Bosch IWHT180, HTH181, HTH182 User Manual

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Operating/Safety Instructions

Consignes d’utilisation/de sécurité

Instrucciones de funcionamiento y seguridad

IMPORTANT

Read Before Using

●

IMPORTANT

Lire avant usage

●

IMPORTANTE

Leer antes de usar

For English Version

See page 2

●

Version française

Voir page 13

●

Versión en español

Ver la página 24

Call Toll Free for Consumer Information and Service Locations

Pour obtenir des informations et les adresses de nos centres de service après-vente, appelez ce numéro gratuit

Llame gratis para obtener información para el consumidor y ubicaciones de servicio

IWHT180

HTH181

HTH182

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 1

-2-

▶ Work area safety

Ke ep work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

▶ Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any a dapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

Avoid body contact with earthed or

grounded su r faces, such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if

your body is earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat,

oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of

electric shock.

When operating a power tool outdoors,

us e an exten sion cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

If operating a power tool in a damp

location is unavoidable, use a Ground

Fa u lt Circuit In terrupter ( G FCI)

protected supply. Use of an GFCI reduces

the risk of electric shock.

▶ Personal safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool

while you are tired or under the influence

Read all safety warnings, instructions, illustrations and specifications

provided with this power tool. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

General Power Tool Safety Warnings

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

!

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

DANGER indicat es a ha zardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardou s situ ation which, if not

avoided, could result in minor or moderate injury.

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 2

-3-

General Power Tool Safety Warnings

of drugs, alcohol or medication. A moment

of inattention while operating power tools

may result in serious personal injury.

Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate conditions

will reduce personal injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and / or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energizing power tools

that have the switch on invites accidents.

Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

pa rt o f the power t ool may result in

personal injury.

Do not overreach. Keep proper footing

and balance at all times. This enables

be t ter control of the po wer tool in

unexpected situations.

Dr e ss proper l y. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

If devic es ar e prov ided for the

co n nection of dust extractio n and

collection facilities, ensure these are

connected and properly used. Use of dust

co l lection can red uce dust-re lated

hazards.

Do not let familiar ity gain ed from

fr e quent use of tools allow you to

become complacent and ignore tool

safety principles. A careless action can

cause severe injury within a fraction of a

second.

▶ Power tool use and care

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be repaired.

Disconnect the plug from the power

source and/or remove the battery pack, if

detachable, from the power tool before

making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk

of starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

Maintain power tools and accessories.

Check for misalignment or binding of

moving parts, breakage of parts and any

other condition that may affect the power

tool’s operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

Keep handles and grasping surfaces dry,

cl ean and f ree from oil and g rease.

Slippery handles and grasping surfaces do

not allow for safe handling and control of

the tool in unexpected situations.

▶ Battery tool use and care

Recharge only wi t h the charger

specified by the manufacturer. A charger

that is suitable for one type of battery

pack may create a risk of fire when used

with another battery pack.

Use power tools only with specifically

designated battery packs. Use of any

other battery packs may create a risk of

injury and fire.

When battery pack is not in use, keep it

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 3

-4-

Hold the power tool by insulated gripping

surfaces, when performing an operation

where the fastener may contact hidden

wiring. Fasteners contacting a “live” wire

may make exposed metal parts of the

power tool “live” and cou ld give the

operator an electric shock.

Brace the tool properly before use. This

tool produces a high output torque and

without properly bracing the tool during

operation, loss of control may o ccur

resulting in personal injury.

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body leaves it unstable and may

lead to loss of control.

Do not drill, fasten or break into existing

walls or other blind areas where electrical

wi ring ma y exist . If th is situ atio n is

unavoidable, disconnect all fuses or circuit

breakers feeding this worksite.

Alwa y s w e ar safety g o g g l es or ey e

protection when using this tool.

Wear ear protectors when using the tool for

extended periods. Prolonged exposure to

high intensity noise can cause hearing loss.

Use thick cushioned gloves and limit the

expo sure time by takin g frequ ent rest

periods. Vibration caused by hammer-drill

action may be harmful to your hands and

arms.

Secure the material being fastened. Never

hold it in your hand or across your legs.

Unstable support can cause loss of control

and injury.

Avoid accide nt al starting. Be sur e the

forw a r d / r e v erse switch is in th e of f

position before inserting battery pack.

Carrying appliances with your finger on the

switch or inserting the battery pack into an

appl i a n c e with th e switch o n invit e s

accidents.

Remove batte ry pack befor e changing

accessories. Accidental starting may occur

because battery appliances with a battery

inserted are in the operative condition.

Be prepared for a reaction torque when

“seati ng” or removing a fa stener. Th e

screwdriver housing may tend to twist in the

oppo s i t e direct i o n of b i t rotation when

“seating” or removing a fastener depending

on the torque setting of the tool.

Do not use dull or damaged impact

Safety Rules for Cordless Impact Wrenches

General Power Tool Safety Warnings

aw ay from other metal obje cts lik e

paper clips, coins, keys, nails, screws,

or other small metal objects that can

make a connection from one terminal to

another. Shorting the battery terminals

together may cause burns or a fire.

Under abusive conditions, liquid may be

ejected from the battery, avoid contact.

If contact accidentally occurs, flush with

water. If l i q u i d contacts ey e s ,

additionally seek medical help. Liquid

eject e d from the battery may cause

irritation or burns.

Do not use a battery pack or tool that is

damaged or modified. Damaged or modified

batte r i e s may e x h i bit unpred i c t a b l e

behaviour resulting in fire, explosion or risk

of injury.

Do not expose a battery pack or tool to

fire or excessive temperature. Exposure

to fire or temperature above 265 °F may

cause explosion.

Follow all charging instructions and do

not charge the battery pack or tool

outside the temperature range specified

in the instructions. Charging improperly

or at temperatures outside the specified

range may damage th e battery and

increase the risk of fire.

▶ Service

Have your power tool serviced by a

qualified re pair p erson using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

Never service damaged battery packs.

Service of battery packs should only be

pe r formed by the manufac t urer or

authorized service providers.

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 4

-5-

sockets and accessories. When installing

an accessory, insert the impact socket well

onto the output drive. Be sure the output

drive has locked onto the socket correctly.

Do not run the tool while carrying it at

your side . A sp inning bit co uld b ecome

entangled with clothing and injury may result.

Pl ace the to ol onto th e f aste ner onl y

when the sc rewdriver is s witch ed off.

Rota t i n g dr i v e r tools can slide off th e

fastener.

Do not use this tool as a dr i l l. Tool s

eq uipp ed w ith shu t-of f c lutc hes are not

designed for drilling applications. The output

drive can shut off automatically and without

warning.

Be careful when driving long screws –

there is a risk of sliding off the fastener

head depending on type of socket or bit

used. First test the run-down of a fastener

and pay attention during the screw driving

process to ensure you do not injure yourself

if th e tool bi t o r s ock et slides off o f t he

fastener.

Additional Safety Warnings

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Develop a periodic maintenance schedule

for your tool . When cleaning a tool be

careful not to disassemble any portion of

th e tool since inter nal wi res ma y be

misplaced or pinched or safety guard return

sp rin gs may be imp roperly mou nte d.

Certain cleaning agents such as gasoline,

carb on tetrac hlori de, ammonia, etc . may

damage plastic parts.

Ensure the switch is in the off position

before inserting battery pack. Inserting the

battery pack into power tools that have the

switch on invites accidents.

Some dust c reated by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

ca use canc er, bi rth def e cts or othe r

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsen ic a nd c hromium from chemically-

treated lumber.

Yo u r ri sk f r om t hese expo s ures var i es,

depending on how often you do this type of

work . To reduce your exposur e to th ese

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Safety Rules for Cordless Impact Wrenches

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 5

-6-

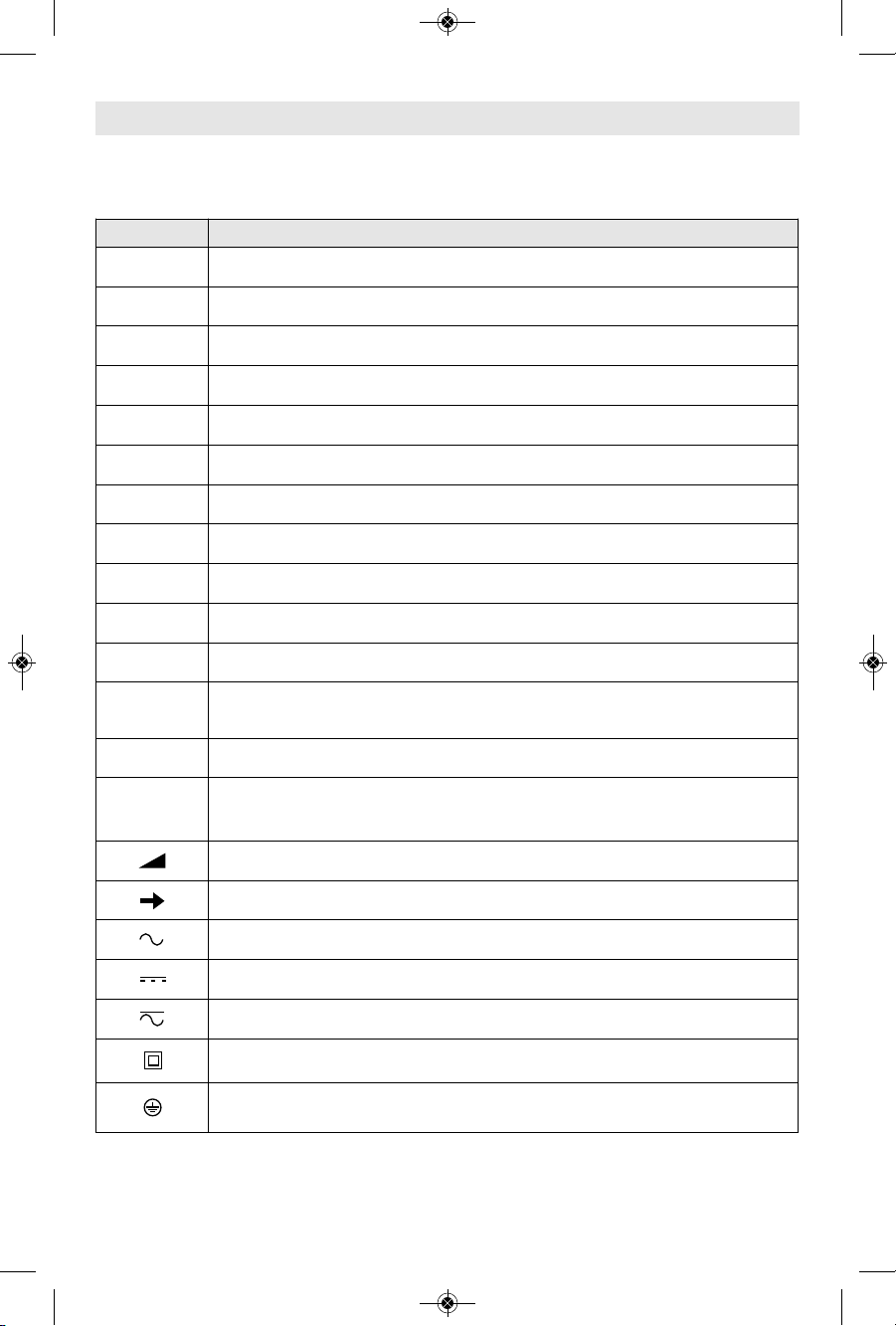

Symbols

Important: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate

the tool better and safer.

Symbol Designation / Explanation

V Volts (voltage)

Ah Amp hour (measurement of battery capacity)

A Amperes (current)

Hz Hertz (frequency, cycles per second)

W Watt (power)

kg Kilograms (weight)

min Minutes (time)

s Seconds (time)

⌀

Diameter (size of drill bits, grinding wheels, etc.)

n

0

No load speed (rotational speed at no load)

n Rated speed (maximum attainable speed)

.../min

Revolutions or reciprocation per minute (revolutions, strokes, surface

speed, orbits etc. per minute)

0 Off position (zero speed, zero torque...)

1, 2, 3, ...

I, II, III,

Selector settings (speed, torque or position settings. Higher number

means greater speed)

0

Infinitely variable selector with off (speed is increasing from 0 setting)

Arrow (action in the direction of arrow)

Alternating current (type or a characteristic of current)

Direct current (type or a characteristic of current)

Alternating or direct current (type or a characteristic of current)

Class II construction (designates double insulated construction tools)

Earthing terminal (grounding terminal)

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 6

-7-

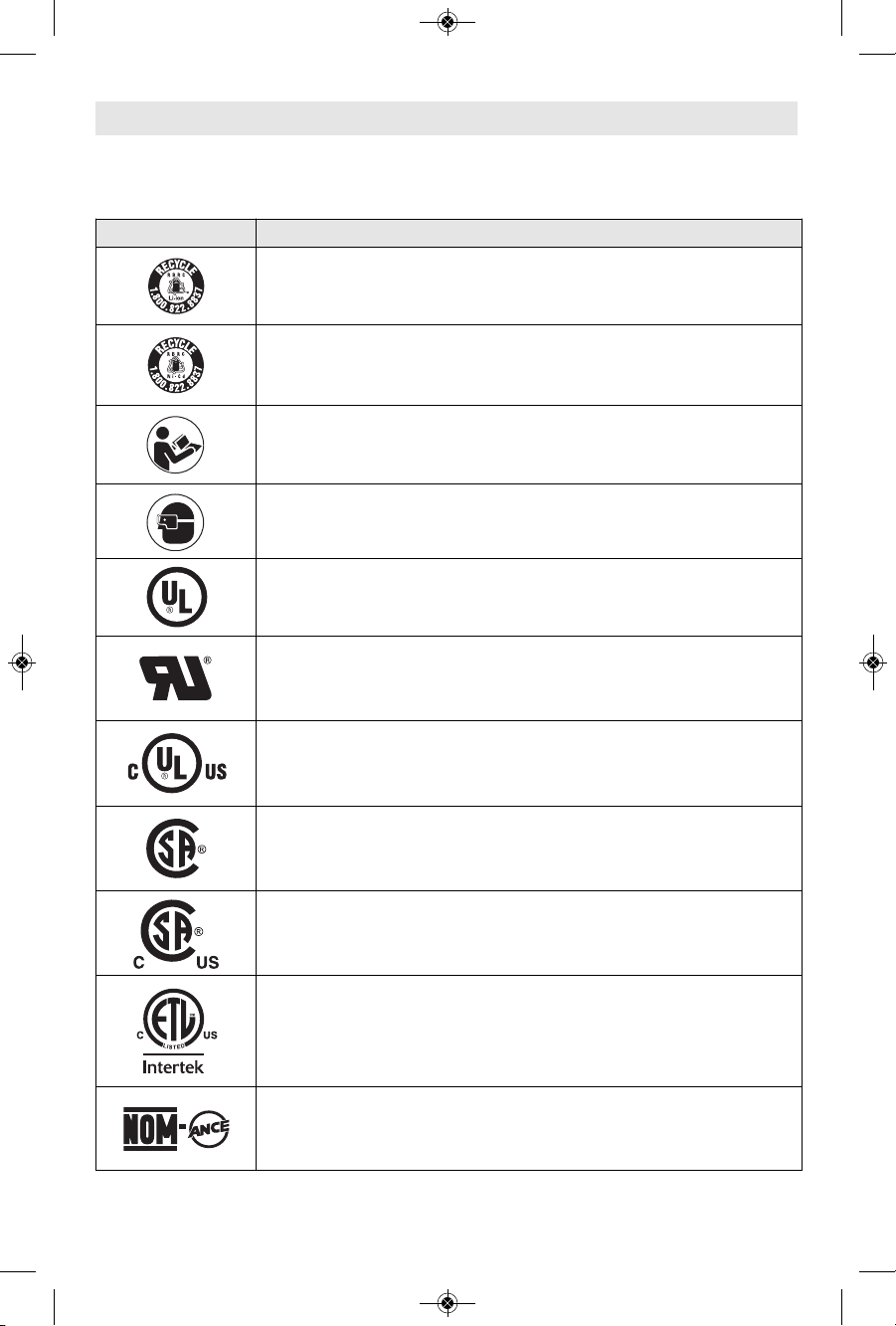

Important: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate

the tool better and safer.

Symbols

Symbol Designation / Explanation

Designates Li-ion battery recycling program

Designates Ni-Cad battery recycling program

Alerts user to read manual

Alerts user to wear eye protection

This symbol designates that this tool is listed by Underwriters

Laboratories.

This symbol designates that this component is recognized by

Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters

Laboratories, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian

Standards Association.

This symbol designates that this tool is listed by the Canadian

Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican

Standards.

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 7

-8-

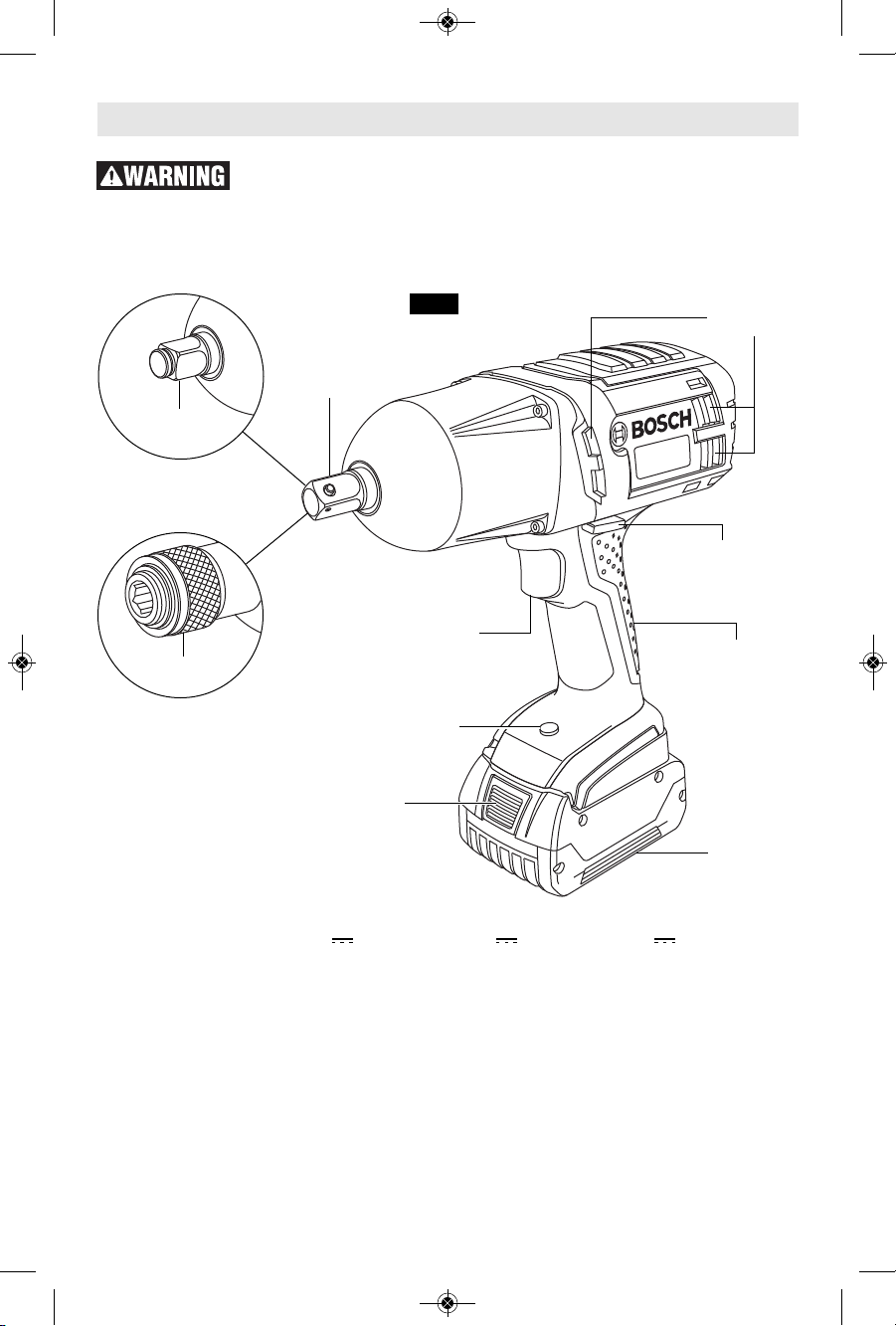

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Cordless Impact Wrench IWHT180, HTH181, HTH182

FIG. 1

Model number IWHT180 HTH181 HTH182

Voltage rating 18 V 18 V 18 V

No load speed n00-1,900/min n00-1,900/min n00-1,900/min

Impact rate 0-2,100 0-2,100 0-2,100

Maximum Capacities

Output drive 1/2" Square drive 1/2" Square drive 7/16" Hex-shank

with friction ring with detent pin with power groove

Model

HTH182 only

Model

IWHT180 only

VENTILATION

OPENINGS

FORWARD/

REVERSING LEVER

& TRIGGER LOCK

BUILT IN

WORK LIGHT

VARIABLE SPEED

TRIGGER SWITCH

BATTERY PACK

RELEASE

BUTTON

BATTERY

PACK

RUBBERIZED

GRIP

OUTPUT

DRIVE

LOCKING

SLEEVE

OUTPUT

DRIVE

Model

HTH181 only

Battery Packs/Chargers

Please refer to the battery/charger list, included with your tool.

Allowed ambient temperature

– during charging

– during operation/storage

32...113 °F (0...+45 °C)

–4...122 °F (–20...+50 °C)

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 8

Disconnect battery pack

from tool before making

any assembly, adjustments or changing

ac c essor i es. S uch p reven t ive s afet y

measures reduce the risk of starting the tool

accidentally.

Attach o nly high qu ality

ac cess orie s w ith th e

proper size square drive designed for use with

impact wrenches.

-9-

Assembly

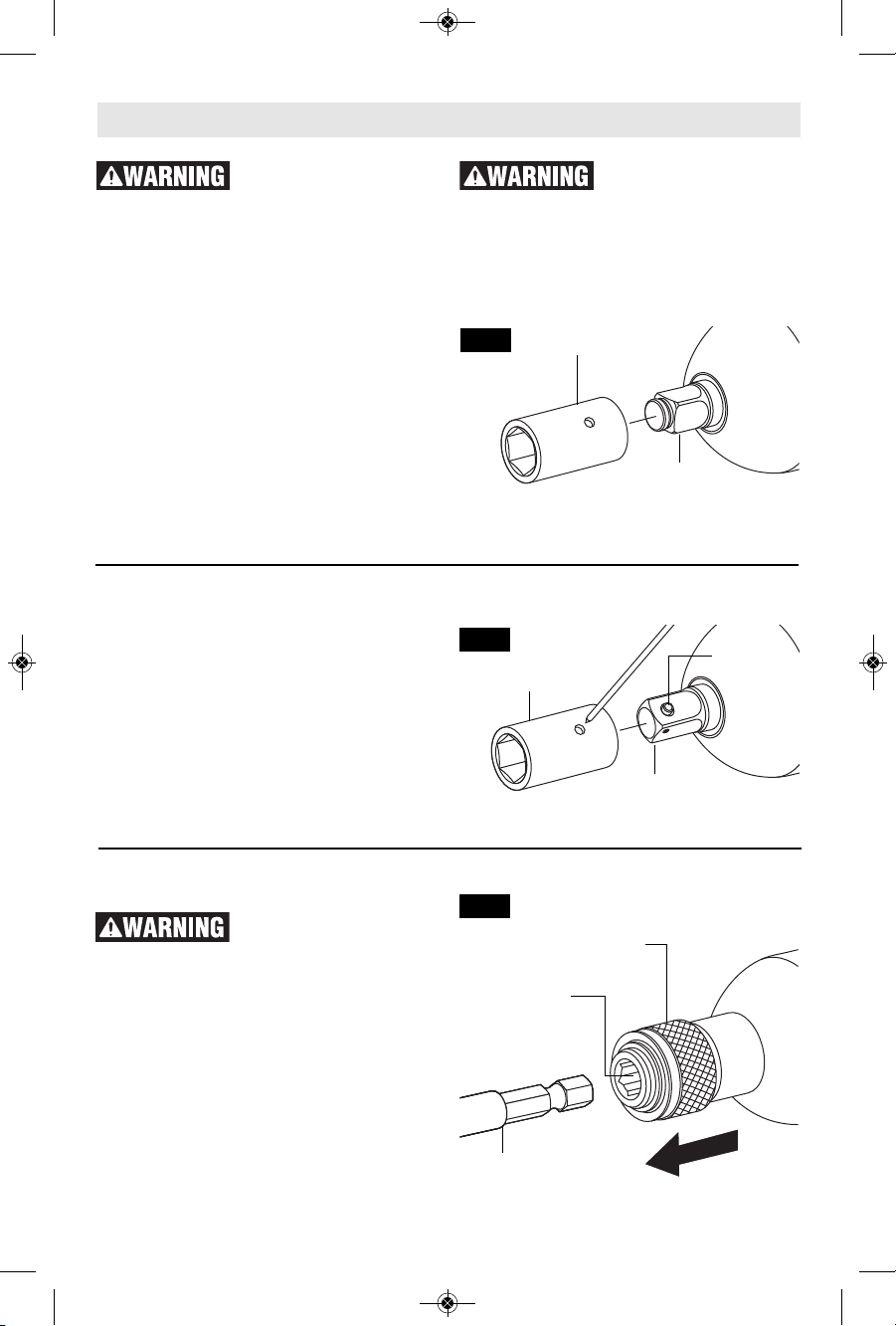

(Models HTH181 only)

Your impact wrench is equipped with a 1/2"

square drive with detent pin.

To install a socket, depress detent pin and

push socket completely onto output drive.

To remove, depress detent pin with a nail

through hole in socket and pull socket off

output drive (Fig. 3).

(Model HTH182 only)

To avoid loss of control,

en s ure bit is locked in

chuck by pulling on bit af ter i t has been

inserted.

The chuck accepts only standard 7/16"

hexagonal shank accessories with power

groove.

Your tool is equipped with a quick release

chuck. To insert an accessory, simply pull

lo c king sleev e for w ard, inser t d e sired

accessory into chuck and release locking

sleeve (Fig. 4).

To remove an accessory, pull locking sleeve

(Model IWHT180 only)

Your impact wrench is equipped with a 1/2"

square drive with friction ring.

To ins tall a s ocke t , si mply pus h so c ket

completely onto output drive.

To remove, pull socket off output drive (Fig. 2).

SOCKET

FIG. 2

INSERTING AND REMOVING ACCESSORIES

OUTPUT

DRIVE

CHUCK

LOCKING SLEEVE

BIT

FIG. 4

FIG. 3

SOCKET

DETENT

PIN

OUTPUT

DRIVE

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 9

-10-

Operating Instructions

forward and simply remove it from the chuck.

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed

trigger switch. The tool can be turned "ON" or

"OFF" by squeezing or releasing the trigger.

The speed can be adjusted from the minimum

to maximum nameplate RPM by the pressure

you apply to the trigger. Apply more pressure

to increase the speed and release pressure to

decrease speed (Fig. 1).

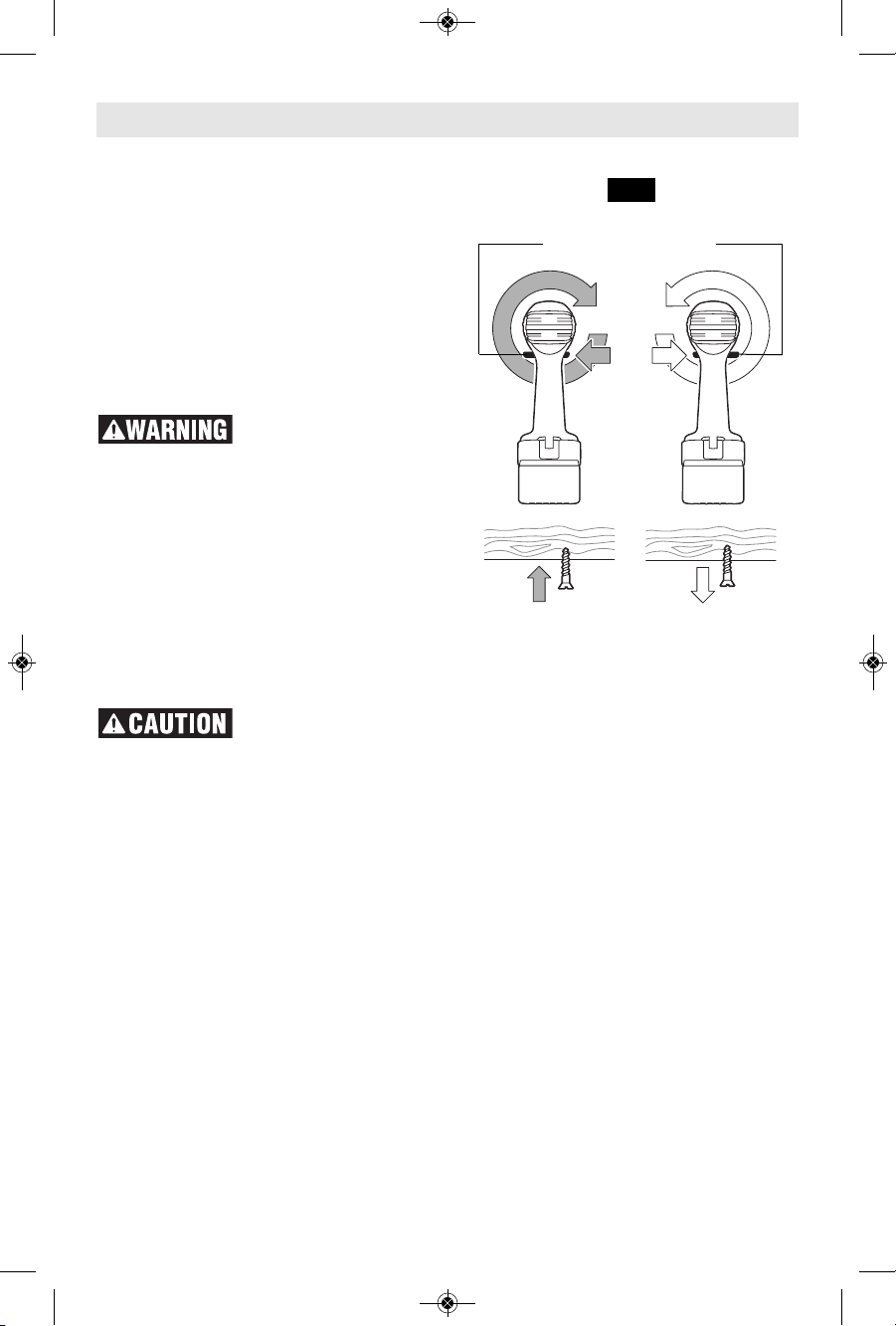

FORWARD/REVERSING

LEVER & TRIGGER LOCK

Af ter tool use , loc k

trigger in “OFF” position

to he lp preven t a cci den tal starts an d

accidental discharge.

Yo u r tool is equ i pped w ith a f o rwar d /

reversing lever and trigger lock located above

the trigger (Fig. 5). This lever was designed

for changing rotation of the bit, and for locking

the trigger in an “OFF” position.

For forward rotation, (with tool pointed away

from you) move the lever to the far left.

For reverse rotation move the lever to the far

right. To activate trigger lock move lever to

the center off position.

Do no t c h a n g e

di r ectio n of rot a tion

until the tool comes to a complete stop.

Shifting during rotation of the tool can

cause damage to the tool.

BUILT IN WORK LIGHT

Your tool is also equipped with a light that

turns on automatically when the switch is

activated, for better visibility when driving

(Fig. 1).

FIG. 5

FORWARD/REVERSING

LEVER & TRIGGER LOCK

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 10

-11-

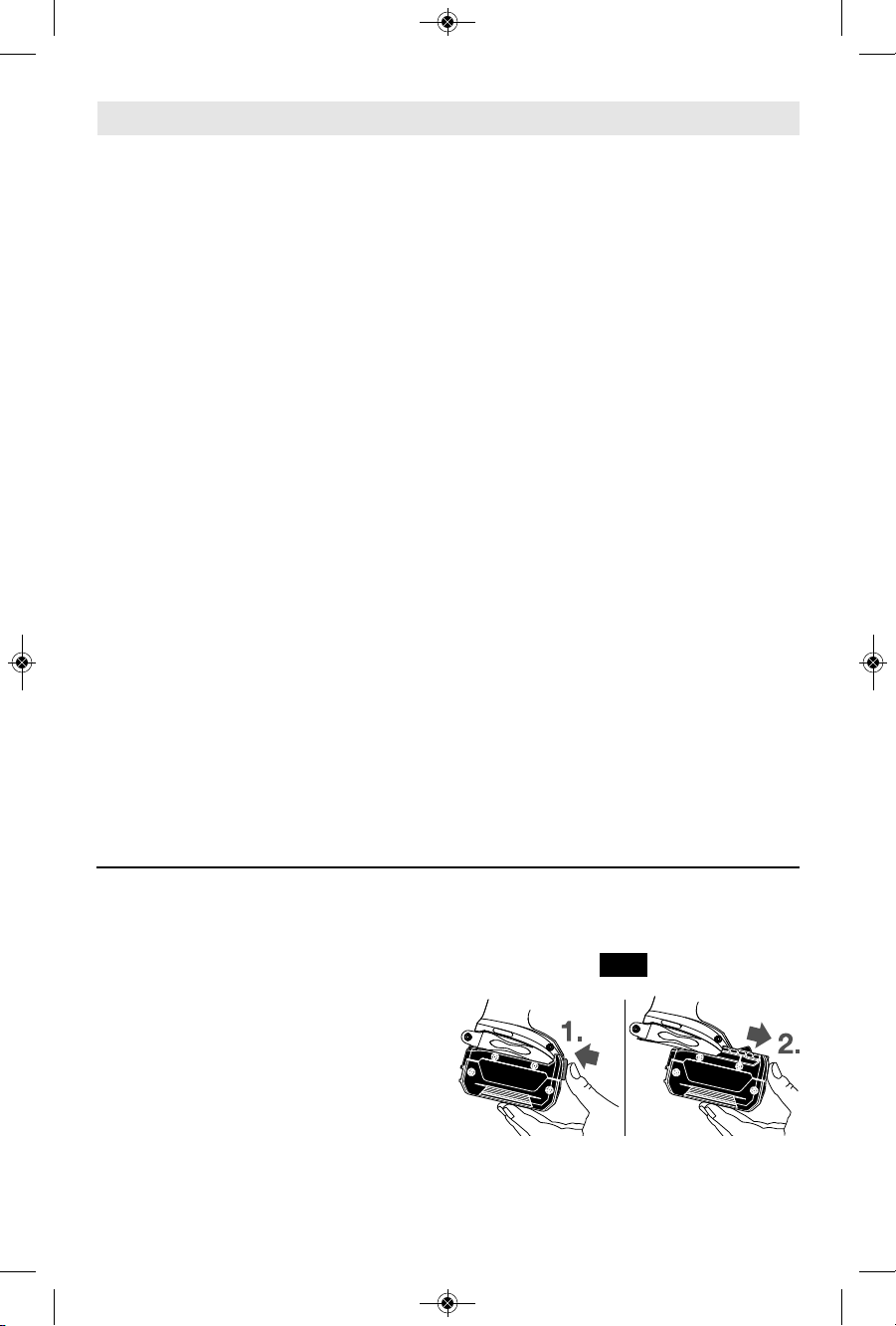

Set Forward/Reversing lever to the center (off

position). Slide charged battery pack into the

housing unti l the b att ery pack locks in to

position (Fig. 6)

Your tool is equipped with a secondary locking

la tch to preve nt th e ba tter y pa ck from

completely falling out of the handle, should it

become loose due to vibration.

To remove the battery pack, press the battery

pack release button and slide the battery pack

forward.

Press the battery pack release button again

and slide the battery pack completely out of

tool housing (Fig. 6).

INSERTING AND RELEASING BATTERY PACK

FIG. 6

Operating Tips

INSTALLING FASTENERS

To fasten: Start the fastener by hand on to or

i

n to its threaded counter part (E.G. nut on to

bolt, bolt in to nut or threaded hole).

Next, with the proper impact socket securely

mounte d to the wren ch, sli de the impact

socket on to the nut or bolt head . Hold the

tool securely with both hands and squeeze

the trigger switch. The impact socket will turn

the fastener and impacting will begin once the

fast ene r enc ounte rs re sistance . See the

following chart to estimate the amount of

impact time requir ed to o btain a desire d

torque.

To loosen: With the proper impact socket

securely mounted to the wrench, slide the

impact socket on to the bolt head. (be sure

the rotational direction is “reverse”).

Hold the tool securely with both hands and

squeeze the trigger switch. The tool will start

to impact immediately. Once the fastener has

“broken loose” it will start to unthread. Be

careful that you do not allow a fastener to

spin freely once it is no longer engaged with

the other threaded part as it may be thrown

out of the socket.

TIGHTENING TORQUE

The tightening torque depends on the duration

of the impacting/tightening action. The largest

tightening torque is achieved after approx. 6 to

10 Sec. impacting/tightening action.

Th e torqu e build - up depe n ds on th e

following factors:

• Hardness of the bolts/nuts.

• Type of washer (disk washer, spring washer,

seal).

• Hardness of the material to be joined.

• Lubricating effect at the surfaces of the

junction.

This leads to the following application cases:

Hard case: The joining of metal to metal with a

disk washer. The maximum torque is reached

after a relative short impacting/tightening

action.

Medium case: The joining of metal to metal

where spring ring washer, disk spring washer,

stud bolts or bolts/nuts with conical seats are

used.

Soft case: The joining of e.g. metal to wood

or insulation material.

For middle or soft joining cases, the maximum

tightening torque is less as for hard cases.

Therefo re, a long er im pacting/ tig htening

action is necessary to arrive at the maximum

tightening torque.

COLD WEATHER USE (32°F)

Due to the lubrication used in the impacting

mechanism, the tool should be run for three

minutes at no load prior to actual usage. This

will warm the lubricant and provide better

performance.

Operating Instructions

2610051968_IWHT180 HTH181 HTH182 1/15/19 10:20 AM Page 11

Loading...

Loading...