Bosch c-Si M 60-225-16, c-Si M 60-240-16, c-Si M 60-230-16, c-Si M 60-235-16 Installation And Safety Manual

Page 1

Solar Energy

Installation and Safety Manual of the Bosch Solar Modules

c-Si M 60-225-16, c-Si M 60-230-16, c-Si M 60-235-16, c-Si M 60-240-16

Read Me

Thank you for buying our Bosch Solar photovoltaic (PV) modules. This manual describes the

installation and maintenance instructions for

the modules intended for use in North America.

Before installing, wiring and using a module, it

is important to thoroughly read this manual and

understand the instructions. Installers must

understand the basic principles of electricity

and electrical apparatuses as well as article 690

of the National Electrical Code. Special attention must be given to the safety instructions.

Disclaimer of Liability

Since the use of this Safety and Installation

Manual and the conditions or methods of installation, operation, use and maintenance of the

module are beyond the control of Bosch Solar,

Bosch Solar does not assume responsibility and

expressively disclaims liability for loss, damage

injury or expense arising out of or in any connected with such installation operation, use or

maintenance of the module.

Bosch Solar assumes no responsibility for infringement of patents or other rights of third

parties which may result from use of the module. No license is granted by implication or otherwise under any patent or patent rights. The

information in this Manual is based on Bosch

Solar‘s knowledge and experience and is believed to be reliable; but such information including product specifications (without limitations) and suggestions do not constitute a warranty, expressed or implied. Bosch Solar reserves the right to make changes to the product, specification or the Manual without prior

notice.

1. Important Safeguards/Warnings

Read this section carefully before installing,

using, repairing or performing maintenance on

the PV modules or the PV power system.

WARNING

• Lethal voltages and/or shock hazard may

be present in modules and arrays during

sunlight hours, even at low light level.

This hazard increases when multiple

modules are connected together to provide higher system voltage or current

levels. Dangerous voltages may also be

present at night from connections to

batteries and feedback from inverters or

other parts of the system.

Bosch Solar modules should only be installed

by qualified installers with adequate solar installation experience. You must comply with the

standards and regulations applicable to PV installations, such as National Electrical Code

(NEC) and other building codes, the grid operator’s technical connection requirements, and

trade association rules concerning accident

prevention. Failure to comply can lead to significant personal injury and equipment damage.

Lethal voltages and/or a shock hazard may be

present in modules and arrays during sunlight

hours, even at low light level. This hazard increases when multiple modules are connected

together to provide higher system voltage or

current levels. Dangerous voltages may also be

present at night from connections to batteries

and feedback from inverters or other parts of

the system.

2. Underwriters Laboratories Information

(U.S. and Canada Only)

Bosch Solar c-Si M 60-225-16, c-Si M 60-230-16,

c-Si M 60-235-16 and c-Si M 60-240-16 are UL

1703 listed. This UL standard covers flat-plate

photovoltaic modules and panels intended for

installation on or integral with buildings or to be

freestanding (not attached to buildings), in

accordance with the National Electrical Code

(NFPA 70), appropriate Building Codes, and any

other applicable Local Codes in the US.

UL Listed Bosch Solar c-Si modules are rated

class C and intended to be installed on “Class

A” fire rated roofs, residential or commercial,

per local codes in US.

1/9

photovoltaikforum.com

Page 2

Solar Energy

For “Class C” modules, the assembly is to be

mounted over a fire resistant roof covering

rated for the application.

Under normal conditions, a photovoltaic module

is likely to experience conditions that produce

more current and/or voltage than reported at

standard test conditions. Therefore, the values

of Isc and Voc marked on this module must be

sized according to section 690-8 of the National

Electrical Code for all component voltage ratings, conductor ampacities, fuse sizes, and size

of controls connected to PV output.

Use only UL Listed grounding lugs suitable for

outdoor use: Burndy P/N CL-50-DB or ILSCO

P/N GBL-4DB in conjunction with an 8-32

stainless steel fastener and star washer. USE

conductor cable of minimum 10 AWG and

minimum 90°C temperature rating, which is

also sunlight resistant rated, for modules and

interconnect wiring that is exposed to weather

as per NEC.

National Electrical Code (NEC)

The National Electrical Code (NEC) covers the

installation of photovoltaic systems and must

be adhered to when systems are designed and

installed. Article 690, Solar Photovoltaic Systems, of the NEC applies to solar photovoltaic

electrical energy systems including the array

circuit(s), power conditioning unit(s) and controller(s) for such systems.

All wiring shall be in accordance with the NEC,

and grounding method of the frame of arrays

shall comply with the NEC, article 250.

USL/CNL

All USL/CNL installations shall be in accordance

with CSA C22.1, Safety Standard for Electrical

Installations, Canadian Electrical Code, Part 1.

2/9

photovoltaikforum.com

Page 3

Solar Energy

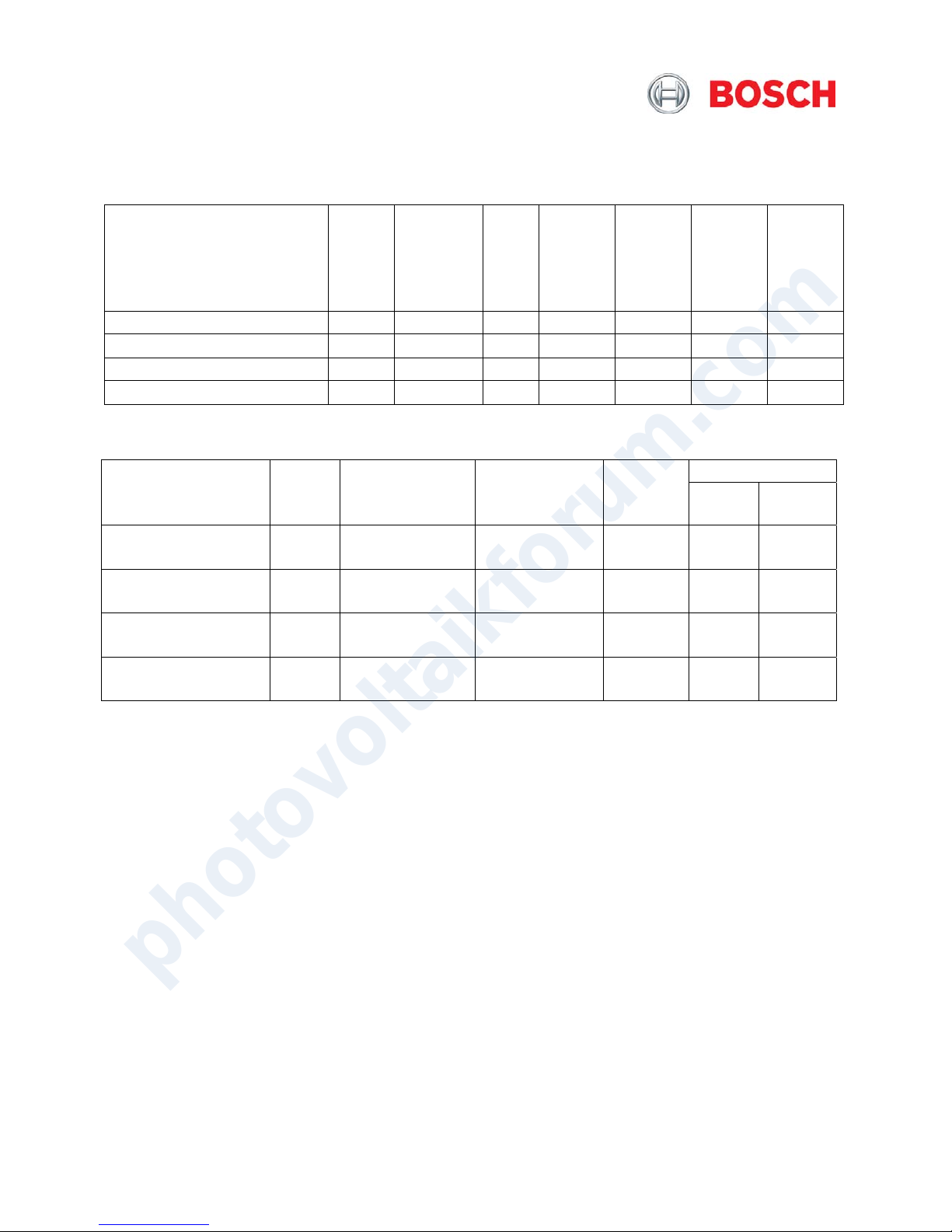

3. Bosch Solar Module Electrical Characteristics

Model

Open

Circuit

Voltage

at STC,

(V dc)

Rated

Voltage at

STC,

(V dc)

Maximum

System

Voltage, (V

dc)

Rated

Current at

STC,

(A dc)

Short

Circuit

Current at

STC,

(A dc)

Rated

Maximum

Power at

STC,

(Watts)

Maximum

Series

Fuse,

(A)

c-Si M 60-225-16

36.0 28.3

600

7.95 8.7 225 15

c-Si M 60-230-16

36.35 28.75

600

8.0 8.75 230 15

c-Si M 60-235-16

36.5 29.35

600

8.0 8.75 235 15

c-Si M 60-240-16

36.7 29.65

600

8.1 8.8 240 15

Module bypass diode type, voltage rating, current rating, and configuration of the diode

Diode Ratings Module series Total #

of Dio-

des

Diodes # in par-

allel for each

string

Diode Manufac-

turer

Diode

Type

(A) (PIV)

c-Si M 60-225-16

3 1 Tyco SL1010 11 40

c-Si M 60-230-16

3 1 Tyco SL1010 11 40

c-Si M 60-235-16

3 1 Tyco SL1010 11 40

c-Si M 60-240-16

3 1 Tyco SL1010 11 40

NOTE:

DO NOT attempt to open the diode housing or junction box located on the back side of any Bosch Solar

module. There are no user serviceable parts inside.

4. SAFETY INSTRUCTIONS

Handling Safety

DO NOT drop, allow objects to fall on,

or stand or step on modules.

DO NOT install during high winds.

Never leave a module unsupported or

unsecured. If a module falls, the glass

could break. A module with broken

glass cannot be repaired and must not

be used.

DO NOT disassemble the module, or

remove any part installed by Bosch Solar. Use modules for their intended use

only and follow all manufacturers’ instructions.

DO NOT attempt to remove snow or ice

from the module.

DO NOT direct artificially concentrated

sunlight on the module.

Installation Safety

DO NOT attempt to install or service

any portion of the PV system unless you

understand the electrical operation and

are fully qualified to do so.

3/9

photovoltaikforum.com

Page 4

Solar Energy

DO NOT drill holes in the frame or glass

of the module. Doing so will void the

warranty.

Have a fire extinguisher, and first aid kit

when performing field work on all energized equipment where the system

open circuit voltage is 30 volts or

greater.

Since sparks may be produced, do not

install module where flammable gases

or vapours are present

DO NOT attempt to open the diode

housing or junction box located on the

back side of any Bosch Solar module.

There are no user serviceable parts inside.

DO NOT work on modules when mod-

ules are wet. If a wet module is cracked

or broken the full system voltage may

be present.

Fire Safety

1. Refer to your local authority for guide-

lines and requirements of building or

structural fire safety.

2. It may be necessary to use components

such as earth ground fault circuit

breakers, fuses and circuit breakers

3. Do not use modules near equipment or

locations where flammable gasses can

be generated or can collect.

Electrical Safety

Rated electrical characteristics are

within ±10 percent of the indicated values of Isc, Voc, Pmax under Standard

Test Conditions. (Irradiance of

100 W/cm, Am 1.5 spectrum and a cell

temperature of 25°C (77°F).

Under normal conditions, a photo-

voltaic module may experience conditions that produce more current and/or

voltage than reported at Standard Test

Conditions. Accordingly, the values of

ISC and VOC marked on UL Listed

modules should be multiplied by a factor of 1.25 when determining component voltage ratings, conductor capacities, fuse sizes and size of controls

connected to the module output. Refer

to Sec. 690-8 of the National Electric

Code for an additional multiplying factor of 125 percent (80 percent of rating) which may be applicable.

DO NOT wear jewellery when working

on the modules.

A two-person team is to be used while

performing field work on all energized

equipment where the system open circuit voltage is 30 volts or greater.

Wear electrical insulating gloves rated

at 1000 volts and suitable eye protection when working on systems where

the system open circuit voltage is 30

volts or greater.

DO NOT touch terminals while the

module is exposed to light without

wearing electrical insulating gloves.

DO NOT use modules in systems that

can exceed 600 volts open circuit under

any combination of solar irradiation and

ambient temperature.

DO NOT connect or disconnect a mod-

ule unless the array string is open- circuited or all of the modules in the

string are covered.

5. Mechanical Installation

NOTE:

The maximum wind and snow loads on a module

mounted in any position must not exceed a resultant surface load of 30lb/ft² over the module

surface. Reference ASCE 7-95 for determining

the proper wind and snow load calculations for

each location. All installations should also be in

accordance with local building codes and regulations. For proper structural design, it is recommended to retain the services of a structural

engineer experienced with the installations of PV

systems.

NOTE:

It is the sole responsibility of the user and/or

installer to verify that the module mounting system and mounting method are properly engineered and in accordance with local building

codes and regulations.

4/9

photovoltaikforum.com

Page 5

Solar Energy

NOTE:

Modules shall be mounted so that the junction

box shall be in the uppermost position to minimize the ingress of water.

Clearance between Modules

A clearance of 6mm/.25” between modules is

sufficient in most installations to accommodate

thermal expansion. However, the appropriate

clearance is dependent upon installation specific factors including the module mounting

system, temperature at the site and the maximum operating temperature of the module. The

maximum distance between modules should

not exceed 12” based on using standard wiring.

Orientation, Tilt Angle & Shading

Photovoltaic modules generate maximum power

when facing directly towards the sun. PV systems can track the sun or remain in a fixed tilt

position. Tracking systems will produce more

energy but are more costly and require more

maintenance. PV systems are predominantly set

at a tilt. The further North from the equator, the

more tilt. Since applications and needs are

different, consult a PV system integrator or use

a commercially available software program to

determine the expected energy output. The

following chart may serve as a rule of thumb.

Site Latitude Horizontal Tilt Angle

0-10 = 10 Degrees

11-20 = Latitude

21-30 = Latitude + 5~

31-40 = Latitude + 10~

41+ = Latitude + 15~

The following paragraphs list some other general rules of thumb:

It is not recommended to set the tilt angle below 10-15 degrees. Dirt tends to accumulate on

modules installed at flatter angles and does not

wash off as readily during rainfall. Dirt accumulation or any debris, even snowfall on the module will reduce its energy output.

Modules should be located in areas with an

unobstructed view of the sun where they will

receive maximum exposure of sunlight for the

longest possible time during the day. Shadowing caused by buildings, trees, utility poles and

other obstructions, significantly reduces the

module energy output.

In systems that are configured with multiple

rows of modules, the rows must be spaced far

enough apart to minimize the impact of shading

on other rows. This distance is dependent on

the latitude and tilt angle at which the system is

installed. The closer to the equator, requires a

lower tilt angle and therefore the shorter this

distance. The further from the equator, higher

tilt angle and therefore the greater this distance

needs to be. If there are questions regarding

the optimum configuration in which to arrange,

mount or wire the modules, obtain assistance

from your Bosch Solar dealer or distributor or

retain the services of an engineer familiar with

the proper design of PV systems.

Suggested Mounting Methods

The information in this section only suggests

possible methods of securing the PV modules to

a ‘module mounting system.’

It is the sole responsibility of the user and/or

installer to verify that the module mounting

system and mounting method is properly engineered and is in accordance with local building

codes and regulations.

Bosch Solar PV modules can be arranged in

either landscape or portrait position on flat or

sloped roofs or surfaces and at flat or tilted

angles.

The modules shall be mounted so that the junction box shall be in the uppermost position to

minimize the ingress of water.

NOTE:

Always use caution when mounting a module on

tilted angles or sloped roofs so the module does

not slide out of position while attaching it to the

module mounting system.

NOTE:

The minimum standoff distance between Bosch

Solar modules and the roof is 40mm.

CAUTION

Never leave a module unsupported or unsecured.

If a module falls, the glass could break. A module

with broken glass cannot be repaired and must

not be installed.

Bosch Solar requires one of the following methods for mounting Bosch Solar PV Modules:

5/9

photovoltaikforum.com

Page 6

Solar Energy

A. The four provided mounting holes

on the bottom of the modules, using ¼” bolts with washers and nuts.

Bolt torque is 15-20 ft-lbs.

B. Uni-Rac type “unistrut” or C-

channel rails, using Uni-Rac clamp

mount clips part numbers

N:320201 (end clamps) or

N:320199 (mid clamps) secured

with ¼” – 14 bolts. Bolt torque is

12-15ft-lbs.

Refer to Figure 2, Details A, B, and C for three

examples of different methods using various

hardware for attaching the PV module to the

module mounting system.

NOTE:

Under no circumstances may the short frame

edges be used for anchoring the module.

Use only the 4 recommended mounting holes

(See Figure 1)

Mounting holes

(4X)

Grounding holes

(4X)

Figure 1: Mechanical Layout

6/9

photovoltaikforum.com

Page 7

Solar Energy

Figure 2: Examples of Attaching Modules

7/9

photovoltaikforum.com

Page 8

Solar Energy

6. Electrical Installation

Module To Module Interconnection

Bosch Solar modules have been designed to be

easily interconnected. Each module comes with

one positive (+) wire with a plug on one end

and one negative (-) wire with a receptacle on

one end. Both wires are connected inside of

the junction box (diode housing). Modules are

interconnected by inserting the plug from one

module into the receptacle of the next module

in the array string. Secure the mated connector

pair to the inside flange of the module frame to

protect it from damage.

Building Source Circuit and Configuring

Modules

PV arrays are comprised of source circuits. A

source circuit is a series of modules connected

together to reach the desired power. The number of modules in a source circuit can vary depending on the module voltage and desired

system voltage, provided the max system voltage does not exceed that allowed by NEC Section 690-7 (600 volts).

When calculating the system operational voltages use the module V

p. However, for NEC

compliance, the maximum system voltage is

calculated using Voc.

When determining component voltage ratings,

conductor ampacities, fuse sizes, and size of

controls connected to PV output, use the values

of Isc and Voc marked on the module or found

in this instruction manual.

NOTE:

Under normal conditions, a photovoltaic module

is likely to experience conditions that produce

more current and/or voltage than reported at

standard test conditions. Accordingly, the values of Isc and Voc marked on this module must

be multiplied by a factor of 1.25 when determining component voltage ratings, conductor ampacities, fuse sizes, and size of controls connected to PV output.

Refer to Section 690-8 of the National Electrical

Code for an additional multiplying factor of 125

percent (80 percent derating) which may be

applicable.

CAUTION

DO NOT connect or disconnect a Bosch Solar

module unless the array string is open-circuited

or all of the modules in the string are covered.

The connectors are not designed to make or

break the full system current.

CAUTION

Be aware that the artificially concentration

sunlight shall not be directed on the modules or

panels.

Module Grounding

The module frame must be properly grounded.

The installer shall ground the frame using the

grounding method described in NEC Article 250.

All USL/CNL installations shall be in accordance

with CSA C22.1, Safety Standard for Electrical

Installations, Canadian Electrical Code, Part 1.

The grounding wire must be properly fastened

to the module using a ground bonding lug. Use

only UL Listed grounding lugs suitable for outdoor use: Burndy P/N CL-50-DB or ILSCO P/N

GBL-4DB in conjunction with an 8-32 stainless

steel fastener and star washer. An uncoated

copper lug is not acceptable for attachment to

the aluminium frame.

Four grounding holes are provided on the inside

of the module frame located in the middle of

each of the four frame flanges. See Figure 3 for

location of module grounding holes.

See Figure 4 for installation of lug.

Note:

The star washers are required for making a

reliable electrical earth connection with the

anodized aluminium frame as well as to prevent

loosening of the screw over time.

To attach grounding lugs, use #8-32 (4mm)

bolts and nuts, star washers, and lock washers

that are provided for use with module ground

points. The ground lug shall be installed from

the bottom side of the frame using the paint

cutting star washers, lock washer and bolt.

Torque hex bolt to 50-70 in-lbs. This ground

hardware can accommodate a 14AWG through

4AWG bare (stranded or solid) wire.

8/9

photovoltaikforum.com

Page 9

Solar Energy

Grounding wire

Figure 3: Grounding Hole Locations

Figure 4: Installation of the grounding lug

Use only UL Listed grounding lugs suitable for

outdoor use: Burndy P/N CL-50-DB or ILSCO

P/NGBL-4DBin conjunction with an 8-32

stainless steel fastener and star washer. Attach

this lug to the module frame with a nut, bolt

and star washer as shown in Figure 4.

Grounding

Holes (4X)

Contact Information:

www.bosch-solarenergy.com

solarenergy@us.bosch.com

9/9

photovoltaikforum.com

Loading...

Loading...