Page 1

BOSCH

Cooktop

Model No’s: PCH 612 DAU

PCH 615 DAU

PCH 615 FAU

MAKERS WARRANTY

BOSCH

Part No: W1532

Version (Bosch) A

USER INSTRUCTIONS

INSTALLATION INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

This cooktop is for use with Natural and Propane gases

Booklet designed and produced by DESIGN MAXIM. (03) 0853 7491

Leave these instructions with the owner

Page 2

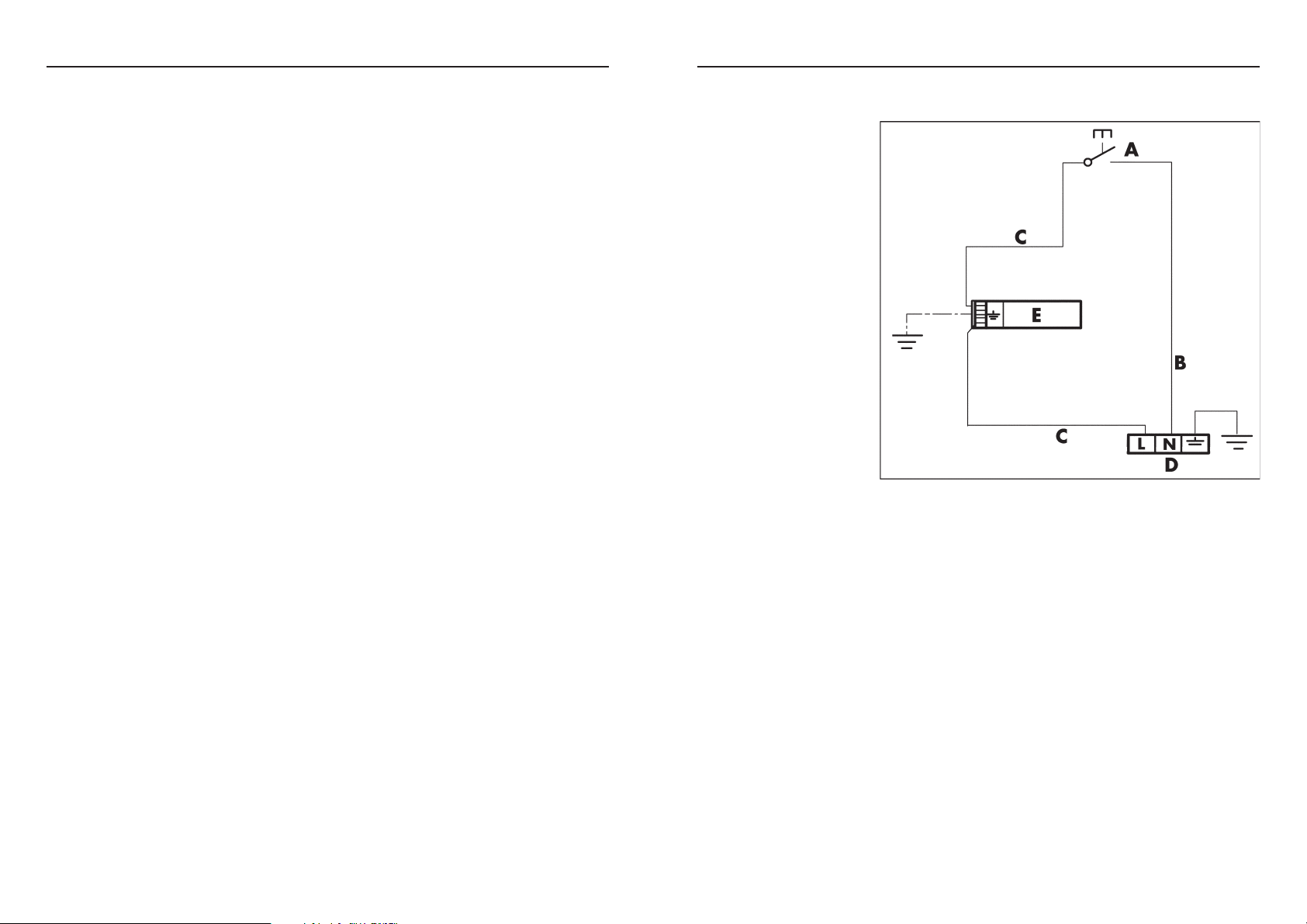

Wiring diagram

A. Switch

B. Blue wire

C. Brown wire

D. Terminal

E. Ignition module

Service agent

For service to this appliance please call an authorised Bosch

service agent or register you fault by phoning us on the numbers listed below.

Toll free

Melbourne: 1300 30 70 37

(head office) Sales, Customer and Technical Service

New Zealand: 0800 4BOSCH

0800 426 724

Sales and Customer Service

Robert Bosch (Australia) Pty. Ltd

(Incorporated in Victoria) ABN 48 004 315 628

Victoria: Cnr. Centre & McNaughton Roads,

New Zealand: 14-16 Constellation Drive, Mairangi Bay,

2 15

Clayton, 3168

Phone: (03) 9541 5555

Fax: (03) 9541 5595

Auckland, 1310

Phone: (09) 478 6158

Fax: (09)478 2914

Page 3

Service

Contents

Trouble shooting

chart

What’s wrong Possible cause Solution

...If none of the electrical • Power turned off. • Turn power on.

systems work. • Faulty fuse. • Check the fuse in the main

...If the electronic ignition • There may be food or • The gap between the spark

system does not work. cleaning product plug and the burner needs to

...If the flame on the • The burner components • Put the components in their

burners is not evenly have not been correct positions.

distributed. assembled properly.

...If the gas flow does not • The isolation valve is • Open the isolation valve.

seem normal or there closed.

is no gas flow at all. • If the gas is supplied • Replace the gas bottle with a

...If the kitchen smells • One of the valves has • Check to see if a valve has

of gas. been left open. been left open.

...If the safety cut-off • The control knob has • Once ignited, keep the

devices on the different not been kept control pressed in for a few

burners do not work. pressed in for long seconds.

It is not always necessary to call the Service Centre. In

some cases, you may be able to solve the problem

yourself. This table contains some useful information.

Important:

Only authorised personnel from the Service Centre

are qualified to work on the main gas and electric

systems.

fuse box and replace if faulty.

• The automatic circuit • Check to see if the circuit

breaker or mains. breaker or a differential has

differential has been been triggered in the mains

triggered. supply box.

particles between the be cleaned carefullly.

spark plugs and the

burners.

• The gas ports on the • Clean the gas ports on the

burners are dirty. burners.

from a gas bottle, it full one.

may be empty.

• Possible leak on the • Check that the coupling on

gas bottle coupling. the gas bottle is in order.

enough.

• The burner ports are • Clean the burner ports.

dirty.

Contents ....................................................... 3

Safety considerations ...................................... 4

For your safety .......................................... 4

What to do if you smell gas ......................... 4

Warnings ................................................. 4

Installation ..................................................... 6

Preparing to install ..................................... 6

Clearances ............................................... 7

Installation of cooktop into kitchen bench ....... 7

Installation procedure ............................. 7

Connection ............................................... 8

Electrical connection .............................. 8

Gas connection..................................... 8

Conversion from Nat. Gas to Propane Gas .... 9

To change injectors ................................ 9

Injector size chart .................................. 9

Minimum flame adjustment ................... 10

Operating instructions ................................... 11

Burner location ........................................ 11

Burner ignition & control ........................... 11

User instructions ........................................... 12

Boiling burners ........................................ 12

Wok trivet .......................................... 12

Wire coffee support ............................. 12

Cleaning and care ................................... 13

Do’s .................................................. 13

Don’t ................................................. 13

Service ....................................................... 14

Trouble shooting ...................................... 14

Wiring diagram ...................................... 15

Service contact telephone numbers ............. 15

14

3

Page 4

Safety considerations

What to do if you

smell gas

Warnings

• If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or death.

• Do not store articles on or against this appliance.

• Do not store flammable materials near this appliance.

• Do not spray aerosols in the vicinity of this appliance while it is in operation.

• Do not try to light the appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbour’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by an

authorised person.

1. Do not allow the flame to extend beyond the edge

of the cooking utensil. This instruction is based on

safety considerations.

2. Do not forget that the unit becomes hot when in

use. Common sense is important. Just because

the flame is out, does not mean parts cannot still

be hot.

3. This appliance shall not be used for space heating. This instruction is based on safety considerations.

4. Be sure to disconnect the electrical supply before

disassembly of the appliance.

5. Keep the appliance area clear and free from combustible materials, gasoline and other flammable

vapours and liquids.

6. This appliance must be installed in a position

with the proper level of ventilation. Do not obstruct the flow of combustion and ventilation air.

7. Cabinets installed above the gas cooktop must

have a minimum clearance of 650 mm (24”).

8. The gas pressure regulator supplied with the appliance must be installed in line with the gas pipe.

(N.G. only)

CleaningFor your safety

Do’s

•Once the appliance is cold, clean it with a sponge

and soapy water. Remove any spills immediately.

This will avoid unnecessary effort later.

• Allow burners and trivets to cool down before cleaning them.

• The burners and trivets must be cleaned regularly to

keep them in good condition. This is done by submerging them in soapy water and scrubbing them

with a non-metal brush to keep the ports and slots

free from obstructions so they give a perfect flame.

Dry the burner caps and trivets whenever wet or

damp.

• After cleaning and drying ensure that the burner

heads and caps are replaced correctly on the burner

body. Refer Fig. 6.

• The high temperatures generated by using the wok

burner may cause the stainless steel hob of your

hotplate to become discoloured over time. THIS IS

NORMAL. Clean the hob with a product suitable

for cleaning stainless steel.

• The trivets on your hob are fitted with rubber feet.

Be careful when cleaning as they may be dislodged

during cleaning, leaving the stainless steel hob unprotected and subject to surface scratching .

Don’t

• Never use abrasive products, sharp objects, steel

scouring pads, knives, etc., to remove stubborn food

remains from the hob surface, trivets and burners.

• Do not allow acidic products such as vinegar, lemon

juice, etc., to come into contact with the hob.

4

13

Page 5

User instructions

Boiling burners

Use ‘High flame’ setting to bring the pan to the boil,

then adjust the flame between ‘High flame’ and ‘Low

flame’ to maintain the required pan temperature.

Important:

The use of a cooktop leads to the production of heat

and moisture in the kitchen. For this reason make sure

that the room is properly ventilated. Keep natural ventilation openings, such as windows, open or provide

a mechanical ventilation device (e.g. a range hood or

overhead exhaust fan).

For safety and economic gas usage you should always use the correct pan on the correct burner. Flames

should not protrude beyond the base of the pan. You

will save energy, time and money by always placing

the correct pan size on the correct gas ring.

See Fig. 15.

15

The chart below gives the correct pan usage for each

burner.

9. For pressure testing in excess of 3.5 kPa

(1/2 psig) the appliance and its individual shutoff valve must be disconnected from the gas supply piping system.

10. Important

When using a very large pot, leave a gap of at

least 50 mm (2”) to avoid damaging any parts in

bench top wood, plastic or other non-heat resistant

materials. Never leave oil or hot fat unattended.

Note: To avoid jeopardising the electrical safety of the

appliance, it is forbidden to use high-pressure or steam

jet cleaning devices.

12

Burner Recommended Minimum

pan diameter pan diameter

Small burner 100 - 240 mm 100 mm

Medium & 180 - 260 mm 180 mm

wok burner

Wok trivet

The hotplate is supplied with an extra wok trivet. This

trivet must be used when using the wok burner for

receptacles with diameters of more than 26cm diameter, griddle plates and all kinds of concave receptacles such as woks, etc.

Wire coffee support

This support is for use only with the small burner when

supporting receptacles with a diameter of less than

10cm.

5

Page 6

Installation

Operating instructions

Preparing to install Burner locations

This installation must conform with the following:

• Manufacturer’s Installation instructions

• Local Gas Fitting Regulations

• Municipal Building Codes,

• AGA Installation Code for Gas Burning Appli-

ances. (AS 5601/AG 601)

• S.A.A. Wiring Code

• Local Electrical Regulations

• Any other statutory regulations

These built-in hobs are intended to be inserted in a

benchtop cutout.

Only an authorised person should connect the appliance.

Installation dimensions are shown in Fig.1

Burner ignition &

control

13

1. Medium burner

2. Medium burner

Depress control knob and turn anti-clockwise to ‘High

flame’ position. Hold the knob down for a few seconds until the flame ignites. Keep control knob depressed for a few seconds to activate the flame failure

device. If ignition fails, depress knob again and wait

for ignition. Turn anti-clockwise to set the flame to the

desired intensity.

All burners are fitted with a flame failure device which

shuts off the gas supply if the flame extinguishes for

any reason. To re-ignite, wait 30 seconds for any

unburnt gas to disperse before repeating the ignition

procedure described above.

To turn off the gas supply to a burner turn the control

knob clockwise to the ‘OFF’ position. (Refer Fig. 14)

3. Wok burner

5. Small burner

1

Before connecting the unit, check whether the local

connection conditions (type of gas) are compatible

with the unit’s settings. Observe any special conditions imposed by local suppliers (utilities). The specifications of this cooktop are stated on the data label

located on the bottom of the cooktop base.

6

The control knob is used to adjust the flame of the gas

burner.

‘Low flame’ graphic = lowest output

‘High flame’ graphic = highest output

14

11

Page 7

Minimum flame adjustment

1 Turn the control knob to minimum.

2 Remove the control knob from the valve spindle.

Refer Fig. 8.

3 Using a screwdriver carefully pry off the hard plas-

tic seal. Refer Fig. 9.

4 Using a small screwdriver carefully remove the soft

rubber seal. Refer Fig. 10.

5 The adjustment screw is positioned at the rear lower

section of the valve. Refer Fig. 11 & 12.

6 To adjust the minimum flame for N.G. replace the

control knob onto the spindle, light the gas and

turn the control knob to the small flame position.

Screw the adjustment screw anti-clockwise to establish a minimum stable flame position. The flame

should remain alight and not burn back to the injector when the valve is turned quickly from ‘Full

On’ to the “Minimum flame” position and back a

few times.

To adjust the minimum flame position for LP Gas

the screw must be fully tightened down clockwise.

7 Remove the control knob, replace the seals in re-

verse order and refit the control knob.

Clearances

Installation of cooktop

into the kitchen bench

A range hood fitted above the top must be installed

according to the installation instructions for the range

hood. A minimum distance of 650 mm is required for

a range hood and 750 mm for an exhaust fan.

If the distance measured from the periphery of the

nearest burner to any vertical surface is less than 200

mm, the surface shall be protected in accordance with

clauses 5.12.1 & 5.12.1.2 of AS 5601/AG 601.

Leave a space at least 100mm between any drawer,

partition or oven that is installed underneath the

cooktop.

Minimum thickness of benchtop is 15mm. See Fig. 2.

2

Installation procedure:

1. For cutout dimensions and clearances refer Fig 1.

2 The hotplate is factory fitted with sealing tape

around the lower edge of the hob and two pressure clamps front and rear. The seal keeps the entire work surface watertight and prevents spillage

from leaking into cupboards underneath. Please

ensure that the sealing tape is not disturbed during

the installation process. Refer Fig. 3.

10

10

11

9

3

3 Place hotplate on top of the bench cut-out and press

down firmly on all edges at the same time to ensure that the hob is resting on its entire perimeter.

NOTE: If it is necessary to dismount the hob, press

upwards only from underneath.

7

8

12

Page 8

Installation continued

Connection

Electrical:

An electrical 10 amp socket needs to be within 1 m of

the hotplate to allow electrical connection. The socket

must remain accessible after installation of the appliance.

Important note:

This appliance is connected to the mains (240 VAC)

by means of the connecting lead which must be fixed

to the kitchen unit to prevent it from coming into contact with hot parts of the hob (or an oven installed

underneath).. When making this connection make sure

that the lead cannot come into contact with hot parts

of the hob.

Important: This appliance must be earthed.

Gas:

During the planning stage, consider the position of

supply connections.

The hob must be connected to the gas supply with

upstream connection of an isolation valve in accordance with the respectively valid regulations. We recommend that the isolation valve be fitted prior to the

cooktop to enable isolation of cooktop from gas supply. The valve must be easily accessible at all times.

To find out the factory set gas type, see bottom of

cooktop next to gas connection.

Remove plastic cap from gas supply line prior to installation.

Fit regulator (N.G.) or Propane fitting (Propane) directly to the R1/2” connection as per Fig. 4 and Fig. 5.

Direction of gas flow is indicated on the rear of the

regulator.

For position of the inlet connection refer Fig.1.

Natural gas connection Propane gas connection

Converting the cooktop

from Nat. Gas to

Propane Gas

It should be expressly noted that we cannot accept

any liability for direct or indirect damage caused by

wrong connection or improper installation. When

being repaired, the appliance must always be

disconnected from the mains supply; if required,

notify our customer service.

To change injectors

Request change-over injectors from our customer service department (refer injector chart below for sizes).

Natural Gas Propane Gas

Burner Injector Hourly Gas Injector Hourly Gas

size(mm) Consumption size (mm) Consumption

(mm) (MJ) (mm) (MJ)

Left Front (wok) 1.70 14.0 0.97 13.25

Left Rear 1.20 6.5 0.67 6.25

Right Front 0.90 4.0 0.5 3.25

Right Rear 1.20 6.5 0.67 6.25

Before conversion the cooktop must be disconnected

from the electricity and gas valves must be turned to

the OFF position.

1 Remove the trivets, burner caps and burner heads.

Refer Fig. 6

2 Change the injectors using a 7-mm socket wrench

and be sure to tighten them down properly so that

they are fully airtight. Refer Fig. 7.

3 Re-assemble the burner component parts in reverse

order.

NOTE: it is not necessary to adjust the primary air

control on these burners.

4

8

5

6

7

9

Loading...

Loading...