Installation Instructions

for the DS778

ASIC-Based

Passive Infrared Intrusion Detector

1.0 Specifications

• Input Power: 6.0 VDC to 15.0 VDC; 18 mA @ 12.0 VDC

• Standby Power: There is no internal standby battery.

Connect to DC power sources capable of

supplying standby power if primary power

fails. For each hour of standby time

needed, 18 mAh are required.

Certificated Installations, A minimum of

4 hours (72 mAh) is required.

• Coverage: 200 ft. by 15 ft. (60 m by 4.5 m)

• Sensitivity: Adjustable for Intermediate or High.

• Alarm Relay: Form “C” reed relay with contacts rated at

28 VDC, 125 mA max. for DC resistive

loads.

• Tamper Switch: Normally Closed (with cover in place)

tamper switch. Contacts rated at 28 VDC,

125 mA max.

• Temperature: The storage and operating range is -40°F

to +120°F (-40°C to +49°C).

Certificated installations, the temperature

range is +32°F to +120°F (0°C to +49°C).

• Options: B328 Gimbal Mount Bracket, B335 Low

Profile Mount Bracket,B338 Ceiling Mount

Bracket, TC6000 Test Cord.

Note: Misalignment of the detector when using an optional

mounting bracket may reduce range.

2.0 Mounting

2.1 Mounting Considerations

• Select a location that is most likely to intercept an intruder moving

across the coverage pattern. The recommended mounting height

range is 6.5 ft. to 8.5 ft. (2 m to 2.6 m).

* The mounting surface should be solid and vibration free.

• Avoid direct hot and/or cold drafts, direct sunlight, heat sources,

windows, air conditioning outlets, and small animals.

• This detector won’t detect through glass.

• See

Section 8.0 Coverage Patterns

2.2 Surface or Corner Mounting

Note: For bracket mounting, refer to the installations supplied

with the bracket.

• Remove the cover. Insert a thin flathead screwdriver into the

notch at the bottom of the cover and pry up.

• Remove the chassis screw in the upper right corner of the

assembly (see

Figure A

). To remove the circuit board/mirror unit

from the enclosure, push the circuit board/mirror unit toward the

top of the enclosure until it clears its four retainer tabs, then lift

out.

.

For UL

For UL

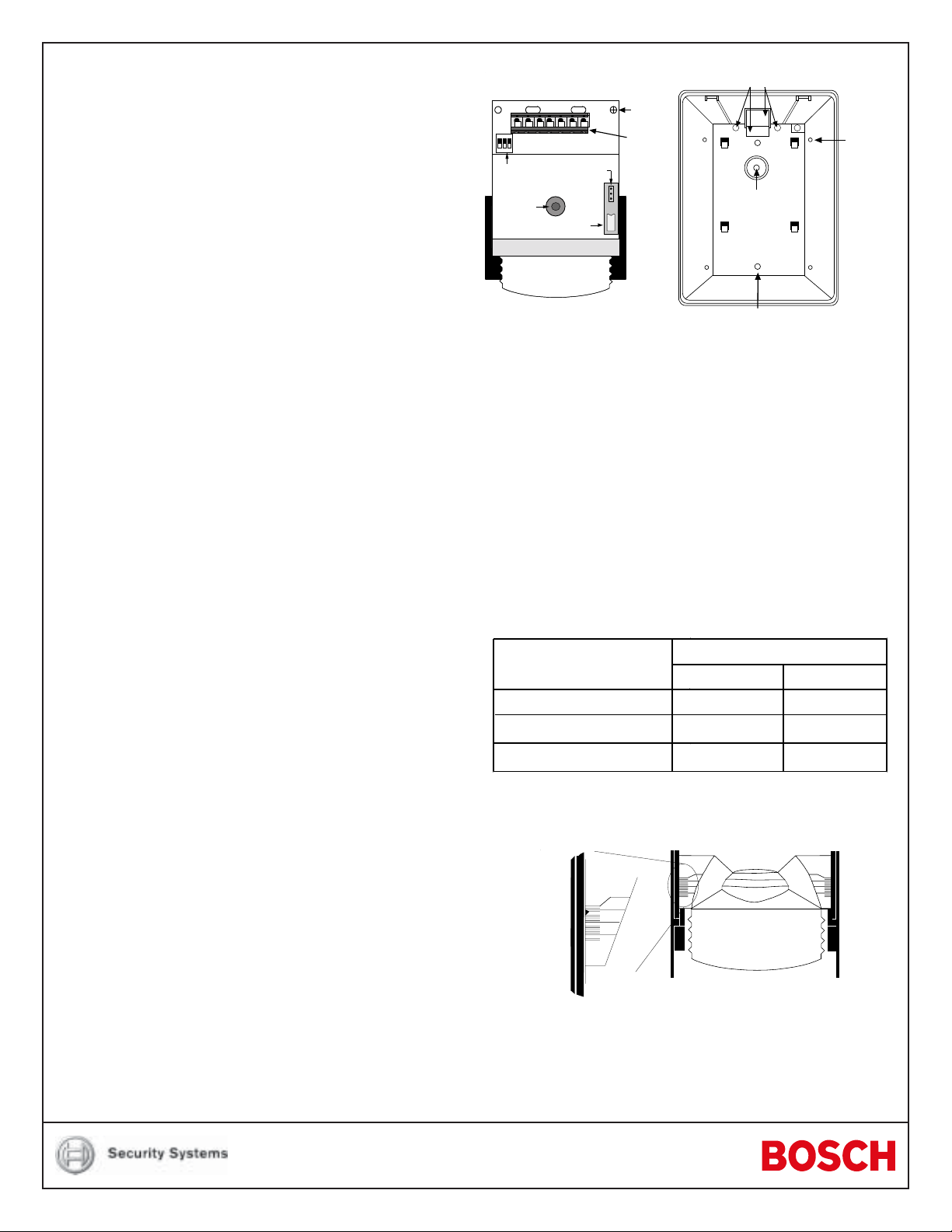

• Open two holes (see

3

12

NO NCCTT

-+

OPEN

Configuration

Switches

LED

+2

0

Tamper Switch

-8

-16

Noise

Voltage

+2

0

-8

-16

Figure A

Chassis

Screw

T-Strip

) for surface or corner mounting.

Wiring Knockouts

Corner

Mounting

Holes (4)

Bracket

Mounting

Hole

Surface Mounting Holes

or Single Gang

Box Holes (2)

Figure A - Location of Major Items -

Circuit Board and Detector Enclosure

• Mark the location for the mounting screws. Use the enclosure

as a template. Pre-start the mounting screws.

• Open the appropriate wiring knockout and route the wiring

through (see

Section 3.0 Wiring

).

• Securely attach the detector.

• Replace the circuit board/mirror unit.

• Adjust the mirror.

Note: Excessive handling of the mirror surfaces may lead to

performance degradation.

- Adjust vertically from +2° to -18° by sliding the mirror forward

or back. See

Figures B

and C to set the correct Vertical Angle

based on the mounting height and desired range.

Vertical Angle Setting

Mounting Height [ft. (m)]

6.5 (2)

7.5 (2.3)

8.5 (2.6)

100 ft. (30 m)

-2°

-2°

-3°

200 ft. (60 m)

-1°

-2°

-2°

Figure B - Mounting Height/Range Chart

- The angle adjust markings are on the sides of the mirror

(see

Figure C

Set

at

-1°

).

-16

+2

0

-8

+2

0

-8

-16

+2

0

-8

-16

Mirror

Figure C - Setting Vertical Angle

- Slide the mirror forward or back until the angle hash marks

are in-line with the markers on each side of the frame.

- Horizontally ±10° by rocking the mirror side to side.

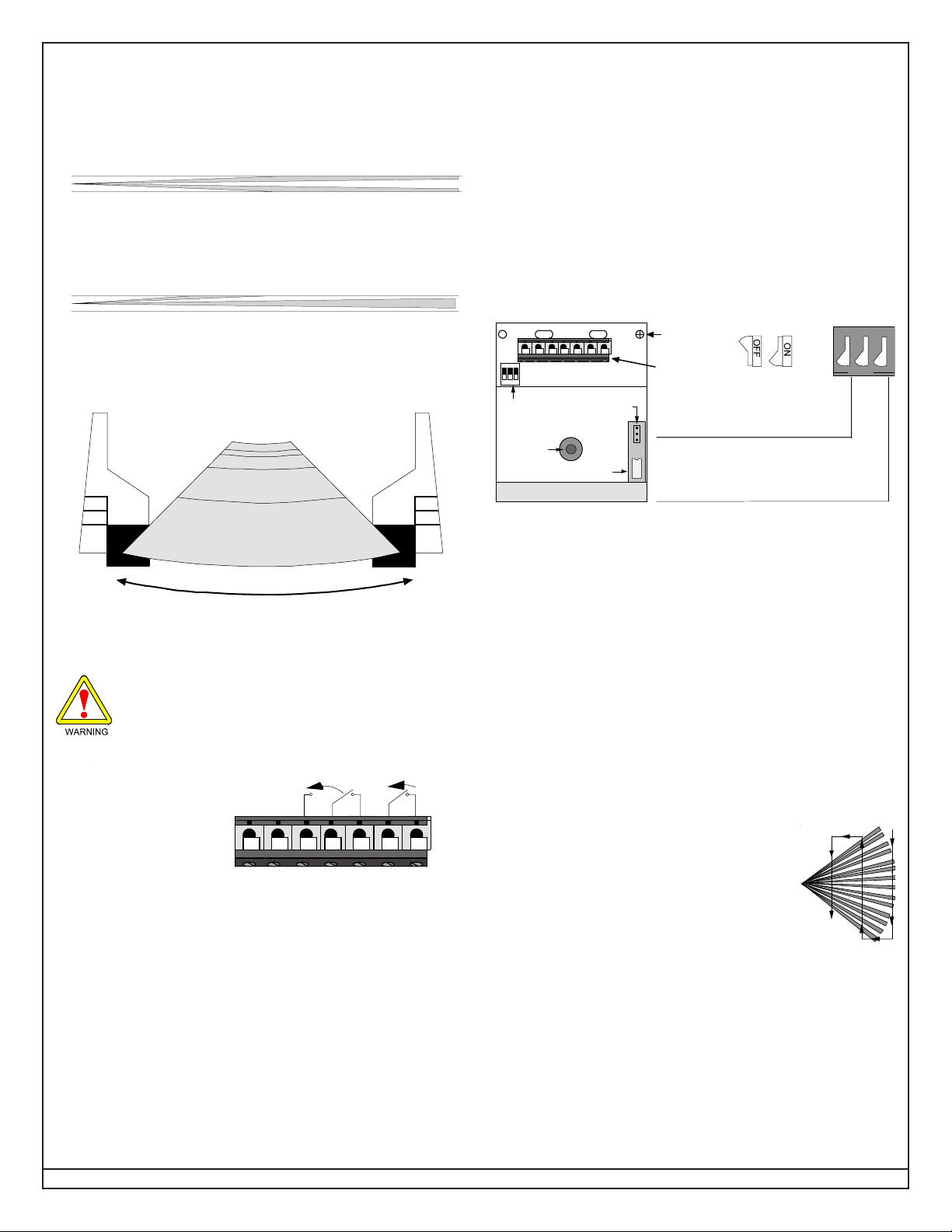

When the detector is installed so that its pattern is centered

down a narrow hallway, the coverage will probably not be

adequate since the detector will be “looking” mostly at the

walls leaving an open channel down most of the hallway as

illustrated here:

Narrow Hallway

Detector centered, Pattern centered

Depending on the dimensions of the hallway this can be

compensated for by mounting it in the center and adjusting

the horizontal angle as illustrated here:

Narrow Hallway

Detector centered, Pattern rotated 1° (1 click)

- Walk test the installation carefully to ensure adequate

coverage. See

Figure D

for horizontal angle adjustment

information.

10°

10°

5°

0°

3.1 Terminal Descriptions

• 1 (-) & 2 (+): Input Power (6 - 15 VDC). Use no smaller than

#22 AWG (0.8 mm) wire pair.

• 3 (NO), 4 (C), 5 (NC): Relay Contacts. Reed relay for silent

operation. Contacts rated at 3 watts, 125 mA, 28 VDC maximum

for DC resistive loads and protected by a 4.7 ohm resistor in the

common “C” leg of the rela y .

Do not use with capacitive or inductive

loads.

• 6 & 7: Normally Closed Tamper Contacts, rated 28 VDC,

125 mA.

4.0 Configuration Switches

• Configure the detector using the appropriate switch settings

(see

Figure F

123

-+

PEN

O

Configuration

Switches

LED

Tamper Switch

).

NO NCCTT

Noise

Voltage

Chassis

Screw

T-Strip

1 ON

= LED ON

1 OFF

= LED OFF

2 ON and 3 OFF

2 OFF and 3 ON

2 ON and 3 ON

= High

= Intermediate

= Not Recommended

5°

0°

Figure F - Configuration Switch Locations

ON

OFF

12

OPEN

3

Left/Right Pattern Adjust (1 click = 1°)

Figure D - Horizontal Angle Adjustment

3.0 Wiring

Only apply power after all connections have been

made and inspected.

• Connect wiring as shown in

Contacts sh own in

normal co nditi on (no

alarm or tamper) with

power applied.

Figure E - Terminal Connections

• Seal the wire entrance with the foam plug provided.

Figure E

-+

.

Alarm Tamper

NO

NCCTT

4.1 LED Operation (S1)

• ON: Allows the LED to operate when activated by alarm.

• OFF: The LED will not operate on alarm.

4.2 Sensitivity Mode (S2 and S3)

• Intermediate Sensitivity: Recommended setting for any location

where an intruder is expected to cover only a portion of the

protected area. Tolerates normal environments on this setting.

• High Sensitivity: Fast response to intruder signals. For use in

quiet environments where thermal and illumination transients

are not anticipated.

5.0 Setup and Walk Testing

• Replace the cover on the unit. The cover should be in place

before testing the unit.

• Apply power to the detector.

• Wait for approximately two minutes, then start

walk testing.

• Walk test across the coverage pattern as

shown:

• The edge of the coverage is determined by

activation of the LED.

• Walk test the unit from both directions to determine the

boundaries.

• If the desired range cannot be achieved, try angling the mirror

up or down to assure the coverage pattern is not aimed too high

or low.

Page 2 © 2004 Bosch Security Systems DS778 Installation Instructions

6.0 Final T ests

Mirror Segment

to Pattern Refe rence

View of Front

Polished Surface

A

C

D

E

B

+2

0

-8

-16

+2

0

-8

-16

• Connect a DC VOM to the Noise Voltage pins (use TC6000).

• Replace the cover, routing the TC6000 cable through the notch

in the top of the case.

• Set meter scale for about 3.0 VDC.

- The base reference level for reading

background noise is approximately

2.0 VDC.

- Installations in quiet environments will

result in a steady reading between

1.9 VDC and 2.1 VDC.

TC6000

- Voltage changes greater than 0.75 VDC from the reference

level are desirable for good catch performance.

- If changes are less than +0.75 VDC, the device may fail to

respond if the temperature between the intruder and the

background is minimal.

• Turn on all heating and cooling sources that would normally be

in operation during times of protection.

• Stand away from the unit and outside the coverage pattern, then

monitor the background noise for at least 3 minutes.

- Readings should not deviate from the reference level by

more than ±0.15 VDC.

- For readings outside these limits; eliminate the cause,

re-point the unit slightly, or mask off the affected zones.

+

-

7.0 Maintenance

• At least once a year, the range and coverage should be checked

in accordance with the Walk Testing section.

• To ensure continual daily operation, the end user should be

instructed to daily walk through the outer edge of the coverage

pattern. This assures an alarm output prior to arming.

8.0 Coverage Patterns

• Masking Information

B

Before attempting any masking, be sure the chosen mirror

R

surface is the correct one (use the Mirror Segment to Pattern

W

Reference illustration to determine the relationship between

mirror sections and the pattern. When attempting to remove

masking, many adhesives will either destroy the mirror surface

or leave enough residue behind to reduce coverage

performance.

meters

0102030405060

6.5

0

7.5

7.5

Long Range Coverage

C

E

D

AB

Top View

2

20 40 600

0102030405060

meters

80 100 120 140 160 180 200feet

Side View

0

20 40 600

80 100 120 140 160 180 200feet

0

2.3

0

2.3

DS778 Installation Instructions © 2004 Bosch Security Systems Page 3

© 2004 Bosch Security Systems

130 Perinton Parkway, Fairpor t, New York, USA 14450-9199

Customer Service: (800) 289-0096; Technical Support: (888) 886-6189

03/04

DS778 Installation Instructions

P/N: 47884D Page 4

Loading...

Loading...