Bosch GGS 6 S Professional, GGS 6 Professional Original Instructions Manual

Robert Bosch GmbH

Power Tools Division

70745 Leinfelden-Echterdingen

Germany

www.bosch-pt.com

3 609 929 C82 (2014.03) O / 210 EURO

GGS Professional

6 | 6 S

de Originalbetriebsanleitung

en Original instructions

fr Notice originale

es Manual original

pt Manual original

it Istruzioni originali

nl Oorspronkelijke

gebruiksaanwijzing

da Original brugsanvisning

sv Bruksanvisning i original

no Original driftsinstruks

fi Alkuperäiset ohjeet

el Πρωτότυπο οδηγιών χρήσης

tr Orijinal işletme talimatı

pl Instrukcja oryginalna

cs Původní návod k používání

sk Pôvodný návod na použitie

hu Eredeti használati utasítás

ru Оригинальное руководство

по эксплуатации

uk Оригінальна інструкція з

експлуатації

kk Пайдалану нұсқаулығының

түпнұсқасы

ro Instrucţiuni originale

bg Оригинална инструкция

mk Оригинално упатство за работа

sr Originalno uputstvo za rad

sl Izvirna navodila

hr Originalne upute za rad

et Algupärane kasutusjuhend

lv Instrukcijas oriģinālvalodā

lt Originali instrukcija

ar

fa

ςТЎϩХʉ ЌТϾϦφЍʉ ʌμВТЎϺυ

ΖЎϩʉ ˒μВЖЙʉʓ ИͳϞφЁʑ

OBJ_DOKU-18463-005.fm Page 1 Friday, March 21, 2014 9:29 AM

3 |

3 609 929 C82 | (21.3.14) Bosch Power Tools

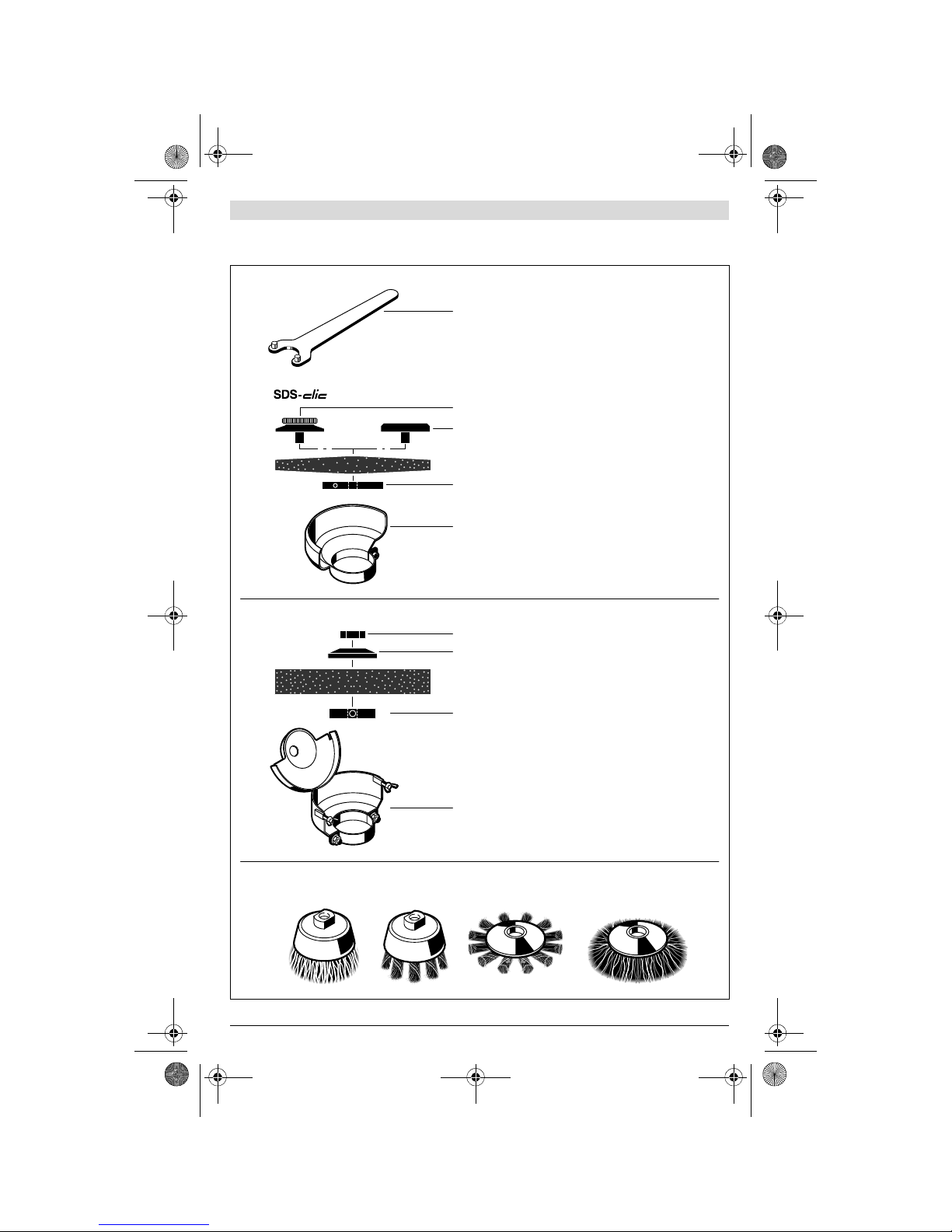

GGS 6 S

GGS 6 / GGS 6 S

GGS 6

1 607 950 048

3 603 301 011

1 603 345 034

1 605 703 065

3 605 510 030

3 605 510 013

1 605 300 012

3 605 703 064

2 605 703 010

OBJ_BUCH-1050-005.book Page 3 Friday, March 21, 2014 9:30 AM

4 |

3 609 929 C82 | (21.3.14) Bosch Power Tools

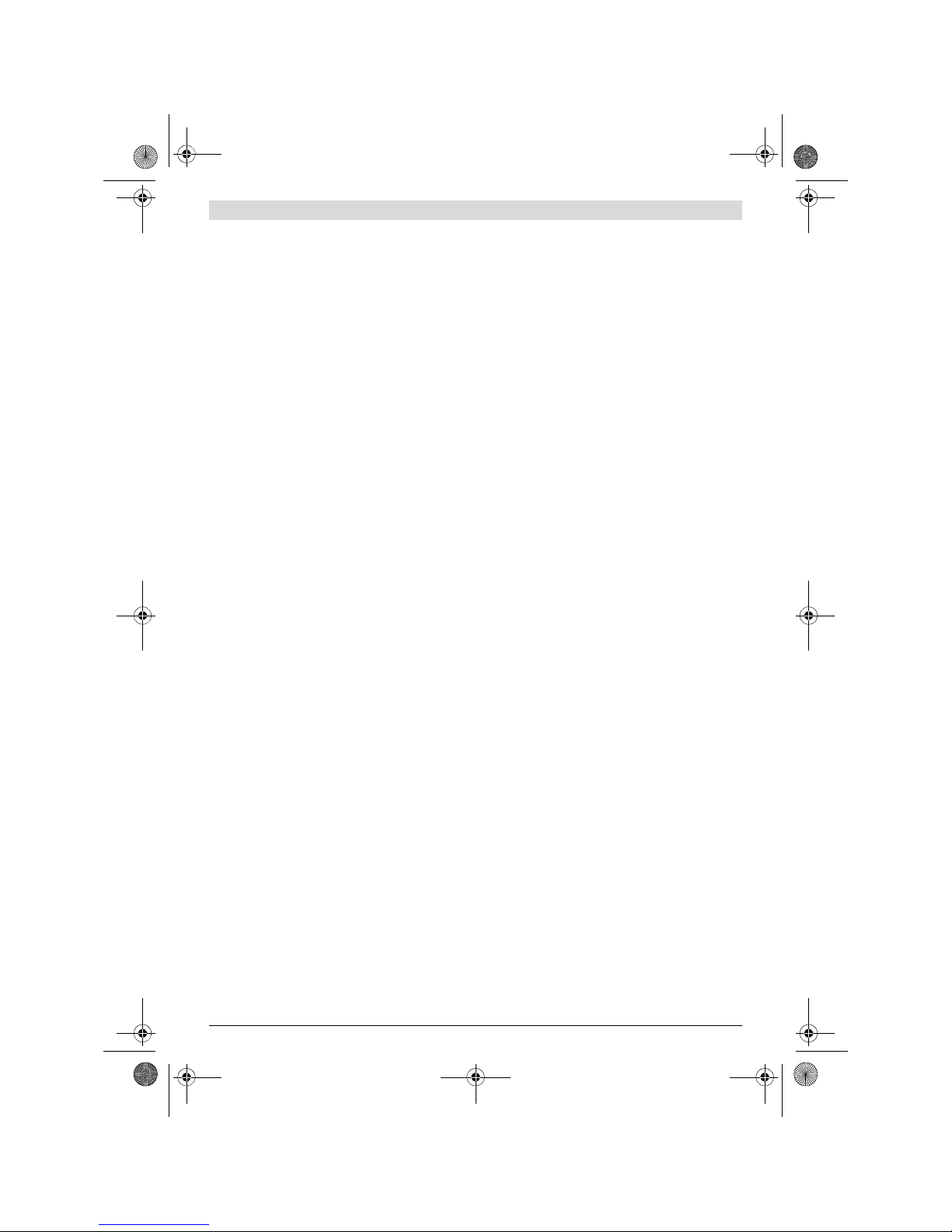

GGS 6

GGS 6 S

1

8

2

3

5

4

9

10

11

3

12

7

13

6

7

6

OBJ_BUCH-1050-005.book Page 4 Friday, March 21, 2014 9:30 AM

5 |

3 609 929 C82 | (21.3.14) Bosch Power Tools

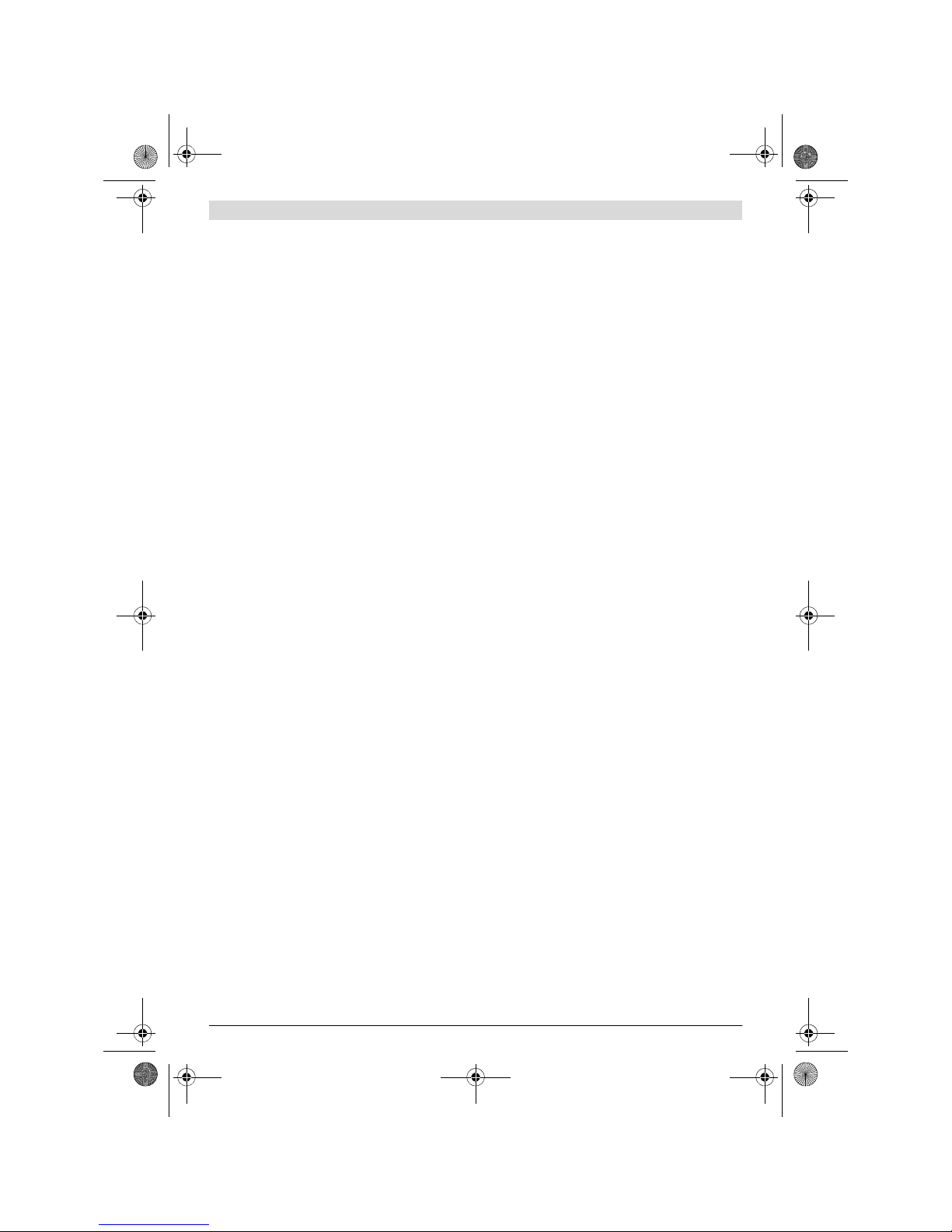

FE

DC

BA

GGS 6 S

17

8

>10 Nm

2

14

11 19

GGS 6 S GGS 6 S

GGS 6 S

GGS 6

16

15

4

1

15

12

10

920

GGS 6GGS 6

43 18

123 18

>10 Nm

19

>10 Nm

OBJ_BUCH-1050-005.book Page 5 Friday, March 21, 2014 9:30 AM

English | 13

Bosch Power Tools 3 609 929 C82 | (21.3.14)

Electrical safety

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges and moving parts. Damaged

or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitab le

for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoid-

able, use a residual current device (RCD) protected

supply. Use of an RCD reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while op-

erating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a ro-

tating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

Use the power tool, accessories and tool bits etc. in ac-

cordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified repair per-

son using only identical replacement parts. This will en-

sure that the safety of the power tool is maintained.

Safety Warnings for Straight Grinders

Safety warnings common for grinding and working w ith

wire brushes

This power tool is to be used as a grinder and wire

brush. Observe all safety warnings, instructions, illustrations and data supplied with the power tool. Non-ob-

servance of the following instructions can lead to electric

shock, fire and/or serious injury.

Operations such as sanding, polishing or cutting-off

are not recommended to be performed with this power

tool. Operations for which the power tool was not de-

signed may create a hazard and cause personal injury.

Do not use accessories which are not specifically de-

signed and recommended by the tool manufacturer.

Just because the accessory can be attached to your power

tool, it does not assure safe operation.

The rated speed of the accessory must be at least equal

to the maximum speed marked on the power tool. Ac-

cessories running faster than their rated speed can break

and fly apart.

OBJ_BUCH-1050-005.book Page 13 Friday, March 21, 2014 9:30 AM

14 | English

3 609 929 C82 | (21.3.14) Bosch Power Tools

The outside diameter and the thickness of your acces-

sory must be within the capacity rating of your power

tool. Incorrectly sized accessories cannot be adequately

guarded or controlled.

Threaded mounting of accessories must match the

grinder spindle thread. For accessories mounted by

flanges, the arbour hole of the accessory must fit the

locating diameter of the flange. Accessories that do not

match the mounting hardware of the power tool will run out

of balance, vibrate excessively and may cause loss of control.

Do not use a damaged accessory. Before each use in-

spect the accessory such as abrasive wheels for chips

and cracks, backing pad for cracks, tear or excess

wear, wire brush for loose or cracked wires . If power

tool or accessory is dropped, inspect for damage or install an undamaged accessory. After inspecting and installing an accessory, position yourself and bystanders

away from the plane of the rotating accessory and run

the power tool at maximum no-load speed for one minute. Damaged accessories will normally break apart during

this test time.

Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing protectors, gloves and shop apron capable of stopping

small abrasive or workpiece fragments. The eye protec-

tion must be capable of stopping flying debris generated

by various operations. The dust mask or respirator must be

capable of filtrating particle s generated by your operation.

Prolonged exposure to high intensity noise may cause

hearing loss.

Keep bystanders a safe distance away from work area.

Anyone entering the work area must wear personal

protective equipment. Fragments of workpiece or of a

broken accessory may fly away and cause inj ury beyond

immediate area of operation.

Hold power tool by insulated gripping surfaces only,

when performing an operation where the cutting accessory may contact hidden wiring or its own cord. Cut-

ting accessory contacting a “live” wire may make exposed

metal parts of the power tool “live” and could give the operator an electric shock.

Position the cord clear of the spinning accessory. If you

lose control, the cord may be cut or snagged and your hand

or arm may be pulled into the spinning wheel.

Never lay the power tool down until the accessory has

come to a complete stop. The spinning wheel may grab

the surface and pull the power tool out of your control.

Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag

your clothing, pulling the accessory into your body.

Regularly clean the power tool’s air vents. The motor’s

fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

Do not operate the power tool near flammable materi-

als. Sparks could ignite these materials.

Do not use accessories that require liquid coolants. Us-

ing water or other liquid coolants may result in electrocution or shock.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged ro-

tating wheel, backing pad, brush or any other accessory.

Pinching or snagging causes rapid stalling of the rotating

accessory which in turn causes the uncontrolled power

tool to be forced in the direction opposite of the accessory’s rotation at the point of the binding .

For example, if an abrasive wheel is snagged or pinche d by

the workpiece, the edge of the wheel that is entering into

the pinch point can dig into the s urface of the material

causing the wheel to climb out or kick out. The wheel may

either jump toward or away from the operator, depending

on direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

Maintain a firm grip on the power tool and position your

body and arm to allow you to resist kickback forces. Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during

start-up. The operator can control torque reactions or

kickback forces, if proper precautions are taken.

Never place your hand near the rotating accessory. Ac-

cessory may kickback over your hand.

Do not position your body in the area where power tool

will move if kickback occurs. Kickback will propel the

tool in direction opposite to the wheel’s movement at the

point of snagging.

Use special care when working corners, sharp edges,

etc. Avoid bouncing and snagging the accessory. Cor-

ners, sharp edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or kickback.

Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent kickback

and loss of control.

Additional safety instructions for grinding

Use only wheel types that are recommended for your

power tool and the specific guard designed for the selected wheel. Wheels for which the power tool was not de-

signed cannot be adequately guarded and are unsaf e.

The grinding surface of the centre depressed wheels

must be mounted below the plane of the guard lip. An

improperly mounted wheel that projects through the plane

of the guard lip cannot be adequately protected.

The guard must be securely attached to the power tool

and positioned for maximum safety, so the least

amount of wheel is exposed towards the operator. The

guard helps to protect operator from broken wheel fragments, accidental contact with wheel and sparks that

could ignite clothing.

OBJ_BUCH-1050-005.book Page 14 Friday, March 21, 2014 9:30 AM

Loading...

Loading...