Bosch GTS1041A Operating/safety Instructions Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de sécurité/d’utilisation

Instrucciones de funcionamiento y seguridad

GTS1041A

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informa-

tions et les adresses de nos

centres de

service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version Version française Versión en español

See page 2 Voir page 49 Ver la página 97

1

1600A009XC 09-15.indb 1 9/14/15 1:51 PM

General Safety Rules

READ ALL INSTRUCTIONS. Failure to follow the safety rules listed below and

other basic safety precautions may result in serious personal injury.

Work Area

KEEP CHILDREN AWAY. Do not let visitors con-

tact tool or extension cord. All visitors should be

kept away from work area.

KEEP WORK AREAS CLEAN. Cluttered areas

and benches invite accidents.

MAKE WORKSHOP CHILD-PROOF with padlocks and master switches.

AVOID DANGEROUS ENVIRONMENTS. Don’t

use power tools in damp or wet locations. Keep

work area well lit. Do not expose power tools to

rain. Do not use tool in presence of flammable

liquids or gases.

Personal Safety

KNOW YOUR POWER TOOL. Read the owner’s

manual and labels affixed to the tool. Learn its

application and limitations as well as the specific

potential hazards particular to this tool.

DON’T OVERREACH. Keep proper footing and

balance at all times.

STAY ALERT. Watch what you are doing. Use

common sense. Do not operate tool when you

are tired. Do not operate while under medication

or while using alcohol or other drug.

DRESS PROPERLY. Do not wear loose clothing

or jewelry. They can be caught in moving parts.

Rubber gloves and non-skid footwear are recommended when working outdoors. Wear protective

hair covering to contain long hair.

USE SAFETY GOGGLES. Also face or dust

mask if cutting operation is dusty, and ear plugs

during extended periods of operation.

GUARD AGAINST ELECTRIC SHOCK. Prevent

body contact with grounded surfaces. For example: pipes, radiators, ranges, refrigerator enclosures.

DISCONNECT TOOL FROM POWER SOURCE.

When not in use, before servicing, when changing blades, bits, cutters, etc.

KEEP GUARDS IN PLACE. In working order,

and in proper adjustment and alignment.

REMOVE ADJUSTING KEYS AND WRENCHES. When not in use, before servicing, when

changing blades, bits, cutters, etc.

AVOID ACCIDENTAL STARTING. Make sure the

switch is in the “OFF” position before plugging in

tool.

NEVER STAND ON TOOL OR ITS STAND. Seri-

ous injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted. Do not

store materials on or near the tool such that it

is necessary to stand on the tool or its stand to

reach them.

CHECK FOR DAMAGED PARTS. Before further

use of the tool, a guard or other part that is damaged should be carefully checked to ensure that

it will operate properly and perform its intended

function. Check for alignment of moving parts,

mounting and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly replaced.

All repairs, electrical or mechanical, should

be attempted only by trained repairmen. Con-

tact the nearest Bosch Factory Service Center,

Authorized Service Station or other competent

repair service.

Use only Bosch replacement parts. Others

may create a hazard.

Use only accessories that are recommended

by the manufacturer for your model. Accesso-

ries that may be suitable for one tool, may become hazardous when used on another tool.

Tool Use

DON’T FORCE TOOL. It will do the job better and

safer at the rate for which it was designed.

USE THE RIGHT TOOL. Don’t force small tool

or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended — for example; don’t use circular saw for cutting tree limbs

or logs.

SECURE WORK. Use clamps or a vise to hold

work. It’s safer than using your hand and it frees

both hands to operate the tool.

USE PROPER DIRECTION OF FEED. Feed

work into a blade or cutter against the direction of

rotation of the blade or cutter only.

NEVER LEAVE TOOL RUNNING UNATTENDED. Turn the power off. Don’t leave tool until it

comes to a complete stop.

Tool Care

DO NOT ALTER OR MISUSE TOOL. These tools

are precision built. Any alteration or modification

not specified is misuse and may result in dangerous conditions.

SAVE THESE INSTRUCTIONS

2

1600A009XC 09-15.indb 2 9/14/15 1:51 PM

General Safety Rules

READ ALL INSTRUCTIONS. Failure to follow the safety rules listed below and

other basic safety precautions may result in serious personal injury.

AVOID GASEOUS AREAS. Do not operate electric tools in gaseous or explosive atmospheres.

Motors in these tools normally spark, and may

result in a dangerous condition.

MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for better and safer performance.

Follow instructions for lubricating and changing

accessories. Inspect tool cords periodically and

if damaged, have repaired by authorized service

facility. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and

free from oil and grease. Keep saw dust from

building up to the horizontal cast stop wall in the

under table blade cover. See Maintenance section for more information.

Before connecting the tool to a power source

(receptacle, outlet, etc.), be sure voltage supplied is the same as that specified on the

nameplate of the tool. A power source with volt-

age greater than that specified for the tool can

result in serious injury to the user — as well as

damage to the tool. If in doubt, DO NOT PLUG IN

THE TOOL. Using a power source with voltage

less than the nameplate rating is harmful to the

motor.

For your own safety, do not operate your table

saw until it is completely assembled and installed according to the instructions.

ENSURE STABILITY OF SAW. Your table saw

MUST BE BOLTED securely to a stand or workbench. In addition, if there is any tendency for the

table saw to tip over or move during certain operations such as cutting long, heavy boards, use

an auxiliary support.

SELECT A PROPER WORKING LOCATION.

Use the table saw in a well lit area and on a level

surface, clean and smooth enough to reduce the

risk of trips and falls. Use it where neither the operator nor the casual observer is forced to stand

inline with the blade.

Kickback and related warnings

Kickbacks can cause serious injury: A “KICKBACK” occurs when a part of the work piece

binds between the saw blade and the rip fence

or other fixed object. A work piece binding in the

blade due to misalignment, can also cause kickback. During kickback, the work piece can rise

from table and be thrown toward the operator.

Keep your face and body to one side of the saw

blade, and out of line with the saw blade.

KICKBACKS AND POSSIBLE INJURY CAN

USUALLY BE AVOIDED BY:

a. Maintaining the rip fence parallel to the saw

blade.

b. Keeping the saw blade sharp and ensuring

there are no broken teeth. Replacing or sharpening anti-kickback pawls when points become

dull.

c. Keeping saw blade guard, riving knife and anti-

kickback pawls in place and operating properly.

The riving knife must be in alignment with the

saw blade and the pawls must stop a kickback

once it has started. Check their action before

ripping.

d. NOT ripping a work piece that is twisted or

warped or does not have a straight edge to

guide along the rip fence.

e. NOT releasing work until you have pushed it all

the way past the saw blade.

f. Using a Push Stick for ripping widths of 2” to 6”

and an auxiliary fence and Push Block for ripping widths narrower than 2” (See “Basic Saw

Operation, Using The Rip Fence” section, page

34).

g. NOT confining the cut-off piece when ripping or

cross cutting.

h. When ripping, apply the feed force to the sec-

tion of the work piece between the saw blade

and the rip fence. Use Push Stick or Push

Block when appropriate (See item f. above).

i. Feeding material at a rate that does not tax the

saw motor.

j. Using featherboards whenever possible.

k. Immediately stopping the cutting process when

resistance beyond that of normal cutting is encountered.

l. Never cutting without the use of the rip fence or

miter gauge.

SAVE THESE INSTRUCTIONS

3

1600A009XC 09-15.indb 3 9/14/15 1:51 PM

Additional Safety Warnings

READ ALL INSTRUCTIONS. Failure to follow the safety rules listed below and

other basic safety precautions may result in serious personal injury.

PROTECTION:

Eyes, hands, face, ears and body.

TO AVOID BEING PULLED INTO THE SPINNING TOOL, DO NOT WEAR:

• LOOSEFITTINGGLOVES

• LOOSECLOTHING

• NECKTIE,JEWELRY

DO:

• TIEBACKLONGHAIR

• ROLLLONGSLEEVESABOVEELBOWS

a. If any part of your saw is missing, malfunction-

ing, has been damaged or broken, such as the

motor switch, or other operating control, a safety device or the power cord cease operating

immediately until the particular part is properly

repaired or replaced.

b. The injury mitigation system requires contact

with the operator’s body in order to react. This

will cause some injury to be sustained if the

contact occurs. The best defense against injury remains the knowledge of how to safely

operate the saw contained within this manual

and the operator’s attention to the cutting operation underway.

c. Be aware of the status indicator lights. Do not

use the tool unless you understand it is safe to

use.

d. Wear safety goggles and a face shield if op-

eration is dusty. Wear ear plugs or muffs during extended periods of operation. Small loose

pieces of wood or other objects that contact

the rear of the rotating blade can be thrown

back at the operator at excessive speed. This

can usually be avoided by keeping the guard

and riving knife in place for all “THROUGHCUTTING” operations (cutting entirely through

the work) AND by removing all loose pieces

from the table with a long stick of wood IMMEDIATELY after they are cutoff.

e. Use extra caution when the guard assembly is

removed for cutting, dadoing or rabbeting —

replace the guard as soon as that operation is

completed.

f. NEVER turn the saw “ON” before clearing the

table of all tools, wood scraps, etc., except the

SAVE THESE INSTRUCTIONS

work piece and related feed or support devices

for the operation planned.

g. NEVER place your face or body in line with the

cutting tool.

• NEVER place your fingers andhands inthe

path of the saw blade or other cutting tool.

Keep your fingers and hands at least 4 inches

away from the blade or other cutting tool.

• NEVER reachin back of the cutting tool with

either hand to hold down or support the work

piece, remove wood scraps, or for any other

reason. Avoid awkward operations and hand

positions where sudden slip could cause fingers or hand to move into a saw blade or other

cutting tool. Even with the injury mitigation system engaged, these actions can lead to your

hand or arms being forced into the blade at

high speeds. A significant injury is likely under

these conditions.

• DONOTperformanyoperation“FREEHAND”

— always use either the rip fence or the miter

gauge to position and guide the work.

• NEVERusetheripfencewhencrosscuttingor

the miter gauge when ripping. DO NOT use the

rip fence as a length stop.

• NEVERholdontoortouchthe“freeend”ofthe

work piece or a “free piece” that is cut off, while

power is “ON” and/or the saw blade is rotating.

• Shut“OFF”thesawanddisconnectthepower

cord when removing the table insert, changing the cutting tool, removing or replacing the

blade guard, resetting the safety system or

making adjustments.

• Provideadequatesupporttotherearandsides

of the saw table for wider or long work pieces.

• Plasticandcomposition(likehardboard)materials may be cut on your saw. However, since

these are usually quite hard and slippery, the

anti-kickback pawls may not stop a kick back.

Therefore, be especially attentive to following

proper set-up and cutting procedures for ripping. Do not stand, or permit anyone else to

stand, in line with a potential kickback.

h. If you stall or jam the saw blade in the work

piece, turn saw “OFF”, remove the work piece

from the saw blade, and check to see if the saw

4

1600A009XC 09-15.indb 4 9/14/15 1:51 PM

blade is parallel to the table slots or grooves

and if the riving knife is in proper alignment

with the saw blade. If ripping at the time, check

to see if rip fence is parallel with the saw blade.

Readjust as indicated.

i. NEVER gang crosscut — lining up more than

one work piece in front of the blade (stacked

vertically, or horizontally outward on the table)

and then pushing through saw blade. The blade

could pick up one or more pieces and cause a

binding or loss of control and possible injury.

j. DO NOT remove small pieces of cut-off mate-

rial that may become trapped inside the blade

guard while the saw is running. This could endanger your hands or cause a kick back. Turn

saw “OFF” and wait until blade stops.

KNOW YOUR CUTTING TOOLS

Dull, gummy or improperly sharpened or set cutting tools can cause material to stick, jam, stall

the saw, or kickback at the operator. Minimize potential injury by proper cutting tool and machine

maintenance. NEVER ATTEMPT TO FREE A

STALLED SAW BLADE WITHOUT FIRST TURNING THE SAW OFF.

a. NEVER use grinding wheels, abrasive cut-off

wheels, friction wheels (metal slitting blades)

wire wheels or buffing and sanding wheels,

molding cutter, wobble or adjustable dado.

b. USE ONLY RECOMMENDED ACCESSO-

RIES.

c. Crosscutting operations are more conveniently

worked and with greater safety if an auxiliary

wood facing is attached to the miter gauge.

(See Page 32).

d. Make sure the top of the cutting tool rotates to-

ward you when standing in normal operating

position. Also make sure the cutting tool, arbor

collars and arbor nut are installed properly.

Keep the cutting tool as low as possible for the

operation being performed. Keep all guards in

place whenever possible.

• Do not use any blade or other cutting tool

marked for an operating speed less than 4800/

min (RPM). Never use a cutting tool larger in

diameter than the diameter for which the saw

was designed. For greatest safety and efficiency when ripping, use the maximum diameter

blade for which the saw is designed, since under these conditions the riving knife is nearest

the blade.

e. Make sure the table insert is flush or slightly

below the table surface on all sides except for

rear side. NEVER operate the saw unless the

proper insert is installed.

THINK SAFETY

SAFETY IS A COMBINATION OF OPERATOR

COMMON SENSE AND ALERTNESS AT ALL

TIMES WHEN THE TABLE SAW IS BEING

USED.

Do not allow familiarity

(gained from frequent use of

your table saw) to become common place. Always remember that a careless fraction of a second is sufficient to inflict severe injury.

The operation of any power tool can result in foreign

objects being thrown into

the eyes, which can result

in severe eye damage. Always wear safety goggles

that comply with ANSI

Z87.1 (shown on package) before commencing

power tool operation.

Do not use a cellular phone

when operating the table saw.

Some dust created by pow-

er sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Leadfromlead-basedpaints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenicandchromiumfromchemicallytreated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

Before each use, review all warnings located

on the table saw.

SAVE THESE INSTRUCTIONS

5

1600A009XC 09-15.indb 5 9/14/15 1:51 PM

Motor Specifications

In the event of a malfunction or breakdown,

grounding provides a path of least resistance

for electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into

a matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. This saw is wired for operation on

110-120 volts, 60 Hz. alternating current. Before

connecting the motor cord to power source, make

certain the switch is in the “OFF” position and be

sure the electric current is of the same characteristics as stamped on the table saw nameplate.

Connection To A Power Source

This machine must be grounded while in use to

protect the operator from electric shock.

Plug power cord into a 110-120V properly grounded type outlet protected by a 15-amp dual element time delay fuse or circuit breaker.

Not all outlets are properly grounded. If you are

not sure that your outlet, as pictured on this page,

is properly grounded; have it checked by a qualified electrician.

To avoid electric shock, do not

touch the metal prongs on the

plug when installing or removing the plug to or

from the outlet.

Failure to properly ground this

power tool can cause electrocution or serious shock, particularly when used

near metal plumbing or other metal objects. If

shocked, your reaction could cause your hands

to hit the tool.

If power cord is worn, cut or

damaged in any way, have it

replaced immediately to avoid shock or fire hazard.

Your unit is for use on 120

volts and is equipped with a

3-conductor cord and

grounding type plug, approved by Underwriters

Laboratories and the Canadian Standards Association.

The ground conductor has a

green jacket and is attached to the tool housing at

one end and to the ground prong in the attachment plug at the other end.

If the outlet you are planning to use for this power

tool is of the two-prong type, DO NOT REMOVE

OR ALTER THE GROUNDING PRONG IN ANY

MANNER. Have a qualified electrician replace

the TWO-prong outlet with a properly grounded

THREE-prong outlet. Do not use any adapter

plugs.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor with insulation having an outer

surface that is green with or without yellow stripes

is the equipment grounding conductor. If repair or

replacement of the electric cord or plug is necessary, do not connect the equipment grounding

conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether

the tool is properly grounded.

Extension Cords

Replace damaged cords im-

cords can shock, burn or electrocute.

extension cords which have 3-prong grounding type plugs and 3-pole receptacles which

accept the tool’s plug. If an extension cord is

necessary, a cord with adequate size conductors

should be used to prevent excessive voltage

drop, loss of power or overheating. The table

shows the correct size to use, depending on cord

length and nameplate amperage rating of tool. If

in doubt, use the next heavier gauge. Always use

U.L. and CSA listed extension cords.

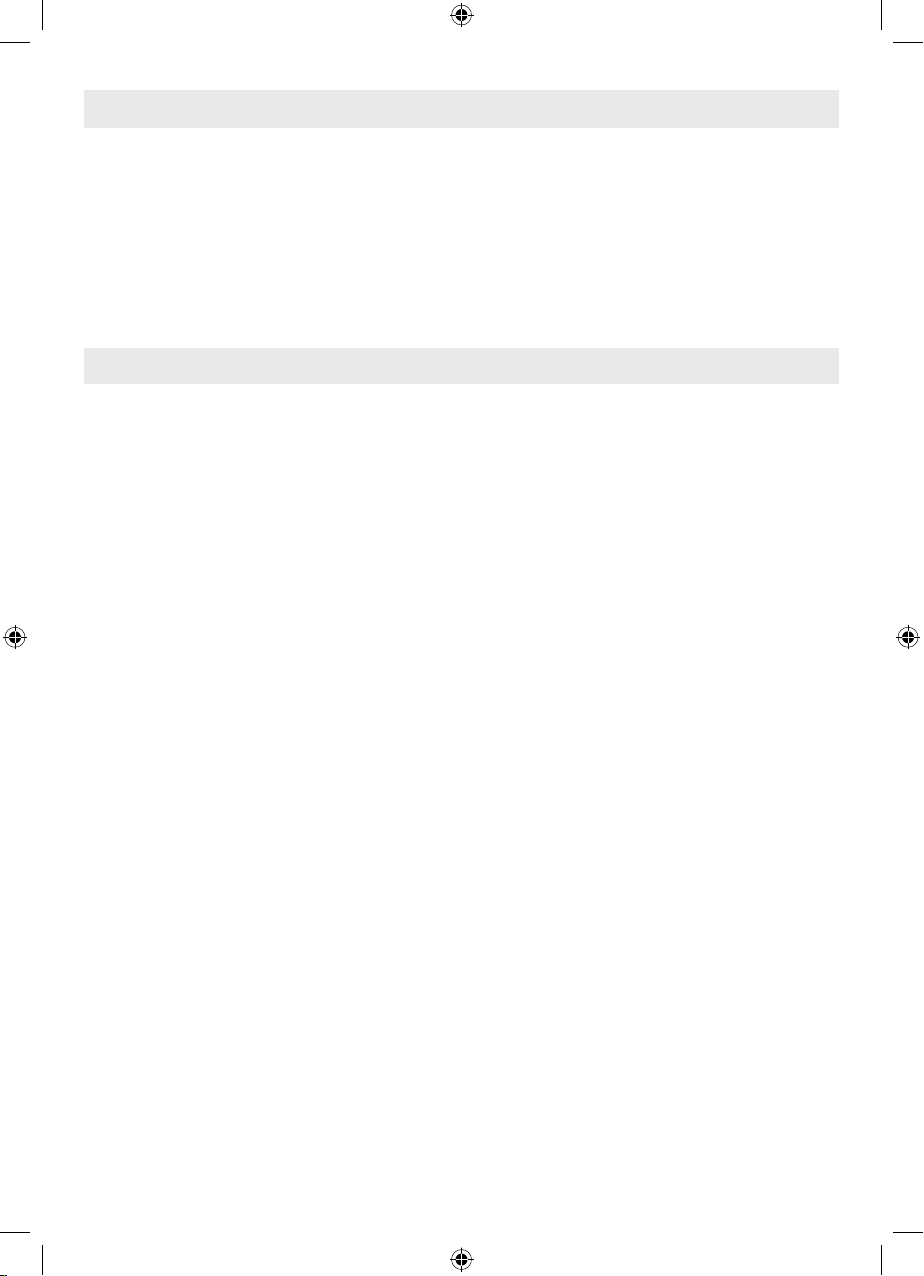

RECOMMENDED SIZES OF EXTENSION

CORDS 120 VOLT ALTERNATING CURRENT

TOOLS

Tool’s

Ampere

Rating

3-6 18 16 16 14 0.75 0.75 1.5 2.5

6-8 18 16 14 12 0.75 1.0 2.5 4.0

8-10 18 16 14 12 0.75 1.0 2.5 4.0

10-12 16 16 14 12 1.0 2.5 4.0 —

12-16 14 12 — — — — — —

NOTE: The smaller the gauge number, the heavier the cord.

mediately. Use of damaged

Always use proper extension cord. Use only 3-wire

Cord Size in A.W.G. Wire Sizes in mm

Cord length in feet Cord length in Meters

25 50 100 150 15 30 60 120

2

SAVE THESE INSTRUCTIONS

6

1600A009XC 09-15.indb 6 9/14/15 1:51 PM

Table of Contents

General Safety Rules....................................2

Additional Safety Warnings ........................... 4

Glossary of Terms ......................................... 7

Tools Needed for Assembly .......................... 8

Getting to Know Your Table Saw ................... 9

Unpacking And Checking Contents .............. 12

Assembly ...................................................... 13

Glossary of Terms

ANTI-KICKBACK PAWLS

Spring-loaded “fingers” that engage the work

piece as it is being fed through the saw. They

restrict movement of the work piece back in the

direction of the operator.

ARBOR

The shaft on which a cutting tool is mounted.

ACTIVE RESPONSE TECHNOLOGY™ INJURY

MITIGATION SYSTEM

The system capable of detecting contact between a human and the saw’s blade, which then

pushes the blade under the table preventing a

more severe injury.

BARRIER GUARD

An assembly that consists of the mounting fork

and two side barriers. This assembly is intended

to provide a physical barrier between the operator and the spinning saw blade.

BEVEL

Blade angle relative to the table surface.

BOSCH TOOLBOX APP

Smart phone application used in conjunction with

NFC to interact with the Active Response Technology™ System

BYPASS SWITCH

The control that allows the saw user to disable

the Active Response Technology™ injury mitigation system for a single cycle of the power switch.

CROSSCUT

A cutting or shaping operation made across the

width of the work piece cutting the work piece to

length.

DADO

A non-through cut which produces a square sided notch or trough in the work piece.

Setting / Resetting the Active Response

Technology™ system .................................... 13

Adjustments .................................................. 19

Basic Table Saw Operation ........................... 25

Maintaining your Table Saw .......................... 41

Accessories .................................................. 43

Troubleshooting ............................................ 44

ELECTRICALLY CONDUCTIVE MATERIALS

Materials that permit the flow of electrical current.

Metals such as steel, aluminum, and copper are

examples of electrically conductive materials.

FEATHERBOARD

A device which can help guide work pieces during rip type operation by keeping work piece in

contact with the rip fence. It also helps prevent

kickback.

FREEHAND

Performing a cut without a fence, miter gauge, fixture, hold down or other proper device to keep the

work piece from twisting during the cut and can

be a safety hazard.

GUM

A sticky, sap-based residue from wood products.

After it has hardened, it is referred to as “RESIN”.

HEEL

Misalignment of the blade which causes the trailing or out feed side of the blade to contact the

cut surface of the work piece. Heel can cause

kickback, binding, excessive force, burning of the

work piece or splintering. In general, heel creates

a poor quality cut and can be a safety hazard.

KERF

The space in the work piece where the material

was removed by the blade.

KICKBACK

An uncontrolled grabbing and throwing of the

work piece back toward the front of the saw during a rip type operation.

LEADING END

The end of the work piece which, during a rip

type operation, is pushed into the cutting tool first.

7

1600A009XC 09-15.indb 7 9/14/15 1:51 PM

MOLDING

A non-through cut which produces a special

shape in the work piece used for joining or decoration.

NEAR FIELD COMMUNICATIONS (NFC)

A wireless technology for communicating between enabled devices such as smart phone.

This tool is NFC enabled.

NON THROUGH-CUTTING

Any cutting operation where the blade does not

extend through the work piece (e.g. Dado, Rabbet).

PUSH BLOCK

A device used for ripping-type operations too

narrow to allow use of a Push Stick. Use a Push

Block for rip widths less than 2 inches.

PUSH STICK

A device used to feed the work piece through the

saw during narrow ripping-type operation and

helps keep the operator’s hands well away from

the blade. Use the Push Stick for rip widths less

than 6 inches and more than 2 inches.

RABBET

A notch in the edge of a work piece. Also called

an edge dado.

REVOLUTIONS PER MINUTE (R.P.M.)

The number of turns completed by a spinning object in one minute.

RIPPING

A cutting operation along the length of the work

piece cutting the work piece to width.

RIVING KNIFE OR SPREADER

A device that keeps the kerf of the work piece

open as the material is cut. This minimizes the

potential of the work piece binding against the

saw blade.

SMART GUARD

A system made up of 3 components: Riving Knife

or Spreader, Anti-Kickback Pawls, and Main Barrier Guard.

THROUGH-CUTTING

Any cutting operation where the blade extends

through the workpiece.

WORK PIECE

The item on which the cutting operation is being performed. The surfaces of a work piece are

commonly referred to as faces, ends and edges.

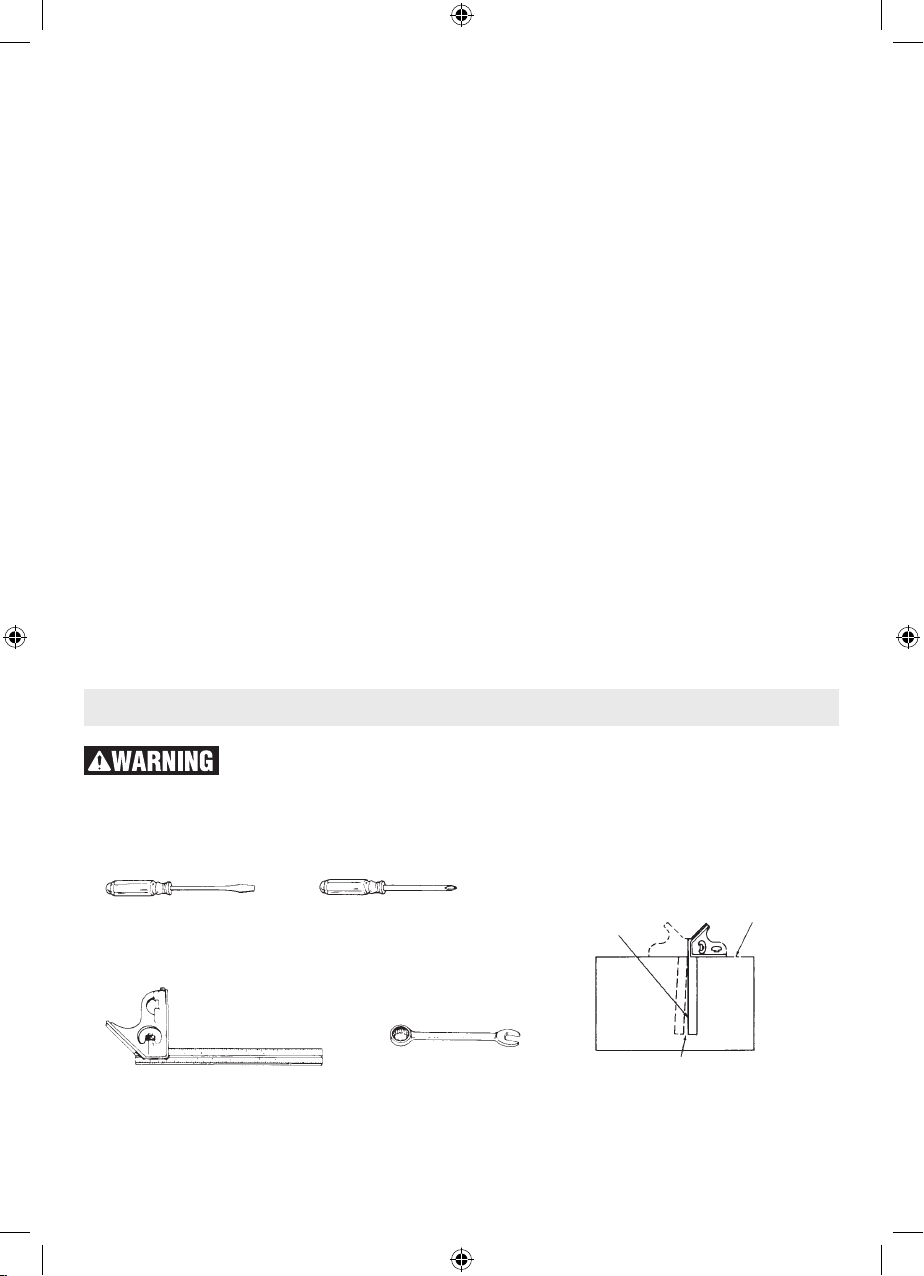

Tools Needed for Assembly

Disconnect plug from power source before performing any assembly,

adjustment or repair to avoid possible injury.

COMBINATION SQUARE MUST BE TRUE

FLAT SCREWDRIVER

COMBINATION SQUARE

1600A009XC 09-15.indb 8 9/14/15 1:51 PM

PHILLIPS SCREWDRIVER

10 MM WRENCH

OR ADJUSTABLE WRENCH

DRAW LIGHT LINE ON

BOARD ALONG THIS EDGE.

SHOULD BE NO GAP OR OVERLAP

HERE WHEN SQUARE IS FLIPPED

OVER IN DOTTED POSITION.

8

STRAIGHT EDGE OF BOARD

3/4” THICK. THIS EDGE

MUST BE PERFECTLY

STRAIGHT.

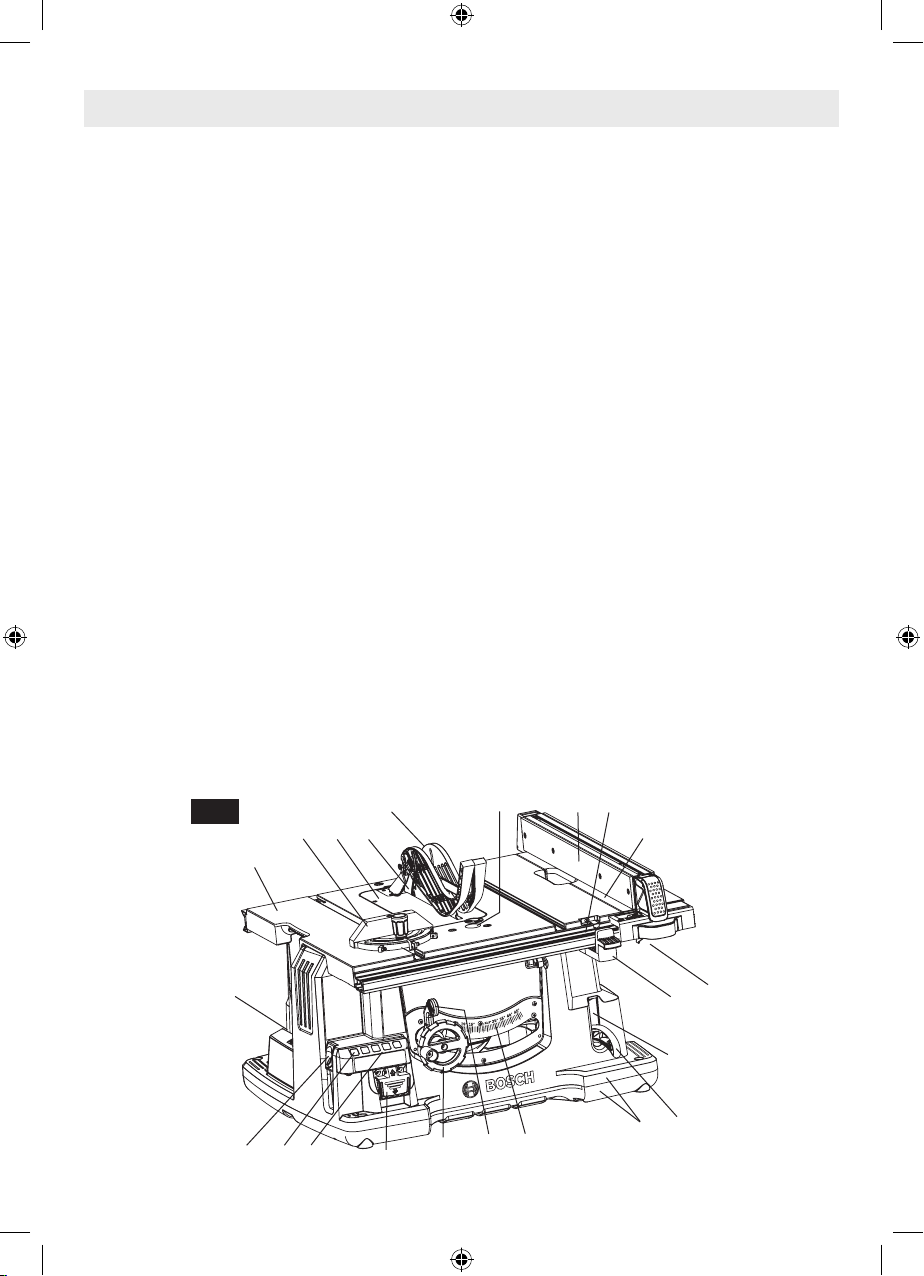

Getting To Know your Table Saw

1. POWER SWITCH

Switch for turning motor on and off. Switch incorporates a hole for use with padlock to prevent

accidental starting.

2. TABLE

Provides large working surface to support work

piece.

3. BASE / SUB-BASE

Supports table saw. Sub-base provides additional

stability and ability for easy sliding onto surfaces.

Holes are provided in base to bolt the saw to a

workbench or stand.

4. BLADE BEVEL LOCK HANDLE

Locks the blade to desired bevel angle.

5. TABLE EXTENSION

Provides a larger work surface for wider work

pieces.

6. TABLE EXTENSION LOCK HANDLE

Allows you to lock the table extension at desired

distances.

7. ELEVATION WHEEL

Elevates or lowers the blade. Also used to tilt the

blade 0 to 45 degrees.

8. BLADE BEVEL SCALE

Shows the degree the blade is tilted.

9. RIP FENCE SCALE

Shows the distance from the blade to rip fence

through a convenient viewing and magnifying

window. Lower portion of scale can be used up to

12.75 inches. Upper portion of scale is used for

cuts beyond 12.75 inches.

10. MITER GAUGE

Head can be locked in desired position for crosscutting or mitering by tightening the lock knob.

ALWAYS SECURELY LOCK IT WHEN IN USE.

11. RIP FENCE STORAGE

Conveniently stores rip fence on bottom of table

when not in use.

12. PRE-CUT (KERF) INDICATOR

Allows you to mark and locate exactly where the

blade will enter the work piece.

13. MITER GAUGE STORAGE

Conveniently stores miter gauge when not in use.

14. BLADE STORAGE & WRENCH

Allows you to store 10” blades, blade wrench

and activation cartridge installation tool. Blade

wrench also has a 10mm hex hole allowing assembly of the Gravity-Rise stand and for use with

dado clamp bolt.

15. HEX WRENCH / PHILLIPS SCREWDRIVER

Hex wrench for adjusting various hex head bolts

on saw. Phillips screwdriver is for assembling the

saw to a Gravity-Rise stand.

16. CORD WRAP

Allows you to easily secure the cord so it’s out of

the way when transporting or storing.

17. VACUUM HOOK-UP

Your table saw is equipped for vacuum hook-up.

This feature will allow you to attach any 2-1/4”

vacuum hose into the dust port provided for convenient saw-dust removal. An adaptor is available

for use with alternate hose sizes.

Fig. 1

13

10 21 35

2

26 27 25

19 12

4 8

7

1

18

9

5

11

6

24

3

23

9

1600A009XC 09-15.indb 9 9/14/15 1:51 PM

18. RIP FENCE

Exclusive Self-Aligning, Squarelock rip fence can

be easily moved or locked in place by simply raising or lowering lock handle.

19. SMART GUARD SYSTEM

Consists of three key elements: Adjustable (3

position) Riving Knife, Anti-Kickback Pawls, and

Barrier Guard Device. All of these are part of a

modular system that requires no tools to assemble or disassemble. This Guard System must

always be in place and working properly for all

through-cutting cuts.

20. SMART GUARD SYSTEM STORAGE

When not in use or for transportation, the Main

Barrier Guard and Anti-Kickback Pawls can be

stored under the right side table extension.

21. TABLE INSERT

Removable for removing or installing blade or

other cutting tools, to adjust or store the riving

knife, and to reset the Active Response Technol-

22. TABLE INSERT LOCK

Rotates to retain or eject the table insert in the

table.

23. PUSH STICK

Allows you to rip smaller pieces of stock with a

greater level of safety.

24. PUSH STICK STORAGE

On tool storage location for the push stick.

25. INFORMATION PANEL

The system of indicator LEDs and the NFC feature that inform the operator about the tool’s current status

26. BYPASS SWITCH

The control that allows the saw user to disable

the Active Response Technology™ injury mitigation system for a single cycle of the power switch.

A hole is provided to padlock this switch so that

only authorized users can disable the Active Response Technology™ system.

ogy™ injury mitigation system.

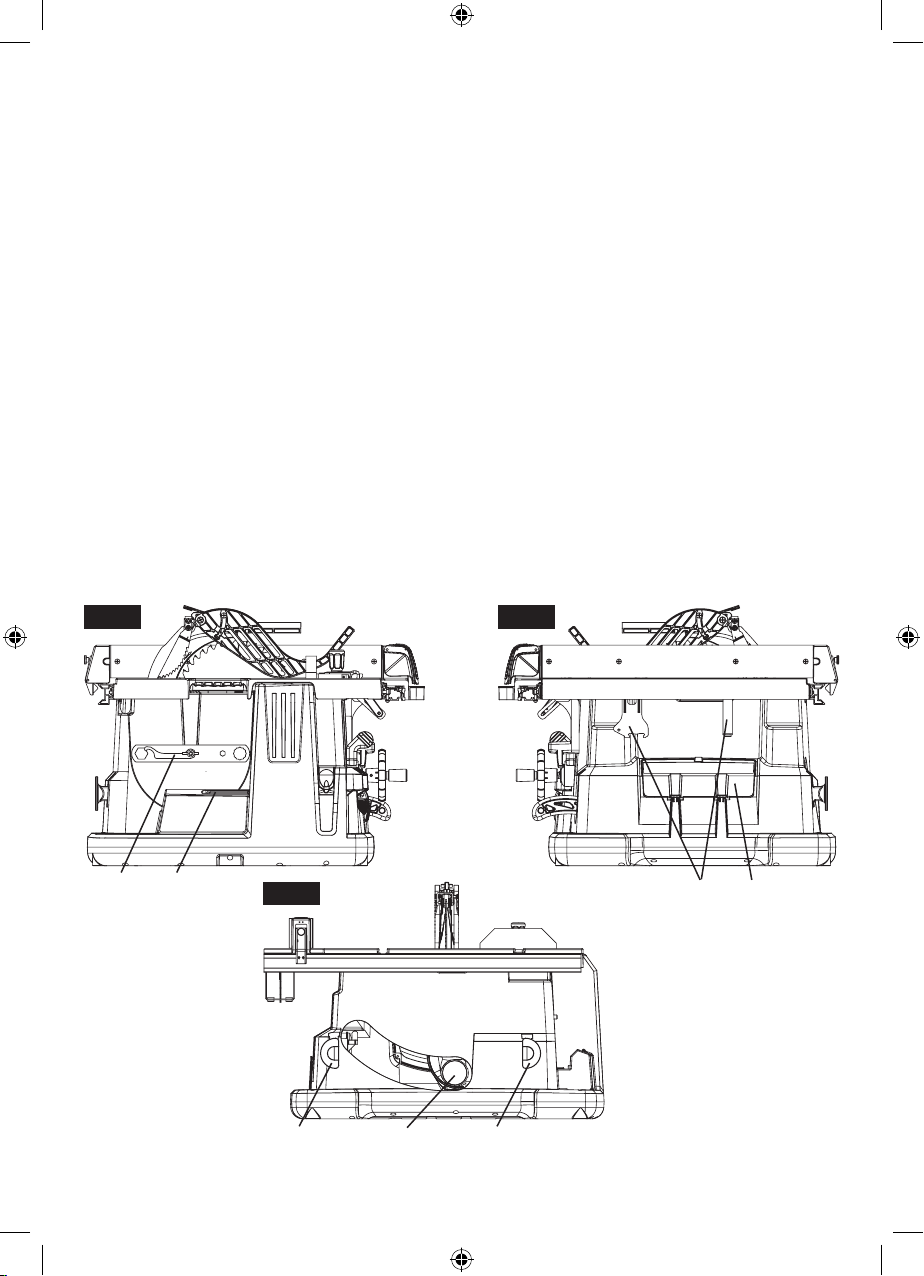

Fig. 2a Fig. 2b

14 15

Fig. 2c

3420

17 1616

10

1600A009XC 09-15.indb 10 9/14/15 1:51 PM

27. NEAR FIELD COMMUNICATION

INTERFACE

Target to place a smart phone with the Bosch

power tools app next to this surface to get a status report about the saw

28. DROP ARM

Moves the blade down and away from the operator after contact between the user and the blade

is detected.

29. ACTIVATION CARTRIDGE

Contains two single shot cylinders each of which

can independently force drop arm to drop below

table surface away from the user. Only one of the

two single shot cylinders is active during operation.

30. LATCH

Ensures the drop arm is held in the proper position for operation. The latch also prevents the

arm returning to the closed position until a new

Activation Cartridge is properly installed

31. DROP ARM LOCK

Ensures the drop arm stays underneath the table

after activation. Release for reset to operating

position.

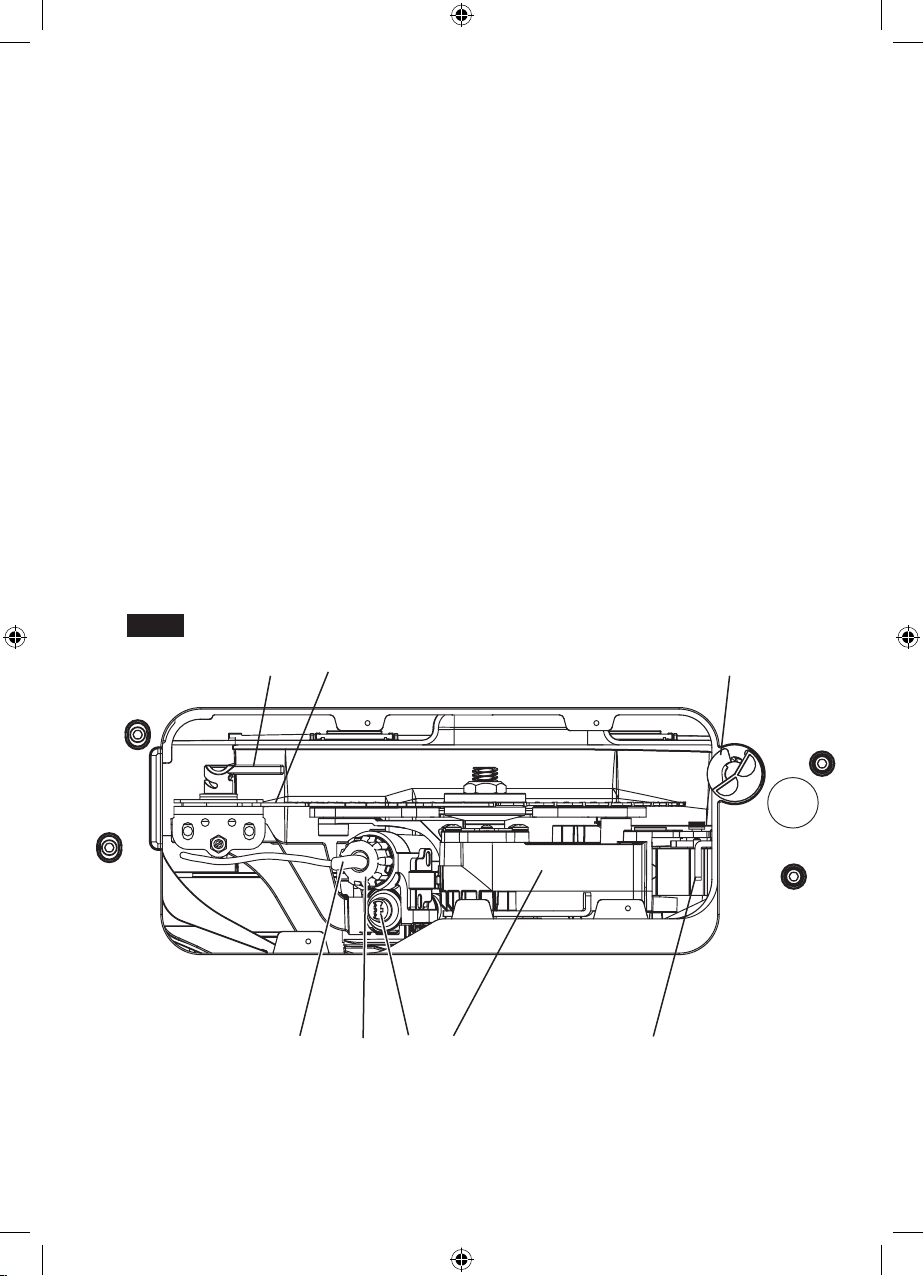

Fig. 2d

32. DETECTION PLATE

Allows the Active Response Technology™ to

measure the blade for signs of user contact with

the saw blade.

33. ACTIVATION CARTRIDGE RETAINER

Holds the Activation Cartridge in place during

operation and activation. It must be installed

properly to latch the drop arm in the operating

position.

34. SIDE STORAGE COMPARTMENT

Holds spare activation cartridges, quick reset instructions, and the manual.

35. RIVING KNIFE OR SPREADER

A device that keeps the kerf of the work piece

open as the material is cut. This minimizes the

potential of the work piece binding against the

saw blade. It is stored under table when not in

use.

36. CARTRIDGE PLUG

Electrical connection that links the saw electronics to the activation cartridge.

37. RIVING KNIFE RELEASE LEVER

Lever that allows for adjustments

35

2237

29 28 313336

11

1600A009XC 09-15.indb 11 9/14/15 1:51 PM

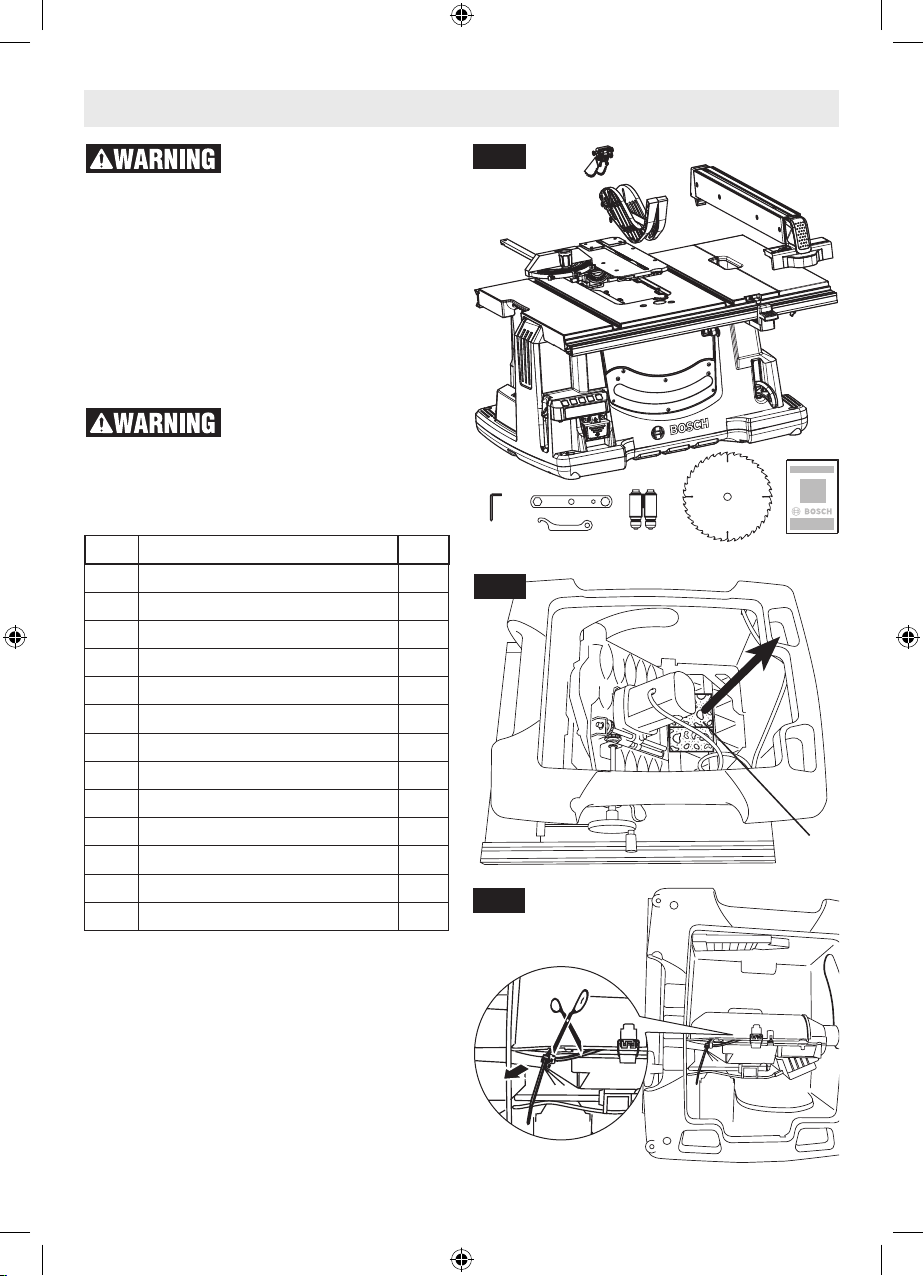

Unpacking And Checking Contents

To avoid injury from unexpected starting or electrical

shock during unpacking and setting up, do not

plug the power cord into a source of power.

This cord must remain unplugged whenever you

are working on the table saw.

Model GTS1041A Table Saw is shipped complete

in one carton.

Separate all parts from packing materials and

check each one with the illustration and the list

of loose parts to make certain all items are accounted for before discarding any packing material

(Fig. 3a).

If any parts are missing, do

not attempt to assemble the

table saw, plug in the power cord or turn the

switch on until the missing parts are obtained

and are installed correctly.

TABLE OF LOOSE PARTS (Fig. 3a)

ITEM DESCRIPTION QTY.

1 Table Saw 1

2 Rip Fence 1

3 Table Insert 1

4 Barrier Guard Assembly 1

5 Anti-Kickback Pawls 1

6 Miter Gauge 1

7 Push Stick 1

8 Activation Cartridge 1

9 Blade, 10”, 40 Tooth 1

10 Blade Wrench 1

11 Activation Cartridge Installation Tool 1

12 Hex Wrench / Philips Screwdriver 1

13 Manual 1

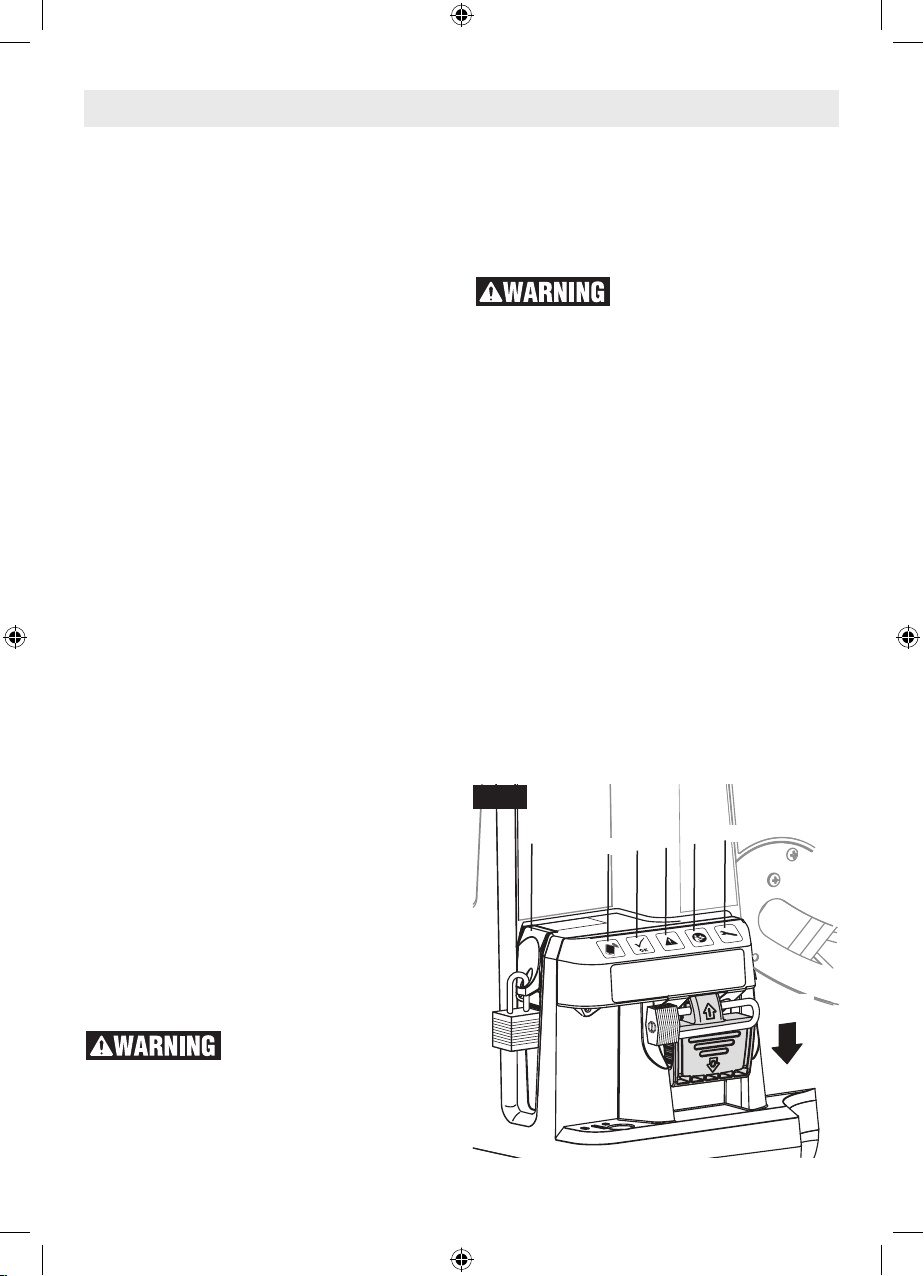

• Remove Styrofoam block A (for shipping pur-

pose only) located between the table and motor

(Fig. 3b). Styrofoam block B (not shown) is located

between the drop arm and throat plate. It needs to

be removed to enable the tool for it’s first use. You

may cause damage to the table saw’s mechanical

systems if the Styrofoam is not removed.

• Cut thecable tie thatholds the drop arm during transportation using scissors or wire cutters as

shown (Fig. 3c). Then pull the cable tie out and

discard.

Fig. 3a

12

Fig. 3b

Fig. 3c

5

4

6

10

3

1

11

8

9

2

7

13

A

12

1600A009XC 09-15.indb 12 9/14/15 1:51 PM

Assembly

SETTING / RESETTING THE ACTIVE

RESPONSE TECHNOLOGY™ INJURY

MITIGATION SYSTEM

To prevent personal injury,

always disconnect the plug

from the power source before making any adjustments.

The Active Response Technology™ system prevents the motor from restarting if the switch is on

when the plug is connected to a power source.

Automatic restart protection helps prevent accidental startups after power has been interrupted,

e.g. the tool was unplugged with the power switch

locked in the ON position. To resume operation,

turn power switch to the OFF position, then restart the tool.

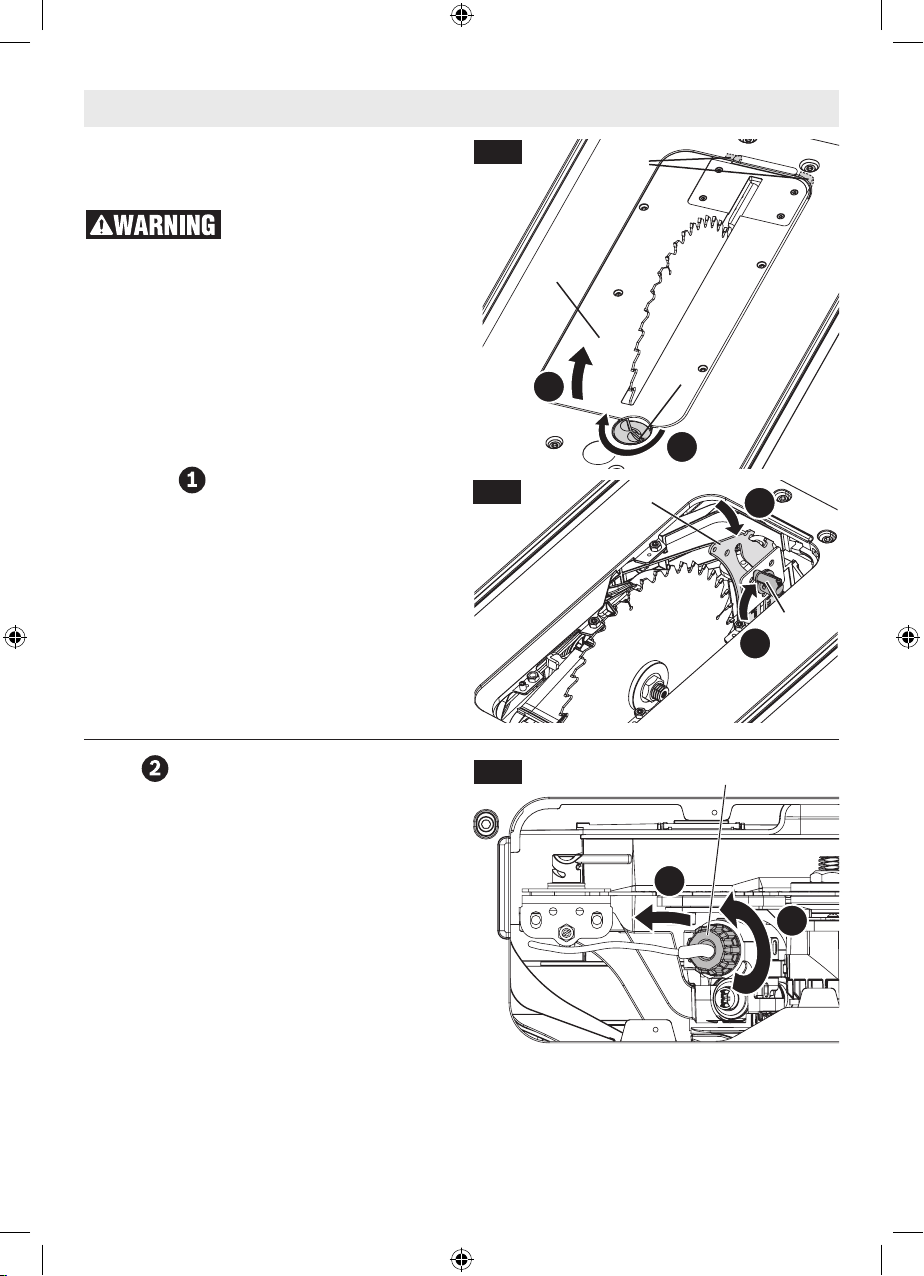

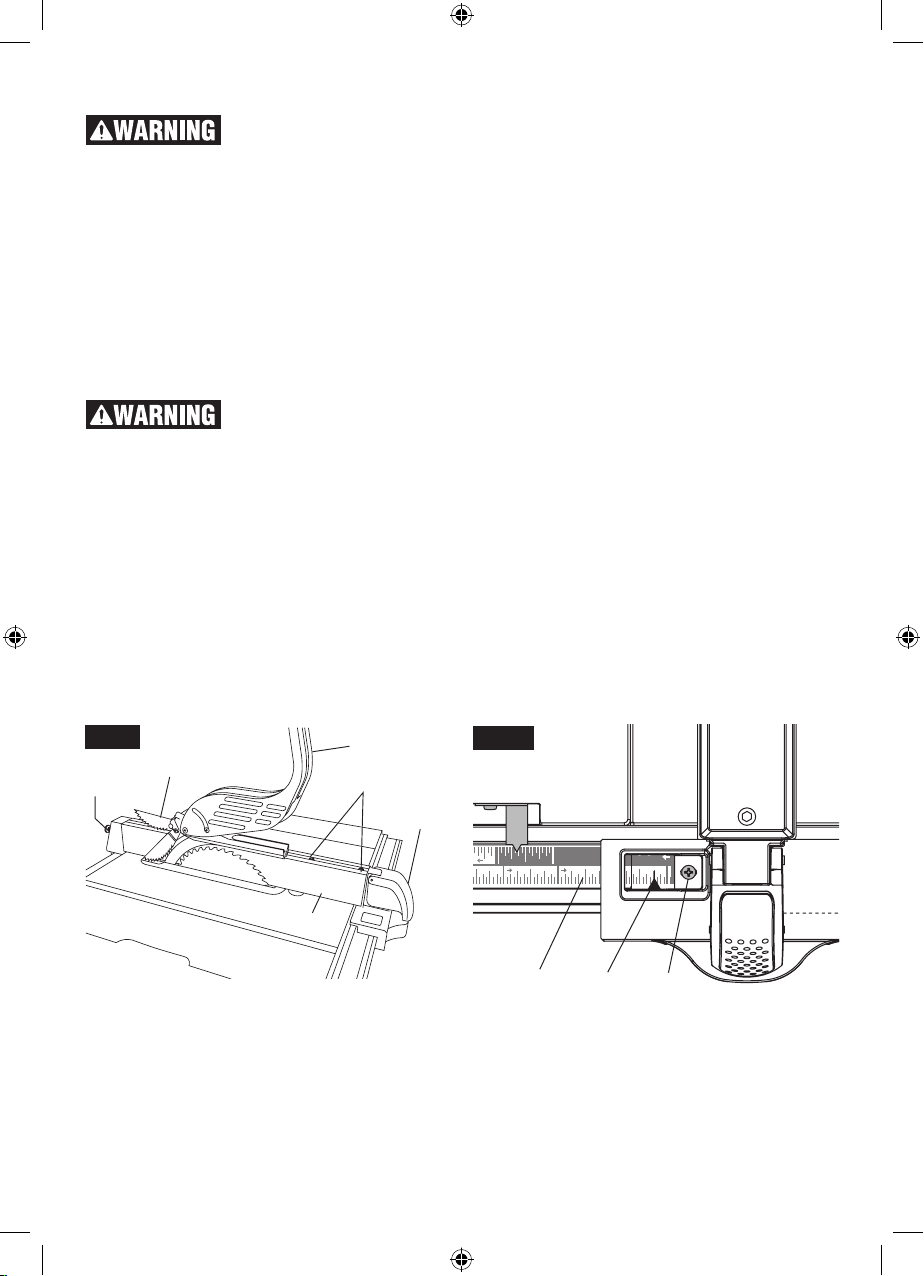

DISASSEMBLE

1. Turn elevation wheel clockwise until the blade

is up as high as it will go, remove any parts of

the Smart Guard system that were in use, then

remove table insert 21 by rotating the table insert lock 22, and use the front edge (Fig. 4) to

lift clear off the table.

2. Ensure the riving knife 35 is set below the top

position. Lower the riving knife by loosening the

riving knife release lever 37 (Fig. 5). For more

information see “POSITIONING THE RIVING

KNIFE” section on page 15.

Fig. 4

Fig. 5

21A

21

B

22

A

35

D

37

C

REPLACE CARTRIDGE

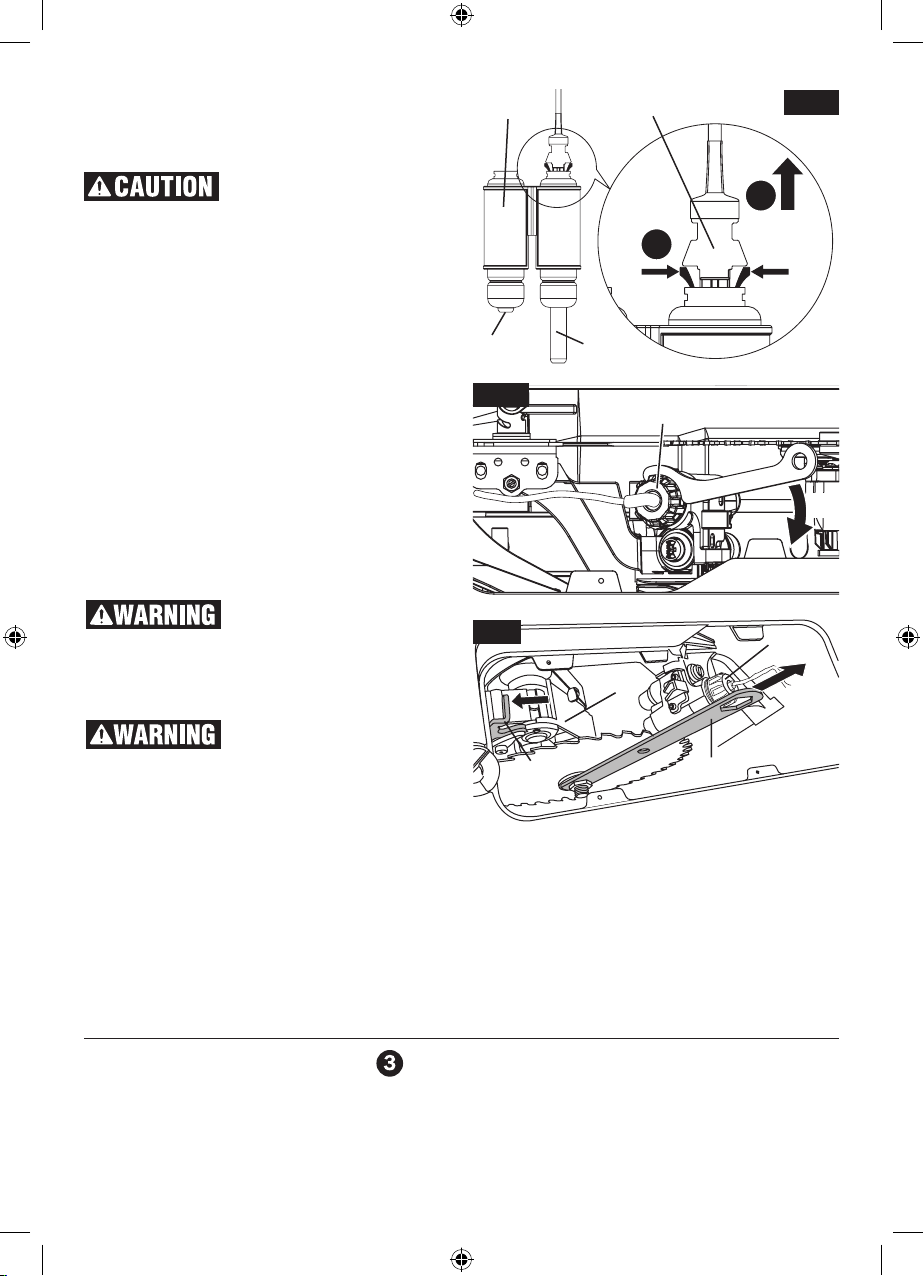

3. Using the activation cartridge installation tool

loosen the activation cartridge retainer 33

counterclockwise then continue to unscrew the

activation cartridge retainer by hand until it is

free on the wire. Slide along the wire to the rear

of the saw near the riving knife (Fig. 6).

Fig. 6

33

F

E

13

1600A009XC 09-15.indb 13 9/14/15 1:51 PM

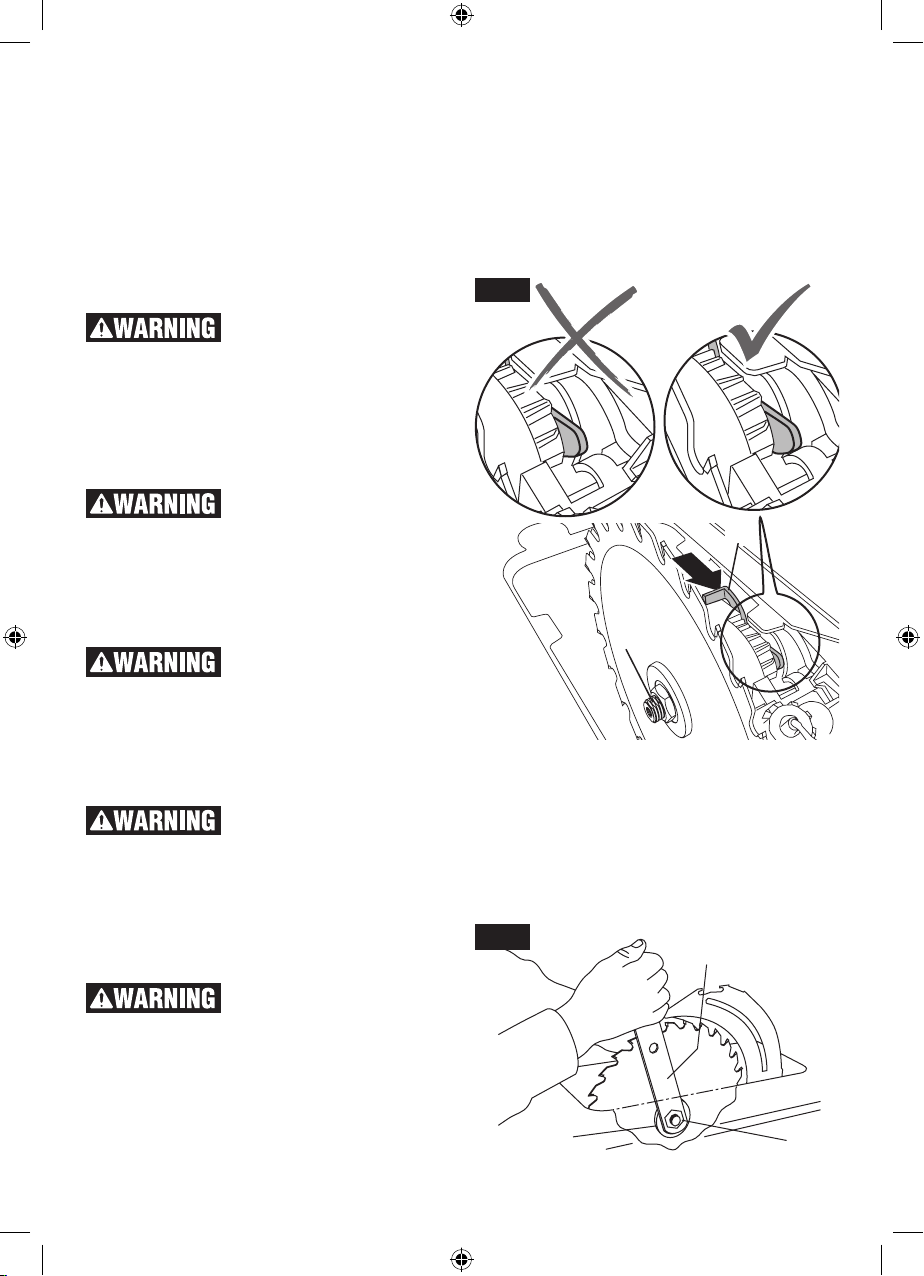

4. If an Activation Cartridge 28 is present, discon-

nect the cartridge plug 36 from the cartridge by

squeezing the latches between the thumb and

forefinger, then sliding the plug back (Fig. 7).

Extreme force on this wire

may damage it. The Active

Response Technology™ system will disable the

saw if the wire is damaged.

5. Grasp the left cylinder of Activation Cartridge

(if present) and slide it up out of the saw. If

the system has just fired the active cylinder,

then the right side piston 28b will extend over

an inch out of the cartridge (Fig. 7). When both

pistons are extended, discard the cartridge.

6. Slide a functioning Activation Cartridge 28a into

the right position.

7. Reattach the cartridge plug 36 to the cartridge’s

right side cylinder.

8. Push down on the left cylinder Activation Car-

tridge 28 with one hand. Tighten the Activation

Cartridge Retainer 33 clockwise with the other

hand into the saw until it is finger tight. Then

using the activation cartridge installation tool

rotate tighten the retainer into place 1/8th turn

further (Fig. 8).

Always tighten the activa-

tion cartridge retainer as

instructed. Failure to tighten the activation car-

tridge retainer as instructed can reduce effectiveness of the Active Response Technology™ system and result in tool damage and personal injury.

Ensure the riving knife is

positioned away from the

path of the hand as it moves upward. Injury to

the hand or fingers is possible if they collide. (See

step 2 above)

9. Pull and hold the drop arm lock 31 toward the

front of the saw. Take the blade wrench 14 and

slide it over the arbor nut. Grasp the handle

tightly. Quickly pull the wrench up. The drop

arm 27 should connect solidly to the latch (Fig.

9). If the drop arm 27 fails to latch, make sure

the Activation Cartridge 28 is properly in place

and the Activation Cartridge Retainer 33 is

screwed down as instructed in step 8 above.

28

36

Fig. 7

H

G

28a 28b

Fig. 8

Fig. 9

31

ACTIVATION CARTRIDGE

DISPOSAL INSTRUCTIONS

Fully used activation cartridges can be recycled

or discarded through standard recycling methods.

For disposal of unused activation cartridges contact your city, county, state or federal government

and request information regarding the proper disposal of hazardous materials such as pyrotechnic

articles and fireworks.

33

1/8

33

27

14

REASSEMBLE

10. Raise the riving knife by loosening the riving

knife release lever 37 (Fig. 5). Position table insert 21 in pocket of table so tabs 21a on table

1600A009XC 09-15.indb 14 9/14/15 1:51 PM

insert 21 are in slots in pocket of table and push

down and secure in place using table insert lock

22 (Fig.4). Re-attach the smart guard system.

14

ATTACHING THE

SMART GUARD SYSTEM

To prevent personal injury,

always disconnect plug

from power source before attaching or removing the Smart Guard System.

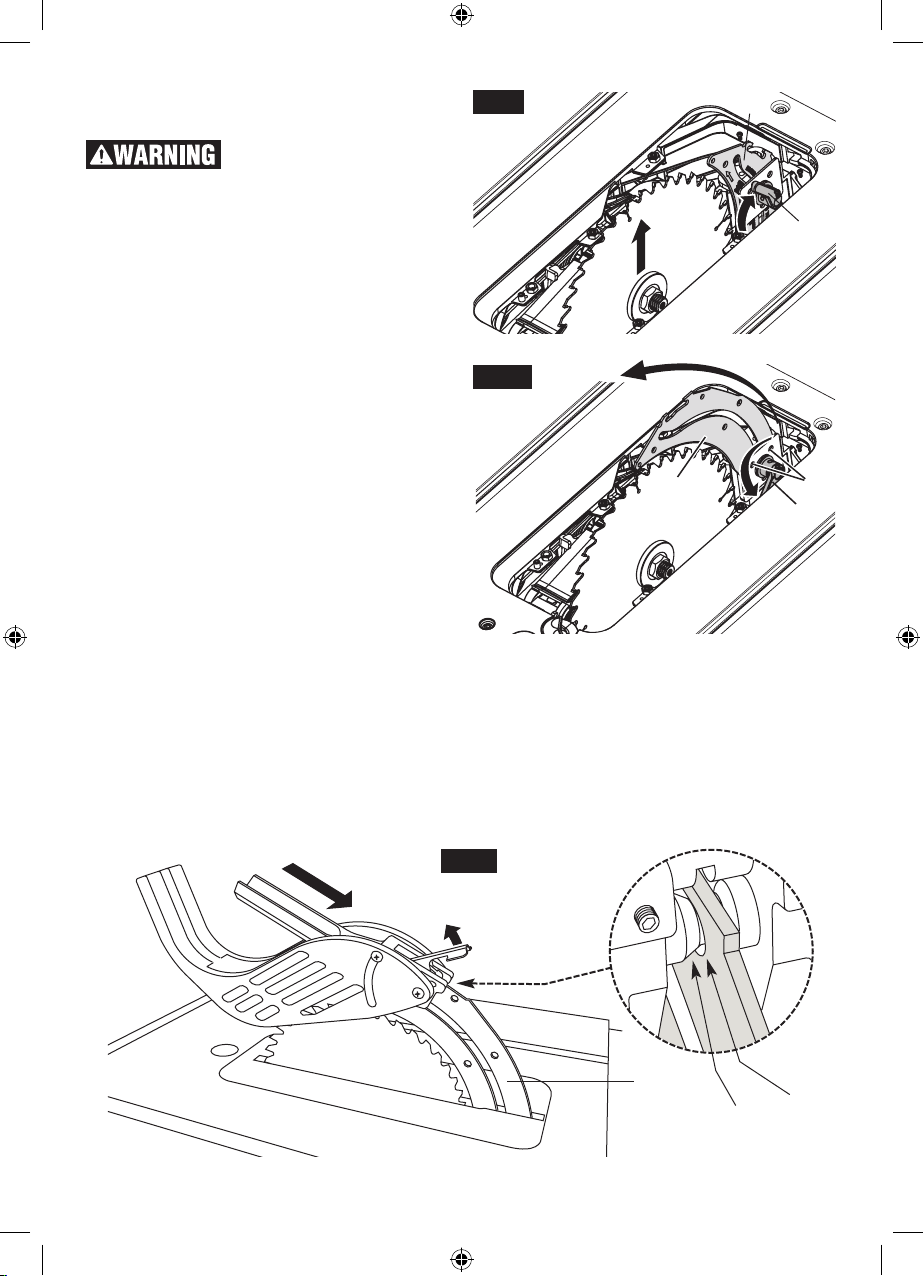

POSITIONING THE RIVING KNIFE

1. Remove table insert using table insert lock.

2. Raise the blade as high as it will go and set it

perpendicular to table (0° on bevel scale) (Fig.

10).

3. Rotate the riving knife release lever 1 clock-

wise, so that it points upward (Fig. 10).

4. Pull riving knife 2 towards release lever to dis-

engage it from the pins 3 (Fig. 11).

5. Slide the riving knife 2 up to its highest posi-

tion, so that it is directly over the center of the

blade (Fig. 11).

6. Align holes in riving knife with pins 3 and lock

the release lever 1 by rotating it counter-clockwise. Push/pull riving knife to verify that it is

locked in place (Fig. 11).

7. Replace table insert and lock.

ATTACHING THE

GUARD ASSEMBLY

8. With one hand, hold the front of the barrier

guard assembly 4 by the metal “fork”. With the

other hand, hold the guard release lever 5 up

(Fig. 12).

9. Lower the rear of guard assembly and slip the

cross bar 6 into the rear notch 7 on top of the

riving knife 2 (Fig. 12).

Fig. 10

Fig. 11

2

1

2

3

1

4

Fig. 12

5

2

7

6

15

1600A009XC 09-15.indb 15 9/14/15 1:51 PM

10. Lower the front of the guard as-

sembly 4 until the metal “fork” is

parallel with the table (Fig. 13).

11. Press down on the guard re-

lease lever 5 until you feel and

hear it snap into the locking position. Check that the guard assembly is properly and securely

connected (Fig. 13).

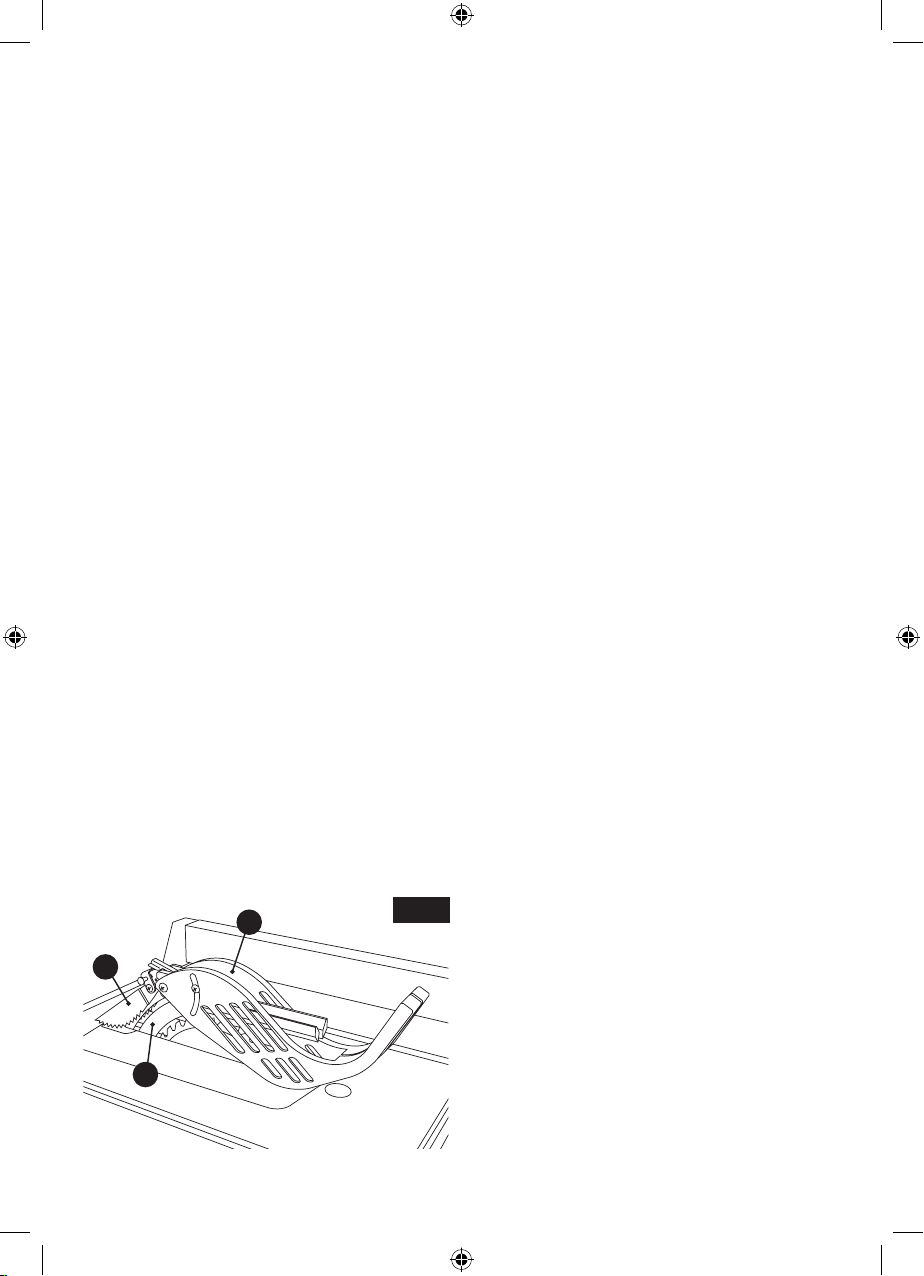

ATTACHING THE

ANTI-KICKBACK PAWLS

12. Attach the Anti-Kickback Pawls

7 into the flat recessed area 8 of

the riving knife 2 (Fig. 14).

13. Squeeze the compression pads

9 while nesting the device into

the flat area (Fig. 14).

14. Release the compression pads

such that the Anti-Kickback

Pawls lock onto the riving knife

immediately behind the guard

assembly. Check that the attachment pin is securely connected

into locking hole. Carefully raise

and lower the pawls 10 – when

letting go, the spring-loaded

pawls must come down and

contact the table insert (Fig. 14).

Hint: Position the Anti-Kickback

Pawls behind the flat recessed

area and slide it towards the front

until it drops into the recessed

area – then release the compression pins.

Note: The two attachments are

independent of each other, so the

Anti-Kickback Pawls can be attached before the Guard Assembly.

Fig. 13

Fig. 14

4

7

5

9

9

10

8

2

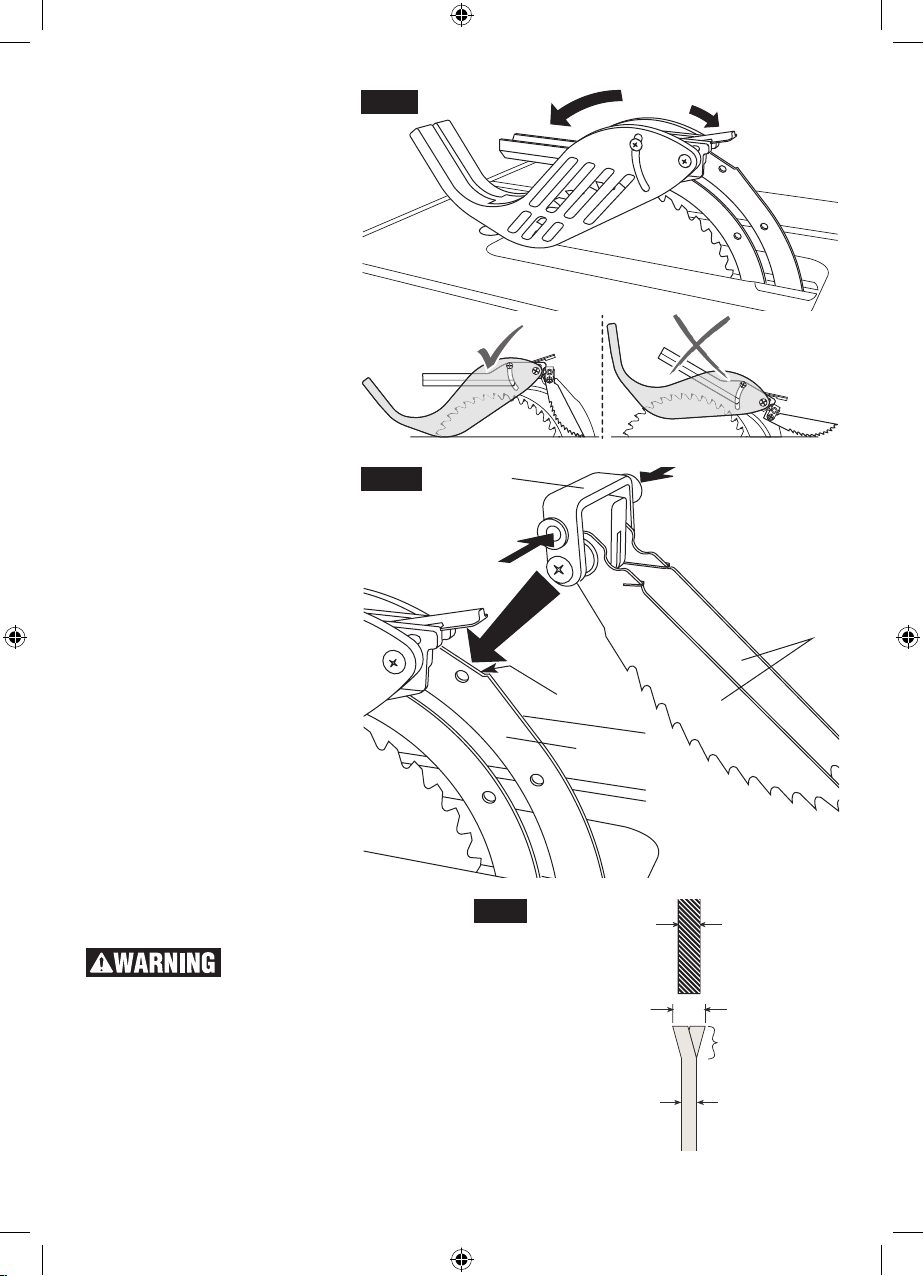

SELECTING AND

CHANGING THE BLADE

Fig. 15

.090” RIVING KNIFE

To prevent personal injury,

always disconnect plug

from power source before changing blades.

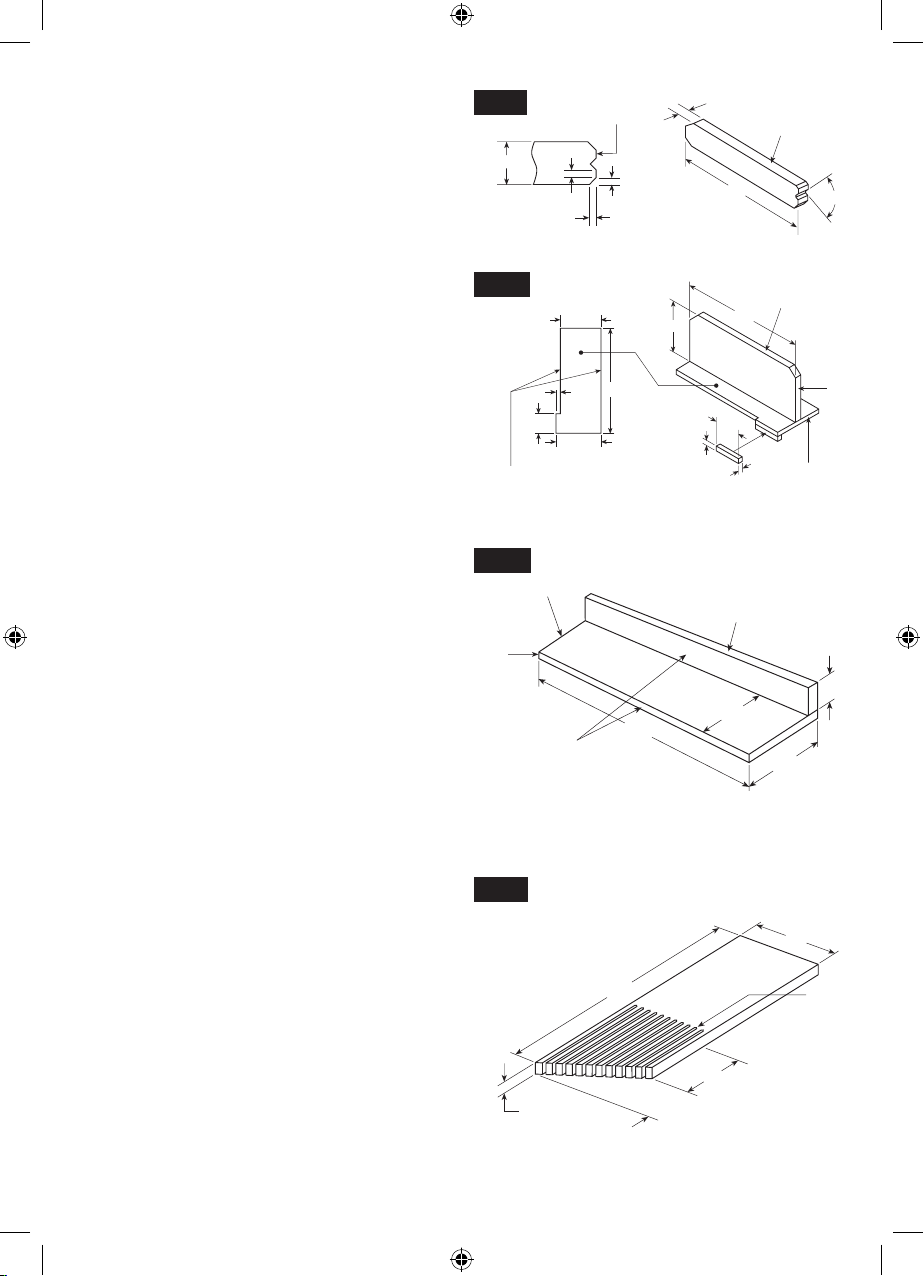

USING THE CORRECT BLADE

IMPORTANT: The saw blade provided on this

MUST BE .094” OR MORE

KERF WIDTH

BLADE TEETH

tool has a carbide-tipped kerf width of .128” and

a plate (body) thickness that is .086” thick. When

looking for a replacement blade, select one with

BLADE BODY PLATEMUST BE LESS THAN .090”

dimensions close to the original blade. This information may not be printed on the blades pack-

16

1600A009XC 09-15.indb 16 9/14/15 1:51 PM

aging. If not, check the manufacturers catalog or

website. Bosch offers an extensive line of Premium-Quality Professional Saw Blades that match

the requirements for this tool. You must select a

blade with a kerf width of .094” or more and a

plate (body) thickness .090” or less (Fig. 15).

The Active Response Technology™ injury mitigation system will function with a large variety of 10”

blades and body coatings. Coatings on the body

of the blade do not impact the system’s ability to

detect human/blade contact.

Make several cuts using

safe crosscutting techniques to wear off any varnish from the blade

teeth before beginning production work at

each blade change. Blades that have varnish

coating on the teeth reduce the ability of the Active Response Technology™ injury mitigation

system to detect contact between the operator

and the blade.

To reduce the risk of injury,

do not use extra thin kerf

saw blades. The kerf of the blade must be .094”

or more. Extra thin kerf saw blades (less than

.094”) may cause the work piece to bind against

the riving knife during cutting. It is recommended

that the kerf of the replacement blade used on

this saw be .094” or more.

To reduce the risk of injury,

do not use saw blades

made with a thick body plate. If the replace-

ment saw blade’s plate thickness is greater than

.088”, the riving knife would not properly serve as

an aid to reduce kickback. The replacement

blade’s plate thickness must be equal to or less

than .088”.

To reduce the risk of injury,

do not use blade “dampeners,” “stabilizers,” or “stiffening collars” on a

replacement blade. Use of these devices on

both sides will prevent the blade from being properly aligned with the riving knife, which may bind

the work piece during cutting and prevent the Active Response Technology™ system from working.

Cutting tool should not be

allowed to touch or wear

against the detection plate when the motor is

running. Contact between the detection plate

and the cutting tool will cause the system to activate. Damage to the detection plate may cause

delay or negate the ability of the Active Response

Technology™ System to detect the operator’s

contact with the blade. Always check to ensure

the blade spins freely before re-applying power to

the saw.

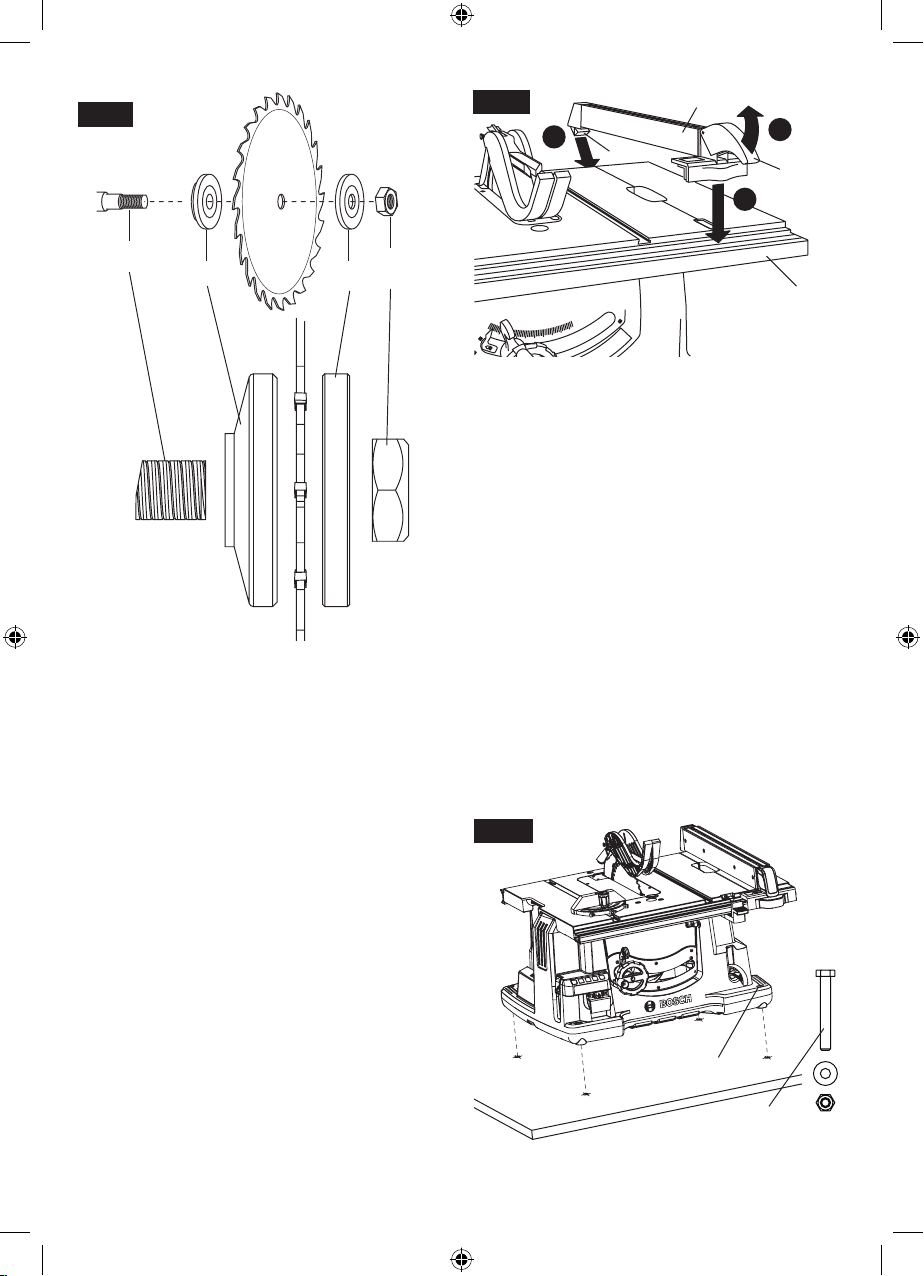

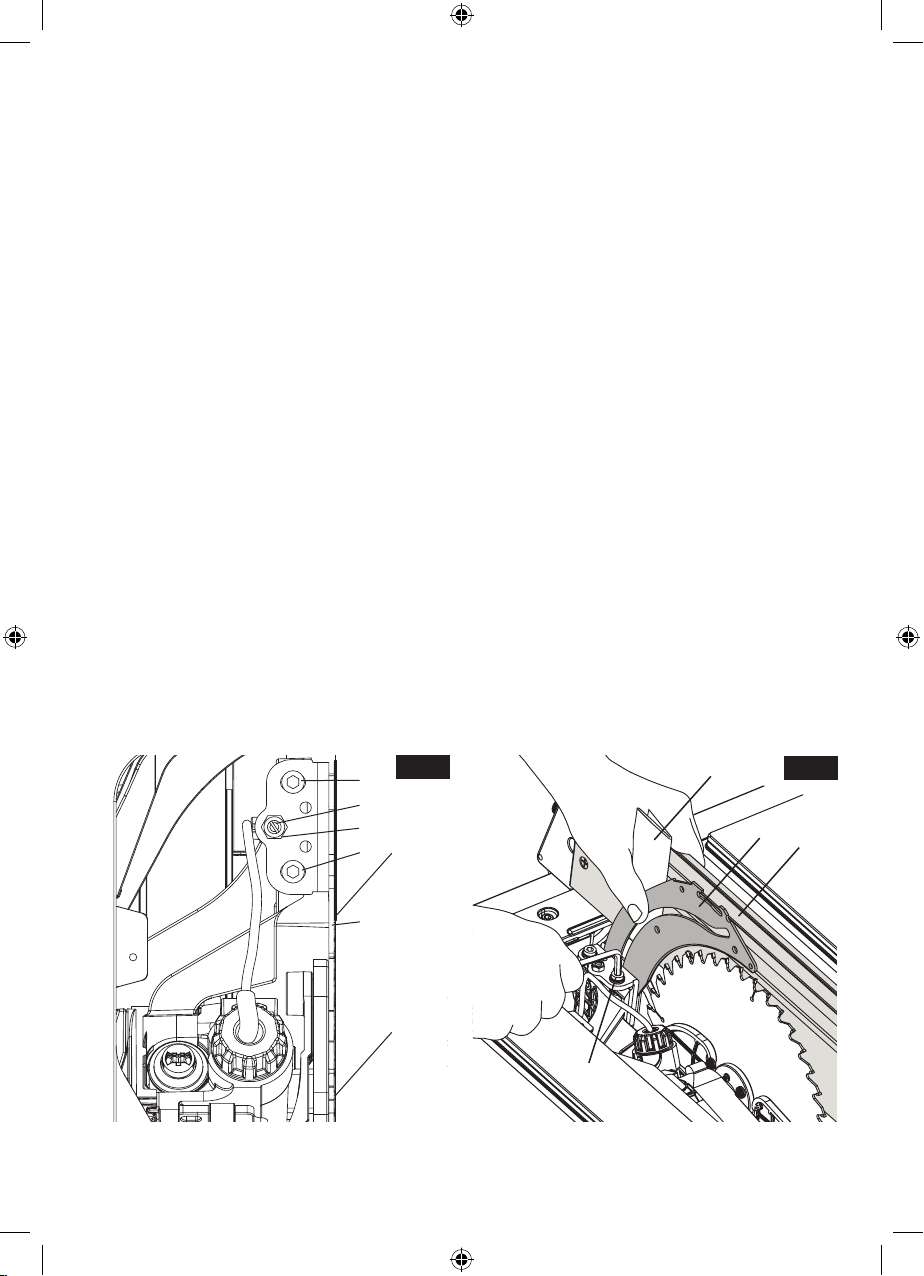

CHANGING THE BLADE

1. Turn elevation wheel clockwise until the blade

is up as high as it will go, remove table insert

21 by rotating the table insert lock 22, and use

the front edge to lift clear off the table (Fig. 4,

page 13).

Fig. 16

2

6

2. Slide and hold the arbor lock lever 2 towards

the back of the saw and slowly rotate blade by

hand until lock fully engages with the saw arbor

and stops rotation (Fig. 16). Loosen arbor nut

3 counter clockwise with the blade wrench 4

provided (Fig. 17). Set wrench aside and continue to loosen arbor nut 3 by hand and remove

arbor nut 3 and outer washer 5. Blade may now

Fig. 17

4

3

17

1600A009XC 09-15.indb 17 9/14/15 1:51 PM

Fig. 18

Fig. 19

4

B

2

A

1

C

3

6

7

be removed or installed by sliding on or off arbor shaft 6 (Fig. 18).

3. Assemble inner washer 7 and new blade as

shown in figure 18, making certain the TEETH

OF THE BLADE ARE POINTING DOWN AT

THE FRONT OF THE TABLE. NOTE: The

printing on different saw blades is not always

on the same side.

4. Assemble outer washer 5 and arbor nut 3 as

shown in figure 17. While holding arbor lock lever 2 securely, tighten arbor nut 3 clockwise

with the wrench 4. (Fig. 16).

5. Position table insert 21 in pocket of table so

tabs 21a on table insert 21 are in slots in pocket of table and push down and secure in place

using table insert lock 22 (Fig.4, page 13).

3

5

ATTACHING RIP FENCE

1. Raise rip fence handle 1, so holding clamp 2 is

out far enough to fit on the table 3 and into “V”

groove located on the back of rear rail (Fig. 19).

2. Position the rip fence 4 over table 3 holding up

the front end, first engage holding clamp 2 with

rear rail.

3. Lower front end onto front rail 5.

5

MOUNTING THE TABLE SAW

If table saw is to be used in a permanent location,

it should be fastened securely to a firm supporting surface such as a stand or workbench, using

the four mounting holes 6 (Fig. 19).

1. If mounting to a workbench, the base should

be bolted securely using 5/16” hex bolts (not

included) through mounting holes 6.

Hint: If workbench is 3/4” thick, bolts will have

to be at least 3-1/2” long - if workbench is 1-1/2”

thick, bolts should be at least 4-1/2” long.

2. Locate and mark where the saw is to be mounted, relative to holes in the base of the tool.

3. Drill four (4) 3/8” diameter holes through workbench.

4. Place table saw on workbench aligning holes

in base with holes drilled in workbench.

5. Insert four (4) 5/16” dia. bolts through holes in

base and supporting surface; then secure with

(4) 5/16” flat washers and (4) 5/16” hex nuts.

Fig. 20

6

5/16” HEX BOLT,

WASHER &

HEX NUT (X4)

18

1600A009XC 09-15.indb 18 9/14/15 1:51 PM

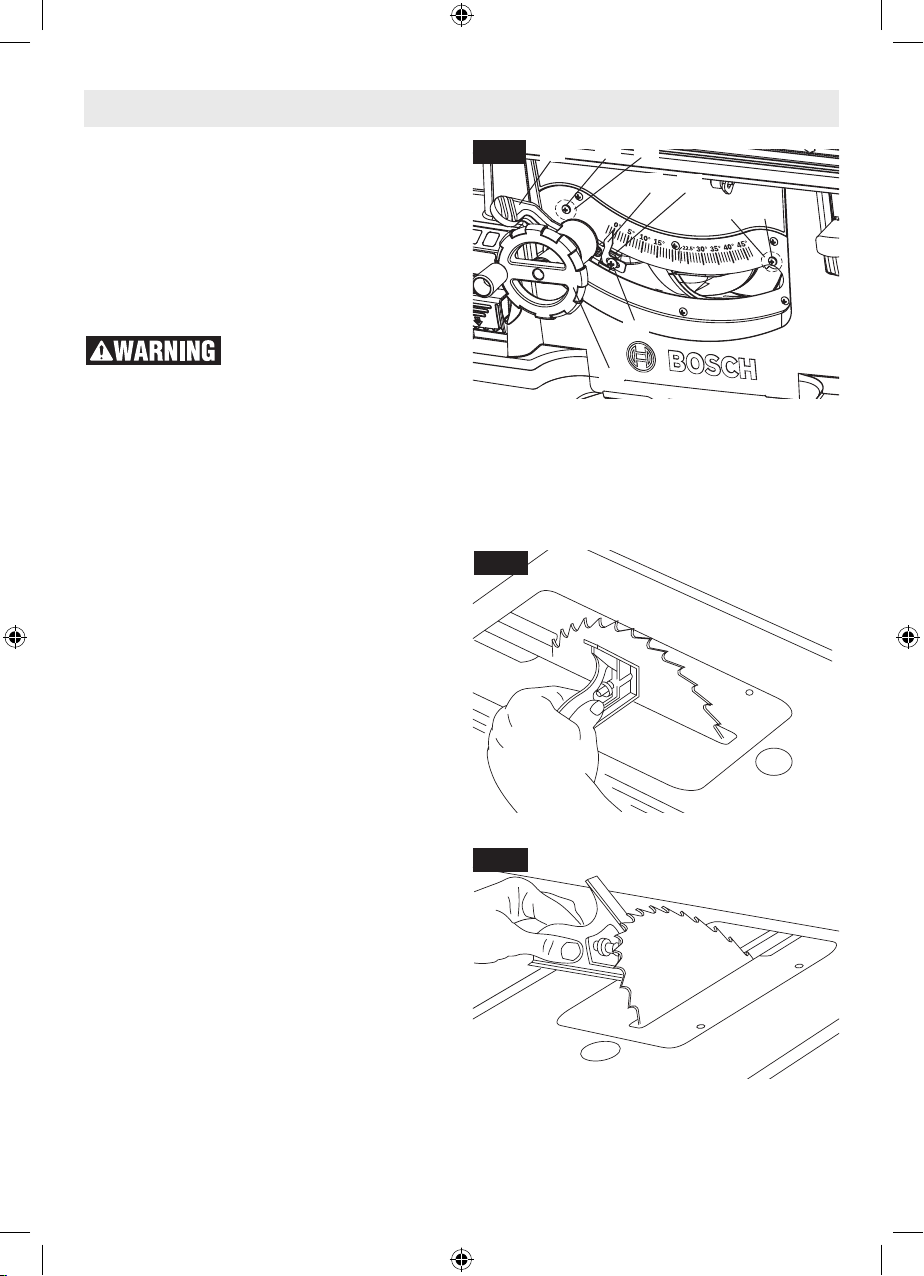

Adjustments

ADJUSTING 0 AND 45 DEGREE POSI-

TIVE STOPS

Your saw is equipped with positive stops for fast

and accurate positioning of the saw blade at 0

and 45 degrees to the table.

The blade was adjusted at the factory. In order to

insure accurate cuts, this adjustment should be

rechecked. If adjustment is necessary, follow the

steps below.

To prevent personal injury,

always disconnect plug

from the power source when making adjustments.

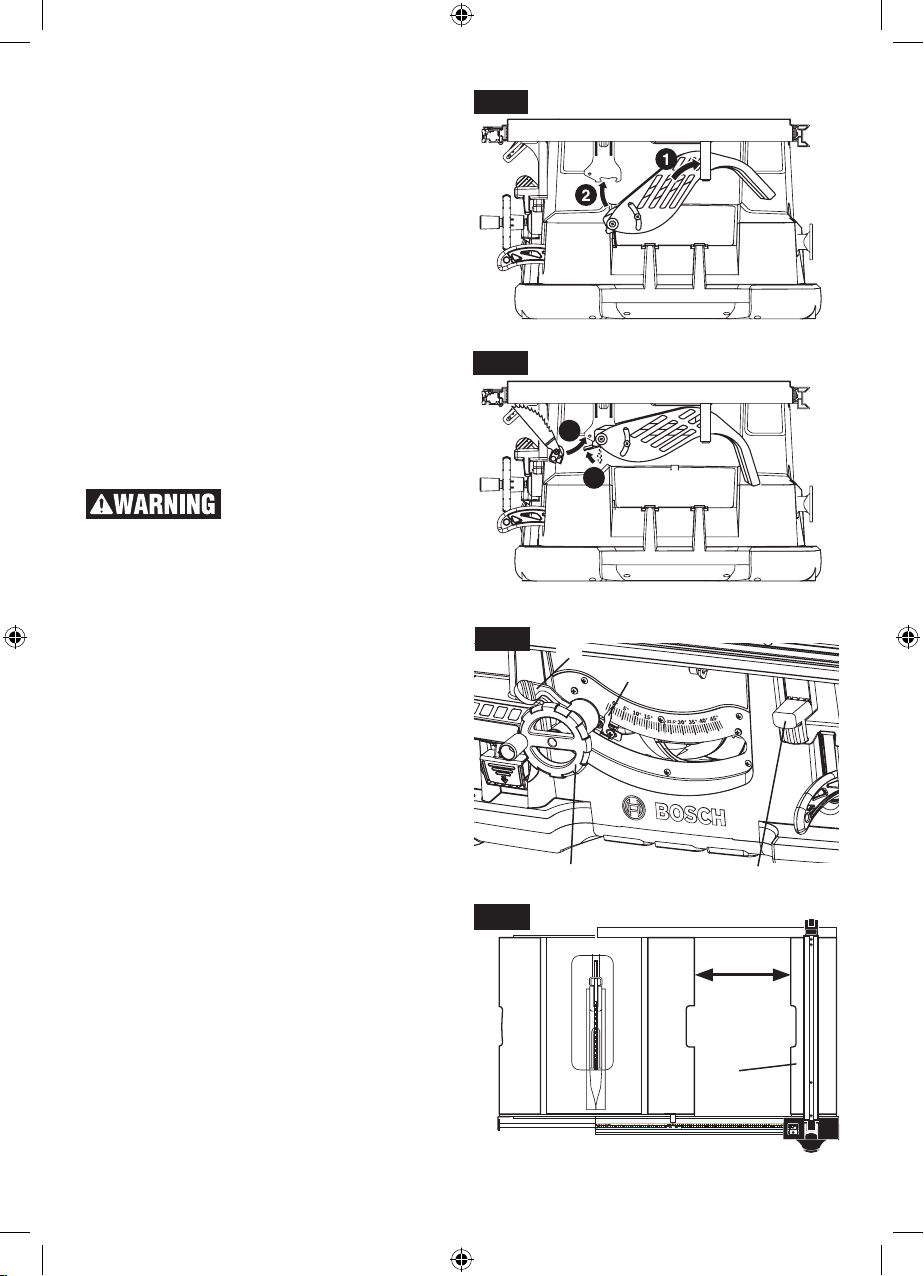

1. Turn elevation wheel 2 clockwise and raise

blade to maximum height (Fig. 21).

ADJUSTING 0 DEGREE POSITIVE

STOP:

2. Loosen the blade bevel lock handle 1 and push

the elevation wheel 2 to the left as far as possible and tighten the blade bevel lock handle 1

(Fig. 21).

3. Place a combination square on the table with

one end of the square against the blade as

shown (Fig. 22), and check to see if the blade

is 90 degrees to the table. If the blade is not

90 degrees to the table, loosen the blade bevel

lock handle 1, loosen 0 degree adjustment

screw 4, loosen 0 degree bevel stop cam 5 and

push the elevation wheel until the blade is 90

degrees to the table.

4. Tighten blade bevel lock handle 1, rotate the

bevel stop cam 5 until it touches the bevel stop

housing 7, then tighten 0 degree adjustment

screw 4.

5. Loosen adjustment screw 6 and adjust pointer

3 to indicate 0 degrees on the bevel scale.

ADJUSTING 45 DEGREE POSITIVE

STOP:

6. Loosen the blade bevel lock handle 1 and push

the elevation wheel 2 to the right as far as possible and tighten the blade bevel lock handle 1.

7. Place a combination square on the table with

one end of square against the blade as shown

(Fig. 23), and check to see if the blade is 45 degrees to the table. If the blade is not 45 degrees

to the table, loosen the blade bevel lock handle

1, loosen 45 degree adjustment screw 8, loosen 45 degree bevel stop cam 9 and push the

4

Fig. 21

8. Tighten blade bevel lock handle 1, rotate the

Fig. 22

Fig. 23

1

elevation wheel until the blade is 45 degrees to

the table.

45 degree bevel stop cam 9 until it touches the

bevel stop housing 7, then tighten 45 degree

adjustment screw 8.

5

3

7

9

8

6

2

19

1600A009XC 09-15.indb 19 9/14/15 1:51 PM

ADJUSTING BLADE PARALLEL TO

THE MITER GAUGE SLOTS

The blade was adjusted parallel to the miter

gauge slots at the factory. In order to insure accurate cuts and help prevent kickback, this adjustment should be rechecked. If adjustment is

necessary, follow the steps below.

To prevent personal injury,

always disconnect the plug

from the power source before making any adjustments.

1. Turn elevation wheel and raise blade as high

as it will go.

2. Select a point on the body of the saw blade that

is set to the left when viewing blade from the

front of saw, and mark 1 with a pencil (Fig. 24).

3. Place the base of a combination square against

the edge of the miter gauge slot, and extend

the sliding rule of square so it just touches the

marked point 1 on the body of the saw blade at

the rear of the table.

4. Rotate blade and check the same marked point

1 of the saw blade at the front of the table (Fig.

24).

5. If the front and back measurements, shown

in Figure 24, are not identical, loosen the four

alignment bolts 2, located on the top of the

table one half turn at the front and rear of the

saw with hex wrench supplied with your saw

(Fig. 25). Carefully move the saw blade until the

blade is parallel to the miter gauge slot using

the combination square, and securely tighten

all four bolts.

MITER GAUGE ADJUSTMENT

To check your miter gauge accuracy, move the

miter gauge in line with blade and use a combination square to make sure the miter gauge body

is 90 degrees to the blade (Fig. 26). To adjust the

miter gauge for 90 degrees:

1. Loosen lock nut 3, adjustment screw 4, and

lock knob 5.

2. Flip stop plate 6 down.

3. Rotate miter gauge body until it is 90 degrees

to the blade.

4. Tighten lock knob 5.

5. Engage stop plate 6 and tighten adjustment

screw 4 until it contacts stop plate 6.

6. Tighten lock nut 3.

7. If pointer 7 is not pointing to 90 degrees, loosen

set screw 8 on side of miter gauge bar and ro-

Fig. 24

Fig. 25

2

Fig. 26

5

7

8

6

tate pointer 7 to 90 degrees mark. Tighten set

screw 8.

8. To adjust the miter gauge for 45 degrees left

and right, repeat steps 1-6, but use 45 degree

stops.

4

3

1

2

20

1600A009XC 09-15.indb 20 9/14/15 1:51 PM

ALIGNING RIP FENCE

To prevent personal injury,

always disconnect plug

from power source before making any adjustments. The rip fence must be parallel with the

Saw blade in order to prevent KICKBACK when

ripping.

Your table saw is equipped with a Self-Aligning,

Quick-Set rip fence. Once the adjustments below

have been made, the rip fence will self align when

the fence is locked into position.

NOTE: The blade must be parallel with the miter

gauge slots (see page 20) and be perpendicular

to table before proceeding with rip fence alignment.

To prevent personal injury,

always make sure the rip

fence is locked before making rip cuts.

1. Lift both guard barriers 2 to their up locked position.

2. Raise lock handle 1 and slide fence 3 until it

is alongside the saw blade, by lifting right side

pawl 4 above fence (Fig. 27). The fence should

touch the blade teeth at the front and rear of

the blade when locked. If fence does not touch

the teeth at front and rear of blade continue

with the following the steps:

3. Loosen the two screws 5 on the top front section of the rip fence using the included 5mm

hex wrench.

4. Move fence 3 until it touches the teeth and is

parallel to the blade.

5. Hold fence in place and lower lock handle,

check to make sure the fence stayed parallel to

the blade then tighten screws (Fig. 27).

6. Clamp rip fence to check if it holds securely at

front and rear. If rear is not clamped securely,

unclamp fence and turn rear clamp adjustment

screw 6 clockwise for increased clamping. Try

clamping the fence to verify if it self-aligns and

clamps tightly at the front and rear. Overtightening of the rear clamp adjustment screw 6 will

cause the rip fence to be non-self aligning (Fig.

27). Overtightening may cause friction or “chatter” when fence is moved side to side.

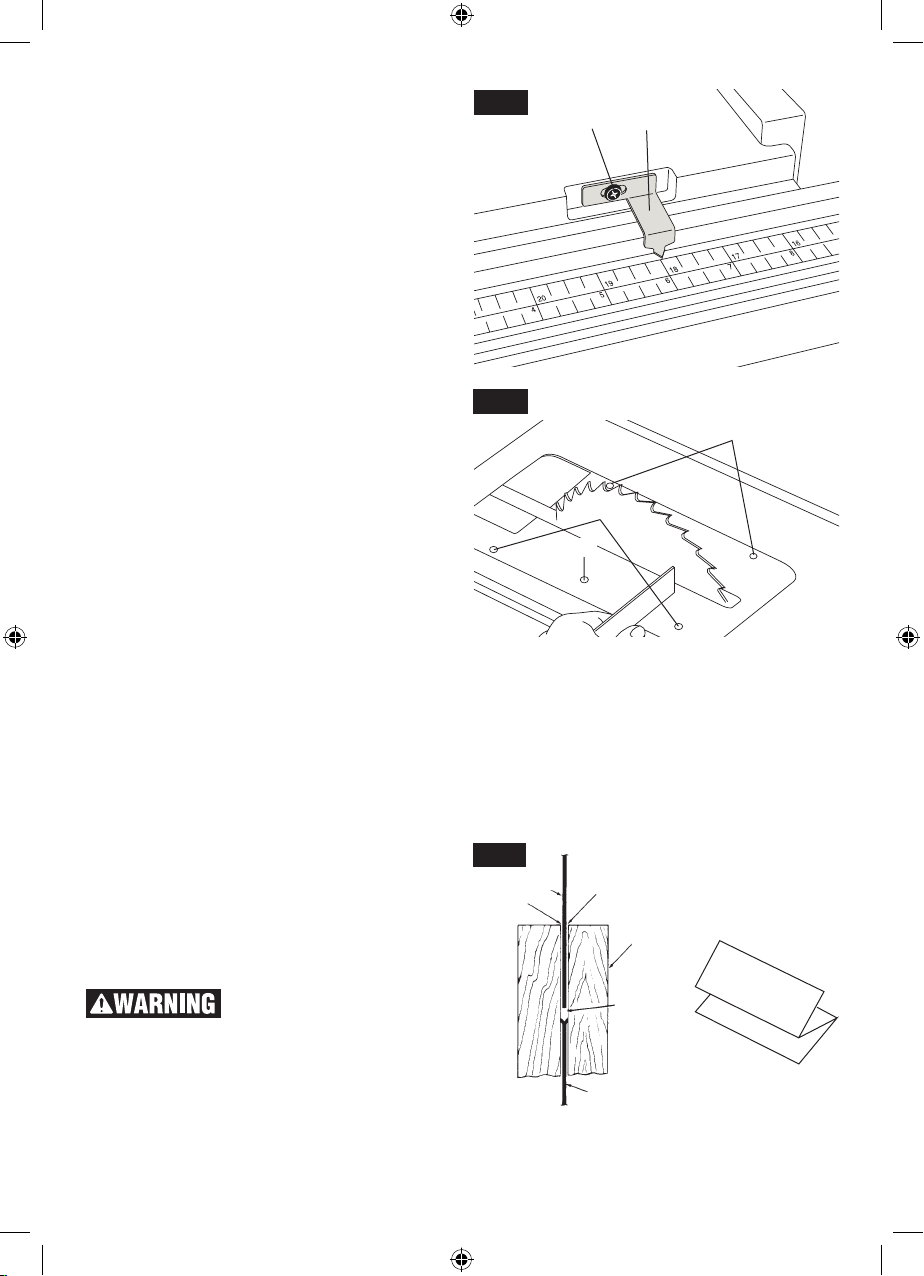

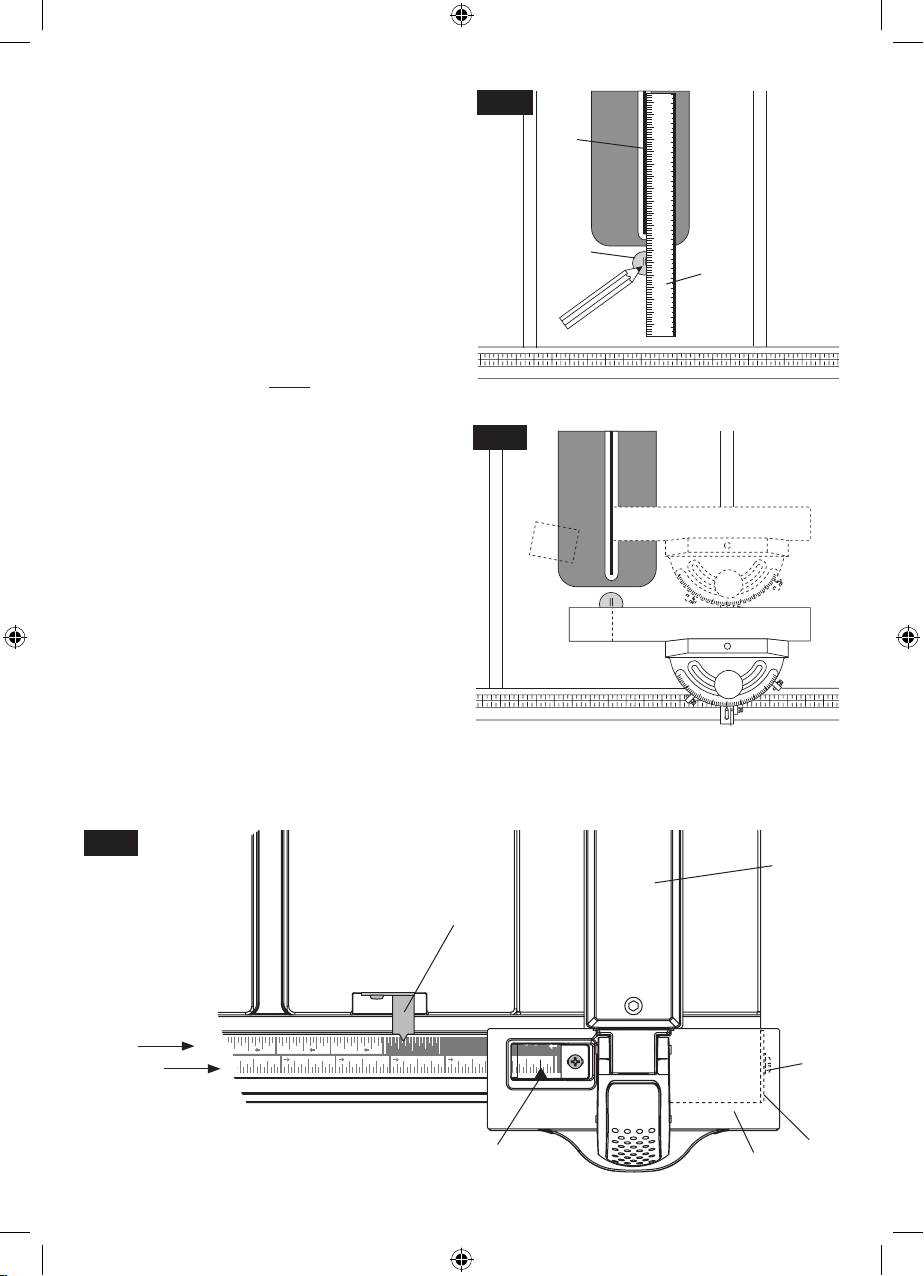

RIP FENCE POINTER ADJUSTMENT

The distance of the rip fence body from the blade

when ripping on the right side of the blade is determined by lining the pointer 7 with the desired

dimension on the scale 8 (Fig. 28).

TO SET THE RIP FENCE POINTER:

1. Lift both guard barriers 2 to their up locked position (Fig. 27).

2. Raise lock handle 1 and slide fence 3 until it

is alongside the saw blade, by lifting right side

pawl 4 above fence (Fig. 27).

3. Loosen pointer adjustment screw 9, adjust

pointer 7 to “0” mark on lower scale 8, then re-

tighten screw 9 (Fig. 28).

Fig. 27

6

4

2

5

Fig. 28

1

13

10 11 12 13

Changing to

Table Pointer

3

7 98

21

1600A009XC 09-15.indb 21 9/14/15 1:51 PM

TABLE POINTER ADJUSTMENT

If an adjustment to the table pointer is necessary,

loosen pointer adjustment screw 1, adjust pointer

2 and tighten screw 1 (Fig. 29). The table pointer

should always be adjusted relative to fence pointer.

1. Adjust fence pointer to (zero) – see “Rip Fence

Pointer Adjustment”.

2. Slide fence to the right until it hits the stop plate

on front rail and lock fence in place.

3. Look at fence pointer and note measurement

on lower scale (at or near 12.75”).

4. Adjust the table pointer 2 to the same reading on upper scale as that shown on the fence

pointer. Both pointers must agree when fence

is at this position.

Example: If fence pointer is at 13-9/16”, then table

pointer should also be set at 13-9/16”.

ADJUSTING THE TABLE INSERT

The table insert includes five (5) adjustment

screws 3 to set the height (Fig. 30). Place the insert into the table. Place a straight edge (such as

the metal ruler from a combination square) across

the table top and insert top – the surfaces should

be at the same level. Alternately, the front edge

may be below the table top by the thickness of

dollar bill folded twice. Place the bill between the

insert and straight edge to check. The rear edge

may be proud of the table by the same amount.

Place the bill between the table and straight

edge to check. If adjustment is necessary, use

flat head screwdriver to adjust all support screws.

First adjust corner adjustment screws 3 to get

the alignment described above. Then adjust the

center adjustment screw 3A such that it does not

change the table insert alignment.

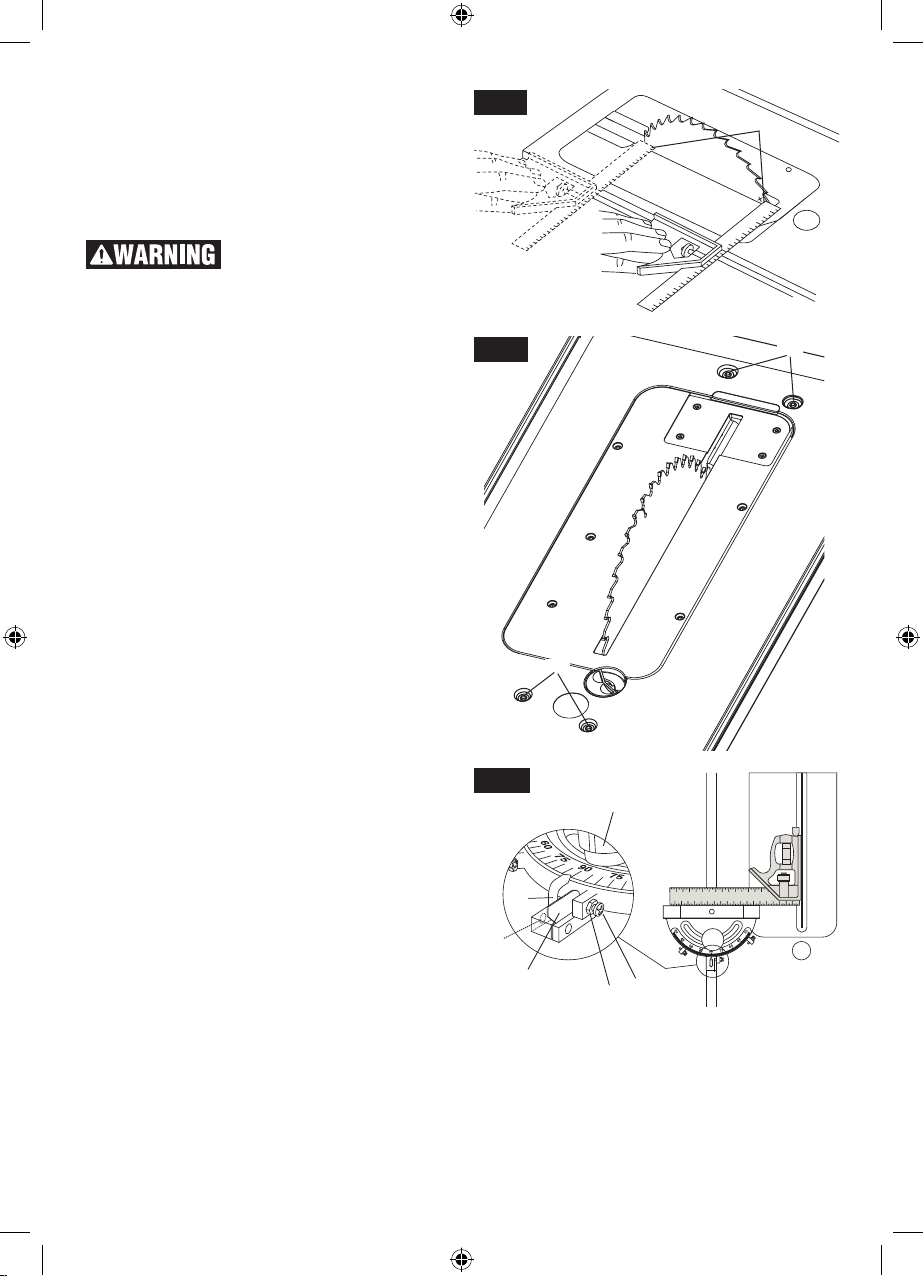

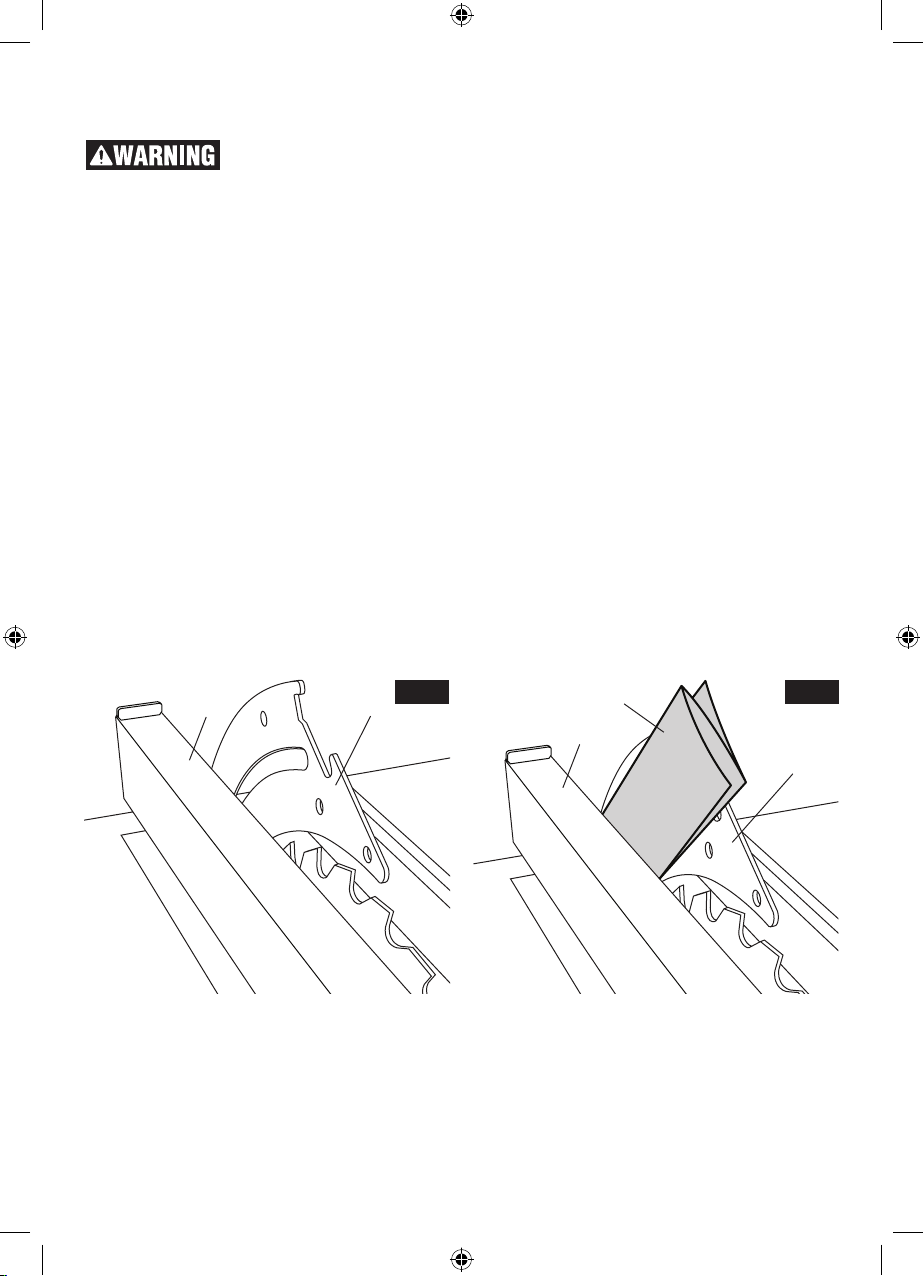

RIVING KNIFE ALIGNMENT

IMPORTANT: The Riving Knife 1 must always be

in line with the Saw Blade 2. The Riving Knife 1

is thinner than the width of the Kerf 4 by approximately three thicknesses of paper 5 on each side

(Fig. 31). Note: The Kerf is the width of the cut

made by the teeth on the saw blade.

To prevent personal injury,

always disconnect plug

from power source before making any adjustments and when attaching or removing the

Smart guard System.

Fig. 29

Fig. 30

3A

Fig. 31

1

5

LOOKING DOWN ON

SAW

1

2

3

5

2

WORK

4

3

5

22

1600A009XC 09-15.indb 22 9/14/15 1:51 PM

CHECKING RIVING KNIFE

ALIGNMENT

Check riving knife align-

ment to blade periodically

and make adjustments as necessary. Improp-

erly aligned riving knife may result in work piece

instability, loss of control, and KICKBACK. If the

riving knife is misaligned and cannot be adjusted,

do not attempt to operate the saw. Have a qualified service technician perform riving knife alignment.

1. Check that the blade is properly aligned paral-

lel with the miter gauge groove per instructions

listed under “Adjusting Blade Parallel to Miter

Gauge slots” (page 20) and adjust the blade if

necessary. Check that the rip fence is aligned

with the blade (see instructions listed under

“Aligning Rip Fence”, page 21) and adjust the

rip fence if necessary.

2. Raise the blade to the full height (up) position.

Raise the riving knife to its full up position (see

instructions listed under “Positioning The Riving Knife”, page 15). Remove the Anti-Kickback

Pawls and Guard Assembly from the riving

knife. Remove the insert plate.

3. Place the rip fence 3 on the left side of the table.

Carefully move the rip fence against the blade

so that the rip fence is parallel to the blade and

just touches the tips of the saw teeth. Lock the

rip fence and make sure the blade at the front

and back is still touching the rip fence (Fig 32).

4. Using the rip fence as a guide, check the riving knife alignment with the plane of the saw

blade. Since the riving knife is thinner, by approximately three thicknesses of paper on each

side, than the width of the blade’s KERF (Fig

31) you must make a temporary paper “spacing gauge“. Make two folds in a small piece

(6” X 6”) of ordinary newspaper making three

thicknesses. Place the paper spacing gauge 5

between the riving knife 1 and the rip fence 3

(Fig 33).

5. Repeat step 4 with the rip fence 3 on the right

of the blade and check with paper spacing

gauge 5 (Fig. 35).

6. If the paper spacing gauge does not fit between the rip fence and the riving knife per

steps 4 and 5 above, the riving knife is not

correctly aligned with the blade and must be

adjusted. If the riving knife needs adjustment

proceed to section Adjusting Riving Knife. If the

riving knife is correctly aligned with the blade

then no adjustment is necessary.

NOTE: The Riving Knife has been properly

aligned at the factory - Check the alignment before making any adjustments.

13

Fig. 32

5

3

Fig. 33

1

23

1600A009XC 09-15.indb 23 9/14/15 1:51 PM

ADJUSTING RIVING KNIFE

1. Check that the blade is properly aligned parallel with the miter guage groove per instructions

listed under “Adjusting Blade Parallel to the Miter Gauge Slots (page 20) and adjust the blade

if necessary. Check that the rip fence is aligned

with the blade (see instructions listed under

“Aligning Rip Fence” on page 21) and adjust

the rip fence if necessary.

2. Raise the blade to the full height (up) position.

Raise the riving knife to its full up position (see

instructions listed under “Positioning The Riving Knife”, page 15). Remove the Anti-Kickback

Pawls and Guard Assembly from the riving

knife. Remove the insert plate.

3. Place the rip fence 3 on the left side of the table.

Carefully move the rip fence against the blade

so that the rip fence is parallel to the blade and

just touches the tips of the saw teeth. Lock the

rip fence and make sure the blade at the front

and back is still touching the rip fence (Fig. 32).

4. Loosen Hex Nut 6 with 10mm open end wrench

(Fig. 34). Slightly loosen Clamping Screws

8 (1/4-1/2 turns) using a 5mm hex wrench

provided with table saw (stored in left side of

base). Loosen Set Screw 7 using a flat screwdriver (Fig. 34).

5. Make two folds in a small piece (6“ X 6“) of

ordinary newspaper making three thicknesses.

Paper 5 is used as a “Spacing Gauge”.

NOTE: The spacing instructions above are based

on using a standard kerf blade (.128” kerf on the

Bosch blade included). If a smaller kerf blade is

used, adjust the paper spacer. For instance, if the

kerf of the replacement blade is near .100”, use 1

thickness of paper as a spacer; if the kerf is near

.110”, use 2 thicknesses.

6. Place the paper spacing gauge 5 between the

riving knife 1 and the rip fence 3 (Fig 35).Hold

or clamp Riving Knife and paper firmly against

Fence (Fig. 35).

a. Lightly tighten the clamp screws 8.

b. Remove the paper - Slide fence away from

blade.

c. Slowly turn the Set Screw 7 while watching

the Riving Knife tilt until it is in line with the

blade.

d. Recheck squareness of riving knife to table

by sliding fence against blade. Readjust if

necessary.

7. After completing adjustments:

a. Lightly tighten hex nut 6 (hold set screw posi-

tion with screwdriver while tightening nut).

b. Fully tighten Clamp Screws 8 with hex

wrench. Then fully tighten the hex nut.

IMPORTANT: The riving knife must always be

INLINE with the saw blade body when blade is at

any bevel angle. Replace the Table Insert Plate,

Barrier Guard Assembly and Anti-Kickback Pawls

before making cuts.

Fig. 34

8

5

Fig. 35

7

6

5

8

1

3

1

2

8

24

1600A009XC 09-15.indb 24 9/14/15 1:51 PM

Basic Table Saw Operation

USING THE ACTIVE RESPONSE

TECHNOLOGY™ INJURY MITIGATION

SYSTEM.

The Active Response Technology™ that is integral to the table saw is intended to be used together with the Smart Guard system to provide

the operator the greatest level of protection.

These two elements must be used together for

all cuts except those that require elements of the

Smart Guard to be removed (i.e. non-through

cuts). Any Smart Guard components that need

to be removed to complete a cut should be immediately reinstalled when finished. Always remember that the best accident prevention is the

operator’s use of common sense and alertness at

all times when using the table saw.

The Active Response Technology™ injury mitigation system is designed to function without limiting the performance or versatility of the table saw.

This system continually monitors the saw blade

for contact with the operator. If a contact is made

with the operator the blade will retract under the

table to reduce injury severity to the operator.

The information panel includes a lighted display

that indicates saw status. Under normal conditions the system turns on a green light above

the power switch. The saw can be used normally

once the green light is illuminated. If the green

light is not on or a blue or red light is on, then refer

to the troubleshooting section on page 45. When

cutting electrically conductive materials the tool

can be placed in bypass mode indicated by the

yellow light.

This system is designed to accommodate 25 system actuations before needing inspection by a

factory authorized service center. After 25 system

activations the tool will become inoperable until

service is performed by a factory authorized service center. It is recommended to perform service

before 25 system activations are reached. When

there is one remaining activation in the system

the blue service light will begin to flash when the

saw is plugged in. Additionally by using the NFC

function in the Bosch Toolbox App the system will

provide information regarding system activations.

Always use the Smart

Guard system to minimize

chances of contact between your body and

spinning blade. The Active Response Technol-

ogy™ injury mitigation system activates after

physical contact between the operator and the

blade is made. In case the Smart Guard system is

not in use the Active Response Technology™

system will mitigate the severity of injury due to

contact between operator and spinning blade.

The degree of injury mitigation will depend on

factors such as the direction and speed of the operator’s body movement at the time it contacts

the spinning blade.

Do not touch the blade until

stop. The Active Response Technology™ injury

mitigation system is armed and will activate anytime the blade is spinning, except at 240 revolutions per minute (RPM) or less, or when in bypass mode. The detection system is active at all

times the saw is connected to power and properly

initiated.

it comes to a complete

THE INFORMATION PANEL

In keeping with the straightforward function of the

system, the Information Panel has four lights to

explain the saws current status (Fig. 36).

Green (3) – The saw is ready to use and the

Active Response Technology™ injury mitigation

system will activate if the user contacts the blade.

Yellow (4) – This indicator lights when the user

disarms the system when using the bypass

switch 1.

Red (5) – An error is present that the user can

correct. For example, if the activation cartridge is

installed incorrectly.

Blue (6) – An error is present that can only be

corrected at a service center. For example, if the

Fig. 36

6

5

4

OFF

25

1

3

2

1600A009XC 09-15.indb 25 9/14/15 1:51 PM

tool has activated 25 times. Also, this light will

flash when service is recommended.

For additional information and Troubleshooting

see page 45.

CUTTING ELECTRICALLY

CONDUCTIVE MATERIALS

The Active Response Technology™ injury mitigation system monitors for change in the detection

plate signal caused by operator contacting the

blade. Some materials such as aluminum veneered plywood may mimic this effect.

Any metal, metal foil composite, or wet lumber

will cause the system to react if cut.

Allow the pressure treated

materials to air dry before

cutting in normal mode. Pressure treated lum-

ber is treated with chemicals that are electrically

conductive when wet.

POWER SWITCH

NOTE: This table saw has two safety features

that helps prevent accidental starting. The switch

can be locked in the off position, see “To prevent

unauthorized use” below. Also, the Active Response Technology™ system prevents the motor

from restarting if the switch is on when the plug is

connected to a power source.

To turn saw on: lift switch lever by pinching side

walls and lifting, or reach under the switch and

pull up. This action starts the saw (Fig. 37)

To turn off power: push switch lever down to its

original position (Fig. 36).

To prevent unauthorized use, the switch can

accommodate a padlock with a 3/16” or 1/4” diameter shackle (not provided with table saw),

(Fig. 36).

BYPASS SWITCH

Use bypass mode only

when cutting electrically

conductive materials. Using bypass mode

when not needed eliminates protection provided

by Active Response Technology™.

If a conductive material needs to be cut, the tool

has a bypass switch which disarms the Active

Response Technology™ injury mitigation system.

Press and hold the bypass switch A with one

hand, then turn on the power switch B with the

other. The saw blade will start to spin. The information panel will change from Green to Yellow

(Fig. 37).

Fig. 37

A

ON

B

When the power switch is turned off, the bypass

mode will be deactivated. Then the indicator will

change from Yellow to Green. The Active Response Technology™ will be active for the next

cut unless the bypass switch is pressed again.

To prevent unauthorized system bypass, the

switch can accommodate a padlock with a 3/16”

or 1/4” diameter padlock (not provided with table

saw), (Fig. 36).

NEAR FIELD COMMUNICATION (NFC)

INTERFACE

The Active Response Technology™ injury mitigation system can interface with smart phones

that have NFC functionality and the Bosch Power

Tools app installed.

Do not use the NFC function while the saw blade is

spinning. Distraction while cutting may result in

tool damage and serious personal injury.

To connect to the NFC, launch the Bosch Toolbox

App and click the “Connect to tool” button. Place

the smart phone against the Near Field Communication interface. The system will send all the

current data to phone.

The operator can use this to get maintenance

recommendations, reset procedures or troubleshooting procedures. You can also use this system to register the tool with Bosch. In case the

tool is stolen, this registration cannot be obscured

by defacing the nameplate.

26

1600A009XC 09-15.indb 26 9/14/15 1:51 PM

ELECTRONICALLY LOCKING THE

SAW

Using the NFC and a smart phone, the operator

can lock or unlock the saw’s motor. The system

ships unlocked. The user can program a fourdigit PIN, then set the lock mode.

Lock Modes:

Unlocked – Any user can use the tool. Green

light indicated.

Locked – The saw cannot be used until unlocked.

Red light indicated.

Timer – Set a duration for the working time in

the day. When time elapses, the system enters

Locked mode.

Single Use – Allow a single cut to be made.

SMART GUARD SYSTEM

The Bosch Smart Guard system is the primary

safety system of this table saw. The Smart Guard

system is supplemented by the Active Response

Technology™. The Active Response Technology™ provides injury mitigation protection when

the table saw is connected to power and smart

guard system is not in use when making special

cuts. Any Smart Guard components that need

to be removed to complete a cut should be immediately reinstalled when finished. Always remember that the best accident prevention is the

operator’s use of common sense and alertness at

all times when using the table saw.

The Bosch Smart Guard System has been designed for modularity, enabling the use of multiple combinations of the three main components

– Main barrier guards, Anti-Kickback Pawls, and

riving knife. Additionally, the riving knife can be

quickly adjusted to three positions (high, middle,

and stored), depending on the application requirement.

Component parts (Fig. 38):

2

3

1

Fig. 38

➊ Riving Knife

The Riving Knife is the central element of the

Bosch Smart Guard blade guarding system,

serving as the attachment point for both the Main

Barrier Guard and the Anti-Kickback Pawls. In the

event that the Main Barrier Guard and Anti-Kickback Pawls are removed, the Riving Knife maintains its functionality as material splitter, and is

adjustable to three positions. Because of this adjustability, the Riving Knife can be appropriately

positioned for all cutting applications.

➋ Main barrier guard

The main guard is comprised of a pair of plastic barriers attached to the metal upper barrier

guard. The side barriers (one to the left and one

to the right of the blade) operate independently

of one another, maintaining maximum blade coverage during cutting operations. The main guard

incorporates a quick-connect attachment point

and can be attached or removed from the blade

guarding system independent of the Anti-Kickback Pawls and Riving Knife.

Note: To best secure the main guard for transport, adjust the blade to its lowest position. This

keeps the guard tight to the table surface and

prevents damage related to the guard swinging

during transport.

➌ Anti-Kickback Pawls

In the event of kickback, the Anti-Kickback Pawls,

(also known as dogs, or pawls) are intended to

help prevent the board from being thrown in the

direction of the user. The sharp teeth of the pawls

are intended to “catch” the material in the event

of kickback.

ATTACHMENT/REMOVAL

(see pages 15 and 16 for detailed instructions)

The three primary components of the Smart

Guard blade guarding system are designed for

rapid attachment, adjustment, and/or removal

without the need for additional tools.

The Main Barrier Guard component can be

quickly attached and detached through the use