Page 1

D340

Installation Guide

EN

Duct Smoke Detector

Housing

Page 2

D340 | Installation Guide | 1.0 Overview

Trademarks

The National Fire Alarm Code® is a registered

trademark of the National Fire Protection Association.

®

Life Safety Code

is a registered trademark of the

National Fire Protection Association.

1.0 Overview

The D340 Air Duct Smoke Detector Housing is

designed to mount to the ducts of heating, ventilation,

and air-conditioning (HVAC) systems to monitor the

presence of smoke in the conditioned air.

Use the D340 with the D285DH Photoelectric Smoke

Detector (provided separately). The detector is

combined with an efficient housing design to sample

the air passing through a duct and detect potentially

hazardous conditions. When it detects smoke, the

detector sends an alarm signal to the control panel.

The control panel initiates the necessary action to shut

off fans and blowers or to switch to other air handling

systems.

The D340 operates on a two-wire loop, and requires a

smoke detector head.

Test the system by placing an external magnet on the

housing or switching the keyswitch from a Remote

Test station. Reset control requires a 24 V supply from

the control panel or an external power supply.

You can reset the detector by shutting down zone

power. If your system has a D344-RT Remote Test Kit,

you can reset the system using the keyswitch.

Install the D340 according to:

• NFPA 90A: Standard for the Installation of Air

Conditioning and Ventilating Systems

®

• NFPA 72: National Fire Alarm Code

• NFPA 101: Life Safety

Code®

• IBC: International Building Code

• IFC: International Fire Code

• Any applicable local and state codes

• Local authority having jurisdiction (AHJ)

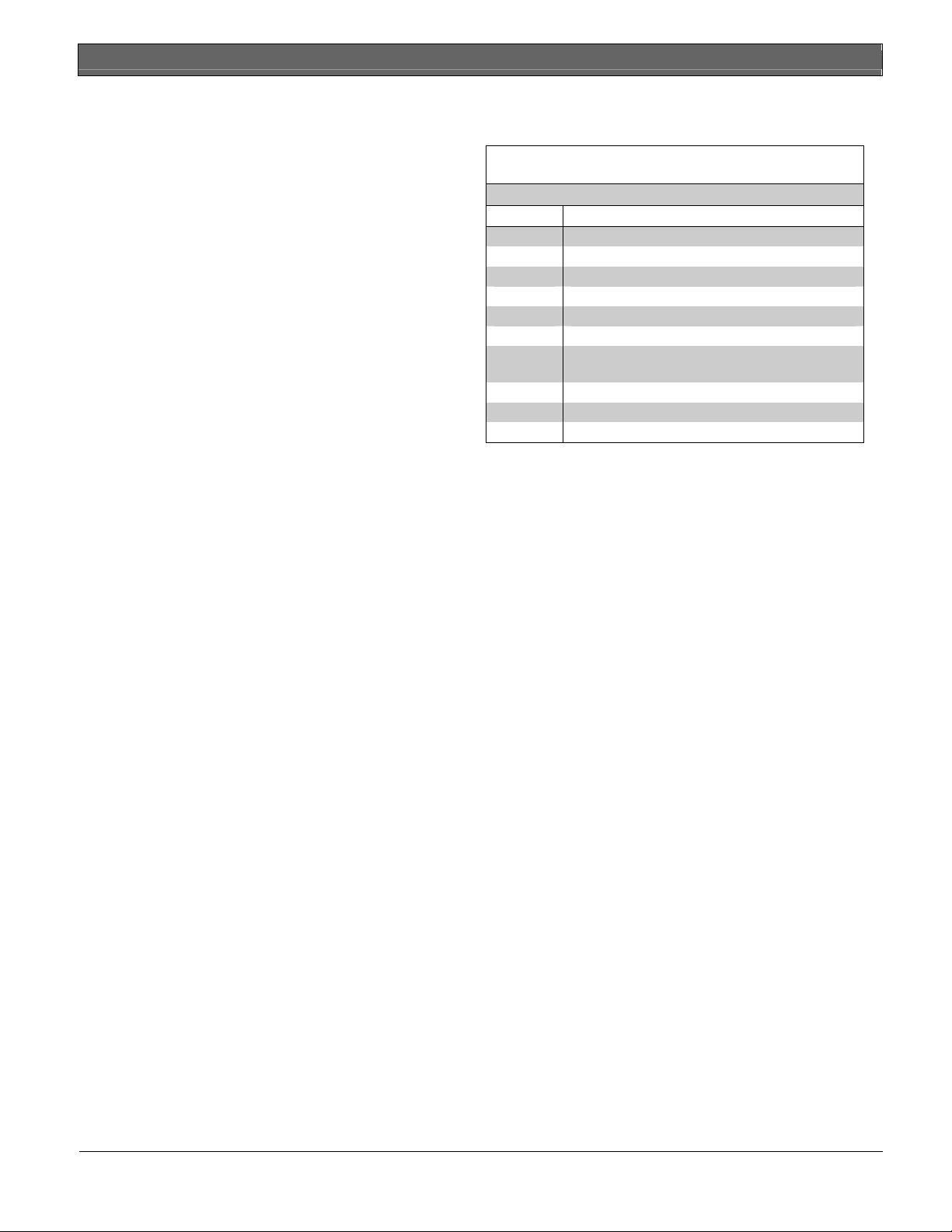

2.0 D340 Options

Table 1: D340 Options

Options Description

D285DH Photoelectric smoke detector head

D344-1.5 1.5 ft (0.5 m) sample tube

D344-3 3 ft (1 m) sample tube

D344-5 5 ft (1.5 m) sample tube

D344-RT Remote Test Kit (D307)

D344-RL Remote LED Indicator Kit (D306)

D344-TF Tube filters for sample and exhaust tubes

(20 per package)

SMK-TM Test magnet

DRA-5 Remote alarm indicator

D275 End-of-line (EOL) module

3.0 Assembly

The D340 includes:

• One housing, power card, and cover assembly

• Two #10-24 x 1 in. machine screws for mounting

• Two #10-24 jack nuts

• One exhaust tube

• Two tube clamps with four screws

• Two foam gaskets

• Two air filters

• One drilling template

• One cover gasket

The D340P also includes a smoke detector head and

1.5 ft (0.5 m) tube.

2 Bosch Security Systems, Inc. | 7/09 | F01U071685-06

Page 3

.

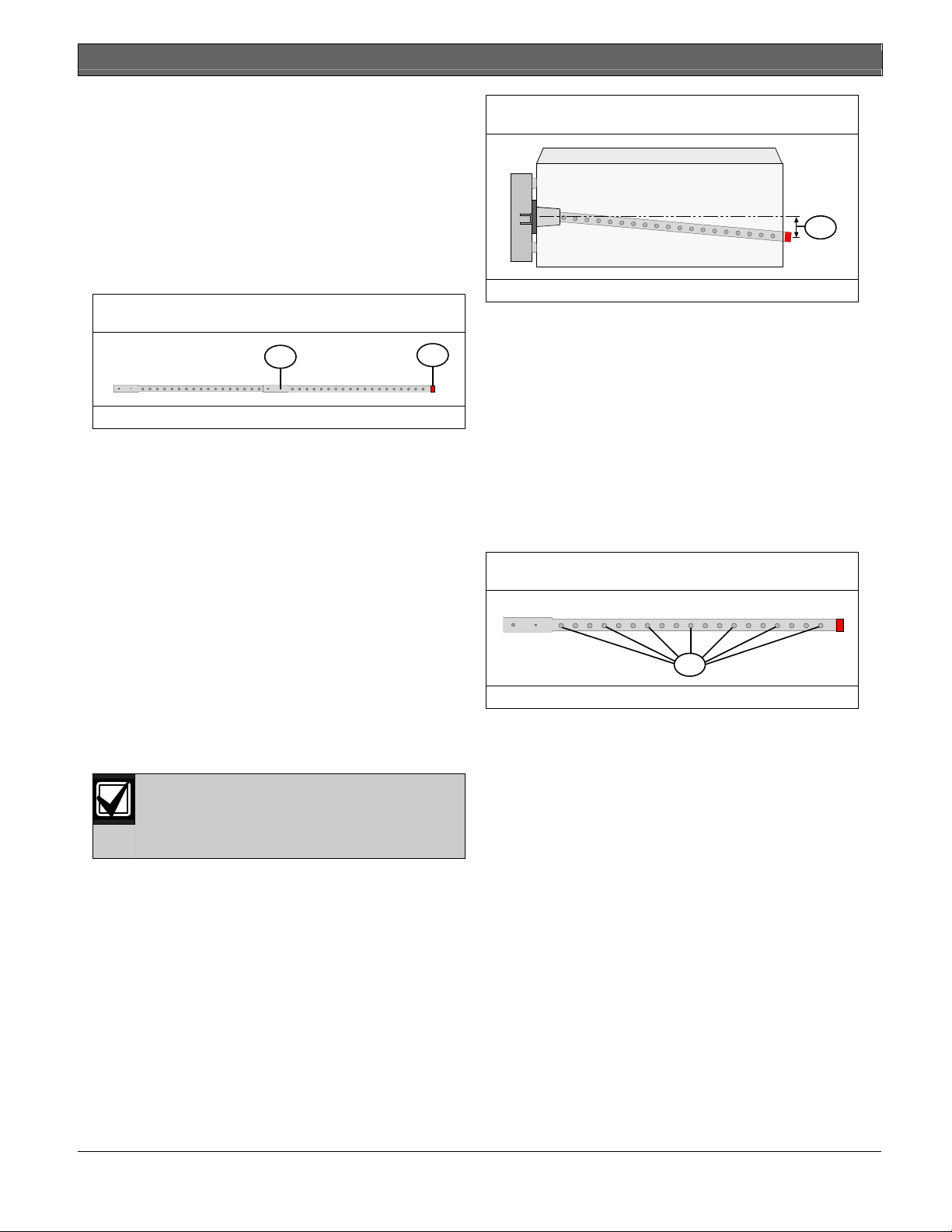

4.0 Sample Tubes

The sample tubes must extend across the width of the

duct. The three sizes of sample tubes are:

• D344-1.5 (1.5 ft [0.46 m])

• D344-3 (3 ft [0.91 m])

• D344-5 (5 ft [1.52 m])

Sample tubes include an end plug that must be

installed in the narrow end of the tube (Figure 1).

Figure 1: D344-1.5 Sample Tube

1

1 - Set screw 2 - End plug

You can combine or cut sample tubes to make

different lengths. A sample tube can be a maximum

length of

10 ft (3 m) or a minimum length of 1 ft (0.3 m). For

example, you can join a 3 ft (1 m) and a 5 ft (1.5 m) to

make an 8 ft (2.4 m) sample tube.

To combine sample tubes:

1. Remove the roll pin and set screw from one of the

sample tubes.

2. Remove the end plug from the other sample tube.

3. Push the flared end over the sample tube you want

to lengthen.

4. Align the holes, insert the set screw, and reinstall

the end plug. For example, if you want a 7 ft (2 m)

sample tube, combine a 3 ft (1 m) sample tube and

a 5 ft (1.5 m) sample tube. Then cut 1 ft (0.3 m)

from the narrow end to get the necessary length.

Sample tubes must have at least 12

sample holes within the duct. Do not cut

sample

tube to less than 12 sample holes.

2

D340 | Installation Guide | 4.0 Sample Tubes

Figure 2: Support Hole Position

1

1 - 1 in. to 2 in. (2.5 cm to 5 cm)

5. Seal the gap between duct and sample tube. You

can remove up to 6 in. (15 cm) from the D344-1.5

for 1 ft (0.3 m) duct installations.

When using the D344-1.5 in installations where the

duct width is between 12 in. (31 cm) and 18 in.

(46 cm), cover some of the sample holes. The

D344-1.5 has 19 sample holes, but only 12 are

required for normal installations. Depending on

the length, you might have to cover some of the

holes with duct tape. Use even spacing when

covering the sample holes to allow an even sample

across the width of the duct. Refer to Figure 3.

Figure 3: D344-1.5 Sample Tube

1

1 - Place tape over these sample holes

Sample tubes over 3 ft (1 m) must be supported at

the end opposite the duct detector. The support

hole should be 1 in. to 2 in. (2.5 cm to 5 cm) below

the entry hole to allow for possible moisture

drainage (Figure 2).

Bosch Security Systems, Inc. | 7/09 | F01U071685-06 3

Page 4

D340 | Installation Guide | 5.0 Mounting

5.0 Mounting

5.1 Preparing the Duct

You must verify the duct air flow and velocity. The

D340 is designed for use in air handling systems with

air velocities between 300 ft/min and 4000 ft/min

(1.5 m/sec to 20.3 m/sec). Check the HVAC

engineering specifications to ensure the air velocity in

the duct falls within these parameters. If necessary, use

a velocity meter to check the air velocity in the duct.

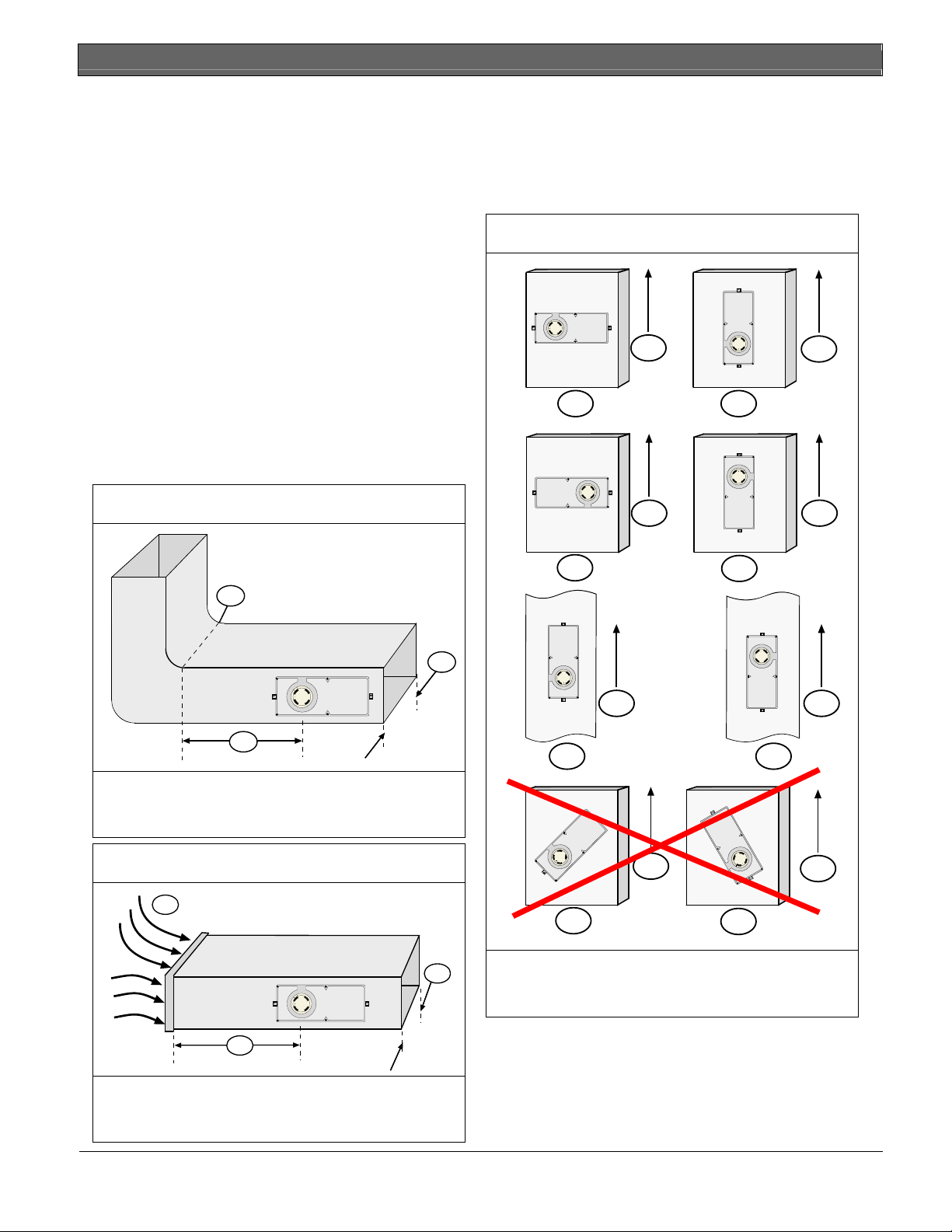

5.1 Determining the Mounting Location

To obtain a representative air sample, avoid

stratification and dead air space. These conditions can

be caused by return duct openings, sharp turns,

connections, or long, uninterrupted runs. For this

reason, place the D340 in the range of six to ten times

the width of the duct from any uninterrupted run.

Refer to Figure 4 and Figure 5.

Figure 4: Typical D340 Placement – Example A

5.2 Positioning the D340

The D340 can be mounted in any direction of 90°

increments without regard to the air flow direction

(Figure 6).

Figure 6: D340 Positions

1

2 2

1 1

2

2

1

1

3

2

1 - Bend or other obstruction

2 - Six to ten times the width of the duct

3 - Width of duct

Figure 5: Typical D340 Placement – Example B

1

3

2

1 - Return air inlet

2 - Six to ten times the width of the duct

3 - Width of duct

1 1

2 2

3

1 - Air flow

2 - Correct mounting position

3 - Incorrect mounting position

1

3

1

4 Bosch Security Systems, Inc. | 7/09 | F01U071685-06

Page 5

.

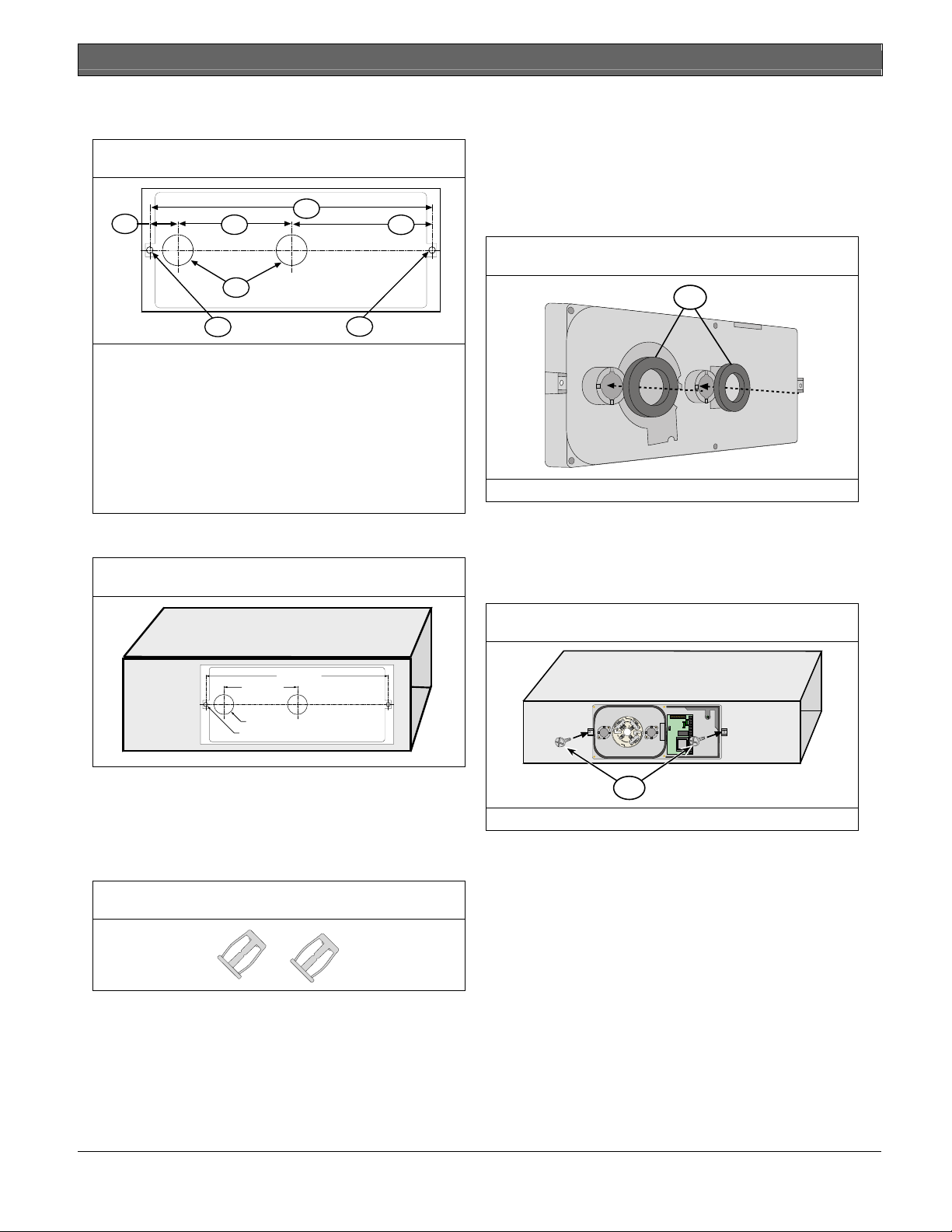

1. Locate the D340 mounting template (Figure 7) and

remove it from its backing.

Figure 7: D340 Mounting Template

5

2

1

DUCT SMOKE DETECTOR

MOUNTING TEMPLATE

REMOVEABLE AFTER DRILLIN G

6

D340 | Installation Guide | 5.0 Mounting

This attaches the jack nuts to the duct. You might

have to hold the jack nuts with a installer wrench

or a pair of pliers while tightening the screws to

stop the jack nut from spinning in the hole.

Remove the screws for later use.

7. Place the two foam gaskets over the sample and

exhaust ports on the back of the D340 (Figure 10).

Figure 10: Gasket Placement

3

4

4

1 - 16 in. (41 cm)

2 - 6.5 in. (16.5 cm)

3 - Two 1-3/4-in. (45-mm) diameter holes for the

sample tubes

4 - Two 3/8-in. (9.5-mm) diameter holes for

mounting to the duct

5 - 1.5 in. (38.1 mm)

6 - 8.0 in. (20.5 cm)

2. Place the template over the desired location on the

duct (Figure 8).

Figure 8: D340 Template Placement

16.070 in. (40.8 cm)

6.480 in. (16.5 cm)

(2) 1-3/4 in. (44.5 mm) DIA. HOLES FOR SAMPLING TUBES

(2) 3/8 in. (9.5 mm ) DIA. HOLES FOR DUCT MOUN TING

DUCT SMOKE DETECTOR

MOUNTING TEMPLATE

REMOVEABLE AFTER DRILL ING

1

1 - Foam gasket (2)

8. Mount the D340 to the jack nuts using the

supplied

10-24 x 1-in. machine screws (Figure 11).

Remember that overtightening the screws can

cause excessive bowing of duct.

Figure 11: Mounting the D340 to the Jack Nuts

3. Drill out the required holes and remove any

remaining debris.

4. Remove the template.

5. Place a #10-24 jack nut (Figure 9) in each of the

1 - Two 10-24 x 1-in. machine screws

9. Locate the wiring knockout holes (Figure 12).

1

3/8 in. (9.5 mm) holes.

Figure 9: Jack Nuts

6. Insert the #10-24 x 1 in. machine screws into the

jack nuts and firmly tighten.

Bosch Security Systems, Inc. | 7/09 | F01U071685-06 5

Page 6

D340 | Installation Guide | 5.0 Mounting

Figure 12: Wiring Knockout Locations

1

2

1

1 - Wiring Knockouts (5) 2 - Earth ground screw

6 Bosch Security Systems, Inc. | 7/09 | F01U071685-06

Page 7

.

10. Locate the sample and exhaust tubes (Figure 13).

Ensure the sample tube has a plug installed at the

narrow end of the assembly.

Figure 13: Exhaust and Sample Tubes

D340 | Installation Guide | 5.0 Mounting

13. Secure the tubes in place using the tube clamps

provided (Figure 16).

Figure 16: Sample and Exhaust Tubes in D340

1

2

4

3

1 - Exhaust tube

2 - Leave end open

3 - Sample tube

4 - Insert plug

11. Note the direction of the airflow in the duct. The

sampling holes in the sample tube must face into

the air flow (Figure 14). The exhaust tube must be

downwind from the sample tube (Figure 15).

Figure 14: Duct Air Flow

1

2

1

2

1 - Exhaust tube

2 - Sample tube

3

3 - D340

4 - Tube clamps (2)

4

14. Place the tube filters over the open ends of the

sample and exhaust tubes (Figure 17).

Figure 17: Tube Filters

1

2

3

4

1 - Air flow 2 - Sample holes

Figure 15: Exhaust Tube Position

1

3

2

1 - Air flow

2 - Sample tube

3 - Exhaust tube down stream from sample tube

12. Insert the sample and exhaust tubes into the D340,

ensuring the sample tube holes face into the air

flow. Ensure the tube alignment point set into the

D340.

1 - Exhaust tube

2 - Sample tube

NFPA-72 requires a semi-annual visual

inspection of detector housings. Clean or

replace the tube filters at this time. If

replacement filters are needed, order the

D344-TF.

3 - D340

4 - Tube filters (2)

Bosch Security Systems, Inc. | 7/09 | F01U071685-06 7

Page 8

D340 | Installation Guide | 6.0 Selecting the Jumper

6.0 Selecting the Jumper

6.1 Location

Figure 18 shows the locations of the tamper and reset

jumpers on the power card.

Figure 18: Jumper Locations

1

BBR

2

LRE

KND

Tamper

Disable

14 13 12 11 10 9

1 - D340 Power card

3 - Reset jumper

2 - Tamper jumper

The Tamper Jumper (Figure 19) enables or disables the

housing cover Tamper Switch. When this jumper is

enabled, a trouble is indicated if the cover is removed.

Figure 19: Tamper Jumper

B

G

Y

O

L

R

E

R

U

N

L

N

Reset

Disable

3

1

2

3

4

5

6

7

8

Figure 20: Reset Jumper w/Remote Display

Units

1

2

1 - Disabled 2 - Enabled

Disable the Reset jumper whenever you are

not using the D344-RT (D307).

7.0 Wiring

7.1 Terminals

Figure 21: Terminal Wiring

(-)

2

3 4

OUT IN

1

(+)

14 13 12 11 910

1

2

1 - Disabled 2 - Enabled

The Reset Jumper (Figure 20) enables or disables the

Remote Reset (keyswitch). The Power Off Reset from

the control panel zone functions normally regardless of

the jumper setting.

1 - Optional external power (24 VAC/VDC)

2 - Remote LED

3 - Loop (+)

4 - Loop (-)

7.2 Primary Power

The D340 is designed for a two-wire loop power

ranging from 8.5 VDC to 32 VDC. For Remote Test

or Remote LED, you must use an external 24

VDC/VAC that can supply a minimum of 170 mA.

8 Bosch Security Systems, Inc. | 7/09 | F01U071685-06

Page 9

.

7.3 D340 Two-Wire D344-RT (D307)

D340 | Installation Guide | 7.0 Wiring

7.4 D344-RL Remote Indicator Plate

NFPA-72 requires that where in-duct

smoke detector housings are installed in

concealed locations more than 10 ft (3 m)

above the finished floor or in arrangements

where the detector’s alarm indicator is not

visible to responding personnel, the

detectors have remote alarm indicators.

Do not exceed 500 ft (152 m) between the

D344-RT (D307) Remote Test/Indicator

Plate and the D340. Use 18 AWG (1.2

mm) or larger wire.

Figure 22: D340 Two-wire to the D344-RT (D307)

Wiring

1

2

3

4

5

6

7

8

14 13 12 11 10 9

1

2

3

4

5

6

7

8

9

1 - Voltage in (+)

2 - Voltage out (-)

3 - Yellow LED

4 - Voltage monitor

5 - Ground (-)

1

2

3

4

5

6

7

8

6 - Remote test

7 - Green LED

8 - Red LED

9 - D340

10 - D307

1

2

6

4

5

8

3

7

10

Do not exceed a distance of 500 ft (150 m)

between the D344-RL (D306) Remote

Indicator Plate and the D340. Use 18

AWG (1.2 mm) or larger wire.

Figure 23: D344-RL (D306) Wiring

1

1

2

3

4

5

6

7

8

3

4

5

7

8

1 - D340 Power card

2 - D306 Remote indicator plate

3 - Yellow wire

4 - Violet wire

5 - Black wire

Ground (-)

7 - Green wire

8 - Red wire

7.5 DRA-5 Remote Alarm LED

Do not exceed a distance of 500 ft (150 m)

between the DRA-5 Remote Alarm

Indicator and the D340. Use 18 AWG (1.2

mm) or larger wire.

2

Bosch Security Systems, Inc. | 7/09 | F01U071685-06 9

Page 10

D340 | Installation Guide | 7.0 Wiring

Figure 24: DRA-5 Wiring

2

1 3

(+) (-)

14 13

14 13 12 11 10 9

OUT IN

12 11 9

1 - Optional external

power (24 VAC/VDC)

2 - Remote LED

3 - Loop (+)

4

5

10

ALARM

6

7

4 - Loop (-)

5 - DRA-5

6 - White wire

7 - Red wire

10 Bosch Security Systems, Inc. | 7/09 | F01U071685-06

Page 11

.

7.6 D340 to Control Panel

Figure 25: D340 to Control Panel Wiring

D340 | Installation Guide | 7.0 Wiring

O

Y

G

B

BBR

G

Y

O

LRE

R

E

R

KND

N

L

N

Tamp er

Reset

Disable

Disable

14 13 12 11 10 9

B

L

U

1

2

3

4

5

6

7

8

BBR

R

E

R

LRE

N

L

N

KND

Tamper

Reset

Disable

Disable

14 13 12 11 10 9

L

U

1

2

3

4

5

6

7

-+

8

3

1 - Control panel

3 - EOL

2 - Alarm Initiating loop

7.7 D340 to Control Panel and External Power

Connect the ground to the screw on the ground plate when using grounded three-wire AC wiring.

Figure 26: D340 to Control Panel (External Power Required with Remote Test Unit)

1

2

1 - Wiring knockouts (5)

2 - Screw for earth ground

3 - Control panel

BBR

G

Y

O

LRE

R

E

R

KND

N

L

N

Tampe r

Reset

Disable

Disable

14 13 12 11 10 9

1

2

1

7

BBR

B

G

Y

B

L

U

1

2

3

4

5

6

7

8

O

LRE

R

E

R

KND

N

L

N

Tampe r

Reset

Disable

Disable

14 13 12 11 10 9

L

U

1

2

3

4

5

6

7

8

7

3

4

-+

5

6

4- Alarm initiating loop

5 - External power (24 VAC/VDC)

6 - EOL

7 - Remote test/display units

Bosch Security Systems, Inc. | 7/09 | F01U071685-06 11

Page 12

D340 | Installation Guide | 8.0 Installation Testing

8.0 Installation Testing

Verify the air flow to ensure the system is properly

operating. Use a manometer to verify the correct

velocity pressure readings ranging from 300 ft/min

to 4000 ft/min (1.5 m/sec to 20 m/sec).

The pressure differential between sampling tubes is

a minimum of 0.01 in. (0.25 mm) of water to a

maximum of 1.8 in. (45.7 mm) of water.

1. Check the wiring from the control panel to the

last duct detector on each run for proper

polarity and continuity.

2. Ensure each run terminates with an EOL

resistor as specified by the control panel

manufacturer.

3. Apply power to the system, and check for

alarms.

a. Note which smoke detectors are in alarm (if

any) and shut down the system.

b. Remove these detectors from their duct

housing and recheck the duct housing for

proper wiring. If the problems persist,

replace the affected smoke detectors or

swap them with known good units. This

determines if the problem is caused by the

detector or the duct housing.

c. If there is a system alarm with no detector

alarms present, remove all smoke detectors

and check the wiring at each duct housing.

Pay close attention to the wiring of each

EOL resistor.

4. When the system is free of alarms, check each

detector to ensure the red LED indicator flashes

approximately every 4 sec for the D285DH.

This verifies the detector is receiving power and

properly operating.

5. Test each detector to ensure it causes a control

panel alarm. Reset the control panel after each

test. Test the detectors by doing one of the

following:

a. Place an SMK-TM magnet against the duct

housing’s Test Point notch on the front

cover (Figure 27).

b. Switch a signal from a D344-RT (D307)

Remote Test Indicator Plate.

When a detector alarms, the red LED

indicator activates and latches to the ON

6. You can reset the detector by momentarily

position. Clear the alarm before proceeding

to the next detector.

removing power.

7. For duct detectors with the D307 Remote Test

Indicator installed, reset by moving the

keyswitch to the appropriate position and

observing the alarm LED.

Figure 27: Detector Testing

1

2

3

1 - D340 Duct Smoke Detector Housing

2 - Test point notch

3 - SMK-TM magnet

8. Check the overall loading of the alarm loop by

measuring the voltage across each EOL resistor.

This voltage should equal or exceed the

minimum specified by the control panel

manufacturer.

9.0 Maintenance

NFPA-72 requires a semi-annual visual

inspection of detector housings. Clean or

Clean the detector and base annually using a

vacuum or clean and dry compressed air.

replace the tube filters at this time. If

replacement filters are needed, order the

D344-TF.

Notify all concerned parties before and

after maintaining or testing the fire alarm

system.

12 Bosch Security Systems, Inc. | 7/09 | F01U071685-06

Page 13

D340 | Installation Guide | 10.0 Specifications

.

10.0 Specifications

Table 2: D340 Specifications

Option Description Option Description

D275 End-of-line (EOL) module D344-RL Remote LED Indicator Kit (D306)

D285DH Photoelectric smoke detector head D344-TF Tube filters for sample and exhaust tubes (20 per package)

D344-1.5 1.5 ft (0.5 m) sample tube SMK-TM Test magnet

D344-3 3 ft (1 m) sample tube DRA-5 Remote alarm indicator

D344-5 5 ft (1.5 m) sample tube

D344-RT Remote Test Kit (D307)

Power Requirements

Operating Voltage

Maximum RMS

Ripple

Current Draw

Operating

Temperature

Humidity

Air Velocity

Weight:

Dimensions

(H x W x D)

Power-up Time

8.5 V to 32 V

Condition

Standby

Trouble

Alarm

Condition

Standby

Trouble

Alarm

Condition

Standby

Trouble

Alarm

8.5 VDC to 32 VDC from two-wire loop. Optional 24 VDC/VAC from control panel or external supply

25% of DC input

Dependent on the control panel that must limit the alarm current to 100 mA maximum.

+32°F to +120°F (0°C to +49°C). For UL listed requirements, the operating temperature range is

+32°F to +100°F (0°C to +37.8°C).

0% to 95% relative humidity

300 ft/min to 4000 ft/min (1.5 m/sec to 20.3 m/sec)

3.75 lbs. (1.7 kg)

6.5 in. x 15.5 in x 4.3 (16.5 cm x 39.5 cm x 11 cm)

22 sec maximum

D340 with D344-RT, D344-RL, and External Power

Loop Power

< 120 μA

< 170 μA 30 μA

Current limit to 100 mA

D340 with D344-RT, D344-RL without External Power

Loop Power

8.5 V to 32 V

< 140 μA

< 170 μA

Current limit to 100 mA

D340 without D344RT, D344RL without External Power

Loop Power

8.5 V to 32 V

< 130 μA

< 150 μA

Current limit to 100 mA

External Power

24 V

5 mA

170 mA in Remote Test

Bosch Security Systems, Inc. | 7/09 | F01U071685-06 13

Page 14

Bosch Security Systems, Inc.

130 Perinton Parkway

Fairport, NY 14450-9199

(800) 289-0096

© 2009 Bosch Security Systems, Inc.

F01U071685-06

Loading...

Loading...