Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

For English Parlez-vous français? ¿Habla español?

See page 2 Voir page 14 Ver página 26

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free

for Consumer

Information &

Service Locations

Pour tous renseignements et

pour obtenir la liste des centres

de service après-vente, appelez

le numéro gratuit :

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

GTA3800

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 1

Page 2

-2-

Read and understand all

ins t r u c tions. F a ilure to

follow all instructions listed below and in your

miter saw manual m ay result in serious

personal injury.

Ful l y ass e m b l e an d ti g h t e n al l th e

fasteners required for this stand. Also

rem e m ber t o o c c asiona l l y c h e ck t h e

stand and make sure it is still tight. A

loose stand is unstable and may shift in use

and cause serious injury.

Turn tool switch off and disconnect power

before mounting to the stand. Unintended

startup during assembly can cause injury.

Before operating make sure the entire unit

is placed on a solid, flat, level surface.

Serious injury could occur if tool with stand is

unstable and tips.

Never stand on tool or its stand or use as

ladder or scaffolding. Serious injury could

occur if the tool is tipped or the cutting tool is

acc i d e n tally con t a c t ed. Do not store

materials on or near the tool such that it is

necessary to stand on the tool or its stand to

reach them.

Use only Bosch replacement parts. Any

others may create a hazard.

The Miter Saw should be firmly mounted to

the stand per the instruction manual.

After mounting the Miter Saw to the stand,

align, position and balance the Miter Saw per

the instruction manual.

Before use, verify that all stand parts are free

from damage and/or deformity.

Bef o r e u se, veri f y t h at all pa r t s o r

com p o n e nts of the stand are prope r l y

installed.

Before use, swing open each of the legs until

the pin clicks, locking the legs in position.

When mounting the Miter Saw to the stand,

make sure that the tool lock knobs are in the

“u nlo ck” position, so the t ool mo unt w ill

engage with the main rail. Be sure to hold the

saw until it is s ecured to prevent it from

falling off the rails. Mounting bracket locking

knobs should then be tightened.

Wh en remo vin g t he Mite r S aw fro m t he

stand, rotate the tool mount lock knobs until

they are in the “unlock” position. Hold the

Miter Saw firmly to prevent the saw from

falling off the rails. Carefully remove the Miter

Saw.

Do not modify the stand in any manner or

use the stand for any purpose other than is

stated in these instructions.

Because cut material may cause the stand to

become unb al anced, always be sure the

material is supported properly. Also, if the

piece being cut is placed far beyond the work

support, stand legs on the opposite side may

sud d e n l y be li f t e d up due t o w eight

imbalance. To prevent this from occurring,

hold the opposite side firmly before cutting.

!

WARNING

Important Safety Instructions for Using This Miter Saw Stand

This GTA3800 Miter Saw Stand is designed to be used with

the following miter saws:

Other units may be compatible, but have not been verified for use with the GTA3800 system.

Bosch

42 1 2 , 42 1 2L, 4310 , 44 1 0 ,

4410(L,) 4412, 4405, 5412(L,)

5312, 3912, 3915, 3918, 3924,

GCM12SD, CM12

Delta

36 - 2 5 5, 3 6 - 255L , 36 - 240,

MS450

DeWalt

DW712, DW705S, DW703,

DW708, DW706, DW718,

DW715, DW716, DW709,

DWS780, DW717, DW713,

DW716

Makita

LS 1 2 1 4, L S 1 221, LS 1013 ,

LS1212, MS1214F

Milwaukee

6497-6

Ridgid

MS1065LZ, MS1250LZ

Ryobi

TS1353DXL, TS1341, TS1552

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 2

Page 3

Safety Instructions for Miter Saw Stands ..................................................................................2

Table of Contents ......................................................................................................................3

Unpacking and Checking Contents............................................................................................4

Getting to Know Your Miter Saw Stand ....................................................................................5

Assembly ..............................................................................................................................6-11

Adjustments ............................................................................................................................12

Operation ................................................................................................................................12

Maintenance ............................................................................................................................13

-3-

Table of Contents

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 3

Page 4

For your own safety, never connect plug to

power source outlet until all assembly steps

are complete and until you have read and

understood the entire owner’s manual.

Model GTA3800 Miter Saw Stand is shipped

complete in one box.

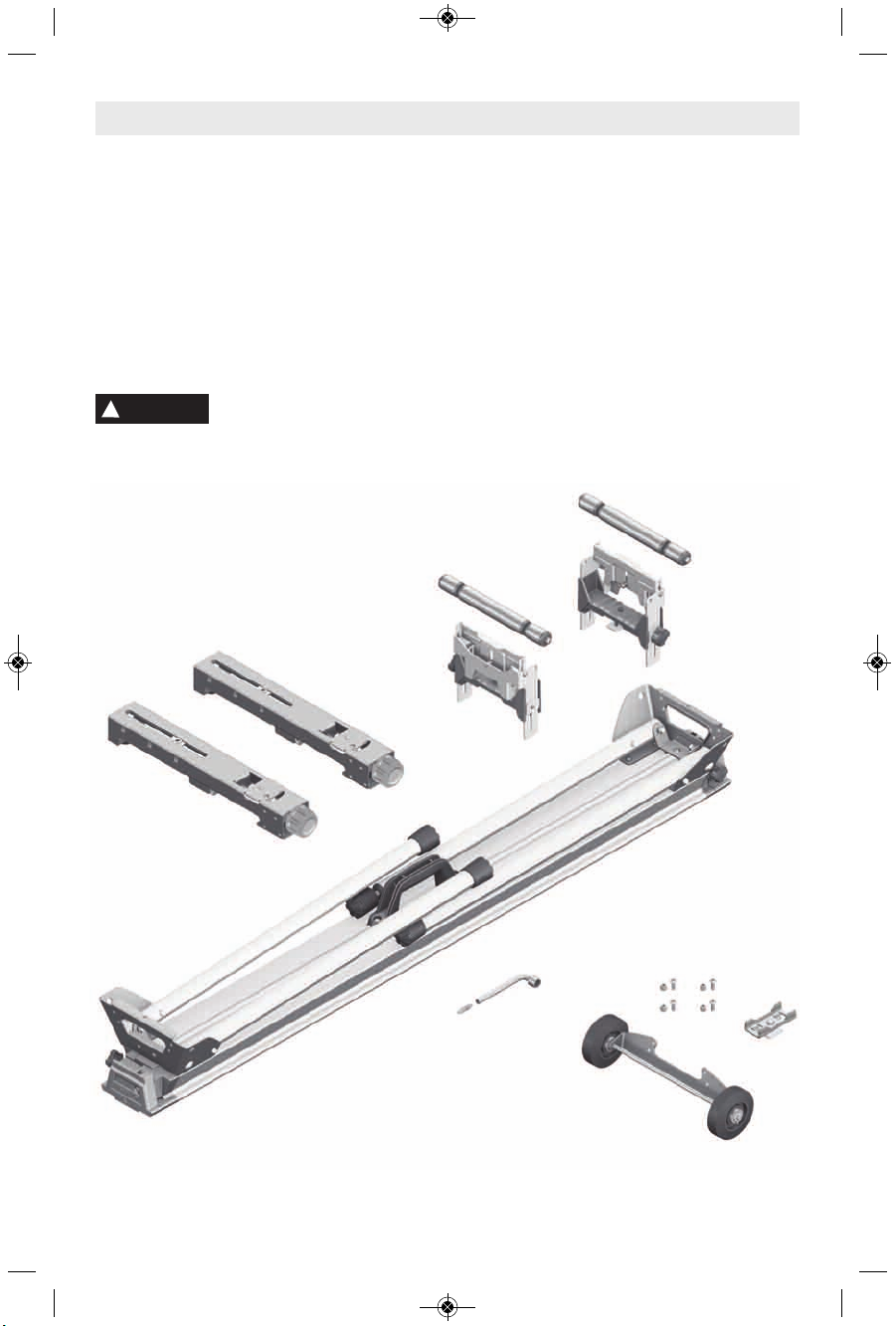

UNpACk ING AND CHECk ING Co NTENTS

Separate all parts from packing materials and

check each one with the “Table of Loose

Parts” to make sure all items are accounted for

before discarding any packing material.

If any parts are missing, do

not at tempt to assemble the

stand until the missing parts are obtained and

are installed correctly.

Table of Loose parts

ITEM DESCRIpTIo N QTY.

A Miter Saw Stand 1

B Tool Mounting Bracket 2

C Material Support 2

D Roller Set 2

E Wheel 2

F Wheel Axle 1

G Transport Stop 1

H Multi-purpose Wrench 1

(in stand handle)

Unpacking and Checking Contents

-4-

A

!

WARNING

B

C

D

E

G

F

H

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 4

Page 5

-5-

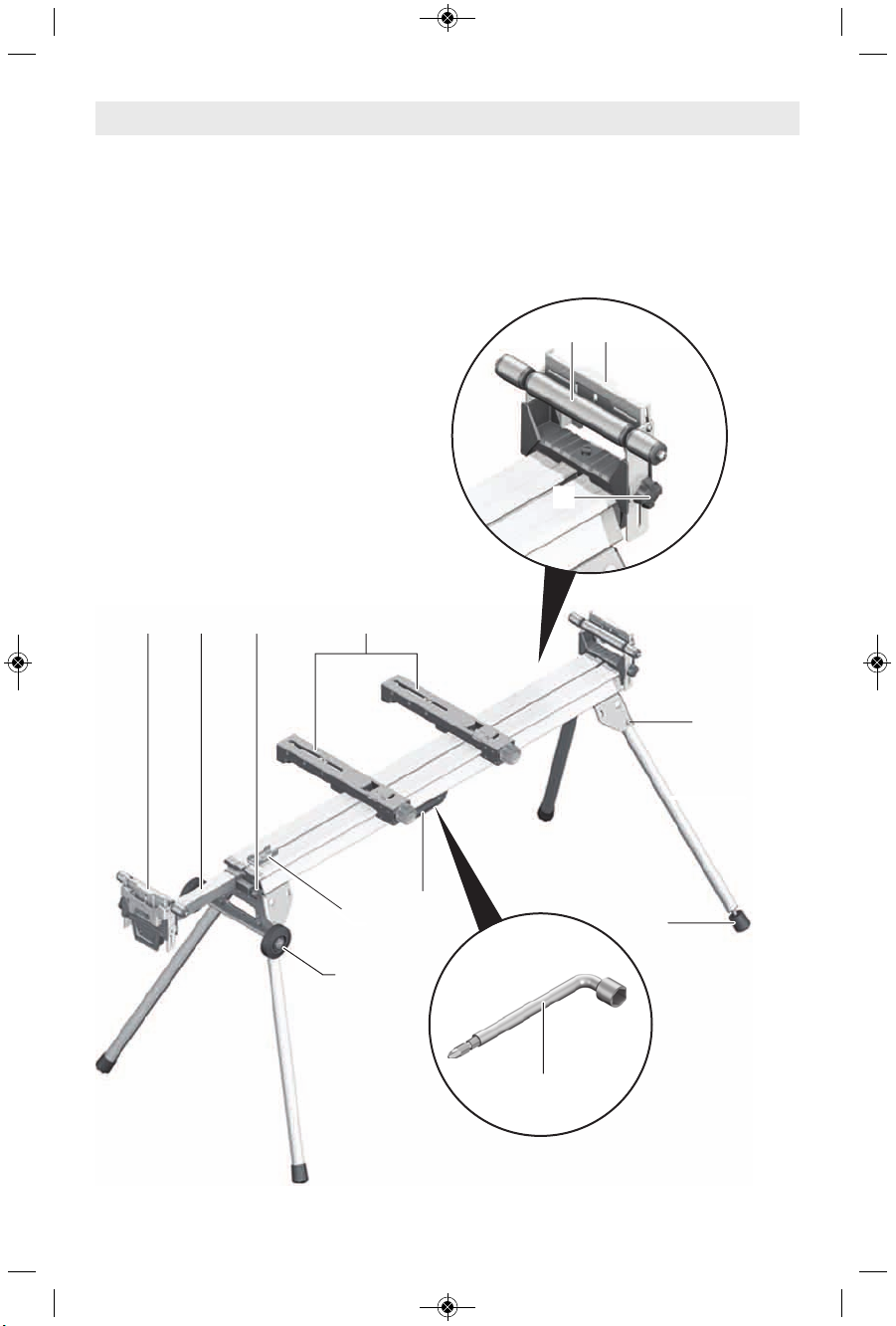

Getting To k now Your Miter Saw Stand

1

23 4

5

6

7

8

13

12

9

10

11

1. Roller/Material Support with

Repetitive Stop

2. Table Extension

3. Table Extension Lock Knob

4. Tool Mounts

5. Roller/Material Support Height

Adjustment Knob

6. Roller

7. Repetitive Stop

8. Adjustable Foot

9. Carry Handle

10. Transport Stop

11. Transport Wheels

12. Multi-purpose Wrench

13. Lock/Unlock Pin

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 5

Page 6

-6-

Assembly

To o LS NEEDED Fo R ASSEMBLY

• Included Multi-purpose Wrench

pREpARING THE STAND

1. Lay the stand’s top surface down on the

floor with the folded legs on top.

2. Push in a leg locking pin and rotate that leg

up until the locking pin clicks into place. See

Fiqure A.

3. Repeat with the remaining three legs.

4. Lift the stand by the carrying handle and

place it in an upright position.

5. Check to ensure the stand is stable and all

the legs have the locking pins engaged.

To LEvEL STAND

The stand is equipped with an adjustable foot

for leveling the stand.

To adjust, turn the foot clockwise to raise leg or

counter-clockwise to lower the leg. See Figure B.

To reduce the risk of injury,

insure the stand is stable

and level before operating the saw. Choose

a level area to set-up the stand and adjust the

ad just abl e foot so tha t a ll f our le gs are

touching the ground.

!

WARNING

FIG. A

FIG. B

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 6

Page 7

-7-

1

2

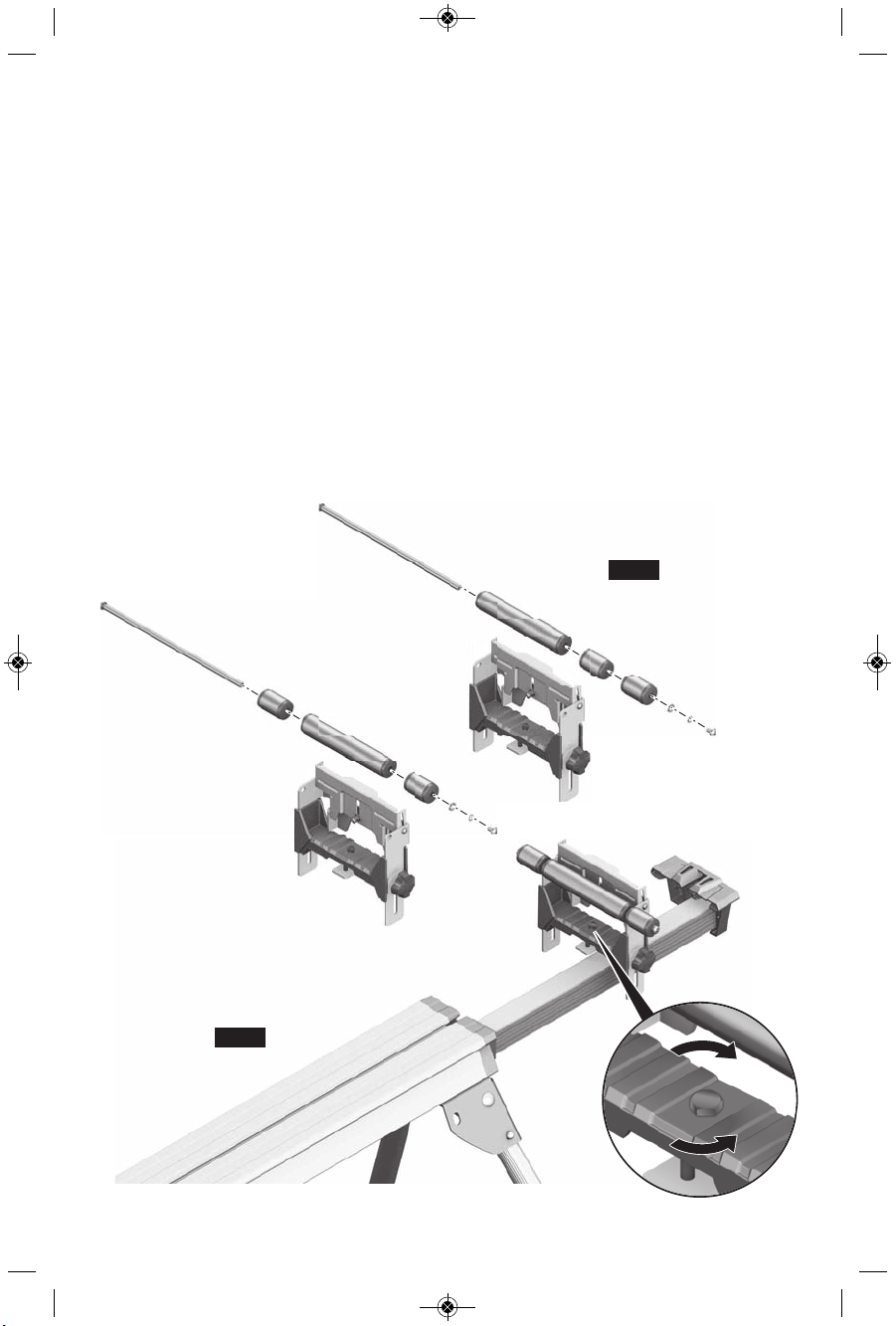

Mo UNTING THE RoLLER/MATERIAL

SUppo RT AND REpETITIvE STo p

1. Loosen the lock knobs and pull out both

table extensions approximately 4-inches

(102 mm) and lock into place.

2. With the Repetitive Stop facing outward,

slide the Roller/Material Support onto the

mounting plate with the bolt fitting into the

vertical slot. Make sure the material support

fully seats onto the mounting plate. See

Figure D.

3. Using the supplied Multi-purpose Wrench,

tighten the hex bolt until the Roller/Material

Support is secured.

4. Test for a secure fit by unlocking the table

extension and moving it in and out by the

Material Support. The Material Support

should remain secured.

Mo UNTING THE RoLLERS To THE

MATERIAL SUppo RT

1. Unscrew the Phillips screw of the roller stand

with the M ul ti-purp os e tool provid ed a nd

disassemble. If required, hold the lock nut on

the other side of the roller using a wrench (10

mm).

2. See Figure C for the two different configurations,

dependi ng on the size miter saw you are

using, for aligning the individual rollers to the

material support with the internally threaded

rod.

Config uration 1 offers even support on both

sides for larger miter saws, while configuration 2

offers more support on either the front or back

for smaller sized miter saws.

3. Arrange the individual rollers as required and

slide the threaded rod through the rollers and

material support.

4. Once threaded through, secure the alignment

by replacing and tightening the Phillips Head

Screw.

FIG. C

FIG. D

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 7

Page 8

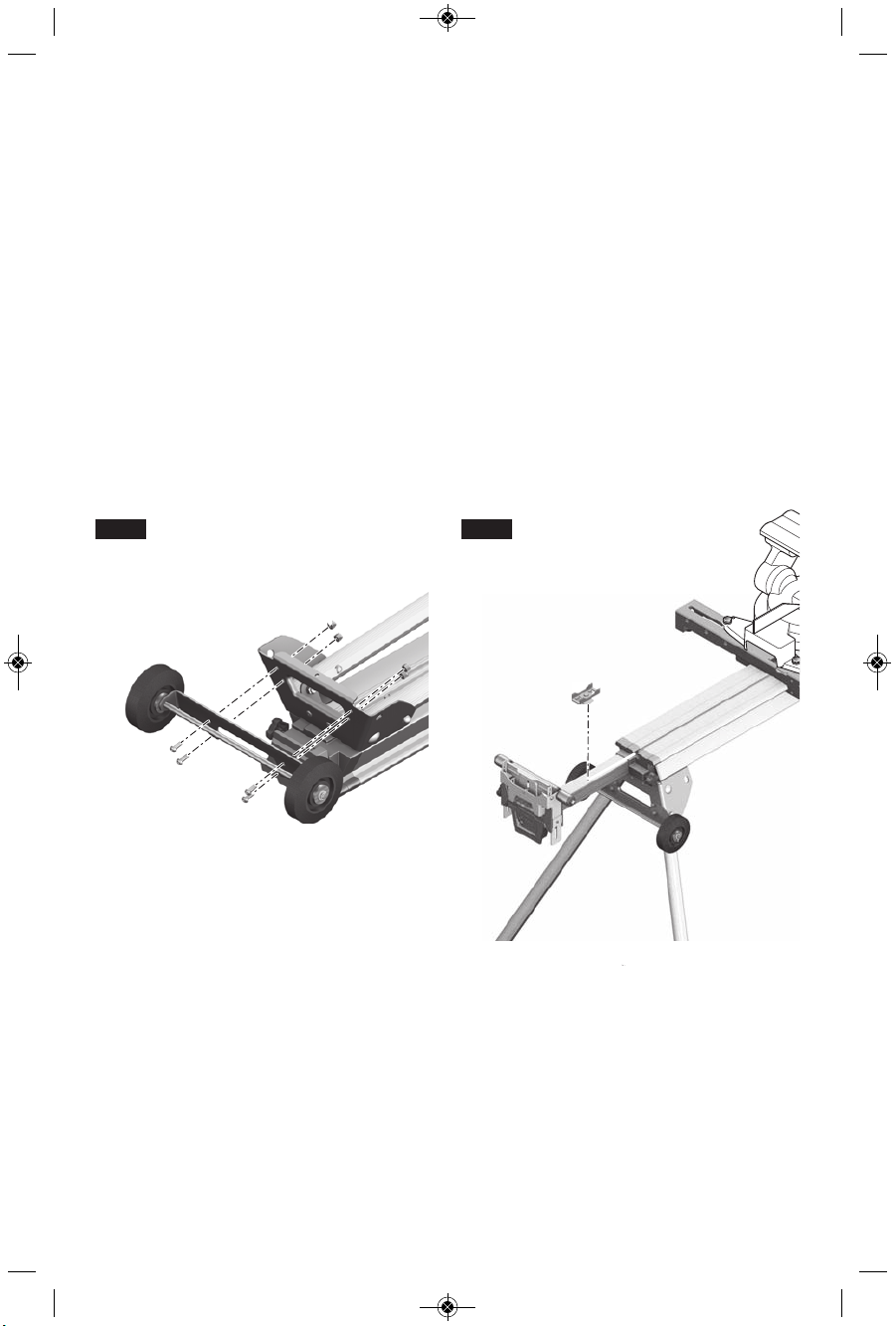

ASSEMBLING TRANSpo RT WHEELS

Th e Tra nsp ort W hee ls al low t he us er to

relocate the stand without moving the saw.

The wheels can be attached to either the right

or left side of the stand.

1. Lay the stand upside down on the floor with

folded legs facing upward.

2. Line up the Transport Wheel Assembly with

the hole pattern either on the right or left

side of the stand.

3. Utilize the included Multi-purpose tool and

insert the M6 x 12mm Allen head screw

through the wall and attach the M6 Nylok

Nut. Repeat with three (3) remaining and

tighten.

4. Roll the stand over s o it is lying on its

wheels and the stand should roll across the

ground smoothly when using the opposite

end as a handle.

TRANSpo RT STo p

1. The GTA3800 includes a Transport Stop to

help prevent the saw from sliding off the

stand in the event it is not secured to the

table prior to transport.

2. Loosen the locking knob on the side of the

saw stand on which the transport wheels

are fastened and pull the table extension

out about 4-inches (102 mm).

3. Insert the transport stop into the groove in

the table top surface and slide it so it is

completely within the main table; beyond

the blue end cap.

4. Use the Multi-purpose tool to firmly tighten

the hex bolt in the stop so it does not move

and will help prevent the tool from slipping

down during transport.

-8-

FIG. E FIG. F

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 8

Page 9

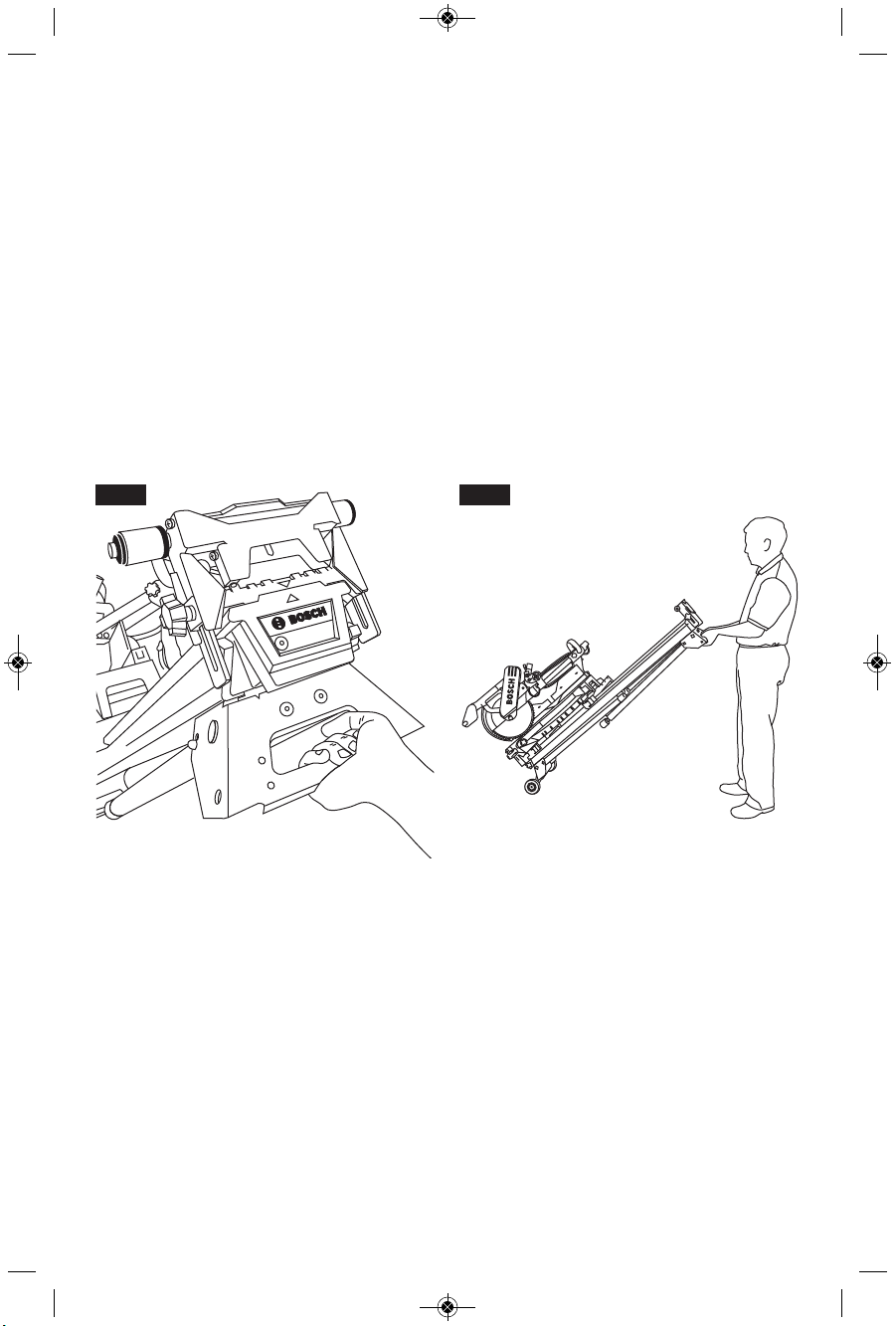

TRANSpo RTING STAND WITH SAW

1. Make sure the tool mount lock knobs on

each mount are in the open and unlocked

position (see fig. I, p10).

2. Slide saw along table top surface until it is

against the Transport Stop (see page 8).

Note: For most comfortable transport, saw

should be positioned at the end of the stand

cl ose st to the Tra nsp ort Wheels. Ad jus t

Transport Stop, if necessary.

3. Close and lock the Extension Rails (see

page 12).

Note: Sticker designating lift handle location

affixed to stand end cap. These are your lift

handles and should be used when lifting the

stand for the following procedures.

4. Fold stand legs: Begin at end with installed

Tr ans por t Wheels. Fir st, lift stan d at

designated lift handle. Push in a leg locking

pin and rotate that leg up until the locking pin

clicks into place. (See page 6) Repeat for

second leg and lower st and down onto

wheels.

5. Repeat same step on opposite side, folding

legs into place.

6. To transport, grip the lift handle (Fig. G) and

roll to location on Transport Wheels (Fig. H).

7. To set up stand for use, fo llo w same

instructions above, starting with either side of

stand desired.

-9-

FIG. G

FIG. H

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 9

Page 10

Mo UNTING MITER SAW To STAND

Note: Unfold legs and set saw up in working

position. (See page 6 for instructions.)

1. Locate the tool mount assemblies, place

one (1) on the rail against the red tool

mount secondary stop, and rotate the lock

knob clockwise to the locked position, as

shown in figures I and J and L.

2. Measure the width of the rear mounting

holes of the miter saw, place the other

to o l m oun t on t h e r ail wit h t he s ame

distance apart as shown in figure K, and

rotate the lock knob clockwise to the locked

position.

-10-

FIG. I

FIG. K

FIG. L

1

2

FIG. J

LOCK KNOB

LOCK KNOB

UNLOCK

LOCK

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 10

Page 11

-11-

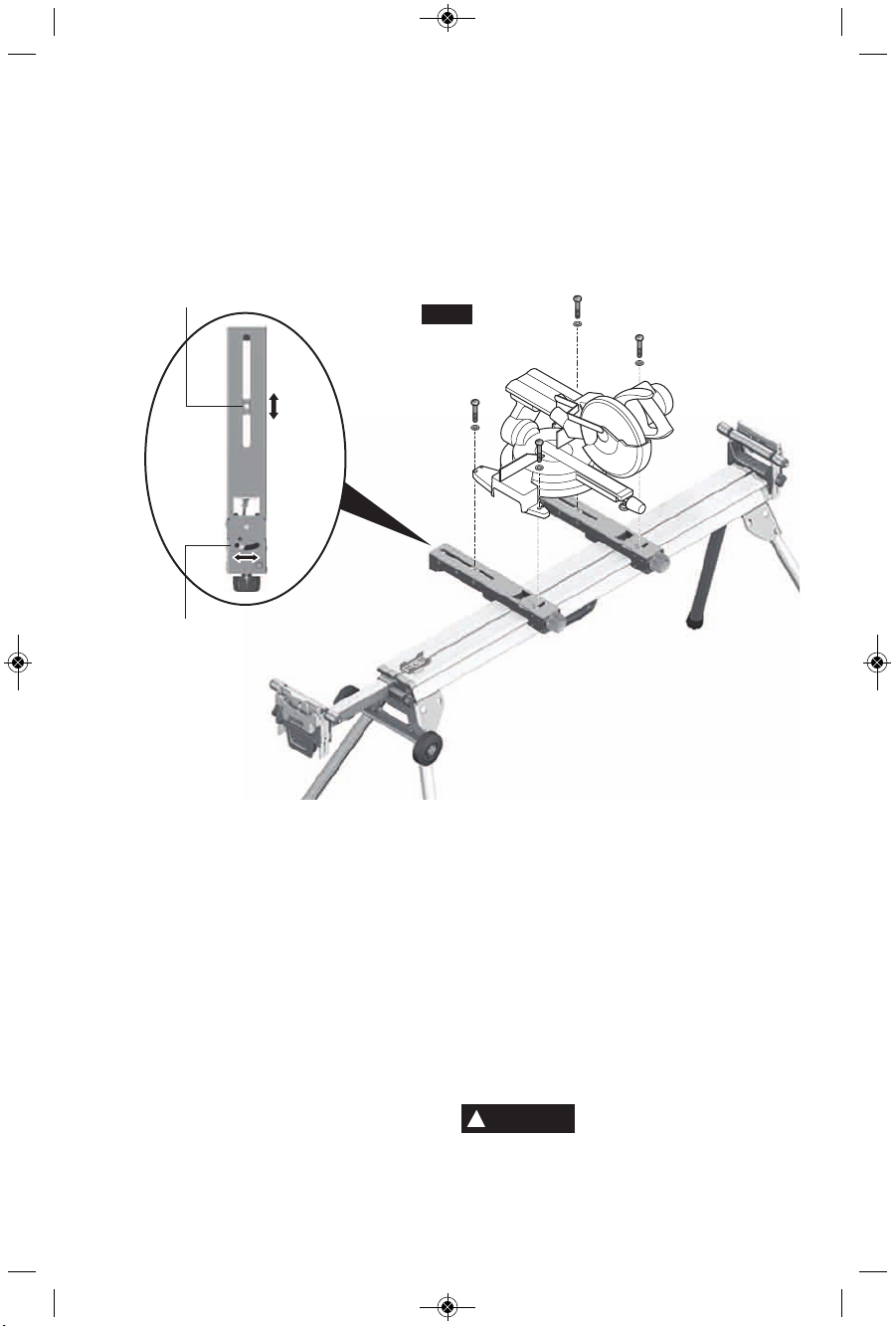

3. Place miter saw on top of the tool mounts,

Fig u r e M. Ali g n m ounting h o les by

adjusting rear sliding nuts and front swivel

nu ts. Be sur e t he fron t o f t he saw is

aligned to the front of both tool mounts.

4. Place one (1) M6 flat washer onto one (1)

8 mm x 45 mm bolt, and insert through

miter saw base and loosely tighten into

tool mounts.

5. Repeat step 4 of this procedure for the

remaining three (3) hole locations.

6. Securely tighten all four (4) bolts. Do not

over tighten.

REMo v E SAW FRo M STAND

(WITH To o L Mo UNTS ATTACHED)

1. Make sure the tool mount lock knobs on

each mount are in the open and unlocked

position (see fig. I, p10).

2. Locate the carry handles at the base of

the saw. Place one hand on the saw base

handle and the second on the saw’s top

handle if available. Holding tightly, tilt the

saw (with the tool mounts still attached)

toward yourself and lift it from the stand.

ATTACH THE SAW To THE STAND

(WITH To o L Mo UNTS ATTACHED)

1. Make sure the tool mount lock knobs on

each mount are in the open and unlocked

position (see fig. I, p10).

2. Locate the carry handles at the base of

the saw. Place one hand on the saw base

handle and the second on the saw’s top

handle if available. Lift the saw to the rail

assembly.

3. Line up the left tool mount next to the red

secondary stop on the rail assembly as

close as possible.

4. Tilt the saw until the front jaws of both tool

mounts are engaged on the rail. With both

hands on the saw handles, guide the saw

back to its level position on the rail (See

Page 10).

5. Rotate lock knob on each tool mount to

the locked position (see fig. L, p10).

Be sure both t ool mounts

are in the locked position

before operating or transporting the saw.

!

WARNING

FIG. M

REAR

SLIDING NUT

FRONT

SWIVEL NUT

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:47 AM Page 11

Page 12

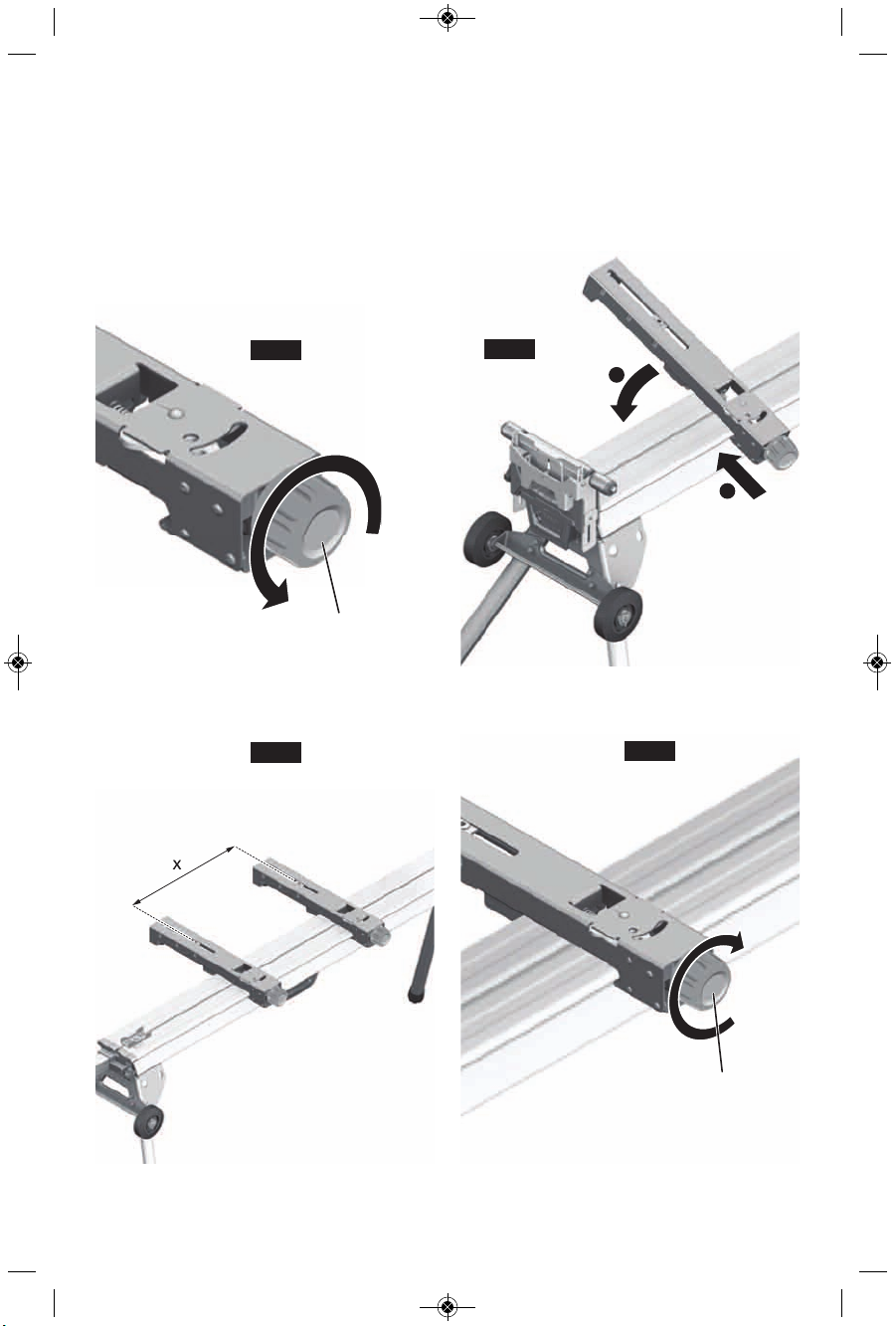

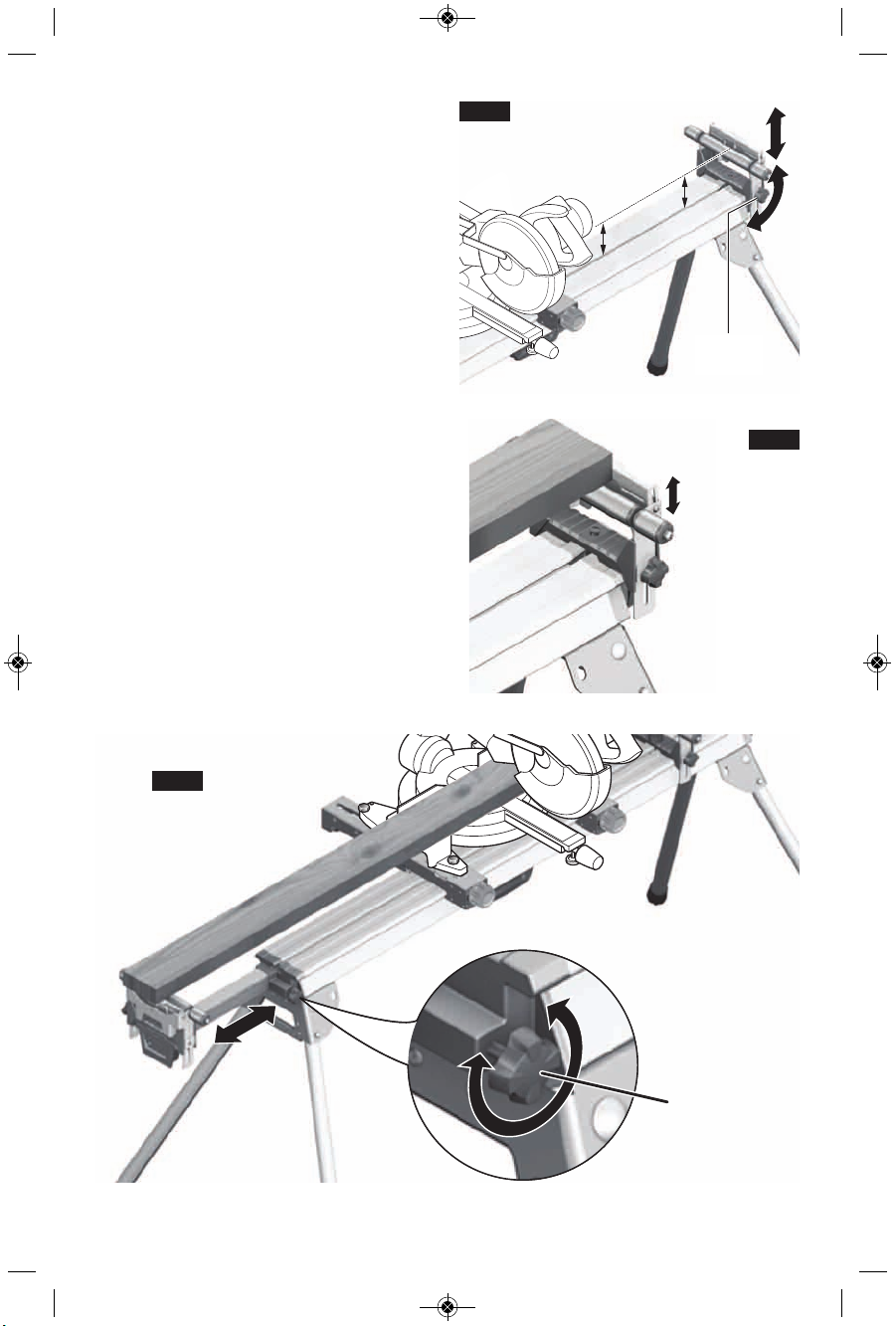

Wo Rk HEIGHT SUppo RT ADj USTMENT

1. Loosen the locking knob located at the end

of the expansion rail, as shown in figure N,

and raise the work height support so it is

level with the table top of the attached

miter saw.

2. Retighten knob and repeat on opposite

side.

REpETITIv E STo p ADj USTMENT

To raise the repetitive stop: Lift up and in

place as shown in figure O.

To stow: Push the repetitive stop in toward

the rail assembly and down.

Repeat on opposite side.

USING THE EXTENSIo N RAILS

See Figure P.

Use the extension rails when working with

larger workpieces.

To extend the rails:

1. Loosen the extension adjustment knob.

2. Extend the rail to the desired position.

3. Tighten the extension adjustment knob.

-12-

FIG. N

FIG. O

FIG. P

LOCK

KNOB

EXTENSION

ADJUSTMENT

KNOB

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 12

Page 13

To reduce the risk of injury,

pe riodically check t hat a ll

fasteners are attached and adjusted according

to the assembly instructions included in this

manual.

SERvICE

Wh en s ervi cin g, u se o nly

identical Bosch replacement

parts. Use of any other parts may create a

hazard or cause product damage.

CLEANING

Avoid using solvents when cleaning plastic

parts. Most plastics are susceptible to damage

from various types of commercial solvents and

may be damaged by their use. Use clean

cloths to remove dirt, dust, oil, grease, etc.

Do not at any time let brake

fluids, gasoline, petroleumbased products, penetrating oils, etc., come in

contact with p lastic part s. Chemical s can

damage, weaken or destroy plastic which may

result in serious personal injury.

Maintenance

!

WARNING

-13-

!

WARNING

!

WARNING

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 13

Page 14

Lisez et comprenez toutes

les instructions. Le non-

respect de toutes les instructions indiquées ci-dessous

et dans le mode d’emploi de votre scie à onglet pourrait

causer des blessures graves.

Assemblez complètement et serrez toutes les

attaches de fixation requises pour ce support.

Souvenez-vous aussi d’inspecter le support de temps

en temps pour vous assurer que ses attaches de

fixation sont toujours bien serrées. Un support dont

les attaches de fixation seraient desserrées est instable

et risquerait de bouger pendant l’emploi et de causer

des blessures graves.

Mettez l’interrupteur de l’outil en position d’arrêt et

débranchez le cordon d’alimentation avant de monter

la scie sur le support. Une mise en marche accidentelle

pendant le montage risquerait de causer des blessures

graves.

Avant de mettre la scie en marche, assurez-vous

qu’elle repose entièrement sur une surface solide,

plate et horizontale. Le placement de la scie sur un

support instable risquerait de la faire basculer et de

causer des blessures graves.

Ne montez jamais sur la scie ou sur son support, et ne

l’utilisez pas pour servir d’échelle ou d’échafaudage.

Vous risqueriez une blessure grave si l’outil basculait ou

en cas de contact accidentel avec l’outil. Ne placez pas

de matériaux sur l’outil ou à proximité de celui-ci de telle

manière qu’il pourrait être nécessaire de monter sur

l’outil ou sur son support pour les atteindre.

N’utilisez que des pièces de rechange Bosch ; l’emploi

de pièces différentes risquerait d’être dangereux.

La scie à onglet doit être montée fermement sur le

support, conformément au mode d’emploi.

Après avoir monté la scie à onglet sur le support,

alignez, positionnez et équilibrez la scie à onglet

conformément au mode d’emploi.

Avant l’emploi, assurez-vous qu’aucune des parties du

support n’est endommagée et/ou déformée.

Avant l’emploi, assurez-vous que tous les éléments ou

composants du support sont installés correctement.

Avant l’emploi, ouvrez chacun des pieds jusqu’à ce que

vous entendiez le déclic indiquant que le pied est

verrouillé en position ouverte.

Lorsque vous installez la scie à onglet sur le support,

assurez-vous que les boutons de verrouillage de l’outil

sont dans la position déverrouillée (« unlock »), de telle

sorte que les pièces de fixation s’engageront sur le rail

principal. Tenez toujours la scie dans vos mains tant

qu’elle n’est pas assujettie en position verrouillée afin de

ne pas risquer qu’elle tombe des rails. Serrez les

boutons de verrouillage des dispositifs de fixation.

Lorsque vous retirez la scie à onglet du support, faites

tourner les boutons de verrouillage des pièces de

fixation de l’outil jusqu’à ce qu’ils soient dans la position

déverrouillée (« unlock »). Tenez fermement la scie à

onglet pour qu’elle ne tombe pas des rails. Puis retirez

la scie à onglet en prenant toutes les précautions

nécessaires.

Ne modifiez pas le support de quelque manière que ce

soit et ne l’utilisez pas dans un but autre que celui qui

est indiqué dans ces instructions.

Étant donné que les matériaux que vous coupez

risquent d’affecter l’équilibre du support, assurez-vous

toujours que l’ouvrage est suffisamment supporté. En

outre, si le matériau que vous coupez est placé de telle

sorte qu’il dépasse nettement le support de la scie, les

pieds du côté opposé risquent d’être soulevés tout à

coup en raison du déséquilibre du poids. Pour ne pas

risquer que cela se produise, tenez fermement le côté

opposé avant de commencer à couper.

-14-

Consignes de sécurité importantes pour l’utilisation

de ce support pour scie à onglet

AVERTISSEMENT

!

Ce support pour scie à onglet GTA3800 est conçu pour emploi avec les

scies à onglet suivantes :

D'autres scies peuvent être compatibles, mais leur compatibilité d'emploi avec le

système GTA3800 n'a pas été vérifiée.

Bosch

42 1 2 , 42 1 2 L , 43 1 0 , 44 1 0,

4410(L,) 4412, 4405, 5412(L,)

5312, 3912, 3915, 3918, 3924,

GCM12SD, CM12

Delta

36 - 2 5 5, 3 6 -255 L , 36 - 2 40,

MS450

DeWalt

DW712, DW705S, DW703,

DW708, DW706, DW718,

DW715, DW716, DW709,

DWS780, DW717, DW713,

DW716

Makita

LS 1 2 1 4, LS12 2 1 , LS 1013 ,

LS1212, MS1214F

Milwaukee

6497-6

Ridgid

MS1065LZ, MS1250LZ

Ryobi

TS1353DXL, TS1341, TS1552

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 14

Page 15

-15-

Table des matières

Consignes de sécurité pour les supports pour scie à onglet....................................................................................14

Table des matières.....................................................................................................................................................15

Déballage et inspection du contenu...........................................................................................................................16

Connaissance élémentaire de votre support pour scie à onglet................................................................................17

Assemblage..........................................................................................................................................................18-23

Réglages....................................................................................................................................................................24

Fonctionnement.........................................................................................................................................................24

Entretien.....................................................................................................................................................................25

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 15

Page 16

-16-

Pour votre propre sécurité,

ne branchez jamais la fiche

dans une prise de courant avant que toutes les étapes

de l’assemblage n’aient été accomplies – et avant

d’avoir lu et compris tout le mode d’emploi.

Le support de la scie à onglet modèle GTA3800 est

expédié au complet dans une seule boîte.

DEBALLAGE ET INSPECTION DU CONTENU

Déballage et inspection du contenu. Séparez toutes les «

pièces en vrac » des matériaux d’emballage et comparez

chaque élément à l’écriture correspondante dans le «

Tableau des pièces en vrac » afin de vous assurer que

tous les éléments sont présents avant de jeter de

quelconques matériaux d’emballage.

Si des pièces sont

manquantes, ne tentez pas

d’assembler le support avant de vous être procuré les

pièces manquantes et de les avoir installées

correctement.

Tableau des pièces en vrac

Article Description Qté

A Support pour scie à onglet 1

B Dispositif de fixation de l’outil 2

C Support du matériau 2

D Jeu de galets 2

E Roue 2

F Axe de la roue 1

G Butée pour le transport 1

H Clé universelle 1

(dans la poignée du support)

Déballage et inspection du contenu

AVERTISSEMENT

!

AVERTISSEMENT

!

A

B

C

D

E

G

F

H

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 16

Page 17

1

23 4

5

6

7

8

13

12

910

11

-17-

Connaissance élémentaire de votre support pour scie à onglet

1. Support du matériau/galet avec butée

répétitive

2. Rallonge de table

3. Bouton de verrouillage de la rallonge de la

table

4. Dispositifs de fixation de l’outil

5. Bouton de réglage de la hauteur du support

du matériau/galet

6. Galet

7. Butée répétitive

8. Pied réglable

9. Poignée pour le transport

10. Butée pour le transport

11. Roues pour le transport

12. Clé universelle

13. Goupille de verrouillage/déverrouillage

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 17

Page 18

-18-

OUTILS NÉCESSAIRES À L’ASSEMBLAGE

• Y compris la clé universelle

PRÉPARATION DU SUPPORT

1. Posez la surface supérieure du support sur le sol

avec les pieds repliés au-dessus.

2. Enfoncez une goupille de verrouillage du pied et faites

tourner ce pied vers le haut jusqu’à ce que la goupille

de verrouillage se bloque en place avec un déclic

(voir Figure A).

3. Faites de même avec les trois autres pieds du support.

4. Soulevez le support en vous servant de la poignée de

transport, et placez-le en position verticale.

5. Inspectez le support pour vous assurer qu’il est

stable et que les goupilles de verrouillage sont bien

engagées dans tous les pieds.

MISE DE NIVEAU DU SUPPORT

Le support est muni d’un pied réglable qui permet

d’effectuer une mise de niveau précise.

Pour ajuster, tournez le pied dans le sens des aiguilles

d’une montre pour élever le pied ou dans le sens

contraire des aiguilles d’une montre pour l’abaisser.

Voir Figure B.

Pour réduire le risque de

blessure, assurez-vous que

le support est stable et de niveau avant de vous servir

de la scie. Choisissez une zone tout à fait horizontale

pour y installer le support et ajustez la hauteur du pied

réglable pour que tous les quatre pieds soient en

contact avec le sol.

FIG. A

FIG. B

AVERTISSEMENT

!

Assemblage

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 18

Page 19

-19-

1

2

FIG. C

FIG. D

MONTAGE DU SUPPORT DU MATÉRIAU/GALET

ET DE LA BUTÉE RÉPÉTITIVE

1. Desserrez les boutons de verrouillage et faites sortir

les deux rallonges de la table d’environ 4 po (100

mm), et verrouillez-les à nouveau dans cette position.

2. La butée répétitive étant orientée vers l’extérieur,

faites glisser le support de matériau/galet sur la

plaque de montage en insérant le raccord à boulon

dans la fente verticale. Assurez-vous que le support

de matériau tient totalement sur la plaque de

montage. Voir Figure D.

3. En utilisant la clé universelle fournie, serrez le boulon

hexagonal jusqu’à ce que le support de matériau/galet

soit bien assujetti.

4. Testez pour vous assurer que le montage est solide

en déverrouillant les rallonges de la table et en les

faisant rentrer et sortir plusieurs fois devant le

support de matériau. Celui-ci ne devrait pas se

libérer.

MONTAGE DES GALETS SUR LE SUPPORT

DE MATÉRIAU

1. Dévissez la vis cruciforme du support de galet en

utilisant la clé universelle fournie et démontez. Si

nécessaire, tenez en place le contre-écrou de l’autre

côté du galet avec une clé (10 mm).

2. Regardez la Figure C pour voir les deux

configurations différentes possibles en fonction de la

taille de la scie à onglet que vous utilisez pour aligner

les galets individuels et le support de matériau avec la

tige filetée à l’intérieur.

La configuration 1 offre un soutien uniforme des deux

côtés pour les scies à onglet de grande taille, tandis que

la configuration 2 offre plus de soutien soit à l’avant,

soit à l’arrière pour les scies à onglet de plus petite

taille.

3. Arrangez les galets individuels suivant les besoins et

faites glisser la tige filetée à travers les galets et le

support de matériau.

4. Après avoir enfilé la tige complètement, assujettissez-la

en position alignée en remettant les vis cruciformes

en place et en les serrant.

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 19

Page 20

-20-

ASSEMBLAGE DES ROUES POUR LE TRANSPORT

Les roues de transport permettent à l’utilisateur de

déplacer le support sans avoir besoin de démonter la

scie. Les roues peuvent être attachées au côté droit ou

au côté gauche du support.

1. Posez le support sur le sol sens dessus dessous avec

les pieds repliés orientés vers le haut.

2. Alignez l’ensemble de roues de transport avec la série

de trous orientée soit du côté droit, soit du côté

gauche du support.

3. Utilisez l’outil universel inclus et insérez la vis à tête à

six pans creux M6 de 12 mm à travers le mur, puis

attachez l’écrou Nylok M6. Faites de même avec les

trois (3) autres vis, puis serrez.

4. Changez la position du support pour qu’il repose sur

ses roues. Le support devrait pouvoir rouler en

douceur sur le sol quand son extrémité opposée est

utilisée comme poignée.

BUTÉE POUR LE TRANSPORT

1. Le modèle GTA3800 comprend une butée de

transport pour aider à empêcher la scie de glisser et

tomber du support au cas où elle n’aurait pas été

assujettie à la table avant le transport.

2. Desserrez le bouton de verrouillage sur le côté du

support de la scie sur lequel les roues de transport

sont attachées et faites sortie la rallonge de la table

d’environ 4 po (100 mm).

3. Insérez la butée de transport dans la rainure de la

surface supérieure de la table et faites-la glisser de

façon qu’elle repose complètement sur la partie

centrale de la table, au-delà du capuchon d’extrémité

bleu.

4. Utilisez l’outil universel pour serrez fermement le

boulon à tête hexagonale dans la butée afin qu’il ne

puisse plus bouger ; ceci empêchera l’outil de glisser

pendant le transport.

FIG. E FIG. F

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 20

Page 21

-21-

TRANSPORT DU SUPPORT AVEC LA SCIE

1. Assurez-vous qu e les boutons d e

blocage/déblocage du dispositif de fixation de l’outil

sur chacun de ces dispositifs sont dans la position

ouverte et débloquée (voir Fig. I, p. 22).

2. Faites glisser la scie de la longe de la surface

supérieure de la table jusqu’à ce qu’elle entre en

contact avec la butée de transport (voir page 20).

Remarque : pour assurer un transport plus confortable,

il convient de positionner la scie à l’extrémité du support

qui est la plus proche des roues de transport. Ajustez la

butée de transport si nécessaire.

3. Fermez et verrouillez les rails de rallonge (voir page

24).

Remarque : des autocollants indiquant l’emplacement

de la poignée pour le transport sont apposés sur le

capuchon d’extrémité du support. Cette partie du

support est la poignée que vous devrez utiliser lorsque

vous soulèverez le support pour les procédures

suivantes.

4. Repli des pieds du support : commencez par

l’extrémité proche de l’endroit où les roues de

transport sont installées. Tout d’abord, soulevez le

support en utilisant la poignée de transport désignée.

Enfoncez une goupille de verrouillage du pied et faites

tourner ce pied vers le haut jusqu’à ce que la goupille

soit bien mise à sa place en faisant un déclic. (Voir

page 18). Faites de même pour le deuxième pied, et

abaissez le support sur les roues.

5. Suivez la même procédure sur le côté opposé en

repliant les pieds en place.

6. Pour transporter le support avec la scie, saisissez la

poignée de transport (Fig. G) et faites rouler

l’ensemble à l’endroit désiré sur les roues de transport

(Fig. H).

7. Pour préparer le support en vue de son utilisant,

suivez les mêmes instructions que ce qui est indiqué

plus haut, en commençant par l’un quelconque des

côtés du support, suivant ce que vous désirerez.

FIG. G FIG. H

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 21

Page 22

-22-

MONTAGE DE LA SCIE À ONGLET SUR LE SUPPORT

Remarque : dépliez les pieds et mettez la scie en

position de travail (voir page 18 pour les instructions).

1. Localisez les ensembles de pièces de fixation de

l’outil, placez-en une (1) sur le rail contre la butée

secondaire rouge prévue pour la pièce de fixation

de l’outil et faites tourner le bouton de verrouillage

dans le sens des aiguilles d’une montre jusqu’à la

position verrouillée, comme illustré aux Figures I, J

et L.

2. Mesurez la largeur des trous de montage à l’arrière

de la scie à onglet, placez l’autre pièce de fixation

de l’outil sur le rail avec la même distance de

séparation que ce qui est illustré à la Figure K, et

faites tourner le bouton de verrouillage dans le

sens des aiguilles d’une montre jusqu’à ce qu’il soit

en position verrouillée.

FIG. I

FIG. K

FIG. L

1

2

FIG. J

BOUTON DE

VERROUILLAGE

BOUTON DE

VERROUILLAGE

DÉVERROUILLÉE

(« UNLOCK »)

VERROUILLÉE

(« LOCK »)

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 22

Page 23

-23-

3. Placez la scie à onglet en dessus des dispositifs de

fixation de l’outil, Figure M. Alignez les trous de

montage en ajustant les écrous coulissants à

l’arrière et les écrous pivotants à l’avant. Assurezvous que le devant de la scie est aligné avec la

partie avant des deux dispositifs de fixation de

l’outil.

4. Placez une (1) rondelle plate M6 sur un (1) boulon

de 8 mm x 45 mm, et insérez le boulon à travers la

base de la scie à onglet, puis serrez légèrement

dans les dispositifs de fixation de l’outil.

5. Recommencez l’étape 4 de cette procédure pour les

trois (3) autres emplacements des trous.

6. Serrez à fond tous les quatre (4) boulons. Ne serrez

pas excessivement.

FIG. M

ARRIÈRE

ÉCROU COULISSANT

AVANT

ÉCROU PIVOTANT

RETRAIT DE LA SCIE DU SUPPORT (AVEC LES

DISPOSITIFS DE FIXATION DE L’OUTIL ATTACHÉS)

1. Faites tourner les boutons de verrouillage pour le

mettre dans la position déverrouillée (voir Fig. I, p.

22).

2. Localisez les poignées de transport à la base de la

scie. Mettez une main sur la poignée du bas de la

scie et l’autre sur la poignée du haut de la scie si

cela est possible. Tout en tenant fermement, faites

basculer la scie (avec les dispositifs de fixation de

la scie toujours attachés) vers vous, et soulevez-la

du support.

FIXATION DE LA SCIE SUR LE SUPPORT (AVEC LES

DISPOSITIFS DE FIXATION DE L’OUTIL ATTACHÉS)

1. As sure z-vous que l es boutons de

blocage/déblocage du dispositif de fixation de

l’outil sur chacun de ces dispositifs sont dans la

position ouverte et débloquée (voir Fig. I, p. 22).

2. Localisez les poignées de transport à la base de la

scie. Mettez une main sur la poignée du bas de la

scie et l’autre sur la poignée du haut de la scie si

cela est possible. Soulevez la scie jusqu’au niveau

de l’ensemble de rail.

3. Alignez la pièce de fixation de l'outil de gauche à

côté (aussi près possible) de la butée secondaire

rouge sur l'ensemble de rail.

4. Inclinez la scie jusqu’à ce que les mâchoires avant

des deux dispositifs de fixation de l’outil soient

engagées sur le rail. Avec les deux mains sur les

poignées de la scie, guidez la scie pour la faire

revenir dans sa position équilibrée sur le rail (voir

page 22).

5. Faites tourner le bouton sur chaque pièce de

fixation de l’outil afin de la mettre dans la position

verrouillée (voir Fig. L, p. 22).

Assurez-vous que les deux

pièces de fixation de l’outil

sont dans la position verrouillée avant de mettre la

scie en marche ou de la transporter.

AVERTISSEMENT

!

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 23

Page 24

-24-

RÉGLAGE DU SUPPORT DE HAUTEUR

DE L’OUVRAGE

1. Desserrez le bouton de verrouillage situé au bout

du rail d’expansion, comme illustré à la Figure N,

puis soulevez le support de hauteur de l’ouvrage

pour qu’il soit au même niveau que le dessus de la

table de la scie onglet attachée.

2. Resserrez le bouton et recommencez la même

procédure du côté opposé.

RÉGLAGE DE LA BUTÉE RÉPÉTITIVE

Pour élever la butée répétitive : soulevez et mettez en

place comme illustré à la Figure O.

Pour ranger : poussez la butée répétitive vers

l’intérieur, en direction de l’ensemble de rail, et vers le

bas.

Faites de même de l’autre côté.

UTILISATION DES RAILS DE RALLONGE

Voir Figure P.

Utilisez les rails de rallonge lorsque vous travaillez

avec des ouvrages longs.

Pour faire sortir les rails :

1. Desserrez le bouton de réglage de la longueur de la

rallonge.

2. Faites sortir le rail jusqu’à la position désirée.

3. Serrez le bouton de réglage de la longueur de

rallonge.

FIG. N

FIG. O

FIG. P

BOUTON DE

VERROUILLAGE

BOUTON DE

RÉGLAGE DE LA

LONGUEUR DE

LA RALLONGE

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 24

Page 25

-25-

Pour réduire le risque de

blessure, inspectez

périodiquement toutes les attaches pour vous assurer

qu’elles sont ajustées et fixées conformément aux

instructions d’assemblage figurant dans ce mode

d’emploi.

SERVICE APRÈS-VENTE

N’utilisez que des pièces de

rechange Bosch identiques

lors de toute opération de service après-vente.

L’utilisation de quelconques autres pièces pourrait créer

un danger ou endommager le produit.

NETTOYAGE

Évitez d’utiliser des solvants lorsque vous nettoyez des

pièces en plastique. La plupart des plastiques peuvent

être endommagés par l’emploi de divers types de

solvants commerciaux. Utilisez des tissus propres pour

détacher les saletés, la poussière, l’huile, la graisse, etc.

Ne laissez jamais des

liquides de freins, de

l’essence, des produits à base de pétrole, des huiles

pénétrantes, etc. entrer en contact avec des pièce en

plastique. Les produits chimiques risquent

d’endommager, d’affaiblir ou de détruire les plastiques,

ce qui pourrait causer indirectement de graves

blessures corporelles.

Entretien

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 25

Page 26

Lea y entienda todas las

instrucciones. Si no se siguen

todas las instrucciones que se indican a continuación y

en el manual de su sierra para cortar ingletes, el

resultado podría ser lesiones corporales graves.

Ensamble y apriete completamente todos los

elementos de sujeción requeridos para esta base de

soporte. Recuerde también comprobar

ocasionalmente la base de soporte y asegurarse de

que sigue estando apretada. Una base de soporte floja

es inestable y podría desplazarse durante el uso y

causar lesiones graves.

Ponga el interruptor de la herramienta en la posición

de apagado y desconecte el enchufe de la fuente de

alimentación antes de montar la base de soporte. Un

arranque accidental durante el ensamblaje puede causar

lesiones.

Antes de la utilización, asegúrese de que toda la

unidad esté colocada sobre una superficie sólida,

plana y nivelada. Podrían ocurrir lesiones graves si la

herramienta con la base de soporte es inestable y se

inclina.

No se suba nunca a la herramienta o a su base de

soporte, ni la utilice como una escalera de mano o un

andamio. Se podrían producir lesiones graves si la

herramienta se vuelca o si se entra en contacto

accidentalmente con la herramienta de corte. No

almacene materiales sobre la herramienta ni cerca de

ella de manera que sea necesario subirse a la

herramienta o a su base de soporte para alcanzar dichos

materiales.

Utilice únicamente piezas de repuesto Bosch;

cualquier otra pieza podría crear un peligro.

La sierra para cortar ingletes se debe montar

firmemente en la base de soporte de acuerdo con el

manual de instrucciones.

Después de montar la sierra para cortar ingletes en la

base de soporte, alinee, posicione y equilibre la sierra de

acuerdo con el manual de instrucciones.

Antes de la utilización, verifique que todas las piezas de

la base de soporte estén libres de daños y/o

deformidad.

Antes de la utilización, verifique que todas las piezas o

componentes de la base de soporte estén instalados

correctamente.

Antes de la utilización, abra completamente cada una de

las patas hasta que la espiga se acople con un

chasquido, bloqueando las patas en esa posición.

Cuando monte la sierra para cortar ingletes en la base

de soporte, asegúrese de que los pomos de fijación de

la herramienta estén en la posición “desbloqueada”,

para que la montura para herramienta se acople con el

riel principal. Asegúrese de sostener la sierra hasta que

esté firmemente sujeta, para evitar que se caiga de los

rieles. Una vez que esté sujeta, se deben apretar los

pomos de fijación de los soportes de montaje.

Cuando retire la sierra para cortar ingletes de la base de

soporte, rote los pomos de fijación de las monturas

para herramienta hasta que estén en la posición

“desbloqueada”. Agarre firmemente la sierra para cortar

ingletes con el fin de evitar que la sierra se caiga de los

rieles. Retire cuidadosamente la sierra para cortar

ingletes.

No modifique la base de soporte de ninguna manera ni

la utilice para propósitos que no sean los que se indican

en estas instrucciones.

Debido a que el material cortado puede hacer que la

base de soporte se desequilibre, asegúrese siempre de

que el material esté soportado apropiadamente.

Además, si la pieza de trabajo que se está cortando se

coloca mucho más allá del soporte de la pieza de

trabajo, las patas de la base de soporte ubicadas en el

lado opuesto se podrían levantar repentinamente debido

al desequilibrio de peso. Para evitar que esto ocurra,

sostenga firmemente el lado opuesto antes de realizar el

corte.

-26-

Instrucciones de seguridad importantes para utilizar esta base

de soporte para sierras para cortar ingletes

ADVERTENCIA

!

La base de soporte para sierras para cortar ingletes GTA3800 está diseñada para utilizarse con

las siguientes sierras para cortar ingletes:

Otras unidades pueden ser compatibles, pero no han sido verificadas para utilizarse con el Sistema GTA3800.

Bosch

42 1 2 , 42 1 2 L , 43 1 0 , 44 1 0,

4410(L,) 4412, 4405, 5412(L,)

5312, 3912, 3915, 3918, 3924,

GCM12SD, CM12

Delta

36 - 2 5 5, 3 6 -255 L , 36 - 2 40,

MS450

DeWalt

DW712, DW705S, DW703,

DW708, DW706, DW718,

DW715, DW716, DW709,

DWS780, DW717, DW713,

DW716

Makita

LS 1 2 1 4, LS12 2 1 , LS 1013 ,

LS1212, MS1214F

Milwaukee

6497-6

Ridgid

MS1065LZ, MS1250LZ

Ryobi

TS1353DXL, TS1341, TS1552

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 26

Page 27

Instrucciones de seguridad para bases de soporte para sierras para cortar ingletes . . . . . . . . . . . . . . . . . . . . . .26

Índice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Desempaquetado y comprobación del contenido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Familiarización con la base de soporte para sierras para cortar ingletes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Ensamblaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30-35

Ajustes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Utilización . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

-27-

Índice

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 27

Page 28

A

B

C

D

E

G

F

H

-28-

Por su propia seguridad, no

conecte nunca el enchufe al

tomacorriente de la fuente de alimentación hasta que se

hayan completado todos los pasos y hasta que usted

haya leído y entendido todo el manual del usuario.

La base de soporte para sierras para cortar ingletes

modelo GTA3800 se envía completa en una caja.

DESEMPAQUETADO Y COMPROBACION

DEL CONTENIDO

Desempaquetado y comprobación del contenido.

Separe todas las “piezas sueltas” de los materiales de

empaquetamiento y compruebe cada artículo con la

“Tabla de piezas sueltas”, para asegurarse de que no

falte ningún artículo antes de desechar cualquier

material de empaquetamiento.

Si falta alguna pieza, no intente

ensamblar la base de soporte

hasta que las piezas que falten se hayan obtenido y se

hayan instalado correctamente.

Tabla de piezas sueltas

ARTICULO DESCRIPCION CANT.

A Base de soporte para

sierras para cortar ingletes 1

B Soporte de montaje para 2

herramienta

C Soporte para el material 2

D Juego de rodillos 2

E Rueda 2

F Eje de las ruedas 1

G Tope de transporte 1

H Llave multiuso 1

(en el mango de la base de soporte)

Desempaquetado y comprobación del contenido

ADVERTENCIA

!

ADVERTENCIA

!

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 28

Page 29

-29-

Familiarización con la base de soporte para sierras

para cortar ingletes

1

23 4

5

6

7

8

13

12

9

10

11

1. Soporte para rodillo / material con tope

repetitivo

2. Extensión de la mesa

3. Pomo de fijación de la extensión de la mesa

4. Monturas para herramienta

5. Pomo de ajuste de la altura del soporte para

rodillo / material

6. Rodillo

7. Tope repetitivo

8. Pie ajustable

9. Mango de transporte

10. Tope de transporte

11. Ruedas de transporte

12. Llave multiuso

13. Pasador de bloqueo / desbloqueo

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 29

Page 30

-30-

Ensamblaje

HERRAMIENTAS NECESARIAS PARA EL ENSAMBLAJE

• Llave multiuso incluida

PREPARACIÓN DE LA BASE DE SOPORTE

1. Coloque la superficie superior de la base de soporte

hacia abajo en el piso con las patas plegadas en la

parte de arriba.

2. Empuje hacia dentro el pasador de fijación de una

pata y rote esa pata hasta que el pasador de fijación

se acople a presión en su sitio (vea la Figura A).

3. Repita el procedimiento con las tres patas restantes.

4. Levante la base de soporte por el mango de

transporte y colóquela en posición al derecho.

5. Asegúrese de que la base de soporte sea estable y

que todas las patas tengan los pasadores de fijación

acoplados.

PARA NIVELAR LA BASE DE SOPORTE

La base de soporte está equipada con un pie ajustable

para nivelarla.

Para ajustar el pie, gírelo en el sentido de las agujas del

reloj para subir la pata o en sentido contrario al de las

agujas del reloj para bajar la pata. Vea la Figura B.

Para reducir el riesgo de

lesiones, asegúrese de que la

base de soporte esté estable y nivelada antes de

utilizar la sierra. Escoja un área nivelada para instalar

la base de soporte y ajuste el pie ajustable para que las

cuatro patas toquen el piso.

FIG. A

FIG. B

ADVERTENCIA

!

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 30

Page 31

-31-

1

2

FIG. C

FIG. D

MONTAJE DEL SOPORTE PARA RODILLO / MATERIAL

Y EL TOPE REPETITIVO

1. Afloje los pomos de fijación, jale hacia afuera ambas

extensiones de la mesa aproximadamente 4 pulgadas

(102 mm) y bloquéelas en la posición deseada.

2. Con el tope repetitivo orientado hacia fuera, deslice el

soporte de para rodillo / material sobre la placa de

montaje, de manera que el perno encaje en la ranura

vertical. Asegúrese de que el soporte para el material

se asiente completamente sobre la placa de montaje.

Vea la Figura D

3. Utilizando la llave multiuso suministrada, apriete el

perno hexagonal hasta que el soporte para rodillo /

material esté firmemente sujeto.

4. Compruebe si el ajuste es seguro desbloqueando la

extensión de la mesa y moviéndola hacia dentro y

hacia fuera por el soporte para el material. El soporte

para el material debería permanecer firmemente

sujeto.

MONTAJE DE LOS RODILLOS EN EL SOPORTE

PARA EL MATERIAL

1. Desenrosque el tornillo Phillips de la base de soporte

para rodillo con la herramienta multiuso suministrada

y realice el desmontaje. Si se requiere, sujete la

tuerca de fijación ubicada en el otro lado del rodillo

utilizando una llave de tuerca (10 mm).

2. Vea la Figura C para conocer las dos configuraciones

distintas, dependiendo del tamaño de la sierra para

cortar ingletes que esté utilizando, para alinear los

rodillos individuales al soporte para el material con la

varilla roscada internamente.

La configuración 1 ofrece soporte uniforme a ambos

lados en el caso de sierras para cortar ingletes más

grandes, mientras que la configuración 2 ofrece más

soporte en la parte delantera o en la parte trasera en el

caso de sierras para cortar ingletes de tamaño más

pequeño.

3. Coloque los rodillos individuales según se requiera y

deslice la varilla roscada a través de los rodillos y el

soporte para el material.

4. Una vez que cada varilla se haya enroscado

completamente, asegure la alineación colocando de

nuevo el tornillo de cabeza Phillips y apretándolo.

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 31

Page 32

-32-

ENSAMBLAJE DE LAS RUEDAS DE TRANSPORTE

Las ruedas de transporte permiten al usuario reubicar la

base de soporte sin mover la sierra. Las ruedas se

pueden instalar tanto en el lado derecho como en el

lado izquierdo de la base de soporte.

1. Coloque la base de soporte en posición invertida

sobre el piso con las patas plegadas orientadas hacia

arriba.

2. Alinee el ensamblaje de las ruedas de transporte con

el patrón de agujeros, ya sea en el lado derecho o en

el lado izquierdo de la base de soporte.

3. Utilice la herramienta multiuso incluida, inserte el

tornillo de cabeza Allen M6 x 12 mm y coloque la

tuerca Nylok M6. Repita el procedimiento con los tres

(3) tornillos restantes y apriételos.

4. Voltee la base de soporte para que quede apoyada

sobre sus ruedas y dicha base de soporte debería

rodar suavemente por el piso cuando se utilice el

extremo opuesto como mango.

TOPE DE TRANSPORTE

1. La GTA3800 incluye un tope de transporte para

ayudar a evitar que la sierra se deslice hasta

separarse de la base de soporte en caso de que no

esté asegurada a la mesa antes del transporte.

2. Afloje el pomo de fijación ubicado a un lado de la

base de soporte para la sierra en el cual las ruedas de

transporte estén instaladas y jale hacia fuera la

extensión de la mesa aproximadamente 4 pulgadas

(102 mm).

3. Inserte el tope de transporte en la ranura ubicada en

la superficie del tablero de la mesa y deslícelo de

manera que quede completamente dentro de la mesa

principal, más allá de la tapa de extremo.

4. Utilice la herramienta multiuso para apretar

firmemente el perno hexagonal en el tope con el fin

de que no se mueva y ayude a evitar que la

herramienta resbale hacia abajo durante el transporte.

FIG. E FIG. F

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 32

Page 33

-33-

TRANSPORTE DE LA BASE DE SOPORTE

CON LA SIERRA

1. Asegúrese de que las fijacións de liberación de las

monturas para herramienta ubicadas en cada

mo ntur a est én en la p osición abierta y

desbloqueada. (vea la fig. I, p34)

2. deslice la sierra a lo largo de la superficie del tablero

de la mesa hasta que esté contra el tope de transporte

(vea la página 32).

Nota:Para que el transporte sea lo más cómodo posible,

la sierra se debe posicionar en el extremo de la base de

soporte más cercano a las ruedas de transporte. Si es

necesario, ajuste el tope de transporte.

3. Cierre y bloquee los rieles de extensión (vea la página

36).

Nota: Un adhesivo que designa la ubicación del mango

de elevación está colocado en la tapa de extremo de la

base de soporte. Éstos son sus mangos de elevación y

se deben utilizar cuando se levante la base de soporte

para los siguientes procedimientos.

4. Pliegue las patas de la base de soporte: Comience en

el extremo que tiene instaladas las ruedas de

transporte. Primero, levante la base de soporte por el

mango de elevación designado. Empuje hacia dentro

el pasador de fijación de una pata y rote esa pata hacia

arriba hasta que el pasador de fijación se acople a

presión en su sitio. (Vea la página 30) Repita el

procedimiento para la segunda pata y baje la base de

soporte sobre las ruedas.

5. Repita el mismo paso en el lado opuesto, plegando las

patas en su sitio.

6. Para realizar el transporte, agarre el mango de

elevación (Fig. G) y ruede la base de soporte hasta la

ubicación sobre las ruedas de transporte (Fig. H).

7. Para montar la base de soporte para utilizarla, siga las

mismas instrucciones que anteceden, comenzando

con cualquiera de los dos lados de la base de soporte

que se desee.

FIG. G FIG. H

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 33

Page 34

-34-

MONTAJE DE LA SIERRA PARA CORTAR INGLETES EN

LA BASE DE SOPORTE

Nota: Despliegue las patas y ajuste la sierra en

posición de trabajo. (Consulte la página 30 para

obtener instrucciones.)

1. Lo cali ce los ensam blajes de mo ntura para

herramienta, coloque uno (1) de ellos sobre el riel

contra el tope secundario rojo de la montura para

herramienta y rote el pomo de fijación en el sentido

de las agujas del reloj hasta la posición bloqueada,

de la manera que se muestra en las figuras I, J y L.

2. Mida la anchura de los agujeros de mon taje

traseros de la sierra para cortar ingletes, coloque la

otra montura para herramienta sobre el riel con la

misma distancia de separación, de la manera que

se muestra en la figura K, y rote el pomo de fijación

en el sentido de las agujas del reloj hasta la

posición bloqueada.

FIG. I

FIG. K

FIG. L

1

2

FIG. J

POMO DE

FIJACION

POMO DE

FIJACION

“DESBLOQUEADA”

“

BLOQUEADA

”

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 34

Page 35

-35-

3. Coloque la sierra para cortar ingletes sobre las

monturas para herramienta, Figura M. Alinee los

agujeros de montaje ajustando las tuercas

deslizantes traseras y las tuercas giratorias

delanteras. Asegúrese de que la parte delantera

de la sierra esté alineada con la parte delantera

de ambas monturas para herramienta.

4. Coloque una (1) arandela plana M6 en un (1)

perno de 8 mm x 45 mm, inserte el perno a

través de la base de la sierra para cortar ingletes

y apriételo flojamente en las monturas para

herramienta.

5. Repita el paso 4 de este procedimiento para las

tres (3) ubicaciones de agujero restantes.

6. Apriete firmemente los cuatro (4) pernos. No los

apriete excesivamente.

FIG. M

TUERCA DESLIZANTE

TRASERA

TUERCA GIRATORIA

DELANTERA

RETIRE LA SIERRA DE LA BASE DE SOPORTE (SIN

MONTURAS PARA HERRAMIENTA INSTALADAS)

1. Rote el pomo des fijacións hasta la posición

desbloqueada (vea la fig. I, p34).

2. Localice las asas de transporte ubicadas en la base

de la sierra. Coloque una mano sobre el asa de la

base de la sierra y la otra mano sobre el asa

superior de la sierra, si está disponible. Agarrando

firmemente, incline la sierra (con las monturas para

herramienta aún instaladas) hacia usted y levántela

de la base de soporte.

INSTALE LA SIERRA EN LA BASE DE SOPORTE

(CON LAS MONTURAS PARA HERRAMIENTA

INSTALADAS)

1. Asegúrese de que las fijacións de liberación de las

monturas para herramienta ubicadas en cada

mo ntur a estén e n la posición abi erta y

desbloqueada. (vea la fig. I, p34)

2. Localice los mangos de transporte ubicados en la

base de la sierra. Coloque una mano sobre el asa

de la base de la sierra y la otra mano sobre el asa

superior de la sierra, si ésta disponible. Levante la

sierra hasta el ensamblaje de rieles.

3.

Alinee la montura para herramienta izquierda

ju nto al tope secundario rojo sobre el

ensamblaje de rieles, lo más cerca posible.

4. In clin e la si erra h asta que la s mandíbul as

delanteras de ambas monturas para herramienta

estén acopladas en el riel. Con ambas manos en los

mangos de la sierra, guíe la sierra de vuelta hasta

su posición nivelada sobre el riel (vea la página 34).

5. Rote el pomo de fijación de cada montura para

herramienta hasta la posición bloqueada (vea la fig.

L, p 34).

As egúr ese de q ue ambas

mo ntur as par a herramienta

estén en la posición bloqueada antes de utilizar o

transportar la sierra.

ADVERTENCIA

!

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 35

Page 36

-36-

AJUSTE DEL SOPORTE DE LA ALTURA DE

LA PIEZA DE TRABAJO

1. Afloje el pomo de fijación ubicado en el extremo del

riel de expansión, de la manera que se muestra en

la figura N, y suba el soporte de la altura de la pieza

de trabajo de manera que quede nivelado con el

tablero de la mesa de la sierra para cortar ingletes

instalada.

2. Reapriete el pomo y repita el procedimiento en el

lado opuesto.

AJUSTE DEL TOPE REPETITIVO

Para subir el tope repetitivo: Súbalo hasta su sitio de

la manera que se muestra en la figura O.

Para almacenar el tope repetitivo: Empuje el tope

repetitivo hacia dentro, hacia el ensamblaje de riel y

hacia abajo.

Repita el procedimiento en el lado opuesto.

UTILIZACIÓN DE LOS RIELES DE EXTENSIÓN

Vea la Figura P.

Utilice los rieles de extensión cuando trabaje con

piezas de trabajo más grandes.

Para extender los rieles:

1. Afloje el pomo de ajuste de la extensión.

2. Extienda el riel hasta la posición deseada.

3. Apriete el pomo de ajuste de la extensión.

FIG. N

FIG. O

FIG. P

POMO DE

FIJACIÓN

POMO DE

AJUSTE DE LA

EXTENSIÓN

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 36

Page 37

-37-

Para reducir el riesgo de lesiones,

compruebe periódicamente que

todos los elementos de sujeción estén instalados y

ajustados de acuerdo con las instrucciones de

ensamblaje incluidas en este manual.

SERVICIO

Cuando haga servicio de ajustes

y reparaciones, utilice únicamente

piezas de repuesto Bosch idénticas. El uso de cualquier

otra pieza puede crear un peligro o causar daños al

producto.

LIMPIEZA

Evite utilizar solventes cuando limpie piezas de plástico.

La mayoría de los plásticos son susceptibles a daños

causados por varios tipos de solventes comerciales y

pueden ser dañados por su uso. Use paños limpios para

quitar la suciedad, el polvo, el aceite, la grasa, etc.

No deje en ningún momento que

líquidos de freno, gasolina,

productos a base de petróleo, aceites penetrantes, etc.,

entren en contacto con las piezas de plástico. Las

sustancias químicas pueden dañar, debilitar o destruir

el plástico, lo cual podría causar lesiones corporales

graves.

Mantenimiento

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

!

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 37

Page 38

-38-

Notes:

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 38

Page 39

-39-

Remarques :

Notas:

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 39

Page 40

2610027815 03/13

LIMITED WARRANTY OF BOSCH PORTABLE AND BENCHTOP POWER TOOLS

Robert Bosch Tool Corporation (“Seller”) warrants to the original purchaser only, that all BOSCH portable and benchtop power tools will be free from

defects in material or workmanship for a period of one year from date of purchase. SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY

under this Limited Warranty and, to the extent permitted by law, any warranty or condition implied by law, shall be the repair or replacement of parts,

without charge, which are defective in material or workmanship and which have not been misused, carelessly handled, or misrepaired by persons

other than Seller or Authorized Service Station. To make a claim under this Limited Warranty, you must return the complete portable or benchtop

power tool product, transportation prepaid, to any BOSCH Factory Service Center or Authorized Service Station. For Authorized BOSCH Power Tool

Service Stations, please refer to your phone directory.

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS SUCH AS CIRCULAR SAW BLADES, DRILL BITS, ROUTER BITS, JIGSAW

BLADES, SANDING BELTS, GRINDING WHEELS AND OTHER RELATED ITEMS.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO ONE YEAR FROM DATE OF PURCHASE. SOME STATES IN THE U.S., SOME

CANADIAN PRO V INCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY

FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES

DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LI MITA TIO N OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO

STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA AND FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PORTABLE AND BENCHTOP ELECTRIC TOOLS SOLD WITHIN THE UNITED STATES OF AMERICA,

CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR WARRANTY COVERAGE WITHIN OTHER COUNTRIES, CONTACT YOUR LOCAL

BOSCH DEALER OR IMPORTER.

GARANTIE LIMITÉE DES OUTILS ÉLECTRIQUES PORTATIFS ET D'ÉTABLI BOSCH

Robert Bosch Tool Corporation (le « vendeur ») garantit à l'acheteur initial seulement que tous les outils électriques portatifs et d'établi BOSCH

seront exempts de vices de matériaux ou d'exécution pendant une période d'un an depuis la date d'achat. LA SEULE OBLIGATION DU VENDEUR ET

LE SEUL RECOURS DE L’ACHETEUR sous la présente garantie limitée, et en autant que la loi le permette sous toute garantie ou condition implicite

qui en découlerait, sera l’obligation de remplacer ou réparer gratuitement les pièces défectueuses matériellement ou comme fabrication, pourvu que

lesdites défectuosités ne soient pas attribuables à un usage abusif ou à quelque réparation bricolée par quelqu’un d’autre que le vendeur ou le

personnel d’une station-service agréée. Pour présenter une réclamation en vertu de cette garantie limitée, vous devez renvoyer l'outil électrique

portatif ou d'établi complet, port payé, à tout centre de service agréé ou centre de service usine. Veuillez consulter votre annuaire téléphonique

pour les adresses.

LA PRÉSENTE GARANTIE NE S’APPLIQUE PAS AUX ACCESSOIRES TELS QUE LAMES DE SCIES CIRCULAIRES, MÈCHES DE PERCEUSES, FERS

DE TOUPIES, LAMES DE SCIES SAUTEUSES, COURROIES DE PONÇAGE, MEULES ET AUTRES ARTICLES DU GENRE.

TOUTE GARANTIE IMPLICITE SERA LIMITÉE COMME DURÉE À UN AN À COMPTER DE LA DATE D’ACHAT. CERTAINS ÉTATS AMÉRICAINS,

CERTAINES PROVINCES CANADIENNES N’ADMETTANT PAS LE PRINCIPE DE LA LIMITATION DE LA DURÉE DES GARANTIES IMPLICITES, IL

EST POSSIBLE QUE LES LIMITATIONS CI-DESSUS NE S’APPLIQUENT PAS À VOTRE CAS.

EN AUCUN CAS LE VENDEUR NE SAURAIT ÊTRE TENU POUR RESPONSABLE DES INCIDENTS OU DOMMAGES INDIRECTS (INCLUANT, MAIS NE

SE LIMITANT PAS AUX PERTES DE PROFITS) CONSÉCUTIFS À LA VENTE OU L’USAGE DE CE PRODUIT. CERTAINS ÉTATS AMÉRICAINS ET

CERTAINES PROVINCES CANADIENNES N’ADMETTANT PAS LE PRINCIPE DE LA LIMITATION NI L’EXCLUSION DES DOMMAGES INDIRECTS ET

CONSÉQUENTIELS, IL EST POSSIBLE QUE LES LIMITATIONS OU EXCLUSIONS CI-DESSUS NE S’APPLIQUENT PAS À VOTRE CAS.

LA PRÉSENTE GARANTIE VOUS ACCORDE DES DROITS BIEN DÉTERMINÉS, Y COMPRIS POSSIBLEMENT CERTAINS DROITS VARIABLES DANS

LES DIFFÉRENTS ÉTATS AMÉRICAINS, PROVINCES CANADIENNES.

CETTE GARANTIE LIMITÉE NE S'APPLIQUE QU'AUX OUTILS ÉLECTRIQUES PORTATIFS ET D'ÉTABLI VENDUS AUX ÉTATS-UNIS D'AMÉRIQUE,

AU CANADA ET AU COMMONWEALTH DE PORTO RICO.POUR COUVERTURE DE GARANTIE DANS LES AUTRES PAYS, CONTACTEZ VOTRE

IMPORTATEUR OU REVENDEUR BOSCH LOCAL.

GARANTIA LIMITADA PARA HERRAMIENTAS MECANICAS PORTATILES Y PARA TABLERO DE BANCO BOSCH

Robert Bosch Tool Corporation ("el Vendedor") garantiza, únicamente al comprador original, que todas las herramientas mecánicas portátiles y

para tablero de banco BOSCH estarán libres de defectos de material o de fabricación durante un período de un año a partir de la fecha de compra.

LA UNICA OBLIGACION DEL VENDEDOR Y EL RECURSO EXCLUSIVO QUE USTED TIENE bajo esta Garantía Limitada y, hasta donde la ley lo

permita, bajo cualquier garantía o condición implícita por ley, consistirá en la reparación o sustitución sin costo de las piezas que presenten

defectos de material o de fabricación y que no hayan sido utilizadas inco rrectamente, manejadas descuidadamente o reparadas incorrectamente

por personas que no sean el Vendedor o una Estación de servicio autorizada. Para efectuar una reclamación bajo esta Garantía Limitada, usted

debe devolver el producto, que consiste en la herramienta mecánica portátil o para tablero de banco completa, con el transporte pagado, a

cualquier Centro de servicio de fábrica o Estación de servicio autorizada. Para Estaciones de servicio autorizadas de herramientas mecánicas

BOSCH, por favor, consulte el directorio telefónico.

ESTA GARANTIA LIMITADA NO SE APLICA A ARTICULOS ACCESORIOS TALES COMO HOJAS PARA SIERRAS CIRCULARES, BROCAS PARA

TALADROS, BROCAS PARA FRESADORAS, HOJAS PARA SIERRAS DE VAIVEN, CORREAS PARA LIJAR, RUEDAS DE AMOLAR Y OTROS

ARTICULOS RELACIONADOS.

TODAS LAS GARANTIAS IMPLICITAS TENDRAN UNA DURACION LIMITADA A UN AÑO A PARTIR DE LA FECHA DE COMPRA. ALGUNOS

ESTADOS DE LOS EE.UU., ALGUNAS PROVINCIAS CANADIENSES NO PERMITEN LIMITACIONES EN CUANTO A LA DURACION DE UNA

GARANTIA IMPLICITA, POR LO QUE ES POSIBLE QUE LA LIMITACION ANTERIOR NO SEA APLICABLE EN EL CASO DE USTED.

EL VENDEDOR NO SERA RESPONSABLE EN NINGUN CASO DE NINGUN DAÑO INCIDENTAL O EMERGENTE (INCLUYENDO PERO NO LIMITADO

A RESPONSABILIDAD POR PERDIDA DE BENEFICIOS) QUE SE PRODUZCA COMO CONSECUENCIA DE LA VENTA O UTILIZACION DE ESTE

PRODUCTO. ALGUNOS ESTADOS DE LOS EE.UU. Y ALGUNAS PROVINCIAS CANADIENSES NO PERMITEN LA EXCLUSION O LIMITACION DE

LOS DAÑOS INCIDENTALES O EMERGENTES, POR LO QUE ES POSIBLE QUE LA LIMITACION O EXCLUSION ANTERIOR NO SEA APLICABLE EN

EL CASO DE USTED.

ESTA GARANTIA LIMITADA LE CONFIERE A USTED DERECHOS LEGALES ESPECIFICOS Y ES POSIBLE QUE USTED TAMBIEN TENGA OTROS

DERECHOS QUE VARIAN DE ESTADO A ESTADO EN LOS EE.UU., DE PROVINCIA A PROVINCIA EN CANADA.

ESTA GARANTIA LIMITADA SE APLICA SOLAMENTE A HERRAMIENTAS ELECTRICAS PORTATILES Y PARA TABLERO DE BANCO VENDIDAS EN

LOS ESTADOS UNIDOS DE AMERICA, CANADA Y EL ESTADO LIBRE ASOCIADO DE PUERTO RICO. PARA COBERTURA DE GARANTIA EN OTROS

PAISES, PONGASE EN CONTACTO CON SU DISTRIBUIDOR O IMPORTADOR LOCAL DE BOSCH.

© Robert Bosch Tool Corporation 1800 W. Central Road Mt. Prospect, IL 60056 -2230

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado en México por: Robert Bosch, S.A. de C.V., Calle Robert Bosch No. 405, Zona

Industrial, Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

!2610027815!

BM 2610027815 03-13_BM 2610027815 03-13.qxp 4/2/13 8:48 AM Page 40

Loading...

Loading...