Page 1

77

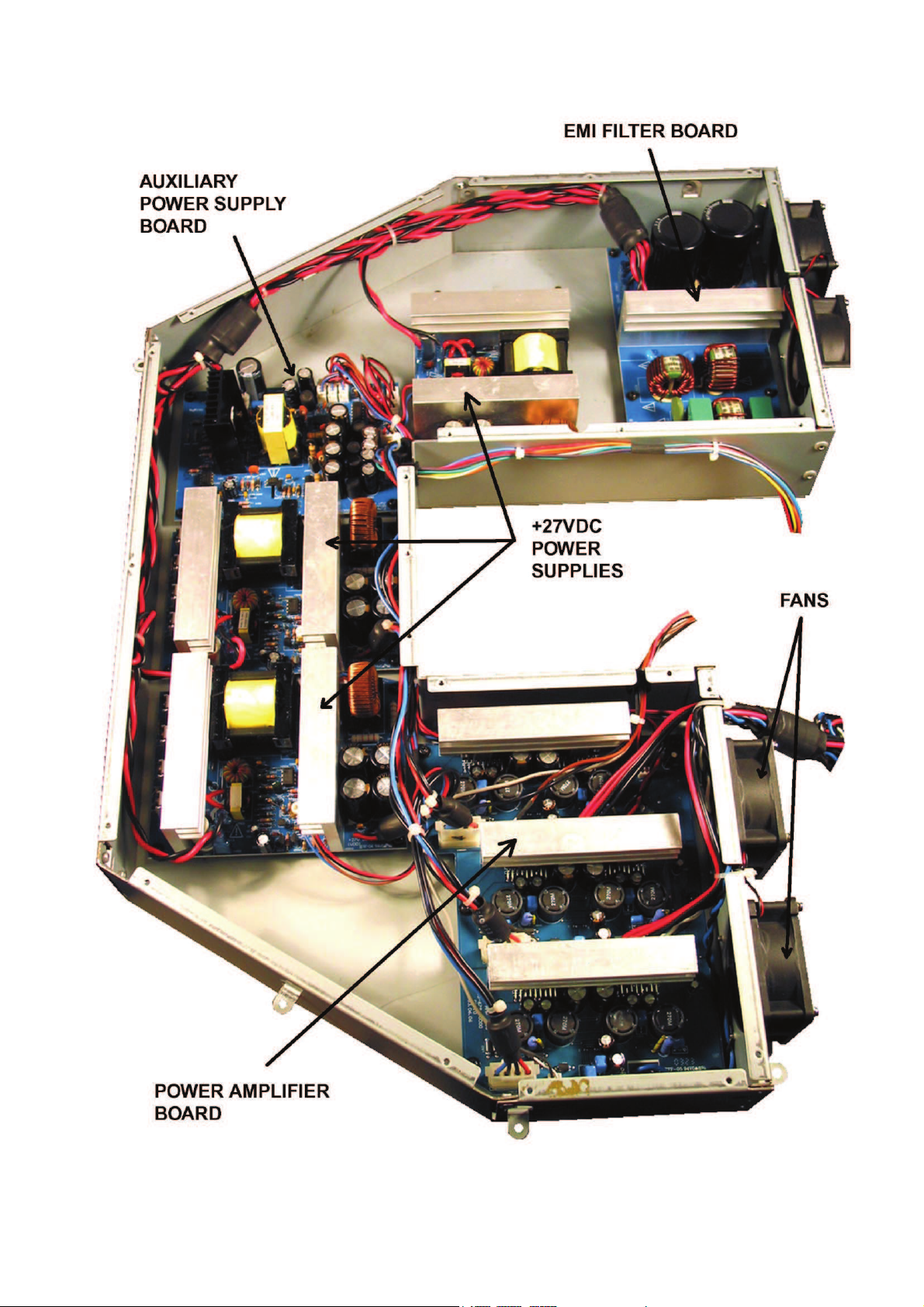

Figure 9. PS1 Power Stand Electronics Module with Top Cover Removed

Page 2

78

Power Stand Procedures

Note: Refer to Figure 9 for the following

procedures.

1. Lower Housing Removal

1.1 Place the power stand on a soft surface

so that the line array opening faces down.

1.2 Using a Phillips-head screwdriver,

remove the 19 screws that secure the lower

housing to the upper housing. Lift off the

lower housing.

2. Amplifier Housing Removal

2.1 Perform procedure 1.

2.2 Make a note of the wiring, and discon-

nect the wiring harnesses and connectors

that run to the amplifier housing. The amplifier housing is the large metal box with the

four fans.

2.3 Using a Phillips-head screwdriver,

remove the four screws that secure the

power stand base plate to the bottom of the

line array cavity. Lift it off of the cavity. Be

careful not to damage any wires.

2.4 Once all of the wiring is disconnected,

use a Phillips-head screwdriver to remove

the 16 screws that secure the amplifier

housing to the power stand upper housing.

Carefully lift the amplifier housing out of the

power stand upper housing.

3. Line Array Cavity Removal

3.1 Perform procedure 2.

3.2 Using a Phillips-head screwdriver,

remove the three screws that secure the line

array cavity to the upper housing. Lift the line

array cavity off of the upper housing. The

power stand foot pedal will disengage from

the shaft.

Disassembly Procedures

Page 3

79

4. Amplifier PCB Removal

4.1 Perform procedure 2.

4.2 Make a note of the wiring and disconnect

all of the wiring harnesses that connect the

power supply box to the DSP PCB and to the

microprocessor PCB.

4.3 Using a Phillips-head screwdriver,

remove the 24 screws that secure the power

supply box top cover in place. Lift off the top

cover.

4.4 Once you have the top cover off, make a

note of the wiring configuration and unplug

the wiring harnesses that connect to the

amplifier PCB.

4.5 Using a Phillips-head screwdriver,

remove the 6 screws that secure amplifier

PCB in place. Lift the amplifier PCB out of

the chassis.

5. Switching DC Power Supply Removal

5.1 Perform procedure 2.

5.2 Make a note of the wiring and disconnect

all of the wiring harnesses that connect the

power supply box to the DSP PCB and to the

microprocessor PCB.

5.3 Using a Phillips-head screwdriver,

remove the 24 screws that secure the power

supply box top cover in place. Lift off the top

cover.

5.4 Once you have the top cover off, make a

note of the wiring configuration and unplug

the wiring harnesses that connect to the

switching DC power supply PCB you wish to

remove.

5.5 Using a Phillips-head screwdriver,

remove the 4 screws that secure power

supply PCB in place. Lift the power supply

PCB out of the chassis.

Disassembly Procedures

Page 4

80

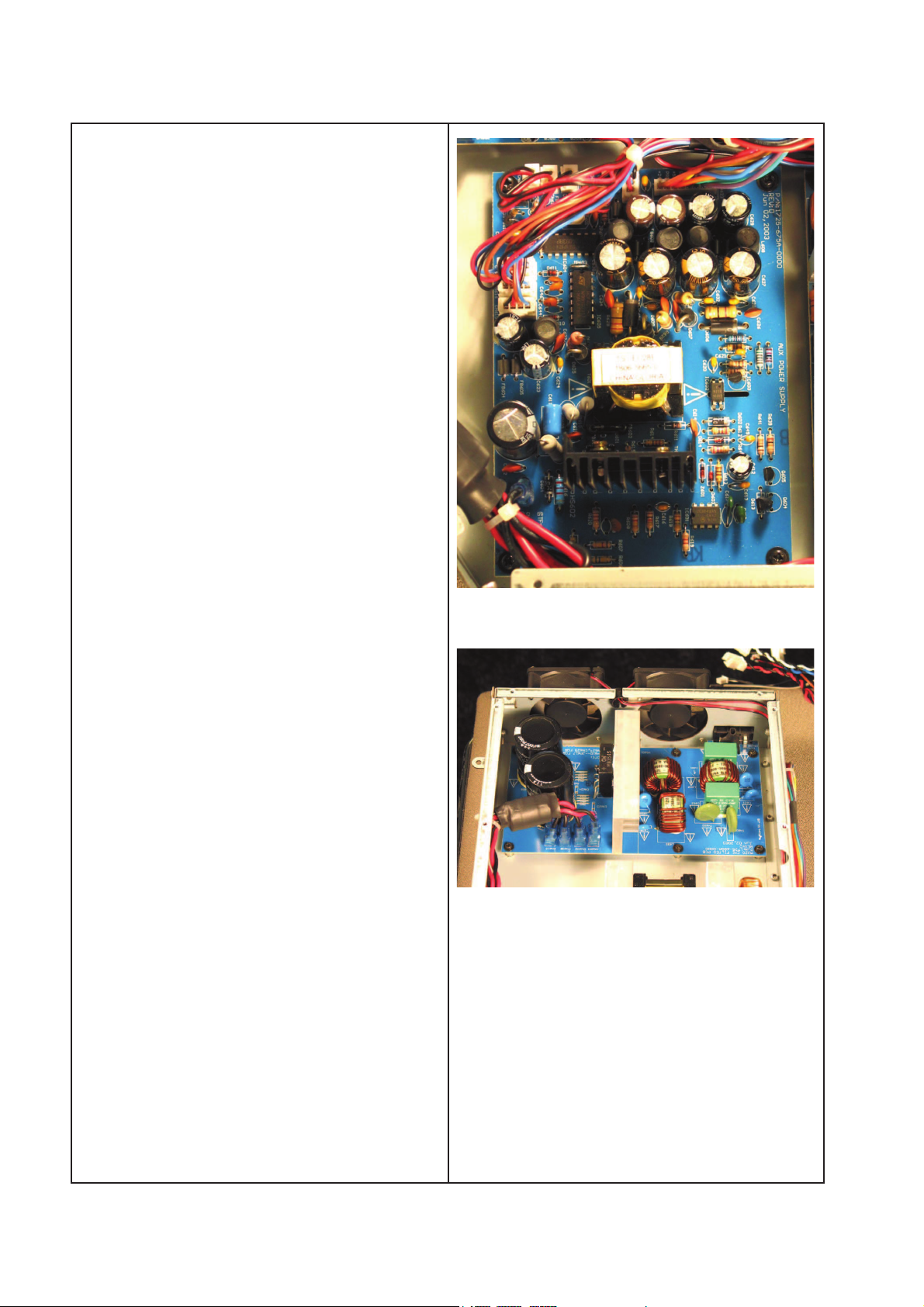

6. Auxiliary Power Supply Removal

6.1 Perform procedure 2.

6.2 Make a note of the wiring and disconnect

all of the wiring harnesses that connect the

power supply box to the DSP PCB and to the

microprocessor PCB.

6.3 Using a Phillips-head screwdriver,

remove the 24 screws that secure the power

supply box top cover in place. Lift off the top

cover.

6.4 Once you have the top cover off, make a

note of the wiring configuration and unplug

the wiring harnesses that connect to the

switching DC power supply PCB you wish to

remove.

6.5 Using a Phillips-head screwdriver,

remove the 4 screws that secure power

supply PCB in place. Lift the power supply

PCB out of the chassis.

7. EMI Filter PCB Removal

7.1 Perform procedure 2.

7.2 Make a note of the wiring and disconnect

all of the wiring harnesses that connect the

power supply box to the DSP PCB and to the

microprocessor PCB.

7.3 Using a Phillips-head screwdriver,

remove the 24 screws that secure the power

supply box top cover in place. Lift off the top

cover.

7.4 Once you have the top cover off, make a

note of the wiring configuration and unplug

the wiring harnesses that connect to the EMI

Filter PCB.

7.5 Using a Phillips-head screwdriver,

remove the 4 screws that secure the EMI

Filter PCB in place. Lift the EMI Filter PCB

out of the chassis.

Disassembly Procedures

Page 5

81

8. Chassis Fan Removal

8.1 Perform procedure 2.

8.2 Using a Phillips-head screwdriver,

remove the 24 screws that secure the power

supply box top cover in place. Lift off the top

cover.

8.3 Using a Phillips-head screwdriver,

remove the 4 screws that secure the fan to

the chassis.

8.4 Follow the wire harness for the fan you

are removing to the auxiliary power supply

PCB and unplug it. Lift the fan out of the

chassis.

Re-assembly note: When installing the new

fan, be sure to match the orientation of the

fan next to it so that it will move air in the

proper direction when in use.

9. Microprocessor PCB Removal

9.1 Perform procedure 1.

9.2 Make a note of the wiring configuration

and unplug the six wire harnesses from the

connectors on the board.

9.3 Lift the microprocessor PCB off of the

connectors that engage it on the bottom of

the board and the pins that connect to the

preset switches.

Re-assembly note: When re-installing this

PCB, be sure that all of the pins from the

preset switches are straight and properly

engage the connectors on the bottom of the

microprocessor PCB.

Disassembly Procedures

Page 6

82

Disassembly Procedures

10. DSP PCB Removal

10.1 Perform procedure 1.

10.2 Make a note of the wiring configuration

and unplug the six wire harnesses from the

connectors on the board.

10.3 Using a pair of needle-nose pliers,

compress the bottoms of the plastic standoff

posts used to attach the DSP PCB to the

Input/Output PCB. Lift the DSP PCB off of

the I/O PCB.

11. Input/Output PCB Removal

11.1 Perform procedures 9 and 10.

11.2 On the front panel of the power stand,

remove the four knobs for the mic trim and

level controls.

11.3 Using a nut driver, remove the nine nuts

and washers for the 1/4 inch phono jacks.

11.4 Using a Phillips-head screwdriver,

remove the 16 screws that secure the XLR,

Data in/out and Neutrik connectors to the

front panel.

11.5 Lift the I/O PCB off of the input panel.

Page 7

83

Disassembly Procedures

Line Array Procedures

Note: The line arrays are divided into a

lower line array, which plugs directly into the

power stand, and an upper line array, which

uses a bayonet arrangement to align the

upper array to the lower array for connection. All electrical connections are automatically made when the arrays are mounted

into the power stand and the upper array is

mounted to the lower array.

Note: Refer to Figure 7 for the following

procedures.

1. Grille Removal

1.1 Using a Phillips-head screwdriver,

remove the six screws that secure the end

cap to the line array enclosure. Lift off the

end cap. Unplug the molex connector from

the speaker harness.

1.2 Grasp the edge of the grille and gently

lift it away from the enclosure.

2. Nameplate Removal

2.1 Perform procedure 1.

2.2 On the back of the grille, unbend the

legs of the logo. Lift off the nameplate.

3. Driver Removal

3.1 Perform procedure 1.

3.2 Using a Phillips-head screwdriver,

remove the four screws that secure the

driver to the enclosure.

3.3 Lift the driver out of the enclosure. Note

the wiring configuration and cut the wires as

close to the driver terminals as possible.

4. Upper Line Array Top End Cap Removal

4.1 Using a Phillips-head screwdriver,

remove the seven screws that secure the

end cap to the line array enclosure. Lift off

the end cap.

Re-assembly note: Make sure that the end

cap gasket is properly aligned to achieve an

airtight seal.

5. Upper Line Array Bottom End Cap

Removal

5.1 Using a Phillips-head screwdriver,

remove the seven screws that secure the

end cap to the line array enclosure. Lift the

end cap away from the enclosure. Unplug

the molex connector from the speaker

harness.

Re-assembly note: Make sure that the end

cap gasket is properly aligned to achieve an

airtight seal.

6. Lower Line Array Top End Cap Removal

6.1 Using a Phillips-head screwdriver,

remove the six screws that secure the end

cap to the line array enclosure. Lift off the

end cap. Unplug the molex connector from

the speaker harness.

Re-assembly note: Make sure that the end

cap gasket is properly aligned to achieve an

airtight seal.

7. Lower Line Array Bottom End Cap

Removal

7.1 Using a Phillips-head screwdriver,

remove the seven screws that secure the

end cap to the line array enclosure. Lift the

end cap away from the enclosure. Unplug

the molex connector from the speaker

harness.

Re-assembly note: Make sure that the end

cap gasket is properly aligned to achieve an

airtight seal.

Page 8

84

Disassembly Procedures

8. Front Cap Removal

8.1 Using a Phillips-head screwdriver,

remove the four screws that secure the front

cap to the bottom front of the line array

enclosure. Lift the end cap away from the

enclosure.

Bass Module Procedures

Note: Refer to Figure 8 for the following

procedures.

1. Grille Removal

1.1 Using an allen wrench, remove

the four screws that secure the grille to the

upper and lower speaker end caps.

1.2 Lift off the grille.

2. Nameplate Removal

2.1 Perform procedure 1.

2.2 On the back of the grille, remove the

retaining nut and spring from the post of the

nameplate. Lift the nameplate off of the

grille.

3. Driver Removal

3.1 Perform procedure 1.

3.2 Using a Phillips-head screwdriver,

remove the four screws that secure the

driver to the bass module enclosure.

3.3 Lift the driver out of the enclosure. Note

the wiring configuration and cut the wires as

close to the driver terminals as possible.

Re-assembly notes:

- When soldering the speaker harness wires

to the new driver, be sure to observe polarity

of the driver harness wires.

- Be sure to properly align the gasket behind

the new driver to ensure an airtight fit.

4. Input Panel Removal

4.1 Using a Phillips-head screwdriver,

remove the four screws that secure the

input panel to the bass module enclosure.

4.2 Lift the input panel away from the bass

module enclosure.

4.3 Make a note of the wiring configuration

and un-solder the speaker harness wires

from the input panel.

Page 9

85

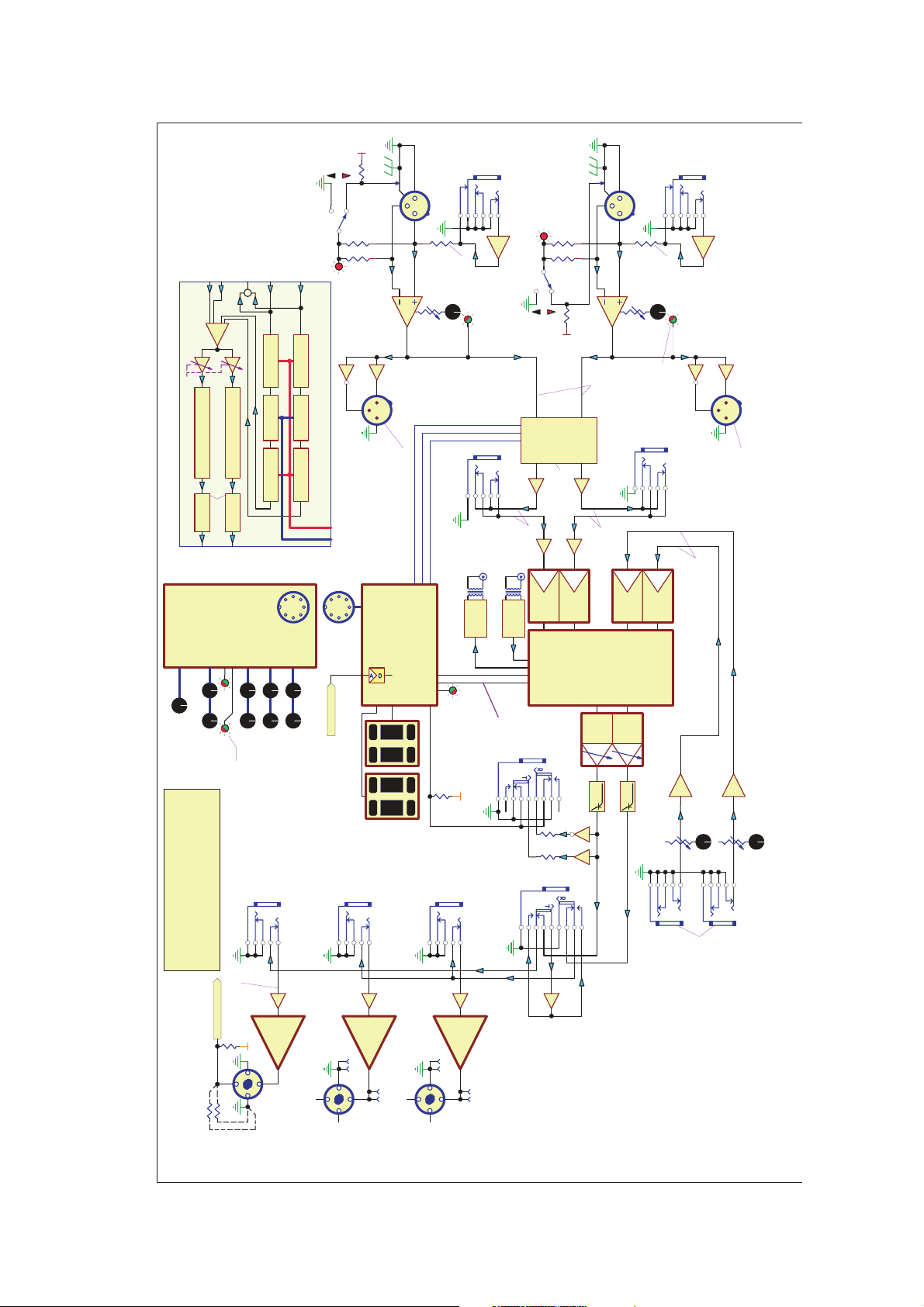

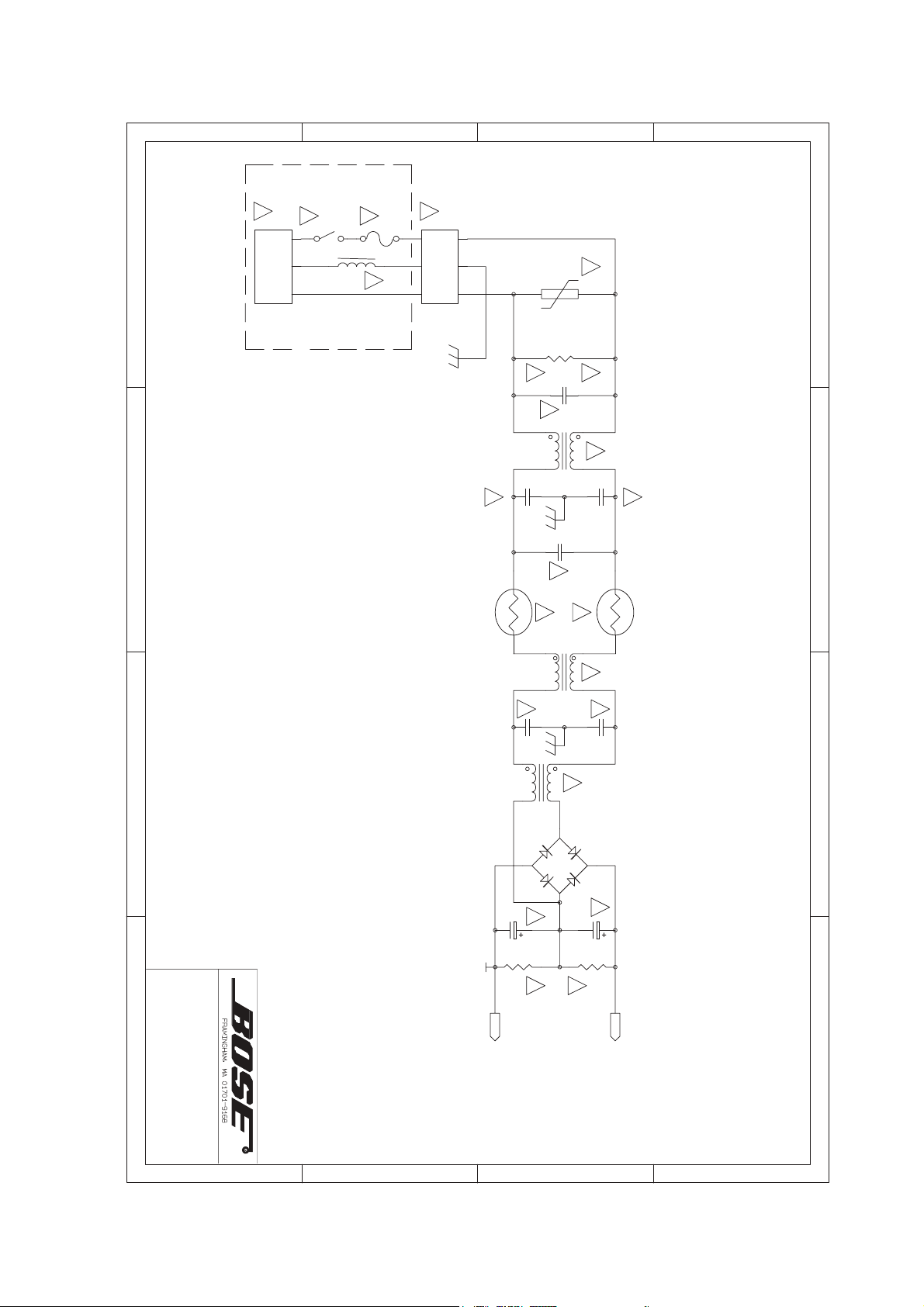

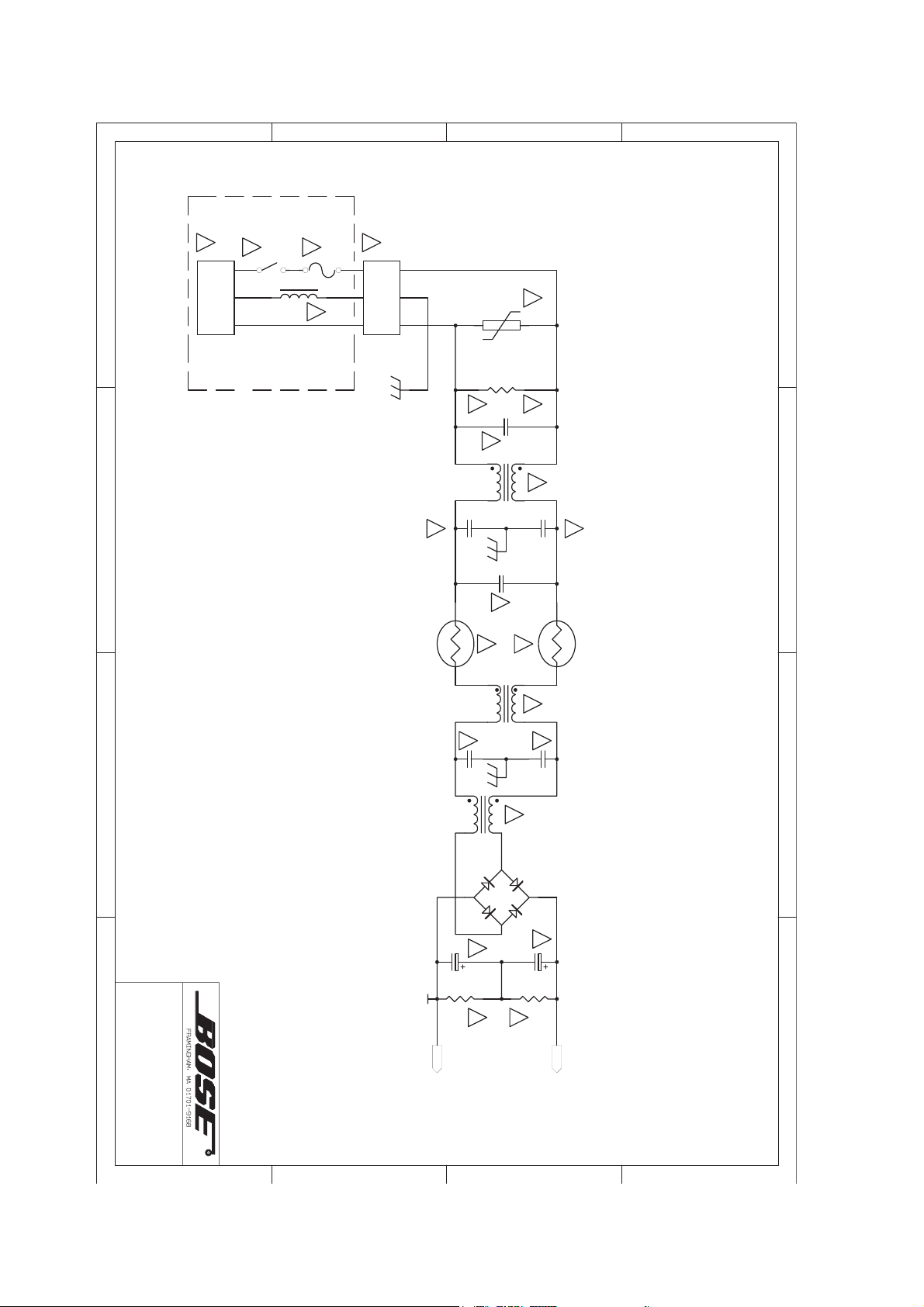

Figure 10. PS1 Power Stand Block Diagram

BLOCK DIAGRAM - Signal Processing + Routing

U

Rev:

0 1

Input-LINE

1 2

3

Input-MIC

INA163

+8 to +50 dB

Trim

PHANTOM

+24

Off

+24v

A/D

CS5361

D/A

CS4392

PHANTOM

Ch1

Digital

Volume

Control

2-Ch.

A/D

Ch1 Insert

Ch2 Insert

High

Remote

Level

Mid

Low

Ch1 Ch2

Ring = Send

Tip = Return

µC

5

432

1

678

9

All-Amps

D/A

12

3

Ch1 Line Out

12

3

Ch2 Line Out

Master

Amp In 1

Amp In 3

Amp In 2

Power

Amp

Amp1

Power

Amp

Amp2

Power

Amp

Amp3

Hi/Full Range

Bass

Bass

LineSource Top

Master Vol Ctrl

0 1

PRESET

Ch1 Ch2

8/4 ohm Sense

8/4 ohm Sense

1-

2+

2-

1+

+5

1-

2+

2-

1+

1-

2+

2-

1+

LineSource Bottom

Sig/OL

Sig/OLSig/OL

BASS SPEAKER SENSING:

R=Open: Amp1&2 Wider-Band EQ

R=10K: 40-150Hz X-Over on Bass, >150Hz-Hi

R=5K: X-Over on Bass Ch, -6dB Hi Range

R<5K: Debug Mode: All outs flat, Limiter Off

Data In

Data-Out

SPDIF

Rcvr

Ring = Send

Tip = Return

DSP

CS8416

A/D

CS5361

+20dB

A/D

Ch 3 IN

Ch 4 IN

20K 15A

Level

Level

+20dB

20K 15A

DSP Processing Block Diag

-1

+1

Ch1/2 Preset

Remote

Ch1 In

Ch2 In

Ch 3 In

Ch 4 In

Hi Out

Bass Out

Sys. EQ+X-Over, Hi

L

R

S-DATA Out

Limiter

S3PC8475

TCA9459F

User EQ Preset EQNoiseGate

User EQ Preset EQNoiseGate

(to SPDIF)

(SPDIF)

(SPDIF)

ADS21065L

+1dBV (1.1V) for

250W@4 Ohms

+29dB

+29dB

+29dB

Clip @ +30dBV

Master Vol. Range: -80 to +22dB (+10 @ 12:00)

Sys. EQ+X-Over, Lo Limiter

(250W 4ohms)

5K 10C

Nom.: 0dBV

Clip@+18dBV

Max. Gain = 0dB

Nom. Gain = -10dB (12:00)

Min. Gain = -40dB

Red=Clip=+6dBV

Green=Signal= -30dBV

Knee=+1.5dBV

Clip= -4dBV into A/D

Signal= -40dBV into A/D

Max. Level = +40dBV+

Nom. Level = -13dBV (pot @ ctr)

Min. Level = -30dBV for full output

Nom. -10dBV

Clip@+6dBV

Nom. -10dBV

Clip@+6dBV

Nom. -10dBV

Clip@+6dBV

Max. Level = +18dBV [input buffer clips]

Nom. Level = -1dBV

Min. Level = -46dBV for full output

(Ch1 Vol+Master @ Max)

Max. Level = +10dBV

Nom. Level = -21dBV(Trim ctr)

Min. Level = -66dBV for full output

(Trim, Ch1 Vol+Master @ Max)

+21dB @ ctr

Persistence = 100msec

0dB

0dB

Nom.: +6dBV (Balanced)

Clip@+24dBV "

0dB

0dB

0dB

0dB

0dB

-1.5dB

-1.5dB

Nom.: +6dBV (Balanced)

Clip@+24dBV "

5

432

1

678

9

Bass Send

Input

+5

Bass Slave Sense

SPDIF

Xmiter

CS8406

Power / Protect / Diagnostic

0dB

-1 +1

+1

+1

+1

+1

+1

+1

LPF

LPF

+1

+1

+1

-1

+1

-20dB

Mic (XLR) input

-12 to +30 dB

+1dB @ ctr

Line (1/4") input

Input-LINE

1 2

3

Input-MIC

INA163

+8 to +50 dB

Trim

Ch2

Sig/OL

5K 10C

+21dB @ ctr

+1

-20dB

Mic (XLR) input

-12 to +30 dB

+1dB @ ctr

Line (1/4") input

+24

Off

+24v

+2.6dB @ 12:00

Page 10

86

Test Procedures

PS1 Power Stand Tests

Equipment Required

• dB Meter

• Digital Multi-meter

• Audio Signal Generator

• Distortion Meter

• 3 - 4 Ohm, 250 Watt Load Resistors

• Test cables, see Appendix

Overall PS1 System Tests

Notes:

1. Do not connect the R1 remote control for

the following tests, unless specified. Powering up the PS1 power stand without the

remote has the same effect as setting all of

the controls on the remote to the midpoint.

2. On the front panel of the PS1, set the

Channel 1 and Channel 2 Preset Select

switches to 00. Short out the 2+ and 2connections on the Amp 3 out connector

using the test cable described in section 1 of

the appendix of this manual. This will put the

PS1 into debug mode for the following tests.

In this mode the crossover, the compressor

and the EQ are disabled. The DSP will pass

a flat response. The level controls and the

clip indicators still operate in this mode.

3. Refer to Figure 10, PS1 Block Diagram,

for the following procedures.

1. Channel 1 and 2 Mic Input Gain Tests

1.1 Place a 1/4! mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

1.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Phantom

Power push button is not pushed in.

1.3 Using a balanced XLR male input cable,

apply a 1 kHz, -30dBV signal to the channel

1 input.

1.4 Reference a dB meter to the input level.

Measure the gain output at the Amp 1 OUT

jack. It should be +48.5 dB

+ 3 dB.

1.5 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 1.1 to 1.4 for the channel 2 Mic input.

2. Channel 1 and 2 Mic Input Frequency

Reponse and Distortion Tests

2.1 Place a 1/4! mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

2.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Phantom

Power push button is not pushed in.

2.3 Using a balanced XLR male input cable,

apply a 1 kHz, -30 dBV signal to the channel

1 input.

2.4 Use an 80kHz low-pass filter on your

measuring equipment. Reference a dB

meter to the input level. Measure the frequency response at the Amp 1 OUT jack. It

should be 0 dB

+ 3 dB from 30 Hz to 15 kHz.

2.5 Measure the Total Harmonic Distortion

(THD) level at the Amp 1 OUT jack.

It should be 0.25% max at 1 kHz and 1.5%

max at 15 kHz.

2.6 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 2.1 to 2.5 for the channel 2 Mic input.

Page 11

87

Test Procedures

3. Channel 1 and 2 Mic Input Signal to

Noise Ratio (Dynamic Range) Tests

3.1 Place a 1/4• mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

3.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Phantom

Power push button is not pushed in.

3.3 Using a balanced XLR male input cable,

apply a 1 kHz, -30 dBV signal to the channel

1 input.

3.4 Reference a dB meter to the output level

at the Amp 1 OUT jack. Remove the input

signal and measure the A-Weighted output

level. It should be -80 dB minimum.

3.5 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 3.1 to 3.4 for the channel 2 Mic input.

4. Channel 1 and 2 Mic Input Phantom

Power Test

4.1 Plug an XLR connector into the channel

1 Mic input. Do not connect any cables to

the channel 1 or channel 2 Mic inputs.

Power on the unit.

4.2 Press the channel 1 phantom power

switch. Verify that the LED lights. Using a

DMM, measure the DC voltage level across

pins 1 and 2 of the XLR connector. Verify

that the DC level is +24Vdc

+ 1Vdc relative

to pin 1.

4.3 Measure the DC voltage level across

pins 1 and 3 of the XLR connector. Verify

that the DC level is +24Vdc + 1Vdc relative

to pin 1.

4.4 Repeat steps 4.1 to 4.3 for channel 2.

5. Channel 1 and 2 Line Input Gain Tests

5.1 Place a 1/4• mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

5.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Phantom

Power push button is not pushed in.

5.3 Using an unbalanced 1/4• phono jack

input cable, apply a 1 kHz, -10 dBV signal

to the channel 1 input.

5.4 Reference a dB meter to the input level.

Measure the gain output at the Amp 1 OUT

jack. It should be +28.5 dB

+ 4 dB.

5.5 On the signal generator, turn the input

level all the way down. Verify that the channel 1 Signal/OL LED is off. Increase the

signal generator level. Verify that the LED

lights green. Increase the signal level again

and verify that the LED lights red.

Note: You may have to increase the Mic

Trim level on the PS1 channel 1 input as

well to get the LED to light red.

5.5 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 5.1 to 5.5 for the channel 2 Line input.

6. Channel 1 and 2 Line Input Frequency

Reponse and Distortion Tests

6.1 Place a 1/4• mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

6.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Phantom

Power push button is not pushed in.

Page 12

88

6.3 Using an unbalanced 1/4! phono jack

input cable, apply a 1 kHz, -10 dBV signal

to the channel 1 input.

6.4 Use an 80 kHz low-pass filter on your

measuring equipment. Reference a dB

meter to the input level. Measure the frequency response at the Amp 1 OUT jack.

It should be 0 dB

+ 3 dB from 30 Hz to

15 kHz.

6.5 Measure the Total Harmonic Distortion

(THD) level at the Amp 1 OUT jack. It should

be 0.25% max at 1 kHz and 1.5% max at

15 kHz.

6.6 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 6.1 to 6.5 for the channel 2 Line input.

7. Channel 1 and 2 Line Input Signal to

Noise Ratio (Dynamic Range) Tests

7.1 Place a 1/4! mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

7.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Phantom

Power push button is not pushed in.

7.3 Using an unbalanced 1/4! phono jack

input cable, apply a 1 kHz, -10 dBV signal to

the channel 1 input.

7.4 Reference a dB meter to the output level

at the Amp 1 OUT jack. Remove the input

signal and measure the A-Weighted output

level. It should be -80 dB minimum.

7.5 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 7.1 to 7.4 for the channel 2 Line input.

Test Procedures

8. Channel 3 and 4 Line Input Gain Tests

8.1 Place a 1/4! mono shorting plug into the

Amp 1 IN and Amp 2 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 1 and 2 amplifiers while

testing the channel 3 amplifier.

8.2 On the left hand side of the input/output

panel, set the channel 3 Level control to the

6 setting.

8.3 Using an unbalanced 1/4! phono jack

input cable, apply a 1 kHz, -20 dBV signal to

the channel 1 input.

8.4 Reference a dB meter to the input level.

Measure the gain output at the Bass/Amp 3

OUT jack. It should be +40.1 dB

+ 3 dB.

8.5 Repeat steps 8.1 to 8.4 for the channel

4 Line input.

9. Channel 3 and 4 Line Input Frequency

Reponse and Distortion Tests

9.1 Place a 1/4! mono shorting plug into the

Amp 1 IN and Amp 2 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 1 and 2 amplifiers while

testing the channel 3 amplifier.

9.2 On the left hand side of the input/output

panel, set the channel 4 Mic Trim control to

the 6 setting.

9.3 Using an unbalanced 1/4! phono jack

input cable, apply a 1 kHz, -20 dBV signal

to the channel 1 input.

9.4 Use an 80 kHz low-pass filter on your

measuring equipment. Reference a dB

meter to the input level. Measure the frequency response at the Amp 1 OUT jack.

It should be 0 dB + 3 dB from 30 Hz to

15 kHz.

9.5 Measure the Total Harmonic Distortion

(THD) level at the Amp 1 OUT jack. It should

be 0.25% max at 1 kHz and 1.5% max at

15 kHz.

Page 13

89

9.6 Repeat steps 9.1 to 9.5 for the channel

4 Line input.

10. Channel 3 and 4 Line Input Signal to

Noise Ratio (Dynamic Range) Tests

10.1 Place a 1/4! mono shorting plug into

the Amp 1 IN and Amp 2 IN jacks on the

right hand side of the input/output panel.

This will disable the channel 1 and 2 amplifiers while testing the channel 3 amplifier.

10.2 On the left hand side of the input/

output panel, set the channel 3 Level

control to the 6 setting.

10.3 Using an unbalanced 1/4! phono jack

input cable, apply a 1 kHz, -10 dBV signal to

the channel 1 input.

10.4 Reference a dB meter to the output

level at the Bass/Amp 3 OUT jack. Remove

the input signal and measure the AWeighted output level. It should be -80 dB

minimum.

10.5 Repeat steps 10.1 to 10.4 for the

channel 4 Line input.

11. Channel 1 and 2 Remote Control,

Preset Switch and Insert Function Tests

11.1 Connect the PS1 power stand to a

known good L1 line array. Set the channel 1

preset switch to 00. Connect the remote

control to the unit using the remote control

MIDI cable supplied with the PS1.

11.2 Connect an analog audio source to the

Channel 1 line input 1/4 inch jack. This

source can be a CD player with a music

disc.

11.3 Adjust the trim level so that the LED is

lit mostly green. The audio should sound

normal.

Test Procedures

11.4 With the audio playing, change the

channel 1 preset to 97 and back to 00. The

channel should mute gracefully when the

preset switch is operated. The audio should

fade back in again about a second after the

switch has stopped operating.

Note: Preset 97 is a 1 kHz band pass

(telephone-type sound). Preset 00 should

sound normal.

11.5 Operate all channel 1 controls on the

remote (high, mid, low, volume and master

volume). All tone controls should have a

clearly audible effect and operate smoothly.

Channel volume may display a little "zipper!

noise, which is normal.

Note: Channel volume all the way down

does not mute the channel, but the output

level should be very low. There is a small,

but noticeable time delay between operating

the control and the audible effect. This is

normal. The master volume control should

operate smoothly without any artifacts.

11.6 Insert a 1/4 inch phono jack all the way

into the channel 1 Insert jack. The audio

should sound normal.

11.7 Insert a 1/4 inch phono jack into the

channel 3 Line IN jack and operate the

volume control on the power stand. The

audio should sound normal.

11.8 Repeat steps 11.1 to 11.7 for the channel 2 input.

12. Channel 1 Send, Line Output and

Digital Output Tests

Note: For these tests you will need an

external device that can accept both 1/4

inch and XLR inputs. A small mixer, such

as a Mackie or Behringer with headphones

connected works well for this. The master

volume control on the PS1#s remote control

should be set all the way down to mute all

sound coming from the unit under test.

Page 14

90

Test Procedures

12.1 Connect the PS1 power stand to a

known good L1 line array. Set the channel 1

preset switch to 00. Connect the remote

control to the unit using the remote control

MIDI cable supplied with the PS1.

12.2 Connect an analog audio source to the

Channel 1 Line IN 1/4 inch jack. This source

can be a CD player with a music disc.

12.3 Adjust the trim level so that the LED is

lit mostly green. The audio should sound

normal.

12.4 Insert a 1/4 inch plug halfway into the

channel 1 Insert jack. The audio should

sound normal.

12.5 Connect the PS1 channel 1 XLR Line

OUT jack to the XLR input of the mixer. The

audio should sound normal.

Note: The PS1 puts out a “professional”

+4dBu level. You may have to turn the the

input trim control on the mixer all the way

down to prevent overloading the signal and

distorting it.

12.6 Connect the Data Out jack of the PS1

to a device that accepts a 48 kHz S/PDIF

data stream. The audio should sound normal.

13. Power Amplifier Tests

13.1 Connect the PS1 power stand to a

known good L1 line array. Set the channel 1

preset switch to 00. Connect the remote

control to the unit using the remote control

MIDI cable supplied with the PS1.

13.2 Connect an analog audio source to the

Amp 1 IN 1/4 inch phono jack. This source

can be a CD player with a music disc.

13.3 Verify that the audio comes from the

upper section of the L1 line array. The audio

should sound clean and undistorted.

13.4 Connect the audio source to the Amp 2

IN 1/4 inch phono jack. Verify that the audio

comes from the lower section of the L1 line

array. The audio should sound clean and

undistorted.

13.5 Connect a B1 bass module to the PS1

power stand at the Bass/Amp 3 OUT jack.

Connect the audio source to the Amp 3 IN

1/4 inch phono jack. Sound should come

from the bass module only and be clean and

undistorted.

13.6 Connect the audio source to the All

Amps IN 1/4 inch phono jack. Sound should

come from both of the L1 line array sections

and the bass module simultaneously. The

audio should be clear and undistorted.

14. High SPL System Sweep Test

CAUTION: This test will be extremely loud.

Hearing protection is advised.

14.1 Connect a R1 remote control to the

PS1 power stand under test. Set the channel 1 controls to mid-level. Set the master

volume control on the remote to the 1

o’clock position. Set the channel 1 Mic Trim

control on the PS1 to 6. Connect a L1 line

array to the PS1. Connect a B1 bass module to the PS1.

14.2 Connect a signal generator to the

channel 1 input on the PS1. Adjust the

signal generator and/or trim control so that

the Signal/OL LED is just below red.

14.3 Sweep the input frequency from 40 Hz

to 14 kHz. Listen for any unusual noises and

excessive distortion or drop-outs.

15. Bass Module Auto-EQ Test

15.1 Connect a L1 line array to the PS1

power stand. Connect an R1 remote control

to the power stand. Connect a B1 bass

module to the Bass/Amp 3 OUT jack on the

power stand. Connect an audio source to

the channel 1 and 2 inputs of the power

stand.

Page 15

91

Test Procedures

15.2 Set the channel 1 and 2 level controls

to identical settings so that both LEDs are

mainly green.

15.3 While the audio is playing, disconnect

the B1 bass module from the power stand.

The system should mute and un-mute and

audio should resume. The audio should

sound normal, but not punchy (no deep

bass).

15.4 Plug a dummy 1/4 inch phono jack into

the Bass Line Out jack. The system should

mute and un-mute again, but the audio

should sound thinner than before.

15.5 Remove the dummy plug. The system

should mute and un-mute and the audio

should sound normal again.

15.6 Re-connect the B1 bass module to the

power stand. The audio should mute and unmute again and sound normal.

15.7 Connect a second B1 bass module to

the first one. The audio should mute and unmute. The audio will sound very similar to

having only one bass module attached.

Disconnect the second bass module. The

system should mute and un-mute and the

audio should sound normal again.

L1 Line Array Tests

Set up the unit under test as shown below.

1. Air Leak Test

1.1 Apply a 100 Hz, 10 Vrms sine wave to

the unit under test.

1.2 Listen carefully for air leaks from around

the end cap, the transducers and the grille.

Air leaks will be heard as a hissing or sputtering sound. All repairs must be hidden.

Test duration should be 5 seconds minimum.

2. Transducer Rub and Tick Test

2.1 Remove the transducer you wish to test

using the disassembly procedures in this

manual. Do not unplug the wires at the

transducer assembly terminals.

2.2 Connect a signal generator directly to

the terminals of the transducer assembly

under test.

2.3 Apply a 20 Hz, 5 Vrms signal to the

transducer assembly.

2.4 Listen carefully for any extraneous

noises such as rubbing, scraping or ticking.

Note: To distinguish between normal suspension noise and rubs or ticks, displace the

cone slightly with your fingers. If the noise

stays the same, it is normal suspension

noise and the driver is good. Suspension

noise will not be heard with program material.

3. Transducer Phase Test

3.1 Apply a DC voltage of 10V, positive

applied to the positive tab of the dual

banana jack on the line array test cable and

negative applied to negative (gnd) tab.

3.2 All of the driver cones should move

outward when the DC voltage is applied.

3.3 Rewire any incorrectly connected transducers.

Power Amplifier

INPUT OUTPUT

Audio Signal

Generator

Upper or Lower

L1 Line Array

Upper or Lower L1

Line Array Test Cable

Page 16

92

Test Procedures

Power Amplifier

INPUT OUTPUT

Audio Signal

Generator

B1 Bass Module

Test Cable

B1 Bass Module

4. L1 Line Array Sweep Test

4.1 Set up the upper or lower line array

section as shown in the figure on the previous page.

4.2 Apply a 100 Hz, 10 Vrms sine wave to

the input.

4.3 While listening to the output of the

system, sweep the input frequency slowly

from 100 Hz to 15 kHz.

4.4 Listen carefully for any extraneous

noises such as buzzing and ticking.

B1 Bass Module Tests

Set up the unit under test as shown below.

1. Air Leak Test

1.1 Apply a 100 Hz, 20 Vrms sine wave to

the unit under test.

1.2 Listen carefully for air leaks from around

the end cap, the transducers and the grille.

Air leaks will be heard as a hissing or sputtering sound. All repairs must be hidden.

Test duration should be 5 seconds minimum.

2. Transducer Rub and Tick Test

2.1 Remove the transducer you wish to test

using the disassembly procedures in this

manual. Do not unplug the wires at the

transducer assembly terminals.

2.2 Connect a signal generator directly to

the terminals of the transducer assembly

under test.

2.3 Apply a 10 Hz, 10 Vrms signal to the

transducer assembly.

2.4 Listen carefully for any extraneous

noises such as rubbing, scraping or ticking.

Note: To distinguish between normal suspension noise and rubs or ticks, displace the

cone slightly with your fingers. If the noise

stays the same, it is normal suspension

noise and the driver is good. Suspension

noise will not be heard with program material.

3. Transducer Phase Test

3.1 Apply a DC voltage of 20V, positive

applied to the positive tab of the dual

banana jack on the bass module test cable

and negative applied to negative (gnd) tab.

3.2 Notice carefully that all driver cones

should move outward when the DC voltage

is applied.

3.3 Rewire any incorrectly connected transducers.

4. System Sweep Test

4.1 Set up the system as shown in the

figure at left.

4.2 Apply a 10 Hz, 20 Vrms sine wave to the

input.

4.3 While listening to the output of the

system, sweep the input frequency slowly

from 10 Hz to 400 Hz.

4.4 Listen carefully for any extraneous

noises such as buzzing and ticking.

Page 17

93

1 2

A

B

C

D

4

321

D

C

B

A

4

3

L603

3.8mH

L604

1mH

C601

1uF 300V

C602

1uF 300V

C604

1n5

C603

1n5

R601

220K 3W

DB601

MB354S

R603

100K 1/2W

R604

100K 1/2W

ACGND

F601

15A 125VAC

C607

2200uF 200V

C608

2200uF 200V

SW601

20A 125V

C606

1n5

C605

1n5

N

E

L

CN601

IEC

1 2

TH601

SCK2R515

V+

EGND

( Earth GND)

1 2

TH602

SCK2R515

(16A)

(16A)

L602

3.8mH

(16A)

VDR601

14D271K

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

L601

N

E

L

CN602

DT-4-3P

!

!

(CN603,605,607,609)

(CN604,606,608,610)

ACGND

(TO AUX PS AND +/-27V PS)

(TO AUX PS AND +/-27V PS)

!

70uH 6Ts

PS1 Power Stand

FCC Filter PCB, Rev. F

P/N:

275436

Sheet 1 of 1

120V Version 1.0 Systems

Page 18

94

1 2 3 4

A

B

C

D

4

321

D

C

B

A

L603

3.8mH

L604

1mH

C601

1uF 300V

C602

1uF 300V

C604

1nF

C603

1nF

R601

220K 3W

DB601

GL3506

R603

100K 1/2W

R604

100K 1/2W

ACGND

F601

10A 250VAC

C607

2200uF 200V

C608

2200uF 200V

SW601

15A 250V

C606

1nF

C605

1nF

N

E

L

CN601

IEC

1

2

TH601

SCK0512

V+

EGND

( Earth GND)

1

2

TH602

SCK0512

(16A)

(16A)

L602

3.8mH

(16A)

VDR601

14D471K

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

L601

N

E

L

CN602

DT-4-3P

!

!

(CN603,605,607,609)

(CN604,606,608,610)

ACGND

(TO AUX PS AND +/-27V PS)

(TO AUX PS AND +/-27V PS)

!

70uH,6Ts

PS1 Power Stand

FCC Filter PCB, Rev. F

P/N: 283370

Sheet 1 of 1

120V Version 1.1 Systems

Page 19

95

1 2 3 4

A

B

C

D

4

321

D

C

B

A

L603

3.8mH

L604

1mH

C601

1uF 300V

C602

1uF 300V

C604

1nF

C603

1nF

R601

220K 3W

DB601

GL3506

R603

100K 1/2W

R604

100K 1/2W

ACGND

F601

10A 250VAC

C607

2200uF 200V

C608

2200uF 200V

SW601

15A 250V

C606

1nF

C605

1nF

N

E

L

CN601

IEC

1

2

TH601

SCK0512

V+

EGND

( Earth GND)

1

2

TH602

SCK0512

(16A)

(16A)

L602

3.8mH

(16A)

VDR601

14D471K

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

L601

N

E

L

CN602

DT-4-3P

!

!

(CN603,605,607,609)

(CN604,606,608,610)

ACGND

(TO AUX PS AND +/-27V PS)

(TO AUX PS AND +/-27V PS)

!

70uH,6Ts

PS1 Power Stand

FCC Filter PCB, Rev. F

P/N: 283369

Sheet 1 of 1

230V Version 1.0 and 1.1 Systems

Page 20

96

1 2 3 4 5 6 7

A

B

C

D

8

7654321

D

C

B

A

8

Z501

18V

Z502

18V

R501

1K

R507

51R

Q501

IRF840

R508

51R

Q502

IRF840

D501

UF4006

Q503

IRF840

Q504

IRF840

R509

51R

R510

51R

R502

1K

Z503

18V

Z504

18V

D502

UF4006

R511

100/2W

C501

100p 1KV

R512

47R 2W

C502

1nF

C503

1nF

R513

47R 2W

D503

BYV32-200

C504

2200uF 35V

C505

2200uF 35V

D504

BYV32-200

C523

100n

D510

1N4148

R514

560R

C515

123

R515

470R

C517

222

R503

8.2K

D511

1N4148

C518

102

D505

1N4148

R516

47K

D506

1N4148

R517

33R

Q505

2N3904

Q507

2N3906

R518

750R 1W

C519

1uF/50V

C508

100n

C516

103

R519

240R

R520

39R

D509

UF4003

ACGND

C520

100uF/50V

C510

100n

D507

1N4148

R521

39K

R522

3K

Q506

2N3904

R523

12K

R524

47K

Z505

18V

R525

200K

R504

1K

TP501

1KB

R505

1K

D508

1N4148

R526

12K

T501

TT-9972

1

4

5

6

7

8

EGND

DGND

C506

2200uF 35V

C522

2200uF 35V

C511

100n

C512

100n

T502

TT-9971

3

1

5

6

3

7

9.10

11.12

13.14

15.16

T503

ETD39

COMP

1

VFB

2

ISEN

3

RT/CT

4

GND

5

OUT

6

VCC

7

VREF

8

IC501

UC2842B

FB501

FB502 FB504

FB503

FB505

FB506

R506

12K

R527

12K

C513

1nF

ACGND

L501

200uH

D512

1N4148

V+

(-27V)

(+27V)

+24VD

VDD

VSS

( Earth GND)

( Digital GND)

FB507

FB508

R528

47R 2W

R529

47R 2W

C524

1nF

C525

1nF

FB509

FB510

FB511

FB512

(or SYN2,SYN3)

FB513

ACGND

NOTE:

This schematic can be applied to three +/-27V power supplies

FAULT

SYN1

12

TH501

BD222/100C

R530

22K

Q508

2N3906

C514

100n

C507

22uF 400V

!

!

!

(FROM EMI FILTER )

(FROM AUX PS CN615 or CN616,CN617)

(TO D AMP CN802A or CN806A,CN810A)

ACGND

(CN501)

(CN502)

(FROM EMI FILTER)

123

4

CN503

(TO D AMP CN802A or CN806A,CN810A)

R531

4K7

-15V

D513

1N4148

D514

1N4148

D515

1N4148

SCR501

MCR100-6

R532

47K

Z506

30V

R533

470R 0.5W

C509

332

TP502

220R

PS1 Power Stand

+/-27V Power Supply PCB, Rev. F

P/N:

273734

Sheet 1 of 1

120V Version 1.0 Systems

Page 21

97

1 2 3 4 5 6 7 8

A

B

C

D

8

7654321

D

C

B

A

Z501

18V

Z502

18V

R501

1K

R507

51R

Q501

IRF840

R508

51R

Q502

IRF840

D501

UF4006

Q503

IRF840

Q504

IRF840

R509

51R

R510

51R

R502

1K

Z503

18V

Z504

18V

D502

UF4006

R511

100/2W

C501

100p 1KV

R512

47R 2W

C502

1nF

C503

1nF

R513

47R 2W

D503

BYV32-200

C504

2200uF 35V

C505

2200uF 35V

D504

BYV32-200

C523

100n

D510

1N4148

R514

680R

C515

153

R515

470R

C517

222

R503

8.2K

D511

1N4148

C518

102

D505

1N4148

R516

47K

D506

1N4148

R517

33R

Q505

2N3904

Q507

2N3906

R518

750R 1W

C519

1uF/50V

C508

100n

C516

103

R519

240R

R520

47R

D509

UF4003

ACGND

C520

100uF/50V

C510

100n

D507

1N4148

R521

39K

R522

3K

Q506

2N3904

R523

12K

R524

47K

Z505

18V

R525

200K

R504

1K

TP501

1KB

R505

1K

D508

1N4148

R526

12K

T501

TT-9972

1

4

5

6

7

8

EGND

DGND

C506

2200uF 35V

C522

2200uF 35V

C511

100n

C512

100n

T502

TT-9971

3

1

5

6

3

7

9.10

11.12

13.14

15.16

T503

ETD39

COMP

1

VFB

2

ISEN

3

RT/CT

4

GND

5

OUT

6

VCC

7

VREF

8

IC501

UC2842B

FB501

FB502 FB504

FB503

FB505

FB506

R506

12K

R527

12K

C513

1nF

ACGND

L501

200uH

D512

1N4148

V+

(-27V)

(+27V)

+24VD

VDD

VSS

( Earth GN D)

( Digital GND)

FB507

FB508

R528

47R 2W

R529

47R 2W

C524

1nF

C525

1nF

FB509

FB510

FB511

FB512

(or SYN2 ,SYN3)

FB513

ACGND

NOTE:

This sche matic can be ap plied to three +/-27V p ower supp lies

FAUL T

SYN1

1

2

TH501

BD222/100C

R530

22K

Q508

2N3906

C514

100n

C507

22uF 400V

!

!

!

(FROM EMI FILTER )

(FROM AUX PS CN615 or CN616,CN617)

(TO D AMP CN802A or CN806A,CN810A )

ACGND

(CN501)

(CN502)

(FROM EMI FILTER)

123

4

CN503

(TO D AMP CN802A or CN806A,CN810A )

R531

4K7

-15V

D513

1N4148

D514

1N4148

D515

1N4148

SCR501

MCR100-6

R532

47K

Z506

30V

R533

470R 0.5W

TP502

220R

PS1 Power Stand

+/-27V Power Supply PCB, Rev. F

P/N: 283371

Sheet 1 of 1

120V Version 1.1 Systems

230V Version 1.0 and 1.1 Systems

Page 22

98

1 2

3

A

B

C

D

4

321

D

C

B

A

4

C610

82uF 400V

C624

100n

COMP

1

VFB

2

ISEN

3

RT/CT

4

GND

5

OUT

6

VCC

7

VREF

8

IC601

UC2843AN

C619

103

IC602

PC817A

Q601

K2645

R614

22R

R615

22K

R613

100R

R621

0.47R 3W

Z601

18V

D603

1N4148

R619

8K2

C617

222

C618

300P

R606

560K

R605

560K

C613

100n

R611

2R2

R612

22R

C614

1nF

D602

UF4003

R607

240K

R608

240K

R620

1K2

R618

1M

R617

1K

C615

100P 1KV

D604

UF4006

R616

2K2 1/2W

D601

UF4006

R610

33K 2W

R609

33K 2W

C611

47nF 630V

IC603

TL431

C621

100n

C620

100n

R622

1K

R623

10K

R626

100R

R627

5K1

R625

3K9

5

3

1

6

8

11

9

7

10

12

11

11

T601

EC28

D608

31DQ10

C630

1nF

C626

1nF

C623

470uF 35V

C641

470uF 25V

D606

31DQ10

R628

22R 1/2W

R629 22R 1/2W

C634

1nF

L610 30uH

C622

1nF

D607 31DQ10

R631

47R 1/2W

R630 47R 1/2W

C629

470uF 35V

L608

30uH

L609

30uH

C633

470uF 35V

D609

1N5822

R632

100R 2W

C637

1nF

D605

UF5404

C640

100n

C632

100n

C635

100n

C628

100n

C636

470uF 25V

L611

30uH

C627

1000uF 35V

C631

1000uF 35V

C638

1000uF 35V

C639

1000uF 35V

C625

470uF 35V

L607

30uH

R624

51K

C616

100n

V+

ACGND

ACGND

ACGND

DGND

AGND

EGND

(Digital gnd)

(Analog gnd)(Earth gnd)

FB604

FB605

FB606

FB607

FB608

FB609

FB603 FB602

+24V

+15V

-15V

+5VD

+3.3VD

ACGND

C642

1nF

ACGND

!

!

C648

100n

FB610

+24VD

C612

100uF 50V

ACGND

(CN613)

(CN614)

(FROM EMI FILTER )

(FROM EMI FILTER )

DGND

AGND

PROT

(TO MCU-1C CN409B)

+5VD

1 2

TH603

BD222/100C

R640

56K

D614

1N4148

C649

100n

MCR100-6

SCR601

1234567

8

CN623

R639

4K7

-15V

C652

1uF/50V

R644

4K7

R645

4K7

R646

3K3

R647

12K

R648

12K

Q604

2N3904

D613

1N4148

D615

1N4148

IC606

PC817A

!

PS1 Power Stand

Auxiliary Power Supply PCB, Rev. F

P/N:

274637

Sheet 1 of 2

120V Version 1.0 Systems

Page 23

99

1 2

3

A

B

C

D

4

321

D

C

B

A

R633

47K

R634

3K9

C643

150P

C646

150P

C644

150P

C645 150P

D610

1N4148

D611

1N4148

D612

1N4148

D

7

CLK

9

R

6

Q05Q14Q23Q3

10

IC605B

CD4015

IC604 IC605 1614

78

+5VD

SYN1

SYN2

SYN3

1

2

3

IC604A

CD4093

5

6

4

IC604B

CD4093

8

9

10

IC604C

CD4093

12

13

11

IC604D

CD4093

D

15

CLK

1

RST

14

Q013Q112Q211Q3

2

IC605A

CD4015

TP601

2K

Q602

2N3904

R635

47K

R636

4K7

Failure

PROT

Q603

BD140

R637

2K

R638

4K7

FC

+24VD

(FANS CONTROL)

(TO D AMP CN812A)

(TO THREE +/-27V PS CN503)

(CN623-2)

123

4

CN615

123

4

CN616

123

4

CN617

1

2

CN618

1

2

CN619

1

2

CN621

1

2

CN620

123

CN622

(TO FAN601) (TO FAN602) (TO FAN603) (TO FAN604)

FB611

+5VP

C650

100n

Z602

15V

R642

750R

-15V

R643

4K7

C651

100n

4

PS1 Power Stand

Auxiliary Power Supply PCB, Rev. F

P/N:

274637

Sheet 2 of 2

120V Version 1.0 Systems

Page 24

100

1 2 3 4

A

B

C

D

4

321

D

C

B

A

C610

82uF 400V

C624

100n

COMP

1

VFB

2

ISEN

3

RT/CT

4

GND

5

OUT

6

VCC

7

VREF

8

IC601

UC2843AN

C619

103

IC602

PC817A

Q601

K2645

R614

22R

R615

22K

R613

100R

R621

0.47R 3W

Z601

18V

D603

1N4148

R619

8K2

C617

222

C618

300P

R606

560K

R605

560K

C613

100n

R611

2R2

R612

22R

C614

1nF

D602

UF4003

R607

240K

R608

240K

R620

1K2

R618

1M

R617

1K

C615

100P 1KV

D604

UF4006

R616

2K2 1/2W

D601

UF4006

R610

33K 2W

R609

33K 2W

C611

47nF 630V

IC603

TL431

C621

100n

C620

100n

R622

1K

R623

10K

R626

100R

R627

5K1

R625

3K9

5

3

1

6

8

11

9

7

10

12

11

11

T601

EC28

D608

31DQ10

C630

1nF

C626

1nF

C623

470uF 35V

C641

470uF 25V

D606

31DQ10

R628

22R 1/2W

R629 22R 1/2W

C634

1nF

L610 30uH

C622

1nF

D607 31DQ10

R631

47R 1/2W

R630 47R 1/2W

C629

470uF 35V

L608

30uH

L609

30uH

C633

470uF 35V

D609

1N5822

R632

100R 2W

C637

1nF

D605

UF5404

C640

100n

C632

100n

C635

100n

C628

100n

C636

470uF 25V

L611

30uH

C627

1000uF 35V

C631

1000uF 35V

C638

1000uF 35V

C639

1000uF 35V

C625

470uF 35V

L607

30uH

R624

51K

C616

100n

V+

ACGND

ACGND

ACGND

DGND

AGND

EGND

(Digital gnd)

(Analog gnd)(Earth gnd)

FB604

FB605

FB606

FB607

FB608

FB609

FB603 FB602

+24V

+15V

-15V

+5VD

+3.3VD

ACGND

C642

1nF

ACGND

!

!

C648

100n

FB610

+24VD

C612

100uF 50V

ACGND

(CN613)

(CN614)

(FROM EMI FILTER )

(FROM EMI FILTER )

DGND

AGND

PROT

(TO MCU-1C CN409B)

+5VD

1

2

TH603

BD222/100C

R640

56K

D614

1N4148

C649

100n

MCR100-6

SCR601

1234567

8

CN623

R639

4K7

-15V

C652

1uF/50V

R644

4K7

R645

4K7

R646

3K3

R647

12K

R648

12K

Q604

2N3904

D613

1N4148

D615

1N4148

IC606

PC817A

!

PS1 Power Stand

Auxiliary Power Supply PCB, Rev. F

P/N: 283368

Sheet 1 of 2

120V Version 1.1 Systems

230V Version 1.0 and 1.1 Systems

Page 25

101

1 2 3 4

A

B

C

D

4321

D

C

B

A

R633

47K

R634

3K9

C643

150P

C646

150P

C644

150P

C645 150P

D610

1N4148

D611

1N4148

D612

1N4148

D

7

CLK

9

R

6

Q05Q14Q23Q3

10

IC605B

CD4015

IC604 IC605 1614

7 8

+5VD

SYN1

SYN2

SYN3

1

2

3

IC604A

CD4093

5

6

4

IC604B

CD4093

8

9

10

IC604C

CD4093

12

13

11

IC604D

CD4093

D

15

CLK1RST

14

Q013Q112Q211Q3

2

IC605A

CD4015

TP601

2K

Q602

2N3904

R635

47K

R636

4K7

Failure

PROT

Q603

BD140

R637

2K

R638

4K7

FC

+24VD

(FANS CONTROL)

(TO D AMP CN812A)

(TO THREE +/-27V PS CN503)

(CN623-2)

123

4

CN615

123

4

CN616

123

4

CN617

1

2

CN618

1

2

CN619

1

2

CN621

1

2

CN620

123

CN622

(TO FAN601) (TO FAN602) (TO FAN603) (TO FAN604)

FB611

+5VP

C650

100n

Z602

15V

R642

750R

-15V

R643

4K7

C651

100n

PS1 Power Stand

Auxiliary Power Supply PCB, Rev. F

P/N: 283368

Sheet 2 of 2

120V Version 1.1 Systems

230V Version 1.0 and 1.1 Systems

Page 26

102

1 2 3 4 5

6

7

A

B

C

D

8

7654321

D

C

B

A

8

C166

47u/25V

C167

47u/25V

D102

1N4148

-15V

C113

47uF/35V

R129

10R 1%

D101

1N4148

+15V

R104

1K 1%

-15V

+15V

R128

2K 1%

R127

2K 1%

R130

10R 1%

C101-C167

R101-R186

U101-U109

J101-J106

CAP:

CN101A-CN104A

RES:

IC:

JACK:

CON:

DIODE: D101-D120

1 3

2

J103

CH1_OUT

CH1_In

SG

AD2_In

+15V

-15V

R133

20R 1%

1 3

2

J104

CH2_OUT

J106

JY-6531-02-250

R131

10K 1%

R132

10K 1%

R134

1M 1%

C114

47uF/35V

C101

100pF

3

2

1

U106A

NJM2068M

C106 20pF

C107 20pF

R119 10K 1%

R121

10K 1%

R135

10R

R120

220R

R124

220R

C112

22uF/63V

C110

22uF/63V

5

6

7

U106B

NJM2068M

3

2

1

U107A

NJM2068M

C123 20pF

C124 20pF

R154 10K 1%

R153

10K 1%

R155

10K 1%

R157

10K 1%

R159

220R

R158

220R

C127

22uF/63V

C129

22uF/63V

5

6

7

U107B

NJM2068M

C117

100n

R175

300R

3

2

1

U101A

TL072

C115

100pF

C116

100pF

C153

100n

C152

100n

C157

100n

C156

100n

C159

100n

C158

100n

4

8

U106C

NJM2068M

SG101-SG110GAP:

CH2_PATCH

To MCU-1C

R101

10M

6

11

U102B

INA163

R102

1M 1%

2

14

8

10

7

1

RG+

RG-

5123

4

9

U102A

INA163

D109

1N4148

-15V

C130

47uF/35V

R164

10R 1%

D110

1N4148

+15V

R139

1K 1%

R163

2K 1%

R162

2K 1%

R165

10R 1%

R168

20R 1%

R166

10K 1%

R167

10K 1%

R169

1M

C131

47uF/35V

C119

100pF

R170

10R

C134

100n

C132

100pF

C133

100pF

R136

10M

R137

1M 1%

2

14

8

10

7

1

RG+

RG-

5123

4

9

U105A

INA163

R118

10K 1%

J105

JY-6531-02-250

R171

300R

CH1_PATCH

C149

100n

C148

100n

4

8

U101C

TL072

6

11

U105B

INA163

4

8

U107C

NJM2068M

C151

100n

C150

100n

R117

100R

R152

100R

+24V

C135

100pF

C138

100pF

D105

1N4148

D106

1N4148

-15V+15V

D107

1N4148

D108

1N4148

-15V+15V

D115

1N4148

D116

1N4148

-15V

+15V

D113

1N4148

D114

1N4148

-15V+15V

C141

100n

3

2

1

U103A

TL072

L101

2.2uH

R123

10K 1%

12345

6

CN101A

To PANEL-C2 Sheet(CN105B)

12345

6

CN102A

To PANEL-C2 Sheet(CN106B)

21

SG109

21

SG110

21

SG108

21

SG104

21

SG101

21

SG103

21

SG105

21

SG107

2

3

G

GN

1

T

R

SS

S

RS

TS

J101

CH1_IN

2

3

G

GN

1

T

R

SS

S

RS

TS

J102

CH2_IN

+24V

Input TRIM

Channel 1

Channel 2

Input TRIM

R231 10K 1%

R232

10K 1%

D139

1N4148

D140

1N4148

-15V

+15V

R234

47K

D141

1N4148

D142

1N4148

-15V

+15V

R235

47K

R226

10K 1%

R227

10K 1%

D136

1N4148

D135

1N4148

-15V

+15V

D137

1N4148

D138

1N4148

-15V+15V

R229

47K

R230

47K

DIODE: D135-D142

XLR_3M

XLR_3M

123

4

5

CN103A

5pin

123

4

5

CN120A

5pin

To MCU-1C (Sheet)

C161

100n

C160

100n

SG

5

6

7

U109B

NJM2068M

R176

100R

3

2

1

U109A

NJM2068M

R172

100R

C139

10uF/25V

C136

10uF/25V

R174

100R

R178 100R

D117

1N4148

D118

1N4148

D119

1N4148

D120

1N4148

-15V

+15V

4

8

U109C

NJM2068M

C165

100n

C164

100n

EARTH

C201

1nF

C202

1nF

C203

1nF

C102

100n

21

SG118

SPC3

21

SG119

SPC3

C214

1nF

C212

1nF

C211

1nF

C213

1nF

C204

1nF

21

SG120

SPC3

C215

1nF

C217

1nF

2 1

SG121

SPC3

C218

1nF

C216

1nF

123

VR102A

5K/10C

123

VR101A

5K/10C

CN120A-CN121ACON:

C201-C218CAP:

R226-R245RES:

SG118-SG121GAP:

11223344556

6

CN104A

To DSP-1C

3

2

1

U108A

NJM2068M

C147

100pF

C144

100pF

R181 51K

R185 51K

R179

220R

R182

220R

5

6

7

U108B

NJM2068M

J107

Aux In-L

C146

2u2/50V

1

2

3

VR103

20K/15A

R183

220R

J108

Aux In-R

C143

2u2/50V

1

2

3

VR104

20K/15A

R186

220R

21

SG111

21

SG112

D124

1N4148

D123

1N4148

+15V-15V

D122

1N4148

D121

1N4148

-15V

+15V

C145

1nF

C142

1nF

C163

100n

C162

100n

4

8

U108C

NJM2068M

CAP: C228-C237

R180

22K

C234

10uF/25V

R239

47K

R238

5K6

R173

12K

R177

12K

-15V

C140

1nF

C137

1nF

C232

10uF/25V

R240

47K

C233

10uF/25VV

R241

47K

C235

10uF/25V

R244

47K

R242 22K

R243

5K6

C241

33pF

C242

1nF

CH3_IN

CH4_IN

R245

100K

R246

100K

R108

15K 1%

R150

15K 1%

R105

15K 1%

R107

15K 1%

R103

51R 1%

MicShort1

R106

50R %

LineShort2

5

6

7

U101B

TL072

5

6

7

U103B

TL072

4

8

U103C

TL072

MicShort2

C118

100n

+15V

C170

220uF/35V

-15V

C173

220uF/35V

C229

*no stuff

C231

*no stuff

LineShort

CH2_IN

CH1_Out

CH2_OUT

R140

10K 1%

D103

1N4148

R138

100R

R142

10K 1%

D104

1N4148

R141

100R

C236

1000uF/16V

C237

1000uF/16V

PS1 Power Stand

Input Panel PCB, Rev. G

P/N:

273731

Sheet 1 of 3

120V Version 1.0 Systems

Page 27

103

1 2 3 4 5 6

7

A

B

C

D

8

7654321

D

C

B

A

2+ 1+

2-

1-

J117

NL-4MD-V

AMP1_O/P+

2+ 1+

2-

1-

J118

NL-4MD-V

2+ 1+

2-

1-

J119

NL-4MD-V

C178-C200

R207-R225

J112-J119

CN112A-CN119A

CAP:

RES:

JACK:

CON:

DIODE: D127-D134

1

2

3

4

5

CN119A

CON3

LED105

POWER/PRO

R224

2K7

R225

2K7

ALL AMP_IN

BASS1_OUT

BASS3_OUT

LED105LED:

To DSP-1C Sheet

P101-P103PAD:

To MCU-B(CN906B)

To MCU-1C Sheet

J112

JACK-9PIN

C195

2u2/50V

D130

1N4148

-15V

C192

2u2/50V

D129

1N4148

+15V

C198

2u2/50V

R252

22K

C184

1n

C185

2u2/50V

21

SG116

21

SG115

21

SG117

1

2

CN801B

To D_AMP1

1

2

CN805B

To CLASS D_AMP2_IN

TO CLASS D_AMP1_IN

C194

10uF/25V

3

2

1

U113A

NJM2068M

C197

10u/25V

R212

100R

5

6

7

U112B

NJM2068M

R216

100R

R214

47K

R215

100R

R218

47K

R219

100R

1

2

CN809B

BASS_OUT

TO CLASS D_AMP3_IN

C200

10u/25V

R220

100R

5

6

7

U113B

NJM2068M

R222

47K

R223

100R

123

CN115A

Full_In

C183

1nF

C182

1nF

J114

Aux In-L

D132

1N4148

-15V

D131

1N4148

+15V

D134

1N4148

-15V

D133

1N4148

+15V

J115

Aux In-L

J116

Aux In-L

C186

2u2/50V

21

SG114

3

2

1

U112A

NJM2068M

R210

12k

C187

1nF

R209

100R

D128

1N4148

-15V

D127

1N4148

+15V

R211

10R

21

SG113

GR

GAP: SG113-SG117

1

2

P101

PAD-2

1

2

P102

PAD-2

1

2

P103

PAD-2

C221

1nF

C223

1nF

C225

1nF

C227

1nF

21

SG127

21

SG126

21

SG128

21

SG129

21

SG130

21

SG131

Line Array 1

Line Array 2

BASS2_OUT

Line Array 3

C219-C227CAP:

U112-U114IC:

J107-J108JACK:

GAP: SG122-SG131

MUZO PANEL-1PCB

CON: CN801B-CN809B

2

1

J110

SPDIF

2

1

J109

SPDIF

Data IN Data Out

MUZO PANEL-4PCB

1

2

CN112A

1

2

CN113A

21

SG123

21

SG122

C239

100p

21

SG125

21

SG124

C240

100p

CAP: C178-C179

CAP: C219-C220

RCA:J J109-J110

956748321

J113

BASS_OUT

R221

12K

C199

1nF

R217

12K

C196

1nF

R213

12K

C193

1nF

3

2

1

U114A

NJM2068M

5

6

7

U114B

NJM2068M

C240

2u2/50V

R247

100K

R253

560R

C236-C240CAP:

R245-R246RES:

R251

10K 1%

R250

10K 1%

R254

10K 1%

R256

22K

C246

1n

C245

2u2/50V

21

SG132

C247

1nF

R257

560R

R248

10K 1%

R249 10K 1%

C243 20pF

C244 20pF

R255

10K 1%

R258

100K

R259

100K

R260

100K

R261

100K

D143

1N4148

+15V

D144

1N4148

-15V

MAP2_O/P+

MAP3_O/P+

4/8 Ohm check

pro

MAP2_O/P-

MAP1_O/P-

1-

1-

1-

MAP3_O/P-

BASS_IN

C178

*no stuff

C219

*no stuff

G1

C179

*no stuff

C220

*no stuff

8

-15V

+15V

4

8

U112C

NJM2068M

4

8

U113C

NJM2068M

C189

100n

C188

100n

C191

100n

C190

100n

4

8

U114C

NJM2068M

C238

100n

C239

100n

PS1 Power Stand

Input Panel PCB, Rev. G

P/N:

273731

Sheet 2 of 3

120V Version 1.0 Systems

Page 28

104

1 2

3

A

B

C

D

4

321

D

C

B

A

R193

3K3

+24V

132

645

SW102

SW-6P2

LED101

RG_LED

R192

2K2

LED102

Red

3

2

1

U110A

NJM2068M

R188 150K

R189

1K

R190

1K

5

6

7

U110B

NJM2068M

R191

30K

Z101

5v6

D125

1N4148

C169

4u7/50V

C168

1uF/50V

Z102

5v1

LED103

RG_LED

R202

2K2

3

2

1

U111A

NJM2068M

R198

150K

R199

1K

R200

1K

5

6

7

U111B

NJM2068M

R201

30K

Z103

5v6

D126

1N4148

C172

4u7/50V

C171

1uF/50V

Z104

5v1

+15V

-15V

4

8

U111C

NJM2068M

C177

100n

C176

100n

4

8

U110C

NJM2068M

C175

100n

C174

100n

R187

51K

R197

51K

Off

+24V

Phantom

GR

GR

CAP: C168-C179

RES: R187-R208

DIODE: D125-D128

ZENER: Z101-Z106

LED: LED101-LED104

IC: U110-U111

CON: CN105B-CN 106B

SW: SW102, SW104

Q101

9013

R125

1K2

Z105

3v3

Q104

9013

R126

1K2

Z106

3v3

R110

22K

R112

1M

Q102

2N3904

R207

220R

12345

6

CN105B

FROM CN101A

-15V

MicShort1

MicShort1

12345

6

CN106B

FROM CN102A

+15V

+24V

MicShort2

MicShort2

Q103

2N3904

C178a

100uF/35V

R111

5K6

R109

10K

R204

3K3

+24V

132

645

SW104

SW-6P2

LED104

Red

Off

+24V

Phantom

R114

22K

R116

1M

Q105

2N3904

R208

220R

Q106

2N3904

C179a

100uF/35V

R115

5K6

R113

10K

D127a

1N4148

D128a

1N4148

TR: Q101-Q106

4

PS1 Power Stand

Input Panel PCB, Rev. G

P/N:

273731

Sheet 3 of 3

120V Version 1.0 Systems

Page 29

105

1 2 3 4 5 6

7

A

B

C

D

8

7654321

D

C

B

A

C166

47u/25V

C167

47u/25V

D102

1N4148

-15V

C113

47uF/35V

R129

10R 1%

D101

1N4148

+15V

R104

1K 1%

-15V

+15V

R128

2K 1%

R127

2K 1%

R130

10R 1%

C101-C167

R101-R186

U101-U109

J101-J106

CAP:

CN101A-CN104A

RES:

IC:

JACK:

CON:

DIODE:

D101-D120

1 3

2

J103

CH1_OUT

CH1_In

SG

AD2_In

+15V

-15V

R133

20R 1%

1 3

2

J104

CH2_OUT

J106

JY-6531-02-250

R131

10K 1%

R132

10K 1%

R134

1M 1%

C114

47uF/35V

C101

100pF

3

2

1

U106A

NJM2068M

C106 20pF

C107 20pF

R119 10K 1%

R121

10K 1%

R135

10R

R120

220R

R124

220R

C112

22uF/63V

C110

22uF/63V

5

6

7

U106B

NJM2068M

3

2

1

U107A

NJM2068M

C123 20pF

C124 20pF

R154 10K 1%

R153

10K 1%

R155

10K 1%

R157

10K 1%

R159

220R

R158

220R

C127

22uF/63V

C129

22uF/63V

5

6

7

U107B

NJM2068M

C117

100n

R175

300R

3

2

1

U101A

TL072

C115

100pF

C116

100pF

C153

100n

C152

100n

C157

100n

C156

100n

C159

100n

C158

100n

4

8

U106C

NJM2068M

SG101-SG110

GAP:

CH2_PATCH

To MCU-1J

R101

10M

6

11

U102B

INA163

R102

1M 1%

2

14

8

10

7

1

RG+

RG-

5123

4

9

U102A

INA163

D109

1N4148

-15V

C130

47uF/35V

R164

10R 1%

D110

1N4148

+15V

R139

1K 1%

R163

2K 1%

R162

2K 1%

R165

10R 1%

R168

20R 1%

R166

10K 1%

R167

10K 1%

R169

1M

C131

47uF/35V

C119

100pF

R170

10R

C134

100n

C132

100pF

C133

100pF

R136

10M

R137

1M 1%

2

14

8

10

7