Bosch FPA-1000-UL, FPA-1000-LC Installation Manual

FPA-1000-UL Compact Fire Panel

en Installation and Operation Guide

FPA-1000-UL Compact Fire Panel Table of Contents | en 3

Table of Contents

1Safety 6

1.1 General 6

1.2 Symbols and Notes Used 6

1.3 FCC Compliance Notice 7

2 Product Description 8

2.1 Introduction 8

2.2 Features 10

2.3 System Overview Mainboard Components 12

2.4 Plug-in Modules 13

2.5 Power Supply 14

2.6 Components Connected to the Option Bus 15

2.7 Signaling Line Circuit Devices 16

2.8 Notification Appliance Circuit Devices 19

2.9 Communicator 19

2.10 Components and Accessories 19

2.11 Related Documents 20

3 Planning Information 21

3.1 Power Supply Calculations 21

3.2 SLC Configuration and Programming Basics 25

3.2.1 Points 25

3.2.2 Advanced Point Features and Processing 26

3.2.3 Events 30

3.2.4 Zones 31

3.3 Address Assignment 34

3.3.1 Option Bus Address Assignment 34

3.3.2 SLC Address Assignment 35

3.4 Telephone Requirements 35

3.5 UL 864 Standard-specific Requirements 38

3.6 NFPA Standard-specific Requirements 40

3.7 Fire Safety Considerations 41

3.7.1 Smoke Detector Layout 41

3.7.2 Installing Family Residences 41

3.7.3 Escape in the Event of Fire 42

4 Installation 43

4.1 Installation Precautions 43

4.2 Installation Considerations for UL Listed Systems 43

4.3 Parts List 44

4.4 Installing the Enclosure 44

4.5 Installing the Mainboard 48

4.6 Installing Optional Plug-in Modules 50

4.7 Wiring Requirements 52

4.7.1 Option Bus Circuit Wiring Distance 54

4.7.2 SLC Wiring Distance and Styles 55

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

4 en | Table of Contents FPA-1000-UL Compact Fire Panel

4.7.3 Measuring Circuit Resistance 56

4.8 Control Panel Terminal Connections 57

4.9 Option Bus Wiring 58

4.10 NAC Wiring 59

4.11 SLC Installation 60

4.11.1 SLC Wiring 60

4.11.2 Addressing Devices 63

4.12 Mainboard Relays 64

4.13 City Tie Connections 65

4.13.1 Reverse Polarity Mode 65

4.13.2 Local Energy Mode 66

4.14 Phone Line Connections (DACT) 67

4.15 Ethernet Connection 68

4.16 Power Supply Wiring 69

4.16.1 AC Power Connection 69

4.16.2 Battery Connection 71

4.16.3 Auxiliary Power Connection 72

4.16.4 External Power Supply 73

5 Keypad Operating and Programming 75

5.1 Panel Access 75

5.2 LCD Keypad 76

5.3 Keypad Operations 79

5.4 Authority Level and PIN Codes 81

5.5 System Normal Display 83

5.6 Off-normal Display 84

5.7 Menu Navigation and Structure 87

5.7.1 HISTORY 94

5.7.2 WALK TEST 95

5.7.3 TEST MENU 95

5.7.4 CHANGE DATE/TIME 99

5.7.5 BYPASS/UNBYPASS 99

5.7.6 PROGRAMMING 100

5.7.7 RESET LEVEL 3 PIN 114

6 Browser-based Operating and Programming 115

6.1 On-site and Off-site Access 115

6.2 Connecting FPA-1000-UL and the User's PC 116

6.2.1 Network connection 116

6.2.2 Direct Connection 116

6.2.3 Dial-up Connection 118

6.3 Access the FPA-1000-UL's Web Sever from the Web Browser on the User's PC 122

6.3.1 Browser Settings 122

6.3.2 Working with Web Pages 125

6.4 Setting the Access Level for Testing and Programming 125

6.4.1 General Remarks 125

6.4.2 Switching Access Levels 125

6.4.3 Make Programming Changes Effective on the FPA-1000-UL 126

6.4.4 Access Level Time-out 126

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Table of Contents | en 5

6.5 Overview of Graphical User Interface 127

6.6 Start Page 128

6.7 Programming 129

6.7.1 Site Data 130

6.7.2 SLC 1 and SLC 2 132

6.7.3 Mainboard 135

6.7.4 Option Bus 136

6.7.5 Reporting 139

6.7.6 Zones 141

6.8 Maintenance 143

6.8.1 Control 143

6.8.2 Testing 145

6.9 Monitoring 149

6.9.1 View Status 149

6.9.2 History 150

7 Diagnostics and Troubleshooting 151

7.1 Phone Monitor Troubleshooting 151

7.2 Diagnostics Data and System Information 152

7.3 FPE-1000-SLC LED Operation 153

7.4 Power and Battery Test 153

8 Maintenance 154

8.1 Battery Maintenance 154

8.2 Fuse Replacement 154

9 Specifications 155

9.1 Electrical 155

9.2 Mechanics 156

9.3 Environmental Conditions 156

9.4 Option Bus (OB) 157

9.5 Notification Appliance Circuits (NAC) 157

9.6 Signaling Line Circuits (SLC) 157

9.7 Relays 157

9.8 Communication Circuits 158

9.9 City Tie 158

9.10 Panel Address Data 158

9.11 Trademarks 159

AAppendices 160

A.1 Abbreviations on the Control Panel Display 160

A.2 Default Programming 162

A.3 Reporting Codes 168

A.4 Operating Instructions Sheet 173

Glossary 174

Index 177

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

6 en | Safety FPA-1000-UL Compact Fire Panel

1Safety

1.1 General

Before using the device, read these instructions. If you do not read and understand these

explanations, you will not be able to operate the device properly. The operating instructions

do not eliminate the need for training by authorized personnel.

Install, operate, test and maintain this device according to this Installation and Operation

Guide, NFPA 72, Local Codes and the Authority Having Jurisdiction (AHJ). Failure to follow

these procedures may cause the device not to function properly. Bosch Security Systems, Inc.

is not responsible for any devices that are improperly installed, tested or maintained.

For proper installation, read and understand NFPA 72, The National Fire Alarm Code before

installation.

The Installation and Operation Guide does not contain special information about local

requirements and safety issues. Information on such issues is provided only to the extent that

it is needed for operation of the device. Ensure that you are familiar with all safety-related

processes and regulations in your area. This also includes how to act in the event of an alarm

and the initial steps to take if a fire breaks out.

The operating instructions should always be available on site. It is a required part of the

system and must be given to the new owner if the system is ever sold.

1.2 Symbols and Notes Used

The various chapters contain only whatever safety information and notes are required for

installation and operation of the system.

The following symbols are used:

NOTICE!

Contains useful information to help you operate the FPA-1000-UL Compact Fire Panel and to

i

avoid damages or possible dangerous situations.

CAUTION!

A hazard or unsafe practice could result in minor injury.

!

WARNING!

A hazard or unsafe practice could result in severe injury or death.

!

Follow the instructions without fail – for your own safety as well as that of the people around

you.

DANGER!

A hazard or unsafe practice will result in severe injury or death.

Follow the instructions without fail – for your own safety as well as that of the people around

you.

For example:

Hazardous Voltage.

Danger of contact with live parts and wires.

Disconnect and lock out power before connecting equipment or servicing!

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Safety | en 7

1.3 FCC Compliance Notice

This equipment was tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy, and if not installed and used in accordance with

the instructions, might cause harmful interference to radio communications. There is no

guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, that can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

– Re-orient or relocate the receiving antenna.

– Increase the separation between the equipment and the receiver.

– Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

– Consult the dealer or an experienced radio or TV technician for help.

FCC Phone Connection to Users

This control panel complies with Part 68 of the FCC rules.

On the inside of the enclosure is a label that contains, among other information, the ringer

equivalence number (REN) for this equipment. You must, upon request, provide this

information to your local telephone company.

The REN is useful to determine the quantity of devices that can be connected to your

telephone line and still have all of those devices ring when your telephone number is called. In

most, but not all areas, the sum of the RENs of all devices connected to one line should not

exceed five. To ascertain the number of devices that you can connect to your line, contact

your local telephone company to determine the maximum REN for your local calling area.

This equipment can not be used on coin service provided by the telephone company. Do not

connect this control panel to party lines. If this equipment causes harm to the telephone

network, the telephone company might discontinue your service temporarily. If possible, they

will notify you in advance. But if advance notice isn’t practical, you will be notified as soon as

possible.

You will be informed of your right to file a complaint with the FCC. The telephone company

might make changes in its facilities, equipment, operations, or procedures that could affect

the proper functioning of your equipment. If they do, you will be notified in advance to give

you an opportunity to maintain uninterrupted telephone service.

If you experience trouble with this equipment, contact the manufacturer for information on

obtaining service or repairs.

The telephone company might ask that you disconnect this equipment from the network until

the problem is corrected or until you are sure that the equipment is not malfunctioning. The

manufacturer, not the user, must make the repairs to this equipment.

To guard against accidental disconnection, there is ample room to mount the telco jack inside

of the control panel cabinet.

The operation of this control communicator might also be affected if events such as accidents

or acts of God cause an interruption in telephone service.

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

8 en | Product Description FPA-1000-UL Compact Fire Panel

2 Product Description

2.1 Introduction

The FPA-1000-UL Compact Fire Panel is an advanced analog addressable control panel for

small to medium facilities in residential, commercial or public building applications. It is listed

by UL for central station, local, auxiliary, and remote station systems.

The FPA-1000-UL combines complete built-in Fire Alarm Control Panel (FACP) equipment

such as Notification Appliance Circuits (NACs), Signaling Line Circuits (SLCs), relays, power

supply, Digital Alarm Communicator Transmitter (DACT) and Ethernet connection with the

expandability through the Option Bus or plug-in boards. The FPA-1000-UL has two integrated

NACs that can be expanded with addressable Remote Notification Appliance Circuit Power

Supplies. These circuits can be programmed with specific activation patterns.

The standard control panel supports one Signaling Line Circuit (SLC) with 254 addressable

points (127 analog addressable detectors and/or modules and 127 analog sounder bases in

combination with a suitable detector). The control panel is easily expandable with a second

FPE-1000-SLC Signaling Line Circuit doubling the address points.

The panel has a compact and solid metal housing with a removable front door with keyed lock

and a removable dead front door to access electronics. It features surface and semi-flush

mounting options.

On the front of the panel, six light-emitting diodes (LEDs) show fire alarm, gas alarm, power,

supervisory, silence and trouble conditions. The built-in keypad can be used for total system

control and programming. In addition, a large 4-line by 20-character alphanumeric LCD display

shows programmed device point information. Four keys enable acknowledge, reset, silence,

and drill functions.

The FPA-1000-UL enables various programming approaches:

– Front panel programming

– On-site programming, using a laptop with the possibility of pre-programming at the office

– Off-site programming, with remote access via Ethernet (browser-based) or phone line

(PSTN).

For front panel programming, the system provides an Auto Learn function, allowing the

installer to configure the system quickly and easily in default mode.

Using a local laptop or remote access through a communicator, the programming is carried

out by means of browser-based user interface. Therefore, no software installation is required.

The panel can receive diagnostics from a Web browser running on a networked PC.

The FPA-1000-UL Compact Fire Panel complies with the relevant standards.

Options

The Remote Command Center FMR-1000-RCMD is a four-wire LCD annunciator with system

control capability. It shows the equivalent LEDs and LCD display and includes a piezo,

scrolling buttons, and operation keys for acknowledge (ACK), drill, reset and silenc The

scrolling functions and the acknowledge key are accessible without restriction. The keys for

reset, silence or drill can be enabled and disabled by the device key lock.

The Remote Annunciator FMR-1000-RA is a LCD annunciator without control. It shows the

equivalent LEDs and LCD display. It includes a piezo sounder, scrolling buttons and

acknowledge key. The scrolling functions and the acknowledge key are accessible without

restriction.

The City Tie Plug-in Module FPE-1000-CITY provides the system with two supervised City Tie

Local Energy circuits or Reverse Polarity circuits. The FPE-1000-CITY plugs into the

FPA-1000-UL mainboard.

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Product Description | en 9

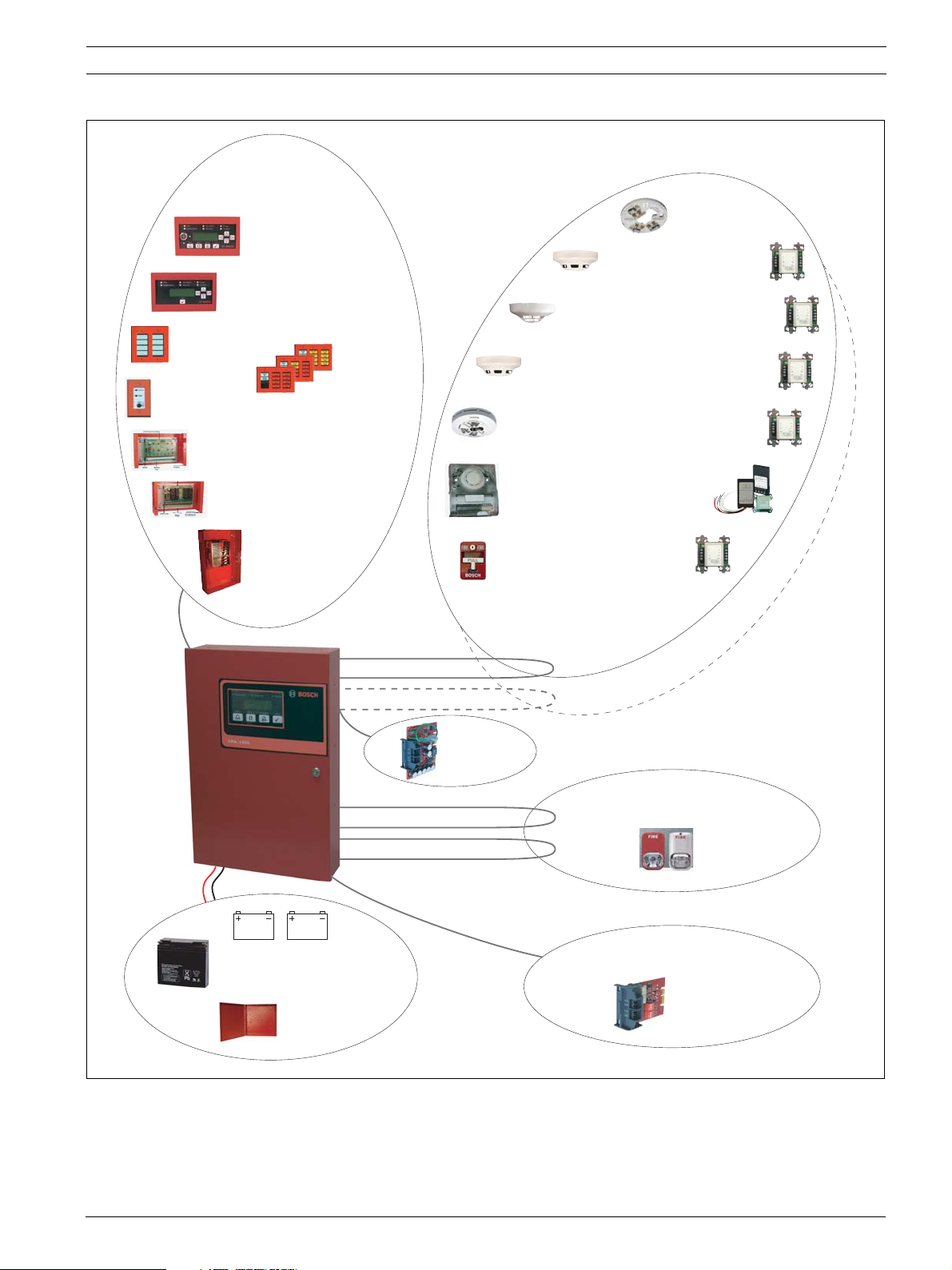

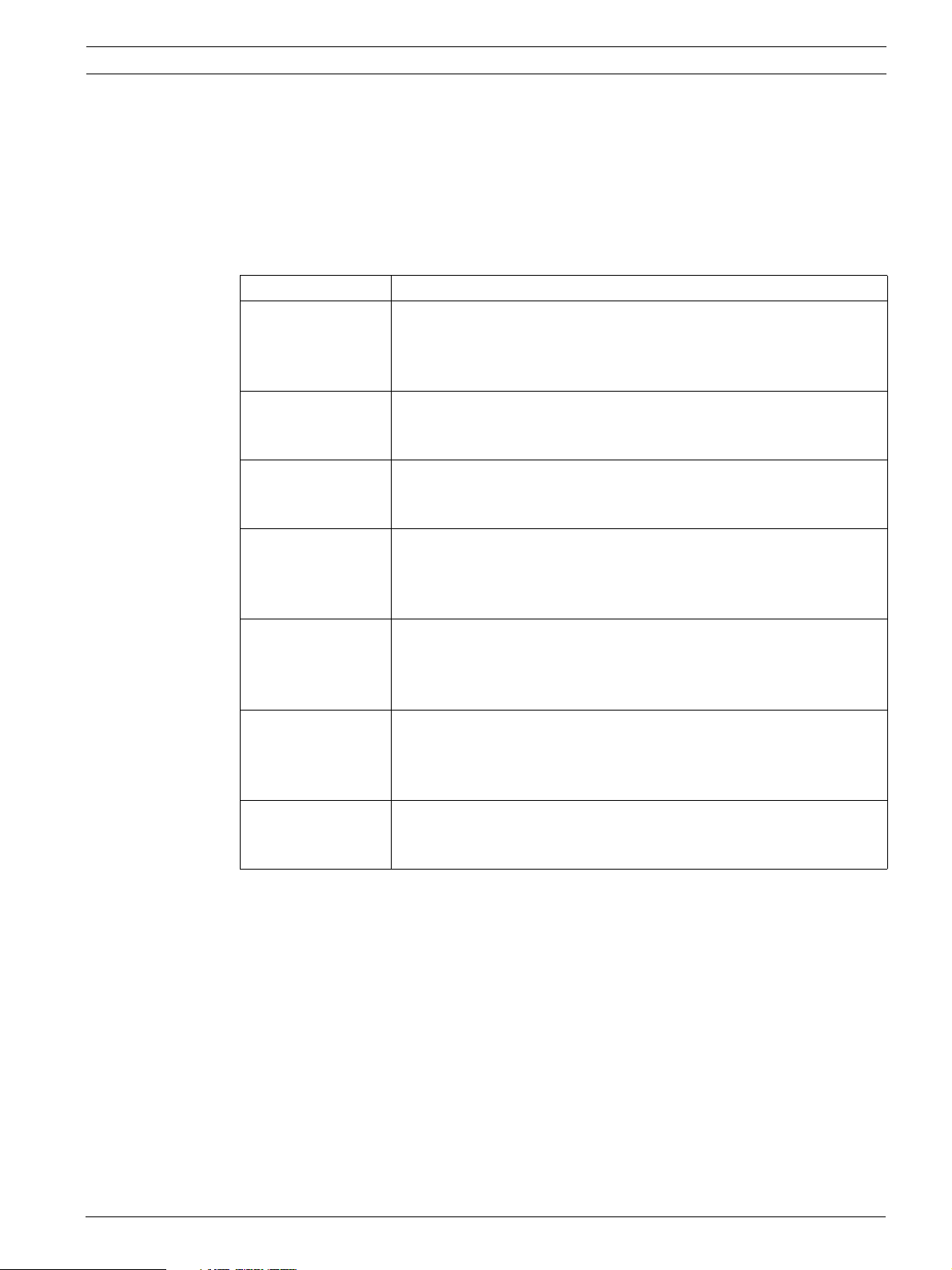

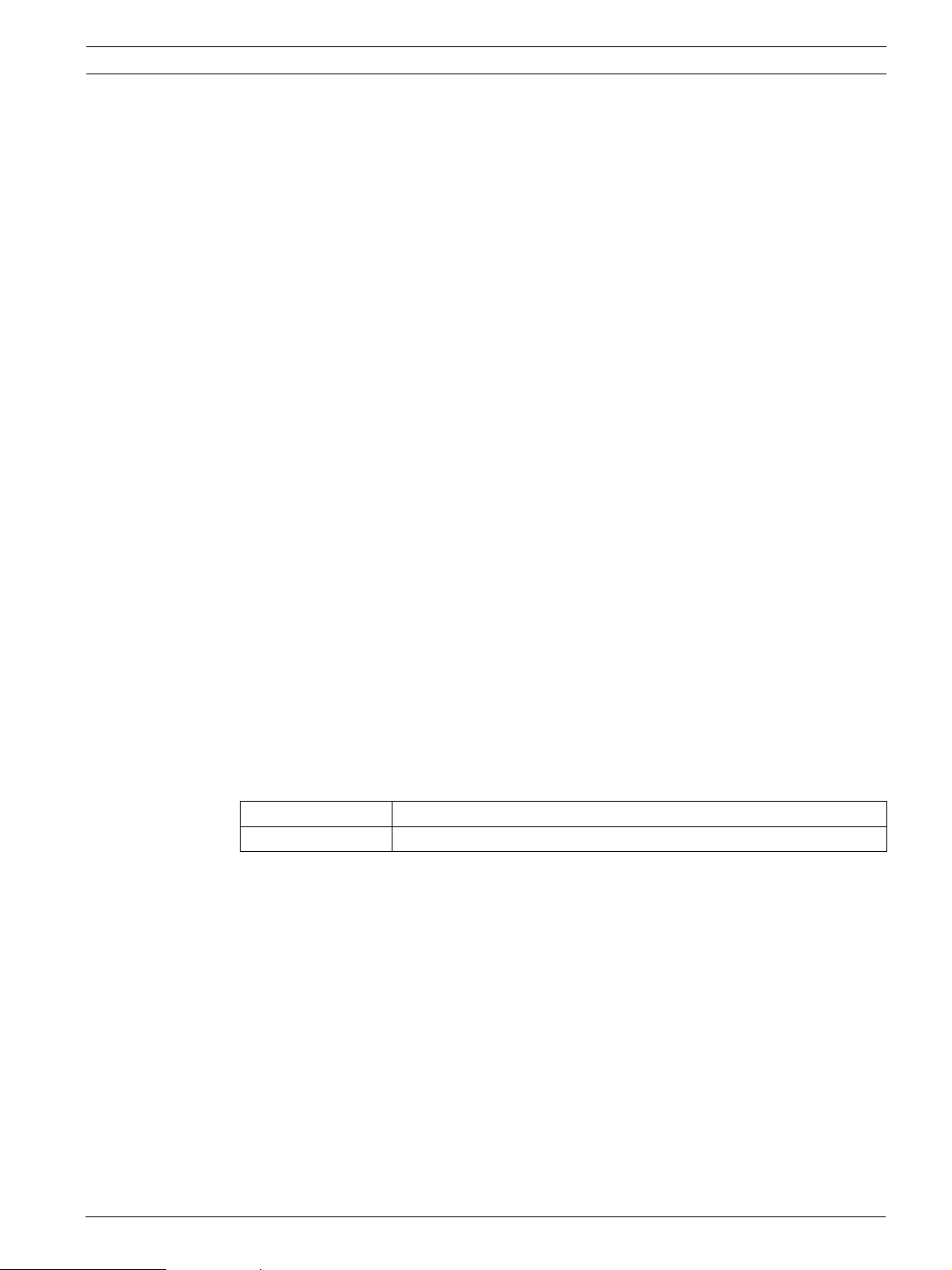

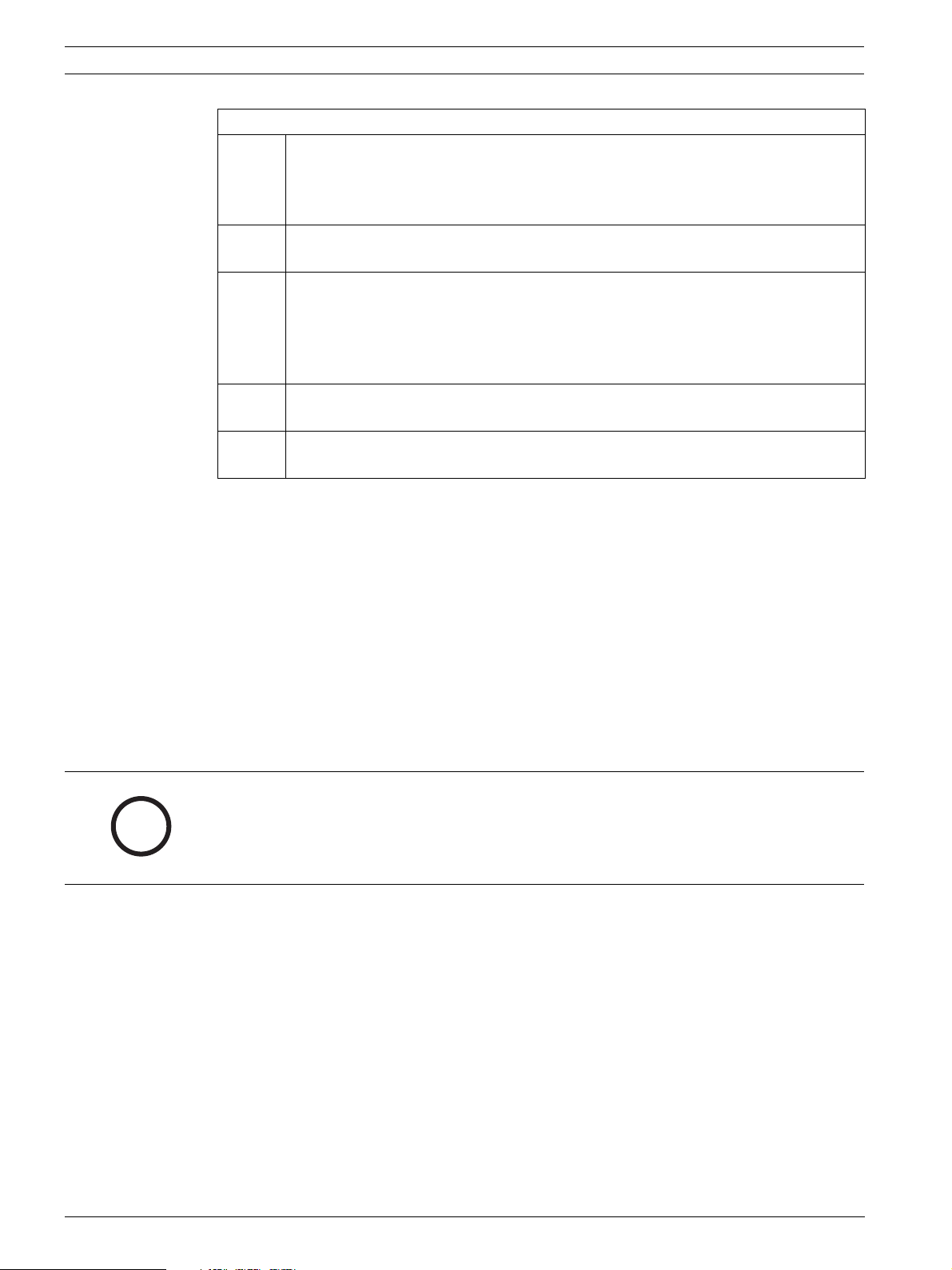

Option Bus

FAA-325-B4

FMR-1000-RCMD

FAP-325

FMR-1000-RA

FAH-325

FAA-325-B6

FLM-325-ISO

FLM-325-2I4

D7032

D7031

D7048/B

D7035/B

FPP-RNAC-8A-4C

D7030X

D7030X-S2

D7030X-S8

FAA-325-B6S

FAD-325

FAD-325-R

FAD-325-DH

FMM-325A

FMM-325A-D

FPE-1000-SLC

FAI-325

FLM-325-2R4

D328A

FLM-325-N4

FLM-325-I4

FLM-325-IS

FLM-325-IW

FLM-325-CZM4

SLC 1

SLC 2

NAC

12 V 12 V

D126 (7 Ah), D1218 (18 Ah),

D1224 (24 Ah), D 1238 (38 Ah)

BATB-40

BATB-80

Figure 2.1 FPA-1000-UL System Architecture with Options

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

CITY TIE

FPE-1000-CITY

10 en | Product Description FPA-1000-UL Compact Fire Panel

2.2 Features

System Configuration

– Basic configuration includes one analog addressable Signaling Line Circuit (SLC),

configurable as two Class B Style 4 or one Class A Style 6 or 7

– Second SLC easily expandable with FPE-1000-SLC Signaling Line Circuit

– Up to 127 detectors and modules, plus 127 analog sounder bases in combination with a

suitable detector, for a total of 254 addressable device capacity per SLC, allowing for

400 addresses or subaddresses per circuit

– Uses standard wire; no shielded or twisted pair required on SLCs

– Programmable sensitivity levels per device, and automatic day and night sensitivity

modes

– Automatic calibration and drift compensation routine

– 120 V/240 V AC power, total 5.5 A transformer output

– Two integrated NAC circuits rated at 2.5 A each, allowing up to 4 A total current (shared

between AUX power, Option Bus, and NAC)

– Up to four addressable Remote Notification Appliance Circuit Power Supplies, providing

Aux power and up to 16 synchronized remote NAC circuits

– Mainboard NAC patterns include Steady, Pulsing, Temporal Code 3, and Temporal

Code 4, Wheelock and System Sensor

– Built-in synchronization for appliances from Wheelock and System Sensor

– Three programmable Form C relays on the mainboard (fire, trouble, supervisory, gas

alarm or activation by zone)

– Option Bus for optional boards and expansions including LCD/LED annunciators, Octal

Driver Module, Octal Relay Module, and Remote Notification Appliance Circuit Power

Supply

– Optional City Tie Plug-in Module FPE-1000-CITY with two circuits, each programmable to

Local Energy or Reverse Polarity

– Built-in Ethernet interface for Conettix IP reporting and/or programming and diagnostics

– Built-in dual phone line PSTN/IP DACT communicator

2

– Contact ID, SIA 300 and Modem IIIa

– UL Listed, FM/CSFM/MEA approved

reporting formats

Ease of Use and Functionality

– Large 4-line by 20-character LCD display

– Six LED status indicators on each panel keypad or remote LCD annunciators, including

gas alarm LED

– Menu-driven user interface on panel

– Easy programming from panel keypad

– Browser-based user interface for programming and diagnostics running on a networked

PC with Microsoft

operating system, no software installation is required

– Programmable authority levels, secured with a user-definable four-digit PIN

– 128 software zones for flexible input-output mapping

– Auto Learn feature for easy start-up programming

– Local piezo sounder

– Fire drill test function

– Walk test function

– Alarm verification feature

– Bypass or unbypass point, output or zone individually

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

Windows XP and Microsoft Windows Vista or Unix/Linux based

FPA-1000-UL Compact Fire Panel Product Description | en 11

– 1000 events history buffer

– Event and history printing via network printer

– Three language versions (English, Spanish, and Portuguese), software configurable, LED

and keypad labeling easy exchangeable

Hardware Features

– Removable front door with keyed lock

– Removable dead front door to access electronics

– Mounting kit available for semi-flush installation with trim ring

– Metal oxide varistors (MOVs) and spark gaps for protection from lightning surges and

static discharges

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

12 en | Product Description FPA-1000-UL Compact Fire Panel

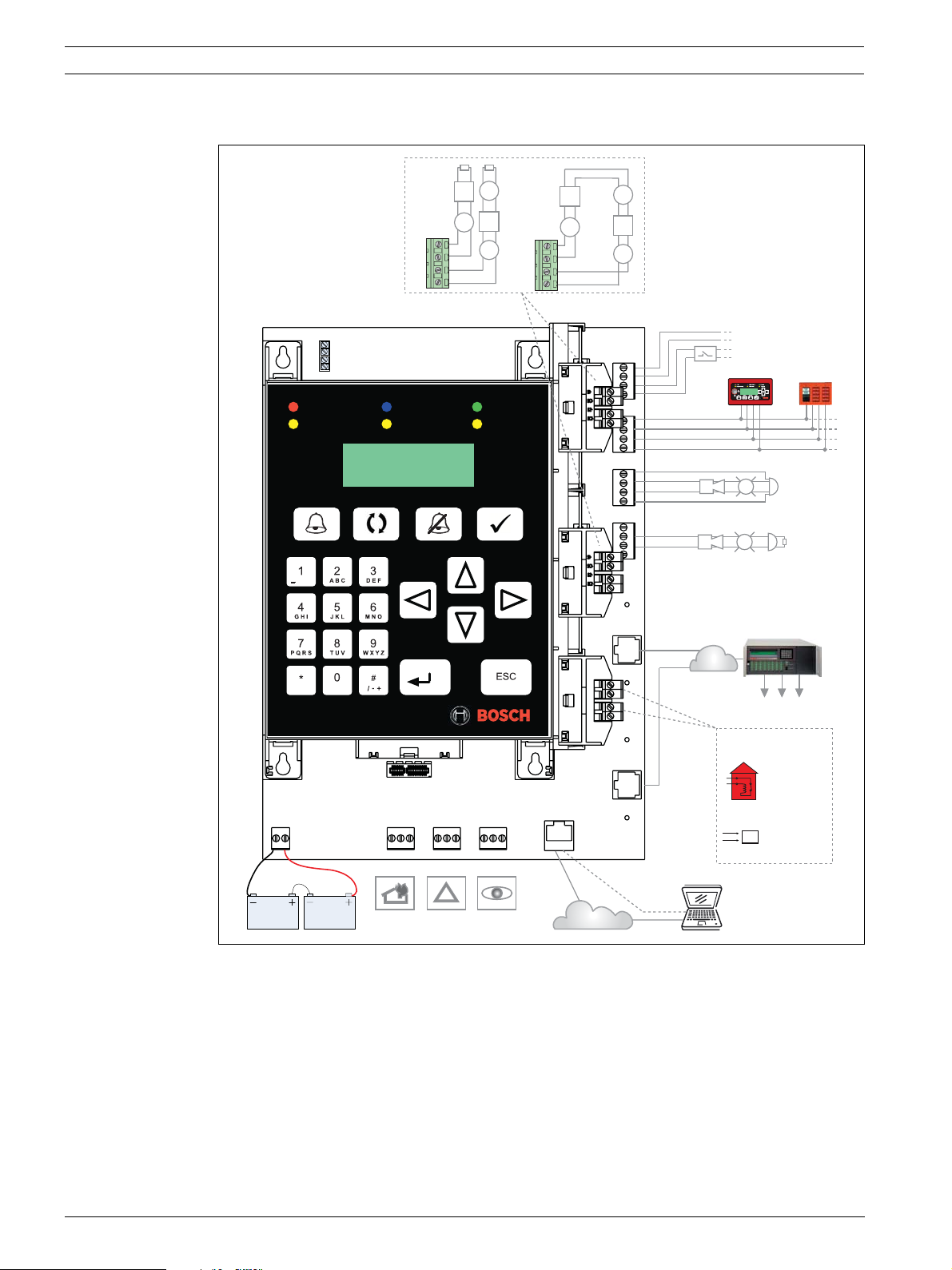

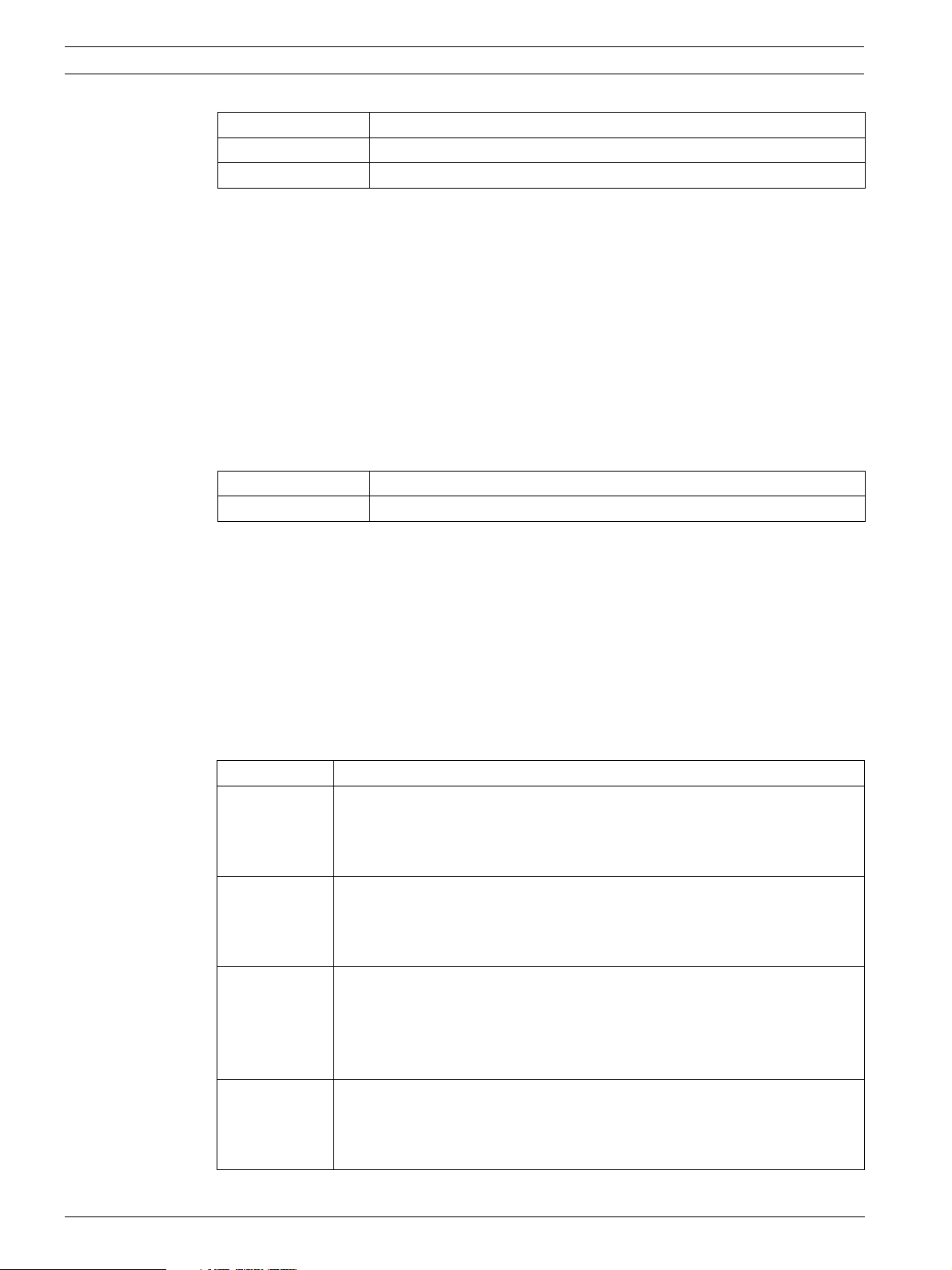

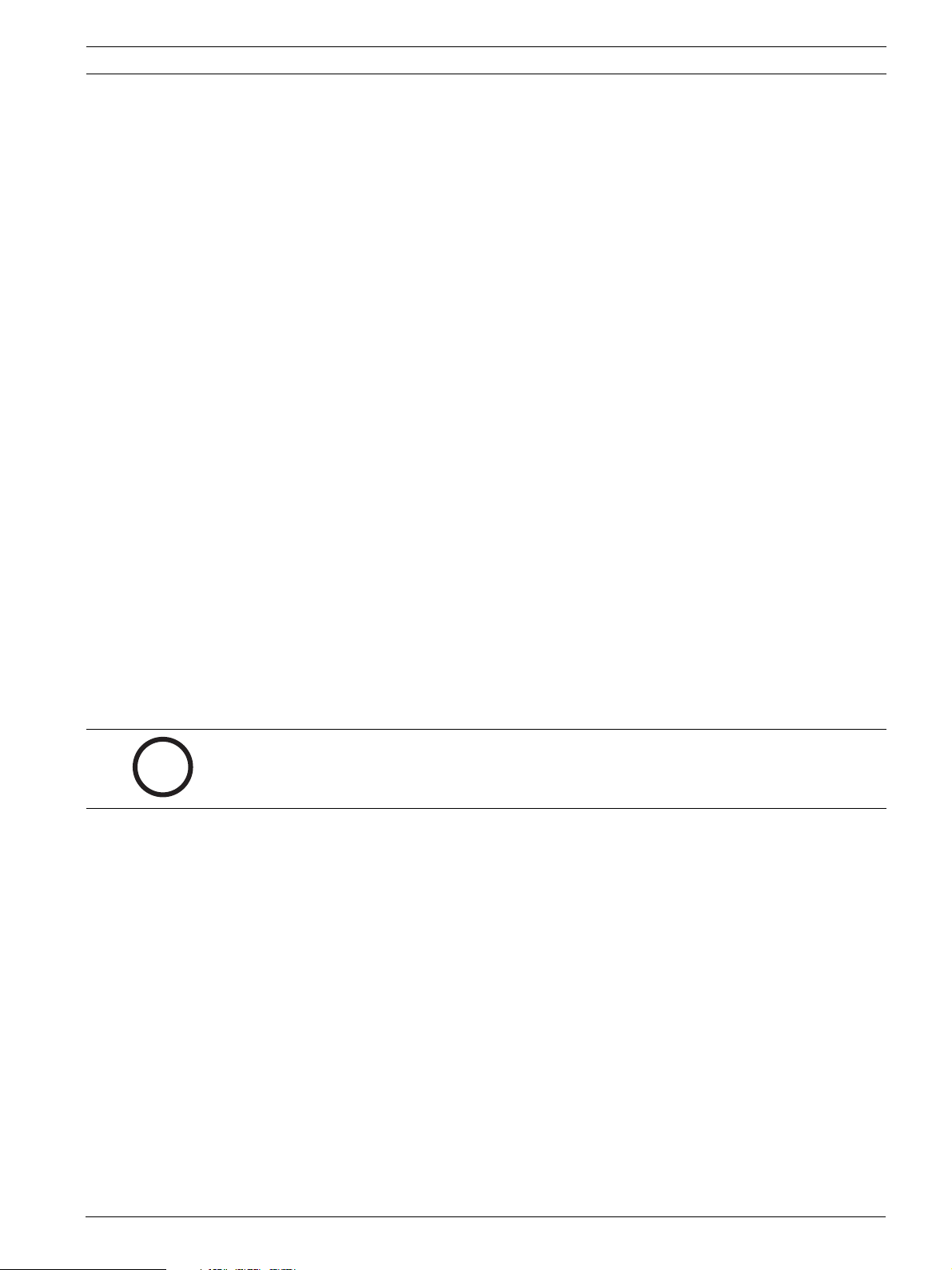

2.3 System Overview Mainboard Components

SLC

AC IN

Fire Alarm

Supervisory

DRILL RESET SILENCE ACK

@ _

. : ,

↔

A a

- BATT +

Gas Alarm

Silenced

?

Power

Trouble

RELAY3RELAY2RELAY1

SLC 1SLC 2

ETHERNET

AUX Power Out

Option Bus

NAC 1

NAC 2

LINE 1

PSTN

LINE 2

CITY TIE

Local

Energy

Reverse

M

Polarity

12 V 12 V

Relay 3Relay 2Relay 1

Ethernet

Figure 2.2 FPA-1000-UL Mainboard

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Product Description | en 13

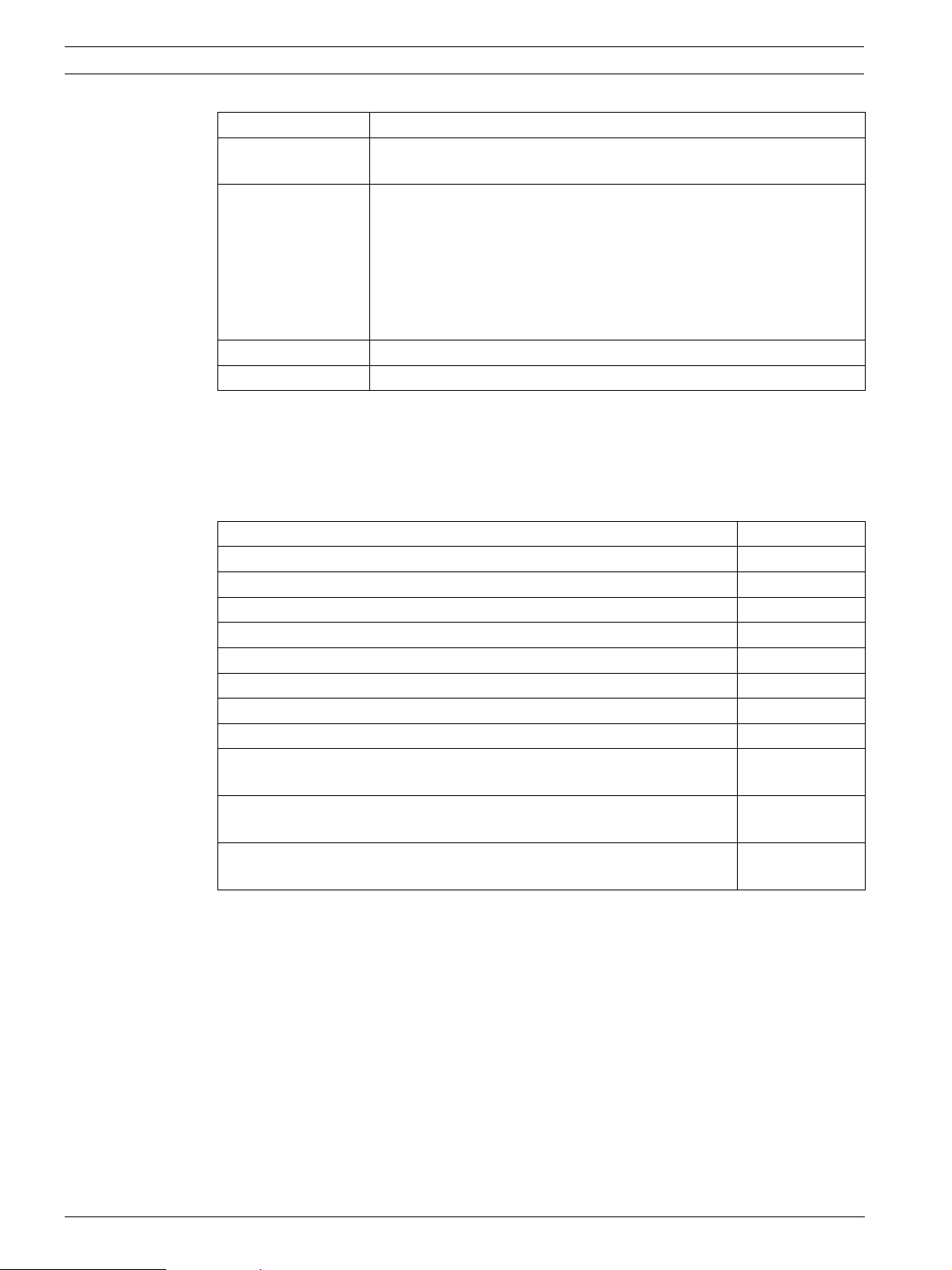

Designation Description

Keypad With LEDs, LCD display and keys.

Transformer Works with 120 V AC, 60 Hz or 240 V AC, 50 Hz.

SLC 1 / SLC 2 Signaling Line Circuit (SLC), standard configuration with one SLC,

second SLC with FPE-1000-SLC Plug-in Module,

nominal 39 V DC (30 to 40 V DC), 200 mA maximum (per SLC), powerlimited, supervised.

Option Bus Provides serial data interface, with 500 mA at 12 V DC, power-limited,

supervised.

AUX :

FWR- | FWR+

RST- | RST+

Two auxiliary power supply terminals, with 500 mA at 24 V DC each,

power-limited, non-supervised,

FWR = Full Wave Rectified, non-switched

RST = Resettable, switched and filtered.

NAC 1 / NAC 2 Terminal strips for two NACs, 2.5 A each.

Wiring options Class A Style Z or Class B Style Y.

See wiring example Figure 2.2 on page 12:

–NAC1: ClassA StyleZ

–NAC2: ClassB StyleY

CITY TIE Slot for City Tie Plug-in Module FPE-1000-CITY.

RELAY 1

RELAY 2

RELAY 3

Mainboard relays, default assignment is for alarm, trouble and

supervisory; individually programmable for alarm, trouble, supervisory,

gas alarm, activation by zone and system events,

rated at 5 A, 30 V DC/10 A, 120 V AC.

LINE 1 / LINE 2 Phone line/IP connections through central station receiver (2 x RJ45).

ETHERNET Ethernet connection (RJ45).

BATT Terminal strip for battery connection, 2 x 12 V, 18 Ah maximum within

enclosure or 40 Ah maximum external.

Tab le 2. 1 Mainboard (MB) Components

The boards, expanders and devices, listed in the following sections, are available from Bosch

Security Systems, Inc. to be used with the FPA-1000-UL Compact Fire Panel. For a complete

description of and installation instructions for each product, refer to the appropriate section

of this manual and the documents supplied with the device.

2.4 Plug-in Modules

A second Signaling Line Circuit (SLC) can easily be added by plugging in the FPE-1000-SLC to

the mainboard.

The City Tie Plug-in Module FPE-1000-CITY provides two circuits which can be programmed as

Local Energy or Reverse Polarity mod

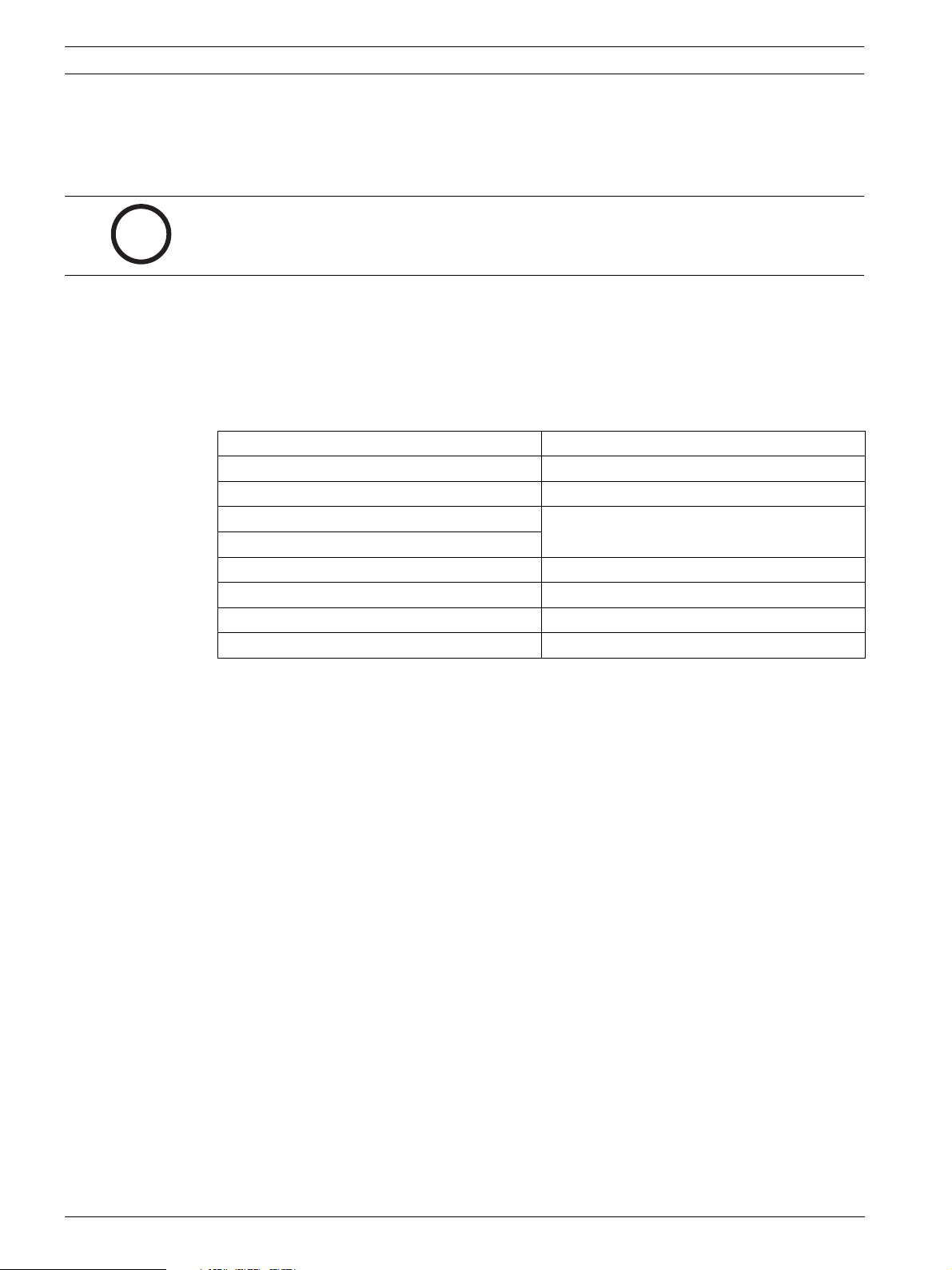

Type Number Description

FPE-1000-SLC Signaling Line Circuit (second circuit or replacement)

FPE-1000-CITY City Tie Plug-in Module

Tab le 2. 2 Plug-in Modules

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

14 en | Product Description FPA-1000-UL Compact Fire Panel

Compatible Gamewell Devices for the City Tie Plug-in Module in Local Energy Mode

Designation Description

M34-56 Local energy Trip, Surface Mount, Cottage Shell

M34-110 Same as M34-56 wth plain door painted blue

M34-111 Same as M34-56 wth plain door painted red

M34-112 Same as M34-56 wth plain door painted yellow

M34-92 Local energy Trip, Flush Mount, Gasketed cast frame for interior and

exterior use

M34-113 Same as M34-92 wth plain door painted blue

M34-114 Same as M34-92 wth plain door painted red

M34-75 Local energy Trip, Surface Mount, Cottage Shell (less inner case test

block, tap key & bell)

M34-115 Same as M34-75 wth plain door painted blue

M34-116 Same as M34-75 wth plain door painted red

M34-72 Local energy Trip, Sheet Metal Housing (less inner case test block, tap

key & bell), Plain Door

Table 2.3 Compatible Gamewell Devices for the City Tie Plug-in Module in Local Energy Mode

2.5 Power Supply

A transformer working with 120 V AC or 240 V AC is supplied standard with the control panel.

Two backup batteries with 7 Ah or 18 Ah each fit inside the fire panel cabinet. A separate

battery box can provide higher capacity.

The FPA-1000-UL provides two auxiliary power supplies with 0.5 A at 24 V DC each, with AUX/

RST switchable. This auxiliary power can run expansion boards or other low current auxiliary

devices.

Table 2.4 lists the available batteries and battery boxes. For selecting the necessary battery

capacity, refer to Section 3.1 Power Supply Calculations on page 21.

Type Number Description

D126 Battery 12 V, 7 Ah

D1218 Battery 12 V, 18 Ah

D1224 Battery 12 V, 24 Ah

D1238 Battery 12 V, 38 Ah

BATB-40 Battery Box

BATB-80 Battery Box

Table 2.4 Available Batteries and Battery Boxes

For installations requiring battery capacity higher than 40 Ah, a regulated and UL 1481 Listed

external power supply can be used. The external power supplies connect through the panel's

battery terminals. Batteries and battery charger are not supervised. For supervision of AC and

battery fault use an input module (for example FLM-325-2I4) on the SLC.

– Provides a single level (two-battery capacity) of battery storage

with an optional shelf that increases the battery capacity to four

batteries.

– Includes a mounted shelf that holds up to four batteries.

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Product Description | en 15

2.6 Components Connected to the Option Bus

Remote Command Center and Annunciators

The FPA-1000-UL supports

– up to a total of eight FMR-1000-RCMD Remote Command Centers and/or FMR-1000-RA

Remote Annunciators

– up to eight D7030X Series LED Annunciators with eight LED Zones each

– up to eight D7030X Series/D7032 combinations.

Type Number Description

FMR-1000-RCMD Remote Command Center

– Remote operational terminal of the FPA-1000-UL panel, providing

buttons for silence, reset, acknowledge, drill, scrolling keys, key

switch with 1358 key, built-in piezo sounder.

FMR-1000-RA Remote Annunciator

– Remote LCD annunciator, providing key for acknowledge and

scrolling keys, built-in piezo sounder.

D7030X LED Annunciator

– Identifies the location of a fire alarm for up to eight zones allowed

per system.

D7030X-S2 LED Annunciator

– With two zones reserved for supervisory functions.

– With power and trouble LEDs plus eight-zone LEDs that can be

individually labeled.

D7030X-S8 LED Annunciator

– With eight zones reserved for supervisory functions.

– With power and trouble LEDs plus eight-zone LEDs that can be

individually labeled.

D7032 Eight-Point LED Annunciator Expander

– Attaches to a D7030X, D7030X-S2 or D7030X-S8.

– Identifies the location of a fire alarm for eight additional zones,

showing 16 LED zones in the D7030X/D7032 combination.

D7031 Remote Key Switch

– Allows resetting the control panel and silencing the notification

appliances from the D7030X Series LED Annunciator's location.

Tab le 2. 5 Controls and Annunciators for Connection to the Option Bus

For requirements of Option Bus address restrictions, refer to Section 3.3.1 Option Bus Address

Assignment on page 34.

For wiring requirements, refer to Section 4.9 Option Bus Wiring on page 58.

Modules

The FPA-1000-UL supports up to two Octal Relay Modules or Octal Driver Modules.

The outputs are fully programmable, and can be activated by system events. These outputs

have the same programming options as the local relays. Each output operates independently

of the other seven to provide complete flexibility. Communication with the D7035/B or

D7048/B is supervised.

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

16 en | Product Description FPA-1000-UL Compact Fire Panel

Type Number Description

D7048/B Octal Driver Module

D7035/B Octal Relay Module

Table 2.6 Modules for Connection to the Option Bus

For wiring requirements, refer to Section 4.9 Option Bus Wiring on page 58.

For requirements of address restrictions, refer to Section 3.3.1 Option Bus Address Assignment

on page 34.

NAC Power Supply

The FPP-RNAC-8A-4C Remote Notification Appliance Circuit Power Supply adds four

additional Notification Appliance Circuits (NFPA 72, Class A Style Z or Class B Style Y) to the

fire panel or serves as a power supply for fire protective signaling systems. This regulated

power supply provides up to 8 A of power that is used to recharge batteries and operate

continuous and intermittent alarm loads. This 8 A of power can be distributed through the

four NAC Power Supply circuits that are part of the FPP-RNAC-8A-4C. The FPP-RNAC-8A-4C is

UL Listed for use in commercial fire alarm applications.

Type Number Description

FPP-RNAC-8A-4C Remote Notification Appliance Circuit Power Supply

Table 2.7 NAC Power Supply Connected to the Option Bus

For wiring requirements, refer to Section 4.9 Option Bus Wiring on page 58.

2.7 Signaling Line Circuit Devices

The FPA-1000-UL Compact Fire Panel uses the patented Digital Communication Protocol

(DCP) to communicate with each of the analog addressable devices located on the SLCs. This

fast and reliable protocol allows the use of standard non-twisted, non-shielded wiring for the

SLCs.

The FPA-1000-UL supports two Class B, Style 4 or one Class A, Style 6 or 7 per SLC.

Table 2.8 lists all compatible devices for the FPA-1000-UL SLCs:

Type Number Description

FAP-325

[FAP325]

FAH-325

[FAH325]

FAI-325

[FAI325]

FAA-325-B4 Analog Detector Base

Analog Photoelectric Smoke Detector

– Detects optically dense smoke typical of fires involving materials such

as soft furnishings, plastic, foam or other similar materials which tend

to smolder and produce large visible smoke particles.

Analog Heat Detector

– Detects heat in environments where smoke detectors are unsuitable

because of the presence of system or cooking fumes, such as in a

kitchen.

Analog Ionization Smoke Detector

– For use in areas where early warning of trouble from superheated or

flaming combustibles is expected; also constructed to be used

effectively where outside Radio Frequency Interference (RFI) and

other electrical interference is expected.

– Compatible with all analog addressable detectors that use the

advanced analog communication protocol, except the FAD-325-DH.

– 4-in (10 cm) diameter.

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Product Description | en 17

Type Number Description

FAA-325-B6 Analog Detector Base

– Compatible with all analog addressable detectors that use the

advanced analog communication protocol, except the FAD-325-DH.

– 6-in (15 cm) diameter.

FAA-325-B6S

[FAA325-BS]

Analog Sounder Base

– Contains an addressable sounder which provides an audible alarm in

the immediate vicinity.

– Compatible with all analog addressable detectors that use the

advanced analog communication protocol, except the FAD-325-DH.

– Auxiliary powered.

– The FAA-325-B6S address is programmed automatically (for this, the

address of the mounted detector plus 127 comes up to the sounder

base address).

FAD-325-DH

[FAD325]

Analog Duct Smoke Detector

– Provides early detection of smoke and products of combustion present

in air moving through HVAC ducts in Commercial, Industrial and

Residential applications.

Three types available:

– FAD-325-DH Analog Duct Smoke Detector Replacement Head

– FAD-325 Analog Duct Smoke Detector (with Housing)

– FAD-325-R Analog Duct Smoke Detector with Relay (with Housing)

FMM-325A,

FMM-325A-D

Analog Manual Stations

– Contact monitor module mounted in a corrosion-resistant rugged die-

cast housing for single-gang mounting.

– Loop powered.

Two types available:

– FMM-325A Single-action Manual Station

– FMM-325A-D Double-action Manual Station

FLM-325-CZM4

[FLM325-CZ]

Conventional Zone Module

– Monitors dry contacts (NO) devices such as two-wire conventional

detectors or pull stations.

– Transmits the status of one zone of devices back to the panel

(25 maximum per zone, number depends on type of connected

devices).

– Class A or Class B wiring is configured with a jumper on the modul

– AUX powered.

For compatible devices refer to the manual supplied with the product.

The number of Conventional Zone Modules (FLM-325-CZM4) per SLC

module is limited to 64.

FLM-325-2I4

[FLM325-2I]

Dual Input Monitor

– Provides two independent contact monitoring circuits while utilizing

only one address on the SLC.

– Can be programmed to monitor normally open or normally closed

contact fire alarm and supervisory devices (NO EOL, NC EOL,

NC no EOL)

– Supervises with Style B (Class B), loop powered.

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

18 en | Product Description FPA-1000-UL Compact Fire Panel

Type Number Description

FLM-325-2R4

[FLM325-2R]

Dual Relay Module

– Allows independent control of two Form C contacts (rated for 1.0 A at

30 V DC or 0.5 A at 125 V DC) for a variety of normally open (NO) and

normally closed (NC) contact applications such as fan operation,

elevator recall, door closure, and auxiliary notification.

– Loop powered.

D328A Analog Relay Module

– Allows the control of one Form C contact (rated for 1.0 A at 30 V DC or

0.5 A at 125 V DC) for a variety of normally open (NO) and normally

closed (NC) contact applications such as elevator recall systems or

HVAC shutdown.

– Loop powered.

FLM-325-ISO Short Circuit Isolator

– Isolates a shorted section on a specific polling circuit from the rest of

the system to minimize the loss of devices.

FLM-325-N4

[FLM325-N]

Supervised Output Module

– Provides a supervised pole reversal output used for acoustic and

optical signaling devices or to trigger a Remote Notification Appliance

Circuit Power Supply.

– Requires a 24 V DC auxiliary input voltag

– The output relay is rated to supply 2 A at 30 V DC.

– Provides Steady, Pulsing and Temporal Code 3 output pattern

FLM-325-I

[FLM325-I]

Contact Monitor

– Designed to use with pull stations, water flow switches, and other

applications requiring the monitoring of dry contact alarm initiating

devices.

– Can be programmed in NO EOL, NC EOL, NC no EOL.

Three types available:

– FLM-325-I4 Contact Monitor 4-inch

– FLM-325-IS Contact Monitor Small

– FLM-325-IW Contact Monitor with Pigtail

Independently from the type, the panel lists only an FLM-325-I.

Table 2.8 Compatible Signaling Line Circuit Devices

Due to limited display space, abbreviated type numbers are used at some places, e.g. in the

SLC programming menu and reports. For the short versions, refer to the type numbers in

brackets in Table 2.8.

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Product Description | en 19

2.8 Notification Appliance Circuit Devices

Two Class A Style Z or Class B Style Y Notification Appliance Circuits (NACs) provide up to 4 A

of 24 V power (maximum 2.5 A on each circuit) to operate horns, strobes, bells, and other

notification appliances. Each NAC can be programmed to provide Temporal Code 4, Temporal

Code 3, and Steady, Pulsing, and synchronized output for Wheelock and System Sensor

notification appliances.

Refer to the Compatibility List (P/N F.01U.075.636), available as a PDF at:

X www. boschsecurity.us

Refer to Section 3.19 Programming Requirements According to UL 864 on page 39 for UL

approved patterns.

2.9 Communicator

The FPA-1000-UL has a dual phone line PSTN/DACT circuit and an Ethernet connection

featuring Conettix IP reporting. The panel communicates in Contact ID, SIA, and Modem IIIa

The panel provides miscellaneous reporting functions such as dialing control and transmission

supervision, priorities of report groups, routing to destinations, manual and auto test reports,

and Anti-Replay featur

For the primary and secondary account, the following features are programmable:

– Two different phone or IP numbers

– Different dialing types for PSTN (pulse only, tone and pulse, or tone only)

– Individual PSTN line supervision (audible and visible trouble signal in the case of a

transmission path failure)

– Selectable options for Report Steering Groups

– Programmable acknowledge wait time for each IP reporting Conettix account (15 to

255 seconds)

– Test call frequency individually programmable for each account (4-, 12-, 24-hour, 7- and

28-day intervals; standard frequency 24 hours)

With modem function, it is possible to program the control panel remotely (upload a new

parameter file to the panel from a remote station).

2

.

Compatible Device for the PSTN/DACT Circuit and Ethernet Connection

Designation Description

D6600 Central Station Receiver

Tab le 2. 9 Compatible Device for the PSTN/DACT Circuit and Ethernet Connection

2.10 Components and Accessories

For semi-flush mounting of the control panel cabinet, the FPM-1000-SFMK Semi-flush

Mounting Kit with trim ring is available.

The D5070 Analog Device Pogrammer provides easy programming of Signaling Line Circuit

device addresses.

Alternatively to the complete FPA-1000-UL Compact Fire Panel, you can order separate

components; the FPA-1000-LC includes the mainbord with keypad, and the FPM-1000-ENC

includes the enclosure with the dead front door.

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

20 en | Product Description FPA-1000-UL Compact Fire Panel

Type Number Description

FPM-1000-SFMK Semi-flush Mounting Kit

– Includes trim ring and mounting accessories.

D5070 Analog Device Programmer

– Hand held device that programs address settings on EEPROM-

programmable analog devices.

– With base for detector head programming and two-module

program adapter for module programming (for 4-in or single-gang

back box).

– Shows the current analog value of a connected detector.

FPA-1000-LC Compact Fire Panel Less Enclosure

FPM-1000-ENC Compact Fire Panel Enclosure With Dead Front Door

Table 2.10 Optional Accessories for the FPA-1000-UL Compact Fire Panel

2.11 Related Documents

To obtain a complete understanding of specific features of the fire control panel and related

peripherals, refer to the documentation listed in Table 2.11 below.

Document Title Part Number

NAC Compatibility List (English version) F.01U.075.636

Operating Instruction Sheet (English version) F.01U.075.632

Wiring Diagram (English version) F.01U.075.634

Program Record Sheet (English version) F.01U.075.637

Release Notes (English version) F.01U.075.638

Installation Guide FPE-1000-SLC Signaling Line Circuit F.01U.078.099

Installation Guide FPE-1000-CITY City Tie Plug-in Module F.01U.078.100

Installation Guide FPM-1000-SFMK Semi-flush Mounting Kit F.01U.078.096

Installation and Operation Guide FMR-1000-RCMD Remote Command Center

F.01U.078.098

(English version)

Installation and Operation Guide FMR-1000-RA Remote Annunciator (English

F.01U.078.097

version)

Installation Guide FPM-1000-ENC Compact Fire Panel Enclosure With Dead

F.01U.133.409

Front Door

Table 2.11 Related Documents

All documents (in PDF format) and panel related software can be downloaded at:

X www. boschsecurity.us

You might also find the current version of all documents supplied with the devices.

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Planning Information | en 21

3 Planning Information

NOTICE!

Be careful to plan properly before installing any devices. Check:

– the compatibility and number of devices to be connected

i

3.1 Power Supply Calculations

i

– the battery capacity needed

– the wiring requirements, including the maximum allowed cable length

– the installation requirements according to this Installation and Operation Guide,

NFPA 72, Local Codes and the Authority Having Jurisdiction (AHJ).

To select the proper battery size for your system, calculate the required total current draw of

your system according to the following steps (1 to 8).

Alternatively, use the Microsoft Excel based FPA-1000-UL_Battery_Calculator.xls. The

spreadsheet is available on the product CD or can be downloaded at www.boschsecurity.us.

NOTICE!

Consider the source when using SLC devices that require auxiliary power. Auxiliary power on

the control panel is limited to 1.0 A maximum in total (0.5 A maximum each for AUX 1 and

AUX 2). If FPA-1000-UL auxiliary power (AUX Power Out) is used, the current required must be

entered in the table. If an external power supply is used, do not include the current draw in

the table (refer to steps 3 and 4 on page 22 and page 23).

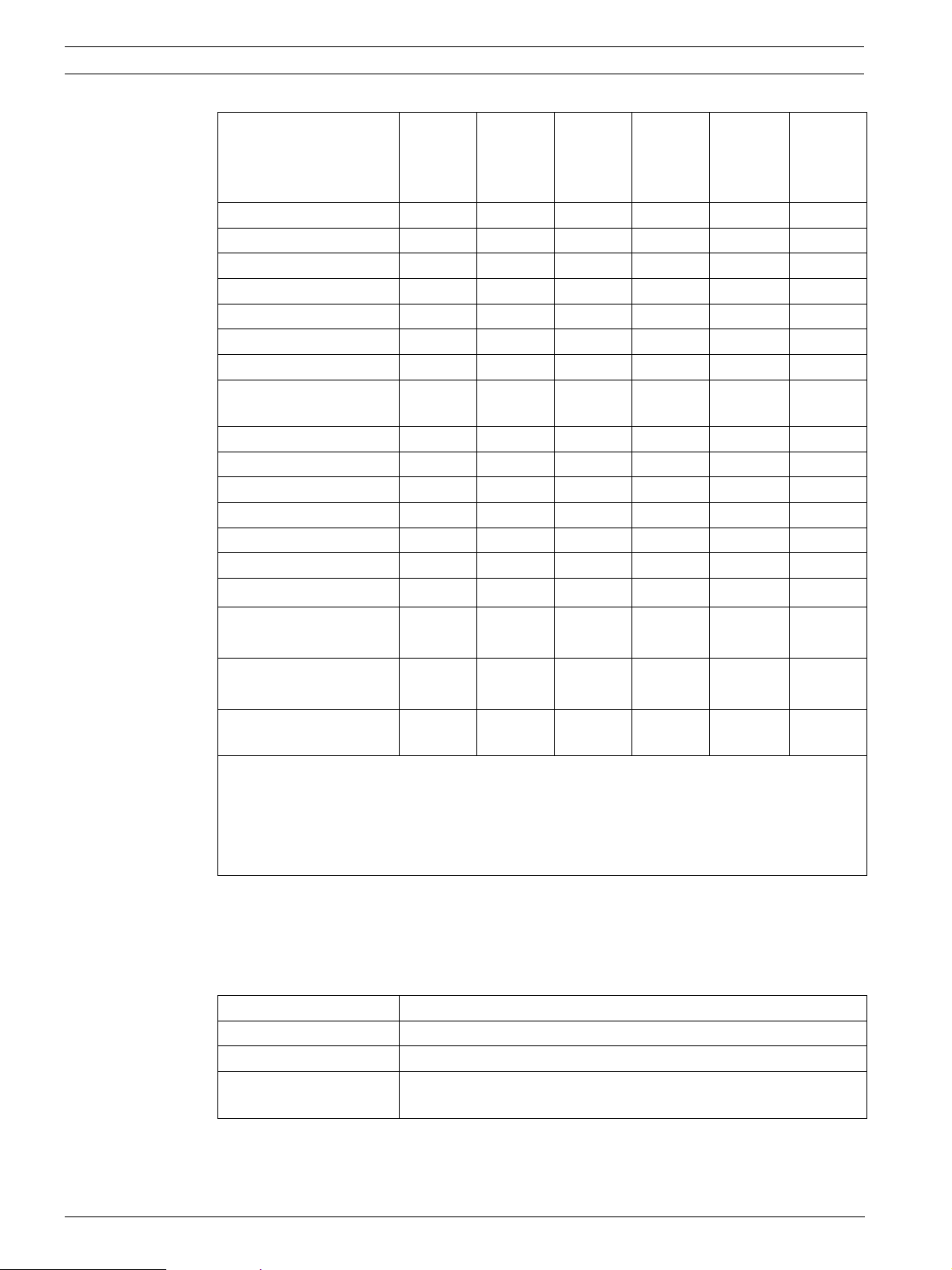

1. In Table 3.1, enter the standby and alarm currents of all control panel hardware devices

used. Enter the total standby and alarm current in the "Total Current [mA] Panel

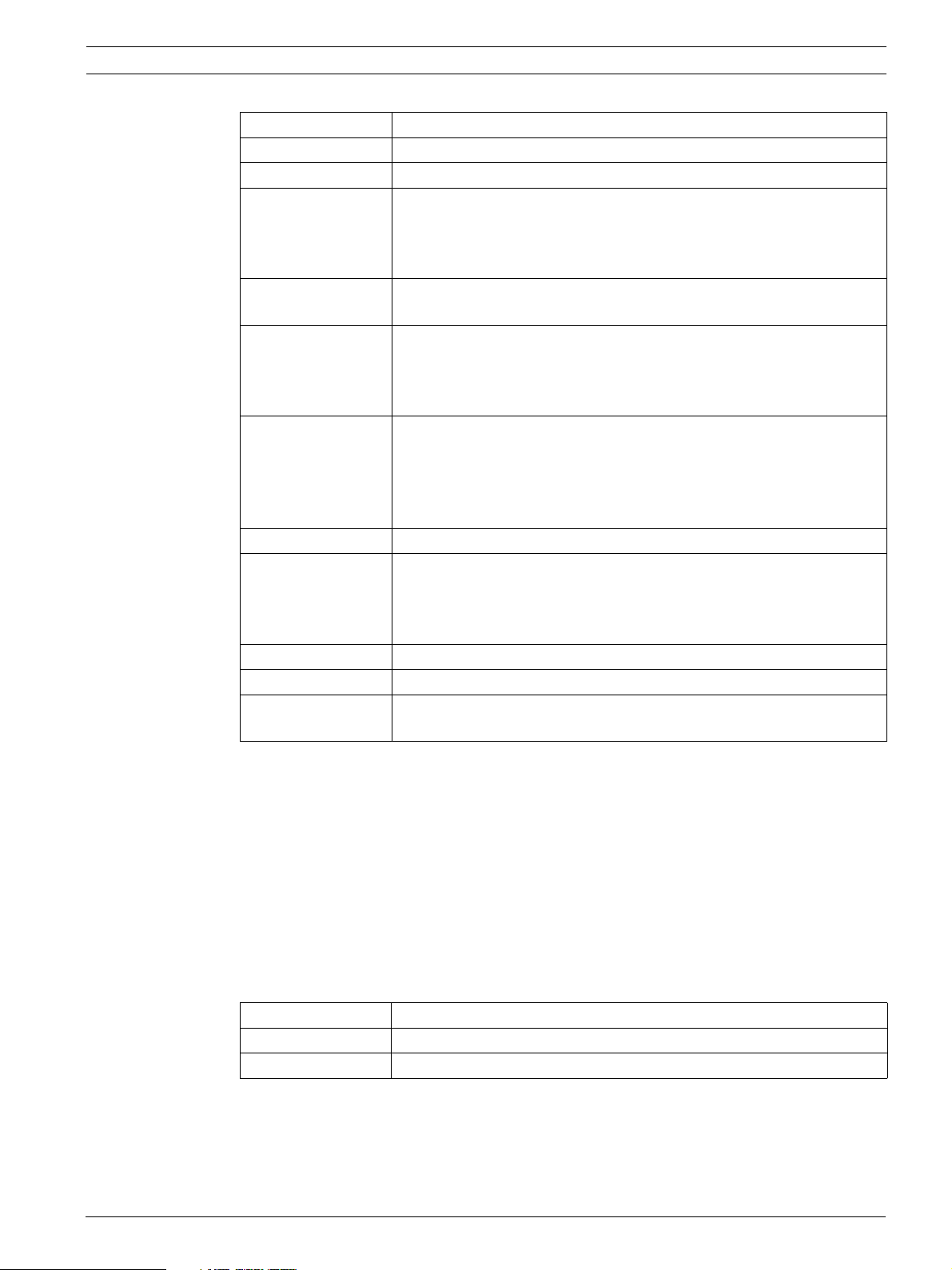

Hardware" field.

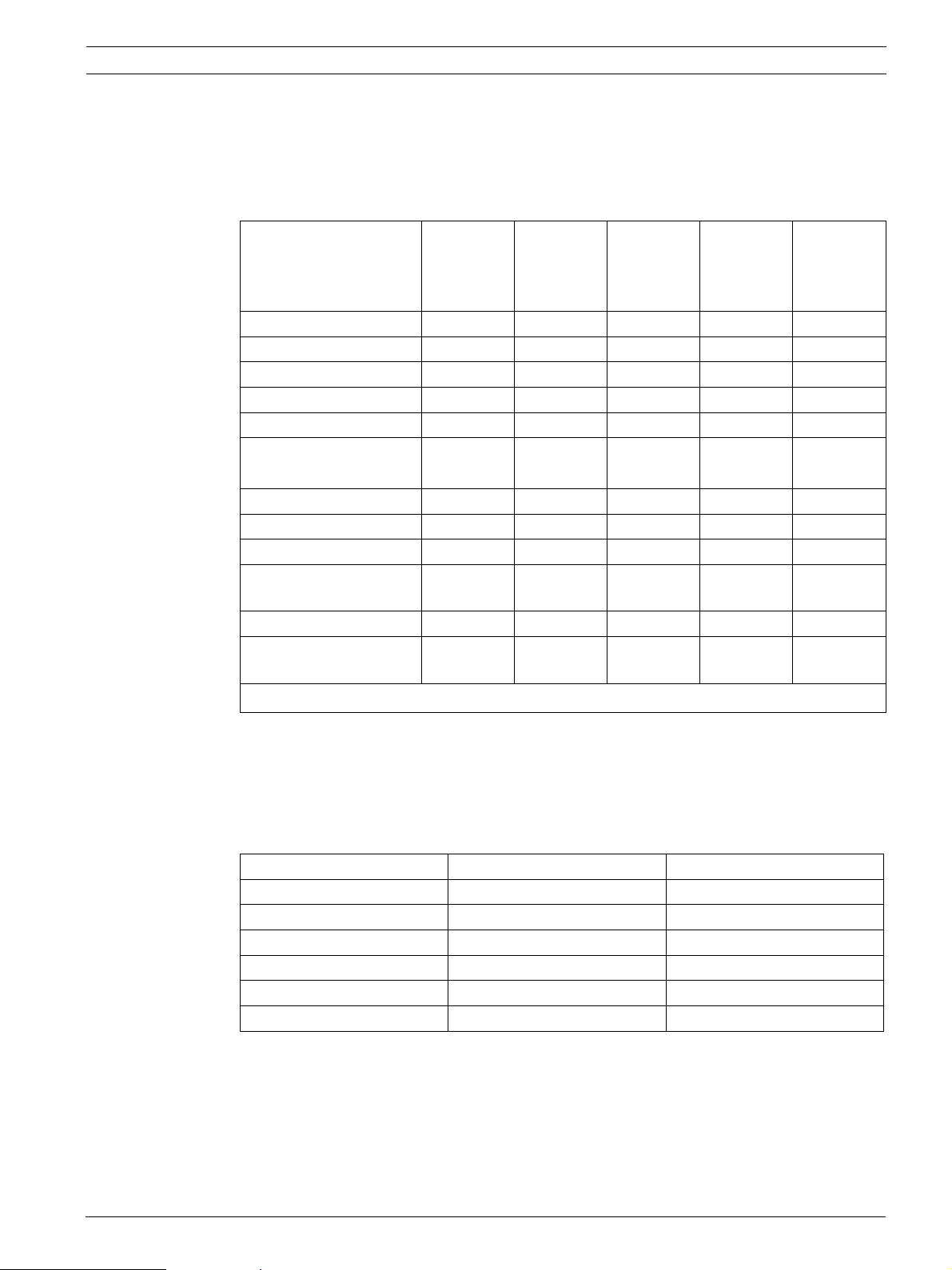

Panel Hardware Standby Current [mA] Alarm Current [mA]

Specification # of Dev.

Applied

FPA-1000-UL 180 1 240 1

Second FPA-1000-SLC 35 35

FPE-1000-CITY

–Local energy

–Reverse Polarity

Total Current [mA]

Panel Hardware ................. .................

# = number

Tab le 3. 1 Power Supply Calculations Step 1: Panel Hardware

2. In Table 3.2, enter the number of all SLC devices on each circuit. Total the number on all

circuits and multiply by the standby and alarm currents. Enter the total standby and

alarm current in the "Total Current [mA] SLC Devices" field.

50

5

Specification # of Dev.

Applied

250

33

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

22 en | Planning Information FPA-1000-UL Compact Fire Panel

SLC Devices # of

SLC 1

Devices

#of

SLC 2

Devices

Device

Standby

Current

[mA]

Total

Standby

Current

[mA]

Device

Alarm

Current

[mA]

Total

Alarm

Current

[mA]

FAP-325 0.39 0.39

FAH-325 0.35 0.35

FAI-325 0.35 0.35

FAD-325 0.39 0.39

FAD-325-R (from SLC) 0.39 0.39

FMM-325A/FMM-325A-D 0.55 0.66

FAA-325-B6S (from SLC) 0.11 0.11

FLM-325-CZM4 (from

0.40 0.40

SLC)

FLM-325-2I4 0.6 0.72

D328A 0.15 0.15

FLM-325-R24 0.15 0.15

FLM-325-ISO 0.27 10

FLM-325-N4 (from SLC) 0.22 0.3

FLM-325-I4/-IS/-IP 0.55 0.66

Device response

5

1)

5

1)

Device indicator LED - 5 x 9 = 45

maximum

2)

Remote indicator LED - 5 x 10 = 50

maximum

2)

Total Current [mA]

SLC Devices ............. .............

1)

Device response: Signal current required as soon as the first device connects to a circuit.

2)

Rolling alarm: Independent from the real number of activated device LEDs and remote

indicator LEDs, the number of activated LEDs is limited to five. Therefore, maximum current

is 9 mA per device LED multiplied by 5, and 10 mA per remote indicator LED multiplied by 5.

# = number

Table 3.2 Power Supply Calculations for Step 2: SLC Devices

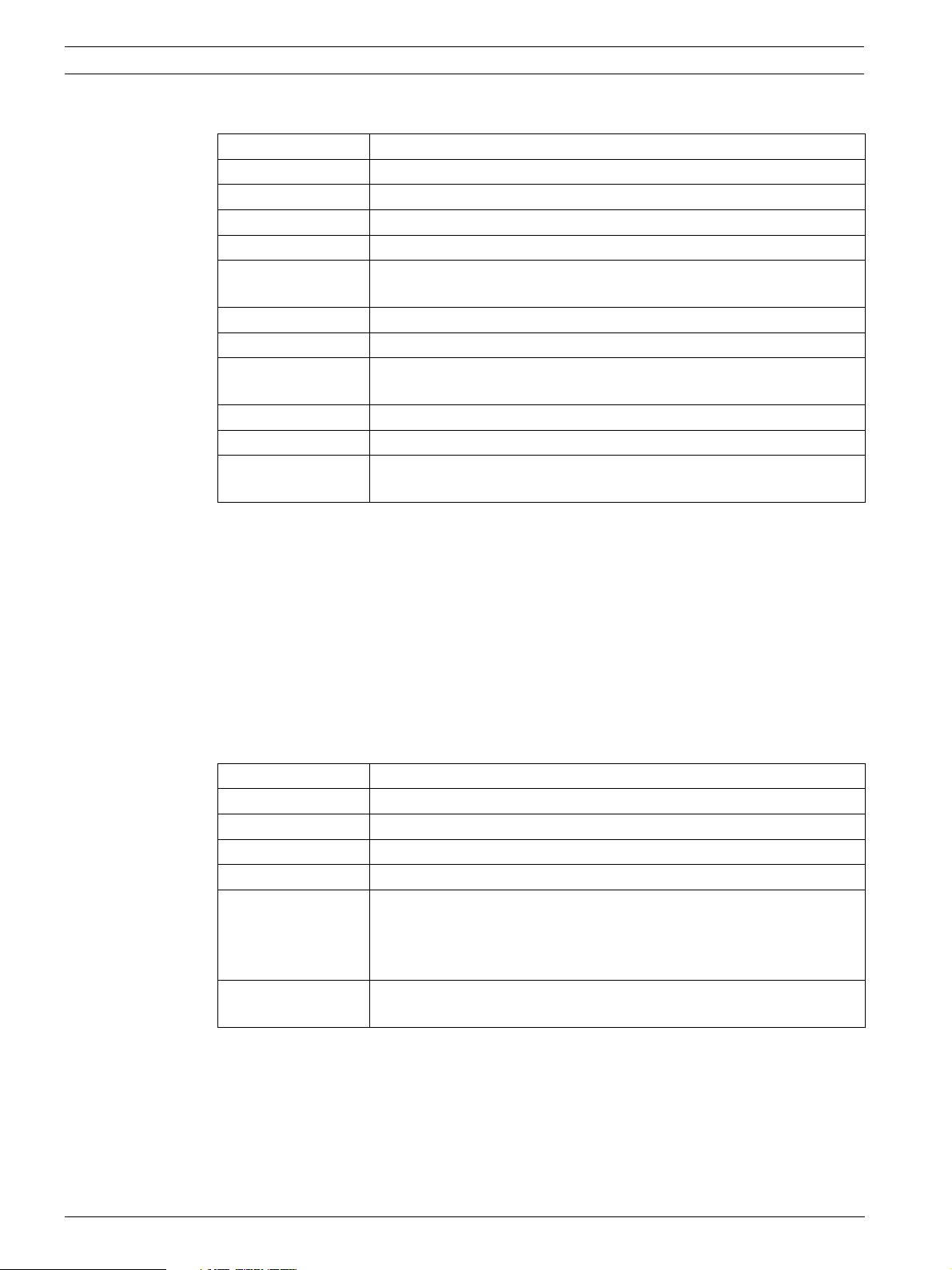

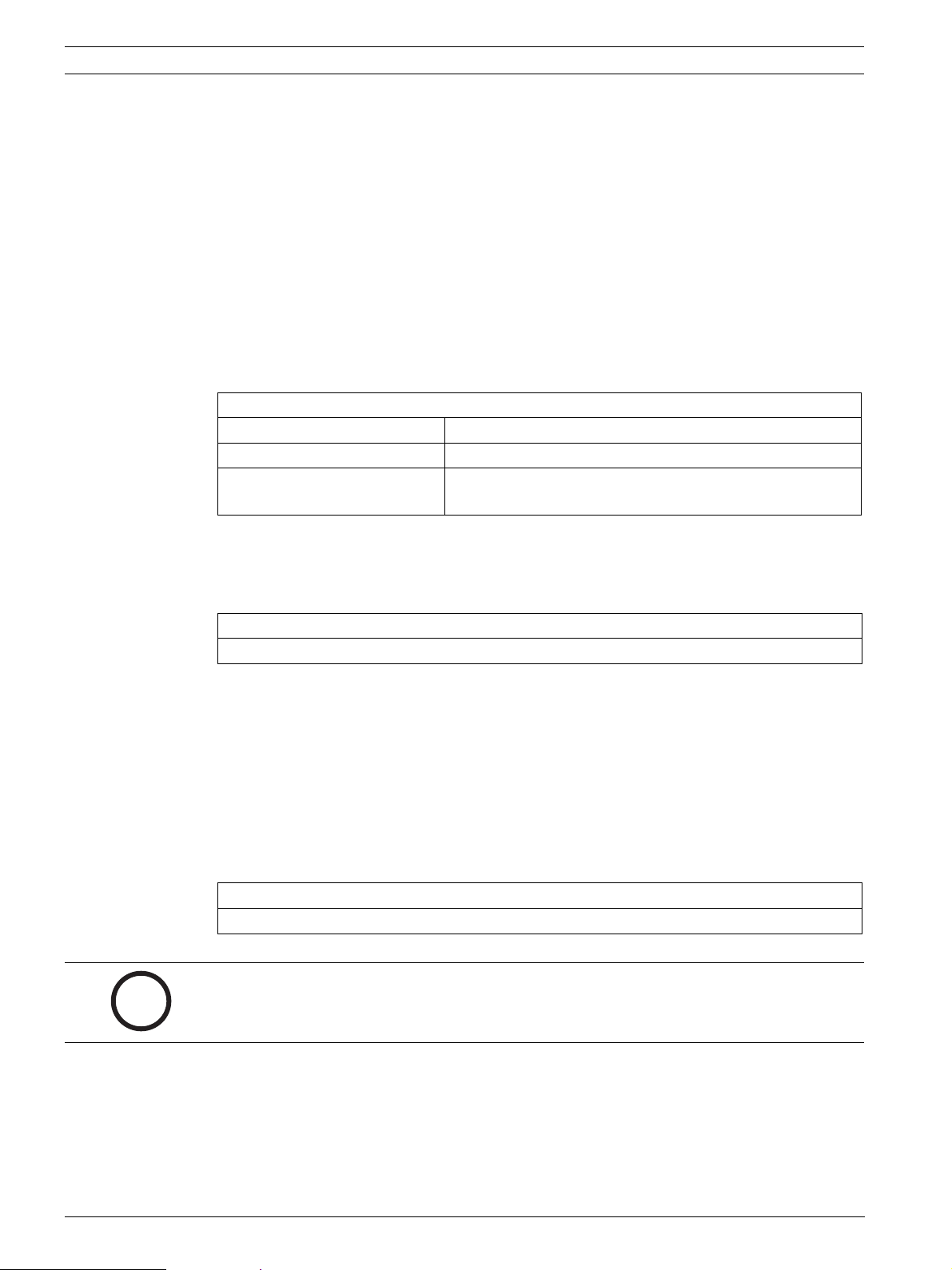

3. In Table 3.3, enter the NAC current required for each NAC circuit. Enter the total NAC

alarm current in the "Total Current [mA] NAC Devices" field. See Notice at the beginning

of Section 3.1 Power Supply Calculations on page 21.

NAC Devices Alarm Current [mA]

NAC 1

NAC 2

Total Current [mA]

NAC Devices

Table 3.3 Power Supply Calculations for Step 3: NAC Devices

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Planning Information | en 23

4. In Table 3.4, enter the number of all devices powered by the auxiliary power output

(annunciators, modules, and so on). Multiply by the device standby and alarm currents.

Enter the total standby and alarm current in the "Total Current [mA] AUX Powered

Devices" field. See Notice at the beginning of Section 3.1 Power Supply Calculations on

page 21.

AUX Powered Devices # Devices Device

Standby

Current

[mA]

Total

Standby

Current

[mA]

Device

Alarm

Current

[mA]

Total Alarm

Current

[mA]

FMR-1000-RCMD 20 150

FMR-1000-RA 20 150

D7030X/-S2/-S8 35 175

D7032 1 145

D7048/B 10 10

D7035/B 8 +

(n x 30)

1)

8 +

(n x 30)

1)

FPP-RNAC-8A-4C 20 20

FAA-325-B6S 0.55 18

FAD-325-R 12 55

FLM-325-CZM4 maximum 1 maximum

60

FLM-325-N4 0.15 0.45

Total Current [mA]

AUX Powered Devices ............. .............

1)

n = number of relays activated

Tab le 3. 4 Power Supply Calculations for Step 4: AUX Powered Devices

5. Total the standby and alarm currents of your panel hardware and all devices attached to

your system. Enter the total system current (in mA) in the "Total System Current [mA]"

field. Divide the total system current (in mA) by 1000 to get the total system current

(in A). Enter the total system current (in A) in the "Total System Current [A]" field.

System Devices Standby Current [mA] Alarm Current [mA]

Panel hardware

SLC devices

NAC devices

AUX powered devices

Total System Current [mA]

Total System Current [A]

Tab le 3. 5 Power Supply Calculations for Step 5: System Devices

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

24 en | Planning Information FPA-1000-UL Compact Fire Panel

6. The required standby and alarm backup time according NFPA 72 is:

– Standby 24 h

– Alarm 5 min = 0.083 h

Multiply the total system current [A] by the required backup time [h]. Enter the

calculated battery capacity [Ah] in Table 3.6.

Standby:

Calculated Standby Battery Capacity [Ah] = Total System Standby Current [A] x 24 [h]

Alarm:

Calculated Alarm Battery Capacity [Ah] = Total System Alarm Current [A] x 0.083 [h]

Add the calculated standby battery capacity [Ah] and the calculated alarm battery

capacity [Ah]. Enter the result in Table 3.6 in the "Total Calculated Battery Capacity [Ah]"

field.

Totaling Standby Battery Capacity [Ah] and Alarm Battery Capacity [Ah]

Standby

Alarm

Total Calculated Battery

Capacity [Ah]

Table 3.6 Power Supply Calculations for Step 6: Total Calculated Batter y Capacity

i

7. Multiply the total calculated battery capacity [Ah] by the derating factor 1.1 and enter

the result in Table 3.7.

Battery Capacity Needed [Ah] = Total Calculated Battery Capacity [Ah] x 1.1

Table 3.7 Power Supply Calculations for Step 7: Battery Capacity Needed

8. Select batteries that meet or exceed the total capacity calculated in the table above.

Refer to Table 2.4 on page 14 for available batteries.

Example 1:

If your system requires a battery capacity of 12 Ah/24 V you need two batteries of 14 Ah/

12 V.

Example 2:

If your system requires a battery capacity of 30 Ah/24 V you need two batteries of 38 Ah/

12 V.

Selected Batteries [Ah]

2x

NOTICE!

Use only batteries of the same capacity and manufacturer!

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Planning Information | en 25

3.2 SLC Configuration and Programming Basics

3.2.1 Points

A point is defined as a device such as an automatic detector, a call point, or input line. Each

point in the system is individually identified by the control unit and can be programmed with

specific functions or responses.

Possible states are:

– Normal

–Active

– Active Silence

–Trouble

– Walk test mode

A point can have only one state at a time.

The point is activated in either of the following cases:

– The analog value of an analog detector crosses its threshold level.

– An input monitor is activated.

The point is dirty if the clean air value reaches a defined upper limit (depending on detector

type). This takes place automatically during the calibration processes. After the panel is

initialized successfully, the test interval for the calibrated detector sensitivity testing is

4 hours. The dirty condition is handled as a trouble status. If the clean air value is out of

range, a calibration trouble status is indicated. The detector is still working, but the sensitivity

set point can be different from the configured value. This means the risk of a false alarm

increases.

The point is in trouble status in any of the following cases:

– Double address fault is detected on an address.

– Wrong type code error is detected.

– Missing device is detected on an address.

– Other types of fault conditions are detected.

If a point is in bypassed status, other status changes are ignored until it is unbypassed.

If a point is placed in walk test mode, activation and deactivation of this point are handled

differently. Any other condition changes are ignored until the point is no longer in walk test

mode.

The point is considered to be normal if it is not in any of the above states.

Point Types

Point type defines the condition that is indicated by activation of a point. Each point is

programmed with a type. Not all point types are possible on a certain point, especially on a

SLC point where a detector exists. Refer to Table 3.8 on page 26 for details on device type

mapping and possible point types for each SLC device type. The panel lists only the

acceptable point types for that SLC device.

Each of the points in the system can be programmed with its own characteristics. Point types

simplify the programming of points by allowing you to define a common set of characteristics

for similar points, and then assigning those characteristics to selected points as a point type.

Each point is assigned to use the characteristics of one point type, and then is individually

programmed for additional characteristics.

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

26 en | Planning Information FPA-1000-UL Compact Fire Panel

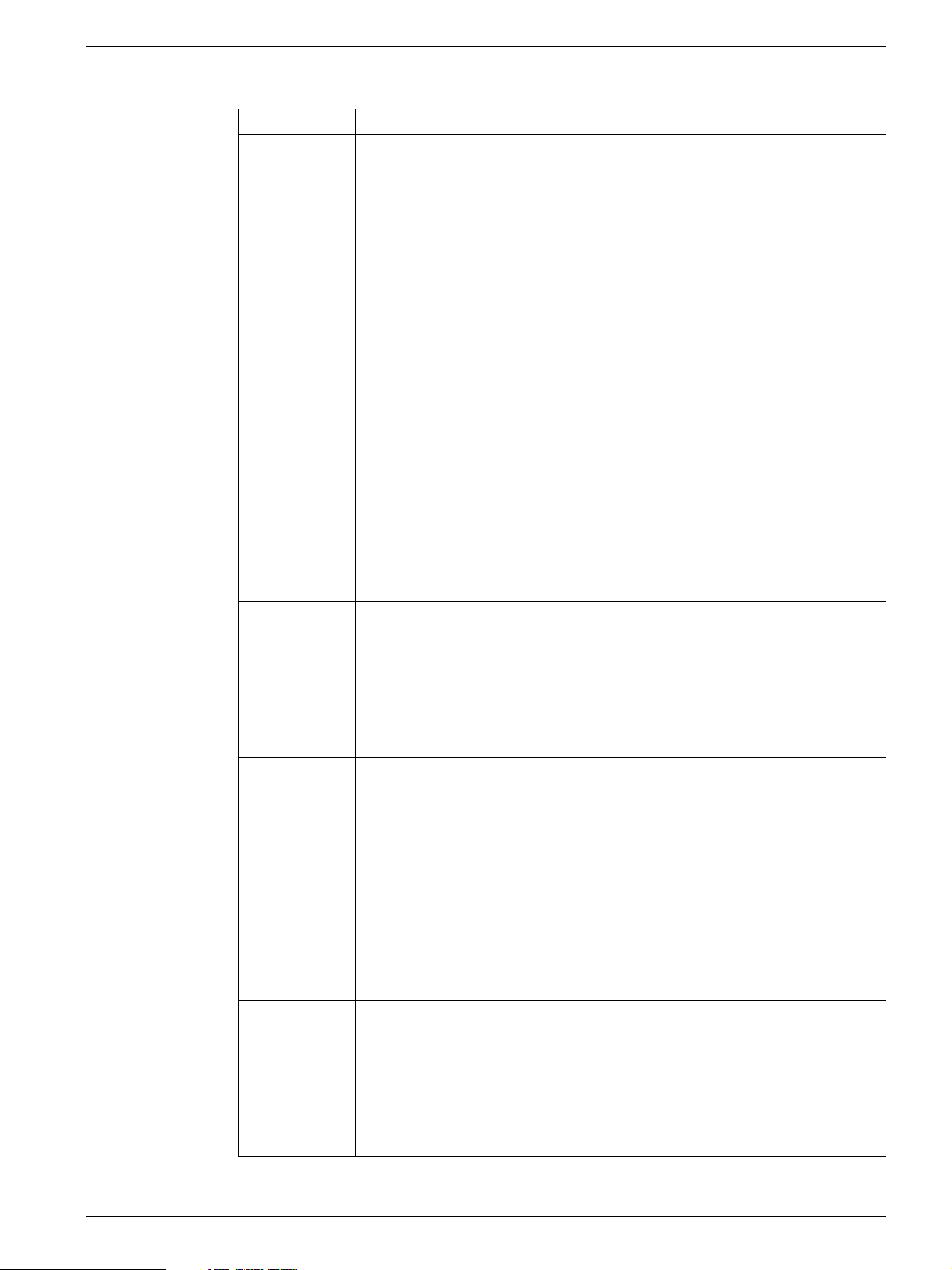

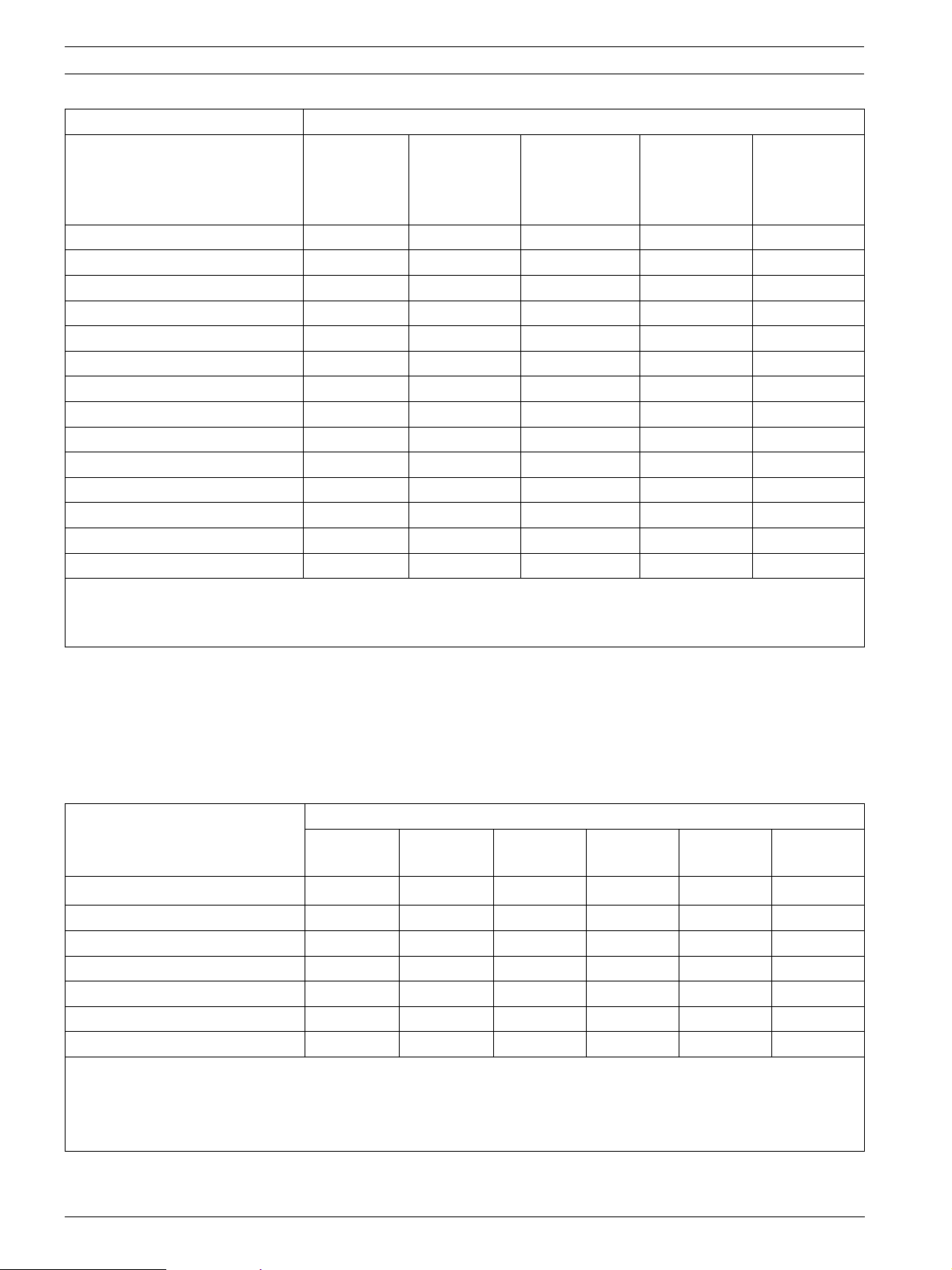

SLC Device Type

FPA-1000-UL

Point Type

FAP-325

FAH-325

FAI-325

FMM-325A

FMM-325A-D

FLM-325-CZM4 FLM-325-2I4 FLM-325-I4

FLM-325-IW

FLM-325-IS

FAD-325-DH

Fire Automatic D D

Fire Alarm Manual D P D D

Waterflow P P P

Waterflow with Delay P P P

Gas Alarm P P P

Supervisory P P P P P

Generic P P P

Trouble P P P

AC Failure P P P

Battery Failure P P P

Reset PPP

Silence P P P

Drill PPP

Acknowledge P P P

D = default point type

P = possible point type

[Blank] = not available

Tab le 3. 8 Mapping Point Types to SLC Device Types

3.2.2 Advanced Point Features and Processing

The panel provides flexible handling on a point so that more optional features are

accomplished. These features are applicable to specific types. The control panel lists only

possible point features for that point type when programming on menu and Web pages.

Refer to Table 3.9 on page 26 for mapping of point type to available point features:

Point Type Point Feature

Latching AV PAS/

Pre-signal

Fire Automatic X

1)

P

P

Fire Alarm Manual X

Waterflow X

Waterflow with delay X X

Gas Alarm X

Supervisory G

AC Failure X

AV = Alarm Verification

PAS = Positive Alarm Sequence

D = Day, N = Night

1)

Not for FAH-325

X = Fixed point feature

P = Programmable point feature

G = Dependent on global setting

Blank = not available

PAS (D)/

AV (N)

1)

P

Water-flow

Delay

AC Fail

Delay

Tab le 3. 9 Mapping Point Types to Point Features

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Planning Information | en 27

The following principles apply:

– For Supervisory point type, programming of latching or non-latching is panelwide.

– The point types Generic, Trouble, AC Failure, Battery Failure, Reset, Silence, Drill, and

Acknowledge are non-latching. Refer to Table 3.8 on page 26.

– For Fire Automatic point type, only one of three programmable features can be selected:

AV, or PAS/Pre-signal or PAS (Day)/AV (Night). AV and PAS (Day)/AV (Night) does not

apply for the FAH-325 Analog Heat Detector.

Delay options can be selected

– for the Day Mode via the SIte Data programming (refer to Section 6.7.1 Site Data on

page 130), and

– individually for each SLC Fire Automatic input (refer to Section 6.7.2 SLC 1 and SLC 2 on

page 132 and/or Section 5.7.6 PROGRAMMING on page 100)

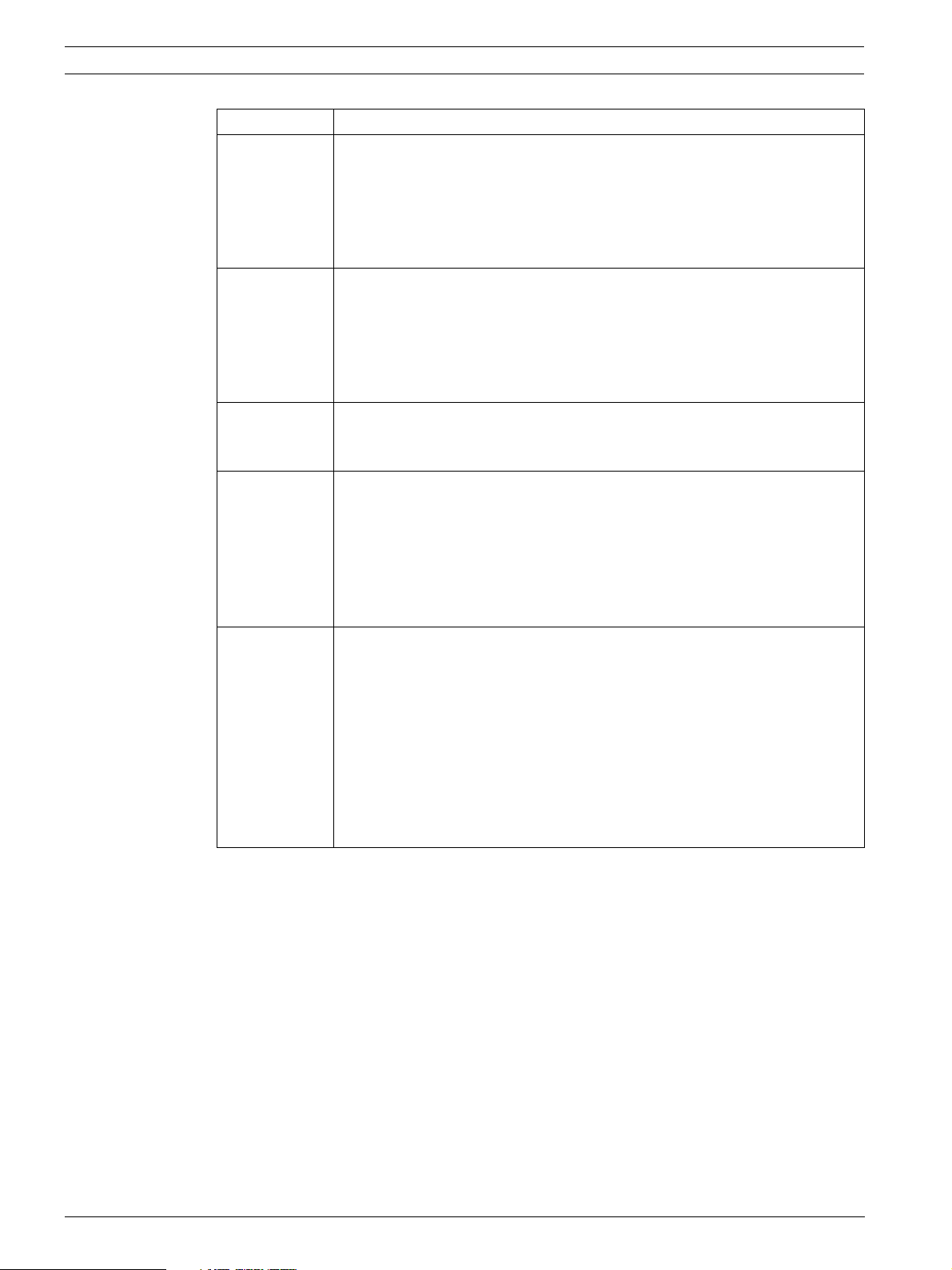

The following table shows the prioritization of both delay settings:

Programming SLC Fire

Automatic Input

No delay PAS Pre-signal

Day Mode (Site Data

No delay No delay No delay No delay

AV AV AV AV

PAS/Pre-signal No delay PAS Pre-signal

PAS (D)/AV (N) AV PAS Pre-signal

AV = Alarm Verification

PAS = Positive Alarm Sequence

D = Day, N = Night

Tab le 3. 1 0 Prioritization of Day Mode and SLC Input Delay Options

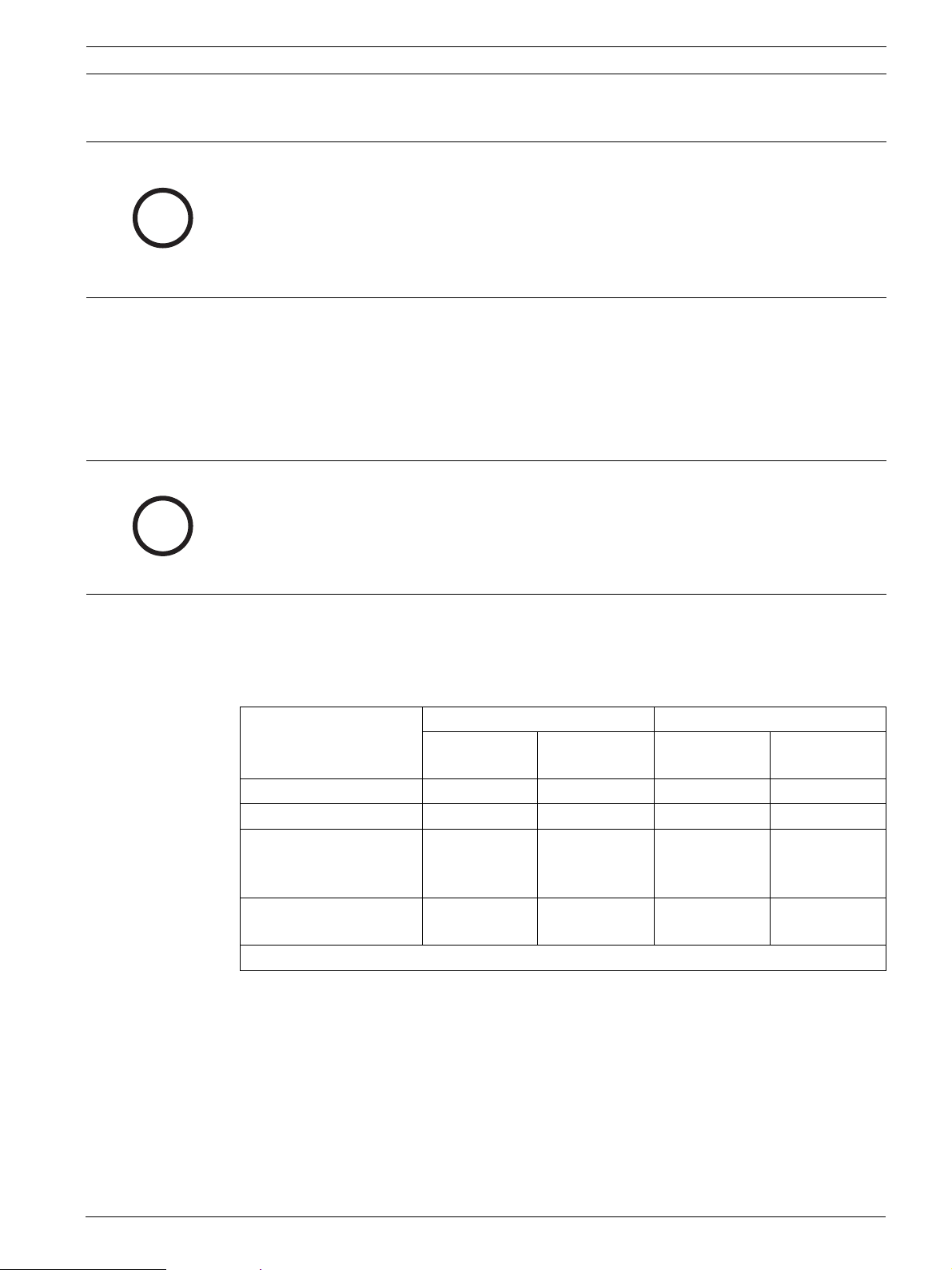

Alarm Verification

If an input point is configured as “Alarm verification enabled” and goes into an active state,

the panel does not immediately indicate the alarm and activate associated outputs, but resets

the input point and waits for a verification period (programmable) to see if the point is still

active.

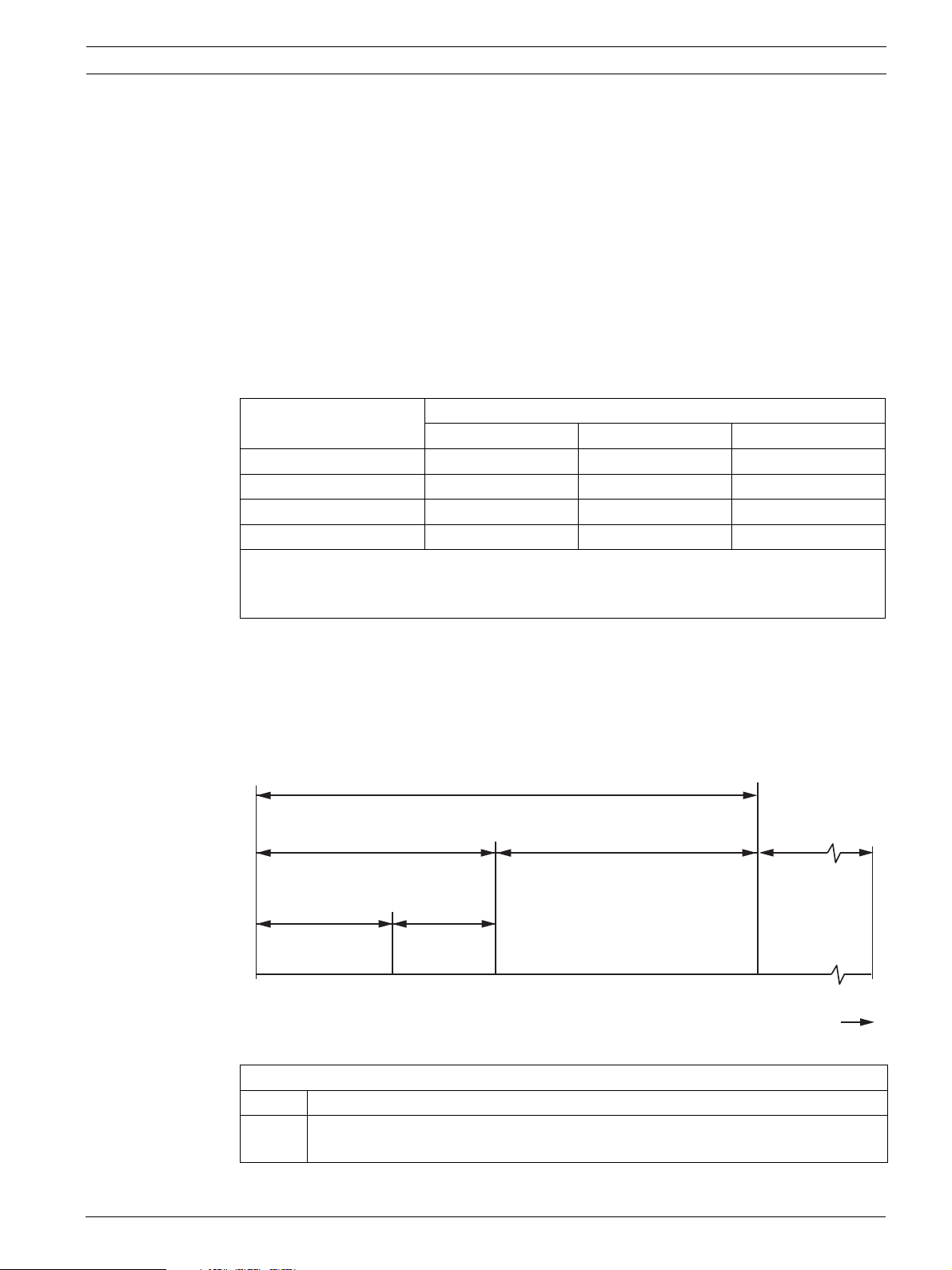

ALARM VERIFICATION PERIOD (programmable 60 to 180 seconds)

RETARD-RESET-RESTART PERIOD

No Alarm At Control Unit

(not configurable, 30 seconds max.)

CONFIRMATION PERIOD

Alarm Required At Control Unit

OPTIONAL

REGION

RETARD-RESET PERIOD

Control Unit

(20 seconds)

AB DEC

0 seconds

Figure 3.1 Alarm Verification Timing Diagram

POWER-UP PERIOD

Detector Restart

time

Legend

A Smoke detector goes into alarm.

A→B RETARD-RESET PERIOD: Control unit senses detector in alarm and retards

(delays) alarm signal. Fixed, 20 seconds.

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

28 en | Planning Information FPA-1000-UL Compact Fire Panel

Legend

B→C POWER UP PERIOD: Power to the detector is reapplied and time is allowed for

detector to become operational for alarm (detector restart). Time depends on the

device type (detector maximum 3 seconds, Conventional Zone Module maximum

10 seconds).

A→C RETARD-RESET-RESTART PERIOD: No alarm obtained from control unit. Not

configurable, 30 seconds maximum.

C→D CONFIRMATION PERIOD: Detector is operational for alarm at point C. If detector is

still in alarm at point C, control unit will alarm. If detector is not in alarm, system

returns to standby. If the detector re-alarms at any time during the confirmation

period the control unit will alarm. Time depends on detector restart and overall

alarm verification period.

A→D ALARM VERIFICATION PERIOD: Consists of the retard-reset-restart and

confirmation periods. Programmable 60 to 180 seconds.

D→E OPTIONAL REGION: Either an alarm can occur at control unit or restart of the

alarm verification cycle can occur.

– Alarm verification is applicable only to analog smoke or 2-wire smoke detectors of the

Fire Automatic type. The alarm verification option is not applicable to Fire Alarm Manual

and Waterflow point types.

– The alarm verification option is arranged on a per point basis.

– After the alarm verification period starts, any alarm from anywhere in the system that

occurs during the alarm confirmation cycle immediately results in an alarm indication.

– The alarm verification timer is system wide; thus, only one timer applies for the whole

system.

– The alarm verification timer is user programmable, ranging from 60 to 180 seconds. The

default is 60 seconds. Refer to Section 3.19 Programming Requirements According to

UL 864 on page 39.

– A reset command is sent to reset the input point on SLCs for alarm verification.

– The global alarm verification zone is activated if the panel is in the verification period.

NOTICE!

CSFM installations require the alarm verification Retard-Reset-Restart (A-C) time to be a

i

maximum of 30 seconds. This time is not programmable and is always less than 30 seconds,

by design. The programmable alarm verification time in this panel is the complete RetardReset-Restart-Confirmation (A-D) cycle.

Waterflow Delay

– The Waterflow delay is applicable only to point type “Waterflow with delay”.

– The Waterflow delay enable option is arranged on a per point basis.

– Each point configured with Waterflow delay has its own timer.

– The Waterflow delay timer is user programmable, ranging from 10 to 90 seconds. The

default is 90 seconds.

– The input point must remain constantly in an active state for the complete time delay.

Any interruption resets the timer.

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

FPA-1000-UL Compact Fire Panel Planning Information | en 29

Latching

If a point is “Latching”, after activation it can return to the normal state only by a reset

operation.

– The latching enable option is arranged on a per point basis.

– Latching is programmable only for points of the supervisory type.

– For other types of points, the latching option is fixed:

– “Latching” for Fire and Waterflow point type

– “Non-latching” for Generic, Trouble, AC Failure, Battery Failure, Reset, Silence, Drill,

and Acknowledge point type.

Pre-signal

If an input point is configured as “Pre-signal enabled” and it becomes active, the activation of

outputs (for example NACs) associated with that input point is delayed. Other responses,

including message display update, LED indication, piezo mode change, central station

reporting, and history log, are immediately generated.

– Pre-signal is applicable to points of the Fire type only.

– Pre-signal is arranged on a per point basis.

– If a second alarm occurs during the Pre-signal delay time, the second alarm is

immediately processed and all outputs associated with both alarmed input points are

activated.

– Any outputs assigned to a Pre-signal zone are activated immediately on initial alarm.

– The Pre-signal timer is system wide; thus, only one timer applies for the whole system.

– The Pre-signal timer is user programmable, ranging from 60 to 180 seconds. The default

is 180 seconds.

– The Pre-signal delay feature can be enabled or disabled for each input device individually.

– The global Pre-signal zone is activated if the panel has a Pre-signal input active and is in

the "waiting for reset" period.

– The Pre-signal feature, if enabled, is valid only under Day Mode. The panel can be in

either PAS mode or Pre-signal mode, not both.

i

NOTICE!

In case the Pre-signal option is configured, install a pull station next to the FPA-1000-UL in

order to activate the alarm manually.

Positive Alarm Sequence (PAS)

The PAS feature is applicable only to automatic fire detection devices that are the Fire type

(analog and 2-wire smoke or heat detectors).

– PAS is arranged on a per point basis.

– All system evacuation signals associated with the activated initiating device and any off-

premises signaling activate immediately and automatically when:

a. The alarm signal from an automatic fire detection device is not acknowledged within

15 seconds of annunciation at the system’s operator interface.

b. The system is not manually reset within the programmed PAS investigation time of

the acknowledgment described in (a).

c. When a second automatic fire detector selected for positive alarm sequence

actuates before the system is reset as described in (b); or when any other fire

initiating device reporting to the system or control unit actuates.

– The PAS timer is system wide; thus only one timer applies for the whole system.

– The PAS timer is user programmable, ranging from 60 to 180 seconds. The default is

180 seconds.

– The PAS feature can be enabled or disabled for each input device individually.

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.075.420 | 2.0 | 2009.04

30 en | Planning Information FPA-1000-UL Compact Fire Panel

– In addition, the panel provides a global option to enable or disable PAS.

– The panel can be in either PAS mode or Pre-signal mode, not both.

– The PAS feature, if enabled, is valid only under Day Mode. In addition, a PAS end time can

be programmed within the day sensitivity period.

NOTICE!

For Positive Alarm Sequence details, refer to NFPA 72 and UL 864.

i

3.2.3 Events

All point and system events are classified by event groups.

Point events are generated as point status changes.

Each type of point event belongs to a group that is based on when the panel displays and

reports the event in a prioritized style. Table 3.11 on page 30 lists point events and the event

groups to which they belong.

Point Event Event Group

Point bypassed Point trouble

Point unbypassed Point trouble restore

Point event upon activation Handled depending on the point type

Point event upon deactivation

Point trouble Point trouble

Point trouble restore Point trouble restore

Point walk test activation Test

Point walk test deactivation Test

Table 3.11 Mapping Point Events to Trouble Event Group

The event generated upon point activation or deactivation is determined by the point type.

Table 3.12 lists possible point events derived from point activation and the group to which the

event belongs.

programmed (refer to Table 3.12)

F.01U.075.420 | 2.0 | 2009.04 Installation and Operation Guide Bosch Security Systems, Inc.

Loading...

Loading...