Bosch Therm 6000 S Installation And Operating Instructions Manual

Installation and operating instructions

Gas Water Heater

Therm 6000 S

6 720 800 095 (2015/11) ZA

Read installation manual prior to installation of this unit!

Read user manual before putting this unit in operation!

Observe the warnings in the manuals!

The installation room must fulfill the ventilation requirements!

Installation by an authorised person only!

6 720 800 095 (2015/11) Therm 6000S

2 | Index

Index

1 Key to symbols and safety instructions . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . 3

2 Technical Characteristics and Dimensions . . . . . . . 4

2.1 Declaration of conformity with relevant

EEC regulations . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Explanation of Model Code . . . . . . . . . . . . . . 4

2.3 Package contents . . . . . . . . . . . . . . . . . . . . . 4

2.4 Description of the heater . . . . . . . . . . . . . . . 4

2.5 Optional accessories . . . . . . . . . . . . . . . . . . . 4

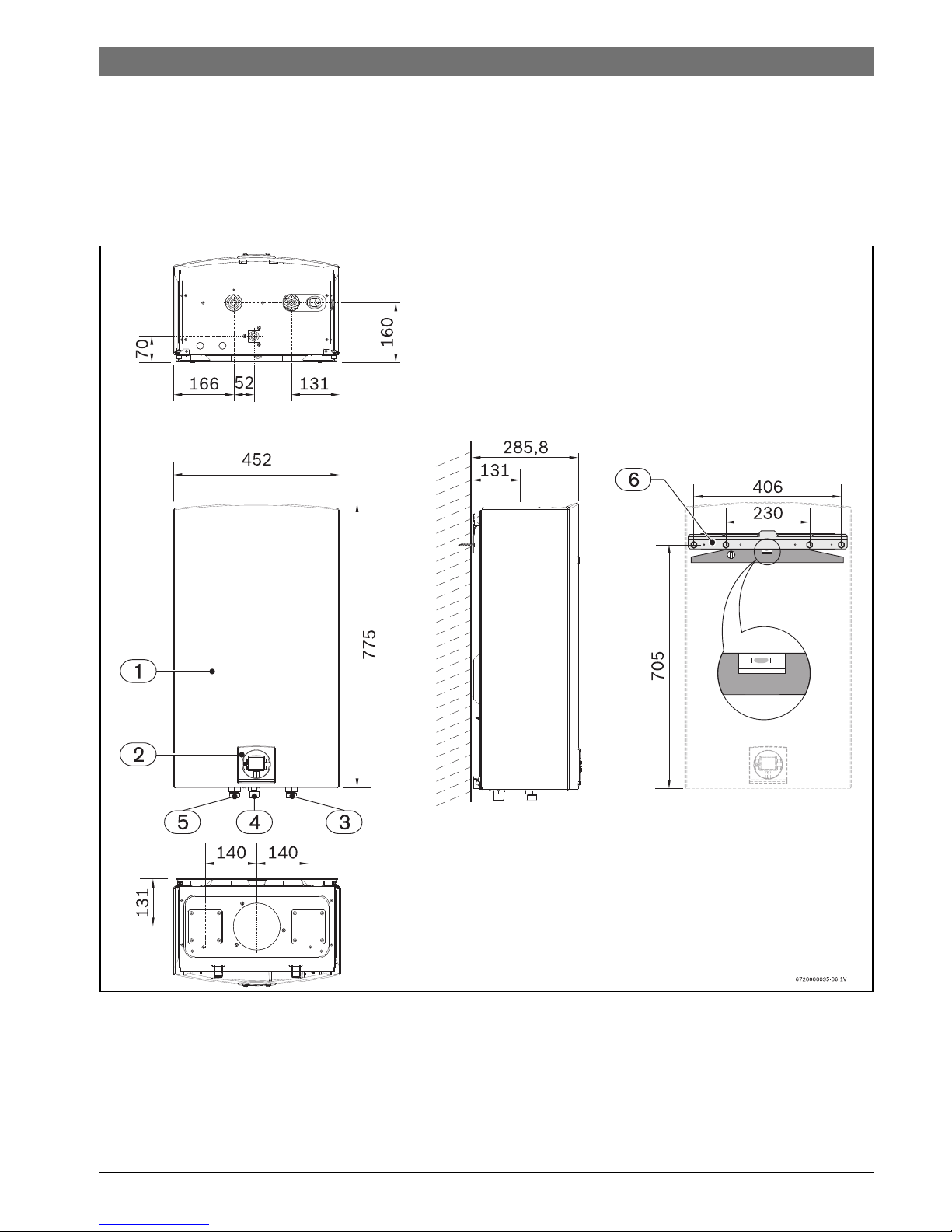

2.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 5

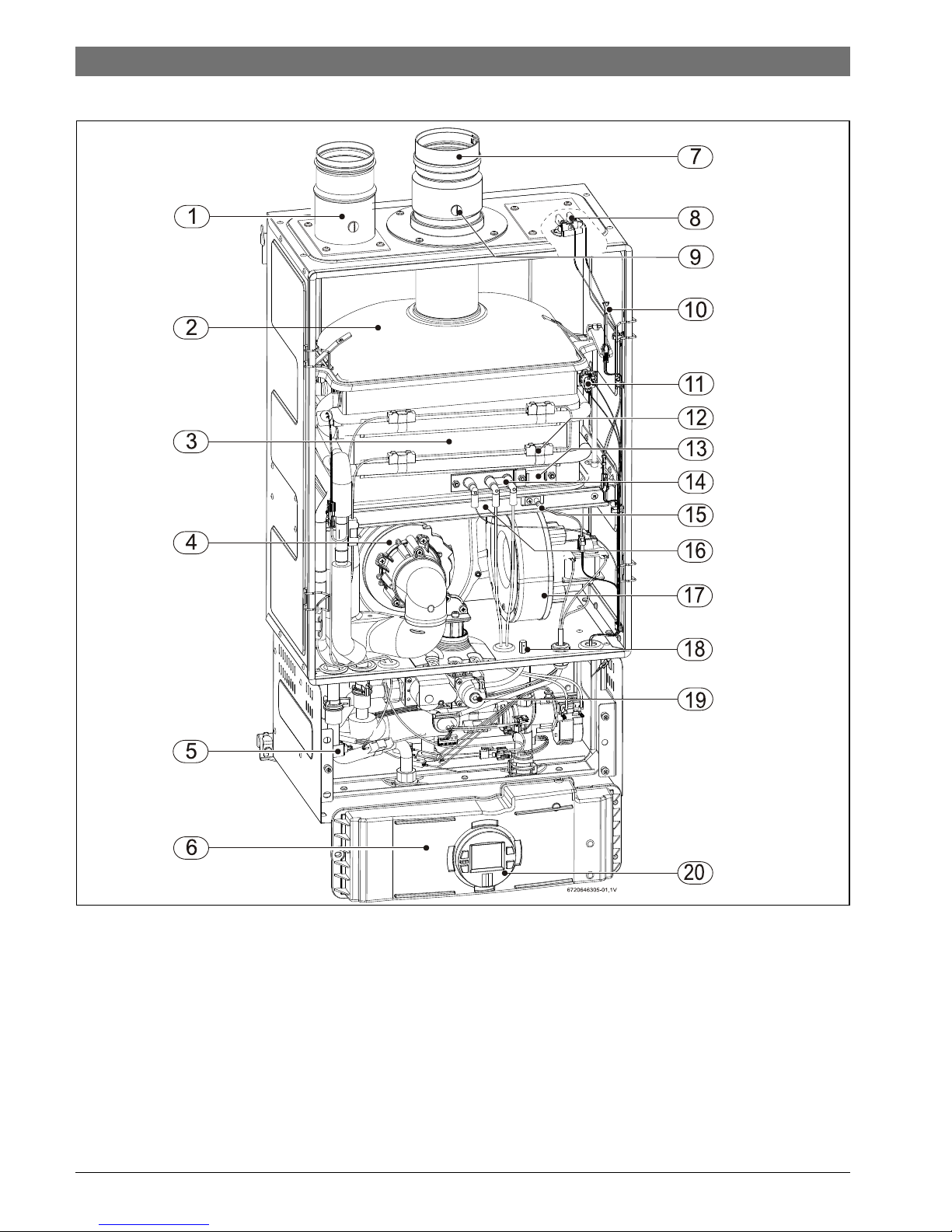

2.7 Appliance overview . . . . . . . . . . . . . . . . . . . . 6

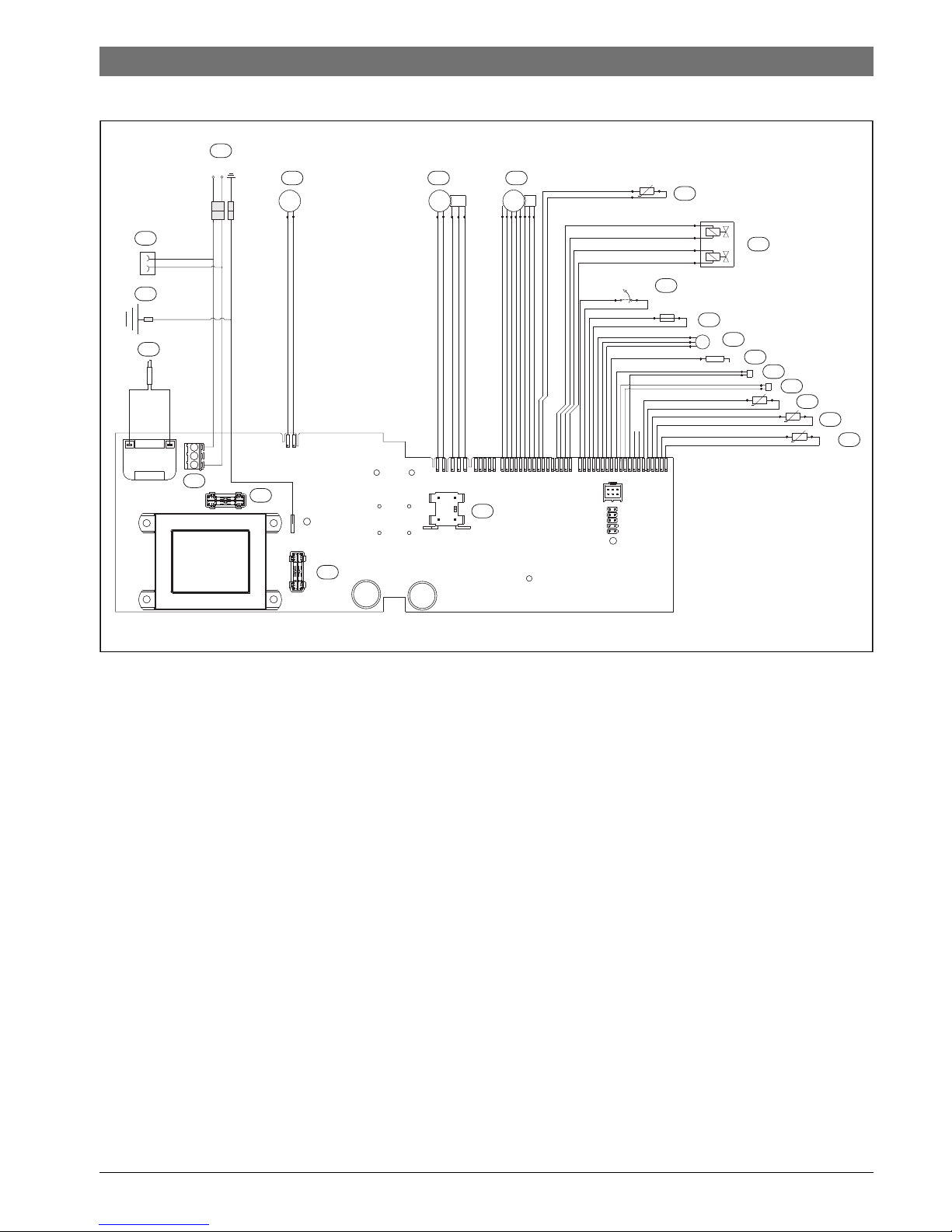

2.8 Electrical diagram . . . . . . . . . . . . . . . . . . . . . 7

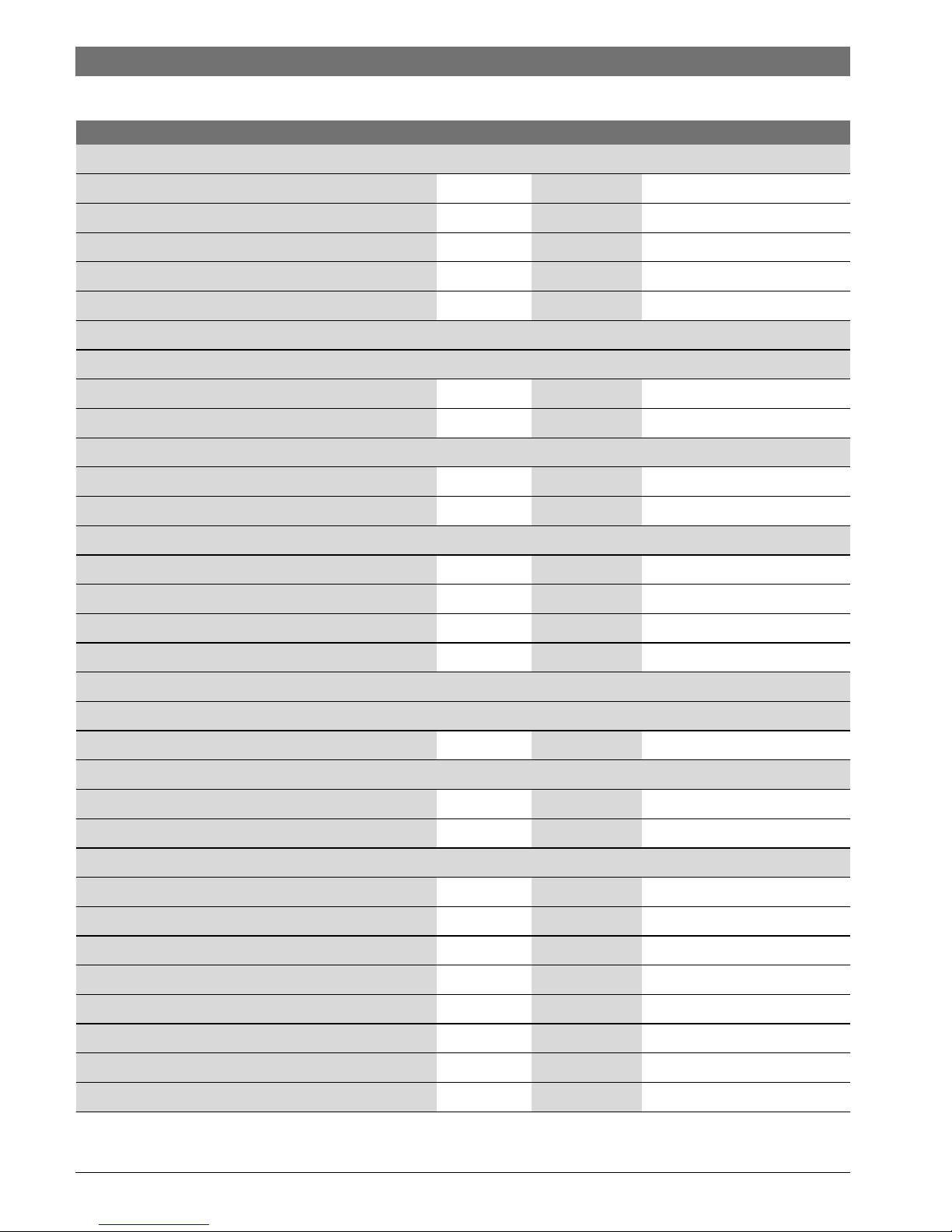

2.9 Technical data . . . . . . . . . . . . . . . . . . . . . . . . 8

2.10 Operational instructions . . . . . . . . . . . . . . . . 9

3 Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Description LCD Display . . . . . . . . . . . . . . . 10

4.2 Before operating the appliance . . . . . . . . . 11

4.3 Connect and disconnect the appliance . . . 11

4.4 Water temperature setting . . . . . . . . . . . . . 11

4.5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.6 Registration of remote control

(accessory no 7 709 003 756) . . . . . . . . . 12

4.7 Remote control operation

(accessory no 7 709 003 756) . . . . . . . . . 12

4.8 Program button . . . . . . . . . . . . . . . . . . . . . . 13

4.9 "Priority" function . . . . . . . . . . . . . . . . . . . . 13

4.10 Purge the appliance . . . . . . . . . . . . . . . . . . 13

4.11 Reset button . . . . . . . . . . . . . . . . . . . . . . . . 14

4.12 Locked condition . . . . . . . . . . . . . . . . . . . . . 14

5 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Important remarks . . . . . . . . . . . . . . . . . . . 15

5.2 Selection of location for installation . . . . . . 15

5.3 Minimum distances . . . . . . . . . . . . . . . . . . . 15

5.4 Installation of fixing bracket . . . . . . . . . . . . 15

5.5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Water connection . . . . . . . . . . . . . . . . . . . . 17

5.7 Gas connection . . . . . . . . . . . . . . . . . . . . . . 17

5.8 Installation of the exhaustion accessory and

admission of air . . . . . . . . . . . . . . . . . . . . . 18

6 Admission / exhaustion accessories

(accessory Ø 80/80 mm) . . . . . . . . . . . . . . . . . . . . . .19

6.1 Admission/exhaustion accessories

(diameter in mm) . . . . . . . . . . . . . . . . . . . . .19

6.2 Fitting instructions . . . . . . . . . . . . . . . . . . . 20

6.3 Explanation of Symbols on Fitting

Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.4 Approved flue systems . . . . . . . . . . . . . . . . 21

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Connection . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Power cable . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3 Position of the fuses in control unit . . . . . . 24

8 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 25

8.1 Factory regulations . . . . . . . . . . . . . . . . . . . 25

8.2 Measuring gas pressure . . . . . . . . . . . . . . . 25

8.3 Adjusting CO2 (carbon dioxide) . . . . . . . . 26

8.4 Program values . . . . . . . . . . . . . . . . . . . . . . 29

8.5 Control board diagnostics . . . . . . . . . . . . . 30

8.6 Fan speed adjustment . . . . . . . . . . . . . . . . 31

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1 Periodic maintenance tasks . . . . . . . . . . . . 33

9.2 Verify the fuses in the control board . . . . . 33

9.3 Startup after maintenance . . . . . . . . . . . . . 34

10 Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 Problem/Cause/Solution . . . . . . . . . . . . . . 35

11 Functional scheme . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12 Environmental protection . . . . . . . . . . . . . . . . . . . . 40

13 Warranty Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6 720 800 095 (2015/11)Therm 6000S

Key to symbols and safety instructions | 3

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this

document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

Additional symbols

1.2 Safety information

If you smell gas:

▶ Close the gas valve.

▶ Open the windows.

▶ Do not operate any electrical appliances or switches (on/

off).

▶Extinguish any fire.

▶ Go to a different location and call the gas supplier or an

authorised technician.

If you smell combustion gases:

▶ Turn off the heater (page 11).

▶ Open doors and windows.

▶ Notify a gas fitter.

Installation, modifications

▶ The installation may only be carried out by registered

installers and shall comply with the requirements of SANS

10087-1.

▶The appliance must be installed along with

a low-pressure gas regulator.

▶ The assembly and modifications during the installation of

the heater can only be performed by an authorised

installer.

▶ Do not modify the pipes which conduct combustion gases.

▶ Do not close or reduce air circulation vents.

Maintenance

▶ We recommend to have the system regularly serviced in

order to ensure that it functions reliably and safely.

▶ The installer is responsible for the safety and

environmental compatibility of the installation.

▶ The heater must be serviced annually.

▶ Only original spare parts must be used.

Explosive and highly inflammable material

▶ Do not store or use inflammable material (paper, solvents,

paints, etc) near the heater.

Combustion air and surrounding air

▶ To avoid corrosion, the combustion air and surrounding air

must be free from harmful substances (e.g. halogenated

hydrocarbons which contain chlorine and fluorine

compounds).

Handover to the user

When handing over the heating system, instruct the user in its

operation and operating conditions.

▶ Explain the operation - with particular emphasis on all

safety-related actions.

▶ Explain that conversions and repairs must only be carried

out by an approved contractor.

▶ Point out the need for inspections and maintenance for

safe and environmentally-compatible operation.

▶ The installation and operating instructions must be given to

the user for keeping.

Warnings in this document are identified by

a warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

This symbol indicates important information

where there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

6 720 800 095 (2015/11) Therm 6000S

4 | Technical Characteristics and Dimensions

Safety of electrical appliances for

domestic use and similar purposes

The following requirements apply in

accordance with EN 60335-1 in order to

prevent hazards from occurring when using

electrical appliances:

“This appliance can be used by children of 8

years and older, as well as by people with

reduced physical, sensory or mental

capabilities or lacking in experience and

knowledge, if they are supervised and have

been given instruction in the safe use of the

appliance and understand the resulting

dangers. Children must not play with the

appliance. Cleaning and user maintenance

must not be performed by children without

supervision.”

“If the power cable is damaged, it must be

replaced by the manufacturer, its customer

service department or a similarly qualified

person, so that risks are avoided.”

2 Technical Characteristics and

Dimensions

2.1 Declaration of conformity with relevant EEC

regulations

This appliance fulfils European directive requirements

2009/142/EEC, 92/42/EEC, 2006/95/EEC, 2004/108/EEC

and corresponds to the specifications described in the

corresponding EEC certificate of proof.

2.2 Explanation of Model Code

[GWH] Gas water heater

[24] Capacity (Liter per minute)

[C] Room sealed box

[T] Thermostatic

[D] LCD

[E] Electric ignition

[23] Appliance adjusted for Natural Gas

[30] Appliance adjusted for LPG

2.3 Package contents

• Gas heater

• Support elements

• Heater documentation

2.4 Description of the heater

• Heater for wall-mounting

• High power pre-mix compact burner with low NOx

emissions

• Modulating Gas Valve with constant gas:air ratio control

• LCD panel with back light

• Failure codes for easy diagnostics and repair

• Electronic ignition

• Modulating water valve:

– Cold water temperature sensor

–Water flow sensor

• Hot water temperature sensor

• Built in frost protection

•Safety devices:

– Flame failure device (ionization flame rod sensor)

– Back flow temperature sensor

– Inlet temperature sensor

– Outlet temperature sensor

– Room sealed box temperature sensor

– Over heat prevention (temperature limiter)

• Power supply: 230 V, 50 Hz

• IP X4 (protection against water drops)

2.5 Optional accessories

• Gas conversion kit (NG)

– Code nº 7 719 002 460

• Freeze prevention kit

– Code nº 7 709 003 709

• Outdoor kit

Model GWH 24 CTD E

Category II

2H3B

Type C

Table 2

GWH 24 C TDE2330

Table 3

6 720 800 095 (2015/11)Therm 6000S

Technical Characteristics and Dimensions | 5

– Code nº 7 709 003 732

•Anti-freeze kit

– Code nº 7 709 003 709

•Cascading kit

– Code nº 7 736 500 272

• Wireless remote control to operate with the appliance

– Code nº 7 709 003 756

• High temperature kit

– Code nº 7 736 500 605

2.6 Dimensions

Fig. 1

[1] Front cover

[2] Key pad

[3] Cold water inlet: Ø ¾ “

[4] Gas connection: Ø ¾ “

[5] Hot water outlet: Ø ¾ “

[6] Support bracket

6 720 800 095 (2015/11) Therm 6000S

6 | Technical Characteristics and Dimensions

2.7 Appliance overview

Fig. 2

[1] Admission accessory (not included)

[2] Flue gas collector

[3] Heat exchanger

[4] Primary fan (Mixer)

[5] Hot water sensor

[6] Control unit

[7] Exhaust accessory (not included)

[8] Room sealed box temperature sensor

[9] CO

2

/ CO measuring point

[10] Exhaust temperature sensor

[11] Over heat prevention (temperature limiter)

[12] Anti-freeze heat element

[13] Observation window

[14] Ignition electrodes

[15] Backflow temperature sensor

[16] Ionization sensor

[17] Secondary air fan

[18] Pressure point gas valve

[19] Gas valve

[20] Key pad

6 720 800 095 (2015/11)Therm 6000S

Technical Characteristics and Dimensions | 7

2.8 Electrical diagram

Fig. 3 Electrical scheme

[1] Intlet water temperature sensor

[2] Outlet water temperature sensor

[3] Backflow temperature sensor

[4] Cascading output connection

[5] Cascading input connection

[6] Ionization sensor

[7] Water flow sensor

[8] Room sealed box temperature sensor

[9] Heat exchanger overheat sensor (104 °C)

[10] Gas valve

[11] Resistance

[12] Water valve

[13] Primary fan

[14] ON/OFF switch

[15] Secondary fan

[16] AC plug

[17] Main connection

[19] Ground post

[20] Antifreeze kit connection

[21] Fuse

[22] Fuse

20 ... 120 ... 1

16 ... 116 ... 1

JP5

JP6

JP7

JP8

JP2

M

PS

M

M

E

FS

T=104°C

T=110°C

2

1

4

5

6

7

9

10

12

1315

16

20

19

18

21

22

17

14

8

3

6720608917-02.1AL

L N

11

T=90°C

6 720 800 095 (2015/11) Therm 6000S

8 | Technical Characteristics and Dimensions

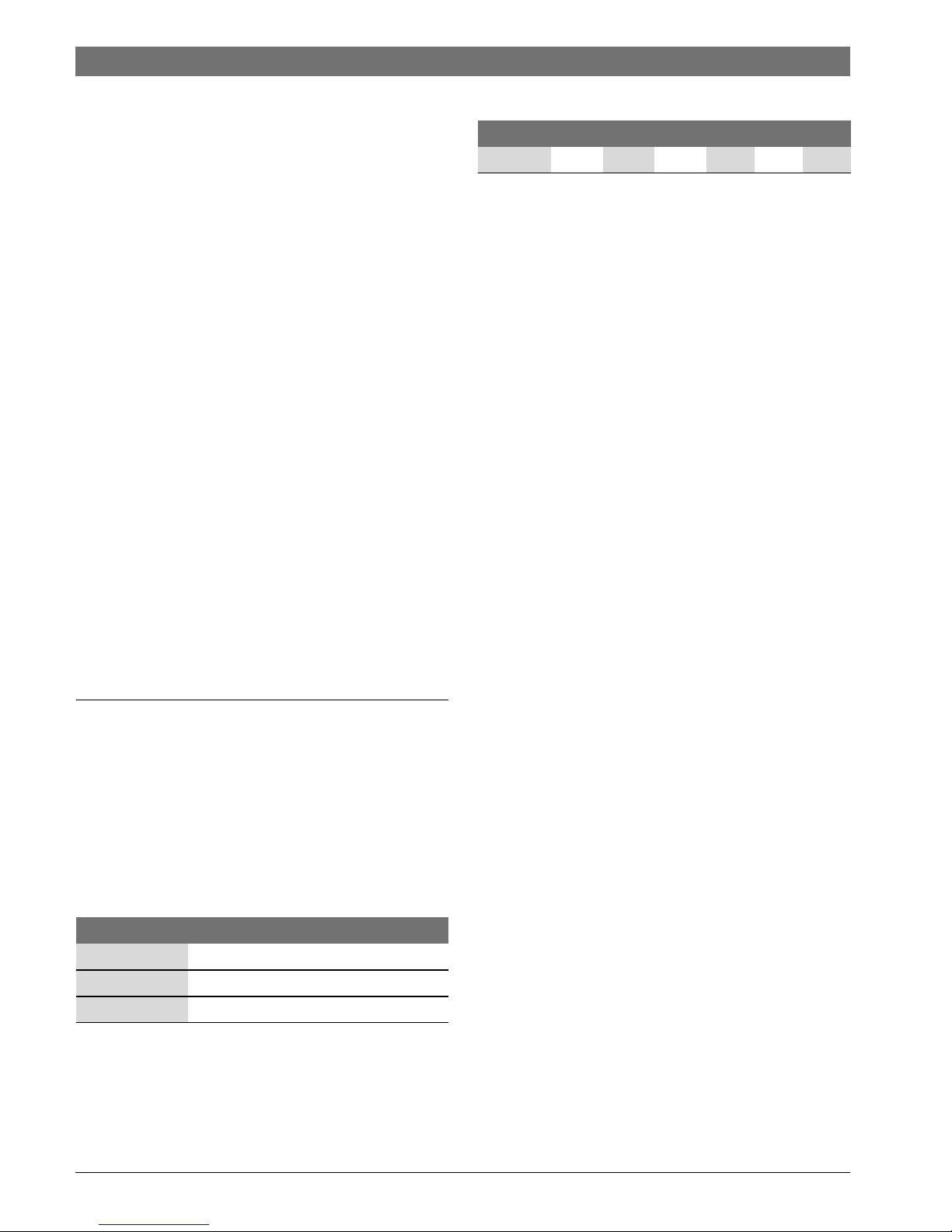

2.9 Technical data

Technical characteristics Symbol Units GWH 24 CTDE

Power and flow

Nominal useful power Pn kW (Btu/h) 42,0 (143 310)

Minimum useful power Pmin kW (Btu/h) 6,0 (20 475)

Useful power (adjustment range) kW 6,0 - 42,0

Nominal thermal flow Qn kW (Btu/h) 48,4 (165 295)

Minimum thermal flow Qmin kW (Btu/h) 6,3 (21 500)

Gas data

Supply pressure

LPG (Butane) G30 kPa 3,0

Natural gas G20 kPa 2,0

Consumption

LPG (Butane) G30 kg/h 3,8

Natural gas G20 m3/h 5,1

Water data

Maximum permissible pressure pw bar 12

Minimum operating pressure pwmin bar 0,3

Minimum activation flow l/min 1,9

Maximum water flow with temperature rise of 25 °C l/min 24

Combustion products contents - DIN 4705

Exhaust gas flow

LPG - Butane kg/h 69,1

Temperature of gases at extractor grill

Exhaust temperature at maximum power °C 215

Exhaust temperature at minimum power °C 48

General Data

Voltage V230

Frequency Hz 50

Maximum power consumption W116

Type of protection IP X4D

Ambient temperature permitted °C 0 - 50

Noise db (A) 59

Efficiency %87

Weight (excluding packaging) kg 31

Table 4

6 720 800 095 (2015/11)Therm 6000S

Regulation | 9

2.10 Operational instructions

Hot water

Open the gas and water valves and ensure that all joints are

hermetic.

Place the principle switch (Fig. 4, [1]) in the operating position

(chapter 4.3), so that the appliance is quickly ready for use.

When a hot tap is opened, the water flow sensor should be in

(Fig. 2, [2]) send a signal to the control unit. This signal

initiates the following:

•The fan starts working

• Simultaneously, sparks are produced and the gas valve

opens.

•The burner lights.

• The ionisation electrode controls the state of the flame.

• The water temperature is controlled automatically by the

sensors/controllers according to the temperature

selected.

Security cut-off when safety period is surpassed

If a flame is not achieved within the stipulated security period

(35 sec), a security cut-off will occur.

The presence of air in the gas inlet pipe (when the appliance is

used after long periods of inactivity for example) may delay

ignition.

In this case, if the attempts to ignite go on too long, the security

mechanisms prevent operation.

Security cut-off due to excessive water heating

The control unit detects the heating temperature via a NTC

resistor located in the hot water exit tube and the temperature

limiter located in the heat exchanger. If it detects an excessive

temperature it provokes a security cut-off.

Restarting after security cut-off

To restart the appliance following a security cut-off:

▶ Press the reset key (Fig. 19).

3Regulation

Any local by-laws and regulations pertaining to installation and

use of gas-heated appliances must be observed. Please refer to

the laws that should be attended in your country.

4 Operating instructions

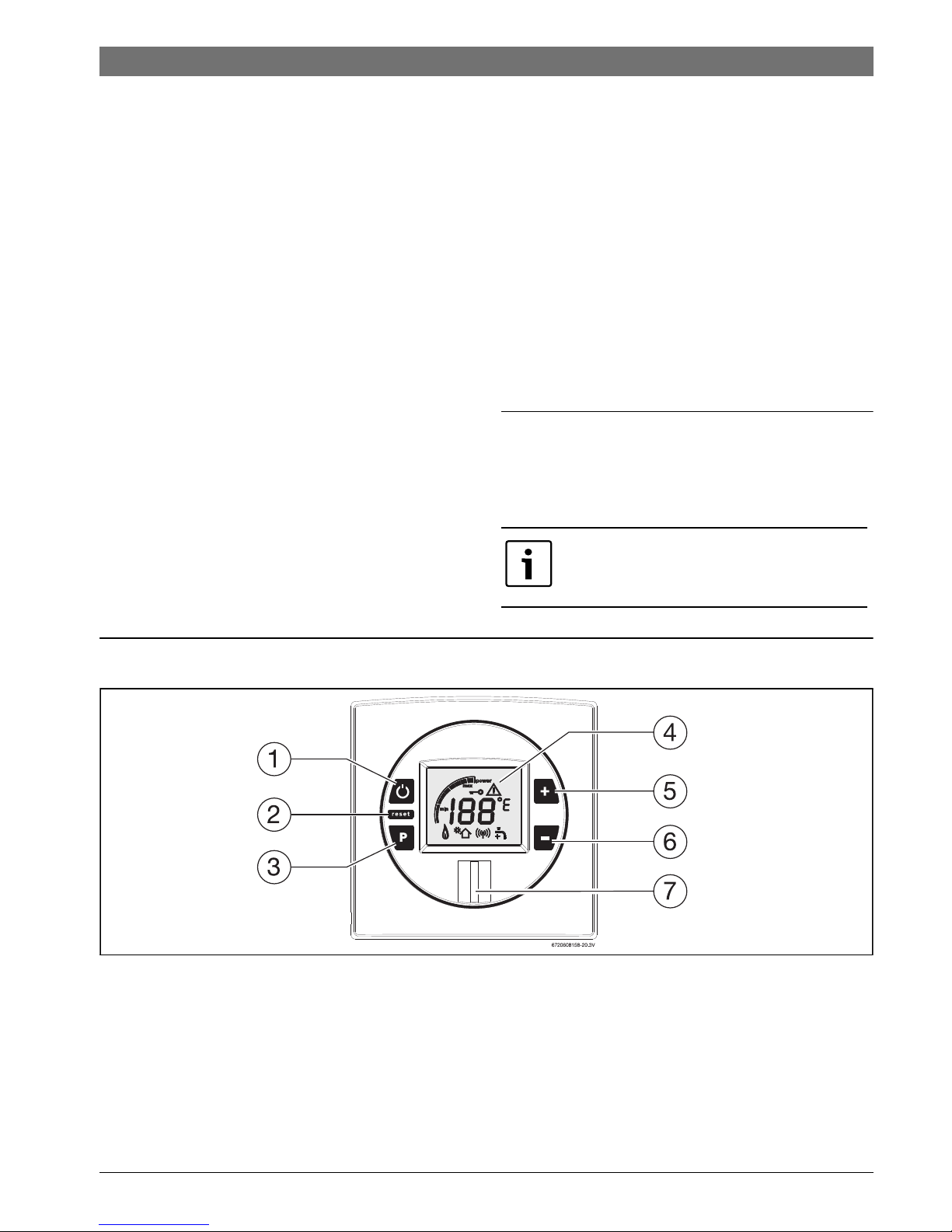

Fig. 4

[1] Main switch ON/OFF

[2] Reset key

[3] Program key

[4] LCD panel

[5] Temperature increase key/ programming key

[6] Temperature decrease key / programming key

[7] LED

The installation may only be carried out by

registered installers and shall comply with

the requirements of SANS 10087-1.

6 720 800 095 (2015/11) Therm 6000S

10 | Operating instructions

4.1 Description LCD Display

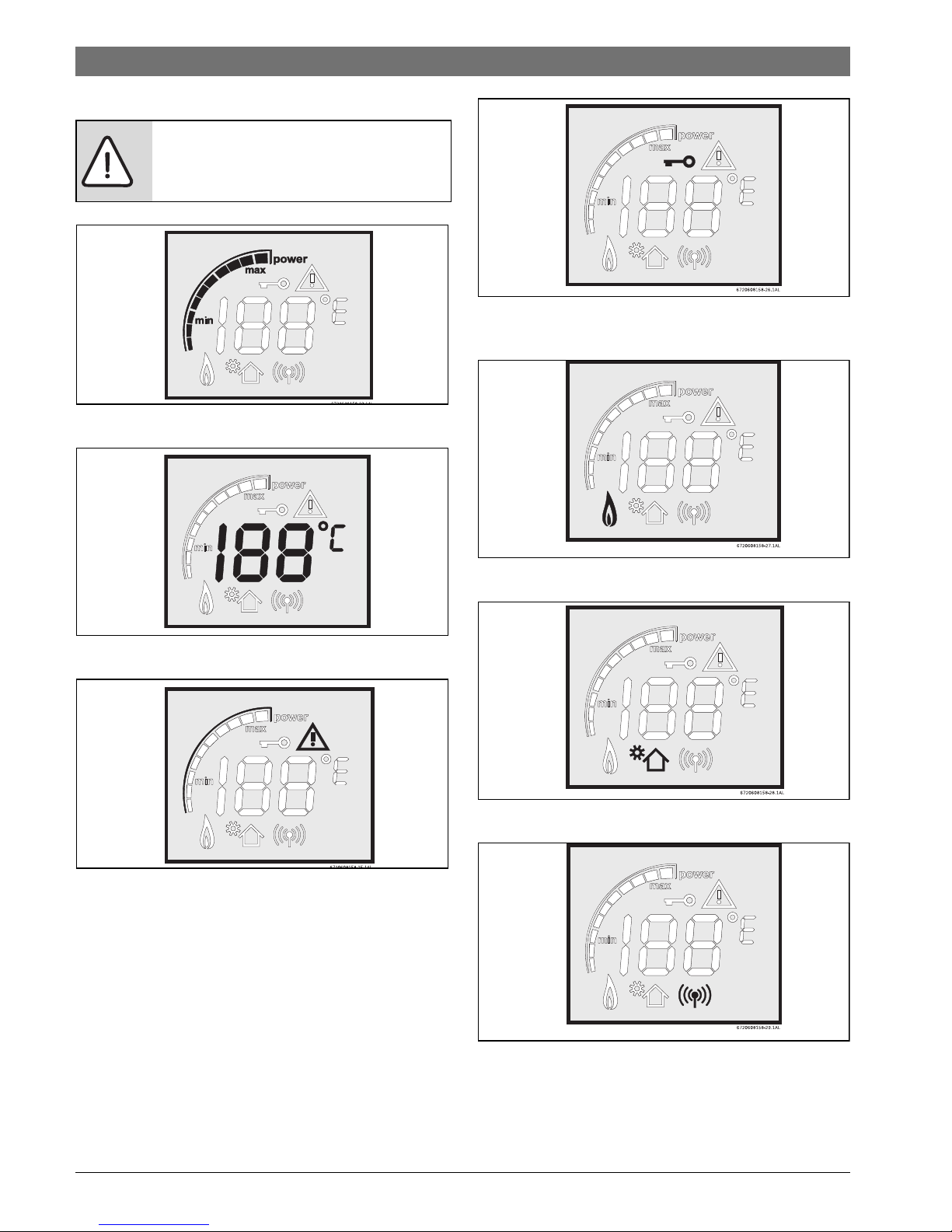

Fig. 5 Power bar indicator (input)

Fig. 6 Temperature indicator

Fig. 7 Error indicator

Fig. 8 Locked condition indicator (only with remote

control)

Fig. 9 Flame indicator

Fig. 10 Solar mode indicator

Fig. 11 Remote control indicator

CAUTION:

▶ Do not use any cleaning aggressive or

corrosive agents to clean the window.

6720608920-31.1AL

6 720 800 095 (2015/11)Therm 6000S

Operating instructions | 11

4.2 Before operating the appliance

▶ Confirm that the gas type of the heater matches the gas

supply you will be connecting the heater.

▶Open gas valve.

▶Open water valve.

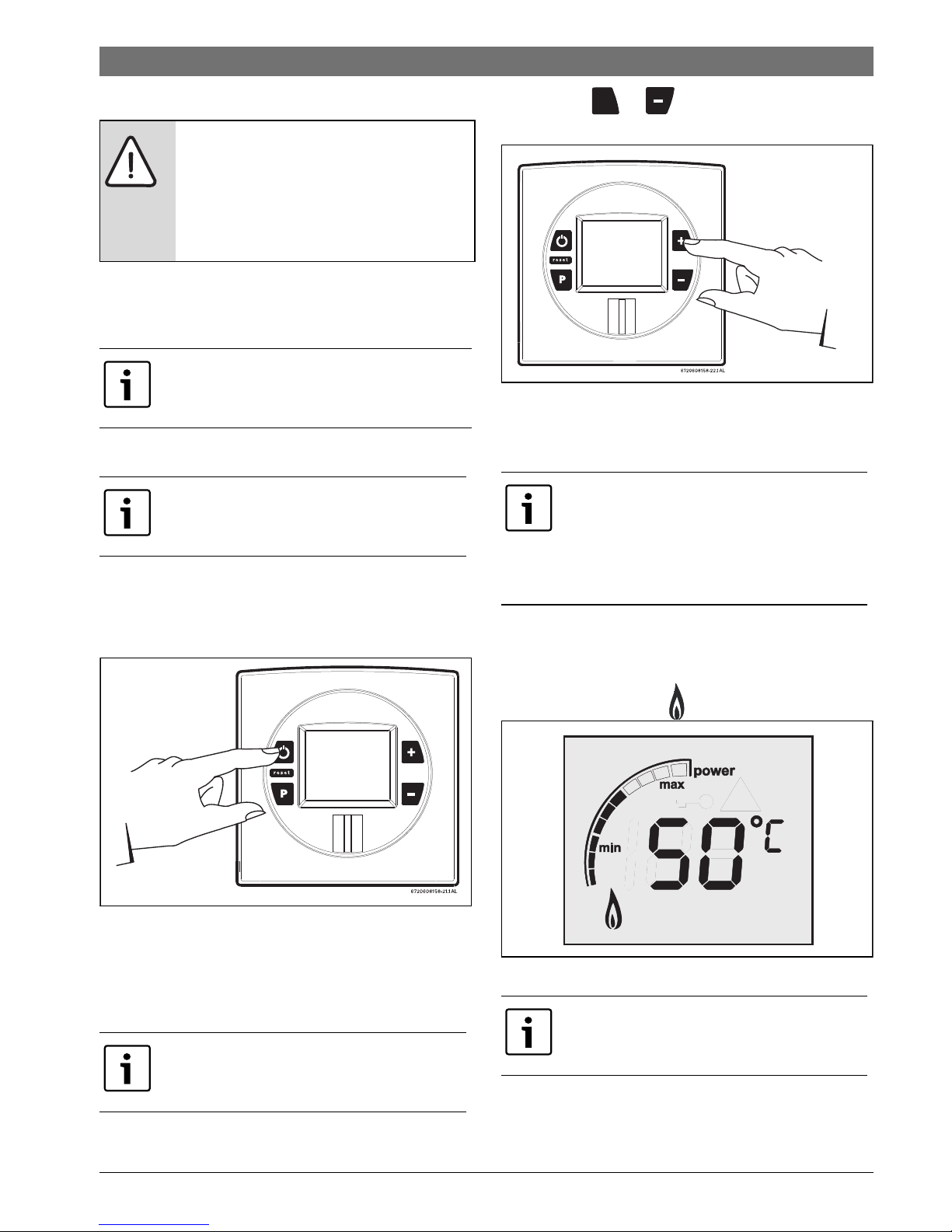

4.3 Connect and disconnect the appliance

Connect

▶ To start the appliance press the On/Off button.

Fig. 12

Disconnect

▶ To shut down the appliance press the On/Off button again.

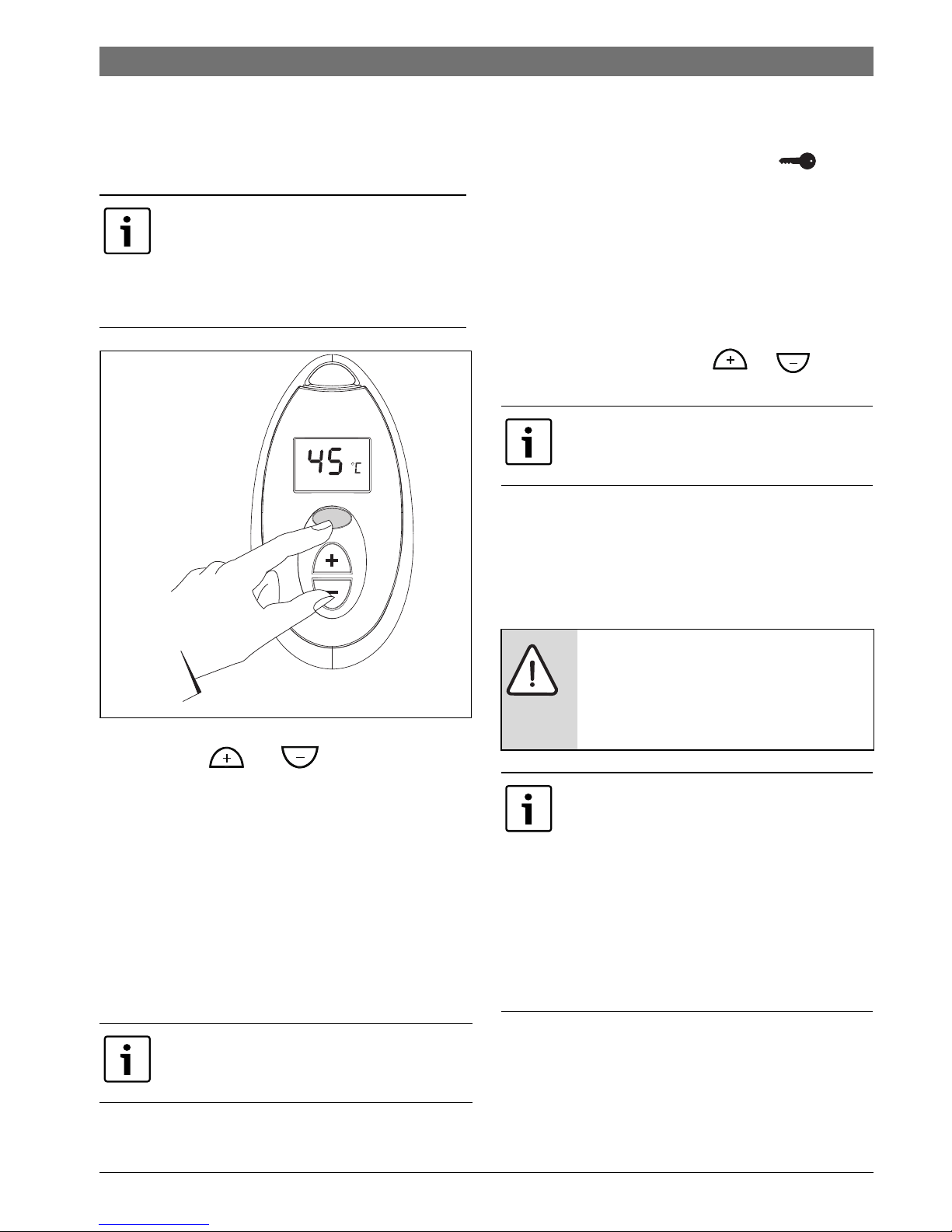

4.4 Water temperature setting

To regulate the emitted water temperature:

▶ Press the or until the desired value is

obtained.

Fig. 13

▶ Once the desired temperature is set, open the hot water

tap.

4.5 Operation

Turn ON the main switch and the appliance is ready to work.

▶ When a hot water tap is opened, main burner ignites and

LCD displays indication .

Fig. 14

CAUTION:

▶ The initial startup of the heater must be

realized by a qualified technician, who

will provide the client with all the

information necessary for its correct

usage.

Check for gas leaks at all joints.

Check for water leaks at all joints.

The temperature value indicated on the

LCD panel corresponds to the water

temperature at the appliance outlet.

These appliance has an electronically

controlled gas valve that modulates the

burner input in response to both varying hot

water flow rates and/or changes in any

incoming and outgoing water

temperatures.

LCD flashes until selected temperature is

reached.

+

6720608920-35.1AL

6 720 800 095 (2015/11) Therm 6000S

12 | Operating instructions

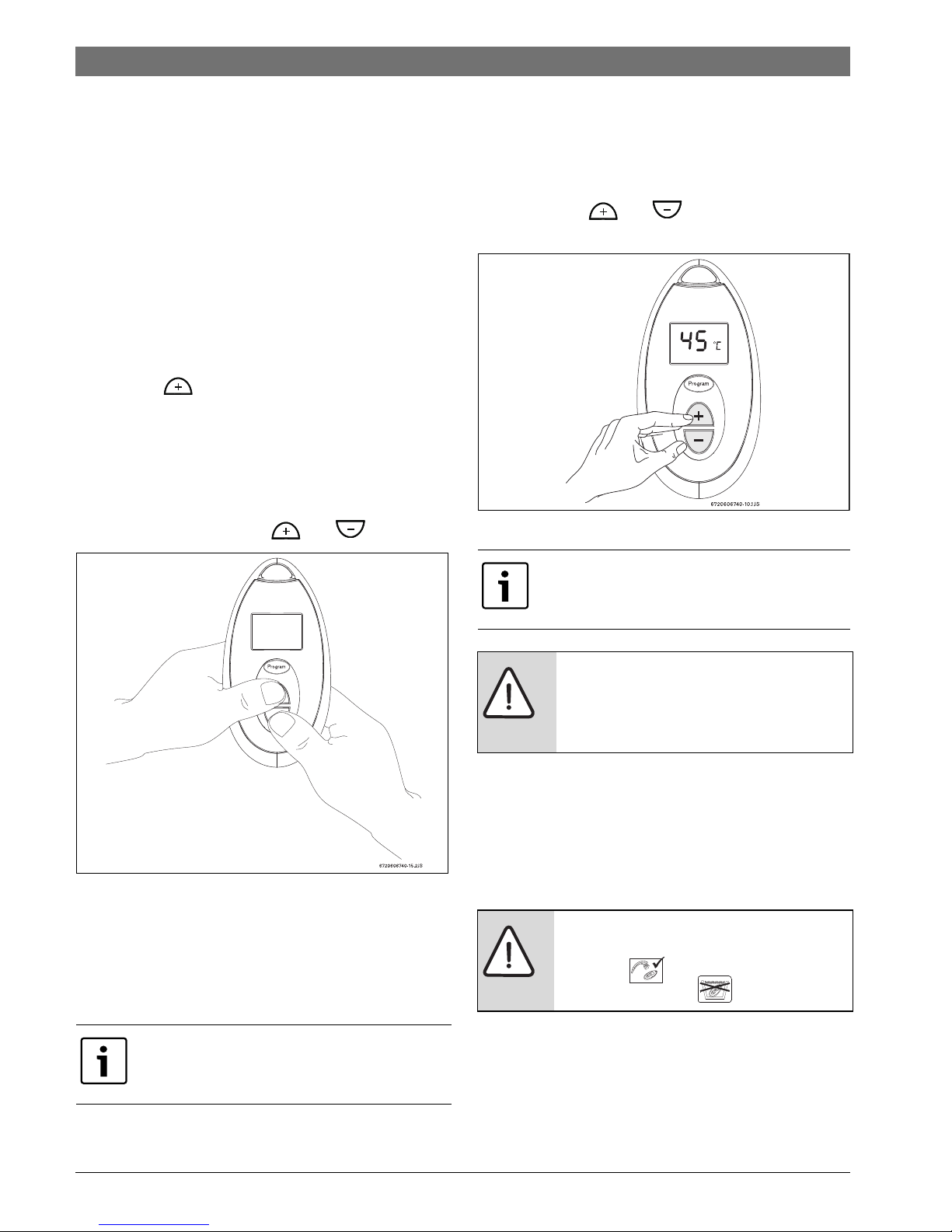

4.6 Registration of remote control (accessory no

7 709 003 756)

Only a qualified technician is allowed to install the additional

PCB that is supplied with the remote. Only after installation of

PCB the registration can be made.

The registration of the remote control must be done near the

appliance.

Hot water tap closed.

Turn OFF the appliance (Fig. 4, [1]).

▶ Press and hold the programming key (Fig. 4, [3]), press

ON/OFF button (Fig. 4, [1]) to connect the appliance.

Release programming key only when LCD displays “188”

The LCD displays the signal "P2".

▶ Press key , until it displays the signal "P3".

▶ Press programming key again for about 1 second.

LCD panel displays one number and one rotating digit.

The number represents the remote control which is to be

registered, the first remote control will be registered with

number “0”, the second with number “1” and so on.

▶ Test the remote control in front of the electronic box by

simultaneously pressing the and control keys.

Fig. 15 Activate new control

▶ Press both keys until the LCD panel stops flashing and

shows the indication “00”.

▶ Press ON/OFF button (Fig. 4, [1]) to disconnect the

appliance .

Remote control is now deactivated.

4.7 Remote control operation (accessory no 7

709 003 756)

This appliance fulfills European directive requirements 1999/

5/CEE (R&TTE) and corresponds to the specifications

described in the cor-responding CE certificate of proof.

▶ Press buttons and in order to reach r equested

temperature.

Fig. 16 Remote control (temperature selection)

Batteries replacement

▶ Remove the 2 screw from the remote control back.

▶Open the cover.

▶ Remove the old batteries and correctly place the new ones.

▶ Close the remote control assuring that both screws are

tighten screwed.

Precautions when using the batteries

• Do not dispose of batteries as domestic waste. Take them

to appropriate collecting places for recycling.

• Do not insert flat batteries.

• Only use the type of batteries indicated.

Press the ON/OFF button to turn ON the

remote control and it’s ready to work.

NOTE: up to 6 remote controls can be

programmed for one single water heater,

each with a range distance of 30m.

CAUTION:

▶ Remote control is not a toy - do not allow

children to play with the remote control

unit.

CAUTION:

▶ remote control can be used under the

shower , however, it’s immersion

must not be forced .

6 720 800 095 (2015/11)Therm 6000S

Operating instructions | 13

4.8 Program button

Program button can be used/programmed in the appliance and

in the remote control.

Programming "Program" function

Fig. 17 "Program" key

▶ Press buttons and to select temperature to

be memorized.

▶ Press "Program" button for 3 seconds to save temperature.

The temperature is saved on "Program" when the LCD

panel stops blinking.

Using "Program" function

In order to select memorized temperature:

▶ Press "Program" key.

LCD shows pre-memorized temperature, which is now the

selected hot water temperature.

4.9 "Priority" function

The appliance does not have a designated default priority.

Priority is attributed when the first user selects a temperature

(see chapter 4.4).

The following symbol appears for other users .

The priority user may change the initial selection at any time.

Non-priority users cannot change the selection made by the

priority user.

The system resets priority function 5 minutes after last water

demand, returning to the initial state.

To select priority

Any user may select temperature selection priority in the

following manner:

▶ Press one of the selection keys or for

5seconds.

4.10 Purge the appliance

If there is a risk of freezing, proceed as follows:

▶ Close the cold water valve of the water heater.

▶ Open hot water taps to drain the water heater.

▶ Remove all the water contained inside of the appliance.

Each remote control program button can

be programmed with different temperature

values according with the user needs. A

temperature value can be programmed in

the remote control and another value in the

appliance.

PRIORITY is a function to prevents the user

from accidentally altering the water

temperature selected by another user.

Program

6720608920-32.1AL

Priority cannot be selected when the

appliance is working.

CAUTION:

▶ The non accomplishment of the

purgative of the appliance whenever the

freezing risk exists, it can damage

components of the appliance.

The internal frost protection is designed to

provide protection for the water heater

down to approximately -10 °C for short term

conditions only. It will not protect the

appliance in areas where the temperature is

frequently expected to be below freezing.

The frost protection will not protect the

installation outside the appliance from

freezing. Suitable measures should be taken

to protect the installation against frost

damage.

6 720 800 095 (2015/11) Therm 6000S

14 | Installation instructions

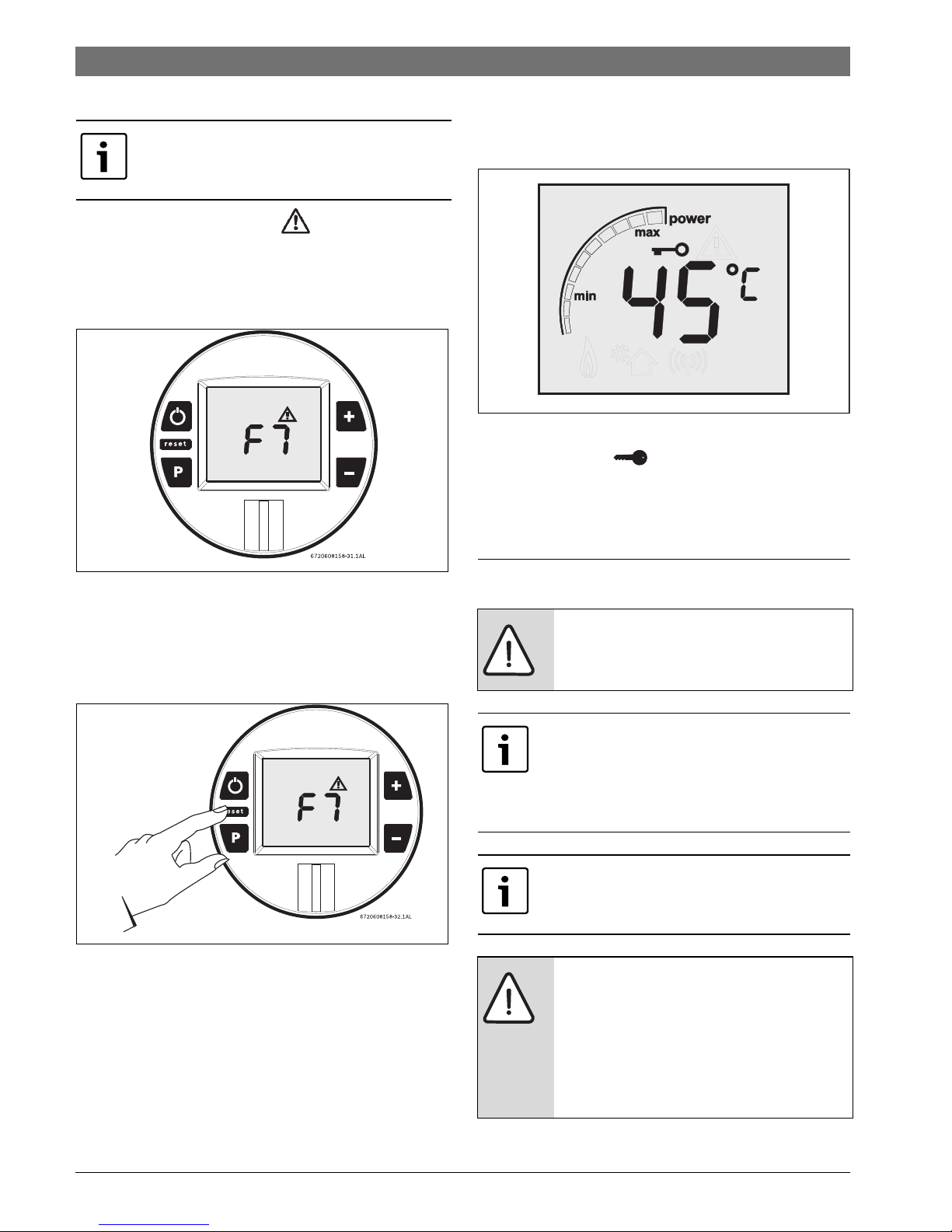

4.11 Reset button

If the LCD shows the error symbol do not shut off power

or unplug the heater. Follow instructions below to reset error

first.

Record the error code on LCD and consult chapter 10 to

identify the error.

Fig. 18 Error code

After following instructions indicated in “Troubleshooting”

section,

▶ press reset button firmly in order to return heater to normal

operation.

Fig. 19 Reset button

If the problem persists, contact your installer.

4.12 Locked condition

This condition is only valid for appliances with one or more

remote controls installed.

Fig. 20 Locked condition

Whenever LCD shows the temperature setting cannot

be adjusted because the appliance is in use by a user which

already selected a different temperature. Appliance will be

automatically unlock 5 minutes after closing hot water tap.

5 Installation instructions

This appliance has a error codes system. The

visualization of these codes is made through

the LCD display. (Fig. 4, [4]).

DANGER: Explosion!

▶ Always close the gas valve before doing

any work in gas components.

The installation, the electric connection, the

gas installation, the installation of the

exhaustion / admission conducts, as well as

the start up must be carried out by a qualified

technician.

The appliance can only be used in the

countries mentioned in the type plate.

CAUTION:

▶ Do not install the appliance where the

inlet water temperature is superior to

60 °C. In such cases we recommended

the installation of a mixer's valve in the

entrance of the appliance as prevention

measure.

6720608920-33.1AL

Loading...

Loading...