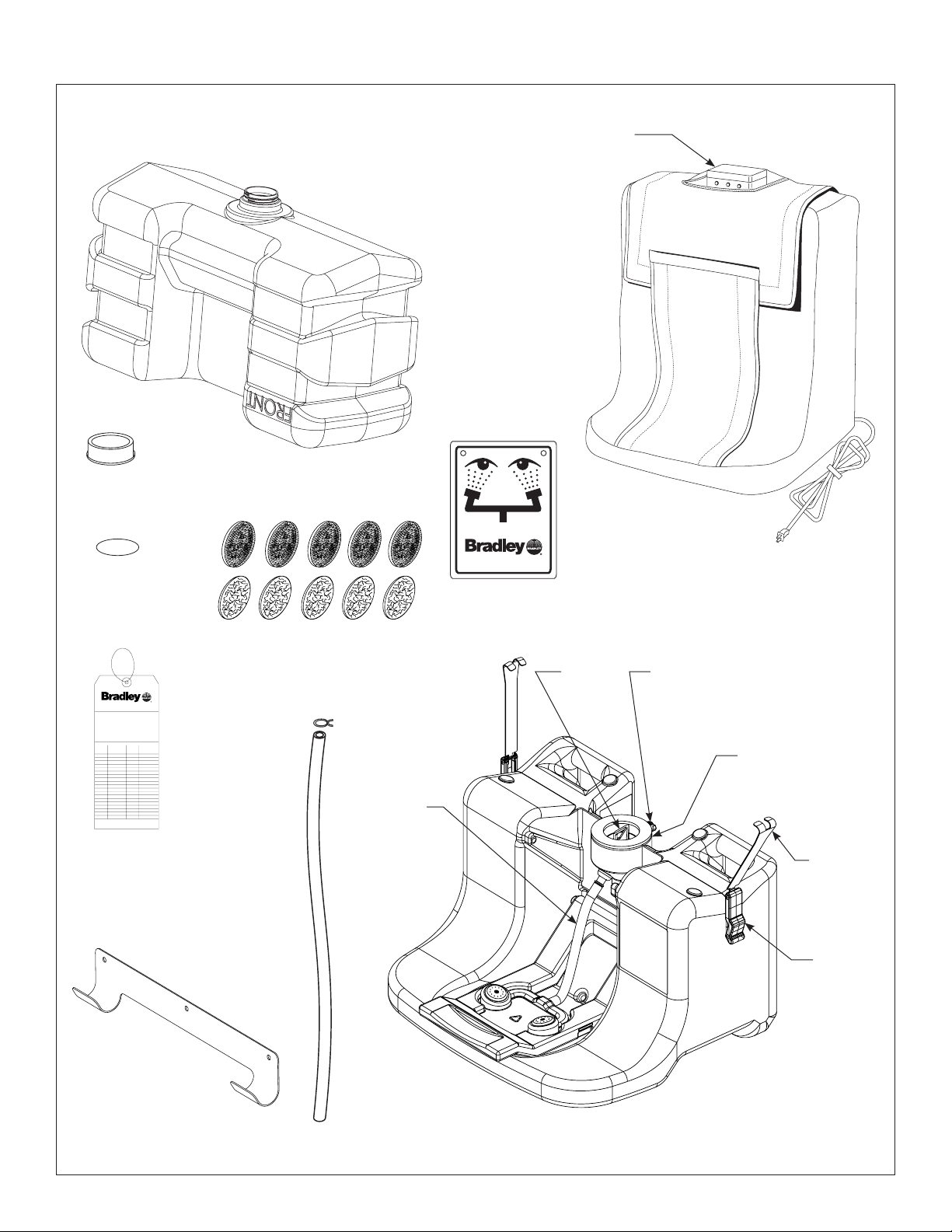

Components

Junction Box

Assembly

(S83-162)

Tank

(133-140)

Cap with Hole

(136-036)

Liner

(269-1379)

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

Inspection

Tag

(204-421)

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

Safety Sign

(114-051)

Hook-and-Loop Fastener Kit

(269-1781)

contains 5 sets

R

Pierce

(152-064)

Snorkel

(198-016)

Clamp

(146-083)

Signed

Signed

Gasket

Replacement Kit

Drain Tube

(269-1676)

Tube

(269-1385)

(S45-2193)

Clamp

(146-072)

Latch

Replacement Kit

(S45-2194)

(includes latch,

clamp and

mounting rivets)

Mounting Bracket

(140-820)

Pedestal Assembly

(S65-335)

Bradley • 215-1714 Rev. F; ECN 16-05-066 11/21/2016

3

Page 4

S19-921H, S19-921HR Installation

Installation

Wall

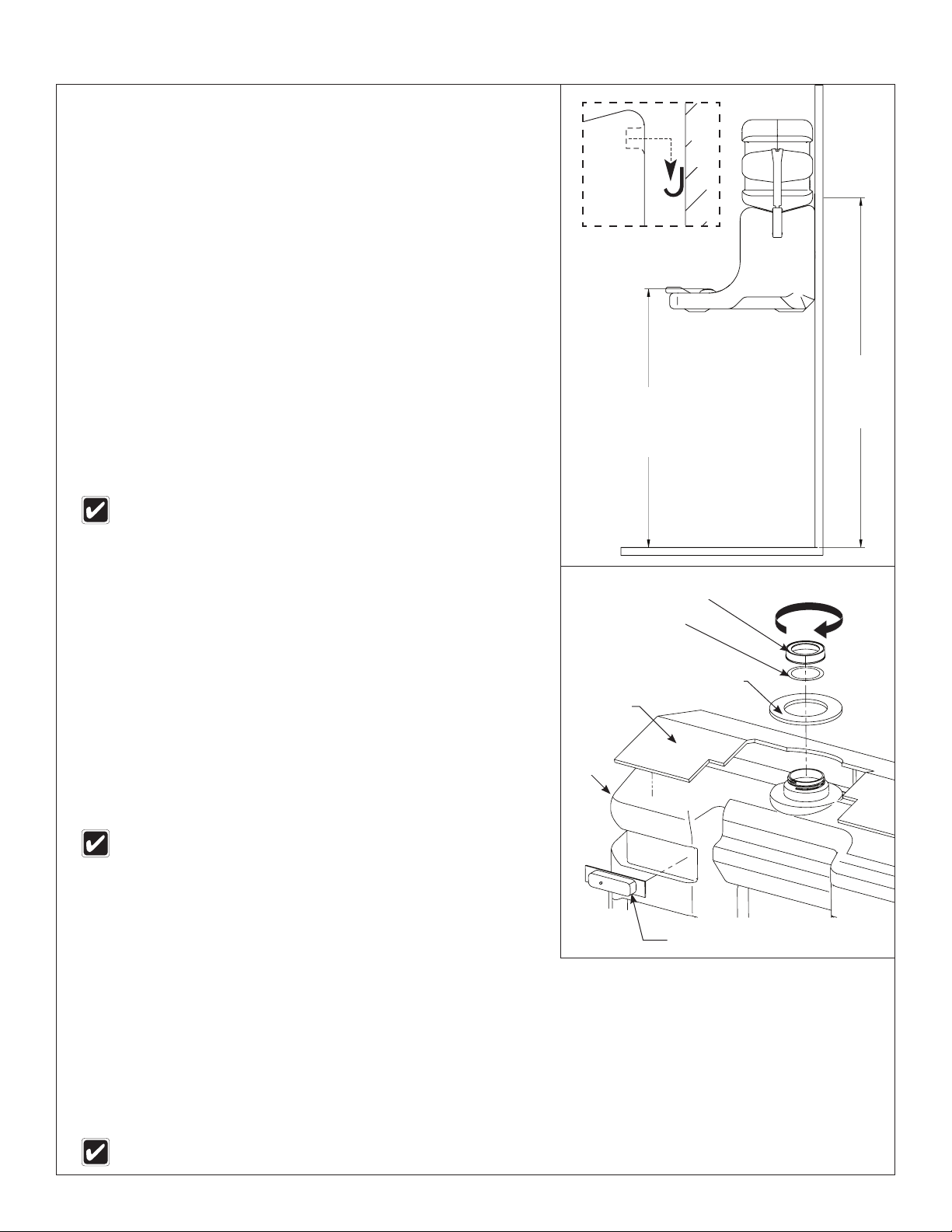

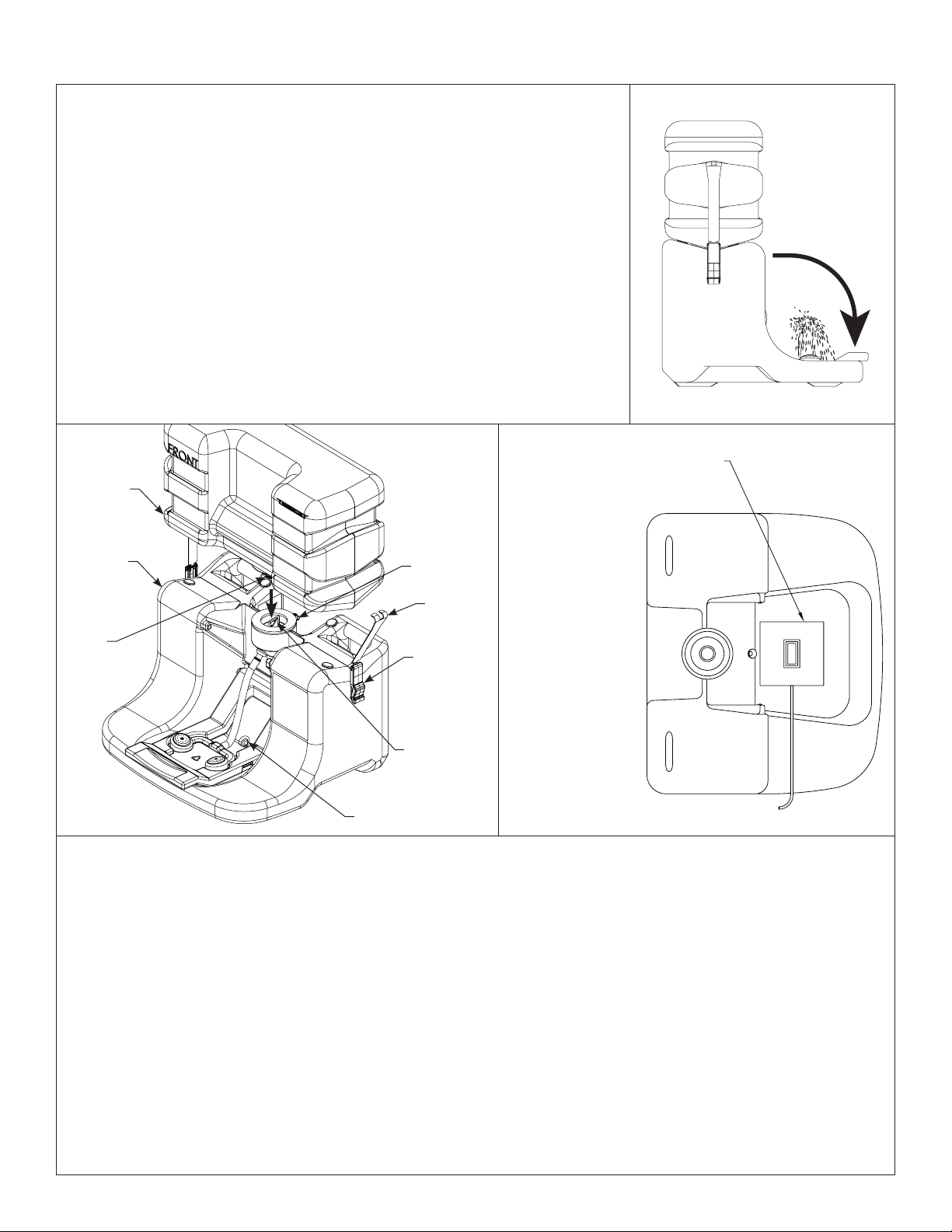

Step 1: Mount eyewash pedestal to wall (optional)

CAUTION: Eyewash station weighs 60 lbs when filled to capacity. Due

to this weight, assistance from another individual is required

to safely install the unit. Mounting bracket screws and wall

anchors must be strong enough to support the filled unit.

1. To mount the pedestal to the wall, follow the procedure

outlined below:

• Secure the mounting bracket to the wall with screws and

wall anchors (provided by installer).

2. Place the pedestal into the heater jacket. Insert the tube from

the drain hole at the bottom of the pedestal through the hole in

the back of the heater jacket. Drain hole location is shown on

page 5.

3. Attach the pedestal to the mounting bracket at the handles on

the back of the unit.

4. Check condition of gasket; ensure clamps are out of the way.

Check location of heater pad and routing of its power cable.

Ensure area is clear to receive water tank.

When mounting the eyewash unit to the mounting bracket, make

sure the unit is level and the sprayheads are at a height of 33-45"

from the floor and situated at least 6" from the wall or nearest

obstruction (ANSI Z358.1-2009).

33"

(838mm)

to 45"

(1143mm)

44⁵⁄₈"

(1133mm)

to 56⁵⁄₈"

(1438mm)

Step 2: Fill and mount tank

1. Pour clean, potable, tepid water into the tank; continue pouring

until the tank is 1/3 to ½ full.

2. Add water preservative (not included) to the eyewash tank

Follow the manufacturer’s instructions for the proper use of

water preservative.

3. Add clean, potable, tepid water to the tank until the water level

reaches the fill line.

4. Insert one liner into the cap (with hole) and attach the cap to

the top of the tank.

• Check location of heating pad and thermostat on tank as

shown in the illustration.

FOR TANK INSTALLATION: To ensure proper installation, the tank

should be placed on the pedestal from the front of the unit.

5. Invert the tank and place it on top of the pedestal as shown on

page 5. The pierce on the pedestal will puncture a hole in the

cap liner and allow solution to flow.

6. Raise the arm to snap fit in an upright position. A slight

adjustment to the position of the tank may be required for

proper level placement of the tank on the pedestal.

• Check to make sure jacket is not pinched under the tank and for proper routing of all cables.

7. Secure the tank to the pedestal using the side tank clamps. Make sure the latches are pulled down tight to the

pedestal (see page 5).

8. Lower the arm to activate the water flow. Allow the water to flow until air bubbles form in the tank. Raise the arm and

“snap” in the upright position. The system is now ready for use.

9. Insert the 5-pin connector from the tank heater assembly into the mating socket on the junction box and screw tight.

Slide the heater jacket up to cover the tank and secure the jacket with the hook-and-loop fasteners. Slide the arm into

pocket of the jacket flap.

After the tank is mounted to the pedestal, minor spillage may occur. Allow the fluid to stabilize completely before inspecting the unit for

leaks.

.

Liner (insert into cap

before attaching cap

Tank

Cap with Hole

to tank)

Gasket

Heater

Pad

Thermostat

Turn cap to close

4

11/21/2016 Bradley • 215-1714 Rev. F; ECN 16-05-066

Page 5

Installation S19-921H, S19-921HR

Step 3: Test eyewash unit

1. After completing installation, test the unit by pulling the front flap down

and all the way out. This action should activate the water spray. Check

the sprayheads for proper water flow and look for possible water leakage

throughout the unit. Visually inspect all areas of the heater jacket to verify

proper operation of the heating element.

Visually inspect the eyewash unit weekly for cleanliness and proper

solution level (per ANSI Standard Z358.1-2009). When the water level

drops below the 15-minute fill line, the tank must be emptied and then

refilled. To refill the eyewash tank, follow the procedures outlined in Step 2

on page 4.

2. Attach the eyewash inspection tag (supplied) to the eyewash unit. This

tag is to be used for weekly inspection documentation. Hook-and-loop

fasteners are provided to attach the tag to the unit.

3. If the eyewash unit is not working properly, remove it from the hazard

area and contact Bradley Corporation immediately.

Position the heater pad evenly

Tank

around the drain hole. Do not

block the drain hole.

Pedestal

Cap

Drain Hole

Snorkel

Clamp

Latch

Pierce

Optional Heater Jacket Junction Box

LED Light

• Green Light: an indication that the unit has power.

• Amber Light: an indication that the heater is in operation and heating the unit. The light will be on only while the heater is operating

(heating the unit).

• Red Light: an indication that the thermostat needs to be reset. To reset the thermostat, follow the procedure outlined below.

1. Remove the top of the heater jacket.

2. Find the “reset” button on the thermostat (located on the tank) and press the button.

• After pressing the button, check to be sure that the red light is off and that the green light is on (the amber light will be on only

if the heater is operating). If the red light is still on, press the “reset” button again.

3. Replace the top of the heater jacket.

Top View of Pedestal

Bradley • 215-1714 Rev. F; ECN 16-05-066 11/21/2016

5

Page 6

S19-921H, S19-921HR Installation

Maintenance

Follow the manufacturer’s instructions for the proper use of water preservative.

Inspect eyewash unit

1. Visually inspect the eyewash unit weekly for cleanliness and proper solution level (per ANSI Standard Z358.1-2009).

2. Activate the eyewash unit each time the solution is replaced to ensure proper operation. If the unit is not working

properly, remove it from the hazard area and contact Bradley Corporation immediately.

• Check the sprayheads’ water spray pattern for an even, continuous flow. The sprayheads are attached to the arm

with screws and can be detached from the tray for cleaning or obstruction removal, if necessary, and reattached

(use a ⁹⁄₆₄" hex-head Allen wrench to remove and reinstall the sprayheads).

• Check the water supply hose at the basin of the eyewash unit for cracks, leaks or wear.

• Check the entire unit for possible water leakage.

• Check the solution for contamination and replace with fresh solution, if necessary.

Clean eyewash unit

When using potable water and water preservative (recommended):

1. Carefully remove the eyewash tank from the pedestal and drain the water solution from the tank (dispose of

the solution properly). For ease of draining, the pedestal has a drain hole which will accept a ½” I.D. tube at the

underside of the hole (tube supplied by others) (see page 5 for drain hole location).

2. Clean the inside of the tank using warm water and a mild soap product; rinse thoroughly.

3. Refill the eyewash tank following the procedures outlined in Step 2 found on page 4. Follow instructions of the

preservative manufacturer for the proper use of water preservative.

4. Reinstall the eyewash tank following the procedure outlined in Step 2 found on page 4.

When using potable water only:

1. Empty the tank any time from once per week to once per month, depending on the quality of your water supply. The

manufacturer is not responsible for variations in the water supply.

2. Clean the inside of the tank using warm water and mild soap. Rinse the tank thoroughly with warm water.

3. Refill the eyewash tank with tepid potable water.

To operate eyewash unit

1. Begin operation by pulling the front flap down and all the way out. This action should automatically activate the water spray.

2. Hold eyelids open with thumbs and forefingers. Rotate eyes back and forth to ensure a complete rinse. Allow water to bathe both

eyes simultaneously for a minimum of 15 minutes.

3. Seek medical attention immediately after use.

Do not lean on the eyewash tray when in the opened position. Damage to unit may result.

6

11/21/2016 Bradley • 215-1714 Rev. F; ECN 16-05-066

Page 7

Installation S19-921H, S19-921HR

F

IMPORTANT

P.O. Box 309, Menomonee F

TEST THIS

60˚ F

Installation

Lire ce manuel d’installation dans son intégralité pour garantir une installation

appropriée. Une fois celle-ci terminée, classer ce manuel auprès du service à la

clientèle ou d’entretien. L’installateur est responsable de la conformité de l’installation

aux codes pour des drain et codes et règlements en vigueur.

Packing List

•

•

•

THIS

SIDE

•

UP

Assurez-vous que toutes les pièces sont incluses dans l’emballage et qu’il n’en

manque aucune avant de jeter l’emballage. Ne commencez pas l’assemblage avant de

recevoir les pièces manquantes.

R

WI 53051

alls,

below.

PRÜFEN.

bestätigt

t melden.

y.

a pas fait

HENTLICH ZU

WEEK

WÖC

DAIRE

Testbetrieb prüfen,

he Störung sofor

alves chaque semaine et

e(s) each week and sign

UNIT EACH

Signed

e chose qui ne v

Signed

Date Signed

y malfunctions immediatel

hentlich im

hrift. Jeglic

Date

DIESES GERÄT 1ST

ESSAI HEBDOMA

Date

Test-operate valv

Report an

Ventil(e) wöc

t immédiatement.

durch Untersc

Signed

Test le fonctionnement des v

Unterschrift

signe en bas. S'il y à quelqu

Signe

un rappor

Date

Datum

Date

Assurez-vous que le débit d’eau est adéquat et qu’il n’y a pas de fuites. Inspectez et

testez cet équipement une fois par semaine pour en assurer le bon fonctionement.

Notez les dates d’inspection. Ce matériel doit être inspecté une fois par an pour

assurer sa conformité à la norme ANSI Z358.1.

Les ouvriers susceptibles d’entrer en contact avec des matières potentiellement

dangereuses doivent recevoir une formation sur la mise en place et le bon

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

fonctionnement du matériel d’urgence conformément à la norme ANSI Z358.1.

Pour toute question concernant le fonctionnement ou l’installation de ce produit,

consulter le site www.bradleycorp.com ou appeler le 1-800-BRADLEY.

Les garanties de produits figurent sous la rubrique « Informations techniques » sur

notre site Internet à www.bradleycorp.com.

100˚

Cet appareil doit être utilisé avec de l’eau potable tiède telle que définie par la norme

ANSI Z358.1. (Remarque : éviter l’exposition prolongée à des sources de chaleur

ambiante supérieures à 38 °C ou inférieures à 16°C).

AVIS IMPORTANT !

À compter du 31 août 2011, Bradley Corporation a cessé de fabriquer et de vendre l’agent de conservation ultraconcentré Kleersight™. En raison de récentes interprétations de la règlementation, il n’est malheureusement plus

possible de fabriquer ce produit de façon rentable.

Suite à ce changement, la douche oculaire On-Site à gravité n’est plus livrée avec du produit de conservation. Les

produits de conservation de l’eau peuvent s’acheter auprès de divers distributeurs, veuillez vous adresser à votre

distributeur local. Malheureusement, en raison de l’évolution du contexte réglementaire, Bradley n’est pas en mesure

de recommander un fournisseur de produit de conservation de l’eau.

Pour toute question ou préoccupation, veuillez vous adresser au Service après-vente Bradley au 800.BRADLEY

(800.272.3539).

Nous vous prions de nous excuser pour la gêne occasionnée et vous remercions d’avoir acheté un produit Bradley.

Bradley Corporation

Bradley • 215-1714 Rev. F; ECN 16-05-066 11/21/2016

7

Page 8

S19-921H, S19-921HR Installation

Composantes

Assemblage du

Boîte de Conexion

(S83-162)

Réservoir

(133-140)

Bouchon Perforé

(136-036)

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

Coupe-débit

(269-1379)

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Signed

Date

Signe

Date

Signed

Étiquette

d’urgence

(204-421)

Paquet d’attaches de tissu pour

attacher l’etiquette á l’unité

(269-1781)

contient 5 ensembles

Pince

(146-083)

Tuyau de

drainage

(269-1676)

Tuyau

(269-1385)

Enseigne de

sécurité

(114-051)

Perforateuer

(152-064)

Tuba

(198-016)

Paquet d’joint

de rechange

(S45-2193)

Pince

(146-072)

Paquet

d’attache de

rechange

(S45-2194)

Support Mural

(140-820)

Assemblage du Socle

(S65-335)

8

11/21/2016 Bradley • 215-1714 Rev. F; ECN 16-05-066

Page 9

Installation S19-921H, S19-921HR

Installation

Mural

Étape 1 : Installer la douche oculaire au mur

(en option)

ATTENTION : Le poste de douche oculaire a un poids de 27,5 kg (60

livres) lorsque plein. En raison de son poids, l’assistance

d’une autre personnes est requise pour installer

l’appareil en toute sécurité. Les supports et l’ancrage

mural doivent être assez solide pour supporter l’unité

lorsqu’elle est pleine.

1. Pour installer le socle au mur, suivre les procédures suivantes :

• Installer le support de douche au mur, à l’aide des vis et

de l’ancrage mural (fournis par l’installateur).

• Placez le socle dans la bande chauffante. Insérer le tube

de trou de drainage au fond du socle par le trou dans

l’arrière de la bande chauffante. Le trou de drainage est

indiqué sur la page 10.

2. Fixer le socle au support, avec les crochets pour installation

murale, à l’arrière de l’unité.

3. Vérifier l’état du joint. S’assurer que les brides sont écartées.

Vérifier l’emplacement de la plaque de chauffage et

l’acheminement de son câble d’alimentation. S’assurer que la

zone est dégagée pour la mise en place du réservoir d’eau.

En fixant la douche oculaire au support mural, s’assurer que

les gicleurs sont à une hauteur située entre 84 et 114 cm (33 et

45 po) du plancher et à au moins 15,5 cm (6 po) du mur ou de

l’obstruction la plus près (ANSI Z358-1-2009).

33"

(838mm)

à 45"

(1143mm)

Bouchon Perforé

Tourner le bouchon

pour fermer

44⁵⁄₈"

(1133mm)

à 56⁵⁄₈"

(1438mm)

Étape 2 : Remplir et installer le réservoir

1. Remplir le réservoir avec de l’eau tiède potable, et arrêter

entre le tiers et la moitié environ.

2. Verser le préservatif pour l’eau (non fourni) dans le réservoir

de la douche oculaire. Suivre les instructions d’utilisation de

l’agent de conservation de l’eau fournies avec ce produit.

3. Continuer de remplir le réservoir avec de l’eau tiède potable,

jusqu’à ce qu’il atteigne la “pleine” ligne.

4. Insérer le coupe-débit dans le bouchon perforé et visser le

bouchon sur le réservoir.

• Vérifier l’emplacement de la plaque de chauffage et

le thermostat sur le réservoir tel que montré dans

l’illustration.

Coupe-débit (insérer le

coupe-débit avant de

fixer le bouchon sur le

réservoir)

Joint

Bande

Chauffante

Réservoir

RELATIVE À L’INSTALLATION DU RÉSERVOIR : Pour assurer une

installation appropriée, le réservoir doit être placé sur le socle du

devant de l’unité.

5. Inverser le réservoir sur le socle, tel qu’indiqué sur la page 10.

Le perforateur du socle perforera le coupe-débit du bouchon,

permettant au mélange de s’écouler.

6. Relever le manchon pour l’enclencher en position relevé. Il

faudra peut-être procéder à un léger réglage de la position du

réservoir pour obtenir un bon emplacement de ce dernier sur le socle.

• Vérifier que la bande chauffante n’est pas pincée sous le réservoir et que tous les câbles ont été correctement acheminés.

7. Aux côté pinces, fixer le réservoir au socle (fixez les attaches au socle, tel qu’indiqué sur la page 10).

8. Abaisser le bras pour activer l’écoulement d’eau. Laisser l’eau s’écouler jusqu’à formation de bulles d’air dans le réservoir. Relever le bras

et « enclencher » en position verticale. Le système est maintenant prêt à l’emploi.

9. Insérer le connecteur à 5 broches du réchauffeur sur le réservoir dans l’embase homologue de la boîte de jonction, et serrer à fond.

Glissez la bande chauffante de réchauffeur jusqu’à le réservoir et fixez la bande avec les attaches de crochet-et-boucle. Glisser la tige

dans le logement du plateau de la bande.

Lorsque le réservoir est installé sur le socle, une légère fuite peut se produire. Laisser le liquide se stabiliser complètement avant de

procéder à la vérification des fuites sur l’unité.

Thermostat

Bradley • 215-1714 Rev. F; ECN 16-05-066 11/21/2016

9

Page 10

S19-921H, S19-921HR Installation

Étape 3 : Tester la douche oculaire

1. Tester l’unité en abaissant le plateau avant. Cette action activera les gicleurs d’eau.

Vérifier le débit d’eau des gicleurs et examiner si l’unité a des fuites. Inspectez

visuellement la bande chauffante pour vérifier l’opération appropriée de l’élément de

chauffe.

Inspection visuelle hebdomadaire de la douche oculaire pour la propreté et pour le

niveau approprié de mélange (selon la norme ANSI Z358.1-2009). Lorsque le niveau

de solution est en deçà de la ligne de remplissage de 15 minutes, le réservoir doit

être vidé et rempli à nouveau. Remplir le réservoir de la douche oculaire selon les

directives décrites à l’étape 2 de la page 9.

2. Attacher l’étiquette d’inspection (étiquette incluse) à la douche oculaire. Cette

étiquette sera utilisée comme documentation hebdomadaire. Des attaches sont

fournies pour attacher l’étiquette à l’unité.

3. En cas de mauvais fonctionnement de la douche oculaire, l’enlever de la zone à

risques et contacter immédiatement Bradley Corporation.

Placez le tampon du chauffante

Réservoir

même autour du trou de drainage.

Ne bloquez pas le trou de drainage.

Socle

Bouchon

Trou de drainage

Tuba

Pince

Attache

Perforateur

Vue supérieure de socle

Boîte de connexion de bande chauffante en option

DEL

• Voyant vert : indique que l’unité est sous tension.

• Voyant jaune : indique que le chauffage fonctionne et chauffe l’unité de douche oculaire. Le voyant ne sera allumé que lorsque le

chauffage fonctionne (et chauffe l’unité de douche oculaire).

• Voyant rouge : indique que le thermostat doit être réenclenché. Pour réenclencher le thermostat, suivre la procédure indiquée

ci-dessous.

1. Retirer le dessus de la bande chauffante.

2. Trouver le bouton de réenclenchement sur le thermostat et appuyer sur le bouton.

• Une fois le bouton enfoncé, s’assurer que le voyant rouge est éteint et que le voyant vert est allumé (le voyant jaune ne sera

allumé que lorsque le chauffage fonctionne). Si le voyant rouge est toujours allumé, appuyer de nouveau sur le bouton de

réenclenchement.

3. Remettre le dessus de la bande chauffante en place.

10

11/21/2016 Bradley • 215-1714 Rev. F; ECN 16-05-066

Page 11

Installation S19-921H, S19-921HR

Entretien

Consulter les instructions du fabricant pour l’utilisation correcte du préservatif pour douche oculaire.

Inspection de la douche oculaire

1. Inspection visuelle hebdomadaire de la douche oculaire pour la propreté et pour le niveau approprié de mélange (selon la norme

ANSI Z358.1-2009).

2. Faire fonctionner la douche oculaire chaque fois que le mélange est remplacé, pour s’assurer de son bon fonctionnement. En cas

de mauvais fonctionnement de la douche oculaire, l’enlever de la zone à risques et contacter immédiatement Bradley Corporation.

• Vérifier si le jet d’eau des gicleurs est uniforme, avec un débit régulier. Les gicleurs sont reliés au manchon par des vis et

si nécessaire, ils peuvent être enlevés pour les nettoyer ou enlever les obstructions, puis réinstallés (utiliser une clé Allen

hexagonale ⁹⁄₆₄" pour enlever et remettre les gicleurs en place).

• Examiner le boyau d’approvisionnement en eau du bassin, pour déceler les fissures, les fuites ou l’usure.

• Examiner l’unité en entier pour déceler les fuites d’eau possible.

• Examiner le mélange afin de savoir s’il est contaminé, le remplacer avec un nouveau mélange si nécessaire.

Nettoyage de la douche oculaire

En utilisant l’eau potable et le préservatif de l’eau (recommandés) :

1. Enlever doucement le réservoir de la douche oculaire de son socle et drainer le mélange d’eau du réservoir (disposer du mélange

de façon appropriée). Pour faciliter le drainage, le socle a un trou de drainage et un boyau de 1,2 cm (½”) peut être relié sous le

côté du trou (boyau non fourni par Bradley) (voir l’emplacement du trou de drainage sur la page 10).

2. Nettoyer l’intérieur du réservoir avec de l’eau chaude et un savon doux; rincer complètement.

3. Remplir le réservoir de la douche oculaire selon les directives décrites à l’étape 2 de la page 9. Suivre les instructions d’utilisation

de l’agent de conservation de l’eau fournies avec ce produit.

4. Réinstaller le réservoir de la douche oculaire selon les directives décrites à l’étape 2 de la page 9.

En utilisant l’eau potable seulement :

1. Videz le réservoir n’importe quand de une fois par semaine à une fois par mois selon la qualité de votre approvisionnement en eau.

Le constructeur n’est pas responsable des variations de l’approvisionnement en eau.

2. Nettoyez l’intérieur du réservoir en utilisant l’eau chaude et un produit doux de savon. Rincez le réservoir complètement avec de

l’eau chaud.

3. Refaire le plein du réservoir de douche oculaire avec de l’eau potable tiède.

Pour faire fonctionner la douche oculaire

1. Abaisser le plateau avant. Cette action devrait activer les jets d’eau.

2. Garder les paupières ouvertes, à l’aide du pouce et de l’index. Bouger les yeux en tous sens pour assurer un rinçage complet.

Laisser l’eau baigner les deux yeux simultanément pendant au moins 15 minutes.

3. Voir un médecin immédiatement après utilisation.

Ne pas s’appuyer sur la douche oculaire pendant son fonctionnement. Des dommages pourraient en résulter.

Bradley • 215-1714 Rev. F; ECN 16-05-066 11/21/2016

11

Page 12

S19-921H, S19-921HR Installation

IMPORTANTE

P.O. Box 309, Menomonee F

TEST THIS

60˚ F

Installation

Lea en su totalidad este manual de instalación para garantizar una instalación

adecuada. Una vez que termine la instalación, entregue este manual al propietario

o al Departamento de Mantenimiento. Es responsabilidad de quien instale el equipo

cumplir con los códigos para desagüe y otra códigos y ordenanzas locales.

Packing List

•

•

•

THIS

SIDE

•

UP

Separar todas las piezas del material de embalaje y asegurarse que todas las piezas

estén incluídas antes de desechar cualquier material de embalaje. Si faltase alguna

pieza, no intentar instalar la unidad combinada Bradley hasta obtener las piezas

faltantes.

R

WI 53051

alls,

below.

PRÜFEN.

bestätigt

t melden.

y.

a pas fait

HENTLICH ZU

WEEK

WÖC

DAIRE

Testbetrieb prüfen,

he Störung sofor

alves chaque semaine et

e(s) each week and sign

UNIT EACH

Signed

e chose qui ne v

Signed

Date Signed

y malfunctions immediatel

hentlich im

hrift. Jeglic

Date

DIESES GERÄT 1ST

ESSAI HEBDOMA

Date

Test-operate valv

Report an

Ventil(e) wöc

t immédiatement.

durch Untersc

Signed

Test le fonctionnement des v

Unterschrift

signe en bas. S'il y à quelqu

Signe

un rappor

Date

Datum

Date

Verificar que no haya fugas y que el flujo de agua sea adecuado. Este equipo se

debe inspeccionar, probar y anotar semanalmente para mantener un funcionamiento

adecuado. Se debe revisar este equipo anualmente para asegurarse de que cumpla

con la norma ANSI Z358.1.

Los trabajadores que puedan tener contacto con materiales potencialmente peligrosos

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

deben recibir capacitación sobre la ubicación y operación adecuada de los equipos de

emergencia en conformidad con la norma ANSI Z358.1.

Para consultas sobre la operación o instalación de este producto, visite www.

bradleycorp.com o llame al 1-800-BRADLEY.

Las garantías del producto se pueden encontrar e n “Información del producto” o en

nuestro sitio Web, www.bradleycorp.com.

100˚ F

Esta unidad se debe utilizar con agua potable tibia, como conforme a la norma ANSI

Z358.1 (Nota: evite la exposición prolongada a fuentes de calor ambiental por sobre

los 38 ºC [100 ºF] y bajo los 16º C [60 ºF]).

¡LEA LO SIGUIENTE!

A partir del 31 de agosto de 2011, Bradley Corporation descontinuó la fabricación y la venta del conservante de agua

ultraconcentrado Kleersight™. Desafortunadamente, debido a recientes interpretaciones reglamentarias, ya no es

posible producir este producto de manera rentable.

A raíz de este cambio, la estación lavaojos de llenado por gravedad On-site ya no se envía con conservante.

El conservante de agua se puede adquirir de diversos distribuidores; comuníquese con su distribuidor local.

Desafortunadamente, debido al cambiante entorno reglamentario, Bradley no puede recomendar una fuente de

conservante de agua.

Si tiene preguntas adicionales o inquietudes, comuníquese con el Servicio de Atención al Cliente de Bradley al 800.

BRADLEY (800.272.3539).

Nos disculpamos por cualquier inconveniente y agradecemos que sea nuestro cliente.

Bradley Corporation

12

11/21/2016 Bradley • 215-1714 Rev. F; ECN 16-05-066

Page 13

Installation S19-921H, S19-921HR

Componentes

Tapa Perforada

(136-036)

Tapaflujo

(269-1379)

para asociar la etiqueta a la unidad

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Signed

Date

Signe

Date

Signed

Tanque

(133-140)

Paquete de sujetadores de la tela

(269-1781)

contiene 5 conjuntos

Abrazadera

(146-083)

Tubo de

drenaje

(269-1676)

Tubo

(269-1385)

Conjunto del Caja

de conexiones

(S83-162)

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

Letero de seguridad

(114-051)

Perforador

(152-064)

Tubo esnórquel

(198-016)

Paquete de junta

del reemplazo

(S45-2193)

Étiqueta de

emergencia

(204-421)

Soporte de pared

(140-820)

Conjunto del Pedestal

(S65-335)

Bradley • 215-1714 Rev. F; ECN 16-05-066 11/21/2016

Abrazadera

(146-072)

Paquete del

pestillo del

reemplazo

(S45-2194)

13

Page 14

S19-921H, S19-921HR Installation

Instalación

Pared

Paso 1: Montaje del pedestal del lavador de

ojos a la pared (opcional)

PRECAUCION: La estación lavadora de ojos pesa 27,5 kg (60 lbs) cuando está

completamente llena. Debido a su peso, se requiere ayuda de

otra persona para instalar la unidad de manera segura. Los

tornillos y los pernos de anclaje del soporte de pared deben

ser lo suficientemente fuertes para soportar el peso de la

unidad cuando esté totalmente llena.

1. Para montar el pedestal a la pared, siga el procedimiento siguiente

•

Fije el soporte de montaje a la pared con tornillos y pernos de

anclaje (provistos por el instalador).

•

Coloque el pedestal en la camisa calentadora. Inserte el tubo del

orificio de drenaje en el fondo del pedestal en el orificio en la parte

posterior de la camisa calentadora. La ubicación del orificio de

drenaje se muestra en la página 15

2. Enganche el pedestal por las ranuras de montaje que se encuentran

en la parte posterior de la unidad al soporte de montaje en la pared.

3. Verifique la condición de la junta. Asegúrese de que las abrazaderas

estén apartadas. Verifique la ubicación de la base del calentador

y el recorrido del cable de alimentación. Asegúrese de que el área

esté despejada para colocar el tanque de agua.

Al montar el lavador de ojos en el soporte de montaje, asegúrese de que

los rociadores se encuentren a una altura de 84-114 cm (33-45 pulg.) del

piso y situados a una distancia mínima de 15,5 cm (6 pulg.) de la pared

o del obstáculo más cercano (ANSI Z358.1-2009).

.

Paso 2: Llenado y montaje del tanque

1. Vierta agua potable tibia dentro del tanque; continúe vertiendo agua

hasta que llene el tanque hasta un 30% ó 50% de su capacidad.

2. Vierta el preservativo para el agua (no incluída) en el tanque del

lavador de ojos. Para darle el uso adecuado al conservante de agua,

siga las instrucciones del fabricante del producto.

3. Vierta más agua potable tibia en el tanque hasta que el agua llegue

al la línea “lleno.”

4. Inserte un tapaflujo en la tapa perforada y colóquele la tapa a la

parte superior del tanque del lavador de ojos

• Verifique la ubicación de la base del calentador y el

ACERCA DE LA INSTALACIÓN DEL TANQUE: Para asegurar una

instalación correcta, el tanque debe ser colocado sobre el pedestal

desde el frente de la unidad.

5. Invierta el tanque y colóquelo encima del pedestal. El perforador en

el pedestal hará un orificio en el tapaflujo de la tapa del tanque para

permitir el flujo de la solución.

6. Suba la palanca hasta cuando se coloque en posición vertical.

Puede ser necesario un leve ajuste de la posición del tanque para

obtener la colocación correcta del mismo sobre el pedestal.

• Asegúrese de que el revestimiento no esté apretado bajo el

tanque y que todos los cables estén cableados de forma adecuada.

7. Monte el tanque al pedestal usando las abrazaderas del tanque. Asegure los pestillos al pedestal (vea página 15).

8. Baje el brazo para activar el flujo de agua. Permita que el agua fluya hasta que se formen burbujas de aire en el tanque. Levante el

brazo y “encájelo” en la posición vertical. Ahora el sistema está listo para su uso.

9. Deslice el brazo dentro del bolsillo del calentador en el tanque de la solapa de la camisa. Resbale la camisa hasta el tanque y

asegure la chaqueta con los sujetadores del gancho-y-bucle. Inserte el conector de 5 pins en el receptáculo correspondiente en la

caja de unión y apriete bien.

Una vez que el tanque esté montado en el pedestal, puede ocurrir algún derrame menor. Permita que se estabilice completamente el

fluido antes de inspeccionar la unidad en busca de fugas.

.

:

Tapaflujo (iinserte el

tapaflujo dentro de la

tapa antes de colocarle

la tapa al tanque)

Almohadilla

del

calentado

Tanque

33"

(838mm)

a 45"

(1143mm)

Tapa perforada

Junta

Termostato

(1133mm)

a 56⁵⁄₈"

(1438mm)

Gire la tapa

para cerrar

44⁵⁄₈"

14

11/21/2016 Bradley • 215-1714 Rev. F; ECN 16-05-066

Page 15

Installation S19-921H, S19-921HR

Paso 3: Ponga a prueba la unidad lavadora de ojos

1. P

ruebe la unidad tirando de la solapa frontal hacia abajo y hacia afuera. Esta

acción debe activar el rociador de agua automáticamente. Verifique el flujo de agua

de los rociadores y revise si existen fugas de agua en toda la unidad. Inspeccione

la camisa calentadora visualmente para verificar la operación correcta del elemento

de la calefacción.

Inspeccione semanalmente la unidad lavadora de ojos para verificar su limpieza y

el nivel de solución adecuado (según la norma ANSI Z358.1-2009). Cuando el nivel

de solución caiga bajo la línea de llenado de 15 minutos, se debe vaciar y volver

a llenar el tanque. Llene el tanque del lavador de ojos siguiendo el procedimiento

descrito en el Paso 2 de la página 14.

2. Fije la etiqueta de inspección (incluída) a la unidad lavadora de ojos. Esta etiqueta

debe usarse para documentar la inspección semanal del lavador de ojos. Los

sujetadores se proporcionan para asociar la etiqueta a la unidad.

3. Si la unidad lavadora de ojos no está funcionando adecuadamente, retírela del área

de riesgo y póngase en contacto con Bradley Corporation inmediatamente.

Tanque

Coloque el almohadilla del calentador

uniformemente alrededor del orificio de drenaje.

No bloquee del orificio de drenaje.

Pedestal

Tapa

Orificio de drenaje

Tubo

esnórquel

Abrazadera

Pestillo

Perforador

Vista superior del pedestal

Caja de conexiones para la camisa calentadora opcional

Luz Indicadora

• Luz verde: indica que la unidad tiene corriente.

• Luz amarilla: indica que el calentador está funcionando y calentando la unidad lavadora de ojos. La luz estará encendida sólo

cuando el calentador esté encendido (calentando la unidad lavadora de ojos).

• Luz roja: indica que hay que reestablecer el termostato. Para reestablecer el termostato, siga el procedimiento descrito a

continuación.

1. Quite la parte superior de la camisa calentadora.

2. Localice el botón de reestablecimiento en la caja el termostato.

• Después de presionar el botón, revise para verificar que la luz roja esté apagada, y la verde encendida (la luz amarilla estará

encendida sólo cuando el calentador esté encendido). Si la luz roja está todavía encendida, presione de nuevo el botón de

reestablecimiento.

3. Vuelva a colocar la parte superior de la camisa calentadora en su lugar.

Bradley • 215-1714 Rev. F; ECN 16-05-066 11/21/2016

15

Page 16

S19-921H, S19-921HR Installation

Mantenimiento

Consulte las instrucciones del fabricante para el uso correcto del preservativo para estación de lavaojos.

Inspección de la unidad lavadora de ojos

1. Inspeccione semanalmente la unidad lavadora de ojos para verificar su limpieza y el nivel de solución adecuado (según la norma

ANSI Z358.1-2009).

2. Ponga a funcionar la unidad lavadora de ojos cada vez que se reemplazca la solución para asegurarse de que funcione

adecuadamente. Si la unidad lavadora de ojos no está funcionando adecuadamente, retírela del área de riesgo y póngase en

contacto con Bradley Corporation inmediatamente.

• Revise el flujo de agua de los rociadores y procure tener un flujo uniforme y continuo. Los rociadores están unidos a la palanca

con tornillos y pueden desmontarse de la bandeja para su limpieza o para eliminar alguna obstrucción, si es necesario (utilize

una llave hexagonal Allen de ⁹⁄₆₄" para desmontar e instalar nuevamente los rociadores).

• Revise la manguera del suministro de agua que se encuentra en la parte inferior de la unidad lavadora de ojos y busque

posibles grietas, fugas de agua o desgaste.

• Revise toda la unidad en busca de posibles fugas de agua.

• Revise que la solución no esté contaminada y reemplácela con una solución nueva, si es necesario.

Limpieza de la unidad lavadora de ojos

Al usar el agua potable y el preservativo del agua (recomendados):

1. Separe cuidadosamente el tanque del pedestal y drene la solución del tanque (disponga de la solución apropiadamente). Para

facilitar el drenaje, el pedestal tiene un orificio de drenaje que recibe un tubo de ½” de diámetro interior en la parte inferior del

orificio (el tubo no está incluído) (vea Figura 2b de la página 15 para la ubicación del orificio de drenaje).

2. Limpie la parte interior del tanque usando agua tibia y un jabón suave; enjuague abundantemente.

3. Llene el tanque del lavador de ojos siguiendo el procedimiento descrito en el Paso 2 de la página 14. Para darle el uso adecuado al

conservante de agua, siga las instrucciones del fabricante del producto.

4. Instale nuevamente el tanque del lavador de ojos siguiendo el procedimiento descrito en el Paso 2 de la página 14.

Al usar el agua potable solamente:

1. Vacie el tanque en caulquier momento de una vez por semana a una vez por mes dependiendo de la calidad de su abastecimiento

de agua. El fabricante no es responsable de variaciones en el abastecimiento de agua.

2. Limpie el interior del tanque usando el agua caliente y un producto suave del jabón. Aclare el tanque a conciencia con agua

caliente.

3. Vuelva a llenar el tanque lavaojos con agua potable tibia.

Funcionamiento de la unidad lavadora de ojos

1. Tire de la solapa frontal hacia abajo y hacia afuera. Esta acción debe activar los rociadores de agua automáticamente.

2. Use los dedos índice y pulgar para mantener los ojos abiertos. Gire los ojos hacia adelante y atrás para enjuagar completamente

los ojos. Deje que el agua le enjuague ambos ojos simultáneamente por un mínimo de 15 minutos.

3. Después de su uso, busque atención médica inmediatamente.

No se apoye en la bandeja del lavador de ojos cuando se encuentre abierta. Se puede dañar la unidad.

16

11/21/2016 Bradley • 215-1714 Rev. F; ECN 16-05-066

Loading...

Loading...