Bosch D285, D285TH Installation Instructions Manual

D285/D285TH

Installation Instructions

EN

Photoelectric Smoke

Detectors

D285/D285TH | Installation Instructions |

1.0 Overview

FCC Notice

The D285 Series Photoelectric Smoke Detectors (D285,

D285TH) comply with Part 15 of the Federal

Communications Commission (FCC) Rules. Operation

is subject to the following two conditions:

1. These detectors might not cause harmful

interference.

2. These detectors must accept any interference

received, including interference that might cause

undesirable operation.

Changes or modifications not expressly approved by

Bosch can void the user’s authority to operate the D285

Series Smoke Detectors.

1.0 Overview

The D285 Series are UL Listed, open-area,

photoelectric, smoke detectors designed for use with

commercial fire protective signaling systems and

household fire warning systems (refer to the National

Fire Alarm Code [NFPA 72]). These detectors are

available in two-wire and four-wire models, and have an

optional +135°F (+57°C) fixed-temperature heat sensor.

For commercial and industrial installations, space the

detectors 30 ft (9.2 m) apart as recommended by

NFPA 72.

When properly installed using the D280/D290 Series

Detector Bases, tamper protection is provided by in/out

wiring of the positive power line. This causes the

control to initiate a trouble signal when a detector is

removed from its base. The master control supervises

the two-wire systems. Four-wire system supervision is

provided by an end-of-line (EOL) power supervision

device such as a D275 or a D293E Power Supervision

Base and an EOL resistor (as specified by the control

manufacturer).

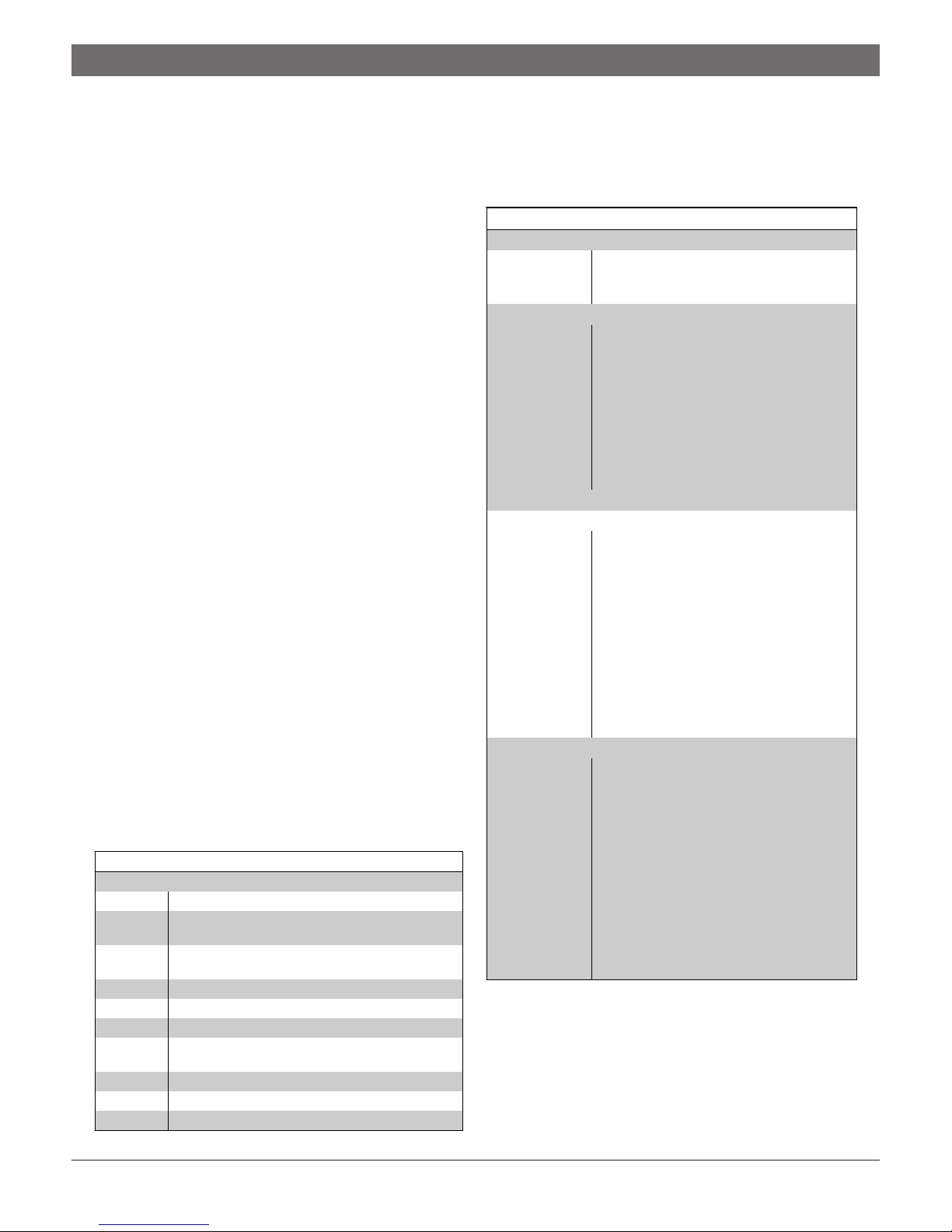

Refer to Table 1 for product descriptions.

Table 1: Product Description

D285

D285TH

D285DH

D287

D292

D293A

D293E

D293S

D275

TP280

Detector only (requires base)

Detector with integral +135°F (+57°C) heat

sensor (requires base)

Detector only, for D340 Series Duct Smoke

Detectors

Base only, two-wire

Base only, four-wire

Base only, four-wire, Form “C” auxiliary relay

Base only for power supervision, four-wire,

EOL relay, Normally Open auxiliary relay

Base only, four-wire, with sounder

EOL supervision module for four-wire systems

Trim Plate 6 in. (16.2 cm) diameter

The letter “A” is the UL compatibility identifier for the

D285 Series. Refer to the Two-Wire Smoke Detector

Compatibility Technical Service Note (P/N: 31866) to

determine the UL compatibility identifier used with the

D287 Base.

Table 2: Specifications

Operating

Temperature

Power Requirements

Standby

Voltage:

Maximum

RMS Ripple:

Start-up

Current:

Standby

Current:

Note: The D293E equals 24 mA at 12 VDC and 24 VDC.

Alarm Current

Two-wire:

Four-wire:

Power-up

Time:

Compatible Control Panels

Two-wire:

Four-wire:

+32° to 100°F (0°C to +38°C )

0 to 95% relative humidity

(non-condensing)

Two-wire: 8.5 VDC to 33 VDC

Four-wire: 10 VDC to 30 VDC

25% of DC input

120 µA maximum

80 µA at 12 VDC

90 µA at 24 VDC

100 µA at 33 VDC

Dependent on the control panel that limits

the alarm current to 100 mA maximum.

D292: 48 mA at 24 VDC and 51 mA at

24 VDC (70 mA maximum at 30 VDC)

D293E: 80 mA at 12 VDC and 24 VDC

(100 mA maximum at 30 VDC)

D293S: Base 48 mA at 12 VDC, sounder

15 mA at 12 VDC, 25 mA at

24 VDC

22 sec maximum

Refer to the

Compatibility Technical Service Note

(P/N: 31866).

Note: Bosch makes no claim (written, oral,

or implied) the D285 Series Smoke

Detectors work with any two-wire control

panels except those specified in the

Two-Wire Smoke Detector Compatibility

Technical Service Note

Compatible with all UL Listed four-wire

control panels. Refer to the

manufacturer's installation instructions for

proper EOL resistor selection.

Two-Wire Smoke Detector

(P/N: 31866).

Bosch | 6/04 | 32029E2

D285/D285TH | Installation Instructions | 2.0 Mounting

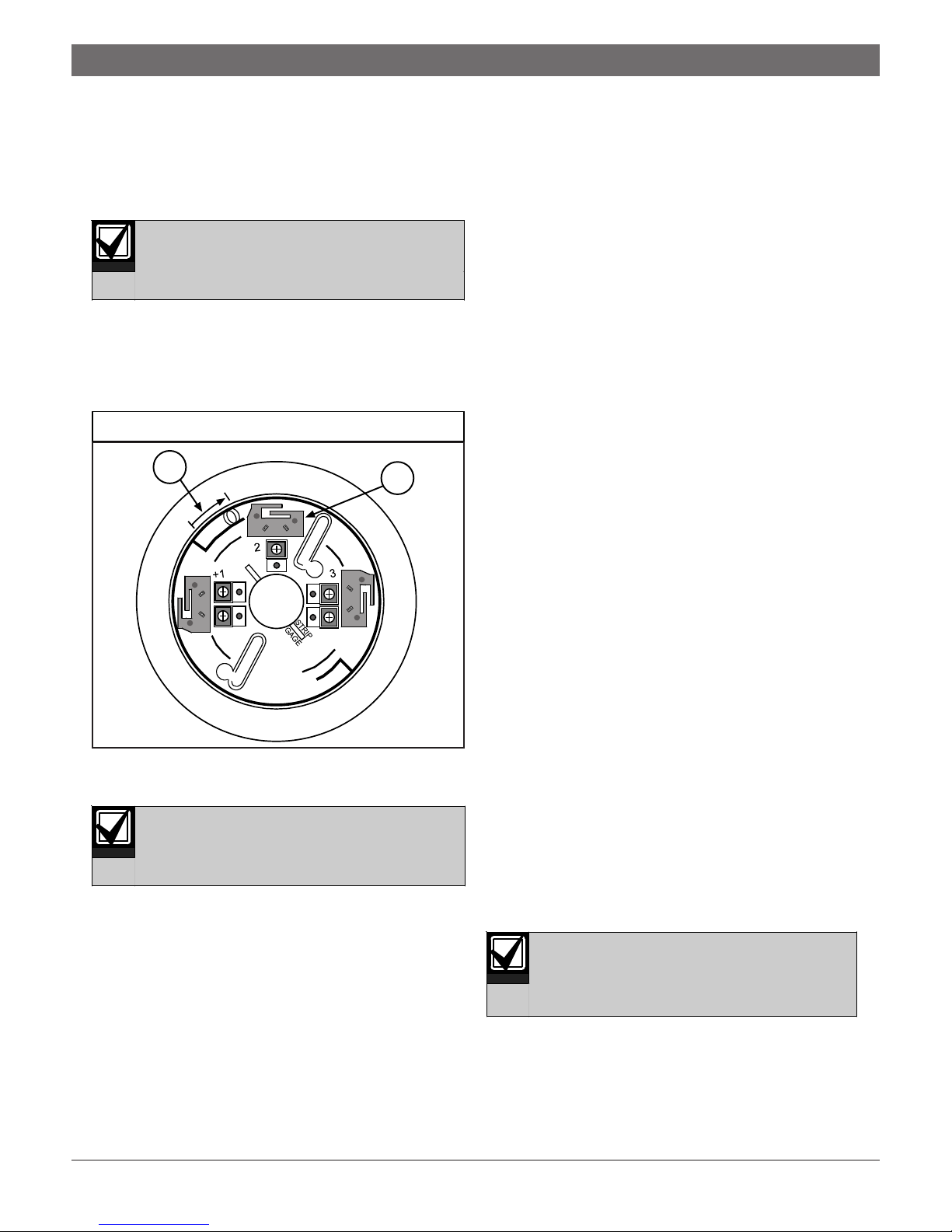

2.0 Mounting

1. Before mounting, remove the dust cover from the

detector. The dust cover can be replaced during

construction periods, but it must be removed once

the alarm system is enabled.

The tamper screw is located in the recess

on the top of the dust cover.

2. Mount the base according to its instructions.

3. Mount the detector to the base by turning it

clockwise until it clicks into place. When it is secure,

the alignment line aligns with the tamper screw hole

(refer to Figure 1).

Figure 1: Mounting the Base

1

1 - Alignment arrow

2 - Base contacts (three sets)

The D285 Series Smoke Detectors are

keyed. Do not force a detector onto its

bases.

2

3.0 Installation Testing

1. Check the wiring from the control panel to the last

head on each run for proper polarity and continuity.

a. Ensure each run terminates with an EOL

resistor as specified by the control panel

manufacturer.

b. Ensure the four-wire runs terminate with EOL

modules or D293E Bases.

2. Apply power to the system, checking for alarms and

troubles.

a. Note which detectors are in alarm (if any) and

then shut down the system.

b. Remove these detectors from their bases and

recheck the bases for proper wiring. If the

problems persist, replace the affected

detectors or swap them with known good

units. This determines if the problem is

caused by the detector or the base.

c. If a system alarm with no detector alarms is

present, remove all detectors and check the

wiring at each base. Pay close attention to the

wiring of each EOL resistor and EOL

module.

3. When the system is free of alarms, check each

detector to ensure the red LED indicator is flashing

approximately every 3 sec. This verifies the detector

is receiving power and operating properly.

4. Test each detector to ensure it will cause a control

panel alarm. This is the only way to ensure proper

operation. Alarm the detectors by doing one of the

following:

a. Place a magnet horizontally against the

detector’s side (centered over the “T” marked

on the head) to activate an internal reed

switch, or

b. Use a UL Listed aerosol smoke detector

tester such as the Home Safeguard Industries’

25S to simulate an alarm. Follow the

instructions with the aerosol smoke detector

tester.

When a detector alarms, the red LED

indicator activates and latches into the ON

position. Clear the alarm before proceeding

to the next detector.

5. Check the overall loading of the alarm loop by

measuring the voltage across each EOL resistor.

This voltage should equal or exceed the minimum

specified by the control panel manufacturer.

3Bosch | 6/04 | 32029E

Loading...

Loading...