Page 1

BOSS MODEL INFINITY

PTO AIR COMPRESSOR

OPERATORS, MAINTENANCE

AND PARTS MANUAL

P/N: 307200

06/05/2008 MCM

Page 2

Page 3

OPERATORS, MAINTENANCE, AND PARTS MANUAL

BOSS INDUSTRIES INFINITY

Operation & Maintenance Section

TABLE OF CONTENTS

Operation & Maintenance Section

Specifications...................................................................................................................... 6

Safety .................................................................................................................................. 7

Compressor T erminology .................................................................................................. 11

Description of Components............................................................................................... 12

Inspection, Lubrication, and Maintenance.......................................................................... 16

Troubleshooting................................................................................................................. 24

Compressor Operation ...................................................................................................... 27

Parts and Illustration Section ............................................................................................. 29

Recommended Spare Parts ................................................................................................ 36

Service Questionnaire........................................................................................................ 37

Instructional Procedures for Installation ........................................................................... 38

Warranty Section

W arranty Information ........................................................................................................ 43

4

Page 4

Page 5

SPECIFICATIONS

GISP051@YREVILEDMFC5406

rosserpmoCotdeepStupnI

MPR

MPG

rosserpmoC-yticapaCdiulF

ciluardyhton(

)

metsySrosserpmoC-stnenopmoC

)

yrd(thgieW .sbl003

0051

@01

ISP0742

metsySsnollaG0.1

pmuSrosserpmoC57.

)snoisnemiDllarevO(

wolebees

1591

@31

ISP0742

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

8

D D

7

Parts List

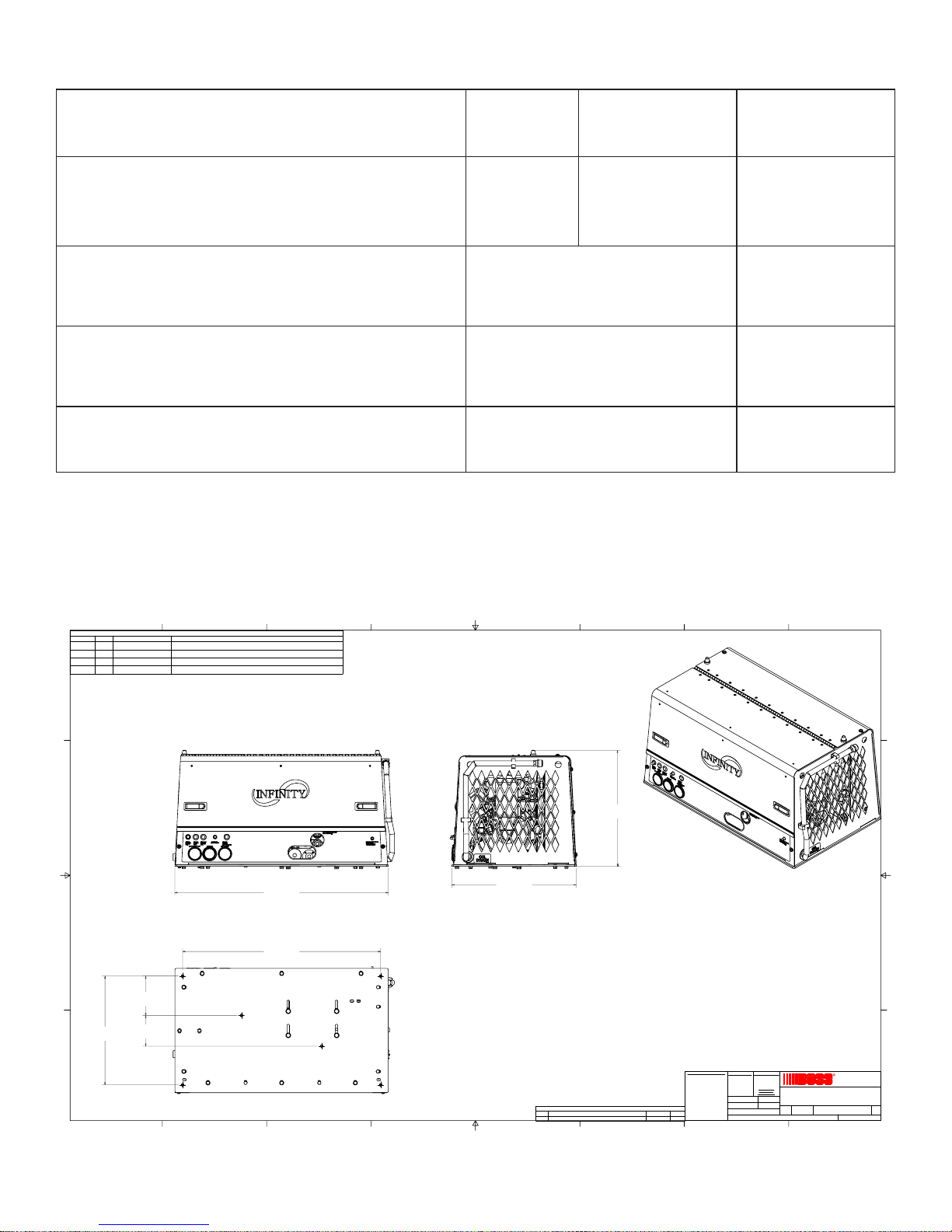

COMPR MTG SYS, INFINITY 45-60-150 SCI8G 0820035311

ELEC SYS, INFINITY 45-60-150 SCI8G 08200355-999 12

OIL-AIR-HYD CLNG SYS, INFINITY SCI8G 08200356-999 13

CANOPY SYS, INFINITY 45-60-150 SCI8G 0820035414

DESCRIPTIONPART NUMBERQTYITEM

6

5

4

3

2

1

C C

34 3/4 in

[882.7 mm]

B B

6 3/8 in

[163.2 mm]

17 3/4 in

[450.9 mm]

5 in

[127.0 mm]

DIMENSIONS OF MOUNTING HOLES

32 1/4 in

[819.2 mm]

A A

8

7

6

19 in

[481.4 mm]

20 1/4 in

[514.4 mm]

PROPRIETARY INFORMATION

THIS DRAWING AND ALL ITS

CONTENTS ARE PROPERTY

OF BOSS INDUSTRIES, INC.

AND MUST NOT BE COPIED

OR MADE PUBLIC. IT IS

LOANED AND IS SUBJEC T TO

RETURN UPON DEMAND. THE

INFORMATION CONTAINED IN

THIS DRAWING IS

CONFIDENTIAL AND MU ST

REV DESCRIPTION DATE ENG

1

5

4

REVISION HISTORY

UPDATED 200353 TO REV 1, 200354 TO REV 1

3

5/22/2008 MCM

NOT BE USED, DIRECTLY OR

INDIRECTLY, IN ANY WAY

DETRIMENTAL TO THE

INTEREST OF BOSS

INDUSTRIES, INC.

UNMACHINED SURFACES

MACHINED SURFACES

NOMINAL DIM.

FRACTIONAL ` 1/16

`

.010

0.000 TO 1.000

`

.03

DECIMAL

`

.015

1.001 TO 5.000

`

1°

ANGULAR

`

.020

5.001 TO 10.000

DO NOT SCALE

TOLERANCES

`

.025

10.001 & OVER

UNLESS NOTED

DRAWN

12/3/2007

DCL

CHECKED

12/3/2007

NDD

MATERIAL

N/A

PATH

G:\Inventor Files\20k\20054-001.dwg

2

DESCRIPTION

INFINITY 45-60 SCI8G 08

SIZE

DWG NO

SCALE

1=4

20054-001

D

R

BOSS INDUSTRI ES

1761 GENESIS DR.

LA PORTE, IN 46350

SHEET

1

REV

1

1 1

OF

6

Page 6

SAFETY

WARNING

ALL UNITS ARE SHIPPED WITH A DET AILED OPERA TORS AND P ARTS

MANUAL. THIS MANUAL CONT AINS VITA L INFORMA TION FOR THE SAFE

USE AND EFFICIENT OPERA TION OF THIS UNIT . CAREFULLY READ

THE OPERAT ORS MANUAL BEFORE ST ARTING THE UNIT . F AILURE T O

ADHERE TO THE INSTRUCTIONS COULD RESULT IN SERIOUS BODILY

INJURY OR PROPERTY DAMAGE.

AIR COMPRESSOR SAFETY PRECAUTIONS

Safety is basically common sense. While there are standard safety rules, each situation has its own

peculiarities that cannot always be covered by rules. Therefore with your experience and common

sense, you are in a position to ensure your safety . Lack of attention to safety can result in:

accidents, personal injury , reduction of efficiency and worst of all - Loss of Life. W atch for safety

hazards. Correct them promptly . Use the following safety precautions as a general guide to safe

operation:

Do not attempt to remove any compressor parts without first relieving the entire system of

pressure.

Do not attempt to service any part while machine is operating.

DANGER

CHECK THE COMPRESSOR SUMP OIL LEVEL ONL Y WHEN THE COMPRESSOR

IS NOT OPERA TING AND SYSTEM IS COMPLETEL Y RELIEVED OF PRESSURE.

OPEN SERVICE VAL VE TO ENSURE RELIEF OF SYSTEM AIR PRESSURE WHEN

PERFORMING MAINTENANCE ON COMPRESSOR AIR/OIL SYSTEM. FAILURE

TO COMPL Y WITH THIS W ARNING MA Y CAUSE DAMAGE TO PROPERTY

AND SERIOUS BODIL Y HARM.

Do not operate the compressor at pressure(s) or speed in excess of its rating as indicated in

“Compressor Specifications”.

Periodically check all safety devices for proper operation.

Do not play with compressed air . Pressurized air can cause serious injury to personnel.

Exercise cleanliness during maintenance and when making repairs by covering parts and exposed

openings.

7

Page 7

SAFETY

Do not install a shut-off valve between the compressor and compressor oil sump.

DANGER

DO NOT USE BOSS INDUSTRIES COMPRESSOR SYSTEMS TO PROVIDE

BREA THING AIR. SUCH USAGE, WHETHER SUPPLIED IMMEDIA TELY FROM

THE COMPRESSOR SOURCE, OR SUPPLIED TO BREATHING TANKS FOR

SUBSEQUENT USE, CAN CAUSE SERIOUS BODIL Y INJURY.

BOSS INDUSTRIES, INC. DISCLAIMS ANY AND ALL LIABILITIES FOR DAMAGE

FOR LOSS DUE TO PERSONAL INJURIES, INCLUDING DEATH, AND/OR

PROPERTY DAMAGE INCLUDING CONSEQUENTIAL DAMAGES ARISING OUT

OF ANY BOSS INDUSTRIES, INC. COMPRESSORS USED T O SUPPL Y BREA THING

AIR.

Do not disconnect or bypass safety circuit system.

Do not install safety devices other than authorized BOSS INDUSTRIES, INC. replacement

devices.

Close all openings and replace all covers and guards before operating compressor unit.

T ools, rags, or loose parts must not be left on the compressor or drive parts.

Do not use flammable solvents for cleaning parts. This can cause the unit to ignite during operation.

Keep combustibles out of and away from the Compressor/Inlet and any associated enclosures.

The owner, lessor , or operator of the Compressor are hereby notified and forewarned that any

failure to observe these safety precautions may result in damage or injury .

BOSS INDUSTRIES, INC. expressly disclaims responsibility or liability for any injury or damage

caused by failure to observe these specified precautions or by failure to exercise that ordinary

caution and due care required when operating or handling the Compressor, even though not

expressly specified above.

8

Page 8

SAFETY

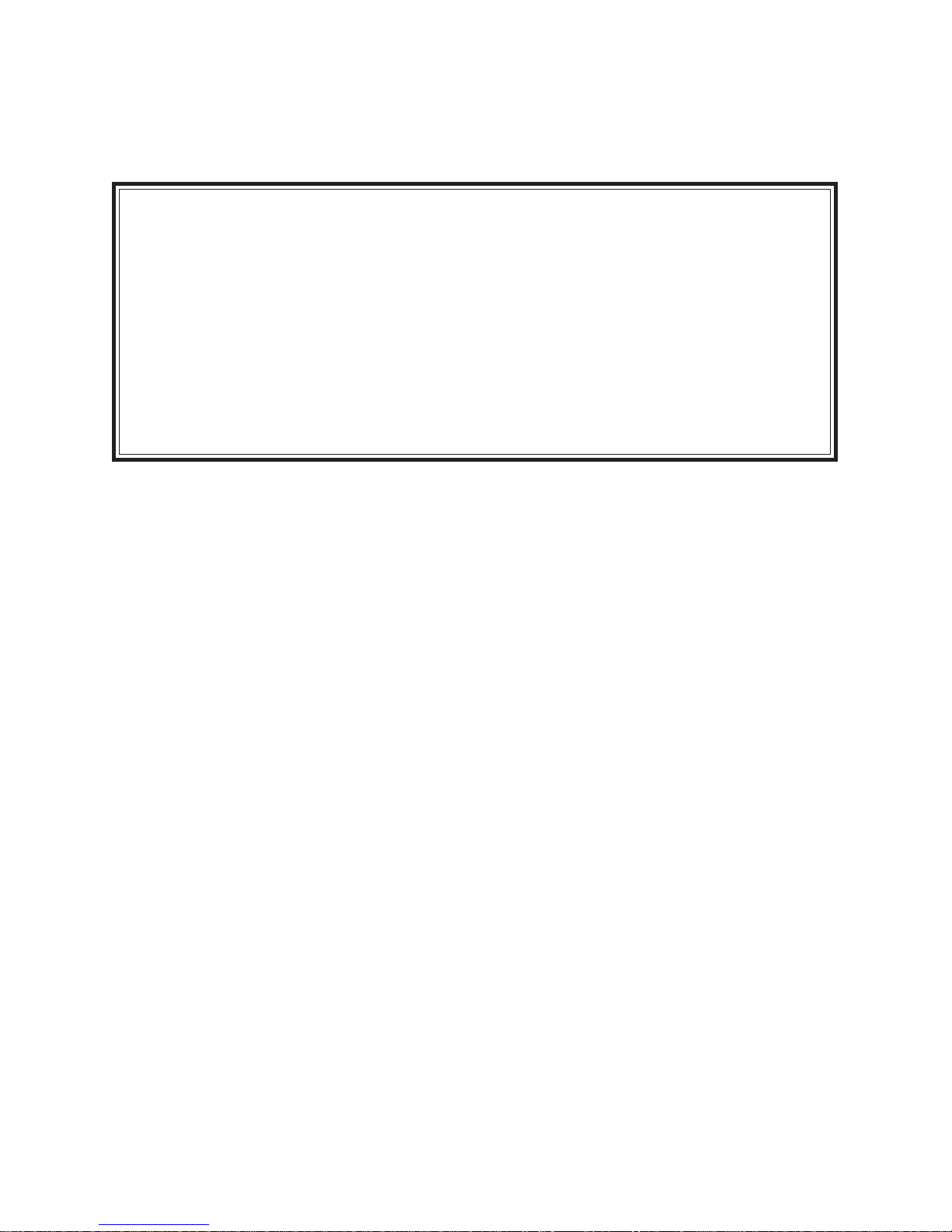

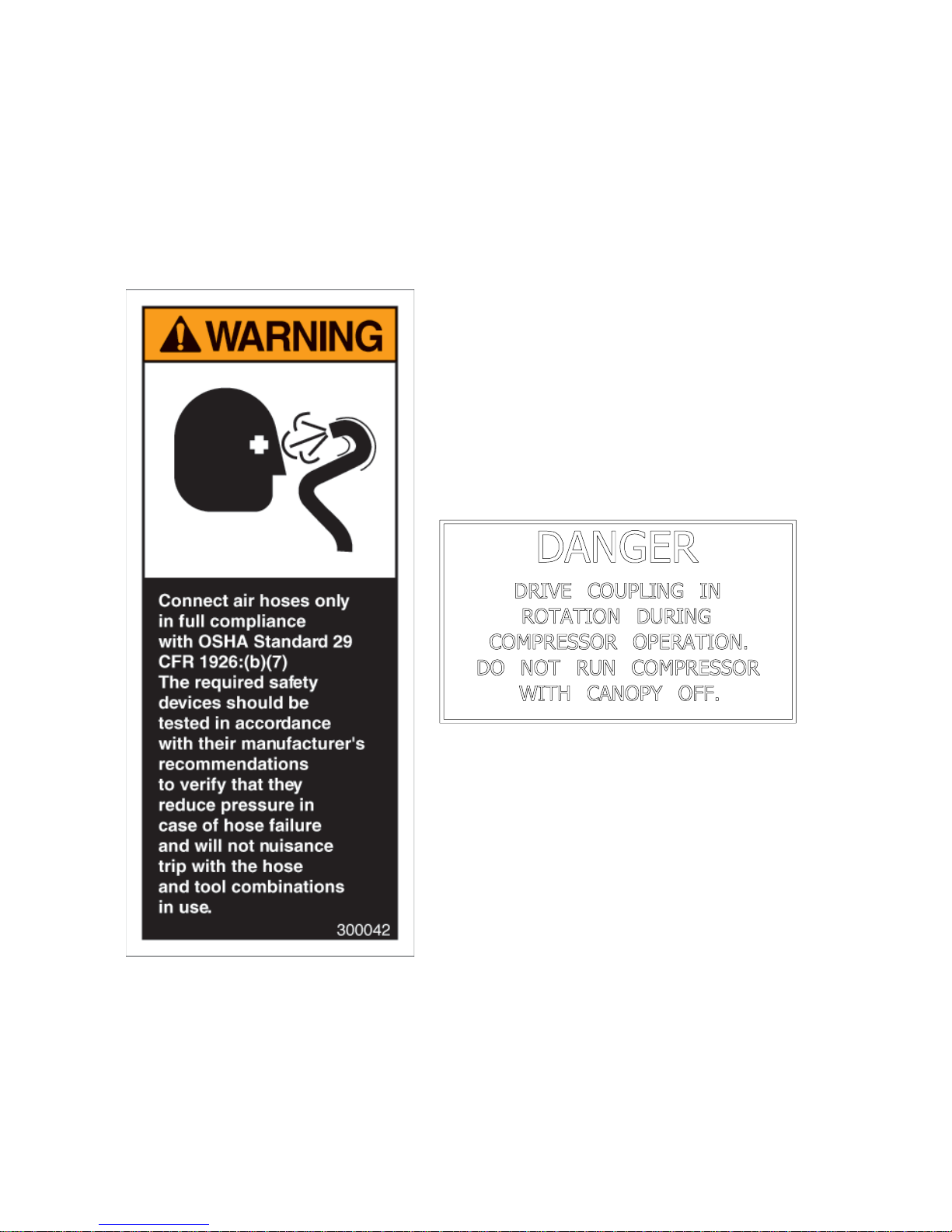

A compliment of warning decals is supplied with each unit. These decals must be affixed to the

comressor package in the locations noted in this manual. If for any reason a safety decal is

removed it is the owners responsibility to make sure it is replaced.

9

Page 9

SAFETY

10

Page 10

COMPRESSOR TERMINOLOGY

AIR/OIL COALESCER - Performs second stage separation of oil from compressed air feeding

air tools. Sometimes referred to as the separator element.

CFM - Refers to the volume of compressed air being produced, expressed as cubic feet of air per

minute.

COMPRESSOR LUBRICANT - DEXTRON III ATF.

GPM - Refers to the amount of gallons per minute of hydraulic fluid flowing through the pump.

OIL SUMP - The first stage of oil separation from compressed air . Also serves as reservoir area

for compressor lubricant and sometimes referred to as the receiver tank.

PSI - Refers to the operating pressure the system is set up at, expressed as pounds per square

inch.

SAFETY VALVE - A valve located on the oil sump which opens in case of excessive pressure.

Sometimes referred to as the pop-off or pressure relief valve.

11

Page 11

DESCRIPTION OF COMPONENTS

COMPRESSOR ASSEMBL Y

The BOSS INDUSTRIES hydraulic drive compressor assembly is a positive displacement, oil

flooded, rotary screw type unit employing one stage of compression to achieve the desired

pressure. Components include a housing (stator), two screws (rotors), bearings, and bearing

supports. Power from the hydraulic motor shaft is transferred to the male rotor through a drive

coupling. The female rotor is driven by the male rotor . There are five lobes on the male rotor

while the female rotor has six roots.

PRINCIPLES OF OPERA TION

In operation, two helical grooved rotors mesh to compress air. Inlet air is trapped as the male

lobes roll down the female grooves, pushing trapped air along, compressing it until it reaches the

discharge port in the end of the stator and delivers smooth-flowing, pulse-free air to the receiver .

During the compression cycle, oil is injected into the compressor and serves these purposes:

1. Lubricates the rotating parts and bearings.

2. Serves as a cooling agent for the compressed air .

3. Seals the running clearances.

LUBRICATION SYSTEM

Oil from the compressor at discharge pressure, is directed into its integral housing, through the

thermal valve and filter, and then out of the integral housing to the oil cooling system, and then back

to the side of the compressor stator, where it is injected into the compressor . At the same time oil

is directed internally to the bearings and shaft seal of the compressor.

OIL SUMP

Compressed, oil-laden air enters the sump from the compressor. As the oil-laden air enters the

sump, most of the oil is separated from the air as it passes through a series of baffles and diffusion

plates. The oil accumulates at the bottom of the sump for recirculation. However , some small

droplets of oil remain suspended in the air and are passed on to the Coalescer .

12

Page 12

DESCRIPTION OF COMPONENTS

SAFETY V ALVE

The pop safety valve is set at 200 PSI and is located at the top of the air/oil sump. This valve acts

as a backup to protect the system from excessive pressure that might result from a malfunction.

AIR/OIL COALESCER

The coalescer is self-contained within a spin-on housing. When air is demanded at the service line,

it passes through the coalescer which efficiently provides the final stage of oil separation.

OIL RETURN LINE

The oil that is removed by the coalescer accumulates and is returned through an internal oil return

line leading to the compressor .

MINIMUM PRESSURE VAL VE

The minimum pressure valve is located at the outlet of the coalescer head and serves to maintain a

minimum discharge pressure of 75 PSIG in operation, which is required to assure adequate

compressor lubrication pressure.

OIL FIL TER

The compressor oil filter is a removable and cleanable screen built into the side of the compressor

housing. Screen replacement may be necessary after several cleanings.

COMPRESSOR OIL AND HYDRAULIC OIL COOLING SYSTEMS

The compressor cooling system consists of a combination hydraulic cooler and compressor cooler

mounted on the common frame. Compressor oil temperature is controlled by a thermal valve

located down stream of the oil filter . The thermal valve maintains the compressor oil temperature

at 185ºF . Cool air is drawn through the vented end panel and across the combo cooler . The air is

heated by the coolers and the hot air exits out the back vented panel . Allow for adequate

clearance (12”) for the air to exit. Also, the package location should not be subjected to above

ambient air temperatures.

13

Page 13

DESCRIPTION OF COMPONENTS

INSTRUMENTATION

The BOSS INDUSTRIES hydraulic drive compressor unit incorporates a gauge panel that monitors

temperature, pressure and hours of operation.

HOURMETER

The hourmeter records the total number of operating hours. It serves as a guide in following the

recommended inspection and maintenance schedule. The hourmeter will only run when there is pressure

in the system.

COMPRESSOR DISCHARGE AIR/OIL TEMPERATURE SWITCHGAUGE

This switchgauge indicates compressor air discharge temperature. The switchgauge ensures safety

shutdown in case of excessive operating temperatures, preventing compressor damage, by stopping

hydraulic flow to the compressor motor.

ELECTRICAL AND SAFETY SYSTEM

The BOSS INDUSTRIES compressor’s standard electrical system consists of:

-Gauge panel with a temperature switchgauge, hourmeter and discharge pressure switchgauge.

-Compressor and hydraulic oil cooler fan assembly and relay .

-Compressor after cooler/oil cooler fan assembly and relay .

-3-way pressure switch and relay to control hourmeter and blowdown.

-12VDC N.O. hydraulic solenoid and relay .

-Switch relay for customer equipment interface during compressor operation.

-Differential pressure switch for air filter maintenance.

-Optical oil level switch and relay .

14

Page 14

DESCRIPTION OF COMPONENTS

CONTROL SYSTEM

The prime component of the compressor control system is the compressor inlet valve. The control

system is designed to match air supply to air demand and to prevent excessive discharge pressure

when compressor is at idle. Control of air delivery is accomplished by the inlet valve regulation

and modulation as directed by the discharge pressure regulator .

NORMALL Y OPEN REGULATOR SOLENOID

A closed Furnas air pressure switch will energize the normally open regulator solenoid, thus closing

it. When the normally open regulator solenoid is closed, air pressure will rise. When it is open air

pressure falls only in the compressor sump.

NOTE: Most air tools operating pressure range is between 90 and 125 psi. Operating

above the tools recommended pressures will decrease the life of the tool. Higher

operating pressure can also over torque nuts and bolts fatiguing the fastener and mating

parts. Strictly adhere to tool operating pressures and torque standards set forth by the

tool manufacturer and the specifications of the equipment that work is being performed

on.

FURNAS SWITCH DESCRIPTION

The Furnas switch is a N.C. electrical switch set to open at 150 PSI and set to close at 115 PSI.

The Furnas switch controls the N.O. regulator solenoid. If service air pressure is under 150 PSI,

the Furnas switch will not trip keeping the N.O. inlet valve open and the compressor making air. If

the service valve is closed or the tool using the air is off, service line pressure will rise over 150

PSI. This will trip the Furnas switch to open. The regulator solenoid will open and send air

pressure to the inlet valve to close. W ith the inlet valve closed, the compressor will stop making

air. If the tool is turned on or the service valve is opened, the service line pressure will drop.

When the pressure falls to 115 PSI the Furnas switch will close energizing the N.O. regulator

solenoid closing off the air supply to the inlet valve. This will allow the inlet valve to open, and the

compressor will start making air to meet the demand.

INLET V A LV E

The compressor inlet valve is a piston operated disc valve that regulates the inlet opening to control

capacity and serves as a check valve at shutdown.

15

Page 15

INSPECTION, LUBRICATION, AND MAINTENANCE

This section contains instructions for performing the inspection, lubrication, and maintenance

procedures required to maintain the compressor in proper operating condition. The importance of

performing the maintenance described herein cannot be over emphasized.

The periodic maintenance procedures to be performed on the equipment covered by this manual

are listed below . It should be understood that the intervals between inspections specified are

maximum interval. More frequent inspections should be made if the unit is operating in a dusty

environment, in high ambient temperature, or in other unusual conditions. A planned program of

periodic inspection and maintenance will help avoid premature failure and costly repairs. Daily

visual inspections should become a routine.

The LUBRICATION AND MAINTENANCE CHAR T lists serviceable items on this compressor

package. The items are listed according to their frequency of maintenance, followed by those

items which need only “As Required” maintenance.

The maintenance time intervals are expressed in hours. The hourmeter shows the

total number of hours your compressor has run. Use the hourmeter readings for determining your

maintenance schedules. Perform the maintenance at multiple intervals of the hours shown. For

example, when the hourmeter shows “100” on the dial, all items listed under “EVER Y 10 HOURS”

should be serviced for the tenth time, and all items under “EVERY 50 HOURS” should be

serviced for the second time, and so on.

DANGER

COMPRESSOR MUST BE SHUT DOWN AND COMPLETELY RELIEVED OF

PRESSURE PRIOR TO CHECKING FLUID LEVELS. OPEN SERVICE VAL VE TO

ENSURE RELIEF OF SYSTEM AIR PRESSURE. F AILURE TO COMPL Y WITH THIS

W ARNING MA Y CAUSE DAMAGE T O PROPERTY AND SERIOUS BODIL Y HARM.

16

Page 16

LAVRETNINOITCA

GNIRUD

NOITAREPO

YLIAD

LUBRICATION AND MAINTENANCE CHART

YLLACIDOIREP

).sisab

2

rlamronehtmorf

idnocralimistagnitarepo

.levelliorosserpmocehtkcehC.1

.gnitareposirosserpmocelihw

.skaelriadnaliorofkcehC.3

.sehctiwstiucricytefaskcehC.4

egnahcynaetoN.sgnidaereguagllaevresbO.1

ehtenimreteddnasgnidae

:ETON(.edamsriaperyrassecenevaH.esuac

nehwgnidaereguaglausuehtsi"LAMRON"

yadotyadanosnoit

rotacidniporderusserP.retlifriakcehC.

SRUOH52YREVE

RO

YLHTNOM

.liorosserpmocmorfretawniarD.1

neercsecalperdnaliorosserpmocegnahC.1

flaestfahsrosserpmockcehC.2

005YREVE

6ROSRUOH

SHTNOM

.stroppusrosserpmockcehC.4

(.tnemeleretlifriawenllatsnI.5

ytsudrednuyrassecenebyamlavretni

.egakaelro

.spmalcdnasgnittif,gnipipretlifriakcehC.3

retrohS

).snoitidnoc

.evlavytefaspmuskcehC.6

YREVE

0001

1ROSRUOH

.tnemelegnicselaocegnahC.1

RAEY

.tnemeleretlifrianaelcdnatcepsnI.1

ROYLLACIDOIREP

DERIUQERSA

.yrassecenfitnemele

recselaocno-nipsecalperdnatcepsnI.2

.snifrelooclionaelcdnatcepsnI.3

NOTE: Compressor oil and filter is to be changed after the first 50 hours of operation. After this,

normal intervals are to be followed.

17

Page 17

LUBRICANT RECOMMENDATIONS

WARNING

IT IS IMPORTANT THAT THE COMPRESSOR OIL BE OF A RECOMMENDED

TYPE AND THA T THIS OIL AS WELL AS THE AIR FIL TER, OIL FIL TER, AND

COALESCER ELEMENTS BE INSPECTED AND REPLACED AS ST A TED IN THIS

MANUAL.

THE COMBINA TION OF A COALESCER ELEMENT LOADED WITH DIR T AND

OXIDIZED OIL PRODUCTS TOGETHER WITH INCREASED AIR VELOCITY AS A

RESUL T OF THIS CLOGGED CONDITION MAY PRODUCE A CRITICAL POINT

WHILE THE MACHINE IS IN OPERA TION WHERE IGNITION CAN T AKE PLACE

AND COULD CAUSE A FIRE IN THE OIL SUMP .

FAILURE TO COMPLY WITH THIS WARNING MAY CAUSE DAMAGE TO

PROPERTY AND SERIOUS BODIL Y HARM.

The following are general characteristics for a rotary screw lubricant. Due to the impossibility of

establishing limits on all physical and chemical properties of lubricants which can affect their

performance in the compressor over a broad range of environmental influences, the responsibility

for recommending and consistently furnishing a suitable heavy duty lubricant must rest with the

individual supplier if they choose not to use the recommended BOSS INDUSTRIES rotary screw

lubricant. The lubricant supplier’s recommendation must, therefore, be based upon not only the

following general characteristics, but also upon his own knowledge of the suitability of the

recommended lubricant in helical screw type air compressors operating in the particular

environment involved.

CAUTION

MIXING DIFFERENT TYPES OR BRANDS OF LUBRICANTS IS NOT

RECOMMENDED DUE TO THE POSSIBILITY OF A DILUTION OF THE

ADDITIVES OR A REACTION BETWEEN ADDITIVES OF DIFFERENT TYPES.

18

Page 18

LUBRICANT RECOMMENDATIONS

LUBRICANT CHARACTERISTICS

1. Flash point 400°F minimum.

2. Pour point -40°F.

3. Contains rust and corrosion inhibitors.

4. Contains foam suppressors.

5. Contains oxidation stabilizer.

NOTE

DUE TO ENVIRONMENT AL F ACT ORS THE USEFUL LIFE OF ALL “EXTENDED

LIFE” LUBRICANTS MA Y BE SHORTER THAN QUOTED BY THE LUBRICANT

SUPPLIER. BOSS INDUSTRIES, INC. ENCOURAGES THE USER TO CLOSELY

MONITOR THE LUBRICANT CONDITION AND TO PARTICIPATE IN AN OIL

ANAL YSIS PROGRAM WITH THE SUPPLIER.

NOTE

NO LUBRICANT, HOWEVER GOOD AND/OR EXPENSIVE, CAN REPLACE

PROPER MAINTENANCE AND A TTENTION. SELECT AND USE IT WISELY.

19

Page 19

MAINTENANCE

If some of the maintenance intervals in the schedule outlined in this manual seem to be rather short,

it should be considered that one hour’s operation of a compressor is equal to about 40 road miles

on an engine. Thus, eight hours operation is equal to 320 road miles, 250 hours is equal to 10,000

road miles, etc.

COMPRESSOR OIL SUMP FILL, LEVEL, AND DRAIN

Before adding or changing compressor oil make sure that the compressor is completely relieved of

pressure. Oil is added at the fill cap on the side of the compressor body . A drain valve/hose

assembly is provided at the bottom of the compressor body . The proper oil level is between the

top and the midpoint of the oil sightglass, when the unit is shut down and has had time to settle.

The truck must be level when checking the oil. DO NOT OVERFILL. The oil sump capacity is

given in “Compressor Specifications”.

DANGER

DO NOT A TTEMPT T O DRAIN CONDENSA TE, REMOVE THE OIL LEVEL FILL

PLUG , OR BREAK ANY CONNECTION IN THE AIR OR OIL SYSTEM WITHOUT

SHUTTING OFF COMPRESSOR AND MANUALLY RELIEVING PRESSURE FROM

THE SUMP . F AILURE TO COMPL Y WITH THIS WARNING MA Y CAUSE DAMAGE

TO PROPERTY AND SERIOUS BODIL Y HARM.

AIR INT AKE FILTER

The air intake filter is a heavy-duty dry type high efficiency filter designed to protect the

compressor from dust and foreign objects. Optional two-stage available.

Optional filter is equipped with an evacuator cup for continuous dust ejection while operating and

when stopped.

Frequency of maintenance of the filter depends on dust conditions at the operating site. The filter

element must be serviced when clogged (maximum pressure drop for proper operation is 15” of

water). The filter is equipped with a pressure drop indicator, and the element should be changed

based on its reading first and then by the maintenance intervals outlined.

20

Page 20

MAINTENANCE

AIR/OIL COALESCER

The air/oil coalescer employs an element permanently housed within a spin-on canister . This is a

single piece unit that requires replacement when it fails to remove the oil from the discharge air , or

pressure drop across it exceeds 15 PSI. Dirty oil clogs the element and increases the pressure

drop across it.

T o replace element proceed as follows:

1. Shutdown compressor and wait for complete blow down (zero pressure).

2. Turn element counterclockwise for removal (viewing element from bottom).

3. Apply a film of fluid directly to seal on the new element.

4. Rotate element clockwise by hand until element contacts seal (viewing element from

bottom).

5. Rotate element approximately one more turn clockwise with band wrench near the top

of element.

6. Run system and check for leaks.

WARNING

DO NOT SUBSTITUTE ELEMENT. USE ONL Y A GENUINE BOSS INDUSTRIES

REPLACEMENT ELEMENT . THIS ELEMENT IS RA TED A T 200 PSI WORKING

PRESSURE. USE OF ANY OTHER ELEMENT MA Y BE HAZARDOUS AND COULD

IMPAIR THE PERFORMANCE AND RELIABILITY OF THE COMPRESSOR,

POSSIBLY VOIDING THE WARRANTY AND/OR RESULTING IN DAMAGE TO

PROPERTY AND SERIOUS BODIL Y HARM.

COALESCER OIL RETURN

This originates at the bottom of the air/oil coalescer and flows through a special recovery pipe and

venturi nozzle. If the coalescer starts to fill with oil there is a good chance the venturi or pipe has

been plugged. Consult factory for cleaning instructions.

21

Page 21

MAINTENANCE

OIL FIL TER

The compressor oil filter is a throwaway type cartridge. It is designed with a built-in bypass so that

if there is a large restriction, due to cold oil or clogged element, the compressor will still be

lubricated.

T o replace filter proceed as follows:

1. Make sure system pressure is relieved.

2. Unscrew with 14mm allen wrench.

3. Remove oil filter from housing.

4. Replace the oil filter screen element.

5. Reinsert oil filter screen into housing and tighten with 14mm allen wrench.

6. Add oil (total system takes one gallon), re-tighten filler cap.

7. Check for leaks in operation.

WARNING

DO NOT SUBSTITUTE ELEMENT. USE ONLY A GENUINE BOSS INDUSTRIES

REPLACEMENT ELEMENT. USE OF ANY OTHER ELEMENT MAY BE

HAZARDOUS AND COULD IMPAIR THE PERFORMANCE AND RELIABILITY

OF THE COMPRESSOR, POSSIBLY VOIDING THE WARRANTY AND/OR

RESUL TING IN DAMAGE TO PROPER TY AND SERIOUS BODILY HARM.

HYDRAULIC OIL COOLER AND COMPRESSOR OIL COOLER COMBINATION

The interior of the oil cooler should be cleaned when the pressure drop across it at full flow

exceeds 25 PSI. The following procedure has been recommended by the vendor who supplies the

cooler:

1. Remove cooler.

2. Circulate a suitable solvent to dissolve and remove varnish and sludge.

3. Flush generously with compressor lubricant (compressor oil cooler section only, use

hydraulic oil to flush the hydraulic cooler portion on the combo cooler).

4. Once the coolers are reinstalled, fill the compressor and hydraulic systems with the

proper fluids to their appropriate levels.

22

Page 22

MAINTENANCE

SHAFT SEAL

SHAFT SEAL INST ALLATION INSTRUCTIONS:

1. Remove hydraulic motor, drive coupling and adapter housing from face of compressor .

2. Remove coupling hub from compressor shaft.

3. Remove 4 screws from shaft seal cover and press seal out.

4. Pull seal wear sleeve off shaft with puller .

5. Clean shaft surface removing all burrs from shaft where the wear sleeve gets installed.

6. Press new wear sleeve on to shaft. Oil heating new wear sleeve to 212°F approximately

aids in the installation of this ring.

7. Press new seal into housing with seal assembly tool, until contact with snapring.

8. Temporarily install new seal installation cone over shaft to protect seal during reinstallation.

9. Reinstall cover.

10. Reinstall coupling hub to compressor shaft.

11. Reinstall adapter housing, drive coupling, and hydraulic motor to face of compressor .

23

Page 23

TROUBLESHOOTING

This section contains instructions for troubleshooting the equipment following a malfunction.

The troubleshooting procedures to be performed on the equipment are listed below . Each

symptom of trouble for a component or system is followed by a list of probable causes of the

trouble and suggested procedures to be followed to identify the cause.

In general, the procedures listed should be performed in the order in which they are listed, although

the order may be varied if the need is indicated by conditions under which the trouble occurred. In

any event, the procedures which can be performed in the least amount of time and with the least

amount of removal or disassembly of parts, should be performed first.

UNPLANNED SHUTDOWN

When the operation of the machine has been interrupted by an unexplained shutdown, check the

following:

1. Check the fuel level and truck dash gauges and indications for possible engine

problems.

2. Check the compressor discharge temperature/switchgauge. If the latching relay circuit

is tripped the 12VDC solenoid will lose power and divert hydraulic oil back to the

reservoir . The compressor blowdown pressure switch and the temperature switchgauge

will not allow power to the hydraulic solenoid until the air has blown down and the

temperature has dropped into its normal operating range and the push button has been

reset. T ake compressor in for service once a high temperature shutdown has occurred.

Failure to do so will void your warranty .

3. Check that the compressor oil is at proper level.

4. Check oil cooler for dirt, slush, ice on the fins, or any other obstructions to the cooling

air flow .

5. Make a thorough external check for any cause of shutdown such as broken hose,

broken oil lines, loose or broken wire, etc.

24

Page 24

TROUBLESHOOTING

IMPROPER DISCHARGE PRESSURE

1. If discharge pressure is too low , check the following:

A. Too much air demand. (Air tools require more air than what the compressor can

produce, air tools are free wheeling without resistance.)

B. Service valve wide open to atmosphere.

C. Leaks in service line.

D. Restricted compressor inlet air filter.

E. Faulty control system operation (i.e.N.0. regulated air solenoid is allowing air through

all the time.)

F . Furnas Switch is not closing at 1 15 psi.

G. Low compressor oil level.

2. If discharge pressure is too high, safety valve blows, or system shuts down on high pressure,

check the following:

A. Faulty discharge pressure switchgauge.

B. Coalescer plugged up.

C. Faulty safety valve.

D. N.O. regulated air solenoid is not opening.

E. Furnas switch is not opening at 150 psi.

3. Sump relief valve activates:

A. Inlet valve leaking or open.

B. Faulty relief valve.

C. Faulty Furnas switch, or N.O. regulated air solenoid, or pressure switchgauge.

SUMP PRESSURE DOES NOT BLOW DOWN

If after the compressor is shutdown, pressure does not automatically blow down, check for:

1. Normally open regulated air solenoid may be stuck closed.

2. Blockage in air line from downstream of the coalescer to the inlet valve.

3. Inlet valve orifice is clogged.

OIL CONSUMPTION

Abnormal oil consumption or oil in service line, check for the following:

1. Over filling of oil sump.

2. Leaking oil lines or oil cooler.

3. Plugged oil return line: check nozzle beneath the sightglass.

4. Defective coalescer element.

5. Compressor shaft seal leakage.

25

Page 25

TROUBLESHOOTING

COALESCER PLUGGING

If the coalescer element has to be replaced frequently because it is plugging up, it is an indication

that foreign material may be entering the compressor inlet or the compressor oil is breaking down.

Compressor oil can break down prematurely for a number or reasons.

(1) Extreme operating temperature, (2) negligence in draining condensate from oil sump, (3) using

the improper type of oil, (4) dirty oil, (5) oil return nozzle plugged.

The complete air inlet system should be checked for leaks.

HIGH COMPRESSOR DISCHARGE TEMPERATURE

1. Check compressor oil level. Add oil if required (see Section for oil specifications).

2. Check thermal valve operation.

3. Clean outside of oil cooler.

4. Clean oil system (cooler) internally.

5. Check fan relay harness.

26

Page 26

COMPRESSOR OPERATION

Before starting the compressor, read this section thoroughly . Familiarize yourself with the controls and

indicators, their purpose, location, and use.

ROLORTNOC

ROTACIDNI

ocehtgnivaelerutxim

ERUTAREPMET

EGUAGHCTIWS

.nwod

ERUSSERP

EGUAGHCTIWS

RETEMRUOH

LEVELDIULF

SSALGTHGIS

idnI

ekrap

htsrotinoM

hcaerrosserpmoc

.noitareporosserpmoc

bebdluohslevel

ESOPRUP

diulf/riaehtfoerutarepmetehtsrotinoM

lamronehT.rosserpm

012ot571yletamixorppaebdluohsgnidaer

ehtnehwyalerotlangissdneS.Fseerged

seerged042se

tuhslliwrosserpmocehtdnaerutarepmet

.knatpmusehtedisnierusserpe

ehtISP561sehcaererusserpehtnehW

nwodtuhslliwrosserpmoc

lautcafosruohdetalumuccarotac

reporP.pmusehtnileveldiulfsetacidnI

fopotdnatniopdimneewte

ehtnehwlevelsihtkcehC.ssalgthgiseht

sielcihevehtdnadegagnesidsirosserpmoc

.dnuorglevelnod

FEILERERUSSERP

EVLAV

ROSSERPMOC

EVLAVLORTNOC

HCTIWSSANRUF

DIONELOS

EVLAV

fierehpsomtaehtoterusserppmusstneV

571sdeecxepmusehtedisnierusserpeht

.ISP

niekatniriafotnuomaehtsetalugeR

TELNI

iulfsetalosI.desugniebria

.nwodtuhsnotinu

Nehtfolortnoccitamotua

.dionelos

RIADETALUGER.O.N

ugercitamotual.n

ERUSSERPMUMINIM

27

oita

bulrosserpmocniatniamotISP56

desserpmocfotnuomaehthtiwecnadrocca

rosserpmocnid

edivorpotpmusmorferusserpriasesneS

riadetaluger.O.

rofevlavekatnioterusserpriasdneS

dnapmusecnalabotwolfriastcirtseR

fomuminimaserussA.erusserpriaecivres

.noitacir

Page 27

COMPRESSOR OPERATION

OPERATING CONDITIONS

The following conditions should exist for maximum performance of the compressor . The truck

should be as close to level as possible when operating. The compressor will operate on a 15

degree sideward and lengthwise tilt without any adverse problems. Operation in ambient temperatures above 100°F (38°C) may experience high temperature shutdown.

NOTE

IF THE COMPRESSOR IS BEING USED TO POWER SANDBLASTING EQUIPMENT , OR AN AIR STORAGE TANK, USE A CHECK V AL VE DIRECTLY AFTER

THE MINIMUM PRESSURE V ALVE TO PREVENT BACKFLOW INT O THE SUMP .

THIS CHECK VAL VE SHOULD HAVE A MAXIMUM PRESSURE DROP RATING

OF 2 PSIG (13.78kPa) OPERATING AND A CAPACITY RATING EQUAL TO THE

COMPRESSOR.

NOTE

A COMPRESSOR SER VICE VAL VE SHOULD BE LOCA TED TO THE HOSE REEL

INLET OR THE CUST OMERS AIR CONNECTION POR T WHEN A HOSE REEL IS

NOT USED. TYPICAL PLUMBING FROM THE MACHINE’S AIR OUTLET PORT

OCCURS IN THE FOLLOWING ORDER:

1. MOISTURE TRAP/GAUGE/OILER COMBINA TION (WHEN USED).

2. AIR T ANK (WHEN USED).

3. HOSE REEL (WHEN USED).

28

Page 28

PARTS AND

ILLUSTRA TION

SECTION

29

Page 29

1

REV

1 1

OF

BOSS INDUST RIES

1761 GENESIS DR.

1

2

3

LA PORTE, IN 46350

R

DESCRIPTION

1/16

1°

.03

`

`

`

ANGULAR

DECIMAL

DO NOT SCALE

FRACTIONAL

UNMACHINED SURFACES

.020

.010

.015

`

`

`

NOMINAL DIM.

5.001 TO 10.000

0.000 TO 1.000

1.001 TO 5.000

MACHINED SURFACES

PROPRIETARY INFORMATION

THIS DRAWING AND ALL ITS

CONTENTS ARE PROPERTY

OF BOSS INDUSTRIES, INC.

AND MUST NOT BE COPIED

OR MADE PUBLIC. IT IS

1

SHEET

20054-001

DWG NO

SCALE

1=4

INFINITY 45-60 SCI8G 08

D

SIZE

TOLERANCES

12/3/2007

12/3/2007

UNLESS NOTED

.025

`

2

10.001 & OVER

N/A

NDD

DCL

CHECKED

DRAWN

PATH

MATERIAL

G:\Inventor Files\20k\20054-001.dwg

LOANED AND IS SU BJECT TO

RETURN UPON DEMAND. THE

INFORMATION CONTAINED IN

THIS DRAWING IS

CONFIDENTIAL A ND MUST

NOT BE USED, DIRECTLY OR

INDIRECTLY, IN ANY WAY

DETRIMENTAL TO THE

INTEREST OF BOSS

INDUSTRIES, INC.

5/22/2008 MCM

3

19 in

[481.4 mm]

REVISION HISTORY

UPDATED 200353 TO REV 1, 200354 TO REV 1

1

REV DESCRIPTION DATE ENG

4

4

20 1/4 in

[514.4 mm]

5

6

34 3/4 in

[882.7 mm]

DESCRIPTIONPART NUMBERQTYITEM

7

Parts List

COMPR MTG SYS, INFINITY 45-60-150 SCI8G 0820035311

ELEC SYS, INFINITY 45-60-150 SCI8G 08200355-999 12

OIL-AIR-HYD CLNG SYS, INFINITY SCI8G 08200356-999 13

CANOPY SYS, INFINITY 45-60-150 SC I8G 0820035414

DIMENSIONS OF MOUNTING HOLES

32 1/4 in

[819.2 mm]

5

6

7

8

D D

5 in

6 3/8 in

[163.2 mm]

[127.0 mm]

8

17 3/4 in

[450.9 mm]

C C

B B

A A

30

Page 30

1

REV

1 1

OF

BOSS INDUST RIES

1761 GENESIS DR.

1

DESCRIPTIONPART NUMBERQTYITEM

2

Parts List

BASE, FRAME INFINITY (REV 5)30239111

MOTOR, 1.58 CIR SAE "A" 3/4 ROUND SIDE PORT30166512

HUB, COUPLING 25MMX8X7 KYWYR28-0 2STL30210113

SPIDER, COUPLING R28-02 98SHR RED302103 14

HUB, COUPLING 3/4 ROUND W 3/16 KYWY R28-03STL

WASHER, LOC 10MM938810-22086

CONNECTOR, 3/4 MJIC X -12 MSAE

ELBOW, HYD 1/2 MJIC X -10 MSAE970408-08818

BOLT, HEX GR8 3/8-16 X 1 1/2929806-15029

ELBOW, HYD 1/2 MBSPP X 1/2 MJIC

INDICATOR, AIR FLTR SRV 15H2O302428 111

PLUG, PIPE 1/8 BSPP HEX DRIVE

ADAPTER, 1/8 MBSPP X 1/8 FNPT970802-012213

NIPPLE, HYD HEX RED 1/4 X 1/8961604-012114

SWITCH, PRESSURE FURNAS

ELBOW, PIPE 45° STREET 1/8960802-012116

AIREND, SCI8 3.69-1 RATIO INTEGRATE D (REV 1)

ADAPTER, HYD MTR TO COMPR SCI8&8G (REV 2)302309 118

SWITCH, OPTIC LIQUID LEVEL 12VDC W ET 1/4NPT307189119

ADAPTER, 1/2 MBSPP X 1/2 FNPT

BUSHING, RED 1/2 X 1/4 GAL907602-010121

NIPPLE, HYD HEX 1/8960402-012122

VALVE, MINI BALL 1/2 NPT302633123

FITTING, 1/2 FLEX-LOC PUSH-ON BARB X 1/2 MNPT307440224

CAP, PLASTIC 1/2 NPT

HOSE, 1/2 OIL DRAIN GRAY3026362 FT26

TEE, MB 1/8 F X 1/8 F X 1/8 M961902-012127

SWITCH, PRESS 3-WAY NO-NC 5PSI307198 128

ELBOW, 1/4 TUBE SWVL X 1/8 MNPT980704-012129

CONNECTOR, 1/2 JIC X 1/2 BSPP FS973108-050130

WASHER, FLAT 10MM938910-200

NUT, COALESCER (REV 4)300233 132

WASHER, LOC GR8 3/8

WASHER, FLAT GR8 3/8938206-071234

BOLT, HEX GR10.9 10MM X 25MM929210-250835

BRACKET, RELAY MTG (REV 7)302608136

DECAL, TEMP. COMPR.- 250 F301594137

DECAL, TEMP. HYD.-140 F30

ADAPTER, 1/2 MNPT X 1/2 FJIC3 07201 139

DECAL, DIRECTION OF ROTATION

WASHER, BRASS .585OD X .405ID X .070 THK

LA PORTE, IN 46350

R

DESCRIPTION

1/16

1°

.03

`

`

`

TOLERANCES

ANGULAR

DECIMAL

DO NOT SCALE

FRACTIONAL

UNMACHINED SURFACES

.020

.025

.010

.015

`

`

`

`

NOMINAL DIM.

10.001 & OVER

5.001 TO 10.000

0.000 TO 1.000

1.001 TO 5.000

MACHINED SURFACES

PROPRIETARY INFORMATION

THIS DRAWING AND ALL ITS

CONTENTS ARE P ROPERTY

OF BOSS INDUSTRIES, INC.

AND MUST NOT BE COPIED

OR MADE PUBLIC. IT IS

LOANED AND IS SU BJECT TO

1

SHEET

200353

DWG NO

SCALE

1=8

COMPR & MTG SYS, INFINITY 45 /60/150 SCI8G

08

D

SIZE

11/19/2007

UNLESS NOTED

2

N/A

NDD

CHECKED

DRAWN

PATH

MATERIAL

G:\Inventor Files\200k\200353.dwg

RETURN UPON DEMAND. THE

INFORMATION CONTAINED IN

THIS DRAWING IS

CONFIDENTIAL A ND MUST

NOT BE USED, DIRECTLY OR

INDIRECTLY, IN ANY WAY

DETRIMENTAL TO THE

INTEREST OF BOSS

INDUSTRIES, INC.

302455 15

970512-10617

970608-050310

305624112

300904 115

301722-369117

3

970808-050120

307439125

937806-094233

301593138

300048140

307203141

5

5/22/2008 MCM

3

31

REVISION HISTORY

1

ADDED (2) 307440, (1) 307439. REMOVED (2)

302634, (1) 906030-020, (2) 300033-075.

26

4

REV DESCRIPTION DATE ENG

302636 WAS 6".

1

4

1

24

1

24

1

25

5

10

12

41

37

13

15

14

23

39

19

21

5

20

30

6

10

10

31

35

16

28

11

27

6

6

22

13

29

31

17

7

8

D D

6

32

17

40

18

35

3

4

1

5

36

8

7

34

2

33

9

7

38

8

C C

B B

A A

31

Page 31

1

REV

1 1

OF

BOSS INDUST RIES

1761 GENESIS DR.

1

DESCRIPTIONPART NUMBERQTYITEM

Parts List

2

PANEL, CANOPY BACK-END INFINITY (REV 4)30239211

PANEL, CANOPY HYD END INFINITY (REV 6)302395 12

PANEL, CANOPY AIR END INFINITY30239613

DOOR, CANOPY INFINITY (REV 4)30239414

LATCH, BULLET

HINGE, INFINITY ALUM 3.0" OPEN FACE .18PIN 1/2

KNUCKLE (REV 1)

NUT, TINNERMAN 1/4-20961504-090127BOLT, BTNHD SS STAR-DRIVE 1/4-20 X 3/4983904-075108

WASHER, NYLON 1/4 X .06 X .62

NUT, TINNERMAN 5/16-18961505-140510

BOLT, WHIZLOCK GR5 5/16-18 X 1

WASHER, FLAT GR8 3/8938206-071212

BUMPER, DOOR STOP INFINITY302639213

DECAL, BOSS

DECAL, HYD PRESS LEXAN302443115

DECAL, HYD TANK LEXAN

DECAL, AIR LEXAN302445117

DECAL, OIL DRAIN300913118

DECAL, INFINITY (REV 1)

RIVET, POP 3/16 X 1/2 ALUMINUM943103-0252420

NUT, NYLOC GR5 5/16-18

WASHER, FLAT WIDE 1/4 SS984004-0711022

DECAL, WARNING CONNECT AIR300042123

DECAL, SERIAL TAG BOSS (REV 1)

GROMMET, 1 7/8 OD X 1 1/4 ID X 1/16 THK307433125

CLIP, 1/2" HYD HOSE HOLDER302613226

TAPE, 1/16 X 1/2 CLOSED CELLO3004448 FTNS

30138325

30244216

977004-062109

929705-100711

300649114

302444116

302323119

924305-166221

305761124

3

LA PORTE, IN 46350

R

DESCRIPTION

1/16

1°

.03

`

`

`

TOLERANCES

ANGULAR

DECIMAL

DO NOT SCALE

FRACTIONAL

UNMACHINED SURFACES

.020

.025

.010

.015

`

`

`

`

NOMINAL DIM.

10.001 & OVER

5.001 TO 10.000

1.001 TO 5.000

0.000 TO 1.000

MACHINED SURFACES

PROPRIETARY INFORMATION

THIS DRAWING AND ALL ITS

CONTENTS ARE PROPERTY

OF BOSS INDUSTRIES, INC.

AND MUST NOT BE COPIED

OR MADE PUBLIC. IT IS

LOANED AND IS SU BJECT TO

1

SHEET

200354

DWG NO

SCALE

1=4

CANOPY SYS, INFINITY 45-60-150 SC I8G 08

D

SIZE

12/3/2007

12/3/2007

UNLESS NOTED

2

N/A

NDD

DCL

CHECKED

DRAWN

PATH

MATERIAL

G:\Inventor Files\200k\200354.dwg

RETURN UPON DEMAND. THE

INFORMATION CONTAINED IN

THIS DRAWING IS

CONFIDENTIAL A ND MUST

NOT BE USED, DIRECTLY OR

INDIRECTLY, IN ANY WAY

DETRIMENTAL TO THE

INTEREST OF BOSS

INDUSTRIES, INC.

5/23/2008 MCM

3

1

1

18

25

3

1

20

4

1

26

8

5

REVISION HISTORY

22

11

9

10

REV DESCRIPTION DATE ENG

ADDED (1) 307433, (2) 302613, (2) 943103-025.

UPDATED 302396 TO REV 4.

1

4

19

7

5

20

5

4

13

9

22

6

8

6

6

11

21

12

1

8

22

9

7

20

7

11

7

8

D D

2

9

24

22

8

14

C C

B B

23

15

16

8

17

A A

32

Page 32

1

Parts List

2

DESCRIPTION

COUPLING, PIPE 1/8 GAL 150PSI

PART NUMBER

QTY

13 1 901215-005

14 1 980604-012 CONNECTOR, TUBE 1/4 PAR X 1/8 NPT

ITEM

15 3 300211 RELAY, POWER

16 1 307196 ENCLOSURE, COMPACT RELAY

0

REV

EN Num.

1 1

1761 GENESIS DR.

12

BOSS INDUSTRIES

LA PORTE, IN 46350

R

TITLE

Released For

12/4/2007

12/3/200 7

11

Rev. Date

DCL

Rev. Num.

NDD

DRAWN

CHECKED

THIS DRAWING AND ALL

INFORMATION THEREIN IS

THE PROPERTY OF BOSS

INDUSTRIES, INC., IS CON-

FIDENTIAL AND MUST NOT

BEMADE PUBLIC OR

COPIED. IT IS LOANED

.010

.015

1

9

7

3

6

4

4

5

13

SHEET OF

1

200355-999

DWG NO

ELEC SYS, INFINITY 45-6 0-150 SCI8G 08

C

SIZE

SCALE

MATERIAL

G:\INVENTOR 9.0\

PATH

2

SUBJECT TO RETURN UPON

DEMAND, IS NOT TO BE

USED DIRECTLY OR IN-

DIRECTLY IN ANYWAY DE-

TRIMENTIAL TO THE IN-

TEREST OF BOSS INDUS-

TRIES, INC .

/

.020

14

TOLERANCES

UNLESS NOTED

MACHINED SURFACES NOMINAL DIM.

DO NOT SCALE

0.000 TO 1.000

1.001 TO 5.000

5.001 TO 10.000

10.001 & OVER

8

17 4 931201-050 SCREW, MACH RD HD #8-32 X 1/2

18 4 924301-156 NUT, NYLOC GR5 #8-32

19 1 302678 BRACKET, RELAY HOLDER INFINITY (REV 2)

20 2 929102-050 BOLT, HEX GR5 #6-32 X 1/2

21 1 302780 TIMER, RELAY 12V 30 SEC N.C.

22 2 924200-114 NUT, MACH #6-32

NS 1 307193 HARNESS, WIRING INFINITY 08

NS .083 307190 RELAY, COMPACT 12VDC 30MA

22

19

2

10

20

3

DESCRIPTION

15

16

17

18

21

7

3

8

Parts List

10 1 300076-004 SWITCHGAUGE, TMP 4 ft - 250

11 1 300075 SWITCHGAUGE, PRESSURE

(REV 1)

4

12 1 302591 SWITCH, SHUTDOWN 117LF WITHOUT FUSE

C C

B B

A A

PANEL, GAUGE & LIGHTS INFINITY 08

4

PART NUMBER

5 1 302592 SWITCH, N O MOMENTARY SPST

3 929705-100 BOLT, WHIZLOCK GR5 5/16-18 X 1

6 1 302486 BREAKER, PANEL MTG RESET

7

8 3 961505-140 NUT, TINNERMAN 5/16-18

9 1 307191 DECAL, INFINITY 08 GAUGE PANEL

QTY

1 1 307192

ITEM

2 1 300074 GAUGE, HOURMETER

3 1 302449 LIGHT, INDICATING GREEN

4 2 302450 LIGHT, INDICATING RED

D D

33

Page 33

1

Parts List

DESCRIPTION

BOX, COOLER SHROUD INFINITY (REV 3)

CONTROL

JIC TO SAE

0

REV

EN Num.

1 1

1761 GENESIS DR.

BOSS INDUSTRIES

LA PORTE, IN 46350

R

SHEET OF

1

9

200356-999

DWG NO

OIL-AIR-HYD CLNG SYS, INFINITY SCI8G 08

1

3

TITLE

Released For

12/4/2007

12/3/200 7

Rev. Date

DCL

Rev. Num.

NDD

DRAWN

CHECKED

C

SIZE

SCALE

MATERIAL

G:\INVENTOR 9.0\

PATH

2

THIS DRAWING AND ALL

INFORMATION THEREIN IS

THE PROPERTY OF BOSS

INDUSTRIES, INC., IS CON-

FIDENTIAL AND MUST NOT

BEMADE PUBLIC OR

COPIED. IT IS LOANED

SUBJECT TO RETURN UPON

DEMAND, IS NOT TO BE

.010

.015

PART NUMBER

QTY

ITEM

14 1 302397

15 4 943104-038 RIVET, POP 1/4 X 3/8 ALUMINUM

16 1 300041 DECAL, WARNING FAN GUARD

17 1 970508-106 CONNECTOR, 1/2 MJIC X -12 MSAE

18 4 938604-071 WASHER, FLAT GR5 1/4

19 2 924304-145 NUT, NYLOC GR5 1/4-20

20 2 929104-325 BOLT, HEX GR5 1/4-20 X 3 1/4

21 1 80056-13-12 KIT, HYD VALVE BLOCK 13GPM FLOW

22 1 304700 VALVE, CHECK -12JIC M X -12SAE M FLOW

23 1 306812-282 ORIFICE, BLACK .282 FOR HYD BLOCK

10

.020

1.001 TO 5.000

5.001 TO 10.000

TOLERANCES

UNLESS NOTED

MACHINED SURFACES NOMINAL DIM.

0.000 TO 1.000

DO NOT SCALE

5

13

2

USED DIRECTLY OR IN-

DIRECTLY IN ANYWAY DE-

TRIMENTIAL TO THE IN-

TEREST OF BOSS INDUS-

TRIES, INC .

/

10.001 & OVER

12

6

3

16

2

3

7

14

5

22

DESCRIPTION

3

11

17

Parts List

COOLER, COMPR/HYD/AIR 30 X 16

PUSHER CURVED BLADE

23

8

19

18

21

4

PART NUMBER

QTY

1 1 302570

ITEM

2 1 302087 BULBWELL, 5/8 UNF X 1/2 NPT

3 14 929705-100 BOLT, WHIZLOCK GR5 5/16-18 X 1

D D

2 960108-075 CONNECTOR, 1/2 MJIC X 3/4 MNPT

1 984112-050 ELBOW, HYD 3/4 MNPT X 1/2 MNPT

4 1 302622 FAN ASSY, WITH MOTOR AND GRILL 14.09

5

6 1 960208-050 ELBOW, 1/2 JIC X 1/2 MNPT

7

8 1 907215-020 COUPLING, PIPE 1/2 GAL 150 PSI

9 14 961505-140 NUT, TINNERMAN 5/16-18

10 1 961612-050 NIPPLE, HYD HEX RED 3/4 X 1/2

11 1 960112-075 CONNECTOR, 3/4 MJIC X 3/4 MNPT

12 1 902615-020 ELBOW, PIPE SIDE OUT 1/2 GAL 150PSI

13 1 960212-075 ELBOW, HYD 3/4 MJIC X 3/4 MNPT

C C

18

20

B B

A A

15

4

4

34

Page 34

35

Page 35

RECOMMENDED SP ARE PARTS

REBMUNTRAPNOITPIRCSEDYTQ

1062038ICSRETLIFLIO,TNEMELE1

2517038/7ICSRETLIFRIA,TNEMELE1

0062038ICSNO-NIPS,RECSELAO

C1

306203G8ICSRIAPERLAESTFAHS,TIK1

9417038/7ICSTELNI,EVLAV1

301203GNILPUOCREDIPS1

406203RIAPERLAESTFAHSROTOMDYH,T

IK1

2062038ICSLAMREHT,EVLAV1

36

Page 36

SERVICE QUESTIONNAIRE

DATE :__________

1. Information given by:______________________________________________

2. Information received by:____________________________________________

3. Has anyone helped you: Yes______ No______

4. Distributor:_____________________________________________________

5. End-User:________________________________________________________

6. Phone Number:___________________________________________________

7. Make and Model for PTO:__________________________________________

8. BOSS INDUSTRIES Serial #:_______________________________________

9. Make and Model of Engine:_________________________________________

10. Engine:________________________________________________________

11. Transmission:___________________________________________________

12. Nature of Problem:________________________________________________

___________________________________________________________________________

_______________________________________________________

___________________________________

___________________________________________________________________________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

13. Engine RPM:_____________________________________________________

14. Compressor RPM:________________________________________________

15. Action Taken:_____________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________

________

_________________________________________________________________________________________

_____________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________

_________________________________________________

__________________________________________________________________________________________________________________________________

Additional Comments:___________________________________________________

______________________________________________________________________

__________________________________________________

____________________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

______________________________

________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________

___________________________________________________________________________________________

_______________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________

_______________________________

_______________________________________________________________________________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________________________________________

37

Page 37

Instructional Procedures for Installation

of BOSS INFINITY Geared Rot ary Screw Air

Compressor

This air compressor should be installed only by those who have been trained and delegated to

do so and who have read and understand both the operators’ manual and the installation manual.

Failure to follow the instructions, procedures, and safety precautions in this manual may result in

accidents and injuries.

Install, use, and operate this air compressor only in full compliance with all pertinent O.S.H.A.

requirements and all pertinent Federal, S tate, and Local codes or requirements and with BOSS

INDUSTRIES, Inc. instructions.

Do not modify this compressor except with written factory approval.

1. MOUNTING COMPRESSOR

When mounting the compressor care should be taken to ensure that its location does not impede the operation of other components on the vehicle. For example, if your vehicle is equipped

with a crane, you must make sure the compressor will not interfere with the swing of the crane.

In addition, the compressor should be installed in an area that permits cool ambient air to enter

the air filter and the hot air from the cooler to exhaust without recirculating into the air filter. One

last consideration in the mounting should be the routing of hoses and electrical wires. The frame

mounting holes are shown below and the unit should be secured to the vehicle with 3/8 inch

grade 8 bolts, washers should be used on the mounting surface. Hardware supplied with unit,

may not work in all applications.

38

Page 38

INSTRUCTIONAL PROCEDURES

2. INSTALLING THE WIRING & CONNECTING THE HYDRAULIC HOSES

This unit is shipped from the factory with all necessary internal wiring installed. The only remaining wiring necessary is the wiring needed to interface your vehicle/power source with the BOSS

INDUSTRIES compressor . (Please refer to drawing 307193 on page 35) The unit is shipped

with 4 loose wires, they need to be connected as follows:

1. Connect red wire to switched 12 vdc power. (or 24 VDC if you have this option)

2. The yellow wire should be spliced into the 12 vdc switched feed for the on/off switch

per the end-users location.(or 24 VDC if you have this option)

3. Connect black wire to ground.

4. The orange wire is used to activate an electronic speed control circuit if required.

Please contact the factory with engine specific information for further assistance.

CONNECTING THE HOSES

The hydraulic hoses to the compressor should be connected directly to the hydraulic control

block. The pressure “P” input line should be made from a good quality high pressure (min. 3000

PSI) hydraulic hose 1/2” or 3/4” i.d. The return line to tank “T” can be made from a medium

pressure (min. 1000 PSI) hydraulic hose 3/4” i.d. Care should be taken to see that the hoses are

not installed with kinks or bends that inhibit flow of the hydraulic oil. Lack of flow could result in

damage to the motor and compressor. Lastly check to make sure hoses are not in contact with

sharp objects or edges that may fray, chafe or cut them over time. Secure all hoses with tie

down straps or clamps.

39

Page 39

INSTRUCTIONAL PROCEDURES

3. PRE-START-UP INSPECTION CHECKS

This inspection should be done prior to removing truck from bay. Final testing of the system,

including checking for leaks, is to be done outside.

ALL TRUCKS SHOULD BE ROAD TESTED PRIOR TO ST ARTING INST ALLA TION TO ISOLA TE ANY

PREVIOUS TRUCK PROBLEMS.

I. Check sales order to verify that all compressor related items originally ordered have

been installed or are ready to ship with the truck. This would include any special filters,

oils, hoses, options, etc.

II. Vacuum all areas that have metal or plastic shavings. Wipe all fingerprints off unit and

vehicle.

III. Apply decals to proper location. Make sure that the area is cleaned prior to applying

decals. All decals should have a professional appearance upon application.

IV. Check all assemblies, clamps, fittings, drivelines, angles, nuts, and bolts to ensure they

are properly tied and secured to the vehicle. This is a very critical area of inspection.

The vehicle should not be moved until this inspection has been completed.

V. Record all serial numbers for this installation.

A. Vehicle V .I.N.

B. Hydraulic Pump Data

C. Air-End Serial Number

D. BOSS INDUSTRIES Serial Number

E. Receiver Tank Serial Number

F. Note any special applications relating to specific installations.

V I. Check all fluid levels (position the unit on a level surface so that proper amount of fluids

can be added).

A. Fuel to provide for three hours of operation.

B. Transmission fluid and PTO box.

C. Compressor.

Check the compressor oil sump level (see lubricant section of the operator and

parts section for type of lubricant to use). 1. Add oil if needed. 2. Additional oil

may need to be added after test. 3. Top off oil level to half the sightglass when

finished with the test.

D. Any other applicable fluids.

4. INITIAL START-UP AND TEST

A. Start power source and allow for warm-up.

B. Read the operation section in the operator and parts manual carefully before proceeding onto

the initial start-up.

40

Page 40

INSTRUCTIONAL PROCEDURES

C. Engage hydraulic system. A direction of rotation arrow is attached to the compressor pack-

age above the hydraulic coupling. The coupling/hub must be rotating in the direction the

arrow is pointing. If for any reason this arrow has been removed the correct compressor

rotation is clockwise when looking directly at the compressor shaft. Check the direction of

rotation by quickly engaging and then disengaging the compressor.

CAUTION

DO NOT RUN THE COMPRESSOR IN A REVERSE ROTATION FOR PERIODS LONGER

THAN 5 SECONDS. CONTINUED OPERATION IN THIS MANNER WILL RESULT IN

EXTENSIVE COMPRESSOR UNIT DAMAGE.

The safety shutdown switch should be wired in series with the solenoid that opens the flow of

the hydraulic oil to the compressor drive motor. In cases of high temperature and/or pressure,

the closing of the valve will stop the compressor operation.

Safety circuit testing for INFINITY

Safety circuit testing can be done in the following manner. Start the truck. Engage the compressor. Take a screwdriver and touch the 1/16” allen head screw on the face of the temperature gauge and simultaneously touch the outside ring on the face of the gauge. This should shut

off the power to the solenoid of the hydraulics. Push the button in on the shutdown switch to

reset. Repeat the test with the pressure gauge if solenoid does not stop flow to compressor,

check wiring.

41

Page 41

WARRANTY SECTION

42

Page 42

WARRANTY INFORMA TION

BOSS Industries, Inc. warrants that this Rotary Screw Compressor unit conforms to applicable

drawings and specifications approved in writing by BOSS. The unit assembly will be free from

defects in material and workmanship for a period of two (2) years from the date of initial operation

or thirty (30) months from the date of shipment, whichever period first expires. All other components

and parts of BOSS manufacture, will be free from defects in material and workmanship for a

period of one (1) year from the date of initial operation or eighteen (18) months from the date of

shipment, whichever period first expires. If within such period BOSS receives from the Buyer

written notice of and alleged defect in or nonconformance of the unit, all other components and

parts of BOSS manufacture and if in the judgment of BOSS these items do not conform or are

found to be defective in material of workmanship, BOSS will at its option either , (a) furnish a

Service Representative to correct defective workmanship, or (b) upon return of the item F .O.B.

BOSS original shipping point, repair or replace the item or issue credit for the replacement item

ordered by Buyer, (Defective material must be returned within thirty (30) days of return shipping

instructions from BOSS. Failure to do so within specified time will result in forfeiture of claim), or

(c) refund the full purchase price for the item without interest. Factory installed units will also

include warranty on installation for a period of one (1) year . This warranty does not cover damage

caused by accident, misuse or negligence. If the compressor unit is disassembled the warranty is

void. BOSS’s sole responsibility and Buyer’ s exclusive remedy hereunder is limited to such repair,

replacement, or repayment of the purchase price. Parts not of BOSS manufacture are warranted

only to the extent that they are warranted by the original manufacture. BOSS shall have no

responsibility for any cost or expense incurred by Buyer from inability of BOSS to repair under

said warranty when such inability is beyond the control of BOSS or caused solely by Buyer .

There are no other warranties, express, statutory or implied, including those of

merchantability and of fitness of purpose; nor any affirmation of fact or

representation which extends beyond the description of the face hereof.

This warranty shall be void and BOSS shall have no responsibility to repair, replace, or repay the

purchase price of defective or damaged parts or components resulting directly or indirectly from

the use of repair or replacement parts not of BOSS manufacture or approved by BOSS or from

Buyer’s failure to store, install, maintain, and operate the compressor according to the

recommendations contained in the Operating and Parts Manual and good engineering practice.

The total responsibility of BOSS for claims, losses, liabilities or damages, whether in contract or

tort, arising out of or related to its products shall not exceed the purchase price. In no event shall

BOSS be liable for any special, indirect, incidental or consequential damages of any charter, including,

but not limited to, loss of use of productive facilities or equipment, loss of profits, property damage,

expenses incurred in reliance on the performance of BOSS, or lost production, whether suffered

by Buyer or any third party .

BOSS Industries, Inc.

1761 Genesis Drive

LaPorte, IN 46350

43

Page 43

SUMMARY OF MAIN WARRANTY PROVISIONS

As claims, policies and procedure are governed by the terms of the BOSS Industries, Inc. warranty, it is

necessary to outline some of the more important provisions.

The BOSS warranty applies only to new and unused products which, after shipment from the factory, have

not been altered, changed, repaired or mistreated in any manner whatsoever. Normal maintenance items

such as lubricants and filters are not warrantable items.

Parts not of BOSS manufacture are warranted only to the extent they are warranted by the original

manufacturer.

Damage resulting from abuse, neglect, misapplication or overloading of a machine, accessory or part is not

covered under warranty .

Deterioration or wear occasioned by chemical and/or abrasive action or excessive heat shall not constitute

defects.

Parts replacement and/or correction of defective workmanship will normally be handled by BOSS or their

authorized distributor.

Failure to file a detailed warranty claim/service report for each occurrence of material defect of defective

workmanship will cause warranty claim to be rejected.

Defective material must be returned within 30 days of receipt of shipping instructions. Failure to do so

within specified time will result in forfeiture of claim.

The distributor is responsible for the initial investigation and write up of the warranty claim.

Distributor shall be allowed no more than 30 days from date of repair to file a warranty claim/service

report.

W arranty for failure of BOSS replacement parts covers the net cost of the party only, not labor and

mileage.

The BOSS warranty does not cover diagnostic calls and travel. That is time spent traveling to the machine

to analyze the problem and returning with the proper tools and parts to correct the problem.

BOSS will deduct from allowable credits for excess freight caused by sender failing to follow return

shipping instructions.

Distributors or end-users automatically deducting the value of a warranty claim from outstanding balances

due and payable to BOSS prior to receiving written notification of BOSS approval of the warranty claim

may be subject to forfeiture of the entire claim.

44

Page 44

W ARRANTY/RETURN GOODS INSTRUCTIONS

The warranty/return procedure outlined below is provided to give the claimant the information

necessary to file a warranty/return claim, and enable BOSS INDUSTRIES the ability to best serve its’

customers.

Please see the following instructions to initiate a return:

Contact BOSS INDUSTRIES Returns Department by telephone at 219.324.7776 or via email at

service@bossair.com. Y ou may also send a fax at 219.324.7470.

W ARRANTY CLAIMS – PREP ARA TION OF PART RETURN

Parts returned to the factory must be properly packaged to prevent damage during shipment.

Damage to a part as a result of improper handling or packing could be cause for denial. When addressing the package for shipment, the following information must be on the outside of, or tagged clearly , to

the package.

1. Return Goods Authorization #.

2. Distributor or end-users return address.

3. Correct factory address.

4. Number of packages pertaining to each claim.

NOTE: Our warranty requires that all defective parts be returned to BOSS INDUSTRIES freight

prepaid. Items sent without RGA number will not be accepted. Unauthorized Returns Will Immediately

Be Refused At Dock.

RETURN OR WARRANTY CLAIMS – FILING PROCEDURES

1. Initiate through a purchase order for warranty part or request for credit.

2. RGA will accompany replacement part.

3. BOSS INDUSTRIES will confirm disposition of failed part within 30 days of receipt and or

request additional information.

4. Claim denial will result in issuance of a letter of denial.

5. BOSS INDUSTRIES will consider each claim on its’ own merit and reserves the right to accept

or reject claim request. In case of air-ends, these will be returned to the manufacturer for their

analysis/input.

6. Send Warranty Claim to:

BOSS INDUSTRIES, INC.

1761 Genesis Drive

LaPorte, IN 46350

Attn: Returns Dept.

45

Page 45

GENERAL

An approved claim depends on the following provision:

1. An RGA # must be issued by BOSS INDUSTRIES. (See filing procedures.)

2. Failed part must be returned within 30 days of original invoice date, freight prepaid, with RGA

#.

3. Part is determined to be defective.

4. Workmanship is determined to be defective.

5. Machine is within warranty period.

6. Machine has been operated within design conditions.

Claims made through distributors must be verified by distributor prior to contacting BOSS IN-

DUSTRIES.

DAMAGE IN TRANSIT

Do not return damaged merchandise to BOSS INDUSTRIES, please follow claim procedure.

1. Loss in transit:

The merchandise in our kit or provided in our factory installations has been thoroughly inspected or carefully installed and tested before leaving our plant. However, regardless of the

care taken at the factory , there is a possibility that damage may occur in shipment. For this

reason, it is recommended that the unit be carefully inspected for evidence of possible damage

or malfunction during the first few hours of operation. Responsibility for the safe delivery of the

kit or factory installed unit was assumed by the carrier at the time of shipment. Therefore,

claims for loss or damage to the contents of the kit or factory installed unit should be made

upon the carrier.

2. Concealed loss or damage:

Concealed loss or damage means loss or damage, which does not become apparent until the kit

is unpacked or the factory-installed unit is run by the end-user. The contents of the kit or

factory installed unit may be damaged due to rough handling while in route to its destination,

even thought the kit or factory installed unit shows no external damage. When the damage is

discovered upon unpacking, make a written request for inspection by the carrier agent within

fifteen days of delivery date. Then file a claim with the carrier since such damage is the carrier’s

responsibility .

By following these instructions carefully , we guarantee our full support of your claims, to protect

you against loss from concealed damage.

3. Visible Loss or Damage

Any external evidence of loss or damage must be noted on the Freight Bill or Express Receipt,

and signed by the carrier’s agent. Failure to adequately describe such external evidence of loss,

or damage may result in the carrier refusing to honor a damage claim. The carrier will supply

the form required to file such a claim.

46

Page 46

SCREW COMPRESSOR AIR-END EXCHANGE PROGRAM

Replacement air-ends are available from the factory . For current prices and availability , contact

BOSS INDUSTRIES, Inc. or an authorized BOSS INDUSTRIES distributor. Prices are F.O.B.

shipping point. Prices do not include labor for removal or installation.

47

Loading...

Loading...