Page 1

BOSCH CLOTHES DRYER GAS CONVERSION KIT INSTRUCTIONS

WARNING WARNING WARNING

FOR TYPE WAT1G DRYERS

The Bosch Clothes Dryer is manufactured for use with natural (city) gas. Installation of this kit

converts the dryer for use with propane gas with a manifold pressure of 11" wc, and supply pressure

between 11" and 14" wc. When the dryer is converted for use with propane gas by means of this kit,

the input rating will be 18,000 Btu/hr for altitudes up to 7,700 feet above sea level. For installations

at an altitude greater than 7,700 feet above sea level, contact a qualified service agency for derating

instructions.

THIS CONVERSION KIT SHALL BE INSTALLED BY A QUALIFIED SERVICE AGENCY IN

ACCORDANCE WITH THE MANUFACTURER’S INSTRUCTIONS AND ALL APPLICABLE CODES AND

REQUIREMENTS OF THE AUTHORITY HAVING JURISDICTION. THE INFORMATION IN THESE

INSTRUCTIONS MUST BE FOLLOWED TO MINIMIZE THE RISK OF FIRE OR EXPLOSION OR TO

PREVENT PROPERTY DAMAGE, PERSONAL INJURY, OR DEA TH. THE QUALIFIED SER VICE AGENCY

IS RESPONSIBLE FOR THE PROPER INST ALLATION OF THIS KIT. THE INSTALLA TION IS NOT

PROPER AND COMPLETE UNTIL THE OPERATION OF THE CONVERTED APPLIANCE IS CHECKED

AS SPECIFIED IN THE MANUFACTURER’S INSTRUCTIONS SUPPLIED WITH THIS KIT.

• These instructions are intended for use by qualified service technicians only. A qualified service technician

is any person or representative of a company who is 1) trained and experienced in the servicing of natural

gas and propane (LP gas) appliances, 2) familiar with the precautions for performing work on natural gas

and propane (LP gas) appliances, and 3) knowledgeable of the applicable municipal codes governing work

on natural gas and propane (LP gas) appliances.

• Do not use these instructions or the materials contained in the Bosch Clothes Dryer Gas Conversion Kit for

any other purpose than that for which they are intended, which is the conversion of the Bosch Gas Clothes

dryer from operation with natural gas to operation with propane (LP gas).

• Follow these instructions carefully to minimize the risk of death and/or serious injury by fire and/or

explosion.

• As Bosch has no control over the customer’s selection of the service technician who will perform the work

described in this manual, Bosch can not be held responsible for death, injury, or property damage that may

result from work performed improperly or from the use of inferior tools and/or materials.

THE CONVERSION SHALL BE CARRIED OUT IN ACCORDANCE WITH THE REQUIREMENTS OF THE

PROVINCIAL AUTHORITIES HAVING JURISDICTION AND IN ACCORDANCE WITH THE

REQUIREMENTS OF THE CSA B149.1, INSTALLATION CODE.

Carefully read and understand these instructions before attempting the appliance conversion.

SAVE THESE INSTRUCTIONS

1

Page 2

BOSCH CLOTHES DRYER

GAS CONVERSION KIT

INSTRUCTIONS

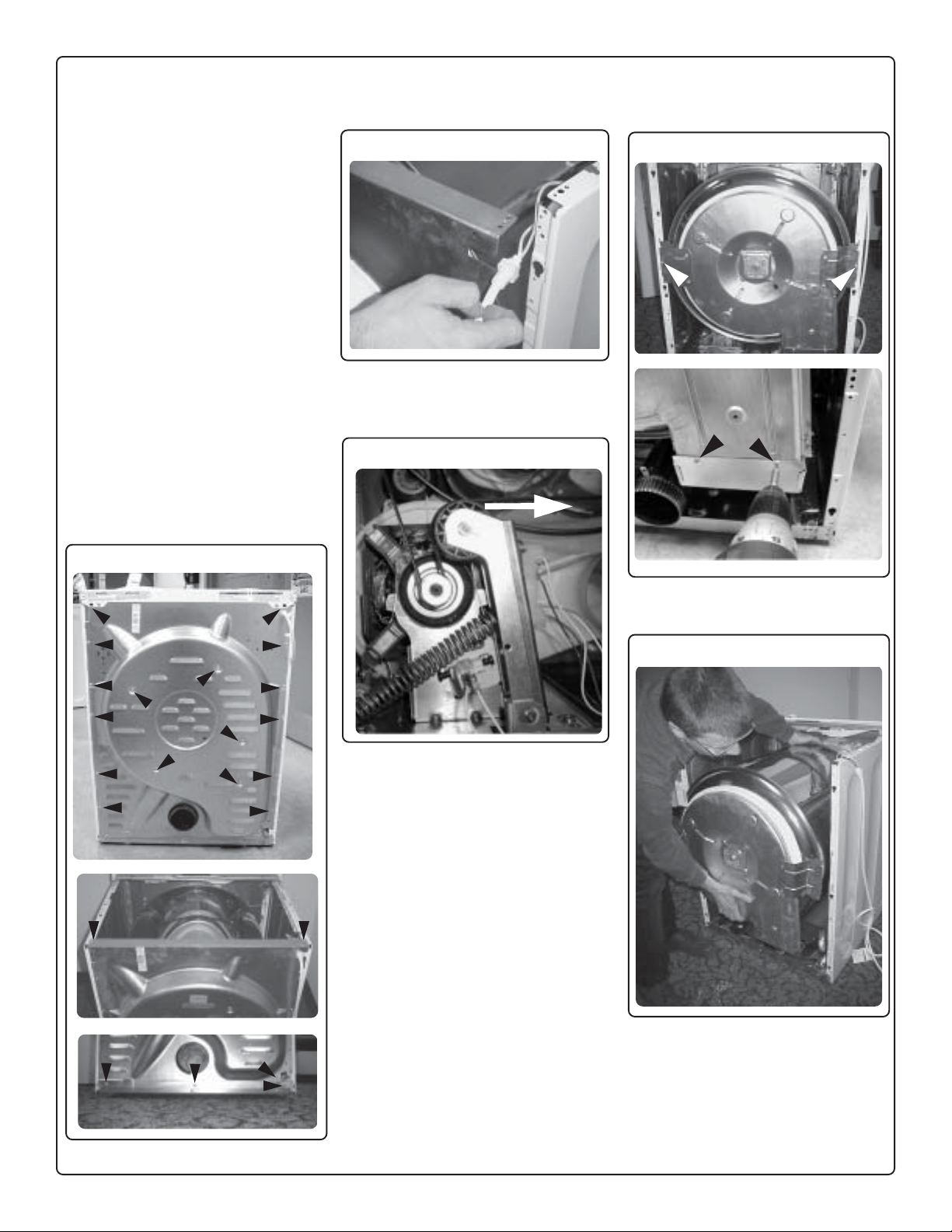

6) Remove the top panel and back

panel, being careful to remove the

power cord from the back panel as

shown in Figure 2.

8) Use a Torx T20 driver to remove the

four screws shown in Figure 4. Set

the screws aside for reinstallation

later.

1. Materials Supplied

• LP gas valve

• Label, Rating Plate

• Label, Conversion Record

• Instructions

2. Materials Needed

• T orx T20 driver

• 1” open-ended wrench

• Torque Wrench (English or metric)

• Torque Screwdriver (English or metric)

3. Procedure

1) Turn off the gas supply to the

dryer.

2) Disconnect the electrical power to

the dryer.

3) Disconnect the gas connection

from the dryer.

4) Move the dryer away from the wall.

5) Use a Torx T20 driver to remove

the screws on the back of the dryer

that secure the top panel and back

panel as shown in Figure 1. Set the

screws aside for reinstallation later.

Figure 1

Figure 2

7) Pull the tension lever to the right as

shown by the arrow in Figure 3,

and remove the belt from the drive

pulley.

Figure 3

Figure 4

9) Lift and remove the drum/hood

assembly as shown in Figure 5.

Figure 5

10) Carefully set the drum/hood

assembly aside.

2

Page 3

CAUTION

NTC Connector

11) Figure 6 shows the dryer interior with

the drum/hood assembly removed.

Figure 6

12) Locate gas valve and wire harness

connections shown in Figure 7.

Figure 7

14) Disconnect the two connectors of the

wire harness from the gas valve

as shown in Figure 9.

Figure 9

15) Disconnect the wires from the

Klixon shown in Figure 10.

Figure 10

17) Disconnect wires from the flame

sensor shown in Figure 12.

Figure 12

18) Disconnect the NTC connector

shown in Figure 13.

Figure 13

13) Use a 1” open-ended wrench to

disconnect the brass elbow from the

valve connection as shown in

Figure 8.

Figure 8

16) Disconnect the igniter wire shown in

Figure 11.

Figure 1 1

Igniter Wire

POSSIBLE DRYER DAMAGE: The

igniter can be damaged when the

combustion chamber is removed.

When removing the combustion

chamber, keep it away from the

igniter.

19) Remove the screw that connects the

combustion chamber to the burner

bracket shown in Figure 14.

Remove the combustion chamber

from the dryer.

Figure 14

3

Page 4

CAUTION

20) Figure 15 shows the burner

WARNING

assembly with an undamaged

igniter.

Figure 15

21) Use the service access to locate

and remove the screw from the side

of the burner bracket as shown in

Figure 16. Set the screw aside for

reinstallation later.

Figure 16

POSSIBLE DRYER DAMAGE: The

igniter can be damaged when the

burner bracket/ gas valve/igniter/

burner assembly is removed from

the dryer. Use caution when

removing the assembly from the

dryer.

23) Remove the burner bracket/ gas

valve/igniter/burner assembly from

the dryer.

24) Once the burner assembly has been

removed from the dryer, remove the

two screws that fasten the burner to

the burner bracket as shown in

Figure 18. Set the screws aside for

reinstallation later.

Figure 18

26) Remove the burner ring.

NOTE: The burner ring will not be

installed on the dryer when the dryer

is converted for use with propane.

However, retain the burner ring for

reinstallation should the dryer be

reconverted for use with natural

gas.

27) Remove the three screws that secure

the natural gas valve to the burner

bracket as shown in Figure 20. Set

the screws aside for reinstallation

later.

Figure 20

22) Remove the screw from the bottom

of the burner bracket as shown in

Figure 17. Set the screw aside for

reinstallation later.

Figure 17

25) Remove the two screws that fasten

the burner ring to the burner as

shown in Figure 19. Set the screws

aside for reinstallation later.

Figure 19

Burner Ring front view

FIRE/INJURY HAZARD: INSTALLING

A NON-LP GAS VALVE IN AN LP GAS

SYSTEM CAN CAUSE FIRE. MAKE

CERTAIN THAT THE LP GAS VALVE

IS INSTALLED WITH THE LP GAS

CONVERSION.

28) Identify the LP gas valve by the

label reading 25MO1A Type 190 at

the top, and Reg. 11.0” at the

bottom left corner.

29) Replace the natural gas valve with

the supplied LP valve. Use the three

previously removed screws to

secure the LP valve to the burner

bracket into the new gas valve.

Torque the screws to 2.6 p-f

(3.5 N-m.)

30) Reinstall the two screws into the

burner as shown in Figure 21.

Torque screws to 1.4 p-f (1.8N-m).

Figure 21

4

Page 5

31) Use the previously removed

screw to secure the burner bracket/

gas valve/igniter/burner assembly to

the dryer as shown in Figure 22.

34) Reconnect the NTC connector as

shown in Figure 25.

Figure 25

37) Reconnect the Klixon wires as shown

in Figure 28.

Figure 28

Figure 22

32) Reinstall the previously removed

burner bracket side screw as shown

in Figure 23.

Figure 23

NTC Connector

35) Reconnect the flame sensor wires

as shown in Figure 26.

Figure 26

38) Reconnect the gas valve wire

harness as shown in Figure 29.

Figure 29

33) Reinstall the combustion chamber

and secure it to the burner bracket

with the previously removed screw

as shown in Figure 24. Torque the

screw to 1.4 p-f (1.8N-m).

Figure 24

36) Reconnect the igniter wire as shown

in Figure 27.

Figure 27

Igniter Wire

39) Use a 1” open-ended wrench to

reconnect the brass elbow to the gas

valve fitting as shown in Figure 30.

Torque the connection to 25N-m.

Figure 30

5

Page 6

40) Reinstall the drum and rotation belt.

Make sure the rotation belt is tight.

Rotate the drum several times

(counter-clockwise, when facing

drum from rear of dryer) before

installing the back panel. This is

done to ensure that the belt is

installed correctly.

41) Reset the broken belt switch by

pressing it in the direction shown in

Figure 31.

Figure 31

48) Note the conversion on the supplied

Conversion Record Label, and afix

the Conversion Record Label and the

Rating Plate Label to the two

postions shown in Figure 32.

Figure 32

42) Install the back panel and top.

Torque all screws to 1.4 p-f

(1.8Nm).

43) Connect all gas connections and

power connections.

44) Pressure test the gas valve.

Remove the pressure tap plug from

the valve body. Insert a pressure tap

and connect a manometer to the

end of the nipple. Turn on the gas

supply and verify that the outlet

pressure is 11" ± .5” water column

(wc). Turn off the gas supply.

Disconnect the manometer and

replace the pressure tap with

the plug.

45) Leak check the dryer prior to

operation.Turn on the gas supply.

Brush or spray a soap and water

solution onto the pressure tap and

all gas connections. Growing

bubbles indicates leaks. If any

bubbles are present, tighten the

leaking connection and retest for

leakage.

46) Check the dryer operation, including

ignition sequence. The gas line

may have air in it, so more than one

ignition cycle may be necessary

before the gas ignites. Check for

proper flame appearance.

NOTE: While there is no

adjustment for the burner flame, the

flame should have a predominantly

blue color.

47) Turn the dryer off. The conversion is

now complete.

6

Loading...

Loading...