Page 1

For English Version Version française Versión en español

See page 2 Voir page 15 Ver la página 28

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations et

les adresses de nos centres de

service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

FNS-250-16

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 1

Page 2

2.

General Pneumatic Tool Safety Rules

ALL USERS AND EMPLOYERS/OWNERS MUST READ AND UNDERSTAND ALL INSTRUCTIONS IN THIS

MANUAL BEFORE OPERATING OR MAINTAINING THIS TOOL. Failure to follow all instructions listed below

may result in electric shock, fire, serious personal injury or death.

SAVE THESE INSTRUCTIONS

Work Area

Ke e p yo u r wo r k ar e a cl e a n an d we l l li t . Cl u t tered

benches and dark areas increase the risks of accidents,

electric shock, fire, and injury to persons.

Do not operate pneumatic tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases, or dust. The tool is able to create sparks

which may ignite the dust or fumes. Never use the tool in

sites containing lacquer, paint, benzine, thinner, gasoline,

gases, adhesive agents, and other materials which are

combustible or explosive.

Keep bystanders, children, and visitors away while

operating a pneumatic tool. Distractions may cause loss

of control of the tool. Fragments of fasteners may cause

injury to bystanders.

Never engage in horseplay with the tool. Respect the

tool as a working implement.

Personal Safety

Do not remove, tamper with, or otherwise cause the tool

operating controls to become disabled or inoperable.

This will cause the tool to work irregularly and may result in

the risk of injury.

Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts and increases the risk of

injury.

Always wear eye and ear protection when using this

tool. Use additional personal protective equipment as

appropriate when operating this tool. Operators and

others in work area must wear safety glasses with side

shields and make sure all other personnel in the work area

wear safety glasses. Safety glasses must conform to the

requirements of American National Standards Institute,

ANSI Z87.1 and provide protection against flying particles

both from the front and side. Prolonged exposure to high

intensity noise is able to cause hearing loss. Dust mask,

non - s k id sa f e t y sh o e s , ha r d hat and o ther p e r s o nal

pro t e ctive e q u ipment, must be u s e d fo r appr o p riate

conditions.

Keep handles dry, clean and free from oil and grease.

Slippery hands cannot safely control the tool.

Avoid directing exhaust air from the tool into your or a

bystander face and eyes. Exhaust air from a tool can

contain water, oil, metal particles or contaminants from the

compressor, which can be blown into the eyes or cause

serious injury. Use adjustable air vent to direct exhaust to

blow exhaust air away from user.

Stay alert. Watch what you are doing, and use common

sense when operating a pneumatic tool. Do not use the

tool while tired or under the influence of drugs, alcohol,

or medication. A moment of inattention while operating the

tool may result in serious personal injury.

Avoid unintentional operation. While connecting air

supply do not depress trigger. Do not carry the tool with

your finger on the trigger or connect the tool to the air

supply with the switch “on.”

Do not overreach. Keep proper footing and balance at

all times. Proper footing and balance enable better control

of the tool in unexpected situations.

Make sure air hose is free of snags and obstructions.

Do not at t a ch an air hose or tool to your bo d y .

Entangled or snarled hoses can cause a loss of balance or

footing in addition to unintentional tool operation. Attach the

hose to the structure to reduce the risk of loss of balance if

the hose shifts.

Tool Use and Care

Use this tool and accessories in accordance with the

instructions. Tools and accessories must be used for the

purpose for which they are designed. Use of the pneumatic

tool for operations different from what's described in this

manual can result in a hazardous situation.

Use only accessories that are recommended by BOSCH

for y our parti cular mode l. Accessorie s t hat ma y be

recom mended for a pa rti cular m odel tool ma y not be

suitable on other model tools and may result in personal

injury.

Before each use, inspect the tool. Do not operate if any

portion of the tool is loose, missing, damaged,

malfunctioning, disconnected or altered. I f the tool

appears to be operating unusually and/or making strange

noises, stop using it immediately and contact your local

service center. There is a risk of bursting if the tool is

damaged.

Do no t fo r c e tool. Use the co rr e c t too l for your

application. The correct tool will do the job better and safer

at the rate for which it is designed.

Do not operate the tool with any power source other

than that sp e c i f ie d in th e tool operating / s a f e t y

instructions. Use of alternative power sources may result

in malfunctions of the tool and the power source which may

lead to serious injury of you or others in your surroundings.

Di scon nect to ol f rom air su pply wh en n ot i n use.

Leaving the tool unattended with the air supply connected

can result in unintentional operation of the tool by users

unfamiliar with tool.

!

WARNING

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 2

Page 3

3.

Disconnect the tool from the air source before making

ad j ustme n ts, c leari ng jams, unload ing f astene rs,

leaving the work area, performing tool maintenance or

storing the tool. Such precautionary safety measures

reduce the risk or unintentional tool operation.

Never carry the tool by the hose. The tool, air fittings and

the air hose may become damaged.

Use clamps or another practical way to secure and

support the work piece to a stable platform. Holding

work by hand or against your body is unstable and may lead

to loss of control or personal injury.

The correct pressure is the lowest pressure that will do

the job. Always follow recommendations for the particular

tool.

Maintain tools with care. Properly maintained tools are

less likely to break and cause injury. Any alteration or

modification is a misuse and may result in a dangerous

condition.

Service

Maintenance performed by unauthorized personnel may

result in misplacing of the internal components which

could cause serious hazard. We recommend that all tool

service be performed by a BOSCH factory service center or

authorized BOSCH service station.

Develop a periodic maintenance schedule for your tool.

When cleaning a tool be careful not to disassemble any

portion of the tool since internal components may be

misplaced or safety components may be improperly

mounted. Certain cleaning agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage plastic parts and

o-rings.

Whe n serv i c ing th e to o l , us e only reco m m ended

BOSCH replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized

parts or failure to follow Maintenance Instructions can cause

a risk of injury.

Use only the air tool lubricants supplied with the tool or

specified by BOSCH. Do not use other lubricants as they

may damage the tool. See the "Lubrication" section for a list

of recommended air tool lubricants.

Replace missing or damaged warning labels. Refer to

tool schematic for correct placement and part number.

Keep the tool clean and lubricated. Clean the tool at least

daily and lubricate as required. Never operate a dirty or

malfunctioning tool.

When not in use, store the tool out of reach of children

and other personnel unfamiliar with tool operation.

When not in use, the tool should be disconnected and

stored in a dry place. Keep out of reach of children. Lock

the storage area. Tools are dangerous in the hands of users

unfamiliar with the tool.

Air Source

Never use oxygen or other bottled gases as a power

source. Explosion may occur. Combustible gases and other

bottled gases are dangerous and may cause the tool to

explode.

Use only clean, dry, regulated, compressed air within

the rated pressure range marked on the tool. Do not

exceed maximum recommended air pressure marked

on the tool. Verify prior to using the tool that the air source

has been adjusted within the rated air-pressure range. Be

sure the air pressure gauge is operating properly and check

it at least twice a day. Tools operated in excess of their

maximum pressure rating may operate abnormally or burst,

resulting in personal injury.

Never connect the tool to an air source that is capable

of producing air pressure exceeding 200 PSI. Excessive

pressure can cause abnormal operation or cause the tool to

burst, resulting in personal injury.

Do not abuse the air hose. Protect all hoses from kinks,

restrictions, solvents or sharp objects. Keep air hose

away from heat, oil, sharp edges or moving parts.

Replace damaged hoses immediately. Damaged hoses can

burst or whip around.

Ch eck all fitti ngs, hos es, pipes , connec tion s an d

compressor before each use of this tool. Repair or

replace damaged or leaking hoses and connections

immediately. Damage to a hose or connection can cause a

pressure hose to break and whip around the work area, and

can lead to injury.

Safety Rules for Pneumatic Nailer Tools

Alway s assume t he tool conta ins na ils. Check th e

magazine for nails that may be left in the tool, even if you

think the tool is empty or disconnected.

Never point the tool at yourself or others in the work

area. Always assume the tool contains nails. If nails are

accidentally fired, it may result in injury. The tool is not a toy

and should not be used like one.

Remove finger from the trigger when not driving nails.

Always carry the tool by the handle only. Removing your

finger from the trigger when not operating the tool reduces

the risk of unintentionally firing a nail and injuring yourself or

someone else.

Do not disable or remove the work contact element.

This tool is equipped with a safety mechanism, the work

contact element, to reduce the risk of accidental firing.

Disabling this component can result in unintentional firing.

Do not use the tool unless the work contact element is

working properly. If the work contacting element is not

functioning correctly, the tool can fire unexpectedly.

Never use non relieving couplers and/or female quick

disconnect couplings on the tool. Non relieving couplings

and female couplings will trap high pressure air in the tool

when the air line is disconnected. This will leave the tool

charged with enough air after it has been disconnected to

drive a nail. Only MALE pneumatic type air connectors

should be fitted to the tool, so that high pressure air in the

tool is vented to atmosphere as soon as the air line is

disconnected.

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 3

Page 4

4.

Follow all recommendations for sizes of hoses, fittings

a

nd other compressed air accessories. Improperly sized

or fitting components may result in the risk of injury or

property damage.

C

heck air supply lines for restrictions before adjusting

the t ool. Ai r v olum e is a s impor tant as air p ressure .

Restricted air flow will prevent the tool from operating as

d

esigned, resulting in slow operation, nail misfeeding or

reduced driving power.

Always load nails into the tool's magazine before the air

s

upply is connected. Connecting the air supply after

loading nails reduces the risk of unintentionally driving a nail

and injuring yourself or someone else.

When loading nails ensure that nails are parallel with

nose of tool. If nails are not parallel with nose the tool will

misfire and nails can be deflected, cause the tool to react in

an unexpected manner, and damage the tool.

When loading the tool's magazine, check that the nail

follower slides smoothly by pulling with finger. If not

smooth, nails can be driven at irregular angle.

Use only the nails meeting the criteria listed in the

“Spe c i f i c a t i o n ” se c t i o n of t h i s manual. Nails n o t

id entifie d for use with th is tool ca n cause the t ool to

malfuncti on and res ult in the risk of i njury and/or tool

damage.

Do not connect the air supply when the trigger or work

contact element is depressed. Keep the tool pointed

do wnwa rd, awa y from yourself a nd b ysta nder s when

connecting the hose to reduce the risk of accidental nail

firing.

Keep hands and feet away from work contact element

of the tool during use. Never place your hands or feet

closer than 8 inches (200 mm) to the work contact element

of the tool. Nails can be deflected by the work piece or

driven away from the point of entry.

Choice of triggering methods is important; understand

the operating characteristics of each option. There are

two possible firing modes; “sequential firing” and “bump

firing.” Read and under stand secti on titled “Actuation

Systems” for details of each mode.

Do not use a frozen tool. Allow tool to thaw before using.

Moisture frozen in the tool may impede internal components

resulting in the risk of injury and/or tool damage.

Operate the tool only when properly positioned on the

work piece. If the tool is not held properly on the work

piece the nail can be deflected or the tool can react in an

unexpected manner.

Use sufficient grip to maintain control of the tool while

allowing tool to recoil away from work surface as nail is

driven. Do not attempt to prevent the recoil by holding

the tool with excessive force against the work piece.

The tool will recoil as the nail is driven. This is normal

function for the tool. Restriction to the recoil can result in

second nail being driven when the tool is in “bump firing”

mode.

Use caution when operating the tool in confined areas.

If the work contact element is allowed to re-contact the work

surface before trigger is released, an unwanted nail will be

fired if the tool is set in “bump firing” mode.

In order to avoid undesirable double fire , take the

f

ollowing actions when the tool is in the following firing

modes:

Sequential firing:

1

. Ensure trigger is in sequential fire mode.

2. Pull the trigger firmly and release.

Bump firing:

1. Do not p r es s the to o l against th e wood wi t h

excessive force.

2. Allow the tool to separate from the wood as it

recoils after nailing.

Never drive nails near flammable materials. Some types

of nails can spark out of the nose during driving operation.

Know what is behind your work piece. Do not fire nails

into walls or floors without assuring the area on the

opposite side is clear. A nail could travel through the work

piece, striking someone.

Do not drive a nail on top of another nail. This could

cause the nail to be deflected or the tool to react in an

unexpected manner.

Do not attempt to drive nails at a steep angle. This could

cause the nail to be deflected or the tool to react in an

unexpected manner.

Use care when nailing thin material or when working

near the edges and corners of the work piece. Nails may

driv e throug h or away from the work piece a nd injure

yourself or someone else. Be aware that the nail may follow

the grain of the wood causing it to protrude unexpectedly

from the side of the work material. Drive the nails

perpendicular to the grain.

Do not drive nails into walls, floors or other work areas

without knowing what may be damaged by the driven

nails. Nails driven into live electrical wires, plumbing, gas

piping, or ot h e r types of ob s t r u c t i o n s can result in

electrocution, explosion, personal injury and/or property

damage.

Make sure the pressure of the compressor is adjusted

so that nails are driven flush into the work piece and

not pushed completely through. The correct pressure is

the lowest pressure that will do the job.

Keep face and body parts away from back of the top

cap when working in restricted areas. Sudden recoil can

result in impact to the body especially when nailing into hard

or dense material.

Handle tool carefully. Because of high air pressure in the

tool, do not drop the tool or strike the tool against hard

surfaces; and do not scratch, stamp, nor engrave signs on

the tool. The tool may burst.

Always disconnect tool from air supply and remove

nails from magazine before leaving the area or passing

tool to an o t h e r operator. T h i s avoids th e ri s k of

unintentional operation.

Do not disconnect air hose from the tool with finger on

trigger or the work contact element depressed. The tool

can fire when reconnected to air supply.

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 4

Page 5

5.

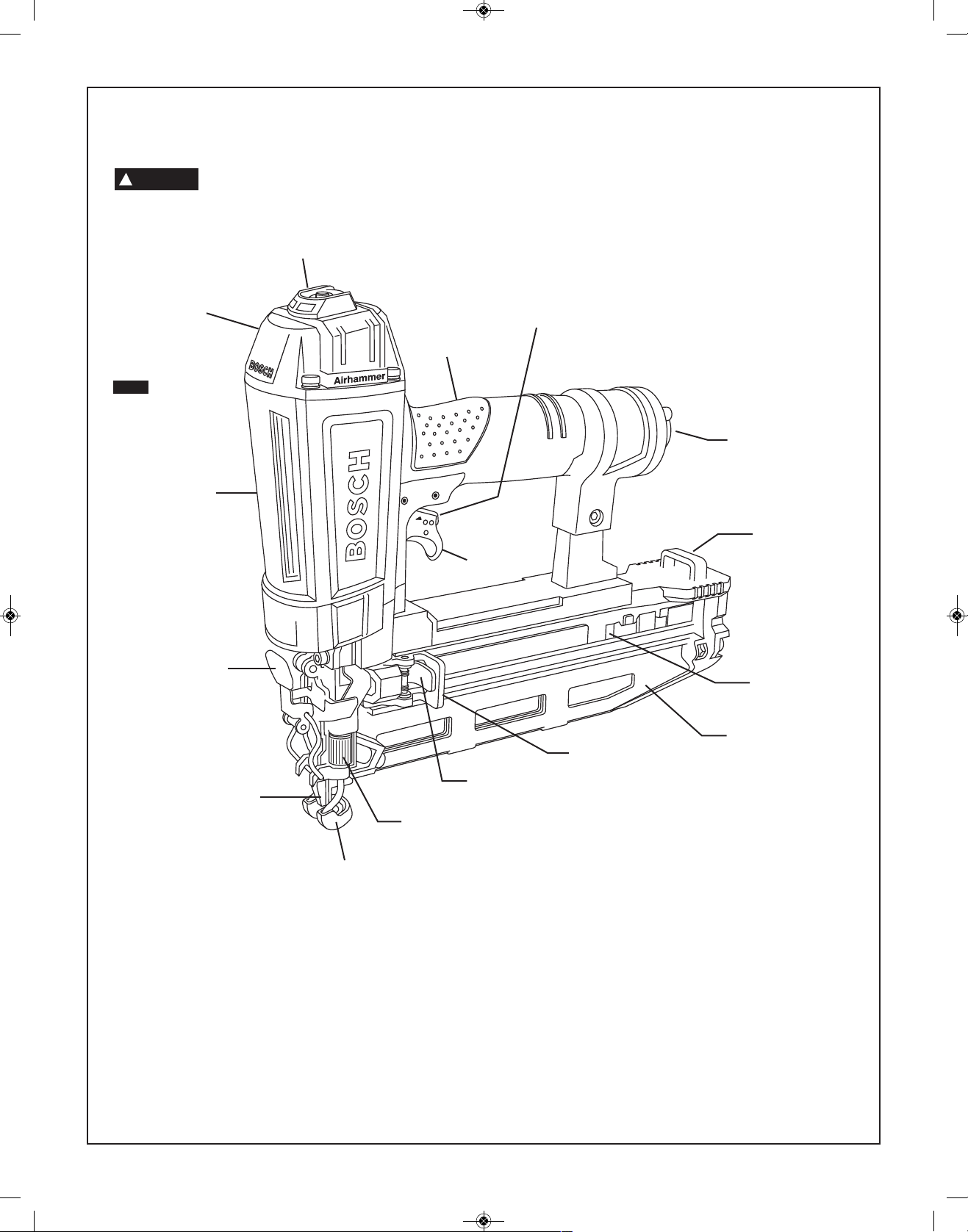

Functional Description and Specifications

Disconnect the tool from the air source before making any adjustments, changing accessories or

s

toring the tool. Such precautionary safety measures reduce the risk or unintentional tool operation.

!

WARNING

Specifications

Product Size:

Height - 11 in.

Width - 2.9 in.

Weight: 3.6 lbs.

Normal Operating Pressure: 60 to 120 PSI

Magazine Capacity: 100 Nails

Maintenance: Oiling

Firing Modes: Bump Fire or Sequential Fire

Air Consumption, one shot per second @ 100 psi: 2.6 CFM

Maximum Capacities

Nails: Diameter 16 gage

Length (Range): 1 in. to 2-1/2 in.

Nail Loading & Change Out: Back

Additional Features

Tool-Less No-Mar Tip

Adjustable Exhaust

Deflector

Depth of Drive Adjustment

No-Mar Tip

Housing

Top Cap

Work Contact

Element

Trigger

Magazine

Selectable Firing

Mode Switch

Nail Follower

Air Fitting

(Not Included)

Handle

Quick

Release

Lever

FIG. 1

Bypass Lever

No Mar Tip

Storage

Nail Hold

Back Spring

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 5

Page 6

6.

Operation

Assembly / Installation

Follow the instructions below t o p repare your tool for

operation.

1. All tool operators and their immediate supervisors must

become familiar with the operator safety instructions

before operating the tool. The instructions begin on page

3 of this manual.

2. In c l u d ed with each t o o l are o n e c o p y of t h e s e

Operating/Safety Instructions and one copy of the Tool

Schematic. Keep these publications for future reference.

3. Install a filter, regulator, lubricator unit and moisture trap

on yo ur air delive ry s ystem p er t he manu fact urer 's

instruction s for these devices. Additionally, install a

pressure g a u g e a s close a s practical to the to o l ,

preferably within ten feet.

4. Select hoses with a minimum inner diameter of 3/8 inches

and a maximum length of 100 feet.

To reduce the risk of injury from a hose

bursting, select hoses that are rated at

least 200 PSI.

5. Select fittings that are appropriately sized for the selected

hoses. The tool and air hose must have a hose coupling

such that all pressure is removed from the tool when the

coupling joint is disconnected.

Never use non re l i e v i n g co u p l e r s

and/or female q u i c k di s c o n n e c t

couplings on the tool. Non relieving couplings and

female couplings will trap high pressure air in the tool

when the air line is disconnected. This will leave the tool

charged with enough air after it has been disconnected to

drive a nail. Only MALE pneumatic type air connectors

should be fitted to the tool, so that high pressure air in the

tool is vented to atmosphere as soon as the air line is

d

isconnected.

6. Set the regulator at the air delivery system to a PSI that

falls within the tool's operating range of 60 to 120 PSI.

The correct pressure is the lowest pressure that will do

the job.

7. If the o pera tor is w orki ng a t a be nch or t able , it is

recommended to run the air line underneath the bench. A

small tray under the bench top can hold the nail supply

and the tool when not in use.

Actuation System

Your tool is equipped with two devices that require actuation

before the tool will fire, the work contact element and the

finger trigger. There are two selectable modes, built into the

trigger, that determine how the tool fires nails.

“Sequential” Firing Mode: In “sequential” firing mode,

there is a predetermined sequence required to fire a nail.

The work contact element must first be depressed against

the work piece. A nail will then fire when the trigger is

depressed. To fire another faster, the work contact element

must be removed from the work piece, the trigger must be

released. The sequence can then be repeated.

“Bump” Firing Mode: In “Bump” firing mode, nails can be

fired each time the work contact element is depressed with

th e tri g ger d e pressed . Wi t h th e tri g ger c o ntinuou s ly

depressed, a nail will fire each time the work contact

element is depressed against the work piece. This allows

for nails to be fired at a faster rate.

Each mode is described in detail in the “Firing Modes”

section of this manual.

Understand t h e differences be t w e e n

actuation modes for this tool. Using the

tool in an inappropriate mode may cause tool to react in an

unexpected manner and may result in personal injury.

Verify the setting of the Selectable trigger

switch before using the tool. Using the tool

before verifying the actuation mode may cause tool to react

in an unexpected manner and may result in personal injury.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 6

Page 7

7.

Operation

2-3 Drops

of Air Tool

L

ubricant

FIG. 2

MAXIMUM

LOAD

FIG. 3

Lubrication

If the tool is not used with an in-line lubrication system on

the air supply it is necessary to periodically lubricate the tool

with air tool lubricant.

U

nder low use, lubricate once a day. Under heavy use,

lubricate twice a day. To lubricate, insert 2-3 drops of

lubricant into the air supply fitting attached to the tool

handle, see figure 2. Using to much oil will cause it to collect

i

n the tool and be noticeable in the exhaust.

Use only the air tool lubricants supplied

with the tool or specified by BOSCH. Do

not use other lubricants as they may damage the tool.

Do not use detergent oil, WD-40, transmission fluid, motor

oil, or other lubricants not specifically designated as air tool

lubricants. These lubricants will cause accelerated wear to

the seals, o-rings, and bumpers in the tool, resulting in poor

tool performance and frequent maintenance.

BOSCH recommended lubricants: 10W Pneumatic Tool Oil,

Fuchs Air Lube 10W/NR.

Nail Loading

Always load nails into the tool's magazine

before the air su p p l y is connected.

Connecting the air supply after loading nails reduces the risk

of unintentionally driving a nail and injuring yourself or

someone else.

When loading the tool's magazine, check

that the nail follower slides smoothly by

pulling with finger. If not smooth, nails can be driven at

irregular angle.

1. Insert appropriate collated nail strips into loading slot in

back of magazine, see figure 3. See tool specifications to

determine appropriate nail sizes and angles.

2. Orient a strip of approved nails with the tips pointed down,

and align the head of the nail with the top “T” portion of

the slot. Insert nails fully into magazine making sure that

the last nail in the strip slides past the Nail Hold Back

Spring, see figure 4.

Note: The tool features a nail follower lockout that will

prevent the tool from firing when there are zero nails left

in the magazine. The tool will not allow the work contact

element to be depressed when there are no nails in the

tool.

Use only the nails meeting the criteria

listed in the “Specification” section of this

manual. Nails not identified for use with this tool can cause

the tool to malfunction and result in the risk of injury and/or

tool damage.

!

WARNING

!

WARNING

!

WARNING

FIG. 4

!

WARNING

H

ead of

nai

l

I

N

S

ER

T

N

A

I

L

S

TR

I

P

Nail Hold

Back

T-slot

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 7

Page 8

8.

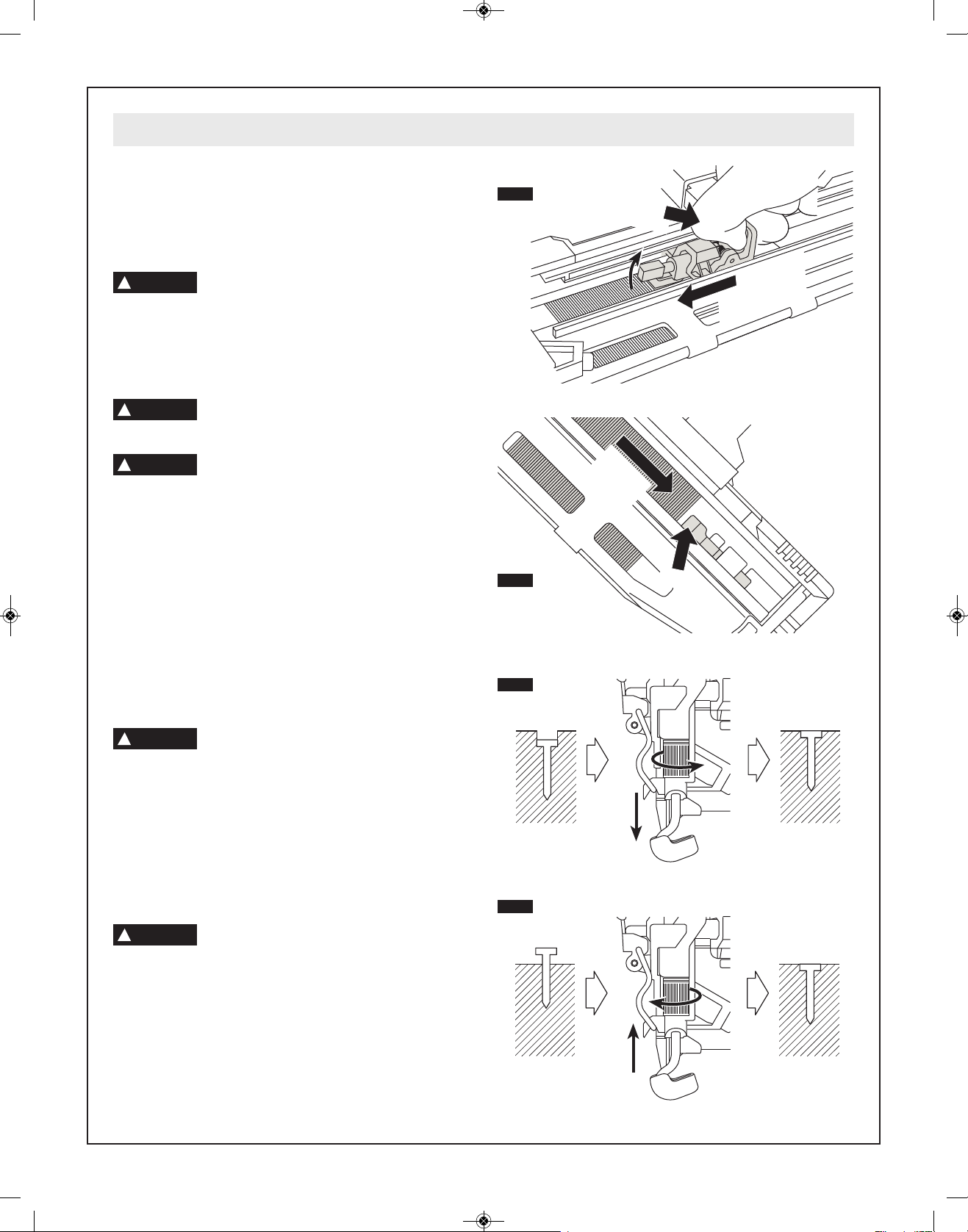

3. This tool uses a spring loaded bypass lever in order to

load and unload the nails. Once the nails are properly

inserted, pull the follower completely to the back of the

magazine, pressing aga ins t the by pas s l eve r of the

follower, see figure 5.

4. Once the follower hits the back of the magazine, allow the

follower to slide forward and engage the nails, pushing

them to the nose of the tool, see figure 6.

Watch for pinch points with the follower.

Never place any part of your body in a

pinch point area. When loading nails consider where your

hand is located. If it is within a pinch point, strongly consider

an alternative position. Injuries occur when hands or fingers

are between moving and stationary parts during the pinching

movement.

Connecting Air Supply

Never use oxygen or other bottled gases

as a power source. Explosion may occur.

Combustible gases and other bottled gases are dangerous

and may cause the tool to explode.

Never connect the tool to an air source

that is capable of producing air pressure

exc e e d i n g 200 PSI. E x cessive p r e s s u re ca n cause

abnormal operation or cause the tool to burst, resulting in

personal injury.

Use only clean, dry, regulated compressed air within the

pressure range as marked on the tool. The correct pressure

is the lowest pressure that will do the job.

Before connecting the tool to the air supply, check the air

compressor regulator gauge to be sure it is functioning

properly, and that the air pressure is within the operational

range of the tool, 60-120 psi.

Do not exceed maximum recommended

air pressure marked on the tool. Verify

prior to using the tool that the air source has been adjusted

within the rated air-pressure range. Be sure the air pressure

gauge is operating properly and check it at least twice a day.

Tools operated in excess of their maximum pressure rating

may operate abnormally or burst resulting in personal injury

To connect the tool to the compressor only use pneumatic air

hoses that meet the following criteria:

• Minimum hose pressure rating, 200 psi

• Minimum hose inner diameter, 3/8 in.

• Maximum hose length, 100 ft.

To connect the air supply:

1. Snap the air hose onto the quick connector, see figure 7.

2. Check for air leakage. If leakage is noted, cease using the

tool immediately and contact your BOSCH service center.

3. Be sure the air pressure gauge is operating properly and

check it at least twice a day.

Operation

!

WARNING

!

WARNING

!

WARNING

!

WARNING

FIG. 7

PRESS

B

y

pa

s

s

L

ev

e

r

S

L

IDE

B

A

C

K

SLIDE FOR

WA

RD

ENGAGE

NAILS

FIG. 5

FIG. 6

Release

Bypass Lever

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 8

Page 9

9.

Firing Modes

The tool is equipped with a trigger that can select one of two

firing modes.

“Sequential” Firing Mode:

To use the tool to drive nails in this actuation mode, the

work contact element and trigger must be used in a specific

order:

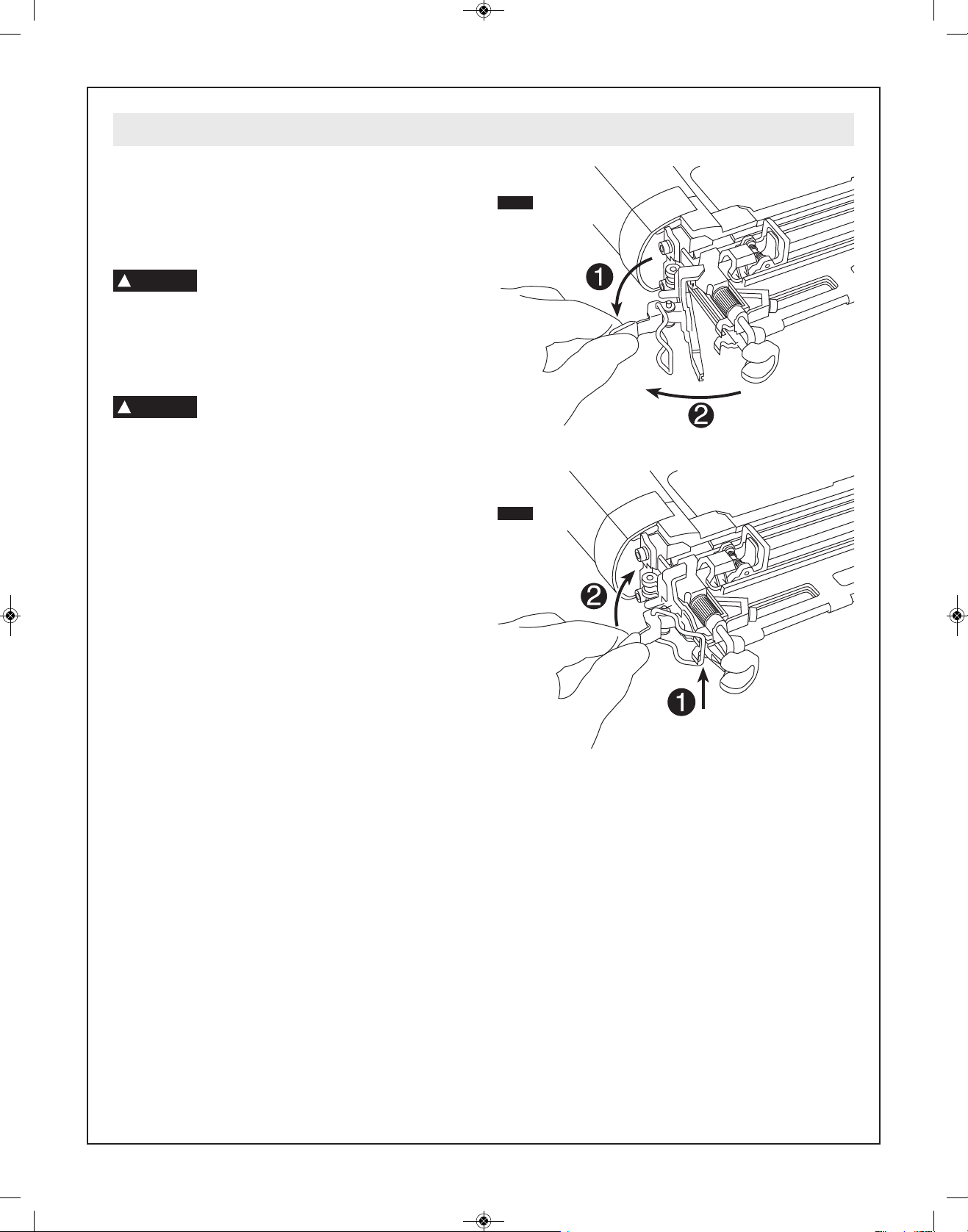

1. Press and turn the selectable fire mode switch in the

downwards position. On the trigger, the firing mode

indicator should be pointing at the single nail icon, see

figure 8.

2. The work contact element must be completely depressed

by placing the nose of the tool against the work piece, see

figure 9.

3. The trigger must be pulled firmly and then released, see

figure 9.

4. The tool must be allowed to recoil away from the work

piece.

To continue operation in a separate location, move the tool

along the wo rk piece, repeating steps 2 through 4 as

required.

“Bump” Firing Mode:

To use the tool to drive nails in this actuation mode the work

contact element and trigger can be actuated in any order.

1. Press and turn the selectable fire mode switch in the

upwards position. On the trigger the actuation mode

indicator should be pointing at the multi-nail icon, see

figure 10.

2. Pull and hold the trigger with the tool off the work piece.

3. Press the work contact element against the work piece. A

nail will be driven, see figure 11.

4. The tool must be allowed to recoil away from the work

piece.

5. Move the tool along the work piece with a bouncing

motion. Each time the work contact element is depressed

a nail will be driven, see figure 11.

6. As soon as the desired number of nails has been driven,

remove finger from trigger.

Remove finger from the trigger when not

driving nails. Always carry the tool by the

handle only. Removing your finger from the trigger when

not operating the tool reduces the risk of unintentionally

firing a nail and injuring yourself or someone else.

The tool must be allowed to recoil away

from the work piece. Do not drive a nail

on top of another nail. If the tool is not moved before the

trigger is pulled again a second nail will be driven on top of

the previously driven nail. This could cause the nail to be

deflected or the tool to react in an unexpected manner.

Operation

!

WARNING

!

WARNING

Bump Fire

Position

Press

then

turn

down

Press

then turn

up

Sequential

Fire Position

Trigger

FIG. 8

FIG. 9

FIG. 10

FIG. 11

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 9

Page 10

10.

Cold Weather Operation

When using the tool in cold conditions the tool will cycle

slower than usual while driving the first nails. The cycle rate

will increase as the tool warms up. Keep tool warm to avoid

r

educed cycle rate.

Do not use a frozen tool. Allow tool to thaw

before using. Moisture frozen in the tool may

impede internal components resulting in the risk of injury

a

nd/or tool damage.

Nail Unloading

Always disconnect tool from air supply

before removing nails from magazine.

This avoids the risk of unintentional operation.

Do not disconnect air hose from the tool

with finger on trigger or work contact

element depressed. The tool can fire when reconnected to

air supply.

1. Disconnect air supply.

2. Pull back follower, pressing bypass lever of the follower to

allow follower to bypass nails and slowly allow follower to

return to nose of the tool, see figure 12.

3. Tilt the tool with the magazine vertical and the nose facing

up, this will allow the nails to slide to the back of the

magazine.

4. Once the nails have slid back to the hold back spring,

press the tab on the hold back spring to push the spring

back and allow the nails to come out of the magazine, see

figure 13.

Do not allow the nail follower to freely

recoil. Guide the follower by hand until it

reaches its full forward position. Free recoil o f t he

follower could result in damage to the follower and/or

magazine or your fingers could become pinched.

Depth of Drive Adjustment

The depth with which nails are driven into the work piece

can be adjusted using the depth adjustment on the nose

piece of the tool.

Disconnect the tool from the air source

before ma k i n g adjustments. Such

precautionary safety measures reduce the risk or

unintentional tool operation.

1. Disconnect tool from air supply.

2. Re m o v e na i l s from tool as described in the “ Na i l

Unloading” section of this manual.

3. Adjust tool driving depth:

• To reduce the nail depth, turn the adjustment knob

counter clockwise, see figure 14.

Operation

PRESS

B

y

pa

s

s

Le

v

e

r

SL

IDE

F

OR

WA

R

D

O

V

E

R

N

A

I

L

S

T

R

I

P

PRE

SS

REL

EA

SE

NA

IL

S

FlushToo Deep

Turn the adjustment knob counter clockwise.

Turn the adjustment knob clockwise.

Too Shallow

Flush

FIG. 13

FIG. 12

FIG. 14

FIG. 15

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 10

Page 11

11.

• To drive the nail deeper, turn the adjustment knob

clockwise, see figure 15.

4. Reload nails as described in the “Nail Loading” section of

this manual.

5. Reconnect air supply

Know what is behind your work piece.

Do not fire nails into w alls o r floor s

without assuring the area on the opposite side is clear.

A nail could travel through the work piece, striking someone.

Jam Clearing

Disconnect the tool from the air source

before attempting to clear a jammed nail.

Such precautionary safety measures reduce the risk or

unintentional tool operation.

If a nail becomes jammed in the nosepiece, follow these

instructions to remove the jammed nail:

1. Release the trigger.

2. Disconnect the air supply from the tool.

3. Remove nails from the magazine as described in “Nail

Unloading.”

4. Open the nose of the tool by pulling quick release lever

forward. Pull open the nose of the tool to access the nail

jam, see figure 16.

5. Remove the nail, using pliers if necessary.

6. Close the nose of the tool by hooking the spring of the

quick clear lever on the two hooks on the nose. Press the

lever closed, see figure 17.

7. Reinsert nails into the magazine as described in “Nail

Loading”.

8. Reconnect air supply as described in “Connecting Air

Supply”.

NOTE: If the driver blade does not return to its up position,

disconnect air supply and contact a Bosch factory service

center or authorized Bosch service station.

NOTE: If nails continue to jam frequently in the nose piece,

contact BOSCH service center for repair.

Adjustable Exhaust Deflector

This tool has an adjustable exhaust deflector that allows the

exhaust air to be blown away from user or workpiece.

Operation

!

W

ARNING

!

WARNING

FIG. 16

FIG. 17

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 11

Page 12

12.

Maintenance

Service

M

aintenance performed by unauthorized

personnel may result in misplacing of the

internal components which could cause serious hazard.

We recommend that all tool service be performed by a

BO SCH fac tory se rvic e cente r or authorized BOSCH

service station.

Contact your BOSCH service center for instructions and the

following user replaceable parts; o-rings, bumpers, and

driver blades.

For all other repairs contact your BOSCH service center.

Cleaning

When cleaning a tool be careful not to

disassemble any portion of the tool since

in t ernal com ponent s ma y be mi s place d or saf e ty

co mpone nts m ay b e im prope rly mount ed. C ertai n

cleaning agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts and o-rings.

Do not att e mpt t o cl ean b y in sertin g

pointed objects through openings. Sharp

edges may damage internal components causing a serious

hazard.

Ventilation openings, the work contact element, and the

trigger must be kep t clean and free of fore ign matter.

Periodically clean the tool with compressed air.

Clean the magazine. Remove plastic or wooden chips

which may have accumulated in the magazine. Lubricate

the magazine with pneumatic tool lubricant.

Storage

When not in use, the tool should be disconnected and

stored in the storage case in a warm and dry place. When

tool will not be in use for an extended period, apply a thin

coat of the lubricant to the steel parts to avoid rust.

Do not store the tool in a cold weather environment.

Keep out o f reach o f c h i l dr e n and

personnel unfamiliar with tool operation.

Lock the storage area. Tools are dangerous in the hands of

personnel unfamiliar with the tool.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

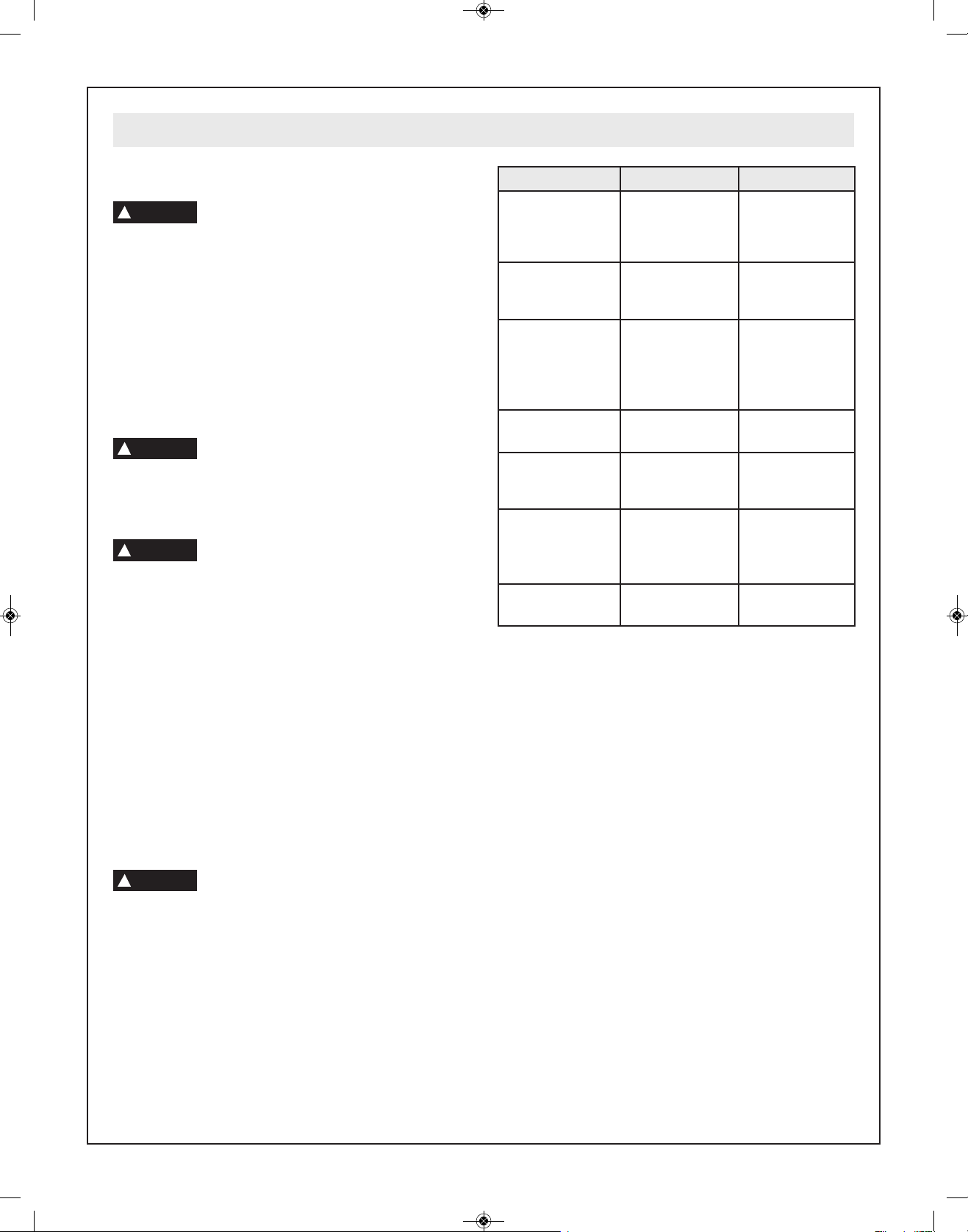

ACTION WHY HOW

D

rain air line filter

daily.

P

revent

accumulation of

moisture

and dirt.

O

pen manual

valve.

Keep lubricator

filled

Keep the Nailer

lubricated

Fill with BOSCH

pneumatic tool

lubricant.

Clean filter element

- then blow air

through filter in

direction opposite

to normal flow.

Prevent clogging

of filter with dirt.

Follow

manufacturer's

instructions.

Clean magazine

and feeder

Prevent a jam. Blow mechanism

clean daily.

Keep work contact

element working

properly

Promote operator

safety and efficient

tool operation.

Blow clean daily.

Lubricate the tool. Extend tool life. Place 2-3 drops of

lubricant

into the tool as

directed.

Drain air

compressor.

Keep water out of

tool.

Open valve on air

compressor tank.

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 12

Page 13

13.

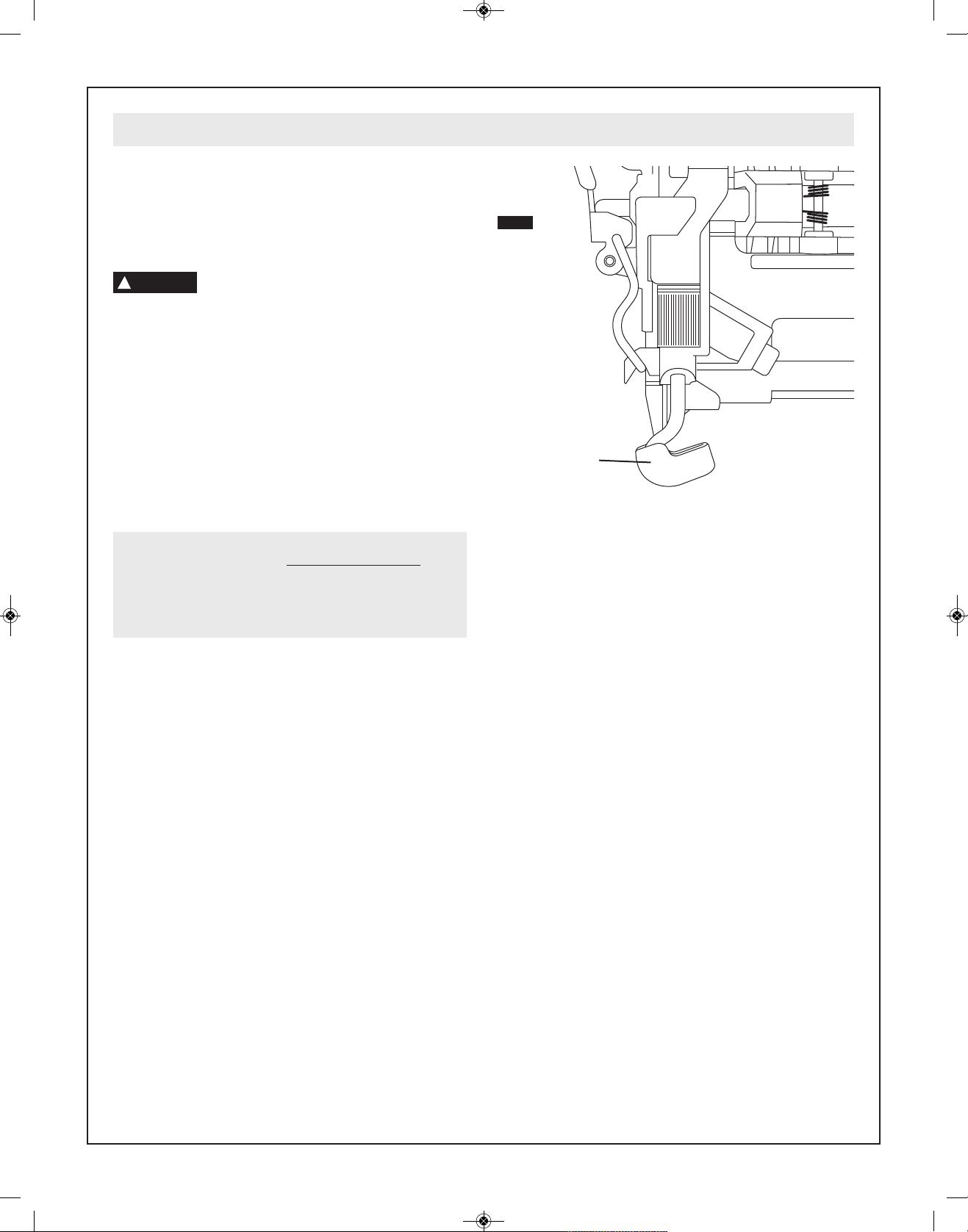

No-Mar Pad

T

he No-Mar Pad on the nose of the work contact element

protects the work piece from the work contact element toe

nailing teeth when the work piece contact is compressed

during actuation. The pad can be removed and replaced.

Disconnect the air supply from the tool

and remove nail strips before removing

or replacing no-mar pads. Such precautionary safety

measures reduce the risk or unintentional tool operation.

To remove the pad: Pull the no mar tip towards the back of

the tool following the bend of the wire nose.

To replace the pad. Push the no mar tip on to the tool

inserting the opening of the no mar tip on to the wire nose.

Compressor

A correctly sized compressor is critical for maximum tool

performance. Use the following calculation to determine the

required compressor size.

Air Consumption, one shot per second @ 100 psi: 2.6 CFM

No-Mar Pad

FIG. 18

Accessories

!

WARNING

Compressor size (CFM) =

60

x Shots per minute x Number of tools x 1.2

Air Consumption(CFM)

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 13

Page 14

14.

Troubleshooting

PROBLEM SYMPTOMS RESOLUTION

Nailer operates, but no

nail is driven.

• Check for a jam.

• Check function of nail follower.

• Follower spring weakened or damaged?

•

Check for proper nails.

• Verify tool is loaded.

• Clear a jam.

• Clean and lubricate.

• Replace follower spring.

•

Use only recommended nails.

• Reload tool.

Nail driving action seems

slow or weak.

• Check air pressure is in operational range.

• Driver blade worn?

• Piston O-ring worn or damaged?

• Bumper worn?

• Check recommend hose diameter and length.

• Increase air pressure (Do not exceed 120 psi).

• Use pneumatic tool lubricant.

• Contact Bosch for replacement or repair.

• Replace Bumper.

• Follow recommendations.

• Check hose for kinks.

Tool drives nails too

deep.

• Check air pressure.

• Check Depth of Drive.

• Check bumper wear.

• Reduce air pressure. Min. Operational

pressure 60 psi.

• Use “Depth of Drive Adjustment”.

• Replace bumper.

Tool drives nails too

shallow.

• Check air pressure.

• Check Depth of Drive.

• Check recommend hose diameter and length.

• Increase air pressure. Max. Operational

pressure 120 psi.

• Use “Depth of Drive Adjustment”.

• Follow recommendations.

• Check hose for kinks.

Tool skips nails or has

intermittent feed.

• Check for proper nails.

• Check function of magazine per page 7.

• Follower spring weakened or damaged?

• Piston O-ring cut or heavily worn?

• Use only recommended nails.

• Clean and lubricate.

• Replace follower spring.

• Contact Bosch for replacement.

Nails jam frequently. • Check for proper nails. • Use only recommended.

Driven nails are bent. • Driver blade worn? • Contact Bosch for replacement.

Nails driven properly

during normal operation,

but does not drive fully at

faster nailing speeds.

• Check inside diameter of air hose.

• Check suitability of compressor.

• Use correct air hose.

• Use correctly sized compressor for number of

tools used and work rate.

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 14

Page 15

15.

Consignes générales de sécurité pour les outils pneumatiques

TOUS LES UTILISATEURS ET EMPLOYEURS/PROPRIÉTAIRES DOIVENT LIRE ET COMPRENDRE TOUTES LES

INSTRUCTIONS DE CE MODE D’EMPLOI AVANT D’UTILISER CET OUTIL OU DE PROCÉDER À SON ENTRETIEN. Le non-

respect des instructions indiquées plus bas risque de causer un choc électrique, une blessure personnelle grave ou même la mort.

CONSERVER CES INSTRUCTIONS

Espace de travail

Gardez votre espace de travail propre et bien éclairé. Les établis

encombrés et les zones mal éclairées augmentent les risques

d’accidents, de chocs électriques, d’incendies et de blessures aux

personnes.

N’utilisez pas d’outils pneumatiques dans des atmosphères

explosives, comme en présence de liquides, de gaz ou de poussières

inflammables. L’outil peut produire des étincelles qui risquent

d’enflammer la poussière ou les fumées. N’utilisez jamais l’outil à des

endroits où il y a de la laque, de la peinture, de la benzine, du diluant, de

l’essence, des gaz, des agents adhésifs ou d’autres matériaux qui sont

combustibles ou explosifs.

Ne laissez pas d’autres personnes, des enfants et autres visiteurs

s’approcher d’un outil pneumatique en marche. Des distractions

risquent de causer une perte de contrôle de l’outil. Des fragments

d’éléments de fixation pourraient causer des blessures aux personnes

présentes.

Ne chahutez jamais avec l’outil. Respectez l’outil comme instrument de

travail.

Sécurité personnelle

Il ne faut pas retirer ou altérer les commandes de l’outil, ou les

désactiver ou les rendre inutilisables de quelque façon que ce soit.

Ceci causerait un fonctionnement irrégulier de l’outil et risquerait de

causer des blessures.

Habillez-vous de façon appropriée. Ne portez pas de vêtements lâches

ou de bijoux. Confinez les cheveux longs. Gardez vos cheveux,

vêtements et gants à distance des pièces en mouvement. Les

vêtements lâches, les bijoux et les cheveux longs risqueraient d’être

happés par des pièces en mouvement et augmenter le risque de

blessure.

Portez toujours des équipements de protection des yeux et des oreilles

lorsque vous utilisez cet outil. Utilisez des équipements de protection

individuelle additionnels suivant les besoins lorsque vous utilisez cet

outil. Les opérateurs et les autres personnes se trouvant sur le lieu de

travail doivent porter des lunettes de sécurité avec des écrans de

protection latéraux, et ils doivent s’assurer que toutes les autres

personnes se trouvant à proximité portent des lunettes de sécurité. Les

lunettes de sécurité doivent être conformes aux stipulations de

l’American National Standards Institute, ANSI Z87.1, et elles doivent

assurer une protection contre les particules atmosphériques sur le devant

comme sur les côtés. Une exposition prolongée à des bruits de grande

intensité risquerait de causer une perte auditive. Il faut utiliser un masque

antipoussières, des chaussures de sécurité à semelle antidérapante, un

casque et d’autres équipements de protection individuelle en fonction des

conditions de travail.

Gardez les poignées sèches, propres et sans huile ni graisse. Des

mains glissantes ne peuvent pas contrôler l’outil de façon sûre.

Évitez de diriger l’air d’échappement sortant de l’outil vers votre

visage et vos yeux, ou vers ceux des autres personnes présentes. L’air

d’échappement d’un outil peut contenir de l’eau, de l’huile, des particules

de métal ou des contaminants du compresseur, qui pourraient être

projetés dans les yeux ou causer d’autres blessures graves. Utilisez

l'évent réglable pour diriger l'air d'échappement dans le sens opposé de

celui où se trouve l'opérateur.

Restez alerte. Surveillez toujours ce que vous êtes en train de faire et

faites preuve de bon sens quand vous utilisez un outil pneumatique.

N’utilisez pas l’outil lorsque vous êtes fatigué ou sous l’influence de

drogues, d’alcool ou de médicaments. Un moment d’inattention

pendant que vous utilisez l’outil pourrait causer des blessures corporelles

graves.

Évitez tout mouvement accidentel de l’outil. N’appuyez pas sur la

gâchette pendant que vous êtes en train de connecter l’outil à la

source d’alimentation en air. Ne transportez pas l’outil avec votre doigt

sur la gâchette, et ne connectez pas l’outil à la source d’alimentation en

air alors que l’interrupteur est sur « On » (Marche).

Faites attention de ne jamais perdre l’équilibre. Soyez toujours bien

stable et équilibré sur vos pieds. La stabilité et un bon équilibre vous

permettent de mieux contrôler l’outil dans des situations inattendues.

Assurez-vous que le tuyau d’air n’est pas obstrué ou partiellement

bouché. N’attachez pas un tuyau d’air ou l’outil sur votre corps. Des

tuyaux emmêlés ou enchevêtrés risquent de vous perdre l’équilibre et de

vous faire tomber, en plus du risque d’utilisation accidentelle de l’outil.

Attachez le tuyau à la structure pour réduire le risque de perte d’équilibre

si le tuyau bougeait.

Utilisation et entretien de l’outil

Utilisez cet outil et ses accessoires conformément aux instructions.

Les outils et leurs accessoires doivent être utilisés dans le but pour lequel

ils sont conçus. L’emploi de l’outil pneumatique pour des opérations

différentes de celles qui sont décrites dans ce mode d’emploi peut créer

une situation dangereuse.

Utilisez seulement des accessoires qui sont recommandés par BOSCH

pour votre modèle particulier. Des accessoires qui peuvent être

recommandés pour un modèle d’outil particulier ne sont peut-être pas

appropriés pour d’autres modèles d’outils et pourraient causer des

blessures corporelles.

Inspectez l’outil avant chaque utilisation. N’utilisez pas cet outil si une

partie quelconque de l’outil est lâche, manquante, endommagée,

défectueuse, déconnectée ou altérée. Si l’outil ne semble pas

fonctionner normalement et/ou s’il fait des bruits inhabituels, cessez

immédiatement de l’utiliser et contactez votre centre de service aprèsvente local. Il existe un risque d’éclatement si l’outil est endommagé.

Ne forcez pas l’outil. Utilisez l’outil correct en fonction de votre

application. L’outil correct fera mieux le travail et avec plus de sécurité à

la vitesse pour laquelle il a été conçu.

N’utilisez pas l’outil avec une source d’alimentation électrique

différente de ce qui est indiqué dans les consignes d’utilisation et de

sécurité de l’outil. L’utilisation de sources d’alimentation électrique

différentes pourrait causer un mauvais fonctionnement de l’outil et de la

source d’alimentation électrique, ce qui risquerait de vous blesser

grièvement ou de blesser grièvement d’autres personnes se trouvant

près de vous.

Débranchez l’outil de la source d’alimentation en air quand il n’est

pas utilisé. Si vous laissez l’outil sans surveillance avec la source

d’alimentation en air connectée, vous risquez de permettre son utilisation

par des tiers qui le maîtrisent mal.

!

AVERTISSEMENT

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 15

Page 16

16.

Débranchez l’outil de la source d’alimentation en air avant de

p

rocéder à des réglages, de déboucher un tuyau obstrué ou de

détacher des éléments de fixation, de vous éloigner de l’aire de

travail, d’effectuer une opération de maintenance de l’outil ou de le

ranger. De telles mesures de précaution réduisent le risque d’utilisation

accidentelle de l’outil.

Ne transportez jamais l’outil en le tenant par le tuyau. L’outil, les

garnitures et le tuyau d’air pourraient être endommagés en conséquence.

Utilisez des pinces ou un autre moyen pratique d’assujettir et de

supporter l’ouvrage sur une plateforme stable. Le maintien de l’ouvrage

à la main ou contre votre corps est instable et risque de causer la perte

de contrôle de l’outil ou une blessure corporelle.

La pression correcte est la pression la plus faible qui permettra de

faire le travail. Suivez toujours les recommandations correspondant à

l’outil concerné.

Entretenez soigneusement les outils. Des outils entretenus correcte -

ment risquent moins de se casser et de causer des blessures. Toute

altération ou modification est considérée comme une utilisation abusive

et risque de produire une situation dangereuse.

Service

Toute opération de maintenance réalisée par du personnel non

autorisé risque de causer un repositionnement erroné de composants

internes et de créer ainsi des dangers graves. Nous recommandons

que toutes les opérations de maintenance et de réparation soient

effectuées dans un centre de service usine BOSCH ou dans une station

service agréée BOSCH.

Préparez un programme de maintenance périodique pour votre outil.

Lorsque vous nettoyez un outil, faites attention de ne pas démonter

une partie quelconque de l’outil étant donné que des composants

internes risqueraient d’être mal remis en place ou que des compo sants nécessaires à la sécurité risqueraient d’être remontés

incorrecte ment. Certains produits de nettoyage, tels que l’essence, le

tétra chlorure de carbone, l’ammoniac, etc. risquent d’endommager les

composants en plastique et les joints toriques.

Utilisez seulement des pièces de rechange recommandées par BOSCH

lors de toute opération de réparation. Suivez les instructions de la

rubrique Maintenance de ce mode d’emploi. L’utilisation de pièces non

autorisées ou le non-respect des instructions de maintenance pourrait

causer un risque de blessure.

Utilisez seulement les lubrifiants pour outil pneumatique fournis avec

l’outil ou spécifiés par BOSCH. N’utilisez pas d’autres lubrifiants car ils

risqueraient d’endommager l’outil. Voir la liste de lubrifiants pour outils

pneumatiques recommandés sous la rubrique ‘Lubrification’.

Remplacez les étiquettes d’avertissement manquantes ou

e

ndommagées. Reportez-vous aux schémas pour déterminer le

positionnement correct avec le numéro de pièce.

Gardez l’outil propre et lubrifié. Nettoyez l’outil au moins une fois par

jour et lubrifiez-le suivant les besoins. N’utilisez jamais un outil sale ou

fonctionnant mal.

Lorsque vous ne vous en servez pas, rangez l’outil hors de la portée

des enfants et des autres personnes ne maîtrisant pas le fonction nement de l’outil. Quand il n’est pas utilisé, l’outil doit être déconnecté et

rangé dans un endroit sec. Gardez hors de la portée des enfants.

Verrouillez le lieu de rangement. Les outils sont dangereux s’ils tombent

entre les mains d’utilisateurs ne maîtrisant pas leur fonctionnement.

Source d’alimentation en air

N’utilisez jamais d’oxygène ou d’autres gaz en bouteille comme

source d’alimentation. Il existerait alors un risque d’explosion. Les gaz

combustibles et les autres gaz en bouteille sont dangereux et risquent

causer l’explosion de l’outil.

N’utilisez que de l’air comprimé propre, sec et contrôlé, et dans la

plage de pression nominale indiquée sur l’outil. Ne dépassez pas la

pression d’air maximum recommandée, qui est indiquée sur l’outil.

Avant d’utiliser l’outil, vérifiez que la source d’alimentation en air a été

ajustée dans la plage de pression d’air nominale. Assurez-vous que le

contrôleur de pression d’air fonctionne correctement, et inspectez-le au

moins deux fois par jour. Les outils utilisés au-delà de leur pression

maximum nominale risqueraient de fonctionner de façon anormale ou

d’éclater, ce qui causerait des blessures corporelles.

Ne connectez jamais l’outil à une source d’alimentation en air qui est

capable de produire une pression d’air supérieure à 200 PSI. Une

pression excessive risquerait de causer un fonctionnement anormal ou

faire éclater l’outil, ce qui entraînerait une blessure corporelle.

Prenez les précautions nécessaires en manipulant le tuyau d’air.

Protégez le tuyau contre les faux plis, les obstructions, les solvants et

les objets tranchants. Gardez le tuyau d’air à distance des sources de

chaleur, d’huile, des bords tranchants et des pièces en mouvement.

Remplacez immédiatement les tuyaux endommagés. Les tuyaux

endommagés risqueraient d’éclater ou de frapper accidentellement

l’opérateur.

Inspectez tous les raccords, tuyaux et conduits, ainsi que les con nexions et le compresseur avant chaque emploi de cet outil. Réparez

ou remplacez immédiatement les tuyaux et raccords en dommagés ou

qui ont des fuites. L’endommagement d’un tuyau ou d’une connexion

risquerait de causer la rupture d’un tuyau sous pression, qui risquerait

alors de frapper accidentellement quelqu’un et de causer des blessures.

Consignes de sécurité pour les cloueuses pneumatiques

Assumez toujours que l’outil contient des clous. Inspectez le magasin

pour vous assurer qu’il ne reste pas de clous dans l’outil, même si vous

pensez que l’outil est vide ou déconnecté.

Ne pointez jamais l’outil vers vous ou vers d’autres personnes dans la

zone de travail. Assumez toujours que l’outil contient des clous.

L’éjection accidentelle de clous pourrait causer des blessures. L’outil

n’est pas un jouet, et il ne doit pas être utilisé comme s’il en était un.

Retirez le doigt de la gâchette quand vous n’êtes pas en train de

clouer. Transportez toujours l’outil en le tenant par la poignée

seulement. Le retrait de votre doigt de la gâchette lorsque vous ne vous

servez pas de l’outil réduit le risque d’éjection accidentelle d’un clou , ce

qui pourrait vous blesser ou blesser d’autres personnes présentes.

Il ne faut pas désactiver ou retirer l’élément de contact avec l’ouvrage.

Cet outil est pourvu d’un mécanisme de sécurité, l’élément de contact

avec l’ouvrage, afin de réduire le risque le risque d’éjection accidentelle

de clous. La désactivation de ce composant pourrait causer une éjection

accidentelle de clous.

N’utilisez pas l’outil si l’élément de contact avec l’ouvrage ne fonc tionne pas correctement. Si l’élément de contact avec l’ouvrage ne fonc -

tionne pas correctement, l’outil risque de se déclencher accidentellement.

N’utilisez jamais de coupleurs sans dégagement et/ou de coupleurs

femelles à déconnexion rapide sur l’outil. Les coupleurs sans

dégagement et les coupleurs femelles emprisonneront de l’air sous

pression dans l’outil lorsque la conduite d’air sera déconnectée. Ceci

laissera l’outil chargé avec suffisamment d’air après sa déconnexion pour

éjecter un clou. Seulement des connecteurs à air de type pneumatique

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 16

Page 17

17.

MÂLES doivent être attachés à l’outil, de façon que l’air sous pression

présent dans l’outil soit expulsé dans l’atmosphère dès que la conduite

d’air est déconnectée.

Suivez toutes les recommandations pour les types de tuyaux, de

raccords et autres accessoires pour l’air comprimé. Des composants

de dimensions incorrectes ou mal ajustés peuvent causer un risque de

blessure ou de dommage aux biens.

Inspectez les conduites d’alimentation d’air pour vous assurer qu’il n’y

a pas de restrictions avant de procéder au réglage de l’outil. Le

volume d’air est aussi important que la pression d’air. Un débit d’air

restreint empêchera l’outil de fonctionner de la manière prévue, ce qui

ralentira son fonctionnement, causera le blocage du mécanisme

d’alimentation en clous ou réduira sa puissance d’éjection.

Chargez toujours les clous dans le magasin de l’outil avant de réaliser

le raccordement de l’alimentation en air. Le raccordement de

l’alimentation en air après le chargement des clous réduit le risque

d’éjection accidentelle d’un clou et de blessure de l’opérateur ou de

personnes se trouvant à proximité.

Lorsque vous chargez des clous dans le magasin, assurez-vous que

les clous sont parallèles au bec de l'outil. Si les clous ne sont pas

parallèles au bec de l'outil, l'outil risque d'avoir des ratés à l'allumage et

les clous pourront être déviés, ce qui peut entraîner une réaction

imprévue de l'outil et causer des dommages à celui-ci.

Lorsque vous chargez le magasin de l’outil, assurez-vous que le

suiveur de clou glisse en douceur en tirant dessus avec le doigt.S’il ne

glisse pas en douceur, cela signifie que les clous risquent d’être éjectés à

un angle irrégulier.

N’utilisez que des clous conformes aux critères indiqués sous la

rubrique « Spécifications » de ce mode d’emploi. Des clous qui ne sont

pas identifiés comme compatibles avec cet outil pourraient causer un

fonctionnement incorrect de l’outil et entraîner le risque de blessure et/ou

d’endommagement de l’outil.

Ne connectez pas l’alimentation en air lorsque la gâchette ou

l’élément de contact avec l’ouvrage est enfoncé. Gardez l’outil pointé

vers le bas, à distance de vous-même et des autres personnes présentes,

lorsque vous connectez le tuyau afin de réduire le risque d’éjection

accidentelle de clous.

Maintenez les mains et les pieds à distance de l’élément de contact

avec l’ouvrage de l’outil pendant l’emploi. Ne mettez jamais les mains

ou les pieds à moins de 8 pouces (20 cm) de l’élément de contact avec

l’ouvrage de l’outil. La trajectoire des clous peut être déviée par l’ouvrage

ou détournée du point d’entrée.

Le choix de la méthode de déclenchement est important : il faut

comprendre les caractéristiques de fonctionnement de chacune des

options. Il y a deux modes de déclenchement possibles : le

« déclenchement à éjection séquentielle » et le « déclenchement à

éjection par butée ». Lisez et comprenez la section intitulée « Systèmes

d’actionnement » pour les détails concernant chaque mode de

déclenchement.

N’utilisez pas un outil gelé. Laissez l’outil se dégeler avant de vous en

servir. L’humidité gelée à l’intérieur de l’outil risquerait d’affecter le

fonctionnement de composants internes et de causer des risques de

blessure et/ou d’endommagement de l’outil.

Ne mettez l’outil en marche que quand il est positionné correctement

sur l’ouvrage. Si l’outil n’est pas maintenu en place correctement sur

l’ouvrage, le clou risque d’être dévié ou l’outil risque de réagir de façon

inattendue.

Tenez l’outil assez fermement pour pouvoir bien le contrôler tout en

lui permettant de rebondir à une certaine distance de la surface de

travail lorsque le clou y est enfoncé. Ne tentez pas d’empêcher le

rebond en appuyant l’outil avec une force excessive contre l’ouvrage.

L’outil rebondira lorsque le clou sera enfoncé. Ceci est normal pour

l’outil. La restriction du rebond pourrait causer l’éjection d’un second

clou lorsque l’outil est dans le mode de « déclenchement à éjection par

butée ».

Prenez les précautions nécessaires lorsque vous utilisez l’outil dans

des zones restreintes. Si vous laissez l’élément de contact avec l’ouvrage

entrer à nouveau en contact avec la surface de travail avant que la

gâchette ne soit relâchée, un autre clou risque d’être éjecté

accidentellement si l’outil est dans le mode de « déclenchement à

éjection par butée ».

Afin de ne pas risquer l’éjection non souhaitée de deux clous à la fois,

faites ce qui suit lorsque l’outil est dans les modes de déclenchement

suivants :

Déclenchement à éjection séquentielle :

1. Assurez-vous que la gâchette est dans le mode de déclenche ment à éjection séquentielle.

2. Tirez fermement sur la gâchette, puis relâchez-la.

Déclenchement à éjection par butée :

1. N’appuyez pas l’outil contre le bois avec une force excessive.

2. Laissez l’outil se séparer du bois pendant le rebond qui fait suite

à l’enfoncement du clou.

N’enfoncez jamais de clous à proximité de matériaux inflammables.

Certains types de clous risquent de sortir par le bec pendant l’opération

de clouage.

Sachez ce qui se trouve derrière votre ouvrage. N’enfoncez pas de

clous dans le mur ou dans le plancher sans vous assurer qu’il n’y a

rien de dangereux de l’autre côté. Un clou pourrait traverser l’ouvrage

et frapper quelqu’un.

N’enfoncez pas un clou au-dessus d’un autre clou. Ceci pourrait faire

dévier le clou ou faire réagir l’outil d’une manière imprévue.

Ne tentez pas d’enfoncer des clous à un angle très incliné. Ceci

pourrait faire dévier le clou ou faire réagir l’outil d’une manière imprévue.

Prenez les précautions nécessaires lorsque vous enfoncez des clous

dans un matériau fin ou lorsque vous travaillez près des bords et des

coins de l’ouvrage. Les clous pourraient traverser complètement

l’ouvrage ou être éjectés à côté de celui-ci, ce qui vous pourrait vous

blesser ou blesser quelqu’un d’autre. Sachez que clou peut suivre le grain

du bois et ressortir de façon inattendue sur le côté de l’ouvrage. Enfoncez

les clous perpendiculairement au grain.

N’enfoncez pas de clous dans des murs, des planchers ou d’autres

surfaces de travail sans savoir ce qui risque d’être endommagé par

les clous ainsi enfoncés. Des clous enfoncés dans des fils électriques

sous tension, des canalisations, des conduites de gaz ou d’autres types

d’obstructions peuvent causer l’électrocution de l’opérateur, une

explosion, une blessure corporelle et/ou des dommages aux biens.

Assurez-vous que la pression du compresseur est ajustée de façon que

les clous soient enfoncés au ras de l’ouvrage et ne traversent pas

complètement celui-ci. La pression correcte est la pression la plus faible

qui permettra de faire le travail.

Gardez le visage et le reste de votre corps à bonne distance du

capuchon du haut lorsque vous travaillez dans des endroits restreints.

Un rebond soudain peut causer un choc affectant le corps, tout particu lièrement lorsque vous enfoncez un clou dans un matériau dur ou dense.

Manipulez l’outil avec précaution. En raison de la pression d’air élevée

dans l’outil, faites attention de ne pas laisser tomber l’outil ou de ne pas

l’égratigner ou heurter de surfaces dures avec lui ; il ne faut pas estamper

ou graver des signes sur l’outil. L’outil risquerait d’éclater.

Débranchez toujours l’outil de l’alimentation en air et retirez tous les

clous du magasin avant de sortir de la zone de travail ou de remettre

l’outil à un autre opérateur. Ceci évite le risque de déclenchement

accidentel.

Ne débranchez pas le tuyau d’alimentation en air lorsque vous avez le

doigt sur la gâchette ou lorsque l’élément de contact avec l’ouvrage

est enfoncé. L’outil peut éjecter des clous quand il est reconnecté à

l’alimentation en air.

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 17

Page 18

18.

Description fonctionnelle et spécifications

D

ébranchez l’outil de la source d’alimentation en air avant de procéder à de quelconques réglages, de remplacer des

accessoires ou de ranger l’outil. De telles mesures de précaution réduisent le risque d’utilisation accidentelle de l’outil.

Spécifications

Dimensions du produit :

Hauteur – 11 po

Largeur – 2,9 po

Poids : 3,6 lbs

Pression d’exploitation normale : 60 à 120 PSI

Capacité du magasin : 100 clous

Maintenance : huilage

Modes d’éjection : éjection par butée ou éjection séquentielle

Consommation d’air, un tir par seconde à 100 psi : 2,6 pi cu/mn

Capacités maximales

Clous : Diamètre – calibre 15

Longueur (plage) : 1 po à 2 1/2 po

Chargement et rechargement des clous : par le haut

Autres caractéristiques

Patin antimarques ne nécessitant pas d’outil pour son

installation/retrait

Déflecteur

d'échappement réglable

!

AVERTISSEMENT

FIG. 1

Poignée

Sélecteur de mode

de déclenchement

Gâchette

Levier à

relâchement

rapide

Logement

Capuchon

du haut

Élément de contact

avec l’ouvrage

Patin antimarques

Réglage de la profondeur de clouage

Levier de dérivation

Suiveur de clou

Magasin

Rangement

du patin

antimarques

Raccord d’air

(non joint)

Ressort de

retenue des

clous

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 18

Page 19

19.

Fonctionnement

Assemblage / Installation

Suivez les instructions ci-dessous pour préparer votre outil en vue de son

utilisation.

1. Tous les opérateurs de l’outil et leurs superviseurs directs doivent se

familiariser avec les consignes de sécurité pour l’opérateur avant de

commencer à se servir de l’outil. Ces consignes commencent à la

p

age 16 de ce mode d’emploi.

2. Une copie de ces consignes d’utilisation / de sécurité et une copie du

schéma de l’outil sont jointes à chaque outil. Conservez ces publi ca tions pour future référence.

3. Installez un filtre, un régulateur, un système de lubrification et un

piège à humidité sur votre système de fourniture d’air conformément

aux instructions du fabricant pour ces dispositifs. De plus, installez un

manomètre aussi près que possible de l’outil, de préférence à moins

de trois mètres de celui-ci.

4. Sélectionnez des tuyaux ayant un diamètre intérieur minimum de 3/8

po et une longueur maximum de 30 mètres.

Pour réduire le risque de blessure pouvant

résulter de l’éclatement d’un tuyau,

sélectionnez des tuyaux prévus pour une pression nominale d’au

moins 200 PSI.

5. Sélectionnez des raccords de taille appropriée pour les tuyaux

sélectionnés. L’outil et le tuyau à air doivent avoir un raccord de

fixation de tuyau tel que toute la pression soit retirée de l’outil lorsque

le joint d’accouplement est déconnecté.

N’utilisez jamais de coupleurs sans

dégagement et/ou de coupleurs femelles à

déconnexion rapide sur l’outil. Les coupleurs sans dégagement et les

coupleurs femelles emprisonneront de l’air sous pression dans l’outil

lorsque la conduite d’air sera déconnectée. Ceci laissera l’outil chargé

a

vec suffisamment d’air après sa déconnexion pour éjecter un clou.

Seuls des connecteurs à air de type pneumatique MÂLES doivent être

attachés à l’outil, de façon que l’air sous pression présent dans l’outil

soit expulsé dans l’atmosphère dès que la conduite d’air est

déconnectée.

6. Réglez le régulateur au système de fourniture d’air à une pression

(exprimée en psi) qui tombe à l’intérieur de plage de fonctionnement

de l’outil, qui est de 60 à 120 psi. La pression correcte est la pression

l

a plus faible qui permettra de faire le travail.

7. Si l’opérateur travaille sur un établi ou sur une table, il est recom mandé de faire passer la conduite d’air en dessous de l’établi. Un petit

plateau au-dessous du dessus de l’établi pourrait contenir la réserve

de clous ainsi que l’outil quand il n’est pas utilisé.

Système d’actionnement

Votre outil est muni de deux dispositifs qui nécessitent un actionnement

avant que l’outil ne puisse éjecter de clous, l’élément de contact avec

l’ouvrage et la gâchette digitale, Il y a deux modes de réglage possible,

qui sont incorporés à la gâchette, et qui déterminent comment l’outil

éjecte les clous.

Mode d’éjection « séquentielle » : dans le mode d’éjection « séquen tielle », une séquence prédéterminée est requise pour éjecter un clou. Il

faut commencer par appuyer l’élément de contact avec l’ouvrage contre

l’ouvrage. Un clou sera ensuite éjecté lorsque la gâchette sera enfoncée.

Pour en éjecter un autre plus vite, l’élément de contact avec l’ouvrage

doit être séparé de l’ouvrage et la gâchette doit être relâchée. La

séquence pourra ensuite être répétée.

Mode d’éjection « par butée » : dans le mode d’éjection « par butée », il

est possible d’éjecter des clous chaque fois que l’élément de contact avec

l’ouvrage est enfoncé avec la gâchette également enfoncée. Lorsque la

gâchette est enfoncée en permanence, un clou est éjecté chaque fois que

l’élément de contact avec l’ouvrage est appuyé contre l’ouvrage. Ceci

permet d’éjecter les clous à un rythme plus rapide.

Chaque mode est décrit en détail dans la section « Modes d’éjection » de

ce mode d’emploi.

Comprenez les différences entre les deux

modes d’éjection pour cet outil. L’utilisation

de l’outil dans un mode inapproprié peut causer une réaction inattendue

de l’outil et de causer des blessures corporelles.

Vérifiez le réglage de la gâchette réglable

avant d’utiliser l’outil. L’emploi de l’outil

avant d’avoir vérifié le mode d’éjection peut causer une réaction

inattendue de l’outil et de causer des blessures corporelles.

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

BM 2610957380 02-09:BM FNS250-16 06-09 6/17/09 8:05 AM Page 19

Page 20

20.

Fonctionnement

Lubrification

Si l’outil n’est pas utilisé avec un système de lubrification en ligne sur

l’alimentation en air, il est nécessaire de lubrifier périodiquement l’outil

avec un lubrifiant pour outils pneumatiques.

Si l’outil n’est pas utilisé fréquemment, ne lubrifiez qu’une fois par jour.

S’il est utilisé fréquemment, lubrifiez deux fois par jours. Pour lubrifier,

versez 2-3 gouttes de lubrifiant dans le raccord d’alimentation d’air

attaché à la poignée de l’outil – FIG 2. L’utilisation d’une quantité

excessive d’huile produira des résidus qui s’accumuleront dans l’outil et

pourront être constatés dans l’échappement.

N’utilisez que les lubrifiants pour outil

pneuma tique fournis avec l’outil ou spécifiés

par BOSCH. N’utilisez pas d’autres lubrifiants étant donné qu’ils

risqueraient d’endommager l’outil.

N’utilisez pas d’huile détergente, de fluide de transmission WD-40, d’huile

pour moteur ou d’autres lubrifiants qui ne sont pas spécifique ment

indiqués comme étant des lubrifiants pour outils pneumatiques. Ces

lubrifiants causeront une usure accélérée des garnitures d’étanchéité, des

joints toriques et des tampons à l’intérieur de l’outil, ce qui entraînera un

mauvais fonctionnement de l’outil et le besoin de réparations plus

fréquentes.

Lubrifiants recommandés par BOSCH : huile pour outils pneumatiques

10W, lubrifiant pour outils pneumatiques Fuchs Air Lube 10W/NR.

Chargement des clous

Chargez toujours les clous dans le magasin de

l’outil avant de connecter l’alimentation en air.

La connexion de l’alimentation en air après le chargement des clous réduit

les risques d’éjection accidentelle d’un clou et de blessure de l’opérateur ou

d’autres personnes présentes.

Lors du chargement du magasin de l’outil,

assurez-vous que le suiveur de clou glisse en

douceur en tirant dessus avec un doigt. S’il ne glisse pas en douceur, les

clous risqueraient d’être enfoncés à un angle irrégulier.

1. Insérez les bandes de clous rangés appropriées dans la fente de

chargement à l'arrière du magasin ; voir Figure 3. Voir les spécifications

de l'outil pour déterminer les tailles de clous et les angles appropriés.

2. Orientez une bande de clous approuvés avec les pointes dirigées vers le

bas, et les têtes des clous doivent être alignées avec la partie supérieure

en forme de « T » de la fente. Insérez les clous à fond dans le magasin

en vous assurant que le dernier clou de la bande glisse au-delà du

ressort de retenue des clous (voir Figure 4).

Remarque : l'outil comporte un mécanisme de verrouillage du suiveur

de clou qui empêchera le déclenchement de l'outil quand il ne reste plus

de clous dans le magasin. L'outil ne permettra pas l'enfoncement de

l'élément de contact avec l'ouvrage quand il ne reste plus de clous dans

l'outil.

Utilisez seulement des clous satisfaisant aux

critères figurant sous la rubrique « Spécifica -

tions » de ce mode d’emploi. Les clous qui ne sont pas identifiés