Bosch XFE 01.1-FB-01, XFE 01.1-FB-20, XFE 01.1-FB-03, XFE 01.1-FB-10 Operating Instructions Manual

IndraControl

XFE 01.1

Extension Modules Profibus, RT-Ethernet, Sercos, CAN

Operating Instructions

R911345570

Edition 04

Bosch Rexroth AG Extension Modules Profibus, RT-

Ethernet, Sercos, CAN

Change Record

Edition Release

Notes

Date

Edition 01 2014-10 First edition

Edition 02 2016-08 CAN modules and Sercos modules supplemented

Edition 03 2016-10 Corrections

Edition 04 2017-02 Explosion protection notes and type plate supplemented

Copyright

© Bosch Rexroth AG 2017

This document, as well as the data, specifications and other information set

forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.

Liability

The specified data is intended for product description purposes only and shall

not be deemed to be a guaranteed characteristic unless expressly stipulated in

the contract. All rights are reserved with respect to the content of this documentation and the availability of the product.

Editorial Department

Development Automation Systems Control Platform BoSc (MaKo/MePe)

RS-5a81c5d9d4f9f2ee0a6846a5006d8d2a-4-en-US-3

Extension Modules Profibus, RTEthernet, Sercos, CAN

Bosch Rexroth AG

Table of Contents

Table of Contents

Page

1 About this documentation..................................................................... 1

1.1 Overview on target groups and product phases.................................... 1

1.2 Scope..................................................................................................... 1

1.3 Related documents................................................................................ 2

1.4 Customer feedback................................................................................ 2

2 Product identification and scope of delivery......................................... 3

2.1 Product identification and type plate.................................................... 3

2.2 Scope of delivery................................................................................... 3

3 Use of the safety instructions................................................................ 4

3.1 Structure of the safety instructions....................................................... 4

3.2 Explaining signal words and safety alert symbol................................... 4

3.3 Symbols used......................................................................................... 5

3.4 Signal graphic explanation on the device.............................................. 5

4 Intended use.......................................................................................... 5

5 Spare parts, accessories and wear parts.............................................. 6

5.1 Connector 24 V...................................................................................... 6

5.2 Connector set for the CAN module........................................................ 6

5.3 Bus base module .................................................................................. 6

5.4 End clamp.............................................................................................. 6

5.5 Wear parts............................................................................................. 6

6 Ambient conditions................................................................................ 7

7 Technical data........................................................................................ 8

7.1 Voltage supply and current consumption.............................................. 8

8 Standards.............................................................................................. 9

8.1 Standards used...................................................................................... 9

8.2 CE marking........................................................................................... 10

8.2.1 Declaration of conformity.................................................................... 10

8.3 UL/CSA certified.................................................................................. 10

8.4 Explosion protection certification (XFE01.1-FB-03, XFE01.1-FB-20)... 11

8.4.1 Power matrix........................................................................................ 13

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

I

Bosch Rexroth AG

Table of Contents

Extension Modules Profibus, RT-

Ethernet, Sercos, CAN

Page

8.4.2 Standards used.................................................................................... 13

8.5 Marine and offshore certification (XFE01.1-FB-03, XFE01.1-FB-20).... 13

9 Interfaces............................................................................................. 14

10 Mounting, demounting and electric installationI................................. 16

10.1 Housing dimensions............................................................................. 16

10.2 Installation notes................................................................................. 16

10.3 Mounting.............................................................................................. 19

10.4 Demounting......................................................................................... 20

10.5 Electric installation.............................................................................. 21

10.5.1 External power supply unit ................................................................. 21

10.5.2 Voltage supply for the control and for the extension modules............ 23

10.5.3 24 V voltage supply.............................................................................. 24

11 Commissioning.................................................................................... 24

12 Device description............................................................................... 24

12.1 LEDs..................................................................................................... 25

12.1.1 LEDs on extension modules................................................................. 25

12.1.2 LED on XD1 plug.................................................................................. 26

13 Error causes and troubleshooting........................................................ 26

13.1 Error cases after commissioning the CAN module............................... 27

14 Maintenance........................................................................................ 28

14.1 General information............................................................................. 28

14.2 Regular maintenance tasks.................................................................. 28

15 Ordering information........................................................................... 29

15.1 Type code............................................................................................. 29

15.2 Accessories and spare parts................................................................ 30

16 Disposal............................................................................................... 30

16.1 General information............................................................................. 30

16.2 Return.................................................................................................. 30

16.3 Packaging............................................................................................. 30

17 Service and support............................................................................ 30

II

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

Extension Modules Profibus, RTEthernet, Sercos, CAN

Index.................................................................................................... 33

Bosch Rexroth AG

Table of Contents

Page

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

III

Bosch Rexroth AG Extension Modules Profibus, RT-

Ethernet, Sercos, CAN

IV

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

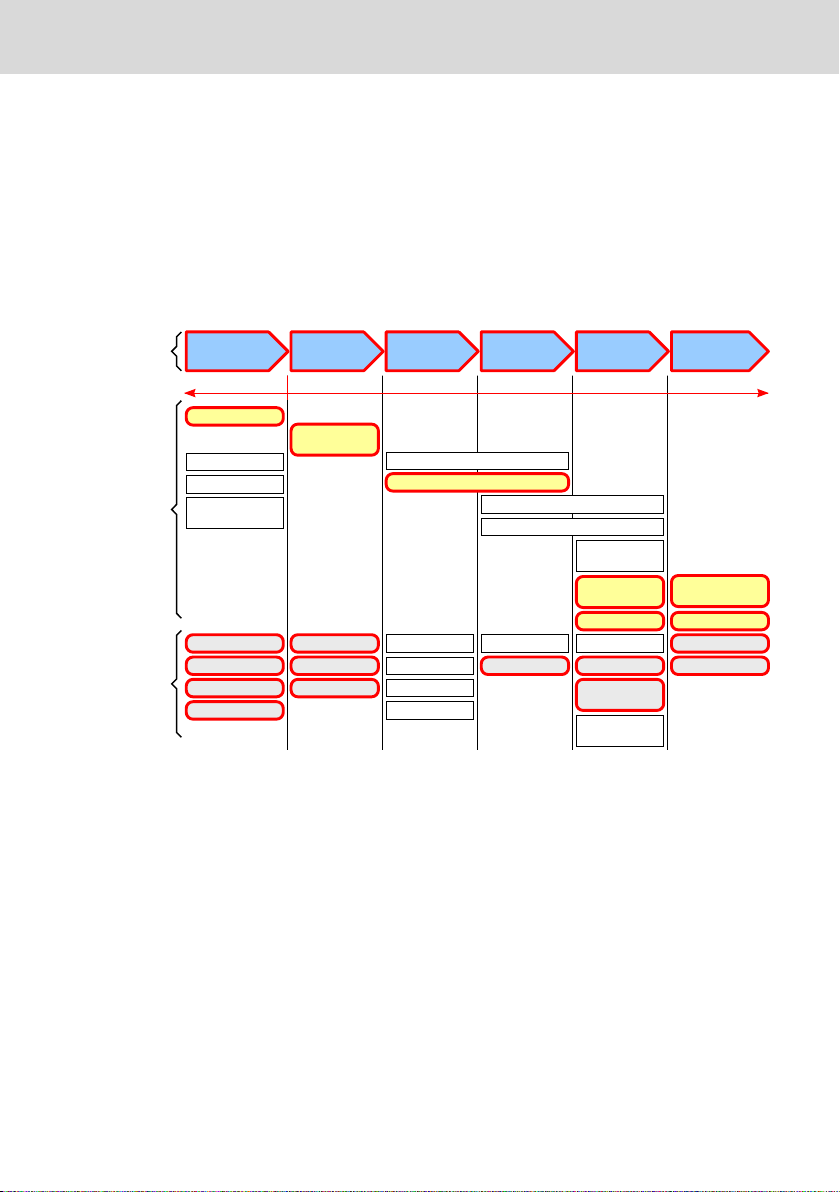

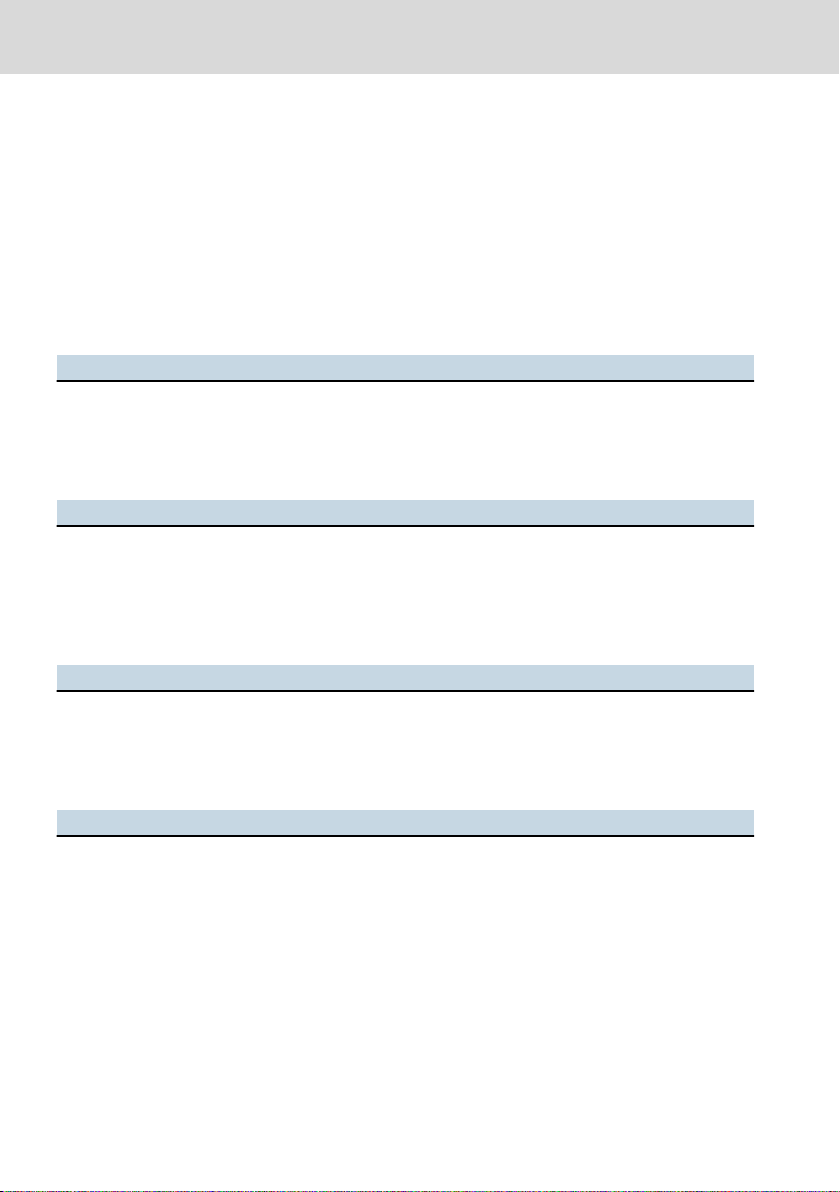

Presales Aftersales

Selection

Mounting

(assembly/installation)

Engineering

Commissioning

Operation

Decommissioning

Product

phases

Target

groups

Activities

Design engineer

Programmer

Technologist

Process

specialist

Select

Prepare

Design

Construct

Mechanic/

electrician

Unpack

Mount

Install

Programmer

Commissioning engineer

Parameterize

Program

Configure

Simulate

Technologist

Process specialist

Optimize

Test

Machine

operator

Maintenance

technician

Service

Operate

Maintain

Remove

faults

Create

the NC program

Mechanic/

electrician

Disposal company

Dismount

Dispose

Extension Modules Profibus, RTEthernet, Sercos, CAN

About this documentation

Bosch Rexroth AG

1 About this documentation

1.1 Overview on target groups and product phases

In the following illustration, the framed activities, product phases and target

groups refer to the present documentation.

Example: In the product phase "Mounting (assembly/installation)", the target

group "mechanic/electrician" can execute the activity "install" using this documentation.

Fig. 1-1:

tivities of the target group

This document instructs the technical staff of the machine manufacturer on how

to safely perform the mechanical and electrical installation and on how to commission the device.

Required qualification: Individual who is able to assess the tasks assigned and

to identify possible safety risks owing to qualification in the subject, knowledge

and experience. The individual should also be familiar with the standards and

regulations.

1.2

Scope

This document is valid for all variants of the modules, whose type code starts

with: XFE01.1-FB ...

The type code specifications are located on the type plate of the module. Also

refer to chapter 2 "Product identification and scope of delivery" on page 3.

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

Assigning the present documentation to the target groups, product phases and ac-

1/37

Bosch Rexroth AG

About this documentation

Extension Modules Profibus, RT-

Ethernet, Sercos, CAN

1.3 Related documents

Title Part number and document type

Rexroth IndraControl XM2x

Controls

Tab. 1-1: Related documents

R911340667

Operating Instructions

For related documents, go to the "Rexroth Media Directory" at http://

www.boschrexroth.com.

1.4 Customer feedback

Customer requests, comments or suggestions for improvement are of great importance to us. Please email your feedback on the documentations to Feed-

back.Documentation@boschrexroth.de. Directly insert comments in the elec-

tronic PDF document and send the PDF file to Bosch Rexroth.

2/37

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

U

0.6 A

Made in Germany

IndraControl S20

SN: 7260007123456BC

FD: 12W16

7260

FW: 101

N

N

I-V-C-B-T-V

Functional

Safety

Type

Approved

FI: 001

CERTIFIED

www.tuv.com

ID 10000000000

MNR: R911172531 -AA0

Bosch Rexroth AG, Bgm.-Dr.-Nebel-Str. 2

DE-97816 Lohr Hotline: +49 9352 405060

DC 24 V

I

Ex ec IIC Gc

IECEx TUR 16.0049 U

TÜV 16 ATEX 7949 U

II 3G

"IND.CONT.EQ"

32FB

16 channels

Wire Range 24-16

2700729

1 2 3 4 5 6 7 8 9

101112

13

14

15

16

17

1819

Extension Modules Profibus, RTEthernet, Sercos, CAN

Product identification and scope of delivery

Bosch Rexroth AG

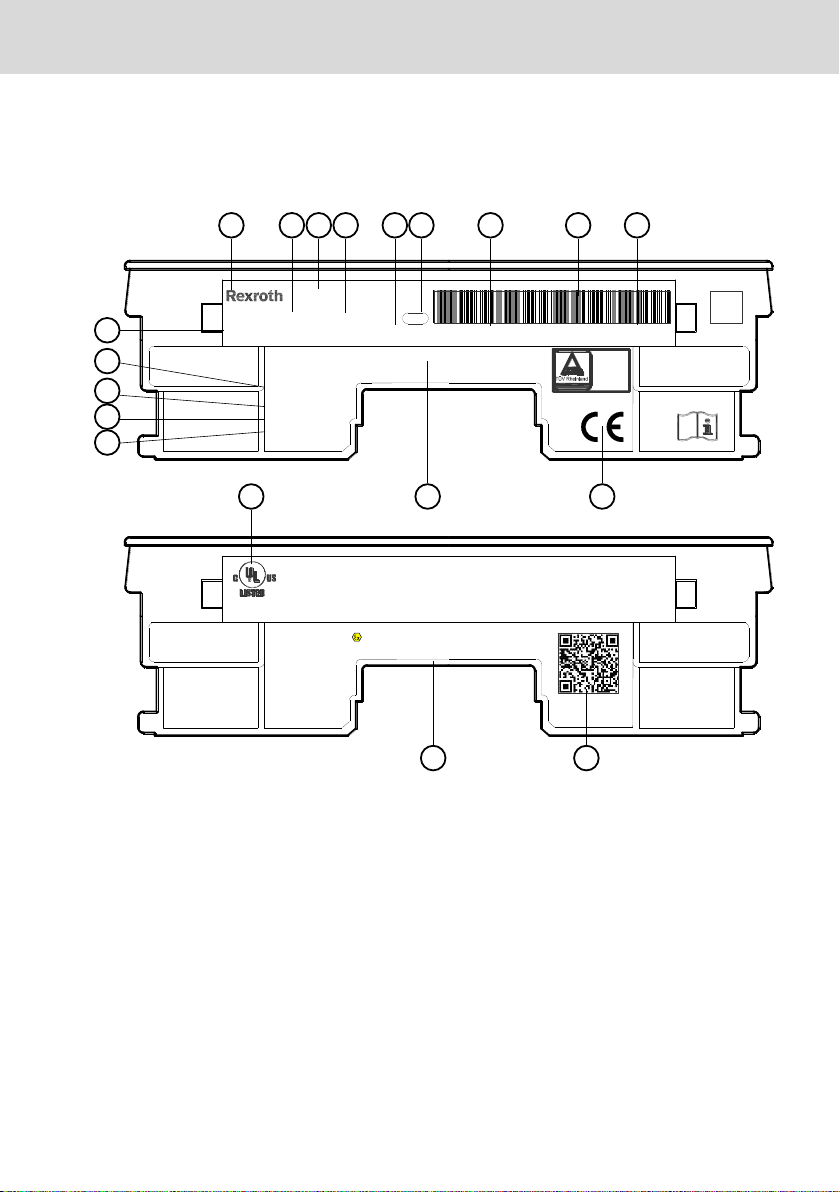

2 Product identification and scope of delivery

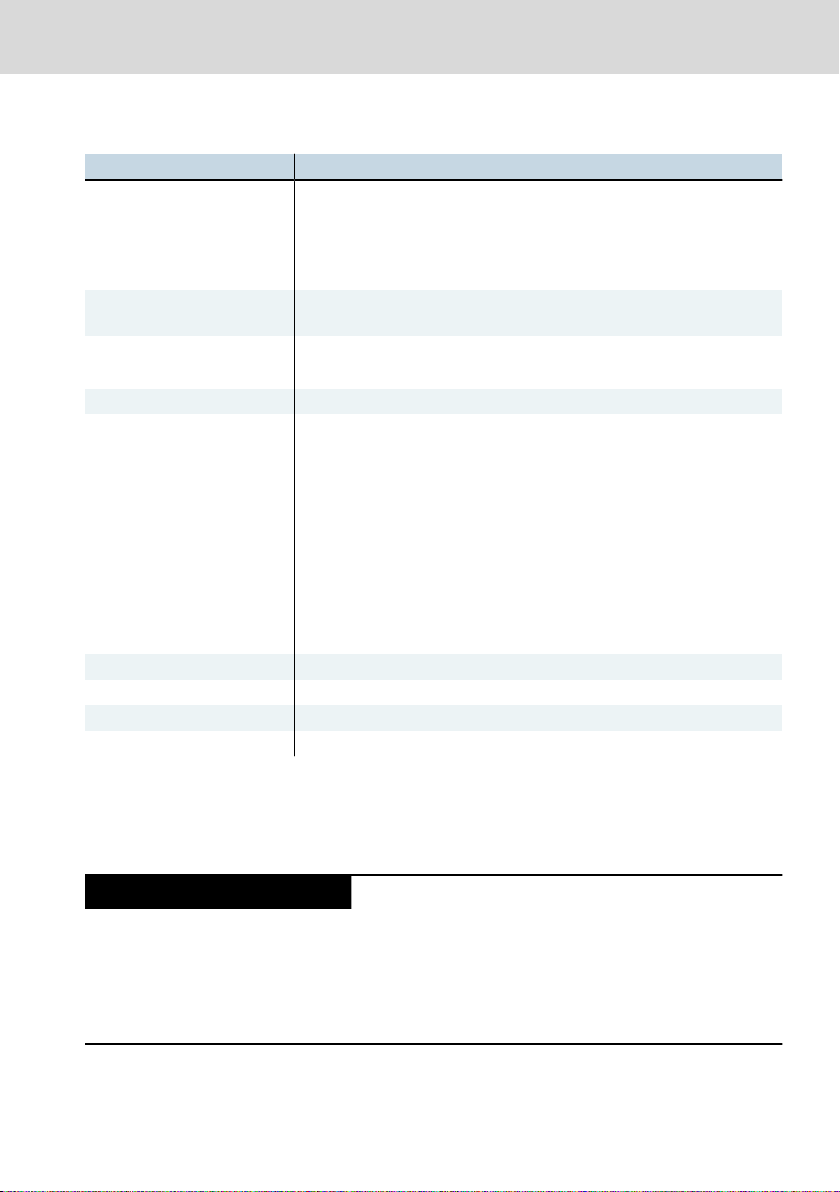

2.1 Product identification and type plate

1 Word mark

2 Part number

3 Device name

4 State of revision

5 Functional index

6 Plant number

7 Serial number

8 Serial number as barcode

9 Date of manufacture (yyWww)

10 CE conformity marking

Fig. 2-1: Exemplary type plate

2.2

Scope of delivery

● Extension module

● Bus base

● 24 V power connector XA-CN01

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

11 Company address

12 Underwriters Laboratories Inc. mark

13 Check digit

14 Nominal current

15 Nominal voltage

16 Manufacturing country

17 Software release

18 QR code

19 Explosion protection marking

3/37

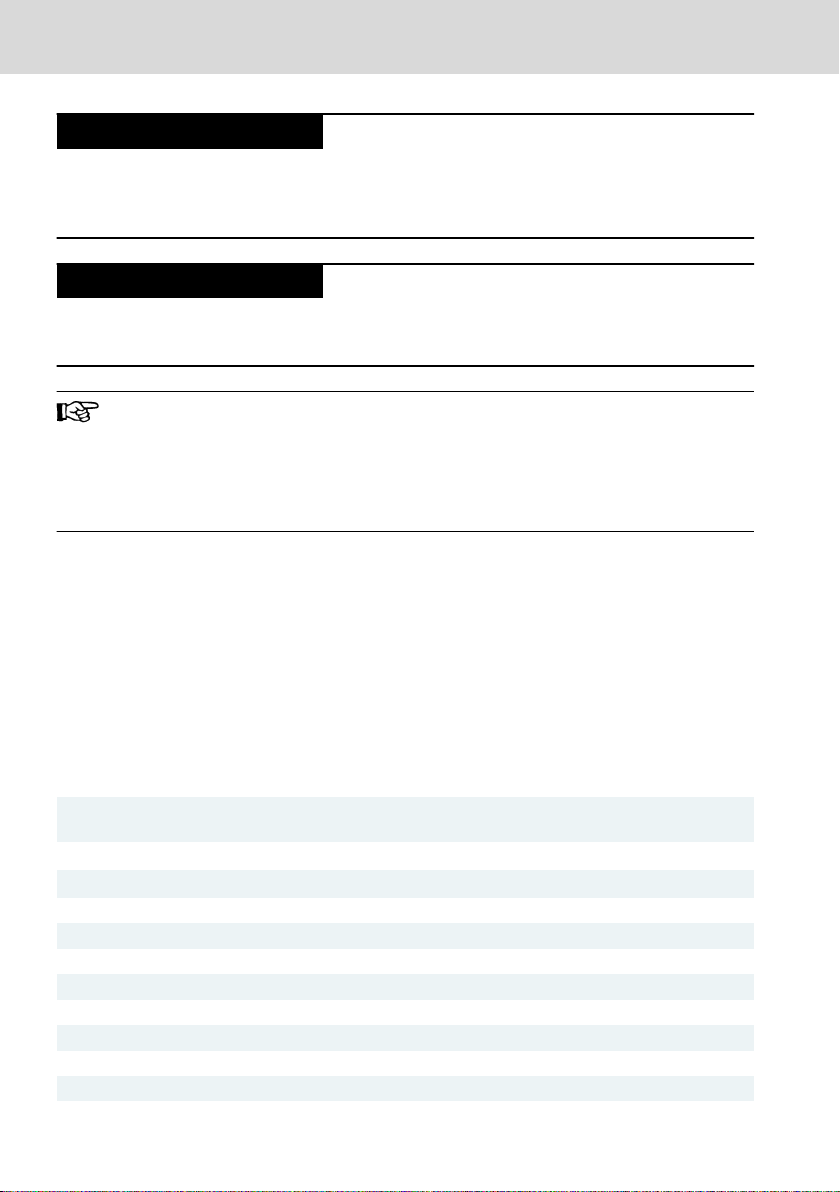

Burns and chemical burns due to wrong

battery treatment!

CAUTION

Safety alert symbol

Signal word

Consequences and

source of danger

Avoiding danger

Do not open the batteries and do not heat them over 80 °C.

DANGER

WARNING

Bosch Rexroth AG

Use of the safety instructions

● Safety instructions

Extension Modules Profibus, RT-

Ethernet, Sercos, CAN

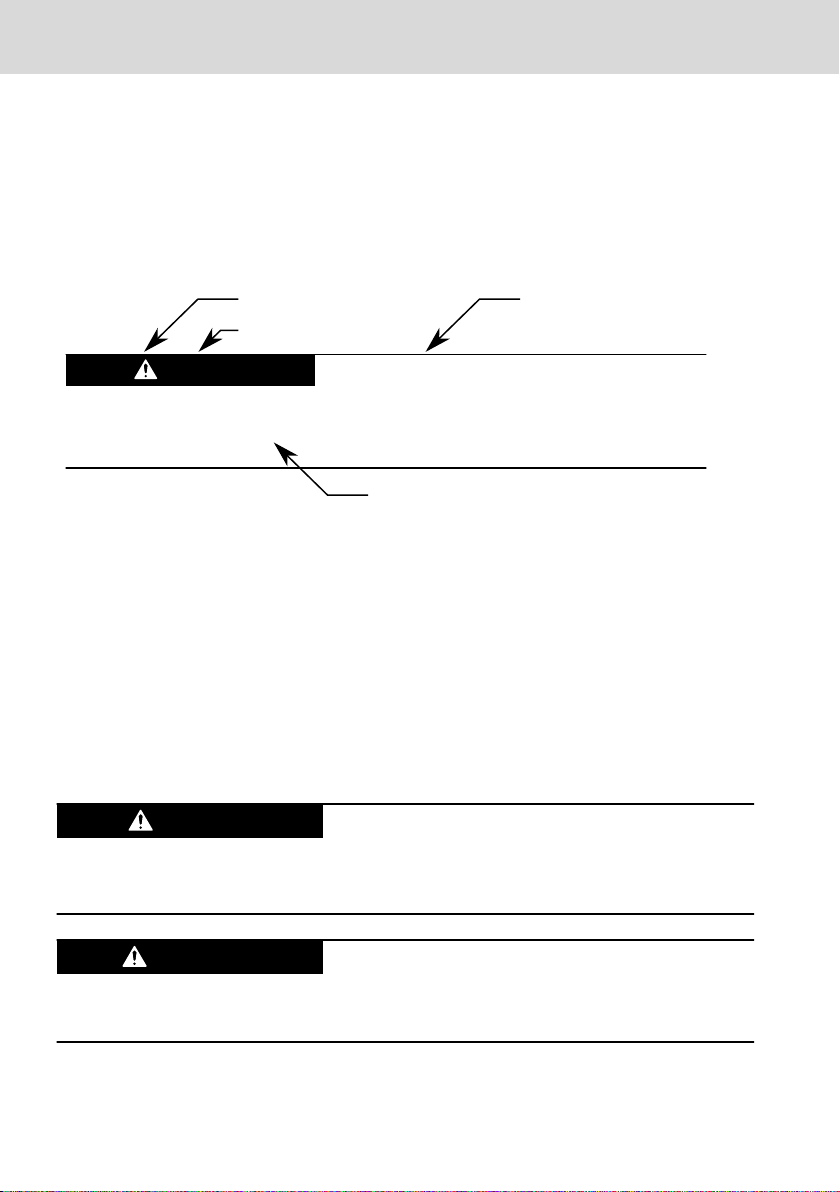

3 Use of the safety instructions

3.1 Structure of the safety instructions

The safety instructions are structured as follows:

Fig. 3-1: Structure of the safety instructions

3.2 Explaining signal words and safety alert symbol

The safety instructions in this documentation contain specific signal words (danger, warning, caution, notice) and, if necessary, a safety alert symbol (according

to ANSI Z535.6-2006).

The signal word is used to draw attention to the safety instruction and also provides information on the severity of the hazard.

The safety alert symbol (a triangle with an exclamation point), which precedes

the signal words danger,warning and caution is used to alert the reader to personal injury hazards.

In case of non-compliance with this safety instruction, death or serious injury

will occur.

In case of non-compliance with this safety instruction, death or serious injury

can occur.

4/37

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

CAUTION

NOTICE

krax

NOTICE

Extension Modules Profibus, RTEthernet, Sercos, CAN

In case of non-compliance with this safety instruction, minor or moderate injury

can occur.

In case of non-compliance with this safety instruction, material damage can occur.

Bosch Rexroth AG

Intended use

3.3 Symbols used

Hints are represented as follows:

This is an information.

Tips are represented as follows:

This is a tip.

3.4 Signal graphic explanation on the device

Prior to the installation and commissioning of the device, refer to the

device documentation.

4 Intended use

Risk of damaging the device if not expressly stated accessories, mounting parts and other components, cables, lines and software and firmware are used.

The IndraControl extension modules may exclusively be used with the accessories and add-on components specified in this documentation. Components that

are not expressly mentioned must neither be attached nor connected. The same

applies to cables and lines.

Only to be operated with the component configurations and combinations expressly defined and with the software and firmware specified in the corresponding functional description.

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

5/37

Bosch Rexroth AG

Spare parts, accessories and wear parts

The IndraControl extension modules can be used for complex connections to

controls that cannot be operated at the S20 bus, such as interface modules to

Profinet, Profibus, CAN and Sercos or Safety connection.

The IndraControl extension modules may only be operated under the mounting

and installation conditions, the position and the ambient conditions (temperature, degree of protection, humidity, EMC etc.) specified in this documentation.

5

Spare parts, accessories and wear parts

Extension Modules Profibus, RT-

Ethernet, Sercos, CAN

5.1 Connector 24 V

Ordering code Part number Description

XA-CN01 R911173741 24 V plug

Tab. 5-1: Connector, 24 V

5.2 Connector set for the CAN module

Ordering code Part number Description

S20-CNS 2S-O/D/UI/E1/E2 R911173804 Connector set for the 24 V module and the

Tab. 5-2: Connector set CAN module

CAN module

5.3 Bus base module

Ordering code Part number Description

XA-BS11 R911173772 Bus base module for extension modules

Tab. 5-3: Bus base module for extension bus

5.4 End clamp

Ordering code Part number Description

SUP-M01-ENDHALTER R911170685 2 pieces of snap-on end brackets for 35

Tab. 5-4: End clamp

mm NS 35/7.5 or NS 35/15 carrier plate;

width: 9.5 mm

5.5 Wear parts

There are no wear parts in the extension modules.

6/37

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

NOTICE

Extension Modules Profibus, RTEthernet, Sercos, CAN

Bosch Rexroth AG

Ambient conditions

6 Ambient conditions

In operation

Ambient temperature in oper-

ation

Ambient temperature during

storage and transport

Permitted air humidity 5 % to 95 % acc. to DIN EN 61131-2

Operating altitude Up to 3,000 m above sea level acc. to DIN 61010-1

Mechanical strength

①

Overvoltage category 2

Contamination level 2

Degree of protection IP20 acc. to DIN EN 60 529

Protection class III, DIN EN 61010-2-201

① The vibration stress specifications assume the use of industrial-suited RJ45 plug connec-

tions. The "Industrial RJ45 plug" of the company Yamaichi is recommended (Y-ConPlug-41). The cables are available as accessories (RKB0020). To protect against vibration,

secure the cables with a short distance (< 20 cm).

Tab. 6-1: Ambient conditions

Up to 2,000 m:

-25 °C to +60 °C

2,000 m to 3,000 m:

-25 °C to +55 °C

–40 °C to +85 °C

Condensation not allowed

Vibration stress:

● Oscillations, sinusoidal in all three axes acc. to DIN EN 60068-2-6

5-9 Hz with an amplitude of 3.5 mm

9-150 Hz with 5 g peak acceleration

● Broadband noise acc. to DIN EN 60068-2-64

5-20-150 Hz with 0.572 g, 5 h per axis

Shock stress: Shock resistance in all three axes acc. to DIN EN

60068-2-27

11 ms semi-sinusoidal 30 g

Failure of the product due to contaminated air

● The ambient air must not contain acids, alkaline solutions, corrosive agents,

salts, metal vapors and other electrically conductive contaminants in high

concentrations

● Housing and installation compartments must at least comply with the degree

of protection IP 54 according to DIN EN 60529

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

7/37

NOTICE

NOTICE

Bosch Rexroth AG

Technical data

Defective product due to gases jeopardizing

functions

Due to the risk of corrosion, avoid sulphurous gases (e.g. sulphur dioxide (SO2)

and hydrogen suphide (H2S)). The product is not resistant against these gases.

Failure of the product due to overheating

To avoid overheating and a trouble-free operation of the product, the ambient air

has to circulate. Also refer to chapter 10.2 "Installation notes" on page 16

This is a product that corresponds to the limit values of the emitted

interference of class A (industrial environments), but not of class B

(residential area and small enterprises).

When using the product in residential areas or small enterprises, the

operator has to take actions to prevent radio interferences (also refer to DIN EN 55022).

7

Technical data

Extension Modules Profibus, RT-

Ethernet, Sercos, CAN

Weight 0.120 kg

Degree of protection IP 20 acc. to DIN EN 60 529

Tab. 7-1: Technical data

7.1 Voltage supply and current consumption

The following specifications include the values acc. to EN 61131-2.

Infeed U

L

Maximum voltage range allowed 18 V DC to 31.2 V DC (incl. all tolerances and rip-

Current consumption from U

Power consumption from U

Reverse voltage protection of the supply voltage Diode

Fuse protection Internal protective fuse, 4 A

Transient protection Present, suppressor diodes

Voltage dips at current supply interfaces Up to 10 ms without impairment

Electrical isolation and isolation of the voltage ranges

Profibus extension module

24 V supply with FE to XF8 845 V AC, 50 Hz, 1 min

8/37

L

L

24 V DC PELV/SELV (safety extra-low voltage)

ple)

0.2 A max.

4.8 W max.

DOK-CONTRL-XFE**EXTMOD-IT04-EN-P

Loading...

Loading...