Page 1

Modular Fire Panel

FPA-5000

en

Networking Guide

Page 2

Page 3

Modular Fire Panel Table of contents | en 3

Table of contents

1

2

3

3.1 Networking layers 7

3.2 Topologies 7

3.2.1 Key 10

3.2.2 Ethernet loop 12

3.2.3 Ethernet loop with OPC server 13

3.2.4 Ethernet loop with OPC server to redundant panel controller 14

3.2.5 Ethernet/CAN double loop 15

3.2.6 Ethernet backbone with sub-loops (Ethernet/CAN) 16

3.2.7 Connecting Ethernet loops 18

3.3 Ethernet network 20

3.3.1 Protocols 20

3.3.2 Network diameter 20

3.3.3 Cables used 22

3.3.4 Creating an Ethernet network 23

3.3.5 Extension of existing networks 24

3.4 CAN network 24

3.4.1 Creating a CAN network 26

3.4.2 Extension of existing networks 26

3.5 Remote Services 27

3.5.1 Remote Connect 27

3.5.2 Remote Alert 29

3.5.3 Remote Maintenance 29

3.6 Voice alarm systems 31

3.7 UGM-2040 networks 33

4

4.1 Installing media converters in the mounting frame 34

4.2 Installing media converters in PSS 0002 A/USF 0000 A 35

4.3 Settings on media converter 36

4.4 Installing switches in PSS 0002 A/USF 0000 A 37

4.5 Settings on switch 38

4.5.1 Assign IP address 39

4.5.2 Program redundancy settings 39

4.5.3 Programming the fault relay 40

4.5.4 Programming connection monitoring 41

4.5.5 QoS priority, only for UGM‑2040 41

4.5.6 Activating IGMP snooping 41

4.6 CAN network 42

5

5.1 Media converter 52

5.2 Ethernet switch 53

5.3 Remote keypad 56

6

6.1 Network nodes 58

6.2 Line numbers 58

6.3 Switches 59

Safety instructions 5

Introduction 6

Connecting FPA-5000 7

Installation 34

Cabling 52

RPS settings 58

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 4

4 en | Table of contents Modular Fire Panel

6.4 OPC servers 59

6.5 UGM-2040 servers 60

7

8

Remote Portal 61

Appendix 64

8.1 Ethernet error messages 64

Index 66

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 5

Modular Fire Panel Safety instructions | en 5

!

!

1 Safety instructions

Notice!

An exclusive Ethernet network is required in order to set up a central fire alarm network.

The use of a fire alarm system in any other Ethernet network is at the own risk of the user.

Bosch disclaims any and all warranties and liabilities for this misapplication.

In case of non-exclusive Ethernet network reliable alarm transmission and IT-security cannot

be ensured.

Notice!

To ensure that the network is set up in compliance with EN 54, use only components that

have been approved for use in central fire alarm networks.

Caution!

For access via the internet use only BOSCH Remote Services.

Caution!

Remote Maintenance for Private Secure Network requires a secure IP connection. For this

reason with Remote Maintenance for Private Secure Network an IP network is provided,

which is based on DSL with an optional wireless access on the panel side. Remote

Maintenance for Private Secure Network is only available in Germany with a service

agreement with Bosch ST-IE.

Notice!

For standard applications, use only standard network settings.

Changes to standard network settings are permitted only for experienced users with

appropriate networking knowledge.

Danger!

Laser light.

Do not look directly into the beam with the naked eye or with visual instruments of any kind

(e.g. magnifying glass, microscope). Failure to observe this notice poses a danger to the eyes

at a distance of less than 100 mm. The light emerges at the visual terminals or at the end of

the fiber optic cables connected to these. CLASS 2M light-emitting diode, wavelength

650nm, output < 2 mW, in accordance with DINEN60825‑1:2003‑10.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 6

6 en | Introduction Modular Fire Panel

2 Introduction

This document is aimed at readers with experience in planning and installing EN 54 compliant

fire alarm systems. In addition, you need networking knowledge.

This networking guide provides an overview of the framework conditions, limit values, and

general procedures for panel network planning and installation.

Detailed descriptions of the installation of the individual components can be found in the

respective installation guides.

You find a description of the user interface of the MPC-xxxx-C in the user guide included with

the device.

The user interface of the FSP-5000-RPS programming software is described in the online help.

Notice!

Dear Customer,

We work tirelessly to keep our documentation up to scratch. Should you have any

suggestions, however, or if you have discovered an error, please e-mail us at

ST.TechComFire@de.bosch.com.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 7

Modular Fire Panel Connecting FPA-5000 | en 7

Ethernet

IP Stack

IP Protocols

Networking over IP

OPC-Server

CAN

Networking

over CAN

Praesideo/PAVIRO

Services

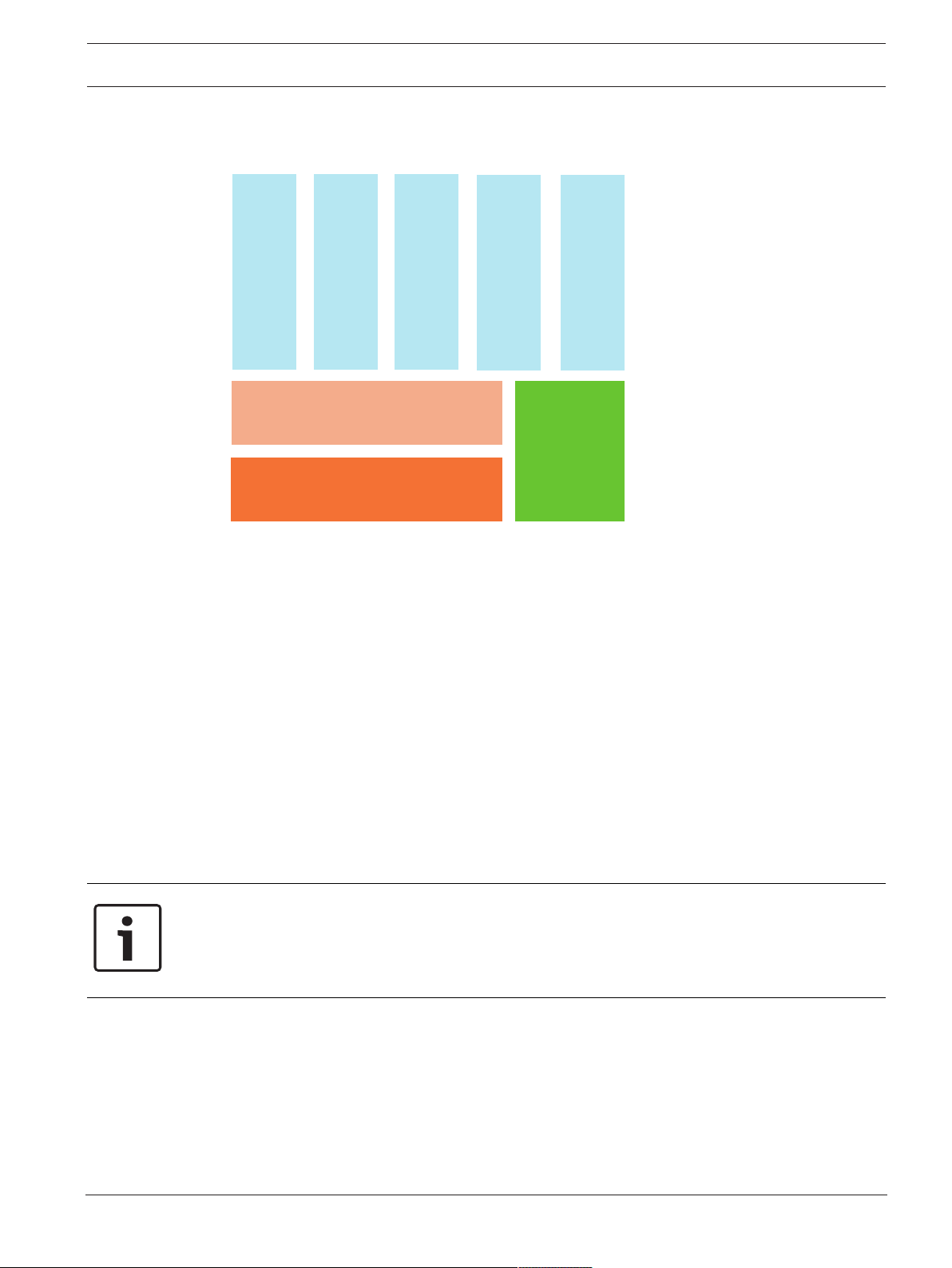

3 Connecting FPA-5000

3.1 Networking layers

In the network, the Ethernet interface and IP protocols are used for different services. The

Ethernet interface can be disabled completely or its use disabled only for networking over

TCP/IP. Disabling may be necessary for networking over CAN.

Enabling services

– networking over TCP/IP

In FSP-5000-RPS, enable panel-to-panel communication in the Ethernet network

– OPC servers

Add an OPC server to the FSP-5000-RPS configuration

– Praesideo/PAVIRO connection

Add a Voice Alarm System to the FSP-5000-RPS configuration and configure virtual

triggers.

– Remote Services (Remote Connect, Remote Maintenance, Remote Alert)

Activate the relevant check box in FSP-5000-RPS

– Remote Connect and Remote Maintenance for Private Secure Network

Add remote access to the FSP-5000-RPS configuration and set up the remote access in

FSP-5000-RPS.

Notice!

Unintentionally data transfer

If the Ethernet interface of the panel controller is used only for communicating with an OPC

server or for Remote Services disable the panel communication over TCP/IP, in FSP-5000RPS. Otherwise fire data could be transferred over the Ethernet unintentionally.

3.2 Topologies

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

To operate Ethernet or TCP/IP-based services, the Ethernet interfaces must be enabled and

the correct TCP/IP settings configured.

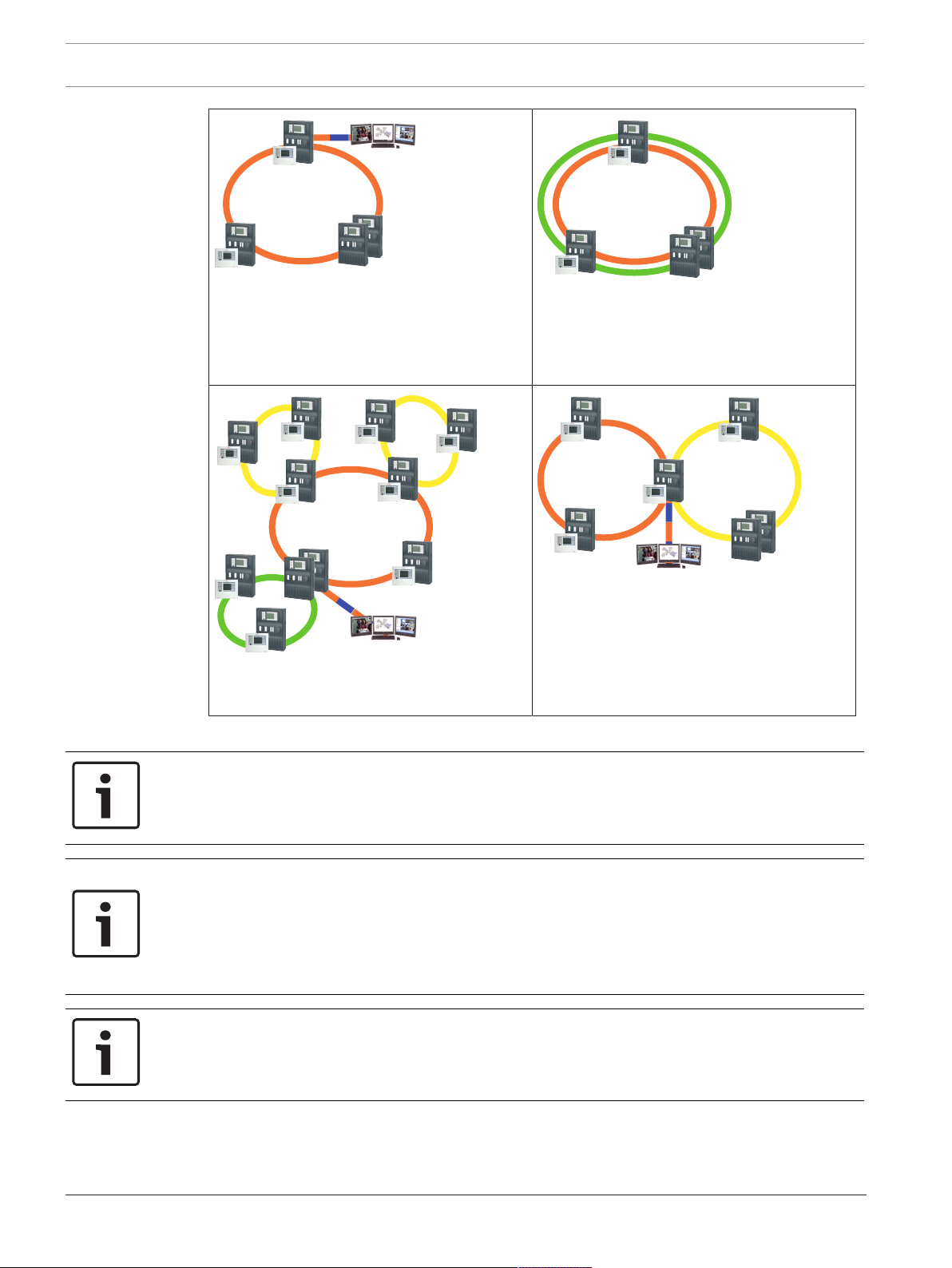

The following topologies are possible:

Page 8

8 en | Connecting FPA-5000 Modular Fire Panel

FPA/FMR

FPA-5000

FPA/FMR

FX

OPC-Server

FX

FPA/FMR

FPA-5000

CAN

FPA/FMR

FPA/FMR

FPA/FMR

FPA/FMR

FPA/FMR

FPA/FMR

FPA/FMR

FPA-5000

OPC-Server

FX

FX

FPA/FMR

FPA/FMR

FPA/FMR

FX

FPA-5000

FPA/FMR

FPA/FMR

FPA/FMR

FPA/FMR

OPC-Server

a

b

FX FX

Ethernet loop, page 12

Ethernet loop with OPC server, page 13

Ethernet/CAN double loop, page 15

Ethernet loop with OPC server to redundant

panel controller, page 14

Connecting Ethernet loops, page 18

Ethernet backbone with sub-loops (Ethernet/

CAN), page 16

The following settings, notes and restrictions apply to all topologies:

Notice!

For each panel, a maximum of 512 detection points may be connected according to EN54‑2.

If this number is exceeded, the panel must be designed redundantly. For technical reasons, a

maximum of 2048 detection points can then be connected.

Notice!

If the panel acts as an interface with a CAN sub-loop, this panel must then also be designed

redundantly according to EN54‑2 if more than 512 detection points are connected in the subloop.

This restriction does not apply in an Ethernet sub-loop, as the switches to connect the 2

loops perform the redundancy.

Notice!

The network used must meet the following minimum requirements:

Minimum throughput: 1 Mbps

Maximum latency: 250 ms

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 9

Modular Fire Panel Connecting FPA-5000 | en 9

Notice!

The requirements of EN54‑13 for data transmission paths can only be met with fiber optic

cable connections for Ethernet.

Connections within a housing may be established with Ethernet cables.

Notice!

Switches and media converters in Ethernet networks must be installed in panel housings.

Installation outside of a panel housing is not compliant with EN54.

Notice!

To ensure that the network is set up in compliance with EN54, use only components that

have been approved for use in central fire alarm networks.

Notice!

Networks with more than 20 RSTP switches or a diameter greater than 20 require special

settings.

The standard setting for the IP configuration is only designed for networks with a maximum of

20 RSTP switches or a maximum network diameter of 20.

Make sure that the RSN assigned to the panel matches that in the programming software. The

latter is responsible for setting the last number of the IP address in the standard settings.

Activate "RSTP" as the redundancy protocol and adopt the default standard values.

Standard Ethernet settings of FPA

In the standard settings of the FPA, both the FSP‑5000‑RPS programming software and the

control unit adopt the set RSN as the last number of the IP address.

Notice!

Correct setting of the RSN on the panel controllers and in the FSP‑5000‑RPS programming

software is a requirement for a run-capable network.

Notice!

Use of the Ethernet redundancy must be activated separately in the panel controller.

– IP settings

– IP address 192.168.1.x

The last digit of the IP address in the standard settings is always identical to the RSN

set on the panel controller.

– Network screen 255.255.255.0

– Gateway 192.168.1.254

– Multicast address 239.192.0.1

– Port number 25001 - 25008 (only the first port can be set, 8 consecutive ports are

always used)

– RSTP parameters (redundancy settings)

– Bridge Priority 32768

– Hello Time 2

– Max. Age 20

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 10

10 en | Connecting FPA-5000 Modular Fire Panel

– Forward Delay 15

Notice!

You can use the standard settings of the IP configuration with networks of up to 20 RSTP

switches.

In the case of networks with more than 20 RSTP switches, additional settings are required

according to the topology. In-depth knowledge of networks is required for this.

Settings for loops with more than 20 RSTP switches

If there are more than 20 RSTP switches in the network, then you must adjust the RSTP

settings on the panel controller and in the programming software. In-depth knowledge of

networks is required for this. The panel controllers and RSTP switches are regarded as RSTP

switches. Redundant panel controllers are not regarded as RSTP switches, as the switch

contained within these is not operated as an RSTP switch.

Parameters

– A maximum of 32 nodes can be used in a loop.

– The diameter of the network must not be greater than 32, see Network diameter, page

20.

– The Ethernet transmission sections outside of the panel housing must be designed as

fiber optic cable connections.

– Switches must not be used outside of panel housings.

– Media converters must not be used outside of panel housings.

– A maximum of one panel only and 3 FMR-5000 can be used in a network, in the case of

the FPA-1200.

Features

– The network is EN54-compliant.

– The network uses RSTP.

Additional information when using the OPC server

OPC servers in your network must be added to the RPS programming software.

You must perform the following settings in both the RPS software and on the OPC server:

– Network nodes

– Network group

– RSN

– IP Address

– Port

The OPC server uses port 25000 as standard.

Notice!

FSP-5000-RPS programming software:

Note that you must assign the OPC server to each network node from which statuses should

be transmitted.

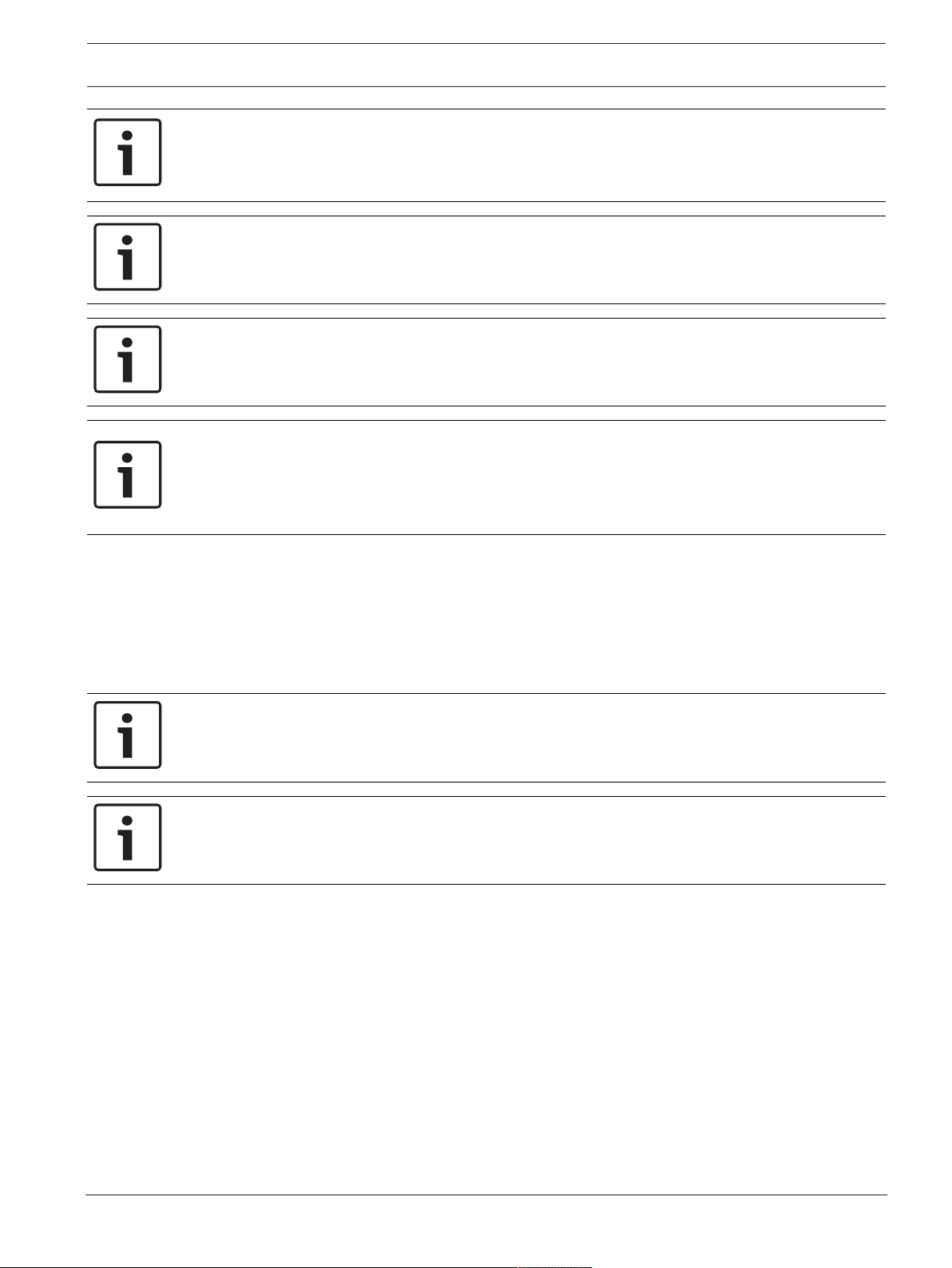

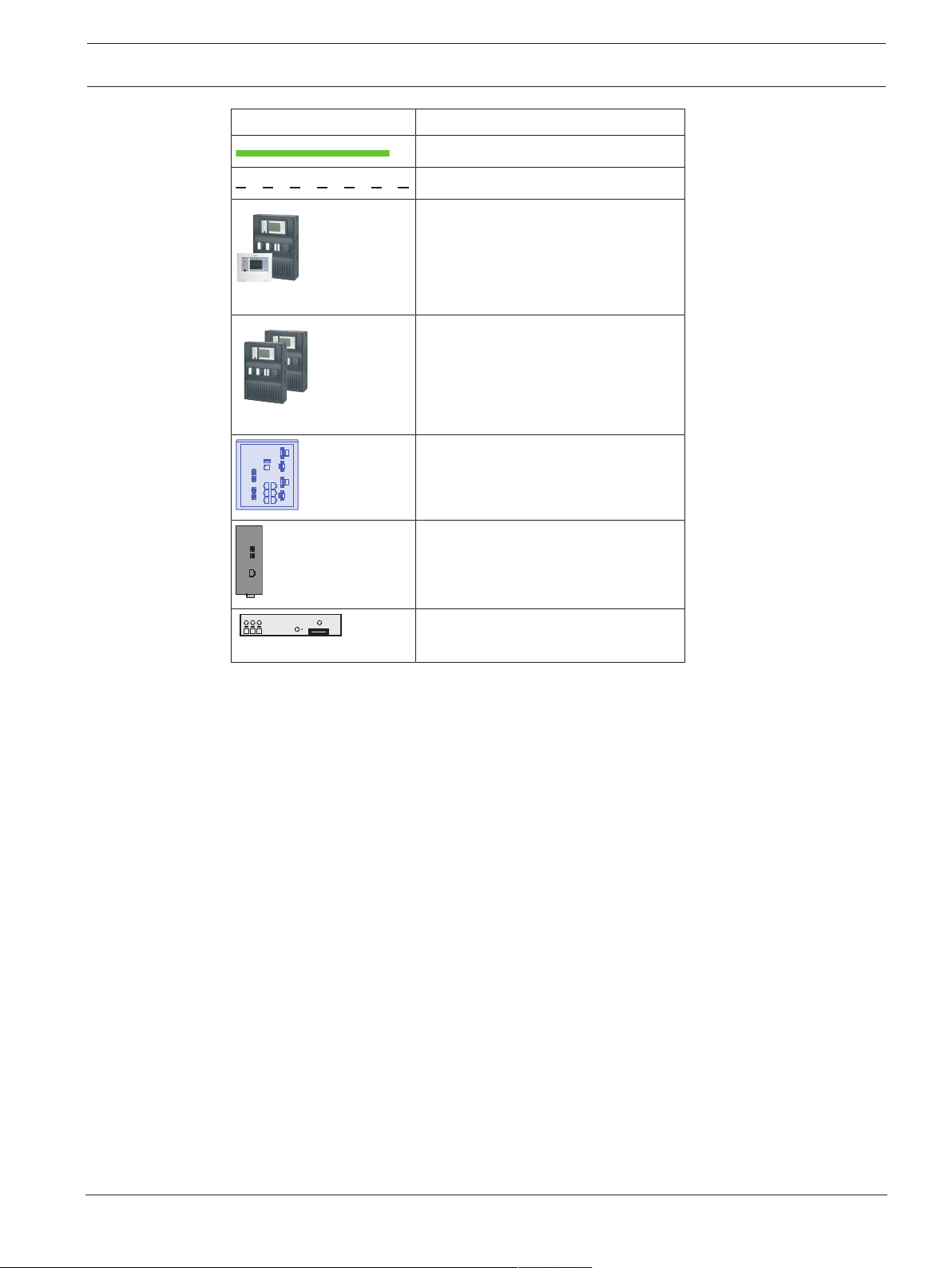

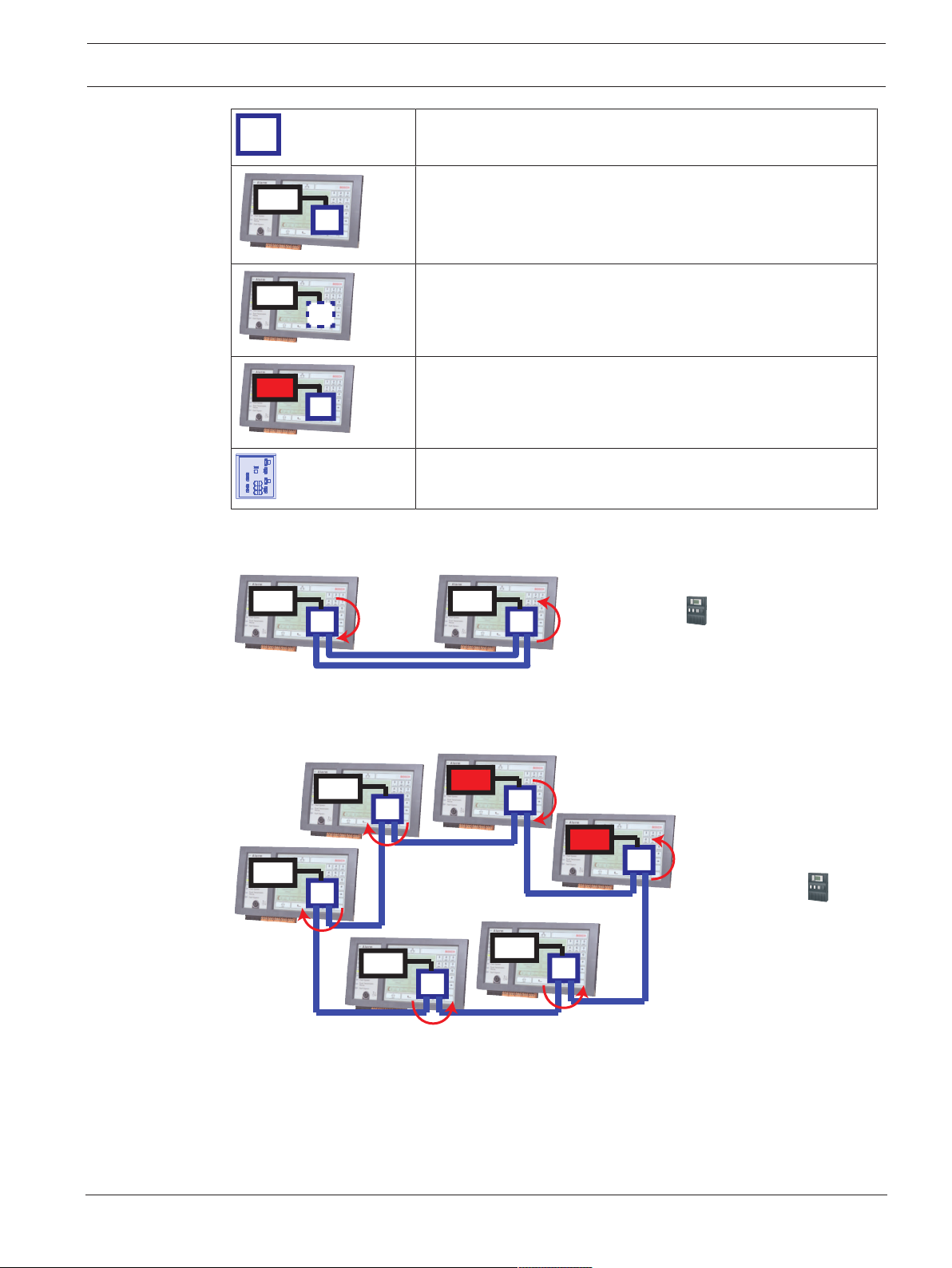

3.2.1 Key

Icon Description

TX Ethernet cable (copper)

FX Ethernet cable (fiber optic cable)

TX or FX Ethernet cable

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 11

Modular Fire Panel Connecting FPA-5000 | en 11

FPA/FMR

FPA-5000

Icon Description

CAN bus

Housing

Panel/Remote Keypad

Redundant panel

Ethernet Switch (in general Ethernet

Switch MM)

Media converter

Secure Network Gateway for Remote

Services

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 12

12 en | Connecting FPA-5000 Modular Fire Panel

FPA/FMR

FPA-5000

FPA/FMR

FX

FX

FX

FX FX

TX TX

TX TX

TX

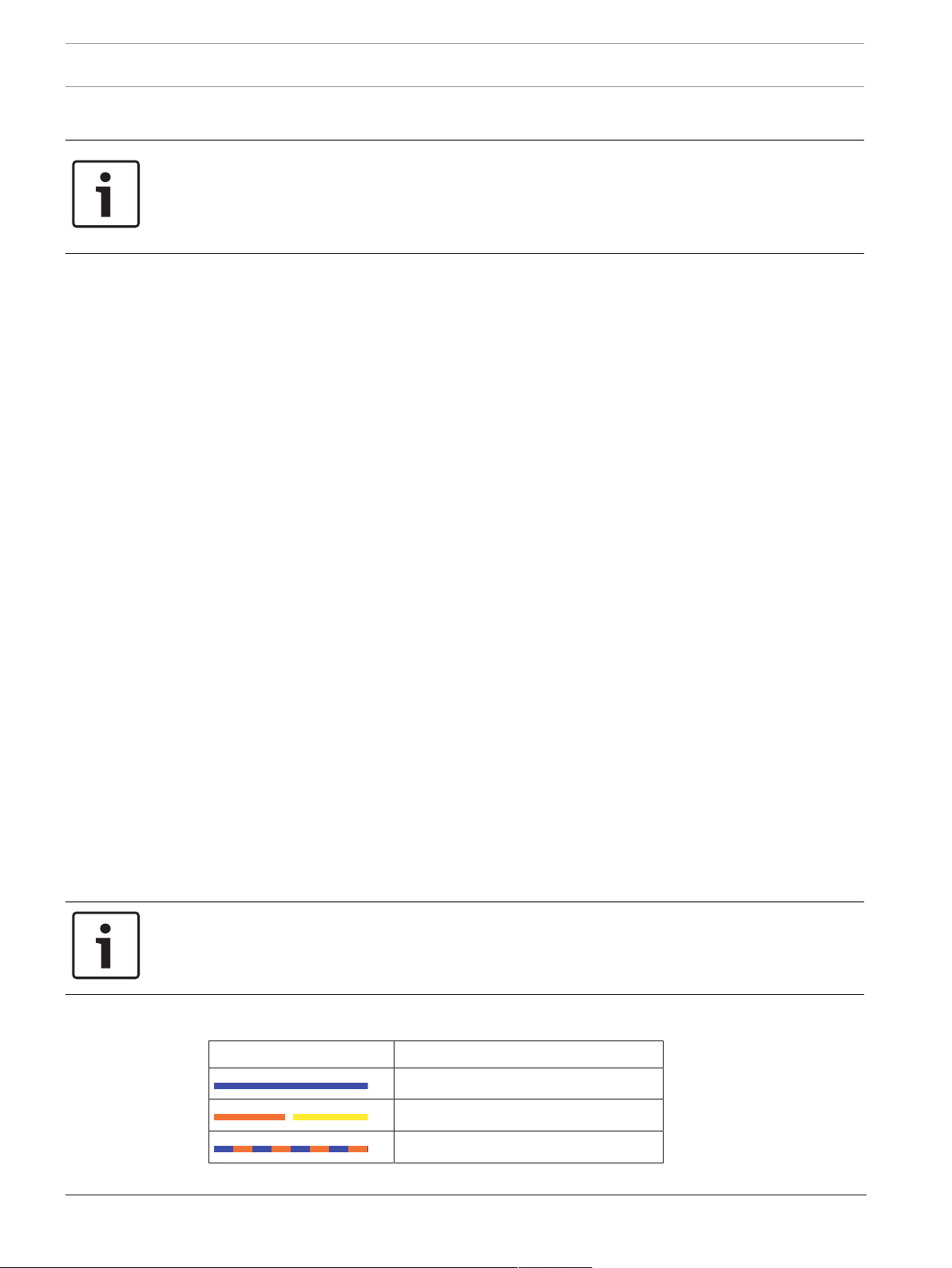

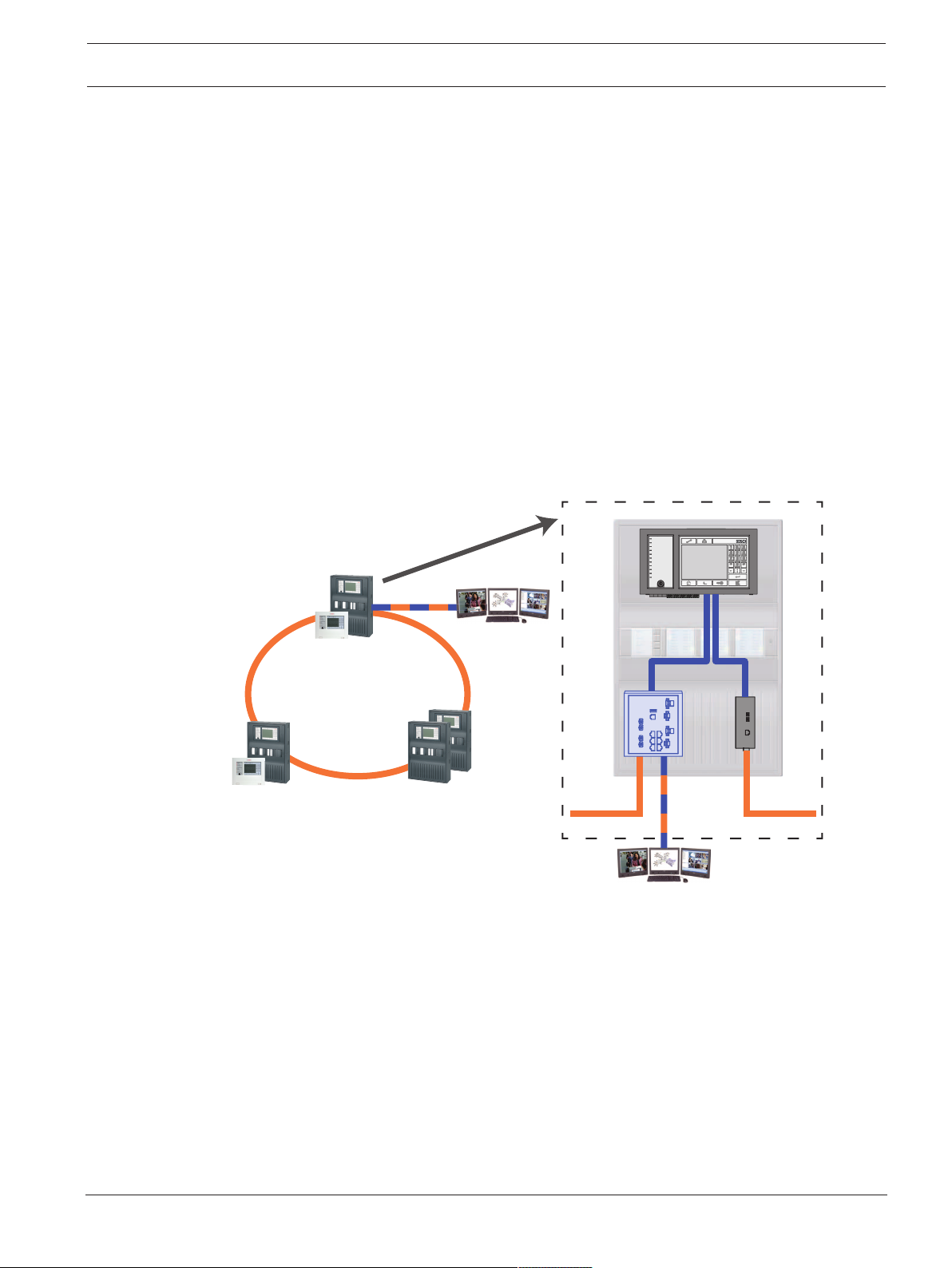

3.2.2 Ethernet loop

For this configuration, the notes, settings, parameters and features specified in Topologies,

page 7 apply.

Figure3.1: Ethernet loop

Key, see Key, page 10

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 13

Modular Fire Panel Connecting FPA-5000 | en 13

FPA/FMR

FPA-5000

FPA/FMR

OPC-Server

OPC-Server

FX

TX

FX

FX

TX

3.2.3 Ethernet loop with OPC server

For this configuration, the notes, settings, parameters and features specified in Topologies,

page 7 apply.

The information given here expands on Topologies, page 7.

Switch for connecting the OPC server must be programmed separately

Program the IP address and redundancy settings of the switch, see Settings on switch, page

38. As the switch is installed in the immediate vicinity (without intermediate space), the

power supply does not have to be designed redundantly and the fault outputs are therefore

not used.

Make sure that the RSTP settings in the panel controllers, RPS programming software and

switch are identical.

OPC server must be programmed separately

Program the IP address, network nodes, network group and RSN, see OPC servers, page 59.

The OPC server uses port 25000 as standard.

Make sure that the settings in the RPS programming software and OPC server are identical.

Parameters

– The OPC server may be connected via an Ethernet cable (copper) or fiber optic cable.

Figure3.2: Ethernet loop with OPC server

Key, see Key, page 10

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 14

14 en | Connecting FPA-5000 Modular Fire Panel

FPA/FMR

FPA/FMR

OPC-Server

OPC-Server

FPA-5000

FX

FX FX

TX TX

3.2.4 Ethernet loop with OPC server to redundant panel controller

Figure3.3: Ethernet loop with OPC server to redundant panel

Key, see Key, page 10

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 15

Modular Fire Panel Connecting FPA-5000 | en 15

FX

FX FX

FX

FX

TX TX

TX TX

TX

CAN

CAN

FPA/FMR

FPA-5000

CAN

CAN CAN

FPA/FMR

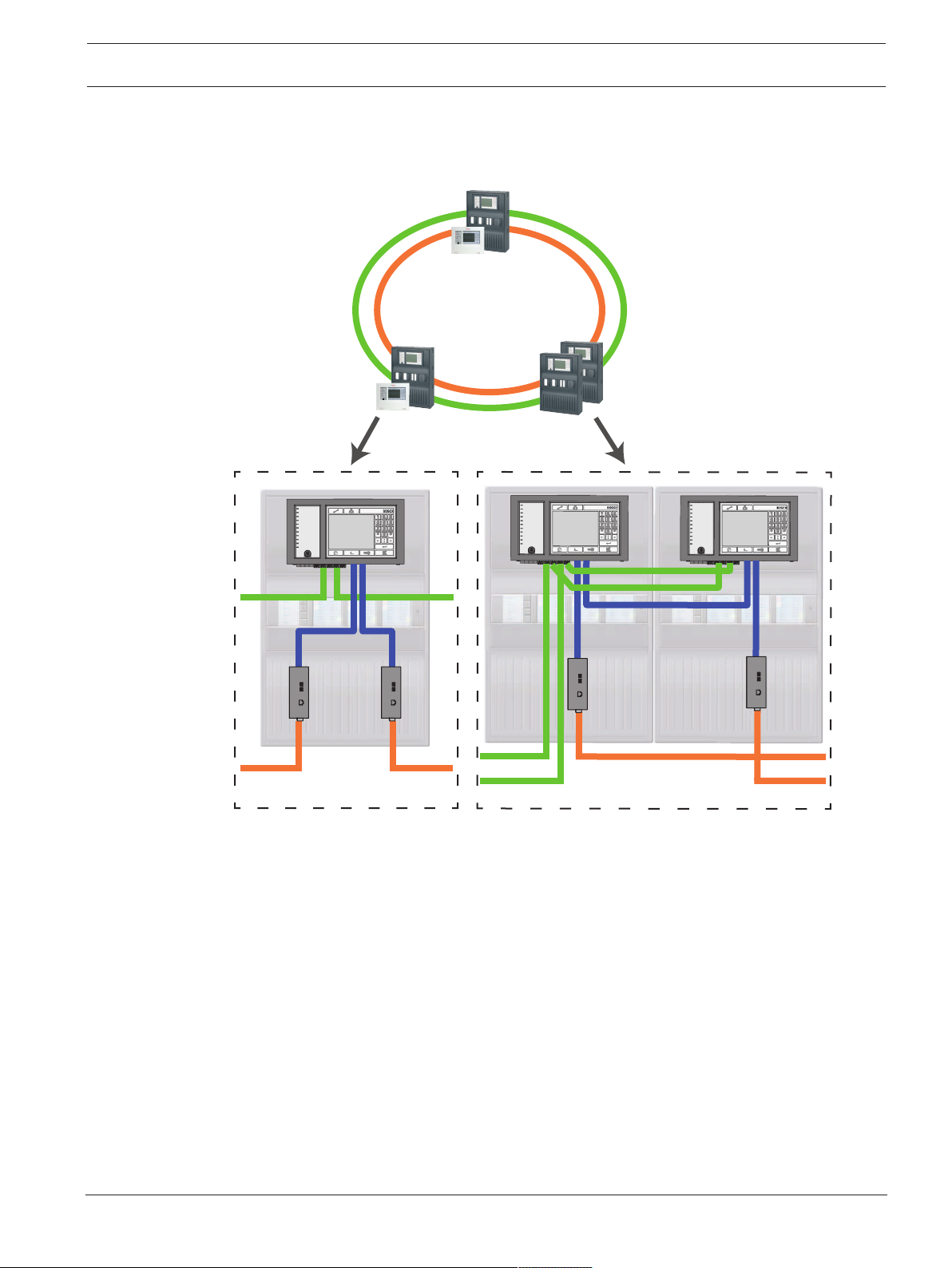

3.2.5 Ethernet/CAN double loop

For this configuration, the notes, settings, parameters and features specified in Topologies,

page 7 apply.

Figure3.4: Double loop of Ethernet and CAN

Key, see Key, page 10

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 16

16 en | Connecting FPA-5000 Modular Fire Panel

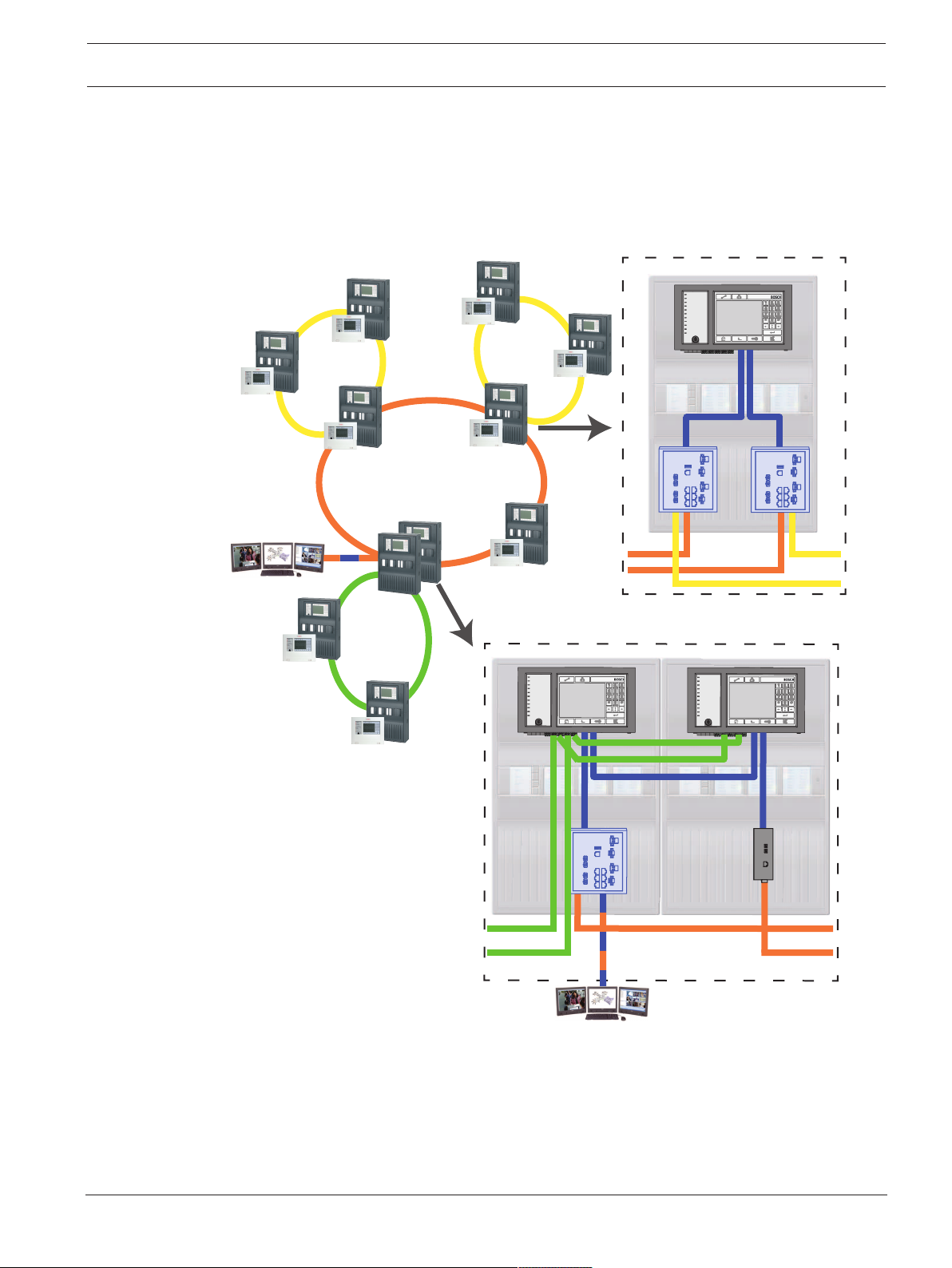

3.2.6 Ethernet backbone with sub-loops (Ethernet/CAN)

For this configuration, the notes, settings, parameters and features specified in Topologies,

page 7 apply.

The information given here expands on Topologies, page 7.

Notice!

This topology requires additional settings for all RSTP nodes in the backbone. More in-depth

knowledge of networks is therefore required.

Please note that with this topology you are required to determine the network diameter, see

Network diameter, page 20. Only RSTP devices are included in the network diameter, CANnetworked panels are disregarded.

Notice!

If the panel acts as an interface with a CAN sub-loop, this panel must then also be designed

redundantly according to EN54‑2 if more than 512 detection points are connected in the subloop.

This restriction does not apply in an Ethernet sub-loop, as the switches to connect the 2

loops perform the redundancy.

Additional settings

You must operate the central loop as the backbone. This must be networked via the Ethernet.

Notice!

For all panels and switches in the backbone, set a higher RSTP priority than in the sub-loops.

This ensures that the RSTP root bridge will always remain in the backbone, even in the event

of a fault.

The switches to connect the loops are part of the backbone!

Use a RSTP priority of 16384 in the backbone.

Notice!

The lower the set value, the higher the RSTP priority.

Settings for loops with more than 20 RSTP devices

Panel controllers connected via CAN are not regarded as RSTP switches when determining the

network diameter.

Switches for connecting the OPC server and the sub-loops must be programmed separately

Program the IP address and redundancy settings of the switches, see Settings on switch, page

38. For this topology, the fault outputs of the switch only have to be used if you have

designed the power supply for the switch redundantly or there is a switch-to-switch

connection, see Switch with power supply and fault relay.

Make sure that the RSTP settings in the panel controllers, RPS programming software and

switch are identical.

Notice!

Change the RSTP priority for the switches for connecting the loops, as they belong to the

backbone.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 17

Modular Fire Panel Connecting FPA-5000 | en 17

FPA/FMR

FPA/FMR

FPA/FMR

FPA/FMR

FPA/FMR

FPA/FMR

FPA-5000

OPC-Server

FX

FX

FPA/FMR

FPA/FMR

FPA/FMR

FX

OPC-Server

FX

FX

TX TX

TX

CAN

CAN

FX

FX

FX

FX

TX

TX

OPC server must be programmed separately

Program the IP address, network nodes, network group and RSN, see OPC servers, page 59.

The OPC server uses port 25000 as standard.

Make sure that the settings in the RPS programming software and OPC server are identical.

Parameters

– The OPC server may be connected via an Ethernet cable or fiber optic cable

Figure3.5: Ethernet backbone with sub-loops

Key, see Key, page 10

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 18

18 en | Connecting FPA-5000 Modular Fire Panel

3.2.7 Connecting Ethernet loops

For this configuration, the notes, settings, parameters and features specified in Topologies,

page 7 apply.

The information given here expands on Topologies, page 7.

Notice!

This topology requires additional settings for all RSTP nodes in the backbone. More in-depth

knowledge of networks is therefore required.

Additional settings

This topology is a special instance of the Ethernet backbone with sub-loops, see Ethernet

backbone with sub-loops (Ethernet/CAN), page 16. You must operate one of the two loops as

the backbone.

Notice!

For all panels and switches in the backbone, set a higher RSTP priority than in the sub-loops.

This will ensure that the RSTP root bridge will always remain in the backbone, even in the

event of a fault.

The switches to connect the two loops are part of the backbone!

Use a RSTP priority of 16384 in the backbone.

Notice!

The lower the set value, the higher the RSTP priority.

Switches for connecting the OPC server and the second loop must be programmed

separately

Program the IP address and redundancy settings of the switch, see Settings on switch, page

38. For this topology, the fault outputs of the switch only have to be used if you have

designed the power supply for the switch redundantly, for connections see Switch with power

supply and fault relay.

Make sure that the RSTP settings in the panel controllers, RPS programming software and

switch are identical.

Change the RSTP priority for the switches for connecting the two loops, as they belong to the

backbone.

OPC server must be programmed separately

Program the IP address, network nodes, network group and RSN, see OPC servers, page 59.

The OPC server uses port 25000 as standard.

Make sure that the settings in the RPS programming software and OPC server are identical.

Parameters

– The OPC server may be connected via an Ethernet cable (copper) or fiber optic cable

In these examples, loop a is the backbone. Loop b is the sub-loop.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 19

Modular Fire Panel Connecting FPA-5000 | en 19

FPA-5000

FPA/FMR

FPA/FMR

FPA/FMR

OPC-Server

a

b

FX

FX

OPC-Server

a

b

TX

FX

FX

FX

FX

TX

FPA/FMR

FPA/FMR

OPC-Server

FPA/FMR

FPA/FMR

FPA/FMR

OPC-Server

FPA-5000

a

a b

b

FX

TX

FX

FX

FX

TX

FX FX

Figure3.6: Connecting Ethernet loop via a non-redundant panel

Figure3.7: Connecting Ethernet loop via a redundant panel

Key, see Key, page 10

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 20

20 en | Connecting FPA-5000 Modular Fire Panel

CPU

3.3 Ethernet network

In the network, the Ethernet network connections are monitored continuously. If a connection

has been severed, then the interruption is detected. Repaired connections are also detected.

MAC addresses

Each panel controller has 3 MAC addresses.

– MAC address for the host

– MAC address for network connection 1 (Eth 1)

– MAC address for network connection 2 (Eth 2)

The network diagnosis of the panel always shows you the MAC address of the hosts

connected via the network.

3.3.1 Protocols

SNMP

SNMP is used to monitor and control network components. To this end, parameters of

network nodes can be read out or modified. For this you require the appropriate network

management software (e.g. Hirschmann HiVision).

Notice!

The network uses the following SNMP password: PUBLIC

LLDP

LLDP is a basic protocol standardized by the IEEE. It is used to share network information

between neighboring devices. This information is

– provided as part of the SNMP data

– displayed via the panel controller as part of the network diagnostic data

RSTP

RSTP is a network protocol standardized by the IEEE. RSTP ensures that there are no loops in

networks. Redundant paths are detected in the network, deactivated and activated when

necessary (failure of a connection).

The protocol is used for exactly this purpose in the network.

A change to the bus topology following the failure of a connection is automatically canceled

once it has been repaired.

3.3.2 Network diameter

The network diameter of FPA-RSTP Ethernet networks must not be greater than 32.

Definition

The diameter of a network corresponds to the number of RSTP switches on the longest

possible section without loops between any 2 end points in the network.

The following must be taken into account in relation to a FPA-RSTP Ethernet network:

– Each MPC contains an end point and an internal RSTP switch.

– A combination of MPC and redundant MPC counts as just one RSTP switch.

– Media converters are not regarded as RSTP switches.

– CAN connections may not be included in the longest possible section.

– OPC servers are not taken into account with respect to the diameter.

Key

Central processor in the panel controller or in the remote

keypad.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 21

Modular Fire Panel Connecting FPA-5000 | en 21

S

CPU

S

CPU

S

CPU

S

1

2

Ø = 2 =

#

MPC MPC

CPU

CPU

CPU

1

2

CPU

CPU

CPU

3

4

5

6

Ø = 6 =

#

MPC

MPC

MPC

MPC

MPC

MPC

Internal RSTP switch in the panel controller or in the remote

keypad.

Panel controller or remote keypad with central processor and

internal RSTP switch.

Redundant panel controller with central processor and internal

RSTP switch.

Panel controller/remote keypad

Starting point/end point for determining the diameter in the

examples.

Ethernet Switch (in general Ethernet Switch MM) as external

RSTP switch

2 connected panels form the smallest possible loop. The diameter of this network is equal to

2, as the internal switches are located between the end points.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Figure3.8: Network diameter of a loop with 2 panels

In a panel loop without external switches, the diameter of the network corresponds to the

number of installed panels.

Figure3.9: Network diameter of a loop with 6 panels

If a backbone and sub-loops are connected to each other via RSTP switches not integrated

into the panel controller, then the RSTP switches must also be taken into account.

Page 22

22 en | Connecting FPA-5000 Modular Fire Panel

3

7

910

11

2

4

12

14

15

16

Ø = 18

# = 14

17

6

1

5

8

13

18

MPC MPC

MPC

MPC MPC

MPC

MPC

MPC

MPC

MPC

MPC

MPC

MPC

MPC

MPC

MPC

Figure3.10: Network diameter of a backbone with sub-loops

The figure shows that the longest path must always be found for the diameter.

3.3.3 Cables used

Use only the following cables for networking:

– Ethernet cable

Ethernet patch cable, shielded, CAT5e or better.

Note the minimum bending radii specified in the cable specification.

– Fiber optic cable

Multi-mode: fiber optic Ethernet patch cable, duplex I‑VH2G 50/125μ or duplex I‑VH2G

62.5/125μ, SC plug.

Single mode: fiber optic Ethernet patch cable, duplex I‑VH2E 9/125μ, SC plug.

Note the minimum bending radii specified in the cable specification.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 23

Modular Fire Panel Connecting FPA-5000 | en 23

3.3.4 Creating an Ethernet network

There are several procedures for creating a network of fire alarm control panels. The 2

procedures described below differ in the size of the networks and the number of installation

and configuration tasks carried out alongside each other.

Procedure for smaller projects

This procedure is suitable for projects involving only a small number of engineers working on

the installation of the fire alarm system concurrently.

1. Plan out the network.

2. Create the network in FSP‑5000‑RPS and configure the network settings.

3. Print the network information out for safe keeping, or store the information on the

laptop.

4. Install the control panels and network cables and connect them to a network.

5. Configure the network settings for the individual control panels directly at the control

unit as per the printout.

6. Reset each of the control panels in the network in order to activate the network

configuration.

7. Connect your computer with the FSP‑5000‑RPS programming software to a control panel

in the network. Load this configuration to all other control panels across the network via

this control panel. Redundant panels use the main panel configuration.

8. Carry out a reset in order to reset the pending error messages. Rectify any errors.

Configure the network settings on the control panels first. This gives you the advantage that

you can program the other control panels in the network from one control panel.

Procedure for medium-sized and large projects

This procedure is suitable for projects involving a number of tasks carried out concurrently by

several teams. As many tasks performed during installation and configuration involve

restarting the fire alarm control panel, the network is not started up in this procedure until a

later stage.

1. Plan out the network.

2. Produce a configuration of the network without peripherals with FSP‑5000‑RPS.

3. Print the network information out for safe keeping, or store the information on the

laptop.

4. Install the network cables and check individual sections or loops.

5. Install the panels and commission them as stand-alone panels.

6. Install the peripherals in the panels.

7. Configure each of the panels with RPS.

8. Ensure that the individual panels are working correctly.

9. Commission the individual loops of the network one after the other, according to the

topology.

Start with the backbone.

– Produce a configuration for the backbone in RPS. Import all of the necessary panel

configurations. Configure the network settings and print them out.

– Connect all panels to a network.

– Configure the network settings for the individual control panels directly at the panel

controller as per the printout.

– Reset each of the control panels in order to load the network configuration.

– Ping the neighboring panels in order to check the network.

– Commission the entire backbone and rectify any errors.

Commission the sub-loops as per the example of the backbone.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 24

24 en | Connecting FPA-5000 Modular Fire Panel

3.3.5 Extension of existing networks

In order to ensure fault-free communication between all connected panels, all panels must

have the same firmware version. Remind for redundand panels, that a firmware update is

possible for the main panel solely. Switch the redundant panel to main panel to perform the

firmware update for this panel.

3.4 CAN network

Up to 32panel controllers, remote keypads and OPC servers can be combined to form a

network.

Depending on the intended application, different panel controllers and remote keypads can be

divided into groups and defined as network nodes or local nodes. As a rule, within any given

group, only the status of control panels within the defined group can be displayed. The status

of all control panels can be displayed and/or processed from network nodes, irrespective of

the group to which the panels belong.

The panels can be networked redundantly as a loop via CAN1 and CAN2.

FOC networking

In a loop, panels can be connected using fiber optic cables via CAN/FOC adapters.

The CAN/FOC converters from EKS enable distances of up to 15km between two nodes to be

overcome in a network (depending on the converter type and the fiber optic cable used). The

following converters are available (PzPCANFOC system/MM):

– DL-CAN/1x13-MM-ST system

– DL-CAN/1x13-MM-SC system

– DL-CAN/1x13-SM-ST system

– DL-CAN/1x13-SM-SC system

Loop topology

– In loop topology, the CAN cable is always routed from a CAN1 terminal to a CAN2

terminal [CAN1 ⇒ CAN2].

A CAN segment thus consists of two bus users. The cable length depends on the cable

cross-section.

– Due to the maximum of 32nodes and the maximum cable length of 1000m between

nodes, a system can be installed with a total cable length of 32km.

Networking of panels and remote keypads

The table below shows the options for networking panels/remote keypads depending on the

network topology.

Topology FPA-1200 FPA-5000

Standalone panel Possible Possible

Standalone panel,

redundant

Loop 1 FPA-1200 + max. 3 FMR‑5000 Max. 32 FPA‑5000/FMR‑5000

Loop with redundant

panel

Not possible Possible

Not possible Max. 32 FPA‑5000/FMR‑5000 +

redundant FPA-5000

Refer to the limits determined by the network topology.

As the FPA-1200 is not operated as the redundant panel, DIP 6 on FPA-1200-MPC is not functional!

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 25

Modular Fire Panel Connecting FPA-5000 | en 25

Limits in network

The number of panels and remote keypads that can be networked depends on the choice of

network topology.

Networked panels and remote keypads are known as "nodes".

– The number of detection points in a network is limited to 32,768.

– The number of detection points per panel operated in a network is limited to 2048.

– The number of nodes per system depends on the type of topology.

A node is either an MPC Panel Controller or an FMR-5000 Remote Keypad.

– The number of nodes in loop topology is limited to 32.

– The number of nodes per CAN segment is limited to eight.

A CAN segment is the physical connection of a CAN line.

– Up to 3 remote keypads to a specific panel can be directly assigned to the network using

the FSP-5000-RPS Programming Software.

The cabling between nodes and the maximum permissible cable length is also determined by

the choice of topology.

Cable type for networking

The CAN connection is a two-wire connection (CAN‑H and CAN‑L). A three-wire connection

(CAN‑H, CAN‑L and CAN‑GND) may be necessary in exceptional cases, e.g. with a high EMC

load or a significant difference in grounding potential. The shield wire of the CAN cable is only

connected to the metal housing of the panel on one side.

Cable length for networking

The maximum permitted cable length depends on the loop resistance of the cable used and on

the number of communicating.

Example: The J-Y (St) Y 2 x 2 x 0,8 mm red fire detector cable enables two nodes with a

maximum distance of around 800 m to be connected.

Notice!

The distance between two nodes in loop topology can be determined by reading off the value

at two nodes in the diagram.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 26

26 en | Connecting FPA-5000 Modular Fire Panel

Figure3.11: CAN network: Achievable cable length, depending on the number of nodes and the cable

resistance

L = cable length in meters

N = number of nodes

3.4.1 Creating a CAN network

This procedure is suitable for projects involving only a small number of engineers working on

the installation of the fire alarm system concurrently.

Procedure

1. Plan out the network.

2. Create the network in FSP‑5000‑RPS.

3. Print the network information out for safe keeping, or store the information on the

laptop.

4. Install the control panels and connect them with CAN cables to a network.

5. Connect your computer with the FSP‑5000‑RPS programming software to a control panel

in the network. Load this configuration to all other control panels across the network via

this control panel. Redundant panels use the configuration of the main panel.

6. Carry out a reset in order to reset the pending error messages. Rectify any errors.

3.4.2 Extension of existing networks

In order to ensure fault-free communication between all connected panels, all panels must

have the same firmware version. Remind for redundand panels, that a firmware update is

possible for the main panel solely. Switch the redundant panel to main panel to perform the

firmware update for this panel.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 27

Modular Fire Panel Connecting FPA-5000 | en 27

FPA/FMR

FPA/FMR

FSP-

5000--

RPS

Remote

Connect

TX

FX

TX

FX

3.5 Remote Services

The following services belong to Remote Services:

– Remote Connect

– Remote Alert

– Remote Maintenance

Prerequisite for Remote Alert and Remote Maintenance is Remote Connect.

3.5.1 Remote Connect

Remote Connect provides a trusted and secure internet connection, which enables remote

access to a panel via FSP-5000-RPS. Remote Connect is the basis for all Remote Services. For

Remote Connect use the Secure Network Gateway (CTN: C1500).

In case of a panel network, one panel of the panel network has to be connected to a Secure

Network Gateway. Exclusively this connection, needs to be a dedicated Ethernet connection.

Notice!

While Remote Connect supports connection to a panel network via Ethernet or CAN, Remote

Alert and Remote Maintenance functionality is only supported when an Ethernet connection is

provided and configured for service usage.

Remote Connect has to be enabled in the FSP-5000-RPS configuration of this panel.

The following topology shows panel controllers connected via Ethernet where a Secure

Network Gateway is connected to the network via a Ethernet Switch (in general Ethernet

Switch MM).

Figure3.12: Remote Connect in an Ethernet loop

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 28

28 en | Connecting FPA-5000 Modular Fire Panel

FPA/FMR

FPA/FMR

CAN

FPA/FMR

FSP5000--

RPS

Remote

Connect

Notice!

Use only media converters to connect the panel via FX.

To prevent sending EN 54-2 relevant multicast traffic to the router, use the Ethernet Switch (in

general Ethernet Switch MM BPA-ESWEX-RSR20) approved with panel version 2.8. Activate

IGMP snooping of the Ethernet Switch, see Activating IGMP snooping, page 41.

Notice!

The internet router (or the company network which provides internet access) as well as the

Secure Network Gateway must provide separated sub-networks. Panels of the panel network

may not be placed in the sub-network of the internet router. Also overlapping of the subnetworks is not possible.

In case of overlapping sub-networks you have to separate the sub-networks by changing the

IP addresses on panel network side.

Additionally you have to propagate the changes to the Secure Network Gateway. To do so,

launch the web interface via a web browser:

- Address: https://192.168.1.254

- User name: bosch

- Password: ipti83

Under Configuration -> Network (LAN) you can change the IP address. Consider, that the

Default gateway: address in the panel controller configuration must match the IP address of

the Secure Network Gateway.

The following topology shows a CAN network where a Secure Network Gateway is connected

to the network via Ethernet port.

Figure3.13: Remote Connect in a CAN loop

For connecting the Secure Network Gateway to a redundant panel controller you can use the

following topology.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 29

Modular Fire Panel Connecting FPA-5000 | en 29

ETH1

ETH1

TX TX

FSP-

5000--

RPS

Remote

Connect

FPA/FMR

Remote

Maintenance

3.5.2 Remote Alert

Through Remote Alert, a panel pushes relevant status information to the Remote Portal.

Remote Alert analyzes these data. In case of an unexpected event, the Remote Portal notifies

the user via SMS and/or E-Mail about the received alerts.

3.5.3 Remote Maintenance

Remote Maintenance offers the possibility to remotely monitor certain parameters of various

security items connected to a fire panel. Via the Remote Portal, you can conduct walk tests.

Figure3.14: Remote Maintenance

Notice!

Ethernet connections used only to transfer Remote Maintenance data may be designed both

as Ethernet cables and fiber optic connections. Note the permitted maximum cable lengths.

Notice!

The connection used for Remote Maintenance must be non-interacting.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 30

30 en | Connecting FPA-5000 Modular Fire Panel

FPA/FMR

FPA/FMR

FX

FPA/FMR

FX

TX

FX

TX

Remote

Maintenance

!

Notice!

Note that Remote Maintenance data is transferred in unencrypted form.

Notice!

Use only media converters to connect the panel via FX.

Figure3.15: Remote Maintenance

When using Remote Maintenance with Ethernet networks, one panel in the network must be

connected to the router for data transfer purposes. All collected data is transfered from the

network via this connection.

Remote Maintenance for Remote Portal

Remote Maintenance is by default configured for Remote Portal: Remote Maintenance collects

data of relevant LSN devices and functional modules and sends them to the Remote Portal

where they are analyzed and visualized for maintenance activities.

Remote Maintenance for Private Secure Network

Remote Maintenance can also be configured for Private Secure Network: Collected data will

be sent to a central management server system (CMS).

Caution!

Remote Maintenance for Private Secure Network requires a secure IP connection. For this

reason with Remote Maintenance for Private Secure Network an IP network is provided,

which is based on DSL with an optional wireless access on the panel side. Remote

Maintenance for Private Secure Network is only available in Germany with a service

agreement with Bosch ST-IE.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 31

Modular Fire Panel Connecting FPA-5000 | en 31

FPA/FMR

FPA/FMR

FX

FPA/FMR

FX

TX

FX

TX

Remote

Maintenance via

Private Secure

Network

Service

Center

Figure3.16: Remote Maintenance for Private Secure Network

For Remote Maintenance, you must enter the server IP address and port of the Remote

Maintenance system server in the FSP-5000-RPS programming software.

Assign a unique Panel Network ID to the network.

Switch for connecting the CMS must be programmed separately

Program the IP address and redundancy settings of the switch, see Settings on switch, page

38. As the switch is installed in the immediate vicinity (without intermediate space), the

power supply does not have to be designed redundantly and the fault outputs are therefore

not used.

Make sure that the RSTP settings in the panel controllers, FSP-5000-RPS programming

software and switch are identical.

3.6 Voice alarm systems

Notice!

If an MPC-xxxx-B panel controller shall be used for the direct connection to a Praesideo/

PAVIRO system a cross-over patch cable is required as neither Praesideo/PAVIRO nor the

MPC-xxxx-B supports Auto-MDI(X).

The following topology shows panel controllers connected via Ethernet where the Praesideo/

PAVIRO system is integrated in the panel loop using an Ethernet interface.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 32

32 en | Connecting FPA-5000 Modular Fire Panel

FPA/FMR

FPA/FMR

FXFX

FPA/FMR

Praesideo/

PAVIRO

Praesideo/

PAVIRO

TX

FPA/FMR

FPA/FMR

FPA/FMR

FPA

FX

FX

TX

CAN

CAN

TX

Praesideo/

PAVIRO

FXFX

Praesideo/

PAVIRO

TX

Figure3.17: Ethernet loop with Praesideo/PAVIRO

Use the Ethernet Switch (in general Ethernet Switch MM BPA-ESWEX-RSR20) approved with

panel firmware version 2.8.

To prevent sending EN 54-2 relevant multicast traffic to the Praesideo/PAVIRO system,

activate IGMP snooping of the Ethernet Switch MM, see Activating IGMP snooping, page 41.

Notice!

If an MPC-xxxx-B panel controller shall be used for the direct connection to a Praesideo/

PAVIRO system a cross-over patch cable is required as neither Praesideo/PAVIRO nor the

MPC-xxxx-B supports Auto-MDI(X).

In every panel controller of a CAN network you can connect one Praesideo/PAVIRO system

using an Ethernet interface. The following topology shows panel controllers connected via

CAN where the Praesideo/PAVIRO system is connected to one panel controller using an

Ethernet interface.

Figure3.18: Praesideo/PAVIRO connection to a CAN network

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 33

Modular Fire Panel Connecting FPA-5000 | en 33

Notice!

Because CAN network traffic shall not be transferred through the Ethernet connection, you

must switch off networking over IP in the FSP-5000-RPS programming software.

If this is not switched off, the network will not be compliant with EN 54.

3.7 UGM-2040 networks

The topologies to be installed and the network settings to be programmed can be obtained

from your UGM 2040 BMA planner. See also the UGM 2040 BMA Anschaltehandbuch.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 34

34 en | Installation Modular Fire Panel

6x KB40 x 12 mm

FBH 0000 A

(FHS 0000 A)

4 Installation

Checklist

Before starting with the installation of the network, please review all of the points set out

below.

– Ethernet and CAN

– The requisite line lengths of the Ethernet TX, Ethernet FX and CAN TX and CAN FX

cables are less than their maximum length.

– The entire peripherals and their cabling in the individual panels are planned.

– Network planning

– All IP addresses and network settings for the individual panels and additional

network components are planned and at your disposal.

– An overview of the additional components to be installed, such as switches and

media converters, and their cabling with neighboring panels is at your disposal.

– An overview of the network topology to be installed is at your disposal.

– All network redundancy settings have been planned and are at your disposal.

Danger!

Laser light.

Do not look directly into the beam with the naked eye or with visual instruments of any kind

(e.g. magnifying glass, microscope). Failure to observe this notice poses a danger to the eyes

at a distance of less than 100 mm. The light emerges at the visual terminals or at the end of

the fiber optic cables connected to these. CLASS 2M light-emitting diode, wavelength

650nm, output < 2 mW, in accordance with DINEN60825‑1:2003‑10.

4.1 Installing media converters in the mounting frame

Install the media converters in the corresponding FPM‑5000‑KMC bracket

Figure4.1: Installation of FPM‑5000‑KMC bracket in mounting frame

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 35

Modular Fire Panel Installation | en 35

M

C

M

C

click

M

C

M

C

3x M4 x 5 mm

PSS 0002 A

USF 0000 A

Figure4.2: Installation of media converters in the FPM‑5000‑KMC bracket

4.2 Installing media converters in PSS0002A/USF0000A

Install the media converters in the FPM‑5000‑KES. bracket

In the case of the USF0000A you need to remove the installed mounting plate.

Figure4.3: Installation of FPM‑5000‑KES bracket in housings

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 36

36 en | Installation Modular Fire Panel

click

M

C

M

C

Figure4.4: Installation of media converters in the FPM‑5000‑KES bracket

4.3 Settings on media converter

Only a few steps are required to use the media converter:

– Set the DIP switches.

– Connect the media converter to the FX network cables and CAT5e network cables.

– Supply the media converter with power via the internal BCM battery controller module.

Notice!

The media converters are only supplied with power via power supply terminal 1.

The error LED on the media converter is therefore continuously lit. However, this does not

affect the functionality of the device.

Notice!

Use only the following cables for networking:

Ethernet cable

Ethernet patch cable, shielded, CAT5e or better.

Note the minimum bending radii specified in the cable specification.

Fiber optic cable

Multi-mode: fiber optic Ethernet patch cable, duplex I‑VH2G 50/125μ or duplex I‑VH2G

62.5/125μ, SC plug.

Single mode: fiber optic Ethernet patch cable, duplex I-VH2E 9/125μ

Note the minimum bending radii specified in the cable specification.

Notice!

Refer to the installation guides for the mounting kits for information on how to install a media

converter in the housing of a panel: FPM 5000 KMC (F.01U.266.845) FPM‑5000‑KES

(F.01U.266.844)

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 37

Modular Fire Panel Installation | en 37

1

0

Notice!

The maximum transmission section for multimode media converters via FX is 2000m.

The maximum transmission section for single mode media converters via FX is 40km.

Using the DIP switches, configure the media converter as shown in the following figure.

Notice!

Only change the DIP switch settings on media converters when they are de-energized.

DIP switch number Setting

1 Link Fault Pass-Through activated

2 Ethernet: automatic mode

3 Ethernet: 100 MBit

4 Ethernet: fully duplex

5 Fiber optic cable: fully duplex

6 Link down: off

4.4 Installing switches in PSS0002A/USF0000A

Notice!

If you are using switches in the network, these must be included in the configuration in the

FSP-5000-RPS programming software.

Notice!

Do not use the supplied network cable to connect the switches, as it is not shielded.

Use an Ethernet patch cable, shielded, CAT5e or better.

Install the switches in the corresponding FPM‑5000‑KES. bracket

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 38

38 en | Installation Modular Fire Panel

3x M4 x 5 mm

PSS 0002 A

USF 0000 A

click

Figure4.5: Installation of FPM‑5000‑KES bracket in housings

Figure4.6: Installation of switches in the FPM‑5000‑KES bracket

4.5 Settings on switch

In order to be able to use the switches in the network, you need to program them.

Connect your laptop to the network and use the HiDiscovery software supplied by the

manufacturer to carry out the initial programming of the switches. Using this software, search

for the switches in the network. Double-click on a switch to select it and assign an IP address

to it.

Following the initial programming of the IP address, you can use a web browser to call up the

configuration user interface for the switch.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 39

Modular Fire Panel Installation | en 39

Notice!

Refer to the manufacturer's user guide for an exact description of the installation and

configuration of the switches. Access data:

User: admin

Password: private

Use a browser to call up the configuration user interface for the switches.

You must perform the following settings in the switch:

– Assign IP address, page 39,

– Program redundancy settings, page 39.

Furthermore, optional settings e.g.:

– Programming the fault relay, page 40,

– Programming connection monitoring, page 41,

– Activating IGMP snooping, page 41.

4.5.1 Assign IP address

Notice!

Practical tip:

In the device part of IP addresses, use numbers greater than 200 (xxx.xxx.xxx.200) for

switches, if your network configuration allows this. This will give you a clearer separation

between the IP addresses of the panels and those of the switches.

Example:

Switch 192.168.1.201 is assigned to the panel with the IP address 192.168.1.1.

Notice!

Please refer to the following manufacturer documents for an exact description of the

installation and configuration of the switches:

Installation user guide

Web-based interface reference guide

Use a browser to go to the configuration user interface for the switch.

In the Basic Settings -> Network menu, set the following values depending on the topology

chosen:

– Mode: local

– IP address: the required IP address, e.g. 192.168.1.201

– Network screen: the required network screen, e.g. 255.255.255.0

– Gateway: the required gateway, e.g. 0.0.0.0 if no gateway is required

Click on Write.

Notice!

The settings in the individual menu items in the switch configuration take effect after clicking

on Write.

The settings are only saved permanently, i.e. so that they are retained even after the device is

restarted, if under Basic Settings -> Load/Save in the Save field you select the item On the

device and click on the Save button.

4.5.2 Program redundancy settings

As the FPA panel networks use RSTP as the redundancy protocol, you must activate and

program the protocol in the configuration user interface:

In the Redundancy -> Spanning Tree -> Global menu, set the following values:

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 40

40 en | Installation Modular Fire Panel

– Function: On

– Protocol version: RSTP

– Protocol configuration: Same settings as for the panel controllers

Click on Write.

Notice!

The settings in the individual menu items in the switch configuration take effect after clicking

on Write.

The settings are only saved permanently, i.e. so that they are retained even after the device is

restarted, if under Basic Settings -> Load/Save in the Save field you select the item On the

device and click on the Save button.

4.5.3 Programming the fault relay

Notice!

The fault relay only has to be programmed for applications where at least one of the following

requirements is met:

There is a connection between 2 switches. This is possible in the case of a backbone with

sub-loops, for example.

The power supply to the switch is designed redundantly.

Notice!

Please refer to the following manufacturer documents for an exact description of the

installation and configuration of the switches:

Installation user guide

Web-based interface reference guide

Use a browser to go to the configuration user interface for the switch.

Under Diagnosis -> Signal Contact in the Signal Contact 1 tab, set the Signal Contact Mode

to Device Status.

Under Diagnosis -> Device Status in the Monitoring field, set the following values:

– Power Supply 1: Monitor

– Connection Error: Monitor

All other settings must be set to Ignore.

Notice!

The settings in Device Status also apply to the fault LED of the switch.

Click on Write.

Notice!

The settings in the individual menu items in the switch configuration take effect after clicking

on Write.

The settings are only saved permanently, i.e. so that they are retained even after the device is

restarted, if under Basic Settings -> Load/Save in the Save field you select the item On the

device and click on the Save button.

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 41

Modular Fire Panel Installation | en 41

4.5.4 Programming connection monitoring

Notice!

You only need the setting for the connection monitoring if you are using the fault relay of the

switch.

If you want to use the fault relay to monitor the connections of the switch, then you must

specify in the switch configuration which ports of the switch should be monitored.

Activate the Forward Connection Error check box for the individual ports in the Basic

Settings -> Port Configuration menu.

Only connections for which Forward Connection Errors has been activated are monitored.

Click on Write.

Notice!

The settings in the individual menu items in the switch configuration take effect after clicking

on Write.

The settings are only saved permanently, i.e. so that they are retained even after the device is

restarted, if under Basic Settings -> Load/Save in the Save field you select the item On the

device and click on the Save button.

4.5.5 QoS priority, only for UGM‑2040

If you use the switches for communication between FPA networks and the UGM‑2040, then

the QoS priority must be set in the switches of the UGM.

In the QoS/Priorität -> Global menu, change the settings of the drop-down list field under

Trusted Mode to trustIpDscp.

Click on Write.

Notice!

The settings in the individual menu items in the switch configuration take effect after clicking

on Write.

The settings are only saved permanently, i.e. so that they are retained even after the device is

restarted, if under Basic Settings -> Load/Save in the Save field you select the item On the

device and click on the Save button.

4.5.6 Activating IGMP snooping

To prevent sending EN 54-2 relevant multicast traffic to other systems connected to the

Ethernet Switch (Praesideo/PAVIRO, Remote Connect) activate IGMP snooping.

On the IGMP configuration page of the Ethernet Switch select the following options:

1. Switch on the IGMP snooping operation.

2. Activate the IGMP Querier.

3. Configure the transmission interval, in which the RSR20 sends IGMP query packets (e.g. 4

seconds).

4. Configure the time within multicast group members are supposed to respond to IGMP

queries (e.g. 3 seconds).

5. Select Discard for packets with unknown multicast addresses.

6. Select Send to Query and registered Ports for packets with known multicast addresses.

7. Enable IGMP only for ports where other systems connected to the switch are connected.

Disable the Static Query Port option for all ports.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 42

42 en | Installation Modular Fire Panel

USB Device RS232

max. 2 m

max. 3 m

OPC

Server

Ethernet

100BaseTX

FPA

4.6 CAN network

Networking and Interfaces

The panel controller has

– two CAN interfaces (CAN1/CAN2) for networking (bus or loop topology)

– two signal inputs (IN1/IN2)

– two Ethernet interfaces

– USB and RS232 interfaces

Note the maximum cable length of 3m for connection to the USB interface or 2m for

connection to the RS232 interface.

When connecting to a building management system (BIS) via an OPC server and Ethernet

100BaseTX in multiple building networks, you must clarify with the network administrator

whether

1. the network is designed for multiple building connections (e. g. there must be no

technical interference due to differences in grounding potential);

2. the bandwidth of the bus users is sufficient for the network.

Figure4.7: MPC, USB and RS232 interfaces

Figure4.8: MPC connection to BIS via OPC server

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 43

Modular Fire Panel Installation | en 43

OPC

Server

Ethernet

100BaseTX

FPA

Figure4.9: MPC connection to BIS via OPC server

Addressing and Settings in the Network

The following pages illustrate connections, addressing and the associated configuration via

DIP switches for different loop and bus topologies:

– Standalone panel

– Standalone panel, redundant

– Loop topology

– Loop topology with redundant panel

– Bus Topology

– Bus topology with redundant panel

– Bus topology with redundant network

– Bus topology with redundant network and redundant panel

The panels and remote keypads are identified in the network by a unique address. This

address is set on the rotary switches and is known as the rotary switch number (RSN) (see

the figures in the circle on the circuit diagrams). The rotary switches are located on the rear of

the panel controller (see Addressing and Configuration of MPCPanel Controller, page 44).

Note the address on the sign below the rotary switches (see Addressing and Configuration of

MPCPanel Controller, page 44, step 2).

The DIP switches are located on the rear of the panel controller (see Addressing and

Configuration of MPCPanel Controller, page 44).

Mark the selected setting on the sign above the DIP switches (see Addressing and

Configuration of MPCPanel Controller, page 44, step 4).

Notice!

Redundant panels must have the same RSN as the assigned primary panels.

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 44

44 en | Installation Modular Fire Panel

2

4

3

1

GND IN2IN1

G

L

H

GLH

G

L

H

G L

H

CAN1

CAN1

CAN2

CAN2

Addressing and Configuration of MPCPanel Controller

Figure4.10: MPCPanel Controller, addressing

Figure4.11: MPCPanel Controller, network connections

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 45

Modular Fire Panel Installation | en 45

FPA-5000

FPA-5000

001001

001

CAN1CAN1

CAN internal

001

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

001

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

Network Address: ________

001

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Standalone Panel and Redundant Standalone Panel

Figure4.12: Standalone panel (regular and redundant): Configuration in network

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 46

46 en | Installation Modular Fire Panel

FPA-5000 FPA-5000

FPA-5000

FMR-5000

FMR-5000

001 002 003 004

005

L

max

L

max

L

max

L

max

L

max

CAN1

CAN1

CAN2

CAN2

CAN2

CAN1

CAN1 CAN2

CAN1

CAN2

FPA-5000

001

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

003

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

005

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

004

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

NA

NA

NA

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

002

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

NA

NA

NA

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

Loop

Figure4.13: Loop topology

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 47

Modular Fire Panel Installation | en 47

CAN2CAN1

CAN1

CAN2

CAN2

CAN1CAN1 CAN2 CAN2

001 002 003 004004

L

max

L

max

L

max

L

max

CAN1

CAN internal

FPA-5000

001

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

004

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

002

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

NA

NA

NA

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

003

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

NA

NA

NA

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

004

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

FPA-5000 FPA-5000 FPA-5000FMR-5000 FMR-5000

Loop with redundant panel

Figure4.14: Loop topology with redundant panel

Bosch Sicherheitssysteme GmbH Networking Guide 2017.12 | 5.7 | F.01U.247.450

Page 48

48 en | Installation Modular Fire Panel

CAN1

CAN1

CAN1

CAN1 CAN1

001 002

003 004

005

L

max

CAN1 CAN1 CAN1 CAN1

CAN1

CAN1

CAN1

FPA-5000

001

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

002

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

NA

NA

NA

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

004

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

NA

NA

NA

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

003

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

005

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

FPA-5000 FPA-5000 FPA-5000FMR-5000

FMR-5000

Bus

Figure4.15: Bus Topology

2017.12 | 5.7 | F.01U.247.450 Networking Guide Bosch Sicherheitssysteme GmbH

Page 49

Modular Fire Panel Installation | en 49

CAN1

CAN1

CAN1

CAN1CAN1

001

002

003 004

004

L

max

CAN1 CAN1 CAN1

CAN1 CAN1

CAN1

CAN1

CAN internal

FPA-5000

001

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

002

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

NA

NA

NA

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

003

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

NA

NA

NA

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

004

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination

CAN1_GND CAN2_GND

CAN2 Termination

Connection

No

No

No

No

No

No

Off

Off

Off

Off

Off

Off

Yes

Yes

Yes

Yes

Yes

Yes

2

3

4

5

6

x100

x10 x1

Network Address: ________

004

Redundant-PCTRL

PCTRL is

CAN2 Ground Fault

Detection

CAN1 Ground Fault

Detection

1

On

On

On

On

On

On

CAN1 Termination