Page 1

Bose® Lifestyle

®

Model CD5 Series I Music Center

Note: The first series CD5 can be distinguished from the later CD5V and CD5VII by the serial

number label located on the bottom of the unit. The CD5 will not have a V on the serial number

label, the CD5V will have a V, and the CD5V2 will have a V with the number 2 above the V.

©

1998 Bose Corporation

Part Number 174798 REV 01

Service Manual

Page 2

Contents

Safety Information............................................................................................................................ 2

Electrostatic Discharge Sensitive (ESDS) Device Handling ........................................................ 2

Specifications................................................................................................................................ 3-4

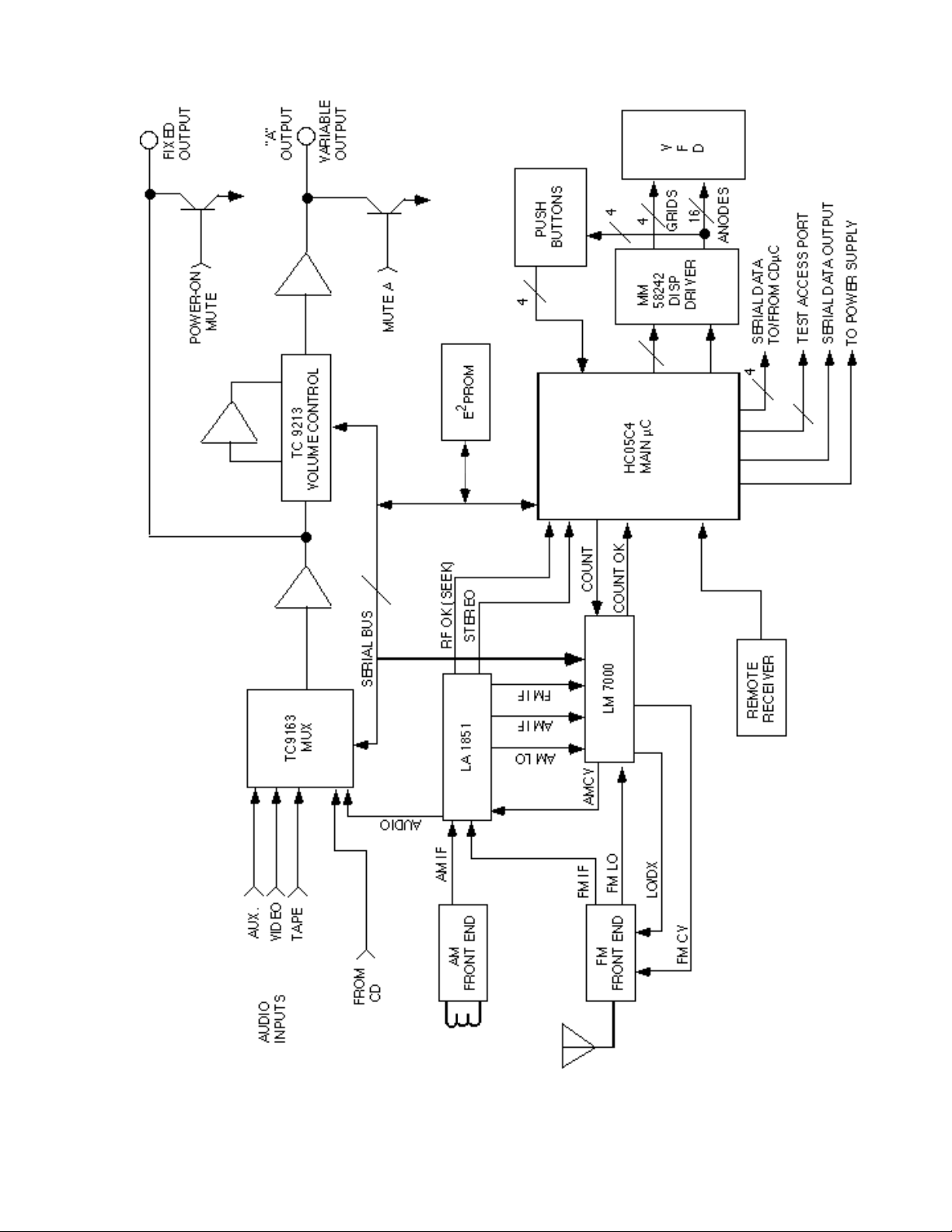

Figure 1. CD5 Block Diagram Sheet 1 of 2 ...................................................................................... 5

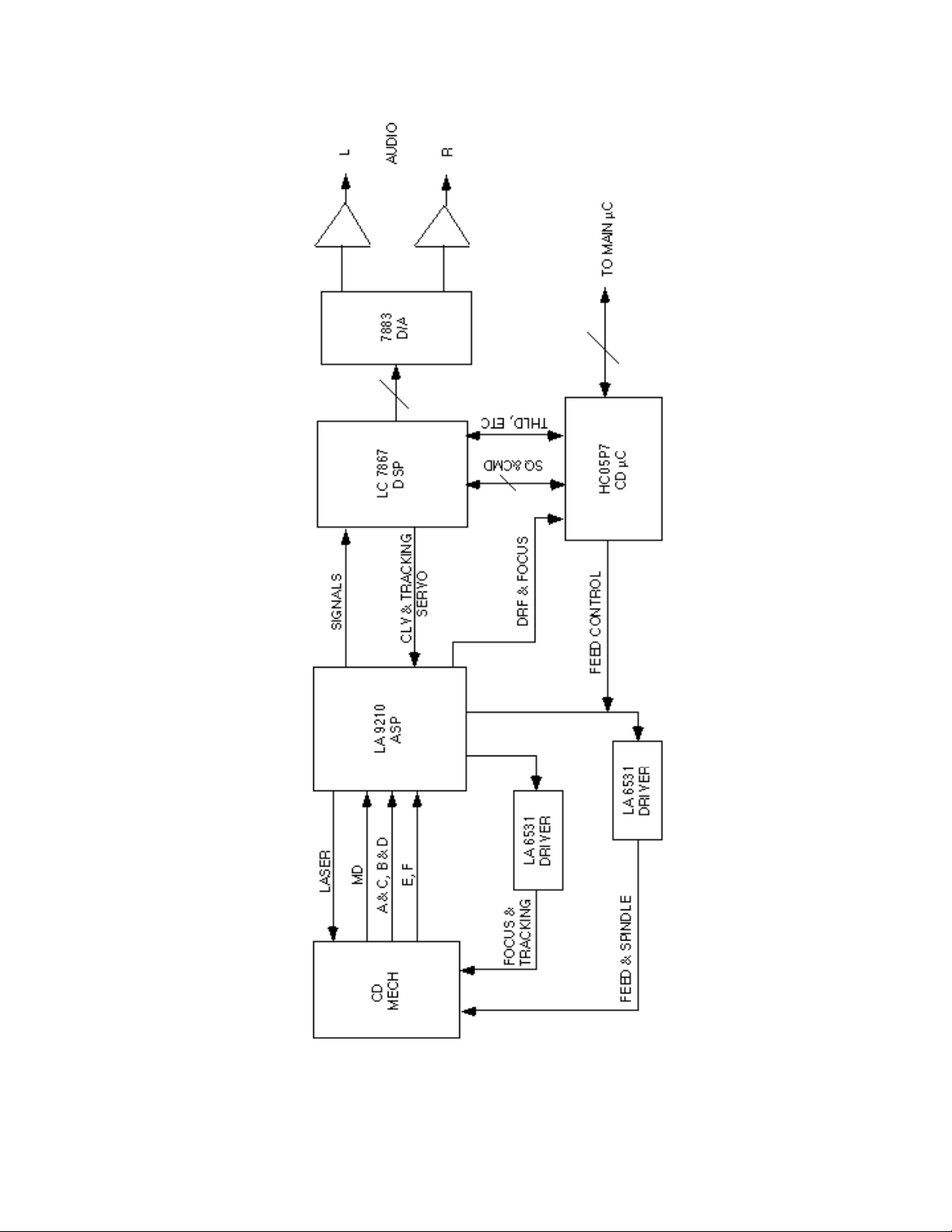

Figure 2. CD5 Block Diagram Sheet 2 of 2 ...................................................................................... 6

CD Terms ..................................................................................................................................... 7-11

Theory of Operation.................................................................................................................. 12-17

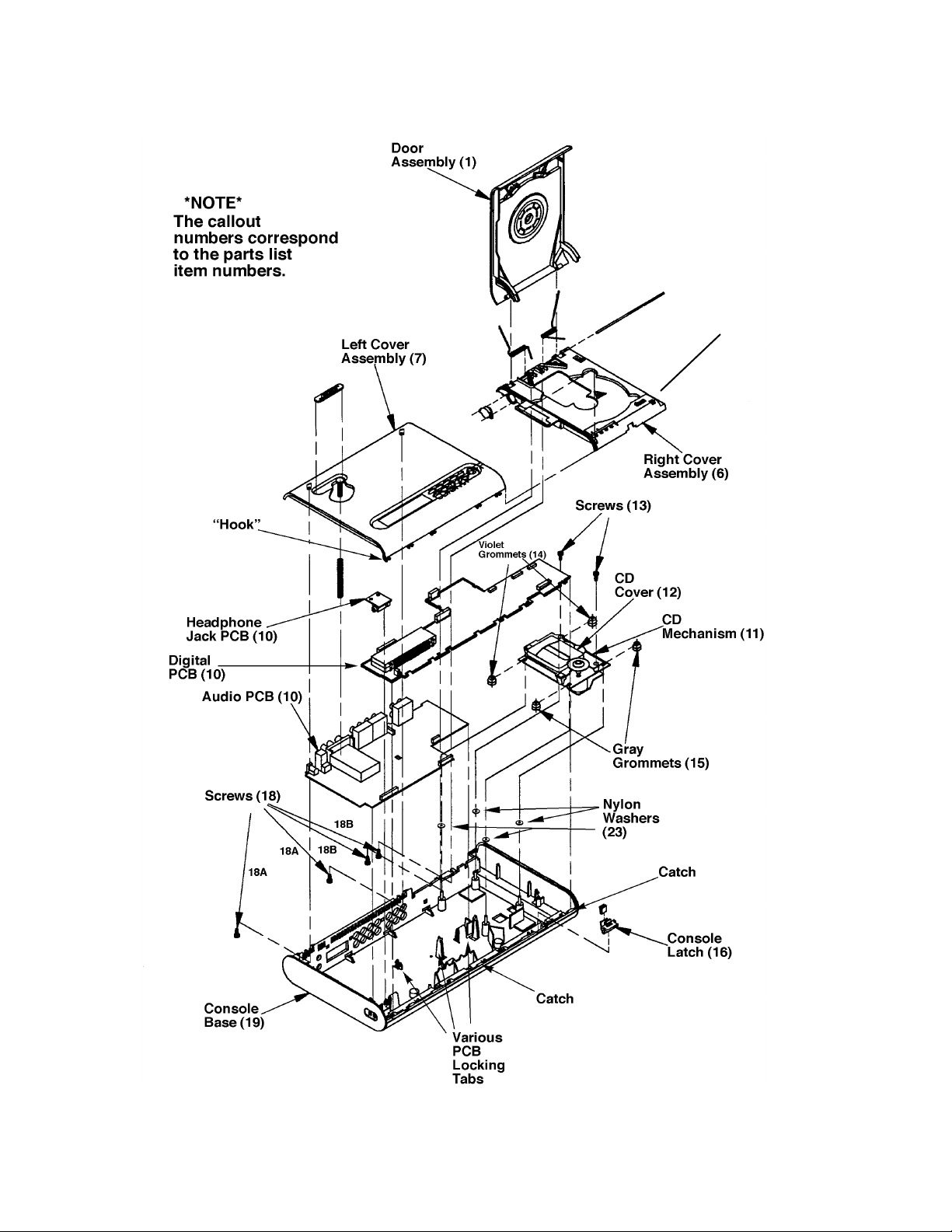

Figure 3. Labelled Exploded View.................................................................................................. 18

Disassembly/Assembly Procedures ....................................................................................... 19-21

Figure 4. APC PCB ........................................................................................................................ 19

Figure 5. Back Panel with Tab Locations ....................................................................................... 22

Figure 6. Right Cover Assembly (side view) .................................................................................. 22

Figure 7. Base Assembly (top view with covers removed)............................................................. 22

RC5 Disassembly/Assembly Procedures .................................................................................... 23

Figure 8. Remote Control Assembly Exploded View...................................................................... 23

Test Procedures ........................................................................................................................ 24-26

Figure 9. AM Test Setup................................................................................................................. 26

Figure 10. Audio PCB Test Section ................................................................................................ 26

CD Test Procedures .................................................................................................................. 27-31

Figure 11. CD Alignment Fixture and Test Setup ........................................................................... 28

Figure 12. Passive Filter Network and Test Setup ......................................................................... 29

Figure 13. Digital PCB Adjustment Locations ................................................................................ 32

Parts List Notes.............................................................................................................................. 33

Console Assembly Parts List........................................................................................................ 34

Figure 14. Exploded View .............................................................................................................. 35

Remote Control Assembly Parts List........................................................................................... 36

Figure 15. RC5 Exploded View ...................................................................................................... 36

Electrical Part List..................................................................................................................... 37-46

RC5 Electrical Part List.............................................................................................................47-49

Packaging Part List........................................................................................................................ 50

Figure 16. Packaging Exploded View ............................................................................................ 50

Service Bulletin ......................................................................................................................... 51-53

CD5 Troubleshooting Guide.......................................................................................................... 54

CD5 Voltages and Waveforms..................................................................................................55-58

Integrated Circuit Diagrams .....................................................................................................59-66

Figure 17. RC5 PCB Layout........................................................................................................... 67

Figure 18. RC5 Schematic ............................................................................................................. 68

CAUTION: THE LIFESTYLE

®

MODEL 5 MUSIC CENTER CONTAINS NO

USER SERVICEABLE PARTS. TO PREVENT WARRANTY INFRACTIONS,

REFER SERVICING TO WARRANTY SERVICE STATIONS OR FACTORY

SERVICE.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

®

CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

1

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes in the part lists. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check: With the unit completely assembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

1492 (71). With the unit's AC switch first in the ON position and then in the OFF position,

measure from a known earth ground (metal water pipe, conduit, etc.) to all exposed metal

parts of the unit (antennas, handle bracket, metal cabinet, screw-heads, metallic overlays,

control shafts, etc.), especially any exposed metal parts that offer an electrical return path to

the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the unit's power

cord plug in the outlet and repeat the test. ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check: (1) Unplug the power supply and connect a

jumper wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3)

Measure the resistance with an ohmmeter between the jumpered AC plug and each exposed

metallic cabinet part on the unit. When the exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2M Ω. When there is no return path to the

chassis, the reading must be "infinite". If it is not within the limits specified, there is the possibility of a shock hazard, and the unit must be repaired and rechecked before it is returned to the

customer.

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

2

Page 4

SPECIFICATIONS

General

Dimensions: 2.5"H x 15"W x 9"D (6 x 38 x 23cm)

Weight: 3.7lb. (1.7kg)

Finish: Plastic, in-mold brushed aluminum finish

Power Input: Detachable power pack, 12VAC compatible with

each country's power requirements

Serial Data Output: 2-3.5mm stereo jacks, Tip: Serial data output,

Ring: +12Vdc turn on output.

Power: 14 Watts max.

Input Impedance (@ 1kHz, max. volume): 5kΩ @ aux./video input, 100kΩ @ tape input

Output Impedance: 600Ω @ Speaker A, B output, 1kΩ @ tape output

Distortion: ≤ 0.02% THD @ 1kHz, 2Vrms

S/N Ratio: ≥ 105dB (A-weighted, max. volume)

Headphone Output (32Ω): 45mW (max. output)

Channel Separation: 70dB

Muting (A, B outputs): -80dB

Max. Output Level: 5Vrms (@ 1kHz, THD < .12%)

FM Electrical

Antenna Input: US: 75Ω F connector, Europe: 75Ω PAL

Usable Sensitivity: US: 12dBf, Europe: 17dBf

50dB quieting sensitivity: Mono: US: 15dBf, Europe: 20dBf

Stereo: US: 37dBf, Europe: 42dBf

S/N ratio (65dBf input): Mono: 75dB, Stereo: 70dB

THD (65dBf, 1kHz input): Mono: ≤ 0.2%, Stereo: ≤ 0.3%

Capture Ratio: 1.5dB

AM Rejection (45 dBf input): 60dB

Alternate Channel Selectivity (45 dBf input): US: 70dB, Europe: 75dB

Image Rejection: 70dB

Frequency Response: ± 0.5dB (30Hz-15kHz)

Stereo Channel Separation: 40dB @ 1kHz

3

Page 5

SPECIFICATIONS

(Continued)

AM Electrical

Antenna Input: Binding posts

Usable Sensitivity: 55dBuV/m (IHF standard test loop antenna)

Alternate Channel Selectivity: 60dB

Adjacent Channel Selectivity: 45dB

Image Rejection Ratio: 40dB

S/N Ratio: 50dB (@ 100dBuV/m)

THD: ≤ 1.0% (@ 100dBuV/m)

Frequency Response (@ 100dBuV/m): 100Hz: -8dB

3kHz: -8dB

CD Electrical

D/A Process: 8x over sampling dual 16-bit D/A conversion

Maximum Output Level: 4V

THD+N: 0.05% (@ 1kHz, 0dB)

S/N Ratio: 100dB (A-weighted)

Channel Separation: ≥ 50dB (@ 1kHz)

Frequency Response: ± 0.5dB (20Hz-20kHz)

Dynamic Range: ≥ 90dB

Defect Tracking (Void): 1.5mm (Pierre Verany Test Disc #2)

Defect Tracking (Black Dot): 1mm (ABEX Test Disc TCD-725R)

Defect Tracking (Scratch): 1.6mm (ABEX Test Disc TCD-721R)

Defect Tracking (Fingerprint): 75um (ABEX Test Disc TCD-725R)

Defect Tracking (Warped disc): 1mm (ABEX Test Disc TCD-732RA)

Defect Tracking (Eccentric Disc): 280um (ABEX Test Disc TCD-741R)

4

Page 6

Figure 1. CD5 Block Diagram Sheet 1 of 2

5

Page 7

Figure 2. CD5 Block Diagram Sheet 2 of 2

6

Page 8

CD TERMS

Basic Terms

Access: See track access.

Access Time: The length of time required to change tracks.

CD Mechanism: The mechanical assembly of components used to read information off of the

CD. It contains the optical pickup, sled assembly, disc motor, sled motor, and spindle.

Disc Motor: The motor which spins the disc.

Focus Actuator: The magnet and coil assembly that moves the optical pickup’s lens up and

down.

Laser: A semiconductor light source similar to an LED that is used to read the data off of a CD.

When the laser is turned on it can be seen as a red glow inside the lens.

Laser Pickup: The portion of the CD mechanism that contains the laser diode, lens, focus and

tracking actuators, and photodetector diodes.

Mechanism: see CD Mechanism.

Optical Pickup: See Laser Pickup.

Playability: The extent to which a player can successfully play less than perfect discs. Play-

ability is measured with special test discs (playability discs) that contain certain types of defects and problems.

Playability Disc: A disc which contains a calibrated defect or problem. These include eccentricity, warp, scratch, void, black dot, and fingerprints.

Parking: When the sled is moved to the innermost position on the disc. This is done before (if

necessary) and after playing a disc.

Sled: The portion of the CD mechanism that moves inside to outside to position the optical

pickup near the desired track.

Sled Motor: The motor which moves the sled back and forth.

Spindle: The hub that the disc sits on.

T rack Access: The process of moving from one track on a disc to a different track.

T racking Actuator: The magnet and coil assembly that moves the optical pickup’s lens inside

and out.

Playability Terms

Dropout: A momentary loss of the audio signal, usually caused by a large scratch or other

optical defect.

7

Page 9

CD TERMS

Eccentricity: The extent to which the hole in the middle of the disc is not located in the geo-

metric center. In other words, the amount that the disc moves in and out as it rotates. Eccentricity is measured as the distance between the center of the hole and the center of the disc (as

determined by the spiral tracks).

Mistracking: When a CD player fails to play the disc in a continuous manner. This may be

caused by a large enough optical defect (scratch, etc.) or by vibration.

Optical Defect: A defect on the surface of the disc which adversely affects the reading of

information by the laser pickup. There are four basic types of optical defects: voids, black dots,

fingerprints, and scratches.

Skipping: When a CD mistracks backwards and gets caught in an “endless loop”. This is

usually caused by a large scratch or other optical defect.

Warp: The extent to which the surface of the disc is not parallel to the seating plane of the disc

(at the center). In other words, the amount that the disc wobbles up and down. Warp is measured as the vertical deviation between the seating plane and the particular point on the disc.

Alignment Terms

CD Alignment: The process of adjusting a CD player for optimum performance, particularly

with respect to its playability.

Free Run Frequency: The VCO frequency in the absence of any signal from the disc. Accu-

rate frequency adjustment is required for the player to be able to read data off the disc. VCO

misalignment results in poor track access and longer access times.

Tracking Offset: The DC offset voltage present at the output of the tracking servo in the

absence of any input signal. For best results, the offset should be adjusted near 0 to keep the

laser positioned in the center of the track. Negative offset causes the laser to be positioned

towards the inside of the track. Misalignment of this parameter can cause the player to skip or

mistrack when playing a dirty or “black dot” disc, especially if the disc is also eccentric.

Scratches and voids may also cause the problem.

Focus Offset: The DC offset voltage present at the output of the focus servo in the absence of

any input signal. For best results, the offset should be adjusted near 0 to keep the laser exactly

in focus. Misalignment of this parameter usually causes dropouts when playing a dirty or “black

dot” disc, especially if the disc is also warped. Scratches may also cause problems. Note that

on the CD5, the focus offset is preset and the adjustment pot is not loaded, however, there is a

spot on the PCB for it.

E-F Balance: The DC offset that results from driving both the E and the F elements of the

photodetector with equal signals. For best results, the offset should be adjusted near 0 to keep

the laser positioned in the center of the track. As with track offset, negative offset causes the

laser to be positioned towards the inside of the track. Misalignment of this parameter can

cause any number of problems including: 1. Poor or slow track access even when playing a

good disc, and 2. Skipping or mistracking when playing a scratched or void disc, especially if

the disc is also eccentric.

8

Page 10

CD TERMS

Tracking Gain: The overall loop gain of the tracking servo. This controls how tightly the laser

is held in the center of the track. If the gain is too low, the player will have trouble with vibration

and eccentric discs, especially during track access. If the gain is too high the player will have

skips or mistracking with voids and scratches. Proper alignment is a compromise between

these two performance parameters.

Focus Gain: The overall loop gain of the focus servo. This controls how tightly the laser is held

in focus. If the gain is too low, the player will have trouble with vibration and warped discs,

especially during track access. If the gain is too high the player will have skips or mistracking

with black dots and scratches. Proper alignment is a compromise between these two performance parameters.

Technical Terms

RFSM: RF SUM. The amplified A+B+C+D signal from the laser pickup.

Eye Pattern: The pattern displayed on an oscilloscope when monitoring the RFSM test point.

Jitter: The extent to which the zero crossings of the eye pattern occur at other than their ideal

times.

Focusing: Before a disc can be played, the player must focus the CD mechanism by changing

the distance between the lens and the surface of the disc. This must occur before the disc can

start rotating. If the player fails to achieve focus, it will retry. This occurs four times in the CD5

before it “gives up” and indicates “no disc” by lighting up the disc icon in the display.

TOC: Table Of Contents. The innermost area on the disc where track and time information is

stored. When a new disc is inserted into a player (i.e. when the door switch is opened), it must

read the TOC before the first track can be played.

CIRC: Cross Interleave Reed-Solomon Coding: The error detection and correction scheme

used on CDs to provide immunity to small scratches, etc.

CLV: Constant Linear Velocity. CD players rotate the disc at a constant linear velocity of 1.25

M/S. The angular velocity changes from about 500 RPM down to 200 RPM as the disc plays

from beginning (inside) to end (outside).

EFM: Eight-to-Fourteen-Modulation. The format in which the digital data is recorded on the

CD.

Photo Diode: The receiving element that translates the modulated light beam into electrical

signals.

Subcode Q data: The track and time information read off the CD.

Three Beam System: The most common system for providing focus and tracking error signals

for the respective servos. A three beam system uses a six element photo diode array, with the

elements designated A through F. The A, B, C, and D elements are located in the center and

read the information as well as supply the focus error signal. The E and F elements are located

on either side and provide the tracking error signal.

9

Page 11

CD TERMS

Major Components of the System

ASP: Analog Signal Processor . The component in the CD circuitry that contains the RF ampli-

fier, VCO, and the tracking, focus, and sled servos.

DSP: Digital Signal Processor. The component in the CD circuitry that performs slicing, EFM

demodulation, CIRC decoding, error correction and concealment, track access, CLV regulation, and drives the D/A.

Digital to Analog Converter (D/A, DAC): A device that converts digital information (usually a

serial data stream) into an analog signal.

µC: Micro Controller. The component of the CD circuitry that performs track access, se-

quences all events (such as focus, disc start, stop, etc.), monitors for servo errors, and processes user information (commands, door open, etc.).

CLV Servo: The circuit that keeps the disc rotating at a constant linear velocity.

Focus Servo: The circuit that keeps the optical pickup’s lens the proper distance away from

the surface of the disc.

Sled Servo: The circuit that keeps the sled positioned within the linear range of the tracking

actuator.

Tracking Servo: The circuit that keeps the optical pickup’s lens positioned within a single track

as the disc rotates.

VCO: Voltage Controlled Oscillator. Part of the phased locked loop circuit that generates an

output frequency dependent on its input voltage.

Signal Names

ATSC: Anti-Shock Circuit.

SLEQ: Sled Equalizer

FDO: Focus Drive Output

FEAO: Focus Error Amplifier Output.

HFL: High Frequency Level

PDO: Phase Detector Output

PH: Peak Hold

SLDO: Sled Drive Output.

SPDO: Spindle Drive Output.

10

Page 12

CD TERMS

Signal Names

(continued)

TAP: Test Access Port. A 3 pin test interface used by automated test to control and observe

the board under test.

TDO: Tracking Drive Output.

TEAO: Tracking Error Amplifier Output.

TGL: Tracking Gain Low.

THLD: Tracking Hold.

TOFF: Tracking Off

TPA+: Tracking Pre-Amplifier (+ input).

TPA-: Tracking Pre-Amplifier (- input).

TPAO: Tracking Pre-Amplifier Output.

VCOO: VCO Output

Vref1: The reference voltage used by the RF amplifier in the ASP.

Vref2: The unbuffered reference voltage used by the servos in the ASP.

Vref3: The buffered reference voltage used by servos in the ASP.

List of Abbreviations

ASP Analog Signal Processor

CE Control Expander™

CIRC Cross Interleave Reed-Solomon Code

CLV Constant Linear Velocity

D/A Digital to Analog

DSP Digital Signal Processor

EEPROM Electrically Erasable Program Read Only Memory

EFM Eight-to-Fourteen Modulation

IC Integrated Circuit

IR Infrared

kHz Kilohertz

MHz Megahertz

PLL Phase Locked Loop

RF Radio Frequency

µC Microcontroller

VCO Voltage Controlled Oscillator

VFD Vacuum Fluorescent Display

11

Page 13

THEORY OF OPERATION

Overview

The Lifestyle® Model 5 music center is a self-contained CD player, AM/FM tuner, preamplifier,

and control center for use with Bose

sources (CD and tuner), it also allows for up to three external devices to be connected (i.e.

AUX, VIDEO, and TAPE). It uses a Radio Frequency (RF) remote control that allows the unit to

be operated from different rooms within a house without the need for a line-of-sight path back

to the console. The remote control commands for the external sources are translated and

passed to the serial data output jack. With the CE-I accessory device this data can be converted to Infrared (IR) for use with many conventional audio devices.

®

powered speaker systems. In addition to the two internal

Power Supply

The unit is powered by an external 12VAC power supply capable of delivering 1.2 amps rms.

Dl, C2, D2, and C6 form positive and negative half-wave rectifiers respectively. Q1, Q2, Q3,

and their respective components make up a discrete low dropout regulator with a nominal

output voltage of 10. 2V. VR1 is the corresponding negative voltage regulator with an output of

-12V. These two regulators create the bipolar supply used by all of the audio circuits. The

supply is turned on and off with the unit by the control signal on J7-10.

R5, D3, C9, and VR2 create an +8V regulated supply that is used by the CD servo circuits and

the remote RF receiver. R6, D4, C11, and VR3 create a +5V regulated supply that is used by

the main and CD microcontrollers (U402 and U505), and the CD control circuits (U501, U502,

etc.). Both supplies are live at all times. R5 and R6 limit the power dissipation of their respective regulators. VR2 and VR3 normally run quite hot to the touch.

R8, D6, and C13 form an unregulated supply (M+) that is used by the CD drive electronics.

C14, D7, D8, and C15 form a charge pump that creates a negative high voltage. This voltage

is regulated down to -24V by R9, D9, and C16. The vacuum fluorescent display (VFD) driver

U403 uses this -24V to shut off segments in the display. C19 and C18 reduce the 12VAC to

approximately 3Vrms. This voltage powers the display’s (VFD401) heater. C16, D10, C17, and

R10 provide a DC bias of -15V for the VFD heater (cathode).

Control Electronics

Main microcontroller (µC) U402 controls the audio circuits, tuner, display, and push buttons.

The µC runs at a nominal frequency of 4.0MHz that is supplied by ceramic resonator X401.

The µC is reset by a rising edge on pin 1 caused by R409 and C404. This occurs automatically

on power-up but may be forced manually by depressing S416 (if installed).

U402 communicates with U403 over a four wire serial data bus (U403, pins 15, 16, 18 and

19). The bus is updated once per millisecond. U403 latches the serial data into its outputs,

driving the VFD. The VFD is a four grid multiplexed display with 16 anodes at each grid. The

grids are turned on sequentially, one each millisecond. As each grid is turned on, the corresponding anodes for that grid are also turned on. This lights the desired segments. When the

next grid is turned on, the anodes are changed to correspond to the desired segments under

this next grid. In this way, the entire display is scanned, 1/4 at a time. The display is blanked for

a brief interval in-between when one grid is turned off and the next is turned on. In this blanking interval, the push buttons are scanned to determine what keys are being pressed. This

data is read in on U402, pins 12 through 15.

12

Page 14

THEORY OF OPERATION

There is one main serial data bus that controls source selection IC U101, volume control IC

U103, PLL frequency synthesizer U302, and EEPROM U401. The clock and data information

for all of these devices is sent out on U402, pins 5 and 7. However, U401, U302, U101 and

U103 each have their own chip select line. Data is sent to U302 whenever the tuner frequency

is changed. During the serial data transmission, U302, pin 3 is driven high. Data is sent to

U101 or U103 whenever a new source is selected or the volume is changed. At the completion

of this transmission, the STRB line (J9-5) is driven high briefly.

U401 is a nonvolatile EEPROM which is used for storing certain data such as tuner presets

and house codes. This data is protected from loss during a power outage. U401 communicates

with U402 over the main serial data bus. During communication to this chip, the chip select line

(U401, pin 1) is driven high.

There is another serial data bus between U402 and U505. These lines are labeled

CD_READY, CD_CLK, CD_ CMD, and CD_DATA on the schematic. The bus sends commands (play, stop, etc.) to U505 and also sends track and time information to U402 so that it

may be displayed. This bus is constantly in use any time “CD” is selected as the source.

RR101 receives and demodulates commands from the RF remote control. R138, C130, C129,

R139, and D109 remove noise and shape the pulse. U106 squares up the pulse edges and

converts them to 5V logic levels. This signal is then fed to U402, pin 37. C401 prevents any

glitches at this pin.

In addition to the major functions mentioned above, U402 also performs several miscellaneous

tasks. The bipolar power supply for the audio circuits (+1OV/-12V) is turned on and off by

U402, pin 19 (power). Both supplies are turned on when this line is high (+5V), and off when it

is low. The unregulated supply is monitored by C414, R407, and R408. In the event of a power

failure, U402 will shut down the system gracefully. There are three independent muting circuits: Mute A, Mute B, and Power-on Mute. Mute A and Mute B are controllable from the

remote, and allows the A and B outputs to be controlled independently. The Power-on Mute is

used only during power-up (when the bipolar supply is turned on) to prevent pops and clicks.

When an external source is selected (AUX, VIDEO, or TAPE), the transport commands (FF,

FR, etc.) are passed through the serial data jack via Q401 and its associated circuitry.

Audio Circuits

There are two internal audio sources (CD and Tuner) and three external sources (AUX,

VIDEO, and TAPE). All of the sources are routed to U101. R101-106 and R201-206 provide

level matching for the different input sources. D101-106, D201-206, C101-103, and C201-203

provide static protection on the inputs. U101 selects 1 of the 5 input sources, and routes it to

its output on pins 5 and 9 (left), and pins 20 and 24 (right).

One half of U102 (pins 1-3 and 12-14) provides gain and buffering for the input signal. The

buffered output is routed to U103 and to the FIXED output on J103. U103 consists of two

sections. The first section attenuates the signal from 0 to 70dB in 10dB steps. The output of

the first section is buffered by the other half of U102 (pins 5-7 and 8-10) and is fed to the

second section. The second section attenuates the signal in 1dB steps. The two sections

together provide smooth attenuation from 0 to 80dB in 1dB steps.

13

Page 15

THEORY OF OPERATION

U103’s output signal is buffered by U105, and is fed to the A and B outputs. These outputs are

independently mutable through transistors Q103-106 and Q203-206. Each pair of transistors

provides approximately 80dB of attenuation when muted. These mute transistors are controlled by the signals on J9-7 and J9-8. U103’s output signal is also routed to headphone

amplifier U104. This provides gain and buffers the signal in order to drive a low impedance

load. When the headphones are inserted into J104, the control signal on J105-3 causes the A

speaker output to be muted.

The TAPE output jack functions like the FIXED output does. There is one exception. The TAPE

output is shut off whenever “TAPE” is selected as the source. This prevents feedback through

the TAPE deck if it was placed in “Record” while “TAPE” was selected as the source. This is

accomplished by feeding the FIXED level output signal from U102, pins 1 and 14 back into

U101. A control signal from U402 allows U101 to pass this signal to its outputs on pins 5 and

17, except when “TAPE” is selected as a source.

The FIXED, TAPE, and headphone outputs all have a single mute transistor which is used to

prevent pops and clicks during power-up and power-down. These transistors are all controlled

by the signal on J9-6. Each transistor provides about 40dB of attenuation when the muting is

switched on.

CD Player

The CD circuitry consists of six major sections: Analog signal processor (ASP) U501, digital

signal processor (DSP) U502, digital to analog converter (D/A) U506, CD microcontroller (µC)

U505, power drivers U503 and U504, and the CD mechanism. U501 contains the RF amplifier

and servo control circuits. U502 performs EFM demodulation, CIRC decoding, and outputs the

digital audio to U506. It also extracts the subcode Q information (track #, time, etc.) and controls U501 during track access. U505 receives and interprets the subcode Q data from U502

and sends it along to U402. It also issues commands to U502 for track access, and controls all

operations of the CD circuitry.

U501 receives its input signal (through P501) from the mechanism’s photo diode pickup. The

A, B, C, and D inputs are added together and amplified. The RF amplifier output appears on

RFSM (U501, pin 72 ). This signal is the familiar “eye pattern.” This signal is sent to EFMIN on

U502, Pin 8 where it is sliced for EFM demodulation. The inverted and non-inverted sliced

outputs appear on the EFMO and EFMO~ lines (U502, pins 6 and 7) . These signals are lowpassed and subtracted and the output appears on SLCO (U501, pin 53). This signal supplies

the DC bias for the RFSM signal. This signal is then sent to the slicer for slice level control.

The RFSM signal is peak-detected and compared to a reference to determine if there is a

signal being received back from the disc. The output appears on DRF (U501, pin 40 ). This

signal is used by U505 to determine if the lens is in focus. The envelope of the RFSM signal is

also used in determining when the laser crosses a track boundary during track access. The

HFL signal (U501, pin 48) conveys this information to U502.

The A+C signal is subtracted from the B+D signal. This produces the focus error signal FEAO

(U501, pin 26 ). The focus gain is adjusted by R527. This signal is amplified and filtered by the

focus servo amplifier (inside U501). It then appears as an output at FDO (U501, pin 22). The

FDO signal is fed to U503. U503 generates the complementary outputs (pins 11 and 14) that

are used to actuate the focus coil (P502, pins 5 and 8).

14

Page 16

THEORY OF OPERATION

The E and F signals are amplified and subtracted. This produces the tracking error signal

TEAO (U501, pin 7 ). The F channel’s gain is adjusted by E-F balance potentiometer R506.

The TEAO signal is used by the anti-shock circuit, the track jump detection circuit, and the

tracking servo. The track jump detection output is sent to U502 on the TES line (U501, pin 47).

R510, which is connected to TPA+ (U501, pin 13 ), adjusts the tracking gain. This signal is

amplified and filtered. It then appears as an output on TPAO (U501, pin 15). R511 adjusts the

tracking offset . The TPAO signal is further amplified and filtered. It then appears as an output

on TDO (U501, pin 21). This signal is fed to U503. U503 generates the complementary outputs (U503) that are used to actuate the tracking coil (P502, pins 6 and 7).

The TDO signal is also used as the input for the sled servo. This signal is filtered and fed to the

sled servo amplifier on SLEQ (U501, pin 20). This signal is amplified and is then added to the

FEED signals from U505. The result appears on SLDO (U501, pin 33). This signal is fed to

U504. U504 generates the complementary outputs (pins 11 and 14) that are used to drive the

sled motor (P503, pins 5 and 6).

The Constant Linear Velocity (CLV) servo is regulated by comparing the playback speed to a

FIXED reference frequency in U502. The error signal appears at U502, pins 10 and 11 (CLV+

and CLV-). These signals are subtracted and the difference appears on SPD (U501, pin 29).

The SPD signal is filtered and amplified. It then appears at the output on SPDO (U501, pin

31). This signal is fed to U504. U504 generates the complementary outputs (pins 3 and 6) that

are used to drive the disc motor (P503, pins 1 and 2).

U501 regulates the laser power by monitoring the MD input (P502-3). This signal is compared

to a reference to generate the proper drive signal on LDD (U501, pin 74). This signal biases

Q501. Q501 drives the laser diode output LD (P502-1). U501’s main DC reference voltage is

Vref3 which appears on pin 9. This voltage is nominally 4V.

The VCO is the final function contained in U501. The VCO is used by U502 for EFM demodulation. The PDO output signal (U502, pin 4) is filtered and amplified by U501. In turn, this

output appears on VCOC (U501, pin 59) This is the VCO control voltage input. The nominal

VCO free-run frequency is 8.64MHz and is set by R558. The VCO also requires a 16.9344MHz

clock input from U502. This input appears on CLK (U501, pin 62). The VCO output appears at

VCOO (U501, pin 60). This signal is buffered by U502. The buffered output appears on AO

(U502, pin 2). The VCO output is divided by 2 in U502. In turn, its output appears on PCK

(U502, pin 18), which is 4.32MHz.

The DSP clock is derived from a 16.9344MHz crystal oscillator (X501). However, this oscillator

is normally turned off by U505. It is only switched on during focusing and when a disc is playing. U502 receives its EFM input from U501 on EFMIN (pin 8). This signal is sliced, EFM

demodulated, and CIRC decoded. The digital audio output signal is sent serially to U506 on

the LRCLK, DFOUT and DACLK lines (U502, pins 33, 35, and 36).

U502 receives servo control commands from U505 on the serial bus (U502, pins 51, 53 and

54). These commands are translated to appropriate control signals for U501 for focusing, disc

start, disc stop, disc braking, and track jumps. The focus servo is controlled by the FOCS and

FST outputs. The CLV servo is controlled through the CLV+ and CLV- lines. The tracking

servo is controlled by the TOFF, TGL, and THLD outputs. Track jumps are created by signals

on the JP+ and JP- lines. Track jump detection is based on signals from U501 on the HFL and

TES inputs.

15

Page 17

THEORY OF OPERATION

U505’s oscillator is obtained from a 4MHz ceramic resonator (X502). U505 is reset by a rising

edge on pin 1 that is caused by R573 and C574. This occurs automatically on power-up, but

may be forced manually by depressing S502 (if installed). U505 communicates with U502 on a

serial bus (U502, pins 50 through 54). U505 sends servo commands for focusing and track

access to U502. U502 sends subcode Q data to U505 which extracts track, time and table of

contents information from it. The time and track data is formatted, and is sent to U402 on a

serial bus (U505, pins 11-13).

During track access, U505 controls the sled motor directly using the FEED+ and FEED- lines

(U505, pins 21 and 22). It also directly controls the laser U503 and VCO using the LASER~

line (U505, pin 9). When the laser is turned on, the VCO and U503 are enabled, otherwise

they are turned off. U505 can also enable and disable U504 with the MOTOR_EN line (U505,

pin 20).

U506 (D/A converter) performs 8x oversampling and digital filtering. It then converts the digital

audio into left and right stereo outputs. D/A reference voltages are obtained from zener diode

D504. U506’s analog outputs are buffered by one-half of U507 (pins 5-7 and 8-10). The

buffered signal is lowpass filtered by the other half of U507. This removes any residual out-ofband digital noise. The recovered audio is then routed to U101.

Tuner

The FM antenna signal is routed through F connector J301 and enters the FM front end module. This contains a tuned RF amplifier, FM local oscillator, and a mixer. The IF output signal

appears on pin 4 (front end) and passes through 10.7MHz ceramic filter CF302. The filter’s

output is amplified by the IF gain stage. This stage consists of Q307, Q308 and their associated components. The signal is then passed through a second ceramic filter, CF303, a second

gain stage (Q309, Q310, etc.) and a third ceramic filter, CF304.

CF304’s output signal is sent to the main tuner IC, U301. This device contains the FM detector, FM stereo MPX decoder, stop level detection, as well as most of the AM circuitry (see

below). U301 further amplifies the IF signal, and then performs FM detection. This detection

uses a double tuned quadrature detector formed by T304 and T305. T305 is adjusted for FM

center frequency by adjusting it for 0VDC between the AFC terminal (U301, pin 4) and the

Vreg terminal (U301, pin 28). T304 is adjusted for minimum distortion (A few iterations may be

required because these two adjustments are dependent on one another). The recovered audio

appears on U301, pin 8.

C313 and its associated components filter the recovered audio and feed it back into U301, pin

9. U301 performs the FM stereo MPX decoding. When you select FM, the decoded L/R chan-

nel signals are sent out on pins 14 and 15. The resistance between pin 12 and ground

controls the separation. 456kHz ceramic resonator CF301 controls the PLL decoder. The PLL

loop filter components are connected to pin 11. Potentiometer R334, which is connected to pin

30, sets the FM stop level to 33dBf (nominal).

C304, R304, C307, and R309 perform FM de-emphasis. Q301, Q302 and their associated

components buffer the signals. MPX filters T301 and T302 remove any unwanted out-of-band

signals before sending them to U101.

The AM loop antenna signal enters the unit through J301’s screw terminals. The signal is then

fed to AM front end module, T303. This device contains an RF tuned section and the AM local

16

Page 18

THEORY OF OPERATION

oscillator tuned circuit. The tuned output appears on pin 12 and is fed to AM buffer FET Q300.

The buffered output is sent to U301, pin 27. U301 contains the AM RF amplifier, mixer, IF

amplifier, AM detector and AM stop level detection. Potentiometer R339, which is connected to

pin 16, sets the AM stop level to 70dB uV/M (nominal). The IF output signal appears on pin 26

and is filtered by IF filter T307. The signal is then fed back into U301, pin 24 for AM detection.

The AM detected output (pin 5) is filtered by C315, R316, and C314. The filtered output is fed

back into U301, pin 6. Finally, it is sent to the L/R outputs (pins 14 and 15) when “AM” is

selected.

U302 controls the AM and FM local oscillators. U402 sets U302 so that it can select the AM or

FM band and can tune to a particular frequency. The PLL reference oscillator originates from

7.2MHz crystal X301. This frequency is divided down to 400KHz (U302, pin 7). U302 divides

down the local oscillator frequencies and compares them to an internal reference frequency.

The error signal resulting from this comparison appears at pin 18. This error signal is integrated and filtered by Q304, Q305, and their associated components. This produces the tuning

voltage which appears at Q304’s collector.

The tuning voltage is further filtered by R323, C326, R322, and C319. This signal is then sent

to AM front end module T303, pin 14. It is used to vary the capacitance of two varactor diodes.

This first diode varies the frequency of the AM local oscillator. The second tunes the AM RF

input section to the desired frequency. Similarly, the tuning voltage is filtered by R330 and

C333. Then it is fed to the FM front end module. The front end uses this voltage to vary the

local oscillator frequency and to tune the RF input sections.

17

Page 19

See Figure

6 for a side

view of this

assembly.

Figure 3. Labelled Exploded View

18

Page 20

DISASSEMBLY/ ASSEMBLY PROCEDURES

1. Left Cover Assembly Removal

Note: Refer to Figures 3 and 5 for Proce-

dures 1 and 2.

1.1 Remove the two screws (18A) that

secure the left cover (7) to the base (19).

1.2 Press in the three recessed gray tabs

located on the connector panel and lift up

on the rear of the cover.

2. Left Cover Assembly Replacement

2.1 Align the five hooks on the left cover (7)

with the five catches on the front of the

base (19).

2.2 Lower the left cover and snap it into

place. The cover should be flush with the

closed door assembly (1).

2.3 Replace the two screws (18A) that

secure the left cover to the base (19).

3. Door Assembly and Right Cover Removal

Note: Refer to Figures 3, 5 and 6 for

Procedures 3 and 4.

3.1 Remove the left cover assembly (Procedure 1).

front of the base assembly (19). Lower the

cover into position.

4.3 There are two black tabs on the bottom

of the right cover. Push them in slightly and

snap the cover into place.

4.4 Replace the two screws (18B) that

secure the right cover to the base.

4.5 Replace the left cover assembly (Procedure 2).

5. CD Mechanism Removal

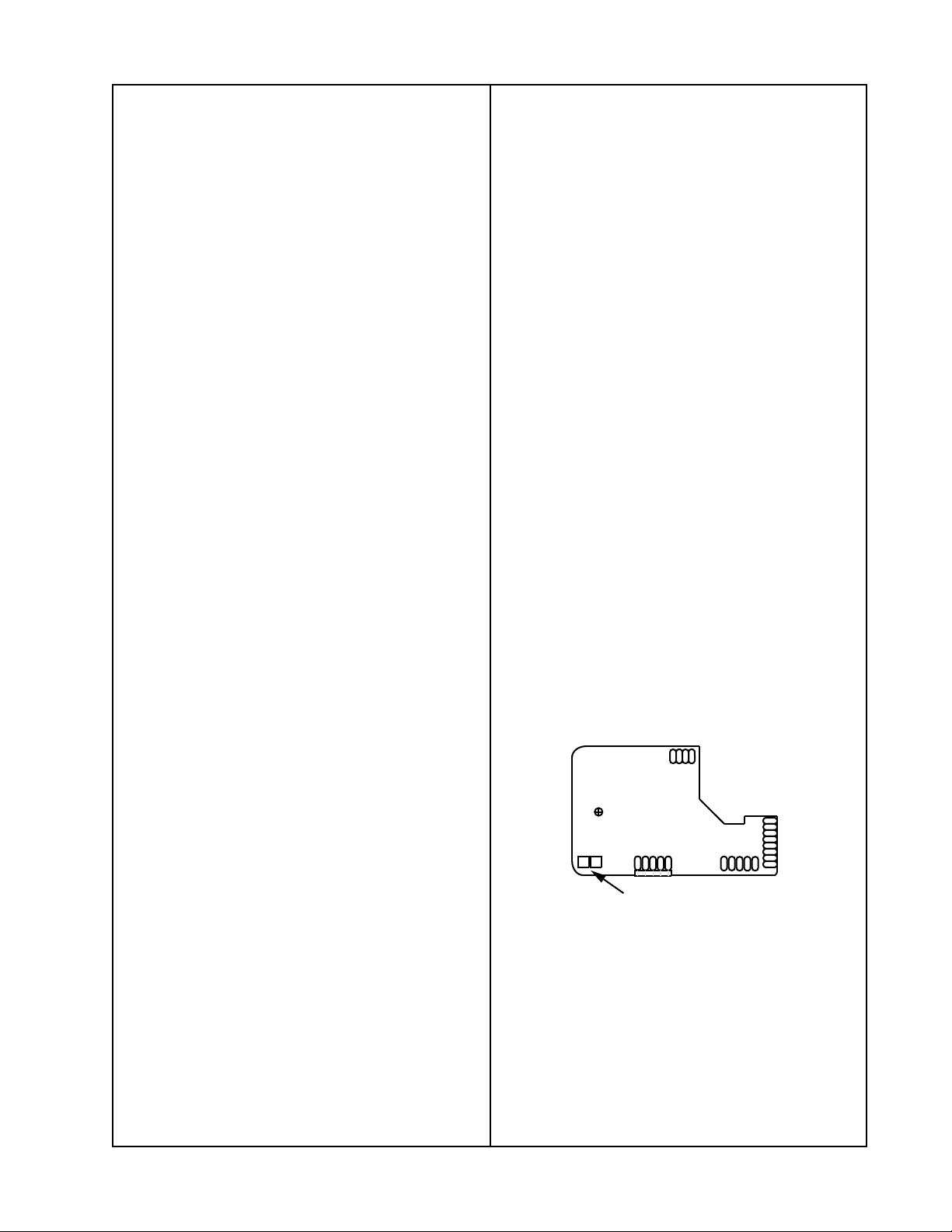

Note: Refer to Figures 3, 4 and 7 for

Procedures 5 and 6.

5.1 Remove the left cover assembly (Procedure 1) and the door/right cover assembly (Procedure 3).

5.2 Lift the CD mechanism (11) straight up

from the four metal posts in the base (19).

Later models have 4 nylon washers (23)

mounted on the posts. Do not remove

them.

5.3 To prevent electrostatic damage to the

mechanism, solder together the two points

indicated in Figure 4.

3.2 Remove the two screws (18B) that

secure the right cover (6) to the base (19).

3.3 Press in the two recessed black tabs

located on the connector panel. Lift up on

the rear of the door assembly (1) and right

cover assembly (6).

3.4 Remove the console latch (16).

4. Door Assembly and Right Cover Replacement

4.1 Position the console latch (16) in the

base (19).

4.2 Align the two hooks on the right cover

assembly (6) with the two catches on the

Shorting point

Figure 4. APC PCB

5.4 Disconnect the 6 pin connector from the

PCB that is attached to the motors and the

5 pin and 8 pin connectors from the APC

PCB.

Note: The support grommets (14, 15) and

CD cover (12) are not supplied as part of

the mechanism. Remove and reuse them if

complete replacement of the mechanism is

required.

19

Page 21

DISASSEMBLY/ ASSEMBLY PROCEDURES

5.5 Slide the violet (14) and gray (15)

grommets away from the slots in each

corner of the mechanism.

5.6 Remove the two screws (13) that

secure the cover (12) to the mechanism.

Unsnap the cover from the mechanism.

6. CD Mechanism Replacement

6.1 Snap the cover (12) into position. Align

the screw holes and replace the two screws

(13) that secure the cover to the mechanism (11).

6.2 Slide the violet (14) and gray (15)

grommets into their respective slots on

each corner of the mechanism. See Figure

3 for their proper locations.

6.3 Connect the 6 pin connector to the PCB

that is connected to the motors and the 5

pin (with black cable) and 8 pin

connectors to the APC PCB.

6.4 Remove the solder from the shorted

points shown in Figure 4.

Note: Make sure that four nylon washers

(23) are mounted on the posts before

installing the mechanism (later models

only).

Note: The CD mechanism wires must be

routed correctly (see Figure 7) for proper

CD operation. A sign of improper routing is

a clicking noise when playing tracks at the

outermost edge of the CD. Perform the CD

Final Verification tests on page 31 to

ensure proper operation.

6.5 Place the mechanism on the four metal

posts located in the base (19). Position as

shown in Figure 3.

6.6 Replace the door/right cover assembly

(Procedure 4) and left cover assembly

(Procedure 2).

7. Digital PCB Removal

Note: Refer to Figures 3 and 7 for Proce-

dures 7 and 8.

7.1 Remove the left cover assembly (Procedure 1) and the right cover/door assembly (Procedure 3).

7.2 Lift up the CD mechanism (11) and

move it aside. Keep the mechanism connected to the PCB unless removal is

required. See Procedure 5 for removal

procedure.

7.3 There are four black plastic tabs that

hold the PCB (10) in position. See Figure 3.

Flex them carefully outward and pull the

PCB up and out.

7.4 Remove any connections required to

troubleshoot the PCB.

8. Digital PCB Replacement

8.1 Replace any connections that were

disconnected during troubleshooting.

8.2 Slide the PCB (10) into position. There

are notches in the PCB which mate with

notches in the base (19). See Figure 7.

8.3 Snap the PCB carefully down under the

four locking tabs.

8.4 Push the CD mechanism (11) down

onto the four metal posts.

8.5 Replace the right cover/door assembly

(Procedure 4) and the left cover assembly

(Procedure 2).

9. Audio PCB Removal

Note: Refer to Figures 3 and 7 for Proce-

dures 9 and 10.

9.1 Remove the left cover assembly (Procedure 1), the door/right cover assembly

(Procedure 3), and the Digital PCB (Procedure 7).

9.2 There are four locking tabs (three on

the PCB edges and one in the middle of the

PCB) that secure the PCB (10) to the base

(19). Flex the tabs carefully away from the

PCB and disengage the PCB.

20

Page 22

DISASSEMBLY/ASSEMBLY PROCEDURES

9.3 Slide the PCB clear of the connector

panel, and pull it away from the base.

9.4 Remove any connections required to

troubleshoot the PCB.

10. Audio PCB Replacement

Note: Make sure that the connections to

the Headphone Jack PCB (10) are routed

through the guiding notch on the side of the

console (see Figure 7).

10.1 Restore any connections that were

disconnected during troubleshooting.

10.2 Slide the PCB's connectors through

the holes in the rear of the base (19).

10.3 Snap the PCB (10) carefully down

under the four locking tabs. Make sure that

the CD mechanism connections are routed

properly. See Figure 7 and procedure 6

note.

12. Headphone Jack PCB Replacement

12.1 Snap the PCB (10) into place by

engaging the two locking tabs.

Note: Make sure that the connector wires

are routed through the guiding notch on the

side of the base (19).

12.2 Replace the door/right cover assembly

(Procedure 4) and the left cover assembly

(Procedure 2).

10.4 Replace the Digital PCB (Procedure

8), the door/right cover assembly (Procedure 4), and the left cover assembly (Procedure 2).

11. Headphone Jack PCB Removal

Note: Refer to Figures 3 and 7 for Proce-

dures 11 and 12.

11.1 Remove the left cover assembly

(Procedure 1) and door/right cover assembly (Procedure 3).

11.2 There are two black plastic snaps that

secure the PCB (10). Flex the snaps

outward and carefully pull the PCB away

from the unit.

21

Page 23

Hooks onto front

of console.

Figure 5. Back Panel with Tab Locations

Tab that fits into cutouts

on back panel

Figure 6. Right Cover Assembly (side view)

Figure 7. Base Assembly (top view with covers removed)

22

Page 24

RC5 DISASSEMBLY/ASSEMBLY PROCEDURES

1. Enclosure Disassembly

1.1 Slide off the battery compartment door

(5) and remove the batteries.

1.2 While holding the top cover (4) with one

hand, place your fingers from your other

hand in the battery compartment and grasp

the lower part of the bottom cover (3) with

your fingers.

1.3 With your finger tips in the battery

compartment, first pull parallel to the unit

and then pull perpendicular.

1.4 With the catches released at the bottom,

work your fingers up the sides to release

the rest of the catches.

2. Enclosure Assembly

2.1 Lower the bottom cover (3) onto the top

cover (4) so that the bottom cover's lip fits

over the top cover.

2.2 Press the top cover and the bottom

cover together until they snap into place.

3. PCB Removal

3.1 Lift the PCB (1) straight up. The springs

will come up with the PCB.

4. PCB Replacement

4.1 Lower the PCB (1) into the top cover (4)

so that the springs are in the battery compartment.

5. Pad Removal

5.1 The pad (2) is not secured. Grasp a

corner of the pad and lift it out.

6. Pad Replacement

6.1 Lower the pad (2) into the top cover (4)

so that the buttons line up with the holes in

the top cover.

5

6

7

9

8

4

3

10

1

2

Figure 8. Remote Control Assembly Exploded View

23

Page 25

TEST PROCEDURES

GENERAL TEST SETUP

Load the outputs as follows:

Headphone output-33Ω, 1% load.

Audio (A, B, Fixed) outputs-10kΩ load.

Note: The remote control or console

buttons can be used to select sources in

these procedures.

1. AUX Gain Test

1.1 Select AUX.

1.2 Apply a 500mVrms, 1kHz signal to the

left (right) AUX input. Adjust the volume to

maximum. Reference a dB meter to the

applied signal.

1.3 Ground the TAPE, VIDEO and the right

AUX inputs.

1.4 Measure the outputs according to the

following table.

2.4 Measure the outputs according to the

following table.

Output Separation (dB)

Speaker A (L,R) ≥50

Speaker B (L,R) ≥50

Tape (L,R) ≥50

Fixed (L,R) ≥50

Headphone (L,R) ≥50

2.5 Repeat this test for the right channel.

Note: This test is the same for the VIDEO

input. Apply a 500mVrms, 1kHz signal to

the left (right) VIDEO input and repeat this

test.

3. TAPE Gain Test

3.1 Select TAPE.

3.2 Apply a 500mVrms, 1kHz signal to the

left (right) TAPE input. Adjust the volume to

maximum. Reference a dB meter to the

applied signal.

Output Min

(dB)

Speaker A (L,R) 4.2 5.4

Speaker B (L,R) 4.2 5.4

Tape (L,R) 3.3 4.5

Fixed (L,R) 4.2 5.4

Headphone (L,R) 5.4 7.4

1.5 Repeat this test for the right channel.

Note: This test is the same for the VIDEO

input. Apply a 500mVrms, 1kHz signal to

the left (right) VIDEO input and repeat this

test.

2. AUX Separation Test

2.1 Select AUX.

2.2 Apply a 500mVrms, 1kHz signal to the

left (right) AUX input. Adjust the volume to

maximum. Reference a dB meter to the

applied signal.

Max

(dB)

3.3 Ground the AUX, VIDEO and the right

TAPE inputs.

3.4 Measure the FIXED level output. It

should be 8.9 to 9.9dB.

3.5 Repeat this test for the right channel.

4. Volume Control Mute

4.1 Select the AUX input.

4.2 Apply a 500mVrms, 1kHz signal to the

left (right) AUX input.

4.3 Set the volume to minimum at the

speaker A output.

4.4 Measure the gain at the A output

(relative to maximum volume). It should be

≥ -75dB.

2.3 Ground the TAPE, VIDEO, and right

AUX inputs.

24

Page 26

TEST PROCEDURES

5. Headphone Mute

5.1 Select the AUX input.

5.2 Apply a 500mVrms, 1kHz signal to the

L/R AUX input.

5.3 Insert a mini-jack into the headphone

output. The A output should mute.

FM ALIGNMENT TESTS AND

ADJUSTMENTS

Unless otherwise noted, set an RF generator to 98.1MHz, 40dBf, 1kHz, mono modulation, pilot off, 100% (75kHz deviation).

1. Front End Mixer Coil Adjustment

1.1 Adjust the FM front end (TUNER) mixer

coil until a maximum DC voltage is measured at U301 pin 25. Adjust the coil until

the voltage comes within +0, -20mV of the

peak voltage.

3.3 Adjust the generator's output to 35dBf.

Verify that U301 pin 21 is < 2.5Vdc.

4. Stereo Separation

4.1 Set the RF generator to 65 dBf, pilot on,

left modulation, 1kHz, 100% (75kHz deviation).

4.2 Reference a dB meter to left FIXED

output.

4.3 Measure the right FIXED output. It

should be ≤ -25dB.

Note: If the unit fails this test, perform the

following procedure.

1. Change R354 to a 560Ω, 5%, 1/10.

2. Remove W302.

3. Add R355 (a 1kΩ, 10%, 1/2 W potentiometer). Adjust R355 for maximum separation. This option is listed on note 9 of the

schematic.

5. FM Sensitivity

2. FM Detector Zero Adjust and Distortion

Adjustment

2.1 Set the RF generator to 65dBf.

2.2 Adjust T305 until the voltage reads

0Vdc ± 110mVdc across C317+ (AFC test

point) and C322+ (VREG test point).

2.3 Adjust T304 for minimum distortion. The

distortion should be < 0.4%.

2.4 Repeat this procedure until optimal

results are obtained.

3. FM Stop Level Adjustment

3.1 Set the RF generator to 31dBf.

3.2 Rotate R334 counterclockwise until the

voltage at U301 pin 21 drops below 2.5Vdc.

Then rotate R334 clockwise until the

voltage goes above 2.5Vdc.

Note: The correct adjustment is at the point

just after the voltage switches high.

5.1 Set the RF generator to 42dBf, L= -R

modulation, pilot on.

5.2 Reference a dB meter to the left FIXED

output.

5.3 Measure the noise (with modulation off

and pilot on) at the right FIXED output. The

SNR should be > 50dB for the 120V version and > 45dB for the 220V version.

Note: If the unit fails this test, the FM front

end should be replaced.

25

Page 27

TEST PROCEDURES

AM ALIGNMENT PROCEDURES

Test setup: Connect the generator to a

standard radiating loop. Unless otherwise

noted, set an RF generator to 70dBu field

strength, 400Hz, 30% modulation.

See Figure 9.

STANDARD

SIGNAL

GENERATOR

TEST

LOOP

STANDARD

SIGNAL

GENERATOR

Figure 9. AM Test Setup

The equivalent field intensity is 26dB less

than the generator output level or 1/20

the output voltage.

(PLAN VIEW)

60cm

(SIDE VIEW)

th

of

1.2 Reference a dB meter to the Fixed level

output.

1.3 Shut off the modulation and measure

the noise. The SNR should be > 30dB.

2. AM Stop Level Adjustment

2.1 Set the RF generator so that the field

strength at the unit's antenna is 59dBµ

(59dBµ V/M).

2.2 Rotate R339 counterclockwise until the

voltage measured at U301 pin 21 goes

below 2.5Vdc. Then, rotate R339 clockwise

until the voltage goes above 2.5Vdc.

Note: The correct adjustment is at the point

just after the voltage switches high.

2.3 Adjust the field strength to 64 dBµ

(64 dBµ V/M). Verify that the voltage at

U301 pin 21 is < 2.5Vdc.

1. AM Sensitivity Alignment

1.1 Set the RF generator so that the field

strength at the unit's antenna is 70dBµ

(70dBµ V/M).

Figure 10. Audio PCB Test Section

26

Page 28

CD TEST PROCEDURES

CD ALIGNMENT PROCEDURES

(WITH FIXTURE)

Note: Some of these procedures require

the use of a CD alignment fixture (P/N

176318). Alternate procedures that do not

require a fixture begin on page 30. Refer to

Figure 11, CD Alignment Fixture Test

Setup. The fixture is required unless otherwise specified. Refer to Figure 13 for

adjustment locations.

Test Equipment Needed

Digital Voltmeter

Frequency Counter

Sony Disc YEDS-18

®

CD Alignment Fixture (176318)

Bose

1. PLL Free Run Frequency (VCO)

Note: This test does not require a test disk

or the alignment fixture.

button until TO lights up). The meter should

read approximately 90mVdc.

2.4 Simulate a closed CD door by placing

an object between S501's two black posts

(the CD door latch can be used). Select CD

(S413).

2.5 After the focusing operation is completed, press ERASE (S403). The meter

should change from its previous reading in

step 2.3 (it will drop). If not, remove power

and repeat the test.

2.6 Adjust R511 until the meter reads

between -7 to 17mVdc.

3. E/F Balance (E/F)

3.1 Advance the alignment fixture (ADV

button) to the E/F setting and set the

voltmeter to read DC voltage.

1.1 Connect the frequency counter to PCK

and ground.

1.2 Simulate a closed CD door by placing

an object between S501's two black posts

(the CD door latch can be used). Select CD

(S413).

1.3 Adjust R558 until the frequency counter

reads 4.320MHz ± 20kHz. (If the adjustment is not done within 4 seconds, then CD

must be selected again).

2. Tracking Offset (TO)

Note: Remove any previously loaded test

disc. This test will not work with a disc

loaded.

2.1 Connect the cable from the test fixture

to connector P504 on the unit.

2.2 Connect a DC voltmeter to the positive

(+) and negative (-) terminals on the test

fixture.

3.2 Simulate a closed CD door by placing

an object between S501's two black posts

(the CD door latch can be used). Load the

YEDS-18 test disc, select CD (S413), and

play track 2.

3.3 Press STORE (S411). This puts the unit

in the E/F balance mode. The time display

will stop.

3.4 Adjust R506 until the meter reads

between - 10 to + 50mVdc.

4. Tracking Gain (TG)

4.1 Shut the unit off.

4.2 Advance the fixture to the TG setting

and set the voltmeter to read AC voltage.

4.3 Simulate a closed CD door by placing

an object between S501's two black posts

(the CD door latch can be used). Load the

YEDS-18 test disc, select CD (S413), and

play track 2.

2.3 Select TO on the fixture (press the ADV

4.4 Adjust R510 until the meter reads

between 440 to 500mVrms.

27

Page 29

CD TEST PROCEDURES

5. Focus Gain (FG)

5.1 Advance the fixture to FG and set the

voltmeter to read AC voltage.

5.2 Simulate a closed CD door by placing

an object between S501's two black posts

(the CD door latch can be used). Load the

test disc, select CD (S413), and play track

2.

5.3 Adjust R527 until the meter reads

between 380 to 420mVrms.

6. Tracking Offset Readjustment

6.1 Refer to procedure 2 and readjust if

necessary.

Front Panel

ADV.

This RJ-45

connection only fits

one way. The other

end plugs directly into

P504 on the Digital PCB.

TO E/F

Back Panel

To

DVM

+-

P504

TG FG

Power

To

12 VAC

CD5

2' cable connects to

“12 VAC ~ IN" on CD5

back panel. Both ends

of the cable are terminated

exactly the same way as

the power pack.

IN

Pack

Figure 11. CD Alignment Fixture and Test Setup

28

Page 30

Figure 12. Passive Filter Network and Test Setup

29

Page 31

CD TEST PROCEDURES

CD ALIGNMENT PROCEDURES

(Without Fixture)

Note: Refer to Figure 12 throughout this

procedure.

Test Equipment Needed

Voltmeter (input impedance > 10MΩ)

Frequency Counter

Sony Disc YEDS-18

Audio Oscillator

1. PLL Free Run Frequency (VCO)

1.1 Connect the frequency counter to PCK

and ground.

1.2 Simulate a closed CD door by placing

an object between S501's two black posts

(the CD door latch can be used). Select CD

(S413).

3. E/F Balance

Note: The test disc is required for this test.

Construct the filter indicated in Figure 12

and connect it to P504 pin 4 (TEAO).

3.1 Connect a DC voltmeter between the

filter output and P504 pin 1 (Vref3).

3.2 Load the test disc, select CD (S413),

and play track 2. Skip forward using S408.

3.3 Press STORE (S411). This puts the

unit in the E/F balance mode. The time

display will stop.

3.4 Adjust R506 until the meter reads

between - 10 to + 50mVdc.

4. Tracking Gain

Note: Shut the unit off. Construct the filter

indicated in Figure 12 and connect it (FLT

IN) to P504 pin 6 (TPA+).

1.3 Adjust R558 until the frequency counter

reads 4.320MHz ± 20kHz. (If the adjustment is not done within four seconds, then

CD must be selected again).

2. Tracking Offset

Note: Remove any previously loaded test

discs. This test will not work with a disc

loaded.

2.1 Connect a DC voltmeter between P504

pins 2 (TDO) and 1 (Vref3). The meter

should read approximately 90mVdc.

2.2 Simulate a closed CD door by placing

an object between S501's two black posts

(the CD door latch can be used). Select CD

(S413).

2.3 After the focusing operation is completed, press ERASE (S403). The meter

should change from its previous reading in

step 2.1 (it will drop). If not, remove power

and repeat the test.

4.1 Connect an AC voltmeter between the

filter output (FLT OUT) and P504 pin 1

(Vref3).

4.2 Connect a 100kΩ resistor to P504 pin 7

(TPA-). Connect an oscillator to the

resistor's other end and apply a .5Vrms,

1.7kHz signal to it.

4.3 Insert the test disc and select CD

(S413) and play track 2.

4.4 Adjust R510 until the meter reads

between 26.3 ± 1.5mVrms.

5. Focus Gain

Note: Construct the filter indicated in

Figure 12 and connect it (FLT IN) to P504

pin 5 (FEAO).

5.1 Connect an AC voltmeter between the

filter output (FLT OUT) and P504 pin 1

(Vref3).

2.4 Adjust R511 until the meter reads

between -7 to +17mVdc.

5.2 Connect a 300kΩ resistor to P504 pin 8

(FSW). Connect an oscillator to the

resistor's other end and apply a .5Vrms,

1.7kHz signal to it.

30

Page 32

CD TEST PROCEDURES

5.3 Skip back to the beginning of track 2.

5.4 Adjust R527 until the meter reads

between 23.2 ± 1.5mVrms.

6. Tracking Offset Readjustment

6.1 Refer to procedure 2 and readjust if

necessary.

Final CD Verification Tests

Note: Audible defects are defined as CD

dropouts or skipping during play. All units

must be able to pass these tests without

any audible defects.

1. Warp

1.1 Insert Abex test disc TCD-732RA (or

equivalent). Play track 16 (.7 mm).

3.4 Fingerprint: Play track 15 (75µm).

Listen for at least 10 seconds.

1.2 Pause the CD and confirm that there

are no mechanical scraping sounds.

1.3 Access track 16 again and confirm that

it plays properly.

2. Eccentricity

2.1 Insert Abex test disc TCD-714R

(equivalent test disc must be eccentric by

210µm).

2.2 Play track 1 (210µm). Listen for at least

4 seconds.

2.3 Access track 15 ( or furthest track on

equivalent disc) and confirm that the unit

plays properly.

3. Optical Defects

3.1 Insert Abex test disc TCD-725 (or

equivalent).

3.2 Void: Play track 6 (1mm). Listen for at

least 6 seconds.

3.3 Black dot: Play track 9 (.8mm). Listen

for at least 8 seconds.

31

Page 33

Figure 13. Digital PCB Adjustment Locations

32

Page 34

PARTS LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Parts List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This PCB is part of a pallet. The pallet contains the Display PCB, Audio PCB, and Headphone PCB. This PCB assembly is manufactured and sold as a pallet.

33

Page 35

CONSOLE ASSEMBLY PARTS LIST

(Figure 14)

Item

Number

1 Door Assembly 187743-001

2 Spring-Torsion, LH 176083

3 Spring-Torsion, RH 176082

4 Pin-Hinge, 5.3" 173210

5 Gear-Damper, Blue 146816-05

6 Cover Assembly, Right 149956

7 Cover Assembly, Left 190819

8 Nameplate, Flat Black 180213

9 Spring, Ground 173449

10 PCB Assembly, 120V

PCB Assembly, 220V

PCB Assembly, 120V/220V

11 CD Mechanism, CD90V1, W/APC 146074

12 Cover, CD Mechanism 148787

13 Screw-Tapp, 2 x 6 mm, PAN, XREC 149954-04

14 Grommet, CD Support, Violet 146822-02

15 Grommet, CD Support, Gray 146822-01

16 Latch, Console 146081

17 Spacer, Foam, Rectangular, .25 172332-04

18 Screw-Tapp, 6-20 x .375, PAN, XRC/S 172779-06

19 Base Assembly 149955-01

20 Cable, 5 conductor, 8" 172599

21 Cable, 8 conductor, 8" 172673

22 Pad, Foam, Adhesive Backed 174231

Description Part Number Note

146075-101A

146075-201A

146075-601A

1, 2, 4

34

Page 36

Figure 14. Exploded View

35

Page 37

REMOTE CONTROL ASSEMBLY PARTS LIST

(Figure 15)

Item

Number

1 PCB ASSY RMT CNTRL, RC-5A 194387 1, 2

2 MAT, SWITCH, CD-5 146088

3 COVER, BOTTOM, CD-5 146089

4 COVER, TOP, CD-5 146090

5 DOOR, BATTERY, CD-5 146226

6 CONTACT, BATTERY, CONE 174001

7 CONTACT, BATTERY, FLAT 174000

8 CONTACT, BATTERY, CONE/FLAT 174002-01

9 CONTACT, BATTERY, FLAT/CONE 174002-02

10 SPACER, PAD, FOAM 173605

Description Part Number Note

5

3

10

1

6

2

7

9

8

4

Figure 15. RC5 Exploded View

36

Page 38

ELECTRICAL PART LIST

Resistors

Reference

Description Part Number Reference

Designator

R1, 4, 113, 213,

330, 333, 336, 342,

1kΩ, 5%, 1/10W,

0805

348, 353, 145, 406,

420-423, 426, 427,

431, 433-442, 502,

503, 553, 572, 598,

600

R2, 315

5.11kΩ, 1%, 1/10

0805

R3, 109, 111, 209,

211

4.75kΩ, 1%, 1/10

0805

R5 2.7Ω, 5%, 1/2W,

52mm, CF

R6 10Ω, 5%, 1W,

Metallic Oxide

R7 1.5kΩ, 5%, 1/4W,

52mm, CF

R8 1.5Ω, 5%, 1W,

Metallic oxide

R9 220Ω, 5%, 1/4W,

52mm, CF

R10 75Ω, 5%, 1/4W,

52mm, CF

R12 27Ω, 5%, 1/10W,

0805

R101, 102, 201, 202

9.76kΩ, 1%, 1/10

0805

R103, 203, 588, 592 1kΩ, 1%, 1/10W,

0805

R104, 105, 204, 205

15.4kΩ, 1%, 1/10

0805

R106, 107, 110,

114, 139, 206, 207,

100kΩ, 5%, 1/10W,

0805

210, 214, 407, 415,

424, 425, 545, 566,

568, 575, 577, 589,

593, 595

R108, 208

12.4kΩ, 1%, 1/10

0805

R112, 212

22.1kΩ, 1%, 1/10

0805

R115, 215

825Ω, 1%, 1/10

W

0805

R116, 117, 119,

120, 123-125, 127,

4.7kΩ, 5%, 1/10W,

0805

130-133, 216, 217,

219, 220, 223-225,

227, 230-233, 318,

331, 337, 323, 327,

335, 356, 357, 410,

414, 509, 524, 560,

580, 603

R118, 218

619Ω, 1%, 1/10

W

0805

W

W

W

W

W

W

,

,

133626-1025

,

,

133625-5111

133625-4751

121243-1512R75

173314-1005

121243-1211525

171259-1R55

121243-1212215

121243-1217505

133626-2705

,

133625-9761

133625-1001

,

133625-1542

133626-1045

,

,

133625-1242

133625-2212

133625-8250

133626-4725

133625-6190

US/Can.

37

Page 39

ELECTRICAL PART LIST

Resistors (Continued)

Reference

Designator

R121, 128, 221, 228 432Ω, 1%, 1/10W,

R122, 129, 222, 229 182Ω, 1%, 1/10W,

R126, 226 150Ω, 1%, 1/10W,

R134-136, 142, 599,

601

R138, 304, 309,

325, 338, 341, 358

R140, 303, 308, 552 330kΩ, 5%, 1/10W,

R141, 522, 557, 578 33kΩ, 5%, 1/10W,

R143 30kΩ, 5%, 1/10W,

R144, 569 1.8kΩ, 5%, 1/10W,

R145 3.3kΩ, 5%, 1/10W,

R145, 302, 307,

504, 565

R300, 525, 540 1.2kΩ, 5%, 1/10W,

R301 220Ω, 5%, 1/10W,

R305, 310, 313, 507 2.7kΩ, 5%, 1/10W,

R306, 311, 516 5.6kΩ, 5%, 1/10W,

R314, W302, W401 Jumper, Chip, 0805 133627

R316 12kΩ, 5%, 1/10W,

R317 8.2kΩ, 5%, 1/10W,

R319 22Ω, 5%, 1/10W,

R320

R322, 345, 350,

530-533, 548-551,

555

R324 43Ω, 5%, 1/4W,

R326 100Ω, 5%, 1/10W,

R328 1.6kΩ, 5%, 1/10W,

R329 620Ω, 5%, 1/10W,

R332, 535 6.8kΩ, 5%, 1/10W,

R334 Potentiometer, 10kΩ,

Description Part Number Note

133625-4320

0805

133625-1820

0805

133625-1500

0805

1MΩ, 5%, 1/10W,

0805

10kΩ, 5%, 1/10W,

0805

0805

0805

0805

0805

0805

2.2kΩ, 5%, 1/10W,

0805

0805

0805

0805

0805

0805

0805

0805

9.10kΩ, 5%, 1/10

0805

22kΩ, 5%, 1/10W,

0805

52mm, CF

0805

0805

0805

0805

10%, 1/2W

W,

133626-1055

133626-1035

133626-3345

133626-3335

133626-3035

133626-1825

133626-3325

133626-2225

133626-1225

133626-2215

133626-2725

133626-5625

133626-1235

133626-8225

133626-2205

133626-9125

133626-2235

121243-1214305

133626-1015

133626-1625

133626-6215

133626-6825

170042-103

Military (120/230V)

Eur./UK/Sing./Aus.

38

Page 40

ELECTRICAL PART LIST

Resistors (Continued)

Reference

Designator

R339, 558 Potentiometer, 20kΩ,

R340 120Ω, 5%, 1/10W,

R343, 501 10Ω, 5%, 1/10W,

R344, 346, 349,

351, 429, 430, 561,

582

R347, 352 18kΩ, 5%, 1/10W,

R354

R354 1.5kΩ, 5%, 1/10W,

R401-405, 411, 413,

416-419, 432, 505,

521, 526, 554, 562,

576, 594

R408, 538 120kΩ, 5%, 1/10W,

R409, 514, 517 390kΩ, 5%, 1/10W,

R412, 543, 544,

546, 547

R428, 556, 563,

581, 583-585, 596,

597

R506, 527 Potentiometer, Trim,

R508, 542 220kΩ, 5%, 1/10W,

R510 Potentiometer, Trim,

R511 Potentiometer, Trim,

R512, 528, 574 4.7MΩ, 5%, 1/10W,

R513

R515, 559 3.9kΩ, 5%, 1/10W,

R518

R519 62kΩ, 5%, 1/10W,

R520

R523, 539, 571 56kΩ, 5%, 1/10W,

R534 3.3kΩ, 5%, 1/10W,

R536

Description Part Number Note

10%, 1/2W

0805

0805

330Ω, 5%, 1/10W,

0805

0805

1.05kΩ, 5%, 1/10

0805

0805

10kΩ, 5%, 1/10W,

0805

0805

0805

27kΩ, 5%, 1/10W,

0805

470Ω, 5%, 1/10W,

0805

5kΩ, 10%, 1/2W

0805

2kΩ, 10%, 1/2W

100kΩ, 10%, 1/2W

0805

15kΩ, 5%, 1/10

0805

0805

150kΩ, 5%, 1/10

0805

0805

1.5MΩ, 5%, 1/10

0805

0805

0805

82kΩ, 5%, 1/10

0805

W,

W,

W,

W,

W,

170042-203

133626-1215

133626-1005

133626-3315

133626-1835

133625-1051

133626-1525

133626-1035

133626-1245

133626-3945

133626-2735

133626-4715

170042-502

133626-2245

170042-202

170042-104

133626-4755

133626-1535

133626-3925

133626-1545

133626-6235

133626-1555

133626-5635

133626-3325

133626-8235

US/Can./Mil.

Eur./UK/Sing./Aus.

39

Page 41

ELECTRICAL PART LIST

Resistors (Continued)

Reference

Designator

R537 160kΩ, 5%, 1/10W,

R541

R567

R570

R573, 579 270kΩ, 5%, 1/10W,

R586, 587, 590, 591

R602 3.9MΩ, 5%, 1/10W,

R604 56Ω, 5%, 1/2W, CF 121243-1515605

Description Part Number Note

133626-1645

0805

91kΩ, 5%, 1/10

0805

200kΩ, 5%, 1/10

0805

68kΩ, 5%, 1/10

0805

0805

2.21kΩ, 1%, 1/10

0805

0805

W,

W,

W,

W,

133626-9135

133626-2045

133626-6835

133626-2745

133625-2211

133626-3955

Capacitors

Reference

Designator

C 1 .01µF, 20%, 100V,

C2, C13 2200µF, 20%, 25V,

C3, 4, 7, 8, 10, 12,

20, 114, 214, 310,

345

C5, 100, 107, 112,

207, 212, 313, 336

412, 413, 523

C 6 470µF, 20%, 25V,

C9, 11 1000µF, 20%, 16V,

C14, 17, 18, 116,

216, 330

C15, 16 100µF, 20%, 50V,

C19 33µF, 20%, 25V,

C101, 102, 201,

202, 354, 533

C103, 104, 117-

120, 203, 204, 217220, 337, 349, 401,

411, 502, 539

C105, 109, 111,

129, 205, 209, 211,

308, 311, 333, 414

C106, 206 47pF, 5%, 50V,

C108, 208, 328 2.2µF, 20%, 50V,

Description Part Number Note

146821-103

Z5U, Disc

149948-222E

85, EL

10µF, 20%, 50V, 85,

EL

100pF, 5%, 50V,

COG, 0805

85, EL

85, EL

100µF, 20%, 25V,