Bosch D296, D297 Installation Manual

Long-range Beam Smoke Detectors

D296/D297

en Installation Instructions

Long-range Beam Smoke Detectors Table of Contents | en 3

Table of contents

1

1.1 Regulatory 4

1.2 Trademarks 4

2

2.1 Description 4

2.2 Operation 5

3

3.1 Avoid air movement sources 6

3.2 Avoid bright light sources 7

3.3 Use correct wire gauge and length 7

3.4 Provide a stable mounting surface 7

3.5 Plan for the effects of stratification in cold environments 8

3.6 Design for the expected fire load 8

4

4.1 Sensitivity setting 11

4.2 Quick start installation flowchart 13

5

5.1 Wiring a single detector 14

5.2 Wiring a remote indicator 15

5.3 Wiring multiple detectors 16

6

6.1 Preliminary alignment 18

6.2 Fine-Tune alignment 20

7

7.1 Transmitter 22

7.2 Receiver - Aim Mode (cover off) 22

7.3 Receiver - Normal Mode (cover on) 23

8

8.1 Fire alarm reset 24

8.2 Reference voltage adjustment 24

8.3 Cleaning 24

8.4 Power outage 24

8.5 Remote test 25

8.6 Field sensitivity measurements 25

9

Notices 4

System overview 4

Installation considerations 6

Mounting 10

Wiring 14

Setup 17

Troubleshooting 22

Maintenance and Testing 24

Specifications 26

Bosch Security Systems, Inc. Installation Instructions 2014.01 | 06 | F.01U.068.899

!

4 en | Notices Long-range Beam Smoke Detectors

1

1.1

Notices

Before installing the module, become familiar with the Installation and Operation Guide for the

control panel you are using.

Caution!

When power is removed and reapplied to the receiver, such as in a power outage and restoral

or an alarm reset, an internal setup procedure is initiated and can last from 1 min to 2 min.

During this period, the detector is not able to initiate signals. Avoid connecting these

detectors to circuits, such as those programmed for alarm verification, that remove and

reapply power.

Regulatory

FCC compliance

This equipment was tested and complies with the limits for a Class B digital device, pursuant

to Part 15 of the Federal Communications Commission (FCC) Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy. When this equipment is

not installed and used according to the instructions, it might cause harmful interference to

radio communications. There is no guarantee that interference will not occur in a particular

installation.

If this equipment causes harmful interference to radio or television reception that can be

determined by turning the equipment off and on, correct the interference by:

– Reorienting or relocating the receiving antenna.

– Increasing the separation between the equipment and the receiver.

– Connecting the equipment to an outlet on a circuit different from the circuit to which

receiver is connected.

– Consulting the dealer or an experienced radio or TV technician for help.

Codes and standards

Install, test and maintain the module according to these instructions, NFPA codes, local codes,

and the authority having jurisdiction (AHJ). Failure to follow these instructions can result in

failure of a detector to initiate an alarm event. Bosch Security Systems, Inc. is not responsible

for improperly installed, tested or maintained devices.

1.2

2

2.1

2014.01 | 06 | F.01U.068.899 Installation Instructions Bosch Security Systems, Inc.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

System overview

Description

The D296 (24 VDC) and D297 (12 VDC) Long‑range Beam Smoke Detectors have a separate

transmitter and receiver. Internal pointability provides coverage flexibility without brackets.

Automatic signal synchronization and range adjustment reduce installation costs. Selectable

sensitivity and alarm response time provide installation flexibility.

Available accessories:

Long-range Beam Smoke Detectors Notices | en 5

– A D306 Remote Indicator Plate, a D1005 Test Cable, and a set of four plastic sensitivity

test filters are included with each detector.

– A D307 Remote Test and Indicator Plate (not supplied) is required for remote alarm

testing.

– A D308 Test Kit (not supplied) is needed for field testing.

– A D309 Alignment Light is also available to aid in transmitter/receiver alignment.

2.2

Operation

Each transmitter sends an invisible infrared beam of a specific frequency and intensity. Each

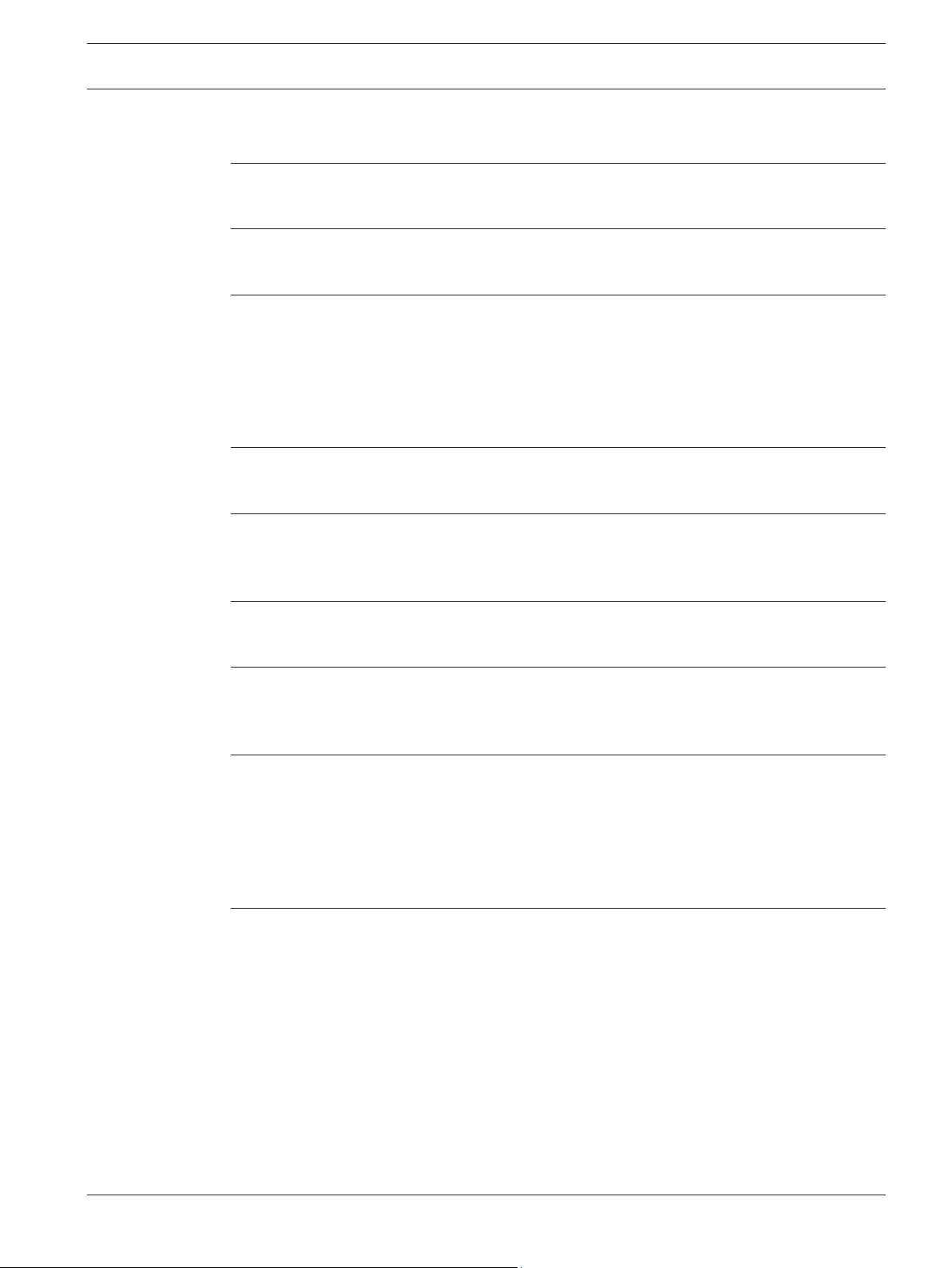

receiver detects and measures the beam’s intensity (see the following figure).

Figure 2.1: Infrared Transmission

1 Transmitter 3 Receiver

2 Beam

As smoke obscures the beam, the receiver senses a decrease in the signal strength and

measures that decrease. The receiver compares the signal level with two preset thresholds: an

alarm threshold that is set using the sensitivity switch and a trouble threshold that is preset at

approximately 10%. If the signal falls below the alarm threshold for the programmed alarm

period, the receiver signals an alarm (see the following figure).

Figure 2.2: Beam Obscuration

1 Transmitter 3 Obscuring matter

2 Beam 4 Receiver

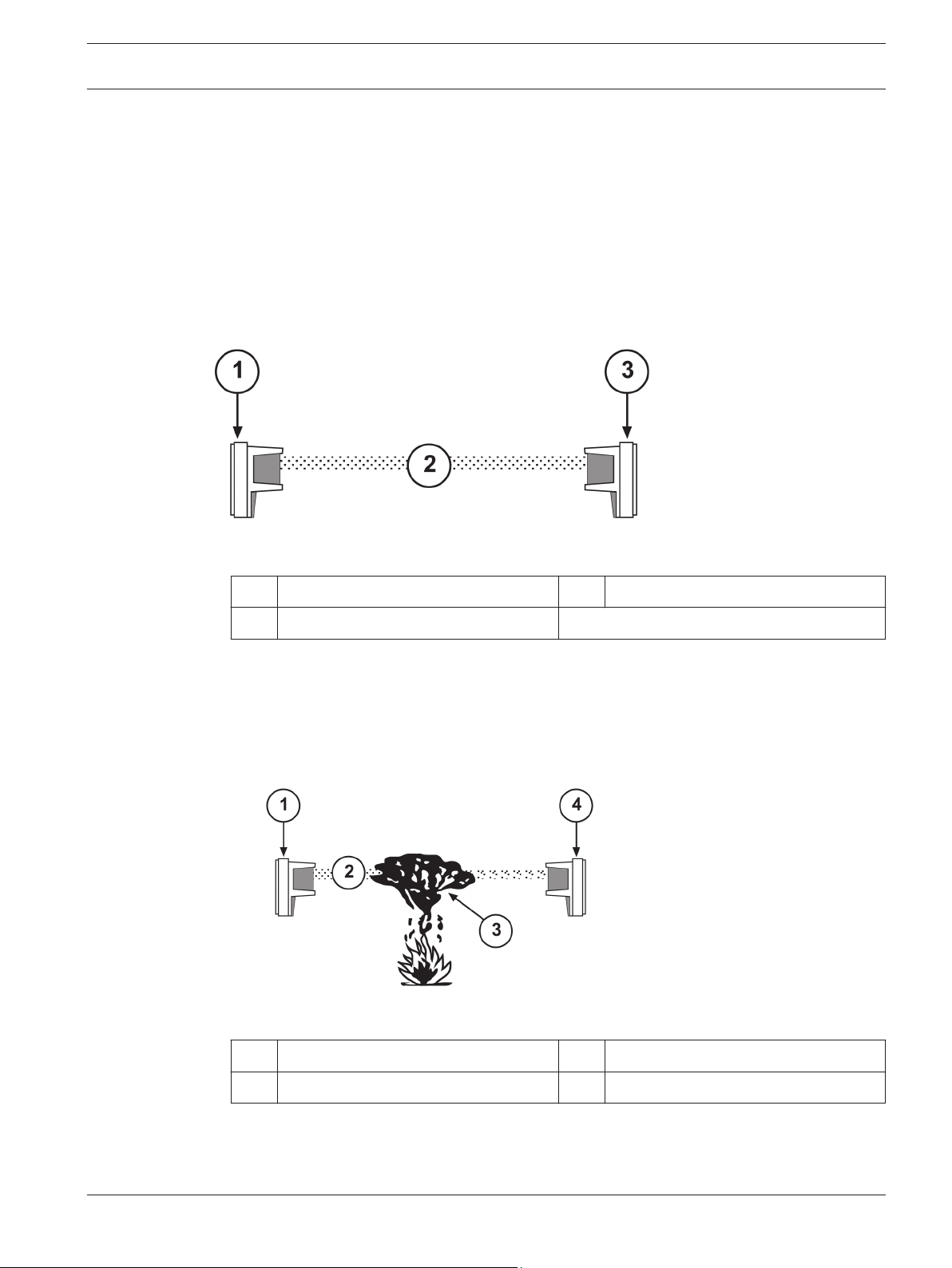

If the signal falls below the trouble threshold for more than 20 sec (caused by an object

blocking the beam for example), the receiver signals a trouble condition (see the following

figure).

Bosch Security Systems, Inc. Installation Instructions 2014.01 | 06 | F.01U.068.899

6 en | Notices Long-range Beam Smoke Detectors

Figure 2.3: Beam Blockage

1 Transmitter 3 Blocking object

2 Beam 4 Receiver

The receiver automatically compensates for the gradual signal loss because of dust and dirt

buildup on the cover. After a signal loss of 50%, the receiver indicates a trouble. When the

built‑up dust and dirt are cleaned or the blockage is removed, the detector automatically

returns to its normal operation level.

The receiver indicates a trouble if the beam strength increases by more than 20% for longer

than 20 sec. A trouble can be caused by an initial misalignment or the removal of a partial

beam blockage during alignment. Perform a fine‑tune alignment.

For alignment details, see Setup, page 17.

3

3.1

Installation considerations

Correct smoke detector location and spacing is critical in a properly installed and operating

fire alarm system. For best results, place and space the detectors according to the National

Fire Protection Association (NFPA) Standard 72, The National Fire Code.

In all installations, good engineering judgment must prevail.

– Do not use mirrors. Install detectors with a clear line-of-sight between the transmitter

and receiver.

– Clear the beam path of moving objects.

– Avoid areas with normal smoke concentrations, such as kitchens and garages.

– Do not install detectors where the normal ambient temperatures are below -22°F (-30°C)

or above +130°F (+54°C).

– Set sensitivity based on the distance between the transmitter and receiver. For

information on selecting and setting sensitivity, see Design for the expected fire load, page

8 and Sensitivity setting, page 11.

Avoid air movement sources

– Place the transmitters/receivers where the beam path does not pass near heating and

cooling outlets. Do not mount where hot or cold air blows directly into the beam path.

Heating, ventilating, and air conditioning (HVAC) systems can blow smoke away from the

beam path. Smoke must accumulate in the beam path to be detected.

– Do not mount heaters close to the beam path. Heat can distort the beam.

– Test for beam distortion by monitoring the signal voltage. After setup, the detector’s

signal voltage must read between 3.8 VDC and 4.2 VDC. Monitor the voltage and turn on

all heating and cooling devices in the area. The signal voltage must not fluctuate more

than 0.20 VDC. If it does, relocate the detector to avoid these disturbances.

2014.01 | 06 | F.01U.068.899 Installation Instructions Bosch Security Systems, Inc.

Long-range Beam Smoke Detectors Notices | en 7

3.2

Figure 3.1: Avoiding Exposed Lights

Avoid bright light sources

Bright light can cause stray signals. Do not point the receiver toward any of the following

sources.

Sunlight: Do not point the receiver directly at the rising or setting sun. If installing the receiver

where sunlight cannot be avoided, mount it slightly higher than the transmitter and aim it

down toward the transmitter. This causes the receiver to look below the horizon.

Bright Lights: Do not mount the receiver where it looks at exposed bulbs of high-pressure

sodium, mercury vapor, and metal halide lights. For an illustration of areas in which to avoid

exposed lights, see the following figure.

1 Receiver 2 Do not place bright lights in this area.

Bare fluorescent lights can also create a problem, especially in long hallways where a series of

lights are perpendicular to the beam. Incandescent lights are not a problem as long as they

are not directly in the beam path.

3.3

3.4

Use correct wire gauge and length

Beam smoke detectors are often used to protect large areas, requiring long wire runs to

power the detectors and signal alarm conditions. The voltage available at the end of long wire

runs might not be sufficient to power the detector, especially when the system is running on

backup battery power. Use the correct wire gauge when installing detectors.

For the proper number of transmitter and receiver pairs depending on wire size and length,

see the following table.

Wire Length Wire Size

14 AWG

(ISO 2.5 mm2)

500 ft (152 m) 20 pairs 13 pairs 8 pairs

1000 ft (304 m) 10 pairs 6 pairs 4 pairs

2500 ft (762 m) 4 pairs 3 pairs 2 pairs

5000 ft (1524 m) 2 pairs 1 pair 1 pair

Table 3.1: Wire Gauge and Length

16 AWG

(ISO 1.5 mm2)

14 AWG

(ISO 0.75 mm2)

Provide a stable mounting surface

Beam smoke detectors depend on the projected beam measurement to sense smoke. Trouble

or alarm conditions can be caused by shifts in beam alignment when the transmitter or

receiver moves.

Bosch Security Systems, Inc. Installation Instructions 2014.01 | 06 | F.01U.068.899

8 en | Notices Long-range Beam Smoke Detectors

Never mount a detector to a suspended support, such as a pipe or length of wood that is

supported at only one end. This type of mounting can create a pendulum effect that greatly

multiplies even very small movements at one end of the support. For example, a 2 in. (5.1 cm)

movement translates into a beam misalignment of more than 20 ft at 350 ft (6 m at 107 m).

Support mounting surfaces at opposite corners to reduce the pendulum effect.

Always select surfaces that are not subject to building movement. The automatic

compensation circuits eliminate most problems created by normal building expansions and

contractions. In some unusual circumstances, the walls and support structure might be

subject to more significant movement because of heavy equipment operation, such as cranes

anchored to the top of the walls.

When you are uncertain about mounting surface stability, measure the detector’s signal

voltage. This voltage must be between 3.8 VDC and 4.2 VDC. Beam misalignment can cause

this voltage to increase or decrease. The detector indicates a trouble condition when the

voltage increases to greater than ~4.8 VDC or decreases to less than ~2 VDC over a long

period. A trouble condition also occurs when voltage decreases to ~0.4 VDC for more than

20 sec. For how to take a voltage reading, see Reference voltage adjustment, page 24.

If you expect the mounting surface to move, relocate the detector to a stable surface or add

supports to the mounting surface to prevent movement.

Mounting the detector to a square or octagonal electrical mounting box of 4 in. (10 cm) can

bow the mounting plate. Bowing can occur because the mounting box screw tabs are below

flush with the top edges of the mounting box. Over tightening the mounting screws bows the

mounting plate inward at the bottom, causing the optics to aim low.

Irregularities in the flatness of the mounting box edge surfaces or at the screw tabs worsens

this condition. Only use mounting boxes with flat, regular surfaces and properly formed screw

tabs. Tightening the mounting screws to secure the mounting plate to 2 in. (5 cm) or 2 lb

(0.9 k) torque minimizes misalignment caused by mounting plate bowing.

3.5

3.6

Plan for the effects of stratification in cold environments

Air stratification might prevent smoke from reaching detectors mounted close to the ceiling.

Stratification occurs when smoke, rising because it is warmer than the surrounding air,

reaches a level where it is the same temperature as the surrounding air and does not rise to

the ceiling. In extremely cold environments such as unheated warehouses, smoke cools very

quickly and is less likely to rise to the ceiling. Add more detectors at lower mounting heights

to compensate.

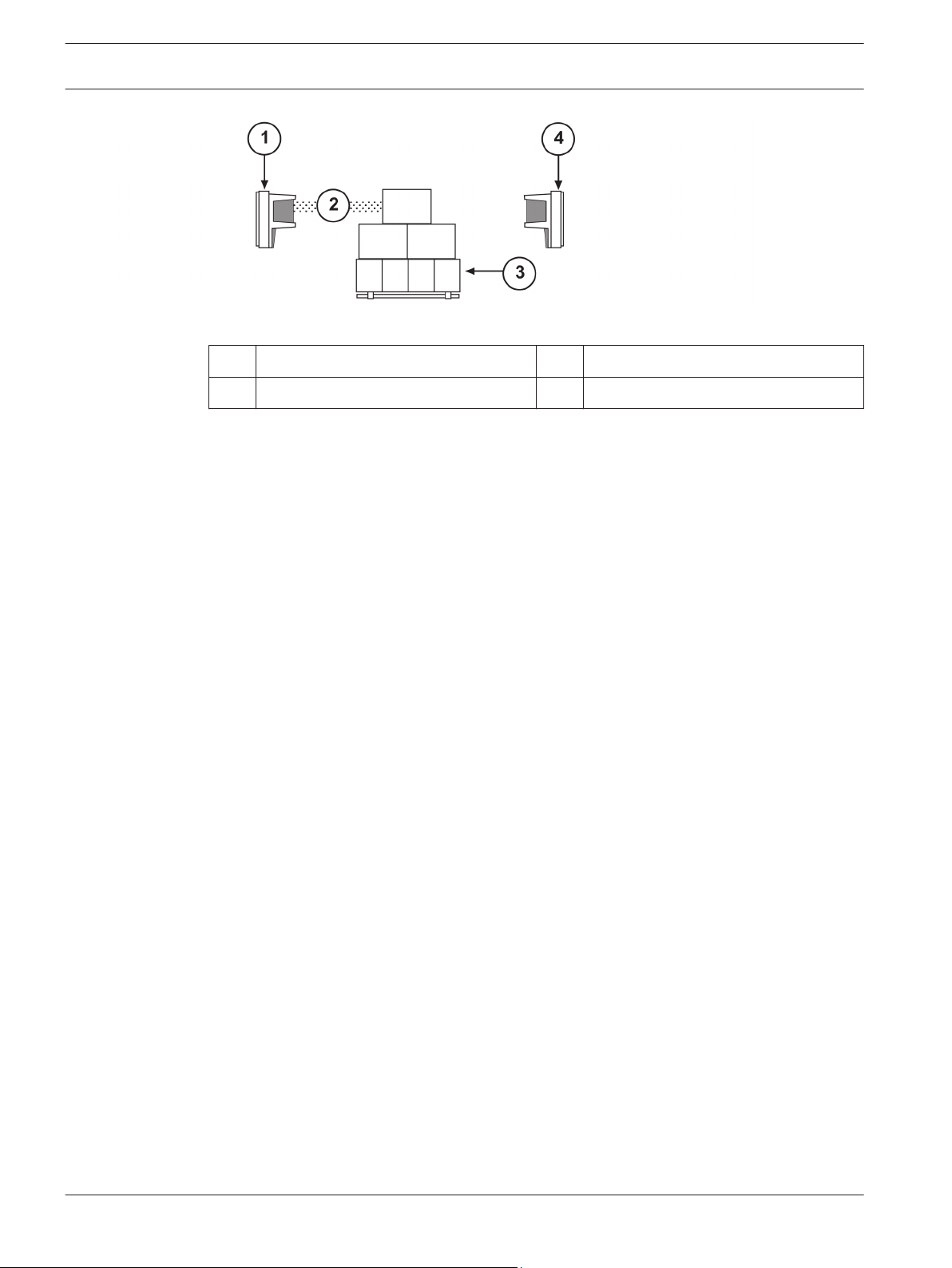

Design for the expected fire load

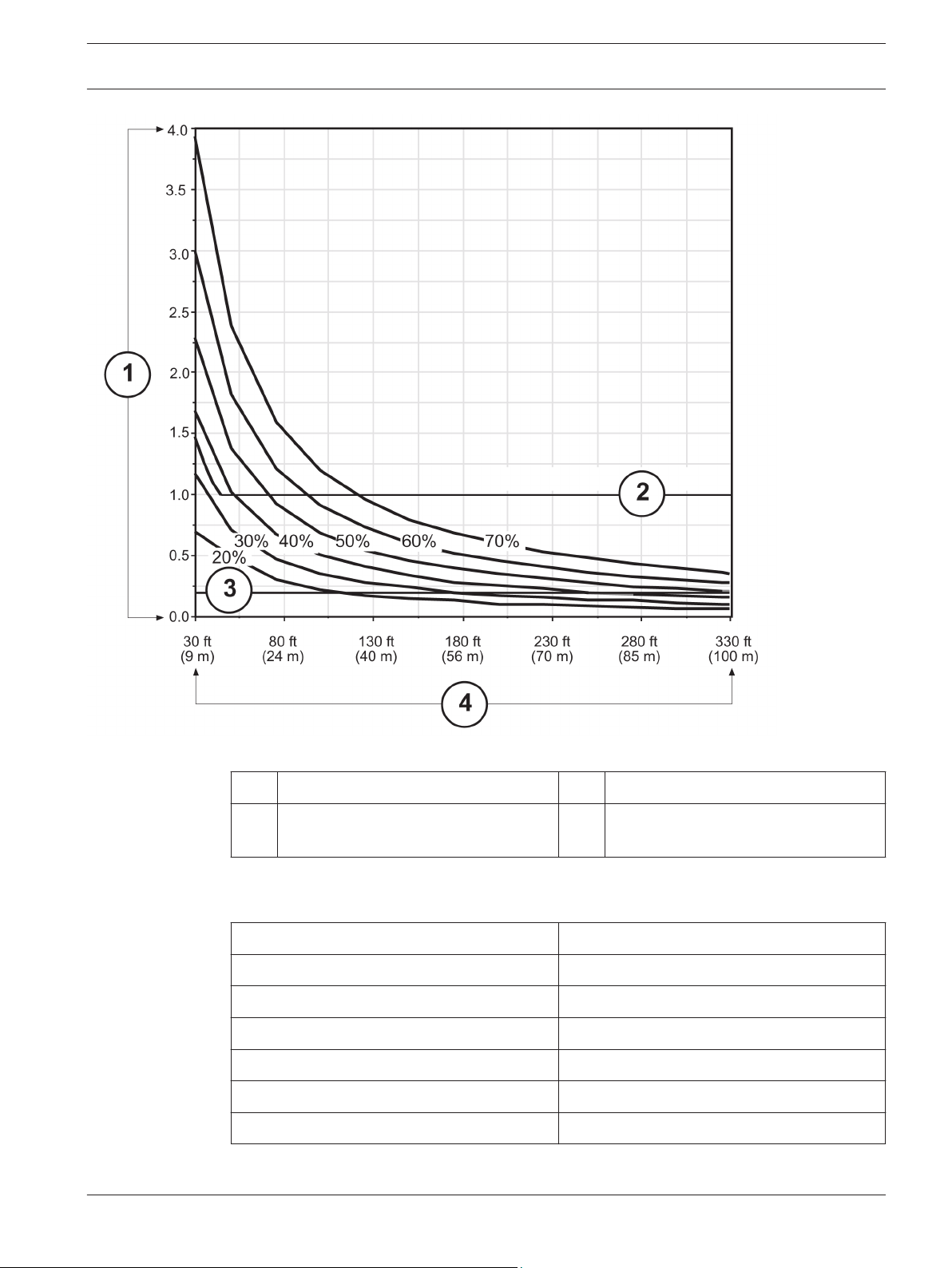

When designing a fire alarm system, set detector sensitivity to respond to the proper smoke

obscuration and to reduce the chance of a false activation within the application. The total

obscuration of the infrared beam depends on the density of the smoke and width of the

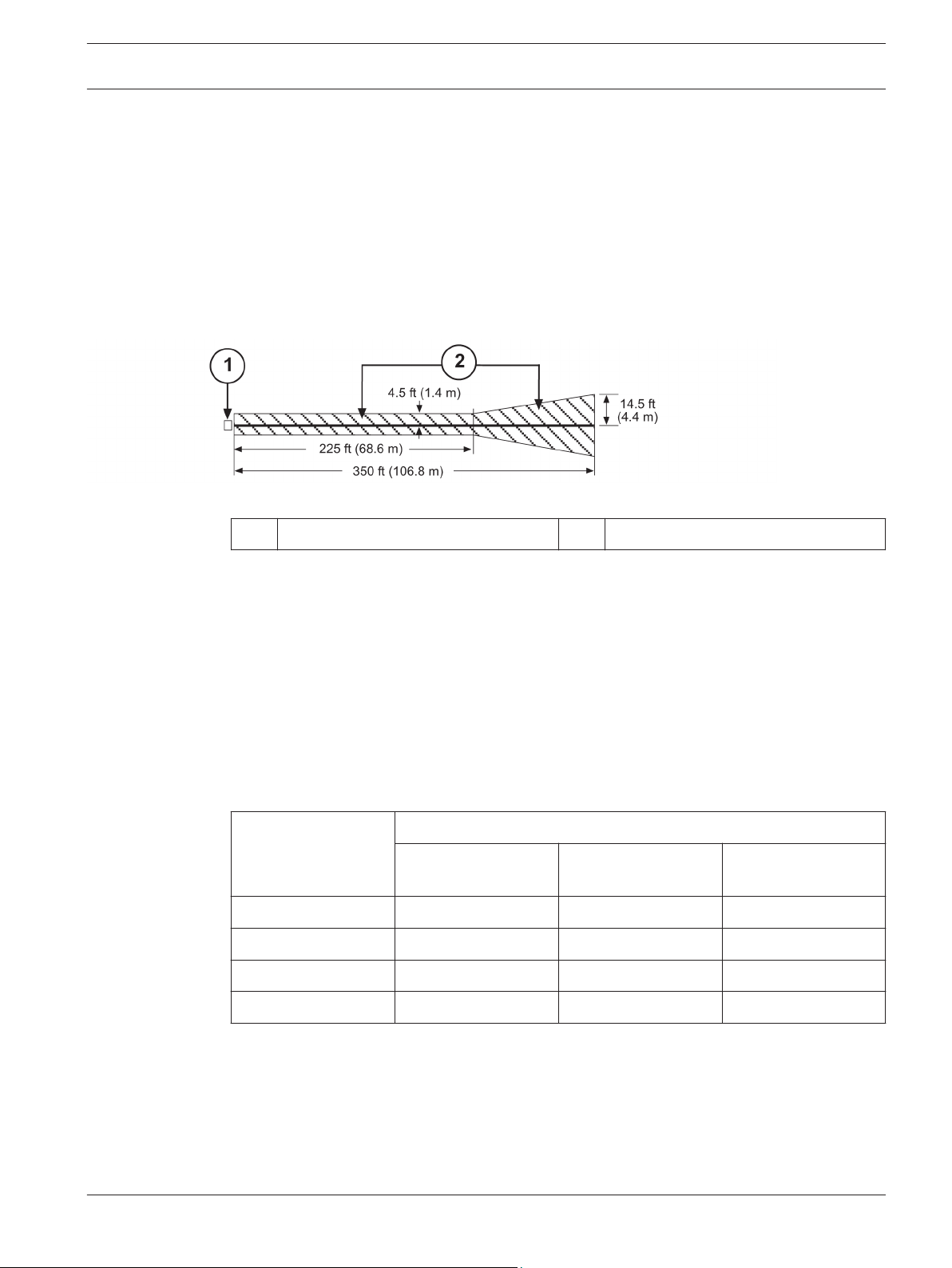

smoke cloud along the beam path as illustrated in the following figure.

2014.01 | 06 | F.01U.068.899 Installation Instructions Bosch Security Systems, Inc.

Long-range Beam Smoke Detectors Notices | en 9

Figure 3.2: Smoke Densty and Obscuration Graph

1 Smoke density 3 UL maximum sensitiivity

2 UL minimum sensitivity 4 Distance between transmitter and

receiver

Determine the total obscuration needed for an alarm and select the sensitivity setting needed

according to the following table.

Total Obscuration at Alarm Sensitivity Switch Setting

20% 2

30% 0 or 3

40% 4

50% 5

60% 1 or 6

70% 7

Bosch Security Systems, Inc. Installation Instructions 2014.01 | 06 | F.01U.068.899

Loading...

Loading...