Page 1

DS484Q/DS486Q

Installation Instructions

Quad Beam

EN

Photoelectric Detectors

Page 2

DS484Q/DS486Q | Installation Instructions | 1.0 Overview

1.0 Overview

1.1 Description

The DS484Q and DS486Q are photoelectric quad beam detectors that use four pulsed infrared beams to activate

an alarm relay upon detection of an intruder. Both models contain a transmitter that emits an invisible infrared

beam, and a receiver. If the beam is broken, the receiver signals an alarm. Multiple channel operation provides

increased system flexibility by allowing multiple devices to be used near each other without cross-talk or other

interference.

1.2 Components

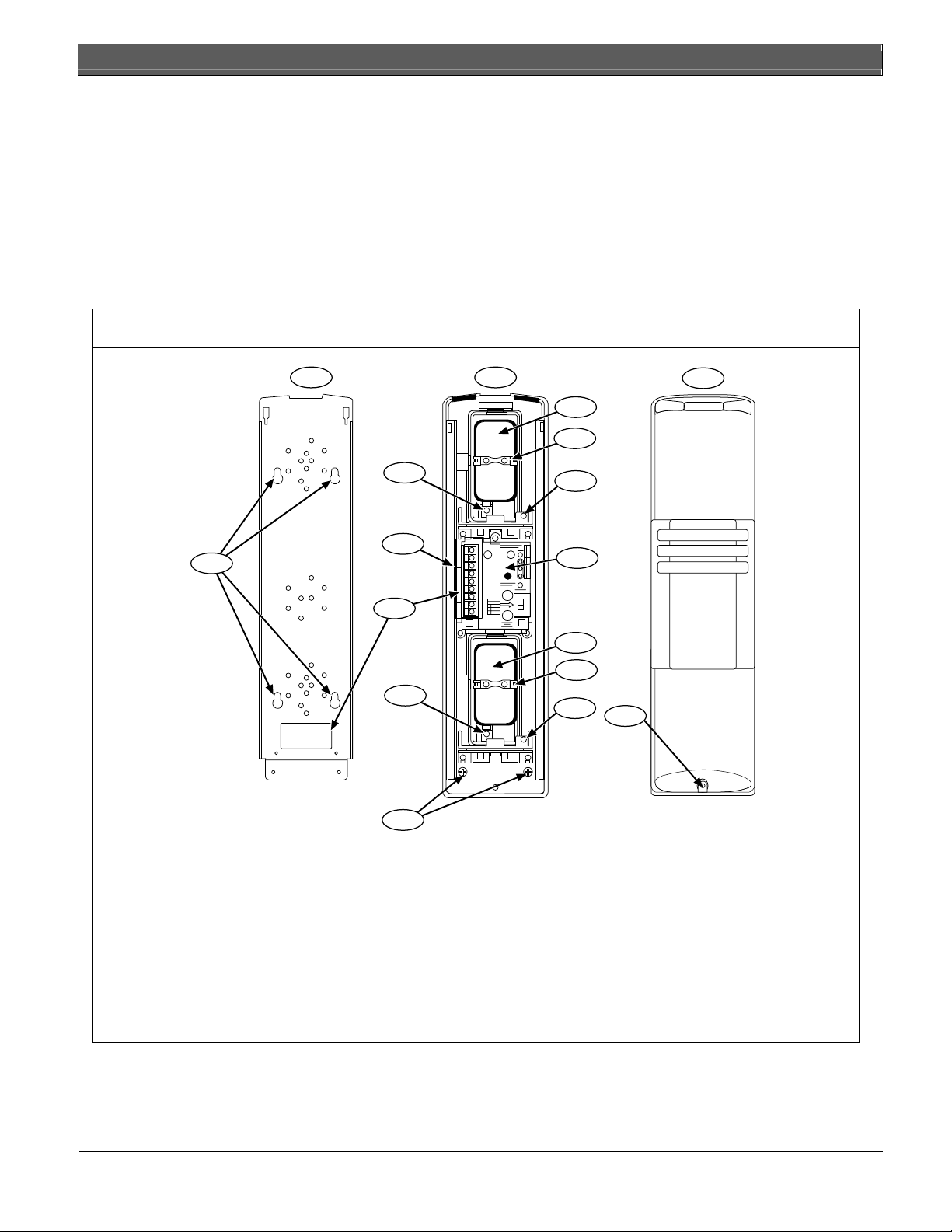

Figure 1: DS484Q/DS486Q Components

1 2

5

6

4

7

8

9

1 - Chassis

2 - Base

3 - Cover

4 - Mounting holes

5 - Vertical adjustment screw (upper)

6 - Terminal block (transmitter has five terminals,

receiver has nine terminals)

7 - Wire entrance

8 - Vertical adjustment screw (lower)

3

10

11

12

13

14

15

16

17

9 - Base mounting screws

10 - Optical module (upper)

11 - Scope (upper)

12 - Horizontal adjustment screw (upper)

13 - Operation panel (refer to Figure 2 or Figure 3)

14 - Optical module (lower)

15 - Scope (lower)

16 - Horizontal adjustment screw (lower)

17 –Cover mounting screw

2 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 3

DS484Q/DS486Q | Installation Instructions | 1.0 Overview

.

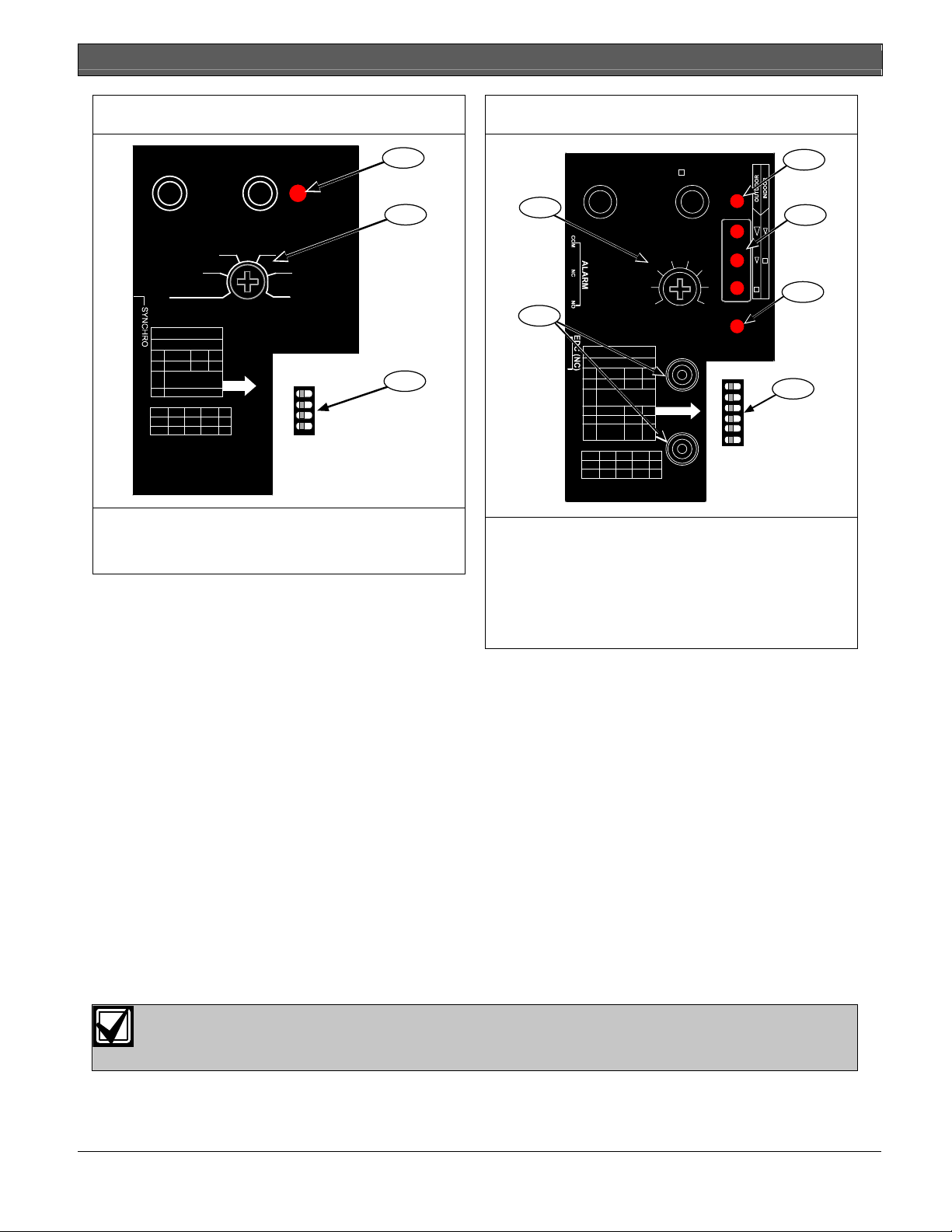

Figure 2: DS486Q Transmitter Operation Panel

1

POWER

2

130

160

260

100

200

OUTDOOR

60

INDOOR

120

BEAM POWER CONTROL (m)

SWITCH

OFF ↔ ON

No

ITEM

OFF ON

1Group

AB

23SEE CHART

BELOW

4NULL

OFF

OFF

--

M

1

2

OFF

ON

ON

OFF

SW2 - 3 : CHANN EL

SW2

SW3

MODEL:DS486Q

320

180

360

200

400

3

3

ON

ON

1 - POWER LED

2 - Beam power control

3 - DIP switches

Figure 3: DS486Q Receiver Operation Panel

3

4

5

6

1

2

ALIGNMENT IS COMPLETED

75

50

SWITCH

OFF ↔ ON

ITEM

No

OFF ON

1Group

AB

23SEE CHART

BELOW

4AND/OR

AND OR

5BYPASS

OFF ON

SOUND

6

OFF ON

CHECK

SW2 - 3 : CHANNEL

M

1

2

OFF

SW2

OFF

ON

OFF

SW3

ON

OFF

WHEN ‘ ‘ IS OFF

200

150

100

INTERRUPTION

TIME (msec)

3

ON

ON

ALIGNMENT

CHECK

TERMINAL S

ALARM

300

400

500

EDC LEVEL

1 - INTERRUPTION TIME switch

2 - Alignment check terminals

3 - ALARM LED

4 - Level meter

5 - Environmental discrimination circuit (EDC) LED

6 - DIP switches

1.3 Features

1.3.1 100 Times Sensitivity Allowance

Stable operation is maintained even if 99% of beam energy is cut by environmental disturbances such as rain, fog,

or frost.

1.3.2 Beam Power Control

Use this feature to select the appropriate beam intensity for the detection range. Controlling beam intensity

minimizes the risk of reflection off nearby walls and cross detection with other detectors.

1.3.3 Beam Interruption Time Control

Use this feature to change the beam interruption time to best fit the application.

1.3.4 Using Multiple Transmitter-and-Receiver Sets

Up to four transmitter-and-receiver sets can be stacked.

1.3.5 Selectable Beams

The beams in the DS484Q and DS486Q are configurable into eight different combinations (two groups by four

channels). These combinations can eliminate false alarms that can occur from cross-talk when multiple beams are

stacked, or when the transmitter and receiver are separated by a long distance.

The diameter of the transmitted beam increases with increased distance between the transmitter and

receiver. At distances that approach the maximum range, the beam might reach two or more

receivers. Refer to Section 2.1.2 Beam Spread on page 5 for additional information.

Bosch Security Systems, Inc. | 7/05 | 4998138530F 3

Page 4

DS484Q/DS486Q | Installation Instructions | 1.0 Overview

1.3.6 Selectable AND/OR Gate

The photoelectric intrusion detection system in the

DS484Q and DS486Q provides alarm relay activation

for different considerations. Use the DIP Switches to

Table 1: EDC BYPASS Switch States

Detector Status BYPASS Switch

select the required protection:

AND gate – All four beams must be blocked

simultaneously to cause an alarm. This setting results in

fewer false alarms caused by birds and other small

animals.

Poor

Environmental

Condition*

OR gate – Either the upper or lower pairs of beams

must be blocked. This setting can detect an intruder

crawling on the ground.

1.3.7 Environmental Discrimination Circuit (EDC)

The Environmental Discrimination Circuit (EDC)

sends a signal when maintaining stable operation

becomes difficult due to environmental disturbances.

The EDC detects the gradual loss of signal along the

beam’s path because of dirt built up on the cover, or

because of rain, fog, or snow. If the signal decreases by

95% over at least 4-seconds, the EDC activates the

EDC LED (refer to Figure 3 on page 3) and relay. This

indicates that something is partially blocking a beam,

or that the covers need cleaning.

The EDC feature was not evaluated by

Underwriters Laboratories (UL).

When either

optical module is

blocked for 3 or

more seconds.

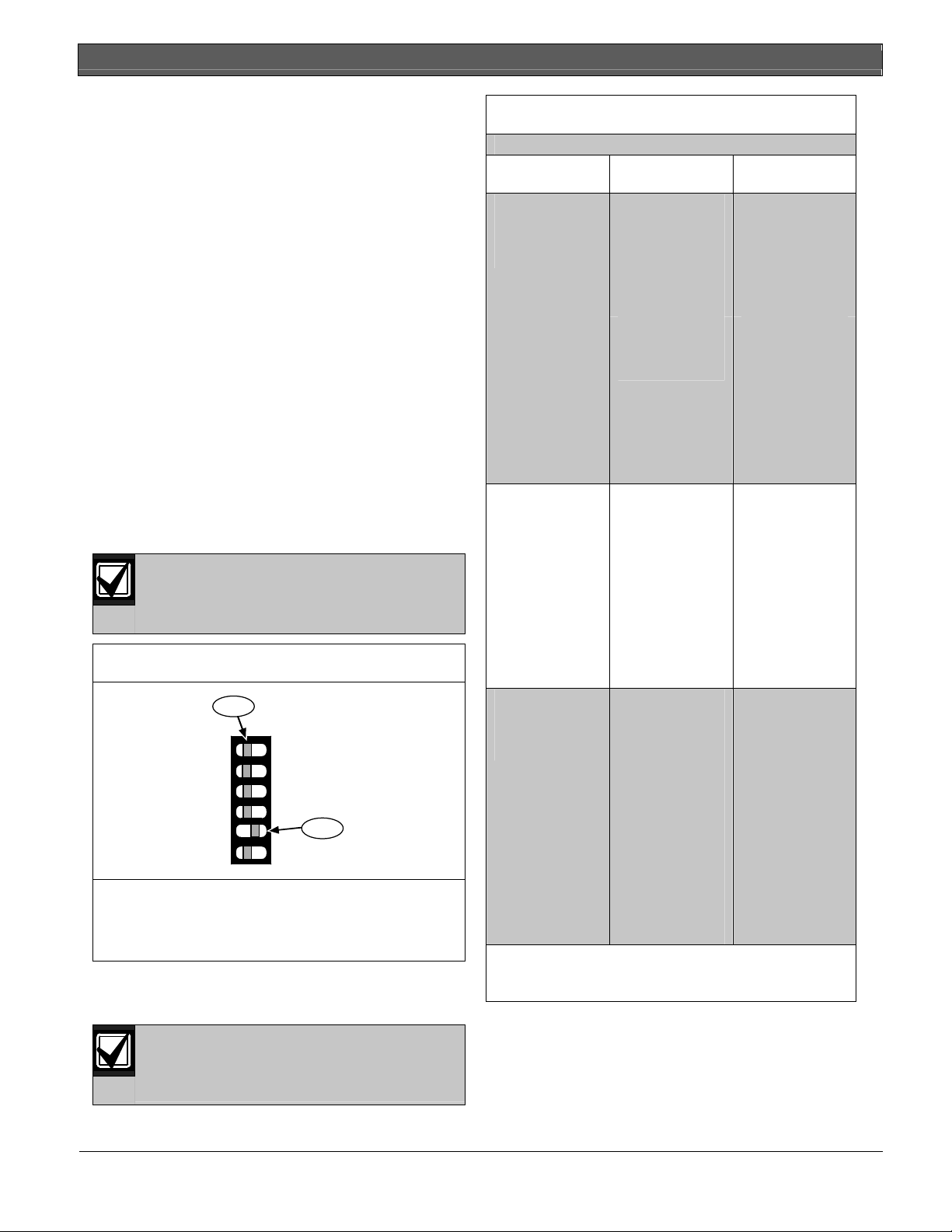

Figure 4: Receiver DIP Switches

1

When both

optical modules

are blocked for 3

seconds.

2

1 - DIP switches 1through 4 and 6 in the OFF

position

2 - DIP Switch 5 (EDC BYPASS Switch) in the

ON position

To use the EDC Bypass Switch, set the receiver’s DIP

Switch 5 to ON or OFF (Figure 4). Refer to Table 1 for

information about the functions and detector status.

∗ Poor environmental condition refers to difficulty in maintaining

stable operation due to environmental disturbances like fog or

rain.

OFF

EDC LED lights

and EDC signal

is provided

through the

normally-closed

relay output at

the receiver.

The alarm is

generated by loss

of beam energy.

EDC LED turns

on and EDC

signal is provided

No alarm output

is generated.

After the

specified

interruption time,

the ALARM LED

turns ON and

alarm signal is

generated.

If beams are

blocked for more

than 3 seconds,

EDC LED turns

ON, and EDC

signal is

generated.

BYPASS Switch

ON

EDC LED turns

on and EDC

signal is provided

through the

normally-closed

relay output at

the receiver.

With the loss of

beam energy, the

ALARM LED

lights but alarm

signal is not

generated (alarm

relay is

automatically

shunted).

EDC LED turns

on and EDC

signal is

provided.

If another optical

module is

blocked, the

ALARM LED

turns ON, but no

alarm signal is

generated.

After the

specified

interruption time,

the ALARM LED

turns ON, and

alarm signal is

generated.

EDC LED does

not turn ON, and

EDC signal is not

provided.

Connect the EDC to a trouble circuit.

Check the system after the EDC relay

activates.

4 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 5

DS484Q/DS486Q | Installation Instructions | 2.0 Installation

.

2.0 Installation

2.1 Installation Considerations

Read the following information before installing,

wiring, and performing regular maintenance on the

equipment.

Do not install the detector:

• near trees and plants where falling leaves can block

the beam

• where intense sources of light and sunlight can

reflect directly into the receiver optics

A beam of light shining at a ±3-degree

angle of each receiver can cause false

• on movable surfaces

• where subject to splashing water or sea spray

• beyond the maximum range of each model

• where strong electrical noise or radio frequency

interference occurs

• where strong vibration occurs

• in the presence of corrosive or explosive gas

Face upper and lower optical modules toward each

other on the transmitter and the receiver.

alarms.

• Do not install or wire detectors during a

thunderstorm.

• Do not supply power until all wiring is

completed.

• Maintain power between 10.5 VDC and

28 VDC at all times.

• Do not disassemble or modify the base.

2.1.1 Beam Strength over Distance

The beam strength is best if used within the maximum

range of the detectors. If used for shorter distances,

excess beam energy reaches the receiver resulting in

reflection off nearby walls and incorrect

communication with other detectors.

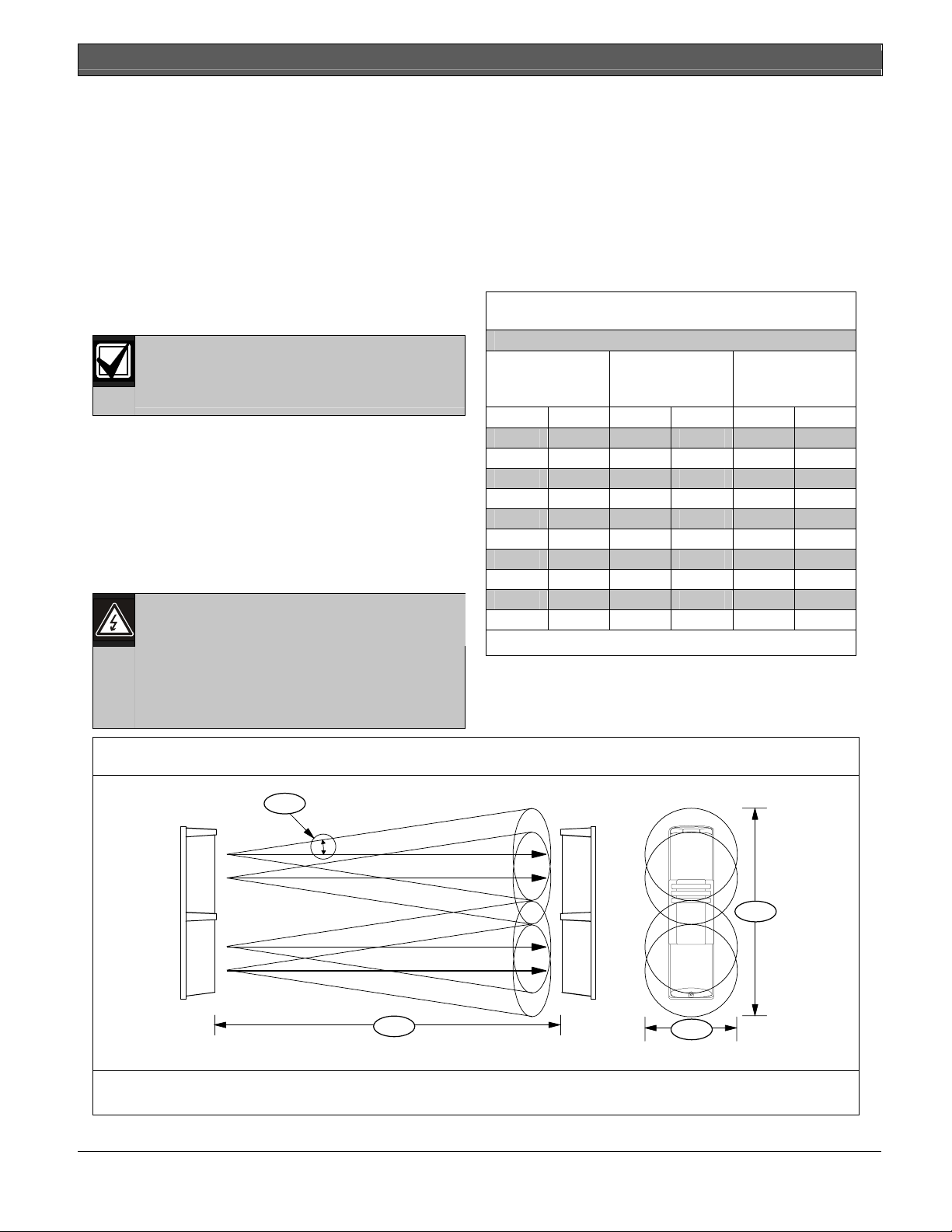

2.1.2 Beam Spread

The beam spread is +0.7°. Refer to Figure 5 and Table 2

to determine the installation conditions.

Table 2: Beam Spread Distances

Between

Transmitter and

Receiver

∗

Refer to Figure 5.

∗

m ft m ft m ft

20 66 0.5 1.7 0.8 2.6

40 131 1.0 3.3 1.3 4.3

60 197 1.5 4.9 1.8 5.9

80 263 2.0 6.6 2.2 7.2

100 328 2.5 8.2 2.7 8.9

120 394 3.0 9.8 3.2 10.5

140 459 3.5 11.5 3.7 12.1

160 525 4.0 13 4.2 13.7

180 591 4.5 14.8 4.7 15.4

200 656 6.0 16.4 5.2 17.1

Horizontal

Spread∗

Total Vertical

Spread∗

Figure 5: Beam Spread

1

4

2

3

1 - Beam spread

2 - Distance between transmitter and receiver

3 - Horizontal spread

4 - Total vertical spread

Bosch Security Systems, Inc. | 7/05 | 4998138530F 5

Page 6

DS484Q/DS486Q | Installation Instructions | 2.0 Installation

2.2 Mounting

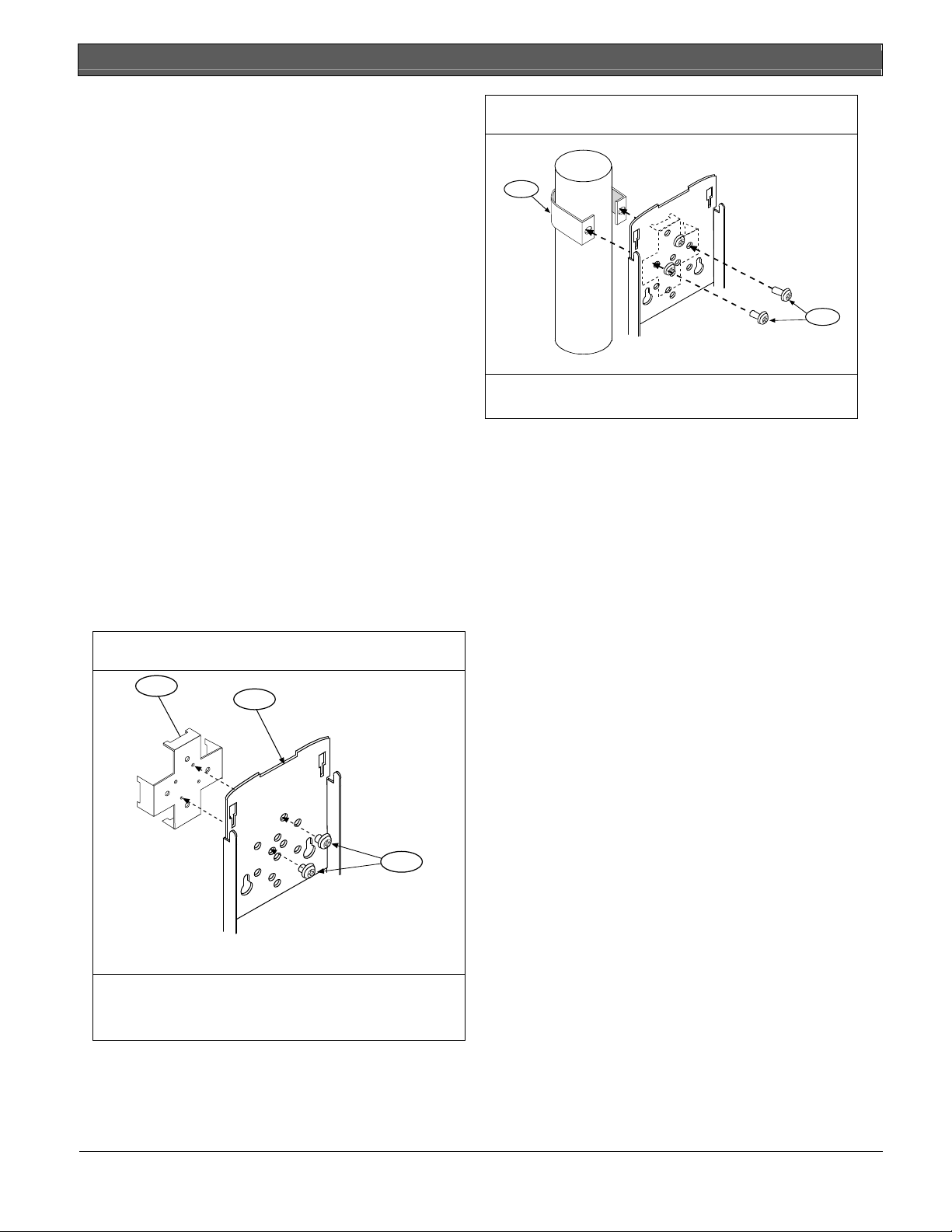

Figure 7: Using U-clamps

Mount the DS484Q and DS486Q in one of two ways:

• Pole mounted

• Wall mounted

1

2.2.1 Pole Mounting

1. Choose an appropriate mounting location for

the system. Install poles with a clear line-ofsight between the transmitter and the receiver.

2. Loosen the transmitter’s cover mounting screw

and remove the cover. Refer to Items 3 and 17

in Figure 1 on page 2.

2

3. Loosen the two mounting screws and remove

the chassis by sliding it down against the base

Refer to Refer to Items 1 and 9 in Figure 1 on

page 2.

Single Unit Pole Mounting

1. Use the short clamping screws to attach the

mounting plates to the chassis. Refer to Figure 6.

2. If the pole diameter is between 3.8 cm and 4 cm

(1.5 in. and 1.6 in.), use the shorter flange

(1.0 cm [0.4 in.]) of the mounting plate.

If the pole diameter is between 4 cm (1.6 in.) and

4.3 cm (1.7 in.), use the longer flange (1.5 cm

[0.6 in.]) of the mounting plate. This ensures that

the end of the screw does not contact the pole.

Figure 6: Using Mounting Plates

1

2

1 - U-clamp

2 - Long clamping screws

4. Insert the wiring through the chassis wire entrance,

leaving enough wire to access the transmitter’s

terminal block. Refer to Items 6 and 7 in Figure 1 on

page 2.

5. Slide the transmitter onto the chassis. Tighten the

base mounting screws. Refer to Figure 1 on page 2.

6. Repeat the mounting process for the receiver.

Make sure to mount the receiver in direct line-ofsight of the transmitter.

3

1 - Mounting plate

2 - Chassis

3 - Short clamping screws

3. Use the U-clamps and the long clamping screws to

attach the chassis firmly. Refer to Figure 7. Make

sure the transmitter is mounted in direct line-ofsight of the receiver.

6 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 7

DS484Q/DS486Q | Installation Instructions | 2.0 Installation

.

Back-to-Back Pole Mounting

Figure 8: Back-to-Back Pole Mounting

1. With spacers between the two units, mount the

transmitter and the receiver back-to-back. Refer to

Figure 8.

2. Use nuts and bolts to attach each unit firmly to the

pole.

3. Make sure that the units are aimed so that the

transmitter and the receiver in the same set are

aligned with each other.

2.2.2 Wall Mounting

Refer to Figure 9 for Steps 1 through 7.

1. Loosen the transmitter’s cover mounting screw and

remove the cover.

2. Loosen the two base mounting screws and remove

the chassis by sliding it down against the base.

3. Insert wiring through the chassis wire entrance,

leaving enough wire to access the transmitter’s

terminal block.

4. Insert the chassis mounting screws through the

mounting holes to mount the chassis on the

mounting surface.

5. Insert wiring through the wire entrance of the

transmitter. Remove the wire entrance at the

bottom of the transmitter.

6. Reattach the transmitter to the chassis.

7. Repeat this mounting procedure for the receiver.

Make sure it is mounted in a direct line-of-sight to

the transmitter.

Figure 9: Wall Mounting

4

1 - Chassis

2 - Base

3 - Cover

4 - Mounting holes

1 2

5

6

7

3

8

5 - Terminal block

6 - Wire entrance

7 - Base mounting screws

8 - Cover mounting screw

Bosch Security Systems, Inc. | 7/05 | 4998138530F 7

Page 8

DS484Q/DS486Q | Installation Instructions | 3.0 Wiring

Figure 10: Transmitter, Terminal Block Wiring

3.0 Wiring

Apply power only after all connections are

made and inspected.

Install these detectors according to the

National Electrical Code, NFPA-70.

Table 7 is based on one set (transmitter and receiver)

connected to the same wire run from the power source.

When installing two or more sets on one wire run,

calculate the maximum length by dividing the

maximum listed wire length by the number of sets

installed.

Connect the transmitters and receivers to a UL Listed

power supply or control panel capable of providing

standby power for at least 4 hours.

Test this system at least once a week to ensure proper

operation.

Table 3: Wire Length / AWG Chart

Wire

Gauge

2

[mm

(AWG)]

(22)

1.06

(19)

1.37

(17)

(14)

12 VDC 24VDC 12VDC 24VDC

0.8

1.8

Maximum Distance [m (ft)]

DS484Q DS486Q

90

(295)

180

(591)

330

(1083)

590

(1936)

850

(2789)

1670

(5479)

3020

(9908)

5370

(17618)

80

(295)

150

(492)

280

(919)

500

(1640)

730

(2395)

1420

(4659)

2580

(8465)

4570

(14993)

+

1

-

COM

2

NC

3

1 - Power (non-polarized), 10.5 VDC to 28.0 VDC

2 - Tamper Output (1b), 30 VDC 0.1 A

3 - Synchronized wiring

Figure 11: Receiver, Terminal Block Wiring

+

1

-

COM

NC

2

NO

EDC

3

NC

TAMPER

4

NC

1 - Power (non-polarized), 10.5 VDC to 28.0 VDC

2 - Alarm Output (1c), 30 VDC 0.2 A

3 - EDC Output (1b), 30 VDC 0.2 A

4 - Tamper Output (1b), 30 VDC 0.1 A

8 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 9

.

Figure 12: Single Set - Wiring Example

4

5

DS484Q/DS486Q | Installation Instructions | 3.0 Wiring

+

+

-

1

COM

NC

1 - Terminal block on transmitter and receiver

2 - Receiver

3 - Transmitter

Figure 13: Two Sets on the Run – Wiring Example

4

5

1

+

-

COM

NC

2

4 - Power output

5 - Alarm input (INC)

+

-

+

-

COM

NC

3

-

32

+

-

2

3

1 - Terminal block on transmitter and receiver

2 - Receiver

3 - Transmitter

4 - Power output

5 - Alarm input (INC)

Bosch Security Systems, Inc. | 7/05 | 4998138530F 9

Page 10

DS484Q/DS486Q | Installation Instructions | 4.0 Setup and Alignment

3. Choose whether or not to bypass alarms by setting

4.0 Setup and Alignment

4.1 Setup

4.1.1 Receiver Setup

Figure 14: Receiver Setup Switches

DIP Switch 5 to ON or OFF when the EDC

activates. Refer to Section 1.3.7 Environmental

Discrimination Circuit (EDC) on page 4 for more

information.

The EDC is always on. DIP Switch 5 (BYPASS)

controls the alarm condition relative to the EDC

relay status. Refer to Figure 4 on page 4.

ALIGNMENT IS COMPLETED

WHEN ‘ ‘ IS OFF

ALARM

1

• If DIP Switch 5 is ON, the system alarms only

if the EDC relay is not activated. If the EDC is

activated, the system does not indicate an

alarm.

• If DIP Switch 5 is OFF, the system alarms

150 200

TIME (msec)

3

ALIGNMENT

CHECK

TERMINALS

300

400

500

EDC LEVEL

2

3

75

50

SWITCH

OFF ↔ ON

ITEM

No

OFF ON

1Group

AB

23SEE CHART

BELOW

4AND/OR

AND OR

5BYPASS

OFF ON

SOUND

6

OFF ON

CHECK

SW2 - 3 : CHANNEL

M

1

2

OFF

SW2

OFF

ON

OFF

SW3

ON

OFF

100

INTERRUPTION

ON

ON

1 - INTERRUPTION TIME switch

2 - DIP Switch 4 (ON or OFF for the AND/OR

gate)

3 - DIP Switch 5

2. Select the beam alarm condition by setting DIP

4. Use a Phillips head screwdriver to adjust the rotary

regardless of whether the EDC relay is

activated or not.

Connect the EDC to a trouble circuit, and

check the system any time the EDC relay

activates.

If the EDC remains activated for prolonged

periods when the beam path is clear, the

beam might be misaligned. Refer to

Section 4.2 Alignment on page 13 to realign the beam.

INTERRUPTION TIME switch according to how

sensitive you want the detector to be to movement

(catch performance). Refer to Figure 14 for the

location of the INTERRUPTION TIME switch.

Refer to Table 4 for interruption times and

corresponding catch performance examples.

Switch 4 ON or OFF for the AND/OR gate. Refer

to Figure 14.

• If DIP Switch 4 is ON, the OR condition is

selected. The upper or lower beam pairs must

be broken to cause an alarm.

• If DIP Switch 4 is OFF, the AND condition is

selected. The upper and lower beam pairs

must be broken to cause an alarm.

For UL applications, the interrupt time

cannot be set above 75 ms.

For best performance when using the AND

mode, do not exceed 100 ms beam

interruption time.

Table 4: Beam Interruption Time Examples

Interrupt Time (ms) Catch Performance

50 Running

100 Jogging

200 Fast Walking

300

400

Normal Walking

500 Slow Moving

10 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 11

DS484Q/DS486Q | Installation Instructions | 4.0 Setup and Alignment

.

4.1.2 Transmitter Setup

Figure 15: Transmitter Setup Switches

POWER

130

100

200

OUTDOOR

INDOOR

BEAM POWER CONTROL (m)

SWITCH

OFF ↔ ON

No

ITEM

OFF ON

1Group

AB

23SEE CHART

BELOW

4 NULL

OFF

OFF

--

M

1

2

OFF

ON

ON

OFF

SW2 - 3 : CHANNEL

SW2

SW3

60

120

260

ON

ON

160

320

180

360

200

400

3

1

2

MODEL:DS486Q

1 - Beam Power Control rotary switch

2 - DIP Switches 1, 2, and 3

Turn the Beam Power Control rotary switch to the

volume setting for the appropriate detection range.

Refer to Figure 15, Table 5 and Table 6.

Table 5: Settings for Outdoor Beam Power

Control

DS484Q DS486Q

Volume

Setting

40 0 to 40

60 40 to 60

80 60 to 80

100 80 to 100

110 100 to 110

120 110 to 120

Range

m (ft)

(0 to 131)

(131 to 197)

(197 to 263)

(263 to 328)

(328 to 361)

(361 to 394)

Volume

Setting

Range

m (ft)

60 0 to 60

(0 to 197)

100 60 to 100

(197 to 328)

130 100 to 130

(328 to 427)

160 130 to 160

(427 to 525)

180 160 to 180

(525 to 591)

200 180 to 200

(591 to 656)

Table 6: Settings for Indoor Beam Power

Control

DS484Q DS486Q

Volume

Setting

80 0 to 80

120 40 to 120

160 120 to 160

200 160 to 200

220 200 to 220

240 220 to 240

Range

m (ft)

(0 to 263)

(263 to 394)

(394 to 525)

(525 to 656)

(656 to 722)

(722 to 787)

Volume

Setting

Range

m (ft)

120 0 to 120

(0 to 394)

200 120 to 200

(394 to 656)

260 200 to 260

(656 to 853)

320 260 to 320

(853 to 1050)

360 320 to 360

(1050 to 1181)

400 360 to 400

(1181 to 1312)

4.1.3 Beam Group and Channel Setup

When installing only one transmitter and

one receiver (a set), beam group and

channel selection is not required. Leave the

switches on the transmitter and receiver in

the original (OFF) positions. Refer to

Figure 17 on page 12.

The transmitter and the receiver have eight selectable

beams. The beams are divided into two groups

(Group A and Group B) of four beams each. The

beams are referred to as channels (Channels M, 1, 2,

and 3). Refer to Figure 16.

Figure 16: Beam Group and Channel

Organization

BEAM GROUP A CHANNEL M

CHANNEL 1

CHANNEL 2

CHANNEL 3

GROUP B CHANNEL M

CHANNEL 1

CHANNEL 2

CHANNEL 3

Channels 1, 2 or 3 can emit beams only when

Channel M in the same group provides those channels

with synchronized (synchro) wiring. Refer to Section

4.1.4 Synchronized Wiring on page 12. When installing

two or more sets in the same group, set only the first

set to Channel M. Set the remaining sets to Channel 1,

2, or 3.

Bosch Security Systems, Inc. | 7/05 | 4998138530F 11

Page 12

DS484Q/DS486Q | Installation Instructions | 4.0 Setup and Alignment

Figure 17: Transmitter and Receiver DIP Switch

Settings – One Set

1

2

3

1 - Transmitter DIP Switches with original settings

(Group A, Channel M)

2 - Receiver DIP Switches with original settings

(Group A, Channel M)

2 - DIP Switches 1, 2, and 3

Figure 18: Example of Transmitter and Receiver

DIP Switch Settings – Two or More

Sets

1

2

3

1 - Transmitter DIP Switches set for Group B,

Channel 3

2 - Receiver DIP Switches set for Group B,

Channel 3

2 - DIP Switches 1, 2, and 3

Set DIP Switches 1, 2 and 3 to OFF or ON on each

transmitter and receiver, according to the desired

group and channel selections. Refer to Table 7 and

Table 8 for the DIP Switches 1, 2, and 3, and the

example for Group B, Channel 2 in Figure 18.

Table 7: Group Selection

DIP Switch 1 Group

OFF A

ON B

Table 8: Channel Selection

DIP Switch

2 3

OFF OFF M

OFF ON 1

ON OFF 2

ON ON 3

Channel

One transmitter and one receiver facing

each other are a set. In a set, each unit

must have the same setting for group and

for channel.

When installing two or more sets, use

different settings for each set (transmitter

and receiver) to avoid incorrect

communication.

4.1.4 Synchronized Wiring

Synchronized (abbreviated “synchro”) wires are

required when installing two or more sets in the same

group by using the SYNCHRO terminal on each

transmitter. Synchro wires are not required between

the receivers.

The synchro wire should be more than 0.8 mm

(22 AWG) in diameter, run no longer than

20 m (66 ft), and be wired only to the same group

(Group A to Group A or Group B to Group B). Do not

wire across groups (Group A to Group B).

Synchronized transmitters must use a common power

supply.

The system does not activate when synchro

wires are connected improperly, or if other

unneeded wires are connected.

The POWER LED flashes when the

required wires are not connected correctly.

When the POWER LED flashes, shut off

the power and reconnect the wires

correctly.

12 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 13

DS484Q/DS486Q | Installation Instructions | 4.0 Setup and Alignment

.

4.2 Alignment

4.2.1 Description

Precise, correct alignment is critical for

these systems to operate effectively.

Aligning a paired transmitter and receiver requires a

coarse, or visual, alignment followed by a fine

alignment.

Coarse Alignment

In the coarse alignment, if the installed devices do not

face each other directly, the upper optical module and

the lower optical module on each device are manually

turned toward the opposite device. Then the opposite

device is viewed through the scopes on the upper and

lower optical modules while the horizontal and vertical

angles are adjusted, using the turntable and the

adjustment screws. Refer to Section 4.2.2 Scope Alignment

on page 14.

Fine Alignment

The detectors have three possible fine alignment

methods: Voltmeter, Level LED, and Sound.

Alignment interruption sheets (Figure 19) are used in all

three procedures to cover all optical modules in the

installation except the pair that are being aligned.

Select a procedure based on the conditions and

considerations of the specific installation. Refer to

Table 9.

The first procedure (Section 4.2.2 Scope

Alignment on page 14) is a visual alignment

and is not precise. Use one of the

additional procedures to complete the

alignment.

Table 9: Fine Alignment Considerations

Alignment Procedure Considerations

Voltmeter

(Refer to Section

4.2.3 Voltmeter

Alignment on

page 15.)

• Requires a voltmeter and a

screwdriver

• Works well at any distance

between the transmitter and

receiver

• Requires repeated

observation of the voltmeter at

the receiver

• Most accurate

• Might require two people

Level LED

(Refer to Section

4.2.4 Level LED

Alignment on

page 15.)

• Requires only a screwdriver

• More difficult to do when the

transmitter and receiver are

installed far apart

• Requires repeated visual

observation of the level meter

on the receiver

• Might require two people

Sound

(Refer to Section 4.2.5

Sound Alignment on

page 15.)

• Requires only a screwdriver

• Works well at any distance

between the transmitter and

receiver

• Does not require visual

observation of the opposite

device

• Difficult to do in a noisy

environment

Figure 19: Alignment Interruption Sheet

Bosch Security Systems, Inc. | 7/05 | 4998138530F 13

Page 14

DS484Q/DS486Q | Installation Instructions | 4.0 Setup and Alignment

4.2.2 Scope Alignment

Figure 21: Optical Module

1. Apply power to all transmitters and receivers in the

installation.

2. Select a transmitter and receiver pair to align.

3. For coarse tuning, rotate the turntable on the upper

or lower optical module of the transmitter

horizontally to face the receiver.

3

1

4. Look into the left or right viewfinder of the optical

module to see the image reflected through the

scope aperture. Stand at a 45° angle and at eye

level to the left or right viewfinder, at a distance of

Interruption

10 cm to 15 cm (4 in. to 6 in.) away. Refer to

Figure 20.

2

4

5

6

Sheet

Figure 20: Using the Optical Module Scope

1

32

4

5

1 - Top view optical module of transmitter or

receiver

2 - Left viewfinder

3 - Right viewfinder

4 - Viewing distance (10 cm to 15 cm

[4 in. to 6 in.])

5 - Viewing angle (approximately 45

°

from

centerline of optical module)

5. Use the turntable to adjust the horizontal angle of

the optical module until the receiver image appears

in the viewfinder. Refer to Figure 21 and Figure 22.

6. Use the horizontal and vertical adjustment screws

to center the receiver image in the outline of the

scope aperture. Refer to Figure 21 and Figure 22.

7. Repeat Steps 3 through 6 for the other optical

module on the transmitter.

8. Do Steps 3 through 6 for the optical modules on the

receiver to align the transmitter image.

1 - Interruption sheet

2 - Optical module

3 - Punched holes

4 - Scope apertures

5 - Viewfinder

8

7

6 - Alignment scope

7 - Turntable

8 - Vertical adjustment

screw

9 - Horizontal

9

adjustment screw

Figure 22: Viewed Image

1

2

1 - Scope aperture

2 - Receiver image

9. Use the supplied alignment interruption sheets to

cover the upper and lower optical modules of all

transmitters and receivers to be aligned.

When covering an optical module, align the

punched holes in the interruption sheet with the

scope apertures in the center of the optical module

(Figure 21).

14 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 15

DS484Q/DS486Q | Installation Instructions | 4.0 Setup and Alignment

.

For synchronized applications or stacked

sets of transmitters and receivers, install

interruption sheets on all optical

modules except the pair to be aligned.

10. Do one of the fine alignments. Refer to Table 9 on

page 13 to determine which procedure to use.

For the following procedures, make sure

that all optical modules are covered with

interruption sheets, except the pair to be

aligned.

Remove the interruption sheets and close

the covers when the alignment is complete.

4.2.3 Voltmeter Alignment

1. Insert voltmeter leads into the alignment check

terminals on the receiver panel. Refer to Figure 3

on page 3

2. Set the voltmeter scale to 10.0 VDC.

3. Use a screwdriver to adjust horizontal and vertical

adjustment screws on the transmitter and the

receiver. Refer to Figure 21 on page 14.

4. Check the voltage reading and continue to adjust

the adjustment screws as necessary. In an ideal

environment, the voltmeter value should be

3.0 VDC or higher. (The maximum voltage is 3.75

VDC.)

5. When the best voltage is achieved, the optical

modules are aligned.

6. Repeat the procedure for the other optical module

pair.

4.2.4 Level LED Alignment

1. Look at the Level Meter on the receiver. Refer to

Figure 23. When you begin this procedure the

LEDs are off.

2. Use a screwdriver to adjust the optical modules.

Adjust the horizontal and vertical adjustment

screws as necessary. Refer to Figure 21.

3. As more beam energy is received, each LED turns

on, flashes quickly, flashes slowly, and then turns

off.

4. Continue fine tuning until the LEDs turn off.

• If outdoors, the alignment is complete when all

LEDs are off.

• If indoors, the alignment is complete when the

lower two LEDs are off.

5. Repeat the procedure for the other optical module

pair.

4.2.5 Sound Alignment

1. Set DIP Switch 6 on the receiver to ON. Refer to

Figure 23.

2. Use a screwdriver to adjust the optical modules.

Adjust the horizontal and vertical adjustment

screws as necessary. Refer to Figure 21.

3. As more beam energy is received, the sound pitch

changes from low to high and from a continuous

tone to a two beat sound.

4. Continue fine tuning until the buzzer is a two-beat

sound.

5. After the beams are aligned, set DIP Switch 6 to

OFF.

6. Repeat the procedure for the other optical module

pair.

Figure 23: Receiver Operation Panel

1

ALIGNMENT IS COMPLETED

WHEN ‘ ‘ IS OFF

ALARM

2

3

200

150

TIME (msec)

3

ALIGNMENT

CHECK

TERMIN ALS

300

400

500

EDC LEVEL

5

4

75

50

SWITCH

OFF ↔ ON

ITEM

No

OFF ON

1Group

AB

23SEE CHART

BELOW

4AND/OR

AND OR

5BYPASS

OFF ON

SOUND

6

OFF ON

CHECK

SW2 - 3 : CHANNEL

M

1

2

OFF

SW2

OFF

ON

OFF

SW3

ON

OFF

100

INTERRUPTION

ON

ON

1 - Outdoor level alignment guide

2 - Indoor level alignment guide

3 - Level meter

4 - Alignment check terminals

5 - DIP switch 6 in the ON position

Bosch Security Systems, Inc. | 7/05 | 4998138530F 15

Page 16

DS484Q/DS486Q | Installation Instructions | 5.0 Walk Test

5.0 Walk Test

Walk across the beam path directly in front of one of the detectors. The ALARM LED should activate. If not, the

beam interrupt time is set too low or the alignment is not correct.

Walk across the beam path in several locations between the detectors (Figure 24).Each time you cross the beam

path, the ALARM LED should activate. If not, the beam interrupt time is set too low or the alignment is not

correct.

Figure 24: Walk Test Pattern

1

1 - Receiver

2 - Transmitter

Inspect the system and perform a walk test at least once a year.

3

2

4

3 - Beam path

4 - Crossing the beam path

16 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 17

DS484Q/DS486Q | Installation Instructions | 6.0 Stacking Information

.

6.0 Stacking Information

When stacking two or more sets, use the group and channel settings shown in Figure 25. The correct DIP switch

settings are shown for each transmitter and receiver.

Figure 25: Examples of Stacking Multiple Transmitter and Receiver Sets

M

1

2

2

4

5

3

1

2

11

3

1 - Receiver

2 - Transmitter

3 - Synchronized wiring

Each top line set must be set to Channel M, and the other line sets to Channels 1, 2, or 3 to avoid incorrect

communication between the stacking sets.

4- Receiver DIP switches

5 - Transmitter DIP switches

Bosch Security Systems, Inc. | 7/05 | 4998138530F 17

Page 18

DS484Q/DS486Q | Installation Instructions | 7.0 Troubleshooting

7.0 Troubleshooting

If the system does not operate as expected, check for the following conditions.

The input voltage is between 10.5 VDC and 28 VDC at the terminal on the transmitter and on the receiver.

The loop resistance of the alarm output is less than 100 Ω.

The monitor LED on the transmitter is ON.

The ALARM LED on the receiver is ON when both upper and lower beams are simultaneously adjusted for the

beam interruption time.

The output of the beam alignment check terminal on the receiver is 3.0 VDC to 3.75 VDC.

Table 10: Common Troubleshooting Problems and Solutions

Problem Cause Solution

Constant alarm output

Frequent false alarms

No alarm when beams are

blocked

EDC LED turns ON

frequently

POWER LED on transmitter

flickers

Something is blocking the beams. Remove the object(s).

Optical modules or covers need

cleaning.

Improper channel selection Select the proper channel.

Synchronized wires are not connected. Connect the synchro wiring correctly. Refer to

Something is blocking the beams. Remove the object(s).

Beam interruption time is set too short. Decrease the sensitivity. Refer to Section 4.1.1

Electrical noise or radio frequency

interferency (RFI) nearby

Wiring too close to power sources or

power line

Unstable installation site Fix the installation site.

Out of maximum protection range Reinstall the units within the maximum protection

Inappropriate Beam Power Control level Readjust the control level. Refer to Table 5 and

Frost or dew is present. Attach the optical heater.

Beams are reflected into the receiver. Remove the reflective object or change the

Beam interruption time is set too slow. Increase the sensitivity. Refer to Section 4.1.1

Not enough beam power Increase the beam power. Refer to Table 5 and

Something is blocking the beams. Remove the object(s).

Installed on unstable ground Fix the installation site.

Out of maximum protection range Reinstall the units within the maximum protection

Inappropriate Beam Power Control level Readjust the control level. Refer to Table 5 and

Frost or dew is present. Attach the optical heater.

Synchro wires are not connected. Connect the synchro wiring correctly. Refer to

Clean the optical modules and the covers.

Refer to Section 4.1.3 Beam Group and

Channel Setup on page 11.

Section 4.1.4 Synchronized Wiring on page 12.

Receiver Setup on page 10.

Change the installation site.

Change the routing of the wiring.

range. Refer to Section 2.1 Installation

Considerations on page 5.

Table 6 in Section 4.2 Alignment on page 13.

installation site.

Receiver Setup on page 10.

Table 6 in Section 4.2 Alignment on page 13.

range. Refer to Section 2.1 Installation

Considerations on page 5.

Table 6 in Section 4.2 Alignment on page 13.

Section 4.1.4 Synchronized Wiring on page 12.

18 Bosch Security Systems, Inc. | 7/05 | 4998138530F

Page 19

DS484Q/DS486Q | Installation Instructions | 8.0 Specifications

.

8.0 Specifications

Table 11: DS484Q and DS486Q Specifications

Alarm Output

Beam Interrupt Time Adjustable from 50 ms to 500 ms

Selectable Beams Two Groups by four Channels

Environmental Discrimination Circuit Output Normally-closed contacts rated at 0.2 A @ 30

Maximum Coverage

Material Polycarbonate

Dimensions (HxWxD) 35 cm x 10 cm x 11 cm

Operating Temperature

IP Rating IP 54 (protection against dust; protection against

Location Surface or pole mount

Pattern Pointability

Voltage 10.5 VDC to 28 VDC non-polarized

Current Draw

Backup Power Requirements 4 hours (120 mAh) minimum required for

Temper Output Normally-closed contacts rated at 0.1 A @ 30 VDC

Trigger Response Time Selectable response time of 35 ms to 700 ms

Alarm Form C 0.2 A @ 30 VDC

Output Period: 3 sec

EDC NC 0.2 A @ 30 VDC

Output Period: 3 sec

Tamper NC 0.1 A @ 30 VDC

Output Period: While the cover is removed

VDC

DS484Q 120 m (400 ft) Outdoor

DS486Q 200 m (660 ft)

Indoor

Enclosure Design

Receiver 1.2 kg (2.64 lb) Total Weight

Transmitter 1.2 kg (2.64 lb)

Environmental Considerations

Power Requirements

Receiver 80 mA standby, 50 mA alarm

Transmitter

DS484Q 240 m (800 ft)

DS486Q 300 m (1000 ft)

(13.75 in. x 4 in. x 4.1 in.)

-25° C to + 55° C

(-13°F to + 130° F)

splashing water)

Mounting

±90° horizontal, ±10° vertical

DS484Q 35 mA

DS486Q 55 mA

UL Certificated Installations

Bosch Security Systems, Inc. | 7/05 | 4998138530F 19

Page 20

Bosch Security Systems, Inc.

130 Perinton Parkway

Fairport, NY 14450-9199

Customer Service: (800) 289-0096

Technical Support: (888) 886-6189

© 2005 Bosch Security Systems

4998138530F

Loading...

Loading...