Page 1

Typ1 osa / CC 220

Machine Parameters

Version

106

Page 2

Typ1 osa / CC 220

Machine Parameters

1070 073 309-106 (96.06) GB

Z4 GA and D4 NA (Type1 osa)

Z25 FO and D25 NJ (CC 220)

Reg. Nr. 16149-03

E 1996

by Robert Bosch GmbH,

All rights reserved, including applications for protective rights.

Reproduction or handing over to third parties are subject to our written permission.

Discretionary charge 20.– DM

Page 3

Page 4

Table of contents

Foreword Foreword − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety instructions Safety − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. General 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Applications 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Function 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Operation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Running the machine parameters program 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Editing (modifying) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Entry 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Cursor functions 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Search 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Delete / Undelete 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 Additional functions 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Transfer 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Delete 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Load (CC 220 / Type1 osa) 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Output (CC 220 / Type1 osa) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Manage EEPROM 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Controlling the machine parameters 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software version

User information

Contents

Type1 osa / CC 220

Machine parameters

Page

5. Machine parameters 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Machine parameter sets 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 100 Axis parameters 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 500 Speeds 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 1000 Axis dynamics 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 1500 Positions 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 2000 Auxiliary functions 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 2500 Potentiometers 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 3000 Powerup state 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 3500 Colour settings 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 3600 Greyscale settings 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 4000 CPL parameters 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 4500 Zero shifts 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 5000 Suppression table 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 5500 Device selection 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 6000 PLC parameters 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents − 1

Page 5

Contents

P 6100 Electronic limit switches normal 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 6200 Electronic limit switches fast 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 6300 Laser applications 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 6400 Tangential tool control 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 6500 Centre parameters 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 6600 Compensation parameters 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 6800 Contourdependent feedrate override (Look ahead) 112. . . . . . . . .

P 7000 Spindle parameters 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 7100 Parameters for 2nd spindle 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 7200 Exact tapping 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 7500 Turning machine 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 7600 Caxis parameters 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 8500 DNC interface with simple protocol 139. . . . . . . . . . . . . . . . . . . . . . . . . .

P 8600 DNC interface with LSV2 protocol 141. . . . . . . . . . . . . . . . . . . . . . . . . . .

P 8700 FMS communications interface with BAB 143. . . . . . . . . . . . . . . . . . . . .

P 9000 Address selection 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 9500 Axis processors 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P 9900 System parameters 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type1 osa / CC 220

Machine parameters

Page

6. Index of all parameters 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

−

Contents − 2

Page 6

Foreword

Software version

Proper use

Foreword

This manual describes software version Z25 GO" for control unit CC 220 M and

D25 NJ" for control unit CC 220T as well as software version Z4 GA" for control

unit Type1 osa M and D4 NA" for control unit Type1 osa T.

IMPORTANT

The group operating mode DIAGNOSIS contains instructions for the current

control unit software version which may be accessed via the softkey DIAGNOSTIC

CONTROL or SOFTWARE VERSION.

As the title suggests, this manual contains information required for normal

operation of the control unit. For reasons of clarity, however, not every detail of

every possible combination of parameters can be included. Similarly, as the

control unit is usually only part of a larger installation or system, not every

conceivable aspect of integration or operation is covered.

Type1 osa / CC 220

Machine parameters

Your Bosch service branch or customer advisory service will be pleased to help you

if you require more detailed information or if problems with the control unit should

arise which are not sufficiently dealt with in this manual. The addresses may be

found on the back cover of this manual.

This manual is intended for technically qualified personnel. The machine

parameter program (MPP) enables significant alterations to be made to the

interaction between the CNC, machine and drives, including the performance of

the CNC itself!

CAUTION !

Only suitably trained specialist personnel may start and operate the MPP and

!

make changes to machine parameters. Such personnel should be capable

of recognising the dangers involved in changing parameters and which can

generally arise from mechanical, electrical or electronic equipment.

Operation of the MPP by inadequately trained or untrained personnel can result in

serious damage to the machine and drives, loss of software or even injury to per

sons. Bosch accepts no liability for damage resulting from incorrectly pro

grammed, calculated or optimised machine parameters, or from unobserved data

limits.

Please note that we offer a comprehensive training program. An overview of

courses may be found on the inside front cover of this manual. Our training centre

will be pleased to provide you with further information. The address may be found

on the back cover of this manual.

Foreword −1

Page 7

Foreword

Type1 osa / CC 220

Machine parameters

Foreword −2

Page 8

Safety instructions

The Type1 osa and CC220 series control units were developed, manufactured

and tested in accordance with the basic safety stipulations of the EC Machine

Guideline.

You should nevertheless be wary of residual risks!

You should therefore read this manual before configuring or commissioning this

type1 osa or the CC 220, or working with the machine parameters for the first time.

Safety instructions

Type1 osa / CC 220

Machine parameters

Pictographs and symbol explanations

The following warnings and instructions can be attached to hardware modules to

draw attention to certain points:

’ Danger of electrocution!

’ Electrostatically sensitive devices!

’ Remove plug before opening!

’ Bolts only for PE conductor connection!

’ Only for cable screen connection!

1Safety −

Page 9

Safety instructions

Hierarchical warning instructions are used in this manual. The warning

instructions are printed in bold, being designated and clearly indicated by a

warning symbol at the side of the page.

The warning instructions are classed hierarchically in the following order:

1. WARNING

2. CAUTION

3. NOTE

WARNING!

The term WARNING is used to warn of immediate danger.

!

This could lead to a fatality or serious injury (personal injuries).

Type1 osa / CC 220

Machine parameters

CAUTION

The term CAUTION is used to warn of a potentially dangerous situation.

!

This could lead to a fatality or serious or light personal injuries or damage to

equipment or to the environment.

NOTE

The term NOTE is used to refer to a recommended course of action.

Damage to equipment, e.g. to the machine or the workpiece, or loss of data, may

result if instructions are not observed.

The symbol IMPORTANT is used in addition to the hierarchy of warning

instructions described above:

IMPORTANT

This designates a passage from the text which contains explanatory information or

tips.

2Safety −

Page 10

Proper use

!

Safety instructions

The Type1 osa or CC 220 is used for

‘ controlling feed drives, spindles and auxiliary axes in a machine tool in

order to guide a machining tool along a programmed path to machine a

work piece (CNC).

In addition, a PLC with corresponding I/O components is required to

control completely the machining process while in communication with

the actual CNC as well as monitoring safetyrelated aspects of the

process.

‘ programming the contour and machining technology (feedrate, spindle

speed, tool change) of a workpiece.

Any other use is against regulations!

CAUTION!

− Improper use may have consequences such as personal injury to the user or a

third party, material damages to the equipment and to the workpiece being

machined, or damage to the environment.

You should therefore use our products only as here instructed!

Type1 osa / CC 220

Machine parameters

− Movements of tools and axes may lead to serious or fatal injuries!

Every operator, production line builder or machine manufacturer is obliged to

connect input signals of the Type1 osa or the CC 220 which can trigger a

machining start (e.g. NCSTART) as well as the contact READY(2) in

compliance with the applicable safety requirements.

In addition to this, the emergency stop circuit must be designed in accordance

with the applicable safety requirements and guidelines.

Equipment such as ‘protective covers

‘protective screens

‘light cabinets etc.

can reduce the risk of accident considerably.

3Safety −

Page 11

Qualified personnel

This manual is intended for specially trained technicians and engineers who

possess expert knowledge of CNC technology. Thorough knowledge of the

hardware and software components involved in the system under control is

essential.

Qualified personnel are

− project planning personnel who are familiar with the safety guidelines for

electrical and automation technology

− commissioning personnel who are authorized to earth, mark, and put into

operation electric circuits and devices/systems in accordance with recognized

safety standards.

CAUTION!

Only suitably qualified personnel may make changes to machine parameters!

!

Such personnel should be capable of recognizing the dangers involved in

changing parameters and which can generally arise from mechanical, electrical or

electronic equipment.

Changes made to machine parameters by inadequately or untrained personnel

can result in serious damage to machines and drives, loss of software or even

injury to persons!

Bosch accepts no liability for damages resulting from incorrectly programmed,

calculated or optimised configuration parameters, or from unobserved data limits!

Safety instructions

Type1 osa / CC 220

Machine parameters

Please note our comprehensive training programme. An overview of courses may

be found on the inside front cover of this manual. Our training centre will be

pleased to provide you with further information (tel: 06062 / 78258).

Retrofittings and changes by the operator

Our units have been designed and constructed to offer the utmost safety.

WARNING!

− Retrofitting the devices or making changes to them may compromise their

!

safety!

This could lead to a fatality, serious or slight injury (personal injuries), or

damage to equipment or to the environment.

You should therefore contact us first before carrying out any retrofittings or

changes to the equipment which involve parts made by manufacturers other

than Bosch. We are in a position to advice you as to whether such parts are

compatible with our products.

4Safety −

Page 12

Maintenance, repairs

WARNING!

− Danger of electrocution!

!

Unless otherwise stated, maintenance work must always be carried out when

the unit is switched off! The unit should be protected against unauthorised or

accidental restart.

If it is necessary to carry out measuring or testing operations on an active unit,

the existing safety and accident prevention regulations must be observed. A

suitable electric tool must be used in any case!

− Risk of fatal injury due to inadequate EMERGENCY OFF devices!

Emergency stop devices must remain operative and accessible in all unit

modes. Ensure when unlocking the EMERGENCY OFF device that the unit is

not restarted without being regulated!

− Movements of tools and axes may lead to serious or fatal injuries!

Feed and spindle motors have very powerful mechanical forces at their

disposal and can accelerate very quickly due to the high dynamic.

You should therefore never be standing in the danger area of the machine while

it is running!

Do not ever − not even briefly − deactivate the safetyrelevant functions of

the unit!

Report any faults in the unit to your servicing and repairs department

immediately!

Safety instructions

Type1 osa / CC 220

Machine parameters

− Danger of explosion from batteries!

Batteries should not be forcibly opened, recharged, soldered or thrown into

fire!

Replace used batteries with new ones!

CAUTION!

− Repairs or maintenance of control unit components may only be carried out by

!

the Bosch Service Department or by maintenance centres authorised by

Bosch.

− Only replacement parts and spares authorised by Bosch may be used!

− Used or rechargeable batteries must be treated as special waste!

5Safety −

Page 13

Safetyconscious work

WARNING!

− Movements of tools and axes may lead to serious or fatal injuries!

!

Feed and spindle motors have very powerful mechanical forces at their

disposal and can accelerate very quickly due to the high dynamic.

You should therefore never be standing in the danger area of the machine while

it is running!

Do not ever − not even briefly − deactivate the safetyrelevant functions of

the unit!

Report any faults in the unit to your servicing and repairs department

immediately!

− The wrong choice of clothing may have fatal consequences!

Where machines with moving parts are involved, careless handling may lead to

clothes or long hair being caught, pulling the user into the machine!

You shoud therefore: ‘ wear a hair net

‘ wear a protective suit

‘ remove protective gloves before

‘ remove jewellery and bracelets

Safety instructions

coming close to moving parts

Type1 osa / CC 220

Machine parameters

− Remember that chippings may be cast out during operation of the machine

unit! They can cause eye injuries and burns.

You should therefore: ‘ wear protective goggles

‘ wear a protective suit

− There is also a danger of injury from sharp edges on workpieces and tools

during transport!

You should therefore: ‘ wear protective gloves

6Safety −

Page 14

1. General

General

The machine parameters program (MPP) is used to adapt the CNC control to the

machine tool. The modifiable data is divided into three groups:

‘ Application data

Data for activating the range of options ordered from the machine tool

manufacturer (MTM), e.g. 5th axis, 128 kB program memory, thread milling.

‘ Machine data

Data for adapting the CNC functions to the specific peculiarities of the

machine (e.g. axis speeds).

‘ System data

Data for adapting the CNC operating system to special requirements

(e.g. interpolation time).

CAUTION!

The drives must always be correctly adjusted before optimising/setting the

machine parameters.

The MTM may only modify the actual machine data independently.

!

Changes to the system data and/or application data should only be made on the

instructions of the Bosch Service department.

Type1 osa / CC 220

Machine parameters

2. Applications

3. Function

The machine parameters program (diagnostic program 4) is permanently present

in the operating system of the CNC (EPROM) and facilitates the display, changing,

loading and outputting of all machine parameter data. This supports the following

applications:

‘ Activating the range of options ordered by the client (from the machine tool

manufacturer).

‘ Documenting or archiving the machine parameters for a particular system

(MTM).

‘ Backing up the machine parameters via external data carriers and/

or EEPROM, so that they can be reloaded if any of the data is lost

(end client).

The machine parameters program is permanently present in the operating system

(EPROM) and includes the following functions:

‘ Displaying the machine parameter data

‘ Changing the machine parameter data

‘ Loading the machine parameter data from a storage medium

‘ Outputting the machine parameter data to a storage medium

‘ Saving data to EEPROM by means of diagnostic program D9 EEPROM

MANAGEMENT".

− 1 −

Page 15

General

Type1 osa / CC 220

Machine parameters

− 2 −

Page 16

Operation

4. Operation

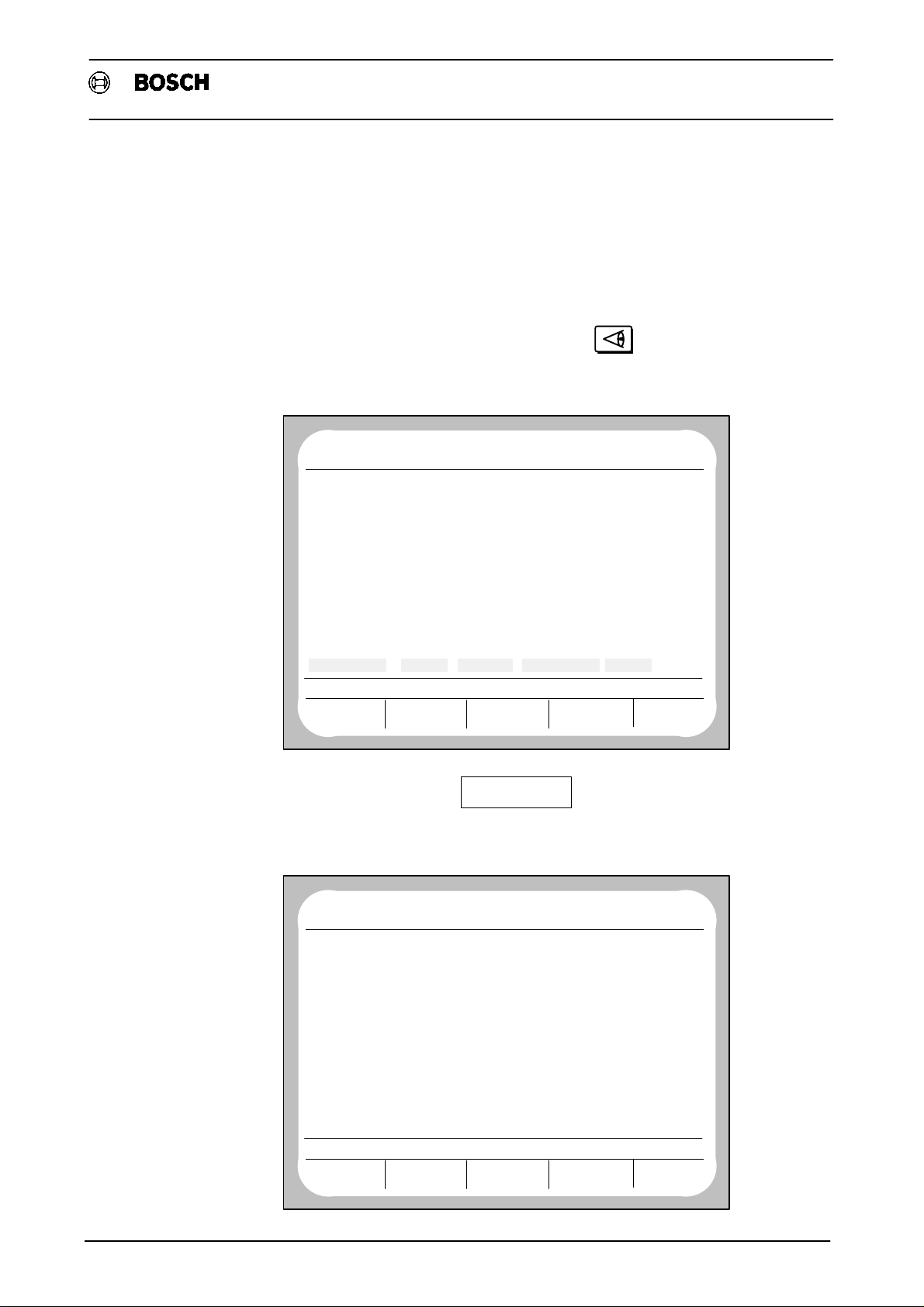

4.1 Running the machine parameters program

The machine parameters program (MPP) may only be accessed in DIAGNOSTIC

operating mode.

This operating mode is selected by pressing

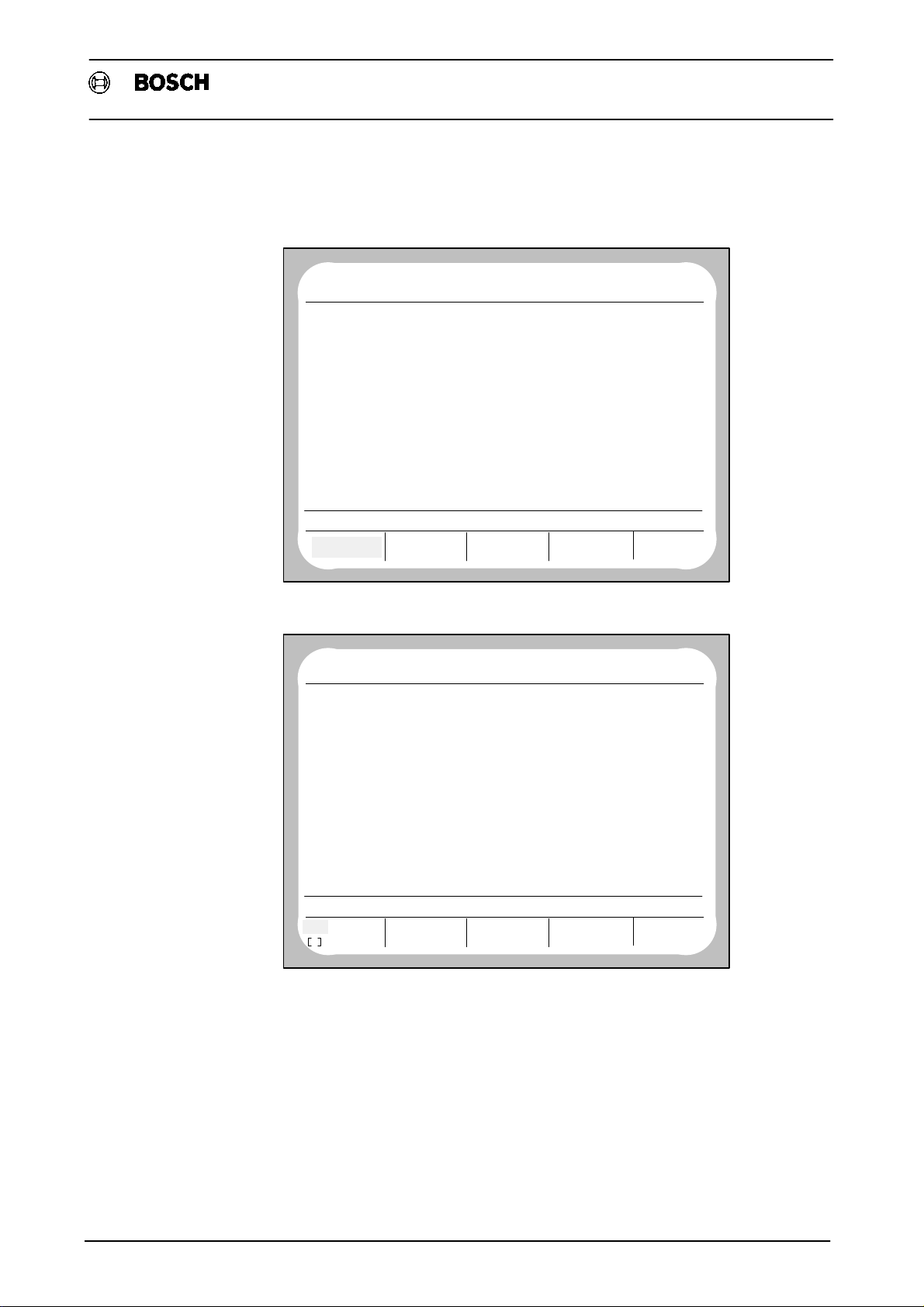

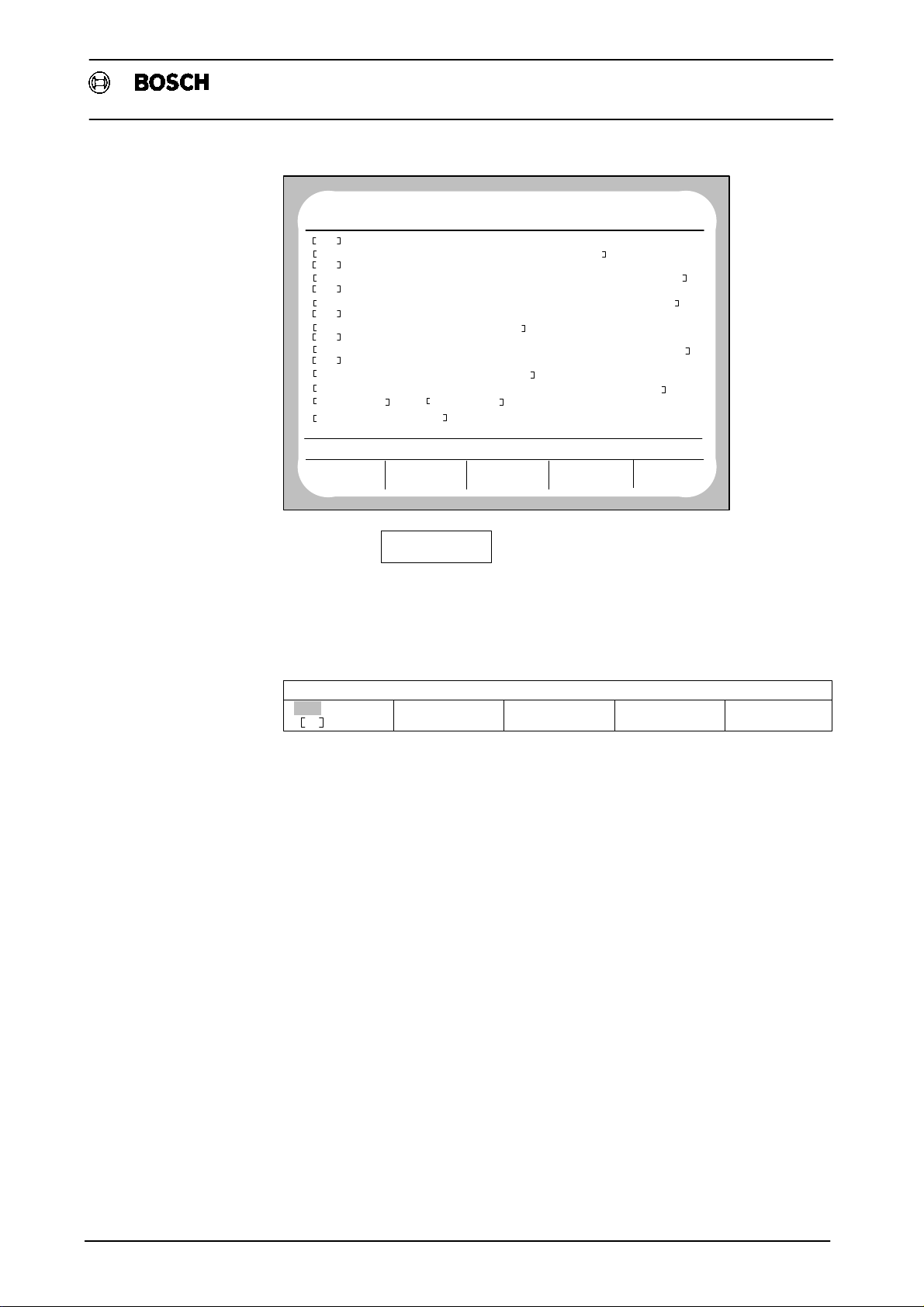

The following display appears onscreen:

Type1 osa / CC 220

Machine parameters

NO

PROGRAM

ERROR CONDITION ON STATUS

LAST PROGRAMMED

DIAGNOSTIC

CONTROL

BF0

NC0

ACT

WAITING

G

G

G

G

G

G

G

G

G

G

DIAGNOSTIC

MACHINE

G1 G71

G

90

G

94

G

17

G

15

G

153

146

994

80

39

65

130

G

253

G

G

G

115

RESET

FUNCTION

DIAGNOSTIC

24. 3 15:25

66

G

40

G

8

G

29

G

G

G

62

G

68

G

G

140

7

27

79

53

67

97

99

167

SERVICE

FUNCTION

NO REF. POINTS

DRIVES ON

FEED STOP

B 0M 30T 1016S 0F 100.0

SERVICE

By actuating the softkey

FUNCTION

and − if requested to do so by the

system − inputting a code number, an overview of all currently resident diagnostic

programs (D) may be obtained.

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH

D

D

D

D

D

D

D

D

D

D

D

D

MEMORY USED BY DIAGNOSTIC

MEMORY AVAILABLE :

SERVICE FUNCTION

BF0

NC0

ACT

WAITING

1

LOGBOOK MONITOR

2

RELOAD OPERATING PROGRAM

3

CLEAR ALL MEMORY

4

MACHINE PARAMETER PROGRAM

5

INTERNAL REF. POINT OFFSET

6

SERIAL IF DATA

7

COMMUNICATION STORAGE DISPLAY

9

MANAGE EEPROM

21

LOGIC ANALYSER

22

AXIS OSCIL.

23

CONTOUR DISPLAY

24

AXIS OPTIMISATION

4156

185946

LOAD START DELETE

OUTPUT

OTHERS: 72042

− 3 −

DIAGNOSTIC

24. 3 15:25

ACCESS

E

E

E

E

E

E

E

E

E

E

E

E

Page 17

Operation

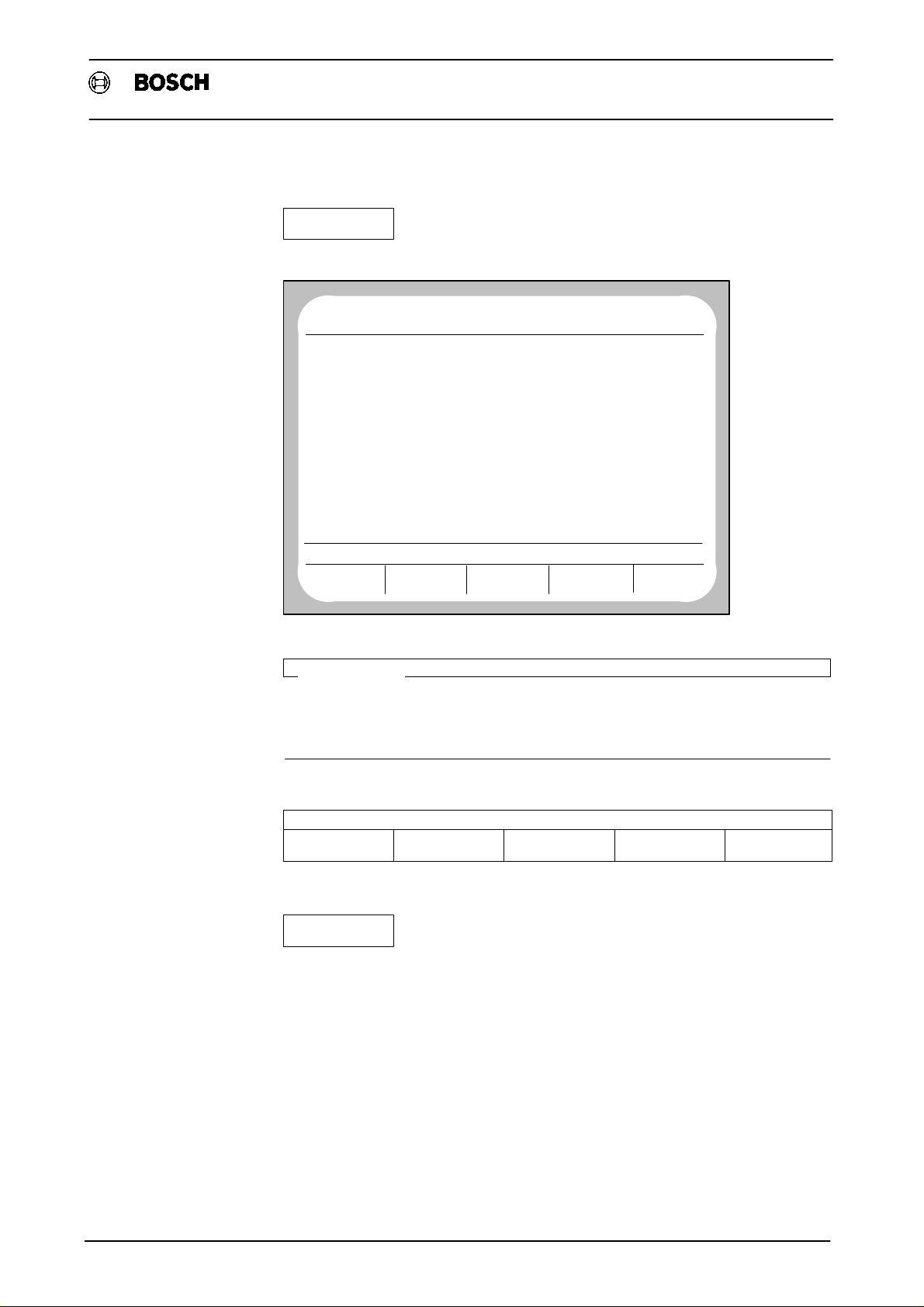

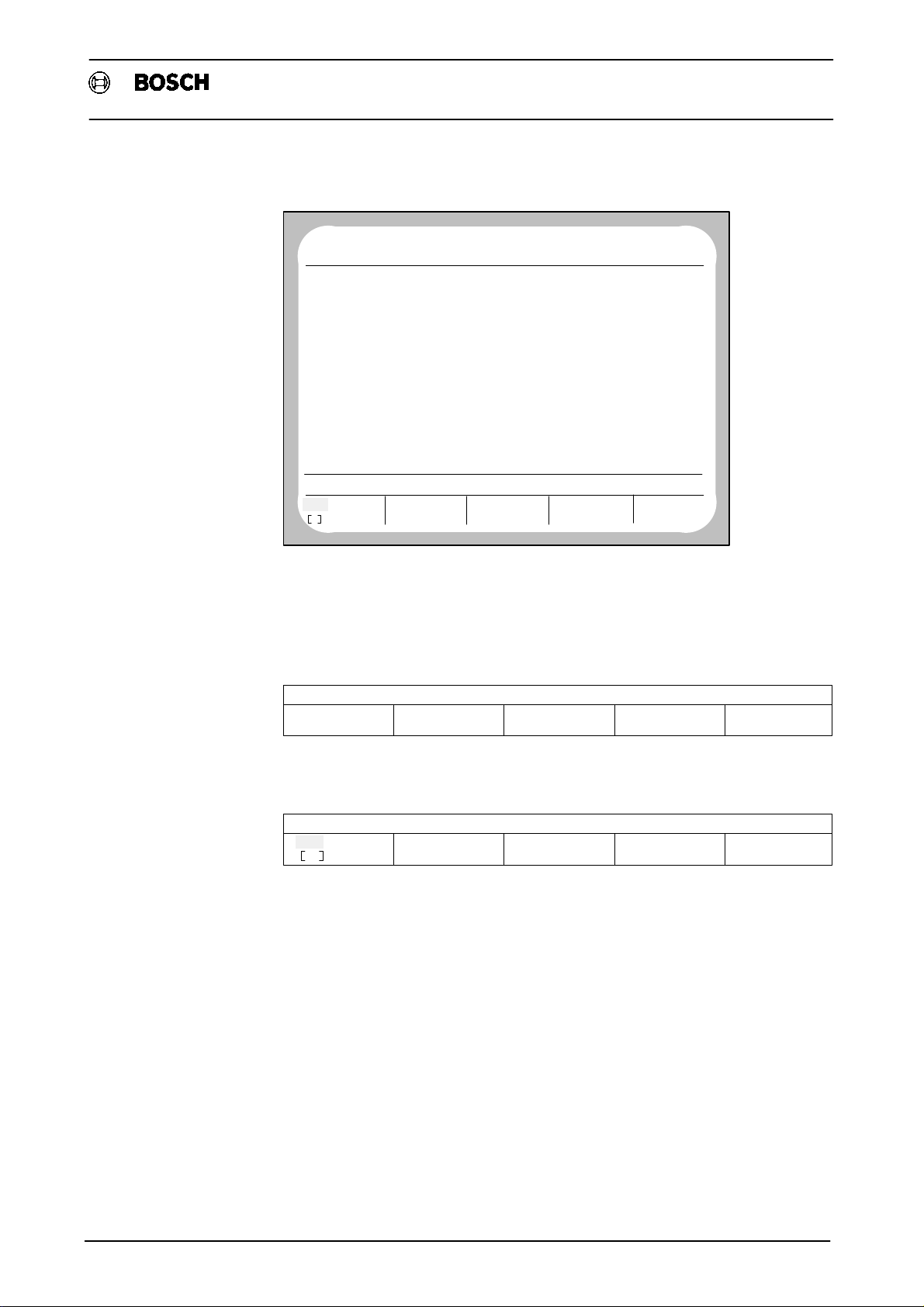

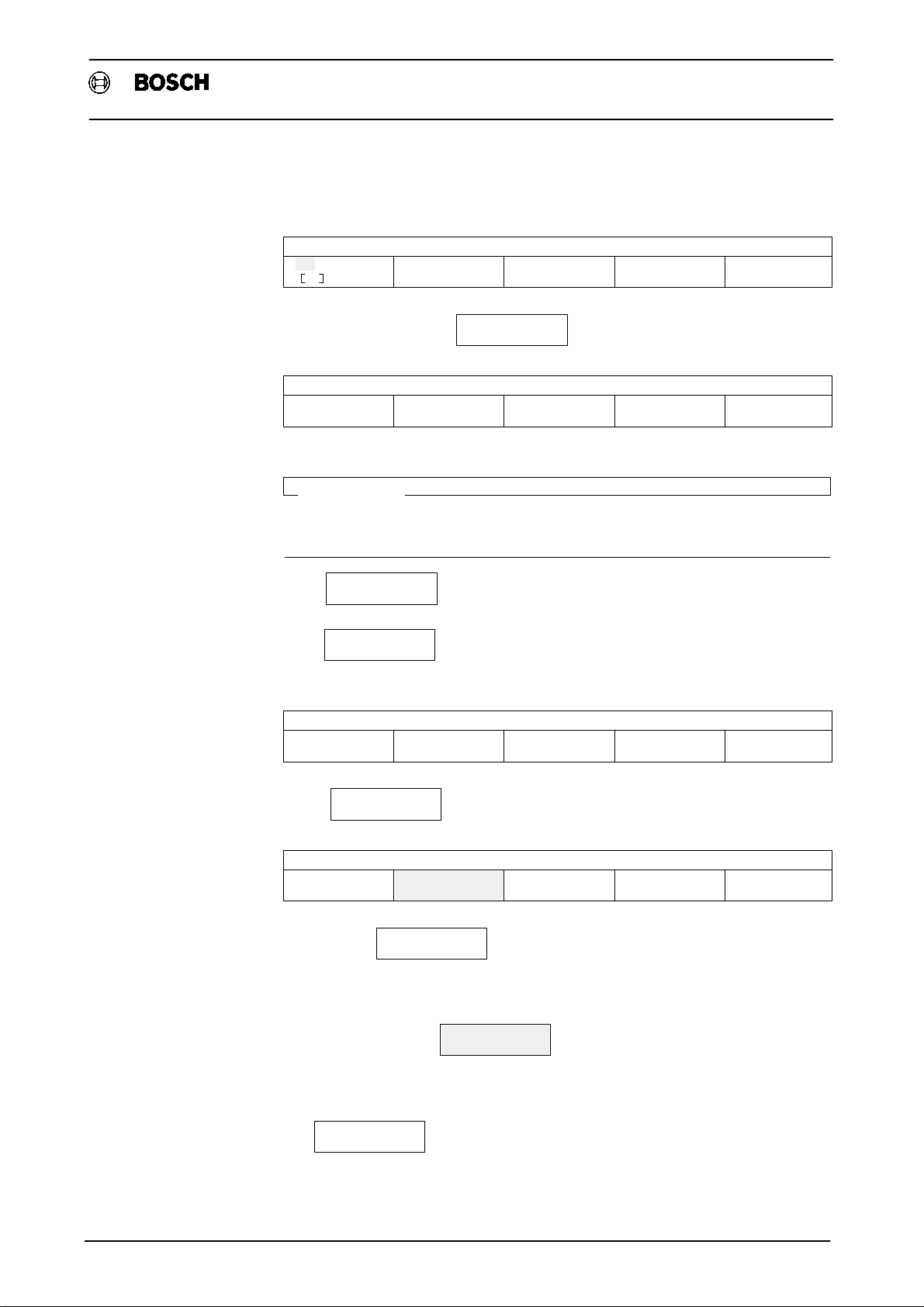

By pressing the softkey

Type1 osa / CC 220

Machine parameters

START

and inputting program number 4, the machine parameter

program may be started.

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH

L

L

L

L

L

L

L

MEMORY USED BY SYSTEM

MEMORY AVAILABLE :

MACHINE PARAMETERS PROGRAM

EDIT

BF0

NC0

ACT

WAITING

870

USER<−HEAP<−BLOCK....................

1

NC LINK TABLE

2

NC LINK TABLE

3

NC LINK TABLE

4

NC LINK TABLE

5

NC LINK TABLE

444

MACHINE PARAMETERS 24.03

28219

330307

LOAD OUTPUT MANAGE

TRANSFER

DIAGNOSTIC

24. 3 15:25

ACCESS

4140

RWED

152

RWED

152

RWED

152

RWED

152

RWED

152

RWED

23319

OTHERS: 34690

IMPORTANT

The files NC LINK TABLE" and USER<−HEAP<−BLOCK" have no connection

with the MPP. L444 only appears if the MP has already been edited or output at least

once.

If on selecting DIAGNOSTIC operating mode, the softkey line

DIAGNOSTIC

CONTROL

DIAGNOSTIC

MACHINE

RESET

FUNCTION

SERVICE

FUNCTION

MPP

is displayed, including the MPP" softkey, pressing the softkey

MPP

is all that is needed to reach the Machine parameters program"

operating level.

− 4 −

Page 18

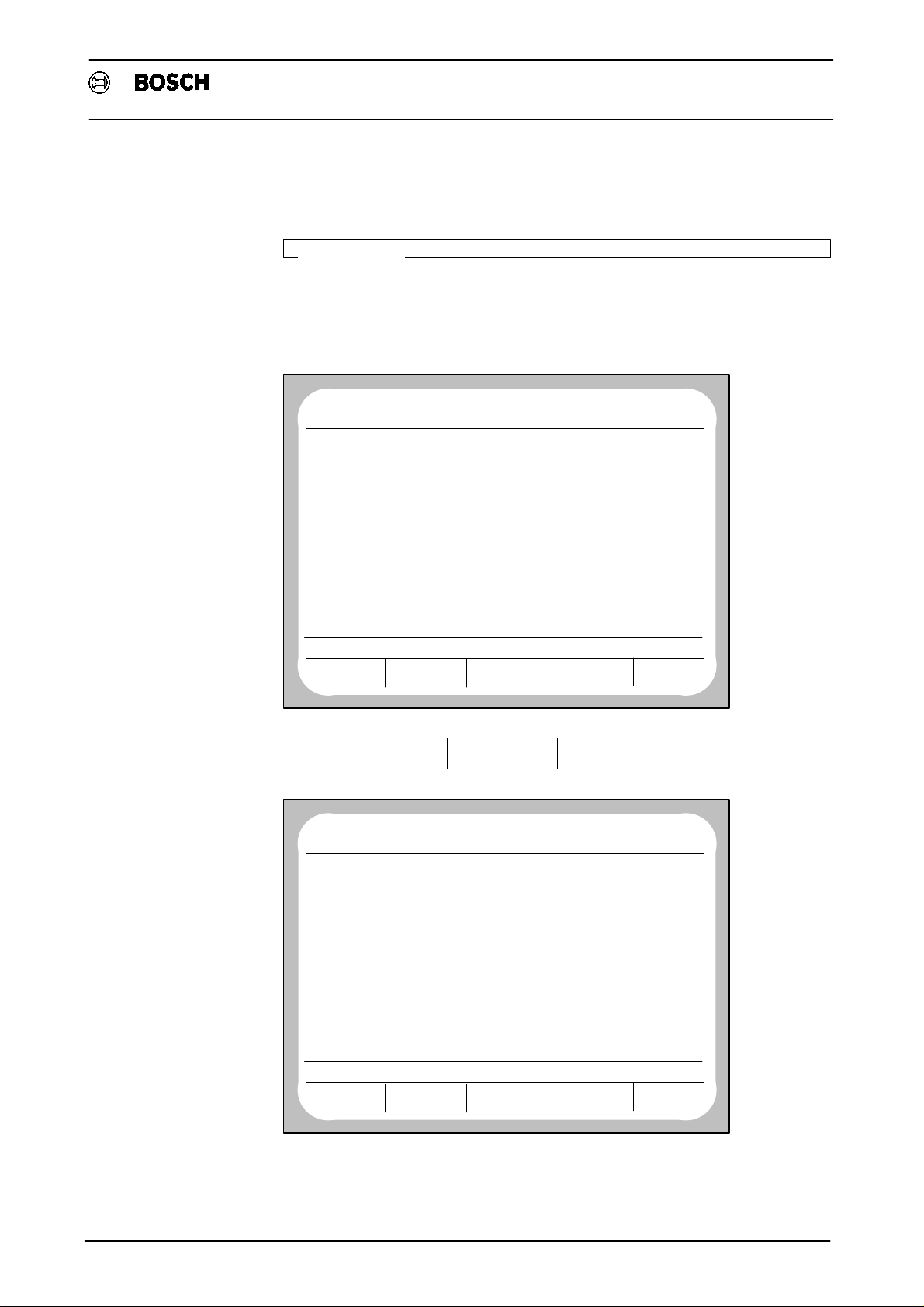

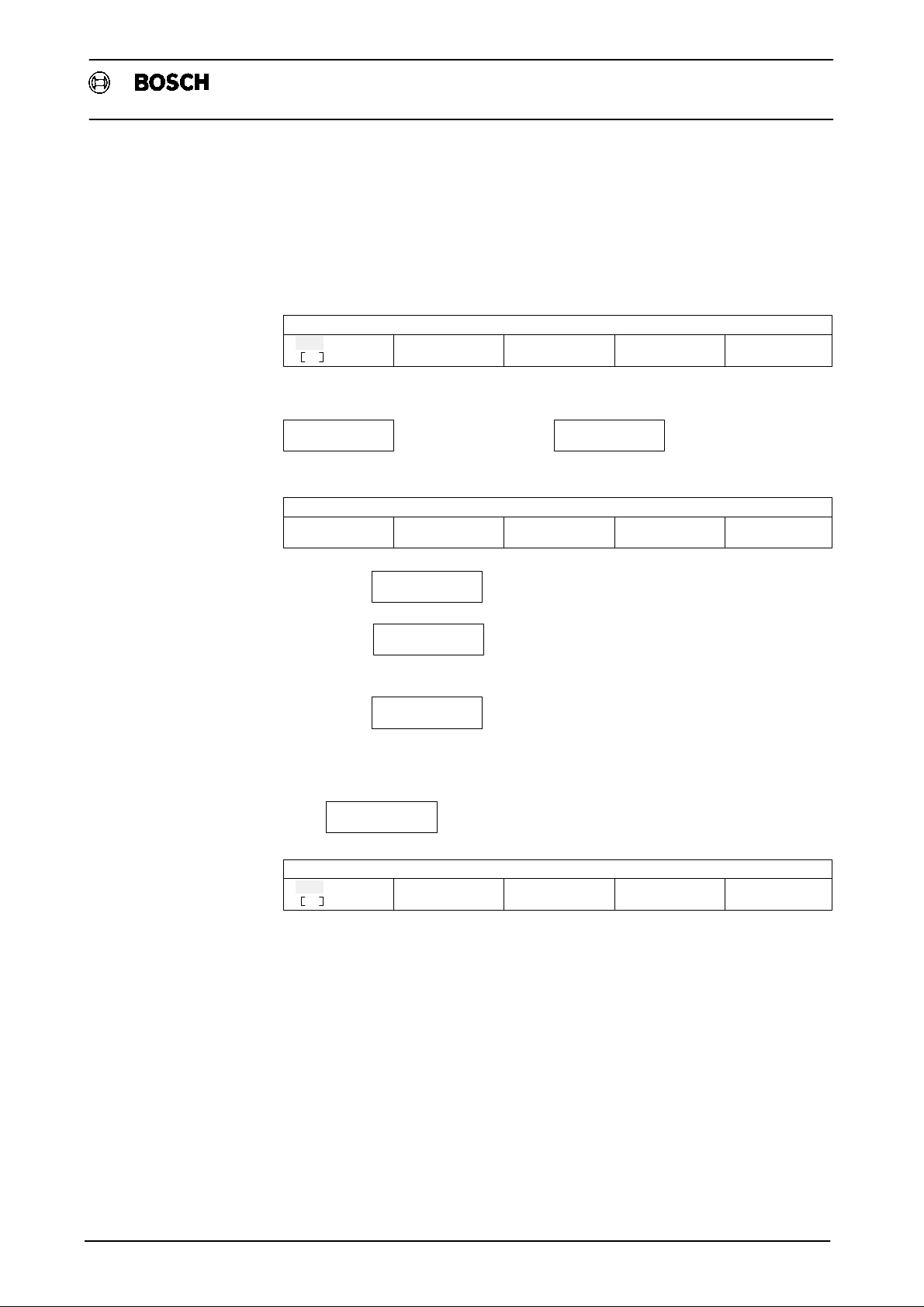

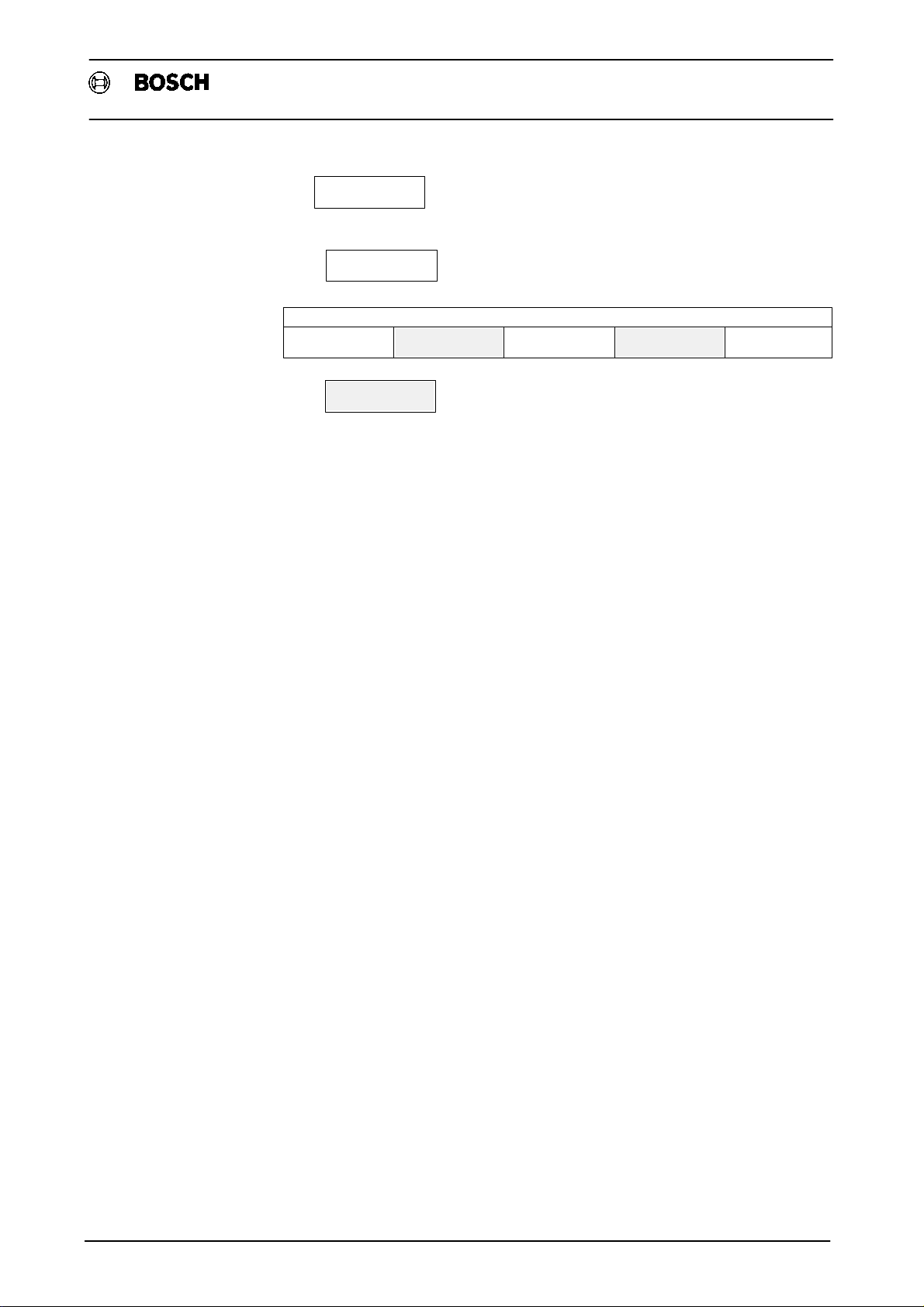

4.2 Editing (modifying)

Operation

Type1 osa / CC 220

Machine parameters

IMPORTANT

Only data which is NOT enclosed in square brackets may be edited!

If the parameters are to be edited for the first time, the following display will normally

appear (link tables are only present if programs were linked together beforehand):

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH

L

L

L

L

L

L

MEMORY USED BY SYSTEM

MEMORY AVAILABLE :

MACHINE PARAMETERS PROGRAM

EDIT

By pressing the softkey

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH

L

L

L

L

L

L

BF0

NC0

ACT

WAITING

870

USER<−HEAP<−BLOCK....................

1

NC LINK TABLE

2

NC LINK TABLE

3

NC LINK TABLE

4

NC LINK TABLE

5

NC LINK TABLE

4900

330307

TRANSFER

EDIT

LOAD OUTPUT MANAGE

BF0

NC0

ACT

WAITING

870

USER<−HEAP<−BLOCK....................

1

NC LINK TABLE

2

NC LINK TABLE

3

NC LINK TABLE

4

NC LINK TABLE

5

NC LINK TABLE

DIAGNOSTIC

24. 3 15:25

ACCESS

4140

RWED

152

RWED

152

RWED

152

RWED

152

RWED

152

OTHERS: 34690

the following operating level is reached

DIAGNOSTIC

24. 3 15:25

ACCESS

4140

RWED

152

RWED

152

RWED

152

RWED

152

RWED

152

MEMORY USED BY SYSTEM

MEMORY AVAILABLE :

MACHINE PARAMETERS PROGRAM

WITH TEXT

4900

330307

WITHOUT TEXT

OTHERS: 58009

By using the soft keys, the L444 machine parameters file can be generated with or

without text. This soft key bar only appears if L444 does not yet exist or has been

deleted.

− 5 −

Page 19

Operation

Type1 osa / CC 220

Machine parameters

After pressing one of the two soft keys, a message appears onscreen indicating

that the file is being generated. The control generates L444 from the default or

application values stored in system memory.

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH

L

L

L

L

L

L

MEMORY USED BY SYSTEM

MEMORY AVAILABLE :

PLEASE WAIT: FILE BEING GENERATED, SET 3500

BF0

NC0

ACT

WAITING

870

USER<−HEAP<−BLOCK....................

1

NC LINK TABLE

2

NC LINK TABLE

3

NC LINK TABLE

4

NC LINK TABLE

5

NC LINK TABLE

LOAD OUTPUT MANAGEEDIT

TRANSFER

4900

330307

DIAGNOSTIC

24. 3 15:25

ACCESS

4140

RWED

152

RWED

152

RWED

152

RWED

152

RWED

152

OTHERS: 58009

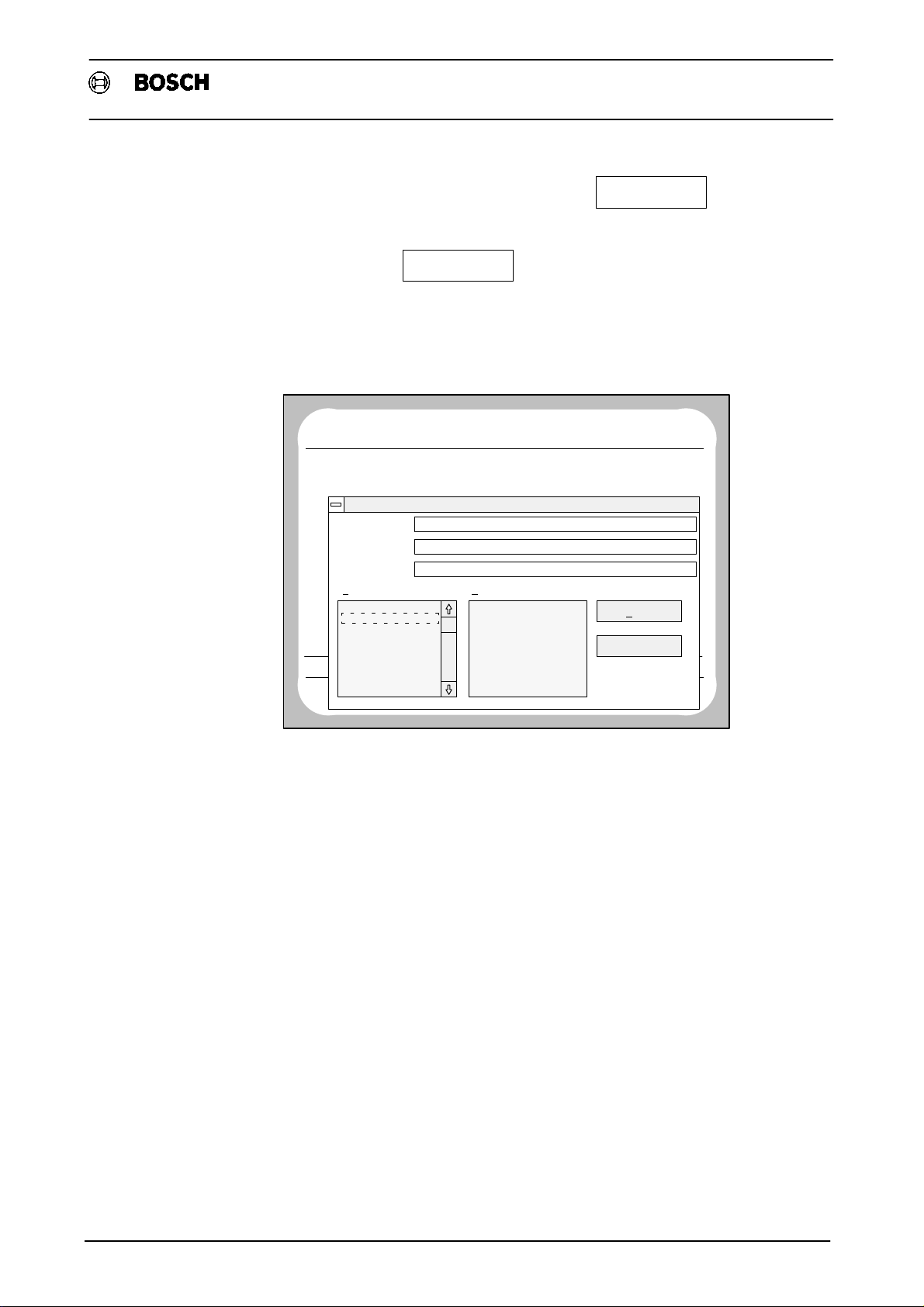

Once file L444 has been generated, the following display appears:

NO

PROGRAM

OPTIONS

B O S C H CC220 BASIC FUNCTIONS

MEMORY 224 (+32) K−BYTE

CLIENT EPROM 2048 K−BYTE

THREAD CUTTING INCL. G95

THREAD MILLING

FEED FORWARD CONTROL

ACCELERATION PROGRAMMING

LOOP FACTOR PROGRAMMING

CORNER DECELERATION/ACCELERATION

16 STANDARD LIMIT SWITCHES IF

4 FAST LIMIT SWITCHES IF

SOFTWARE LIMIT SWITCHES SUPPRESSED

3 ADDITIONAL AUXILIARY FUNCTIONS

PROGRAMMABLE SPINDLE ORIENTATION

EXTERNAL PROGRAM SELECTION

LEAD SCREW ERROR COMPENSATION

CPL WITH GRAPHIC COMMANDS

DNC INTERFACE WITH SIMPLE PROTOCOL

EDIT

YES NO

$ LF

BF0

ACT

A D G J M

P S V Y

NC0

WAITING

L 444

B E H K N

Q T W Y

C F I L O

R U X

DIAGNOSTIC

24. 3 15:25

FUNCTIONS

All active options are listed before an overview of the machine parameter sets is

displayed.

− 6 −

Page 20

Operation

Example of a machine parameters file (L444) with text

Type1 osa / CC 220

Machine parameters

4.2.1 Input

NO

PROGRAM

MACHINE PARAMETER SETS

P

100

P

500

P

1000

P

1500

P

2000

P

2500

P

3000

P

3500

P

4000

P

4500

P

5000

P

5500

P

6000

P

6100

6200

P

P

6500

EDIT

YES NO

$ LF

BF0

NC0

ACT

WAITING

A X I S P A R A M E T E R S

S P E E D S

A X I S D Y N A M I C S

P O S I T I O N S

A U X I L I A R Y F U N C T I O N S

P O T E N T I O M E T E R S

P O W E R − U P S T A T E

C O L O U R S E T T I N G S

C P L − P A R A M E T E R S

Z E R O S H I F T S

S U P P R E S S I O N T A B L E

D E V I C E S E L E C T I O N

P L C P A R A M E T E R S

E L E C T R: L I M I T S W I T C H N O R M A L

E L E C T R: L I M I T S W I T C H F A S T

T O O L C O M P E N S A T I O N S

L 444

A D G J M

P S V Y

B E H K N

Q T W Y

C F I L O

R U X

DIAGNOSTIC

24. 3 15:25

FUNCTIONS

If there is already a keyboard available (e.g. with Type1 osa keyboard), then

characters are selected via the keyboard (SK:Keyboard available is in reverse

video; see chapter 4.2.5), and the highest level of the editor appears as follows:

EDIT L 444

DELETE SEARCH

POSITION

CURSOR

FUNCTIONS

The softkey bar

EDIT L 444

YES NO

$ LF

A D G J M

P S V Y

B E H K N

Q T W Z

C F I L O

R U X

FUNCTIONS

identifies the highest editor level if no keyboard is available or the softkey

Keyboard available is not in reverse video (see chapter 4.2.5).

At this level, it is possible to input any of the alphabetic characters displayed.

It is possible to insert the softkey character displayed in reverse video into the MP

file by pressing the RETURN key.

By pressing a soft key repeatedly, the characters which can be selected from this

menu are displayed in reverse video one after the other.

The cursor indicates the point at which any characters entered are inserted into the

file.

− 7 −

Page 21

4.2.2 Cursor functions

Operation

Type1 osa / CC 220

Machine parameters

The cursor can be moved anywhere on the screen using the cursor keys. In

addition, the cursor can be placed in certain positions, which must be specified.

Position cursor

Starting at operating level

EDIT L 444

YES NO

$ LF

A D G J M

P S V Y

B E H K N

Q T W Z

C F I L O

R U X

FUNCTIONS

by selecting

FUNCTIONS

and then selecting

POSITION

CURSOR

the operating level is

reached.

EDIT L 444

RETURN BLOCK WORD 8 LINES

BLOCK

By selecting

By selecting

WORD

the cursor always jumps to the start of a new line.

the cursor jumps to the first character of the next

* DOWN

UP

word.

8 LINES

By selecting

the cursor always jumps down 8 lines.

By selecting the down/up" softkey, the cursor functions become effective towards

the end/start of the file.

RETURN

Press

EDIT L 444

YES NO

$ LF

to return to operating level

A D G J M

P S V Y

B E H K N

Q T W Z

C F I L O

R U X

FUNCTIONS

Scroll

The screen display can be scrolled up and down line by line using the cursor keys.

− 8 −

Page 22

4.2.3 Search

Operation

Type1 osa / CC 220

Machine parameters

It is possible to carry out searches for specific individual terms in the editor.

EDIT L 444

YES NO

$ LF

The softkey

FUNCTIONS

A D G J M

P S V Y

B E H K N

Q T W Z

C F I L O

R U X

FUNCTIONS

should be pressed at the highest operating level of

the editor.

This initiates the transition to the next operating level.

EDIT L 444

DELETE SEARCH

By selecting

SEARCH

POSITION

CURSOR

the following display is reached:

FUNCTIONS

EDIT L 444

RETURN

DEFINE

STRING

SEARCH FOR

STRING

END

*DOWN

UP

Direction of search

The direction of search must be determined before specifying the string to be

searched for.

* DOWN

UP

This can be done by pressing

.

The asterisk indicates the active direction.

The softkey END is displayed if search direction DOWN is selected, and allows a

jump directly to the end of MP file L444.

The softkey START appears if search direction UP is active, and allows a jump

directly to the beginning of MP file L444.

The softkey RETURN allows a jump back into the highest level of the editor.

Searching for character strings

DEFINE

STRING

By pressing

the following softkey bar appears:

EDIT L 444 SEARCH FOR : P3500

YES NO

$ LF

A D G J M

P S V Y

B E H K N

Q T W Z

C F I L O

R U X

READY

The character string to be searched for may now be entered. Every single letter

must be confirmed by pressing <ENTER>. Numbers are entered directly via the

appropriate keys and cannot/need not be confirmed by pressing <ENTER>.

The

function initiates the search procedure. The cursor jumps to

READY

the searchedfor location.

− 9 −

Page 23

Operation

Type1 osa / CC 220

Machine parameters

NO

PROGRAM

−62

P3009 FEED COMPENSATION ON/OFF (G64/G65)

−65

P3010 OUTSIDE CORNERS AS A RADIUS OR INTERSECTION (G68(69)

−68

P3011 TOOL TABLE COMPENSATION ON/OFF (G145/G46)

− 146

P3012 FEED FORWARD CONTROL (G114/G115)

− 115

P3013 EXTERNAL ZERO SHIFT ON/OFF (G160/G167)

− 167

P3500 C O L O U R S E T T I N G S

P3501 COLOUR "AREA" (FOREGROUND AND BACKGROUND)

FOREGROUND BLACK BACKGROUND LIGHT BLUE

P3502 COLOUR "SOFTKEY"

FOUND

EDIT

RETURN

BF0

ACT

DEFINE

STRING

NC0

WAITING

L 444

SEARCH

STRING

END

DIAGNOSTIC

24. 3 15:25

*DOWN

UP

SEARCH

STRING

By pressing

the search for the specified search word is

continued in the remaining program text, starting at the current location. The

message STRING NOT FOUND" appears if the soughtfor character string is not

found in the active search direction.

The softkey RETURN can be pressed to jump back to the highest operating level.

EDIT L 444

YES NO

$ LF

A D G J M

P S V Y

B E H K N

Q T W Z

C F I L O

R U X

FUNCTIONS

− 10 −

Page 24

4.2.4 Delete / Undelete

Operation

Type1 osa / CC 220

Machine parameters

Starting at operating level

EDIT L 444

DELETE SEARCH

DELETE

by pressing the softkey

EDIT L 444

RETURN

Pressing the softkey

DELETE

BLOCK

DELETE

BLOCK

POSITION

CURSOR

FUNCTIONS

the following operating level is reached:

DELETE

WORD

DELETE

CHARACTER

*DELETE

UNDELETE

deletes the line in the machine parameters

file at the beginning of which the cursor is positioned. If the cursor is positioned in

the middle of a line, the remainder of the line (after the cursor) is deleted.

DELETE

CHARACTER

Pressing the softkey

deletes the character on which the cursor is

positioned.

DELETE

WORD

Placing the cursor on the first letter of a word and pressing

de

letes the word. The cursor must be positioned on a word.

After deleting a line or character, the procedure can be reversed and the text can be

restored to its original condition (undeleting).

DELETE

*UNDELETE

This is achieved by pressing the

softkey. The softkey bar

changes to

EDIT L 444

RETURN

UNDELETE

BLOCK

UNDELETE

WORD

UNDELETE

CHARACTER

DELETE

*UNDELETE

The last item to be deleted (line, word, character) is always stored in an

intermediate buffer.

By pressing

UNDELETE

BLOCK

or

UNDELETE

CHARACTER

or

UNDELETE

WORD

the contents of this buffer memory (i.e. the last item to be deleted) is inserted back

into the MP file. The cursor indicates the position at which the text will be reinserted.

− 11 −

Page 25

4.2.5 Additional functions

Operation

Type1 osa / CC 220

Machine parameters

Starting at highest editor operating level

EDIT L 444

YES NO

$ LF

and pressing the softkey

EDIT L 444

RETURN ABORT FUNCTIONS

A D G J M

P S V Y

B E H K N

FUNCTIONS

Q T W Z

C F I L O

R U X

twice, the following level is reached

FUNCTIONS

IMPORTANT

If the MP file (L444) is not being edited, an additional softkey is displayed entitled

INSERT FILE. This has no significance for the MP file.

RETURN

Press

Press

to return to the original operating level.

ABORT

to leave the editor. The system ignores all data edited up to

this moment and jumps to the level:

MACHINE PARAMETERS PROGRAM

EDIT LOAD

FUNCTIONS

Select

DELETE

TO EOL

The softkey

TRANSFER

again to switch to operating level:

*M30

INSERT

DELETE

TO EOL

SECTION CALCULATE FUNCTIONS

deletes all characters from the current cursor

OUTPUT MANAGE

position until the end of the line.

(The deleted sequence may be restored via UNDELETE BLOCK").

*M30

INSERT

Ensure that the softkey

is in reverse video. This is the only way to

guarantee that an M30 is automatically positioned at the end of the MP file after

editing. Without the M30 the MP file cannot be transferred to the operating system.

The

function allows the calculation of a numerical value to be

CALCULATE

entered, by using arithmetical operations.

The dot before dash" rule applies. Intermediate results are not stored.

The result appears at the current cursor position if ENTER" is pressed.

− 12 −

Page 26

Operation

SECTION

The

complete areas of the text to be edited.

FUNCTIONS

Press

function makes it possible to select, copy, insert and shift

to reach the next softkey level.

Type1 osa / CC 220

Machine parameters

If the

KEYBOARD

AVAILABLE

CHANGE

WORD

function is in reverse video, then text and numbers are

KEYBOARD

AVAILABLE

RETURN

entered using the keyboard (e.g. Type1 osa keyboard). Text and numbers can also

be entered using the five softkeys if this softkey is not displayed in reverse video.

− 13 −

Page 27

4.3 Transfer

Operation

Type1 osa / CC 220

Machine parameters

By jumping back through the levels from the editor the following operating level

may be reached

MACHINE PARAMETERS PROGRAM

EDIT LOAD

TRANSFER

OUTPUT MANAGE

The edited machine parameters are only transferred to the operating system in the

TRANSFER

form of an internal data record by pressing the

softkey. The

operating system is then restarted. Once the machine parameters have been

transfered, file L444 can be deleted and the appropriate memory area made

reavailable via CONTROL REST". L444 is only required in order to edit or output

the machine parameters.

The machine parameters are not automatically transferred into the EEPROMs on

the memory card. This can only be done by using diagnostic program 9 EEPROM

MANAGEMENT" (see 4.7).

NOTE

The CNC power supply must not be interrupted during transfer of machine

parameters!

Error detection

If an error is detected during the transfer process, the faulty line in the MP file is

displayed onscreen under the message INCORRECT MACHINE PARAMETER",

and the error displayed in reverse video. In addition, an error message appears in

the command line.

The transfer is aborted.

Possible error messages

− Machine parameters are missing:

File L 444, which is to be transferred or deleted, does not exist.

− Invalid application data:

May have been edited by mistake.

Remedy: delete L 444 and read in again/regenerate.

− Memory full:

Not enough memory for L 444.

Remedy: control reset or delete other files + control reset.

− To o many or invalid characters:

A parameter contains more than ten characters or an invalid character.

− Invalid block number:

The previous parameter block may be missing in L 444.

− Invalid value:

A parameter value does not fall within the valid range of values.

− Invalid relationship with block XXX:

Inpermissible parameter combinations.

− Interruption of transfer:

During the transfer, the file is read through" a total of three times. During the

first two passes, the process can be interrupted by changing operating mode

or moving back to another level.

If no error is detected, the operating system is restarted.

− 14 −

Page 28

4.4 Delete

Operation

Type1 osa / CC 220

Machine parameters

By pressing the

edited machine parameters file (L444) is deleted without any further request for

confirmation. The DELETE" function has no effect on machine parameters data

stored in system memory.

4.5 Load (CC 220 / Type1 osa)

Loading with CC 220:

By pressing the softkey

LOAD

*SELECT

DEVICES

The softkey

LOAD, *SELECT DEVICES, V24.2

*INTER

FACE

The transfer rate most appropriate to the device must be selected. The active baud

rate is displayed in reverse video.

*STATUS

*SELECT

DEVICES

*DCR

4800 BAUD

MANAGE

DELETE

and

LOAD

the following operating level is reached:

FILE

NUMBER

SEARCH FOR

DFS FILE

accesses the operating level

*DCR

9600 BAUD

*CCDISK

9600 BAUD

softkeys, the entire

START

*XTRANS

9600 BAUD

*INTER

FACE

By pressing

the interface from which data should be loaded is

selected:

LOAD, *SELECT DEVICES, *INTERFACE

V24. 1

20 MA

V24. 2

*DNC CHANNEL

(Optional)

Pressing return twice restores the original operating level:

LOAD

*SELECT

DEVICES

*STATUS

FILE

NUMBER

SEARCH FOR

DFS FILE

Handshake with V24.1 / 20mA and V24.2

To transfer data with a software handshake, the

*STATUS

and then the

The file is selected by pressing the softkey

*SOFTWARE

CONTROL

should be actuated.

FILE

NUMBER

number 444 (MP file) or by using the cursor to select.

START

and entering the

START

By pressing the

softkey, the transfer of the externally stored

machine parameters file into the CNC is initiated.

− 15 −

Page 29

Operation

Type1 osa / CC 220

Machine parameters

IMPORTANT

If *DEVICE CONTROL is used to read out, *DEVICE CONTROL must also be used

to read in.

At baud rates < 600 only software handshake is permissible.

FILE

NUMBER

The file is selected by pressing the softkey

and entering the

number L 444 (MP file) or by using the cursor to select.

By pressing the

softkey, the transfer of the externally stored

START

machine parameters file into the CNC is initiated.

Loading with the Type1 osa:

LOAD

*SELECT

DEVICES

softkey the following operating level is reached

FILE

NUMBER

SEARCH FOR

DFS FILE

START

accesses the operating level

By pressing the

LOAD

*SELECT

DEVICES

The softkey

LOAD, *SELECT DEVICES, PC CHANNEL

*INTER

FACE

The transfer rate most appropriate to the device must be selected, if V24.1/ 20mA is

selected (see also CC220).

*INTER

FACE

Press

to select the interface from which data should be loaded:

The PC channel enables the program (file) to be loaded from the internal hard disk

of the Type1 osa PC. Loading is possible from a device with a serial interface via the

V24.1 /20mA interface:

LOAD, *SELECT DEVICES, *INTERFACE

V24. 1

20 MA

PC CHANNEL

Pressing return twice restores the original operating level:

LOAD PC CHANNEL

*SELECT

DEVICES

FILE

NUMBER

SEARCH FOR

DFS FILE

Handshake with V24.1 / 20mA

To transfer data with a software handshake, the

*SOFTWARE

CONTROL

softkeys should be actuated.

*STATUS

and

− 16 −

START

Page 30

Operation

Type1 osa / CC 220

Machine parameters

FILE

NUMBER

The file is selected by pressing the softkey

and entering the

number L 444 (MP file) or by using the cursor to select.

By pressing the

softkey, the transfer of the externally stored

START

machine parameters file into the CNC is initiated.

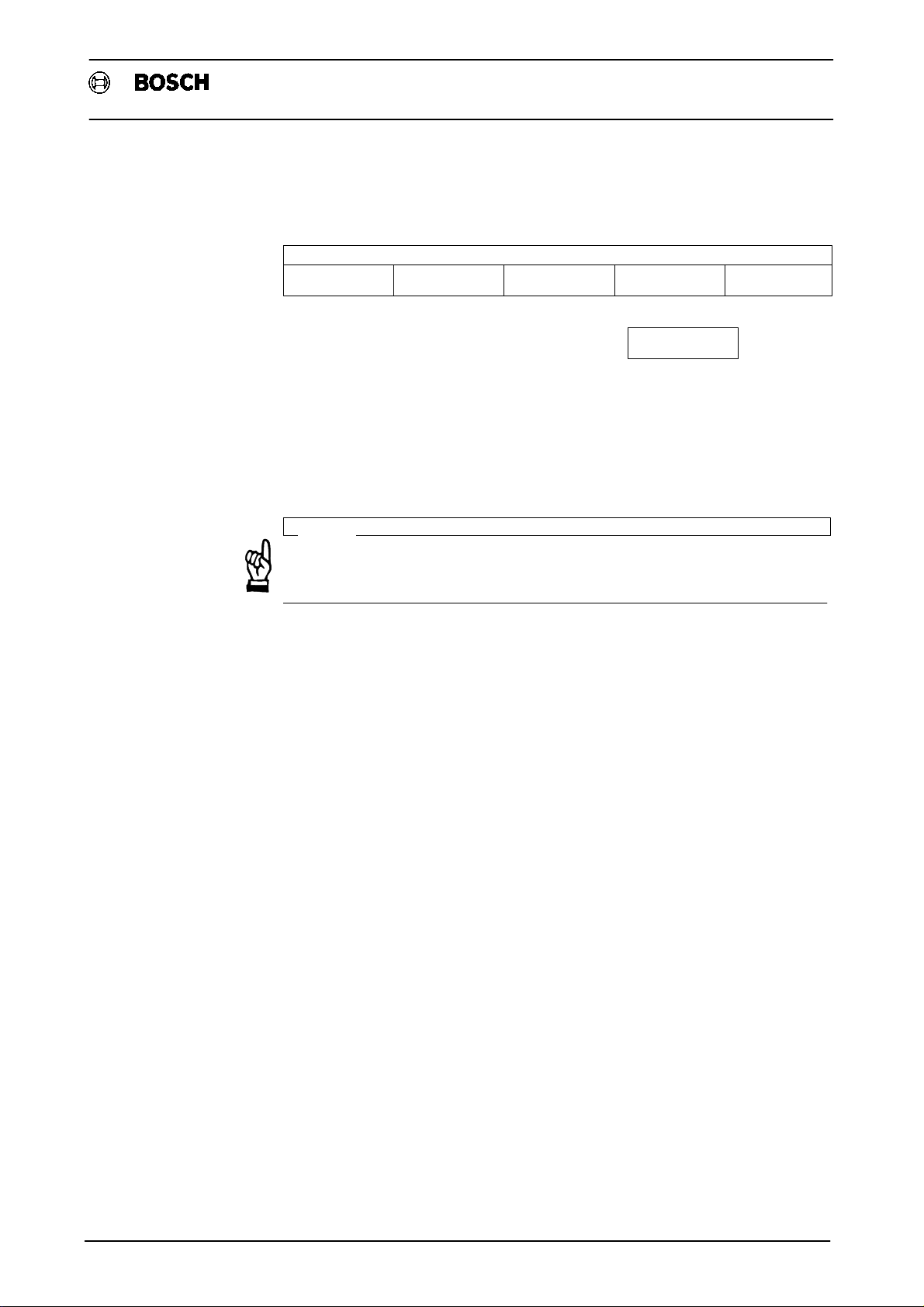

If data are to be transfered from the Type1 osa display to the Type1 osa module, this

Load procedure can be controlled via the Data transfer from PC −> NC"

selection window.

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH ACCESS

L

L

File

Path c:\osa1_ap2

DFS Identifier

File: Path selection:

english.txt

MP010296.txt

MEM

MEM

Prog1.txt

Prog2.txt

Prog3.txt

MAC

Prog3.txt

Prog3.txt

E

BF0

NC0

ACT

WAITING

5

NC LINK TABLE

444

MACHINE PARAMETER 24.03

Data transfer from PC −> NC

MP010296.txt

(DFS,L 444,MACHINE PARAMETER 102,RWED)

[..]

[−a−]

[−c−]log2_96.txt

DIAGNOSTIC

24. 3 15:25

152

23319

START

ABORT

RWED

RWED

For a description of the operating sequence, see page 20.

Once all MP data has been transferred or integrated, the machine parameters

should be stored in the EEPROM in nonvolatile form (see 4.3 TRANSFER, or 4.7

MANAGE EEPROM)*

− 17 −

Page 31

4.6 Output (CC 220 / Type1 osa)

After pressing the

selecting devices, baud rates and interfaces as appeared under LOAD (refer to

appropriate heading) are called up.

The files of the Type1 osa module (machine parameters, part programs etc.) can

be saved on the hard disk of the Type1 osa display. Please note the following

sequences for data output:

Output with text

If the machine parameters are stored in control without text, the machine parameter

texts should be generated before they are output for documentation. To do this it

may be necessary to delete L 444 (see also chapter 4.8!) before regenerating with

texts (see 4.2 Editing").

Operation

OUTPUT

Type1 osa / CC 220

Machine parameters

softkey, the same operating levels for

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH

D

D

D

D 4 MACHINE PARAMETERS PROGRAM E

D

D

D

D

D

D

D

D

MEMORY USED BY DIAGNOSTIC

MEMORY AVAILABLE :

SERVICE FUNCTION

BF0

NC0

ACT

WAITING

1

LOGBOOK MONITOR

2

RELOADING OPERATING PROGRAM

3

CLEAR ALL MEMORY

5

INTERNAL REF. POINT OFFSET

6

INTERFACE DATA

7

COMMUNICATION STORAGE DISPLAY

9

MANAGE EEPROM

21

LOGIC ANALYSER

22

AXIS OSCIL.

23

CONTOUR DISPLAY

24

AXIS OPTIMISATION

4156

185946

LOAD START DELETE

OUTPUT

OTHERS: 72042

DIAGNOSTIC

24. 3 15:25

ACCESS

E

E

E

E

E

E

E

E

E

E

E

Before the machine parameter program is output, start the diagnostic machine

START

parameter program (softkey

) by either selecting with cursor

keys or entering D4".

− 18 −

Page 32

Operation

Type1 osa / CC 220

Machine parameters

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH

L5NC LINK TABLE RWED

L 444 MACHINE PARAMETER 24.03 RWED23319

MEMORY USED BY PROGRAM

MEMORY AVAILABLE :

MACHINE PARAMETERS PROGRAM

EDIT

BF0

NC0

ACT

WAITING

28219

330307

LOAD OUTPUT MANAGE

TRANSFER

OTHERS: 34690

DIAGNOSTIC

24. 3 15:25

ACCESS

152

The actual machine parameter file L444" then appears in the menu. If you press

OUTPUT

the softkey

NO

PROGRAM

L5NC LINK TABLE RWED

L 444 MACHINE PARAMETER 24.03 RWED23319

BF0

NC0

ACT

WAITING

NUMBER NAME OF PROGRAM LENGTH

you will be required to select a file.

DIAGNOSTIC

24. 3 15:25

ACCESS

152

MEMORY USED BY PROGRAM

MEMORY AVAILABLE :

OUTPUT

*SELECT

DEVICES

PC CHANNEL

STATUS

28219

330307

FILE

OTHERS: 34690

Ensure that the correct output interface is preset with the

(see status line above the softkey to check)

FILE

Press the

softkey and select by either using the cursor keys or

entering D4".

− 19 −

SELECT

DEVICES

softkey.

Page 33

Operation

Type1 osa / CC 220

Machine parameters

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH

L5NC LINK TABLE RWED

L 444 MACHINE PARAMETER 24.03 RWED23319

MEMORY USED BY PROGRAM

MEMORY AVAILABLE :

OUTPUT

*SELECT

DEVICES

BF0

NC0

ACT

WAITING

28219

330307

FILE NUMBER

STATUS START

444

FILE

OTHERS: 34690

DIAGNOSTIC

24. 3 15:25

152

ACCESS

Data transfer from the control unit (NC) to the hard disk (PC) is called up using the

START

softkey

.

If data in the Type1 osa display are to be stored, the new selection window Data

transfer from NC −> PC" appears:

NO

PROGRAM

NUMBER NAME OF PROGRAM LENGTH ACCESS

L

L

File

Path c:\osa1_ap2

DFS Identifier

File: Path selection:

english.txt

L1.txt

MEM

MEM

Prog1.txt

Prog2.txt

Prog3.txt

MAC

Prog3.txt

Prog3.txt

E

BF0

NC0

ACT

WAITING

5

NC LINK TABLE

444

MACHINE PARAMETER 24.03

Data transfer from NC −> PC

MP010296.TXT

[..]

[−a−]

[−c−]log2_96.txt

DIAGNOSTIC

24. 3 15:25

152

23319

START

ABORT

RWED

RWED

Enter the file name in the upper entry field which the machine parameter program is

to be stored under in on the hard disk, e.g. MP010296.txt" for machine parameters

from 01 Feb. 96, txt ending for text file.

Remember to include a full stop in the file name. The stop should be preceded by a

maximum of 8 characters (no special characters such as . , ; ! ? etc.) and followed

by a maximum of 3 characters.

− 20 −

Page 34

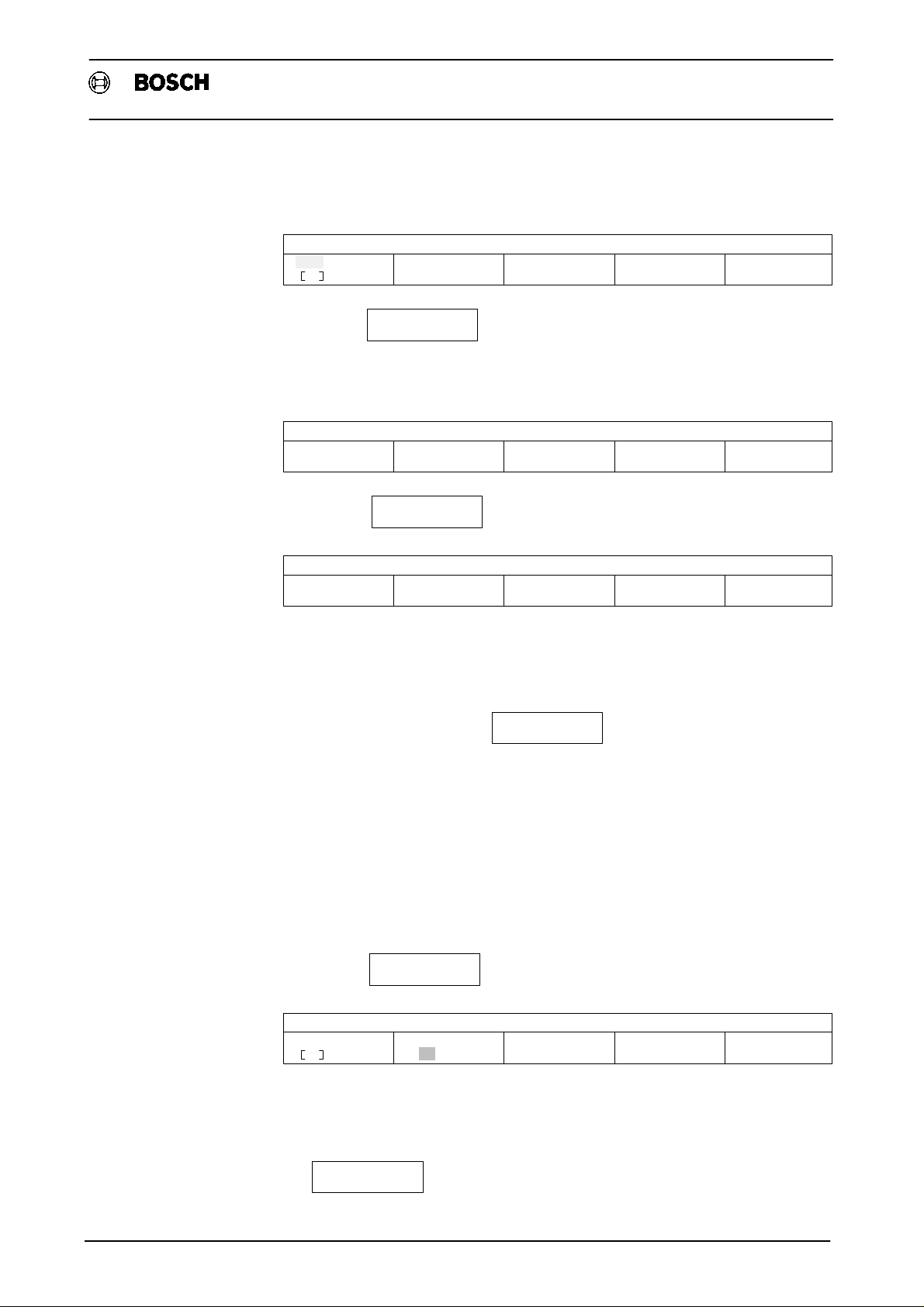

4.7 Manage EEPROM

Operation

Type1 osa / CC 220

Machine parameters

After entering the file name, press the TAB key and keep it pressed down until the

entry position (position currently highlighted by the cursor) is on the START field.

Now start data transfer by pressing the ENTER key. If you do not wish to carry out a

data transfer or you want to use another file name, use the TAB key to reach ABORT

and press the ENTER key.

Once transfer has started, a window appears, indicating which stage the data

transfer is currently at.

If the machine parameters are loaded into the EEPROM of the CP/MEM 5card (CC

220) or the FEPROM of the Type1 osa module, they are safeguarded against loss.

This ensures that even after a power loss (e.g. battery failure), the customerspe

cific machine parameters are still available whenever required.

In the diagnostic" operating mode the softkeys

SERVICE

FUNCTION

and then

START

should be pressed.

Further information may be found in Type1/CC 220/320 Diagnosis, Operation,

Application", order no. 1070 073 305.

After program number 9 (EEPROM management) is entered and confirmed by

pressing ENTER, the CNC carries out CONTROL RESET. The following display

appears:

NO

PROGRAM

LIST OF PROGRAMS FOR OUTPUT

NO

NAME OF PROGRAM IN RAM SAME

0

MEMORY USED IN PROGRAM

MEMORY AVAILABLE :

EDIT

BF0

NC0

ACT

WAITING

MACHINE PARAMETERS YES NO

SELECT

L 444

DELETE COPY

943

26705

OTHERS: 3258

DIAGNOSTIC

24. 3 15:25

EEPROM

PROGR.

All programs in the EEPROM (FEPROM) area are listed.

The IN RAM" column indicates whether the listed files are present in RAM. The

SAME" column shows whether the contents of the file in EEPROM (FEPROM) are

the same as those of the corresponding file in RAM.

− 21 −

Page 35

Operation

EEPROM

PROGR.

Now press the

The following display appears:

Type1 osa / CC 220

Machine parameters

softkey and enter the appropriate code number.

NO

PROGRAM

LIST OF PROGRAMS FOR OUTPUT

NO0NAME OF PROGRAM IN RAM SAME

LANGUAGE ENGLISH

MEMORY USED BY PROGRAM

MEMORY AVAILABLE :

PROGRAM EEPROM

MACHINE

PARAMETERS

BF0

NC0

ACT

WAITING

MACHINE PARAMETERS YES NO

AREA

27648

0

OTHERS: 3258

DIAGNOSTIC

24. 3 15:25

STARTPROGRAM

The softkeys in reverse video indicate the EEPROM (FEPROM) areas to be

programmed. Since only the machine parameters and no tables or programs are

to be transferred in our example, deactivate the softkey PROGRAM AREA (softkey

reverts to normal text).

Programming may then be started via softkey START (softkey now appears in

reverse video). The message PROGRAMMING IS ACTIVE" appears in the

command line while programming is taking place, together with the number of

bytes which have already been transferred to EEPROM. The NC may not be

operated during programming.

The character *" preceding list number 0" indicates that the machine parameters

were transferred to the EEPROM (FEPROM).

Programming is complete when the START" softkey no longer appears in reverse

video. The entire EEPROM memory store is initialised if this programming

procedure is taking place for the first time. This lasts about 5 minutes.

When programming is complete, the display indicates that the status of the

machine parameters in the RAM is the same as that in EEPROM (FEPROM)

(column SAME: YES).

− 22 −

Page 36

Operation

4.8 Management of the machine parameters

The machine parameters program (D4) is stored in the CC 220 control unit’s

EPROM or the Type1 osa module FEPROM area as a program capable of being

run, and can be initiated in DIAGNOSTIC" operating mode. It enables access to

machine parameter data.

A distinction should be made between machine parameter data in the form of an

MP record stored internally in the RAM area and the machine parameters file L444.

Only the values in the MP record determine the behaviour of the control system.

Machine parameters file L444 is only required if machine parameters need to be

edited or, for example, output to or read in from an external storage medium. L444

can always be generated from the currently active MP record (with/without text).

The MP record can only be modified by TRANSFERRING" an appplication file or

machine parameters file L 444.

If a valid MP record, or one which has been adapted to the particular machine, is

active in the control, file L444 is no longer required and can be deleted (thus saving

memory space). Diagnostic program D9 EEPROM MANAGEMENT" uses the MP

record to program the EEPROM (or FEPROM) area. The record is displayed

onscreen in the list of programs to be output" as a file with the number 0" and the

text MACHINE PARAMETERS".

Type1 osa / CC 220

Machine parameters

IMPORTANT

It is also possible to program file L444 into the EEPROM (FEPROM) area. It should,

however, be noted that L444 requires considerably more memory area than the MP

record. This could mean that valuable EEPROM (FEPROM) memory space is

being unnecessarily wasted.

The MP record is located in a RAM area which the user has no access to. By

contrast, the file L444 (if present) is located in the user RAM. If the machine

parameter data is to be edited, the system copies file L444 from user RAM into a

special RAM area, which we will call EDIT memory. Only here can machine

parameters be edited or read in/out.

IMPORTANT

If machine parameters are to be edited when there are not enough free RAM

memory locations, the message MEMORY FULL" is output.

Remedy: Activate Control reset" to gain more free memory space.

−

− 23 −

Page 37

Operation

Type1 osa / CC 220

Machine parameters

− 24 −

Page 38

Overview

Type1 osa / CC 220

Machine parameters

5. Machine parameters

Here you will find the machine parameters for the Ty pe1 osa M / T and CC 220 M / T control unit series. The way in

which individual parameters are displayed will depend on the type of control system used (T or M) and the options

applicable in each case. The values specified for the various parameters correspond to the input values.

Specific information on the SERVO i, SCP, PIC250 control unit series relates to the CC 220 control unit series. Infor

mation on the Typ e1 osa modul 3 / 5 control unit series relates to the Ty p e1 osa control unit series. For explanations

of hardware configuration in the control unit series, refer to the CC 220 Connection conditions part 1" manual and in

the T ype1 osa Connection conditions" manual.

5.1 Machine parameter sets

P 100 AXIS PARAMETERS

P 500 SPEEDS

P 1000 AXIS DYNAMICS

P 1500 POSITIONS

P 2000 AUXILIARY FUNCTIONS

P 2500 POTENTIOMETER

P 3000 POWERUP STATE

P 3500 COLOUR SETTINGS

P 3600 GREYSCALE SETTINGS

P 4000 CPL PARAMETERS

P 4500 ZERO OFFSETS

P 5000 SUPPRESSION TABLE

P 5500 DEVICE SELECTION

P 6000 PLC PARAMETERS

P 6100 ELECTRONIC LIMIT SWITCH NORMAL

P 6200 ELECTRONIC LIMIT SWITCH FAST

P 6300 LASER APPLICATIONS *)

P 6400 TANGENTIAL TOOL CONTROL *)

P 6500 CENTRE PARAMETERS *)

P 6600 COMPENSATION PARAMETERS

P 6800 CONTOURDEPENDENT FEEDRATE OVERRIDE

P 7000 SPINDLE PARAMETERS

P 7100 SPINDLE PARAMETERS 2ND SPINDLE **)

P 7200 EXACT TAPPING

P 7500 TURNING MACHINE **)

P 7600 CAXIS PARAMETERS

P 8500 DNC INTERFACE WITH SIMPLE PROTOCOL***)

P 8600 DNC INTERFACE WITH LSV2 PROTOCOL***)

P 8700 FMS COMMUNICATIONS INTERFACE WITH BAB***)

P 9000 ADDRESS SELECTION

P 9500 AXIS PROCESSORS

P 9900 SYSTEM PARAMETERS

*) only in Type1 osa M and CC 220 M,

**) only in Type1 osa T and CC 220 T

***) only in CC 220 M and CC 220 T

− 25 −

Page 39

Overview

Type1 osa / CC 220

Machine parameters

− 26 −

Page 40

P 100 Axis parameters

P 100 Axis parameters

P 101 No. of axes

[SYN] 3 [ASY] 1

This parameter is used to specify the number of applied system axes to be used as

synchronous/asynchronous axes (depending on option, CC 220: max. 8; Type1

osa: max. 5). The sum of both values should correspond to the total number of axes

in the system.

The spindle is treated as an asynchronous axis and must be taken into account at

this point (analog output as asynchronous axis). At least 2 synchronous axes

must be applied.

P102 Axis addresses (− = not defined)

[1.A] X [2.A] Y [3.A] Z [4.A] −

Type1 osa / CC 220

Machine parameters

The machine parameter allocates logical addresses to the individual system axes

(designated in the machine parameters as [1.A]" to max. [8.A]"). The axes are

then operated via these logical addresses in part programs or CPL programs.

Permissible logical addresses: A−C, E, O, S−Z.

These addresses should not overlap with auxiliary function addresses (see

P 2001) or with polar coordinates’ addresses (P 9909)!

Where an axis is specified as a spindle in parameter 7001, the S" address may

only be allocated to this system axis. However, the spindle address should not be

specified here; a −" is entered in its place. For setting the spindle parameters, see

parameter set 7000.

Always bear in mind that all synchronous axes are specified before the

asynchronous axes in P 102.

IMPORTANT

The individual axes can be allocated different addresses to the ones given for the

screen display. See P 122.

The allocation of the individual system axes to inputs/outputs of the SERVOicards

can be specified via P 9502!

P 103 Axis format postdecimal position Range of values: 0 − 4

[1.A] 3 [2.A] 3 [3.A] 3 [4.A] 3

By means of this parameter, you can specify the postdecimal positions in the

display, as well as the computational accuracy (resolution, increment size). In

parameter set 9000, you can (amongst other things) specify the total number of

digits for every address letter.

Example: Determining the size of increments

0 = 1 Increment = 1 mm

1 = 1 Increment = 1/10 mm

2 = 1 Increment = 1/100 mm

3 = 1 Increment = 1/1000 mm

4 = 1 Increment = 1/10000 mm

− 27 −

Page 41

P 100 Axis parameters

P 104 Measuring system resolution in pulses/rev (0 = linear scale) Range of values: 10 − 8000

[1.A] 1000 [2.A] 1000 [3.A] 1000 [4.A] 1000

The number of strokes of the measuring system encoder (e.g. 1000" at 1000

pulses/rev.) should be entered here. P 104 is used for checking markers, i.e. by

monitoring the pulses between two cyclic reference markings of a rotary encoder.

Enter 0" for the corresponding system axis when using a linear scale or for

encoders with more than 8000 strokes (e.g. for Caxis encoder).

The number of strokes must be entered between two cyclic reference markings for

distancecoded measuring systems. The watchdog on each individual axis can be

switched off if a HIGH level prevails at the axisrelated NC input INHIBIT

MEASURING SYSTEM MONITOR (23.x).

IMPORTANT

The value entered here for the spindle axis must correspond to P7022.

P 105 Measuring system evaluation in pulses/incr. Range of values: 0.025 − 24.000000

Type1 osa / CC 220

Machine parameters

[1.A] 0.500000 [2.A] 0.500000 [3.A] 0.500000 [4.A] 0.500000

The evaluation depends on the number of strokes of the encoder, the leadscrew

pitch, the gearing transmission ratio and the required resolution.

The value entered here for the spindle axis must correspond to the value in P7024.

Calculation formula for linear axis:

No. of strokes x transmission ratio

Lead screw pitch x resolution

Resolutions:

1 m = 1000 Incr./mm]; if P 9904 = MM and P 103 = 3m

10 m =m

100 m =m 10

[

[

Incr./mm]; if P 9904 = MM and P 103 = 2

100

[

Incr./mm]; if P 9904 = MM and P 103 = 1

= Measuring system evaluation

− 28 −

Page 42

P 100 Axis parameters

Examples of calculations for linear axes

Type1 osa / CC 220

Machine parameters

Encoder:

Lead screw pitch:

Resolution:

2500 [pulses/rev]

10 mm/rev x 1000 Incr./mm

[

Encoder:

Lead screw pitch:

Gearing:

Resolution: 1 m = 1000 [Incr./mm]

2500 [pulses/rev] x 5

10 [mm/rev] x 1000 [incr./mm]

Calculation formulae for rotary axes:

When programming in degrees(e.g. C−axis)

No. of strokes pulses/rev

[

360 deg/rev x resolution

2500 [pulses/rev]

[]

10 mm/rev

1 m = 1000 [Incr./mm]

m

]

]

[]

2500 [pulses/rev]

10 [mm/rev]

1 : 5 (transmission ratio)

As the spindle is the driving component and the

encoder the driven part, the encoder rotates

5 times for every time the spindle rotates.

m

[]

fixed coupling spindle/encoder

= 0.25 [Pulses/incr.] Input: 0.25

= 1.25 [Pulses/incr.] Input: 1.25

=

Measuring system evaluation

[]

pulses/incr.

Note:

Parameters P501 − P508 and P511 should be entered accordingly

in degrees, degrees/min. etc.

When programming in revolutions

No. of strokes pulses/rev

Resolution incr./rev

Note:

Parameters P501 − P508 and P511 should be entered accordingly

in degrees, degrees/min. etc.

Resolutions:

[]

1000 Incr./deg

[]

100

Incr./deg if P103 = 2

[]

10

Incr./deg if P103 = 1

P 106 Locking the asynchronous axes or suppressing the spindle display (YES/NO)

[1.A] NO [2.A] NO [3.A] NO [4.A] YES

[]

[]

if P103 = 3

Measuring system evaluation

=

pulses/incr.

[

]

If this parameter was set to YES" for an asynchronous axis, the following functions

may no longer be carried out: jogging, approach reference point, positioning via

the interface (external setpoint input) and largescale screen display formats.

− 29 −

Page 43

P 100 Axis parameters

YES" should always be entered for the spindle axis. NO" must be entered for

ANALOG" type axes.

IMPORTANT

For Caxis: If the spindle axis is separated from the axis of the tool being operated

(P7604 does not equal P7001), NO" must be entered for the corresponding

system axis of the tool.

P 107 Type of axis (ROTARY/LINEAR/ENDLESS/ANALOG)

[1.A] LINEAR [2.A] LINEAR [3.A] LINEAR [4.A] ROTARY

Specifying the type of axis

LINEAR: The axis can only be moved within the travel limit range (see

P 1505 and P 1506). Where there is active suppression of soft

ware limits (P 1504 = YES), the maximum range of motion will be

equal to 2 * 109 increments.

Type1 osa / CC 220

Machine parameters

ROTARY: The axis can only be moved within the travel limit range (see

P 1505 and P 1506). Where there is active suppression of soft

ware limits (P 1504 = YES), the maximum range of motion will be

equal to 2 * 109 increments. The only difference between

ROTARY" and LINEAR" axis types is that LINEAR" axes are

programmed in mm" and ROTARY" axes are programmed in

degrees.

ENDLESS: When programming a single block, endless rotary axes are

treated in the same way as ROTARY" axis types. During a block,

the axis is first moved to its programmed end position. However,

at the end of block a modulo calculation is then carried out (mod

360) on the end position. In this way, the end position (if it lies

outside the limits) 0º x end position t 360º is always changed

back into the range 0º x end position t 360º . This means that

the endless rotary axis can be traversed in one and the same

direction as often as necessary.

ANALOG: In the case of an axis type defined as ANALOG", a voltage pro

portional to the programmed value is output at the analog output

(without measuring system feedback). The maximum value

which can be programmed should be specified in P 501. This

value corresponds to an output voltage of +10V. The output volt

age is adapted rampwise as setpoint values change in accor

dance with the acceleration value stored in machine parameter

P (for example, see P 1002). If an axis was defined as ANALOG",

an axis address must be allocated to this axis in

P 102. Every analog axis must be defined as a synchronous axis

(P 101).

IMPORTANT

If Hirth logic (P 108) is activated for ROTARY" and ENDLESS" axis types and at

the same time parameters are set for the affected axis P 117 by a YES" input, their

positional value in MACHINE operating mode will always be displayed in the range

o=<

0 position value < 360 .

o

− 30 −

Page 44

P 100 Axis parameters

An additive compensation of the axis set position is permitted for the axis type

ROTARY (provided it is not declared as Hirth axis P 108) using the digital

handwheel.

The LINEAR axis type can also be moved endlessly" in one direction. See P 6516

for more detailed explanations and settings (only Type1 osa M / CC 220M).

An external acceleration input (see P1002 ff.) via a wordcoupled PLC is not

effective for the ANALOG axis type.

P 108 Positions per circle for the Hirth axis (0 = no Hirth axis) Range of values: 0 − 360000

[1.A] 0 [2.A] 0 [3.A] 0 [4.A] 0

An input in the range from 1 to 360000 defines the axis concerned as a Hirth axis.

Hirth axes are rotary axes which can take part in interpolation, but may only travel to

certain positions.

P 108 only applies to ROTARY and ENDLESS axis types. The number of positions

which may be approached per

o

is entered here (Hirth logic).

360

Type1 osa / CC 220

Machine parameters

P 108 = 0 no Hirth logic

P 108 u 0 Hirth logic

If 0" is entered, the parameters P 110, P 117, P 119 and P 120 have no effect.

Example:

P 108 = 360 360 approachable positions per revolution

P 108 = 720 720 approachable positions per revolution

IMPORTANT

‘ P 108 may only be set to values greater than 0" in the case of rotary axes

programmed in degrees (not in the case of rotary axes programmed in revo

lutions).

‘ The Hirth axis reference point and limit switch must lie on the Hirth grid.

‘ Hirth axes may not be operated by handwheel or online compensation with

handwheel".

‘ If positions have been programmed which do not lie on the Hirth grid, P 121

should be taken into consideration.

P 109 Currently unused Range of values: 1

[1.A] 1.00 [2.A] 1.00 [3.A] 1.00 [4.A] 1.00

− 31 −

Page 45

P 100 Axis parameters

P 110 Position programming (YES/NO)

[1.A] NO [2.A] NO [3.A] NO [4.A] NO

If a value greater than 0" was input in P 108, it may be specified in P 110 whether

that axis should be programmed in degrees or in positions.

Enter YES" if the axis should be programmed in positions. The axis letter is then

programmed together with the position number (used in the case of tool

magazines, for example).

In this instance the position number 0 always corresponds to the position 0"

degrees.

Example:

Tool magazine (asynchronous axis : A). P 110 = YES, P 108 = 12.

The tool magazine is subdivided into 12 positions (i.e. there are 12 approachable

positions in any one revolution of the axis).

Programming (if P 111 = 2):

N 100 A 7= magazine traverses to position 7 (in positive direction)

N 110 A−6 = magazine traverses to position 6 (in negative direction)

N 120 A 0= magazine traverses to position 0 (in positive direction)

Type1 osa / CC 220

Machine parameters

IMPORTANT

P 110 can also be combined with P 111.

P 111 Hirth programming mode (1, 2, 3, 4)

[1.A] 3 [2.A] 3 [3.A] 3 [4.A] 3

The programming mode of normal" rotary axes, endless axes and Hirth axes can

be defined in P 111.

Entering 1" = programming with search logic"

Entering 2" = programming with +/− sign determines direction"

Entering 3" = programming as for a normal rotary axis

Entering 4" = combination of 2" and 3" (effective only with synchronous rotary

axis)

+

350

1080

720

360

0

o

o

o

o

o

10

370

o

730

20

o

380

o

o

o

−

990o630o270

o

− 32 −

180

540

900

90o450o810

o

o

o

o

Page 46

P 100 Axis parameters

Type1 osa / CC 220

Machine parameters

Search logic: Search logic means that the axis always travels to the pro

grammed position via the shortest route (in relation to the unit

circle) (maximum distance to be traversed =

The actual position equals e.g.

o

. A set position of

350

180

o

).

o

10

then entered. Physically, this position occurs several times for a

rotary axis

10o370o730

, , , 1090

(

o

o

etc.)

. The search logic now se

lects as a set position the physical position which is the shortest

o

distance from the the actual position − in this case

370

. Only

absolute values may be programmed.

A −" sign is ignored by the control.

Any G91 which may be active is not taken into consideration dur

ing this process.

Examples:

Actual position =

N100 A10 axis traverses

350

o

to

370

o

20

o

(in pos. direction)

or N100 A−10 as for A10" (+/− sign is

ignored)

or N100 A180 axis traverses

170

o

to

180

o

(in neg. direction)

or N100 A710 axis does not traverse.

is

+/− sign: The direction from which the set position is approached is en

tirely dependent on the programmed sign (max. traverse path

per record <

o

). If a negative sign is programmed, the axis

360

approaches the set position in negative direction; if the sign is

positive, it approaches in the positive direction (positive signs do

not need to be programmed). The actual position equals e.g.

o

. The value −20" is now programmed. Physically, this

730

position occurs several times for a rotary axis

20o380o740

, , , 1100

( etc.)

o

tive direction to the position corresponding to

o

. Any G91 which may be active is effective for this setting.

380

o

. The axis traverses in nega

o

− in this case

20

Examples:

Actual position =

N100 A10 axis traverses

350

o

20

o

to

370

o

(in pos. direction)

or N100 A10 axis traverses

340

o

to

10

o

(in neg. direction)

or N100 A180 axis traverses

190

o

to

540

o

(in pos. direction)

or N100 A370 axis traverses

340

o

to

10

o