Bosch FMR-1000-RCMD User Manual

Remote Command Center

FMR-1000-RCMD

en Installation and Operation Guide

es Guía de Instalación y Operación

pt Manual de Instalação e Operação

FMR-1000-RCMD 3

en Installation and Operation Guide 5

es Guía de Instalación y Operación 17

pt Manual de Instalação e Operação 31

Bosch Security Systems, Inc. F.01U.078.098 | 3.0 | 2011.11

4 FMR-1000-RCMD

F.01U.078.098 | 3.0 | 2011.11 Bosch Security Systems, Inc.

Remote Command Center Table of Contents | en 5

Table of Contents

1Notice 6

2 Scope of Delivery 6

3 Device Description 6

4Mounting 7

4.1 Removing the Cover Frame 7

4.2 Surface Mounting 7

4.3 Flush Mounting 8

5 Wiring 9

5.1 Option Bus Circuit Wiring Distance 9

5.2 Wiring Connections 9

5.3 Removing the Cover Frame for Service 10

6 Inserting the Language Tab 10

7 Address Setting 11

8Programming 11

9Operating 12

9.1 LEDs and LCD Keypad 12

9.2 Lamp Test 14

9.3 Keypad Operations 14

10 Troubleshooting 15

11 Specifications 15

11.1 Electrical 15

11.1.1 Wiring Specification 16

11.2 Mechanics 16

11.3 Environmental Conditions 16

11.4 Trademarks 16

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.078.098 | 3.0 | 2011.11

6 en | Notice Remote Command Center

1Notice

These instructions cover the installation of the Bosch FMR-1000-RCMD Remote Command

Center in a fire system supervised by a Bosch FPA-1000 Analog Addressable Fire Panel or a

Fire Alarm Control Panel with similar connection conditions.

Install, test and maintain the FMR-1000-RCMD according to these instructions, NFPA 72,

Local Codes, and the Authority Having Jurisdiction. Failure to follow these instructions may

result in failure of the device to operate properly. Bosch Security Systems Inc. is not

responsible for improperly installed, tested or maintained devices.

Refer to FPA-1000- Installation and Operation Guide (P/N F.01U.174.607) for detailed wiring

style requirements and complete programming instructions.

NOTICE!

NFPA 72 requires a complete system-wide functional test be performed following any

modifications, repair, upgrades, or adjustments made to the system’s components, hardware,

wiring, programming, and software/firmware.

CAUTION!

These instructions contain procedures to follow in order to avoid personal injury and damage

to equipment.

2 Scope of Delivery

Description

One Remote Command Center (in back box with cover frame)

Tabs with different language versions for LED and key text

One hardware pack

One FMR-1000-RCMD Installation and Operation Guide

3 Device Description

The Remote Command Center FMR-1000-RCMD is a four-wire LCD annunciator with system

control capability. It shows the LEDs and LCD display identically to the panel’s and includes a

piezo, scrolling buttons, and operation keys for acknowledge [ACK], drill, reset and silence.

The scrolling functions and the acknowledge [ACK] key are accessible without restriction. The

keys for reset, silence or drill can be enabled and disabled by the device key lock. In addition,

the operation keys or all keys can be locked using DIP switches (refer to Table 7.1 on

Page 11).

The Remote Command Center features tabs with different language versions for LED and key

text. The device allows for surface and semi-flush mounting.

Each FPA-1000 Analog Addressable Fire Panel supports up to a total of eight FMR-1000-RA

Remote Annunciators and/or FMR-1000-RCMD Remote Command Centers.

F.01U.078.098 | 3.0 | 2011.11 Installation and Operation Guide Bosch Security Systems, Inc.

Remote Command Center Mounting | en 7

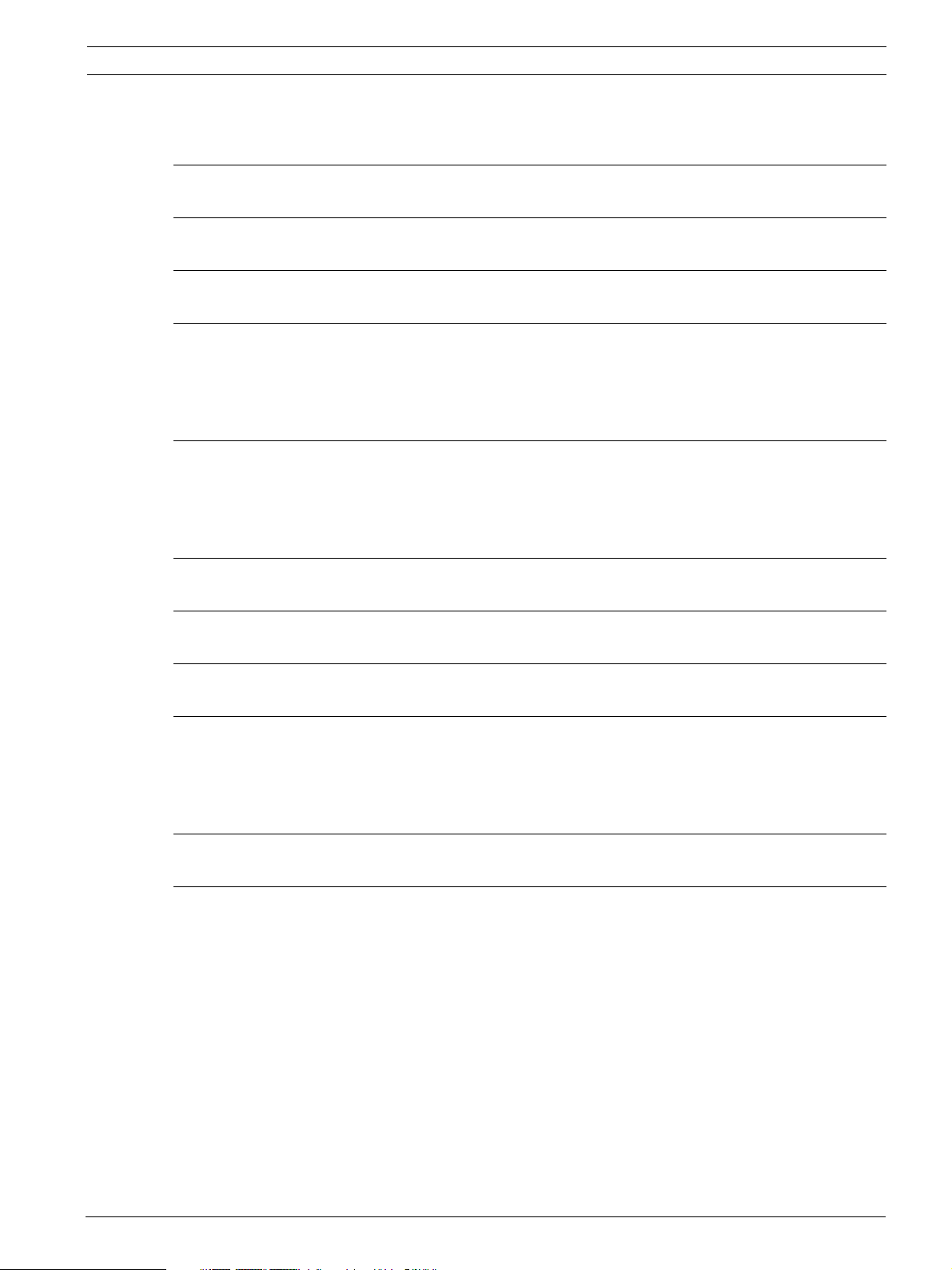

FPA-1000 FMR-1000-RCMD FMR-1000-RA

Figure 3.1 System Overview

4 Mounting

The Remote Command Center should be mounted no higher than shoulder height of the

shortest person operating the system.

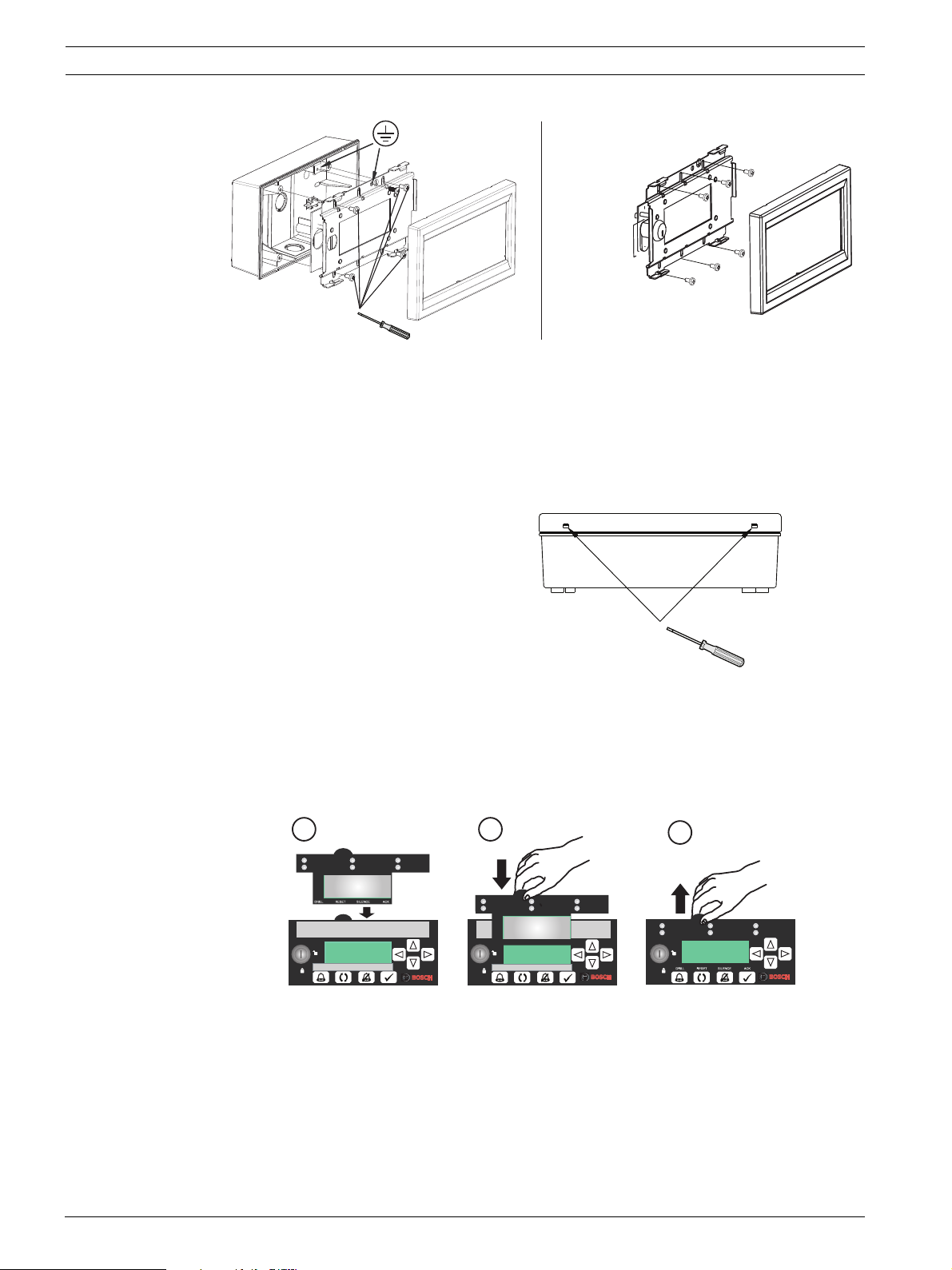

4.1 Removing the Cover Frame

The device comes with the

mounting material and language

tabs in separate bags. For

removing the device’s cover

frame from the annunciator unit,

hold the assembly and unlock

the snap-fit hooks on one side.

Pull the cover frame off.

Figure 4.1 Removing the Cover Frame (before Installation)

4.2 Surface Mounting

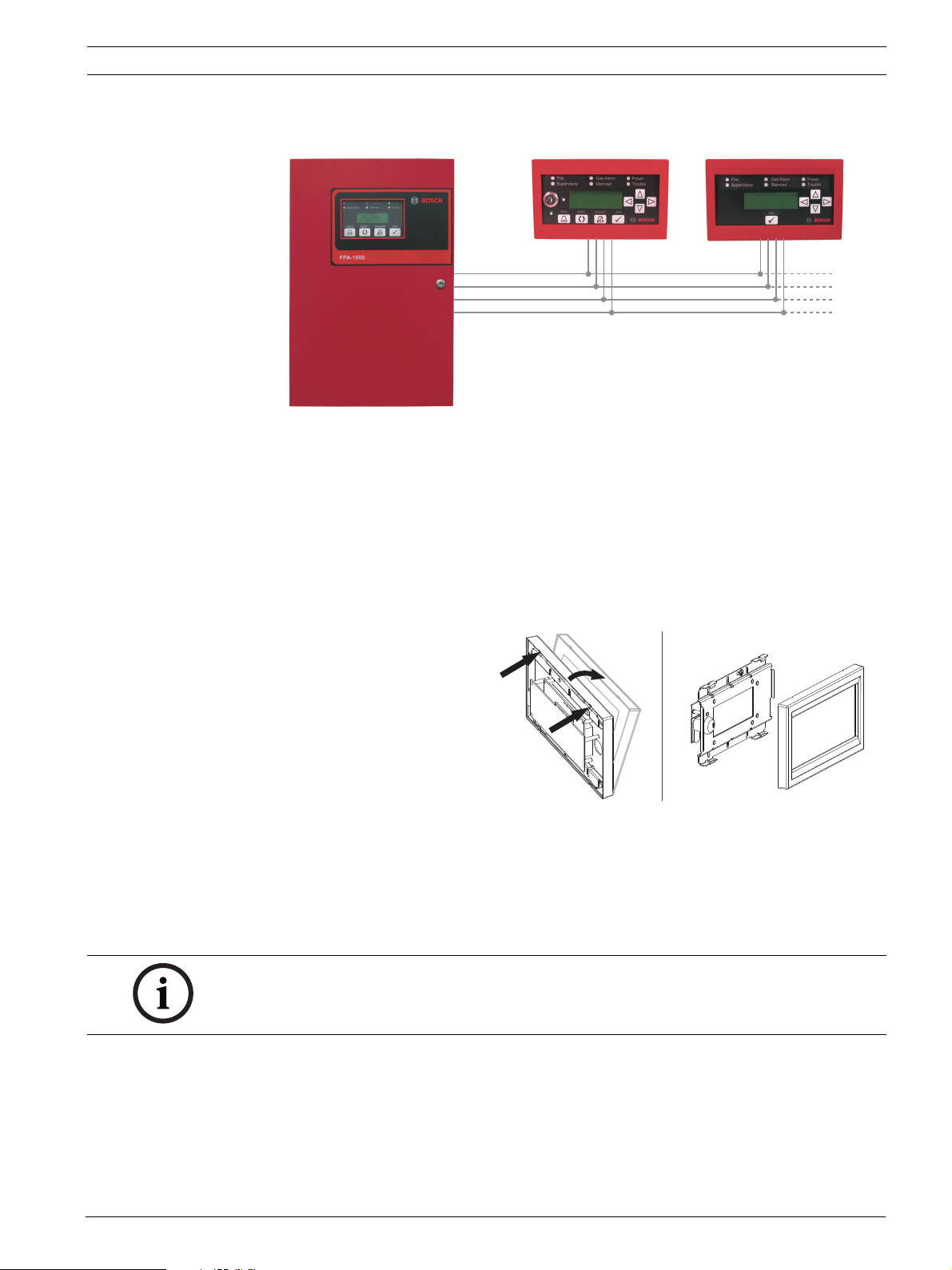

1. The back box provides three knockouts for 1/2 in. diameter conduit connectors in the

back, bottom and top side (refer to Figure 4.2, Item 1). To get a clean break, remove the

knockout from the inside of the box.

NOTICE!

To get a clean break, remove the knockout from the inside of the box.

2. Install the back box with the arrow pointing up (refer to Figure 4.2, Item 2).

3. Use the back box as a template to mark the location of the mounting holes (refer to

Figure 4.2, Item 3). Provide an opening in the mounting surface for the wiring. Pre-start

the screws. Do not secure the screws at this point.

4. The built-in bubble level allows you to level horizontally without extra tools when

securing the base (refer to Figure 4.2, Item 4).

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.078.098 | 3.0 | 2011.11

8 en | Mounting Remote Command Center

5.5 in. (140 mm)

4.41 in. (112 mm)

7.40 in. (188 mm)

3

2

3

4

5

55

5

1

1.02 in. (26 mm)

1.02 in. (26 mm)

1

1

7/8 in. (20 mm)

Before mounting the unit, follow the instructions in

– Section 6 Inserting the Language Tab on Page 10

– Section 7 Address Setting on Page 11

– Section 5 Wiring on Page 9.

4.3 Flush Mounting

Figure 4.2 Back Box of the FMR-1000-RCMD Remote Command Center

Legend

1 Knockout for 1/2 in. conduit connector in the in the back, bottom and top side

2 Arrow pointing up

3 Mounting holes for surface mounting

4 Bubble level

5 Fixing points for annunciator unit (4 screws)

For flush mounting, use a 3 gang

electrical box. Refer to

1.82 in.

(46 mm)

1.82 in.

(46 mm)

Figure 4.3 to select the mounting

holes.

111

Before mounting the unit, follow

the instructions in

– Section 6 Inserting the

Language Tab on Page 10

– Section 7 Address Setting on

Page 11

– Section 5 Wiring on Page 9.

3.54 in. (90 mm)

3.19 in. (81 mm)

111

Figure 4.3 Flush Mounting

Legend

1 Mounting holes for flush mounting

F.01U.078.098 | 3.0 | 2011.11 Installation and Operation Guide Bosch Security Systems, Inc.

Remote Command Center Wiring | en 9

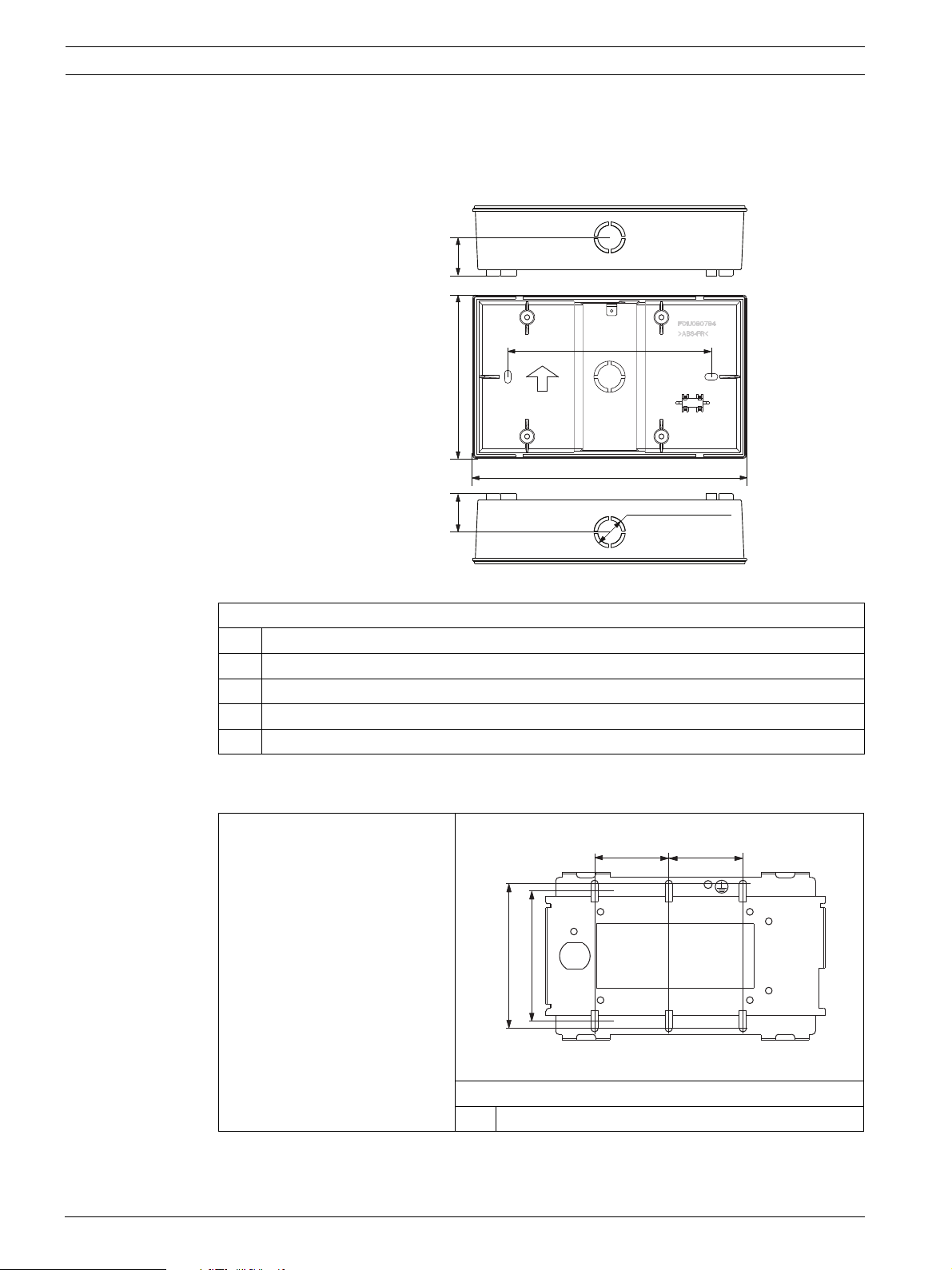

P7

P3

YGGND PWR+

G

Y

R

B

5 Wiring

DANGER!

Explosion and burn hazard. Do not short terminals.

Incorrect connections can result in damage to the unit and personal injury.

Before servicing this equipment, remove all power connections.

5.1 Option Bus Circuit Wiring Distance

Use four conductor, 18 AWG (0.8 mm2) or larger wire to connect Option Bus devices to the

FACP. The total length of wire connected to the Option Bus terminals must not exceed 4000 ft

(1219 m), regardless of the wire gauge used.

The maximum length between any one device and the panel terminals depends on the current

drawn on the branch that the device is on. The current draw on a particular branch can be

found by adding together the individual current draws of each device connected to the

branch. Refer to FPA-1000 Installation and Operation Guide (P/N F.01U.173.607) for detailed

wire length calculations.

5.2 Wiring Connections

The FMR-1000-RCMD is powered by either of the following power outputs from the FPA-1000:

– 12 V DC power (Option bus)

– 24 V FWR unfiltered Aux power output

or UL listed external power supply with common reference ground with the FPA-1000:

– 12 V DC power

– 24 V DC power.

To wire the FMR-1000-RCMD:

1. Power down the control panel.

2. Route the wiring from the FACP to the annunciators.

3. Bring the wiring through one of the knockouts in the annunciator’s base (surface

mounting) or the 3 gang electrical box (flush mounting). Refer to Figure 4.2 on Page 8 for

wire entrance location in the back box.

Legend

GND Ground

V+/PWR Power supply

Y Yellow, Data OUT

G Green, Data IN

P3 Power supply

connection

P7 Data connection

Figure 5.1 Wiring Connections

4. Connect the wiring to the FMR-1000-RCMD terminals. Refer to Figure 5.1.

5. For surface mounting with back box: Secure the base. Use the bubble level to make sure

that the back box is perfectly horizontal. Refer to Figure 4.2 on Page 8.

6. Fasten the annunciator unit with the four mounting screws using a Phillips (crossheaded) screwdriver. Secure the screw for the earth ground connection. Refer to

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.078.098 | 3.0 | 2011.11

7. Place the cover frame onto the base along the top side. Press the bottom part until it

snaps into place.

10 en | Inserting the Language Tab Remote Command Center

Figure 5.2 Position of Mounting Screws and Earth Ground Screw

When the device is powered on, the system performs a selftest. The routine includes checking

of all interfaces, address switches, LEDs, LCD, buzzer, keys, current consumption, and lamp

test.

5.3 Removing the Cover Frame for Service

For removing the device’s cover

frame when the annunciator unit

is already mounted, insert a

small flathead screwdriver in

each slot at the bottom or at the

top of the frame. Press up and

pull the cover frame off.

Figure 5.3 Removing the Cover Frame (after Installation)

6 Inserting the Language Tab

For different language versions of LED and key lettering, use the tabs provided with the

FMR-1000-RCMD.

1

Power

Gas Alarm

Fire

Silenced

Supervisory

Trouble

Figure 6.1 Inserting the Language Tab

1. Insert the tab carefully in the slot at the top of the keypad.

2. Slide the tab down carefully until it is completely flush with the keypad.

3. For tab removal, carefully pull upwards at the strap.

2

Fire

Supervisory

Gas Alarm

Silenced

Gas Alarm

Silenced

Power

Trouble

3

Fire

Supervisory

Gas Alarm

Silenced

Power

Troub le

F.01U.078.098 | 3.0 | 2011.11 Installation and Operation Guide Bosch Security Systems, Inc.

Remote Command Center Address Setting | en 11

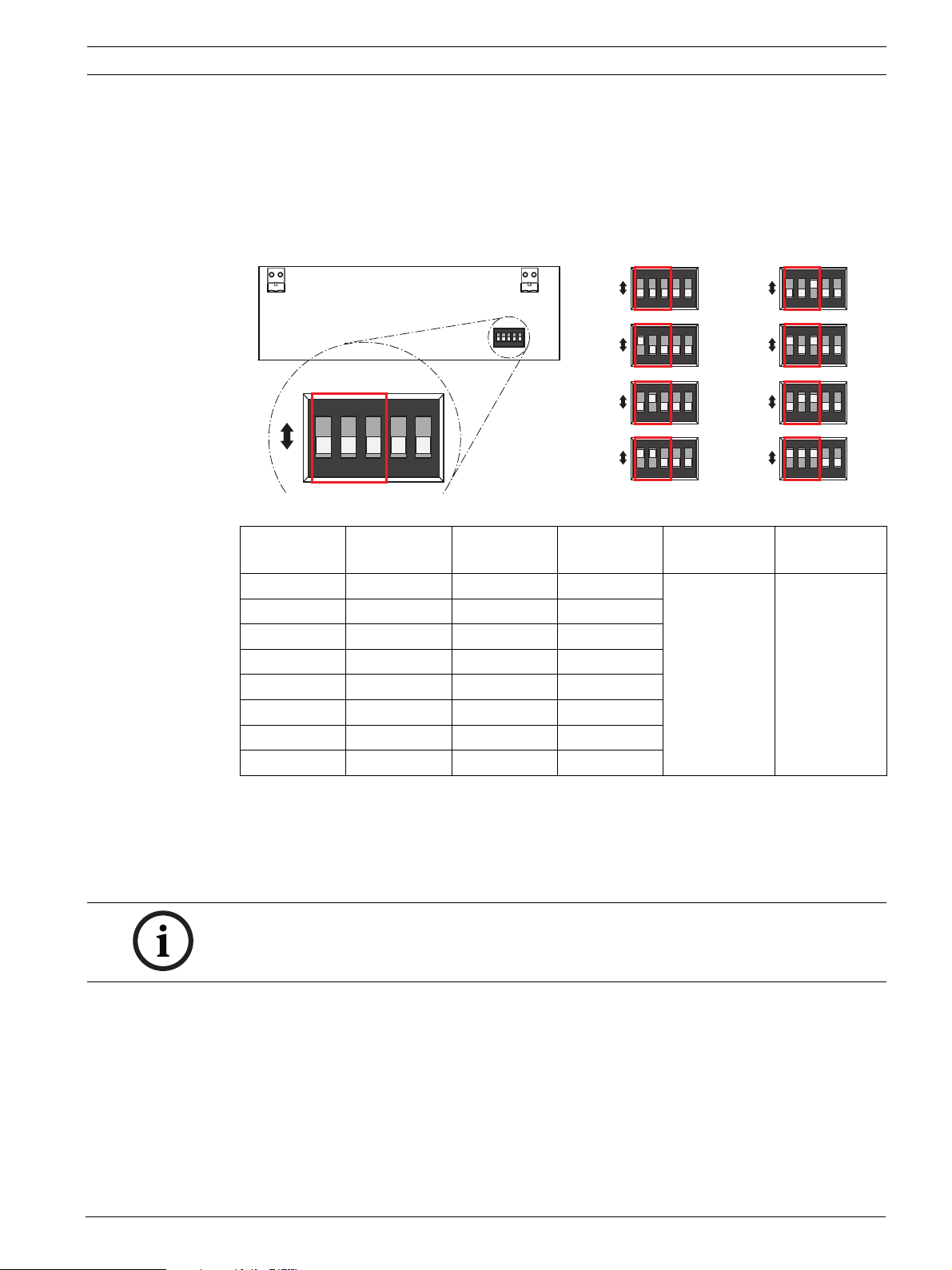

7 Address Setting

Each FMR-1000-RCMD connected to the Option Bus of the FPA-1000 must be set to a unique

Option Bus address ranging from 16 to 23. The devices must also be programmed at the

control panel (refer to FPA-1000 Installation and Operation Guide (P/N F.01U.173.607).

The address is set using the DIP switches at the main board of the annunciator unit. Refer to

Table 7.1.

ON

ON DIP

ON DIP

1 2 3 4 5

GND PWR+

P3

OFF

ON

OFF

ON

OFF

ON

OFF

1 2 3 4 5

ON DIP

1 2 3 4 5

ON DIP

1 2 3 4 5

ON DIP

1 2 3 4 5

YG

P7

ON DIP

ON

OFF

1 2 3 4 5

Figure 7.1 Address Setting

Option Bus

DIP 1 DIP 2 DIP 3 DIP 4 DIP 5

Address

16 OFF OFF OFF OFF position:

17 ON OFF OFF

18 OFF ON OFF

19 ON ON OFF

20 OFF OFF ON

21 ON OFF ON

22 OFF ON ON

23 ON ON ON

16

17

18

19

Control keys

are locked.

ON position:

All keys are

locked.

ON

ON DIP

1 2 3 4 5

OFF

ON

ON DIP

1 2 3 4 5

OFF

ON

ON DIP

1 2 3 4 5

OFF

ON

ON DIP

1 2 3 4 5

OFF

OFF position:

Key lock

active.

ON position:

Key lock

bypassed.

20

21

22

23

Table 7.1 DIP Switch Function

The DIP switch 4 allows for locking the control keys (drill, reset and silence) in OFF position

and for locking all keys in ON position.

The DIP switch 5 enables the device’s key lock in OFF position and bypasses the key lock in

ON position.

NOTICE!

Each Option Bus device must have its own address, and each address can support only one

device. Ensure that there are no duplicate addresses on the bus.

8 Programming

All Remote Annunciators and Remote Command Centers have to be configured as elements

connected to the Option Bus.

The FPA-1000 enables various programming approaches:

– On-site at the front panel to program another panel, but not all parameters can be

programmed

– On-site through a Web server using a laptop (connected to the panel with CAT5 cable)

– Remote, using a Web page and a dial-up connection

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.078.098 | 3.0 | 2011.11

12 en | Operating Remote Command Center

– Remote, using a Web page and an Ethernet connection.

For front panel programming, the system provides an auto learn function, allowing the

installer to configure the system quickly and easily in default mode.

Using a local laptop or remote access through a communicator, the programming is carried

out by means of browser-based user interface (virtual keypad).

Refer to the FPA-1000 Installation and Operation Guide (P/N F.01U.173.607) for detailed

programming instructions.

9 Operating

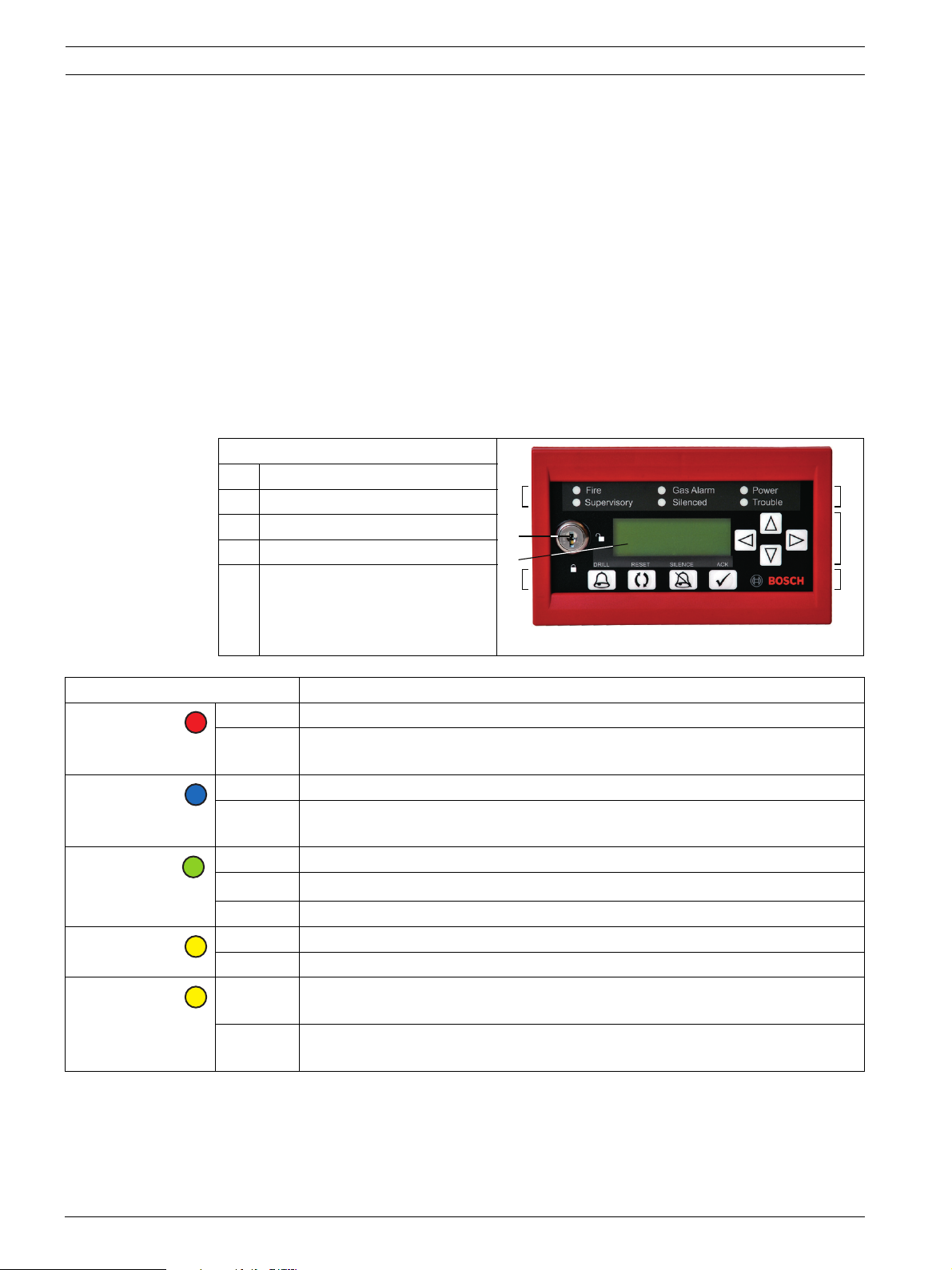

9.1 LEDs and LCD Keypad

The LEDs on the Remote Command Center follow the global system status (refer to

Table 9.1). In addition, a communication fault on the Option Bus is indicated by the trouble

LED flashing at 1 Hz (refer to Section 10 Troubleshooting on Page 15).

Legend

1LEDs

2 Device key

3 LCD screen

4 Scroll keys

5 Keys for Drill, Reset, Silenced,

and Acknowledge [ACK]

1

2

3

5

1

4

5

Fire

Red

Gas Alarm

Blue

Power

Green

Supervisory

Yellow

Silenced

Yellow

LED System Status

On Whenever the system registers a fire alarm and is not reset

Off – If no alarm registered

– After resetting

On When the system registers a gas alarm and is not reset

Off – If no gas alarm registered

– After resetting

On If AC power is applied to the panel

1)

Flashing

Off When no power (AC or battery) is applied

On When the system registers a supervisory condition

Off When no supervisory condition is registered

On – When an alarm or trouble condition is silenced manually by the user

Off – When no condition is silenced

When AC power fails and the unit operates from battery power

– If the system auto-silence timer expires

– When a silenced condition is corrected

Figure 9.1 Front View FMR-1000-RA

F.01U.078.098 | 3.0 | 2011.11 Installation and Operation Guide Bosch Security Systems, Inc.

Remote Command Center Operating | en 13

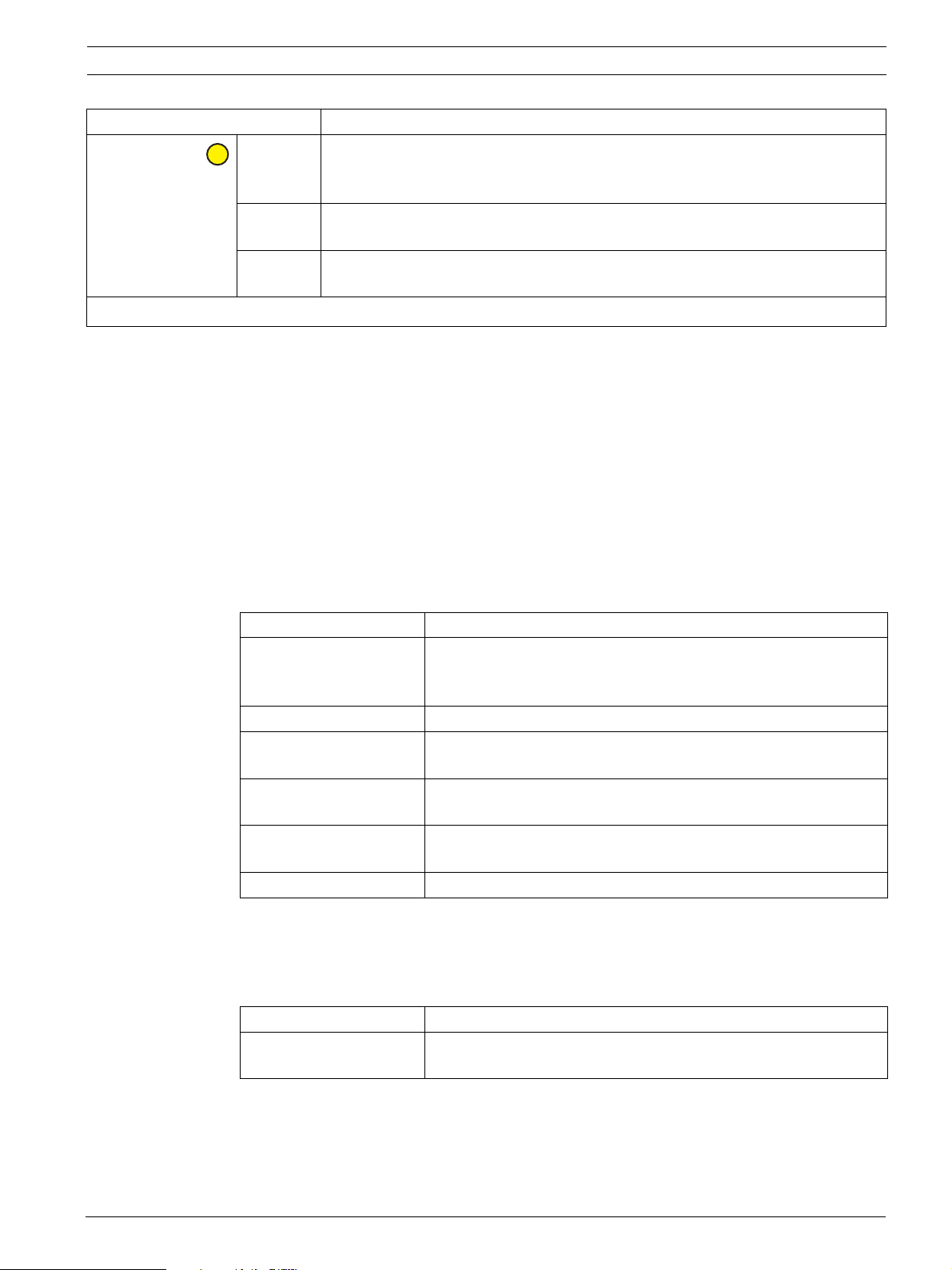

LED System Status

Trouble

Yellow

On – When the panel is initializing

– When the panel registers a trouble condition from a point, or the panel

– When inputs or outputs or other elements are bypassed

1)

Flashing

– When the panel is not operating

– When walk test is in progress

Off – When no trouble condition exists

– When the panel is resetting

1)

LED flash rate is 1 Hz (0.5 s on, 0.5 s off).

Table 9.1 LED Operation

Display

The FMR-1000-RCMD Remote Command Center uses an 80-character (4 lines x 20 characters)

wide viewing-angle LCD display. The display includes a long-life LED backlight. The backlight

is controlled by the panel, or locally turned on upon any key press and turned off after

30-second time-out without key press. Even when AC power is lost, the LED backlight remains

lit if a user is operating the keypad.

Piezo Sounder

The FMR-1000-RCMD Remote Command Center has a piezo that provides audible indication

of the system status. Refer to Table 9.2 for piezo modes when FMR-1000-RCMD is controlled

by the panel:

Piezo Operation System Status

Silent The panel is in a normal state (no alarm, supervisory or trouble

condition). The panel was silenced or acknowledged after an off-

normal condition.

Continuous beep The panel is in fire alarm condition.

Periodic beep

The panel is in gas alarm condition.

(0.5 s every 2 s)

Periodic beep

The panel is in supervisory condition.

(0.5 s every 4 s)

Periodic beep

(0.5 s every 10 s)

The panel is in trouble condition or a communication fault exists

on the Option Bus.

Short beep With every valid key press.

Table 9.2 Piezo Operation with FMR-1000-RCMD Panel Controlled

In case of multiple piezo activation, the system status with highest priority is indicated.

If the Remote Command Center is not controlled by the panel or during a communication

fault, refer to Table 9.3 for piezo modes:

Piezo Operation System Status with FMR-1000-RA Controlled Locally

Periodic beep

A communication fault exists on the Option Bus.

(0.5 s every 10 s)

Table 9.3 Piezo Operation with FMR-1000-RCMD Controlled Locally

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.078.098 | 3.0 | 2011.11

14 en | Operating Remote Command Center

9.2 Lamp Test

A lamp test is accomplished by pressing and holding the acknowledge [ACK] key for more

than 3 seconds. All LEDs on the FMR-1000-RA are turned on and the LCD display is filled with

black blocks when the lamp test starts. As soon as the acknowledge [ACK] key is released, the

revision number, Option Bus address, and key lock status appear on LCD display for

3 seconds. Then the LEDs and the LCD display return to normal working mode (controlled by

the panel).

9.3 Keypad Operations

With the key lock in the locked position, the user can use the scroll keys only for navigating

the LCD display and operate the acknowledge [ACK] key. Upon an invalid key press, the

display shows “KEY LOCKED” for 3 seconds. Refer to Table 7.1 on Page 11 for key lock bypass

option.

With either the key lock in unlocked position or the DIP switch setting for the key lock

bypassed, the user may operate any of the device’s keys.

View Status

With no alarms or troubles in the system, the display message is "SYSTEM NORMAL" or

"SYSTEM NORMAL DAY" along with the current date and time.

During initialization by start-up or re-configuration, the screen indicates "System Initializing”.

The panel shows the “System Resetting” screen upon reset, until the system returns to the

normal supervising condition.

If PAS or Pre-signal is turned on, the screen indicates “SYSTEM NORMAL DAY”.

Any off-normal conditions are shown in groups classified as fire alarm, gas alarm, supervisory

and trouble.

Use the arrow keys to view events or conditions in the same group. Up and down keys move

the user to the previous or next event. The left and right keys switch to other groups.

NOTICE!

For system display information, refer to FPA-1000 Installation and Operation Guide

(P/N F.01U.173.607).

Acknowledge

During an alarm, pressing the acknowledge [ACK] key turns off the piezo that is sounding on

an annunciator. All the ongoing events or conditions are marked as “Acknowledged”. The

24-hour trouble reminder timer starts. Any trouble event not cleared within 24 hours is sent

again and the piezo begins to beep again.

If a fire input point configured as "PAS enabled" (with global PAS enabled) is activated,

pressing the acknowledge [ACK] key within 15 seconds after a PAS activation starts the

investigation timer. This allows the user to investigate the fire alarm or take other appropriate

actions until the timer expires.

An acknowledgement operation can also be initiated by the activation of an input point

configured as an acknowledge type.

Silence

Pressing the silence key performs all functions of the acknowledge operation.

When the silence operation is initiated, the panel goes into a “Silenced” status and the

“Silenced" LED lights. The piezos on all keypads and annunciators turn off. All outputs are

silenced if configured as “Silenceable”. NACs play the “Silenced” pulse for the programmed

F.01U.078.098 | 3.0 | 2011.11 Installation and Operation Guide Bosch Security Systems, Inc.

Remote Command Center Trou bleshooting | en 15

pattern, or they fully de-energize, as defined by the global option “Silence Config”. Strobes

continue flashing.

If programmed, the panel transmits a silence report to the central station.

If the panel is already silenced, pressing [SILENCE] again causes an unsilence command in the

panel. Silence operation does not reset the alarm status and does not return the activated

input to normal service. Any new alarm reactivates any silenced outputs.

Trouble Reminder

If any events are not cleared within 24 hours after the [SILENCE] or [ACK] key was pressed,

the panel turns on the piezo again and events are transmitted to the central station again.

Reset

Pressing the reset key turns off the piezo and all activated or silenced outputs. The reset

operation turns off auxiliary power AUX/RST for 5 seconds, and activates the global resetting

zone. All alarms, supervisories, and troubles caused by activation of SLC points are cleared.

Then the panel tries to reset all points that are in off-normal status. Not all system trouble

conditions are affected by the reset operation. If programmed, the panel transmits a reset

report to the central station.

Any alarm or trouble that exists after a reset causes the system to sound again.

Drill

To activate the drill operation, the [DRILL] key must be pressed twice to prevent accidental

activation. Pressing the key once the system prompts for confirmation. Pressing the [DRILL]

key again turns on all unbypassed NACs and drillable relay outputs.

The drill operation stops if the reset key is pressed, or it is automatically cancelled if the

operation was started for a programmed time. A system reset is automatically performed by

stopping the drill so that the panel and all field devices restore to their normal operation.

If programmed, a drill start report and a drill stop report are transmitted to the central

station.

10 Troubleshooting

Display LED Piezo Description

NOT PROGRAMMED 0.5 s on/

NO COMMUNICATION 0.5 s on/

COMMUNICATION OK off off Communication on the device

11 Specifications

11.1 Electrical

Operating voltage Nominal 12 V DC or 24 V DC/FWR

Current consumption at 12 V DC

– Standby current 25 mA maximum (only Power LED on)

– Alarm current 150 mA maximum (with annunciator lit and piezo

0.5 s off

0.5 s off

on)

0.5 s every

10 s

0.5 s every

10 s

No communication activities on

the device address.

After 60 seconds of no

communication activities on any

Option Bus address.

address; no text received yet.

Bosch Security Systems, Inc. Installation and Operation Guide F.01U.078.098 | 3.0 | 2011.11

Loading...

Loading...