Page 1

Robert Bosch Power Tools GmbH

1 609 92A 5RK

70538 Stuttgart

GERMANY

www.bosch-pt.com

1 609 92A 5RK (2020.10) O / 88

GWS Professional

18V-15 C | 18V-15 SC

en Original instructions

zh 正本使用说明书

zh 原始使用說明書

ko 사용 설명서 원본

th หนังสือคู่มือการใช้งานฉบับ

ต้นแบบ

id Petunjuk-Petunjuk untuk

Penggunaan Orisinal

vi Bản gốc hướng dẫn sử dụng

Page 2

2 |

English . . .. .. .. .. .. . .. .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. Page 6

中文 . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 页 16

繁體中文. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. . 頁 26

한국어 .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. 페이지 35

ไทย. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. . หน้า 46

Bahasa Indonesia. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. Halaman 60

Tiếng Việt . .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. .. Trang 72

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 3

6 082 850 6DU

L-BOXX 136

1 600 A01 2G0

1 600 A01 3WF

| 3

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 4

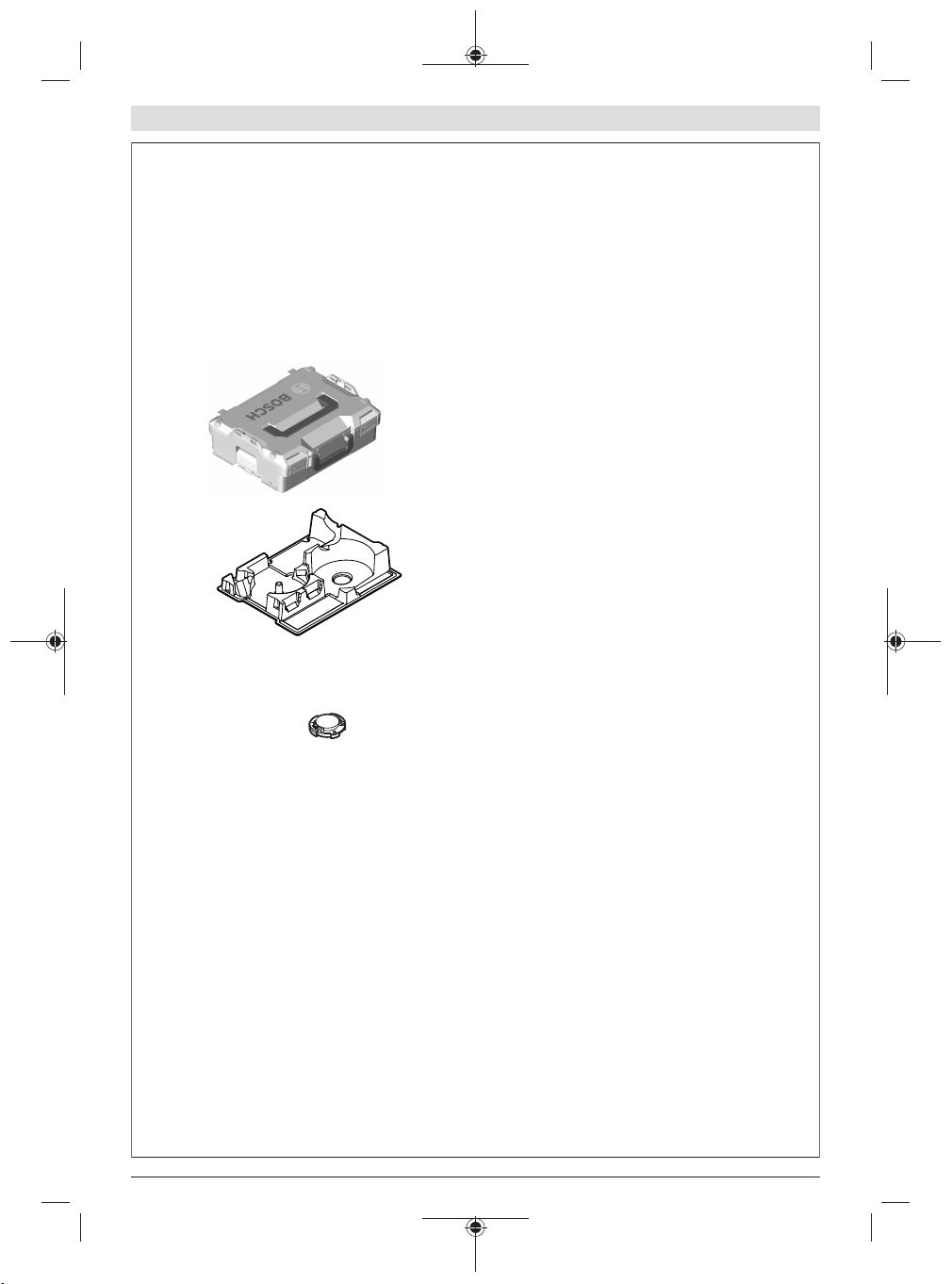

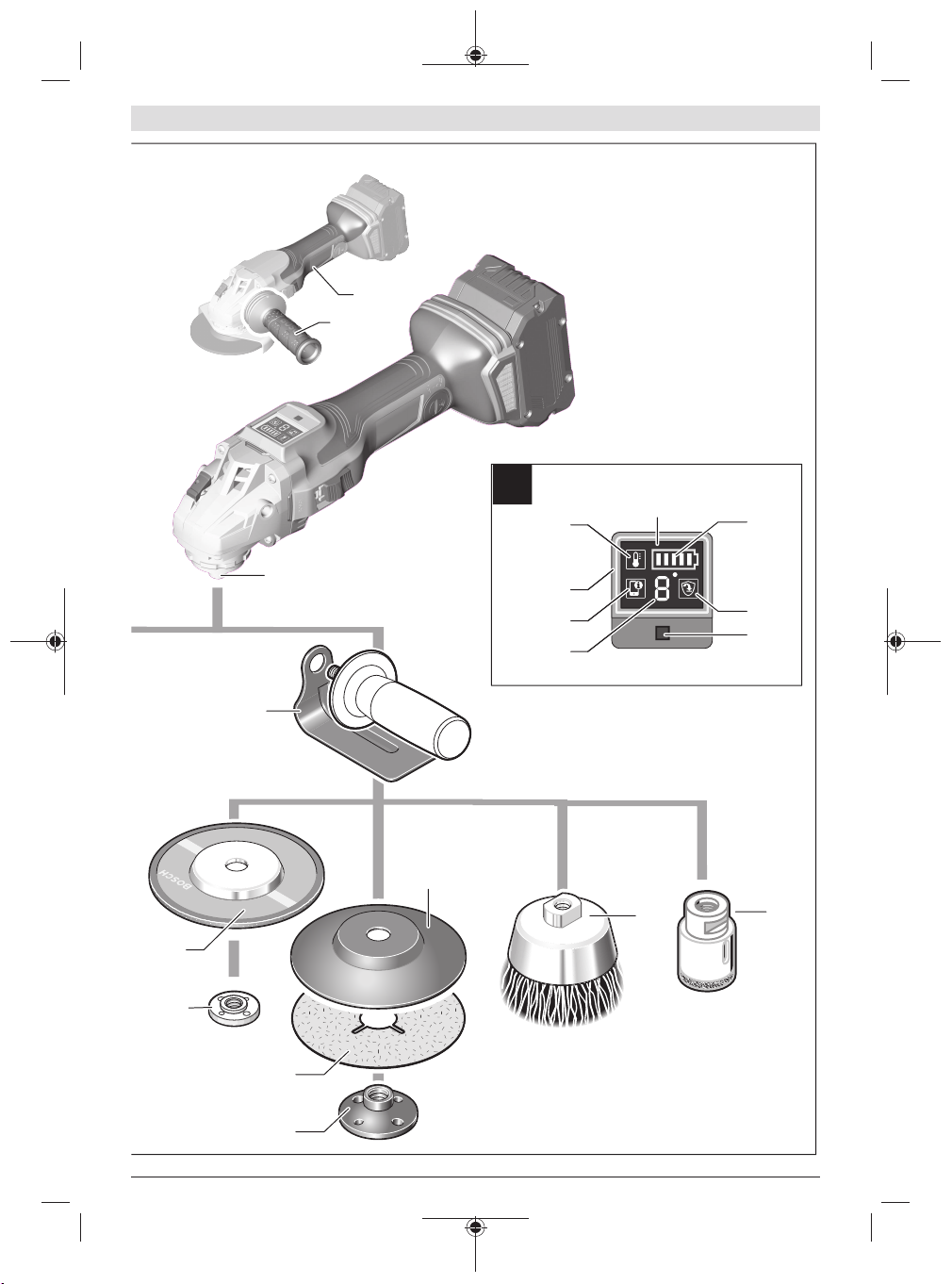

(1)

(2) (3) (4) (5)

(7)

(8)

(6)

(9)

(10)

(11)

(12)

(11)

(14)

(15)

(16)

(13)

(13)

4 |

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 5

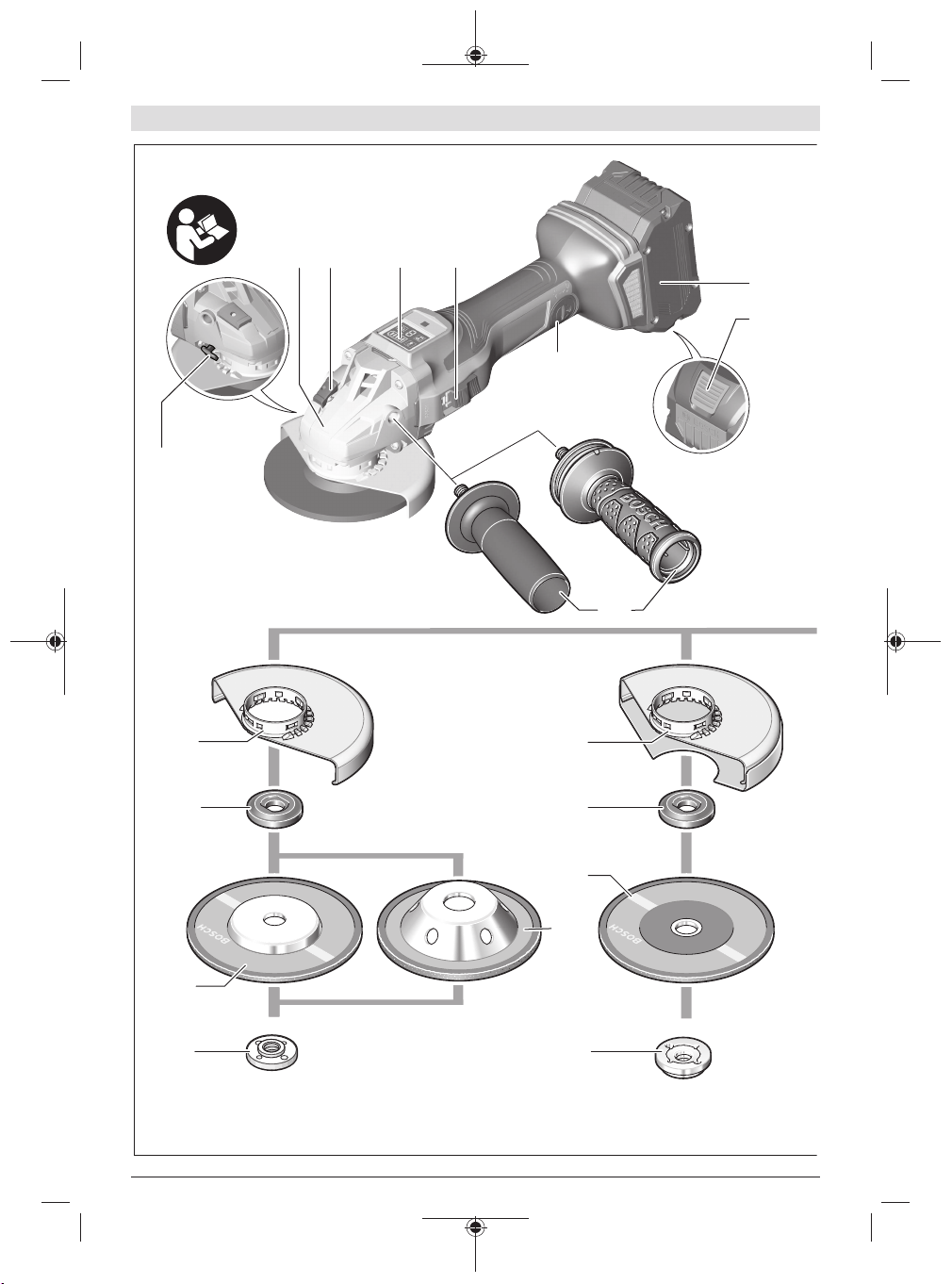

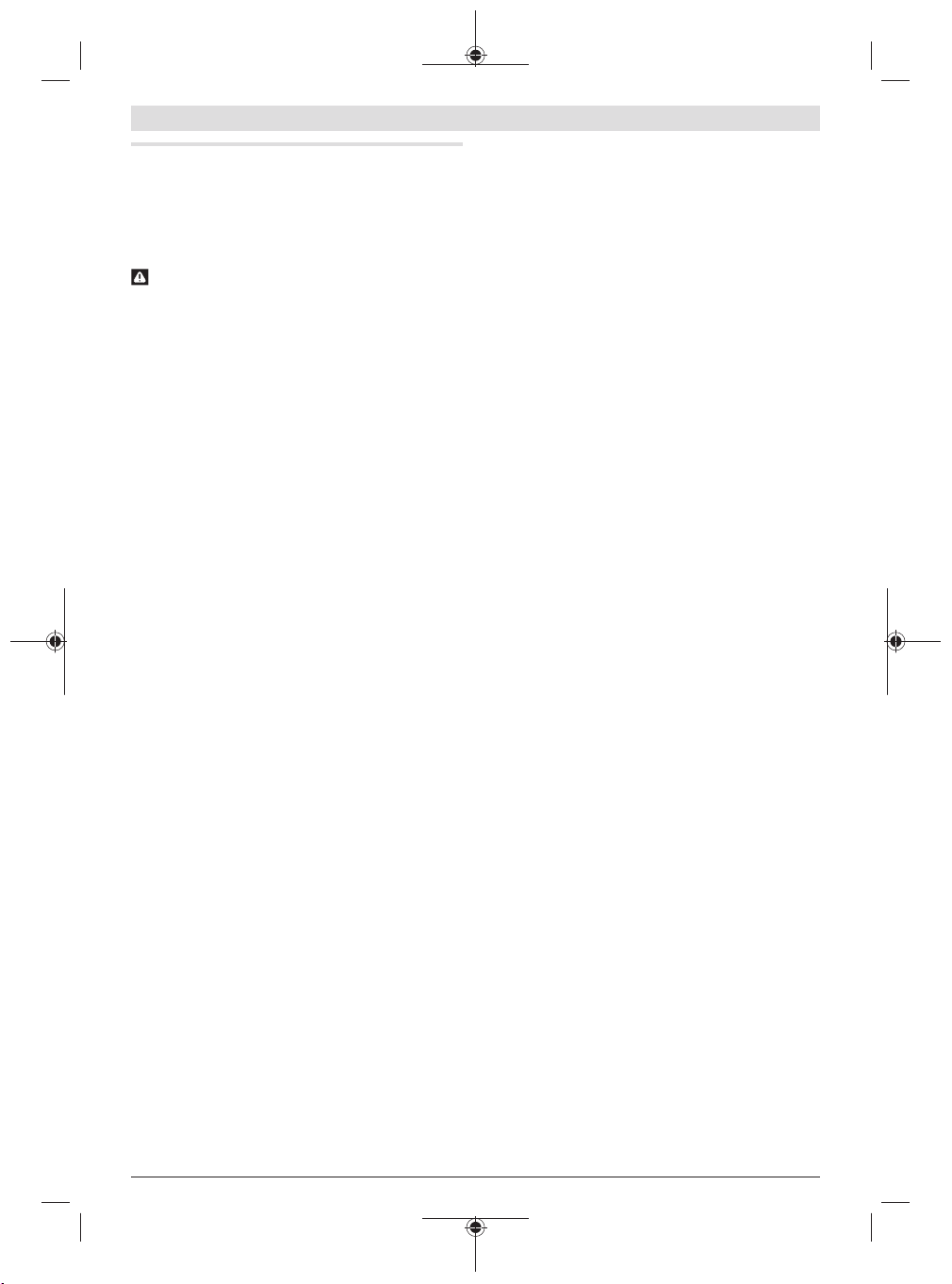

GWS 18V - 15 ..

(17)

(9)

(18)

(19)

(20)

(21)

(22)

(23)

(24)

(4)

(25)

(27)

(30)

(26)

(31)

A

A

(32)

(29)

(28)

(13)

| 5

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 6

6 | English

English

Safety instructions

General Power Tool Safety Warnings

WARNING

warnings and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

u Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

u Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

u Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

u Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

u Avoid body contact with earthed or grounded sur-

faces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your

body is earthed or grounded.

u Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

u Do not abuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

u When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock..

u If operating a power tool in a damp location is un-

avoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

Personal safety

u Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

tion while operating power tools may result in serious personal injury.

Read all safety warnings and all instructions. Failure to follow the

u Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

u Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

u Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

u Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

u Dress properly. Do not wear loose clothing or jew-

ellery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

u If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

Power tool use and care

u Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was designed.

u Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

u Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk

of starting the power tool accidentally.

u Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

u Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation.

If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

u Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

u Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the working conditions and the work to be per-

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 7

English | 7

formed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

Battery tool use and care

u Recharge only with the charger specified by the manu-

facturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another

battery pack.

u Use power tools only with specifically designated bat-

tery packs. Use of any other battery packs may create a

risk of injury and fire.

u When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys,

nails, screws or other small metal objects, that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause burns

or a fire.

u Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the bat-

tery may cause irritation or burns.

Service

u Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

Safety information for the angle grinder

Safety Warnings common for Grinding, Sanding, Wire Brushing or Abrasive Cutting Off operations

u This power tool is intended to function as a grinder,

sander, wire brush or cut-off tool. Read all safety

warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all

instructions listed below may result in electric shock, fire

and/or serious injury.

u Operations such as polishing are not recommended to

be performed with this power tool. Operations for

which the power tool was not designed may create a hazard and cause personal injury.

u Do not use accessories which are not specifically de-

signed and recommended by the tool manufacturer.

Just because the accessory can be attached to your

power tool, it does not assure safe operation.

u The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated speed

can break and fly apart.

u The outside diameter and the thickness of your ac-

cessory must be within the capacity rating of your

power tool. Incorrectly sized accessories cannot be ad-

equately guarded or controlled.

u Threaded mounting of accessories must match the

grinder spindle thread. For accessories mounted by

flanges, the arbour hole of the accessory must fit the

locating diameter of the flange. Accessories that do not

match the mounting hardware of the power tool will run

out of balance, vibrate excessively and may cause loss of

control.

u Do not use a damaged accessory. Before each use in-

spect the accessory such as abrasive wheels for chips

and cracks, backing pad for cracks, tear or excess

wear, wire brush for loose or cracked wires. If power

tool or accessory is dropped, inspect for damage or install an undamaged accessory. After inspecting and

installing an accessory, position yourself and bystanders away from the plane of the rotating accessory and

run the power tool at maximum no load speed for one

minute. Damaged accessories will normally break apart

during this test time.

u Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron capable of stopping small abrasive or workpiece fragments. The eye

protection must be capable of stopping flying debris generated by various operations . The dust mask or respirator must be capable of filtrating particles generated by

your operation. Prolonged exposure to high intensity

noise may cause hearing loss.

u Keep bystanders a safe distance away from work area.

Anyone entering the work area must wear personal

protective equipment. Fragments of workpiece or of a

broken accessory may fly away and cause injury beyond

immediate area of operation.

u Hold the power tool by insulated gripping surfaces

only, when performing an operation where the cutting

accessory may contact hidden wiring. Cutting access-

ory contacting a "live" wire may make exposed metal

parts of the power tool "live" and could give the operator

an electric shock.

u Never lay the power tool down until the accessory has

come to a complete stop. The spinning accessory may

grab the surface and pull the power tool out of your control.

u Do not run the power tool while carrying it at your

side. Accidental contact with the spinning accessory

could snag your clothing, pulling the accessory into your

body.

u Regularly clean the power tool’s air vents. The motor’s

fan will draw the dust inside the housing and excessive

accumulation of powdered metal may cause electrical

hazards.

u Do not operate the power tool near flammable materi-

als. Sparks could ignite these materials.

u Do not use accessories that require liquid coolants.

Using water or other liquid coolants may result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes rapid stalling of the rotating access-

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 8

8 | English

ory which in turn causes the uncontrolled power tool to be

forced in the direction opposite of the accessory’s rotation

at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by

the workpiece, the edge of the wheel that is entering into the

pinch point can dig into the surface of the material causing

the wheel to climb out or kick out. The wheel may either

jump toward or away from the operator, depending on direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect

operating procedures or conditions and can be avoided by

taking proper precautions as given below.

u Maintain a firm grip on the power tool and position

your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction

during start-up. The operator can control torque reac-

tions or kickback forces, if proper precautions are taken.

u Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

u Do not position your body in the area where power

tool will move if kickback occurs. Kickback will propel

the tool in direction opposite to the wheel’s movement at

the point of snagging.

u Use special care when working corners, sharp edges

etc. Avoid bouncing and snagging the accessory.

Corners, sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of control or

kickback.

u Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent kickback and loss of control.

Safety Warnings specific for Grinding and Abrasive Cutting-Off operations

u Use only wheel types that are recommended for your

power tool and the specific guard designed for the selected wheel. Wheels for which the power tool was not

designed cannot be adequately guarded and are unsafe.

u The grinding surface of centre depressed wheels must

be mounted below the plane of the guard lip. An improperly mounted wheel that projects through the plane

of the guard lip cannot be adequately protected.

u The guard must be securely attached to the power tool

and positioned for maximum safety, so the least

amount of wheel is exposed towards the operator.

The guard helps to protect operator from broken wheel

fragments, accidental contact with wheel and sparks that

could ignite clothing.

u Wheels must be used only for recommended applica-

tions. For example: do not grind with the side of cutoff wheel. Abrasive cut-off wheels are intended for peri-

pheral grinding, side forces applied to these wheels may

cause them to shatter.

u Always use undamaged wheel flanges that are of cor-

rect size and shape for your selected wheel. Proper

wheel flanges support the wheel thus reducing the possibility of wheel breakage. Flanges for cut-off wheels may

be different from grinding wheel flanges.

u Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not suitable for the higher speed of a smaller tool and may burst.

Additional Safety Warnings specific for Abrasive Cutting Off operations

u Do not “jam” the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive depth

of cut. Overstressing the wheel increases the loading

and susceptibility to twisting or binding of the wheel in

the cut and the possibility of kickback or wheel breakage.

u Do not position your body in line with and behind the

rotating wheel. When the wheel, at the point of operation, is moving away from your body, the possible kickback may propel the spinning wheel and the power tool

directly at you.

u When wheel is binding or when interrupting a cut for

any reason, switch off the power tool and hold the

power tool motionless until the wheel comes to a complete stop. Never attempt to remove the cut-off wheel

from the cut while the wheel is in motion otherwise

kickback may occur. Investigate and take corrective ac-

tion to eliminate the cause of wheel binding.

u Do not restart the cutting operation in the workpiece.

Let the wheel reach full speed and carefully re-enter

the cut. The wheel may bind, walk up or kickback if the

power tool is restarted in the workpiece.

u Support panels or any oversized workpiece to minim-

ize the risk of wheel pinching and kickback. Large

workpieces tend to sag under their own weight. Supports

must be placed under the workpiece near the line of cut

and near the edge of the workpiece on both sides of the

wheel.

u Use extra caution when making a “pocket cut” into ex-

isting walls or other blind areas. The protruding wheel

may cut gas or water pipes, electrical wiring or objects

that can cause kickback.

Safety Warnings specific for Sanding operations

u Do not use excessively oversized sanding disc paper.

Follow manufacturers recommendations, when selecting sanding paper. Larger sanding paper extending bey-

ond the sanding pad presents a laceration hazard and

may cause snagging, tearing of the disc, or kickback.

Safety Warnings specific for Wire Brushing operations

u Be aware that wire bristles are thrown by the brush

even during ordinary operation. Do not overstress the

wires by applying excessive load to the brush The wire

bristles can easily penetrate light clothing and/or skin.

u If the use of a guard is recommended for wire brush-

ing, do not allow any interference of the wire wheel or

brush with the guard. Wire wheel or brush may expand

in diameter due to work load and centrifugal forces.

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 9

English | 9

Additional safety information

Wear safety goggles.

u Use suitable detectors to determine if there are hid-

den supply lines or contact the local utility company

for assistance. Contact with electric cables can cause

fire and electric shock. Damaging gas lines can lead to explosion. Breaking water pipes causes property damage.

u Do not touch grinding and cutting discs until they have

cooled down. The discs can become very hot while working.

u Release the On/Off switch and set it to the Off posi-

tion when the power supply is interrupted, e.g. when

the battery pack is removed. This prevents uncontrolled

restarting.

u Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more secure than by

hand.

u In case of damage and improper use of the battery, va-

pours may be emitted. The battery can set alight or explode. Ensure the area is well ventilated and seek medical

attention should you experience any adverse effects. The

vapours may irritate the respiratory system.

u Do not open the battery. There is a risk of short-circuit-

ing.

u The battery can be damaged by pointed objects such

as nails or screwdrivers or by force applied externally.

An internal short circuit may occur, causing the battery to

burn, smoke, explode or overheat.

u Only use the battery with products from the manufac-

turer. This is the only way in which you can protect the

battery against dangerous overload.

Protect the battery against heat, e.g. against

continuous intense sunlight, fire, dirt, water

and moisture. There is a risk of explosion and

short-circuiting.

u Caution! When using the power tool with Bluetooth

®

, a

fault may occur in other devices and systems, aeroplanes and medical devices (e.g. pacemakers, hearing

aids). Also, damage to people and animals in the immediate vicinity cannot be completely excluded. Do

not use the power tool with Bluetooth® in the vicinity of

medical devices, petrol stations, chemical plants,

areas with a potentially explosive atmosphere or in

blasting areas. Do not use the power tool with

Bluetooth® in aircraft. Avoid using the product near

your body for extended periods.

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such

marks by Robert Bosch Power Tools GmbH is under license.

Product Description and Specifications

Read all the safety and general instructions.

Failure to observe the safety and general instructions may result in electric shock, fire

and/or serious injury.

Please observe the illustrations at the beginning of this operating manual.

Intended use

The power tool is intended for cutting, roughing and brushing metal and stone materials without the use of water.

A special protective guard for cutting must be used when

cutting bonded abrasives.

Sufficient dust extraction must be provided when cutting

stone.

With approved abrasive tools, the power tool can be used for

sanding with sanding discs.

With the Bluetooth® Low Energy Module GCY42 inserted,

power tool data and settings can be transferred between the

power tool and a mobile device by means of Bluetooth® wireless technology.

Product Features

The numbering of the product features refers to the diagram

of the power tool on the graphics page.

Unlocking lever for protective guard

(1)

Direction of rotation arrow on housing

(2)

Spindle lock button

(3)

User interface

(4)

On/off switch

(5)

Cover for GCY42 Bluetooth® Low Energy Module

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

(24)

A)

Battery

Battery release button

A)

Auxiliary handle (insulated gripping surface)

Protective guard for grinding

Mounting flange with O‑ring

Grinding disc

Clamping nut

Carbide grinding head

Protective guard for cutting

Cutting disc

A)

A)

A)

Handle (insulated gripping surface)

Grinding spindle

Hand guard

Rubber sanding pad

Abrasive disc

Round nut

Cup brush

Diamond core bit

A)

A)

A)

A)

A)

A)

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 10

10 | English

Battery charge indicator (user interface)

(25)

Kickback shutdown indicator (user interface)

(26)

Speed preselection button (user interface)

(27)

Speed setting/mode indicator (user interface)

(28)

Smartphone indicator (user interface)

(29)

Power tool status indicator (user interface)

(30)

Temperature indicator (user interface)

(31)

(32)

A)

Accessories shown or described are not included with the

product as standard. You can find the complete selection of

accessories in our accessories range.

Flap disc

A)

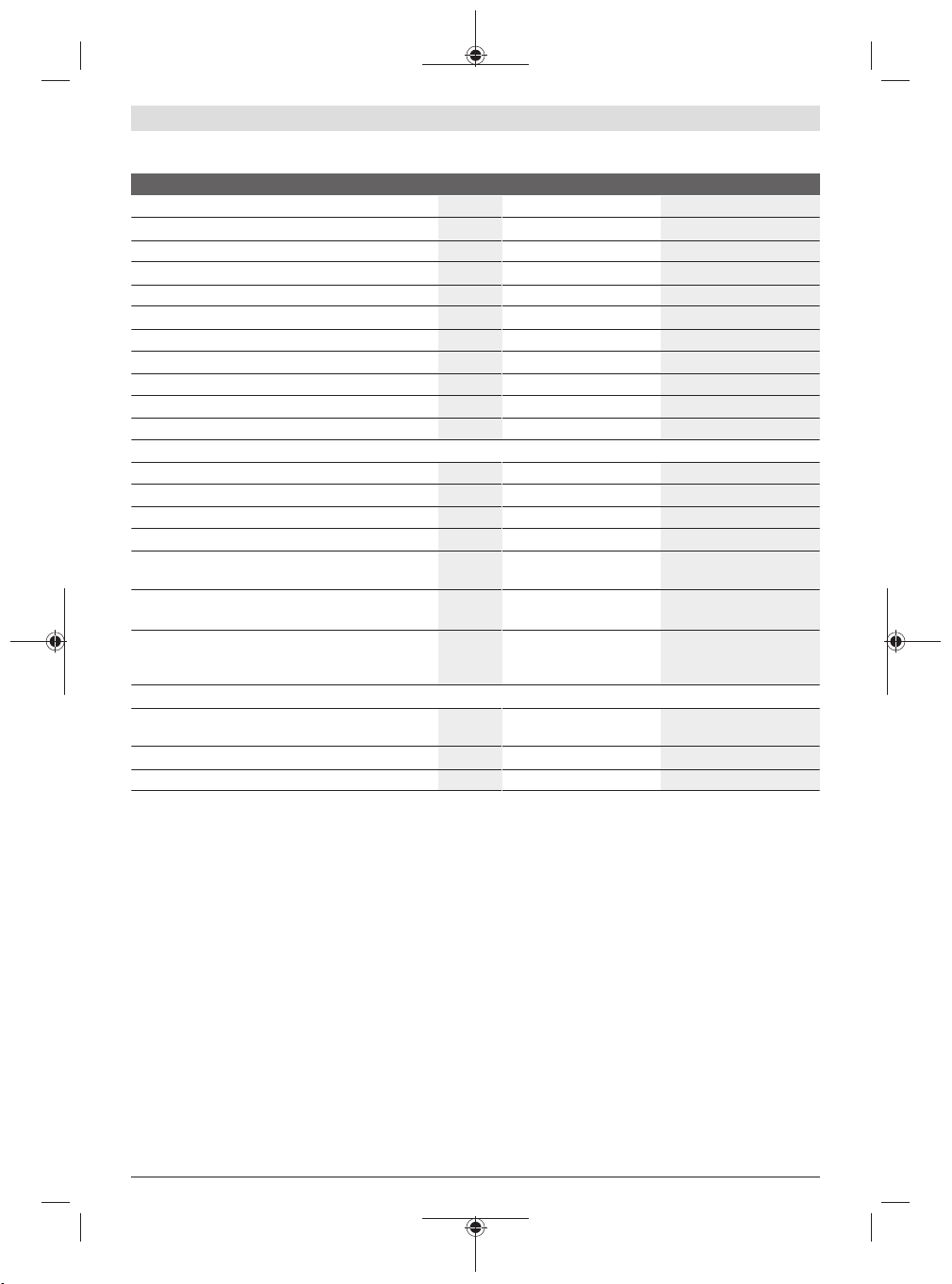

Technical Data

Angle grinder GWS 18V-15 C GWS 18V-15 SC

Article number

Rated voltage V= 18 18

Rated speed

No-load speed

A)

B)

min

min

-1

-1

Max. grinding disc diameter mm 100 100

Grinding spindle thread M 10 M 10

Max. thread length of grinding spindle mm 16 16

Kickback stop ● ●

Restart protection ● ●

Run-out brake ● ●

Speed preselection – ●

Weight according to EPTA-Procedure01:2014

C)

– with low-vibration auxiliary handle kg 2.5–3.5 2.5–3.5

– with standard auxiliary handle kg 2.3–3.3 2.3–3.3

Recommended ambient temperature during charging °C 0...+35 0...+35

Permitted ambient temperature during operationD) and

°C –20...+50 –20...+50

during storage

Compatible rechargeable batteries GBA 18V...

Recommended rechargeable batteries for maximum

ProCORE18V... ≥5.5Ah ProCORE18V... ≥5.5Ah

performance

Recommended chargers GAL 18...

Data transmission

®

Bluetooth

Signal interval s 8 8

Max. signal range

A) Rated speed in accordance with EN 60745-2-3

B) Measured at 20–25°C with rechargeable battery ProCORE18V8.0Ah and depending on the battery's state of charge as well as the tool's

operating temperature

C) Depends on battery in use

D) Limited performance at temperatures <0°C

E) The mobile terminal devices must be compatible with Bluetooth® Low Energy devices (version 4.2) and support the Generic Access Profile

(GAP).

F) The signal range may vary greatly depending on external conditions, including the receiving device used. The Bluetooth® range may be signi-

ficantly weaker inside closed rooms and through metallic barriers (e.g. walls, shelving units, cases, etc.).

F)

m 30 30

3601JH60.. 3601JH61..

11,000 11,000

9800 3400–9800

GBA 18V...

ProCORE18V...

ProCORE18V...

GAL 18...

GAX 18...

GAL 36...

Bluetooth®4.2

(Low Energy)

E)

GAX 18...

GAL 36...

Bluetooth®4.2

(Low Energy)

E)

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 11

English | 11

Fitting

Using the GCY42 Bluetooth® Low Energy

Module

Note: The GCY42 Bluetooth ® Low Energy Module is avail-

able as an accessory with GWS18V-15C power tools; it is

included in the scope of delivery for GWS18V-15SC power

tools.

Read the corresponding operating instructions for information about the Bluetooth® Low Energy ModuleGCY42.

Charging the battery

u Use only the chargers listed in the technical data. Only

these chargers are matched to the lithium-ion battery of

your power tool.

Note: The battery is supplied partially charged. To ensure

full battery capacity, fully charge the battery in the charger

before using your power tool for the first time.

The lithium-ion battery can be charged at any time without

reducing its service life. Interrupting the charging process

does not damage the battery.

The lithium-ion battery is protected against deep discharge

by the "Electronic Cell Protection (ECP)". When the battery

is discharged, the power tool is switched off by means of a

protective circuit: The application tool no longer rotates.

u Do not continue to press the On/Off switch after the

power tool has automatically switched off. The battery

can be damaged.

Follow the instructions on correct disposal.

Removing the Battery

The battery (7) is equipped with two locking levels to prevent the battery from falling out if the battery release button

(8) is pressed unintentionally. As long as the battery is inserted in the power tool, it is held in position by means of a

spring.

To remove the battery (7), press the release button (8) and

pull the battery out of the power tool. Do not use force to

do this.

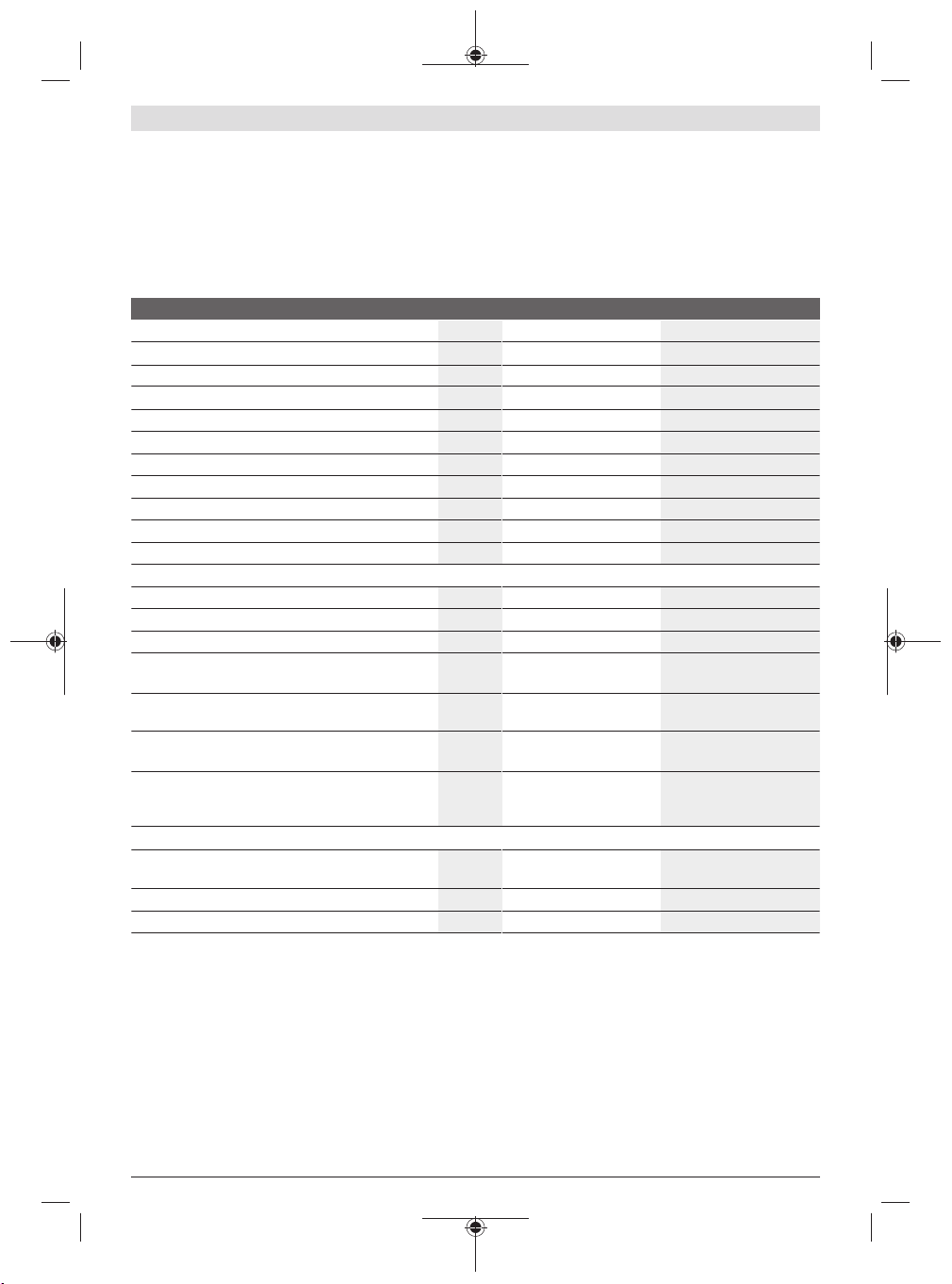

Battery charge indicator

The green LEDs on the battery charge indicator indicate the

state of charge of the battery. For safety reasons, it is only

possible to check the state of charge when the power tool is

not in operation.

Press the button for the battery charge indicator or to

show the state of charge. This is also possible when the battery is removed.

If no LED lights up after pressing the button for the battery

charge indicator, then the battery is defective and must be

replaced.

Note: The state of charge of the battery is also displayed on

the user interface(4) (see "Status Indicators", page14).

Battery model GBA 18V...

LEDs Capacity

3× continuous green light 60−100%

2× continuous green light 30−60%

1× continuous green light 5−30%

1× flashing green light 0−5%

Battery model ProCORE18V...

LEDs Capacity

5× continuous green light 80−100%

4× continuous green light 60−80%

3× continuous green light 40−60%

2× continuous green light 20−40%

1× continuous green light 5−20%

1× flashing green light 0−5%

Fitting Protective Equipment

u Remove the battery from the power tool before carry-

ing out work on the power tool (e.g. maintenance,

changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury

from unintentionally pressing the on/off switch.

Note: If the grinding disc breaks during operation or the

holding fixtures on the protective guard/power tool become

damaged, the power tool must be sent to the after-sales service immediately; see the "After-Sales Service and Application Service" section for addresses.

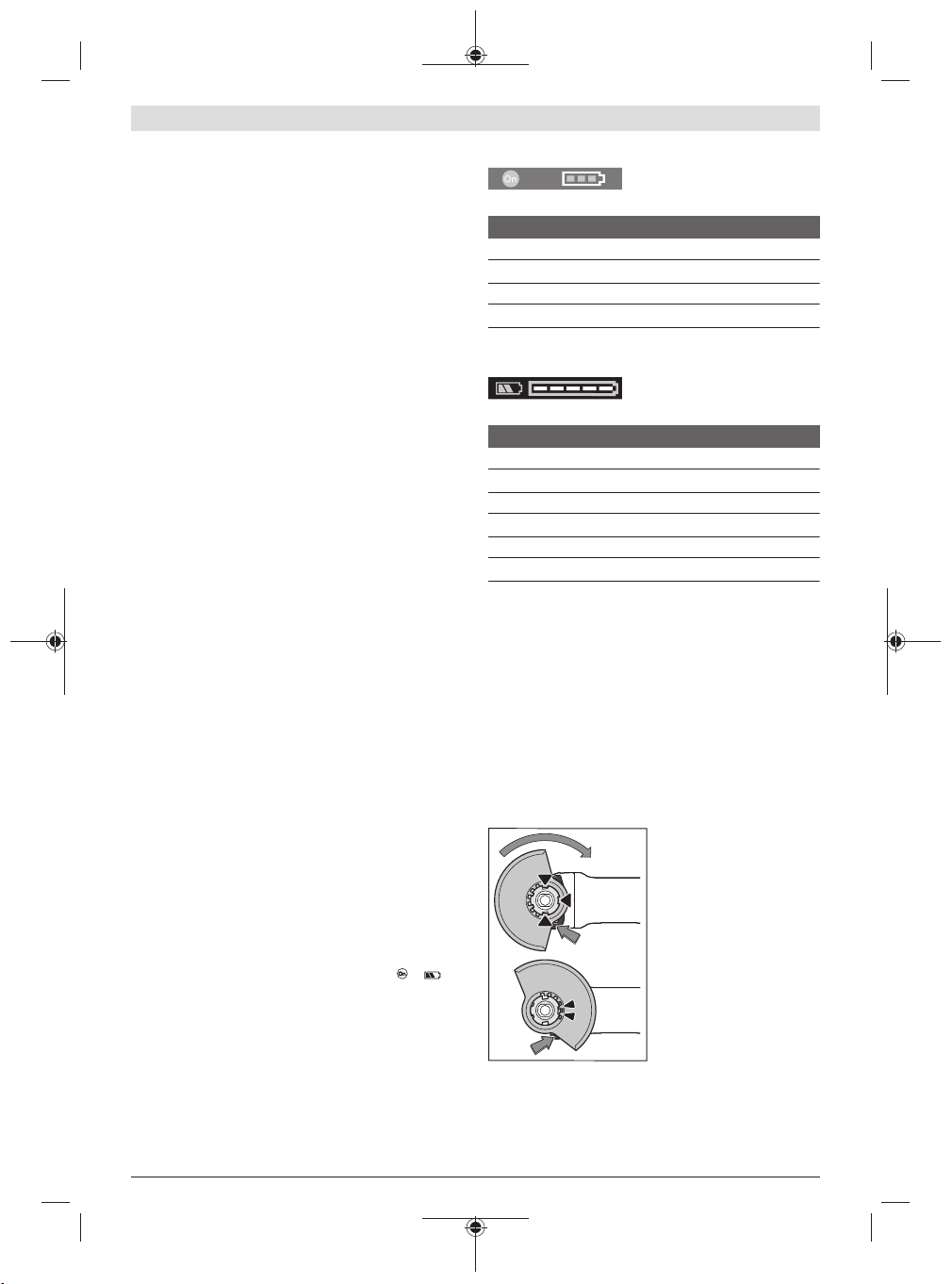

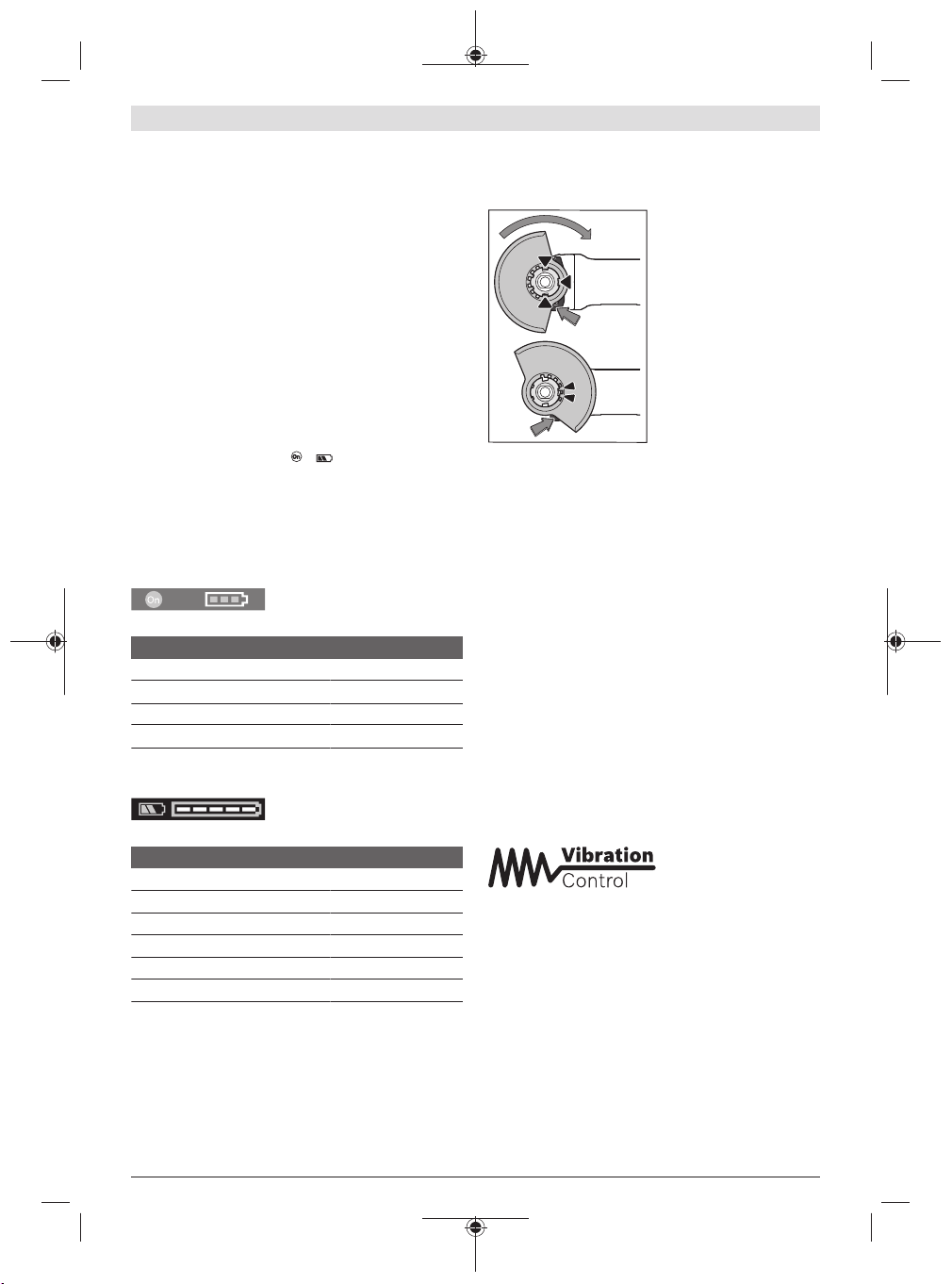

Protective guard for grinding

Place the protective guard

(10) onto the holder on the

power tool until the coding

cams of the protective guard

are aligned with the holder.

When doing so, press and

hold the unlocking lever (1).

Press the protective guard

(10) onto the spindle collar

until the shoulder of the protective guard is sitting on the

flange of the power tool and

rotate the protective guard

until it audibly clicks into

place.

Adjust the position of the protective guard (10) to meet the

requirements of the operation. To do this, push the unlocking lever (1) upward and rotate the protective guard (10)

into the required position.

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 12

12 | English

u Always position the protective guard(10) such that

the two cams on the unlocking lever(1) engage in the

corresponding openings on the protective guard(10).

u Adjust the protective guard (10) such that sparking in

the direction of the operator is prevented.

u The protective guard (10) must only be adjustable

while the unlocking lever (1) is actuated. Otherwise,

the power tool must not be used any more under any

circumstances and must be sent to the after-sales service.

Note: The coding cams on the protective guard (10) ensure

that only a protective guard that is suitable for the power

tool can be fitted.

Protective guard for cutting

u Always use the protective guard for cutting (15) when

cutting bonded abrasives.

u Provide sufficient dust extraction when cutting stone.

The protective guard for cutting (15) is fitted in the same

way as the protective guard for grinding (10).

Side handle

u Do not operate your power tool without the side

handle (9).

Screw the side handle (9) on the left or right of the machine

head depending on how your are working.

Low-vibration auxiliary handle

The low-vibration auxiliary

handle reduces vibration,

enabling the tool to be used

safely and more comfort-

ably.

u Do not make any alterations of any kind to the auxili-

ary handle.

Do not continue to use a damaged auxiliary handle.

Hand guard

u Always fit the hand guard (19) when working with the

rubber sanding plate (20) or with the cup brush/disc

brush/flap disc.

Attach the hand guard (19) to the side handle (9).

Fitting the abrasive tools

u Remove the battery from the power tool before carry-

ing out work on the power tool (e.g. maintenance,

changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury

from unintentionally pressing the on/off switch.

u Do not touch grinding and cutting discs until they have

cooled down. The discs can become very hot while working.

Clean the grinding spindle (18) and all the parts to be fitted.

Lock the grinding spindle with the spindle lock button (3)

before clamping and releasing the abrasive tools.

u Do not press the spindle lock button while the grind-

ing spindle is moving. The power tool may become damaged if you do this.

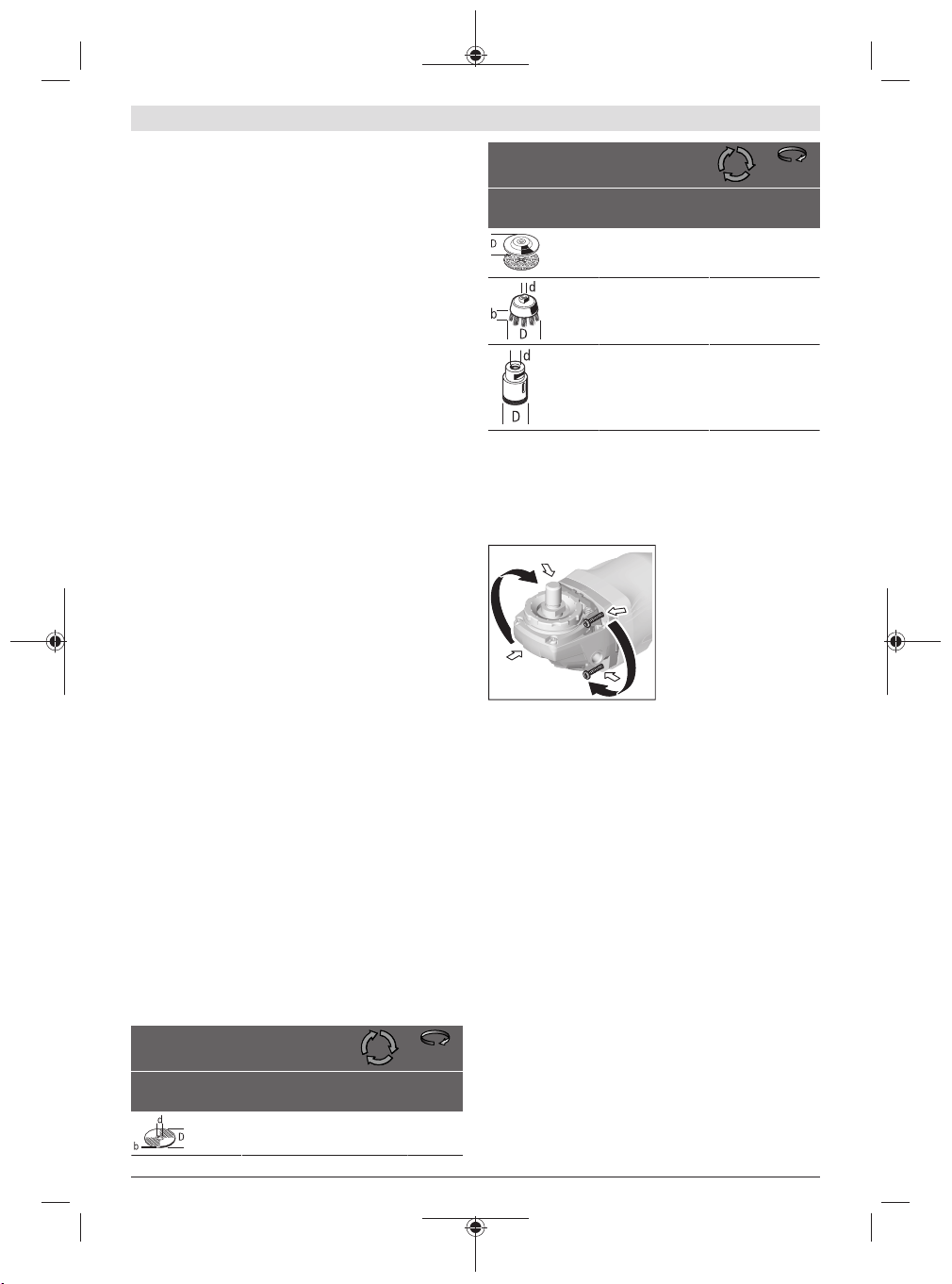

Grinding/Cutting Disc

Pay attention to the dimensions of the grinding tools. The

mounting hole diameter must fit the mounting flange without

play. Do not use reducers or adapters.

When using diamond cutting discs, pay attention that the

direction-of-rotation arrow on the diamond cutting disc and

the direction of rotation of the machine (see direction-of-rotation arrow on the machine head) agree.

See graphics page for the mounting sequence.

To fasten the grinding/cutting disc, screw on the clamping

nut (13) and tighten with the two-hole spanner.

u After fitting the abrasive tool, check that the abrasive

tool is fitted correctly and can turn freely before

switching on the power tool. Make sure that the abrasive tool does not brush against the protective guard or

other parts.

Flap disc

u Always fit the hand guard (19) when working with the

flap disc.

Rubber Sanding Pad

u Always fit the hand guard (19) when working with the

rubber sanding pad (20).

See the graphics page for fitting instructions.

Slide the rubber sanding pad (20) onto the grinding spindle

(18).

Press the sanding sheet (21) firmly onto the underside of

the rubber sanding pad (20).

Screw on the round nut (22) and tighten with a two-pin

spanner.

Cup brush/disc brush

u Always fit the hand guard (19) when working with the

cup brush or disc brush.

See the graphics page for fitting instructions.

The cup brush/disc brush must be screwed onto the grinding

spindle until it rests firmly against the grinding spindle flange

at the end of the grinding spindle thread. Tighten the cup

brush/disc brush with an open-ended spanner.

Carbide Grinding Head

u A grinding head may be used only with a suitable pro-

tective guard.

Approved abrasive tools

You can use all the abrasive tools mentioned in these operating instructions.

The permissible speed [min-1] or the circumferential speed

[m/s] of the abrasive tools used must at least match the values given in the table.

It is therefore important to observe the permissible rota-

tional/circumferential speed on the label of the abrasive

tool.

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 13

English | 13

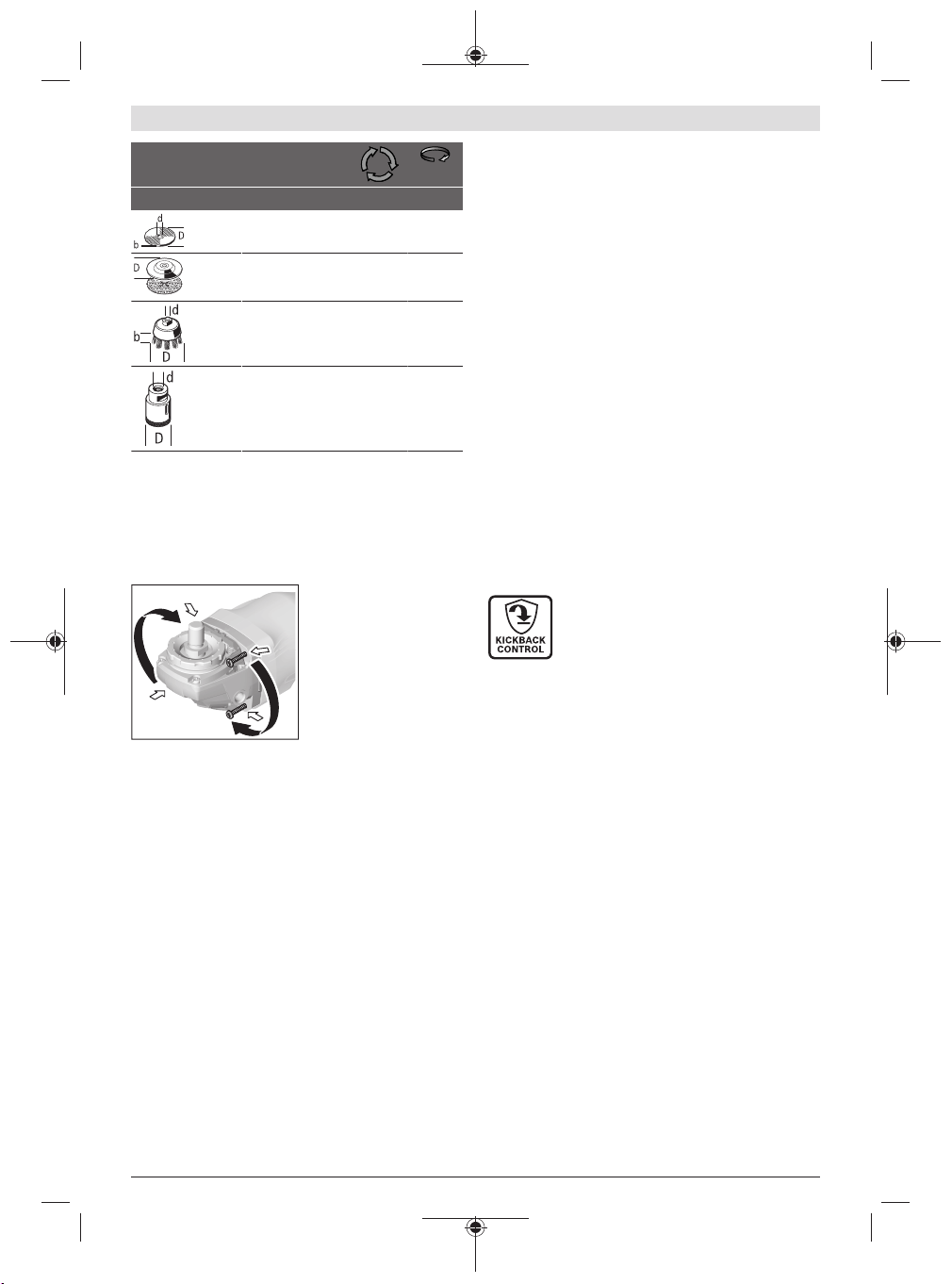

max. [mm] [mm]

D b d [min-1] [m/s]

100 7 16 11,000 80

u Avoid dust accumulation at the workplace. Dust can

easily ignite.

Operation

Start-up

100 – – 11,000 80

75 30 M 14 11,000 45

82 – M 14 11,000 80

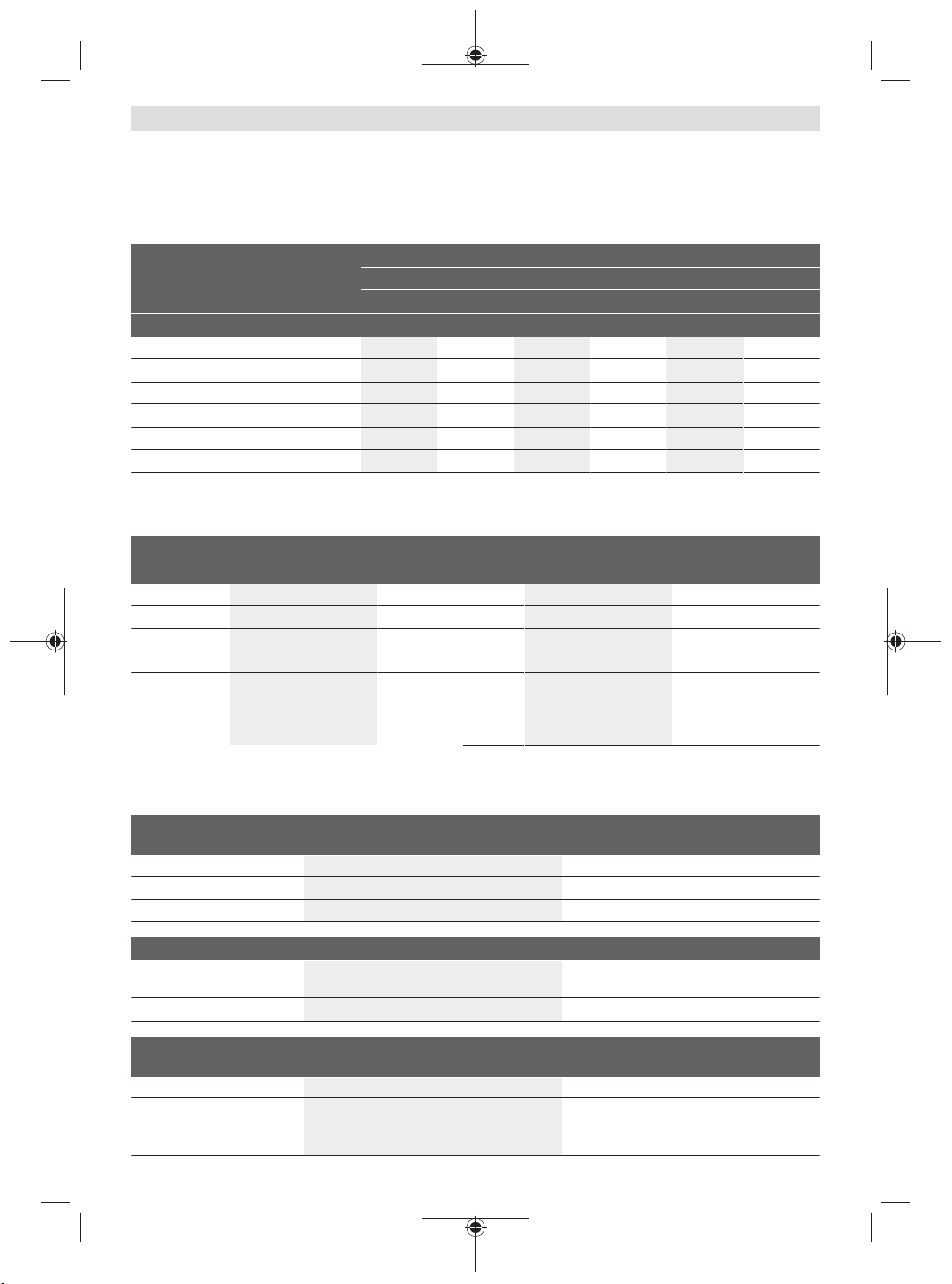

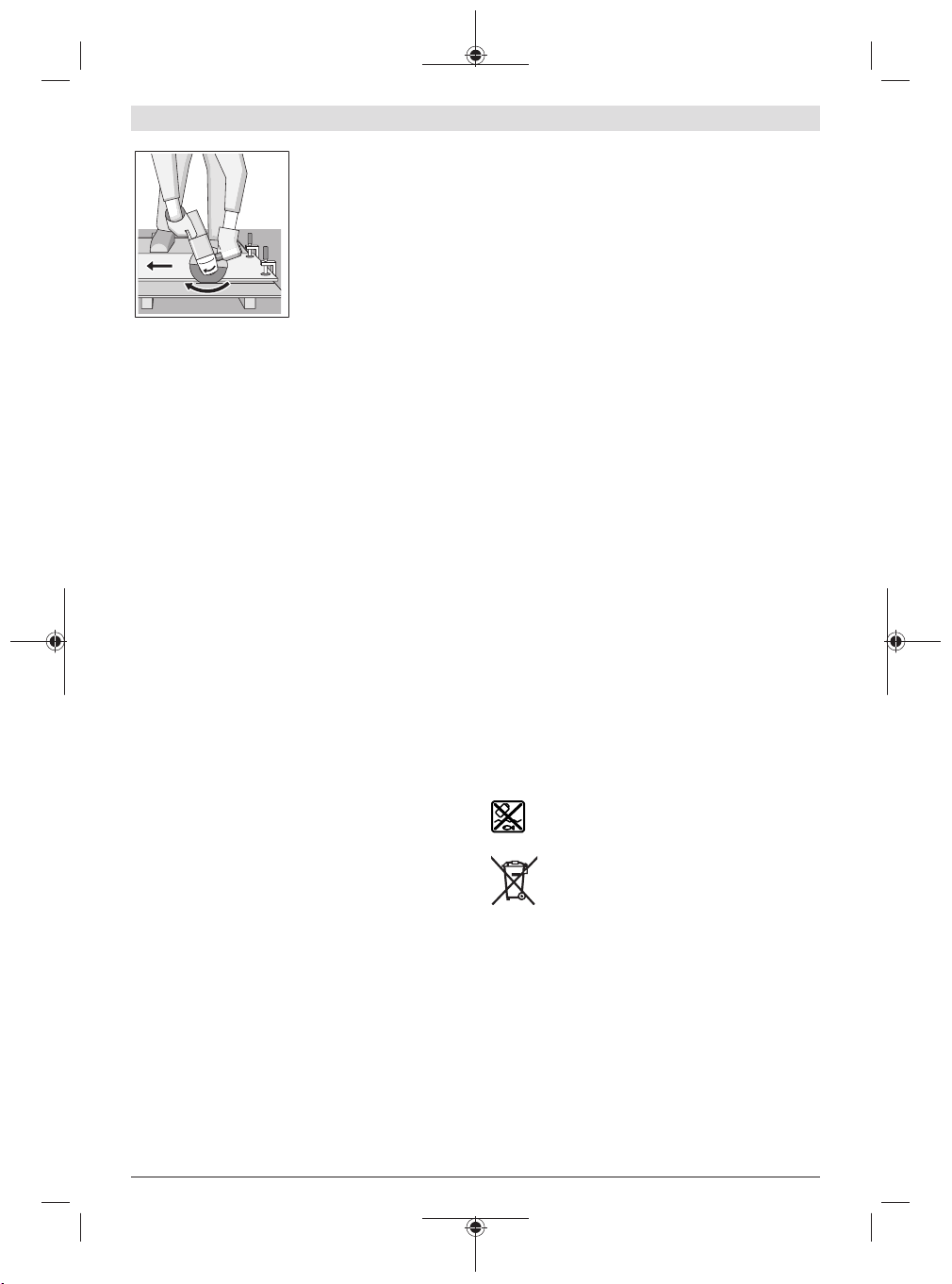

Rotating the Machine Head (GWS 18V-15 C)

u Remove the battery from the power tool before carry-

ing out work on the power tool (e.g. maintenance,

changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury

from unintentionally pressing the on/off switch.

The machine head can be

rotated in 90° increments.

In this way, the on/off

switch can be brought into

a more favourable handling

position for particular applications, e.g. for lefthanded tool users.

Completely unscrew the

four screws. Rotate the ma-

chine head carefully, without removing it from the hous-

ing, into the new position. Screw in and retighten the four

screws.

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some

wood types, minerals and metal can be harmful to one’s

health. Touching or breathing-in the dust can cause allergic

reactions and/or lead to respiratory infections of the user or

bystanders.

Certain dust, such as oak or beech dust, is considered carcinogenic, especially in connection with wood-treatment additives (chromate, wood preservative). Materials containing

asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the ma-

terials to be worked.

Speed Preselection (GWS 18V-15 SC)

The factory settings include three preset speeds. Using a special application (Bosch Toolbox app), up to six speed settings can

be programmed.

Inserting the battery

Push the charged battery (7) into the base of the power tool

from the front until the battery is securely locked.

Switching on/off

To start the power tool, push the on/off switch (5) forward.

To lock the on/off switch (5) in position, push the on/off

switch (5) forward and down until it clicks into place.

To switch off the power tool, release the on/off switch (5);

or, if the switch is locked, briefly push the on/off switch (5)

backward and down and then release it.

u Always check abrasive tools before using them. The

abrasive tool must be fitted properly and be able to

move freely. Carry out a test run for at least one

minute with no load. Do not use abrasive tools that are

damaged, run untrue or vibrate during use. Damaged

abrasive tools can burst apart and cause injuries.

Kickback stop

If there is a sudden kickback in the power tool,

e.g. jamming in a separating cut, the power

supply to the motor will be interrupted electronically. The kickback stop indicator(26)

then lights up. When kickback stop is activ-

ated, the status indicator (30) flashes red.

To restart the tool, set the on/off switch (5) to the off posi-

tion and then switch the power tool on again.

Restart protection

The restart protection feature prevents the power tool from

starting unintentionally after the power supply to it has been

interrupted.

When restart protection is activated, the status indicator

(30) flashes red.

To restart the tool, set the on/off switch (5) to the off position and then switch the power tool on again.

Impact shutdown

The integrated impact shutdown switches the power tool off

as soon as it hits the floor. The status indicator (30) then

flashes red.

To restart the tool, set the on/off switch (5) to the off position and then switch the power tool on again.

User interface (see figure A)

The user interface (4) is used to preselect the speed and to

indicate the status of the power tool.

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 14

14 | English

If the number of speeds is changed, the values of the preset individual speed settings are adjusted. In this case, the speed setting/mode indicator(28) lights up white. If a speed value is individually programmed, the speed setting/mode indicator(28)

lights up blue for this speed setting (i.e. does not correspond to a default setting). It is possible to individually adjust the speed

settings in steps of 200min-1. Keep in mind the logically ascending sequence of the settings (2≥1, 3≥2, etc.) when doing so.

The following table shows the preset speeds (default settings) for each programmed number of settings.

GWS 18V-15 SC Basic speed setting at level

1 2 3 4 5 6

[min-1] [min-1] [min-1] [min-1] [min-1] [min-1]

Number of speed settings

1

2

3

4

5

6

The specified speed setting values depend on the rechargeable battery in use, the battery's state of charge and the tool's operating temperature.

3400 – – – – –

3400 9800 – – – –

3400 6600 9800 – – –

3400 5600 7600 9800 – –

3400 5000 6600 8200 9800 –

3400 4600 6000 7200 8600 9800

You can use the button for speed preselection (27) to preselect the required speed, even during operation. The information in

the table below describes the recommended values for the default settings with 3 preset speed levels.

Material Application Application tool Speed preselection

level

GWS 18V-15 SC

[min-1]

Metal Brushing, removing rust Cup brush 1 3400

Stainless steel Grinding Fibre disc 2 6600

Metal Rough grinding Grinding disc 3 max.

Metal Cutting Grinding disc 3 max.

Stone Cutting Diamond cutting disc and

3 max.

cutting guide (cutting of

stone is permitted only

with a cutting guide)

u The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated speed

can break and fly apart.

Status indications

Battery charge indicator

Meaning/cause Solution

(user interface)(25)

Green Battery charged –

Yellow Battery almost empty Replace or charge battery soon

Red Battery empty Replace or charge battery

Temperature indicator(31) Meaning/cause Solution

Yellow Critical temperature has been reached (mo-

tor, electronics, battery)

Run the power tool at no load and allow it to

cool down

Red Power tool is overheated and will switch off Leave the power tool to cool down

Power tool status

Meaning/cause Solution

indicator(30)

Green Status OK –

Yellow Critical temperature has been reached or bat-

tery is almost empty

Run the power tool at no load and allow it to

cool down, or replace or charge the battery

soon

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 15

English | 15

Power tool status

Meaning/cause Solution

indicator(30)

Illuminated red Power tool has overheated or battery is empty Allow the power tool to cool down, or replace

or charge the battery

Flashing red Kickback shutdown, restart protection or im-

Turn the power tool off and on again

pact shutdown has been triggered

Flashing blue Power tool is connected to a mobile device or

–

settings are being transferred

Connectivity functions

In conjunction with the Bluetooth® Low Energy Module

GCY42, the following connectivity functions are available

for the power tool:

– Registration and personalisation

– Status check, output of warning messages

– General information and settings

– Management

Read the corresponding operating instructions for informa-

tion about the Bluetooth® Low Energy ModuleGCY42.

The connection of the power tool with the app must be con-

firmed by pressing the speed preselection button (27) on

the user interface (4). The app requests this when connecting.

Practical advice

u With the Bluetooth® Low Energy Module GCY 42, the

power tool is equipped with a radio interface. Local

operating restrictions, e.g. in aircraft or hospitals,

must be observed.

u In areas where the Bluetooth® wireless technology is

not allowed to be used, the Bluetooth® Low Energy

Module GCY42 and the button cell must be removed.

u Exercise caution when cutting slots in structural walls;

see the "Information on structural design" section.

u Clamp the workpiece if it is not secure under its own

become too hot or discolour and that grooves are not

formed.

Flap disc

The flap disc (accessory) enables you to machine curved

surfaces and profiles.

Flap discs have a considerably longer service life, lower

noise levels and lower sanding temperatures than conventional grinding discs.

Cutting metal

u Always use the protective guard for cutting (15) when

cutting bonded abrasives.

When carrying out abrasive cutting, use a moderate feed

that is suited to the material being machined. Do not exert

pressure on the cutting disc and do not tilt or swing the

power tool.

Do not attempt to reduce the speed of a cutting disc coming

to a stop by applying pressure from the side.

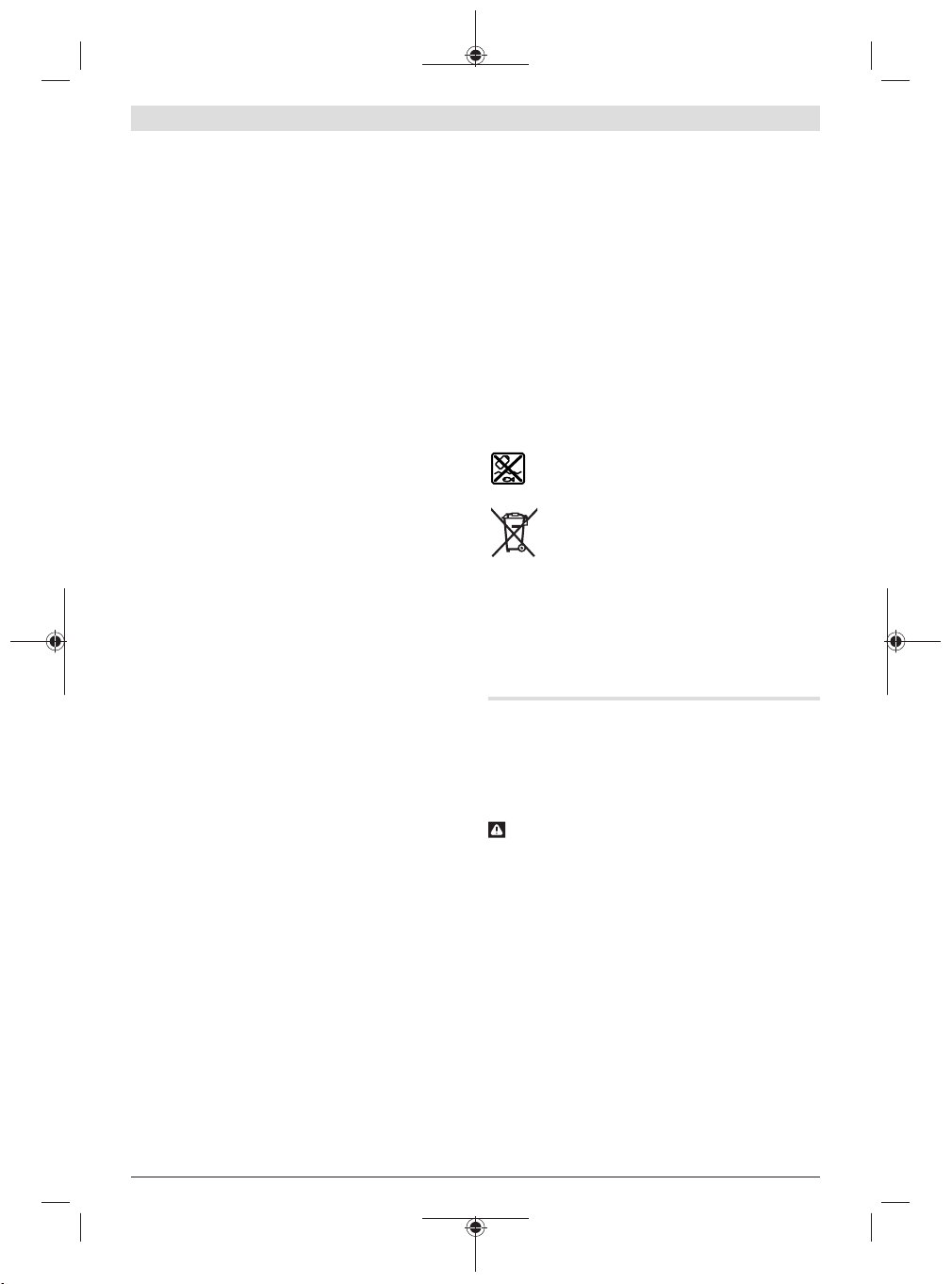

The power tool must always

work in an up-grinding motion. Otherwise there is a

risk that it will be pushed

uncontrolled out of the cut.

For best results when cutting profiles and rectangular

tubing, start at the smallest

cross section.

weight.

u Do not load the power tool so heavily that it comes to a

stop.

u If the power tool has been subjected to a heavy load,

continue to run it at no-load for several minutes to

cool down the accessory.

u Do not use the power tool with a cut-off stand.

u Do not touch grinding and cutting discs until they have

cooled down. The discs can become very hot while working.

If the power tool becomes electrostatically charged, the

built-in electronics will switch the power tool off. Press the

on/off switch (5) again to restart the power tool.

Rough grinding

u Never use cutting discs for rough grinding.

The best rough grinding results are achieved with a set angle

of 30° to 40°. Move the power tool back and forth with moderate pressure. This will ensure that the workpiece does not

Cutting stone

u Provide sufficient dust extraction when cutting stone.

u Wear a dust mask.

u The power tool may be used only for dry cutting/grind-

ing.

For best results when cutting stone, use a diamond cutting

disc.

When cutting especially hard materials such as concrete

with a high pebble content, the diamond cutting disc can

overheat and become damaged as a result. This is clearly indicated by circular sparking, rotating with the diamond cutting disc.

If this happens, stop cutting and allow the diamond cutting

disc to cool down by running the power tool for a short time

at maximum speed with no load.

Working noticeably slower and with circular sparking indicate that the diamond cutting disc that has become dull. You

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 16

16 | 中文

can resharpen the disc by briefly cutting into abrasive material (e.g. lime-sand brick).

Information on structural design

Slots in load-bearing walls are subject to DIN 1053 part 1 or

country-specific regulations. These regulations must be observed under all circumstances. Seek advice from the responsible structural engineer, architect or construction supervisor before starting work.

Recommendations for optimal handling of the battery

Protect the battery against moisture and water.

Only store the battery only within a temperature range of -20

to 50 °C. Do not leave the battery in your car in the summer,

for example.

Occasionally clean the ventilation slots on the battery using a

soft brush that is clean and dry.

A significantly reduced operating time after charging indicates that the battery has deteriorated and must be replaced.

Follow the instructions on correct disposal.

Maintenance and Service

Maintenance and Cleaning

u Remove the battery from the power tool before carry-

ing out work on the power tool (e.g. maintenance,

changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury

from unintentionally pressing the on/off switch.

u To ensure safe and efficient operation, always keep

the power tool and the ventilation slots clean.

Store and handle the accessories carefully.

After-Sales Service and Application Service

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare

parts. You can find explosion drawings and information on

spare parts at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you

with any questions about our products and their accessories.

In all correspondence and spare parts orders, please always

include the 10‑digit article number given on the nameplate

of the product.

Malaysia

Robert Bosch Sdn. Bhd.(220975-V) PT/SMY

No. 8A, Jalan 13/6

46200 Petaling Jaya

Selangor

Tel.: (03) 79663194

Toll-Free: 1800 880188

Fax: (03) 79583838

E-Mail: kiathoe.chong@my.bosch.com

www.bosch-pt.com.my

You can find further service addresses at:

www.bosch-pt.com/serviceaddresses

Transport

The contained lithium-ion batteries are subject to the Dangerous Goods Legislation requirements. The batteries are

suitable for road-transport by the user without further restrictions.

When shipping by third parties (e.g.: by air transport or forwarding agency), special requirements on packaging and labelling must be observed. For preparation of the item being

shipped, consulting an expert for hazardous material is required.

Dispatch battery packs only when the housing is undamaged. Tape or mask off open contacts and pack up the battery in such a manner that it cannot move around in the

packaging. Please also observe the possibility of more detailed national regulations.

Disposal

Power tools, rechargeable batteries, accessories and packaging should be sorted for environmental-friendly recycling.

Do not dispose of power tools and batteries/rechargeable batteries into household waste!

Battery packs/batteries:

Li-ion:

Please observe the notes in the section on transport (see

"Transport", page16).

中文

安全规章

电动工具通用安全警告

警告!

击、着火和/或严重伤害。

保存所有警告和说明书以备查阅。

在所有下列的警告中术语"电动工具"指市电驱动(有

线)电动工具或电池驱动(无线)电动工具。

工作场地的安全

u 保持工作场地清洁和明亮。混乱和黑暗的场地会

引发事故。

u 不要在易爆环境,如有易燃液体、气体或粉尘的

环境下操作电动工具。电动工具产生的火花会点

燃粉尘或气体。

u 让儿童和旁观者离开后操作电动工具。注意力不

集中会使操作者失去对工具的控制。

电气安全

u 电动工具插头必须与插座相配。绝不能以任何方

式改装插头。需接地的电动工具不能使用任何转

阅读所有警告和所有说明! 不遵

照以下警告和说明会导致电

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 17

换插头。未经改装的插头和相配的插座将减少电

击危险。

u 避免人体接触接地表面,如管道、散热片和冰

箱。如果你身体接地会增加电击危险。

u 不得将电动工具暴露在雨中或潮湿环境中。水进

入电动工具将增加电击危险。

u 不得滥用电线。绝不能用电线搬运、拉动电动工

具或拔出其插头。使电线远离热源、油、锐边或

运动部件。受损或缠绕的软线会增加电击危险。

u 当在户外使用电动工具时,使用适合户外使用的

外接软线。适合户外使用的软线将减少电击危

险。

u 如果在潮湿环境下操作电动工具是不可避免的,

应使用剩余电流动作保护器(RCD)。使用RCD

可减小电击危险。

人身安全

u 保持警觉,当操作电动工具时关注所从事的操作

并保持清醒。当你感到疲倦,或在有药物、酒精

或治疗反应时,不要操作电动工具。在操作电动

工具时瞬间的疏忽会导致严重人身伤害。

u 使用个人防护装置。始终佩戴护目镜。安全装

置,诸如适当条件下使用防尘面具、防滑安全

鞋、安全帽、听力防护等装置能减少人身伤害。

u 防止意外起动。确保开关在连接电源和/或电池

盒、拿起或搬运工具时处于关断位置。手指放在

已接通电源的开关上或开关处于接通时插入插头

可能会导致危险。

u 在电动工具接通之前,拿掉所有调节钥匙或扳

手。遗留在电动工具旋转零件上的扳手或钥匙会

导致人身伤害。

u 手不要伸展得太长。时刻注意立足点和身体平

衡。这样在意外情况下能很好地控制电动工具。

u 着装适当。不要穿宽松衣服或佩戴饰品。让衣

服、手套和头发远离运动部件。宽松衣服、佩饰

或长发可能会卷入运动部件中。

u 如果提供了与排屑、集尘设备连接用的装置,要

确保他们连接完好且使用得当。使用这些装置可

减少尘屑引起的危险。

电动工具使用和注意事项

u 不要滥用电动工具,根据用途使用适当的电动工

具。选用适当设计的电动工具会使你工作更有

效、更安全。

u 如果开关不能接通或关断工具电源,则不能使用

该电动工具。如果开关不能接通或关断工具电

源,则不能使用该电动工具。

u 在进行任何调节、更换附件或贮存电动工具之

前,必须从电源上拔掉插头和/或使电池盒与工具

脱开。这种防护性措施将减少工具意外起动的危

险。

u 将闲置不用的电动工具贮存在儿童所及范围之

外,并且不要让不熟悉电动工具或对这些说明不

了解的人操作电动工具。电动工具在未经培训的

用户手中是危险的。

u 保养电动工具。检查运动件是否调整到位或卡

住,检查零件破损情况和影响电动工具运行的其

中文 | 17

他状况。如有损坏,电动工具应在使用前修理

好。许多事故由维护不良的电动工具引发。

u 保持切削刀具锋利和清洁。保养良好的有锋利切

削刃的刀具不易卡住而且容易控制。

u 按照使用说明书,考虑作业条件和进行的作业来

使用电动工具、附件和工具的刀头等。将电动工

具用于那些与其用途不符的操作可能会导致危

险。

电池式工具使用和注意事项

u 只用制造商规定的充电器充电。将适用于某种电

池盒的充电器用到其他电池盒时会发生着火危

险。

u 只有在配有专用电池盒的情况下才使用电动工

具。使用其他电池盒会发生损坏和着火危险。

u 当电池盒不用时,将它远离其他金属物体,例如

回形针、硬币、钥匙、钉子、螺钉或其他小金属

物体,以防一端与另一端连接。电池端部短路会

引起燃烧或火灾。

u 在滥用条件下,液体会从电池中溅出;避免接

触。 如果意外碰到了,用水冲洗。如果液体碰到

了眼睛,还要寻求医疗帮助。 从电池中溅出的液

体会发生腐蚀或燃烧。

维修

u 让专业维修人员使用相同的备件维修电动工具。

这将保证所维修的电动工具的安全。

针对角磨机的安全规章

砂磨、砂光、钢丝砂光或砂磨切割操作的通用安全 警告

u 该电动工具是用于实现砂轮机、砂光机、钢丝刷

或切断工具功能的。阅读随该电动工具提供的所

有安全警告、说明、图解和规定。不了解以下所

列所有说明将导致电击、着火和/或严重伤害。

u 不推荐用该电动工具进行抛光操作。电动工具不

按指定的功能去操作,可能发生危险和引起人身

伤害。

u 不使用非工具制造商推荐和专门设计的附件。否

则该附件可能被装到你的电动工具上,而它不能

保证安全操作。

u 附件的额定速度必须至少等于电动工具上标出的

最大速度。附件以比其额定速度大的速度运转会

发生爆裂和飞溅。

u 附件的外径和厚度必须在电动工具额定能力范围

之内。不正确的附件尺寸不能得到充分防护或控

制。

u 砂轮、法兰盘、靠背垫或任何其他附近的轴孔尺

寸必须适合于安装到电工工具的主轴上。带轴孔

的、与电动工具安装件不配的附件将会失稳、过

度振动并会引起失控。

u 不要使用损坏的附件。在每次使用前要检查附

件,例如砂轮是否有碎片和裂缝,靠背垫是否有

裂缝,撕裂或过度磨损,钢丝刷是否松动或金属

丝是否断裂。如果电动工具或附件跌落了,检查

是否有损坏或安装没有损坏的附件。检查和安装

附件后,让自己和旁观者的位置远离旋转附件的

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 18

18 | 中文

平面,并以电动工具最大空载速度运行1分钟。损

坏的附件通常在该试验时会碎裂。

u 戴上防护用品。根据适用情况,使用面罩,安全

护目镜或安全眼镜。适用时,戴上防尘面具,听

力保护器,手套和能挡小磨料或工件碎片的工作

围裙。眼防护罩必须挡住各种操作产生的飞屑。

防尘面具或口罩必须能够过滤操作产生的颗粒。

长期暴露在高强度噪音中会引起失聪。

u 让旁观者与工作区域保持一安全距离。任何进入

工作区域的人必须戴上防护用品。工件或破损附

件的碎片可能会飞出并引起紧靠着操作区域的旁

观者的伤害。切割附件触及带电导线会使电动工

具外露的金属零件带电,并使操作者触电。

u 当在切割附件有可能切割到暗线的场所进行操作

时,只能通过绝缘握持面来握住电动工具。切割

附件碰到一根带电导线可能会使电动工具外露的

金属零件带电并使操作者发生电击危险。

u 直到附件完全停止运动才放下电动工具。并且不

得使用任何外力迫使金刚石切割片停转。旋转的

附件可能会抓住表面并拉动电动工具而让你失去

对工具的控制。

u 当携带电动工具时不要开动它。意外地触及旋转

附件可能会缠绕你的衣服而使附件伤害身体。

u 经常清理电动工具的通风口。电动机风扇会将灰

尘吸进机壳,过多的金属粉末沉积会导致电气危

险。

u 不要在易燃材料附近操作电动工具。火星可能会

点燃这些材料。

u 不要使用需用冷却液的附件。用水或其他冷却液

可能导致电腐蚀或电击。

反弹和相关警告

反弹是因卡住或缠绕住的旋转砂轮,靠背垫,钢丝

刷或其他附件而产生的突然反作用力。卡住或缠绕

会引起旋转附件的迅速堵转,随之使失控的电动工

具在卡住点产生与附件旋转方向相反的运动。

例如,如果砂轮被工件缠绕或卡住了,伸入卡住点

的砂轮边缘可能会进入材料表面而引起砂轮爬出或

反弹。砂轮可能飞向或飞离操作者,这取决于砂轮

在卡住点的运动方向。在此条件下砂轮也可能碎

裂。

反弹是电动工具误用和/或不正确操作工序或条件的

结果。可以通过采取以下给出的适当预防措施得以

避免。

u 保持紧握电动工具,使你的身体和手臂处于正确

状态以抵抗反弹力。如有辅助手柄,则要一直使

用,以便最大限度控制住起动时的反弹力或反力

矩。采取合适的预防措施,操作者就可以控制反

力矩或反弹力。

u 绝不能将手靠近旋转附件。附件可能会反弹碰到

手。

u 不要站在发生反弹时电动工具可能移动到的地

方。反弹将在缠绕点驱使工具逆砂轮运动方向运

动。

u 当在尖角、锐边等处作业时要特别小心。避免附

件的弹跳和缠绕。尖角,锐边和弹跳具有缠绕旋

转附件的趋势并引起反弹的失控。

u 不要附装上锯链、木雕刀片或带齿锯片。这些锯

片会产生频繁的反弹和失控。

对磨削和砂磨切割操作的专用安全警告

u 只使用所推荐的砂轮型号和为选用砂轮专门设计

的护罩。不是为电动工具设计的砂轮不能充分得

到防护,是不安全的。

u 安装弯曲的砂轮时,砂轮的研磨面不可以突出于

防护罩缘之外。防护罩无法遮蔽因为安装不当而

突出于防护罩缘之外的砂轮。

u 防护必须牢固地装在电动工具上,且放置得最具

安全性,只有最小的砂轮部分暴露在操作人面

前。护罩帮助操作者免于受到爆裂砂轮片和偶然

触及砂轮的危险。

u 砂轮只用作推荐的用途。例如:不要用切割砂轮

的侧面进行磨削。施加到砂轮侧面的力可能会使

其碎裂。

u 始终为所选砂轮选用未损坏的,有恰当规格和形

状的砂轮法兰盘。合适的砂轮法兰盘支承砂轮可

以减小砂轮破裂的可能性。切割砂轮的法兰盘可

以不同于砂轮法兰盘。

u 不要使用从大规格电动工具上用剩的磨损砂轮。

用于大规格电动工具上的砂轮不适于较小规格工

具的高速工况并可能会爆裂。

对砂轮切割操作的附加专用安全警告

u 不要"夹"住切割砂轮或施加过大的压力。不要试

图做过深的切割。给砂轮施加过应力增加了砂轮

在切割时的负载,容易缠绕或卡住,增加了反弹

或砂轮爆裂的可能性。

u 身体不要对着旋转砂轮,也不要站在其后。当把

砂轮从操作者身边的操作点移开时,可能的反弹

会使旋转砂轮和电动工具朝你推来。

u 当砂轮被卡住或无论任何原因而中断切割时,关

掉电动工具并握住工具不要动,直到砂轮完全停

止。决不要试图当砂轮仍然运转时使切割砂轮脱

离切割,否则会发生反弹。调查并采取校正措施

以消除砂轮卡住的原因。

u 不能在工件上重新起动切割操作。让砂轮达到全

速后再小心地重新进入切割。如果电动工具在工

件上重新起动,砂轮可能会卡住、爬出或反弹。

u 支撑住板材或超大工件可使得砂轮卡住和反弹的

危险降到最低限度。大工件凭借自重而下垂。必

须在工件靠近切割线处和砂轮两侧近工件边缘处

放置支承。

u 当进行"盲切割"进入墙体或其他盲区时要格外小

心。伸出的砂轮可能会割到煤气管或水管,电线

或由此引起反弹的物体。

砂光操作的专用安全警告

u 当砂光时,不要使用超大砂盘纸。选用砂盘纸时

应按照制造商的推荐。超出砂光垫盘的大砂盘纸

有撕裂的危险并且会引起缠绕、砂盘的撕裂或反

弹。

钢丝刷操作的专用安全警告

u 要意识到即使正常操作时钢丝线也会从刷子甩

出。 不要对钢丝刷施加过大的负荷而使得钢丝线

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 19

承受过 应力。钢丝线可能会轻易刺入薄的衣服

和/ 或皮肤内。

u 如果建议钢丝刷使用护罩,则不允许该护罩对钢

丝轮或钢丝刷有任何干扰。钢丝轮或钢丝刷在工

作负荷和离心力作用下直径会变大。

其他安全规章

请佩戴护目镜。

u 使用合适的侦测装置侦察隐藏的电线,或者向当

地的相关单位寻求支援。 接触电线可能引起火灾

並让操作者触电。损坏了瓦斯管会引起爆炸。如

果水管被刺穿了会导致财物损失。

u 在磨片和切割片尚未冷却之前,切勿抓取。 工作

时砂轮会变得非常炙热。

u 如果由于取出充电电池等原因导致电源突然中

断,请立即解锁起/停开关并调到关闭位置。 这

样可以避免机器突然起动。

u 固定好工件。使用固定装置或老虎钳固定工件,

会比用手持握工件更牢固。

u 如果充电电池损坏或者未按照规定使用,充电电

池中会散发出有毒蒸汽。充电电池可能会燃烧或

爆炸。工作场所必须保持空气流通,如果身体有

任何不适必须马上就医。蒸汽会刺激呼吸道。

u 切勿打开充电电池。可能造成短路。

u 钉子、螺丝刀等尖锐物品或外力作用可能会损坏

充电电池。 有可能出现内部短路、蓄电池燃烧、

发出烟雾、爆炸或过热。

u 只能将此充电电池用在制造商的产品中。 这样才

能确保充电电池不会过载。

保护充电电池免受高温(例如长期阳光

照射)、火焰、脏污、水和湿气的侵

害。有爆炸和短路的危险。

u 注意!在使用有

®

蓝牙

功能的电动工具时,其他装

置和设备、飞机和医疗器械(例如心脏起搏器、

助听器)可能会出现故障。同样不能完全排除周

围的人和动物会受到伤害。请不要在医疗设备、

加油站、化工厂、有爆炸危险的地区附近和在爆

破区内使用有

飞机上使用有

®

蓝牙

蓝牙功能的电动工具。请勿在

®

蓝牙

功能的电动工具。请避免在身

体附近较长时间使用。

蓝牙

®文字标记和图形符号(标志)是Bluetooth

SIG公司的注册商标和财产。Robert Bosch

Power Tools GmbH根据许可使用这些文字标记/

图形符号。

产品和性能说明

请阅读所有安全规章和指示。不遵照以

下警告和说明可能导致电击、着火和/或

严重伤害。

请注意本使用说明书开头部分的图示。

中文 | 19

按照规定使用

本电动工具适合在金属和石材上进行切割、粗磨和

刷磨,而无需使用水。

使用合成磨料进行切割时,必须使用切割专用防护

罩。

切割石材时必须进行足够的集尘。

安装允许的磨具后,也可以使用本电动工具进行砂

纸研磨。

装入

块)后,通过

®

蓝牙

Low Energy Module GCY42(低能耗模

®

蓝牙

无线技术在电动工具和移动终端

设备之间传输电动工具的数据和设置。

插图上的机件

机件的编号和电动工具详解图上的编号一致。

(1) 针对防护罩的解锁开关

(2) 机壳上的转向箭头

(3) 主轴锁定键

(4) 用户界面

(5) 电源开关

(6)

Bluetooth

板

(7) 充电电池

(8) 充电电池解锁按钮

(9) 辅助手柄(绝缘握柄)

(10) 研磨防护罩

(11) 带O形环的固定法兰

(12) 砂轮

(13) 夹紧螺母

(14) 硬质合金杯形砂轮

(15) 切割防护罩

(16) 切割片

(17) 手柄(绝缘握柄)

(18) 研磨主轴

(19) 护手

(20) 橡胶磨盘

(21) 砂纸

(22) 圆形螺母

(23) 杯形钢丝刷

(24) 金刚石钻头

(25) 充电电池电量指示灯(用户界面)

(26) 回弹断开指示灯(用户界面)

(27) 转速预选按键(用户界面)

(28) 转速等级/模式指示灯(用户界面)

(29) 智能手机指示灯(用户界面)

(30) 电动工具状态指示灯(用户界面)

(31) 温度指示灯(用户界面)

(32) 千叶砂磨轮

A) 图表或说明上提到的附件,并不包含在基本的供货范围

中。本公司的附件清单中有完整的附件供应项目。

®(蓝牙)低能耗模块GCY42的盖

A)

A)

A)

A)

A)

A)

A)

A)

A)

A)

A)

A)

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 20

20 | 中文

技术参数

角磨机

物品代码

额定电压

额定转速

空载转速

A)

B)

最大砂轮直径

V= 18 18

转/分钟 11000 11000

转/分钟 9800 3400–9800

毫米 100 100

研磨主轴螺纹

研磨主轴上的最大螺纹长度

毫米 16 16

回弹断开

重启保护

防外滑制动器

转速预选

重量符合EPTA-Procedure01:2014

– 带减震辅助手柄

– 带标准辅助手柄

充电时建议的环境温度

工作时和存放时允许的环境温度

C)

公斤 2.5–3.5 2.5–3.5

公斤 2.3–3.3 2.3–3.3

D)

摄氏度 0至+35 0至+35

摄氏度 –20至+50 –20至+50

兼容的充电电池

推荐的确保全功率的充电电池

推荐的充电器

数据传输

®

蓝牙

信号间隔

信号最大作用距离

A) 测量转速根据EN60745-2-3标准

B) 在20–25摄氏度下带18伏8.0安培小时的充电电池ProCORE测得,并与充电电池的充电量以及设备的工作温度有关

C) 视所使用的充电电池而定

D) 温度<0 摄氏度时功率受限

E) 移动终端设备必须可与

F) 根据外部条件包括所用接收设备的不同,覆盖范围会有很大差别。在封闭的室内以及由于金属障碍物(如墙壁、台架、

箱子等),蓝牙®覆盖范围可能明显缩小。

F)

®

蓝牙

®低能耗装置(版本4.2)兼容并支持通用访问配置(GAP)。

秒 8 8

米 30 30

GWS 18V-15 C GWS 18V-15 SC

3601JH60.. 3601JH61..

M 10 M 10

● ●

● ●

● ●

– ●

GBA 18伏...

ProCORE18伏...

ProCORE18伏...

≥5.5安培小时

GAL 18...

GAX 18...

GAL 36...

®

蓝牙

4.2

(低能耗)

E)

GBA 18伏...

ProCORE18伏...

ProCORE18伏...

≥5.5安培小时

GAL 18...

GAX 18...

GAL 36...

蓝牙

(低能耗)

®

4.2

E)

安装

装入

Bluetooth

GCY42

提示:

Bluetooth

Module(低能耗模块)GCY42作为电动工具GWS

18V-15C的附件提供;对于电动工具GWS

18V-15SC,则包含在供货范围中。

有关蓝牙®Low Energy Module(低能耗模块)

GCY42的信息请见相应的使用说明。

®(蓝牙)低能耗模块

®(蓝牙)Low Energy

为充电电池充电

u 请只使用在技术参数中列出的充电器。只有这些

充电器才适用于本电动工具上的锂离子电池。

提示:充电电池在交货时只完成部分充电。首度使

用电动工具之前,必须先充足充电电池的电以确保

充电电池的功率。

可以随时为锂离子电池充电,不会缩短电池的使用

寿命。如果充电过程突然中断,也不会损坏电池。

本锂离子电池配备了电池电子保护装置 "Electronic

Cell Protection (ECP)",可以防止电池过度放电。

电池的电量如果用尽了,保护开关会自动关闭电动

工具:安装在机器上的工具刀头会停止转动。

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 21

u 电动工具被关闭之后,切勿继续按住起停开关。

否则可能会损坏电池。

请注意有关废弃处理的规定。

取出充电电池

本充电电池(7)具备双重锁定功能,即使不小心触动

了充电电池的解锁按钮(8),充电电池也不会从机器

中掉落下来。只要充电电池安装在电动工具中,就

会被弹簧固定在其位置上。

如需取下充电电池(7),则请按压解锁按钮(8),并

将充电电池从电动工具中拔出。在此过程中请勿过

度用力。

充电电池电量指示灯

充电电池电量指示灯的绿色LED灯显示充电电池的

电量。基于安全原因,只能在电动工具静止时检查

充电电池的电量。

按压充电电量指示灯按键 或 ,来显示充电电

量。也可以在充电电池取下时操作。

如果按压充电电量指示灯按键后没有LED灯亮起,

则说明充电电池损坏,必须进行更换。

提示:用户界面(4)上也会显示充电电池的电量。

(参见 “状态指示灯”, 页24).

充电电池型号GBA 18V...

LED指示灯 电量

3个绿灯常亮 60−100%

2个绿灯常亮 30−60%

1个绿灯常亮 5−30%

1个绿灯闪烁 0−5%

充电电池型号ProCORE18V...

LED指示灯 电量

5个绿灯常亮 80−100 %

4个绿灯常亮 60−80 %

3个绿灯常亮 40−60 %

2个绿灯常亮 20−40 %

1个绿灯常亮 5−20 %

1个绿灯闪烁 0−5 %

安装保护装置

u 在电动工具上进行任何维护的工作(例如维修,

更换工具等等),以及搬运、保存电动工具之前

都必须从机器中取出蓄电池。无意间操作开关可

能会造成伤害。

提示:使用过程中砂轮片断裂或防护罩/电动工具上

的固定装置损坏后,必须立即将电动工具寄给客户

中文 | 21

服务部门,地址参见章节“客户服务和应用咨

询”。

研磨防护罩

将防护罩(10)放到电动工

具的支座上,直至防护罩

的编码凸轮与支座重合。

按压并按住解锁杆(1)。

将防护罩(10)压到主轴颈

上,直至防护罩的凸肩套

在电动工具的法兰上,然

后转动防护罩,直至能够

清楚地听见卡止声。

根据工作需要调整好防护

罩(10)的位置。为此朝上

推动解锁杆(1),然后将

防护罩(10)转到所需位

置。

u 不断调整防护罩(10),使解锁杆(1)的两个凸轮卡

入防护罩(10)相应的开口中。

u 调整防护罩(10),以防有火花朝操作人员方向飞

溅。

u 唯有通过操纵解锁开关(1)才能使防护罩(10)转

动!否则,在任何条件下都不得继续使用电动工

具,必须将其交给客户服务部门。

提示:防护罩(10)上的编码凸轮确保只能安装一个

与电动工具匹配的防护罩。

切割防护罩

u 使用合成磨料切割时,必须使用切割专用防护罩

(15)。

u 切割石材时必须进行足够的集尘。

切割防护罩(15)与研磨防护罩(10)的安装方法一

样。

辅助手柄

u 操作电动工具时务必使用辅助手柄(9)。

视操作方法而定,在机头左侧或右侧旋入辅助手柄

(9)。 具备减震功能的辅助手柄

具备减震功能的辅助手

柄不仅能够降低工作时

的震动,更可以提高操

作机器的舒适性和确保

工作安全。

u 切勿在辅助手柄上做任何修改。

请勿继续使用已经损坏的辅助手柄。

护手

u 使用橡胶磨盘(20)或杯型钢丝刷/轮刷/千叶砂磨

轮操作时,请务必安装护手 (19)。

用辅助手柄(9)固定护手(19)。

安装磨具

u 在电动工具上进行任何维护的工作(例如维修,

更换工具等等),以及搬运、保存电动工具之前

都必须从机器中取出蓄电池。无意间操作开关可

能会造成伤害。

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 22

22 | 中文

u 在磨片和切割片尚未冷却之前,切勿抓取。 工作

时砂轮会变得非常炙热。

清洁研磨主轴(18)和所有待安装的零件。

夹紧及松开磨具时,请按压主轴锁定键(3)以固定研

磨主轴。

u 待主轴完全静止后,才可以操纵主轴锁定键。否

则可能会损坏电动工具。

砂轮/切割片

注意磨具的规格。孔径必须和固定法兰完全吻合。

请勿使用转接件或异径管。

使用金刚石切割片时,金刚石切割片上的箭头方向

必须和机器的旋转方向一致(参考机头上的旋转方

向箭头)。

安装过程请参考插图页。

拧入夹紧螺母(13)以固定砂轮/切割片,然后使用双

销扳手拧紧螺母。

u 在安装好磨具且尚未开动磨机之前,必须检查磨

具是否正确地安装,磨具能否自由无阻地旋转。

务必确保磨具转动时不会和防护罩或其他机件产

生磨擦。

千叶砂磨轮

u 使用千叶砂磨轮操作时,请务必安装护手(19)。

橡胶磨盘

u 使用橡胶磨盘(20)操作时,请务必安装护手

(19)。

安装过程请参考插图页。

将橡胶磨盘(20)推到研磨主轴(18)上。

将砂纸(21)牢固地按压到橡胶磨盘(20)的底面。

拧上圆形螺母(22),然后用双销扳手拧紧。

杯形钢丝刷/轮刷

u 使用杯形钢丝刷/轮刷操作时,请务必安装护手

(19)。

安装过程请参考插图页。

将杯形钢丝刷/轮刷尽量拧入磨削主轴中,使得能紧

靠在磨削主轴螺纹末端的法兰上。使用开口扳手拧

紧杯形钢丝刷/轮刷。

硬质合金杯形砂轮

u 仅允许在装有合适的防护罩的情况下使用杯形砂

轮。

允许使用的磨具

您可以使用本说明书中提到的所有磨具。

所用磨具的许可转速[转/分钟]或圆周转速[米/秒]必

须和以下表格中的数据一致。

因此,请遵守磨具标签上所允许的转速或圆周速

度。

最大[毫米] [毫米]

D b d [转/分钟][米/秒]

100 7 16 11000 80

最大[毫米] [毫米]

D b d [转/分钟][米/秒]

100 – – 11000 80

75 30 M 14 11000 45

82 – M 14 11000 80

转动机头(GWS 18V-15 C)

u 在电动工具上进行任何维护的工作(例如维修,

更换工具等等),以及搬运、保存电动工具之前

都必须从机器中取出蓄电池。无意间操作开关可

能会造成伤害。

可将机头旋转90度。这

样就能在特殊工作状况

下将电源开关置于比较

容易操作的位置,例如

针对左撇子。

将4个螺丝完全拧出。

将机头小心地转入新位

置,而无需从壳体上取

下。重新拧紧4个螺

丝。

吸锯尘/吸锯屑

含铅的颜料以及某些木材、矿物和金属的加工废尘

有害健康。机器操作者或者工地附近的人如果接

触、吸入这些废尘,可能会有过敏反应或者感染呼

吸道疾病。

某些尘埃(例如加工橡木或山毛榉的废尘)可能致

癌,特别是和处理木材的添加剂(例如木材的防腐

剂等)结合之后。只有经过专业训练的人才能够加

工含石棉的物料。

– 工作场所要保持空气流通。

– 最好佩戴P2滤网等级的口罩。

请留心并遵守贵国和加工物料有关的法规。

u 避免让工作场所堆积过多的尘垢。尘埃容易被点

燃。

运行

投入使用

安装充电电池

将充好电的充电电池(7)从前部推入电动工具的脚座

中,直至充电电池牢牢锁定。

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 23

中文 | 23

接通/关闭

如要运行电动工具,请将电源开关(5)向前推。

如要锁定电源开关(5),请向前按下电源开关(5)直

至卡止。

如要关闭电动工具,请松开电源开关(5),或当电源

开关卡止时短促向后按下电源开关(5),然后松开。

u 使用前,请先检查磨具。必须正确安装磨具,使

其可以自由转动。进行至少1分钟的无负载试机。

切勿使用损坏、变形或转动时会振动的磨具。损

坏的磨具可能断裂并造成伤害。

回弹断开

当电动工具突然回弹时(比如切割边卡

住),将以电子方式中断电机供电。同

时,回弹断开指示灯(26)亮起。在回弹

断开功能激活后,状态指示灯(30)闪红

光。

如需再次使用,请将电源开关(5)置于关闭位置,然

后重新接通电动工具。

重启保护

重启保护功能可以避免电动工具在供电中断之后突

然失控地重新启动。

重启保护功能激活后,状态指示灯(30)闪红光。

如需再次使用,请将电源开关(5)置于关闭位置,然

后重新接通电动工具。

撞击断开

一旦撞击到地面,内置的撞击断开功能就会关闭电

动工具。同时,状态指示灯(30)闪红光。

如需再次使用,请将电源开关(5)置于关闭位置,然

后重新接通电动工具。

用户界面(参见插图A) 用户界面(4)用于预选转速和显示电动工具的状态。

转速预选(GWS 18V-15 SC)

出厂设置中已预设3个转速等级。通过特殊的应用程序(Bosch Toolbox 应用程序)可以编程最多6个转速

等级。

如需更改转速等级的数量,则调整每个等级的预设数值。在这种情况下,转速等级/模式指示灯(28)亮白

光。如需个性化编程转速值,则转速等级/模式指示灯(28)在该转速等级时亮蓝光(即不符合基本设置)。

转速等级可以个性化调整为每200转每分的步进。对此请注意等级的上升逻辑(2≥1 / 3≥2,以此类

推)。

以下表格显示每个已编程等级数量的预设转速(基本设置)。

GWS 18V-15 SC 等级的转速基本设置

1 2 3 4 5 6

[转/分钟] [转/分钟] [转/分钟] [转/分钟] [转/分钟] [转/分钟]

转速等级数量

1 3400 – – – – –

2 3400 9800 – – – –

3 3400 6600 9800 – – –

4 3400 5600 7600 9800 – –

5 3400 5000 6600 8200 9800 –

6 3400 4600 6000 7200 8600 9800

给出的转速等级数值与所使用的充电电池、充电量以及设备的工作温度有关。

利用转速预选按钮(27)也可以在运行过程中预选所需的转速。以下表格中的数据只供带3个预设转速等级的

出厂设置作参考。

工件材料 用途 切削附件 转速预选等级 GWS 18V-15 SC

[转/分钟]

金属 刷磨,除锈 杯形钢丝刷 1 3400

不锈钢 研磨 纤维垫圈 2 6600

金属 粗磨 砂轮 3 最大

金属 切割 砂轮 3 最大

石材 切割 金刚石切割片和引导

3 最大

滑座(仅允许在搭配

引导滑座的情况下切

割岩石)

u 附件的额定速度必须至少等于电动工具上标出的

最大速度。附件以比其额定速度大的速度运转会

发生爆裂和飞溅。

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 24

24 | 中文

状态指示灯

充电电池电量指示灯(用

含义/原因 解决方案

户界面)(25)

绿色 充电电池已充电 –

黄色 充电电池的电量几乎耗尽 尽快更换充电电池或为其充电

红色 充电电池的电量用尽了 更换充电电池或为其充电

温度显示(31) 含义/原因 解决方案

黄色 已达到临界温度(电机、电子系统、充

让电动工具空转、冷却

电电池)

红色 电动工具过热并关闭 让电动工具冷却

电动工具状态指示灯(30) 含义/原因 解决方案

绿色 状态正常 –

黄色 已达到临界温度或充电电池的电量几乎耗尽让电动工具空转、冷却或尽快更换充电

电池或为其充电

亮红光 电动工具过热或充电电池电量耗尽 让电动工具冷却或更换充电电池或为其

充电

闪红光 触发了回弹断开功能、重启保护功能或

关闭并再次接通电动工具

撞击断开功能

闪蓝光 电动工具已与移动终端设备连接或正在

–

传输设置

连接功能

搭配

Bluetooth

®(蓝牙)Low Energy Module(低

能耗模块)GCY42,为电动工具提供以下连接功

能:

– 注册和个性化设置

– 状态检查,警告信息输出

– 通用信息和设置

– 管理

有关蓝牙®Low Energy Module(低能耗模块)

GCY42的信息请见相应的使用说明。

电动工具与应用程序的连接必须通过按压用户界面

(4)上的转速预选(27)键进行确认。应用程序在连接

时将发送该请求。

工作提示

u 装入了

u 在不允许使用

u 在支撑墙上开缝时必须特别小心,参考段落“有

u 固定好站立不稳的工件。

u 勿让电动工具因为过载而停止转动。

u 强烈过载之后必须让电动工具在无载的状况下运

u 不要将电动工具安装在切割研磨架上使用。

Bluetooth

®(蓝牙)低能耗模块GCY42

的电动工具配有一个无线接口。必须注意本地运

行限制,例如在飞机上或医院里。

Bluetooth

®(蓝牙)无线技术的区

域内,必须取出蓝牙®低能耗模块GCY 42和纽扣

电池。

关静力学的注意事项”。

转数分钟,这样能够帮助电动工具冷却。

u 在磨片和切割片尚未冷却之前,切勿抓取。 工作

时砂轮会变得非常炙热。

如果电动工具产生静电充电,电子装备会自动关闭

电动工具。重新按压电源开关(5),以再次运行电动

工具。

粗磨

u 不要使用切割片进行粗磨。

粗磨时如果砂轮和研磨表面成30至40度角,能实现

最好的工作效果。操作时只需轻压并来回移动电动

工具,这样工件不会变热、变色,也不会出现凹陷

的痕迹。

千叶砂磨轮

使用千叶砂磨轮(附件)可以在隆起的表面和型材

上研磨。

千叶砂磨轮的使用寿命比一般砂轮的使用寿命长,

而且工作噪音和研磨温度也比较低。

切割金属

u 使用合成磨料切割时,必须使用切割专用防护罩

(15)。

切割时必须施力均匀,根据要加工的材料决定推动

的力道。请勿对切割片施加压力,请勿倾斜和摇

晃。

请勿通过侧压的方式来制动仍然继续转动的切割

片。

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 25

必须逆着切割片的转向

推动电动工具,否则容

易失控,导致电动工具

从切线中滑出。

切割型材和方管时最好

使用最小的截面。

切割石材

u 切割石材时必须进行足够的集尘。

u 请佩戴防尘面具。

u 本电动工具只能够进行干式切割/干式磨削。

切割石材时最好使用金刚石切割片。

切割高硬度的工件时,例如碎石含量很高的水泥,

可能因为金刚石切割片过热而导致切割片损坏。金

刚石切割片的周围会出现明显的火花。

在这种情况下应暂停切割过程,让金刚石切割片在

空载的状况下以最高转速旋转片刻,以便冷却。

如果工作进度明显降低而且出现火花环,则表示金

刚石切割片已经变钝。此时可以将切割片在研磨材

料(例如石灰砂石)上来回刷磨数次,重新磨利切

割片。

有关静力学的提示

关于在支撑墙上开缝时应该注意的事项,请参考

DIN1053第一部的规定或各国有关的法规。务必遵

守相关的法律规定。开始工作之前,先向负责的静

力学专家、工程师或工程负责人请教有关细节。

有关以最佳方式使用充电电池的提示

保护充电电池,避免湿气和水分渗入。

充电电池必须储存在–20 °C至50 °C的环境中。夏

天不得将充电电池搁置在汽车中。

不定时地使用柔软、清洁而且乾燥的毛刷清洁充电

电池的通气孔。

充电后如果充电电池的使用时间明显缩短,代表充

电电池已经损坏,必须更换新的充电电池。

请注意有关废弃处理的规定。

维修和服务

中文 | 25

博世应用咨询团队乐于就我们的产品及其附件问题

提供帮助。

询问和订购备件时,务必提供机器铭牌上标示的10

位数物品代码。

中国大陆

博世电动工具(中国)有限公司

中国 浙江省 杭州市

滨江区 滨康路567号

102/1F 服务中心

邮政编码:310052

电话:(0571)8887 5566 / 5588

传真:(0571)8887 6688 x 5566# / 5588#

电邮:bsc.hz@cn.bosch.com

www.bosch-pt.com.cn

制造商地址:

Robert Bosch Power Tools GmbH

罗伯特· 博世电动工具有限公司

70538 Stuttgart / GERMANY

70538 斯图加特 / 德国

其他服务地址请见:

www.bosch-pt.com/serviceaddresses

搬运

随着机器一起供货的锂离子充电电池必须符合危险

物品法规。使用者无须另外使用保护包装便可以运

送该充电电池。

但是如果将它交由第三者运送(例如:寄空运或委

托运输公司)则要使用特殊的包装和标示。此时必

须向危险物品专家请教有关寄送危险物品的相关事

宜。

确定充电电池的外壳未受损后,才可以寄送充电电

池。粘好未加盖的触点并包装好充电电池,不可以

让充电电池在包装中晃动。必要时也得注意各国有

关的法规。

处理废弃物

必须以符合环保的方式,回收再利用损

坏的电动工具、充电电池、附件和废弃

的包装材料。

不可以把电动工具和充电电池/蓄电池丢

入一般的家庭垃圾中!

保养和清洁

u 在电动工具上进行任何维护的工作(例如维修,

更换工具等等),以及搬运、保存电动工具之前

都必须从机器中取出蓄电池。无意间操作开关可

能会造成伤害。

u 电动工具和通气孔必须随时保持清洁,以确保工

作效率和工作安全。

小心地保存和使用附件。

充电电池/电池:

锂离子:

请注意“搬运”段落中的指示 (参见 “搬运”,

页 25)确认设置。

CMIIT ID显示在蓝牙设备铭牌上

客户服务和应用咨询

本公司顾客服务处负责回答有关本公司产品的修

理、维护和备件的问题。备件的展开图纸和信息也

可查看:www.bosch-pt.com

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 26

26 | 繁體中文

繁體中文

安全注意事項

電動工具通用安全警告

警告

擊、著火和/或嚴重傷害。

保存所有警告和說明書以備查閱。

在所有警告中,「電動工具」此一名詞泛指:以市

電驅動的(有線)電動工具或是以電池驅動的(無

線)電動工具。

工作場地的安全

u 保持工作場地清潔和明亮。雜亂和黑暗的場地會

引發事故。

u 不要在易爆環境,如有易燃液體、氣體或粉塵的

環境下操作電動工具。電動工具產生的火花會點

燃粉塵或氣體。

u 讓兒童和旁觀者離開後操作電動工具。注意力不

集中會使您失去對工具的控制。

電氣安全

u 電動工具插頭必須與插座相配。 絕不能以任何方

式改裝插頭。 需接地的電動工具不能使用任何轉

換插頭。未經改裝的插頭和相配的插座將減少電

擊危險。

u 避免人體接觸接地表面,如管道、散熱片和冰

箱。如果您身體接地會增加電擊危險。

u 不得將電動工具暴露在雨中或潮濕環境中。水進

入電動工具將增加電擊危險。

u 不得濫用電線。 絕不能用電線搬運、拉動電動工

具或拔出其插頭。 將電線遠離熱源、油、銳利邊

緣或移動零件。受損或纏繞的軟線會增加電擊危

險。

u 當在戶外使用電動工具時,使用適合戶外使用的

延長線。適合戶外使用的軟線,將減少電擊危

險。

u 如果在潮濕環境下操作電動工具是不可避免的,

應使用剩餘電流動作保護器(RCD)。使用RCD

可降低電擊危險。

人身安全

u 保持警覺,當操作電動工具時關注所從事的操作

並保持清醒。 當您感到疲倦,或在有藥物、酒精

或治療反應時,不要操作電動工具。在操作電動

工具時瞬間的疏忽會導致嚴重人身傷害。

u 使用個人防護裝置。 務必佩戴護目鏡。安全裝

置,諸如適當條件下使用防塵面具、防滑安全

鞋、安全帽、聽力防護等裝置能減少人身傷害。

u 防止意外起動。 確保開關在連接電源和/或電池

組、拿起或搬運工具時處於關閉位置。手指放在

已接通電源的開關上或開關處於接通時插入插頭

可能會導致危險。

閱讀所有警告和所有說明。不

遵照以下警告和說明會導致電

u 在電動工具接通之前,拿掉所有調節鑰匙或扳

手。遺留在電動工具旋轉零件上的扳手或鑰匙會

導致人身傷害。

u 手不要伸展得太長。 時刻注意立足點和身體平

衡。這樣在意外情況下能很好地控制電動工具。

u 著裝適當。 不要穿著寬鬆衣服或佩戴飾品。 衣

服、手套和頭髮請遠離移動零件。寬鬆衣服、佩

飾或長髮可能會捲入移動零件中。

u 如果有排屑、集塵設備連接用的裝置,請確保其

連接完好且使用得當。使用這些裝置可減少塵屑

引起的危險。

電動工具使用和注意事項

u 請勿濫用電動工具, 根據用途使用適當的電動工

具。選用適當設計的電動工具會使您工作更有

效、更安全。

u 如果開關不能開啟或關閉工具電源,則不能使用

該電動工具。不能用開關來控制的電動工具是危

險的且必須進行修理。

u 在進行任何調整、更換附件或貯存電動工具之

前,必須從電源上拔掉插頭和/或將電池組拆

下。這種防護性措施將減少工具意外起動的危

險。

u 將閒置不用的電動工具貯存在兒童所及範圍之

外,不得讓不熟悉電動工具或對這些說明不瞭解

的人操作電動工具。由未經訓練的人員使用電動

工具相當危險。

u 保養電動工具。 檢查移動零件是否調整到位或卡

住,檢查零件破損情況和影響電動工具運轉的其

他狀況。 如有損壞,電動工具應在使用前修理完

成。許多事故由維護不良的電動工具引發。

u 保持切削刀具鋒利和清潔。保養良好的有鋒利切

削刃的刀具不易卡住而且容易控制。

u 按照使用說明書,考慮作業條件和進行的作業來

使用電動工具、配件和工具的尖端等。將電動工

具用於那些與其用途不符的操作可能會導致危

險。

電池式工具使用和注意事項

u 只用製造商規定的充電器充電。將適用於某種電

池組的充電器用到其他電池組時會發生著火危

險。

u 只有在配有專用電池組的情況下才使用電動工

具。使用其他電池組會發生損壞和著火危險。

u 當電池組不用時,請遠離其他金屬物體,例如迴

紋針、硬幣、鑰匙、釘子、螺絲或其他小金屬物

體,以防一端與另一端連接。電池接點短路會引

起燃燒或火災。

u 在誤用的情況下,液體會從電池中濺出;請避免

接觸。 如果意外接觸,應立刻用水沖洗。 如果液

體碰到了眼睛,務必就醫。從電池中濺出的液體

會發生腐蝕或燃燒。

檢修

u 將您的電動工具送交專業維修人員,必須使用同

樣的備件進行更換。這樣將確保所維修的電動工

具的安全性。

1 609 92A 5RK | (07.10.2020) Bosch Power Tools

Page 27

針對角磨機的安全規章

研磨、砂磨、鋼絲刷或砂輪切割作業的一般安全警 告

u 本電動工具可作為砂輪機、砂磨機、鋼絲刷或切

割工具。請詳讀電動工具隨附的所有安全警告、

指示、插圖以及規格等資料。若不遵照以下列出

的指示,將可能導致電擊、著火和/或人員重

傷。

u 不建議以此電動工具進行諸如打蠟等項作業。使

用本電動工具進行非設計用途的作業將產生危險

並導致人員受傷。

u 請勿使用非針對本工具設計的配件或非工具製造

商建議使用的配件。即使該配件可安裝至電動工

具上,並不代表可以安全地操作電動工具。

u 配件的額定速率必須至少等於電動工具上所標示

的最大速率。配件的運轉速度若高於其額定速

率,可能會造成其破損並解體。

u 配件的外徑及厚度必須在電動工具的額定功率範

圍內。規格不正確的配件無法讓防護機制發揮應

有功能,或者可能失控。

u 配件的螺紋部位必須符合砂輪機的主軸螺紋。如

果是利用凸緣安裝的配件,則配件的軸孔必須符

合凸緣位置的直徑。配件若無法完全符合電動工

具的安裝硬體,那麼運轉時將造成失衡、震動幅

度過大,甚至造成失控。

u 不可使用已受損的配件。每次使用前請檢查配

件,確認研磨砂輪片是否有缺口和裂縫、托盤是

否有裂縫、撕裂或過度磨損的現象、鋼絲刷是否

發生鬆脫或鋼絲缺損的狀況。電動工具或配件萬

一掉落,請檢查是否受損或直接換裝完好的配

件。檢查並安裝好配件之後,請您與旁觀者遠離

配件的旋轉平面,接著讓電動工具以最高空載速

度,持續運轉一分鐘。配件若有受損,通常會在

此測試期間分解。

u 請穿戴個人防護裝備。根據實際操作狀況,使用

面罩、安全護目鏡或防護眼鏡。在適當情況下,

請戴上防塵面罩、聽力防護裝置、手套以及可防

止細小磨料或工件碎片的工作圍裙。護目裝置必

須能有效阻擋各種操作中所產生的噴飛碎屑。防

塵面罩或口罩必須能過濾操作中所產生的粉塵。

暴露在高分貝噪音中過久,會造成聽力受損。

u 請旁觀者與工作區保持安全距離。進入工作區的

所有人員都必須穿戴個人防護裝備。工件碎片或

破損的配件可能會四處噴飛,造成作業區範圍以

外的附近人員受傷。

u 進行作業時,負責進行切割的配件可能會碰觸到

隱藏的配線,請務必從絕緣握把處拿持電動工

具。負責進行切割的配件若是觸及「導電」電

線,可能導致電動工具外露的金屬部件「導

電」,進而使操作人員遭受電擊。

u 在配件完全靜止之前,請勿放下電動工具。旋轉

中的配件可能會扣住放置表面,電動工具因為被

拉扯而失控。

u 當您將電動工具握在身體側邊時,請勿讓它運

轉。萬一不小心碰觸到旋轉中的配件,衣物可能

會被撕裂並將配件導向自己的身體。

繁體中文 | 27

u 請定期清理電動工具的通風口。馬達風扇會將粉

塵捲入機殼內,累積過多的金屬粉塵可能危及電

氣安全。

u 請勿在易燃材料旁操作本電動工具。火花可能引

燃這些易燃物。

u 請勿使用需要冷卻液的配件。使用水或其他冷卻

液可能導致觸電或電擊事件。

反彈與相關警告

反彈是旋轉中之砂輪、底盤、鐵刷或任何其他配件

卡住或斷裂時瞬間產生的反作用力。旋轉中的配件

發生卡住或斷裂時會突然停止轉動,這將從連接位

置造成電動工具失控並以配件旋轉相反的方向運

轉。

舉例來說,工件如果造成研磨砂輪片斷裂或卡住,

已推入卡住位置的砂輪邊緣可能會鑽進材料表面

裡,而使砂輪脫出或反彈。依據砂輪卡住時的移動

方向,它有可能彈向或跳離操作人員。在上述情況

下,研磨砂輪片亦可能斷裂。

反彈是不當使用電動工具及/或操作程序(條件)

不正確所造成的結果。採取以下適當預防措施,則

可避免此一情況。

u 緊緊握好電動工具,並穩住您的雙臂和身體,以

抵抗反彈力道。 務必使用輔助握把(若有配

備),以求有效掌控啟動時的反彈或扭力。操作

人員只要採取適當防護措施,即可控制扭矩的反

作用力以及反彈力道。

u 雙手請勿靠近旋轉中的配件。配件可能會反彈並

擊中您的手。

u 請勿將身體任何部件放置在發生反彈時電動工具

位移的範圍之內。斷裂時,反彈力道會將本工具

推往砂輪移動的相反方向。

u 處理尖角、銳利邊緣等物時,請穿戴特殊的防護

裝備,防範配件彈跳和斷裂。尖角、銳利邊緣或

彈跳力道往往會扯斷旋轉中的配件,並造成工具

失控或反彈。

u 請勿加裝鏈鋸型木雕鋸片或鋸齒型鋸片。此類刀

片會產生規律性反彈,進而導致本工具失控。

研磨及研磨切割操作的安全警告

u 僅可使用電動工具建議的砂輪類型,以及專為選

用之砂輪而設計的特定防護套。使用非專為電動

工具設計的砂輪,防護機制將無法發揮應有功

能,亦無法確保安全。

u 中心凹陷的砂輪其研磨表面必須安裝在防護套緣

的下方。如果安裝不當而導致砂輪突出於防護套

緣時,將無法提供應有的保護。

u 防護套須確實固定於電動工具上,且位於最安全

位置,以確保砂輪只有最小部分外露於操作人員

面前。防護套可保護操作人員,以免被已損壞之

砂輪的碎片擊傷、意外碰觸砂輪,或是被火花引

燃衣物的危險。

u 砂輪僅可用於建議用途。例如:勿以切割砂輪的

兩側進行研磨。切割砂輪係專為周邊研磨而設

計。對砂輪側面施力,可能會使其解體。

u 所使用的砂輪凸緣必須完好無損並符合選用之砂

輪的規格及形狀。合適的砂輪凸緣可支撐砂輪,

Bosch Power Tools 1 609 92A 5RK | (07.10.2020)

Page 28

28 | 繁體中文

進而降低砂輪破裂的風險。切割砂輪的凸緣可能

與研磨砂輪的凸緣不同。

u 請勿使用大型電動工具磨耗後的砂輪。大型電動

工具使用的砂輪並不適合用於高速運轉的小型工

具,可能會造成砂輪碎裂。

研磨切割作業的其他安全警告

u 切割砂輪不可「卡死」或對其施力過大。 不可作

太深的切割。對砂輪施力過大時會增加負載,容

易造成切割時砂輪扭曲變形或卡死不動,並且增

加發生反彈或砂輪破損的可能性。

u 您所處的位置不可與旋轉中的砂輪呈一直線,亦

不可站在其後。砂輪運轉時其方向若是轉離您的

身體,萬一發生反彈時,會將旋轉中的砂輪與電

動工具直接推向您。

u 當砂輪因任何原因卡死不動或中斷切割時,請關

閉本電動工具,然後握住它不要移動,直至砂輪

完全停止轉動。 請勿嘗試在切割砂輪仍運轉時將

它移出切口,否則可能引發反彈。瞭解情況並採

取更正措施,以消除砂輪卡死的原因。

u 請勿於工件內部重新開始切割作業。 請讓砂輪全

速轉動,並小心重新進入切口。若是在工件內部

重新開始運轉電動工具,砂輪可能會卡死不動、

往上滑移或發生反彈。

u 支撐控制板或超大尺寸的工件可降低砂輪卡住及

發生反彈的風險。大型工件可能因其本身的重量

而下垂。必須在工件下方、靠近切割線及靠近工

件邊緣的砂輪兩側加以支撐。

u 在牆面上或其他盲蔽區域進行開孔切割時,請格

外小心。突出的砂輪可能會切斷瓦斯管或水管、

電線或任何物件,繼而造成反彈。

砂磨作業的安全警告

u 所使用的砂紙尺寸不得超出原本尺寸過多。 選用

砂紙時,請遵循製造商建議。砂紙若超出砂紙碟

的尺寸,則存在撕裂風險,並且可能造成磨片斷

裂、撕裂或發生反彈。

鋼絲刷磨作業的安全警告

u 即使是執行一般作業,也請小心刷子可能會甩出

鋼絲。 刷子超載時請勿對鐵刷施力過大。鋼絲可

以輕易的刺穿輕薄衣物和/或皮膚。

u 建議您在鋼絲刷磨時應使用防護套,但需注意不

得因防護套而干擾鋼絲輪或鐵刷的運作。鋼絲輪

或鐵刷使用一段時間後,並在離心力的影響之