Installation and

service instructions

Room controller

Logamatic EMS

6 720 618 477-00.1RS

Programming unit RC35

6 720 801 387 (2011/05) GB

Table of contents

Logamatic EMS – 6 720 801 387 (2011/05)

2

Table of contents

Guide to instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Included in Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Validity of these instructions for function modules (accessories) . . . . . . . . . . . . . . . . . . 9

2.6 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Replacement of ERC with RC35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Choosing the right installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.1 Installation in the reference room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.2 Installation on boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Types of installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Installation and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Hooking in or removing the programming unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Principles of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.1 Overview of controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Introduction to the service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Overview of the service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 General commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 Checklist: important parameters for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Quick start-up (quick programmer menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Detailed commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.5 System handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.6 Shutting down/switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7 Operating information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Logamatic EMS – 6 720 801 387 (2011/05)

3

Table of contents

6 System settings (Service menu – Settings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1 System data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.1 Building type (adjusting the outside temperature) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.2 Minimum outside temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 Hybrid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3 Boiler data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4 Heating circuit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.1 Assignment of programming unit / remote control unit in the software . . . . . . . . . . . . . 35

6.4.2 Control mode (outside temperature compensated/room influence) . . . . . . . . . . . . . . . . 35

6.4.3 Heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.4 Reduction modes (night reduction) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.5 Frost prot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.5 DHW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.6 Solar data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.7 RC35 calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.8 Contact details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1 Function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2 Monitor value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3 Error message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.4 Heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.5 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11 Service menu RC35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Guide to instructions

Logamatic EMS – 6 720 801 387 (2011/05)

4

Guide to instructions

These installation and maintenance instructions contain all the information about the functions and

settings of the Logamatic RC35 programming unit.

Introduction to the service menu

Chapter 4.2 explains in detail the steps needed for programming all the settings in the service menu.

Operation is only briefly dealt with in the following sections.

Display texts

Words appearing on the display are shown in bold in the text.

Example: USER MENU

standard display

operation modes

switching programme

sum./win. threshold

USER MENU

Logamatic EMS – 6 720 801 387 (2011/05)

5

Key to symbols and safety instructions

1

1 Key to symbols and safety instructions

1.1 Explanation of symbols

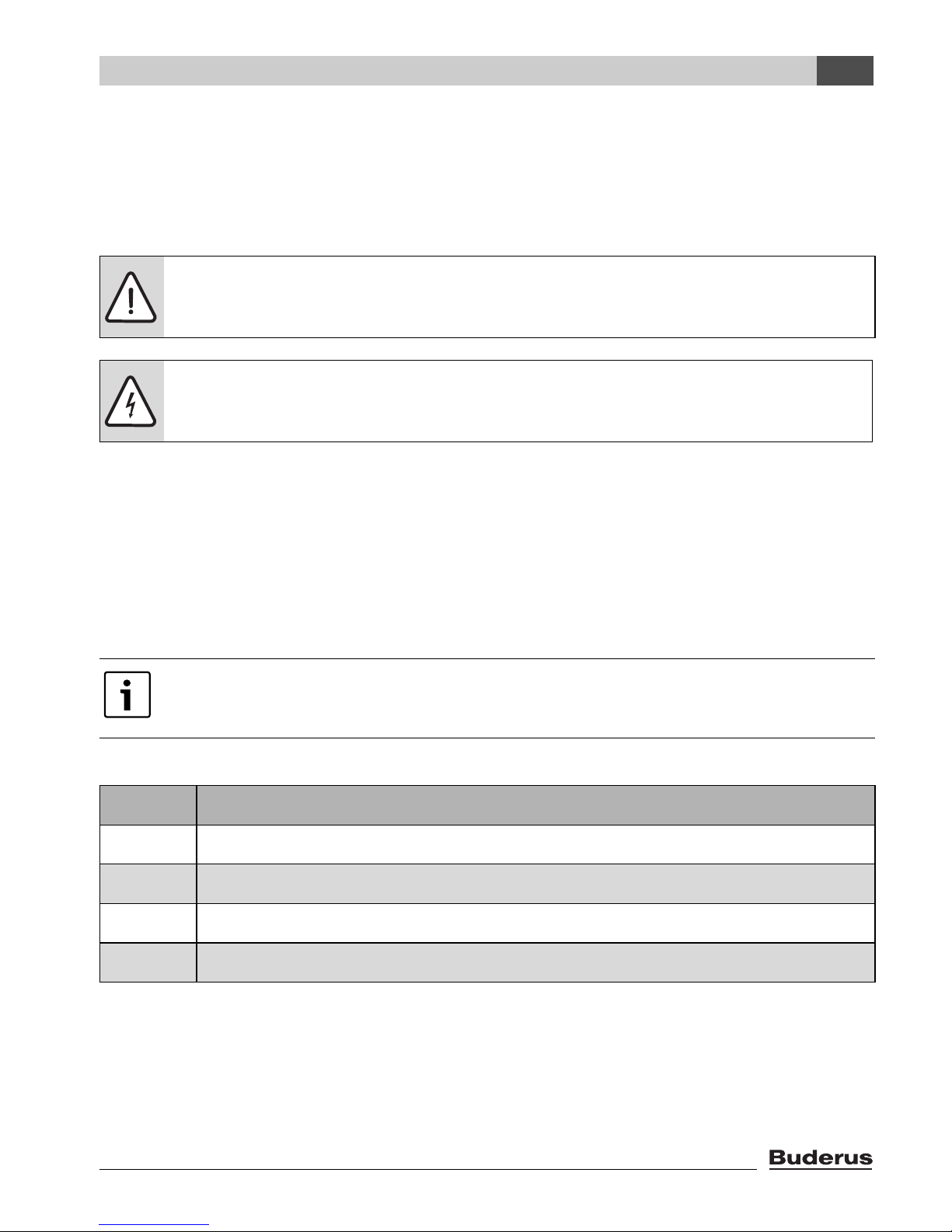

Warnings

Signal words at the start of a warning indicate the type and seriousness of the ensuing risk if

measures to prevent the risk are not taken.

• NOTE indicates that material losses may occur.

• CAUTION indicates that minor to medium injury may occur.

• WARNING indicates that serious injury may occur.

• DANGER indicates a risk to life.

Important information

Additional symbols

Warnings in this document are framed and identified by a warning triangle printed

against a grey background.

If there is a risk of electric shock, the exclamation mark in the warning triangle is

replaced by a lightning symbol.

Important information where there is no risk to people or property is indicated with the

adjacent symbol. It is bordered by lines above and below the text.

Symbol Explanation

B Action step

Æ Cross-reference to other parts of this document or to other documents

• List/list entry

– List/list entry (second level)

Table 1

Key to symbols and safety instructions

Logamatic EMS – 6 720 801 387 (2011/05)

6

1

1.2 Safety instructions

Installation and commissioning

B Observe these instructions to ensure satisfactory operation.

B The appliance must only be installed and commissioned by an authorised installer.

Risk of death from electric shock

B The power supply must be connected by a qualified electrician.

B Observe the connection diagram.

B Before installation: isolate all poles of the power supply (230 V AC). Secure against unintentional

reconnection.

B Never install this appliance in wet rooms.

B Never connect this appliance to the 230 V mains.

Damage through operator error

Operator errors can lead to injuries and/or material losses.

B Ensure that children never operate this appliance unsupervised or play with it.

B Ensure that only individuals who can operate this appliance correctly have access to it.

Warning: frost

The heating system can freeze up in cold weather if it is not in operation:

B Leave the heating system permanently switched on.

B Enable frost protection.

B In case of faults: remedy any faults immediately.

Logamatic EMS – 6 720 801 387 (2011/05)

7

Product information

2

2 Product information

2.1 Correct use

The RC35 programming unit must only be used to operate and control Buderus heating systems in

detached houses and residential buildings.

B Always use this appliance correctly and in conjunction with the specified control systems.

B Observe all regulations and standards applicable to the installation and operation of the system

in your country!

The boiler must be equipped with EMS (Energy Management System) or UBA1.x (Universal Burner

Automation).

Do not operate the programming unit with controllers of the Logamatic 2000/4000 control systems.

We recommend that you always operate the heating system with a programming unit (without a

programming unit only emergency mode is possible).

If RC2xremote programmers are used, which were manufactured up to and including 2005, only two

remote programmers can be connected. In case of related questions, please contact your local

Buderus sales office.

These instructions describe all possible functions of the RC35 programming unit. Some of these

functions may not be available, depending on which boiler (combustion controller) is used. You will

find information on this in the relevant chapter.

For information regarding the combustion controller, see menu DIAGNOSIS\VERSIONS

(Æ page 50).

RC35 as replacement for ERC

If the RC35 programming unit is used as a replacement for the ERC controller, there are differences

for example as regards the basic settings. For an overview of these, see Tab. 4, page 10.

2.2 EU Declaration of Conformity

The design and operation of this product conform to the European Directives and the supplementary

national requirements. Its conformity is demonstrated by the CE designation. You can call up the

Declaration of Conformity for this product on the internet at www.buderus.de/konfo or request a

copy from your local Buderus sales office.

2.3 Included in Delivery

• RC35 programming unit

• Operating instructions

• Installation and maintenance instructions

• Wall mounting base, fixing material

Product information

Logamatic EMS – 6 720 801 387 (2011/05)

8

2

2.4 Specification

Temperature sensor characteristics

When measuring temperature sensors, observe the following requirements:

• Isolate the system before measuring.

• Measure the resistance at the cable ends.

• The resistances represent mean values and are subject to tolerances.

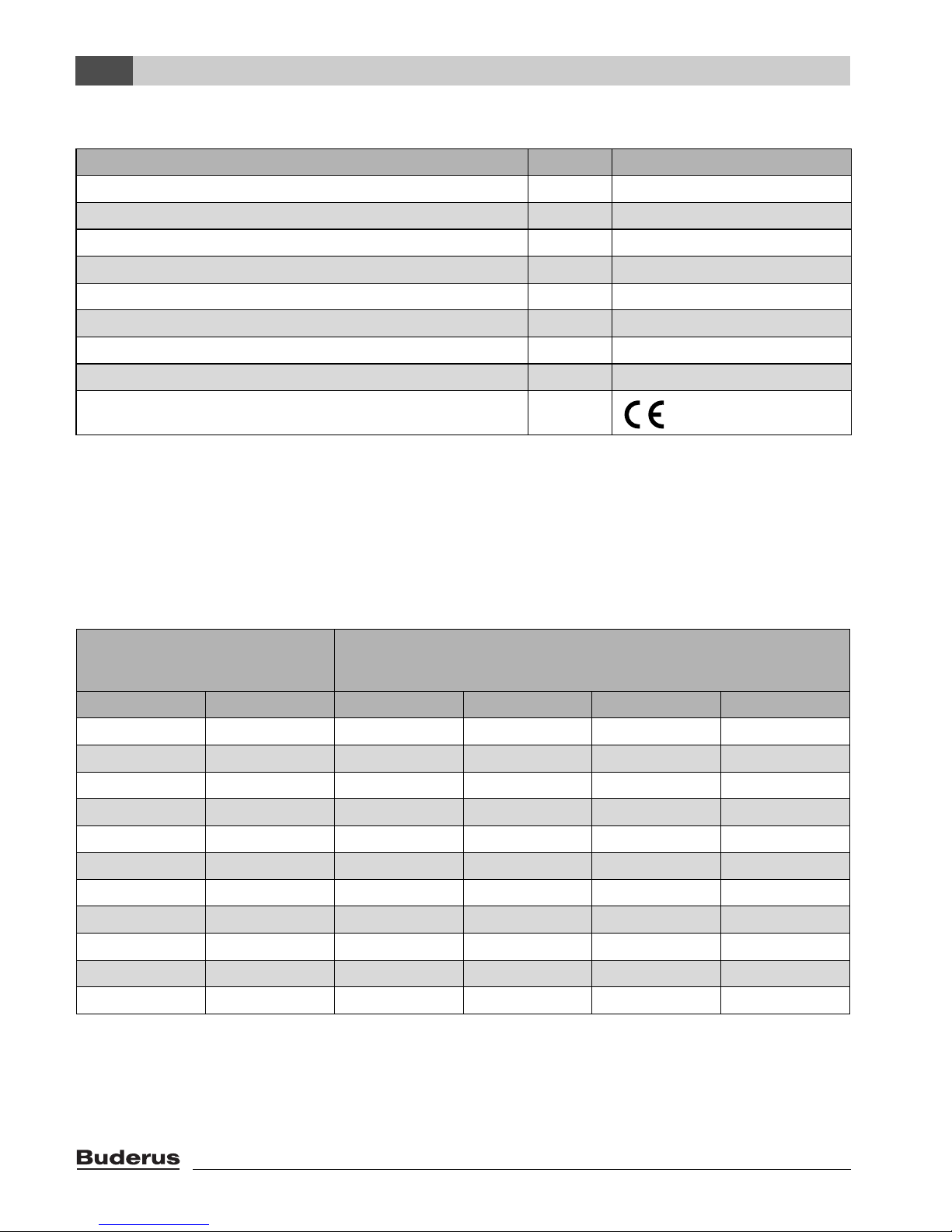

Unit RC35

Power supply via BUS system V 16 V DC

Power consumption W 0.3

Power consumption with backlighting W 0.6

Dimensions (width/height/depth) mm 150/90/32

Weight g 233

Operating temperature °C 0 to +50

Storage temperature °C 0 to +70

Relative humidity % 0 to 90

CE designation

Table 2 Specification - programming unit RC35

Outside temperature sensor

Flow temperature sensor

DHW temperature sensor

°C k Ω °C k Ω °C k Ω

– 20 96.358 10 19.872 60 2.49

– 15 72.51 16 15.699 65 2.084

– 10 55.054 20 12.488 70 1.753

– 5 42.162 25 10.001 75 1.481

0 32.556 30 8.060 80 1.256

5 25.339 35 6.535 85 1.070

10 19.872 40 5.331 90 0.915

15 15.699 45 4.372 95 0.786

20 12.488 50 3.606 100 0.677

25 10.001 55 2.989

30 8.060

Table 3 Resistances of the temperature sensors, for EMS only

Logamatic EMS – 6 720 801 387 (2011/05)

9

Product information

2

2.5 Validity of these instructions for function modules (accessories)

These instructions also apply to the programming unit when used in conjunction with the MM10

mixer module and the WM10 low loss header module.

Additional setting options may be found in some menus, if your heating system is equipped with

alternative function modules (e.g. solar module SM10). These setting options are explained in a

separate manual.

2.6 Accessories

For detailed information regarding suitable accessories, see the catalogue.

• Mixer module MM10

1)

for triggering a 3 way valve is not possible. A description of the MM10 is

included in the RC35 instructions.

• Switching moduleWM10

1)

for operation of a hydraulic low loss header

• Solar module and further EMS modules (e.g connection module ASM10)

1)

• Hybrid module HM10 for combined operation of the boiler with an air heating pump external unit.

• Remote programmer

1)

(e.g. RC2x,RC20/RF) for triggering one heating circuit at a time

• External temperature sensor

2)

, external room temperature sensor

1) With heating boilers with UBA1.x or DBA the use of modules

2) Required with weather compensated control.

Product information

Logamatic EMS – 6 720 801 387 (2011/05)

10

2

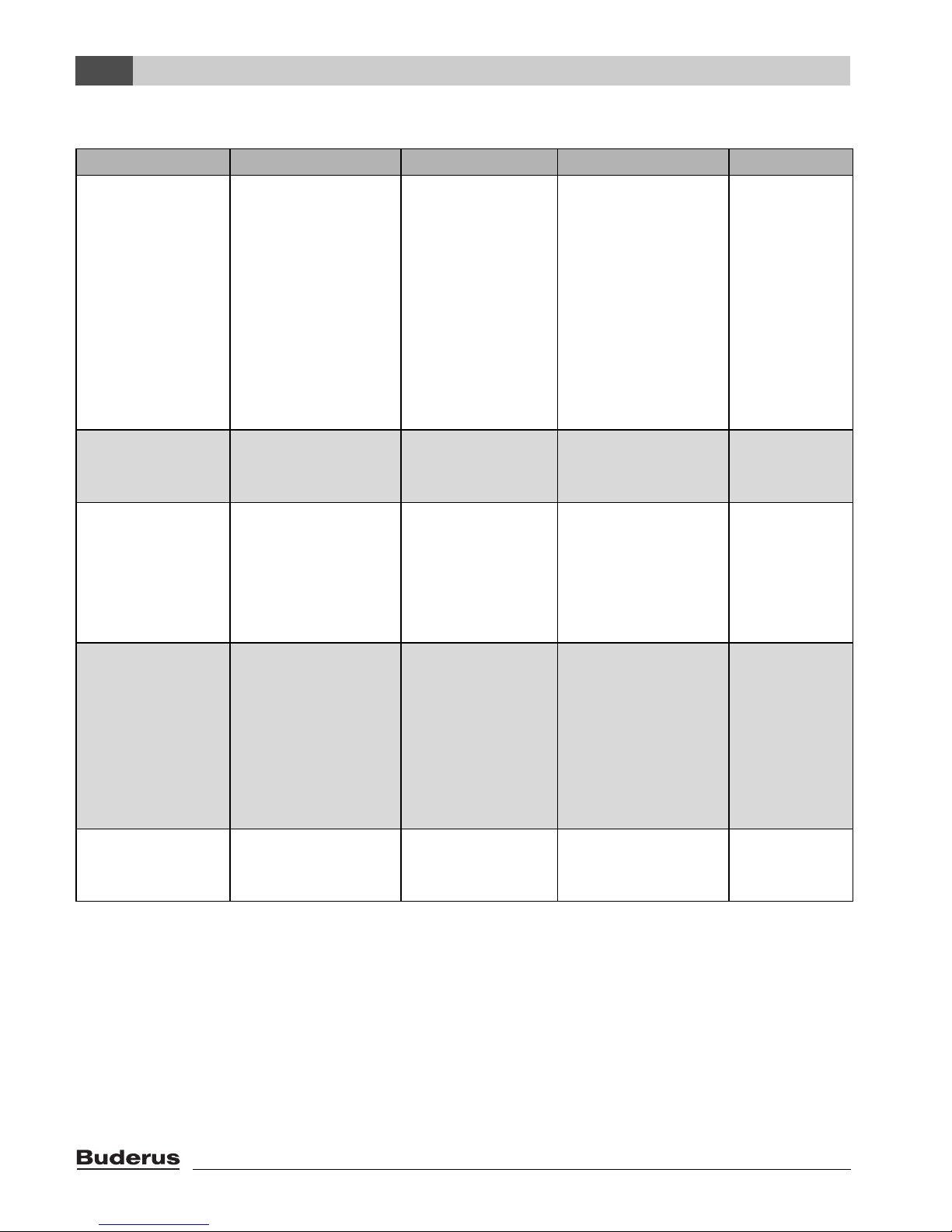

2.7 Replacement of ERC with RC35

Topic ERC RC35 Note See page

Setback modes

(night setback)

Changeover

between

“Shutdown” and

“Outdoor setback

mode” subject to

the selected outside

temperature

threshold.

Selection of four

setback modes:

• Reduced

operationShutdown

modeRoom

setback

modeOutdoor

setback mode

Deviation, e.g.

modified outside

temperature

threshold for outside

setback mode.

Settings at the

RC35 programming

unit possible as for

the ERC – requires

clarification with the

end user.

37 – 38

HS day,

night temperature

Day: 19/21 °C

Night: 16 °C

Day: 21 °C

Night: 17 °C

13

(operating

instructions)

Control method Room flow/room

output can be

changed over.

Room flow is the

default setting and

can only

be switched over

at the customer

service level.

If room output is to

be used, contact

your Buderus

customer service.

–

Self-test Self-test available

and can be

activated.

Permanent selftest in the

background - no

activation

required.

The RC35

programming unit

tests the system

continually If a fault

is found, the RC35

programming unit

automatically gives a

fault display.

–

Room

temperature hookup (control type)

HS = 3 K HS = 0 K 36

Table 4 Differences between ERC and RC35

Logamatic EMS – 6 720 801 387 (2011/05)

11

Installation

3

3 Installation

3.1 Choosing the right installation position

3.1.1 Installation in the reference room

If the system is operated in room temperature-dependent mode, observe the following requirements:

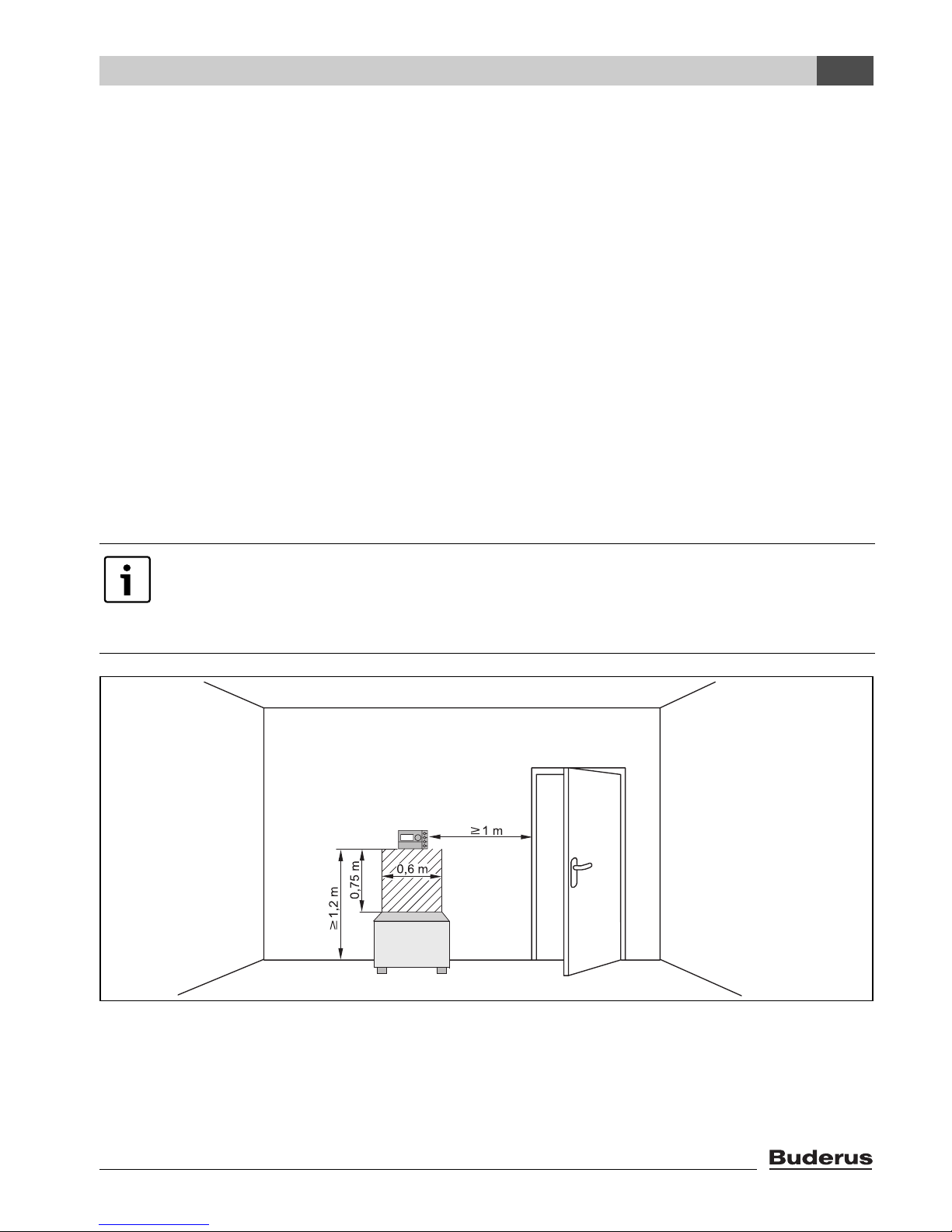

• Installation position on an internal wall (Æ fig. 1)

• Maintain the specified distance from the door (to avoid draughts).

• Allow clearance below the programming unit (Æ fig. 1, shaded area) to ensure correct

temperature measurement.

• The reference room (= installation room) must be as representative as possible of the entire

home. External heat sources in the reference room (e.g. sunlight or other heat sources such as

an open fire) affect the control functions. This means it may be too cold in rooms without external

heat sources.

• Always open the thermostatic radiator valves fully in the reference room to prevent the two

temperature controllers influencing each other.

Fig. 1 Minimum clearances for installation in a reference room

If there is no suitable reference room, we recommend setting the system to weathercompensated control instead (this requires an outside temperature sensor).

Alternatively, you could install an external room temperature sensor in the room with the

greatest heat demand (e.g. living room).

6 720 618 477-01.1RS

Installation

Logamatic EMS – 6 720 801 387 (2011/05)

12

3

3.1.2 Installation on boiler

Installation directly on the boiler is possible where the boiler is equipped with the Energy

Management System (EMS).

The outside temperature sensor for weather-compensated control is not delivered as standard, but

can be ordered as an accessory.

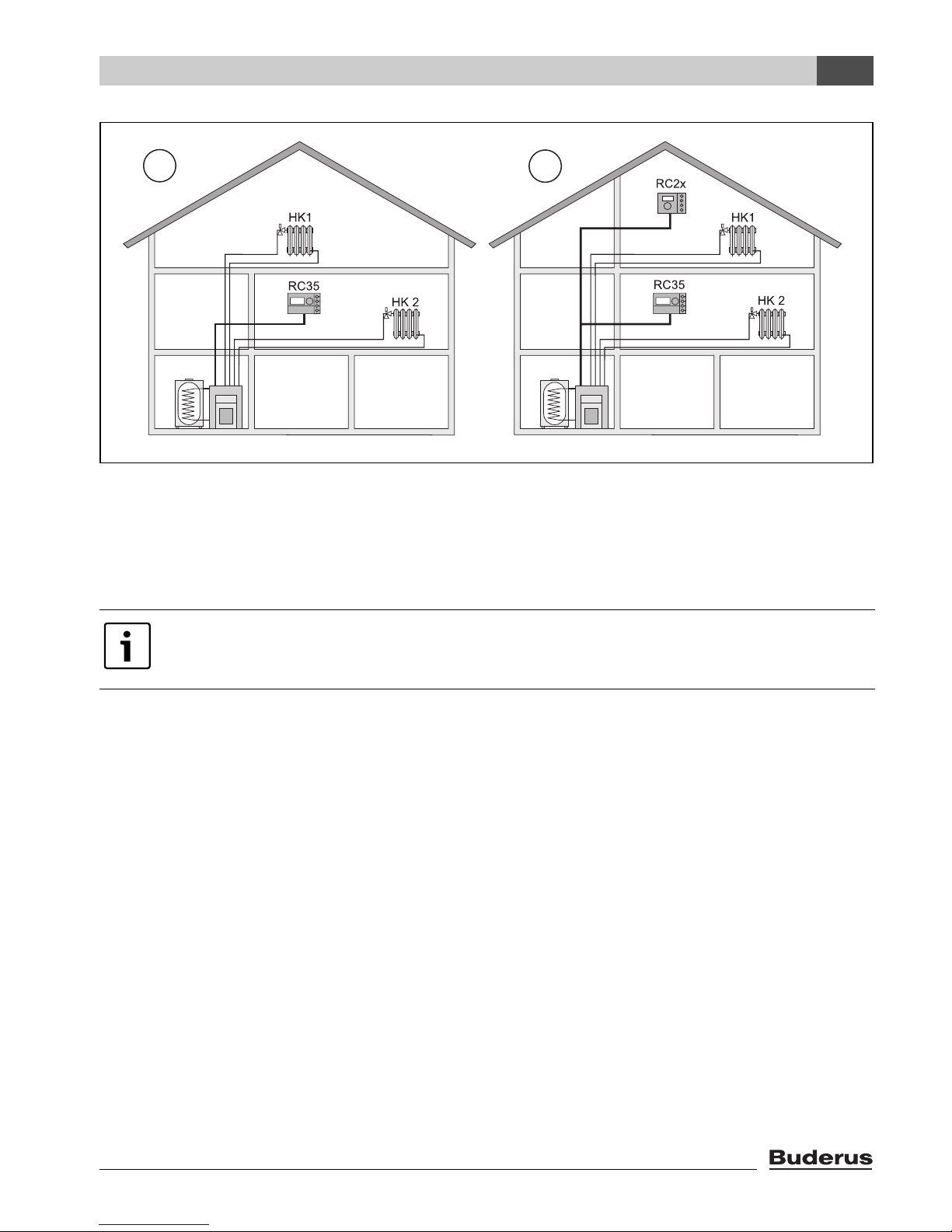

3.2 Types of installation

The programming unit can be installed in three different ways:

• As the only programming unit in the system (basic setting): the programming unit is installed in a

living room (reference room) or on the boiler

1)

.

Example: single family house with one heating circuit.

• As the only programming unit in a heating system with two or more heating circuits

2)

(Æ fig. 2, [1]).

Examples: underfloor heating on one storey, radiators in the others, or a home combined with a

separate dwelling unit or with a medical practice room.

• In association with a remote programmer (e.g.RC2x, RC20/RF, fig. 2, [2]) In this case there are

always two separate heating circuits. Remote control units cannot be used for boilers with

UBA1.x.

Examples: underfloor heating on one floor, radiators on the others; or a main flat together with a

separate granny flat or doctor's surgery.

If a HM10 hybrid module is used, the installation must be carried out with the wall

bracket. If it is installed on the boiler, it does not function correctly.

1) Not possible if the HM10 hybrid module is used

2) Not possible with boilers with UBA1.x and DBA.

Logamatic EMS – 6 720 801 387 (2011/05)

13

Installation

3

Fig. 2 Options for a heating system with two heating circuits

1 Both heating circuits are controlled by one programming unit.

2 Each heating circuit has its own programming unit / remote control unit.

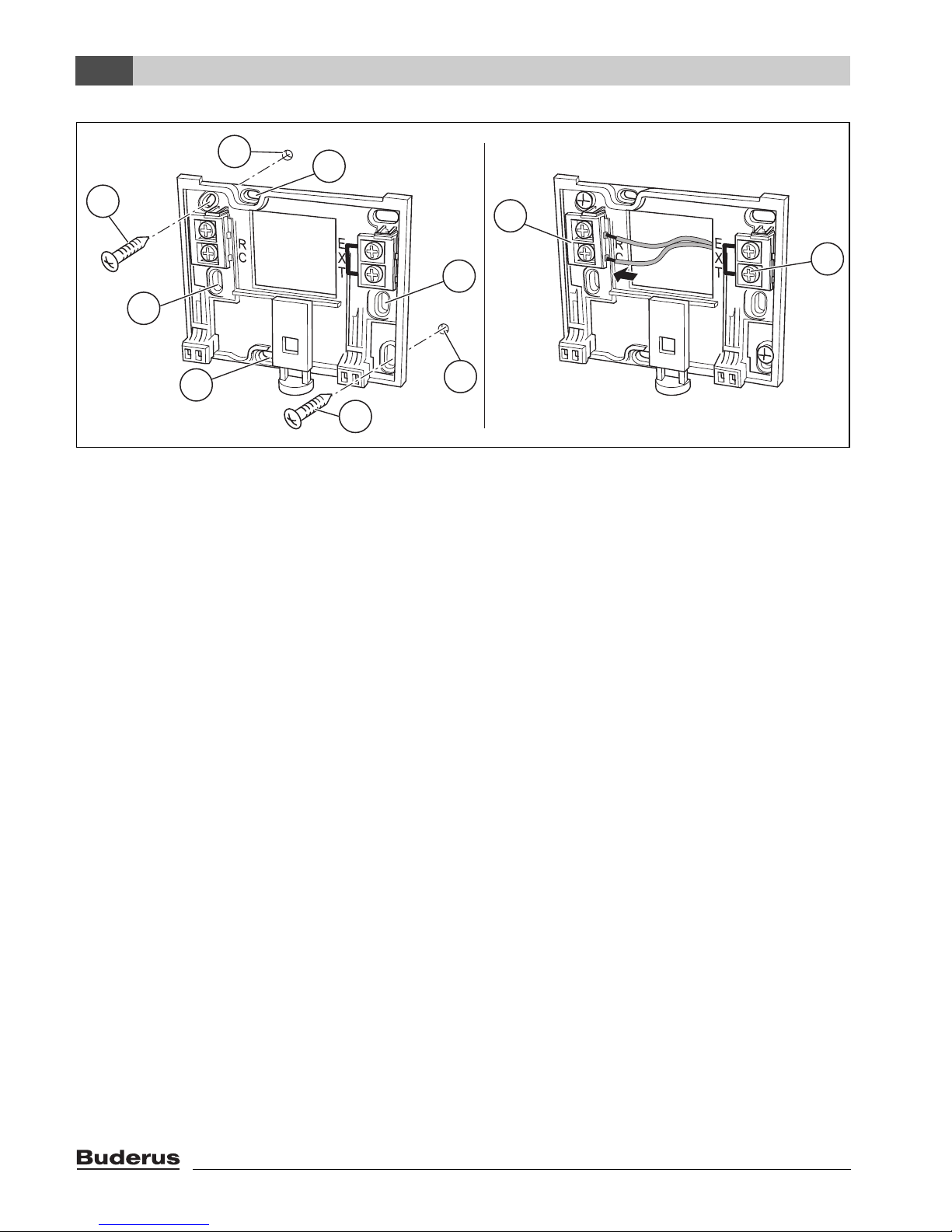

3.3 Installation and connections

The wall bracket can be attached directly to the wall or on a flush-mounting box.

When mounting on a flush box, note the following:

B Draught from within the flush box must not be able to falsify the capture of the room temperature

by the programming unit.

If required, stuff the flush box with insulation material.

B Use horizontal or vertical fixing holes [4].

B Fit the wall mounting base (Æ fig. 3, left).

B Connect a two-core BUS cable from the Energy Management System (EMS) to the “RC” cable

terminals [5].

– Cable type: 2 x 0.75 mm

2

(0.5 – 1.5 mm2), max. length 100 m

– Polarity is irrelevant for the two wires.

B Do not lay the cables parallel to power cables.

Only use the wall mounting base with screw terminals.

B Replace wall mounting bases without screw terminals that may already be installed.

6 720 641 642-01.1RS

2

1

Installation

Logamatic EMS – 6 720 801 387 (2011/05)

14

3

Fig. 3 Mounting the wall mounting base (left) and connecting the wires (right)

1 Hole drilled in the wall

2 Screws (included with the unit) for surface-mounting on the wall

3 Vertical mounting holes for mounting on a flush box

4 Horizontal mounting holes for mounting on a flush box

5 “RC” connection to the EMS (boiler)

6 “EXT” terminals for external room temperature sensor or for jumper

B If the RC35 programming unit is operated without external room temperature sensor, a jumper is

required at the “EXT” cable terminals [6] (condition as supplied from the factory).

B If the RC35 programming unit operates together with an external room temperature sensor,

remove the factory-fitted jumper at “EXT” and connect the external room temperature sensor in

its place.

6 720 618 477-03.1RS

2

2

3

3

4

4

5

6

1

1

Logamatic EMS – 6 720 801 387 (2011/05)

15

Installation

3

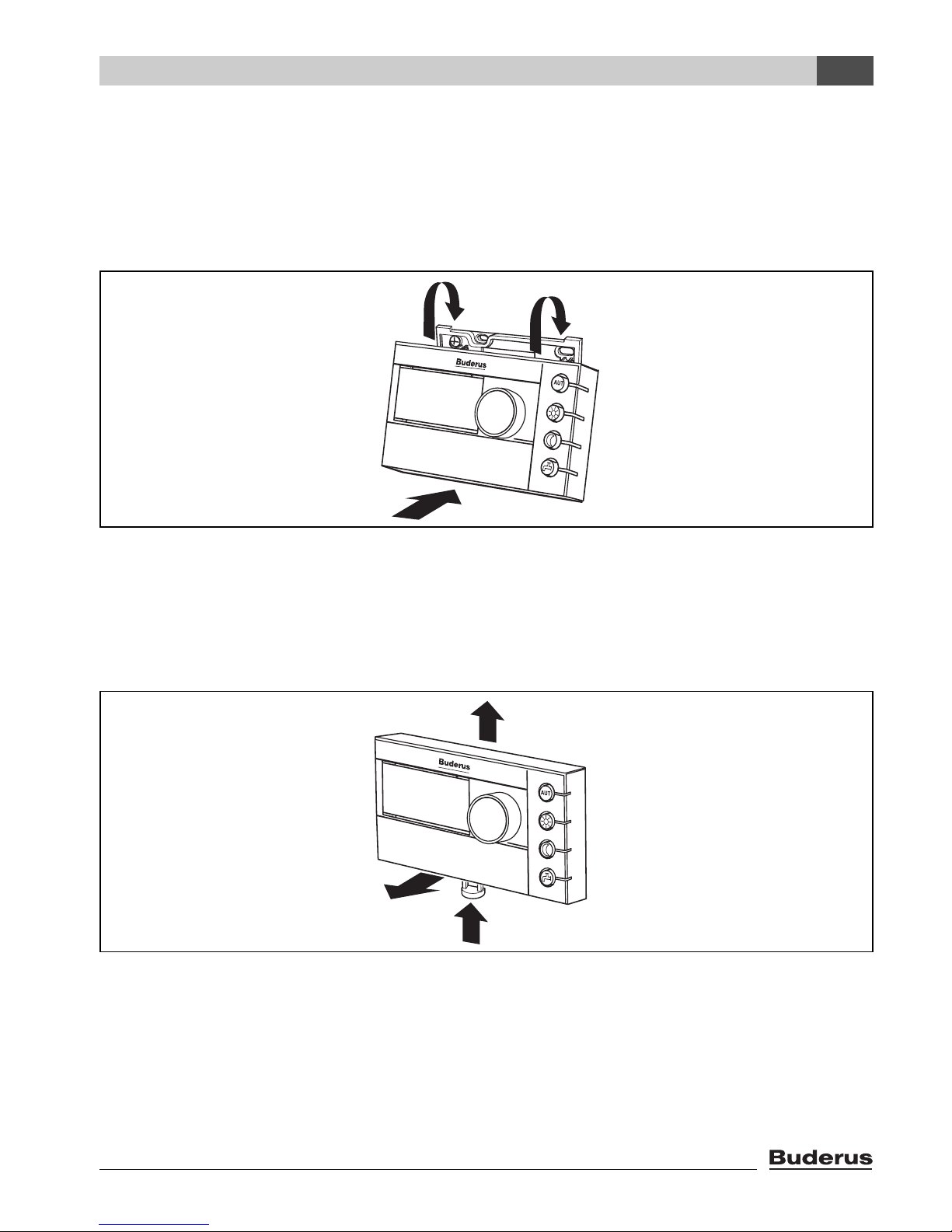

3.4 Hooking in or removing the programming unit

Hooking in the programming unit

1. Hook the programming unit at the top into the mounting plate in the direction of the arrows.

2. Push the programming unit at the bottom in the direction of the arrow against the mounting plate

until it clicks into place.

Fig. 4 Hooking in the programming unit

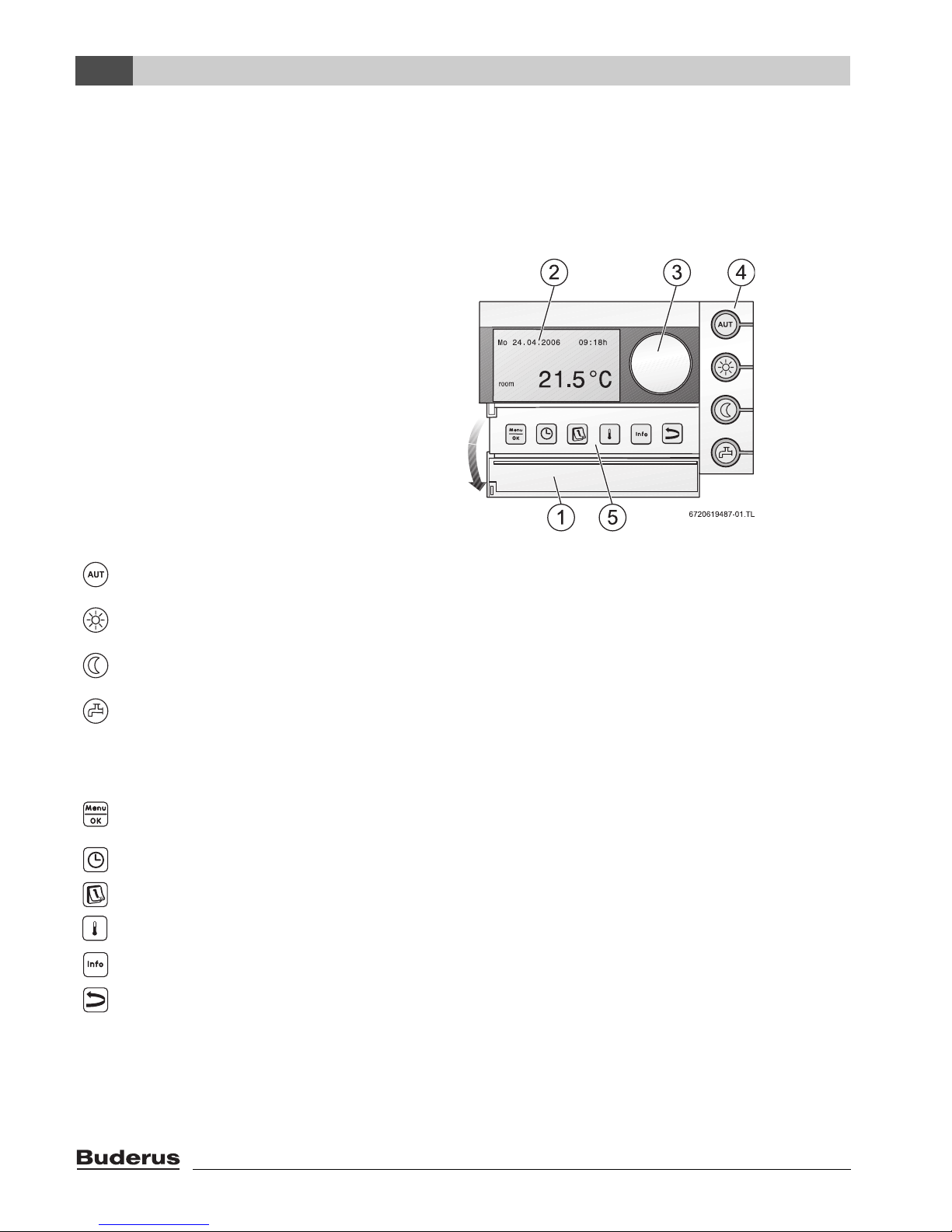

Removing the programming unit

1. Press the key underneath the mounting plate in the direction of the arrow.

2. At the same time pull the programming unit forwards.

3. Remove the programming unit by lifting upward.

Fig. 5 Removing the programming unit

6 720 618 477-04.1RS

2.

1.

6 720 618 477-10.1RS

3.

2.

1.

Principles of operation

Logamatic EMS – 6 720 801 387 (2011/05)

16

4

4 Principles of operation

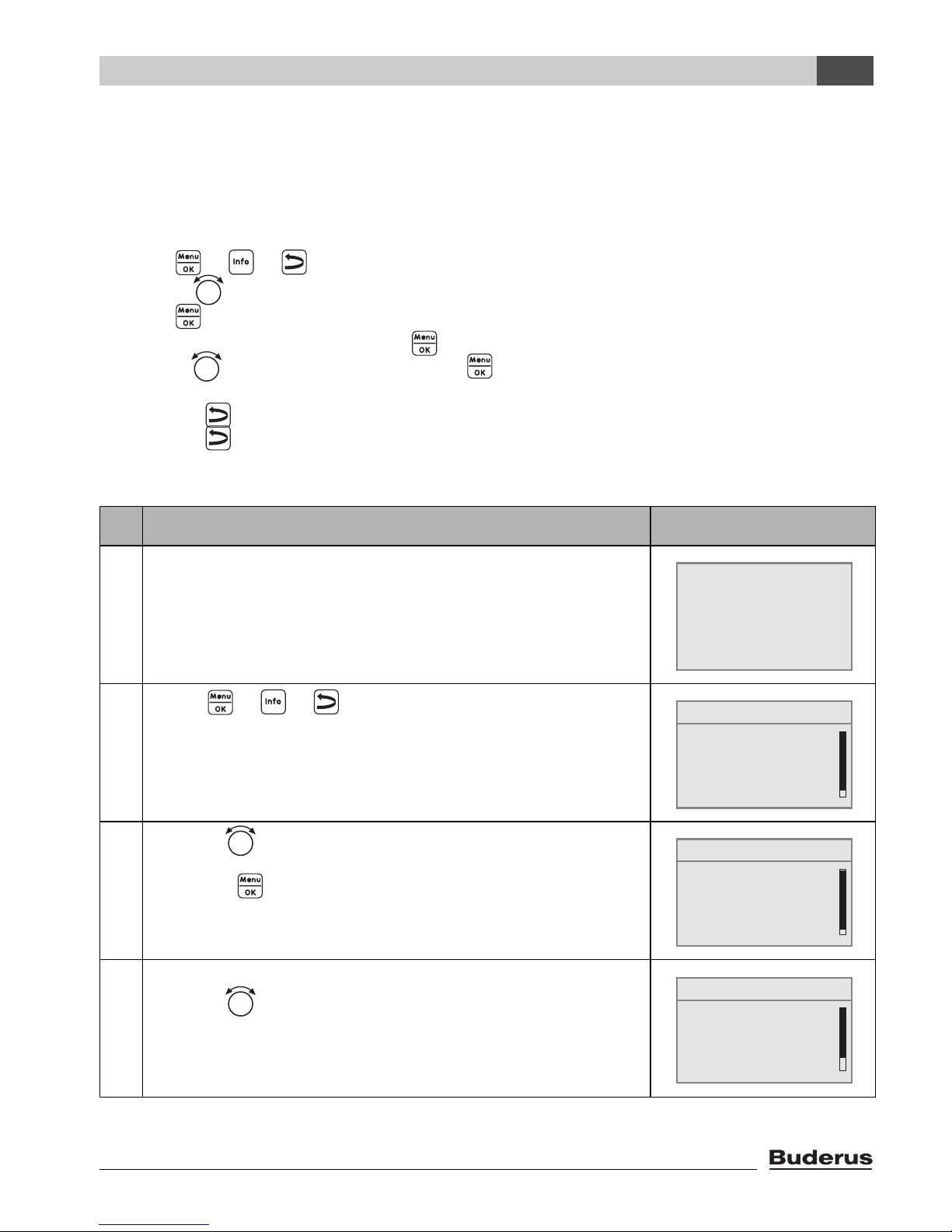

4.1 Overview of controls

Key to diagram:

1 Flap; pull the recessed grip

on the left to open

2 Display

3 Rotary selector for changing values

and temperatures or for moving within

the menus

4 Keys for basic functions: When the LED lights up,

“AUT” (automatic) • the switching program is active (automatic changeover between day and

night room temperatures).

“Day mode” (manual) • the heating system operates at the set day room temperature. The DHW

is switched on (basic setting).

“Night mode” (manual) • the heating system operates at the set night room temperature. Frost

protection is active. DHW heating is off (default setting).

“DHW” • the DHW temperature has fallen below its set value. Pushing this key

means DHW will be heated up again (the LED flashes during heat-up).

5 Keys for

additional functions:

Function:

“Menu/OK” Open the user menu and confirm the current selection.

When the rotary selector is turned simultaneously: change setting.

“Clock time” Set the time.

“Date” Set the date.

“Flow/returntemperature” Set the room temperature.

“Info” Open the Info menu (to view values).

“Back” Go back one step or one menu item.

In automatic mode the LED for the display of the current operating condition (“day” or “night”) also lights up in addition to the

LED “AUT”. Exception: with boilers with UBA1.x only the LED “AUT” lights up. The “DHW” LED can also be switched off. With

boilers with UBA1.x the “DHW” LED does not light up at all.

Logamatic EMS – 6 720 801 387 (2011/05)

17

Principles of operation

4

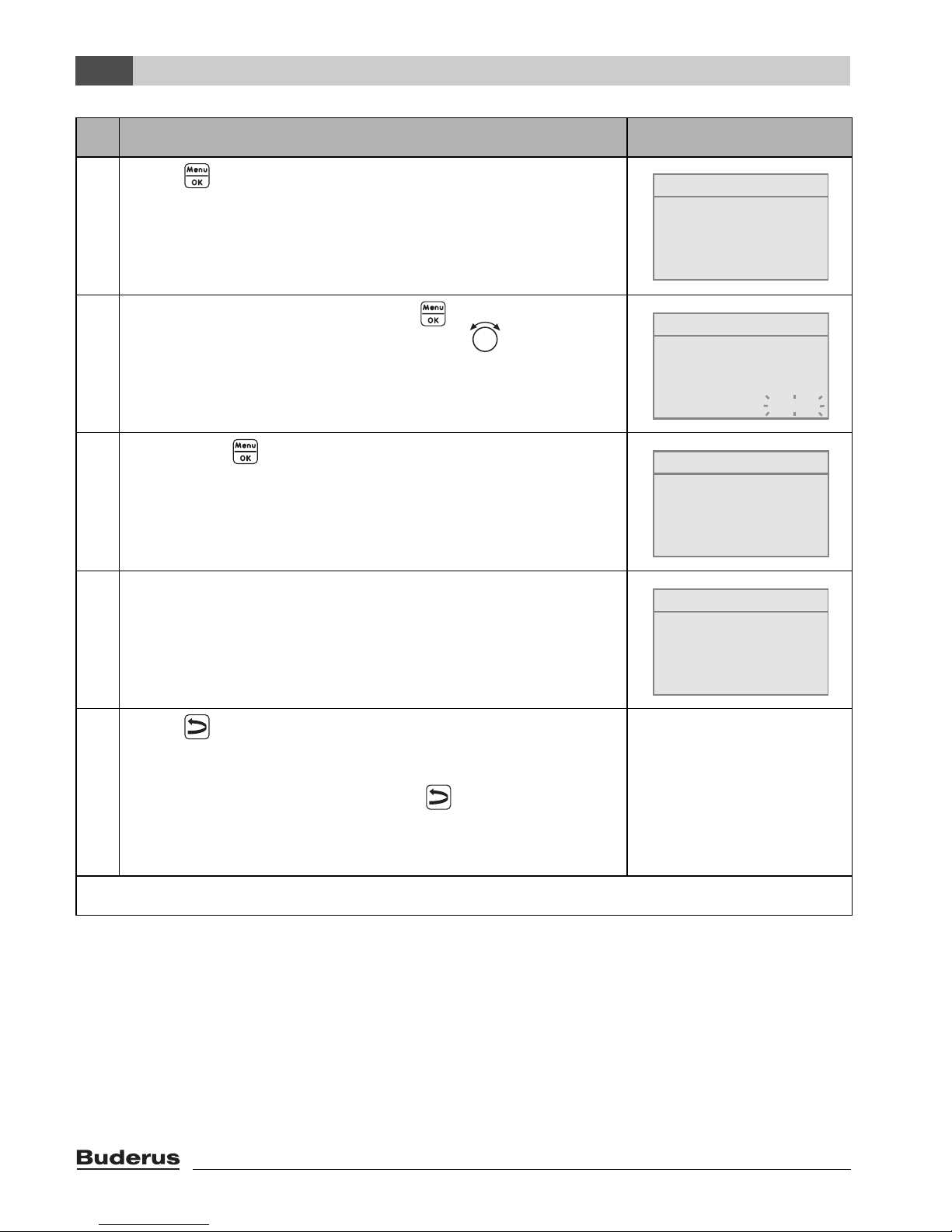

4.2 Introduction to the service menu

You can use the SERVICE MENU to set the parameters for the system. It also contains functions

for diagnosis, maintenance purposes, and carrying out a reset. The procedure for operation is

always the same:

1. Open the flap (by pulling the recessed grip on the left).

2. Press + + simultaneously to open the SERVICE MENU.

3. Turn the rotary selector to change the selection.

4. Press to make your selection.

5. To change the value, hold down the button (the value starts flashing) and turn the rotary

selector at the same time. Release the button.

The modified value is saved.

6. Press the button to go back one step.

Press the button several times or close the flap to show the standard display again.

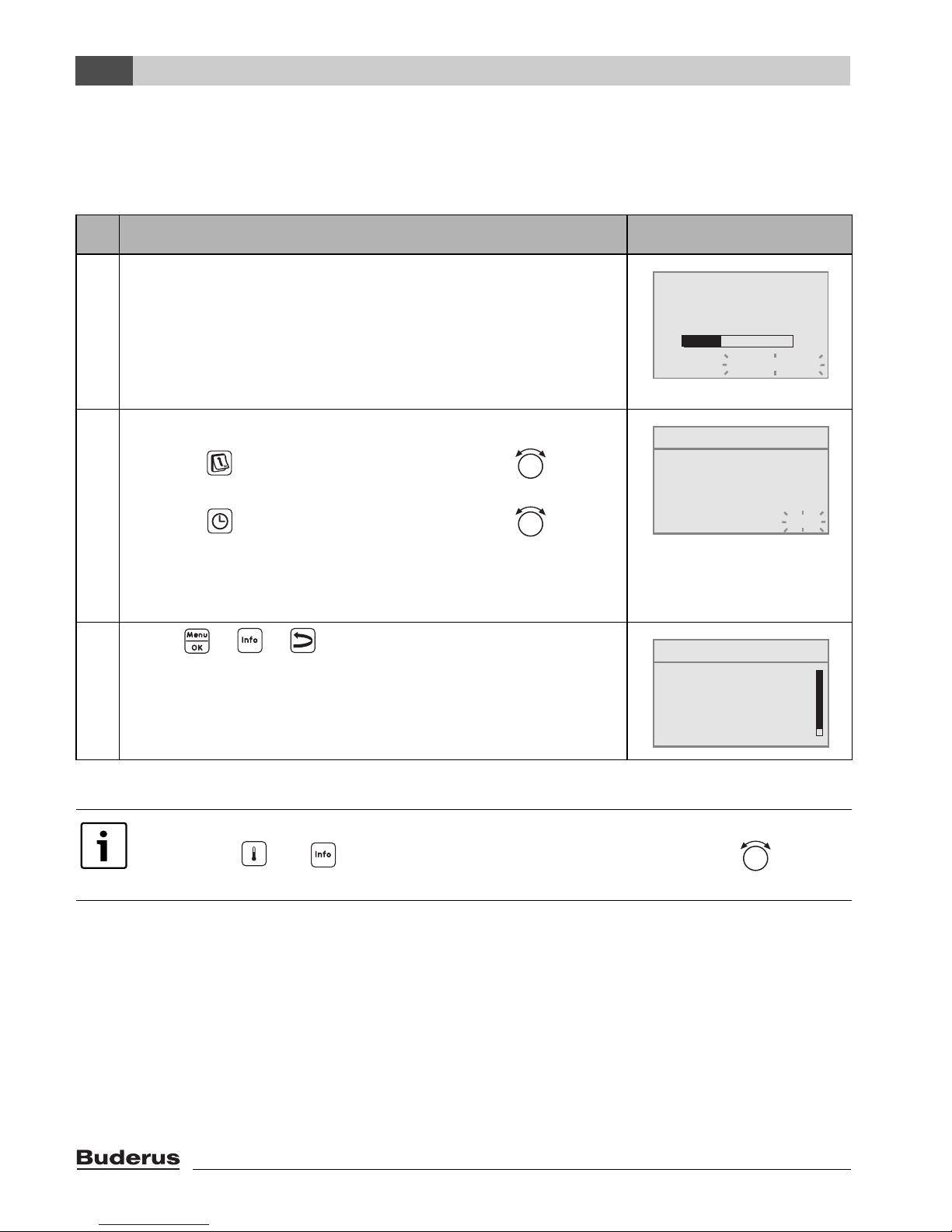

Example: Setting the building type (adjusted time)

Operation Result

1. Open the flap (by pulling the recessed grip on the left).

2. Press + + simultaneously,

to open the SERVICE MENU.

3. Turn the rotary selector to the left until settings is

selected.

Press the button to confirm the selection.

4. The SERVICE\SETTINGS menu is opened.

Turn the rotary selector to the left until boiler data is

selected.

Table 5 How to use the service menu (example)

6° 02.12.2005 10:20h

Temp. Exterior -1°C

21.5°C

SERVICE MENU

B

quick operation

settings

diagnosis

servicing

SERVICE MENU

quick operation

settings

diagnosis

servicing

B

SERVICE\SETTINGS

B

plant data

boiler data

domestic hot water

heating circuit 1

Principles of operation

Logamatic EMS – 6 720 801 387 (2011/05)

18

4

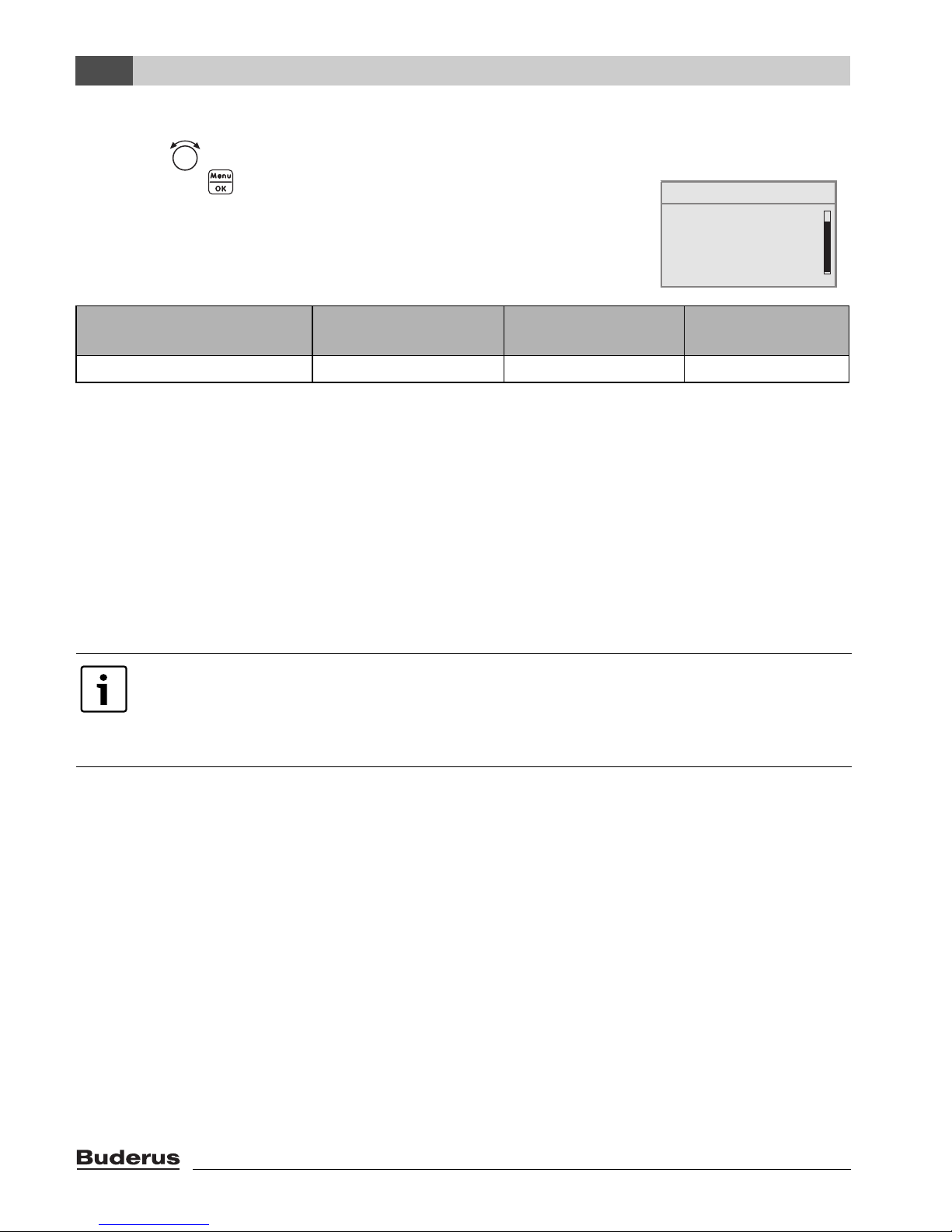

5. Press to select boiler data.

The menu SETTINGS\BOILER is opened.

6. To change the value, hold down the button (the value

starts flashing) and turn the rotary selector at the same

time.

7. Release the button.

The value stops flashing. The modified value is saved.

8. If you have carried out this example as practice only, make

sure that the original setting is retained.

To do so, repeat steps 6 and 7 if necessary.

9. Press to go back one step.

-or-

To finish entering the settings: press several times or

shut the flap.

The standard display reappears.

You can enter all settings in the SERVICE MENU using this procedure.

Operation Result

Table 5 How to use the service menu (example)

SETTINGS\BOILER

What type of building

do you have?

medium

SETTINGS\BOILER

What type of building

do you have?

medium

SETTINGS\BOILER

What type of building

do you have?

light

SETTINGS\BOILER

What type of building

do you have?

medium

Logamatic EMS – 6 720 801 387 (2011/05)

19

Principles of operation

4

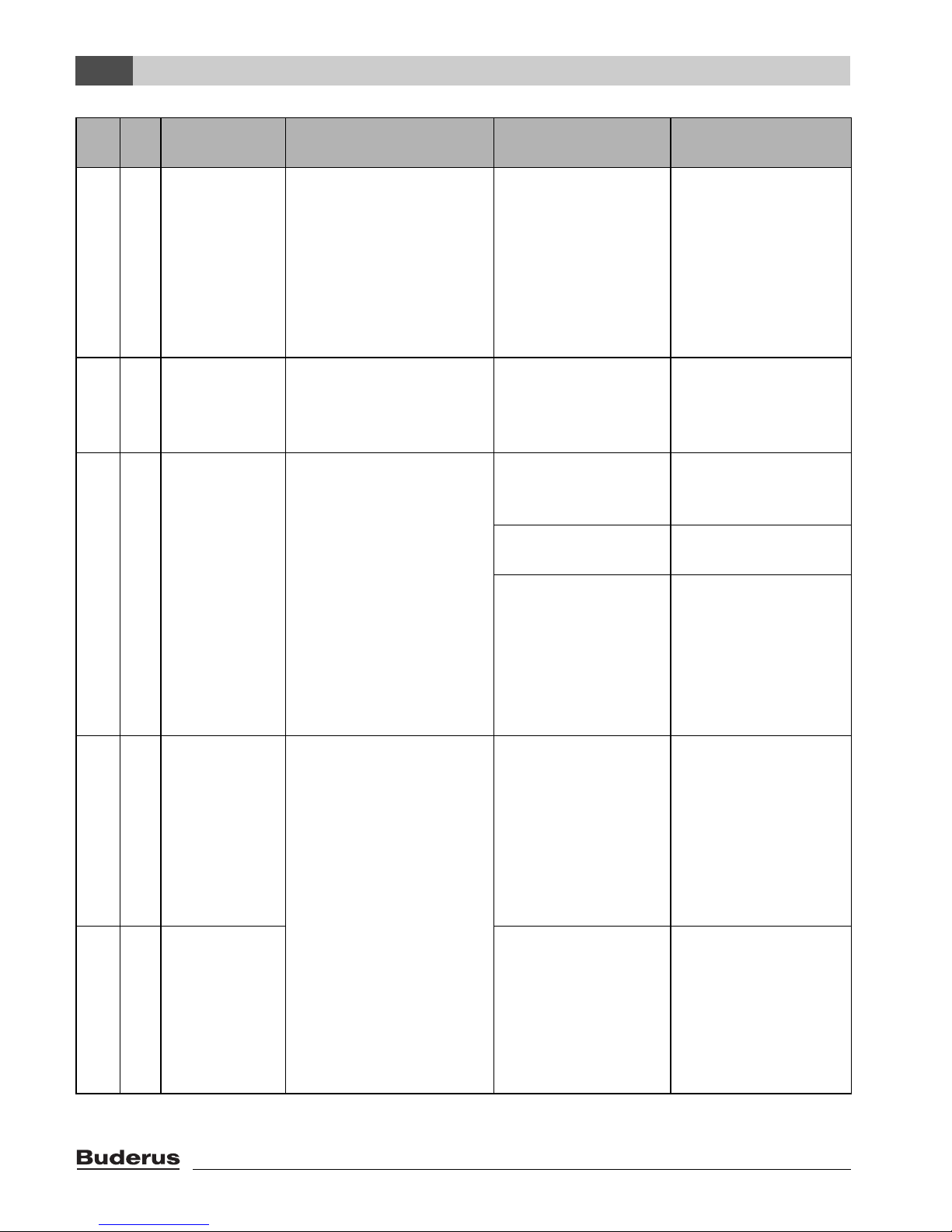

4.3 Overview of the service menu

The SERVICE MENU is divided into the following menus and submenus:

Menu Sub-menu Contents/function Page

Quick operation The most important parameters from the

“settings” menu to configure the heating

system

22

Settings (all

parameters)

Plant data

1)

1) Limited use depending on the boiler used.

Parameters: language, number of heating

circuits, installed modules, building type,

minimum outside temperature

26

Hybrid If HM10 hybrid module is installed: see

documents on the hybrid system

29

Boiler data

1)2)

2) May not be available or possible, depending on the boiler used.

Parameters: pump run-on time and modulation 30

Heating circuit

data

1)

Parameters of the installed heating circuits 31

Domestic hot

water

1)

Parameters for DHW 40

Solar data

2)

If solar is installed: see documentation for the

solar module

43

RC35 calibration Parameters: calibration of the displayed room

temperature

44

Contact details Entering the heating contractor's name and

telephone number

45

Diagnosis Function test

1)2)

Activating individual components for test

purposes

47

Monitor value Viewing target values and actual values 48

Error message

1)

Viewing faults 49

Heating curve Display the set heating curve graphically 50

Versions Viewing software versions 50

Service

1)2)

Maintenance interval Setting times for maintenance, by hours run or

by date

51

Current messages Viewing service messages 51

RESET servicing Resetting service messages 51

Reset

1)

Factory setting Resetting of parameters to basic settings 52

Error list 52

Service message 52

Working hours 52

Table 6 Service menu navigator

Commissioning

Logamatic EMS – 6 720 801 387 (2011/05)

20

5

5 Commissioning

5.1 General commissioning

Operation Result

1. Switch on the heating system.

While setting up the connection between the RC35 and EMS

or UBA1.x, the display shows the message on the right.

If the display shows a different message, look it up in

Chapter 10, page 53.

2. Set the date and time:

Hold the button pressed down and with the rotary

selector set the respective flashing value. Release button.

Hold the button pressed down and with the rotary

selector set the respective flashing value. Release button.

In the event of a power failure, the date and time are retained

for up to 8 hours. All other settings are saved.

3. Press + + simultaneously,

to open the SERVICE MENU.

Table 7 General commissioning

If necessary, you can change the contrast on the display:

B Hold the and buttons pressed down and simultaneously turn the rotary

selector.

RC35 version:

connect to:

connection setup ...

please wait

SET DATE

set year

01.01.2000

SERVICE MENU

B

quick operation

settings

diagnosis

servicing

Logamatic EMS – 6 720 801 387 (2011/05)

21

Commissioning

5

5.2 Checklist: important parameters for commissioning

When commissioning the device, ensure the satisfaction of both parties, making sure that the

heating system meets the customer's needs and will not give cause for complaints. In our

experience, the following parameters are very important for the satisfaction of the system user:

B Find out the system owner's requirements and preferences regarding:

Setting options

Standard

setting

SERVICE

MENU\

Settings\

The required type of reduction

(night setback)

Outdoor setback

mode; Reduced

operation; Room

setback mode; Shutdown mode

Outdoor

setback

mode

Heating circuit x,

page 32

The required control mode Outside temperature

compensated, room

temperature

compensated

Outside

temperature

compensated

Heating circuit x,

page 35

of the correct heating curve

By means of the

following parameters:

design temperature,

minimum outside

temperature, offset, and

set room temperature

Heating circuit x,

page 32

of the correct building type

(damping of the outside

temperature)

Light, medium, heavy Medium Plant data,

page 27

of the switching frequency of the

circulation pump.

1)

1) This function is not possible with boilers with UBA1.x, DBA, UBA-H3 or with DHW with

instantaneous water heating.

Permanent operation,

1 x, 2 x, 3 x, 4 x, 5 x, 6 x

per hour for 3 minutes

at a time

2 x DHW, page 41

DHW priority Yes, No Yes Heating circuit x,

page 33

Switching program

(times)

Standard program

(e.g. family), user

defined program

Family Heating circuit x,

page 34

Table 8 Checklist: important parameters for commissioning

Commissioning

Logamatic EMS – 6 720 801 387 (2011/05)

22

5

5.3 Quick start-up (quick programmer menu)

B Press button to open the quick operation menu.

SHORTPROG\ Menu item Input range

Standard

setting Other information

LOW LOSS

HEADER

Have you installed a

module for the

hydraulic low loss

header?

Yes, No no In association with

MCM10 the setting is

automatically set to

“Yes”the screen is

hidden.

1)2)

Is a sensor for the low

loss header

connected?

No, at the

boiler, at the

low loss

header

module

no If a low loss header

module is used, connect

the temperature sensor

to the low loss header

module.

3)

SYSTEM Is heating circuit 1

installed (unmixed

heating circuit)?

Yes, No Yes

NO. OF MIXERS How many mixed

heating circuits are

installed?

0 to 3 0 Set the address on the

rotary coding selector of

the mixer module (basic

setting HK2).

1)

HEATING CIRCUIT

1

(and other heating

circuits)

Which operating unit

is assigned to heating

circuit 1?

RC2x/

RC20/RF,

RC35, none

RC35 Assigning programming

units to heating circuits

(Æ page 35). General

heating circuit data (Æ

page 31).

Set up any other heating

circuits as per heating

circuit 1.

How should heating

circuit 1 be

controlled?

Outside

temperature

compensate

d, room

temperature

compensate

d

Outside

temperatur

e

compensat

ed

Which heating system

does heating circuit 1

have?

Radiator,

convector,

floor

Radiator Heating curve (Æ

page 36)

Table 9 Quick programmer menu navigator

SERVICE MENU

B

quick operation

settings

diagnosis

servicing

Logamatic EMS – 6 720 801 387 (2011/05)

23

Commissioning

5

DHW Have you installed

domestic hot water?

Yes, No no

4)

What should be used

for domestic hot

water heating?

3-way

diverter valve

cylinder

primary

pump

Three-way

diverter

valve

5)

To which temperature

should your domestic

hot water be heated?

30 °C to

80 °C

60 °C In order to be able to

change the DHW

temperature, set the

DHW on the boiler

programming unit to

“AUT” or activate DHW.

SOLAR MODULE Have you installed a

solar module?

Yes, No no

1)

1) Not possible or not available with boilers with UBA1.x or DBA.

2) Not possible with boilers with UBA4.

3) Only possible with boilers with UBA4

4) Not possible or not available with boilers with DBA.

5) Not available with boilers with UBA1.x, DBA or UBA-H3.

Check whether further settings are required using the checklist on page 21.

SHORTPROG\ Menu item Input range

Standard

setting Other information

Table 9 Quick programmer menu navigator

Commissioning

Logamatic EMS – 6 720 801 387 (2011/05)

24

5

5.4 Detailed commissioning

B Check whether the basic settings in the SERVICE\SETTINGS menu match the heating system.

B Note down modified settings if needed.

5.5 System handover

B Ensure that no temperature limits for central heating and DHW have been set at the boiler

programming unit, so DHW and flow temperature can be regulated via the RC35 programming

unit.

B Explain to the customer how the appliance works and how to operate it.

B Inform customer about the selected settings.

5.6 Shutting down/switching off

The RC35 programming unit is powered via the heating system and remains permanently on. The

heating system is only switched off for maintenance work, for example.

B For switching the heating system on or off: switch the On/Off switch on the boiler programming

unit to position 1 (ON) or 0 (OFF).

B With hybrid systems with HM10: shut off power to the hybrid module.

We recommend that you hand over these installation and maintenance instructions to

the customer for safe keeping at the heating system.

After shutting down or in the event of a power failure, the date and time are retained for

up to 8 hours. All other settings are retained permanently.

Logamatic EMS – 6 720 801 387 (2011/05)

25

Commissioning

5

5.7 Operating information

Subscribers on the EMS-BUS

In a BUS system, only one subscriber can carry out the calculations for a heating circuit.

Consequently, only one RC35 programming unit may be installed in each heating system. If

additional programming units (e.g. RC2x) are required, they must be installed as remote

programmer

1)

with a set heating circuit address (Æ page 31).

Thermostatic radiator valves in the reference room

Thermostat valves on the radiators in the reference room2) are not required with room temperature

compensated control. Fully open any thermostatic radiator valves in the reference room.

Anti-block protection

1)

In all operating modes all heating pumps are switched on for 10 seconds and then switched off

again each Wednesday at 12:00 o'clock, in order to prevent damage to the pumps. The mixers are

then set to "OPEN" for 10 seconds and then "CLOSED". All pumps and mixers then return to their

normal, regulated operation.

1) this function is not possible with boilers with UBA1.x or DBA)

Disable this on boilers with integral weather-compensated control.

2) room in which a RC35 or RC2x/RC20/RF is fitted)

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

26

6

6 System settings (Service menu – Settings)

B Press + + simultaneously, to open the SERVICE MENU.

B Turn the rotary selector to the left until settings is selected.

B Press to open menu SERVICE\SETTINGS.

6.1 System data

B Press button to select plant data.

The menu SETTINGS\SYSTEM opens.

Note that the menu items shown will vary depending on the heating system.

Menu item

Input

range

Standard

setting

Other information

Have you installed a module for

the low loss header?

Yes, No No In association with MCM10 the

setting is automatically set to “Yes”;

screen is hidden.

1)2)

Is a sensor for a low loss header

connected?

No,

at the

boiler, at

the low loss

header

module

No If a low loss header module is used,

connect the temperature sensor to

the low loss header module.3)

4)

Is heating circuit 1 installed

(unmixed heating circuit)?

Yes, No Yes

How many mixed heating circuits

are installed?

0 to 3 0 Setting the address on the rotary

coding selector of the mixer module

(basic setting HK2).

1)

Have you installed a solar

module?

Yes, No No

1)

Table 10 Navigator for service menu SETTINGS\SYSTEM

SERVICE MENU

quick operation

settings

diagnosis

servicing

B

SERVICE\SETTINGS

B

plant data

boiler data

domestic hot water

heating circuit 1

Logamatic EMS – 6 720 801 387 (2011/05)

27

System settings (Service menu – Settings)

6

6.1.1 Building type (adjusting the outside temperature)

A building's heat storage capacity and its characteristic resistance to heat transfer will delay the

effect of outside temperature fluctuations on the rooms inside. Consequently, it is not the current

outside temperature that is crucial but the so-called adjusted outside temperature. Parameter

building type enables the adjustment to be applied that takes account of the fluctuating outside

temperatures. This enables the control to be matched to the characteristics of the building.

The control unit calculates the time constant for adjusting the outside temperature, using the factor

given in Tab. 11 for the stated building type and an internal multiplier, the "runtime" (= 6 minutes).

The time constant is the product of: factor x runtime = adjustment time constant in hours.

Should the adjusting of the

outside temperature be switched

off?

Yes, No No When selecting “yes” the following

parameter building type will be

hidden.

What type of building do you

have?

Light,

medium,

heavy

Medium Building type (heat storage capacity),

Æ Chapter 6.1.1, page 27.

What is the lowest expected

outside temp. in your region?

– 30 °C to

0°C

– 10 °C Æ Chapter 6.1.2, page 28

1) Not possible or not available with boilers with UBA1.x or DBA.

2) Not possible with boilers with UBA4

3) Only possible with boilers

4) UBA4

Parameter:

building type Type Factor

Light E.g. prefabricated building, wood-frame construction 10

Medium e.g. house made of hollow blocks (basic setting) 30

Heavy E.g. brick house 50

Table 11 Calculating the adjustment time constant

Menu item

Input

range

Standard

setting Other information

Table 10 Navigator for service menu SETTINGS\SYSTEM

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

28

6

Example:

Fig. 6 This greatly simplified example shows how the adjusted outside temperature follows the

outside temperature, but does not reach its extreme values.

1 Current outside temperature

2 Adjusted outside temperature

6.1.2 Minimum outside temperature

The minimum outside temperature is the average value of each of the coldest outside temperatures

or recent years, and it has an influence on the heating curve. The value can be taken from the heat

demand calculation which should be done for every building, or from the climatic zone chart for your

region.

In the basic setting any changes in the outside temperature have an effect after a delay

of three hours at the latest (30 x 6 minutes = 180 minutes) on the calculation of the

outside temperature compensated control.

B To control the calculated, adjusted outside temperature and the actual measured

outside temperature: open the menu for Diagnostics\monitor value 4

boiler\burner.

6 720 618 477-05.1RS

2

1

Logamatic EMS – 6 720 801 387 (2011/05)

29

System settings (Service menu – Settings)

6

6.2 Hybrid

B Turn the rotary selector to the left until Hybrid is selected.

B Press to select Hybrid.

The SETTINGS\HYBRID menu is opened

Menu item Input range Standard setting

Other

information

Is there a buffer in the

system?

Yes, No no

Triggering of boiler / heat

pump depends on:

Environmental factors,

costs, switching threshold,

environment and costs

Environment

Energy price ratio for

electricity / fossil fuel

0.0 to19.9 3.3

What is the primary energy

factor for the fossil fuel?

0.0 to 5.0 1.1

What is the primary energy

factor for the electrical

energy?

0.0 to 5.0 2.6

What should the dual-mode

switching threshold be?

-20 °C to +20 °C +6 °C

How is the pump on the

HM10 integrated

hydraulically?

serial, parallel serial

By what amount of time

should the boiler switch-in

be delayed?

5 to 120 minutes

Temperature difference for

delayed boiler switch-in?

1K to 99K

Table 12 Navigator for Service menu\Settings\Hybrid

You can find explanations on the settings in the documents for the hybrid system.

plant data

SERVICE\SETTINGS

B

hybrid

boiler data

heating circuit 1

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

30

6

6.3 Boiler data

B Turn the rotary selector to the left until boiler data is selected.

B Press to select boiler data.

The menu SETTINGS\BOILER is opened.

Menu item Input range

Standard

setting

Other information

Boiler pump after-run time

after burner stops?

deactivated,

1 to 60

minutes,

24 hours

5 min Setting is only possible with boilers

with internal pump.

1)

1) Not possible or not available with pumps with UBA1.x.

Set the pump logic

temperature.

0 to 65 °C 47 °C Setting only possible in conjunction

with BRM10.

Table 13 Navigator for service menu SETTINGS\BOILER

SERVICE\SETTINGS

B

plant data

boiler data

domestic hot water

heating circuit 1

Logamatic EMS – 6 720 801 387 (2011/05)

31

System settings (Service menu – Settings)

6

6.4 Heating circuit data

This chapter explains the settings for all heating circuits using heating circuit 1 as an example.

B Turn the rotary selector to the left until heating circuit 1 is selected.

B Press to select heating circuit 1.

The menu for SETTING\HEATING CIRCUIT 1 is opened.

Menu item Input range

Standard

setting Other information

Do you want to enable

heating circuit 1?

Yes, No Yes

Which programming unit

is assigned to heating

circuit 1?

RC2x/RC20/RF,

RC35, none

RC35 See page 35. With UBA1.xyou can

not select RC2x.

With selection of“None”the control

mode is switched to“Outside

temperature” compensatedand it is

hidden.

How should heating

circuit 1 be controlled?

Outside

temperature

compensated,

room temperature

compensated

Outside

temperature

compensated

“Room temperature compensated”

can only be set if RC2x or RC35 has

been allocated. If “room temperature

compensated” is selected, room

flow is used.

Which heating system

does heating circuit 1

have?

Radiator,

convector, floor

Radiator With HK1 “underfloor” setting only if

it is a case of a oil/gas condensing

boiler. Additional heating circuits

can then be installed.

Use a safety thermostat with

underfloor heating systems.

Table 14 Navigator for service menu of SETTING\HEATING CIRCUIT 1

SERVICE\SETTINGS

B

plant data

boiler data

domestic hot water

heating circuit 1

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

32

6

Heating curve

Std. tmp. ( – 10 °C) 30 °C to 90 °C 75 °C

(radiator,

convector)

45 °C

(floor)

The value in brackets is the setting

for the minimum outside

temperature (Æ page 31). Setting

only if the control mode is set to

“outside temperature

compensated”(Æ page 36).

Max flow temp. Radiators,

convectors: 30 °C

to 90 °C.

1)

Underfloor heating:

30 °C to 60 °C

Radiators,

convectors:

75 °C

Underfloor

heating:

50 °C

Setting only if the control mode is

set to“outside temperature

compensated”(Æ page 36).

Enter the maximum

flow temperature:

Setting only if the control mode is

set to“room temperature

compensated”(Æ page 36).

Min flow temp. 5 °C to 70 °C 5 °C Setting only if the control mode is

set to“outside temperature

compensated”(Æ page 36)

Enter the minimum flow

temperature:

Setting only if the control mode is

set to“room temperature

compensated”(Æ page 36).

Rm. tmp. offset -5.0 K to +5.0 K 0.0 K Offset of heating curve.

Setting only if the control mode is

set to “outside temperature

compensated”(Æ page 36).

Enter the maximum room

influence:

0 K to 10 K 3 K Setting only if the control mode is

set to “outside temperature

compensated”(Æ page 35).

Which reduction mode

should be implemented?

Outdoor

compensation

mode,

reduced mode,

room compensation

mode (only if RC35

or RC2x have been

allocated to the

heating circuit),

switch-off mode

Outdoor

setback

mode

Night reduction

(Æ page 37)

Menu item Input range

Standard

setting Other information

Table 14 Navigator for service menu of SETTING\HEATING CIRCUIT 1

Logamatic EMS – 6 720 801 387 (2011/05)

33

System settings (Service menu – Settings)

6

What outside temp.

should be used for

reduced operation?

– 20 °C to +10 °C 5 °C Temperature threshold for outdoor

setback mode (Æ page 37).

Adjustment only if the setback mode

is set to “outdoor setback mode”.

Frost prot.

What temp. should be

used to trigger frost

protection?

Outside

temperature, room

temperature, no

frost protection

Outside

temperatur

e

Room temperature adjustment only

if RC2x or RC35 have been

assigned to the heating circuit

(Æ page 38).

Which frost protection

temp. should be used?

-20 °C to +10 °C 5 °C Refers to outside temperature

(Æ page 38).

From which outside

temperature should the

reduction be

interrupted?

OFF,

-30 °C to +10 °C

OFF Reduction in accordance with

DIN 12831 (Æ page 39).

Should domestic hot

water priority be

activated?

Yes, No no

Mixer

2)

Is a mixer installed? Yes, No Yes Can only be set for heating circuit 2

onwards.

2)

What running time

does the mixer have?

10 s to 600 s 120 sec.

2)

What increase should

be used for the boiler?

0K to 20K 5K

2)

Screed drying

2)

Should a drying cycle

be carried out?

Yes, No no Adjustment only if floor has been

selected. DHW heating is not

enabled while screed is drying.

2)

Every how many days

should the flow temp.

be raised?

Every day, every

2nd day to

every 5th day

Every day

2)

By how many Kelvin

should the flow

temperature be

increased in each

case?

0K to 40K 5K

2)

Menu item Input range

Standard

setting Other information

Table 14 Navigator for service menu of SETTING\HEATING CIRCUIT 1

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

34

6

What is the desired

maximum flow

temperature?

25 °C to 60 °C 45 °C

2)

For how many days

should maximum flow

temp. be maintained?

0 days to 20 days 4 days

2)

Every how many days

should the flow temp.

be reduced?

Direct normal

operat., every day,

every 2nd day to

every 5th day

Every day

2)

By how many K should

the flow temperature

be reduced

respectively?

0 K to 20 K 5 K Adjustment only if, for flow

temperature reduction,“direct

normal operation” has not been

selected.

4)

Do you wish to change

the switching program?

Yes, No no When selecting “yes” the system

jumps to the heating circuit

switching program.

Should the switching

programme be

optimised?

Yes, No no Start and stop times are

automatically adjusted according to

the outside temperature, room

temperature and building type (heat

storage capacity).

What reduction mode

should be used for

holiday?

Outdoor

compensation

mode,

reduced mode,

room compensation

mode, switch-off

mode

Outdoor

setback

mode

See page 37.

Setting for “room compensation

mode” only if a remote programmer

(e.g. RC2x) has been allocated to

the heating mode. If “reduced

mode” is selected, the normal night

temperature is used.

What outside temp.

should be used?

-20 °C to +10 °C 5 °C Temperature threshold for outdoor

setback mode (Æ page 37).

Adjustment only if setback mode for

holiday was set to “outdoor setback

mode.”

1) Depending on the boiler the setting range can be limited

2) Not possible or not available with boilers with UBA1.x or DBA.

Menu item Input range

Standard

setting Other information

Table 14 Navigator for service menu of SETTING\HEATING CIRCUIT 1

Logamatic EMS – 6 720 801 387 (2011/05)

35

System settings (Service menu – Settings)

6

6.4.1 Assignment of programming unit / remote control unit in the software

This function is not available with boilers with UBA1.x and DBA.

Example: heating system with heating circuit 1 and heating circuit 2 (Æ page 12)

6.4.2 Control mode (outside temperature compensated/room influence)

In the Logamatic control unit the heating curve specifies the temperature of the heating water in the

boiler. It can be selected whether this heating curve is influenced solely by the outside temperature,

or whether a mix from the characteristics of the outside temperature and the room temperature

define the heating curve.

• Outside temperature compensated: with this setting a boiler temperature, which is

calculated in the control unit, is controlled by means of a change in the adjusted outside

temperature combined with selected settings for room target value, offset, design temperature

and minimum outside temperature. This temperature is then delivered to the radiators or

underfloor heating system by means of permanent operation of the heating circuit pump.

The only circumstances in which this setting can result in the heating circuit pump being

switched off are summer mode, night setback (subject to the selected setback mode) or DHW

mode (only with DHW priority).

• Outside temperature compensated with the influence of room temperature (basic

setting): this type of control works exactly as the pure weather compensated control, but with the

difference that, by means of the parameters for maximum room influence, it can be defined

whether, and to what degree, the room temperature has an influence on the heating curve.

The programming unit/remote control must be installed in a reference room to ensure that a

representative room temperature is captured.

The larger the parameter is set, the larger is the proportion of the room temperature on the design

formation of the heating curve (basic setting 0 Kelvin) This applies when the room temperature

exceeds or falls below the set room temperature. If the maximum room influence parameter

is set to 0, the heating characteristics will be controlled solely by outside temperature.

AlternativeSetting: Which operating unit is

assigned to the heating circuit?

Effect

A HK 1 = RC35, HK 2 = RC35

(Æ fig. 2, [1],Seite 13)

same room temperatures for HK 1 and HK 2

B HK 1 = none, HK 2 = RC35

(Æ fig. 2, [1],Seite 13)

Room temperatures for HK 1 and HK 2 can be

set separately

C HK 1 = RC2x, HK 2 = RC35

(Æ fig. 2, [2], Seite 13)

Room temperatures for HK 1 and HK 2 can be

set separately;

set room temperature for HK 1 at RC2x

Table 15 Settings for room temperature depending on programming unit

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

36

6

6.4.3 Heating curve

Parameter: design temperature, maximum and minimum flow temperature and room temperature

offset (parallel shift).

The heating curve is the decisive basic factor for an economic and convenient operation of the

heating system with outside temperature compensated control. For the calculation of this curve the

Logamatic control system requires information about some of the heating system characteristics,

and from this it calculates automatically and by means of a mathematical formula the optimum

heating curve. As part of this it takes into account the adjusted outside temperature and the room

control temperature. The room control temperature is in turn an internal calculation factor, which is

comprised of the desired room temperature (room target temperature) and the room influence. By

means of this the user can immediately influence the heating curve by changing the room target

temperature. The heating curve (Æ display 7, page 37) is essentially defined by its base point and

end point. The base point is located at 20 °C flow temperature at a room temperature of 20 °C with

an adjusted outside temperature of 20 °C. The end point of the heating curve must be set according

to the design temperature of the heating system. The defining factors for the run of heating curve

(incline/steepness) are the two parameters minimum outside temperature (the lowest expected

outside temperature in a region, page 28) and the design temperature (the flow temperature

which should be reached at the minimum outside temperature), Æ display 7, left.

With the parameter for minimum flow temperature a minimum target value can be specified

(Æ display 7, [4], page 37). The burner starts again if the set value is no longer achieved.

The heating characteristic curve can be shifted up or down parallel to the original curve by adjusting

the room temperature offset parameter and/or the set room temperature (Æ fig. 7, right,

page 37). Setting the offset may be advisable should the room temperature measured by a

thermometer deviate from the selected set value.

The X axis of the heating curve depicted graphically in the display relates to the area of

+20 °C to – 20 °C.

Under design parameter the minimum outside temperature, which is set under system

data, is depicted by a circle. If a minimum outside temperature of under – 20 °C is

entered, the depiction is however no longer completely correct (the circle no longer lies

on the heating curve).

Logamatic EMS – 6 720 801 387 (2011/05)

37

System settings (Service menu – Settings)

6

Fig. 7 Setting of the heating curve. Left: setting the gradient by means of design temperature

and minimum outside temperature. Right: parallel offset possible by means of offset or

set room temperature.

T

minA

Minimum outside temperature

T

A

Design temperature (flow temperature that should be achieved at min. outside temperature)

1 Setting: design temperature 75 °C, minimum outside temperature – 10 °C (standard curve)

2 Setting: design temperature 75 °C, minimum outside temperature – 20 °C

3 Setting: design temperature 50 °C, minimum outside temperature – 10 °C

4 Setting: minimum flow temperature 35 °C

5 Setting: design temperature 75 °C, minimum outside temperature – 10 °C (standard curve)

6 Parallel offset of standard curve by changing the offset +3 or by increasing the set room temperature

7 Parallel offset of the standard curve by changing the offset – 3 or by reducing the set room temperature

6.4.4 Reduction modes (night reduction)

There are a number of different setback modes available, which allow night setback to be adjusted

to suit the differing needs of the user:

• Reduced operation: the rooms are maintained at a reasonable temperature at night by constant

heating operation (pump runs constantly). A set room temperature for nighttime can be set. It is

at least 1 K lower than the set day temperature. The heating curve is calculated in accordance

with these details.

We recommend these settings for an underfloor heating system.

• Shutdown operation: boiler and heating circuit pump are off, frost protection is active. The

pump only starts in frost protection mode.

This setting is not recommended if there is a risk that the building would cool down too severely.

T

minA

T

A

T

A

T

minA

6 720 618 477-06.1RS

2

3

4

5

6

7

1

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

38

6

• Room setback mode: The heating system operates as if in setback mode (as described under

“reduced operation”), if the room temperature falls below the selected night temperature (set

value). Boiler and heating circuit pump stop (as described under setback mode “shutdown

operation”) if the room temperature exceeds the set night temperature by more than 1 K.

This setback mode is only possible if a programming unit/remote control is installed in a

representative room (reference room) or if the room temperature is captured by an external room

temperature sensor.

• Outdoor compensation mode: if the adjusted outside temperature falls below the value of a

settable outside temperature threshold, the heating system works as in the reduced heating

mode (as described under “reduced mode).” The heating system remains off above this threshold

(as described under setback mode “shutdown operation”). This setback mode is suitable for

heating circuits which do not have their own programming unit / remote control unit. The

operating mode protects the rooms from cooling down too much once a certain outside

temperature is reached.

6.4.5 Frost prot.

The frost protection function offers the following options:

• No frost protection (frost protection is switched off).

• Outside temperature(outside temperature sensor required)If the outside temperature falls

below the threshold of the settable frost limit temperature, the heating circuit pump is

automatically switched on.

• Room temperature(Room temperature sensor of the RC35 or RC2x). If the room temperature

falls below the fixed set value of 5 °C, the heating circuit pump is automatically switched on. The

heating circuit pump stops automatically if the room temperature rises above 7 °C.

CAUTION: System damage through frost!

The settings no frost protection and room temperature provide either no frost

protection or inadequate frost protection. When these settings are selected, the display

shows a message indicating the risk of freezing.

B For reliable frost protection, use the outside temperature setting.

The setting room temperature offers no absolute frost protection, as lines routed

through external walls may freeze up, for example, although the temperature in the

reference room may be significantly above 5 °C.

Logamatic EMS – 6 720 801 387 (2011/05)

39

System settings (Service menu – Settings)

6

From which outside temperature should the reduction be interrupted?

DIN-EN 12831 requires that, for the maintaining of a comfortable heat, all heating surfaces and heat

generators are designed to a defined output, if the heating system cools down below a defined value

due to night reduction.

In the parameter From which outside temperature should the reduction be interrupted?

it is possible to set an outside temperature threshold (related to the adjusted outside temperature,

(Æ page 27).

Fig. 8 shows how the frost protection function works, with and without this parameter activated.

Settings selected: frost protection by outside temperature; frost protection temp. 5°C.

Fig. 8 Effect of the parameter 'From which outside temperature should the reduction be

interrupted?'. Left: parameter is set to 'Off' (basic setting).

Right: parameter is set to – 15 °C

T

A

Outside temperature

T

V

Flow temperature

1 Shut-down mode

2 Reduced mode (at set nighttime room temperature)

3 Heating mode (at set daytime room temperature)

If the outside temperature falls below – 15 °C, the heating system goes out of reduced mode into

heating mode[3]. This allows smaller heating surfaces to be utilised.

T

A

T

A

T

V

5°C

T

V

5°C -15°C

2

3

1

2

1

6 720 618 477-07.1RS

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

40

6

6.5 DHW

B Turn the rotary selector to the left until DHW is selected.

B Press to select domestic hot water.

Menu SETTINGS\DOMESTIC HOT WATER opens.

WARNING: Scalding hazard at the DHW taps.

If DHW temperatures over 60 °C are settable and present during thermal disinfection,

there is a scalding hazard at the DHW taps.

B Inform the customer that he should only turn on mixed water.

Menu item Input range

Standard

setting Other information

Have you installed domestic hot

water?

Yes, No no DHW cannot be uninstalled in

the case of boilers with DBA.

Limiting value for maximum

dom. hot water temp. setting:

60 °C to 80 °C 60 °C Subject to the boiler in use, a

the maximum possible set

DHW temperature is limited to

60 °C.

To which temperature should

your domestic hot water be

heated?

30 °C to 80 °C 60 °C If the limit has been set to

> 60 °C, this higher value can

also be selected in the“USER

MENU”.

What should be used for

domestic hot water heating?

3-way diverter

valve, cylinder

primary pump

Three-way

diverter

valve

1)

Do you wish to change the dom.

hot water switching

programme?

Yes, No no When selecting “yes” the

system jumps to the DHW

switching program.

Table 16 Navigator for service menu SETTINGS\DHW

SERVICE\SETTINGS

B

plant data

boiler data

domestic hot water

heating circuit 1

Logamatic EMS – 6 720 801 387 (2011/05)

41

System settings (Service menu – Settings)

6

Circulation

2)3)

Is a circulation pump

installed?

Yes, No no

How frequently should the

circul. pump be switched on

per hour?

once for 3

minutes, twice for

3 minutes, 3 times

for 3 minutes, 4

times for 3

minutes, 5 times

for 3 minutes, 6

times for 3

minutes,

permanent

operation

twice for 3

minutes

Switch on circ. pump Graphical display of number of

times the pump is switched on

per hour.

Do you wish to change the

circulation switching

programme?

Yes, No no When selecting “yes” the

system jumps to the DHW

circulation switching program.

Thermal disinfection

2)

Should a thermal

disinfection be carried out?

Yes, No no

At which temperature

should the thermal

disinfection take place?

60 °C to 80 °C

4)

70 °C At temperatures above 60 °C

there is a risk of scalding at the

draw-off points during and after

thermal disinfection!

On which day of the week

should the thermal

disinfection take place?

Monday, Tuesday,

Wednesday,

Thursday, Friday,

Saturday, Sunday,

daily

Tuesday

At which time should the

thermal disinfection take

place?

00:00h to 23:00h 1:00h Times entered must be whole

hours only (no minutes).

Menu item Input range

Standard

setting Other information

Table 16 Navigator for service menu SETTINGS\DHW

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

42

6

Should the LED of the single

charge key be activated?

Yes, No Yes The single loading function

remains, but it is not displayed

via LED.

5)

Start delay in case of preheated

DHW (e.g. solar)

Off,

1 second to 50

seconds

OFF This function depends on the

boiler used.

1) Not possible or available on boilers with UBA1.x, UBA-H3 or DBA.

2) Not possible or not available with boilers with UBA1.x or DBA.

3) With boilers with UBA-H3 depending on the existence of a PZ output (e.g. on module LM10)

4) Subject to the boiler in use, the temperature is permanently fixed an cannot be modified.

5) Not possible or not available with boilers with UBA1.x.

Menu item Input range

Standard

setting Other information

Table 16 Navigator for service menu SETTINGS\DHW

Logamatic EMS – 6 720 801 387 (2011/05)

43

System settings (Service menu – Settings)

6

6.6 Solar data

B Turn the rotary selector to the left until solar data1) is selected.

B Press to select solar data.

Menu SETTINGS\SOLAR opens.

Menu item Input range Standard setting

Other

information

What is the max. stor.

cylinder temp. of the solar

system?

30 °C to 90 °C 60 °C

1)

1) Not possible or not available with boilers with UBA1.x or DBA.

Below which temperature

should the cylinder not fall?

30 °C to 54 °C, off OFF

1)

What is the minimum pump

rating?

20 % to 100 % 100 %

1)

Table 17 Navigator for service menu\Settings\Solar data

For explanations of the settings, see the documentation for the solar module.

boiler data

domestic hot water

heating circuit 1

solar data

SERVICE\SETTINGS

B

System settings (Service menu – Settings)

Logamatic EMS – 6 720 801 387 (2011/05)

44

6

6.7 RC35 calibration

B Turn the rotary selector to the left until RC35 calibration is selected

B Press button to select RC35 calibration.

The menu for SETTING/RC35 CAL is opened.

Calibrating the displayed room temperature (calibration)

If there is a separate thermometer near the programming unit, it may show a different room

temperature to that shown on the programming unit. You can use this function to adjust (“calibrate”)

the programming unit to match the thermometer.

Before adjusting the room temperature, consider the following:

• Is the thermometer more accurate than the programming unit?

• Is the thermometer located close to programming unit so that they are both subject to the same

heat influences (e.g. sunlight, fireplace)?

Example: if the thermometer is showing a temperature 0.5 °C higher than the programming unit,

enter +0.5 K as the calibration value.

Menu item Input range Standard setting

Other

information

RC35 calibration – 5.0 K to +5.0 K 0.0 K

Table 18 Navigator for service menu SETTINGS\CALIB. RC35

A thermometer may indicate temperature fluctuations more slowly or rapidly than the

programming unit.

B Therefore, never calibrate the programming unit during phases when the heating

system is cooling down or heating up.

domestic hot water

heating circuit 1

solar data

RC35 calibration

SERVICE\SETTINGS

B

Logamatic EMS – 6 720 801 387 (2011/05)

45

System settings (Service menu – Settings)

6

6.8 Contact details

Contact details are automatically displayed to the end user if a fault develops.

B Turn the rotary selector to the left until contact data is selected.

B Press to select contact data.

Menu SETTING\CONTACT opens.

Entering company name and telephone number

Two rows are available, each with 21 characters (capital letters, numbers and some other symbols).

The current cursor position will flash (marked by “_”).

1. Hold the button pressed down and simultaneously turn the rotary selector to select

another character. Release the button.

The modified character is saved.

2. Turn the rotary selector to the left or right to move the cursor position.

3. Enter a space to delete a character.

4. Press to save your entries and leave the menu.

Menu item Input range Other information

Name and tel. No. of

supplier:

_ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _

Table 19 Navigator for service menu SETTINGS\CONTACT

heating circuit 1

SERVICE\SETTINGS

B

solar data

RC35 calibration

contact data

Diagnosis

Logamatic EMS – 6 720 801 387 (2011/05)

46

7

7 Diagnosis

The diagnosis service menu contains a number of tools for diagnosis:

• Function test:

1), 2)

• Monitor value

• Fault display:

3)

• Heating curve

•Versions

B Press + + simultaneously, to open the SERVICE MENU.

B Turn the rotary selector to the left until diagnosis is selected.

B Press to open the SERVICE\DIAGNOSIS menu.

1) this function is only possible to a limited extent with boilers with UBA-H3

2) This function is not possible or not available with boilers with UBA1.x or DBA.

3) this function is only possible to a limited extent with boilers with DBA, UBA1.x or UBA-H3.

Note that the menu items shown will vary depending on the heating system.

SERVICE MENU

quick operation

settings

diagnosis

servicing

B

Logamatic EMS – 6 720 801 387 (2011/05)

47

Diagnosis

7

7.1 Function test

With this menu you can trigger specific individual EMS components, in order to test their function.

1), 2), 3)

The available functions and the possible settings vary depending on the system installed.

B Hold the button pressed down and simultaneously turn the rotary

selector to change the setting:

e.g. BURNER OFF to BURNER ON.

The change takes effect when you release the button .

B Turn the rotary selector to switch between different displays

(function test).

1) This function is only possible to a limited extent with boilers with UBA-H3.

2) This function is not possible or not available with boilers with UBA1.x or DBA.

3) This function is only possible to a limited extent if a HM10 hybrid module is used.

Observe the information which appears on the display when you switch to menus or

enter settings. Press any button or turn the rotary selector to confirm the information.

No settings will be allowed that might result in damage to the components. This is why

some settings may not be accepted.

valve 1 cl. 2 cl.

FCT. TEST\BOILER

ignition OFF

flame OFF

flame current 0.0μA

B

BURNER ON

act. boil. tmp. 60°C

FCT. TEST\BOILER

air temperature 32°C

flue gas temp. 78°C

flame OFF

B

BURNER OFF

Diagnosis

Logamatic EMS – 6 720 801 387 (2011/05)

48

7