Bosch DS7200V2-EXP Installation Manual

EN

DS7200V2-EXP

Installation Guide

DS7200V2-EXP

Control Panel

Addendum

DS7200 Installation Guide

TS50131-3 compliance

2011-09-16

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

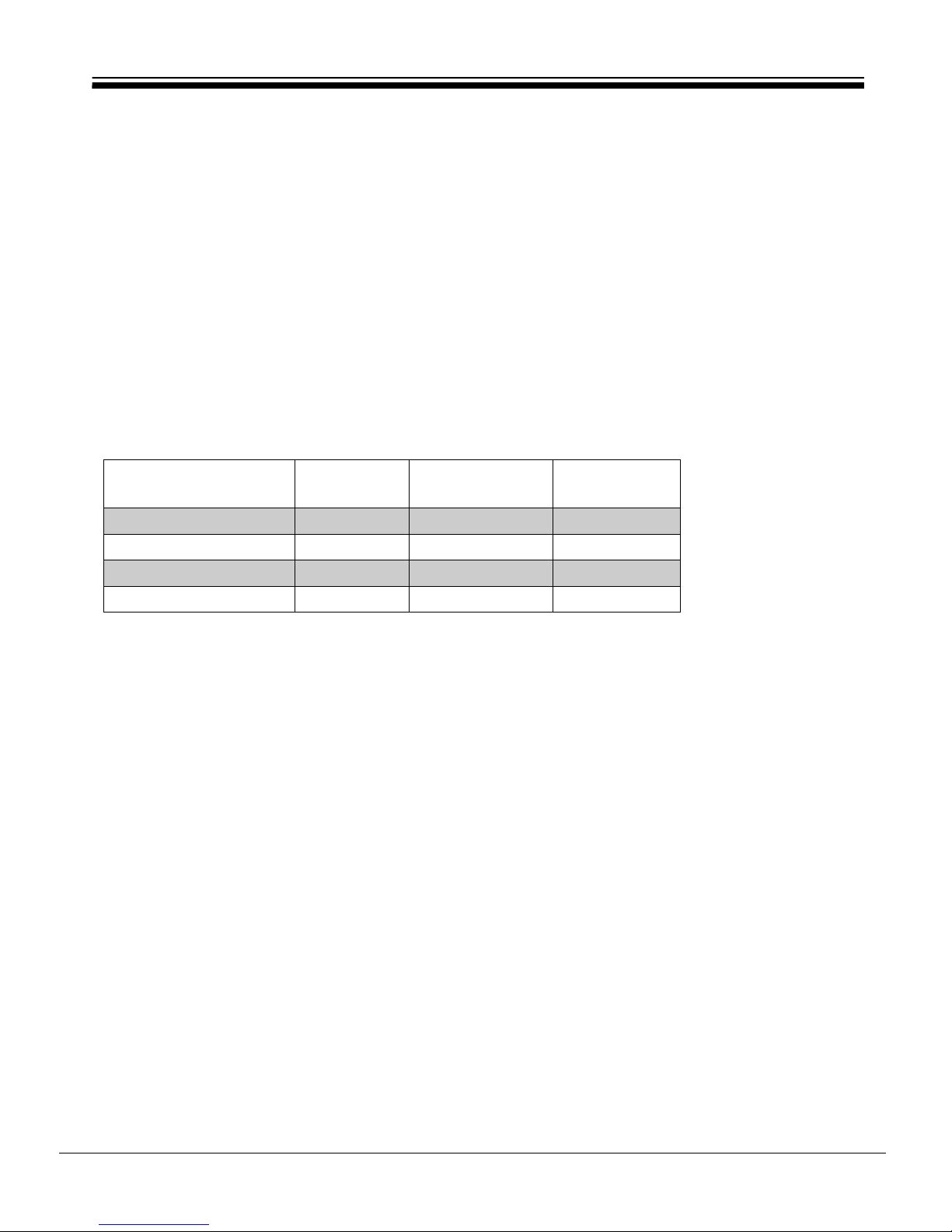

Max current draw

(Panel excluded)

Battery

capacity

Recharge time

(max)

System type

Prioritization of signals & indicators

Incoming signals are prioritized in chronological order. All signals are processed within 10 s.

Indicators displayed individually with text.

The control panel can meet all the options in Table 13, regarding notification outputs in the European standard for Intrusion

Systems.

Zone expanders

The zone expenders should be mounted inside the control panels enclosure for EN-approved systems.

Classification

DS7200 meets the Security Grade 2, Environmental Class 2

Current and battery capacity

400 ma 7,2 Ah 12 hours EN

800 mA 2 x 7,2 Ah 24 hours EN

1 A 18 Ah 48 hours EN

1,2 A 7-18 Ah - Non approved

Code combinations

The number of code combinations:

4-digit code allows for 10,000 combinations

5-digit code allows for 100,000 combinations

6-digit code allows for 1 million combinations

7-digit code allows 10 million combinations

The number of free combinations = code combinations – number of users

Weight and dimensions

Material: 1.0 mm thick cold-rolled steel

Dimensions (H x W x D): 36.8 x 31.8 x 7.6 cm

Weight 5.5 kg

DS7200V2-EXP | Installation Guide | Contents

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

EN | 3

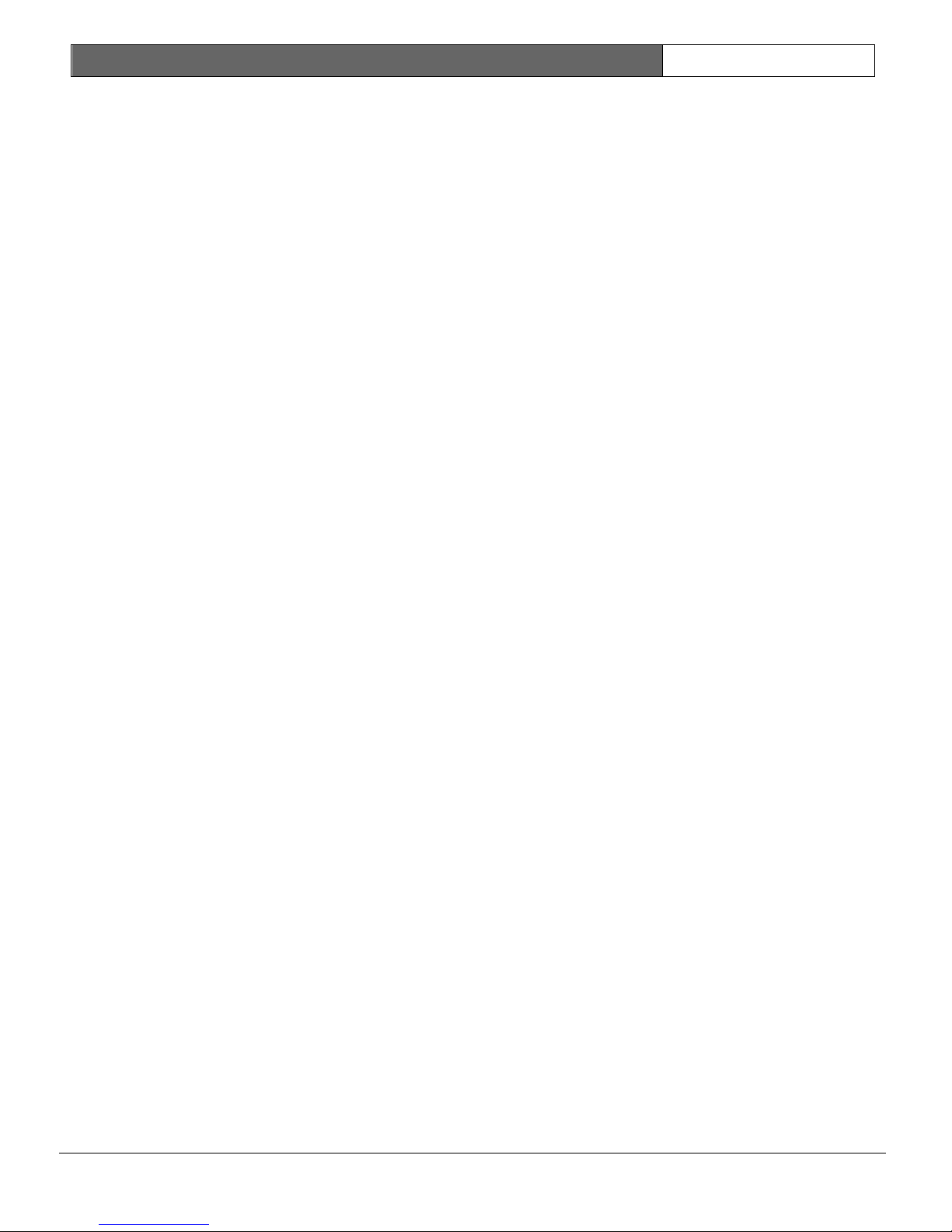

Contents

1. Introduction ............................................................................................................................ 7

1.1 Documentation Conventions ..............................................................................................................7

1.2 Scope of Document ............................................................................................................................7

1.3 Specifications .....................................................................................................................................8

1.4 Standard Features ..............................................................................................................................8

1.5 Control Panel Assembly ......................................................................................................................9

1.6 Listings and Approvals ........................................................................................................................9

1.7 System Options ..................................................................................................................................9

1.8 System Batteries .............................................................................................................................. 10

1.9 Available Power ................................................................................................................................ 10

1.10 Installer Keypad/RPS Connector ...................................................................................................... 10

2. System Installation and Setup ............................................................................................... 11

2.1 Control Panel Installation ................................................................................................................. 11

2.2 Arming Device Installation ................................................................................................................ 15

2.3 On-board Sensor Loop Setup ........................................................................................................... 18

2.4 On-board Output Setup .................................................................................................................... 21

2.5 RF3227E RF Receiver Setup ............................................................................................................. 22

2.6 Off-board Sensor Loop Setup (DX2010) .......................................................................................... 23

2.7 Off-board Output Setup (DX3010) ................................................................................................... 29

2.8 RS-232 Serial Interface Setup (DX4010i/DX4010) ............................................................................ 31

2.9 Network Interface Module (DX4020) ................................................................................................ 36

2.10 Door Access Control Module (DACM) .............................................................................................. 38

2.11 System Power Up ............................................................................................................................. 40

2.12 System Status LED ........................................................................................................................... 40

2.13 Installer Keypad ................................................................................................................................ 40

2.14 Installer Mode ................................................................................................................................... 41

2.15 Installer Menu ................................................................................................................................... 41

2.16 Keypad Programming ........................................................................................................................ 45

2.17 Keypad Test [#][9][1] ....................................................................................................................... 47

2.18 Always Force Arm ............................................................................................................................. 48

3. Control Panel Programming .................................................................................................. 49

3.1 Understanding the Option Parameter Charts ................................................................................... 49

3.2 Panel-Wide Parameters ..................................................................................................................... 50

3.3 Area-Wide Parameters ...................................................................................................................... 65

3.4 User Interface ................................................................................................................................... 68

3.5 Zone Parameters .............................................................................................................................. 80

3.6 Output Parameters ........................................................................................................................... 86

3.7 Sked Parameters .............................................................................................................................. 96

3.8 Data Bus Device Parameters............................................................................................................. 99

3.9 Network Communication ................................................................................................................ 101

3.10 DACM Configuration ....................................................................................................................... 105

3.11 Test the System .............................................................................................................................. 107

4. Reference Materials ............................................................................................................ 108

4.1 Control Panel Events and Reporting Formats ................................................................................. 108

4.2 Troubleshooting .............................................................................................................................. 120

4.3 Data Bus Address Quick Reference ................................................................................................ 122

4.4 Communication Attempt Tables ..................................................................................................... 123

4.5 Call for Service Details ................................................................................................................... 125

4.6 User Keypad Commands ................................................................................................................. 126

4.7 History Log ..................................................................................................................................... 127

4.8 Standby Battery Calculation ........................................................................................................... 128

4.9 Wiring Label .................................................................................................................................... 129

4.10 Glossary .......................................................................................................................................... 131

DS7200V2-EXP | Installation Guide | Figures

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

EN | 4

Figures

Figure 1: Enclosure Installation .......................................................................................................... 11

Figure 2: Control Panel Board Mounting ............................................................................................ 12

Figure 3: Standby Battery Connections .............................................................................................. 12

Figure 4: RAM Backup Battery ............................................................................................................ 13

Figure 5: RJ31X/RJ38X Wiring ............................................................................................................ 13

Figure 6: Ground Start ........................................................................................................................ 14

Figure 7: Keypad Jumper Plug Configuration ..................................................................................... 15

Figure 8: Keypad to Control Panel Wiring ........................................................................................... 15

Figure 9: Keypad to Control Panel Wiring (External Power Supply) .................................................. 16

Figure 10: Keyswitch: Tamper Wired Zone Configuration .................................................................... 16

Figure 11: Maintained Keyswitch: Single EOL Resistor Configuration ................................................. 17

Figure 12: Momentary Keyswitch: Single EOL Resistor Configuration ................................................. 17

Figure 13: Keyswitch: Zone Doubled Configuration ............................................................................. 17

Figure 14: Keyswitch: No EOL Resistor Configuration ......................................................................... 17

Figure 15: Tamper-Wired Zone Configuration ...................................................................................... 18

Figure 16: Single Zone Sensor Loop Wiring ......................................................................................... 19

Figure 17: On-board Doubled Zone Sensor Loop Wiring ...................................................................... 19

Figure 18: Single Zone Sensor Loop Wiring (No EOL) ......................................................................... 20

Figure 19: 4-wire Smoke Detector (Tamper-wired) .............................................................................. 20

Figure 20: 4-wire Smoke Detector (Single EOL Resistor) ................................................................... 21

Figure 21: PO 1 Wiring (PO 1 Jumper Shorted) ................................................................................... 21

Figure 22: PO1 Dry Contact Wiring (No PO 1 Jumper) ........................................................................ 21

Figure 23: PO 1 Positive Alarm Trigger Wiring ...................................................................................... 22

Figure 24: PO 2 to PO 4 Wiring ............................................................................................................ 22

Figure 25: RF3227E Address Jumper Settings ..................................................................................... 22

Figure 26: RF3227E to Control Panel Wiring ........................................................................................ 23

Figure 27: Standard DX2010 Installation Locations ............................................................................. 23

Figure 28: Optional DX2010 Mounting Locations ................................................................................. 24

Figure 29: DX2010 to Control Panel Wiring .......................................................................................... 24

Figure 30: DX2010 to Control Panel Wiring (External Power Supply) .................................................. 25

Figure 31: DX2010 Auxiliary Output Wiring .......................................................................................... 25

Figure 32: DX2010 Tamper Input Wiring .............................................................................................. 26

Figure 33: DX2010 No Tamper .............................................................................................................. 26

Figure 34: DX2010 Tamper-Wired Zone Wiring..................................................................................... 26

Figure 35: DX2010 Single EOL Zone Wiring ......................................................................................... 27

Figure 36: DX2010 Doubled Zone Wiring ............................................................................................. 27

Figure 37: DX2010 DIP Switch Configuration ....................................................................................... 28

Figure 38: DX2010 Status LED Location .............................................................................................. 28

Figure 39: DX3010 to Control Panel Enclosure Installation ................................................................. 29

Figure 40: DX3010 to Control Panel Wiring .......................................................................................... 30

Figure 41: DX3010 Output States ......................................................................................................... 30

Figure 42: DX3010 to Control Panel Wiring (External Power Supply) .................................................. 30

Figure 43: DX3010 DIP Switch Configuration ....................................................................................... 31

Figure 44: DX4010i to Control Panel Wiring ......................................................................................... 32

Figure 45: DX4010i to Control Panel Wiring (External Power Supply) ................................................. 32

Figure 46: DX4010i RPS Direct Connect Address Setting .................................................................... 33

Figure 47: DX4010i Direct Connection ................................................................................................. 33

Figure 48: DX4010 Direct Connection .................................................................................................. 34

Figure 49: P1 Jumper Pin Settings ....................................................................................................... 34

Figure 50: DX4010 P2 Jumper Pin Settings.......................................................................................... 35

Figure 51: RS-232 Device DIP Switch Setting ...................................................................................... 35

Figure 52: DB9 Connector Layout ........................................................................................................ 35

DS7200V2-EXP | Installation Guide | Figures

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

EN | 5

Figure 53: Network Communication DIP Switch Setting ...................................................................... 36

Figure 54: Standard DX4020 Mounting Locations ................................................................................ 36

Figure 55: Optional DX4020 Mounting Locations ................................................................................. 36

Figure 56: DX4020 to Control Panel Wiring .......................................................................................... 37

Figure 57: DX4020 to Control Panel Wiring (External Power Supply) .................................................. 37

Figure 58: DX4020 Ethernet/Serial Status LEDs .................................................................................. 38

Figure 59: DACM to Control Panel Wiring ............................................................................................ 39

Figure 60: DACM to Control Panel Wiring (External Power Supply) .................................................... 39

Figure 61: System Status LED .............................................................................................................. 40

Figure 62: Installer Keypad to Control Panel Wiring ............................................................................. 40

Figure 63: PK32 to Control Panel Connections .................................................................................... 44

Figure 64: Routing Destination Phone Number Configured for Basic Pager ........................................ 53

Figure 65: DS7200V2 Wiring Label ..................................................................................................... 129

DS7200V2-EXP | Installation Guide | Tables EN | 6

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

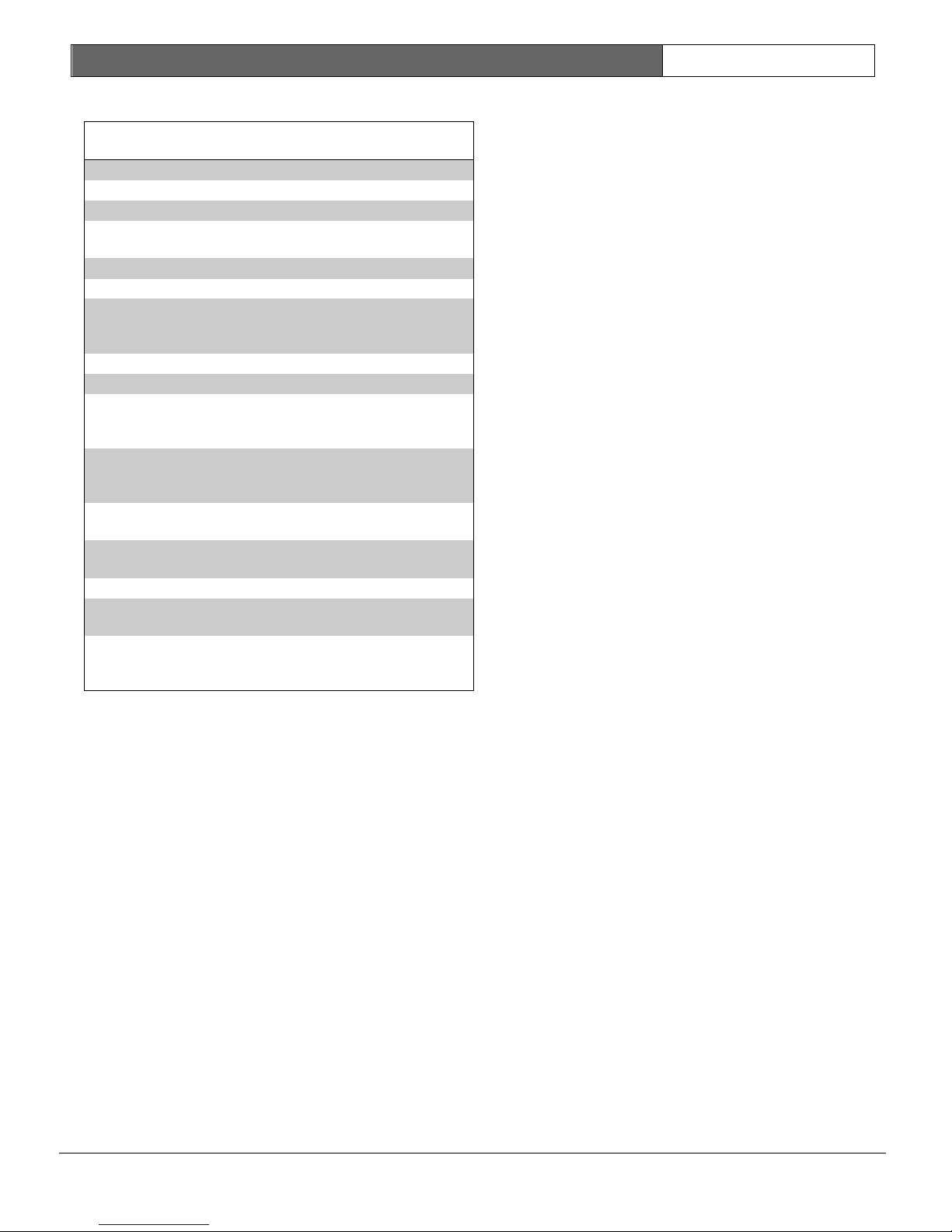

Tables

Table 1: Document Overview .............................................................................................................. 7

Table 2: Control Panel Specifications ................................................................................................. 8

Table 3: Keypad Address Pin Settings ............................................................................................... 15

Table 4: Keypad to Control Panel Wire Length ................................................................................. 15

Table 5: DX2010 to Control Panel Wire Length ................................................................................. 24

Table 6: DX2010 to External Power Supply Wire Length .................................................................. 24

Table 7: Control Panel Locations for DX2010 Address 106 .............................................................. 27

Table 8: Control Panel Locations for DX2010 Address 107 (DS7240V2 only) .................................. 27

Table 9: DX2010 Address Settings .................................................................................................... 28

Table 10: DX2010 DIP Switch Settings ............................................................................................... 28

Table 11: DX3010 Wire Lengths .......................................................................................................... 30

Table 12: DX3010 Address DIP Switch Settings ................................................................................. 31

Table 13: DX4010i/DX4010 Wire Lengths ........................................................................................... 31

Table 14: DX4010i/DX4010 Diagnostic LED Functions ....................................................................... 35

Table 15: DB9 Pin Configuration ......................................................................................................... 35

Table 16: DX4020 Wire Lengths .......................................................................................................... 37

Table 17: Ethernet/Serial Status LED Functions ................................................................................. 38

Table 18: DACM Wire Lengths ............................................................................................................. 38

Table 19: System Status LED Operation ............................................................................................. 40

Table 20: Reserved and Expert Addresses .......................................................................................... 46

Table 21: Key/Character Assignments ................................................................................................. 47

Table 22: Phone Number Entry Selections .......................................................................................... 50

Table 23: Personal Dialing Format Configuration ................................................................................ 52

Table 24: Report Tone Selections ....................................................................................................... 52

Table 25: Format Field Options ........................................................................................................... 54

Table 26: Account Number Addresses/Defaults .................................................................................. 65

Table 27: Account Number Entry Selections ....................................................................................... 65

Table 28: User Configuration ............................................................................................................... 70

Table 29: DS7446KP Keypad Icon Functions ...................................................................................... 73

Table 30: Location Configuration Parameters ..................................................................................... 80

Table 31: Default Zone Function Type Selections ............................................................................... 83

Table 32: Location Text Addresses/Defaults ....................................................................................... 84

Table 33: Output Configuration Parameters ....................................................................................... 86

Table 34: Output Function Types ........................................................................................................ 88

Table 35: Output Mode Options .......................................................................................................... 93

Table 36: Pulse Mode Configuration ................................................................................................... 95

Table 37: One Shot Mode Configuration ............................................................................................. 95

Table 38: Sked Configuration Parameters ........................................................................................... 96

Table 39: IP Address Entry Selections .............................................................................................. 101

Table 40: Control Panel Events and Reporting Formats ................................................................... 109

Table 41: Data Bus Address Quick Reference ................................................................................... 122

Table 42: Destination 1 Only ............................................................................................................. 123

Table 43: Destination 2 Only ............................................................................................................. 123

Table 44: Destinations 1 and 2 .......................................................................................................... 124

Table 45: Call for Service Details ...................................................................................................... 125

Table 46: System Arming/Disarming Functions ................................................................................. 126

Table 47: Other System Functions .................................................................................................... 126

Table 48: History Log Display Descriptions ....................................................................................... 127

Table 49: History Log Communication Status Values ........................................................................ 127

Table 50: Standby Battery Calculation .............................................................................................. 128

Table 51: Terminal Descriptions ........................................................................................................ 130

DS7200V2-EXP | Installation Guide | 1. Introduction

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

Table 1: Document Overview

Document

Part

Number

Description

included.

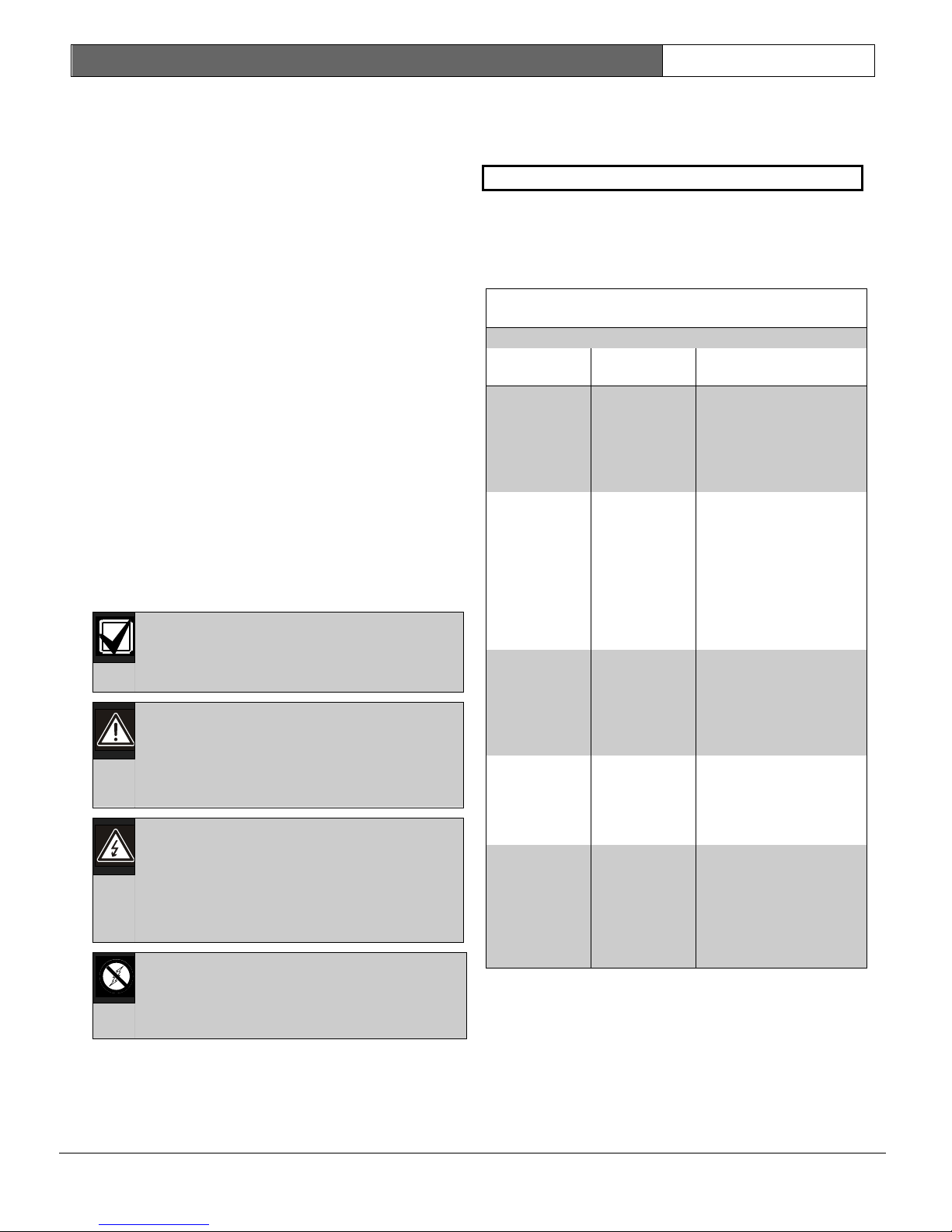

1.1.3 Other Conventions

1. Introduction

1.1 Documentation Conventions

1.1.1 Type Styles Used

To help identify important items in the text, the

following type styles are used:

Bold text Indicates important text or terms

that you should note.

Italicized text Refers you to a drawing, table, or

other section of this document.

[#][9][1] Bracketed numbers represent

keypad keys. When next to one

another, they represent the key

sequence to press for a particular

function. For this example, pressing

[#] followed by [9] and [1] begins

the keypad test function.

1|6

1.1.2 Notes, Cautions, and Warnings

Throughout this document there are important

Numbers separated by a vertical bar

represent output function types.

This example is for Output Function

Type 1|6:

Strobe.

Programming parameter titles are identified as

follows:

Programming Parameter Title

1.2 Scope of Document

See below for an overview of this document and

other documents related to the

DS7240V2/DS7220V2 Control Panels:

User’s Guide 4998153894 Contains keypad

Installer’s

Guide (this

document)

notes that address personal and/or equipment

safety issues, system operation issues, etc. They

are set off as follows:

The Important Note identifies

information intended for successful

operation.

Expert

Programmin

g Guide

The Caution Note identifies

information intended to prevent an

incident that could prohibit the

functionality of the

program/equipment.

Release

Notes

The Warning Note identifies

information intended to prevent an

incident that could prohibit the

System

Worksheet

functionality of the

program/equipment and/or personal

injury.

The No Static Note identifies

components that are static-sensitive.

Follow anti-static procedures when

handling these components.

EN | 7

operation instructions

for the end-user.

Covers use of the LCD

(text) keypad and the

LED keypad.

4998153893 Contains all wiring and

setup instructions,

and basic

programming

parameters with

descriptions.

Troubleshooting

information also

4998153891 Contains all

programming

parameters with

descriptions and

keypad programming

instructions.

4998153890 Contains issues with

control panel that

were found after

printing of the

documentation.

4998153887 Contains all

programming

parameter defaults

and space to record

any default changes

made during setup of

the control panel.

DS7200V2-EXP | Installation Guide | 1. Introduction

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

Table 2: Control Panel Specifications

Environmental Specifications

Voltage Input to Control Panel

Power Outputs

Keypads

1.3 Specifications

1.4.3 Areas and Accounts

The DS7240V2 supports up to 4 independent

areas. The DS7220V2 supports up to 2

Temperature +32°F to +122°F (0°C to +50°C)

Relative Humidity 5 to 85% at 86°F (30°C) non-

condensing

independent areas.

All zones can be assigned to a single area, or

spread out over the available areas.

Users arm and disarm the control panel by area,

and can arm and disarm several areas with one

function. The installer can assign an authority

Primary 18 VAC, 50 VA

Secondary Sealed lead acid rechargeable

battery

(12 VDC, 7 Ah or 18 Ah).

level to a PIN that allows a user to arm an area

from a remote keypad in another area.

Assigning each area its own account number

creates separate accounts in one control panel.

Assigning the same account number to different

areas groups them together into one account.

Continuous Power Up to 1.2 A at 12 VDC nominal

(continuous supply) total for all

devices and outputs.

Alarm Power 1.85 A for fire and combined

fire/burglary. Applies to all four

outputs combined.

Minimum

Operating Voltage

Data Bus 12 VDC nominal. 305 m of 0.8 mm

10.2 VDC

(#22 AWG) cable

Area options include exit tone and delay,

separate fire and burglary outputs and auto

opening and closing Skeds (see Sked Parameters

on page 96 for more information).

Area 1 can be programmed as a “common” area.

See Arming Options 2 on page 63.

A “First to Open, Last to Close” arming option is

available (see Arming Options 2 on page 63).

1.4.4 Programmable Outputs

Four on-board programmable outputs (PO 1 to

Maximum Number

per System

Compatible

Keypads

1.4 Standard Features

1.4.1 Communicator

The control panel uses a built-in digital

communicator to send reports to the receiver. It

can send reports in Contact ID, SIA 300, SIA 300

with Text, Personal Dialing Format, and Basic

Pager Format.

1.4.2 Zones

The DS7240V2 supports up to 40 zones using on-

board and off-board (including input expanders

and wireless devices). The DS7240V2 supports

up to 5 DX2010 Input Expanders.

The DS7220V2 supports up to 24 zones using onboard and off-board (including input expanders

and wireless devices). The DS7220V2 supports

8

DS7445i or DS7445V2 LED

Keypad; DS7447E or DS7447V2

Text Keypad; DS7446KP Keypad

PO 4) are available on both control panels.

The DS7240V2 supports up to 20 programmable

outputs (4 on-board, 16 off-board using two

DX3010 Output Expanders).

The DS7220V2 supports up to 12 programmable

outputs (4 on-board, 8 off-board using one

DX3010 Output Expander).

See On-board Output Setup on page 21 and Offboard Output Setup (DX3010) on page 29.

1.4.5 Users

The control panel allows up to 32 individual

users. Each user is assigned a Personal

Identification Number (PIN) and an authority

level. Authority levels determine which functions

users can perform.

1.4.6 Keyswitch

Users can arm and/or disarm any available area

with maintained or momentary closure devices

such as keyswitches. Zone programming

determines the keyswitch’s operation.

up to 3 DX2010 Input Expanders.

On-board sensor loops are marked L-1 to L-8 on

both control panel types.

EN | 8

DS7200V2-EXP | Installation Guide | 1. Introduction

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

C

1.4.7 Alarm Event Memory

The system uses alarm event memory to store

alarm events for each area. You can view the area

alarm events at a keypad assigned to the area.

The control panel clears the area’s alarm event

memory and starts storing new alarm events

when you arm the area. Alarm events are

permanently stored in the control panel’s history

log.

1.4.8 History Log

The system stores 254 events from all areas in its

event log.

Events can be stored even if the control panel

does not send a report for them. You can view

the log at a text keypad, print it locally using the

DX4010i/DX4010 RS-232 Serial Interface Module

and a serial printer, or upload it to the Remote

Programming Software (RPS).

1.4.9 Wireless (RF) Devices

The control panel supports a variety of wireless

sensor devices, which can be included in the 40zone maximum.

1.5 Control Panel Assembly

You should receive the following parts:

Documentation Pack

• DS7200V2 Installation Guide (this document)

(P/N: 4998153893)

• DS7200V2 Expert Programming Guide

(P/N: 4998153891)

• System Worksheet (P/N: 4998153887)

• Release Notes (P/N: 4998153890)

• User’s Guide (P/N: 4998153894)

Assembly

• Control Panel Assembly

• Red Battery Lead (P/N: 47720B)

• Black Battery Lead (P/N: 47721B)

• 2.2 k EOL Resistors (16 total)

• 3.65 k EOL Resistors (8 total)

• Tamper Switches

1.6 Listings and Approvals

•

• This product fulfills the requirements of

EN 50131-1, 50131-2, CLC/TS 50131-3

1.7 System Options

1.7.1 Arming Devices

• DS7445i LED Keypad: LED keypad that

displays up to 16 zones.

• DS7445V2 LED Keypad: LED keypad in new

faceplate design.

• DS7447E LCD (Text) Keypad: Text keypad

that displays system information and

programmable text.

• DS7447V2 LCD (Text) Keypad: Text keypad

in new faceplate design.

• Door Access Control Module (DACM): The

DACM grants or restricts access to a door

using a keypad/credential reader, a Request

to Exit (REX) input, and/or a door contact.

Each DACM supervises one door.

1.7.2 Data Bus Devices

• DX2010 Input Expander: Provides 8

additional input loops. The DS7240V2

supports up to 5 modules; the DS7220V2

supports up to 3 modules. Also available:

DX2014 (DX2010 with AE20 ABS plastic

enclosure).

• DX3010 Octo-Output Expander: Provides 8

independent, programmable Form “C” relay

outputs. The DS7240V2 supports up to 2

modules; the DS7220V2 supports 1 module.

• DX3020 Module: The DX3020 is an X-10

Interface Module. It can emulate up to 2

DX3010 Octo-Output Expanders. One allowed

per system.

• DX4010i RS-232 Serial Interface Module:

DTE RS-232 serial interface module that

provides a connection point to the system for

serial devices such as a printer. Can also be

used to create a remote programming direct

connection with RPS. It does not occupy a

control panel address when used this way.

One allowed per system

• DX4010 RS-232 Serial Interface Module:

Provides a connection point to the system for

serial devices such as a printer. Can also be

used to create a remote programming direct

connection with RPS. It does not occupy a

panel address when used this way. One

allowed per system.

• DX4020 Network Interface Module:

Provides bi-directional communication over

an Ethernet network. Can also be used for

remote programming sessions with RPS. One

allowed per system. Firmware revision 2.10

or greater is required to use the DX4020.

EN | 9

DS7200V2-EXP | Installation Guide | 1. Introduction

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

1.7.3 RF Devices

• RF3227E RF Receiver: Supervises the use of

wireless devices. Up to 2 allowed per system.

• RF3332E RF Keyfob: 2-button keyfob that

can arm/disarm the system and create a

Panic event if programmed.

• RF3334E RF Keyfob: 4-button keyfob that

can arm/disarm the system and create a

Panic event if programmed. It can also

control other devices.

• RF3401E Point Transmitter: Point

transmitter that features a supervised sensor

loop and a magnetic reed switch. External

magnet assembly allows for quick and easy

installation on doors and windows.

• RF3405E Inertia Transmitter: Magnetic and

dry contact wireless transmitter with a builtin inertia sensor used for monitoring doors,

windows, or other dry contact devices.

• RF3503E Two-Button Transmitter:

Wireless, two-button transmitter that sends a

medical or panic alarm signal to the

monitoring system.

• RF1100E Glassbreak Detector: Wireless

transmitter used for detecting breaking glass.

• RF280ETHS Wireless Smoke Detector:

Wireless photoelectric smoke detector with

built-in 135°F (57°C) heat sensor and 85 dB

sounder.

• RF835E Wireless TriTech PIR/Microwave

Detector: Wireless detector that utilizes

passive infrared (PIR) technology, microwave

(MW) technology, and artificial intelligence to

detect motion.

• RF940E Wireless PIR Detector: High

performance PIR motion sensor.

1.7.4 Programming Tools

• DS7447E/DS7447V2 Text Keypad: Required

for keypad programming.

• PK32 Program Key: Copy system

programming entries to key for quick delivery

to another system. Can also be used as a

backup disk.

• Remote Programming Software (RPS):

Remote programming and diagnostic tool.

1.8 System Batteries

1.8.1 Standby Battery

12 V, 7 Ah or 18 Ah sealed lead-acid rechargeable

battery

• Power Sonic: PS-1270; PS-12180

• YUASA: NP7-12; NPG18-12

1.8.2 RAM Backup Battery

• 3 V coin-type lithium battery (Panasonic

CR2032 or equivalent)

1.9 Available Power

1.9.1 Auxiliary Power

Use auxiliary power terminals to power devices

requiring continuous power. Up to 1.2 A is

available for continuously powered devices.

1.9.2 Alarm Power

The Alarm Power (ALRM +) terminal provides

positive 12 VDC for Programmable Output 2 (PO

2) when it is configured as a siren driver and PO

1 when it is configured as the alarm output. Up to

1.85 A of alarm power is available.

1.10 Installer Keypad/RPS Connector

Use the Aux/Data connector to connect an

Installer Keypad or a DX4010i/DX4010 to the

control panel for programming and diagnostics.

EN | 10

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

EN | 11

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

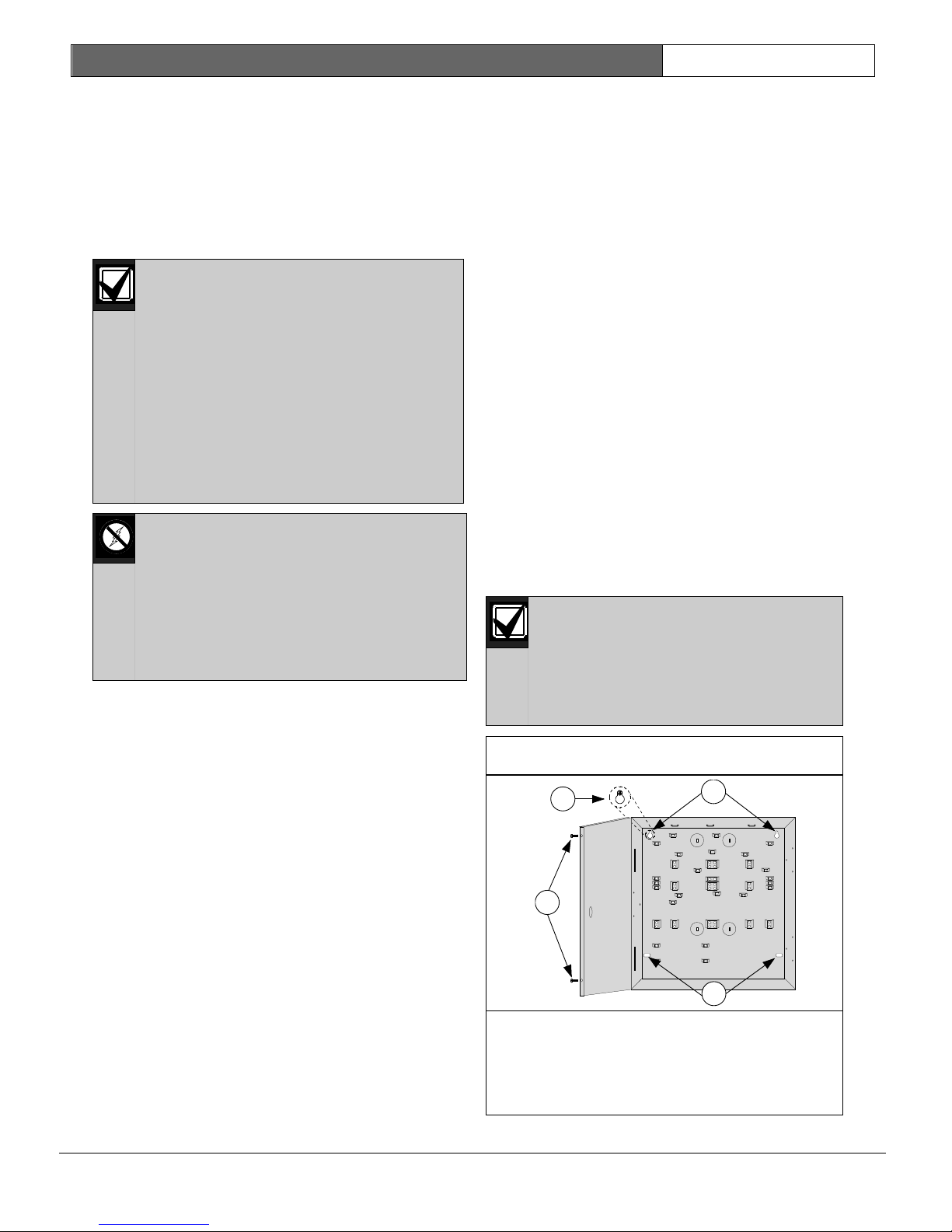

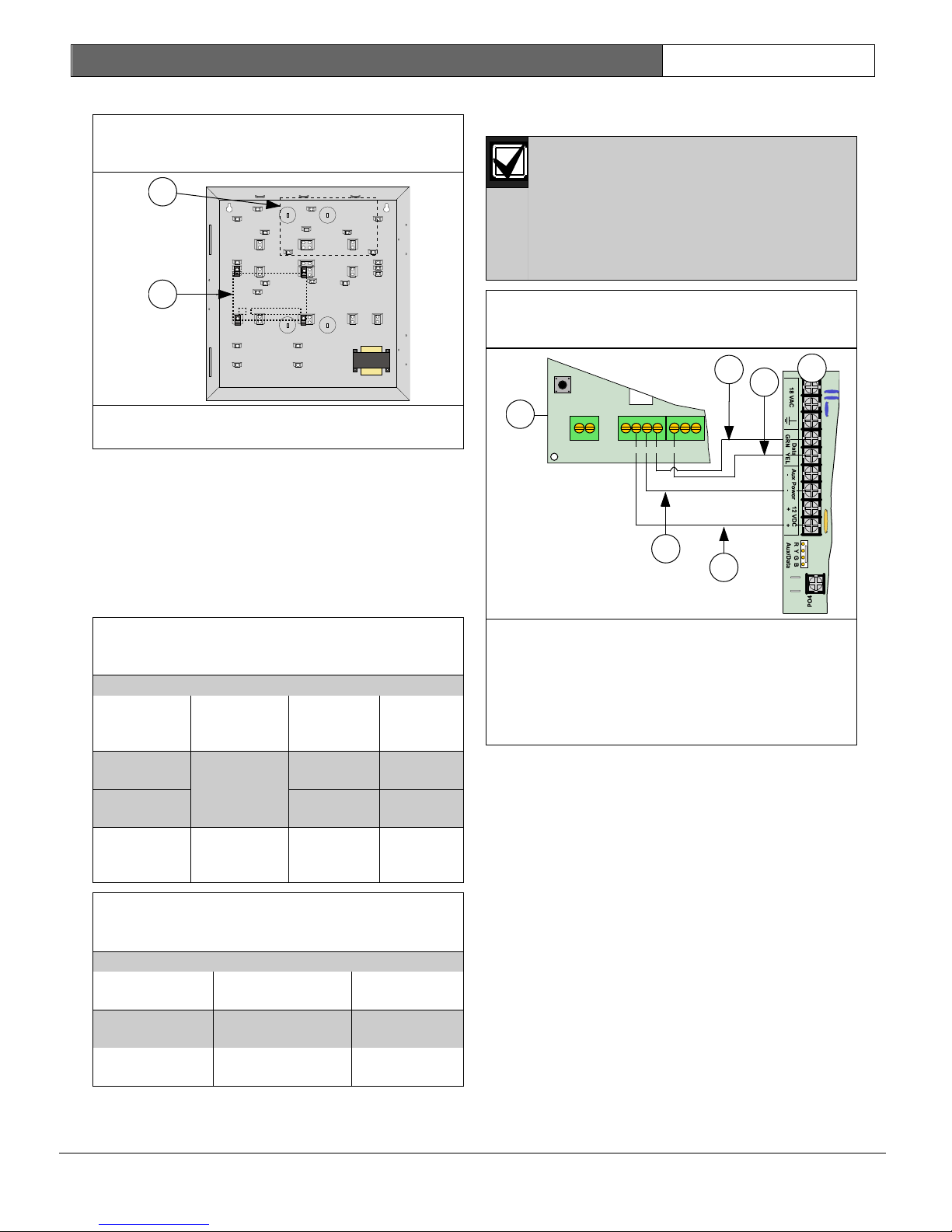

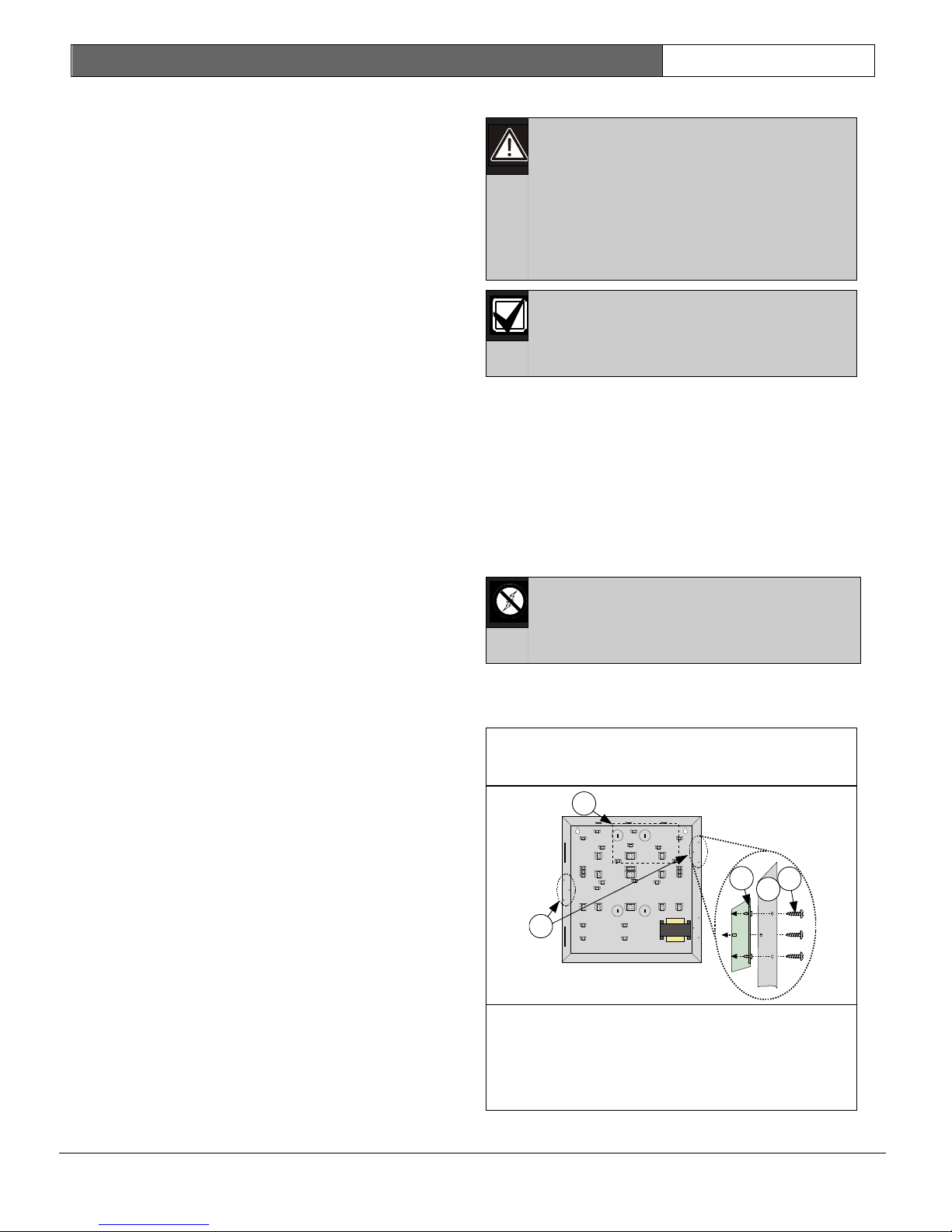

Figure 1: Enclosure Installation

1

3

2

4

If you think that EMI could be a problem, use

2. System Installation and

shielded cable. The drain wire for the shielded

cable must have continuity from the earth ground

Setup

2.1 Control Panel Installation

The control panel and enclosure are shipped

together. Hardware to attach the enclosure to the

wall is not supplied.

terminal on the control panel to the end of the

wire run. If continuity is not maintained, the

shielded cable can aggravate potential noise

problems rather than eliminate them.

Connecting the drain wire to ground at any place

other than the control panel’s earth ground

Only qualified, authorized service

personnel should install and maintain

this system. Test the entire system at

least once a week, and have a

qualified technician check the system

at a minimum of once every three

years.

As this is permanently connected

equipment, a readily accessible

disconnect device shall be

incorporated into the building

installation wiring.

The control panel contains staticsensitive components and must be

handled with care. Follow anti-static

procedures when handling it.

Touch the control panel’s earth

ground terminal to discharge any

static charge you may be carrying

before working on it.

2.1.1 Electro Magnetic Interference (EMI)

EMI might occur if you install the system or run

system wires near any of the following:

terminal might also create problems. If you cut

the drain wire to install devices, be certain to

splice it together. Carefully solder and tape all

splices.

2.1.2 Enclosure Installation

Knock out the desired wire entrances on the

enclosure.

Use the enclosure as a template and mark the top

mounting holes on the mounting surface.

Pre-start the screws (not supplied) for these

holes.

Place the enclosure onto these screws. See

Figure 1.

Tighten the screws.

Screw in the remaining two screws into the

bottom holes. See Figure 1.

Use proper anchor and screw sets

when installing the enclosure on

non-load-bearing surfaces, such as

dry wall.

Use the screws provided to secure

the enclosure cover (see Figure 1).

• Computer network system

• Electrical lines, fluorescent fixtures, or

telephone lines

• Amateur radio transmitter site

• Heavy machinery and motors

• High voltage electrical equipment or

transformers

• PBX telephone system

• Public service (police, fire, etc.) using radio

communications

• Radio station transmitter site or other

broadcast station equipment

• Welding shop

1- Screws for securing the cover

2- Slide enclosure screws into upper portion of

mounting hole

3- Top holes

4- Bottom holes

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

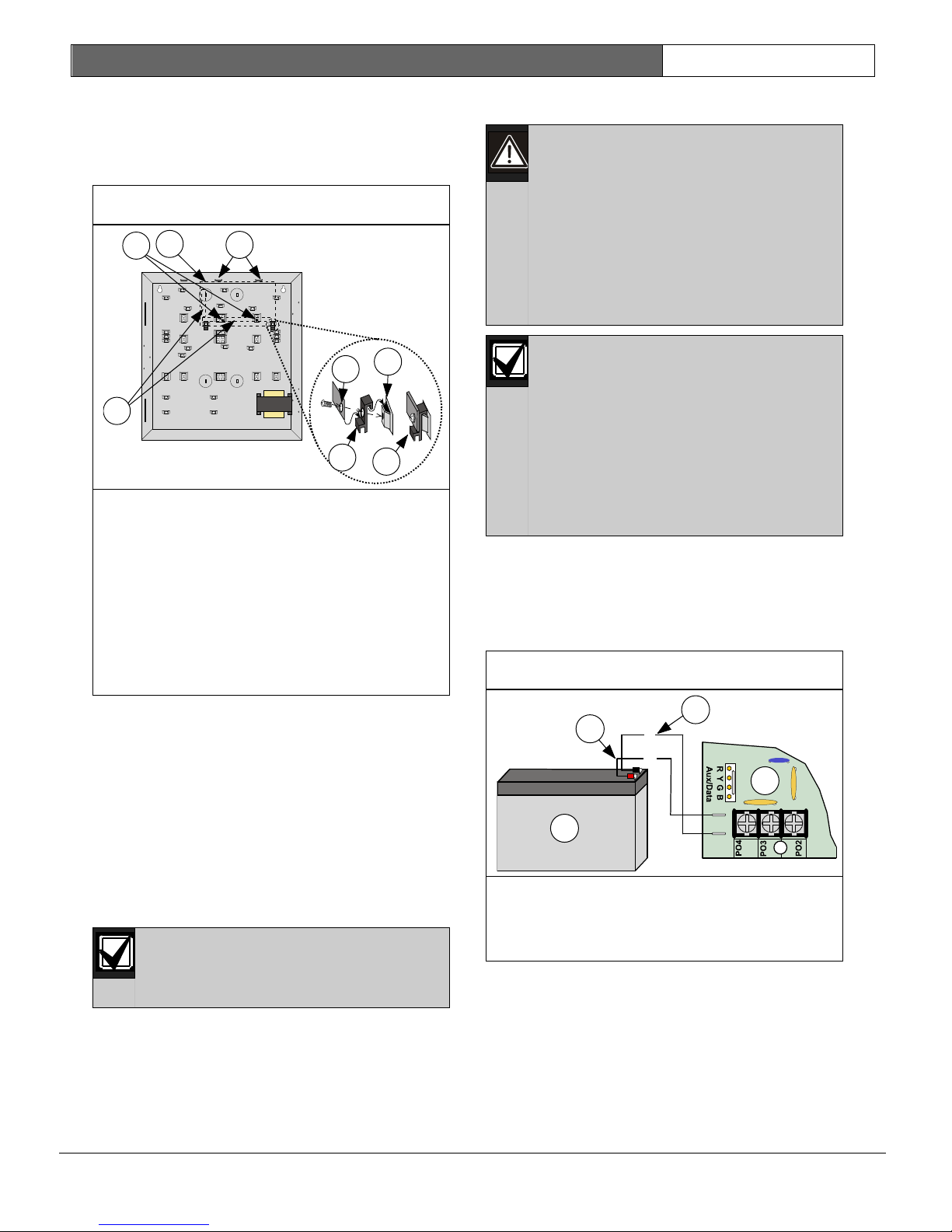

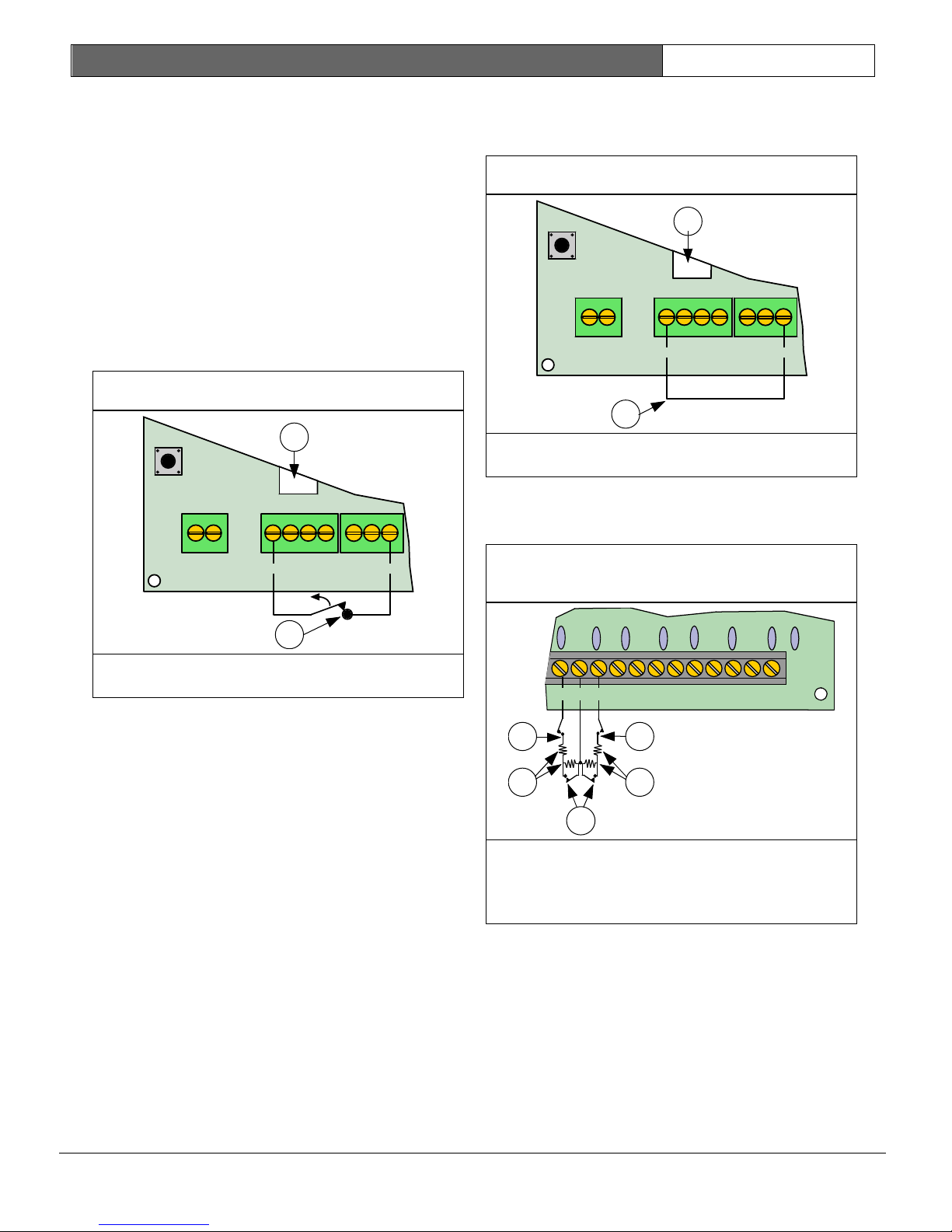

Figure 2: Control Panel Board Mounting

Figure 3: Standby Battery Connections

1

2

=

4

5

6

7

3

8

BATT+

BATT-

(+)

(-)

1

2

3

4

2.1.3 Control Panel Board Installation

1. Place the control panel board clips on the

appropriate standoffs in the enclosure. See

Figure 2.

1- Install support standoffs (0.08 mm) here

2- Control panel board location

3- Place edge of control panel board between

slots

4- Corner of control panel board

5- Control panel board clip

6- Enclosure standoff

7- Completed assembly

8- Control panel board terminal block

locations

EN | 12

2.1.6 Standby Battery Installation

High current arcs are possible. The

red (+) battery lead and the control

panel’s “BATT +” connector can

create high current arcs if shorted to

terminals or enclosure. Use caution

when working with the red lead and

the control panel’s “BATT +”. Always

disconnect the red lead from the

battery before removing the red lead

from the control panel.

Replace the standby battery every 3

to 5 years under normal use.

Exceeding the maximum output

ratings, or connecting the control

panel to an outlet that is routinely

switched off, causes heavy

discharges. Routine heavy

discharges can lead to premature

battery failure. Record the date of

installation directly on the battery.

When the standby battery and the transformer

connections are made, the control panel charges

the standby battery as you finish the installation.

See Figure 3 for details when installing the

standby battery.

Slide the control panel board into the slots at the

top of the enclosure, and then secure it with the

two screws provided. See Figure 2.

2.1.4 Ground and Transformer Connection

1. Connect the green/yellow earth ground wire

from the earth ground stud to the control

panel as shown in Figure 65 on page 129.

2. Connect the orange and yellow wires from

the transformer to the control panel as shown

in Figure 65 on page 129.

2.1.5 Mains Connection

1- Standby battery

2- Control panel board

3- Black (-) line

Make sure you have a good earth

ground before completing the

following steps.

4- Red (+) line

Follow all electrical codes when routing the AC

Mains power connection to the control panel.

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

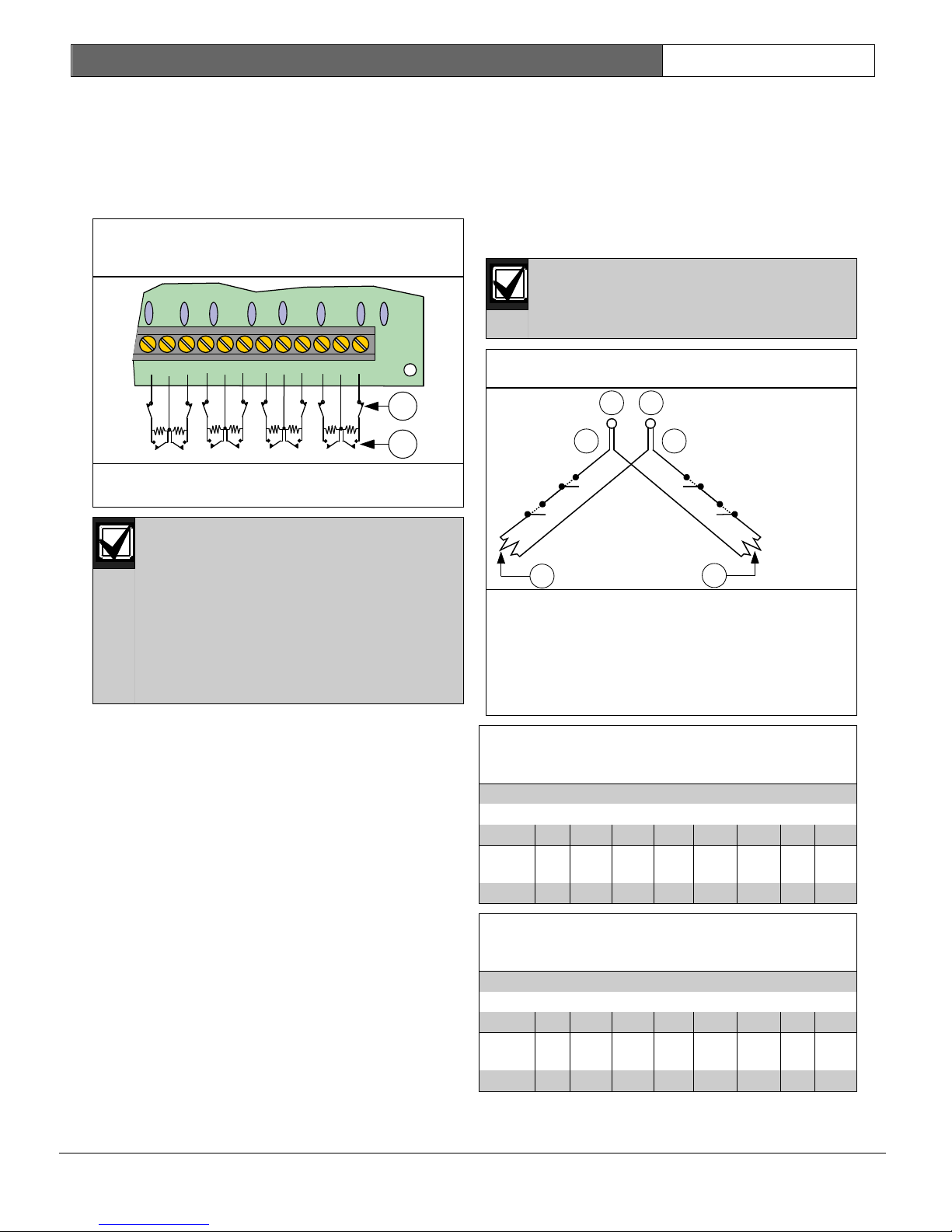

Figure 4: RAM Backup Battery

REMOVE

Figure 5: RJ31X/RJ38X Wiring

AUXILIARY

2

1

3

3

4

5

6

1

2 3

6

7 8

1 2

3

4 5

6 7

8

R1

T1R

T

4

5

T

R

T1

R1

1

2

2.1.7 RAM Backup Battery Installation

The control panel uses a 3 V coin-type lithium

battery to save system settings, including

date/time and programming settings.

Remove the insulator tab from between the

battery and battery clip before completing

system installation.

1- RAM Backup Battery

2- Battery Clip

3- Insulator -

EN | 13

2.1.8 Telephone Connections

See System Status LED on page 40 for a complete

function description.

1. To prevent jamming of signals, wire the

RJ31X jack or RJ38X jack to support line

seizure as shown in Figure 5.

2. Install the jack on the street side of the

phone switch, wired ahead of any PBX

equipment. Line seizure temporarily

interrupts normal phone usage while the

communicator transmits data.

3. Confirm that the panel seizes the line,

acquires dial tone, reports correctly to the

receiver, and releases the phone line to the

in-house phone system.

1- Outside Telco (PSTN)

2- Premises telephone

3- RJ31X or RJ38X jack

4- Telco connector block

5- Phone line connections to control panel

6- Bar short removed on Telco connector

block insertion – positions 1 & 4 and 5 & 8

4. Connect the telephone cord’s flying leads to

the telephone terminals (Red to R; Gray to

R1; Brown to T1; Green to T). The terminals

are located on the right side of the control

panel board.

5. Plug the other end of the cord to the RJ31X

jack or RJ38X jack.

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

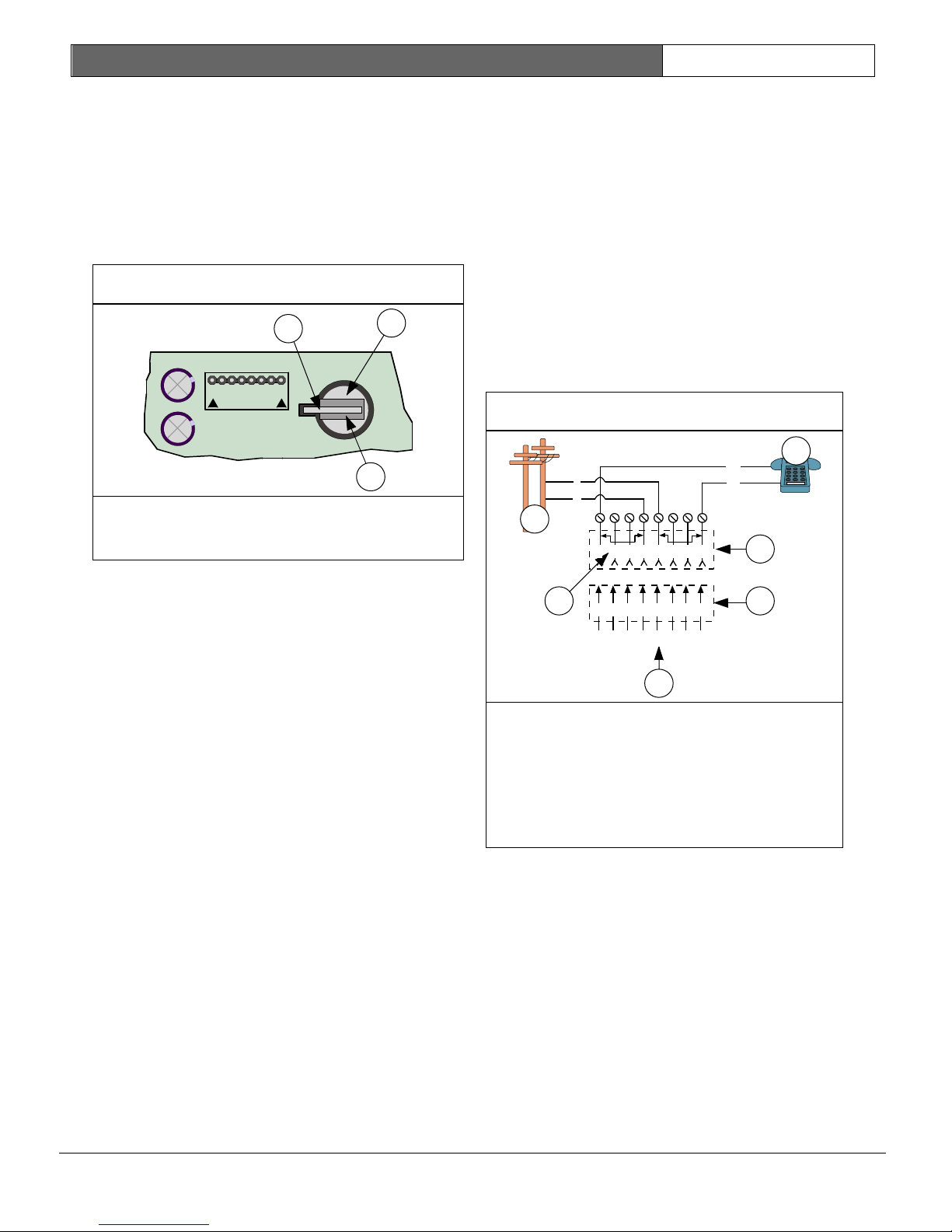

Figure 6: Ground Start

BATT+

BATT-

ALRM

+

PO1

L-1

SMK

+

L-2COM

L-4COML-3 L-6COML-5

L-8COML-7

T

T1

R1

AUXILIARY

PO1 SELECT

STATUS

R

B

A

1

2.1.9 Ground Start

Some telephone systems require a momentary

ground input to initiate a dial tone. To interface

with a ground start system, wire PO 1 as shown

in Figure 6. The PO 1 Jumper must be open.

Program PO 1 for Ground Start. See

Programmable Output 1 (PO 1) on page 21 for

programming instructions.

Connect a proper earth ground

reference to the earth ground

terminal.

Ground Start is not intended for use

in fire or combined fire/burglary

applications.

1- Place PO1 jumper in OPEN position as

shown

2.1.10 Phone Line Fault

The control panel has a circuit that tests the

phone line for voltage. The normal voltage on a

telephone line is approximately 48 VDC (24 VDC

for some phone systems). The phone line monitor

senses trouble when the voltage drops low

enough (between 1 and 3 V).

If the control panel senses trouble for 40 sec, it

begins a phone line trouble response.

Programming determines the response type. See

“Phone Line Fault Response Options” in the

DS7200V2 Expert Programming Guide (P/N:

4998153891) for details.

Bad line may test OK: The telephone line test

circuit uses the voltage level to test the status of

the phone line. In some instances, a given

telephone line might be out of service without

affecting the voltage on the line. The phone line

monitor cannot recognize this trouble condition.

EN | 14

2.1.11 Communication Failure (Comm Fail)

The control panel routes reports to two routing

destinations. Each destination can be

programmed with two phone numbers or IP

addresses.

The numbers in {} are the numbers assigned to

control panel events.

Communication Attempt Tables on page 123

shows the circumstances when Communication

Failure Events are created. When a Comm Fail

occurs, the control panel responds as follows:

1. Clear (dump) the initiating report and any

pending reports from the dialer buffer for the

destination where the Comm Fail event

occurred.

2. Create a Comm Fail {69} or Alternate Comm

Fail {70} report that includes the Destination

Number (1 or 2). The Alternate Comm Fail

report is used when an alternate

communications path is used (for example,

network communication).

3. The Comm Fail, Comm Restoral {71},

Alternate Comm Restore {72} reports follow

the System Status Reports routing.

4. If the Comm Fail occurred on Destination 1

and System Status Reports routing is set to

Destination 2 or set to Destination 2 on

Destination 1 fail, then send Comm Fail

report.

5. If the Comm Fail occurred on Destination 1

and System Status Reports routing is set to

Destination 1 then send a Comm Restore

report with the next report for destination 1.

6. If the Comm Fail occurred on Destination 2

and System Status Reports routing is set to

Destination 1, then send Comm Fail report.

7. If the Comm Fail occurred on Destination 2

and System Status Reports routing is set to

Destination 2 then send a Comm Restore

report with the next report for Destination 2.

8. If a Comm Fail report is sent successfully to

the other destination, a Comm Restore event

should be sent when there is a successful

communication on the failed destination.

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

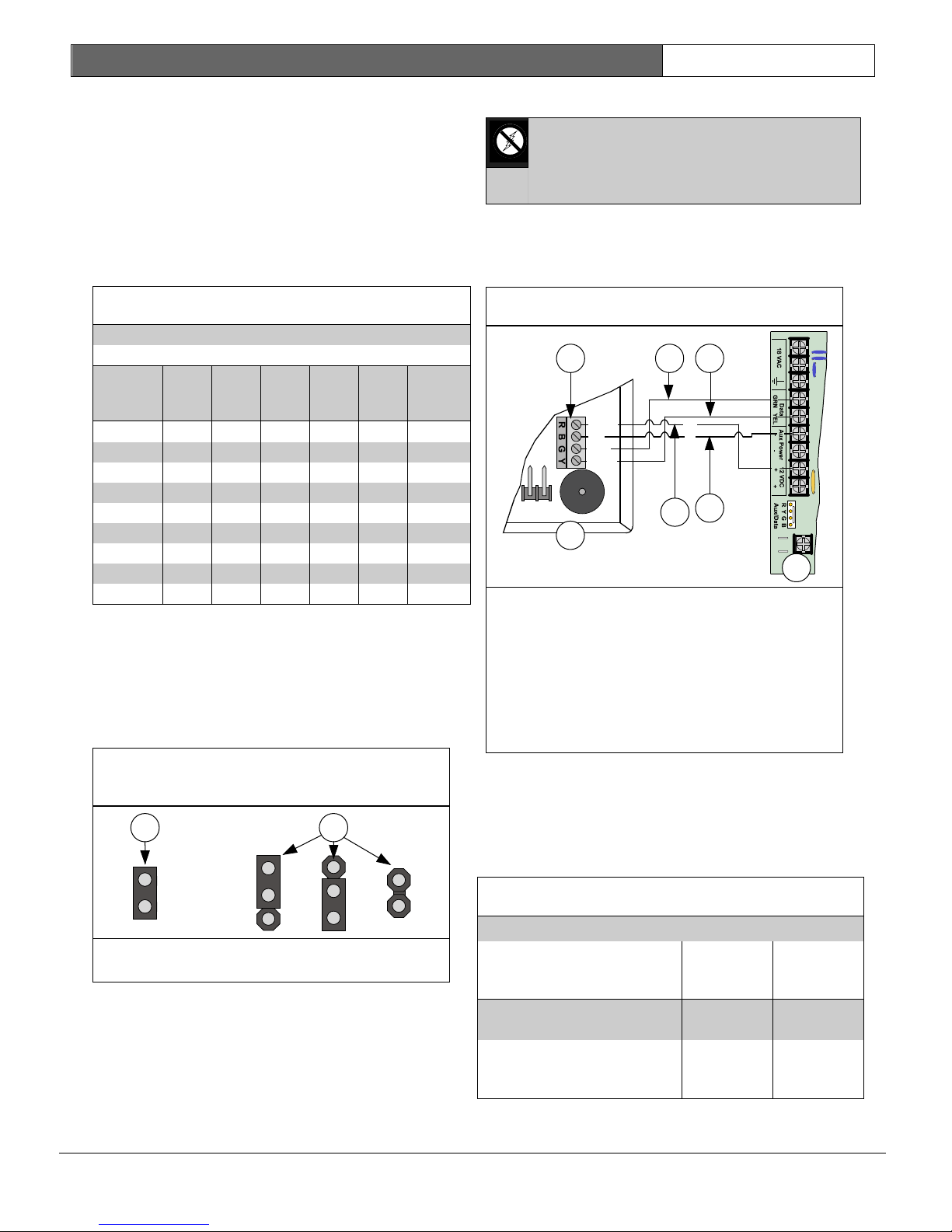

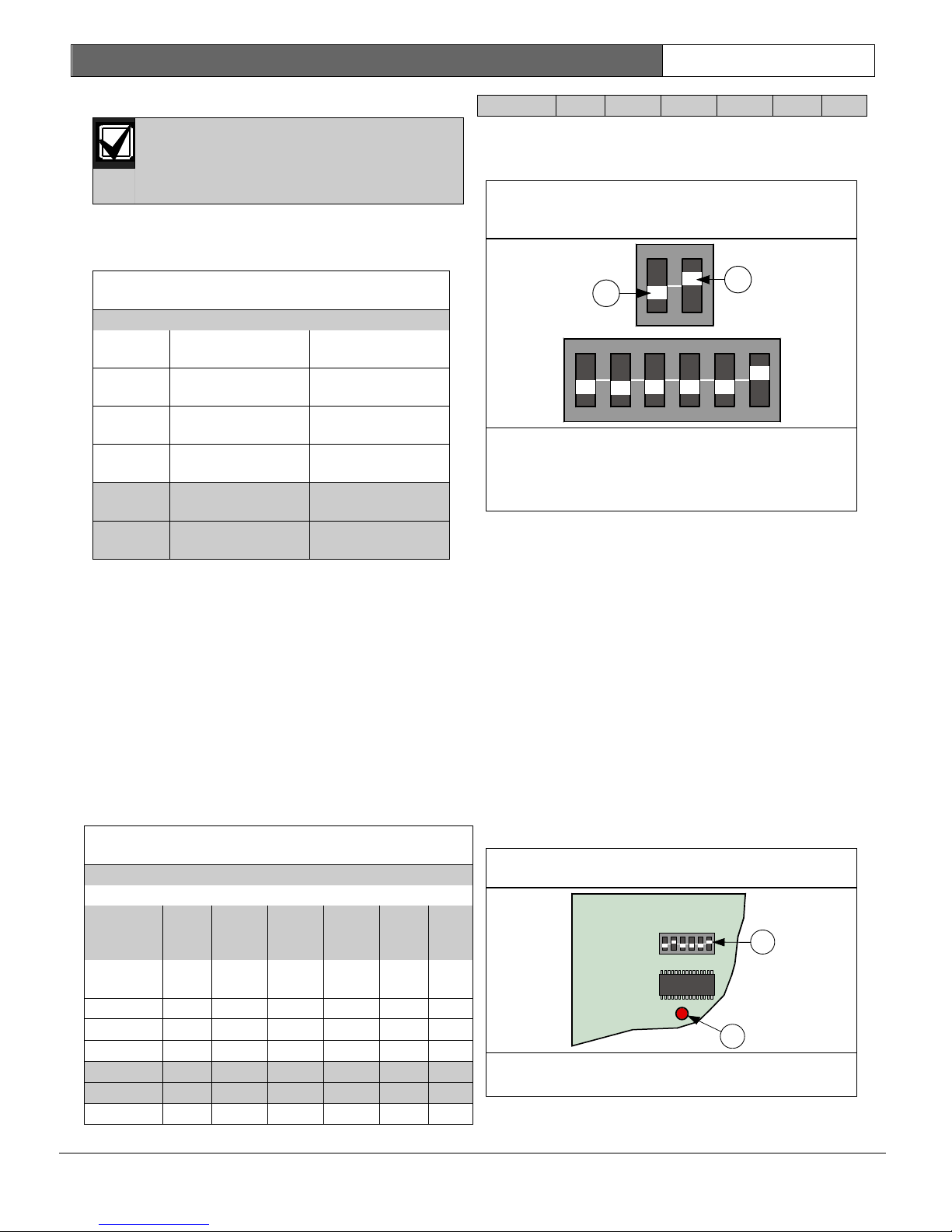

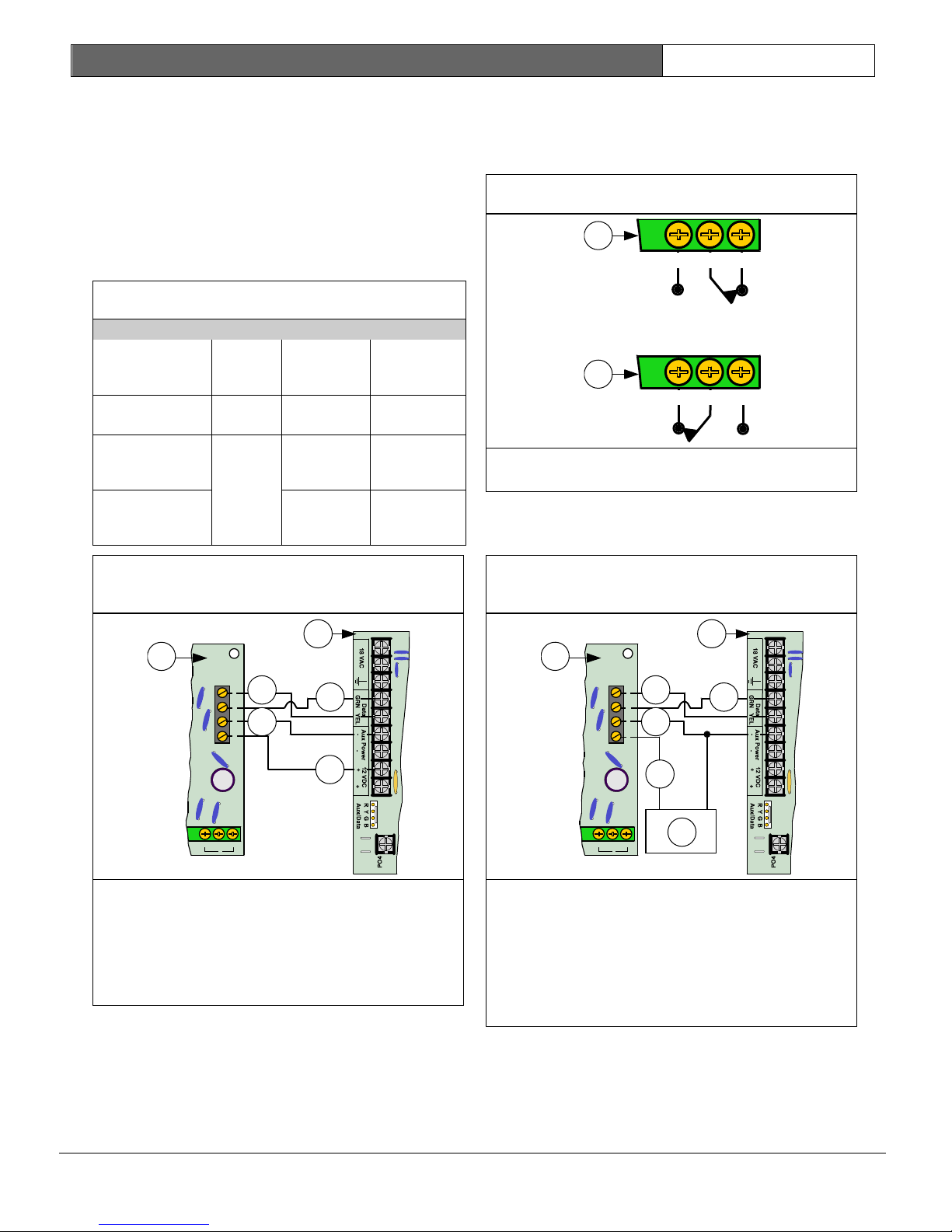

Table 3: Keypad Address Pin Settings

Keypad Address Pins

Keypad

Addres

s

1 2 4 8 16

MODE

ON

ON

ON

ON

ON ON

ON

ON

ON

ON

ON

ON

ON ON

ON

ON ON ON

ON

ON

ON

Figure 7: Keypad Jumper Plug

Configuration

Figure 8: Keypad to Control Panel Wiring

7- Control panel board

Table 4: Keypad to Control Panel Wire Length

0.8 mm

(#22

AWG)

1.2 mm

(#18

AWG)

1

2

BATT+

BATT-

7

Data In

Data Out

+12 VDC

Com

1

2 3 4

6

5

(+)

(-)

2.2 Arming Device Installation

The Door Access Control Module (DACM) is also

an arming device. See Door Access Control Module

(DACM) on page 38 for more information.

2.2.1 Keypad Addressing

Keypads 1 to 8 are assigned to Data Bus

Addresses 1 to 8.

Table 3 shows the correct address setting for

each keypad address.

0* OFF OFF OFF OFF OFF OFF

1

2 OFF

3

4 OFF OFF

5

6 OFF

7

8 OFF OFF OFF

* Address 0 is reserved for the Installer Keypad.

This keypad is not intended for permanent

installation and should remain with the

installer/service technician.

Some keypads use jumper plugs to set the

address. See Figure 7 for correct jumper plug

orientation.

OFF OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF

OFF

OFF OFF

OFF OFF

OFF OFF

OFF

EN | 15

2.2.2 Keypad Installation

Keypads contain static-sensitive

components. Follow anti-static

procedures when handling the

keypads.

Consult your keypad’s installation manual for

complete installation instructions. Keypads

connect to the control panel in parallel as shown

in Figure 8.

1- DS7447E/DS7445i Keypads, or

DS7447V2/DS7445V2 Keypads

2- Keypad terminal block

3- Green data wire

4- Yellow data wire

5- Red (+12 VDC) wire

6- Black (-12 VDC) wire

You can use either one of the Aux Power (-)

terminals and either one of the 12 VDC (+)

terminals when connecting devices to the control

panel.

See Table 4 for control panel data bus-to-keypad

wire length requirements.

1- Jumper plug ON position

2- Jumper plug OFF positions

Control Panel to Keypad 305 m

Control Panel to Keypad

using an External Power

Supply

(1000 ft)

305 m

(1000 ft)

610 m

(2000 ft)

610 m

(2000 ft)

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

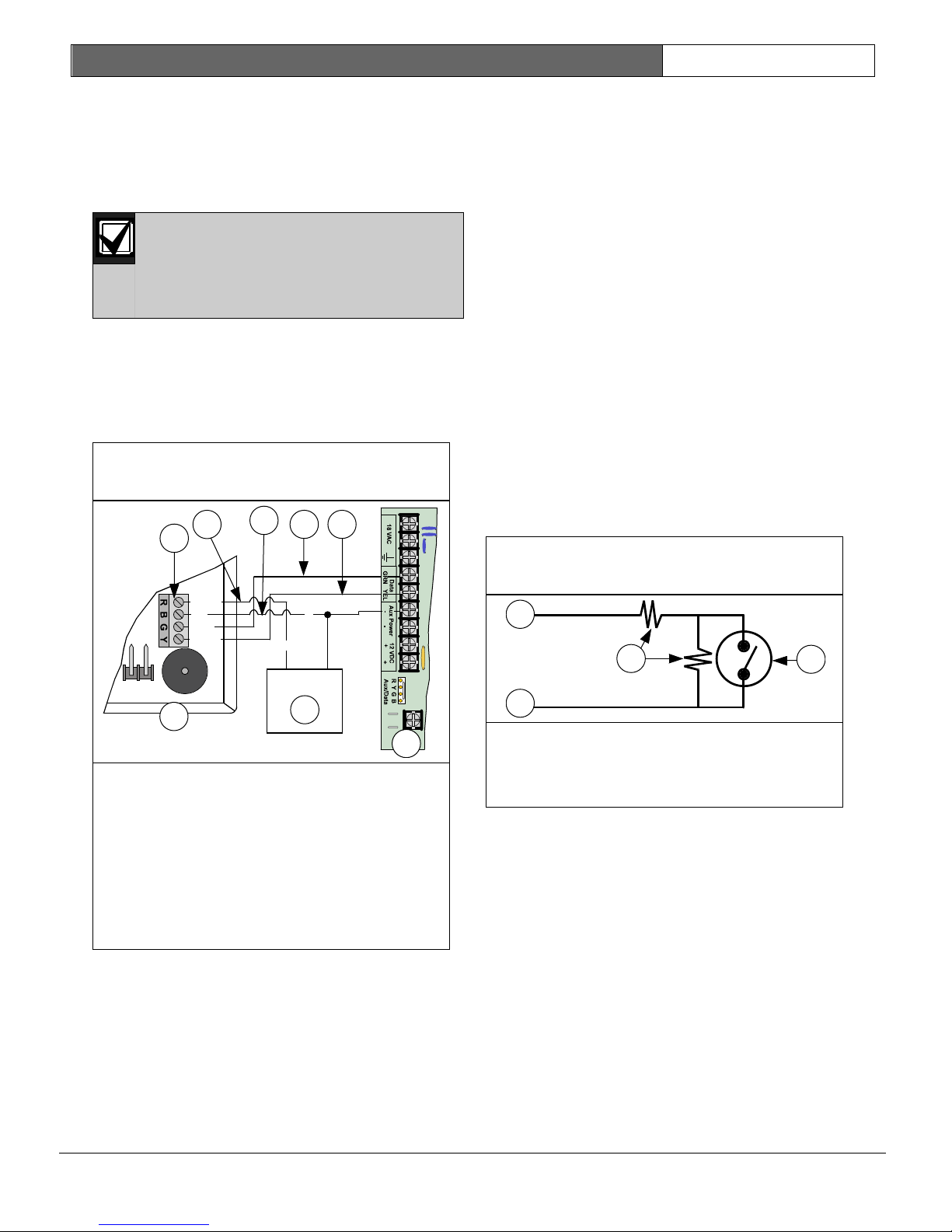

Figure 9: Keypad to Control Panel Wiring

(External Power Supply)

Figure 10: Keyswitch: Tamper Wired

Zone Configuration

1- Zone input

Data In

Data Out

+12 VDC

(+)

(-)

Com

(+)

(-)

1

2

3

4

8

5

6

BATT+

BATT-

7

3

1

2

4

See Power Outputs on page 8 to determine the

total power available for your system. You might

need to add one or more external power supplies

for the number of keypads you want to use. See

Figure 9 to connect an external power supply to a

keypad.

Do not tie the black (-) output to

earth ground when using an external

power supply. A ground fault

condition is reported if black (-) is

grounded.

You can use either one of the Aux Power (-)

terminals when connecting to the control panel.

Figure 9 shows the common from the external

power supply connected to both the keypad’s

common terminal and the control panel’s Aux

Power (-) terminal.

EN | 16

2.2.4 Keyswitch Overview

You can connect a maintained or momentary

contact arming device to arm or disarm any of the

areas in the system. The keyswitch is connected

to an on-board or off-board zone’s sensor loop.

The control panel offers a wide variety of

keyswitch arming options. The default keyswitch

configuration is tamper-wired. See “Controlled

Keyswitch Types” in “Zone Function

Configuration” in the DS7200V2 Expert

Programming Guide (P/N: 4998153891) for

alternative keyswitch configurations.

Outputs can be programmed to activate LEDs,

sound alarm outputs, or activate strobes to

indicate arming status for keyswitch arming

stations. See Output Parameters on page 86 for

more information.

2.2.5 Keyswitch Installation

Keyswitch Wiring – Tamper Wired Zone

Configuration

For maintained or momentary operation, wire the

keyswitch as shown in Figure 10.

1- DS7447E/DS7445i Keypads, or

DS7447V2/DS7445V2 Keypads

2- Keypad terminal block

2- Common

3- 2.2 kΩ resistors

4- Keyswitch

3- Red (+12 VDC) wire

4- Black (-12 VDC) wire

5- Green data wire

6- Yellow data wire

7- Control panel board

8- External 12 VDC power supply

2.2.3 Keypad Supervision

The control panel supervises communication to

the keypad. If it fails to communicate with the

keypad, it sends a “DBus Missing” {125} report.

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

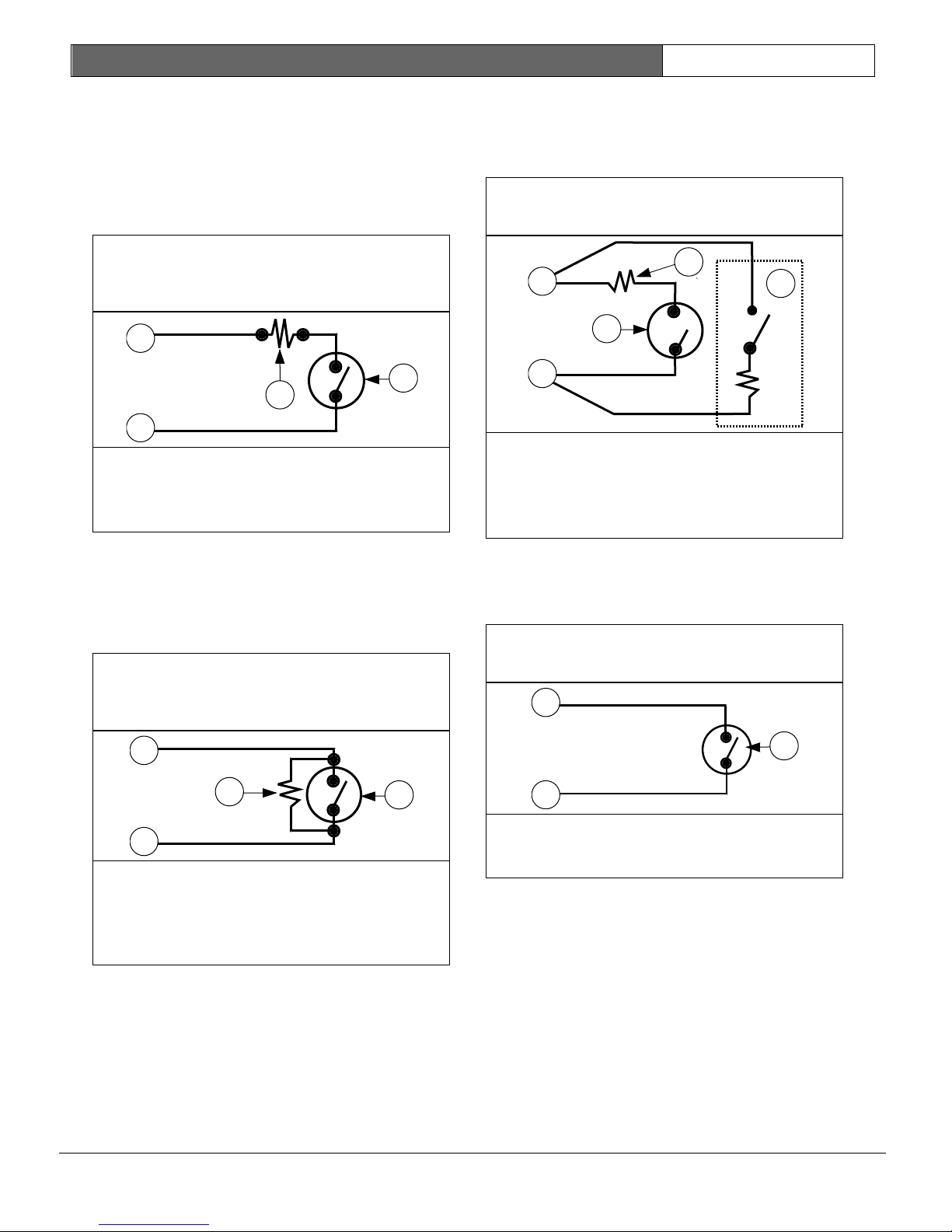

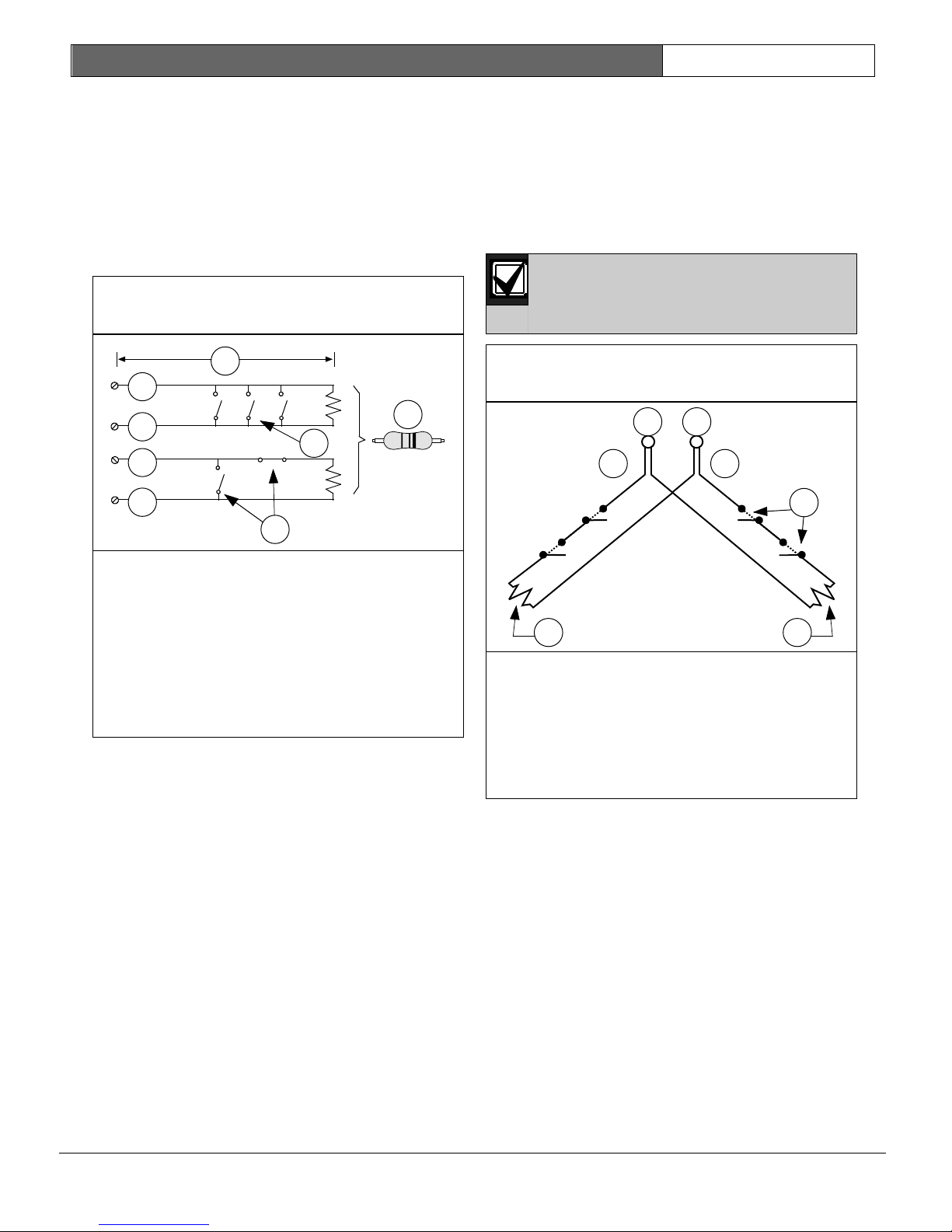

Figure 11: Maintained Keyswitch:

Single EOL Resistor

Configuration

Figure 12: Momentary Keyswitch:

Single EOL Resistor

Configuration

Figure 13: Keyswitch: Zone Doubled

Configuration

Figure 14: Keyswitch: No EOL Resistor

Configuration

3

1

2

4

3

4

1

2

1

2

3

Keyswitch Wiring – Single EOL Configuration

For maintained switches, connect the EOL

resistor for the zone at the keyswitch so that the

switch opens the circuit when it operates. A

short on the circuit produces an alarm if the area

is armed and a trouble if it is disarmed. See

Figure 11.

EN | 17

Keyswitch Wiring – Zone Doubled

Configuration

For maintained or momentary operation, wire the

keyswitch as shown in Figure 13.

4

1

3

5

2

1- Zone input

2- Common

3- 2.2 kΩ resistor

4- Keyswitch (Open on circuit arms area)

For momentary switches, connect the EOL

resistor for the zone at the keyswitch so that the

switch shorts the resistor when it operates. An

open on the circuit produces an alarm if the area

is armed and a trouble if it is disarmed. See

Figure 12.

1- Zone input

2- Common

3- 2.2 kΩ resistor

4- Keyswitch (Short on circuit toggles arming

state)

1- Zone input

2- Common

3- Second zone wiring

4- 2.2 kΩ or 3.65 kΩ resistor

5- Keyswitch

Keyswitch Wiring – No EOL Resistor

Configuration

For maintained or momentary operation, wire the

keyswitch as shown in Figure 14.

1- Zone input

2- Common

3- Keyswitch

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

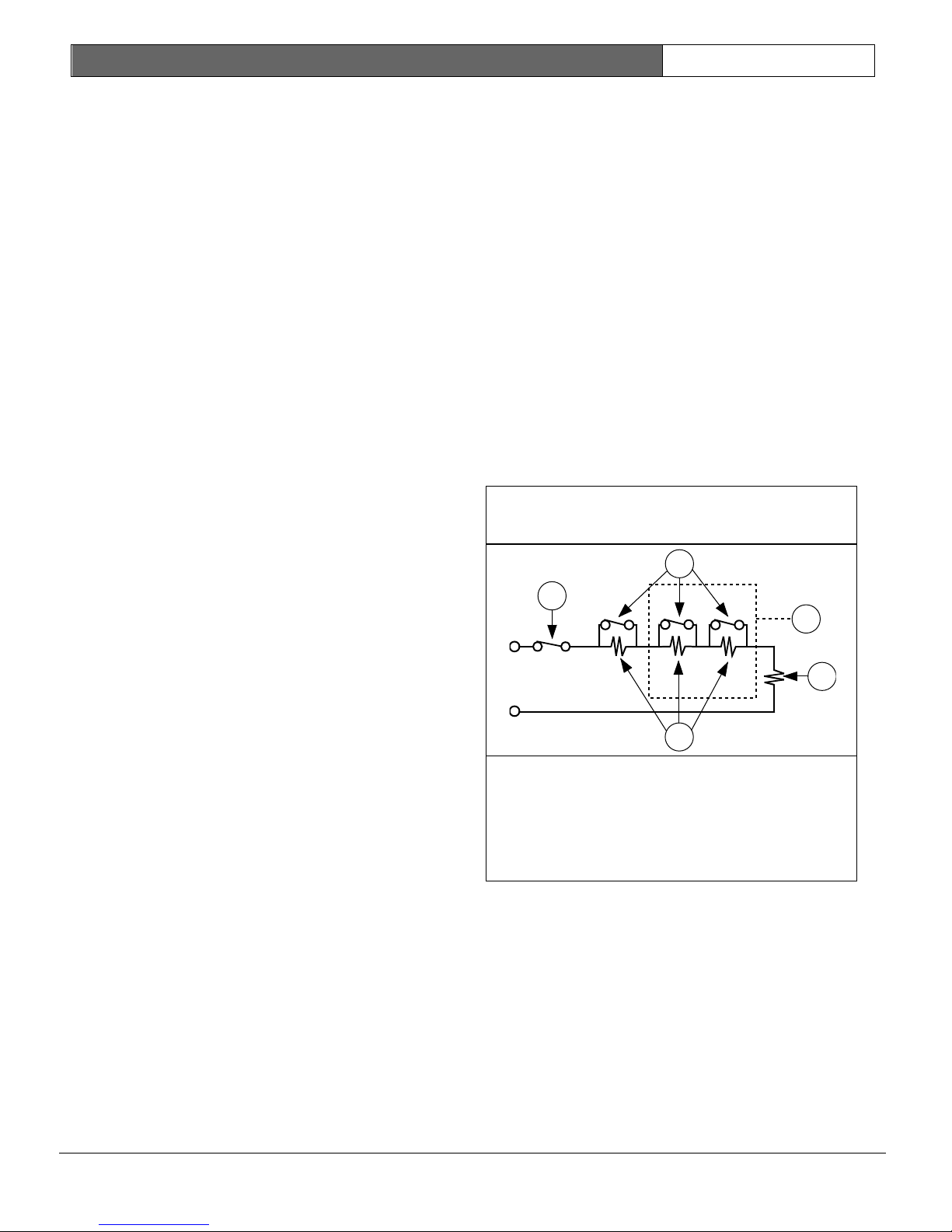

Figure 15: Tamper-Wired Zone

Configuration

3

4

1

2

5

2.2.6 Silencing an Alarm with a Keyswitch

Momentary Keyswitch: To silence alarms (stop

Alarm output), operate the keyswitch. If the area

is armed, operating the keyswitch to silence the

alarm also disarms the area. If the area is

disarmed, operating a momentary keyswitch to

silence the alarm does not arm the area.

Maintained Keyswitch: If the area is armed, turn

the keyswitch to the disarmed position. The

control panel disarms the area and silences the

alarm. If the area is disarmed, turn the keyswitch

to the armed position (the control panel does not

arm) and then return to the disarmed position.

2.2.7 Exit Terminator Button

When the Keyswitch Zone Function Options 1

parameter (see “Options 1, Zone Function ##” in

the DS7200V2 Expert Programming Guide

[P/N: 4998153891]) is set to 15, the input

functions as an exit terminator button. This zone

function activates in the same manner as the

momentary keyswitch. When Exit Delay is active,

operating the exit terminator button terminates

Exit Delay and immediately arms the control

panel. If Chime Mode is enabled and Exit Delay is

not active, pressing the exit terminator button

activates the chime tone and the button

functions as a doorbell.

EN | 18

2.3 On-board Sensor Loop Setup

2.3.1 Overview

The control panel provides eight on-board sensor

loops (L-1 to L-8). Each sensor loop operates

independently and does not interfere with the

operation of the others.

The default End-of-Line (EOL) resistor selection

for the on-board sensor loops is the single alarm

contact tamper-wired configuration.

See “Global Zone Configuration” in the DS7200V2

Expert Programming Guide (P/N: 4998153891) to

modify the on-board sensor loop EOL resistor

configuration.

2.3.2 Tamper-Wired Zone Configuration

The on-board sensor loops can be used as

tamper-wired zones to report tamper conditions

when the zone has become open or shorted.

See Figure 15 to wire a sensor loop as a tamper-

wired zone.

1- Tamper contact

2- Alarm contact

3- Multiple alarm contact configuration only

(5 contacts max)

4- 2.2 kΩ EOL resistor

5- 2.2 kΩ alarm resistor

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

Figure 16: Single Zone Sensor Loop

Wiring

Figure 17: On-board Doubled Zone

Sensor Loop Wiring

5

4

2

3

1

6

7

8

6

5

2

3

1

7

4

2.3.3 Single Zone Configuration (Loops 1-8)

When wiring the on-board sensor loops in the

single zone configuration, install the resistor of

the appropriate value (2.2 kΩ resistors are

provided) at the far end of the sensor loop to

provide a reference for supervision. You can

connect dry contact sensing devices in series

(Normally-Closed) and/or in parallel (NormallyOpen) to any of these loops (see Figure 16).

EN | 19

2.3.4 Doubled Zone Configuration

When wiring the on-board sensor loops in the

doubled zone configuration, install the resistors

of the appropriate value (2.2 kΩ and 3.65 kΩ) as

shown in Figure 17. The control panel can be

configured to function with either Normally-Open

or Normally-Closed contacts. Normally-Closed

contacts are recommended.

Each sensor loop is monitored as a

separate zone.

1- Sensor loop terminal

2- Common

3- Sensor loop terminal

4- Common

5- 100Ω maximum

6- 2.2 kΩ EOL resistor (P/N: 47819)

7- Normally-Open contacts

8- Combination of Normally-Open contacts and

Normally-Closed contacts

Loop resistance limits the number of NormallyOpen and/or Normally-Closed detection devices

that each sensor loop can supervise. The total

resistance for wire length and contacts, minus

the end-of-line resistor, must not exceed 100 Ω.

1- Common

2- Sensor Loop 1 to Sensor Loop 8

3- On-board Locations 1 to 8

4- Alarm Contacts

5- 3.65 kΩ EOL resistor

6- 2.2 kΩ EOL resistor

7- On-board Locations 9 to 16

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

Figure 18: Single Zone Sensor Loop

Wiring

(No EOL)

Figure 19: 4-wire Smoke Detector

(Tamper-wired)

5

4

2

3

1

6

7

BATT+

BATT-

ALRM

+

PO1

SMK

+

PO1 SELECT

4

1

2

3

5

6

A

B COM

L-1

2.3.5 No EOL Zone Configuration

See Figure 18 when wiring a zone with no EOL

resistors.

1- Sensor loop terminal

2- Common

3- Sensor loop terminal

4- Common

5- 100 Ω maximum

6- Normally-Open contacts

7- Normally-Closed contacts

EN | 20

2.3.6 Four-Wire Smoke Detector

Configuration

A four-wire smoke detector can be connected to

any of the control panel’s on-board sensor loops

(L-1 to L-8). A four-wire smoke detector must use

a relay module to interrupt power to the detector

in order for the detector to reset.

Configure the output controlling the relay as

Output Function 1|13 “Fire Verification” (see

Output Parameters on page 86 for more

information).

Make loop connections to L-X (where X = Loop #)

and COM terminals. See Figure 19, and Figure 20

on page 21.

1- Remove jumper plug from PO 1 SELECT

jumper

2- 2.2 kΩ alarm resistor

3- 2.2 kΩ EOL resistor

4- Smoke detector

5- AUX (+)

6- AUX (-)

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

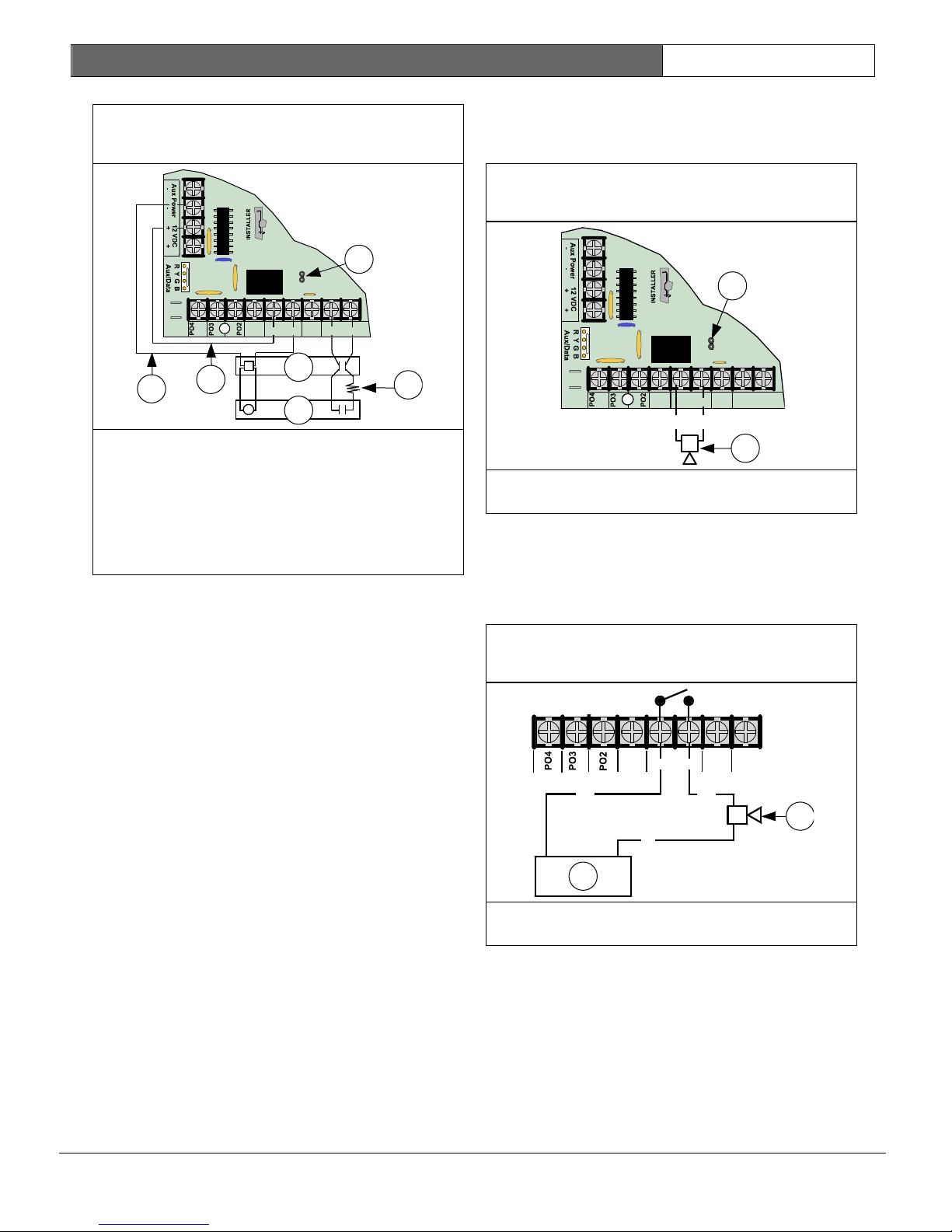

Figure 20: 4-wire Smoke

Detector (Single EOL Resistor)

Figure 21: PO 1 Wiring (PO 1 Jumper

Shorted)

Figure 22: PO1 Dry Contact Wiring (No

PO 1 Jumper)

BATT+

BATT-

ALRM

+

PO1

SMK

+

PO1 SELECT

2

5

6

4

3

A

B

COM

1

L-1

PO1

L-1

SMK

+

ALRM

+

(+) (-)

A B

(+) (+)

(-)

2

1

1- Remove jumper plug from PO 1 SELECT

jumper

2- 2.2 kΩ EOL resistor

3- EOL200 End-of-Line Module

4- DS250 with MB4W Base

5- AUX (+)

6- AUX (-)

2.4 On-board Output Setup

2.4.1 Overview

The control panel has four on-board

programmable outputs (PO 1 to PO 4).

Programmable Output 2 (PO 2) can be

configured as a supervised siren driver. See

“Global Output Options” in the DS7200V2 Expert

Programming Guide (P/N: 4998153891) for

programming instructions. When programmed as

a siren driver, PO 2 draws power from the ALRM

+ terminal. When connected to a 4 Ω

horn/speaker, PO 2 draws 380 mA of current.

When connected to an 8 Ω horn/speaker, it draws

330 mA of current. Use the appropriate current

draw in your total alarm power calculation.

EN | 21

2.4.2 Programmable Output 1 (PO 1)

By default, PO 1 is the Bell output, and the PO 1

SELECT jumper should be shorted. See Figure 21.

1

PO1 SELECT

BATT+

BATT-

ALRM

SMK

PO1

+

A

(+)

(-)

L-1

B

COM

+

2

1- Short PO 1 SELECT jumper with jumper plug

2- Audible notification appliance

PO 1 can also be configured as an alarm power

output (short PO 1 SELECT jumper). PO 1

operates as a dry contact, Normally-Open relay

with PO 1 SELECT jumper open. See Figure 22,

and Figure 23 on page 22 for details.

1- Audible notification appliance

2- DC power source

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

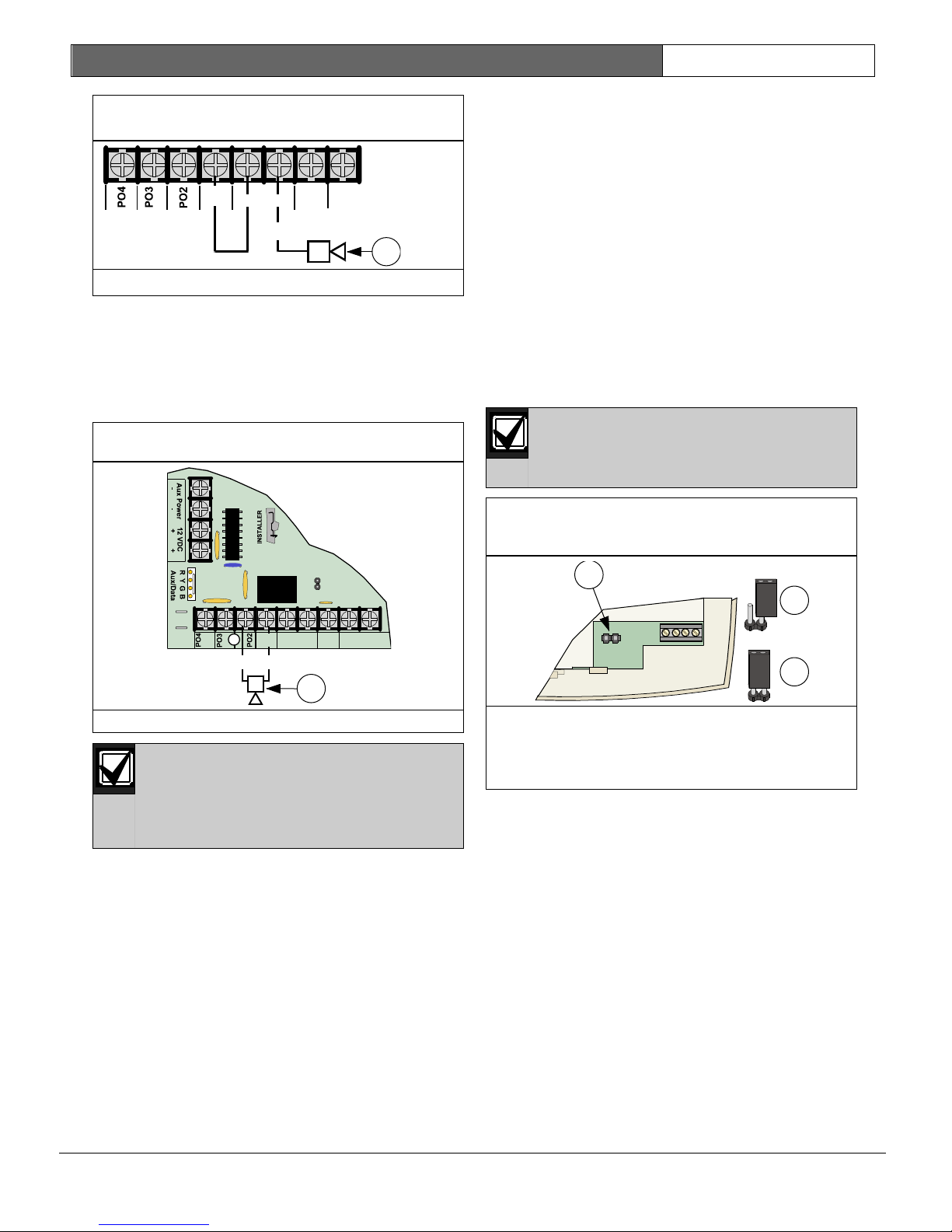

Figure 24: PO 2 to PO 4 Wiring

Figure 25: RF3227E Address Jumper

Settings

PO1

L-1

SMK

+

A B

(+)

1

ALRM

+

R

B G

Y

ADDR

1

2

3

Figure 23: PO 1 Positive Alarm Trigger

Wiring

1- Audible notification appliance

2.4.3 Programmable Outputs 2 to 4 (PO 2 to

PO 4)

PO 2 can be used with ALRM+ as a supervised

siren driver. Connect an approved 4 or 8

speaker. Alternatively, PO 2 can sink up to 500

mA 12 VDC. See Figure 24.

EN | 22

If PO 1 to PO 4 do not provide the alarm output

you expect, do the following:

Check the programming for Programmable

Outputs in Output Parameters on page 86.

Check “Zone Function Configuration” in the

DS7200V2 Expert Programming Guide

(P/N: 4998153891) to verify the zones you are

activating are programmed for alarm output.

2.5 RF3227E RF Receiver Setup

For complete installation instructions regarding

the RF3227E Premises RF Receiver, see the

RF3227E Installation Guide (P/N: 4998122415).

2.5.1 RF Receiver Addressing

Set the RF3227E’s address by placing the

address jumper pin as shown in Figure 25.

Remove power from the system and

RF receiver so that RF receiver

address changes can take effect.

PO1 SELECT

BATT+

BATT-

(+)

ALRM

+

(-)

PO1

A B

SMK

L-1

COM

+

1

1- Audible notification appliance

If PO 2 is configured as a supervised

siren driver (in combination with the

ALRM + terminal), you must connect a

4 or 8 speaker to PO 2 to clear the

speaker supervision trouble.

PO 3 and PO 4 can be configured for Alarm

Output. These outputs can sink up to 500 mA

12 VDC each.

Defaults for PO 2 to PO 4 are as follows:

PO 2: 1|6 (Strobe)

PO 3: 0|1 (Armed: All, Perimeter Only, Partial On)

PO 4: 2|13 (Ready to Arm)

See Output Parameters on page 86 for

programming instructions.

1- RF receiver address jumper pins

2- RF Receiver #1 (Address 50) jumper plug OFF

(default position)

3- RF Receiver #2 (Address 51) jumper plug ON

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

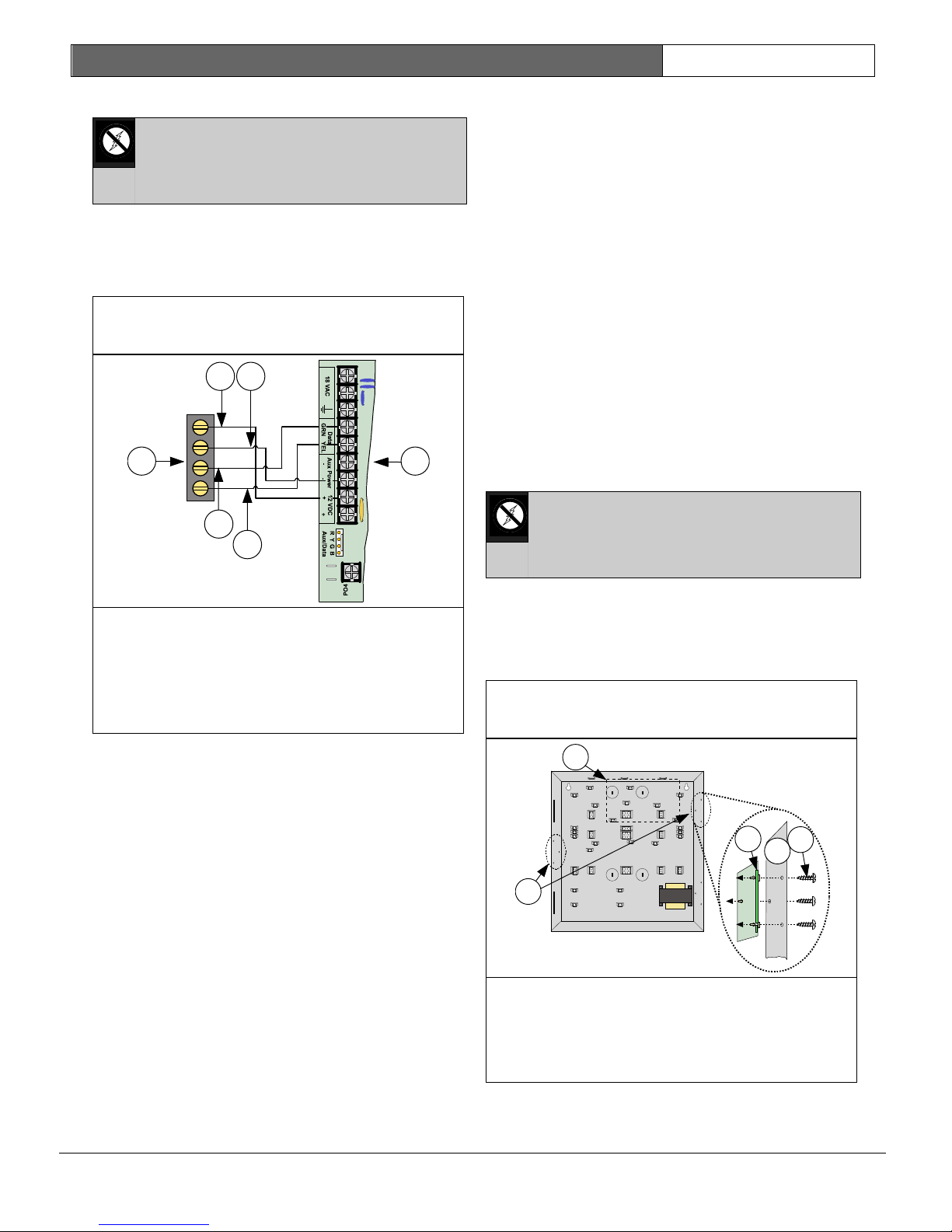

Figure 26: RF3227E to Control Panel

Wiring

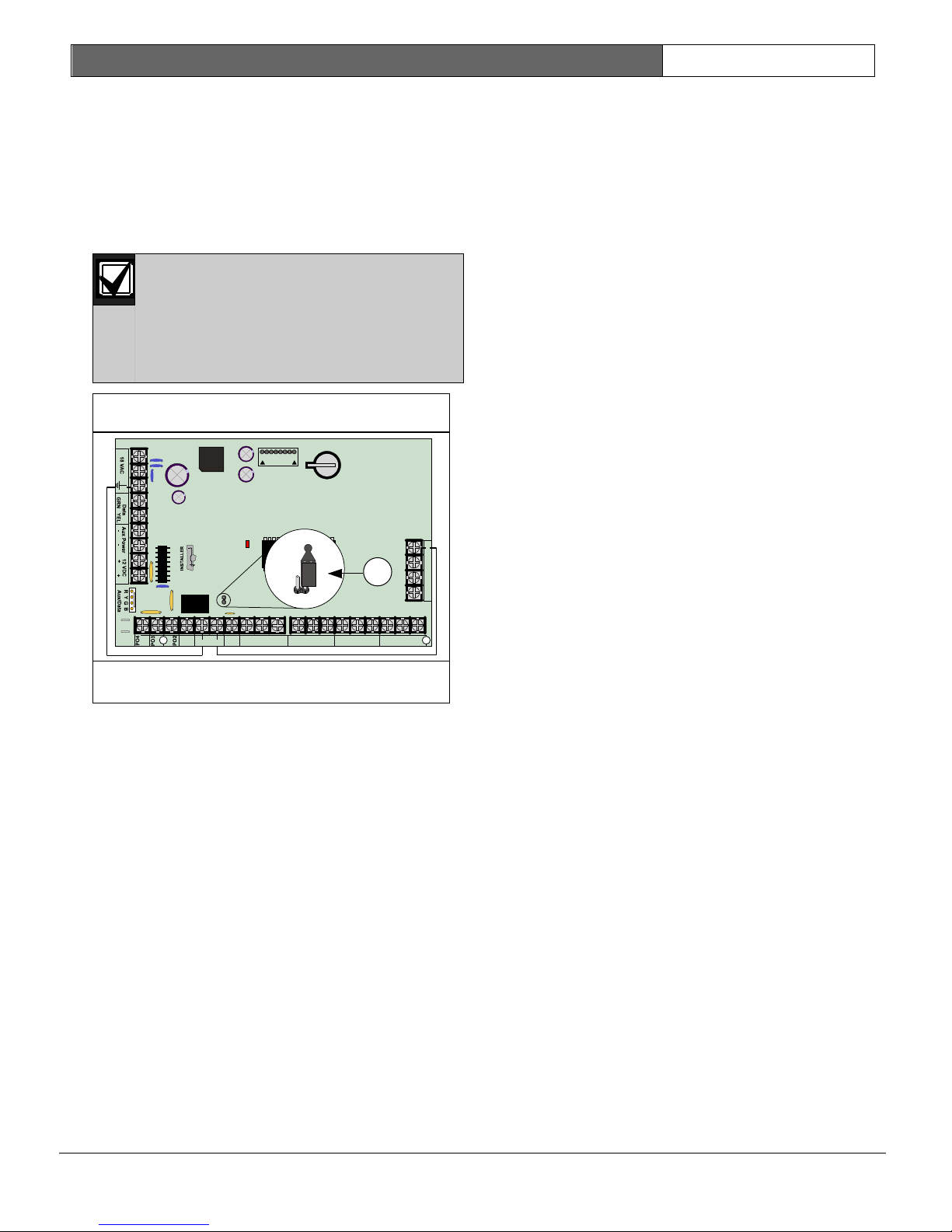

Figure 27: Standard DX2010 Installation

Locations

BATT+

BATT-

6

1

2 3

4

5

R

G

B

Y

1

3

4

2

5

2.5.2 RF Receiver to Control Panel Wiring

The RF3227E contains static-sensitive

components. Follow anti-static

procedures when handling this

module.

Wire the RF3227E to the control panel as shown

in Figure 26. When power is applied to the

system, the red LED at the center of the RF3227E

lights.

EN | 23

2.6 Off-board Sensor Loop Setup

(DX2010)

2.6.1 DX2010 (DX2014) Overview

The DS7240V2 supports up to 5 DX2010 Input

Expanders. The DS7220V2 supports up to 3

DX2010 Input Expanders.

Each DX2010 provides eight sensor loops. See

Location ##, Zone Function on page 83 for

information on how the DX2010 sensor loops are

assigned to zone locations.

• DX2014 Input Expander: A DX2010 mounted

inside a plastic enclosure with tamper switch

for remote installation.

• Current Draw without Aux Output

Terminals: 35 mA Standby

• Current Draw with Aux Output Terminals:

135 mA maximum with 100 mA of connected

accessories.

2.6.2 DX2010 Installation

The DX2010 contains static-sensitive

components. Follow anti-static

procedures when handling this

module.

1- RF3227E terminal block

2- Red wire (+) or (R)

3- Black wire (-) or (B)

Up to three DX2010 modules can be installed in

the control panel’s enclosure (two on interior

side walls of enclosure and one on back wall of

enclosure). See Figure 27 and Figure 28 for

installation locations.

4- Green data wire (G)

5- Yellow data wire (Y)

6- Control panel board

You can use either one of the Aux Power (-)

terminals and either one of the 12 VDC (+)

terminals when connecting devices to the control

panel.

2.5.3 RF Receiver Programming

See Data Bus Device Parameters on page 99 for

programming instructions.

2.5.4 RF Reciever Supervision

The control panel supervises communication to

the RF receiver. If it fails to communicate with

the RF receiver, it sends a “DBus Missing” {125}

report.

1- Control panel board location

2- Standard DX2010 mounting locations

3- DX2010 module

4- Enclosure wall

5- Screws (supplied with DX2010)

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

Figure 28: Optional DX2010 Mounting

Locations

Table 5: DX2010 to Control Panel Wire

Length

Power

Source

08 mm

(#22

AWG)

1.2 mm

(#18

AWG)

Used

(98.4 ft)

(249.3 ft)

Table 6: DX2010 to External Power Supply

Wire Length

08 mm

(#22 AWG)

1.2 mm

(#18 AWG)

Figure 29: DX2010 to Control Panel

Wiring

5

6

2

1

BATT+

BATT-

2

3

4

5

6

1

+OUT- TMPR 1 COMR B YG

1- Control panel board location

2- DX2010 optional mounting location

Up to five DX2014 modules can be connected to

the DS7240V2 (up to 2 on a DS7220V2). See

Figure 29 for wiring details.

2.6.3 DX2010 Wiring

Do not use twisted pair or shielded cable when

wiring the DX2010.

See the following tables for Data Bus wire length

requirements.

Aux Output

Not Used

Aux Output

Aux Output

Used or Not

Used

Control

Panel

External

Power

Supply

305 m

(1007.7 ft)

30 m

305 m

(1007.7 ft)

610 m

(2001 ft)

76 m

610 m

(2001 ft)

EN | 24

Connect the control panel’s Data and Aux Power

terminals to the DX2010 as shown in Figure 29.

If the DX2010’s Aux Output (“+Out-“

terminals) is used as an auxiliary

power source, the DX2010’s “R” and

“B” wires must be “home-run” to

either the control panel or to an

available power supply. Do not use a

daisy-chain wire configuration.

1- DX2010 module

2- Green (G) data wire

3- Yellow (Y) data wire

4- Black (-) wire

5- Red (+) wire

6- Control panel board

You can use either one of the Aux Power (-)

terminals and either one of the 12 VDC (+)

terminals when connecting devices to the control

panel.

Aux Output

Not Used

Aux Output

Used

305 m

(1007.7 ft)

30 m

(98.4 ft)

610 m

(2001 ft)

76 m (249.3

ft)

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

Figure 30: DX2010 to Control Panel

Wiring (External Power Supply)

Figure 31: DX2010 Auxiliary Output

Wiring

BATT+

BATT-

2

3

4

7

+OUT- TMPR 1 COM

B

Y

G

5

(+)

(-)

R

6

1

TMPR 1 COM

R

B

G Y

+OUT-

2

3

4

1

If you need to power the DX2010 with an external

12 VDC power supply, wire it as shown in Figure

30.

1- DX2010 Module

2- Green (G) data wire

3- Yellow (Y) data wire

4- Black (-) wire

5- Red (+) wire

6- External 12 VDC power source

7- Control panel board

Do not tie the black (-) output to

earth ground when using an external

power supply. A ground fault

condition is reported if black (-) is

grounded.

EN | 25

2.6.4 DX2010 Auxiliary Output Wiring

The DX2010 can provide 12 VDC at up to 100 mA

from the Auxiliary Output (-) OUT (+) terminals to

power external devices such as motion detectors.

See Figure 31.

1- DX2010 Module

2- Motion detectors, photo beams, etc.

3- Black (-) wire

4- Red (+) wire

The following maximum wire lengths

apply when wiring the DX2010’s

auxiliary output to remotely powered

devices, such as PIRs and smoke

detectors:

− 15 m (49.2 ft) for 0.8 mm (#22

AWG) wire.

− 30 m (98.4 ft) for 1.2 mm (#18

AWG) wire.

DS7200V2-EXP | Installation Guide | 2. System Installation

and Setup

Bosch Security Systems, Inc. | 04/12 | F01U253045-02

Figure 32: DX2010 Tamper Input Wiring

Figure 33: DX2010 No Tamper

Figure 34: DX2010 Tamper-Wired Zone

Wiring

1R B G Y+OUT-

TMPR COM

1

2

1

2

1

R B

G

Y+OUT-

TMPR

COM

3 4 5 6 7 8COM COM COM

1

2COM

3

1

1

2

2

2.6.5 DX2010 Tamper Input Wiring

Each DX2010 module provides an input for

tamper devices. The tamper input is in addition

to the zone sensor loops. Supervising an

enclosure tamper does not occupy a zone. A fault

on the tamper input is reported as a tamper

event to which the Data Bus address the DX2010

is set.

The tamper input can monitor external NormallyClosed (N/C) tamper switches when wired as

shown in Figure 32. The tamper circuit must be

closed to provide proper Input Expander tamper

supervision to the control panel. Do not use an

EOL resistor.

EN | 26

Use either the tamper input or the on-board

tamper switch. Both cannot be used

simultaneously.

1- DX2010 Module

2- Tamper Jumper

2.6.6 DX2010 Tamper-Wired Zone Wiring

For tamper-wired sensor loop configuration, wire

as shown in Figure 34.

1- DX2010 Module

2- External tamper switch

The DX2014 configuration includes a tamper

spring. Do not use the DX2010 TMPR input in the