Bosch ISW-EN1242 Installation Manual

ISW-EN1242 Installation Guide Smoke Detector-Transmitter

Overview

The ISW-EN1242 Smoke Detector-Transmitter is a wireless, battery-powered

photoelectric smoke sensor. Under non-alarm conditions, the LED flashes

once every 8 sec while the sensor monitors the surrounding conditions. When

the sensor detects smoke, the LED lights, the built-in sounder beeps loudly,

and the detector sends an alarm signal. The smoke sensor is powered by two

3 V lithium batteries.

1.0 Open the Detector-Transmitter Housing

1. Using a small screwdriver, press the sensor cap release tab and turn the

cap approximately 25 mm (1 in.) counter-clockwise to remove the cap

(Figure 1).

Figure 1: Remove the Sensor Cap

2. Place both thumbs on opposite sides of the optical chamber and push

down to detach the sensor housing (Figure 2).

Figure 2: Push Down the Optical Chamber

2.0 Mount the Housing Back Plate

Use the provided anchors and screws to mount the smoke detector, while

following these best practices:

• Install a minimum of two smoke sensors in any household.

• Put a smoke sensor in the hallway outside of every bedroom area.

• Put a smoke sensor on every level of a multi-level residence.

• In rooms with sloped ceilings, install smoke sensors 0.9 m (3 ft)

• Install basement sensors on the ceiling as close to the center of the

• If ceiling mounting is not practical, install the sensor on an inside wall

• Put smoke sensors at both ends of a bedroom hallway if the hallway is

• Areas with rough ceilings or short walls coming down from the ceiling

• Install second-floor smoke sensors on the ceiling at the top of the first-

Do not install sensors:

• On a drop ceiling tile. Mount them on a metal runner.

• In or near areas such as kitchens or garages, where smoke or vehicle

• In damp or very humid areas, or next to bathrooms with showers. Install

• In very cold or very hot areas. Refer to Section 8.0 on page 2 for

• In dusty, dirty, or insect-infested areas.

Regulations pertaining to smoke sensor installations vary. For

more information, contact your local fire department or local

authority having jurisdiction.

measured down from the highest point of the ceiling.

room as possible. If this is not practical, install on the ceiling no closer

than 10 cm (4 in.) from any wall or corner.

between 10 and 15 cm (4 and 6 in.) from the ceiling.

more than 9 m (30 feet) long. Large rooms over 84 square meters (900

square feet) require more than a single sensor.

require additional smoke sensors.

to-second floor stairwell. Ensure that no door or other obstruction

blocks the path of smoke to the sensor.

exhausts normally occur (protect these areas with heat-detection

devices, not with smoke sensors); near furnaces, hot water heaters, or

gas space heaters.

sensors at least 1.5 m (5 ft) away from bathrooms.

operating temperature specifications.

• Near fresh air inlets or returns or excessively drafty areas. Air

conditioners, heater, fans, and fresh air intakes and returns can drive

smoke away from smoke sensors.

• In dead air spaces at the top of a peaked ceiling or a wall or ceiling

intersection. Dead air might prevent smoke from reaching smoke

sensors.

• Near fluorescent light fixtures. Install smoke sensors at least 3 m (10 ft)

away from fluorescent light fixtures.

• Between protruding ceiling structures such as beams or walls which

might prohibit smoke from reaching the sensors.

All sensors are subject to possible compromise or failure-towarn for a variety of reasons. For example, smoke sensors

cannot detect smoke in chimneys, walls, roofs, or smoke

blocked by a closed door; sensors might not detect smoke on

other levels of a building; sensors might not warn in time

when fires are caused by smoking in bed, explosions,

improper storage of flammables, overloaded electrical

circuits, or other hazardous conditions.

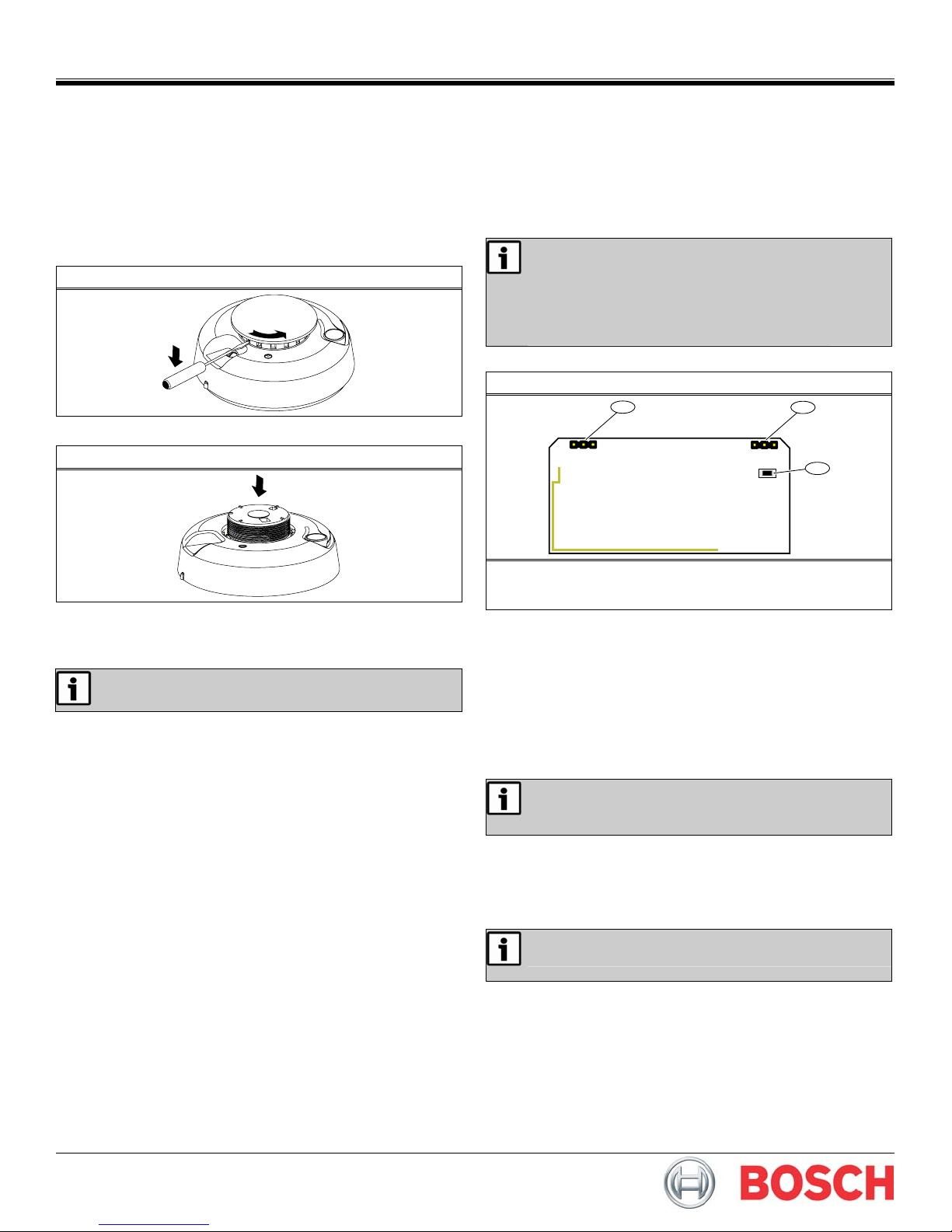

3.0 Configure the Detector

Figure 3: Detector-Transmitter Components

1

LOW BAT CLEAN

2

NZ

AU

3

1 - LOW BAT/CLEAN pins (default = CLEAN)

2 - Frequency Band pins

3 - Reset button

3.1 Select the Frequency Band

Select the appropriate frequency band for your geographic area.

1. Place a selection jumper on the appropriate Frequency Band pins (refer

to Figure 3). The default is no jumper (North America).

• Place the jumper on the left two pins, marked AU, to set the

frequency range to 915-928 MHz for Australia.

• Place the jumper on the right two pins, marked NZ, to set the

frequency range to 921-928 MHz for New Zealand.

• Leave the jumper off the pins to set the frequency range to 902-

928 MHz for North America.

2. Press the Reset button.

When pressing the Reset button, do not touch the Frequency

Band pins. Touching the Frequency Band pins while pressing

the Reset button can inadvertently set the detector to the

wrong frequency band.

3.2 Set Clean/Low Battery Reporting

With the factory default CLEAN setting (refer to Figure 3), the smoke detector

combines the low battery signal with a signal indicating that the detector

needs cleaning. If multiple-condition indication is not desired, disable

wireless reporting of the CLEAN status by moving the jumper to LOW BAT.

With the LOW BAT setting, the detector sends only a low battery signal.

If CLEAN notification is disabled, the sensitivity test still

indicates the sensor condition.

4.0 Install the Battery

1. Rotate the sensor housing counterclockwise approximately 25 mm

(1 in.), and then detach it from the mounting base.

2. Remove the battery compartment cover (Figure 4 on page 2).

9

2

2

Figure 4: Battery Compartment Cover

1

1 - Battery compartment cover

3. Install or replace the two 3 V batteries.

4. Allow up to 10 sec for sensor and transmitter to fully power on before

registration and testing.

5.0 Register the Transmitter

To ensure that the detector is supervised by the system receiver, you must

register its transmitter with the system receiver. Each detector has a unique

factory-programmed identification number. Refer to the receiver, network

coordinator, or control panel installation instructions for details on

registering a transmitter.

1. Open the detector-transmitter housing. Refer to Section 1.0 on page 1.

2. When prompted to reset the detector, press the Reset button. Refer to

Figure 3 on page 1.

3. Close the detector housing.

6.0 Test the Detector

To avoid a fire department dispatch, contact the central

monitoring station or, if possible, put the system into sensor

test mode.

You can test the smoke detector sensor in two ways: the sensitivity test and

the smoke test. Perform the sensitivity test every week, and perform the

smoke test at least once a year. Both tests activate the alarm sounder and

send alarm signals.

The smoke detector should also be tested after initial registration, as well as

each time the smoke chamber is changed or the batteries are replaced.

6.1 Smoke Test

Test smoke sensors annually using aerosol simulated smoke.

The LED illuminates while the built-in transmitter sends an alarm signal, and

the sensor produces a three-beep pattern until you press the Test/Silence

button (Figure 5). The sensor automatically resets when smoke is no longer

present. A sensor that fails to activate might require cleaning. If a sensor still

fails to activate after cleaning, return the unit for service.

Figure 5: Smoke Detector Features

2

1

3

1 - Sounder vent

2 - LED

3 - Test/Silence button

© 2009 Bosch Security Systems, Inc.

130 Perinton Parkway, Fairport, NY 14450-9199 USA

(800) 289-0096

6.2 Sensitivity Test

Press and hold the Test/Silence button for 4 sec, then release it. The LED

flashes correspond to the sensor’s sensitivity.

Flashes Sensor Condition/Action

1 Self-diagnostics failure. Return sensor for service/replacement.

2 - 3

4 - 7 The sensor is within the normal sensitivity range.

8 - 9

During this test, the control panel, serial receiver, or network coordinator

should receive an alarm and a low battery signal (if LOW BAT is selected),

followed a few seconds later by a restoral.

If the control device does not respond, it is possible the smoke detector

failed to reset properly when the batteries were installed. To force a reset,

remove the batteries from the smoke detector for at least 30 sec, reinstall

them, press the RESET button, and then repeat the test as described above.

The sensor is becoming insensitive. Clean the sensor (refer to

Section 7.1) and repeat the test. If the error persists, replace

the sensor.

The sensor is becoming too sensitive. Verify that the smoke

chamber is snapped down securely. Clean the sensor and

repeat the test.

7.0 Operation and Maintenance

Test/Silence button

Status LED

7.1 Clean the Smoke Detector

Clean the sensor cover with a dry or damp cloth as needed to keep it free of

dust and dirt. Clean the sensor interior and replace the optical chamber at

least once each year. Use only ESL Model 211 optical chambers for

replacement. To clean the sensor chamber:

1. Remove the sensor body from the mounting base.

2. Remove the batteries.

3. Slide a flat-blade screwdriver into the slot on the sensor cap and gently

push the handle down to pry the cap off.

4. Squeeze the optical chamber where indicated on the chamber and pull

it up and away from the sensor. Then discard the optical chamber.

5. Use a soft-bristled brush to remove dust and dirt from the smoke

chamber base.

6. Align the new optical chamber with the base and snap it into place.

7. Replace the sensor cap.

8. Reinstall the batteries.

9. Replace the battery cover.

The base does not fit properly if the batteries are not

installed.

10. Reattach the sensor to the mounting base.

11. Perform the sensitivity test. Refer to Section 6.2.

Press to perform the sensitivity test, as well

as to silence the low battery chirp. The low

battery chirp resumes after 24 hours if the

condition is not corrected.

Flashing = The LED flashes every 8 sec to

indicate normal operation

On = Sensor detects smoke, and is sending

an alarm

Off = Maintenance required

8.0 Specifications

Dimensions

(H x W x D):

Operating Temperature: 0°C to 38°C (32°F to 100°F)

Humidity: 10 - 90% (non-condensing)

Battery: (2) 3 V lithium (CR123A recommended)

Transmitter Frequency

Range:

Average Alarm Current: 120 mA

Average Standby Current:

Typical Test Current: 2 mA Low Battery

Chirp Rate: 1 every 45 sec ± 2 sec

UL listings: UL 268, UL 985

F01U126802-02

Installation Guide

Detector: 14.2 cm x 6.1 cm (5.6 in. x 2.4 in.)

Base: 13.7 cm x 1.17 cm (5.4 in. x 0.46 in.)

902 – 928 MHz (United States)

915 – 928 MHz (Australia)

922 – 928 MHz (New Zealand)

35 μA

11/0

ISW-EN124

Page 2 of

Loading...

Loading...