Bosch Multi-Detector DMD4 Operating/safety Instructions Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

DMD4

For English Version

Version française

Versión en español

See page 2 Voir page 12 Ver la página 22

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

BM 2609140574 08-08 9/3/08 8:40 AM Page 1

-2-

k

1

2

3

4

5

6

7

j

i

h

g

a

b

c

d

e

f

8

9

10

8

11

12

FIG. 1 FIG. 3

FIG. 2

BM 2609140574 08-08 9/3/08 8:40 AM Page 2

-3-

The multi-detector’s ability to detect objects

is affected by the proximity of other equipment

that produce strong magnetic or

electromagnetic fields, and by moisture,

metallic building materials, foil-laminated

insulation materials and/or conductive

wallpaper.

The multi-detector’s ability to detect wood

substructures (studs) is also affected by

inconsistency on the thickness of the surface

material, such as plaster and lath.

It is possible that there may be metal, wood or

wiring or something else, such as plastic

pipes, beneath the scanned surface that is not

detected.

The detector alone should

not be relied on exclusively

to locate items below the scanned surface.

Use other information sources to help locate

items before penetrating the surface. Such

additional sources include construction plans,

visible points of entry of pipes and wiring into

walls, such as in a basement, and standard

16” and 24” stud spacing practices.

Before penetrating a

surface (such as with a

drill, router, saw or nail), always shut off

the electrical power, gas and water

supplies.

Cutting, drilling, etc… into these

items when operational can result in personal

injury.

Optimal operation of the multi-detector is possible only when the operating instructions

and information are read completely, and the instructions contained therein are strictly

followed.

SAVE THESE INSTRUCTIONS

Functional Description

INTENDED USE

The multi-detector is intended for the detection

of metals (ferrous and non-ferrous metals,

such as pipes, metal studs and rebar), wood

studs and joists, and “live” wires/conductors in

walls, ceilings and floors.

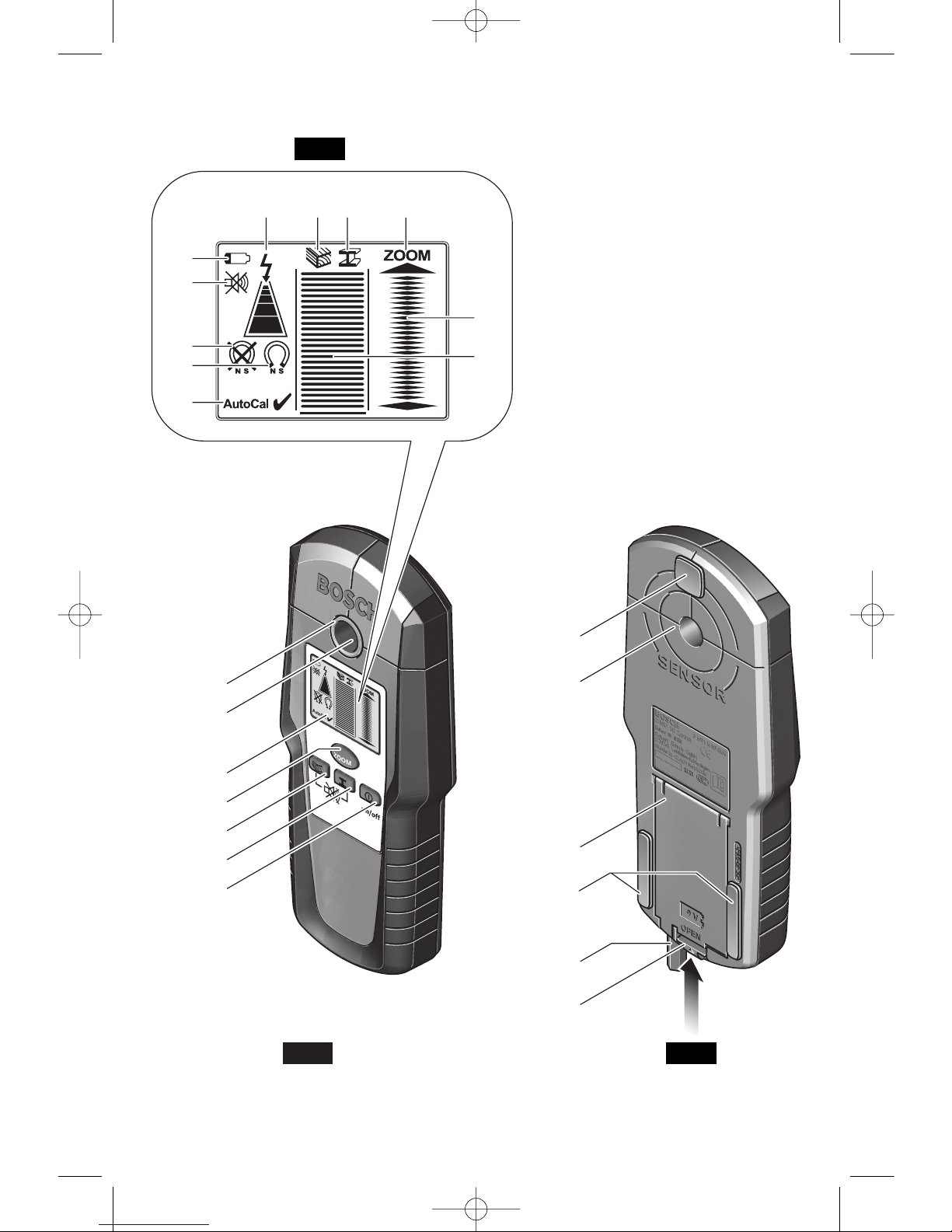

PRODUCT FEATURES

The numbering of the product features shown

refers to the illustration of the multi-detector on

the graphic page 2.

1 Illuminated ring

2 Marking hole

3 Display

4 Metal mode “ZOOM” button (also used for

wood calibration)

5 Wood detection mode button

6 Metal detection mode button

7 “On/off” button

8 Felt pads

9 Sensor area

10 Battery lid

11 Pencil for marking (removable)

12 Latch of battery lid

DISPLAY ELEMENTS

a

“Live” wire indicator

b Wood detection mode indicator

c Metal detection mode indicator

d

“ZOOM”

indicator

e “ZOOM” measuring indicator

f Main measuring indicator

g “AutoCal” calibration indicator

h Magnetic metal indicator

i Non-magnetic metal indicator

j Switched-off audio signal indicator

k Battery indicator

Safety Rules for Multi-Detector

Read all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

!

WARNING

!

WARNING

!

WARNING

BM 2609140574 08-08 9/3/08 8:40 AM Page 3

Preparation

-4-

DIGITAL MULTI-DETECTOR DMD4

Article number 3 601 K10 010

Maximum scanning depth*:

Ferrous metals 4" / 100 mm

Non-ferrous metals (copper) 3-1/8" / 80 mm

Copper wiring (live) 2" / 50 mm

Wood Substructures (studs) 3/4" / 20 mm

Automatic switch-off After approx. 5 min

Operating temperature 14 °F 122 °F

–10 °C +50 °C

Storage temperature – 4 °F –158 °F

–20 °C +70 °C

Battery 1 x 9 V 6LR61

Rechargeable battery 1 x 9 V 6F22

Operating lifetime (alkali-manganese batteries) Approx. 6 h

Weight according to EPTA-Procedure 01/2003 0.53 lbs/ 0.24 kg

* Depends on material and size of objects as well as material and condition of structure.

** Less scanning depth for wires/conductors that are not “live”.

Please observe the article number on the type plate of your multi-detector.

Technical Data

INSERTING/REPLACING THE BATTERY

Use only alkali-manganese or rechargeable

batteries.

To open the battery lid

10, press the latch 12

in the direction of the arrow and fold up the

battery lid. Insert the supplied battery. Pay

attention that the polarity is correct, according

to the + and - symbols on the inside of the

battery lid.

• When the battery indication

k in the display

lights up, measuring is possible for approx. 1

h when using alkali-manganese batteries

(service life is shorter with rechargeable

batteries).

• When the battery indication

k flashes,

measuring is still possible for approx. 10

minutes.

• When the battery indication k and the

illuminated ring

1 (red) are flashing,

measuring is no longer possible and the

battery or the rechargeable battery

respectively, must be replaced.

•

If the multi-detector is not used for a long

period of time, the battery must be

removed.

The battery can corrode or

discharge itself over long periods.

BM 2609140574 08-08 9/3/08 8:40 AM Page 4

-5-

Operating Instructions

SWITCHING ON

Before switching the multi-detector on, make

sure that the sensor area 9 is not moist.

If

required, wipe the multi-detector dry using a cloth.

The multi-detector detects objects that are

below the sensor area

9.

If the multi-detector was subject to an

extreme temperature change, allow it to

adjust to the ambient temperature before

switching on.

To switch the multi-detector on, press any button.

• When switching the multi-detector on with

the wood detection mode button

5 or with the

metal-detection mode button

6, it will

automatically be in the respective detection

mode. After a brief self-check, the multidetector is ready for operation.

• When switching the multi-detector on with

the “on/off” button

7 or with the “ZOOM”

button 4, it will be in the detection mode last

used. After a brief self-check, the multidetector is ready for operation.

• When the multi-detector is in the metal-

detection mode, the service readiness is

indicated through a check mark behind the

“AutoCal” calibration indicator g.

RECOMMENDATIONS FOR

PROPER SCANNING

• Avoid wearing jewelry such as rings or

watches when using the detector. The metal

may cause inaccurate detection.

• Move the multi-detector uniformly the surface

without lifting it off or changing the applied

pressure.

• During the scan, all three of felt pads

8 must

always have contact with the surface.

• Make sure that your fingers of the hand

holding the multi-detector do not touch the

surface being scanned, which could interfere

with the tool’s ability to effectively detect

items below the surface.

• Do not touch the surface being scanned with

your other hand or any other part of part of

your body, because the moisture may affect

the scanning.

• Always measure SLOWLY to achieve

maximum sensitivity.

MARKING OBJECTS

Detected objects can be marked as required.

For this, remove the pencil

11 from the multi-

detector and carry out the scan as usual.

Once you have found the limits or the center

of an object, simply mark the sought after

location through the marking opening

2. It is a

good idea to establish a consistent practice of

making one type of mark over places in which

you

do not want to penetrate (drill, nail, cut),

such as O, and a different symbol over places in

which you do want to penetrate, such as an X.

SWITCHING OFF

To switch the multi-detector off, press the

“on/off” button

7.

• If none of the multi-detector buttons are

pressed for approx. 5 minutes, the multidetector switches off automatically in order to

extend the service life of the battery.

SWITCHING OFF THE SIGNAL TONE

The signal tone can be switched on and off.

For this, press the metal-detection mode

button

6 and the wood-detection mode button

5 at the same time. When the signal tone is

switched off, the switched-off audio signal

indicator j appears on the display. The signal

tone setting is maintained after switching the

multi-detector off and on again.

BM 2609140574 08-08 9/3/08 8:40 AM Page 5

-6-

PRELIMINARY METAL SCAN

When scanning for metal objects, press the

metal detection mode button

6. The metal

detection mode indicator

c is indicated in the

display and the illuminated ring

1 lights up green.

Position the multi-detector then move it

uniformly across the surface.

• When the multi-detector

comes close to a metal object,

then the amplitude increases,

as represented by the number

of bars shown in the main

measuring indicator

f.

• When it moves away from the

object, the amplitude and

number of bars shown

decreases.

At the position of maximum

amplitude, the metal object is

located below the center of the

sensor (below the marking

opening

2).

As long as the multi-detector is above the

metal object, the illuminated ring

1 lights up

red and a steady tone sounds.

Notes:

• The ability to detect nails, screws, rebar and

other metal objects is somewhat dependent

on their orientation. For example, at any

given depth it is easier for the unit to detect

the length of a screw or nail than it is to

detect the end of a screw or nail.

• The entire width (3-1/8” / 8 cm) of the detector

can detect metal near the surface of scanned

items, so the unit is wide enough to scan for

metal near the surface of a 3” wide board prior

to sanding or planing.

• When a metal item is much narrower than

the SENSOR area, the maximum signal

might be displayed when the item is just

under the left and right of the center hole,

rather than the center of the hole, especially

if the item is near the surface.

• Always measure SLOWLY to achieve

maximum accuracy and sensitivity

• Use the ZOOM feature to maximize

sensitivity, especially important when

searching for deep items prior to drilling,

sawing, nailing and/or routing.

ZOOM METAL SCAN

The ZOOM mode should be used AFTER the

Preliminary Metal Scan for the purposes listed

below.

• ALWAYS start the ZOOM Metal Scan near

the location that the metal object was

detected in the Preliminary Metal Scan.

• Press the “ZOOM” button

4 and KEEP IT

PRESSED while continuing to move the

multi-detector over the area. Observe only

the ZOOM measuring indicator

e.

Precision Location

- The ZOOM function can

be used to more-precisely locate the center of

a metal object and for distinguishing between

close metal objects. The “ZOOM” measuring

indicator e has the greatest amplitude over the

center of the metal object.

Detection of Small or Deep Objects - The

ZOOM function can also be used when very

small or deeply embedded metal objects are

being detected but the main measuring

indicator

f does not react.

Detection Though Material With Metal

inclusions

- The ZOOM function can also be

used if there are any metal inclusions in the

material being scanned, such as wire mesh in

lath and plaster walls, then a continuous

signal is indicated in the main measuring

indicator

f.

MAGNETIC VS. NON-MAGNETIC METALS

If the metal object found is a magnetic (e.g.

iron or steel), then the indicator for magnetic

metals

h is displayed.

For non-magnetic metals, the indicator for

non-magnetic metals

i is displayed.

In order for the multi-detector to differentiate

between the metal types, it must be positioned

above the detected metal object and the

detection must be strong enough that the

illuminated ring

1 lights up red.

For weak signals, the indication of the metal

type is not possible. For steel wire mesh and

similar reinforcements in the scanned

structural material, amplitude of the main

measuring indicator

f is displayed over the

complete surface. In this case, always use the

“ZOOM” function for the scan. When scanning

over steel mesh in concrete, typically (but not

always) the indicator for magnetic metals

h is

displayed directly above the rebar; the

indicator for non-magnetic metals

i is

displayed between the rebars.

Scanning in Metal-Detection Mode

BM 2609140574 08-08 9/3/08 8:40 AM Page 6

-7-

Scanning in Wood-Detection Mode

The wood-detection mode actually detects

more than just wood substructures (studs and

joists). It may also detect metal and other

dense materials such as water-filled pipes

plastic pipes near the back of the surface in

the wall or ceiling. To help identify wood

substructures, first conduct a metal scan and

mark the location of any detected metal items.

Then conduct a scan in the wood-detection

mode. Items that are detected in the wooddetection mode but not in the metal-detection

mode are items that are possibly wood

substructures.

To scan for wood objects,

1. Press the wood detection mode button 5.

• The wood mode indicator

b and the

“ZOOM” indicator d are shown in the

display, the arrow below the

“ZOOM”

indicator d flashes, and the “AutoCal”

calibration indicator g and the illuminated

ring

1 go out.

2. Position the multi-detector onto the surface

to be scanned.

3. Then press the “ZOOM” button* 4 AND

KEEP IT PRESSED.

• Now the illuminated ring 1 lights up green,

the

AutoCal” calibration indicator g is

displayed again, and the

“ZOOM” indicator

d as well as the arrow below it go out, all

indicating that the multi-detector is calibrated

for the wood scan.

4. After the multi-detector has

been calibrated and while

continuing to press the

“ZOOM” button 4, move the

multi-detector uniformly over

the surface without lifting it off

or changing the applied

pressure. During the scan, the

felt pads

8 must always have contact with the

surface.

• When an object is detected, an amplitude is

displayed in the main measuring indicator

f.

Move the multi-detector over the surface

repeatedly to locate the object more

precisely. After moving over the same area

several times, the object can be indicated

quite accurately: The illuminated ring

1 lights

up red and a steady tone sounds as long as

the multi-detector is over the object. The

main measuring indicator

f has the greatest

amplitude (as represented by the number of

bars shown in the main measuring indicator

f )

over the center of the object.

Note: While the “ZOOM” button 4 is pressed

during the wood scan, the “ZOOM” feature

and ZOOM measuring indicator

e are inactive.

Notes:

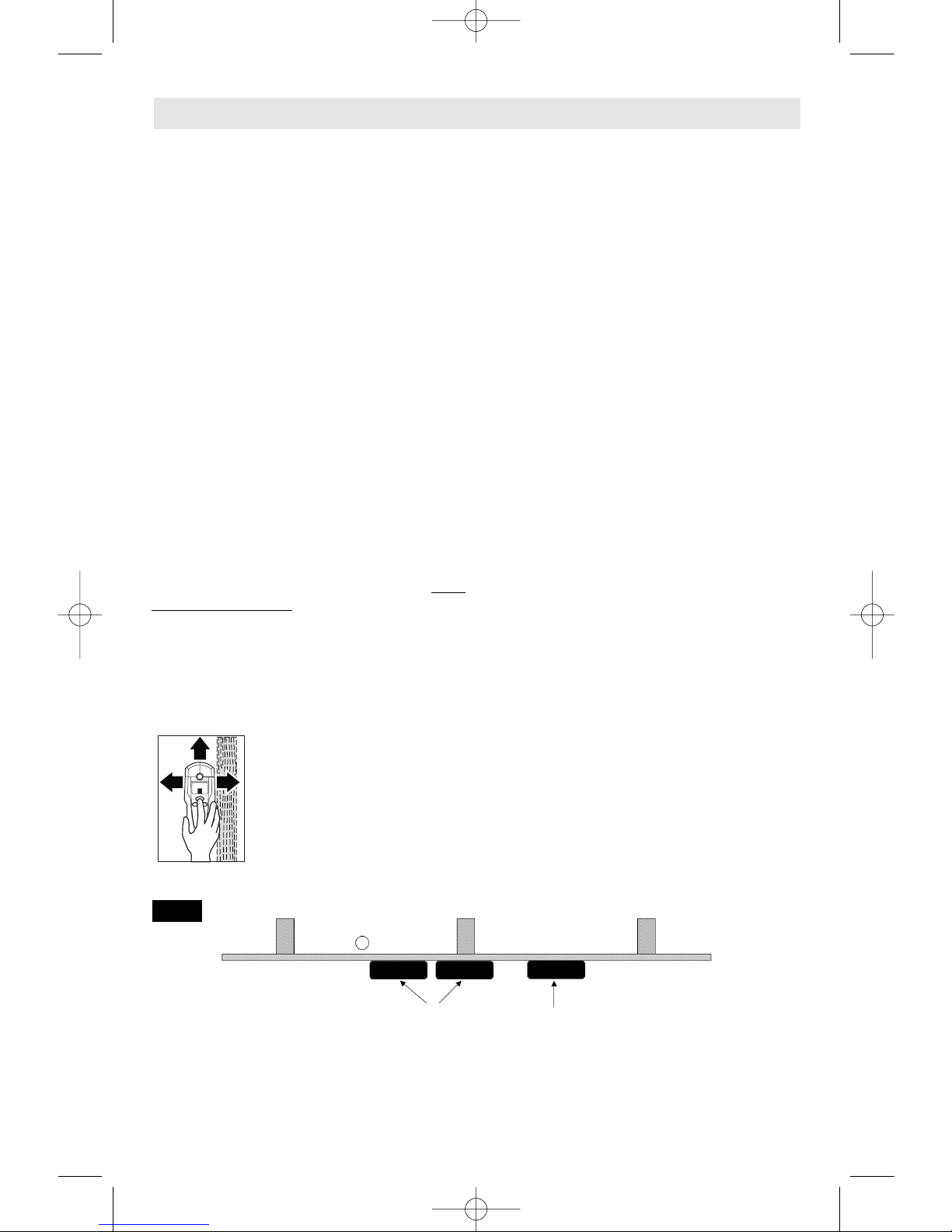

• If the scan (and thus calibration) starts

over a dense object, such as a stud or a

pipe, and is then moved across the

surface

, the main measuring indicator f and

the arrow below the “ZOOM” function

indicator

d flash and the illuminated ring 1

flashes red, indicating a calibration failure. If

this happens, move the detector horizontally

to a different location and start the scan

again (Fig. 4).

•

During a wood scan, metal objects at

depths between 3/4" and 2" may also be

detected.

To help distinguish between

wood and metal objects, switch to metaldetection mode (see “Detecting Metal

Objects”). When an object is indicated at the

same location in the metal-detection mode,

then it is likely a metal object or a wood stud

or joist with nails or screws in it. To continue

searching for wood objects, switch back to

the wood-detection mode.

PIPE

STUD

STUD

STUD

MULTI-DETECTOR

AT PROBLEM

LOCATIONS FOR

STARTING

“WOOD” SCAN

MULTI-DETECTOR

AT GOOD

LOCATIONS FOR

STARTING

“WOOD” SCAN

WALL

FIG. 4

BM 2609140574 08-08 9/3/08 8:40 AM Page 7

-8-

Lath and Plaster

Because of the uneven thickness of the

plaster, it is difficult to detect wood studs using

the wood detection mode. It will probably be

easier to locate the studs by changing to the

metal-detection mode to locate the nails that

hold the lath to the studs.

Lath and Plaster with Metal Mesh

Reinforcement

(See SCANNING IN METAL–DETECTION

MODE).

Textured or Acoustic Walls and Ceilings

When scanning a wall or ceiling with an

uneven surface, place thin cardboard on the

surface to be scanned and scan over the

cardboard. In wood-detection mode, calibrate

with cardboard in place.

Wallpaper

If paper contains metallic foil, metallic fibers,

see SCANNING IN METAL-DETECTION

MODE. If paper is wet, it must be allowed to

dry before scanning.

Wood Flooring, Wood Subflooring and

Drywall Over Plywood Sheathing

Because of the thickness of these materials, it

is difficult to detect wood joists or studs using

the wood-detection mode. It will probably be

easier to locate these items by changing to the

metal-detection mode to locate the nails that

hold the materials to the joists or studs.

Carpeting

The DMD4 cannot detect wood studs and

joists through carpeting. It might be possible to

use the metal-detection mode to locate nails

or screws that were used to attach the wood

floor to the joist.

The multi-detector can indicate “live”

wires/conductors with 50 or 60 Hz of 120V AC

or at higher voltages. If other wires/conductors

are detected, they are indicated only as metal

objects. “The multi-detector automatically

scans for “live” wires/conductors in both the

metal mode and wood mode.

When a “live” wire/conductor is detected, the

indicator

a appears in the display. Move the

multi-detector over the surface repeatedly in

order to locate the “live” wire/conductor more

precisely. After moving the multi-detector over

the surface several times, the “live”

wire/conductor can be located quite precisely.

If the multi-detector is very close to the

wire/conductor (four or five bars in indicator a),

the illuminated ring

1 flashes red and the

signal tone sounds with a rapid tone

sequence.

• “Live” wires/conductors can be detected

more-easily when power consumers (e.g.,

lamps, appliances) are connected to the

wire/conductor being sought and switched

on.

• Wires/conductors with 110 V, 240 V and

380 V (three-phase current) are detected

with about the same scan capacity.

• Under certain conditions (such as when

behind metal surfaces, shielded in conduit or

behind surfaces with high water content),

“live” wires/conductors cannot be detected

with certainty. These ranges may be

recognized in the metal detection mode as

metal objects.

• Wires that are not “live” might be detected as

metal objects with the metal-detection mode.

However, unlike solid copper cables,

stranded copper cables are not detectable.

• When “live” wiring is detected over a wide

area, the scan for “live” wiring is not reliable

because something in the surface material is

shielding or distorting the electrical field.

Before penetrating a

surface (such as with a

drill, router, saw or nail), always shut off

the electrical power, gas and water

supplies.

Cutting, drilling, etc… into these

items when operational can result in personal

injury.

Scanning for “Live” Wires

Detection Through Special Surface Materials

!

WARNING

BM 2609140574 08-08 9/3/08 8:40 AM Page 8

-9-

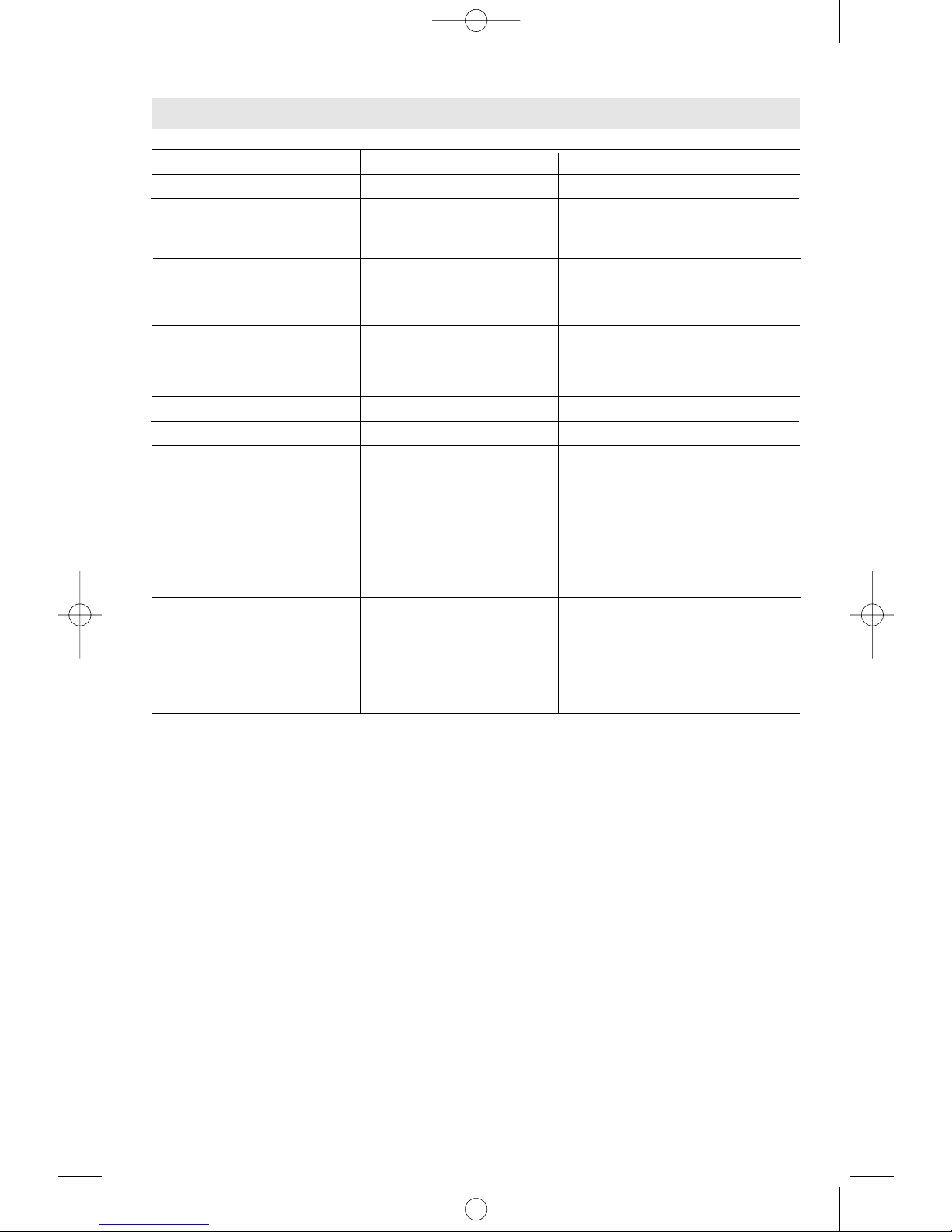

Metal Scan

Issue Possible Reason Remedy

Image of metal object • DMD4's metal detection • Use ZOOM feature to more

appears wider than actual is very sensitive. precisely determine location

size. and center of metal object(s).

Difficulty detecting metal. • Metal objects are too • Use ZOOM feature

deep. (See Maximun

• Scan in vertical direction as

Scanning Depth, page 4.)

well as horizontal direction.

Seemingly false metal • Jewelry or mechanical • Remove jewelry

detection. pencil are too close to

• Use non-mechanical pencil

SENSOR area.

• Recalibrate detector.

Wood Scan

Issue Possible Reason Remedy

Difficult detecting wood • Studs and joists are • Change to metal scan to search

studs and joists. too deep. for nails or screws that may

indicate location of the stud

or joist.

Difficult to successfully • Double and triple studs • Start scan farther away so

starting scan near doors are usually found around that outer edge of multiple

and/or windows. doors and windows. studs and /or headers are

detected.

More items than anticipated • Wood scan detects • Conduct metal scan as well

are detected. metal and other dense to help determine which

objects as well as studs detected items are metal,

and joists. rather than something else,

such as wood studs or

plastic pipes.

Trouble Shooting

BM 2609140574 08-08 9/3/08 8:40 AM Page 9

-10-

Maintenance and Service

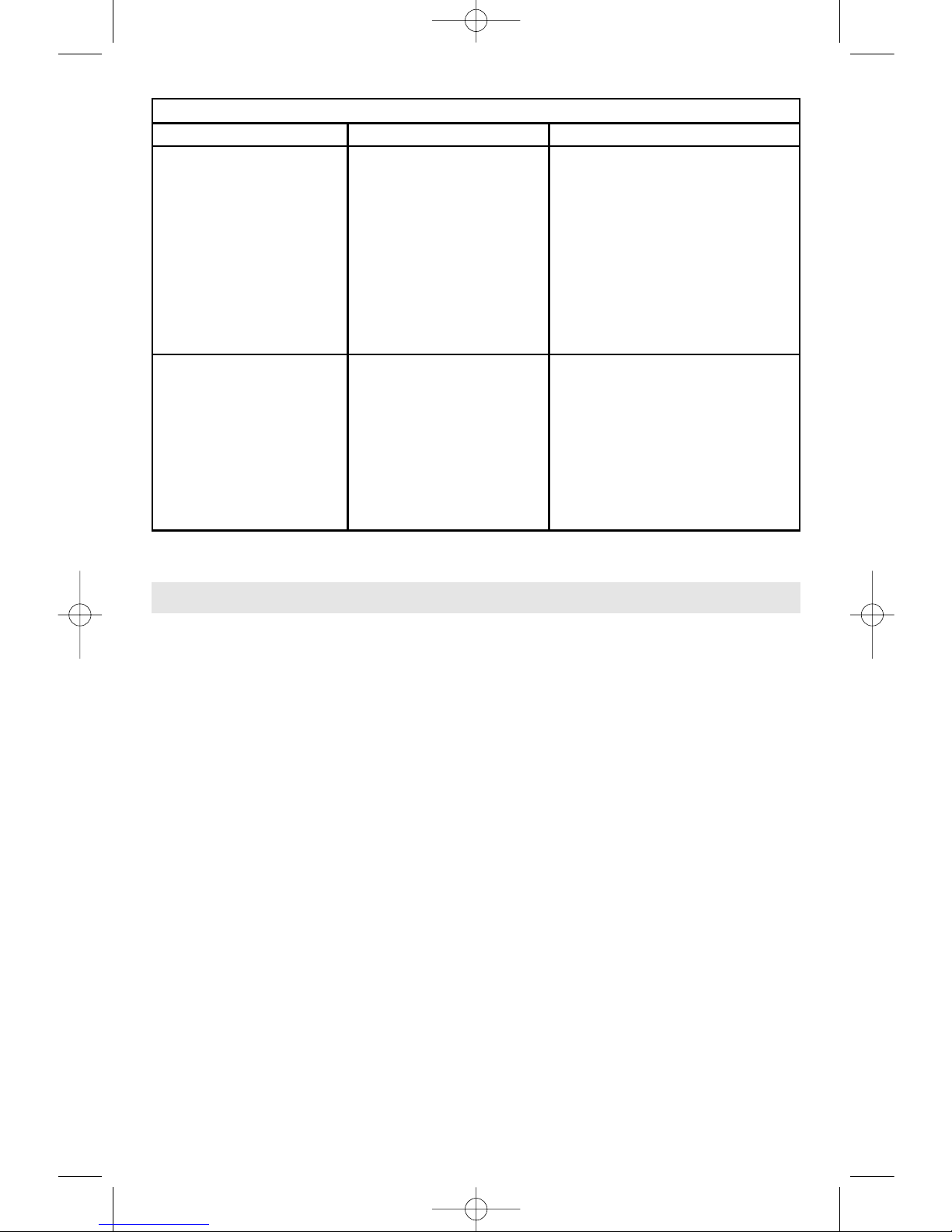

Detection of Electrical Wiring

Issue Possible Reason Remedy

Area of voltage appears

much larger than actual

electrical wire.

• Static charge may be

present on drywall,

spreading voltage as

much as 12 inches (305

mm) on either side of an

actual electrical wire.

• It may help to put the other hand

on the wall and measure again.

• Turn unit off then back on again at

edge of where voltage was first

detected and scan once more.

• Shut off the appropriate building

circuit and restart scan. If

searching for electrical wiring, use

metal mode to search for metal

objects that might be wiring.

Electrical wiring is not

detected in area where it is

thought to be.

• Wires may not be live (hot)

• Wires may be inside of

metal wall covering.

• Wires may be too deep.

(See Maximum Scanning

Depth, page 4.)

• Make sure that circuit has power;

make sure that power switches

are turned on.

• Try plugging in a lamp into outlet

and turning on switch to increase

current and chance of detection.

• Use metal scan to check for

detection of metal.

RECALIBRATION

If the main measuring indicator f continuously

shows an amplitude even though there is no

metal object in the vicinity of the multidetector, the multi-detector can be calibrated

manually:

1. Remove all objects in the vicinity of the

multi-detector (including wrist watches or

rings of metal) and hold the multi-detector

up in the air.

2. With the multi-detector switched off, press

both the “on/off” button 7 and the wooddetection mode button

5 until the

illuminated ring

1 lights up red and green at

the same time. Then release both buttons.

When the calibration process is successful,

the multi-detector will start over after a few

seconds and is then ready for operation.

MAINTENANCE AND CLEANING

• Protect multi-detector against moisture and

direct sunlight.

• Wipe away debris or contamination with a

dry, soft cloth. Do not use cleaning agents or

solvents.

• In order not to affect the measuring ability of

the multi-detector, decals/stickers or name

plates, especially metal ones, may not be

attached in the sensor area

9 on the front or

back side of the multi-detector.

• Do not remove the felt pads

8 on the back

side of the multi-detector. Replace the felt

pads when they are damaged or used. For

this, completely remove the felt pads and

glue the new felt pads onto the same spots.

• Store and transport the multi-detector only in

the supplied protective case.

• In all correspondence and spare parts

orders, please always include the 10-digit

article number given on the type plate of the

multi-detector.

“AutoCal” CALIBRATION INDICATOR

When the check mark behind the “AutoCal”

calibration indicator g flashes over a longer

period or if it is not displayed anymore (other

than when the

“ZOOM” button 4 has been

pressed down in the wood-detection mode),

reliable scanning is no longer possible.

BM 2609140574 08-08 9/3/08 8:40 AM Page 10

Loading...

Loading...