Page 1

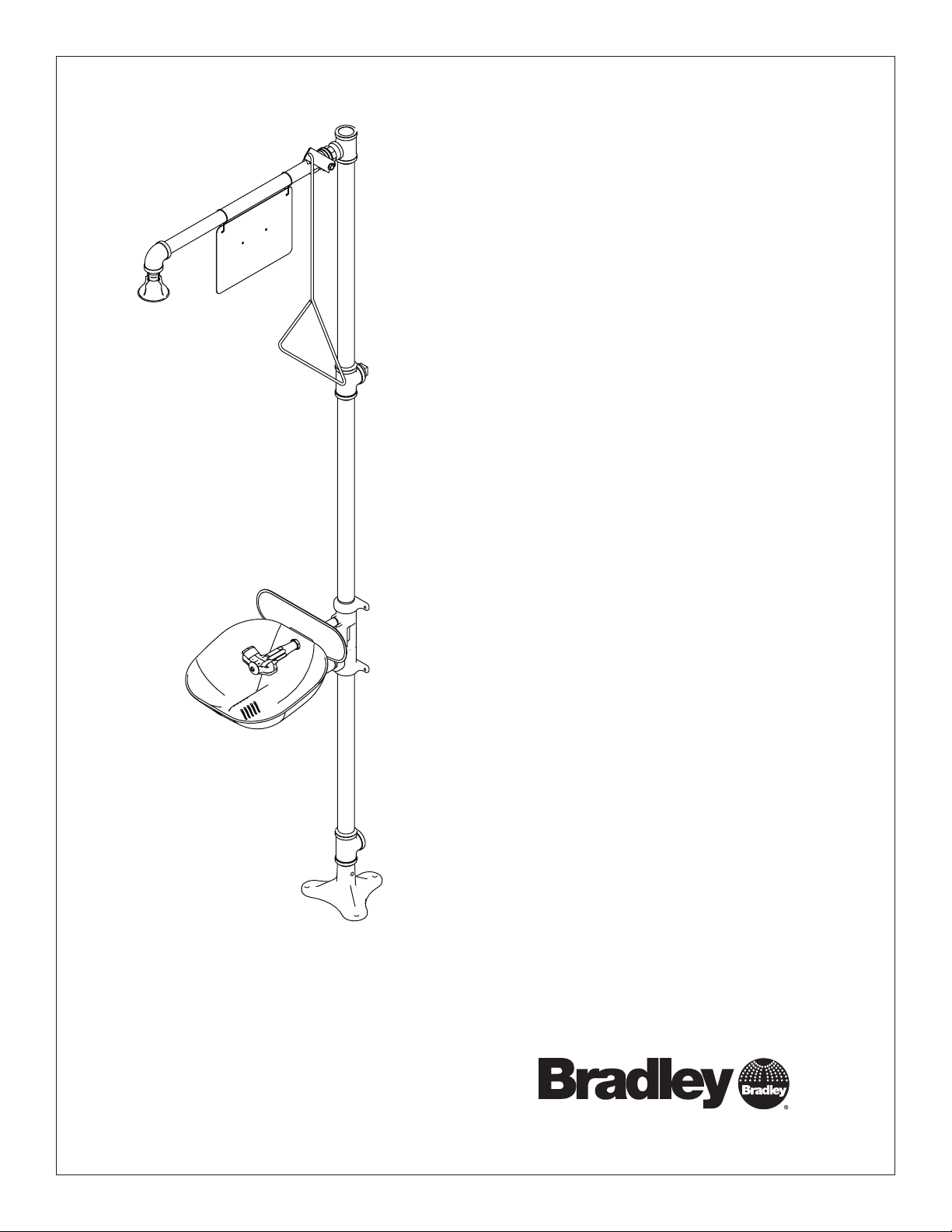

Installation

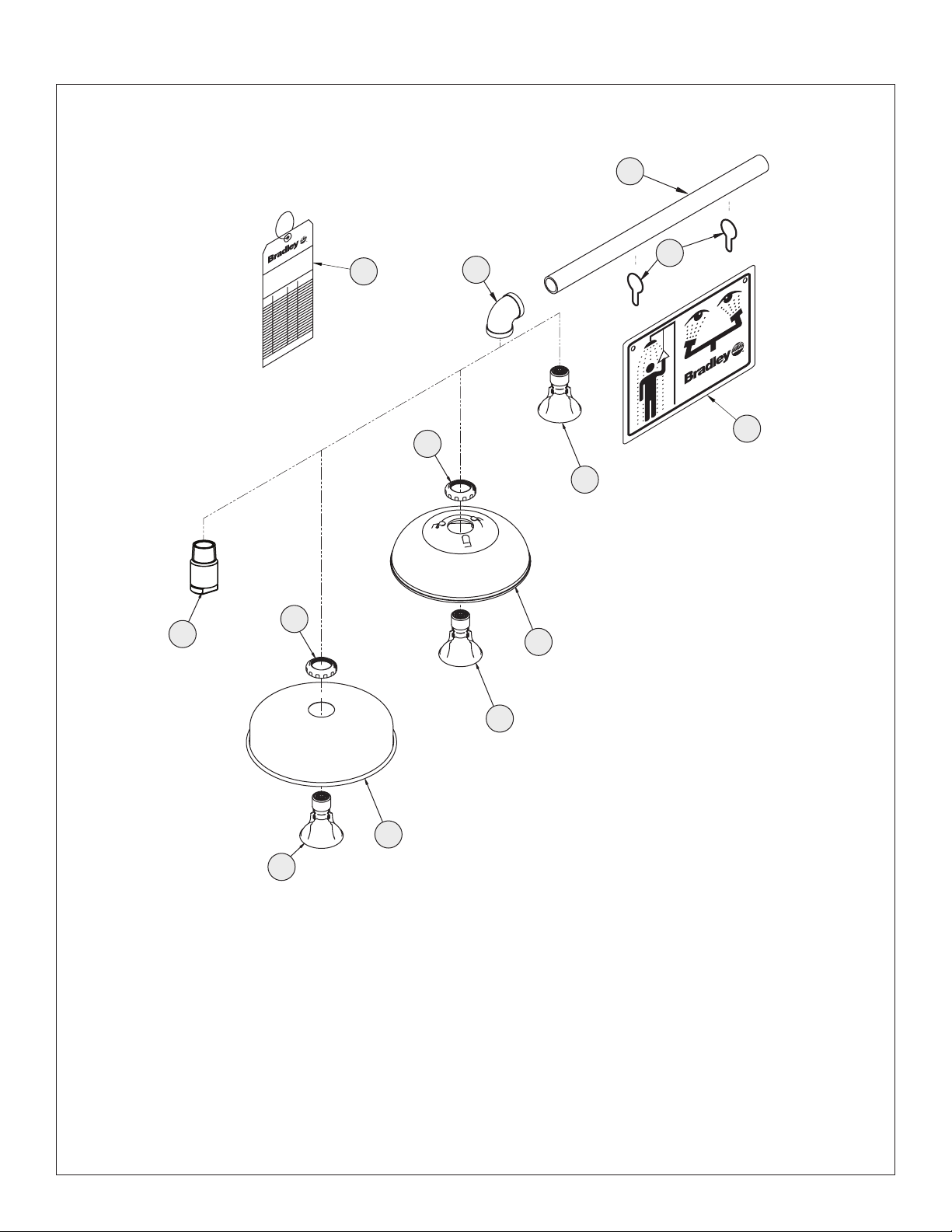

S19314 Series

Halo™ Combination Drench Shower

and Eyewash or Eye/Face Wash

215-1684 Rev. P; ECN 15-05-019

© 2015 Bradley

Page 1 of 56 8/5/2015

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

800 BRADLEY (800 272 3539) +1 262 251 6000

bradleycorp.com

Page 2

S19314 Installation

Table of Contents

Table of Contents..........................................................................2

Pre-Installation Information ................................................................ 3-4

Halo Pre-Configured Models ................................................................5-6

Halo Configurator..........................................................................7

Dimensions .............................................................................. 8

Installation Instructions .................................................................. 9–10

Service Parts — Bowl and Hub ........................................................... 11–12

Service Parts — Eyewash, Eye/Face Wash and Bowl Covers ................................... 13–15

Service Parts — Base and Drain............................................................. 16

Service Parts — Drench Shower.......................................................... 17–19

Service Parts — Optional Accessories ........................................................20

Avant l’installation ..................................................................... 21-22

Modèles préconfigurés Halo ..............................................................23-24

Configuration du produit ...................................................................25

Dimensions ............................................................................. 26

Instructions d'installation ................................................................ 27–29

Pièces de remplacement — Récepteur et moyeu............................................. 30–31

Pièces de remplacement — Douche oculaire, Douche oculaire/faciale et couvercle anti-poussières ..... 32–33

Pièces de remplacement — Bride et drain ..................................................... 34

Pièces de remplacement — Douche d'urgence .............................................. 35–37

Pièces de remplacement — Accessoires en option ..............................................38

Información previa a la instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39-40

Modelos preconfigurados Halo ............................................................41-42

Configuración del producto .................................................................43

Dimensiones ............................................................................ 44

Instrucciones de instalación. ............................................................. 45–46

Piezas de repuesto — Receptor y buje..................................................... 47–48

Piezas de repuesto — Lavaojos, lavaojos/rostro y cubierta contrapolvo ........................... 49–51

Piezas de repuesto — Base y drenaje ........................................................ 52

Piezas de repuesto — Ducha de aspersión ................................................. 53–55

Piezas de repuesto — Accesorios opcionales ..................................................56

2

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 3

Installation S19314

WARNING

Flush the water supply lines before beginning installation and after installation is complete. Test

the unit for leaks and adequate water flow. Main water supply to the eyewash should be “ON” at all

times. Provisions shall be made to prevent unauthorized shutoff.

CAUTION

Emergency equipment must be supplied with tepid water (60°F to 100°F/15.6°C to 37.8°C). Any

prolonged exposure to near freezing water affects the body's ability to maintain body temperature,

increasing the risk of hypothermia.

NOTICE

Before installing this product, ensure that there are adequate clearances around the product and

activation of the product does not interfere with other products or obstructions.

Avoid cleaners containing organic solvents, alcohols and hydrocarbons. Rinse with water after

cleaning.

IMPORTANT

The installation and location of all safety drench showers, eye and eye/face washes must comply

with the requirements of ANSI/ISEA Z358.1.

Read this installation manual completely to ensure proper installation, then file it with the owner or

maintenance department. Compliance and conformity to drain requirements and other local codes

and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding any

packaging material. If any parts are missing, do not begin installation until you obtain the missing

parts.

The ANSI/ISEA Z358.1 standard requires an uninterrupted supply of flushing fluid. Bradley plumbed

emergency fixtures require a minimum of 30 PSI (0.21MPa) flowing pressure.

Self-closing spring-loaded valves are not UL classified to ANSI/ISEA Z358.1.

Weekly activation must be conducted on all plumbed emergency equipment to ensure a suitable

flushing fluid supply is present and any sediment build-up in the supply line is cleared. Emergency

equipment should be inspected monthly to address any maintenance issues ensuring the

equipment is in good operating condition and that there are no signs of wear.

Workers who may come in contact with potentially hazardous materials should be trained regarding

the placement and proper operation of emergency equipment per ANSI/ISEA Z358.1.

For questions regarding the operation or installation of this product, visit www.bradleycorp.com or

call 800-BRADLEY (272.3539).

Product warranties and parts information may also be found under ”Products” on our web site at

bradleycorp.com.

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

3

Page 4

S19314 Installation

Supplies Required:

• (3) 3⁄8" floor anchors and bolts

• Teflon tape and pipe sealant

• 30 PSI (2.0 bar) min/90 PSI (6.1 bar) max flow pressure

• 125 PSI (8.6 bar) max static pressure

• Piping to 1¼" NPT (BSPP) water supply inlet (30–90 psi [2.0-6.1 bar])

• Piping to 1¼" NPT drain outlet on unit (if included with unit)

• Adequate supply pipe supports

• Provisions to dispose of shower waste water (minimum 30 gallons [115 liters]) should be made (minimum 4" [102mm] drain.

• OPTIONAL: sign-mounting hardware

• DVGW certified teflon tape (for DVGW certified models only)

Local codes may require the installation of a backflow prevention valve to complete proper installation. Compliance with

local codes is the responsibility of the installer. Valve must be tested annually to verify that it is functioning properly.

Backflow prevention valves are not included with the fixture and may be supplied by the contractor or purchased from

Bradley Corporation.

4

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 5

Installation S19314

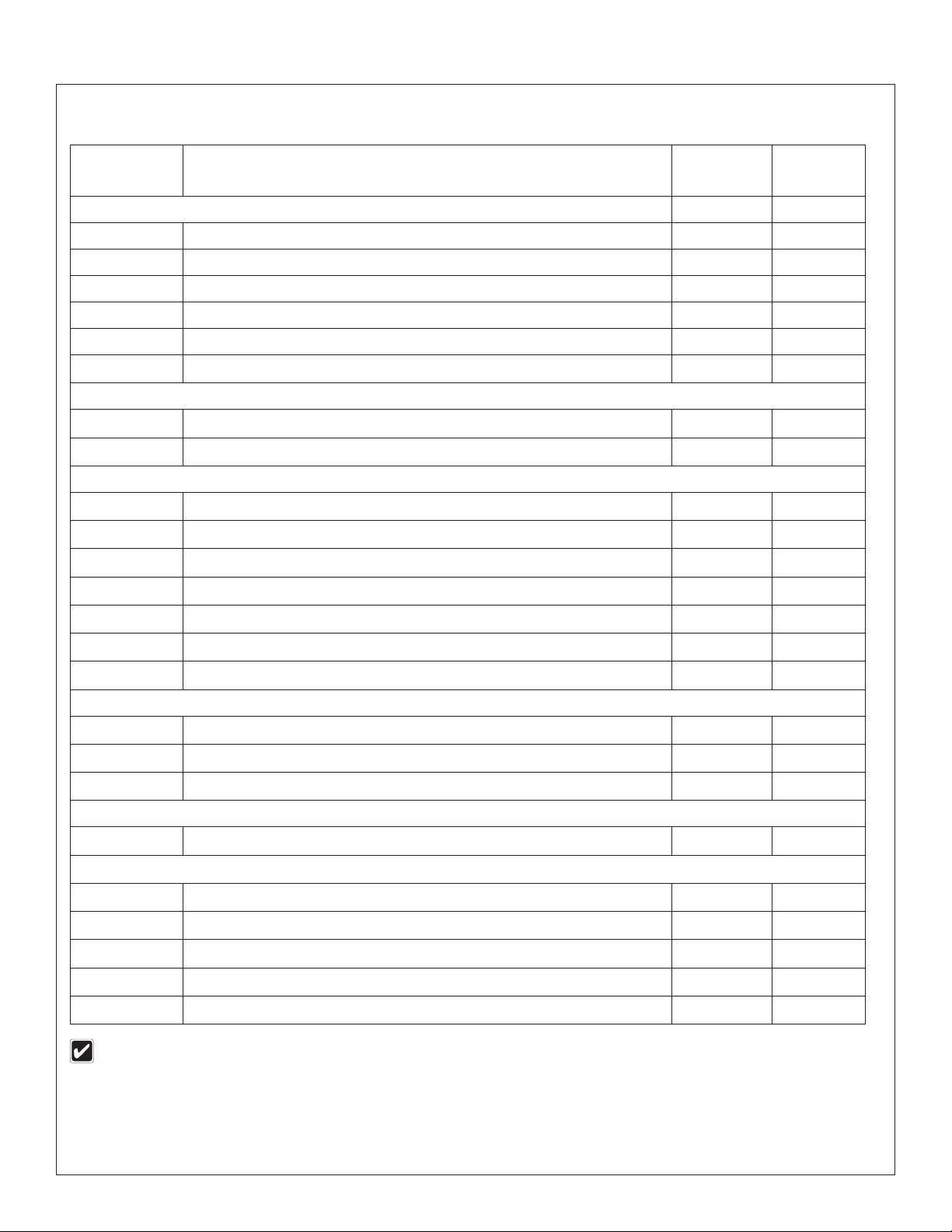

Halo Pre-Configured Models

Halo Model

Number

Eyewashes

S19314EW

S19314P*

S19314SB

S19314LL

S19314F

S19314UU

Halo Eyewash, plastic showerhead & bowl

Halo Eyewash, plastic showerhead & bowl w/ hose spray

Halo Eyewash, plastic showerhead, stainless steel bowl

Halo Eyewash, plastic showerhead, stainless steel bowl, hand/foot activated

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl, hand/foot operated eyewash

Eyewashes with Dust Cover

S19314PDC

S19314DC

Halo Eyewash, plastic showerhead & bowl w/ dust cover

Halo Eyewash, plastic showerhead, stainless steel bowl & hinged dust cover

Eye-Face Washes

S19314FW

S19314SBFW

S19314AC

S19314TT

Halo Eye/face wash, plastic showerhead & bowl

Halo Eye/face wash, plastic showerhead, stainless steel bowl

Halo Eye/face wash, plastic showerhead, stainless steel bowl, hand/foot operated eyewash

Halo Eye/face wash, plastic showerhead w/ stainless steel shroud & bowl

Description

UL certified to

ANSI/ISEA

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

Intertek

certified to

EN standards

S19314SPR

S19314BFPB

S19314BF

Halo Eye/face wash, stainless steel showerhead & bowl, hand/foot operated eyewash

Halo Eye/face wash, barrier-free, plastic showerhead & bowl

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl

Eye-Face Washes with Dust Covers

S19314PDCFW

S19314DCFW

S19314DCBF

Halo Eye/face wash, plastic showerhead & bowl w/ dust cover

Halo Eye/face wash, plastic showerhead, stainless steel bowl & hinged dust cover

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl w/ dust cove

Eye-Face Washes without Eyewash Bowl

S19314GG

Halo Eye/face wash, plastic showerhead, no bowl

All Stainless Steel Eye-Face Wash

S19314BFSS

S19314FSS

S19314SC

S19314SS

S19314SS16

Halo stainless steel eye/face wash and showerhead, barrier free

Halo stainless steel eye/face wash and showerhead

Halo stainless steel eye/face wash, bowl, cover and showerhead

Halo stainless steel eye/face wash and showerhead with foot activation

Halo 316 stainless steel eye/face wash and showerhead with foot activation

Models with BSPP threading available. For BSPP threading, add a Z to end of existing part

number. For example, S19314EW will be S19314EWZ.

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

5

Page 6

S19314 Installation

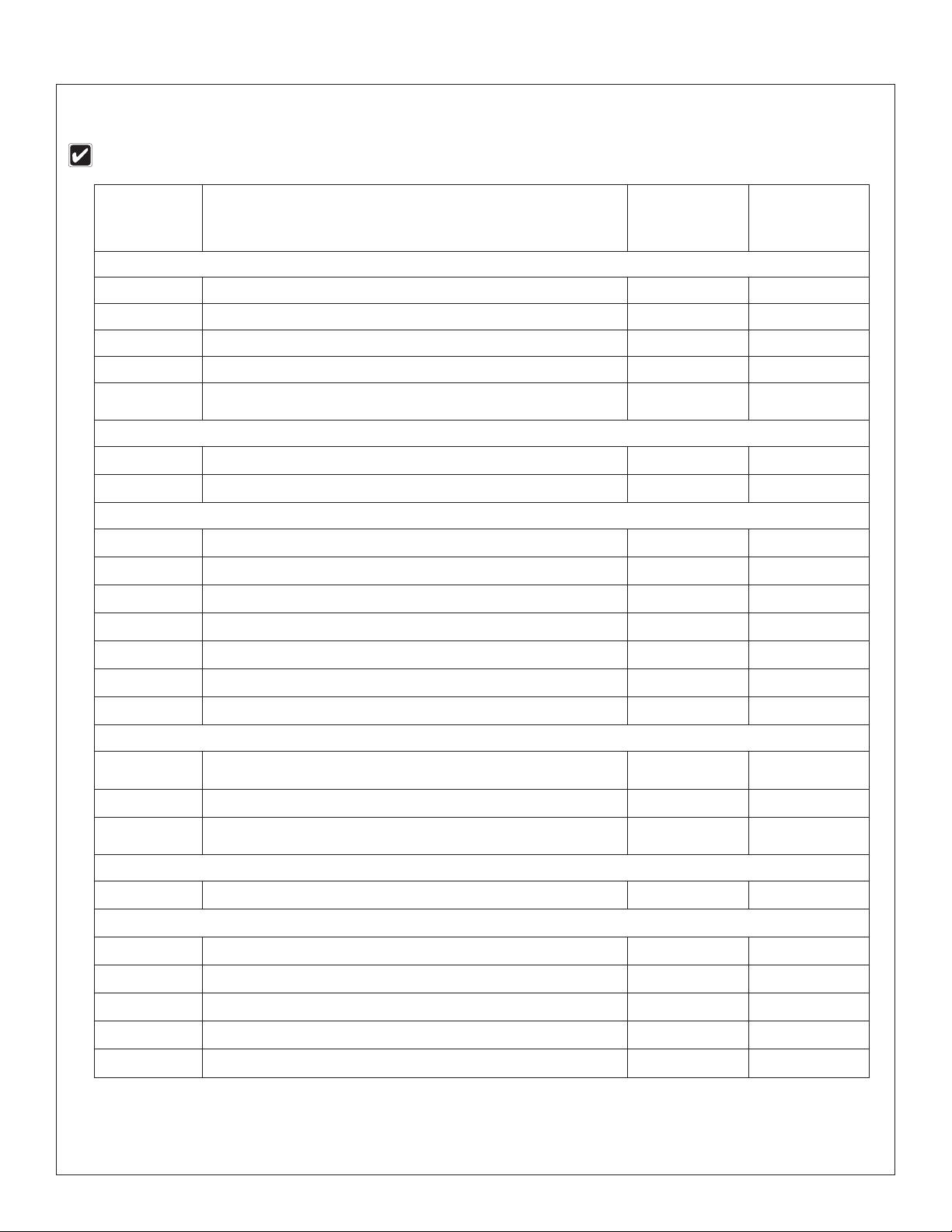

Halo Pre-Configured Models

All models with DIN-DVGW, AS4775 & AS/NZS 4020 Certification include stainless steel pipe material with BSPP threading.

Halo Model

Number

Eyewashes

S19314EWZS

S19314SBZS

S19314LLZS

S19314FZS

S19314UUZS

Halo Eyewash, plastic showerhead & bowl

Halo Eyewash, plastic showerhead, stainless steel bowl

Halo Eyewash, plastic showerhead, stainless steel bowl, hand/foot activated

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl,

hand/foot operated eyewash

Eyewashes with Dust Cover

S19314PDCZS

S19314DCZS

Halo Eyewash, plastic showerhead & bowl w/ hinged dust cover

Halo Eyewash, plastic showerhead, stainless steel bowl & hinged dust cover

Eye-Face Washes

S19314FWZS

S19314SBFWZS

S19314ACZS

S19314TTZS

Halo Eye/face wash, plastic showerhead & bowl

Halo Eye/face wash, plastic showerhead, stainless steel bowl

Halo Eye/face wash, plastic showerhead, stainless steel bowl, hand/foot operated eyewash

Halo Eye/face wash, plastic showerhead w/ stainless steel shroud & bowl

Description

IAPMO Oceana

certified to

AS4775 & AS4020

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

DIN-DVGW

certified to

DIN EN 15154-1 &

DIN EN 15154-2

S19314SPRZS

S19314BFPBZS

S19314BFZS

Halo Eye/face wash, stainless steel showerhead & bowl, hand/foot operated eyewash

Halo Eye/face wash, barrier-free, plastic showerhead & bowl

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl

Eye-Face Washes with Dust Covers

S19314PDCFWZS

S19314DCFWZS

S19314DCBFZS

Halo Eye/face wash, plastic showerhead & bowl w/ hinged dust cover

Halo Eye/face wash, plastic showerhead, stainless steel bowl & hinged dust cover

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl w/

hinged dust cover

Eye-Face Washes without Eyewash Bowl

S19314GGZS

Halo Eye/face wash, plastic showerhead, no bowl

All Stainless Steel Eye-Face Wash

S19314BFSSZ

S19314FSSZ

S19314SCZ

S19314SSZ

S19314SS16Z

Halo stainless steel eye/face wash & showerhead, barrier free

Halo stainless steel eye/face wash & showerhead

Halo stainless steel eye/face wash, bowl, cover & showerhead

Halo stainless steel eye/face wash and showerhead with hand/foot activation

Halo 316 stainless steel eye/face wash and showerhead with hand/foot activation

X

X X

X X

X X

X X

X X

X X

X

X

X

X

X

6

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 7

Installation S19314

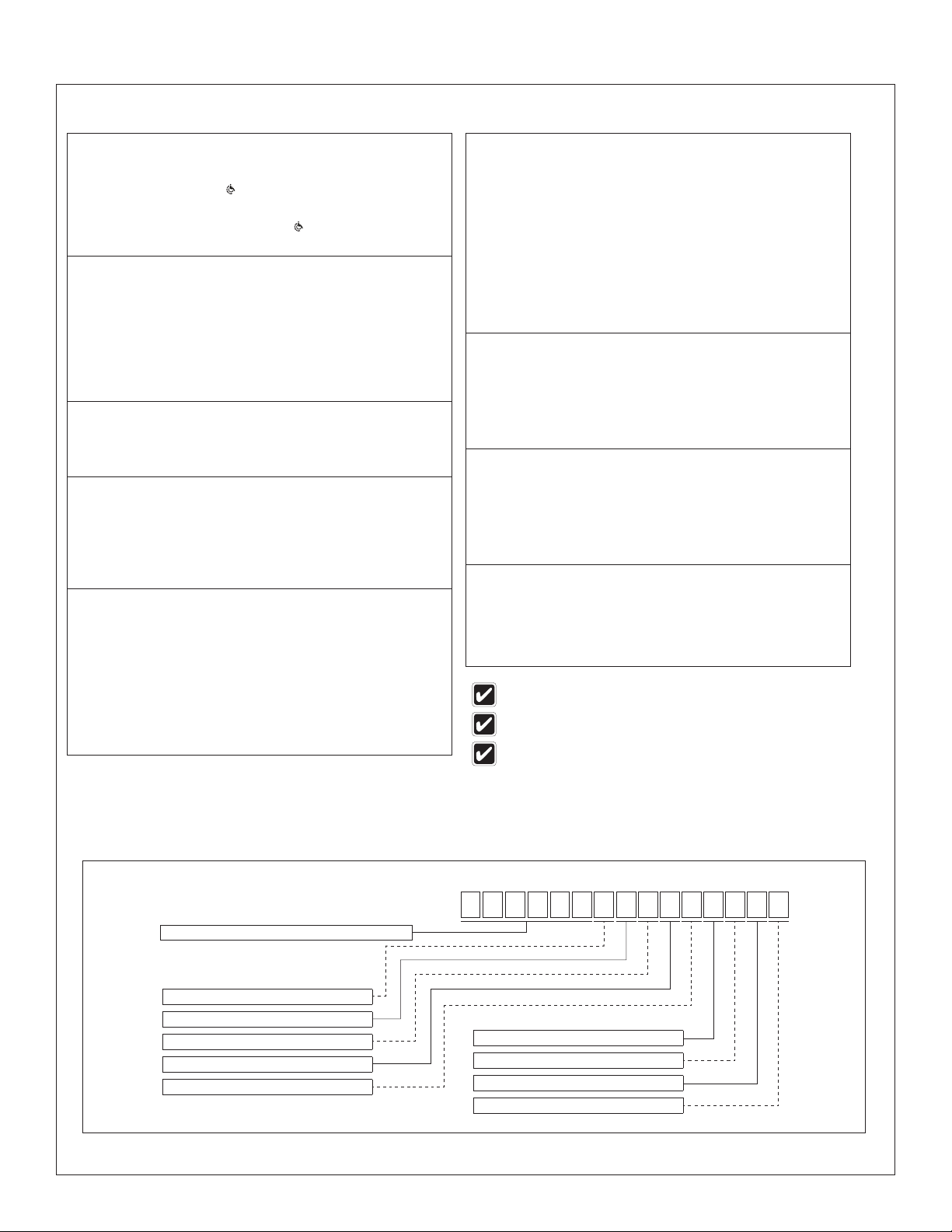

Halo Configurator

Standard Selections (Must select one from each category)

Configuration

¨A

¨B

¨C

¨0

Pipe Material

¨A

¨B

¨C

¨D

¨F

¨G

¨J

Ball Valve

¨1

¨2

¨3

Showerhead

¨A

¨B

¨C

¨D

¨E

Eyewash – Eye/Face Wash

¨A

¨B

¨D

¨E

¨F

¨G

¨H

¨J

* Not available with barrier-free configurations.

** Self-closing valves are not ANSI/ISEA Z358.1 compliant.

‡

Not available in the U.S.

B

arrier Free

24" Drain Height

24" Drain Height, B

Standard, 6" Drain Height

NPT, Yellow BradTect Galvanized Steel

NPT, All 304 Stainless Steel

NPT, All 316 Stainless Steel *

NPT, Chrome-Plated

BSPP, Yellow BradTect Galvanized Steel ‡

BSPP, All 304 Stainless Steel ‡

BSPP, Chrome-Plated ‡

Stay-Open Shower and Eyewash, Chrome-Plated Brass

Stay-Open Shower and Eyewash, 316 SS

Self-Closing Shower and Stay-Open Eyewash, Chrome-Plated Brass **

Plastic Showerhead

Plastic Showerhead with Plastic Shroud

Plastic Showerhead with Stainless Steel Shroud

304 SS High Performance Showerhead

316 SS High Performance Showerhead

Halo Eyewash

Halo Eye/Face Wash

Halo Eyewash, 304 SS Yoke

Halo Eye/Face Wash, 304 SS Yoke

304 SS Halo Eye/Face Wash, 304 SS Yoke

Halo Eyewash, 316 SS Yoke

Halo Eye/Face Wash, 316 SS Yoke

316 SS Halo Eye/Face Wash, 316 SS Yoke

arrier Free

Bowl and Dust Cover

¨A

¨B

¨D

¨E

¨F

¨G

¨H

¨J

¨0

Activation

¨A

¨B

¨C

¨D

¨E

Drench Hose and Backflow Prevention

¨A

¨B

¨C

¨D

¨0

Freeze and Scald Protection

¨N

¨P

¨R

¨0

Plastic Bowl, No Dust Cover

Plastic Bowl, Plastic Dust Cover

304 SS, No Dust Cover

304 SS, 304 SS Dust Cover

304 SS, Plastic Dust Cover

316 SS, No Dust Cover

316 SS, 316 SS Dust Cover

316 SS, Plastic Dust Cover

No Bowl or Dust Cover

300 SS Handle

316 SS Handle

300 SS Handle, 300 SS Foot Pedal

300 SS Handle, 316 SS Foot Pedal *

316 SS Handle with 316 SS Foot Pedal *

Drench Hose Kit with Vacuum Breaker

Drench Hose Kit with N9 Backflow Preventer

Drench Hose Kit with 9D Backflow Preventer

Drench Hose Kit without Backflow Preventer

No Drench Hose and No Backflow Prevention

Anti-Freeze Valve

Anti-Scald Valve

Anti-Freeze and Anti-Scald Valves

No Anti-Freeze Valve and No Anti-Scald Valve

NPT = National Pipe Thread

BSPP = British Standard Pipe Parallel Threads

All selections made through the configurator are only

UL certified to ANSI/ISEA Z358.1

How to Specify Model and Configurations

for Bradley Halo Products:

Model No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .S19314

1. Configuration

2. Pipe Material

3.

Ball Valve

4.

Showerhead

5. Eyewash – Eye/Face Wash

S

6. Bowl and Dust Cover

7. Activation

8. Drench Hose and Backflow Prevention

9. Freeze and Scald Protection

3 1 4

9

1

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

3

421

5 6

7 8 9

7

Page 8

S19314 Installation

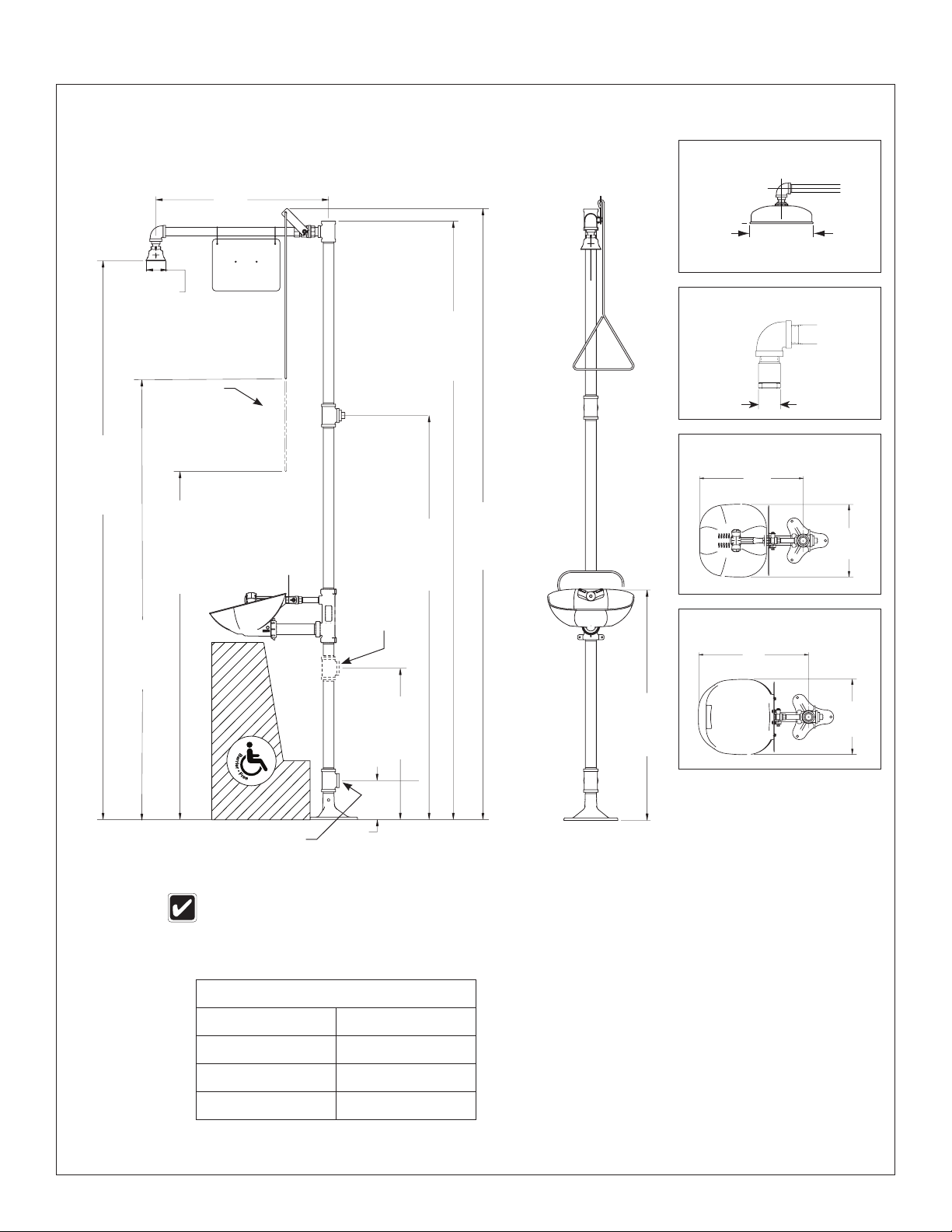

Dimensions

S19314 shown with Plastic Bowl and Plastic Showerhead

13

⁄16"

26

(681mm)

Ø 3.1"

(78.7mm)

Optional

barrier free

pull rod

861⁄8"

(2188mm)

to bottom

of base

47"

(1193mm)

to bottom

of base for

barrier free

option

7

67

⁄8"

(1724mm)

to bottom

of base

Optional

drain

outlet

92

(2342mm)

to bottom

of base

62¼"

(1581mm)

to bottom

of base

3

⁄16"

94

(2391mm)

to bottom

of base

Plastic Showerhead with Plastic

or Stainless Steel Shroud

Plastic Ø 10" (254mm)

Stainless Steel Ø 10¾" (273mm)

Type 304 and 316 Stainless Steel

Showerheads

1½"

(38mm)

Eyewash Bowl

18½"

(470mm)

1

⁄8"

13"

(330mm)

Dust Cover

19¾"

(502mm)

34¾"

(883mm)

to bottom

of base

Standard

drain

outlet

24½"

(622mm)

to Bottom

of Base

6"

(152mm)

All dimensions assume standard thread engagement. Variations in manufacturing allow for +/- 1⁄8"

(3mm) per threaded joint. To find the tolerance of a dimension, add the number of thread joints

across the length of the dimension and multiply it by 1⁄8" (3mm).

Water Flow Rate

Showerhead 20–26 gpm

Eyewash 4–5¼ gpm

Eye/Face Wash 4–5¼ gpm

Body Wash 2–8 gpm

13¼"

(337mm)

8

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 9

Installation S19314

1

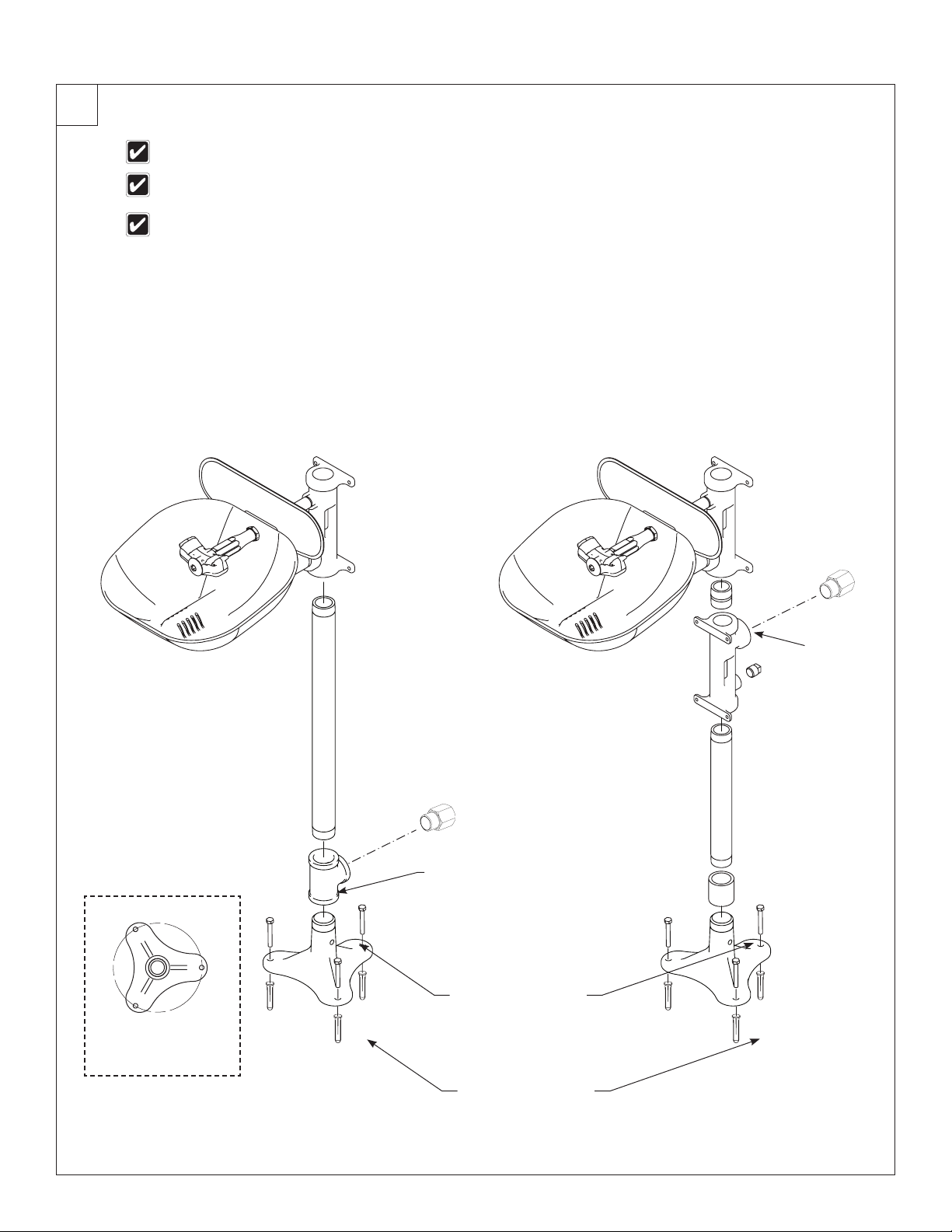

Assembly — Connect Base and Eyewash

Standard eyewash unit is shown. Other units are similar.

Connect components before securing the base to the floor. When connecting

components, use the rubber grip pad (provided) around pipes to prevent marring.

Apply pipe sealant (supplied by installer) to all male-threaded pipe joints, making

sure not to get any excess over the edge of the pipes.

Halo unit with standard

drain option

20½"

(521mm)

pipe length

BSPP-NPT

1-1/4" Adapter

if supplied

with provided

option

Halo unit with 24"

drain option

BSPP-NPT

1-1/4" Adapter

if supplied

with provided

option

1¼" NPT

drain outlet

12¾"

(324mm)

pipe length

1¼" NPT

drain outlet

For optional foot pedal

installation, the base

(3) Ø 3⁄8" (10mm) holes on

Ø 8" (203mm) bolt circle

must be positioned

so that the hole in the

base is perpendicular

to the user.

³⁄₈" bolts and anchors

supplied by installer.

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

9

Page 10

S19314 Installation

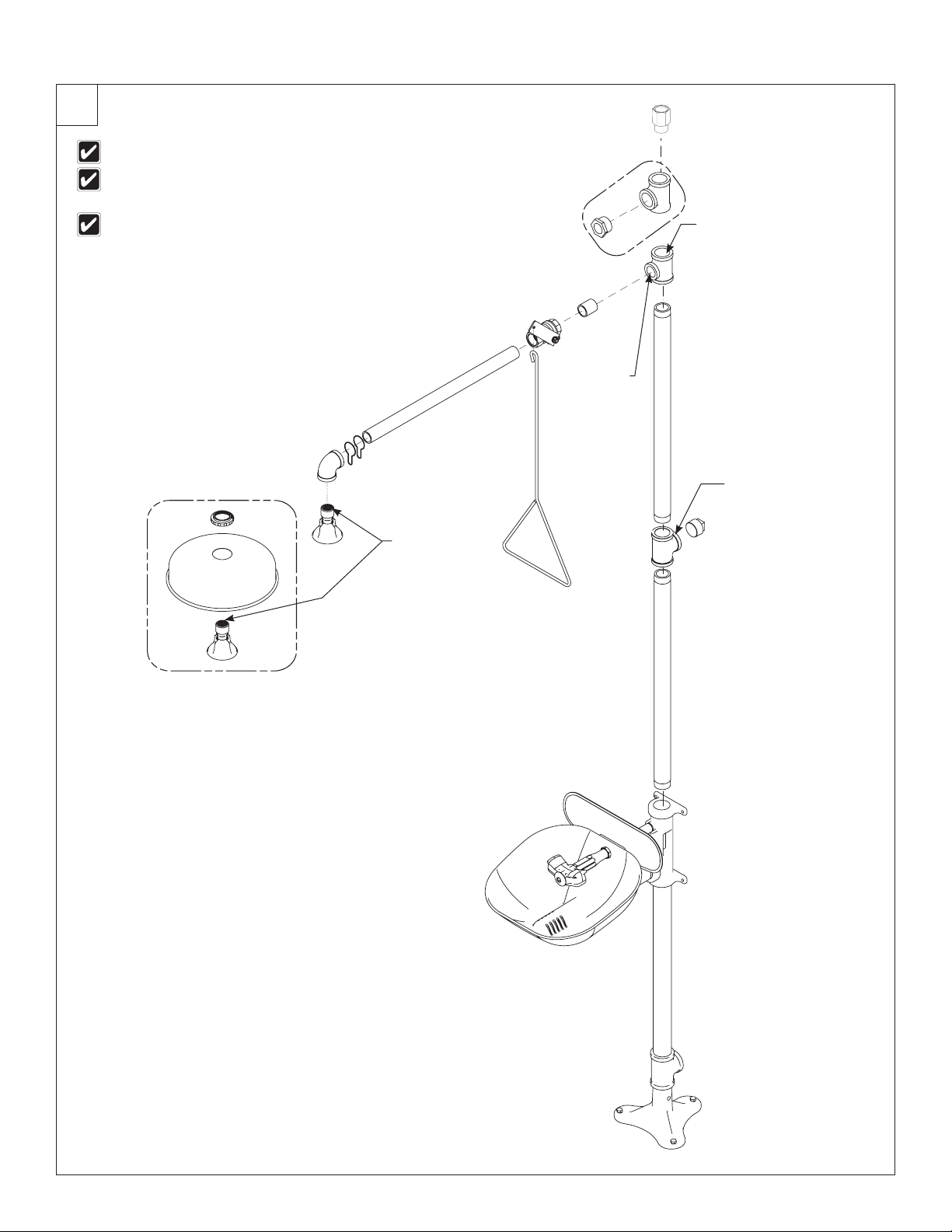

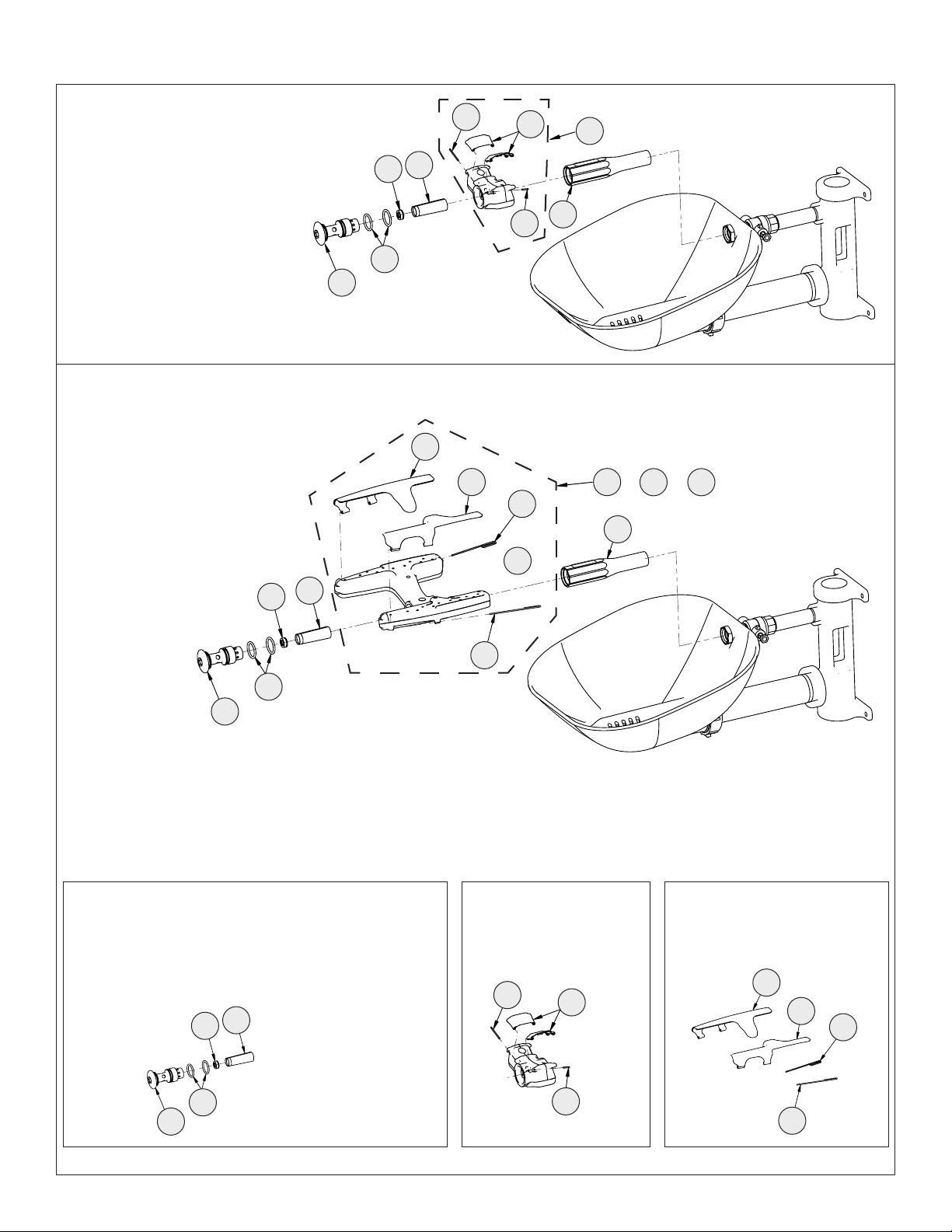

2

Assembly — Connect Drench Shower Components

Standard eyewash unit is shown. Other units are similar.

Apply pipe sealant (supplied by installer) to all male-threaded pipe

joints, making sure not to get any excess over the edge of the pipes.

BSPP = British Standard Pipe Parallel Thread (not available in the

U.S.)

Showerhead with

stainless steel

shroud option

Use teflon

tape only.

Stainless

steel tee with

reducer

1" outlet

for shower

BSPP-NPT

1-1/4" Adapter

if supplied

with provided

option

1¼" NPT below supply inlet

26" (660mm)

pipe length

Alternate 1¼" NPT below

supply inlet

If this tee is used as the

supply inlet, use the plug

on the top supply inlet

and use BSPP adapter

here if supplied with

provided option.

26" (660mm)

pipe length

10

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 11

Installation S19314

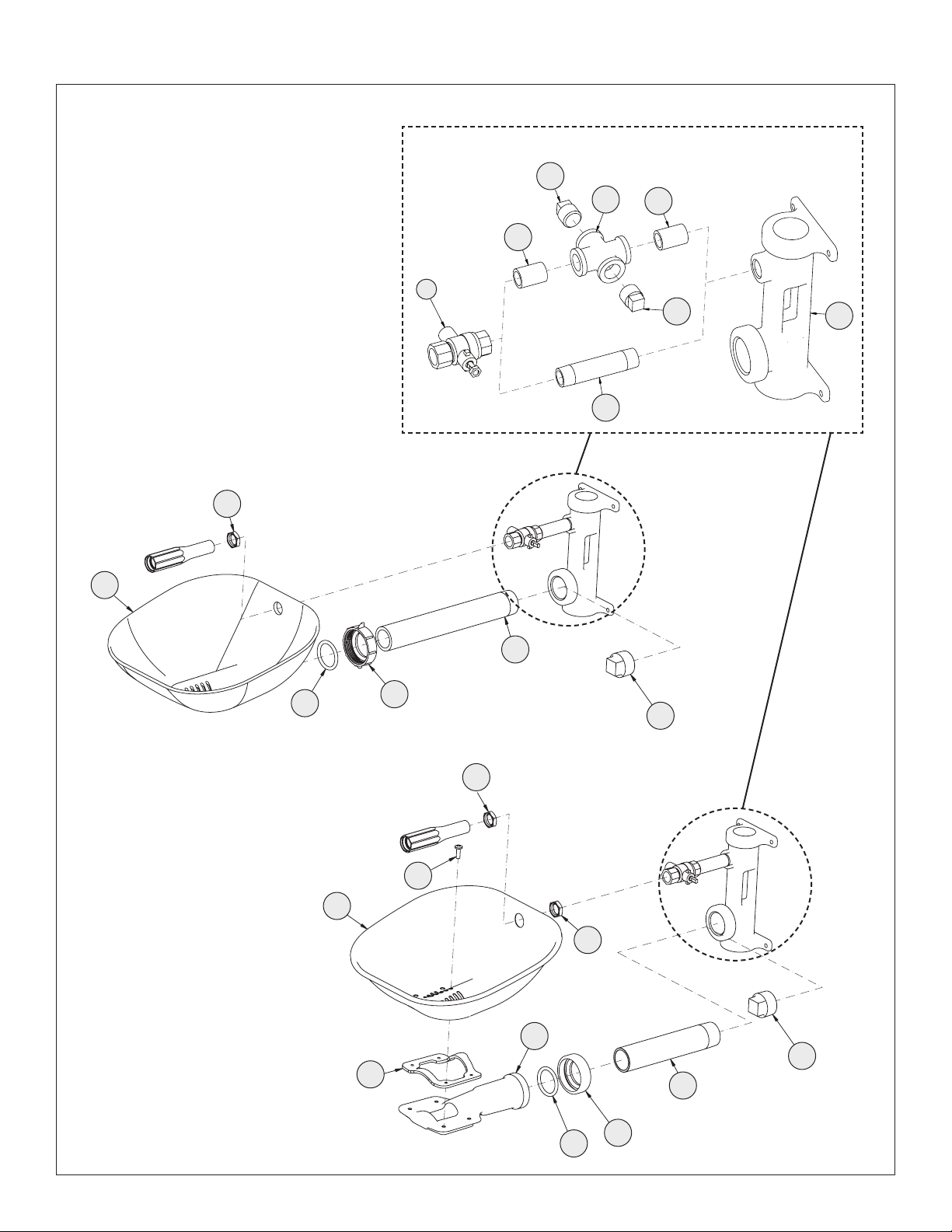

Service Parts — Bowl and Hub

Cross (Item #3) is for use with freeze/scald

valves and drench hose accessories only.

4

3

2b

5

2a

Hub with Plastic Bowl

2b

4

1

15a

17

12

Hub with Stainless Steel Bowl

15b

10a

11a

10c

17

16

17

13

14

11b

12

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

10c

10b

11

Page 12

S19314 Installation

Service Parts List — Bowl and Hub

Item Part No. Qty Description

1 111-092 1 Hub

1 111-093 1 Hub stainless steel

1 111-095 1 Hub stainless steel 316

1 111-094 1 Hub stainless steel polish

2a 113-006LQ 1 Pipe ½" x 3½"

2a 113-965 1 Pipe ½" x 3½" stainless steel

2a 113-1211 1 Pipe ½" x 3½" stainless steel 316

2a 113-596 1 Pipe ½" x 3½" chrome

2b 113-006LG 2 Pipe ½" x close

2b 113-867 2 Pipe ½" x close stainless steel

2b 113-1210 2 Pipe ½" x close stainless steel 316

2b 113-006aw 2 Pipe ½" x close chrome

3 169-1090 1 Cross ½"

3 169-1091 1 Cross ½" stainless steel

3 169-1098 1 Cross ½" stainless steel 316

3 169-1097 1 Cross ½" chrome

4 300-0393 2 Plug ½" chrome

4 153-230 2 Plug ½" stainless steel

4 153-460 2 Plug ½” stainless steel 316

5 S27-327 1 Ball valve ½" with nut

5 S27-328 1 Ball valve ½" ss 316 with nut

5 S27-329 1 Ball valve ½" frost proof with nut

5 S27-330 1 Ball valve ½" ss 316 frost proof with nut

5.1 110-215 1 Nut

5.1 110-248 1 Nut stainless steel 316

Item Part No. Qty Description

10a 113-1202 1 Pipe 1¼" x 11" thd. one end

10a 113-1203 1 Pipe 1¼" x 11" thd. one end stn. steel

10b 113-1204 1 Pipe 1¼" x 7" thd. one end

10b 113-1205 1 Pipe 1¼" x 7" thd. one end stainless steel

10b 113-1206 1 Pipe 1¼" x 7" thd. one end chrome

10b 113-1212 1 Pipe 1¼" x 7" thd. one end stn. steel 316

10c 169-724 1 Plug 1¼" painted galvanized

10c 269-251 1 Plug 1¼" chrome

10c 269-238 1 Plug 1¼" stainless steel

10c 269-1402 1 Plug 1¼" stainless steel 316

11a 110-239 1 Nut plastic, slip joint

11b 110-240 1 Nut, stainless steel slip joint

11b 110-242 1 Nut, stainless steel 316 slip joint

12 125-176 1 O-ring

13 111-099 1 Bowl mount aluminum

13 111-100 1 Bowl mount aluminum painted

13 111-101 1 Bowl mount stainless steel

13 111-102 1 Bowl mount stainless steel 316

14 124-082 1 Bowl gasket

15a 187-320 1 Bowl plastic

15b S90-393 1 Bowl stainless steel (includes Item 14)

15b S90-394 1 Bowl stn. steel 316 (includes Item 14)

16 160-467 4 Screw

17 110-115a as req’d. Nut ½" NPSM chrome brass

17 110-238 as req’d. Nut ½" NPSM stainless steel

17 110-241 as req’d. Nut ½" NPSM stainless steel 316

S90-395 Plastic Prepack includes items 10a, 11a, 12, 15a

15a

12

12

11a

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

10a

300 Series SS Prepack S90-391 includes items 10b, 11b, 12, 13, 14, 15b

316 Series SS Prepack S90-392 includes items 10b, 11b, 12, 13, 14, 15b

15b

13

14

12

10b

11b

Page 13

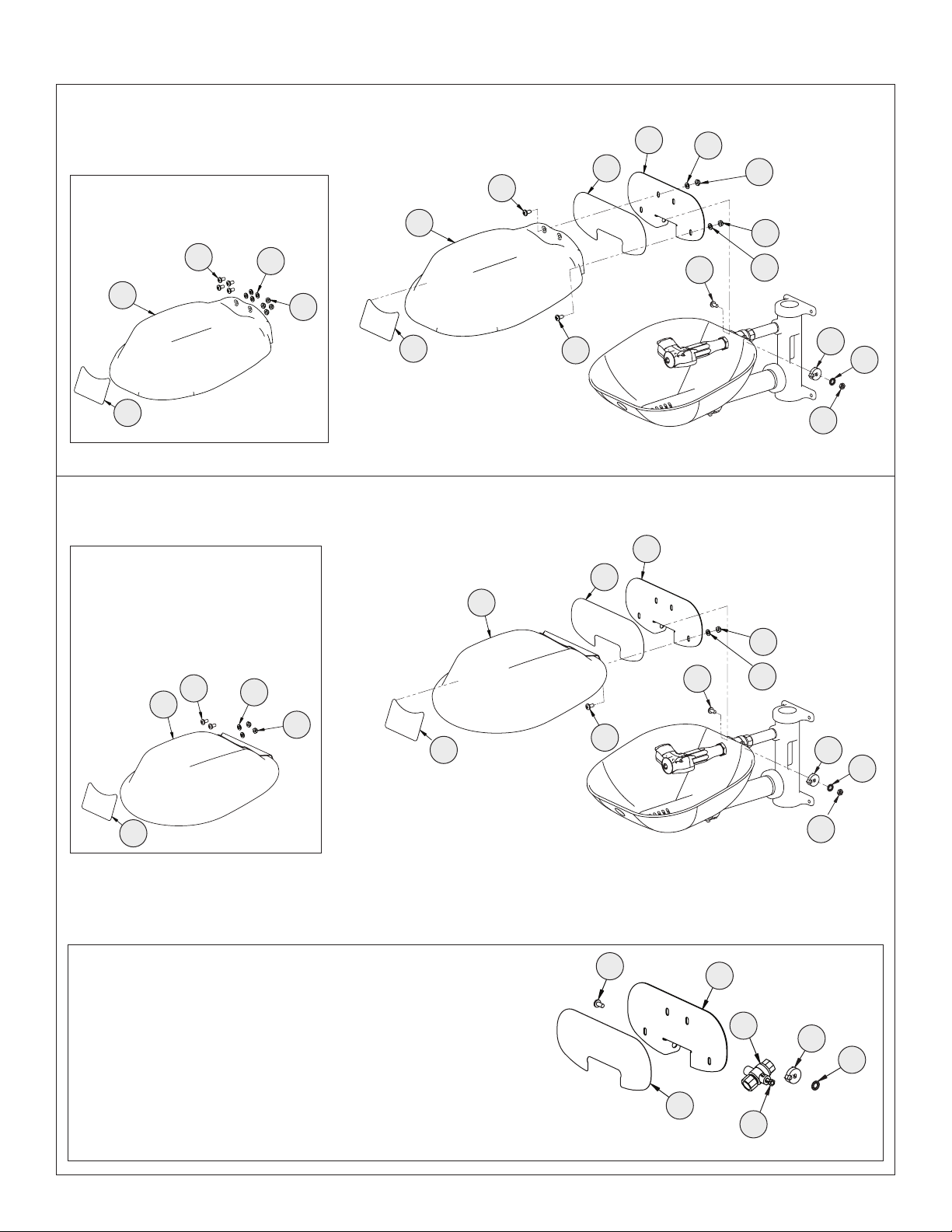

Installation S19314

Service Parts — Eyewash

25

Service Parts — Eye/Face Wash

22

28

27

26

24b

24a

23

22

22

21a

20

or or

21b

21f 21j

20

28

27

26

25

Prepack S65-339 includes items 26, 27, 28

Prepack S88-068 includes items 25, 26, 27, 28

Prepack S88-069 includes items 25, 26, 27, 28 (300 series ss)

Prepack S88-070 includes items 25, 26, 27, 28 (316 ss)

28

27

21b

22

Eyewash Cover Prepack

S45-2675 includes items

22 and 23

22

23

Eye/Face Wash Cover Prepack

S45-2676 includes items 22,

24a and 24b

24b

24a

22

26

25

22

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

22

13

Page 14

S19314 Installation

Service Parts — Plastic Bowl Cover

Plastic Bowl Cover Prepack S90-390

includes items 35a, 36, 39, 42, 43

39

35a

36

42

43

35a

36

Service Parts — Stainless Steel Bowl Cover

Stainless Steel Bowl Cover Prepack

S90-388 includes items 35b, 36, 39,

42, 43

Stainless Steel (316) Bowl Cover

Prepack S90-389 includes items 35b,

36, 39, 42, 43

35b

40

41

39

39

40

41

42

43

43

39

42

44

45

5.1

43

39

35b

36

42

43

36

Handle Prepacks include items 39, 40, 41, 44, 45, 5, 5.1

Prepack S08-390 (for units with brass ball valve)

Prepack S08-391 (for units with stainless steel ball valve)

Prepack S08-392 (for units with brass frost-proof ball valve)

Prepack S08-393 (for units with stainless steel frost-proof ball valve)

Prepack S08-394 (for units with 316 stainless steel ball valve and handle)

Prepack S08-395 (for units with 316 stainless steel frost-proof ball valve

and handle)

39

39

39

41

42

44

45

5.1

40

5

44

45

5.1

14

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 15

Installation S19314

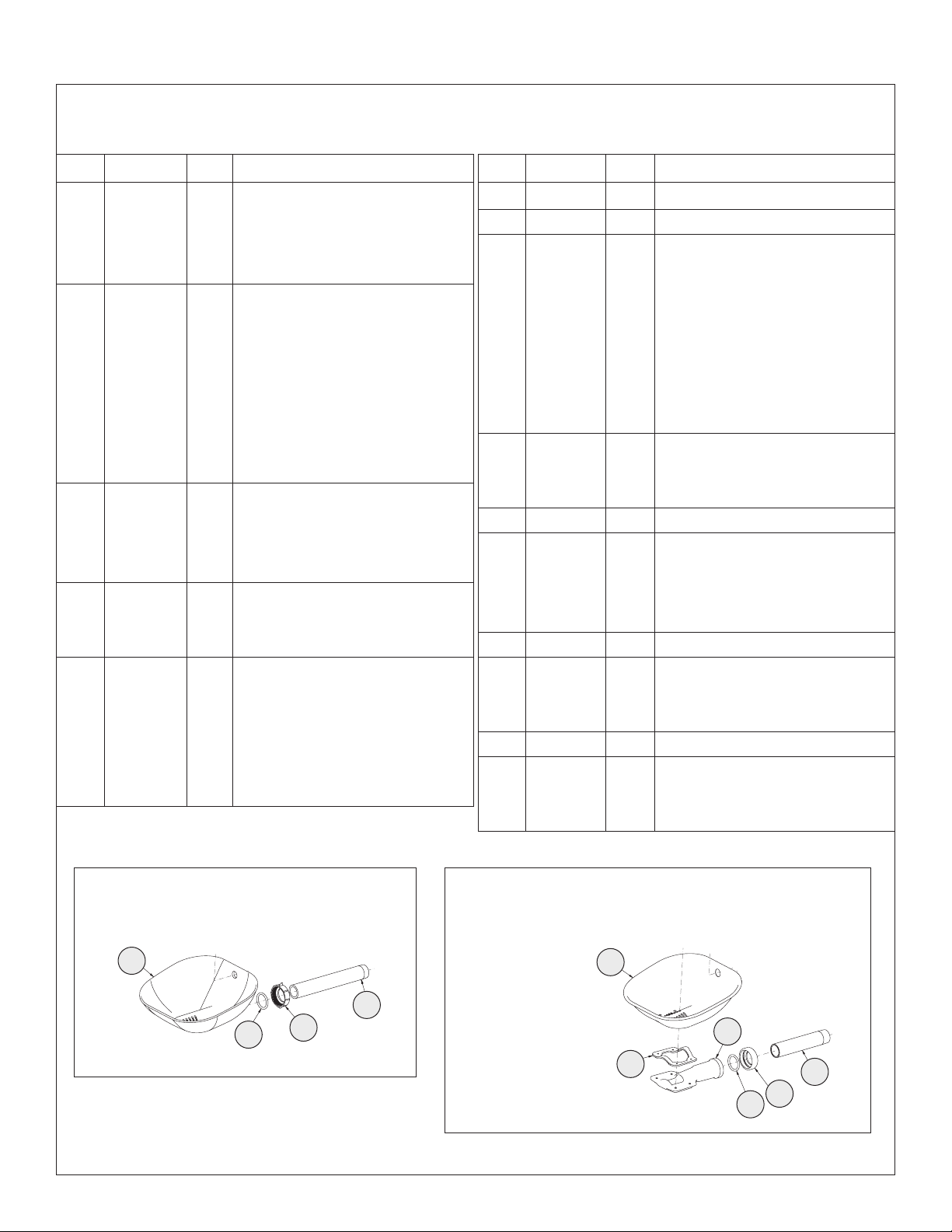

Service Parts List — Eyewash, Eye/Face Wash and Bowl Covers

Item Part No. Qty Description

20

20

20

20

21a

171-001

171-002

171-003

171-004

S05-190

1

Body

1

Body stainless steel

1

Body stainless steel 316

1

Body polished

1

Sprayhead ass’y. eyewash

(includes)

22

23

21b

in service kit

in service kit

S05-192

Pivot pin

2

Flip cover eyewash

2

1

Sprayhead ass’y. eye/face wash

(includes)

22

24a

24b

21f

in service kit

in service kit

in service kit

S05-204

Pivot pin

2

Flip cover right

1

Flip cover left

1

1

Sprayhead stainless steel 304

ass'y. eye/face (includes)

22

24a

24b

21j

in service kit

in service kit

in service kit

S05-205

Pivot pin

2

Flip cover right

1

Flip cover left

1

1

Sprayhead stainless steel 316

ass'y. eye/face (includes)

22

24a

24b

25

25

25

25

in service kit

in service kit

in service kit

115-158

115-159

115-164

115-165

Pivot pin

2

Flip cover right

1

Flip cover left

1

1

Cap

1

Cap stainless steel

1

Cap stainless steel 316

1

Cap polished

Item Part No. Qty Description

26 125-157 2 O-ring

27 125-175 1 Flow control

28 S65-340 1 Screen (incl. 3 per pack)

35a

35b

35b

in service kit

in service kit

in service kit

1

Bowl cover plastic

1

Bowl cover stainless steel

1

Bowl cover stainless steel 316

36 114-097 1 Bowl cover decal

3939160-389

160-469

4040S08-385

as req'd.

as req'd.

Screw ¼-20 x ½" stn. steel

Screw ¼-20 x ½" stn. steel 316

11Handle ss (incl. items 41, 44,

45, 5.1)

S08-388

Handle ss 316 (incl. items 41,

44, 45, 5.1)

41 114-096 1 Decal

42 142-002AV

4343161-060

161-062

as req'd.

as req'd.

as req'd.

Bowl cover washer

Nut stainless steel

Nut stainless steel 316

44 153-372R 1 Adapter ball valve

44

153372R316

1 Adapter ball valve stainless steel

316

45 142-002DA 1 Lockwasher

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

15

Page 16

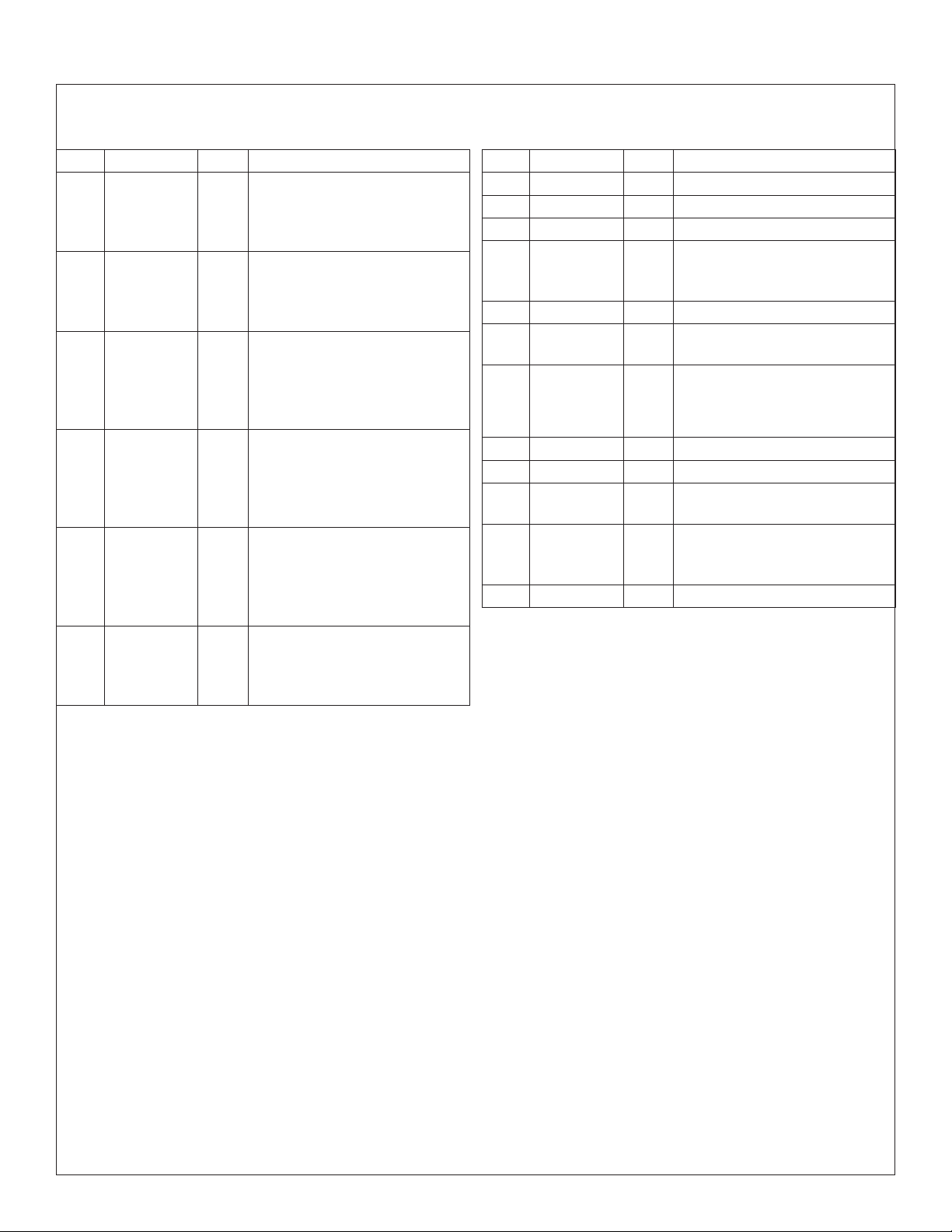

S19314 Installation

Service Parts and Parts List — Base and Drain

Foot Pedal kits

S45-572 (standard foot pedal kit)

S45-1314SS (stainless steel foot pedal kit)

S45-1314SS16 (316 stainless steel foot pedal kit)

303

1

4

321

Base and Drain Kits for 24" Drains include

items 1, 4, 301b, 302b, 303

S29-098 (standard)

S29-099 (stainless steel)

303

1

4

S29-100 (316 stainless steel)

S29-101 (chrome)

301b

302b

Item Part No. Qty. Description

1 111-092 1 Hub

1 111-093 1 Hub stainless steel

1 111-095 1 Hub stainless steel 316

1 111-094 1 Hub stainless steel polish

4 300-0393 2 Plug ½" chrome

4 153-230 2 Plug ½" stainless steel

4 153-460 2 Plug ½" stainless steel 316

301a 113-1197 1 Pipe 1¼" x 20½"

301a 113-1198 1 Pipe 1¼" x 20½" chrome

301a 113-541 1 Pipe 1¼" x 20½" stainless steel

301a 113-1213 1 Pipe 1¼" x 20½" stainless steel 316

301b 113-1217 1 Pipe 1¼" x 12¾"

301b 113-1218 1 Pipe 1¼" x 12¾" chrome

301b 113-1219 1 Pipe 1¼" x 12¾" stainless steel

301b 113-1220 1 Pipe 1¼" x 12¾" stainless steel 316

302a 169-727 1 Tee 1¼" painted galvanized

302a 269-237 1 Tee 1¼" stainless steel

302a 269-1398 1 Tee 1¼" stainless steel 316

302a 269-253 1 Tee 1¼" chrome

301b

301a

Supplied

with BSPP

Thread

options only

302b

302a

304

305b

326

305a

Item Part No. Qty. Description

302b 169-853 1 Coupling 1¼" galvanized

302b 269-257 1 Coupling 1¼" chrome

302b 269-1048 1 Coupling 1¼" stainless steel

302b 269-2016 1 Coupling 1¼" stainless steel 316

303 113-006NA 1 Pipe 1¼" x close painted galvanized

303 113-865 1 Pipe 1¼" x close stainless steel

303 113-1223 1 Pipe 1¼" x close stainless steel 316

304 S06-189 1 Plug chrome solid

305a 131-059 1 Base painted

305a 131-062 1 Base stainless steel

305a 131-079 1 Base stainless steel 316

305b 131-044 1 Base chrome

321 169-1117 1 BSPP-NPT 1-1/4" 303SS

321 169-1118 1 BSPP-NPT 1-1/4" 316SS

326 169-724 1 Plug 1¼" painted galvanized

326 269-251 1 Plug 1¼" chrome

326 269-238 1 Plug 1¼" stainless steel

326 269-1402 1 Plug 1¼" stainless steel 316

16

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 17

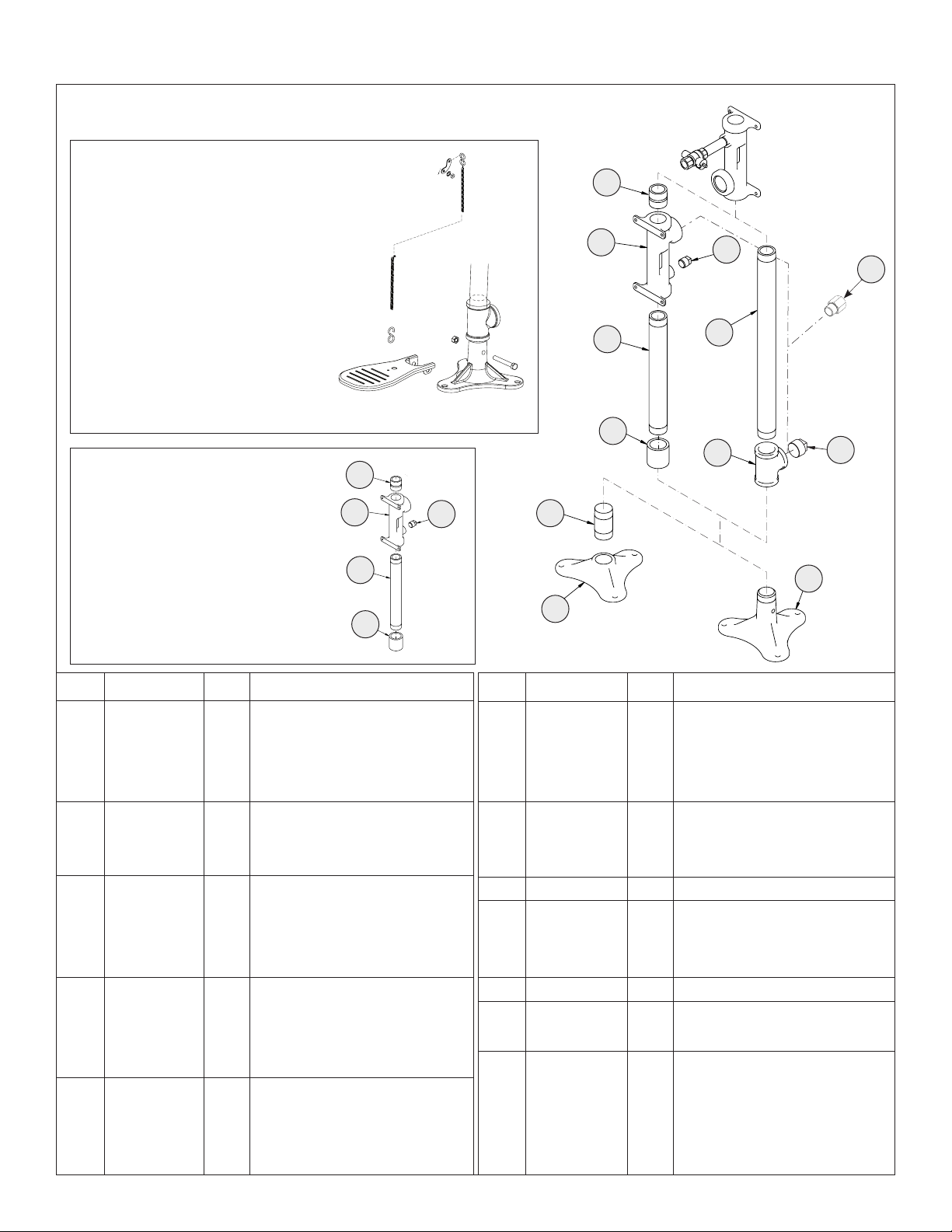

Installation S19314

Service Parts — Drench Shower

330

360b

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Date Signed

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

Date

durch Unterschrift. Jegliche Störung sofort melden.

Date

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

Signed

un rapport immédiatement.

Unterschrift

Signe

Date

Datum

Date

362

R

343

Signed

Signed

341

331

http://www.bradleycorp.com

TEL: 1-800-BRADLEY FAX: (262-251-5817)

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

114-052

342

362

360a

361b

360a

360a

361a

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

17

Page 18

S19314 Installation

Service Parts — Drench Shower

Stainless Steel Valve Prepacks include items

350b, 354b, 355b

S30-061 (for stainless steel valve)

S30-081 (for 316 stainless steel valve)

S30-104 (for frost-proof stainless steel valve)

350b

355b.1

354b

Self-Closing Valve Prepacks

S19-0011 (for standard brass valve)

S30-107 (for frost-proof brass valve)

includes items 350c, 351, 353, 354a, 355a

350c

350b.2

350a

350b

329

351

BSPP Adapter Supplied with BSPP

Thread options only

328

352

354a

355a

321

302

327

325

350a.1

351

353

354a

350a.1

355a

Brass Valve Prepacks include items 350a, 351, 353,

354a, 355a

S30-059 (for standard brass valve)

S30-103 (for frost-proof brass valve)

350a

351

352

350c

351

353

354b

354a

355a

344a

350b.1

326

350b.2

302

325

350a.1

344b

18

354a

340

355a

350a.1

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 19

Installation S19314

Parts List — Showerhead and Shower Valves

BSP = British Standard Pipe Thread (not available in the U.S.)

Item Part No. Qty Description

302 169-727 1 Tee 1¼" painted galvanized

302 169-727B 1 Tee 1¼" painted galvanized BSP

302 269-237 2 Tee 1¼" stainless steel

302 269-1398 2 Tee 1¼" stainless steel 316

302 269-253 1 Tee 1¼" chrome

321 169-1117 2 BSPP-NPT 1-1/4" 303SS

321 169-1118 2 BSPP-NPT 1-1/4" 316SS

325 113-1199 2 Pipe 1¼" x 26"

325 113-1195 2 Pipe 1¼" x 26" stainless steel 316

325 113-1200 2 Pipe 1¼" x 26" stainless steel

325 113-1201 2 Pipe 1¼" x 26" chrome

326 169-724 1 Plug 1¼" painted galvanized

326 269-251 1 Plug 1¼" chrome

326 269-238 1 Plug 1¼" stainless steel

326 269-1402 1 Plug 1¼" stainless steel 316

327 169-722 1 Tee 1¼" x 1" x 1¼"

327 269-249 1 Tee 1¼" x 1" x 1¼" chrome

328 269-1400 1 Reducer 1¼" x 1" stainless steel 316

328 269-236 1 Reducer 1¼" x 1" stainless steel

329 113-006LN 1 Pipe 1" x close painted galvanized

329 113-1214 1 Pipe 1" x close stainless steel 316

329 113-006NL 1 Pipe 1" x close stainless steel

329 113-625 1 Pipe 1" x close chrome

330 113-006MT 1 Pipe 1" x 21" painted galvanized

330 113-1215 1 Pipe 1" x 21" stainless steel 316

330 113-864 1 Pipe 1" x 21" stainless steel

330 113-1216 1 Pipe 1" x 21" chrome

331 169-847 1 Elbow 1" painted galvanized

331 169-1073 1 Elbow 1" chrome

331 169-1074 1 Elbow 1" stainless steel

331 169-1075 1 Elbow 1" stainless steel 316

Item Part No. Qty Description

340 269-915 1 Rubber Grip Pad

341 204-421 1 Emergency Inspection Tag

342 114-052 1 Safety Sign

342 114-052E 1 Safety Sign (not available in the U.S.)

343 151-001 2 Curtain Hook for Safety Sign

344a 128-156A 1 Pull Rod

344b S90-365D 1 Pull Rod ADA

344a 128-157 1 Pull Rod stainless steel 316

350a S27-278 1 Ball valve 1"

350a S27-301 1 Ball valve 1" frost proof

350a.1 110-214 1 Nut

350b S27-276 1 Ball valve 1" stainless steel

350b S27-325 1 Ball valve 1” stainless steel frost proof

350b.1 142-002BC 1 Lockwasher

350b.2 161-079 1 Nut

350c S27-286 1 Ball valve 1" self-closing

351 140-720 1 Bracket stop ball

352 124-048 1 Washer flat

353 S19-001 1 Spring

354a 128-129 1 Handle

354b 128-142 1 Handle stainless steel

354b 128-155 1 Handle stainless steel 316

355a 142-002DC 1 Lockwasher 3⁄8"

360a S24-188 1 Drench shower assembly

360b S24-191 1 Drench shower stainless steel

360b S24-201 1 Drench shower stainless steel 316

361a 187-053 1 Shroud stainless steel

361b 154-058 1 Shroud plastic

362 154-147 1 Shroud ring

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

19

Page 20

S19314 Installation

Service Parts and Parts List — Optional Accessories

to

accessory

to

freeze

valve

370

to

drench

hose

372

370

371

Accessory

Mounting (for

units with two

accessories)

accessory

370

to

Accessory

Mounting (for

units with three

accessories)

to

scald

valve

Item Part No. Qty. Description

370 169-025 as req’d. Elbow ½"

370 269-241 as req’d. Elbow ½" stainless steel

370 269-1396 as req’d. Elbow ½" stainless steel 316

370 169-862 as req’d. Elbow ½" chrome

371 113-006LG 1 Pipe ½" x close

371 113-867 1 Pipe ½" x close stainless steel

371 113-1210 1 Pipe ½" x close stainless steel 316

371 113-006AW 1 Pipe ½" x close chrome

372 169-838 1 Tee ½"

372 169-1100 1 Tee ½" stainless steel

372 269-280 1 Tee ½" chrome

372 169-1099 1 Tee ½" stainless steel 316

Freeze/Scald

Valves

370

376

377

Item Part No. Description

376 S45-1986 Freeze Valve kit

377 S45-1989 Scald Valve kit

370

Drench Hose

390

387b

Preventers for

Drench Hose

Backflow

370

387a

387c

Item Part No. Qty. Description

387a S27-303 1 Vacuum breaker in-line 3⁄8"

387b S45-2309 1 Backflow preventer N9

387c S45-2310 1 Backflow preventer 9D

390 S19-430EH 1 Spray Kit

20

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 21

Installation S19314

AVERTISSEMENT

Rincez la conduite d’alimentation avant et apres l’installation. Assurez-vous que le débit d’eau est

adéquat et qu’il n’y a pas de fuites. L’alimentation principale en eau doit être toujours OUVERTE. On

devra prévoir des dispositions pour empêcher tout arrêt non autorisé.

ATTENTION

Le matériel d’urgence doit être alimenté en eau tiède (15,6 °C à 37,8 °C/60 °F à 100 °F). Toute

exposition prolongée à de l’eau proche de la température de congélation peut altérer la capacité de

l’organisme à maintenir la température corporelle, ce qui accroît le risque d’hypothermie.

AVIS

Avant d’installer ce produit, vérifier qu’il y a des dégagements suffisants autour du produit et que

l’activation du produit n’est pas entravée par d’autres produits ou obstructions.

Éviter les produits nettoyants qui contiennent des solvants organiques, des alcools et des

hydrocarbures. Rincer à l’eau après nettoyage.

IMPORTANT

L’installation et l’emplacement de toutes les douches d’urgence, oculaires et oculaires-faciales

doivent être conformes aux exigences d’ANSI/ISEA Z358.1.

Lire ce manuel d’installation dans son intégralité pour garantir une installation appropriée. Une fois

celle-ci terminée, classer ce manuel auprès du service à la clientèle ou d’entretien. L’installateur est

responsable de la conformité de l’installation aux codes pour des drain et codes et règlements en

vigueur.

Assurez-vous que toutes les pièces sont incluses dans l’emballage et qu’il n’en manque aucune

avant de jeter l’emballage. Ne commencez pas l’assemblage avant de recevoir les pièces

manquantes.

La norme ANSI/ISEA Z358.1 prévoit une alimentation ininterrompue du liquide de rinçage. Les

appareils d’urgence Bradley raccordés au réseau nécessitent une pression d’écoulement d’au moins

30 PSI (0,21 MPa).

Les soupapes à ressort à fermeture automatique ne sont pas classifiées UL selon ANSI/ISEA Z358.1.

Une activation hebdomadaire doit être effectuée sur tout le matériel d’urgence à tuyauterie

d’alimentation pour vérifier que l’arrivée de liquide de rinçage est suffisante et éliminer tout dépôt

de sédiment de la conduite d’alimentation. Le matériel d’urgence doit être contrôlé chaque mois

pour régler tout problème d’entretien éventuel et s’assurer que le matériel est en bon état de

marche et ne présente aucun signe d’usure.

Les ouvriers susceptibles d’entrer en contact avec des matières potentiellement dangereuses

doivent recevoir une formation sur la mise en place et le bon fonctionnement du matériel d’urgence

conformément à la norme ANSI/ISEA Z358.1.

Pour toute question concernant le fonctionnement ou l’installation de ce produit, consulter le site

www.bradleycorp.com ou appeler le 1-800-BRADLEY.

Les garanties de produits figurent sous la rubrique « Informations techniques » sur notre site

Internet à www.bradleycorp.com.

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

21

Page 22

S19314 Installation

Equipements nécessaires :

• (3) ancrages au sol et boulons de 3⁄8"

• Produit d’étanchéité pour tuyaux

• Pression d’écoulement de 30 PSI (2,0 bar) min/90 PSI (6,1 bar) max

• Pression statique de 125 PSI (8,6 bar) max

• Tuyauterie vers entrée d’alimentation de 1¼ po NPT (BSPP) (30 à 90 psi [2,0 à 6,1 bar])

• Tuyau de vidange de 1¼" NPT (s'il est incluse avec l'unité)

• Supports adéquats pour la tuyauterie d’alimentation

• Un renvoi de 4" minimum pour la douche d’urgence assurant une capacité de vidange de 30 gal/mn (115 l/mn)

• Quincaillerie pour l’installation de l’enseigne (en option)

• Ruban Teflon certifié DVGW (modèles certifiés DVGW seulement)

Les codes locaux peuvent exiger l’ installation d’une soupape de prévention d’écoulement de retour pour réaliser une

installation appropriée. L’installateur est responsable de la conformité aux codes locaux. La soupape doit être testée une

fois par an pour vérifier qu’elle fonctionne correctement. Les soupapes de prévention d’écoulement de retour ne sont pas

fournies avec l’appareil et peuvent être fournies par l’entrepreneur ou achetées auprès de Bradley Corporation.

22

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 23

Installation S19314

Modèles préconfigurés Halo

Numéro de

modèle Halo

Douches oculaires

S19314EW

S19314P*

S19314SB

S19314LL

S19314F

S19314UU

Douche oculaire Halo, pomme de douche / vasque en plastique

Douche oculaire Halo, pomme de douche / vasque en plastique avec tuyau de lavage

Douche oculaire Halo, pomme de douche en plastique, vasque en acier inoxydable

Douche oculaire Halo, pomme de douche en plastique, vasque en acier inoxydable, activation à la

main/au pied

Douche oculaire Halo, pomme de douche en plastique avec gaine et vasque en acier inoxydable

Douche oculaire Halo, pomme de douche en plastique avec gaine et vasque en acier inoxydable,

douche oculaire activée à la main/au pied

Douches oculaires avec cache-poussière

S19314PDC

S19314DC

Douche oculaire Halo, pomme de douche / vasque en plastique avec cache-poussière

Douche oculaire Halo, pomme de douche en plastique, vasque et cache-poussière à charnières

en acier inoxydable

Douches oculaires-faciales

S19314FW

S19314SBFW

S19314AC

S19314TT

S19314SPR

S19314BFPB

S19314BF

Douche oculaire-faciale Halo, pomme de douche / vasque en plastique

Douche oculaire-faciale Halo, pomme de douche en plastique, vasque en acier inoxydable

Douche oculaire-faciale Halo, pomme de douche en plastique, vasque en acier inoxydable,

douche oculaire activée à la main/au pied

Douche oculaire-faciale Halo, pomme de douche en plastique avec gaine et vasque en acier

inoxydable

Douche oculaire-faciale Halo, pomme de douche / vasque en acier inoxydable, douche oculaire

activée à la main/au pied

Douche oculaire-faciale Halo, accès immédiat, pomme de douche / vasque en plastique

Douche oculaire-faciale Halo, accès immédiat, pomme de douche en plastique, vasque en

plastique

Douches oculaires-faciales avec cache-poussière

Description

Certifié UL

suivant ANSI/

ISEA

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

Certifié

Intertek

suivant les

normes EN

S19314PDCFW

S19314DCFW

S19314DCBF

Douche oculaire-faciale Halo, pomme de douche / vasque en plastique avec cache-poussière

Douche oculaire-faciale Halo, pomme de douche en plastique, vasque et cache-poussière à

charnières en acier inoxydable

Douche oculaire-faciale Halo, accès immédiat, pomme de douche en plastique, vasque en

plastique avec cache-poussière

Douches oculaires-faciales sans vasque

S19314GG

Douche oculaire-faciale Halo, pomme de douche en plastique, sans vasque

Douche oculaire-faciale tout inox

S19314BFSS

S19314FSS

S19314SC

S19314SS

S19314SS16

Douche oculaire-faciale et pomme de douche en acier inoxydable Halo, accès immédiat

Douche oculaire-faciale et pomme de douche en acier inoxydable Halo

Douche oculaire-faciale, vasque, cache-poussière et pomme de douche en acier inoxydable Halo

Douche oculaire-faciale et pomme de douche en acier inoxydable Halo, activation au pied

Douche oculaire-faciale et pomme de douche en acier inoxydable 316 Halo, activation au pied

Modèles à filetage BSPP également proposés. Pour le filetage BSPP, ajouter un Z à la fin du

numéro de référence. Par exemple, S19314EW devient S19314EWZ.

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

X X

X X

X X

X X

X X

X X

X X

X X

X X

23

Page 24

S19314 Installation

Modèles préconfigurés Halo

Tous les modèles certifiés DIN-DVGW, AS4775 et AS/NZS 4020 comportent une tuyauterie en acier inoxydable à filetage BSPP.

Numéro de modèle

Halo

Douches oculaires

S19314EWZS

S19314SBZS

S19314LLZS

S19314FZS

S19314UUZS

Douche oculaire Halo, pomme de douche / vasque en plastique

Douche oculaire Halo, pomme de douche en plastique, vasque en acier inoxydable

Douche oculaire Halo, pomme de douche en plastique, vasque en acier inoxydable,

activation à la main/au pied

Douche oculaire Halo, pomme de douche en plastique avec gaine et vasque en acier

inoxydable

Douche oculaire Halo, pomme de douche en plastique avec gaine et vasque en acier

inoxydable, douche oculaire activée à la main/au pied

Douches oculaires avec cache-poussière

S19314PDCZS

S19314DCZS

Douche oculaire Halo, pomme de douche / vasque en plastique avec cache-poussière à

charnières

Douche oculaire Halo, pomme de douche en plastique, vasque et cache-poussière à

charnières en acier inoxydable

Douches oculaires-faciales

S19314FWZS

S19314SBFWZS

S19314ACZS

S19314TTZS

S19314SPRZS

S19314BFPBZS

S19314BFZS

Douche oculaire-faciale Halo, pomme de douche / vasque en plastique

Douche oculaire-faciale Halo, pomme de douche en plastique, vasque en acier inoxydable

Douche oculaire-faciale Halo, pomme de douche en plastique, vasque en acier inoxydable,

douche oculaire activée à la main/au pied

Douche oculaire-faciale Halo, pomme de douche en plastique avec gaine et vasque en

acier inoxydable

Douche oculaire-faciale Halo, pomme de douche / vasque en acier inoxydable, douche

oculaire activée à la main/au pied

Douche oculaire-faciale Halo, accès immédiat, pomme de douche / vasque en plastique

Douche oculaire-faciale Halo, accès immédiat, pomme de douche en plastique, vasque en

plastique

Douches oculaires-faciales avec cache-poussière

S19314PDCFWZS

S19314DCFWZS

S19314DCBFZS

Douche oculaire-faciale Halo, pomme de douche / vasque en plastique avec cachepoussière à charnières

Douche oculaire-faciale Halo, pomme de douche en plastique, vasque et cache-poussière

à charnières en acier inoxydable

Douche oculaire-faciale Halo, accès immédiat, pomme de douche en plastique, vasque en

plastique avec cache-poussière à charnières

Douches oculaires-faciales sans vasque

Description

Certifié IAPMO

Oceana suivant

AS4775 et AS4020

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X

X X

X X

X X

X X

X X

Certifié DIN-DVGW

suivant

DIN EN 15154-1 et

DIN EN 15154-2

S19314GGZS

Douche oculaire-faciale tout inox

S19314BFSSZ

S19314FSSZ

S19314SCZ

S19314SSZ

S19314SS16Z

24

Douche oculaire-faciale Halo, pomme de douche en plastique, sans vasque

Douche oculaire-faciale et pomme de douche en acier inoxydable Halo, accès immédiat

Douche oculaire-faciale et pomme de douche en acier inoxydable Halo

Douche oculaire-faciale, vasque, cache-poussière et pomme de douche en acier

inoxydable Halo

Douche oculaire-faciale et pomme de douche en acier inoxydable Halo, activation à la

main/au pied

Douche oculaire-faciale et pomme de douche en acier inoxydable 316 Halo, activation à la

main/au pied

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

X X

X

X

X

X

X

Page 25

Installation S19314

Configuration du produit

Sélections standard (devez sélectionner un de chaque catégorie)

Configuration

¨A

¨B

¨C

¨0

Tuyau

¨A

¨B

¨C

¨D

¨F

¨G

¨J

Robinet

¨1

¨2

¨3

Tête de douche

¨A

¨B

¨C

¨D

¨E

Douche oculaire – faciale

¨A

¨B

¨D

¨E

¨F

¨G

¨H

¨J

* Non disponible avec configurations sans barrière.

** Les soupapes à ressort à fermeture automatique

ne sont pas classifiées UL selon ANSI/ISEA Z358.1.

‡

Non disponible aux États-Unis

Sans barrière

Hauteur de vidange 24"

Hauteur de vidange 24" sans barrière

Hauteur de vidange standard 6"

Acier inox NPT galvanisé avec jaune BradTect

Acier inox 304 NPT

Acier inox 316 NPT*

Laiton chromé NPT

BSPP, Acier inox galvanisé avec jaune BradTect

BSPP, Acier inox 304‡

BSPP, Laiton chromé‡

Restant ouvert (douche d’urgence et douche oculaire), laiton chromé

Restant ouvert (douche d’urgence et douche oculaire), 316 SS

Fermeture automatique (douche d’urgence) et restant ouvert (douche

oculaire), laiton chromé**

Tête de douche plastique

Tête de douche plastique avec pommeau en plastique

Tête de douche plastique avec pommeau en acier inox

Tête de douche acier inox 304 haute performance

Tête de douche acier inox 316 haute performance

Douche oculaire Halo

Douche oculaire/faciale Halo

Douche oculaire Halo, guidon acier inox 304

Douche oculaire/faciale Halo, guidon acier inox 304

Douche oculaire/faciale inox 304 Halo, guidon acier inox 304

Douche oculaire Halo, guidon acier inox 316

Douche oculaire/faciale Halo, guidon acier inox 316

Douche oculaire/faciale inox 316 Halo, guidon acier inox 316

®

®

‡

Récepteur avec couvercle anti-poussières

¨A

¨B

¨D

¨E

¨F

¨G

¨H

¨J

¨0

Activation

¨A

¨B

¨C

¨D

¨E

Gicleur et Prévention d’écoulement de retour

¨A

¨B

¨C

¨D

¨0

¨Z

Vanne antigel et vanne anti-échaudage

¨N

¨P

¨R

¨0

¨Z

Récepteur plastique, sans couvercle anti-poussières

Récepteur plastique, couvercle anti-poussières plastique

Récepteur acier inox 304, sans couvercle anti-poussières

Récepteur acier inox 304, couvercle anti-poussières acier inox 304

Récepteur acier inox 304, couvercle anti-poussières plastique

Récepteur acier inox 316, sans couvercle anti-poussières

Récepteur acier inox 316, couvercle anti-poussières acier inox 316

Récepteur acier inox 316, couvercle anti-poussières plastique

Pas de récepteur, pas de couvercle anti-poussières

Manette acier inox 300

Manette acier inox 316

Manette acier inox 300 avec pédale acier inox 300

Manette acier inox 300 avec pédale acier inox 316*

Manette acier inox 316 avec pédale acier inox 316*

Gicleur avec dispositif la prévention des casse-vide

Gicleur avec dispositif de prévention d’écoulement de retour N9

Gicleur avec dispositif de prévention d’écoulement de retour 9D

Gicleur sans prévention d’écoulement de retour

Pas de gicleur, pas de prévention d’écoulement de retour

Connexions pour le gicleur (le gicleur n'est pas inclus)

Vanne antigel

Vanne anti-échaudage

Vanne antigel et vanne anti-échaudage

Pas de vanne antigel, pas de vanne anti-échaudage

Connexions pour les vannes (les vannes ne sont pas inclus)

NPT = National Pipe Thread

BSPP = Filetage British Standard Pipe Parallel (non

disponible aux États-Unis)

Toutes les sélections effectuées à l’aide du configurateur

sont uniquement certifiées UL suivant ANSI/ISEA Z358.1

Comment spécifier le modèle et les

spécifications des produits Bradley :

Modèle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .S19314

1. Configuration

2. Tuyau

3.

Robinet

4.

Tête de douche

5.

Douche oculaire – faciale

S

6. Récepteur avec couvercle anti-poussières

7. Activation

8. Gicleur et Prévention d’écoulement de retour

9. Vanne antigel et vanne anti-échaudage

3 1 4

9

1

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

3

421

5 6

7 8 9

25

Page 26

S19314 Installation

Dimensions

S19314 montré avec récepteur en plastique et tête de douche en plastique

13

⁄16"

26

(681mm)

Ø 3.1"

(78.7mm)

Tige pour

l'option

1

⁄8"

86

(2188mm)

au fond de

la bride

(1724mm)

au fond de

la bride

(1193mm)

au fond de

la bride pour

l'option "sans

7

⁄8"

67

47"

barrière"

"sans

barrière"

Orifice de

vidange

standard

62¼"

(1581mm)

au fond de

la bride

Orifice de

vidange

en option

24½"

(622mm)

au fond de

la bride

6"

(152mm)

3

⁄16"

92

(2342mm)

au fond de

la bride

(2391mm)

au fond de

la bride

Tête de douche en plastique avec

pommeau en plastique ou acier inox

Plastique Ø 10" (254mm)

Acier Inox Ø 10¾" (273mm)

Tête de douche en acier inox 304

et acier inox 316

1½"

(38mm)

Récepteur

1

⁄8"

94

18½"

(470mm)

13"

(330mm)

Couvercle anti-poussières

19¾"

(502mm)

34¾"

(883mm)

au fond de

la bride

13¼"

(337mm)

26

Toutes les dimensions supposent un engagement de filetage standard. Les variations de

fabrication prévoient +/- 3,1 mm (1⁄8") par joint fileté. Pour trouver la tolérance d’une dimension,

ajouter le nombre de joints filetés entre une dimension et le multiplier par 3,1 mm (1⁄8").

Débit d'eau

Tête de douche 20–26 gpm

Douche oculaire 4–5¼ gpm

Douche oculaire/faciale 4–5¼ gpm

Douche pour le corps 2–8 gpm

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 27

Installation S19314

1

Assemblage — Bride et douche oculaire

Douche oculaire standard illustrée. Les autres unités sont similaires.

Connectez les composants avant de fixer la base au sol. Utilisez des tampons autour

des tuyaux pour ne pas les endommager lors du serrage.

Mettez du produit d’étanchéité (non fourni) sur tous les filetages mâles. Ne laissez

pas le produit d 'étanchéité à déborder sur le bord des tuyaux.

Unité de Halo avec l'option

de vidange standard

20½"

(521mm)

la longueur

du tuyau

Adaptateur

BSPP-NPT

1¼ po si fourni

avec l’option

considérée

Unité de Halo avec l'option

de vidange de 24"

Adaptateur

BSPP-NPT

1¼ po si fourni

avec l’option

considérée

Orifice de

vidange

1¼" NPT

12¾"

(324mm)

la longueur

du tuyau

Orifice de

vidange

1¼" NPT

Pour une installation à pédale

au pied en option, la base doit

être positionnée de manière

(3) trois trous de Ø 3⁄8" (10mm)

sur un de Ø 8" (203mm)

que le trou dans la base soit

perpendiculaire à l’utilisateur.

Vissez la bride dans

les ancrages à l’aide

des vis de ³⁄₈" (non

fournies).

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

27

Page 28

S19314 Installation

2

Assemblage — Raccorder les tuyaux de la douche d’urgence

Douche d'urgence standard illustrée. Les autres unités sont similaires.

Mettez du produit d’étanchéité (non fourni) sur tous les filetages mâles.

Ne laissez pas le produit d 'étanchéité à déborder sur le bord des tuyaux.

BSPP = Filetage British Standard Pipe Parallel (non disponible aux

États-Unis)

Tête de douche avec

pommeau en acier

inox en option

Utiliser

uniquement du

ruban de téflon.

Té de réduction

acier inox

Vidange 1"

pour douche

d'urgence

Adaptateur

BSPP-NPT

1-1/4 po si fourni

avec l’option

considérée

Arrivée d’eau par le dessous

1 1/4 po NPT

26" (660mm)

la longueur

du tuyau

Arrivée d’eau par le dessous 1

1/4 po NPT supplémentaire

Si ce té est utilisé en tant

qu’entrée d’alimentation,

poser le bouchon sur

l’entrée d’alimentation du

haut et utiliser l’adaptateur

BSPP ici s’il est fourni avec

l’option considérée.

26" (660mm)

la longueur

du tuyau

28

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 29

Installation S19314

Pièces de remplacement — Récepteur et moyeu

La croix (réf. n° 3) est à utiliser avec les vannes

anti-échaudage/gel et les accessoires de tuyau

4

2b

5

2a

Moyeu avec récepteur en plastique

d’arrosage uniquement.

3

2b

4

1

17

15a

12

Moyeu avec récepteur en acier inox

10a

11a

10c

17

16

15b

17

13

14

11b

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

10c

10b

29

Page 30

S19314 Installation

Liste des pièces — Récepteur et moyeu

Pièce Réf. Qté. Description

1 111-092 1 Moyeu

1 111-093 1 Moyeu acier inox

1 111-095 1 Moyeu acier inox 316

1 111-094 1 Moyeu acier inox poli

2a 113-006LQ 1 Tuyau ½" x 3½"

2a 113-965 1 Tuyau ½" x 3½" acier inox

2a 113-1211 1 Tuyau ½" x 3½" acier inox 316

2a 113-596 1 Tuyau ½" x 3½" chromé

2b 113-006LG 2 Tuyau ½" x ferme

2b 113-867 2 Tuyau ½" x ferme en acier inox

2b 113-1210 2 Tuyau ½" x ferme en acier inox 316

2b 113-006AW 2 Tuyau ½" x ferme chromé

3 169-1090 1 Croix ½"

3 169-1091 1 Croix ½" acier inox

3 169-1098 1 Croix ½" acier inox 316

3 169-1097 1 Croix ½" chromé

4 300-0393 2 Bouchon ½" chromé

4 153-230 2 Bouchon ½" acier inox

4 153-460 2 Bouchon ½" acier inox 316

5 S27-327 1 Robinet ½" avec écrou

5 S27-328 1 Robinet ½" acier inox 316 avec écrou

5 S27-329 1 Vanne antigel ½" avec écrou

5 S27-330 1 Vanne antigel ½" acier inox 316 avec écrou

5.1 110-215 1 Écrou

5.1 110-248 1 Écrou acier inox 316

Pièce Réf. Qté. Description

10a 113-1202 1 Tuyau 1¼" x 11" extrémité filetée

10a 113-1203 1 Tuyau 1¼" x 11" acier inox extrémité filetée

10b 113-1204 1 Tuyau 1¼" x 7" extrémité filetée

10b 113-1205 1 Tuyau 1¼" x 7" acier inox extrémité filetée

10b 113-1206 1 Tuyau 1¼" x 7" chromé extrémité filetée

10b 113-1212 1 Tuyau 1¼" x 7" acier inox 316 extrémité filetée

10c 169-724 1 Bouchon 1¼" peint galvanisé

10c 269-251 1 Bouchon 1¼" chromé

10c 269-238 1 Bouchon 1¼" acier inox

10c 269-1402 1 Bouchon 1¼" acier inox 316

11a 110-239 1 Écrou, plastique

11b 110-240 1 Écrou, acier inox

11b 110-242 1 Écrou, acier inox 316

12 125-176 1 Bague

13 111-099 1 Support récepteur aluminum

13 111-100 1 Support récepteur peint aluminum

13 111-101 1 Support récepteur acier inox

13 111-102 1 Support récepteur acier inox 316

14 124-082 1 Joint d’etanchéité

15a 187-320 1 Récepteur plastique

15b S90-393 1 Récepteur acier inox (incl. le élément 14)

15b S90-394 1 Récepteur acier inox 316 (incl. le élément 14)

16 160-467 4 Vis

17 110-115a Écrou ½" NPSM laiton chromé (qté. au besoin)

17 110-238 Écrou ½" NPSM acier inox (qté. au besoin)

17 110-241 Écrou ½" NPSM acier inox 316 (qté. au besoin)

Paquet récepteur plastique S90-395 comprend les

éléments 10a, 11a, 12, 15a

15a

12

30

Paquet récepteur acier inox 300 Serie S90-391 comprend les

éléments 10b, 11b, 12, 13, 14, 15b

Paquet récepteur acier inox 316 Serie S90-392 comprend les

éléments 10b, 11b, 12, 13, 14, 15b

15b

10a

11a

14

13

10b

11b

12

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 31

Installation S19314

Pièces de remplacement — Douche oculaire

22

28

27

26

25

23

20

22

Pièces de remplacement — Douche oculaire/faciale

24b

24a

22

21a

21b

20

or or

21f 21j

28

27

26

25

Paquet S65-339 comprend les éléments 26, 27, 28

Paquet S88-068 comprend les éléments 25, 26, 27, 28

Paquet S88-069 comprend les éléments 25, 26, 27, 28

(acier inox 300 serie)

Paquet S88-070 comprend les éléments 25, 26, 27, 28

(acier inox 316)

28

27

21b

22

Paquet couvertures à

bascule (douche oculaire)

S45-2675 comprend les

éléments 22 et 23

22

23

Paquet couvertures à

bascule (douche oculaire/

faciale) S45-2676 comprend

les éléments 22, 24a et 24b

24b

24a

22

26

25

22

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

22

31

Page 32

S19314 Installation

Pièces de remplacement — Couvercle plastique

Paquet couvercle plastique S90-390

comprend les éléments 35a, 36, 39,

42, 43

35a

39

36

42

43

35a

36

Pièces de remplacement — Couvercle acier inox

Paquet couvercle acier inox S90-388

comprend les éléments 35b, 36, 39,

42, 43

Paquet couvercle acier inox (316)

S90-389 comprend les éléments 35b,

36, 39, 42, 43

35b

40

41

39

39

40

41

42

43

43

39

42

44

45

5.1

43

39

35b

36

42

43

36

Paquets manette comprend les éléments 39, 40, 41, 44, 45, 5, 5.1

Paquet S08-390 (pour les unités avec robinet laiton)

Paquet S08-391 (pour les unités avec robinet acier inox)

Paquet S08-392 (pour les unités avec vanne antigel laiton)

Paquet S08-393 (pour les unités avec vanne antigel acier inox)

Paquet S08-394 (pour les unités avec robinet et manette acier inox 316)

Paquet S08-395 (pour les unités avec vanne antigel et manette acier inox 316)

39

39

39

41

42

44

45

5.1

40

5

44

45

5.1

32

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 33

Installation S19314

Liste des pièces — Douche oculaire, Douche oculaire/faciale, et couvercle

Pièce Réf. Qté. Description

20

171-001

20

171-002

20

171-003

20

171-004

21a

S05-190

22

kit de remplacement

kit de remplacement

23

21b

22

kit de remplacement

kit de remplacement

24a

kit de remplacement

24b

21f

22

kit de remplacement

kit de remplacement

24a

kit de remplacement

24b

21j

22

kit de remplacement

kit de remplacement

24a

kit de remplacement

24b

25

115-158

25

115-159

25

115-164

25

115-165

S05-192

S05-204

S05-205

1

Corps

1

Corps acier inox

1

Corps acier inox 316

1

Corps poli

1

Douche oculaire (comprend)

2

Axe de pivotement

2

Couverture à bascule

1

Douche oculaire (comprend)

2

Axe de pivotement

1

Couverture à bascule droite

1

Couverture à bascule gauche

1

Tête de douche en acier inoxydable

304 oculaire/faciale (comprend)

Axe de pivotement

2

Couverture à bascule droite

1

Couverture à bascule gauche

1

1

Tête de douche en acier inoxydable

316 oculaire/faciale (comprend)

Axe de pivotement

2

Couverture à bascule droite

1

Couverture à bascule gauche

1

1

Bouchon

1

Bouchon acier inox

1

Bouchon acier inox 316

1

Bouchon poli

Pièce Réf. Qté. Description

26 125-157 2 Bague

27 125-175 1 Contrôle du débit

28 S65-340 1 Filtrer (paquet de 3)

kit de remplacement

35a

kit de remplacement

35b

kit de remplacement

35b

3939160-389

160-469

4040S08-385

1

Couvercle plastique

1

Couvercle acier inox

1

Couvercle acier inox 316

qté. au

besoin

qté. au

besoin

Vis ¼-20 x ½" acier inox

Vis ¼-20 x ½" acier inox 316

11Manette acier inox (incl. les

éléments 41, 44, 45, 5.1)

S08-388

Manette acier inox 316 (incl.

les éléments 41, 44, 45, 5.1)

41 114-096 1 Étiquette

42 142-002AV

4343161-060

161-062

qté. au

besoin

qté. au

besoin

qté. au

besoin

Rondelle

Écrou acier inox

Écrou acier inox 316

44 153-372R 1 Adaptateur robinet

44 153-372R316 1 Adaptateur robinet acier inox

316

45 142-002DA 1 Rondelle de blocage

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

33

Page 34

S19314 Installation

Pièces de remplacement et Liste des pièces — Bride et Drain

Paquet pédale

S45-572 (standard)

S45-1314SS (acier inox)

S45-1314SS16 (acier inox 316)

303

1

4

321

Paquet bride et drain (vidange de 24")

comprend les éléments 1, 4, 301b, 302b, 303

S29-098 (standard)

S29-099 (acier inox)

S29-100 (acier inox 316)

303

1

S29-101 (chromé)

301b

302b

1 111-092 1 Moyeu

1 111-093 1 Moyeu acier inox

1 111-095 1 Moyeu acier inox 316

1 111-094 1 Moyeu acier inox poli

4 300-0393 2 Bouchon ½" chromé

4 153-230 2 Bouchon ½" acier inox

4 153-460 2 Bouchon ½" acier inox 316

301a 113-1197 1 Tuyau 1¼" x 20½"

301a 113-1198 1 Tuyau 1¼" x 20½" chromé

301a 113-541 1 Tuyau 1¼" x 20½" acier inox

301a 113-1213 1 Tuyau 1¼" x 20½" acier inox 316

301b 113-1217 1 Tuyau 1¼" x 12¾"

301b 113-1218 1 Tuyau 1¼" x 12¾" chromé

301b 113-1219 1 Tuyau 1¼" x 12¾" acier inox

301b 113-1220 1 Tuyau 1¼" x 12¾" acier inox 316

302a 169-727 1 Té 1¼" peint galvanisé

302a 269-237 1 Té 1¼" acier inox

302a 269-1398 1 Té 1¼" acier inox 316

302a 269-253 1 Té 1¼" chromé

301b

302b

304

4

305b

301a

302a

Pièce Réf. Qté. Description Pièce Réf. Qté. Description

302b 169-853 1 Couplage 1¼" galvanisé

302b 269-257 1 Couplage 1¼" chromé

302b 269-1048 1 Couplage 1¼" acier inox

302b 269-2016 1 Couplage 1¼" acier inox 316

303 113-006NA 1 Tuyau 1¼" x étroit peint galvanisé

303 113-865 1 Tuyau 1¼" x étroit acier inox

303 113-1223 1 Tuyau 1¼" x étroit acier inox 316

304 S06-189 1 Bouchon chromé plein

305a 131-059 1 Bride peint

305a 131-062 1 Bride acier inox

305a 131-079 1 Bride acier inox 316

305b 131-044 1 Bride chromé

321 169-1117 1 BSPP-NPT 1-1/4" 303SS

321 169-1118 1 BSPP-NPT 1-1/4" 316SS

326 169-724 1 Bouchon 1¼" peint galvanisé

326 269-251 1 Bouchon 1¼" chromé

326 269-238 1 Bouchon 1¼" acier inox

326 269-1402 1 Bouchon 1¼" acier inox 316

Fourni avec

les options

à filetage

BSPP

seulement

326

305a

34

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 35

Installation S19314

Pièces de remplacement — Douche d'urgence

330

360b

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Date Signed

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

Date

durch Unterschrift. Jegliche Störung sofort melden.

Date

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

Signed

un rapport immédiatement.

Unterschrift

Signe

Date

Datum

Date

362

R

343

Signed

Signed

341

331

http://www.bradleycorp.com

TEL: 1-800-BRADLEY FAX: (262-251-5817)

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

114-052

342

362

360a

361b

360a

360a

361a

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

35

Page 36

S19314 Installation

Pièces de remplacement — Douche d'urgence

Paquet acier inox (comprend les éléments 350b,

354b, 355b

S30-061 (robinet acier inox)

S30-081 (robinet acier inox 316)

S30-104 (vanne antigel acier inox)

350b

355b.1

350a

354b

Paquets robinet fermeture automatiques

S19-0011 (robinet laiton standard)

S30-107 (vanne antigel laiton)

comprend les éléments 350c, 351, 353, 354a, 355a

350c

350b.2

350b

329

351

352

354a

355a

Adaptateur BSPP

- Fourni avec les

options à filetage

BSPP seulement

328

350a.1

321

302

327

325

351

353

354a

350a.1

355a

Paquet robinet laiton comprend les éléments 350a,

351, 353, 354a, 355a

S30-059 (robinet laiton standard)

S30-103 (vanne antigel laiton)

350a

351

352

350c

351

353

354b

354a

355a

344a

350b.1

326

350b.2

302

325

350a.1

344b

36

354a

340

355a

350a.1

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 37

Installation S19314

Liste des pièces — Tête de douche et robinet

BSP = filetage British Standard Pipe (Non disponible aux États-Unis)

Pièce Réf. Qté. Description

302 169-727 1 Té 1¼" peint galvanisé

302 169-727B 1 Té 1¼" peint galvanisé, BSP

302 269-237 2 Té 1¼" acier inox

302 269-1398 2 Té 1¼" acier inox 316

302 269-253 1 Té 1¼" chromé

321 169-1117 2 BSPP-NPT 1-1/4" 303SS

321 169-1118 2 BSPP-NPT 1-1/4" 316SS

325 113-1199 2 Tuyau 1¼" x 26"

325 113-1195 2 Tuyau 1¼" x 26" acier inox 316

325 113-1200 2 Tuyau 1¼" x 26" acier inox

325 113-1201 2 Tuyau 1¼" x 26" chromé

326 169-724 1 Bouchon 1¼" peint galvanisé

326 269-251 1 Bouchon 1¼" chromé

326 269-238 1 Bouchon 1¼" acier inox

326 269-1402 1 Bouchon 1¼" acier inox 316

327 169-722 1 Té 1¼" x 1" x 1¼"

327 269-249 1 Té 1¼" x 1" x 1¼" chromé

328 269-1400 1 Réducteur 1¼" x 1" acier inox 316

328 269-236 1 Réducteur 1¼" x 1" acier inox

329 113-006LN 1 Tuyau 1" x ferme peint galvanisé

329 113-1214 1 Tuyau 1" x ferme acier inox 316

329 113-006NL 1 Tuyau 1" x ferme acier inox

329 113-625 1 Tuyau 1" x ferme chromé

330 113-006MT 1 Tuyau 1" x 21" peint galvanisé

330 113-1215 1 Tuyau 1" x 21" acier inox 316

330 113-864 1 Tuyau 1" x 21" acier inox

330 113-1216 1 Tuyau 1" x 21" chromé

331 169-847 1 Coude 1" peint galvanisé

331 169-1073 1 Coude 1" chromé

331 169-1074 1 Coude 1" acier inox

331 169-1075 1 Coude 1" acier inox 316

Pièce Réf. Qté. Description

340 269-915 1 Tampon anti dérapant

341 204-421 1 Etiquette d’inspection

342 114-052 1 Enseigne de sécurité

342 114-052E 1

États-Unis)

343 151-001 2 Crochet

344a 128-156A 1 Tige

344b S90-365D 1 Tige ADA

344a 128-157 1 Tige acier inox 316

350a S27-278 1 Robinet 1"

350a S27-301 1 Vanne antigel 1"

350a.1 110-214 1 Écrou

350b S27-276 1 Robinet 1" acier inox

350b S27-325 1 Vanne antigel 1” acier inox

350b.1 142-002BC 1 Rondelle de blocage

350b.2 161-079 1 Écrou

350c S27-286 1 Robinet fermeture automatique 1"

351 140-720 1 Support d’arrêt

352 124-048 1 Rondelle

353 S19-001 1 Ressort

354a 128-129 1 Manette

354b 128-142 1 Manette acier inox

354b 128-155 1 Manette acier inox 316

355a 142-002DC 1 Rondelle de blocage 3⁄8"

360a S24-188 1 Tête de douche

360b S24-191 1 Tête de douche acier inox

360b S24-201 1 Tête de douche acier inox 316

361a 187-053 1 Corps de douche acier inox

361b 154-058 1 Corps de douche plastique

362 154-147 1 Anneau

Enseigne de sécurité (Non disponible aux

Bradley • 215-1684 Rev. P; ECN 15-05-019 8/5/2015

37

Page 38

S19314 Installation

Pièces de remplacement — Accessoires en option

à l'accessoire

vanne

antigel

370

gicleur

372

370

371

Accessoire de

montage pour les

unités avec deux

accessoires

à l'accessoire

370

Accessoire de

montage pour les

unités avec trois

accessoires)

vanne

anti-échaudage

Pièce Réf. Qté. Description

370 169-025 Coude ½" (qté. au besoin)

370 269-241 Coude ½" acier inox (qté. au besoin)

370 269-1396 Coude ½" acier inox 316 (qté. au besoin)

370 169-862 Coude ½" chromé (qté. au besoin)

371 113-006LG 1 Tuyau ½" x

371 113-867 1 Tuyau ½" x ferme acier inox

371 113-1210 1 Tuyau ½" x

371 113-006AW 1 Tuyau ½" x

372 169-838 1 Té ½"

372 169-1100 1 Té ½" acier inox

372 269-280 1 Té ½" chromé

372 169-1099 1 Té ½" acier inox 316

ferme

ferme acier inox 316

ferme chromé

vanne antigel

et vanne

anti-échaudage

370

376

377

Pièce Réf. Description

376 S45-1986 Vanne antigel

377 S45-1989 Vanne anti-échaudage

370

Gicleur

390

Prévention

d’écoulement

387b

de retour pour

gicleur

370

387a

387c

Pièce Réf. Qté. Description

387a S27-303 1 Prévention des casse-vide ³⁄₈"

387b S45-2309 1 Prévention d’écoulement de retour N9

387c S45-2310 1 Prévention d’écoulement de retour 9D

390 S19-430EH 1 Gicleur

38

8/5/2015 Bradley • 215-1684 Rev. P; ECN 15-05-019

Page 39

Installation S19314

ADVERTENCIA

Aclarar el conducto del suministro de agua antes y después de la instalación. Verificar que no haya

fugas y que el flujo de agua sea adecuado. El suministro principal de agua a la unidad debe estar

siempre en posición “ON” (abierto). Se deben tomar medidas a fin de evitar el corte no autorizado

del suministro.

ATTENCIÓN