BOSCH SECURITY SYSTEMS, INC.

130 Perinton Parkway

Fairport, NY 14450 USA

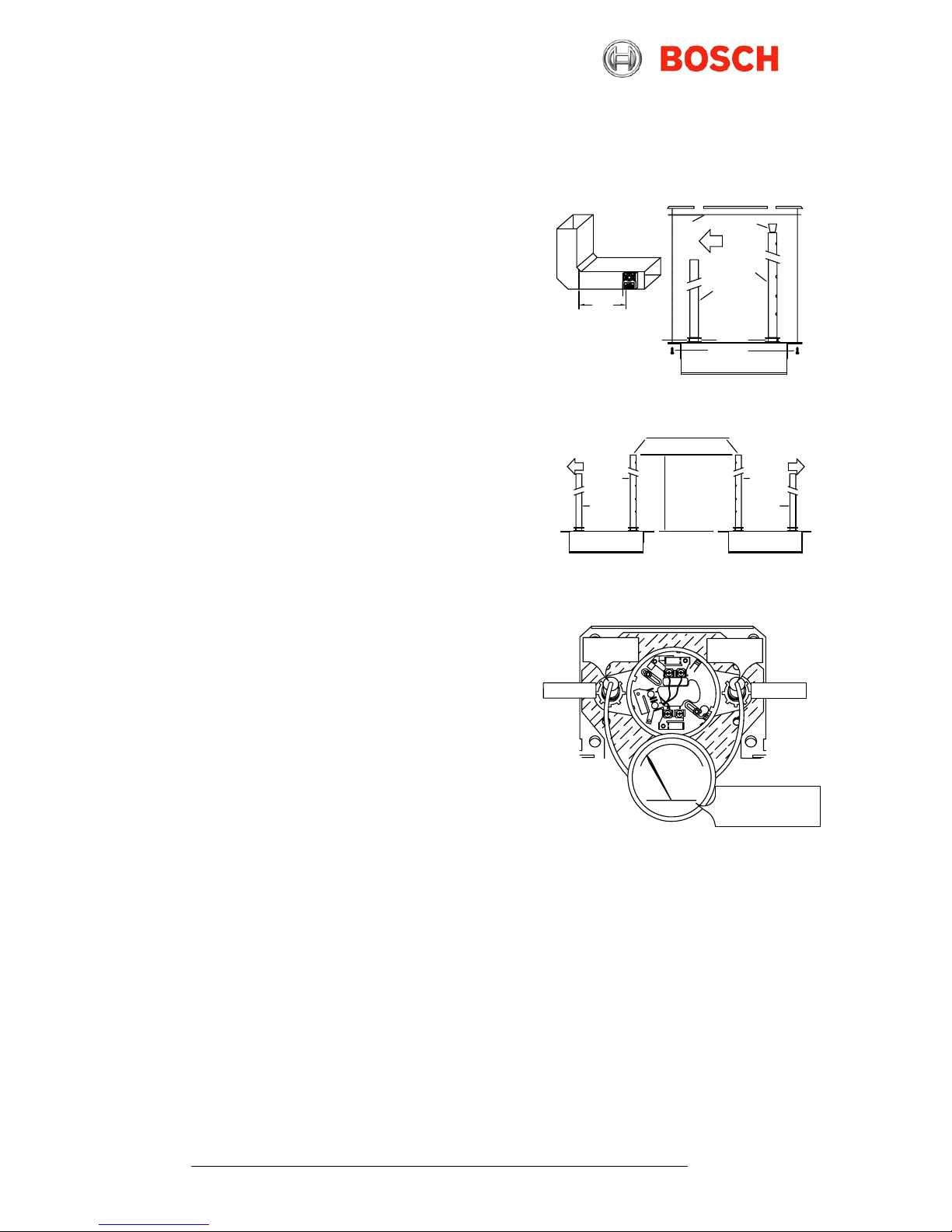

II. MOUNTING THE DETECTOR

The sampling tubes may be ordered to a desired length or ordered in one of 3 standard lengths and cut

per requirements. The intake sampling tube consists of a piece of steel piping with a series of holes

drilled the entire length of the tube and should extend the entire width of the duct. The holes must be

facing into the air flow (see Figure 2). The exhaust tube consists of a piece of steel piping

approximately 7-1/2" long.

1. Remove paper backing from mounting template AP 121 (packaged in installation kit) and affix to

duct at desired location.

2. Using template as a guide, drill 4 mounting holes (3/32" diameter) for duct mounting screws (4 #12

x 1/2" sheet metal screws packaged in installation kit). Drill or punch holes for sampling tubes in air

ducts (1-3/8" diameter), using template as a guide. Clean all holes.

Duct Smoke Detector Location Requirements:

detectors should not be mounted in areas of extreme high or low temperatures, in

areas where high humidity exist, or in areas where duct air may contain gases or

excess dust. The duct detector should, when possible, be located a minimum of six

duct widths downstream from a source of turbulence (bends, inlets, or deflection

plates). At these locations, air flow is less turbulent and the air/smoke mixture

should be more homogenous.Refer to NFPA 90A, 72, and 101 for more information.

See Figure 1A and 1B.

Exception: Where it is physically impossible to locate the duct detector accordingly,

the duct detector can be positioned closer than six duct widths, but as far as

possible from inlets, bends, or deflection plates .

*These products are compatible exclusively with fire alarm control panels that utilize BOSCH's protocol, DCP.

These are Installation Instructions (DWG.# HA-06-184) for the Analog Duct Housing customized as follows:

FAD-325 Duct Housing with the FAD-325-DH Analog Photoelectric Smoke Sensor*

FAD-325-V2F Duct Housing with the FAD-325-V2F-DH Analog Photoelectric Smoke Sensor*

FAD-325-R Duct Housing with the FAD-325-DH Analog Photoelectric Smoke Sensor & Relays*

FAD-325-V2F-R Duct Housing with the FAD-325-V2F-DH Analog Photoelectric Smoke Sensor & Relays*

INSTALLATION INSTRUCTIONS FOR THE DUCT SMOKE DETECTOR

A. DUCT PREPARATION

The Duct Detectors are designed for use in ducts where the air velocities are from 300 to 4000 feet per

minute. Verify this by checking specifications of installation and if necessary, use an Alnor Model

6000P velocity meter (or equivalent) to check the air velocity. See Figure 2 for sampling tube

orientation to air flow direction.

SET

SCREW

CONNECTORS

FIG URE 1B: DUCT HOUSING MOUNTING

TOP OF DUCT HOUSING

DUCT MOUNTING

SCREWS

FIGURE 2 SAMPLING TUBE ORIENTAT ION

INSERT STOPPER AT THIS END OF

INTAKE TUBE

TOP OF DUCT HOUSING

EXHAUST

TUBE

AIR FLOW

INTAKE

TUBE

INTAKE

SAMPLING

TUBE TO BE

SUPPORTED

WHERE THE

WIDTH OF

THE DUCT IS

GREATER

THAN 3 FEET.

WIDTH OF DUCT

TOP OF DUCT HOUSING

EXHAUST

TUBE

INTAKE

TUBE

AIR FLOW

EXHAUST

TUBE

Bend or

Other

Obstruction

6 Duct

Widths

Minimum

FIGURE 1A

TEMPLATE

AIR FLOW

FOR THIS

ILLUSTRATION

INTAKE

SAMPLING

TUBE

STOPPER

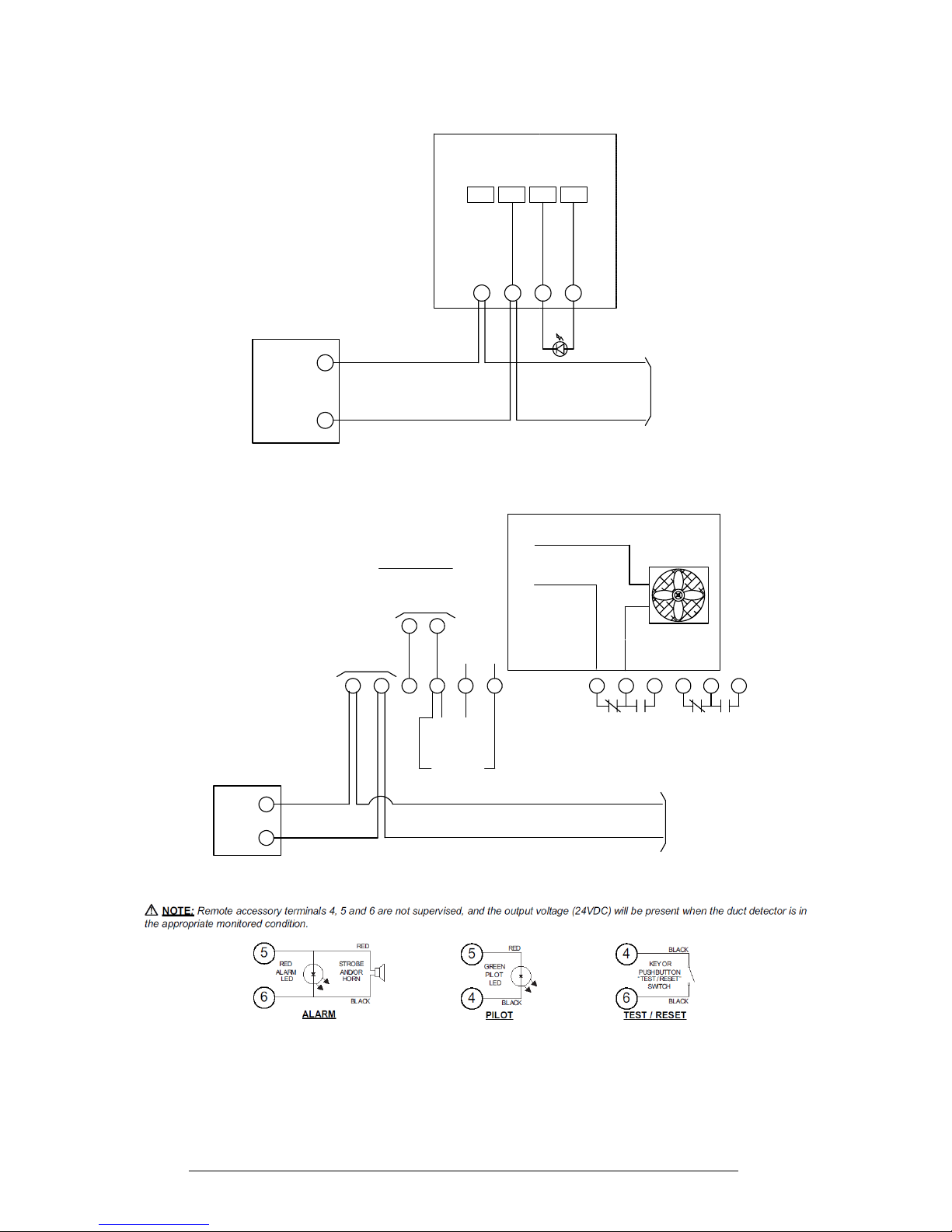

1. With power source de-energized and the smoke detector not installed, wire all connections per engineering drawings.

Refer to the applicable figures below depending on your duct housing model number.

2. With all wiring in place, install the detector head.

3. Energize the duct detector.

Wiring must conform to applicable local codes, ordinances and regulations covering these types of devices. Wire the detectors according to the engineering drawings for the

particular job requirements. These detectors are not intended for open area protection, nor should they be used for open air protection. Refer to NFPA 90A and NFPA 72 for

general and additional information on Duct Smoke Detectors concerning operation and installation. Terminals are suitable for up to #14 gauge wire.

To verify proper sampling of air, use a Dwyer Model 4000 differential pressure gauge (or equivalent).

See Figure 3 for gauge connections. The pressure differential between input sampling tube and

exhaust tube should be greater than 0.01" of water and less than 1.2" of water.

Move duct housing/sampling tube assembly to desired location. Use 4 mounting screws (4 #12 x 1/2" sheet

metal screws, packaged in installation kit) to secure the housing to the air duct.

1. Sampling tube connectors are equipped with set screws, which allow the tubes to be mounted

only in directions shown in Figure 2. Establish proper orientation considering airflow direction.

2. Insert intake and exhaust tubes into connectors, align set screw to set screw hole in tubes and

tighten firmly.

1. Cut the intake sampling tube to the desired length.

2. Firmly insert the stopper (packaged in installation kit) in the end of the INTAKE sampling tube.

INTAKE SAMPLING TUBES STANDARD LENGTHS:

III. ELECTRICAL INSTALLATION

FIG. 3 AIR SAMPLING

VERIFICATION

For duct widths of 1.0' to 2.5'

For duct widths of 2.5' to 5.0'

For duct widths of 5.0' to 10.0'

EXHAUST TUBE

HOLE &

CONNECTOR

LOW PRESSURE

SIDE

FAA-325-2.5

FAA-325-5

FAA-325-10

DWYER #4000 DIFFERENTIAL

PRESSURE GAUGE (OR

EQUIVALENT) WITH TUBING

AND SIZE 0 RUBBER STOPPERS

(HA PART# 0700-01118).

HIGH PRESSURE

SIDE

INTAKE TUBE

HOLE &

CONNECTOR

Note: All duct detector models can be tested with actual smoke. Remove the duct detector cover. Test the detector head by lighting a piece of cotton

clothesline. and placing it approximately 3 inches from the detector head. Blow across the lit end of the clothesline toward the detector. The LEDs on the

detector should illuminate within one minute. After performing this test sequence, reinstall the duct detector cover.

These duct sensors are analog addressable and can be calibrated by a U.L. Listed analog control panel. See the FACP Installation

Instructions for specific directions.

Models FAD-325/FAD-325-V2F/ FAD-325-R and FAD-325-V2F-R

BOSCH Security Systems, Inc. * FAD-325 Installation Instructions (HA-06-184. P/N 1700-11140 Page 1 of 2)

Specifications subject to change without notice. * February 2017

B. VERIFY AIR FLOW AND DIRECTION

C. SAMPLING TUBE ASSEMBLY (See Figure 2)

D. MOUNT SAMPLING TUBES (See Figure 2)

E. MOUNT THE DUCT HOUSING (See Figure 1B & 2)

F. VERIFY AIR SAMPLING (See Figure 3)

A. GENERAL INFORMATION

B. DETECTOR WIRING

I. LOCATION REQUIREMENTS

To prevent false alarms the

Terminate Remote Accessories as indicated above (if required).

This is not a self-contained stand alone detector.

A U.L. Listed Analog Addressable Fire System is required.

ANALOG ADDRESSABLE

FIELD LOOP WIRING

REMOTE TEST

SWITCH

(Test function only. does not reset.)

REMOTE

ALARM

LED

6

III. ELECTRICAL INSTALLATION, continued

OBSERVE POLARITY

INPUT VOLTAGE

24 V.D.C.

S (+)

SC (-)

UL LISTED

CONTROL PANEL

A.A.

CONTROL

PANEL

ADDRESSABLE

LOOP

1 2

+

-

REMOTE

PILOT LED

10 mA Standby

55mA Alarm

3 4

+

-

+

5

FAD-325-R/FAD-325-V2F-R WIRING DIAGRAM

FAD-325/FAD-325-V2F WIRING DIAGRAM

The FAD-325, FAD-325-V2F, FAD-325-R and

FAD-325-V2F-R are not self-contained sensors.

This product is compatible only with fire alarm

control panels that utilize BOSCH's Digital

Communications Protocol, DCP.

For example the FPA-1000 Family of Control Panels

D. WIRING DIAGRAMS, continued

UL LISTED

CONTROL PANEL

LOOP INTERFACE

S (+)

SC (-)

SUPPLY VOLTAGE

TO NEXT SENSOR

OR RETURN

TO CONTROL PANEL

ALARM CONTACTS

10.0A @ 250VAC

NC

ALARM CONTACTS

10.0A @ 250VAC

NONC

C

7 8 9 10

NO

C

1211

THE D304 REMOTE ALARM LED

WIRING MUST HAVE POLARITY AS

SHOWN 24 VDC (8mA MAX.)

-R +RL2L1

FAN SHUTDOWN EXAMPLE

421 3

(-)

FAN

TO NEXT

SENSOR

(+)

FAD-325-DH/FAD-325-V2F-DH

ANALOG SENSOR

* Remote common alarm indication, remote pilot indication, remote common reset, common shutdown and common visual indication.

* Common fault indication (when green pilot LED is extinguished) cannot be achieved on the FAD-325 Duct Units. Individual Remote

Pilot LED's must be installed to monitor detector head or power source removal for each unit.

* In the event of an alarm, the detector head and duct unit alarm (Red) LED's will be illuminated. All remaining duct unit alarm LED's will

not be illuminated. All remote alarm LED's fitted to the duct units will be illuminated when any of the units go into alarm. Only the duct

unit in alarm will permit resetting of the system from the built in test/reset switch on that particular duct unit.

* A common Remote reset switch will reset all detectors.

Common functions include one or all of the following:

BOSCH Security Systems, Inc. * FAD-325 Installation Instructions (HA-06-184. P/N 1700-11140 Page 2 of 2)

Specifications subject to change without notice. * February 2017

The Bosch D304/D305 Remote Duct Annunciator and the Bosch

FAD-325-R/FAD-325-V2F-R Duct Detectors are compatible when

wired as the following.

STANDBY 350µA

ALARM 800µA

Loading...

Loading...