Bosch TRANSFLOW j-45096 Operation Manual

Transmission Cooling System

J-45096

Operation Manual

TRANSFLOW Transmission Cooling System Service Tool J-45096 1

Safety Precautions

WARNING: TO PREVENT PERSONAL INJURY AND/OR DAMAGE TO EQUIPMENT:

• ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE THE UNIT. Before operating the unit, read and follow the instructions and warnings in this manual.

If the operator cannot read English, operating instructions and safety precautions must be read and discussed in the operator’s native language.

• Do not use this equipment in a manner not specified by the manufacturer.

• Wear eye protection that meets OSHA standards.

• Correctly connect power supply cord to the vehicle 12V DC battery and

chassis ground.

• Use only GM Approved

• Do not overfill the supply vessel with automatic transmission fluid (ATF).

• A minimum of 90 psi of shop air is required to operate this machine.

• Operate and store this machine in an upright position.

• Disconnect the machine from the shop air supply at the conclusion of each

day to ensure correct operation of the water separator.

• Dispose of waste ATF in accordance with all applicable federal, state and

local requirements.

Dexron VI® Automatic Transmission Fluid.

2 TRANSFLOW Transmission Cooling System Service Tool J-45096

Table of Contents

Introduction

Glossary of Terms .............................................................................................................. 2

Equipment Specifications ................................................................................................... 2

Component Location Overview

Front View .......................................................................................................................... 3

Rear View ........................................................................................................................... 3

Control Panel ..................................................................................................................... 4

Set-Up Instructions

Initial Set-Up Instructions ................................................................................................... 5

Waste Vessel Drain Set Up ................................................................................................ 6

Power Up ........................................................................................................................... 8

TransFlow Self-Test ............................................................................................................ 9

Operating Instructions

Machine Set-Up ............................................................................................................... 11

Flow Test/Flush Operation ............................................................................................... 12

Waste Oil Removal .............................................................................................................. 15

Maintenance Instructions

Service Parts ................................................................................................................... 16

Accessories ..................................................................................................................... 16

Transmission Oil Cooler (T.O.C.) Adapters....................................................................... 17

Useful Information/Hepful Hints ....................................................................................... 18

Troubleshooting ................................................................................................................... 19

Warranty Information/Technical Support .................................................... Inside Back Cover

TRANSFLOW Transmission Cooling System Service Tool J-45096 1

Introduction

The TransFlow machine is a product designed to measure the transmission oil cooler (T.O.C.) oil

ow capability and to remove contaminated oil from the T.O.C. system after a transmission repair.

Measuring the transmission cooler system oil ow rate determines if the cooler meets the current

GM ow rate specication.

Glossary of Terms

ATF Automatic Transmission Fluid, Dexron VI® ATF or equivalent

GPM Gallons per Minute

T.O.C. Transmission Oil Cooler

Equipment Specifications

Component Specification

TransFlow Part Number J-45096

Power Supply Operating Voltage 11 Volts DC–16 Volts DC

Air Pressure 90 PSI (Minimum)

Minimum ATF Temperature 65° F

Supply Vessel Capacity 32 Quarts US

Waste Vessel Capacity 34 Quarts US

Flow Rate 0.5-2.5 gpm

2 TRANSFLOW Transmission Cooling System Service Tool J-45096

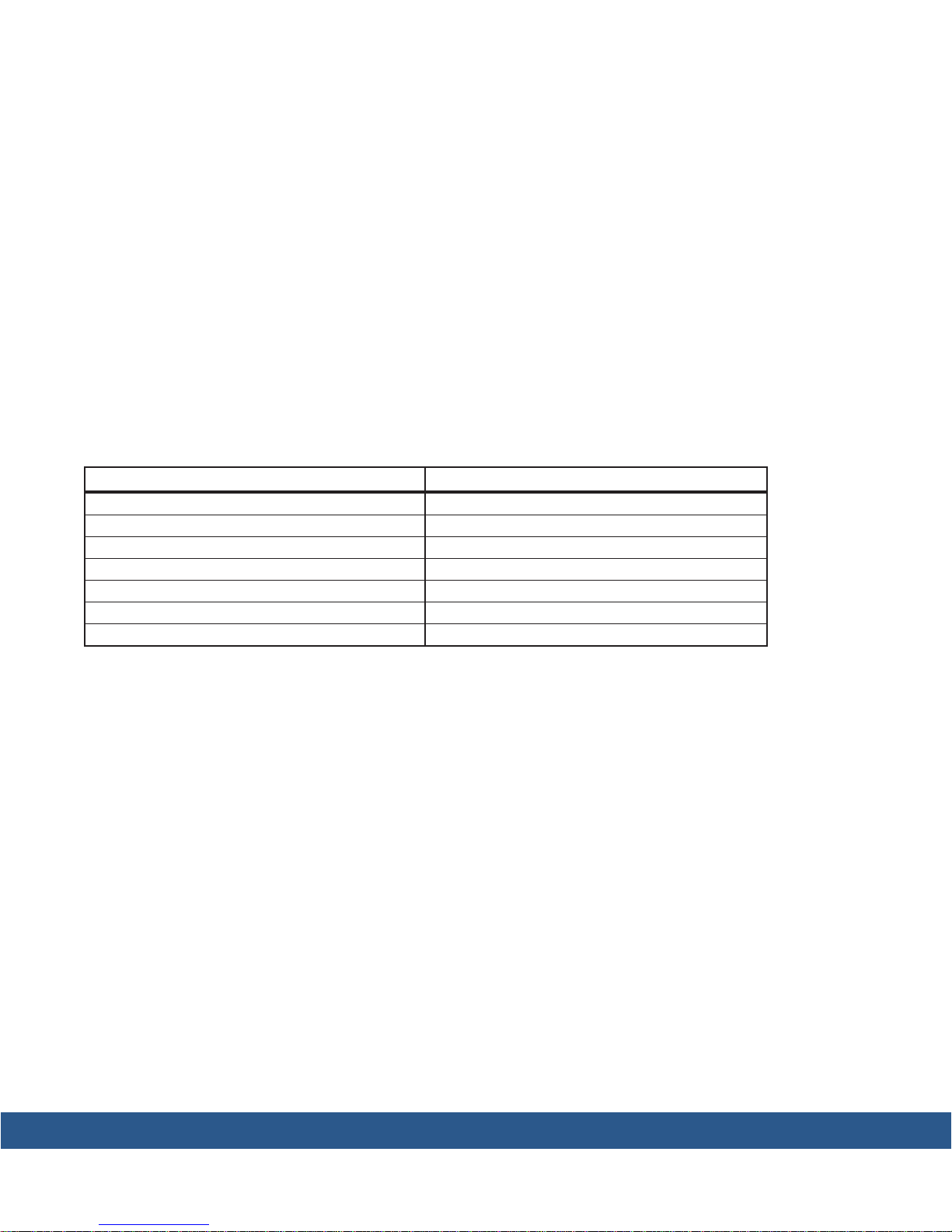

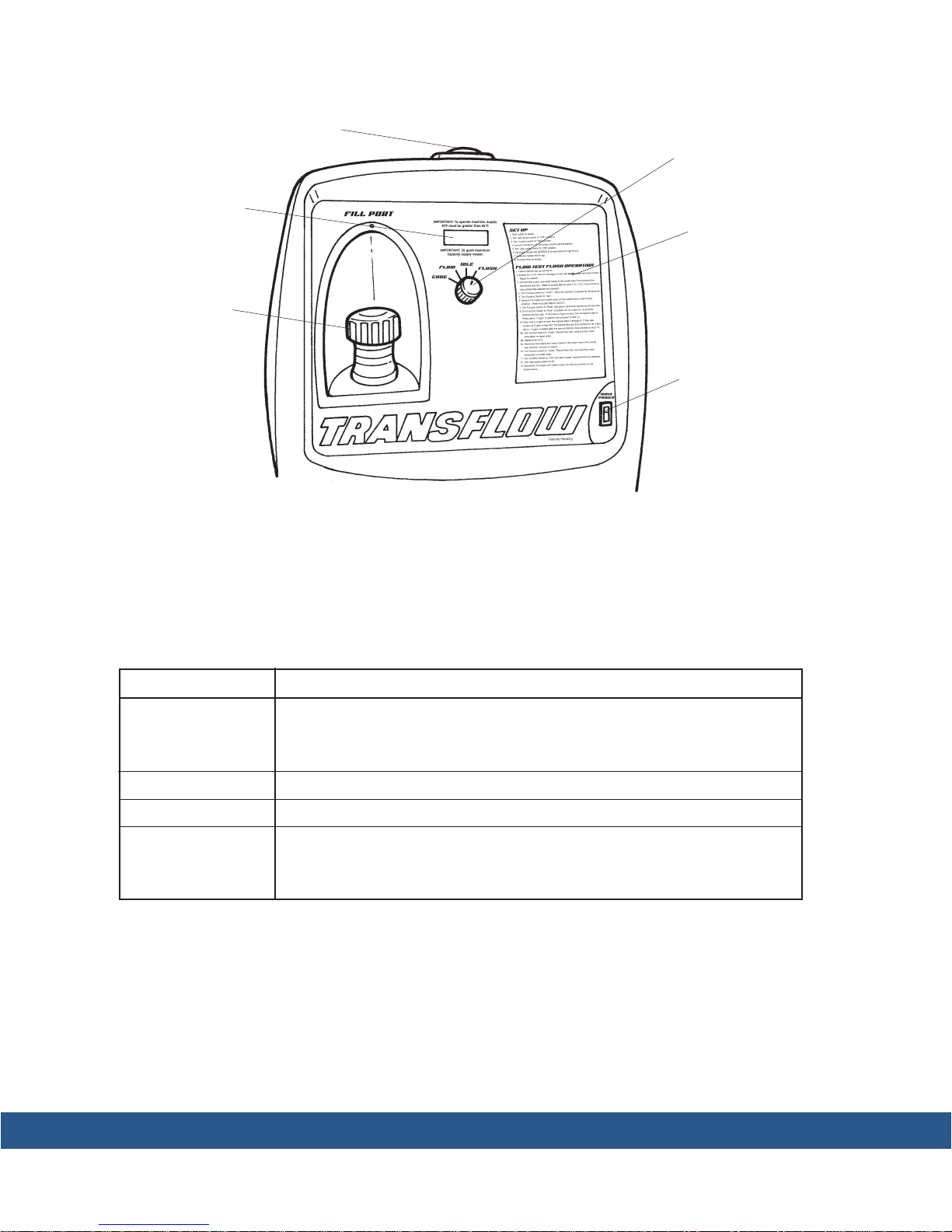

Component Location Overview

ATF Fill

Port

Control Panel

Polypropylene

Cabinet for

Durability

Front View

Operation

Instructions

Convenient Handle

for Cord and

Hose Storage

Waste Oil

Vessel

Large Wheels for

Mobility across

Air Lines, Power

Cords, and Grates

Locking Casters

Shop Air

Supply

Rear View

Waste Oil

Inlet

Supply Oil

Outlet

TRANSFLOW Transmission Cooling System Service Tool J-45096 3

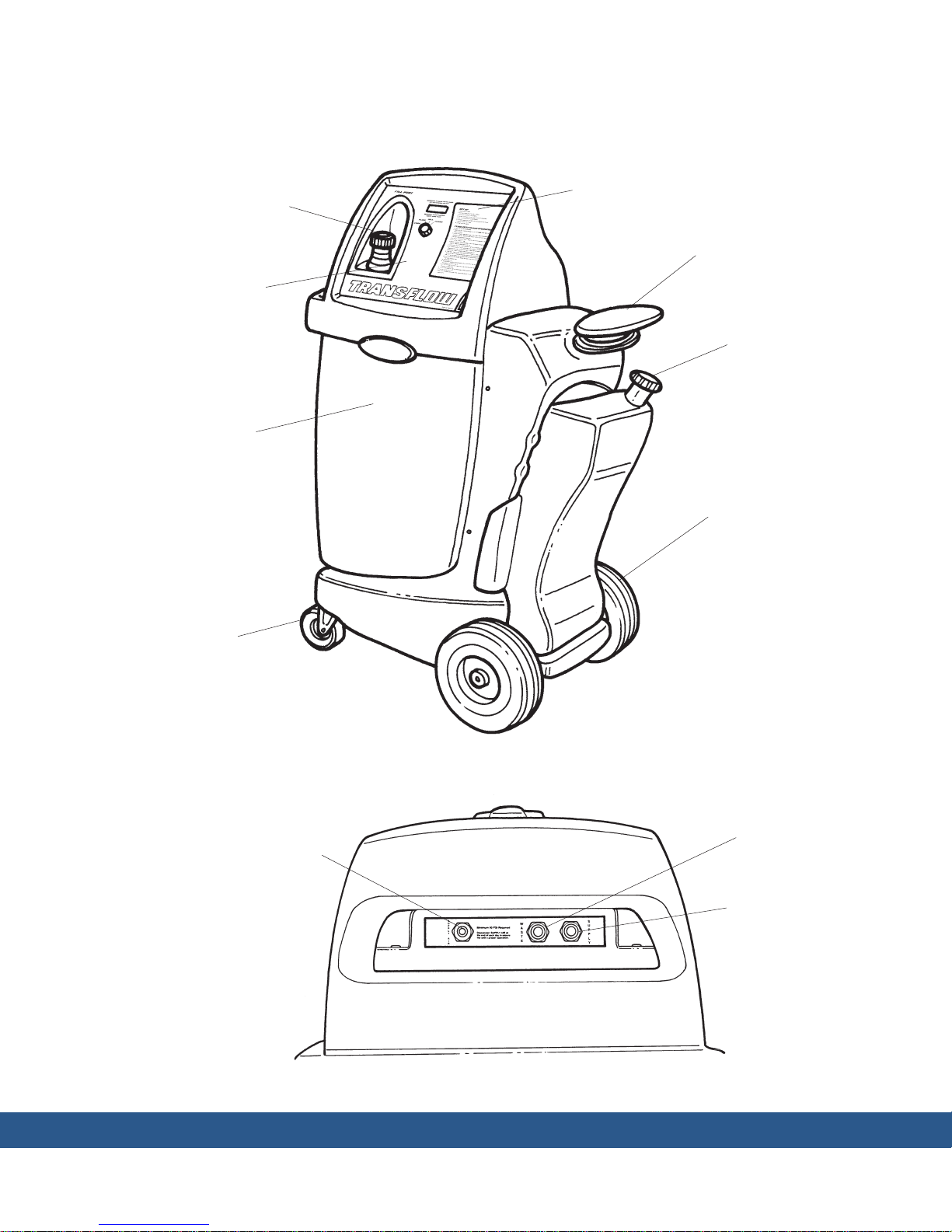

Red light indicates when

machine is pressurized

LCD Display

Window

ATF Fill

Port

Control Panel

Main Function

Switch

Operating

Instructions

Main Power

Switch

Main Function Switch

The following table provides a quick reference for the main function switch positions:

Switch Position

Flush

Idle

Flow

Code

Allows pressurized automatic transmission uid with a high pressure pulse

of air to ush the contaminated oil from the T.O.C. If any debris exists in

the T.O.C., it will also be ushed when the machine is in this mode.

Standby mode; zero pressure applied to the T.O.C. and cooler lines.

Tests the ow rate of the T.O.C. and cooler lines.

Provides a seven-character, encrypted warranty code following a successful ow test. Note: The ow test must run for a minimum of 8–10 seconds

and be above 0.5 gpm for a code to be generated.

Description

4 TRANSFLOW Transmission Cooling System Service Tool J-45096

Set-Up Instructions

Initial Set-Up

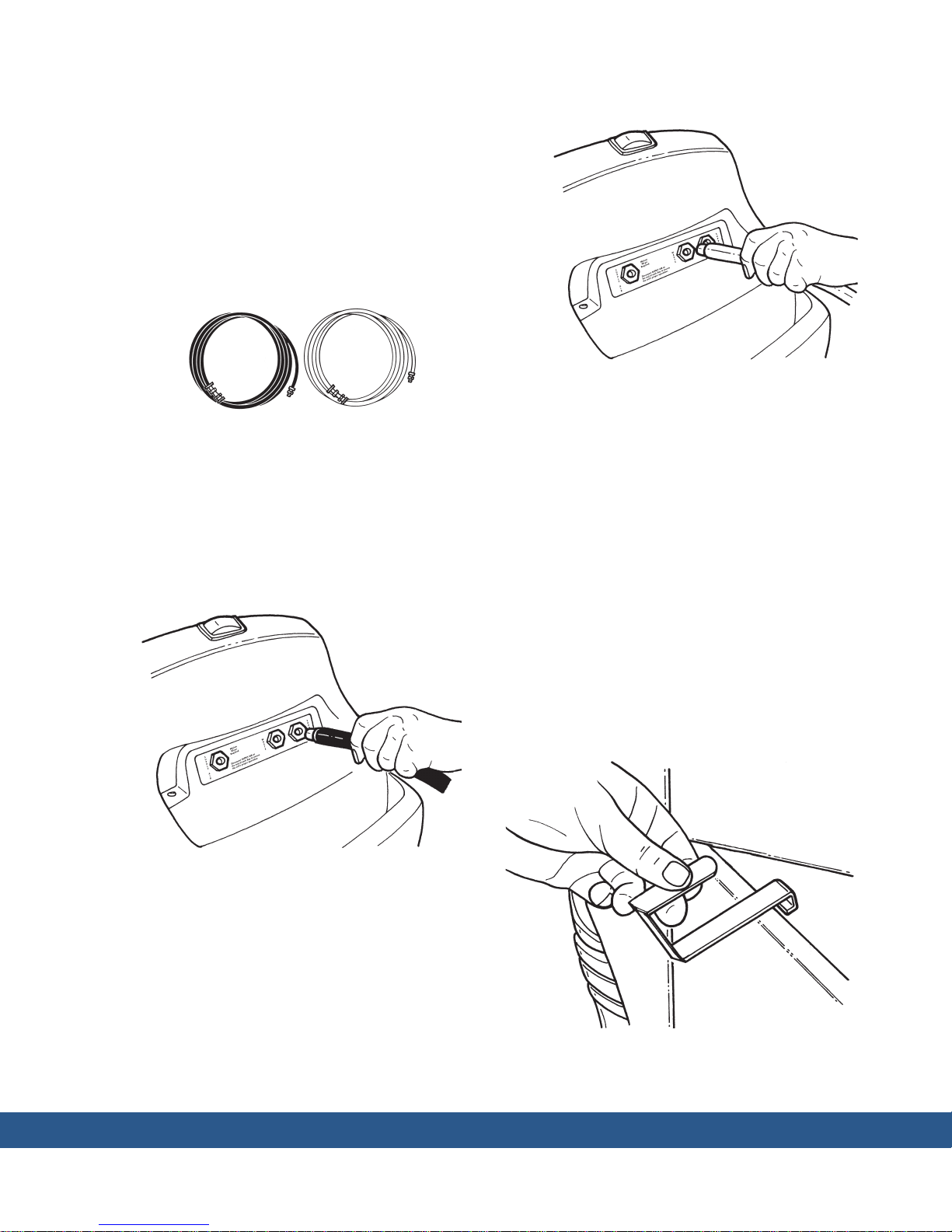

1. Remove the TransFlow unit from the packaging.

2. Locate the accessory package and remove

the black supply hose and the clear waste

hose. See Figure 1. Also locate and remove

the two hose storage brackets.

Figure 1

3. Apply Loctite® 565 sealant (supplied) to the

threaded male end of the black supply hose.

4. Thread the supply hose clockwise onto the

TransFlow tting, located on the rear panel

of the TransFlow unit, marked SUPPLY. See

Figure 2.

Figure 3

8. Tighten the tting.

9. Apply Loctite® 565 thread sealant to the

threads of an air line quick-disconnect tting

(customer supplied).

10. Thread the quick-disconnect tting clockwise onto the TransFlow tting, located on

the rear panel of the TransFlow unit, marked

Supply AIR.

11. Tighten the quick-disconnect tting.

12. Open the door on the unit by using a screwdriver to turn the fasteners counterclockwise

about a quarter-turn. Snap one hose storage

bracket over the top of the door as shown

in Figure 4, and position the other hose

storage bracket 8"–10" away from the rst.

Figure 2

5. Tighten the tting.

6. Apply Loctite® 565 thread sealant to the

threaded male end of the clear waste hose.

7. Thread the waste hose clockwise onto the

TransFlow tting, located on the rear panel

of the TransFlow unit, marked WASTE. See

Figure 3.

Figure 4

TRANSFLOW Transmission Cooling System Service Tool J-45096 5

Set-up Instructions contd.

The waste and supply hoses can be stored on

these brackets when not in use. See Figure 5.

Figure 5

IMPORTANT: Dispose of the waste ATF in

accordance with all applicable federal, state

and local requirements.

1. If draining from the bottom of the waste

vessel, rst remove the drain tting cap plug

by turning the cap plug counterclockwise

while supporting the hexagonal drain tting.

Note: Be sure to support the hexagonal drain

tting while removing the cap plug to prevent

potential damage to equipment. See Figure

1.

Waste Vessel

Cap Plug

Waste Vessel Drain Set Up

Before TransFlow is used, it is recommended to

consider a draining strategy for the waste ATF

that will be stored in the waste vessel on the

side of TransFlow. The waste vessel may be

drained through a tting at the bottom or by

removing the waste vessel cap at the top of the

vessel to use an oil transfer pump to evacuate the

oil. This section describes a procedure to outt

the drain tting at the bottom of the waste vessel

with a standard 1/2" pipe to make it more

convenient for you to adapt to. It is your responsibility to either cap this 1/2" pipe once installed,

or to adapt a tting or hose to it to allow you to

drain the waste vessel.

Hexagonal

Drain Fitting

Figure 1

2. Locate the drain support bracket and screws

from the accessory kit. Place the drain support bracket underneath the plastic lip of the

left side base of the TransFlow machine (or

towards front of TransFlow). The drain support bracket should be at against the inside

plastic lip and the hole in the drain support

bracket should be clearly below the plastic.

6 TRANSFLOW Transmission Cooling System Service Tool J-45096

Loading...

Loading...