Page 1

Typ1 osa / CC 220

Diagnosis

Operation, Application

Version

101

Page 2

Typ1 osa / CC 220

Diagnosis

Operation, Application

1070 073 306-101 (91.10) GB

(V25)

E 1991

by Robert Bosch GmbH,

All rights reserved, including applications for protective rights.

Reproduction or handing over to third parties are subject to our written permission.

Discretionary charge 10.– DM

Page 3

Page 4

Flexible Automation

Contents

Contents

1. General 1 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Safety instructions − 1 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Calling the diagnostic programs 1 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Description of the diagnostic programs

D1 Logbook − D1 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D5 Internal reference point offset D5 – 1. . . . . . . . . . . . . . . . . . . . . . .

D6 Interface data D6 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D7 Communication store display D7 – 1. . . . . . . . . . . . . . . . . . . . . . .

D9 EEPROM management − D9 – 1. . . . . . . . . . . . . . . . . . . . . . . . .

D21 Logic analyzer − D21 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D22 Axis oscilloscope − D22 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D23 Contour display − D23 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D24 Axis optimization D24 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D25 Lead screw error compensation − D25 – 1. . . . . . . . . . . . . . . . .

D26 CNC remote diagnosis (information) D26 – 1. . . . . . . . . . . . . . . .

D27 Putting into operation for circular compensation ‘ D27 – 1. . .

D28 Tapping ‘ D28 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC 220 / 320

Diagnosis

Notes: Diagnostic programs which are not available in the CC 200/300 are identified by

an ‘ in front of the page number.

If a diagnostic program contains new or modified functions – compared with the

controls of the Type CC 200/300 –, this is indicated by a − in front of the page num-

ber.

The following diagnostic programs are intended exclusively for BOSCH service

personnel and are not described in this manual:

D2 Reloading the operating program

D3 Cancelling all memory

Separate manuals are available for the diagnostic programs D4 and D26:

D4 Machine parameter program CC 220 M/T: P. No.: 4201

CC 320 M: P. No.: 4180

D26 CNC remote diagnosis P. No.: 4184

The diagnostic programs

D8 Change language

D10 Library management

implemented in the CC 220/320 are no longer present as special diagnostic programs in controls of the type CC 220/320, but can now be called directly by way

of softkey. Please refer to the appropriate operating manual for operating instructions.

C – 1

Page 5

Flexible Automation

Contents

CC 220 / 320

Diagnosis

C – 2

Page 6

Flexible Automation

1. General

This manual refers to the software version V25 for the controls CC 220/320.

The diagnostic programs D21 to D28 are options which are subject to charge.

2. Safety instructions

Diagnostic programs permit critical changes to be made in the interaction of CNC,

machine and drives right up to complete deletion of the CNC memory.

If they are used by insufficiently trained or untrained personnel, this may thus result

in serious damage to the machine and drives, loss of software or even injury!

For this reason, diagnostic programs must be started and operated only by

correspondingly trained expert personnel.

In this context, please note our extensive range of training courses. You will find

an overview of the available seminars on the inner cover of this manual. Our training center will gladly provide you with further information.

General

CC 220 / 320

Diagnosis

MOVE

MP

In some diagnostic programs, axes have to be traversed in order to optimize CNC

servo loops and drives.

For this reason, make sure that no one enters the machine’s danger area during execution of such diagnostic programs.

The following symbols are used in this manual in order to point out certain things

which are relevant to safety:

Axis movement possible!

For this reason, make sure that there are no persons or objects in the machine’s

danger area.

Make sure that no collisions are possible in the axis traversing range.

Machine parameter record is modified! This is followed by a CNC restart. The modified machine parameters are active after this.

Is there a backup of the original machine parameters?

BOSCH will not be liable for damaging resulting from incorrectly calculated, programmed or optimized machine parameters or non–observance of limit data!

Active axis processor data is modified!

This effects the axis response.

SERVO

Data loss possible!

Data in the user RAM (part programs, tables etc.) may possibly be deleted or over-

DATA

written.

Do you possess a backup of this data?

3. Calling the diagnostic programs

1 – 1

Page 7

Flexible Automation

General

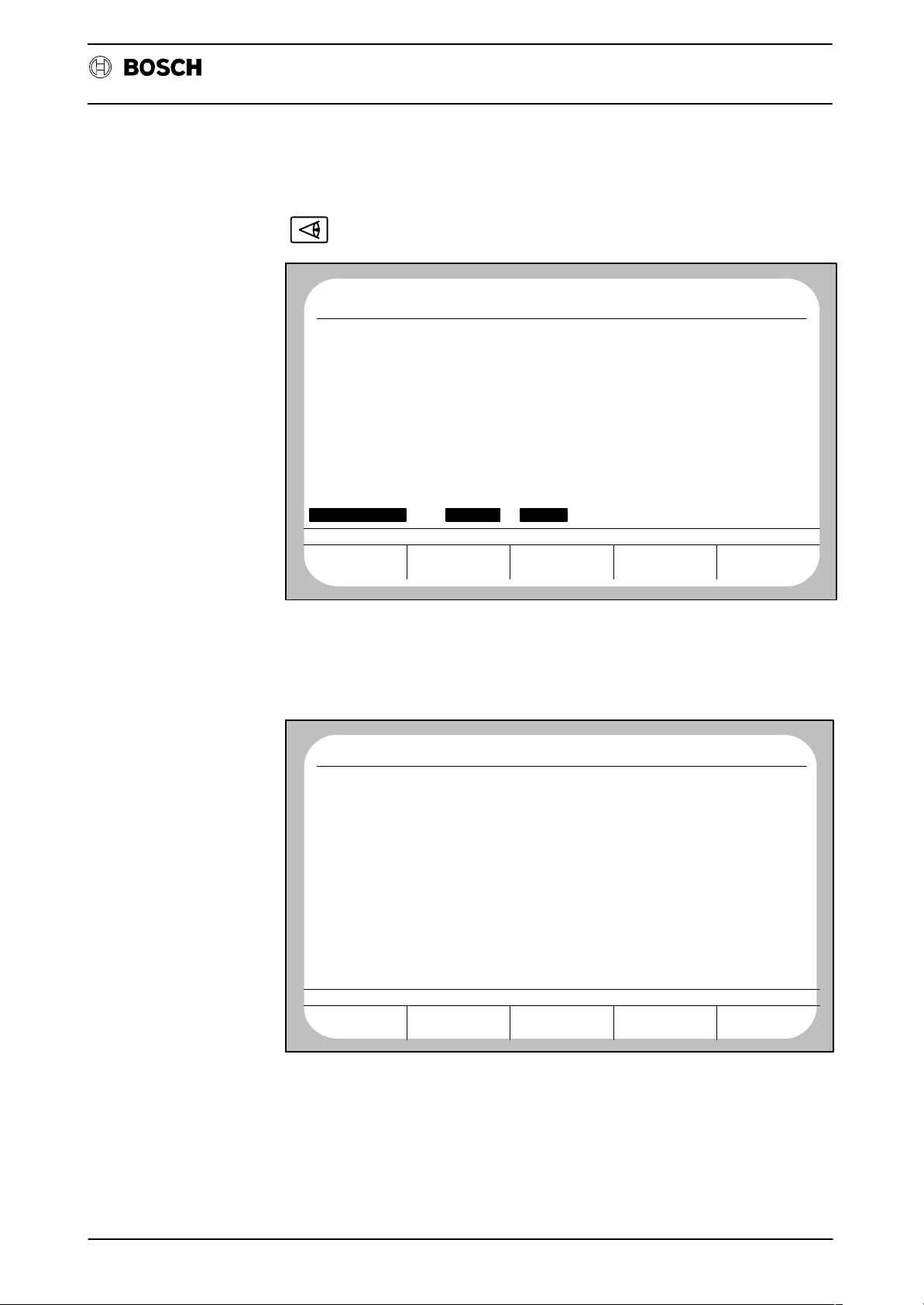

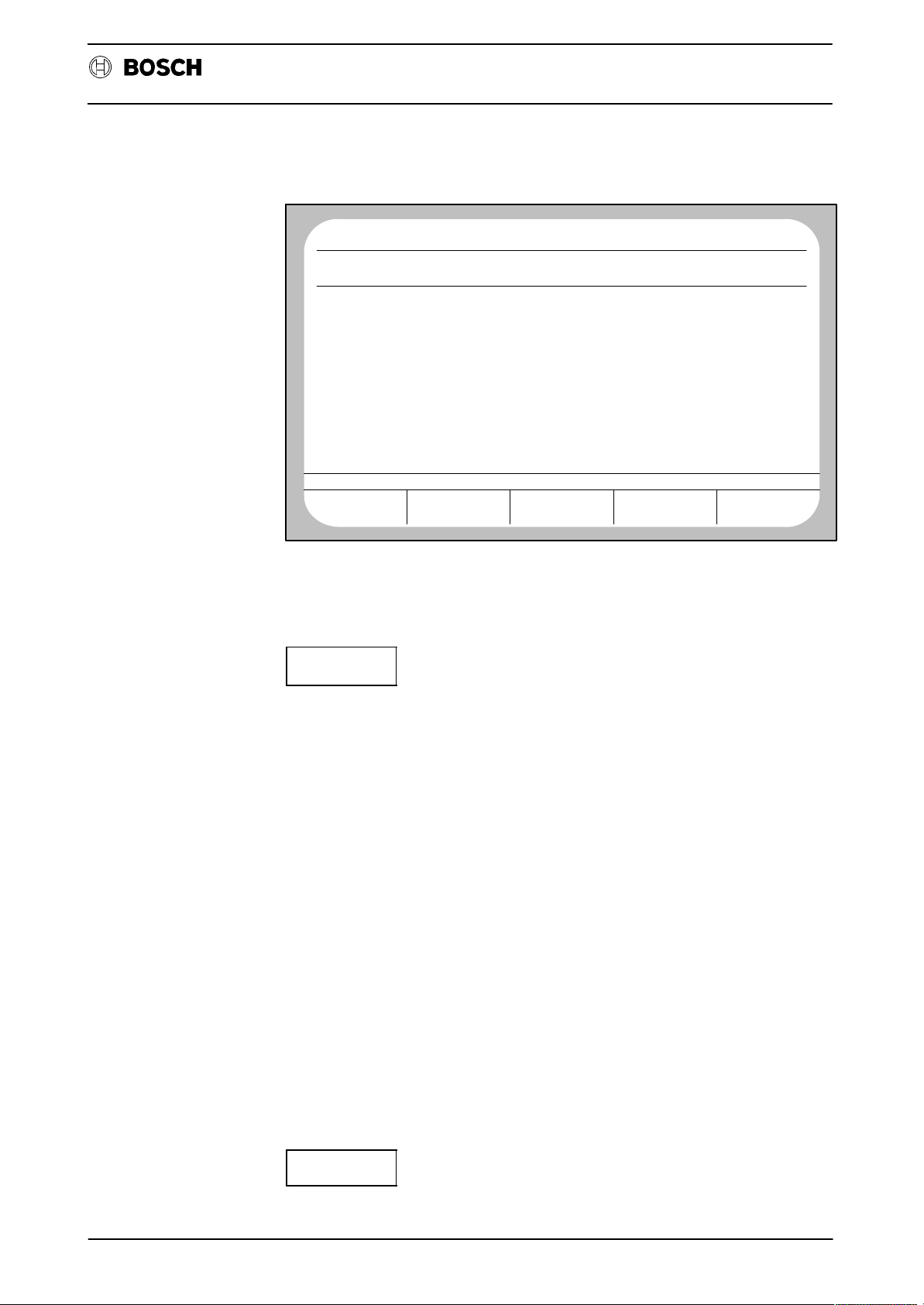

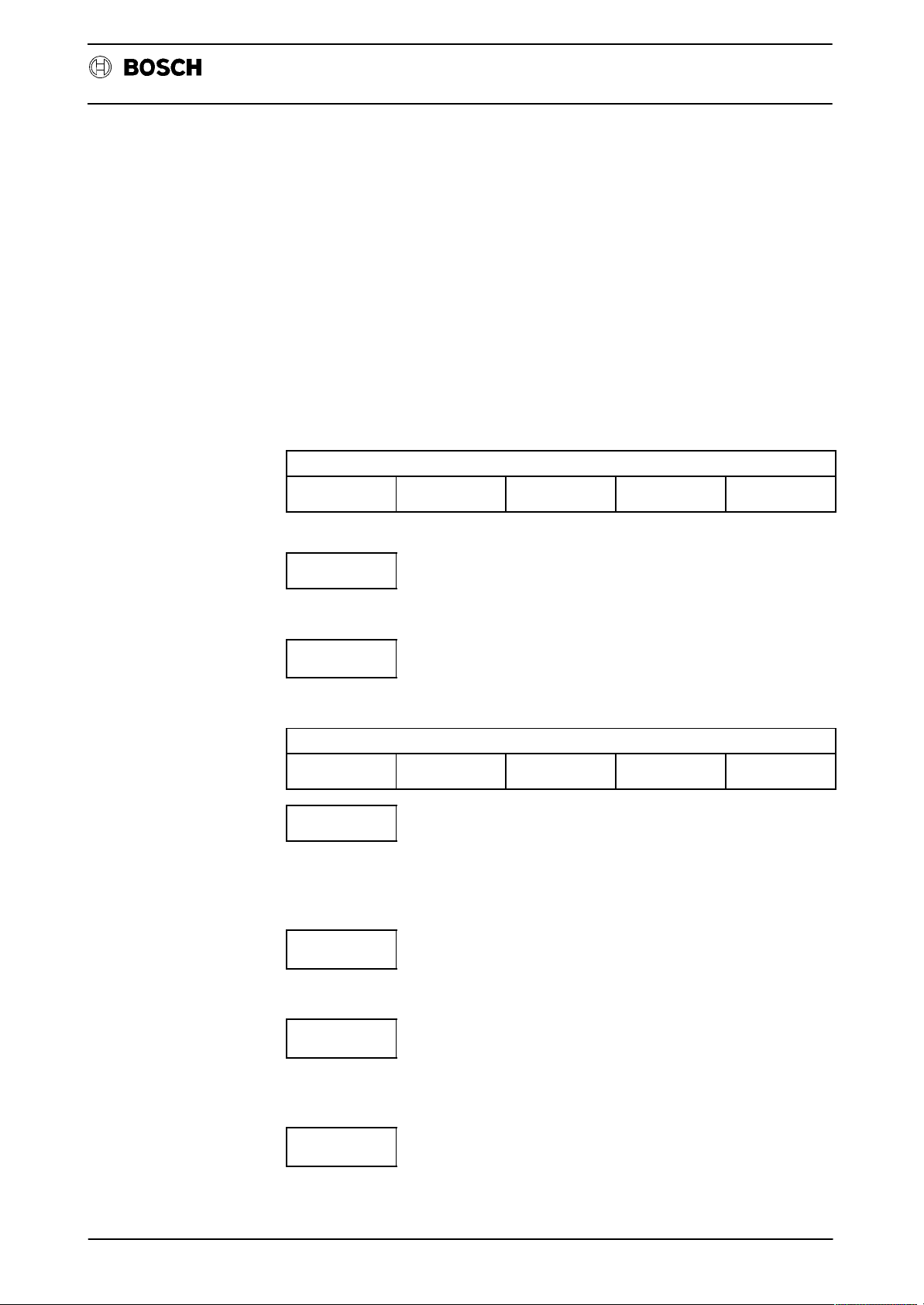

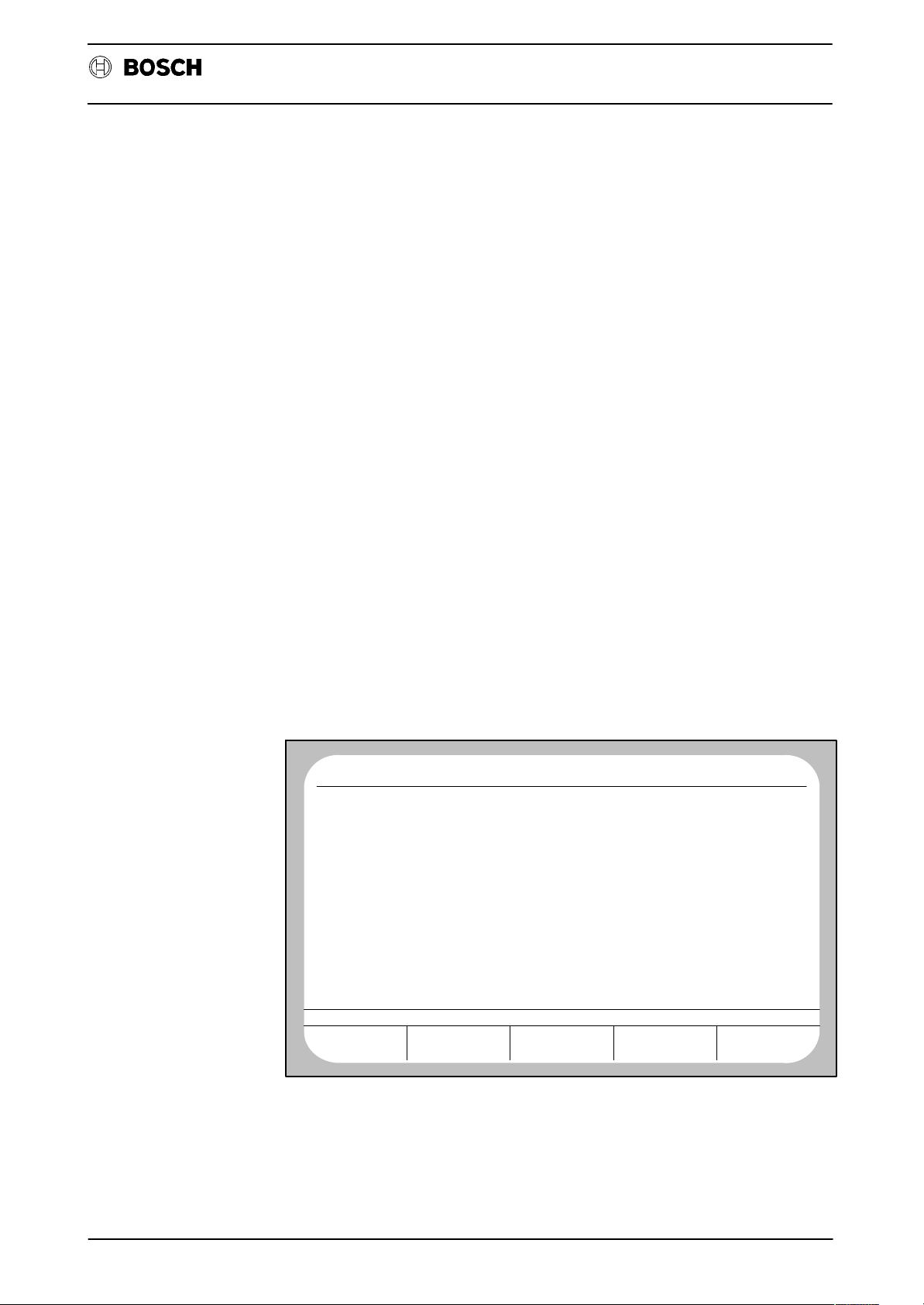

The following monitor display appears after selection of group operating mode

(DIAGNOSTIC):

Diagnosis

CC 220 / 320

No CP0

ERROR CONDITION ON STATUS

AT LAST PROGR.

F 0.0 M 0T 0

DIAGNOSTIC

CONTROL

ACT

DIAGNOSTIC

MACHINE

NC0

STOP

G

90

G

94

G

14

G

15

G

80

G

153

G

39

G

65

G

146

G

994

FUNCTION

G

G

G

G

G

G

130

G

253

G

G

G

115

RESET

66

40

29

62

68

DIAGNOSTIC

12. 5 16:53PROGRAM

G

1

8

71

G

140

G

G

27

G

79

G

53

G

67

G

97

G

99

G

167

DRIVE ON

7

SERVICE

FUNCTION

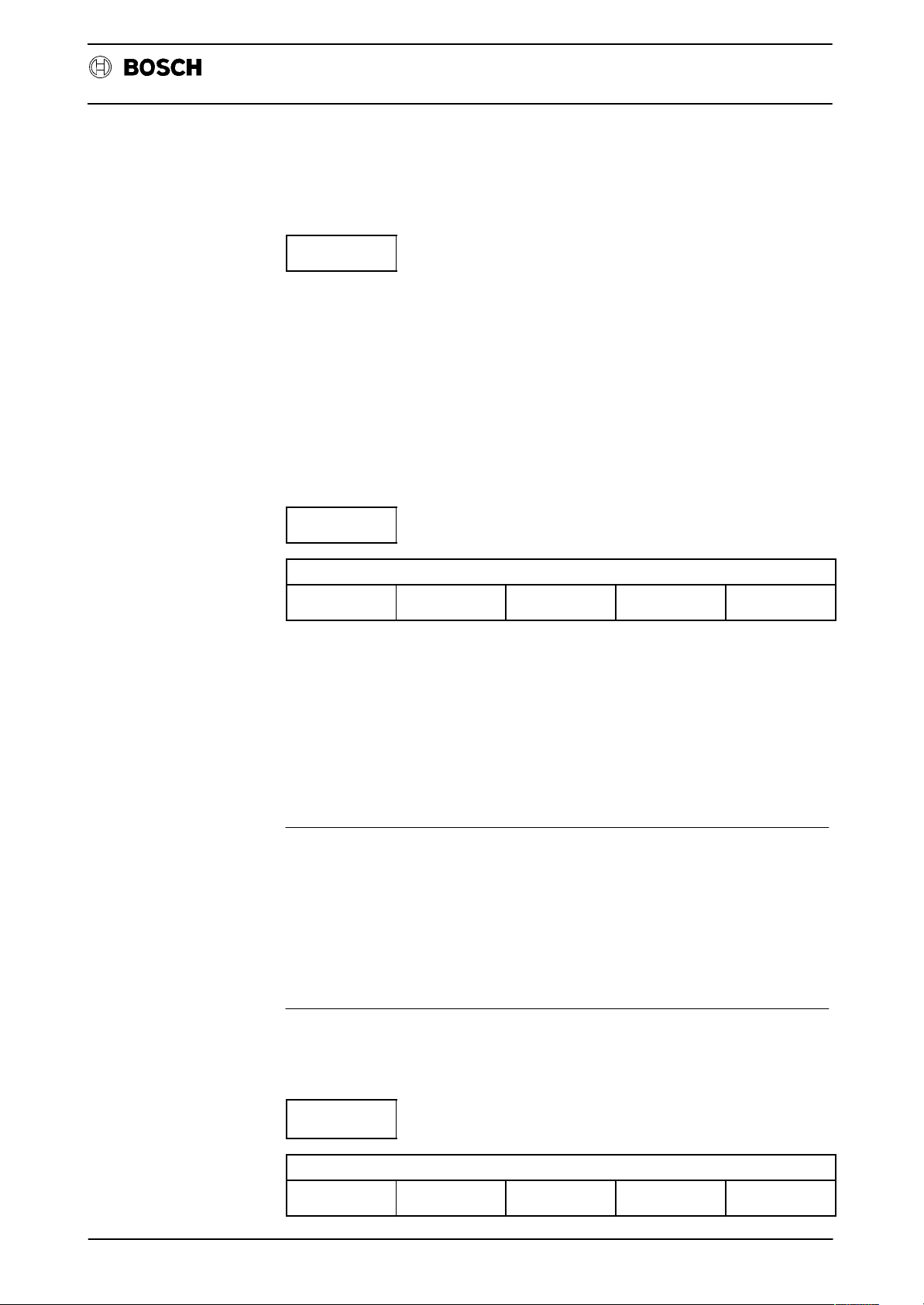

The control displays all available diagnostic programs after operation of the softkey

SERVICE FUNCTION (possibly only after input of a code number; refer to the section ”Notes”):

No CP0

NUMBER PROGRAM NAME LENGTH

D

D

D

D

D

D

D

D

D

D

D

D

D

D

MEMORY USED BY DIAG.:

MEMORY A V AILABLE:

SERVICE FUNCTION

21

22

23

24

25

27

1

2

3

4

5

6

7

9

ACT

LOGBOOK MONITOR

RELOAD OPERATING PROGRAM

CANCEL ALL MEMORY

MACHINE PARAMETER PROGRAM

INTERNAL REF. POINT OFFSET

INTERFACE DATA

COMMUNICATION STORE DISPLAY

MANAGE EEPROM

LOGIC–ANALYZER

AXIS OSCILLOSCOPE

CONTOUR DISPLAY

AXIS OPTIMIZATION

LEAD SCREW ERROR COMPENSATION

PUTTING INTO OPERATION FOR CIRCULAR COMPENSATION

DATA IN DATA OUT START DELETE

NC0

WAIT

DIAGNOSTIC

14.10 8:28PROGRAM

ACCESS

E

E

E

E

E

E

E

E

E

E

E

E

E

E

44384 OTHERS: 2658

2574398

The system asks for the number of the desired program when the softkey START

is pressed. Input of the program number is acknowledged with the ENTER key. The

CNC then starts the corresponding diagnostic program.

1 – 2

Page 8

Flexible Automation

General

Notes:

‘ If the softkey RESET FUNCTION and then softkey CLEAR ALL LOGIC are

pressed in group operating mode DIAGNOSTIC, it is possible to enter the

softkey level SERVICE FUNCTION only by input of a code number as from

this point in time.

When a correct code number has been entered, the softkey level SERVICE

FUNCTION is accessible without input of the code number until renewed operation of the softkey sequence DIAGNOSTIC, RESET FUNCTION, CLEAR

ALL LOGIC.

‘ Some diagnostic programs create files with the group identifier ”L” or ”D” for

recording data. This reduces the memory space which is available for part

programs.

‘ Data recordings can be repeated any number of times within diagnostic pro-

grams, since the previous recording is overwritten by each new recording.

All other operating modes of the control can be used during recording of data

by a diagnostic program.

Exception: CONTROL RESET and selection of a different diagnostic program cancel the currently active diagnostic program (except for D21).

Diagnosis

CC 220 / 320

1 – 3

Page 9

Flexible Automation

General

CC 220 / 320

Diagnosis

1 – 4

Page 10

Flexible Automation

D1 Logbook

4. Description of the diagnostic programs

D1 – Logbook

General

The diagnostic program D1 is used for management of one or more ”logbooks”. A

logbook is a file with the identifier ”D” which contains various data for reconstruction

of operating sequences, error messages or warnings etc. This file is divided into

5 ring memories which store warnings, errors, system errors, other messages and

operating steps in the order of their occurrence.

Activating/deactivating a logbook

There are two possibilities for activation of a logbook:

CC 220 / 320

Diagnosis

‘ Input of a logbook file number in machine parameter P 9914. Then ACTI-

V ATE the machine parameters. The logbook is automatically initialized with

the specified file number after control start–up and is active as from this point

in time. The ring memories are created with the following sizes: R1 to R4:

512 bytes, R5: 0 byte.

‘ Operation of softkey INIT in diagnostic program D1.

An already active logbook can be deactivated in diagnostic program D1 by pressing

softkey INIT, input of ”0” and acknowledgement with the ENTER key or by selection

of a different logbook (also refer to softkey LOGBOOK SELECTION). A logbook

cannot be activated again once it has been deactivated. Only deactivated logbooks

can be deleted.

User interface/softkey assignments

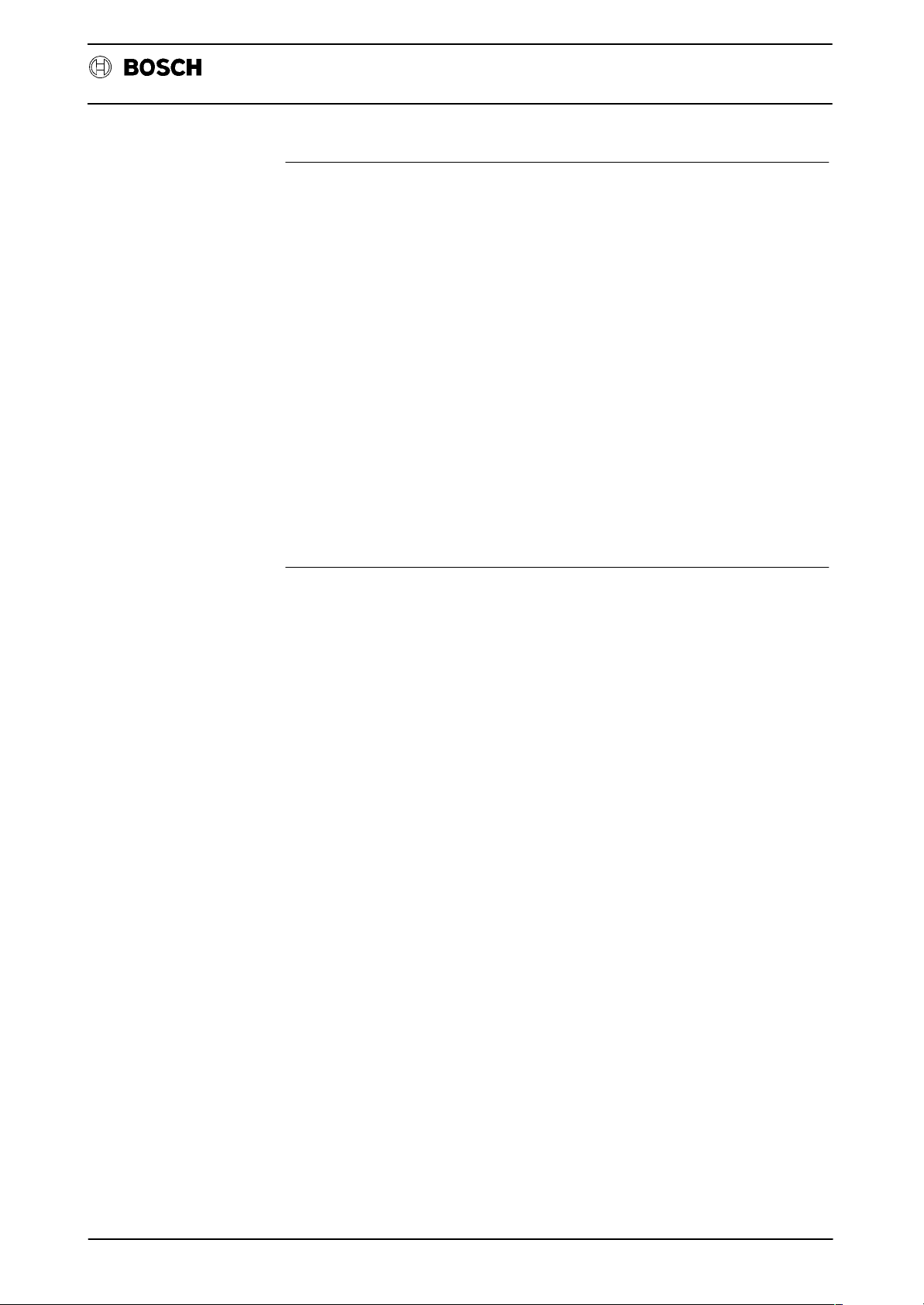

The following display appears if no logbook is yet active when D1 is selected:

No CP0

ACT

LOGBOOK NOT INITIALIZED!

NC0

STOP

DIAGNOSTIC

12. 5 16:59

12. 5 16:59PROGRAM

DISPLAY

RING STORE

D1 – 5

INIT

LOGBOOK

SELECTION

LOGBOOK

PUNCHOUT

Page 11

Flexible Automation

D1 Logbook

CC 220 / 320

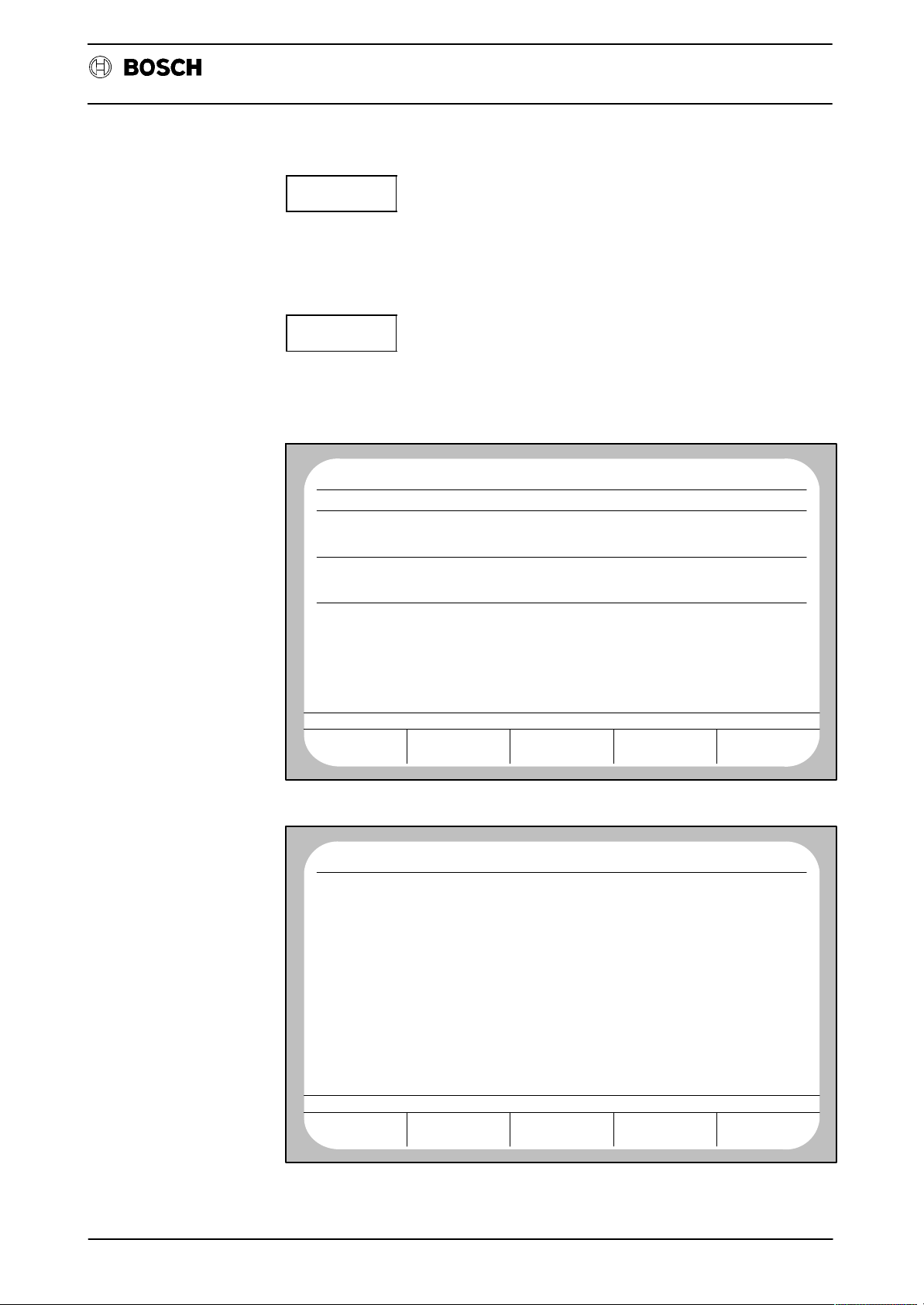

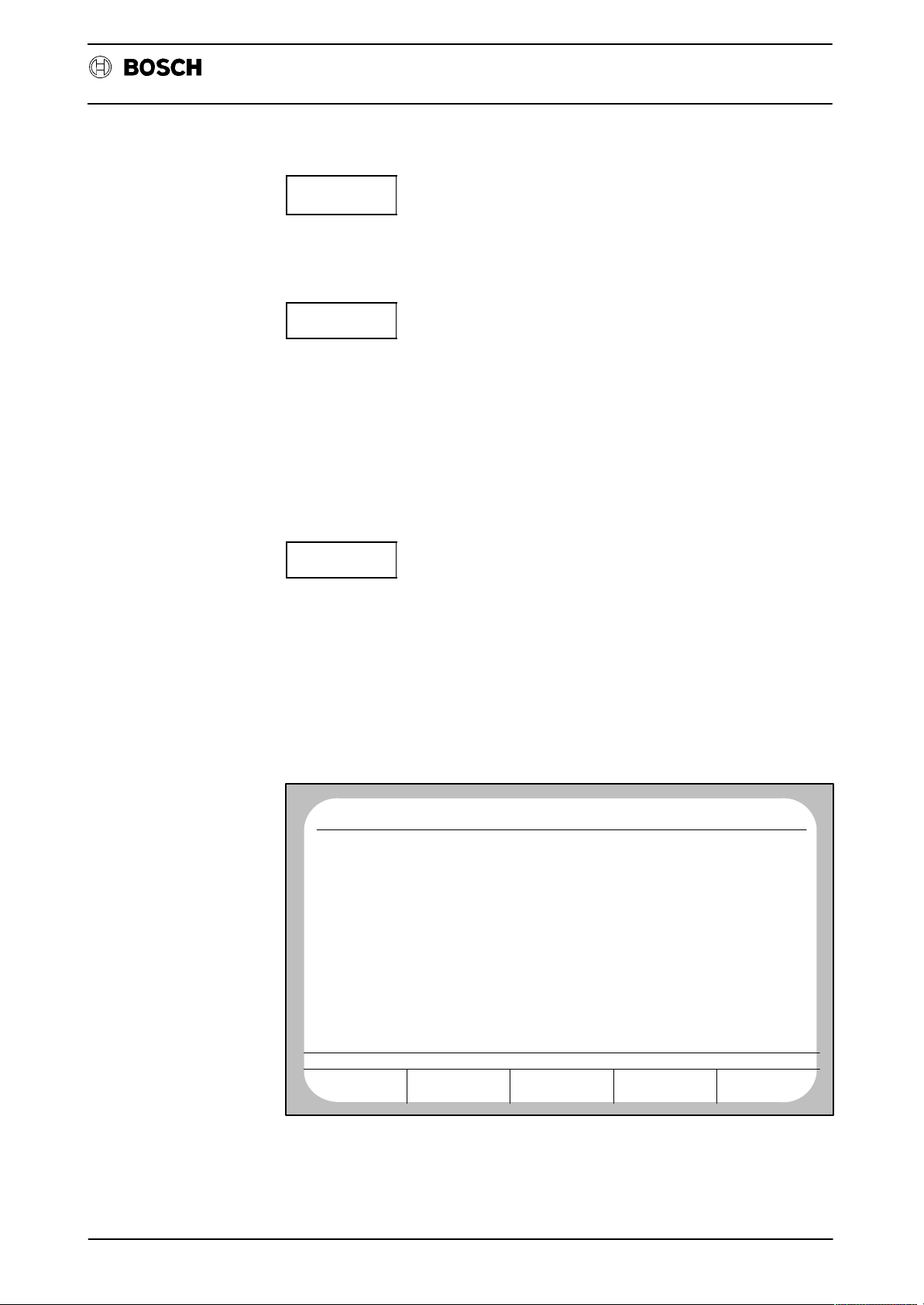

The following monitor display is shown if a logbook is already active:

Diagnosis

No CP0

PROGRAM

LOGBOOK D 11000 ACTIVE

RING STORE FOR WARNING

RING STORE 2 FOR ERRORS

RING STORE 3 FOR SYSTEM ERRORS

RING STORE 4 FOR OTHER MESSAGES

RING STORE 5 FOR OPERATING STEPS

TEST POINT 1 ADDRESS 0000064

TEST POINT 2 ADDRESS 00000000

TOTAL LOGBOOK SIZE: 605 BYTES

DISPLAY

RING STORE

INIT

ACT

NC0

STOP

INIT

DIAGNOSTIC

12. 5 16:59

SIZE = 100 BYTES

SIZE = 100 BYTES

SIZE = 100 BYTES

SIZE = 100 BYTES

SIZE = 100 BYTES

LOGBOOK

SELECTION

LOGBOOK

PUNCHOUT

Initialization of a logbook (creation of a new logbook file).

When the softkey INIT is pressed, the CNC expects input of a logbook file number

(value range 0.3000–999999999).

Input of ”0” deactivates a currently active logbook (”active” means that recordings

take place in this logbook). A logbook cannot be activated again once it has been

deactivated. Only deactivated logbooks can be deleted.

Two test points are interrogated after input of the file number. However, these are

of importance only for service purposes. Skip test point input by pressing the ENTER key twice.

The system then asks for the memory size for the individual ring stores. Reservation of approx. 500 bytes per ring store will already permit a sensible recording to

be made.

After this, the logbook is initialized and automatically activated. Any events which

occur are recorded from this point in time onwards.

The number of logbooks which can be created is limited by the available memory

space. Only one logbook can be active at any time.

In order to use the file number of a deactivated logbook again for an active logbook,

it is first necessary to delete the deactivated logbook in the softkey level SERVICE

FUNCTION and to then create a logbook again in D1 under softkey INIT.

LOGBOOK

SELECTION

Selection of any existing deactivated logbooks for display on the monitor.

D1 – 6

Page 12

Flexible Automation

D1 Logbook

CC 220 / 320

Diagnosis

LOGBOOK

PUNCHOUT

The currently displayed logbook is output on an external data medium. The current

setting in group operating mode DATA I/O, softkey DATA OUT, determines via

which interface output takes place. A change in operating mode aborts active output. Output via the DNC interface is not possible.

DISPLAY

RING STORE

This softkey results in display of the contents of the individual ring stores. The store

contents are displayed in plain text with data, time and message.

Example: Ring store 1 (warnings):

No CP0

PROGRAM

LOG 11 23.05 09:31 WARNING: DATA PROTECTED

KEYING: DATA SK1+ SK1− 0 ENTR

TEST POINT: 1=00000000 2=00000000 MODE: DATA

LOG 7 16.05 11:34 WARNING: AXIS MOVING

KEYING: SK5+

TEST POINT: 1=00000000 2=00000000 MODE: DIAGNOSTIC

DISPLAY END

PAG E

FORWARDS

ACT

NC0

STOP

1

SK5− DIAG SK3+ SK3− SK3+

PAG E

BACK

LAST

KEY

Example: Ring store 5 (operating steps):

No CP0

SK4−

ERET

SK4−

DIAG

SK4+

SK3+

SK4+

SK5−

SK5+

2

SK3+

ENTR

SK2+

SK4−

SK4+

ERET

SK4+

SK4−

2

SK4−

SK3−

SK5+

ERET

SK1−

DATA

5

SK1−

SK4+

ERET

SK4−

SK4+

5

SK4+

SK3+

ENTR

SK4−

SK1+

SK2−

SK1−

SK1+

ENTR

ACT

ERET

SK4+

ENTR

2

SK4−

DIAG

0

SK4+

SK3−

SK2+

SK1+

ENTR

2

NC0

STOP

RESET

ENTR

6

SK4−

SK4+

ERET

2

SK3−

SK3+

SK1−

ERET

1

SK4−

SK3+

6

5

SK4+

DIAG

SK5−

SK1−

SK3+

SK5−

SK1+

SK2−

SK1−

SK4+

ENTR

SK3−

5

RESET

2

DIAG

DATA

SK5+

SK1+

SK5−

SK5+

SK1−

SK2+

SK1+

ERET

SOFTKEY

MASK

1

SK3+

2

SK3+

7

SK3−

RESET

ENTR

SK1−

SK5+

SK1−

SK1+

SK1−

ENTR

SK4−

DIAGNOSTIC

DIAGNOSTIC

12. 5 17: 5PROGRAM

SK4−

DIAG

7

SK3−

2

SK3+

SK5+

0

SK1+

ENTR

SK1+

SK1−

SK1+

3

SK4+

SK4+

ERET

2

SK3+

SK4−

SK3−

SK4−

1

SK5−

0

SK3−

SK1+

SK2−

3

SK4−

PAG E

FORWARDS

PAG E

BACK

The last–pressed key is shown at the top left in the uppermost data line of the monitor (”ENTR” here in the example).

D1 – 7

Page 13

Flexible Automation

D1 Logbook

The following abbreviations are used for display of the keys:

ABAR, MDI, MASC, DATA, DIAG, KORR Group operating modes

CUP+, CDN+, CRI+, CLE+ Cursor keys pressed

CUP–, CDN–, CRI–, CLE– Cursor keys released

LPE+ Magnifier pressed

LPE– Magnifier released

SK1+, SK2+, SK3+, SK4+, SK5+ Softkey pressed

SK1–, SK2–, SK3–, SK4–, SK5– Softkey released

ERET Level return

DEL Delete key

ENTR Enter key

1 ... 0 Numeric keys

: * – + = Arithmetic operation keys

+/– Sign change

. Decimal point

RESET Stands for Control Reset,

CAL = System error 1

NC reset, switching on/off,

Logbook Init

?? Unknown key code

CC 220 / 320

Diagnosis

SOFTKEY

MASK

The softkey mask present at the time of the entry is displayed. If the key assignment

is displayed by a number, this indicates variable softkey designations, such as occur, for example, for wool sub–tables.

D1 – 8

Page 14

Flexible Automation

D5 – Internal reference point offset

D5 Internal reference point offset

CC 220 / 320

Diagnosis

The currently active axis offset values are displayed after selection of the program

D5.

These may have been generated by G92 or by ZERO SET. Zero offsets by way of

G54 – G59, G154 – G159, G254 – G259, G60 or G160 are not taken into account

here.

No CP0

AXIS

X

Y

Z

ACT

OFFSET VALUE

767.766 MM

− 715.692

124.423

NC0

WAIT

MM

MM

DIAGNOSTIC

14.10 8:32PROGRAM

D5 – 9

Page 15

Flexible Automation

D5 Internal reference point offset

CC 220 / 320

Diagnosis

D5 – 10

Page 16

Flexible Automation

D6 – Interface data

General

User interface/softkey assignments

D6 Interface data

CC 220 / 320

Diagnosis

Data arriving at the standard interfaces can be displayed with D6. The data is not

stored during this operation.

No check is made of the data (e.g. with respect to correct file header, program end,

ECODE etc.). Reading–in is not subject to any time monitoring function. No mes-

sage is issued if data transfer is faulty.

The following functions are offered after program selection:

DEVICE

SELECT

DEVICE

SELECT

STATUS

DFS

SEARCH

DFS–NO.

SEARCH

START

Selection of the data interface and definition of the connected peripheral device.

STATUS

The following softkey bar appears when STATUS is pressed:

SW

CONTROL

SW

CONTROL

HEX CHAR/HEX CHAR/SYMB

Activation/deactivation of the XON/XOFF protocol.

Softkey is shown inverted: software handshake active (Xon/Xoff).

Softkey is displayed normally: hardware handshake active (DTR/DSR).

HEX

Display of the incoming data in HEX format.

CHAR/HEX

Incoming data is displayed as ASCII characters. Exception: display of control characters occurs in HEX format.

CHAR/SYMB

Incoming data is shown as ASCII characters. Exception: control characters are displayed symbolically (e.g. <SP> = Space, <LF> = Line Feed).

D6 – 11

Page 17

Flexible Automation

D6 Interface data

CC 220 / 320

Diagnosis

START

Start of the reading–in operation. This operation continues until the screen is full.

Half of the screen is filled again in each case by repeated operation of this key.

DFS

SEARCH

Reading–in is started by pressing the softkeys DFS SEARCH and START and is

then continued until a correct DFS identifier is found. After this, a maximum of 17

lines of the program/table are displayed. The rest of the incoming program/table

data of this file is skipped after renewed operation of DFS SEARCH and then

START. The control displays the first 17 lines of the program/table again only after

the next DFS identifier has been found.

Note: ”DFS search” is active as long as the softkey is shown inverted. The function

is executed only if the DFS identifier is correctly received.

DFS–NO.

SEARCH

The system asks for the file number for which a search is to be made after operation

of this softkey. After input of this number and subsequent operation of the softkey

START, reading–in takes place until the specified file number (DFS identifier) is

found. The incoming data is displayed only after this has occurred.

Note: ”DFS search” is active as long as the softkey is displayed inverted. The

function is executed only if the DFS identifier is received correctly.

Example: Display of read–in data in the format CHAR/HEX:

No CP0

<13><12><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00

<00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00

<00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00

<00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><14><12

<00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00

<00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00

<00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00><00

<00><00><02><0D><0A>

<14><12>(DFS,P 55555,TEACH IN 18.08,RWED)<

D><0A>

<14><12>1 A%=3:REM NUMBER OF AXES <0D><0A>

1 A1$="X":REM AXIS ADDRESS<0D><0A>

1 A2$="Y"<0D><0A>

1 A3$="Z"<0D><0A>

1 A4$="B"<0D><0A>

1 A5$="B"<0D><0A>

1 <14><12>B%=250:REM INTERFACE OUTPUT FOR SETTING MODE

ACTIVATION <0D><0A>

INTERFACE DATA

DEVICE

SELECT.

ACT

STATUS

NC0

WAIT

DFS−

SEARCH

DFS−No.

SEARCH

DIAGNOSTIC

14.10 8:40PROGRAM

START

D6 – 12

Page 18

Flexible Automation

D7 – Communication store display

General

D7 Communication store display

CC 220 / 320

Diagnosis

The content of the communication store from the point of view of the PLC can be

displayed on the monitor of the CNC in hexadecimal format using the diagnostic

program D7. D7 is offered only if word coupling exists between the CNC and PLC.

The communication store is a 128 KByte dual port RAM area on the NC–PLC–word

module (WK3). Both the CNC and the PLC (PC 600) have read and write access

to this area.

Start address Page 0

End address Page 0

Start address Page 1

End address Page 1

User interface/softkey assignments

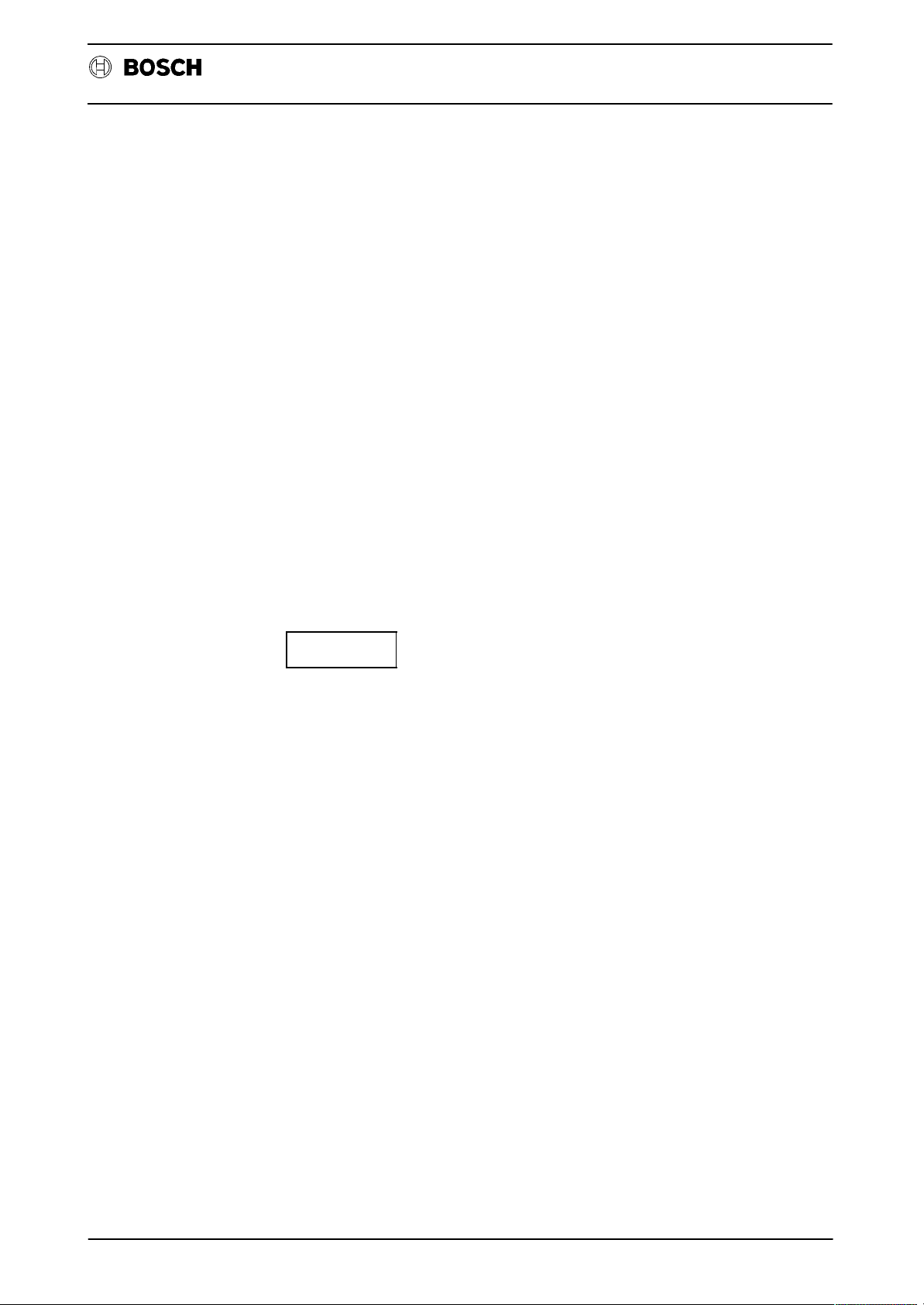

After D7 is started, the control always displays the communication store content

from address C000 H to C07F H (address information as hexadecimal numbers

from the point of view of the PLC):

No CP0

C00 C01 C02 C03 C04 C05 C06 C07

0002

E752

E852

E010

E73E

E746

E952

F000

EA26

F006

F026

F0BA

E000

0000

F092

BB00

C000 COMMUNICATION STORE DISPLAY

C400

F212

F24C

F04E

E95E

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

*000 0*00 00*0

ACT

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

NC0

WAIT

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

BC34

BC34

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

8000 H

FFFF H

8000 H

FFFF H

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

.

.

.

.

.

.

.

.

.

.

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

Page 0

Page 1

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

BACKUP PAG E 1

DIAGNOSTIC

17.10 14: 0PROGRAM

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

PAG E 0*ADVANCE

128 data words (256 bytes) can be displayed on one screen page. The data is displayed in a table form (8 columns of 16 lines each). It is possible to see the assign-

D7 – 13

Page 19

Flexible Automation

D7 Communication store display

CC 220 / 320

Diagnosis

ment between the displayed data words and their addresses in the communication

store by way of the inversely displayed bars above and on the right of the table.

The three most significant positions of an address (e.g. ”C02” of address ”C02F”)

are shown in the top, highlighted bar, while the least significant position is shown

in the bar on the right of the table (e.g. ”F” of the address ”C02F”).

The address of the top left data word is displayed in the prompt line (here in the

example: ”C000 COMMUNICATION STORE DISPLAY”).

Example:

No CP0

C00 C01 C02 C03 C04 C05 C06 C07

0002

E752

E852

E010

E73E

E746

E952

F000

EA26

F006

F026

F0BA

E000

0000

F092

BB00

C000 COMMUNICATION STORE DISPLAY

C400

F212

F24C

F04E

E95E

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

*000 0*00 00*0

ACP

0000

0000

0000

0000

0000

0000 0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

Address C025 H Address C046 H

NC0

WAIT

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

BC34

BC34

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

BACKUP PAG E 1

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

0000

DIAGNOSTIC

17.10 14: 0PROGRAM

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

PAG E 0*ADVANCE

Search for an arbitrary address

Select the required memory area by means of the softkey PAGE 0/PAGE1. The currently displayed memory area is shown inverted on the softkey.

The individual digits of the address displayed in the prompt line can be incremented

or decremented by means of the three softkeys *000,0*00 and 00*0. The asterisk

on the softkey indicates the position which is changed.

The least significant address need not be specified, since all 16 possible addresses

are displayed underneath each other in one column.

It is possible to switch between incrementation and decrementation of the corresponding position by means of the softkey ADVANCE/BACKUP. The active condition is shown inverted.

D7 – 14

Page 20

Flexible Automation

D7 Communication store display

Example:

You are on Page 0. The prompt line shows the address C000 H.

You are looking for the content of the address D123 H on Page 0.

Switch to ”Increment” (the field ADVANCE on the softkey ADVANCE/BACKUP is

then shown inverted).

Press the softkey *000 once.

Press the softkey 0*00 once.

Press the softkey 00*0 twice.

The 4th data value (from the top) in the left column now shows the content of address D123 H.

CC 220 / 320

Diagnosis

D7 – 15

Page 21

Flexible Automation

D7 Communication store display

CC 220 / 320

Diagnosis

D7 – 16

Page 22

Flexible Automation

D9 – EEPROM management

General

D9 EEPROM management

CC 220 / 320

Diagnosis

The MEM5 memory module (or CP/MEM4 in the case of CC220) contains a 32

KByte EEPROM area as standard (optionally 64 KBytes).

Important data should be saved in the EEPROM since the content of the EEPROM

area is not lost – in contrast to the RAM area – after a total power failure on the MEM

module or after forced backup loading.

The following files can be written into the EEPROM area and read out again using

the diagnostic program D9:

Part programs

LSEC tables

W tables

Zero offset tables

Compensation tables

Machine parameters.

For example, it is then possible to choose whether machine parameters and tables

are to be copied back from the EEPROM to the RAM when the control is put into

operation again.

User interface/softkey assignment

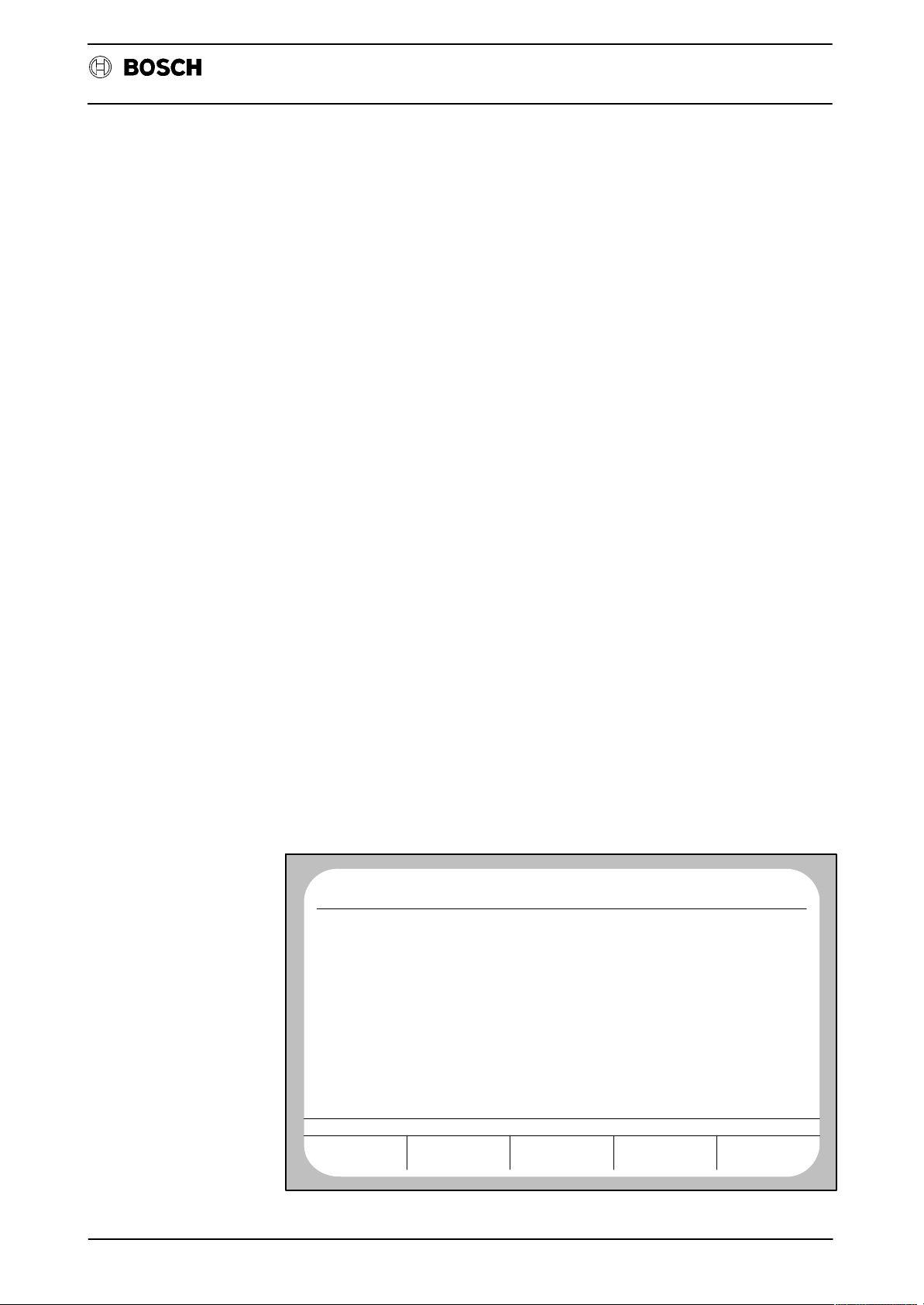

After D9 has been started, the monitor displays a list of all files stored in the EEPROM area.

Each entry in the list additionally contains information as to whether a file with the

same name already exists in the RAM area (column ”IN RAM”) and whether this

file also contains the same data (column ”EQUAL”).

No CP0

LIST OF PROGRAMS TO BE SPECIFIED

No PROGRAM NAME IN RAM EQUAL

0

1

P

2

P

3

P

4

P

ACT

3000

3001

3002

1131

NC0

WAIT

MACHINE PARAMETER

MAIN PROGRAM MOD. DIA 18.08

SR SELECT MODULE

SR TEST DIAGNOSTIC CHANNEL

SR CP

22.06

02.07

22.01

DIAGNOSTIC

14.10 8:45PROGRAM

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

MEMORY USED BY PROGRAM:

MEMORY AVAILABLE: :

MANAGE EEPROM

MACHINE

PARAMETER

PROGRAM

SELECTION

5409

22239

DELETE COPY

OTHERS: 3224

EEPROM

PROGR.

This list can now be extended by new entries or be shortened by deleting entries.

The functions PROGRAM EEPROM and COPY (from EEPROM to RAM) refer

to the files displayed here!

If it is wished to store files in addition to the files which are already contained in the

EEPROM, it is not necessary for files which are already stored in the EEPROM to

also be present in the RAM for programming of the EEPROM.

D9 – 17

Page 23

Flexible Automation

D9 EEPROM management

CC 220 / 320

Diagnosis

The following functions can be initiated by means of the softkeys:

MACHINE

PARAMETER

The currently active machine parameter record (not file L444!) is incorporated in

the list under number ”0”.

A machine parameter record stored in the EEPROM can be copied into the RAM

area again only if the softkey FROM EEPROM is selected when reloading the complete operating system (diagnostic program D2).

File L444 must be stored in the EEPROM (by means of the softkey PROGRAM

SELECTION) if it i s w i shed to permit restoration of machine parameters without reloading the complete operating system.

PROGRAM

SELECTION

PROGRAM

ALL

PROGRAMS

NEXT

GROUP

PREVIOUS

GROUP

Files can be entered in the list from the groups P, L, V, K, W after pressing PROGRAM SELECTION.

To do this, first select the desired file group with the softkeys NEXT GROUP or

PREVIOUS GROUP. The control then shows you all existing files of the selected

group.

All files of this group can be included in the list by pressing the softkey ALL PROGRAMS.

The softkey PROGRAM permits selection of a single file.

Notes:

‘ When programs are entered in the list, the CNC checks whether the size of

the EEPROM area is sufficient for later programming. If not, the error mes-

sage ”MEMORY FULL” appears in the prompt line.

‘ Link files cannot be included in the list.

‘ The K1 table must not be stored in the EEPROM.

DELETE

DELETE LIST ENTRIES

PROGRAM

ALL

PROGRAMS

D9 – 18

Page 24

Flexible Automation

DATA

D9 EEPROM management

CC 220 / 320

Diagnosis

It is possible to delete either individual entries or all entries in the list. This function

relates only to modification of the displayed list! If it is wished to delete a file

in the EEPROM, it is first necessary to delete the corresponding file in this list. The

EEPROM must then be reprogrammed with the thus modified list. Files existing in

the EEPROM are then possibly overwritten by newer file versions (which are contained in the RAM).

If an individual list entry is deleted (by means of the softkey PROGRAM), it is necessary to enter not the file number but the list number of the corresponding file (column ”NO”) and confirm this with the ENTER key.

COPY

COPY FILES FROM EEPROM

PROGRAM

ALL

PROGRAMS

Files can be copied from the EEPROM area to the RAM area of the control by

means of the function COPY.

All files entered in the list are copied into the RAM after operation of the softkey ALL

PROGRAMS.

If you wish to copy an individual file (by means of the softkey PROGRAM), you must

enter the list number of the corresponding file (column ”NO”) after operation of the

softkey PROGRAM and then confirm this with the ENTER key.

Notes:

‘ Copying of the machine parameter record (list entry ”0”) to the RAM area

is not possible using this function. A machine parameter record stored in the

EEPROM can be copied into the RAM area again only if the softkey FROM

EEPROM was selected when reloading the operating system.

‘ The function COPY is protected by a code.

EEPROM

PROGR.

Programming the EEPROM area with the files entered in the list.

The system first asks for input of a code in order to prevent unintentional programming.

After this, the operator can enter an identifier consisting of a maximum of 50 ASCII

characters. This identifier is of no significance in the current software version. If it

is wished to start programming, skip input of the identifier by pressing the ENTER

key. However, if it is wished to abort the function EEPROM PROGRAMMING at this

point, simply press the level return key.

D9 – 19

Page 25

Flexible Automation

DATA

D9 EEPROM management

The softkey EEPROM PROGR. is displayed inversely during programming. CNC

operation is not possible during this time. The message ”PROGRAMMING IS AC-

TIVE!” flashes in the prompt line. The number of programmed bytes is displayed

continuously. An asterisk appears in front of the list number of a file as soon as this

file has been completely programmed.

The list is moved up on the screen if not all previously programmed files can be displayed on one screen page.

CC 220 / 320

Diagnosis

D9 – 20

Page 26

Flexible Automation

D21 – Logic analyzer

General

D21 Logic analyzer

CC 220 / 320

Diagnosis

The logic analyzer permits recording of a maximum of 16 signals of the CNC–PLC

interface.

During a recording, 500 sampling operations of all selected signals (refer to softkey

CHANNEL SELECTION) are always stored. The interval between two sampling

steps is adjustable.

File D121 is used to record the data. If this file does not yet exist, the system creates

it automatically before a recording (file size: approx. 2 – 2.5 KByte part program

memory). An existing file D121 is overwritten by each new recording.

In addition, recorded data (including the current logic analyzer settings at the time

of recording) or arbitrary logic analyzer settings can also be stored in separate files

for possible subsequent use (refer to softkey FILE SELECTION).

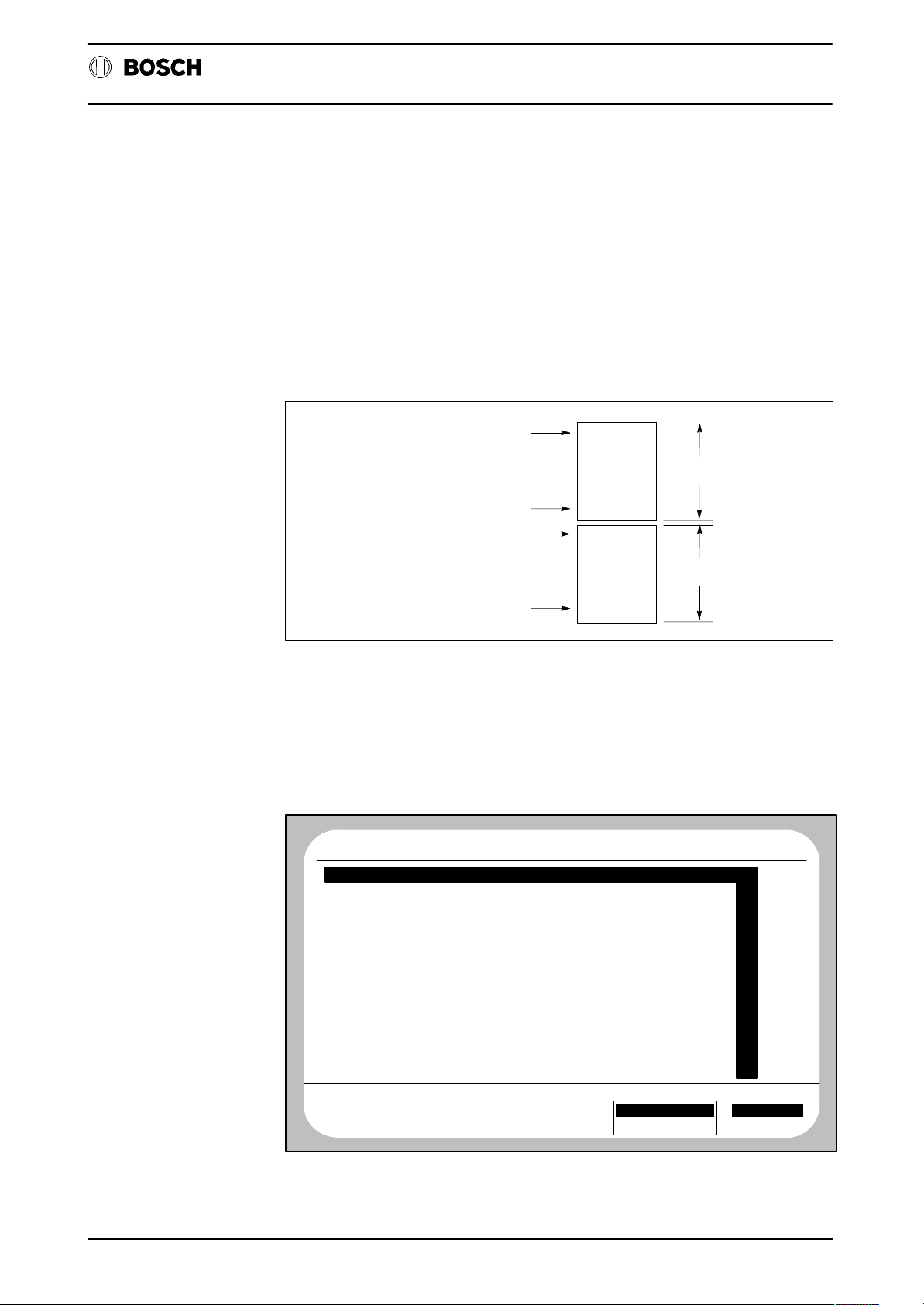

Functional principle of the logic analyzer:

0 ...................500 (Sampling steps)

Trigger

position

Memory

Trigger condition Comparator Clock

Delay

Data stream

Clock

D21 – 21

Page 27

Flexible Automation

User interface/softkey assignments

D21 Logic analyzer

The following display appears after selection of D21:

CC 220 / 320

Diagnosis

No CP0

LOGIC−ANALYZER

WAITING

STARTING VALUES

CHANNELS 8

STORE

CLOCK

TRIGGER−POS.

DISPLAY

STARTING

VALUES

STARTING VALUES

CHANNELS

8 OR 16

POSITION

ACT

LOGIC−ANALYZER STATUS

500 CLOCKS

1 PLC−CY

250 CLOCKS

CHANNEL

SELECTION

TRIGGER

NC0

WAIT

No TYPE ADDR. BIT TRIGGER COND.

0 I 40.7 1

1 O

2 O

3 O

4 O

5 O

6 O

7 O

STARTING

VALUES

CHANNELS

36.0

36.1

36.2

36.3

36.4

36.5

36.6

FILE

SELECTION

*

*

*

*

*

*

*

CLOCK

DIAGNOSTIC

13. 5 8:57PROGRAM

START

RECORDING

The functions of the logic analyzer can be adapted to the respective task by means

of these softkeys:

CHANNELS

8 OR 16

It is possible to record 8 or 16 channels simultaneously. The number of channels

can be set to 8 or 16 by means of this softkey.

TRIGGER

POSITION

You define here how many sampling steps are to be stored before occurrence of

the trigger event.

500 sampling steps are always stored in total in the recording file.

Examples:

Trigger position = 250:

The sampling step executed when the trigger event occurs is assigned the ”num-

ber” 250. A further 250 sampling steps (500 – 250) are then stored additionally as

from this point.

Trigger position = 10:

The sampling step executed when the trigger event occurs is assigned the ”num-

ber” 10. A further 490 sampling steps (500 – 10) are then stored additionally as from

this point.

D21 – 22

Page 28

Flexible Automation

D21 Logic analyzer

CLOCK

CC 220 / 320

Diagnosis

Specification of the time interval between two sampling steps. It is possible to set

three different types of time interval here. In addition, it is necessary to enter the

size of an individual time interval. The following table provides an overview of the

possible inputs:

Interval type Size Meaning

1 (MS) 1 ms – 50 ms Channels can be sampled at ms inter-

vals.

Possible interval size:

1 ms to 50 ms, depending on set size.

2 (TASKS) 1 – 9999 The channels can be sampled on the

basis of task changes. This type of interval is relevant only for users who

possess extremely good system knowledge of the control.

3 (PLC CYCLES) 1 – 9999 The channels can be sampled each

time the PLC performs a ”PE”.

(Possible interval size: time from PE to

PE.)

(Possible only for PIC 250 or word–

coupled PC 600).

CHANNEL

SELECTION

INPUT OF CHANNEL AND TRIGGER CONDITION

PLC INPUTIPLC OUTPUTOPLC MARKER

M

STORE

S

TRIGGER

CONDITION

Select the channel number to be changed (0 – 7 or 0 – 15) with the cursor keys

after operation of CHANNEL SELECTION. It is then possible to assign an

input, output, marker or memory address to the selected channel number by means

of softkey and numeric input. The input must be acknowledged with the ENTER

key.

Setting the trigger condition:

Selection of the channel number with the cursor keys

. The active channel

is shown inverted.

Input of 0 results in low–level triggering,

1 results in high–level triggering,

* (multiplication symbol) No trigger.

An input, output, marker or memory bit is assigned to the active channel by pressing the corresponding softkey (1 – 4) and subsequently making a numeric input.

The following input values are permitted:

Input/output: bits 0.0 to 255.7

Marker: markers 0.0 to 511.7

D21 – 23

Page 29

Flexible Automation

MOVE

D21 Logic analyzer

START

RECORDING

The logic analyzer records. The message ”RECORDING” appears underneath the

line ”LOGIC ANALYZER”. The condition ”WAITING” is displayed here when the re-

cording has been completed.

Notes:

‘ The recording is aborted by selection of a different diagnostic program.

‘ CONTROL RESET does not normally interrupt recording. However , if active

remote diagnosis is aborted by selection of D21 and a restart then performed

by CONTROL RESET, this operating sequence results in termination of the

recording and of diagnostic program D21.

CC 220 / 320

Diagnosis

D21 – 24

Page 30

Flexible Automation

D21 Logic analyzer

FILE

SELECTION

LOGIC ANALYZER DIAGRAM/PARAMETER FILES

SAVE LOAD

MODIFY

HEADER FILE

PARAMETER

ONLY

CC 220 / 320

Diagnosis

COMPLETE

DIAGRAM

The softkey FILE SELECTION permits access to a number of functions which are

used for storage or loading of current logic analyzer settings or complete logic analyzer recordings (time diagrams). The control displays all logic analyzer recording

or setting files which exist in the system on this softkey level.

SAVE

Using the softkey SAVE, it is possible to store current settings or the current recording (including settings) in a file of the group ”D”, depending on which softkey (PA-

RAMETER ON LY or COMPLETE DIAGRAM) is shown inverted. File numbers from

3101 to 3300 are permitted. A recording (time diagram) can be stored only after

completion of storage in one of these files.

LOAD

Loading of a stored setting or stored recording. Only the files which contain recordings are displayed on the monitor after operation of LOAD if the softkey COMPLETE DIAGRAM is shown inverted.

MODIFY

HEADER FILE

The file header (text) can be modified after input of the file number. The text ”LOGIC

DIAGRAM” is entered as standard in the file header for recording files and the text

”LOGIC PARAMETER” for setting files.

PARAMETER

ONLY

Only current settings of the logic analyzer are taken into account for LOAD or SAVE

if this softkey is inverted. Settings should be understood as all parameters which

can be influenced on the softkey levels INITIAL VALUES and CHANNEL SELECTION.

COMPLETE

DIAGRAM

If this softkey is shown inverted, recordings (time diagrams) are also taken into account in addition to settings (refer to SK PARAMETER only) for LOAD or SAVE.

D21 – 25

Page 31

Flexible Automation

D21 Logic analyzer

DISPLAY

The current recording (time diagram) appears on the monitor:

CC 220 / 320

Diagnosis

No CP0

PROGRAM

CT

5.4

O

0.0

I

0.1

I

2.0

I

0.2

I

0.3

I

2.1

I

36.6

O

0 250 500

CUR:

0 REF: 500 REF−CUR: 500 ( 5.0005)

*1 CURSOR

ACT

NC0

STOP

*10 REFERENCE

DIAGNOSTIC

R

START

RECORDING

CR

00

01

00

10

00

01

10

00

The recording contains three markings in the form of vertical lines. These are identified by C (cursor), T (trigger position) and R (reference mark).

The cursor is located at the cursor position ”0” (1st sampling step) in the initial display condition. The mark T indicates the defined trigger position. The mark T is

moved to the respective sampling step if fewer sampling steps are performed than

defined under softkey TRIGGER POSITION after the start of recording before the

trigger condition occurs. The mark R is initially located at the cursor position 500.

The marks C and R can be moved – after corresponding softkey selection (CURSOR or REFERENCE) – with the cursor keys

or by input of a sampling step

number.

The positions of the marks C and R and the distance of the reference mark from

the cursor mark (in sampling steps and seconds) are displayed in the message line

under CUR, REF and REF–CUR. The current level (0 or 1) at the markings C and

R is displayed at the right edge of the screen (under C and R) for each channel.

The current signal assignment (input, output, marker, store) is shown for each

channel at the left edge of the screen.

The time axis can be expanded by a factor of ten (*10) by softkey.

D21 – 26

Page 32

Flexible Automation

D22 – Axis oscilloscope

General

D22 Axis oscilloscope

The diagnostic program allows the user to assess the dynamic response of the

axes. It is thus possible to establish sluggish movement, jamming or overshoot of

the axes or excessively slow axis circling.

For this purpose, D22 offers the possibility of simultaneously recording axis movements and 2 logical signals and displaying these as diagrams on the CNC monitor .

The file D122 is used for data recording. If this file does not yet exist, the system

creates it automatically before a recording (file size approx. 5 KByte part program

memory). An existing file D122 is overwritten by each new recording.

In addition, recorded data (including the axis oscilloscope settings valid at the time

of recording) or arbitrary axis oscilloscope settings can also be stored in separate

files for possible subsequent use (refer to softkey FILE SELECTION).

Diagnosis

CC 220 / 320

480 actual axis position values are always stored during a recording at the time interval defined in machine parameter P9901 (interpolation time in ms). From these

values, the control calculates the following:

‘ Setpoint/actual speed

‘ Setpoint/actual acceleration

‘ Setpoint speed/lag

This data can then be displayed on the monitor as diagrams.

User interface/softkey assignments

The following display appears after selection of D22:

No CP0

AXIS−OSCIL.

WAITING

ADJUSTMENTS

AXIS: 1

PC1

PC2

Y1:

Y2:

X:

X−EXP.START =

TRIGGER−POS.

JOG BUT TON 1st AXIS

A

E

TRIGGER ACTIVATION

ACT

0.0

0.0

1.000000

1.000000

240.00

NC0

STOP

OSCILLOSCOPE STATUS

"

M/S 2 PER SCALE DIVISION

"

M/S 2 PER SCALE DIVISION

MS PER SCALE DIVISION

0

SCALE DIVISIONS

0

SCALE DIVISIONS

2670

DIAGNOSTIC

10. 4 16:12PROGRAM

DISPLAY

SELECT

DISPLAY

D22 – 27

DISPLAY

SPLITTING

OTHER

COMMANDS

START

RECORDING

Page 33

Flexible Automation

D22 Axis oscilloscope

SELECT

DISPLAY

CC 220 / 320

Diagnosis

CMD. SPEED

ACT. SPEED

CMD. ACCEL.

ACT. ACCEL.

CMD. SPEED

LAG

Select the diagram which is desired after operation of the softkey DISPLAY here.

It is possible to choose between setpoint and actual speed (CMD. SPEED/ACT.

SPEED), setpoint and actual acceleration (CMD. ACCEL.

ACT. ACCEL.) or setpoint speed and lag (CMD. SPEED/LAG). The inverted softkey indicates the currently active setting.

The settings can also still be changed after recording.

DISPLAY

SPLITTING

X–DISPLAY

START

EXPAND X

*10

SCALE

1.Y–AXIS

SCALE

2.Y–AXIS

The diagram representation can be influenced by means of these functions:

X–DISPLAY

START

The time axis of a diagram is divided into 20 scale divisions. Complete representation of the diagram is not possible if the time axis is expanded by a factor of 10. Using the softkey X–DISPLAY START, it is thus possible to specify as from which scale

division the diagram is displayed on the monitor with an expanded time axis (inputs:

0–18) (also refer to softkey EXPAND X*10). The scale division specified here is

marked on the non–expanded representation of the diagram with the character ”D”

(also refer to softkey DISPLAY).

EXPAND X

*10

This softkey allows the diagram to be expanded by a factor 10 in the X–axis (time

axis). The softkey is shown inverted if axis expansion is active. It is possible to

switch back to the non–expanded diagram by pressing the softkey once more.

The time axis of a diagram is subdivided into 20 scale divisions. Two scale divisions

are shown on the screen in the expanded diagram. One scale division of the time

axis corresponds here to the time t = 2.4 x P9901.

SCALE

1.Y–AXIS

SCALE

2.Y–AXIS

The scale of the two Y–axes is set here.

SCALE 1.Y–AXIS acts on the Y–AXIS of the top diagram, while SCALE 2.Y–AXIS

acts on the Y–AXIS of the bottom diagram (refer to softkey DISPLAY for diagram

structure).

Input range: 0.0000001–9999999 m/min.

D22 – 28

Page 34

Flexible Automation

D22 Axis oscilloscope

Examples:

Input: 1 Setpoint speed of 1 m/min. corresponds to a Y–value of 1 scale divi-

sion.

Input: 2 Setpoint speed of 1 m/min. corresponds to a Y–value of 1/2 scale

division.

Input: 0.25 Setpoint speed of 1 m/min. corresponds to a Y–value of 4 scale divi-

sions.

OTHER

COMMANDS

Diagnosis

CC 220 / 320

RECORDING

SELECTION

RECORDING

SELECTION

AXIS

NUMBER

TRIGGER

CONDITION

PLC INPUTIPLC OUTPUT

TRIGGER

POSITION

O

FILE

SELECTION

STORE

S

The axis for which recording is desired is defined on this softkey level (softkey AXIS

NUMBER).

In addition, it is possible to use the cursor keys

to select channels to which

an interface signal or, in the case of word coupling between CNC and PC 600, also

a memory bit can be assigned with the softkeys PLC INPUT I, PLC OUTPUT O and

STORE S (maximum of 2 channels can be selected).

These 2 channels are then recorded during recording and later displayed on the

DISPLAY between the top and bottom diagrams. The bits 0.0 to 255.7 are permitted as input values for an input or output.

D22 – 29

Page 35

Flexible Automation

D22 Axis oscilloscope

TRIGGER

CONDITION

CC 220 / 320

Diagnosis

JOG

BUTTON

PROG.–NO.

BLOCK NO.

PLC INPUTIPLC OUTPUT

O

STORE

S

Setting the trigger condition. When the softkey START RECORDING is pressed,

the start of recording is delayed until the trigger event set here occurs. The active

trigger condition is identified by inverse display of the corresponding softkey . I f t h e

trigger event does not occur , the axis oscilloscope must be reset by means of a control reset.

Note:

If JOG BUTTON is selected as the trigger condition, jog mode must have been activated in group operating mode MACHINE. If not, triggering is initiated by the jog

button, but no axis movement takes place.

TRIGGER

POSITION

You define here how many actual axis position values are to be stored before the

trigger event occurs. 480 actual axis position values are always stored in total.

The input must be made in the unit ”Scale divisions” (see example). The permitted

value range for inputs lies within the limits 0.0 to 20.0. The time interval from scale

division to scale division is calculated as follows:

nt = Machine parameter P9901 * 24.

Example:

It is wished to store 252 actual axis position values before the trigger event occurs:

252 : 24 = 10.5 ! Input: 10.5

The recording thus consists of 252 values before the trigger event occurs plus 228

values after this trigger event (always making up a total of 480 actual axis position

values).

D22 – 30

Page 36

Flexible Automation

DATA

D22 Axis oscilloscope

FILE

SELECTION

AXIS OSCILLOSCOPE DIAGRAM/PARAMETER FILES

SAVE LOAD

MODIFY

HEADER FILE

The softkey FILE SELECTION allows access to a number of functions which can

be used to store or load current axis oscilloscope settings or complete axis oscilloscope recordings (time diagrams). The control displays all axis oscilloscope recording or setting files which exist in the system on this softkey level.

SAVE

The softkey SAVE allows current settings or the current recording (including

settings) to be stored in a file of the group ”D”, depending on which softkey (PARAMETER ON LY or COMPLETE DIAGRAM) is shown inverted. File numbers from

3301 to 3500 are permitted. A recording (time diagram) can be stored only after

inclusion in one of these files.

Memory requirement of a recording: approx. 5 KByte.

Memory requirement of a setting: approx. 100 Byte.

PARAMETER

ONLY

Diagnosis

COMPLETE

DIAGRAM

CC 220 / 320

LOAD

Loading of a stored setting or stored recording. If the softkey COMPLETE DIAGRAM is shown inverted, only the files which contain recordings are displayed on

the monitor after operation of LOAD.

MODIFY

HEADER FILE

The header of a file (text) can be changed after input of the file number. The text

”OSCIL–DIAGRAM” is entered in the file header as standard for recording files and

”OSCIL–PARAMETER” for setting files.

PARAMETER

ONLY

If this softkey is shown inverted, only current settings of the axis oscilloscope are

taken into account for LOAD or SAVE.

COMPLETE

DIAGRAM

Recordings, (time diagrams) are taken into account as well as settings (refer to SK

PARAMETER ONLY) for LOAD or SAVE if this softkey is shown inverted.

D22 – 31

Page 37

Flexible Automation

D22 Axis oscilloscope

START RE-

CORDING

The axis oscilloscope records. The message ”RECORDING” appears under the

line ”AXIS OSCILLOSC.”. The status ”WAITING” is displayed here when the recording has been completed.

Notes:

‘ An ongoing recording is aborted by selection of a different diagnostic pro-

gram or by CONTROL RESET.

‘ If the trigger event does not occur, the axis oscilloscope must be reset by

means of a control reset.

‘ If JOG BUTTON was activated as the trigger condition, jog mode must have

been activated in group operating mode MACHINE. Otherwise, no traversing movement occurs.

Diagnosis

CC 220 / 320

DISPLAY

The axis oscilloscope recording appears on the monitor. Once scale division of the

time axis corresponds to the time t = 24 x P9901 in non–expanded form and

t = 2.4 x P9901 in expanded form.

The recording contains the marks D (for the expansion function) and T (trigger position). The mark D can be moved with the cursor keys

COMMAND SPEED

D

T

ACTUAL SPEED

.

The display is expanded by a factor of 10 in the X–axis (time axis) by pressing the

MAGNIFIER key. The starting point for the expanded display is the position of the

mark D in this case (refer to following monitor screen for an example of an expanded display). The display switches back to non–expanded form if ”MAG-

NIFIER” is pressed again (same function as softkeys EXPAND X *10 and X–DIS-

PLAY START).

D22 – 32

Page 38

Flexible Automation

D22 Axis oscilloscope

CC 220 / 320

Diagnosis

The display can be quit by pressing the level return key.

D22 – 33

Page 39

Flexible Automation

D22 Axis oscilloscope

CC 220 / 320

Diagnosis

D22 – 34

Page 40

Flexible Automation

D23 – Contour display

General

User interface/softkey assignments

D23 Contour display

The contour display permits comparison of a programmed contour with the con-

tour generated by the machine tool.

Evaluation is performed by means of the measuring system feedback function with

the resolution set in the machine parameters (P 9901). The actual values are recorded exactly to 1 increment for each sampling step.

If D23 is selected, the control first checks whether file D123 exists. This file is required by D23 to store a recording. If D123 does not exist, it is necessary to enter

the number of desired sampling steps. Approx. 16 KByte of part program memory

is required for D123 for every 1000 sampling steps.

The maximum number of sampling steps is restricted only by the available free part

program memory. The recording duration depends on the number of defined sampling steps and on machine parameter P9901:

T [ms] = number of sampling steps * P9901

Diagnosis

CC 220 / 320

Example: Number of sampling steps = 2000; P9901 = 10

. Duration of recording = 20 s;

required part program memory: approx. 32 KByte

Note:

D123 must be deleted if it is wished to change the number of sampling steps. Only

after this can the number of desired sampling steps be entered again when starting

D23.

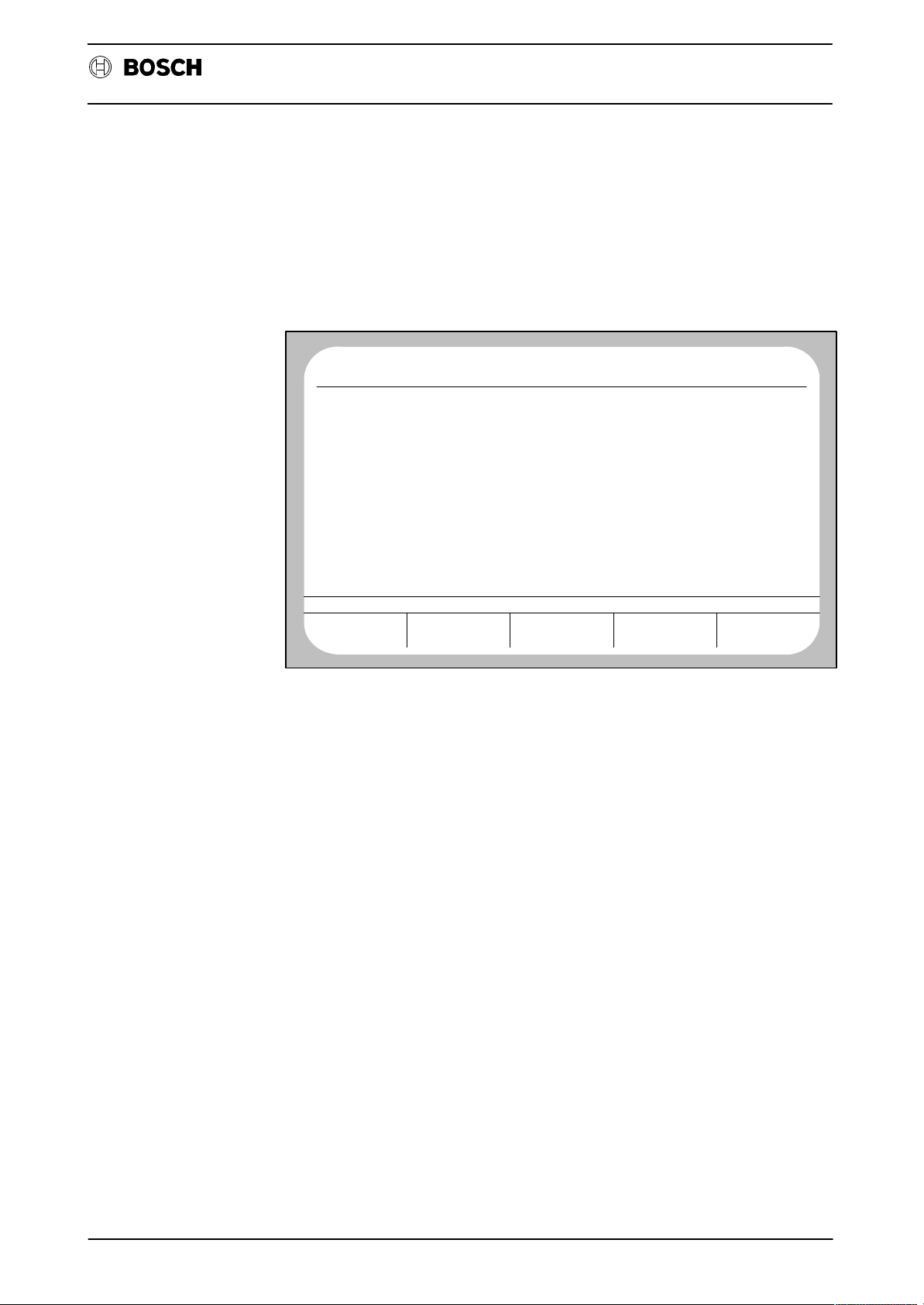

The following display appears when the number of sampling steps has been entered:

No CP0

CONTOUR DISPLAY

WAITING

DISPLAY AXIS:

X:

X

Y:

Y

ACT

ADJUSTMENTS

NC0

STOP

CONTOUR DISPLAY STATUS

DIAGNOSTIC

14.10 8:48PROGRAM

TRIGGER:

JOG BUT TON

SCALING FACTOR

DISPLAY

1st AXIS

STARTING

VALUE

D23 – 35

TRIGGER

START

RECORDING

Page 41

Flexible Automation

STARTING

VALUES

D23 Contour display

CC 220 / 320

Diagnosis

DISPLAY

X–AXIS

DISPLAY

Y–AXIS

Y–AXIS

EXPANSION

X–AXIS

EXPANSION

The softkeys DISPLAY X–AXIS and DISPLAY Y–AXIS are used to assign an arbitrary machine axis (axis number) to the abscissa (DISPLAY X–AXIS) and to the ordinate (DISPLAY Y–AXIS) of the contour diagram.

The softkeys Y–AXIS EXP ANSION and X–AXIS EXPANSION should be used only

in conjunction with D27 (circular compensation).

In order to optimize parameters set with D27, it is necessary to expand the representation of one axis involved in circular interpolation more than the other (e.g. X

and Y). This makes it possible to see the contour errors at quadrant transitions of

a circle more easily.

The expansion factor can be entered separately for each axis (value range: 1 –

1000).

In order to avoid a situation where the contour can no longer be completely dis-

played on the monitor as a result of axis expansion, reduction of the non–expanded

axis by the specified factor occurs instead of an increase in the expanded axis. The

displayed proportions are thus correct.

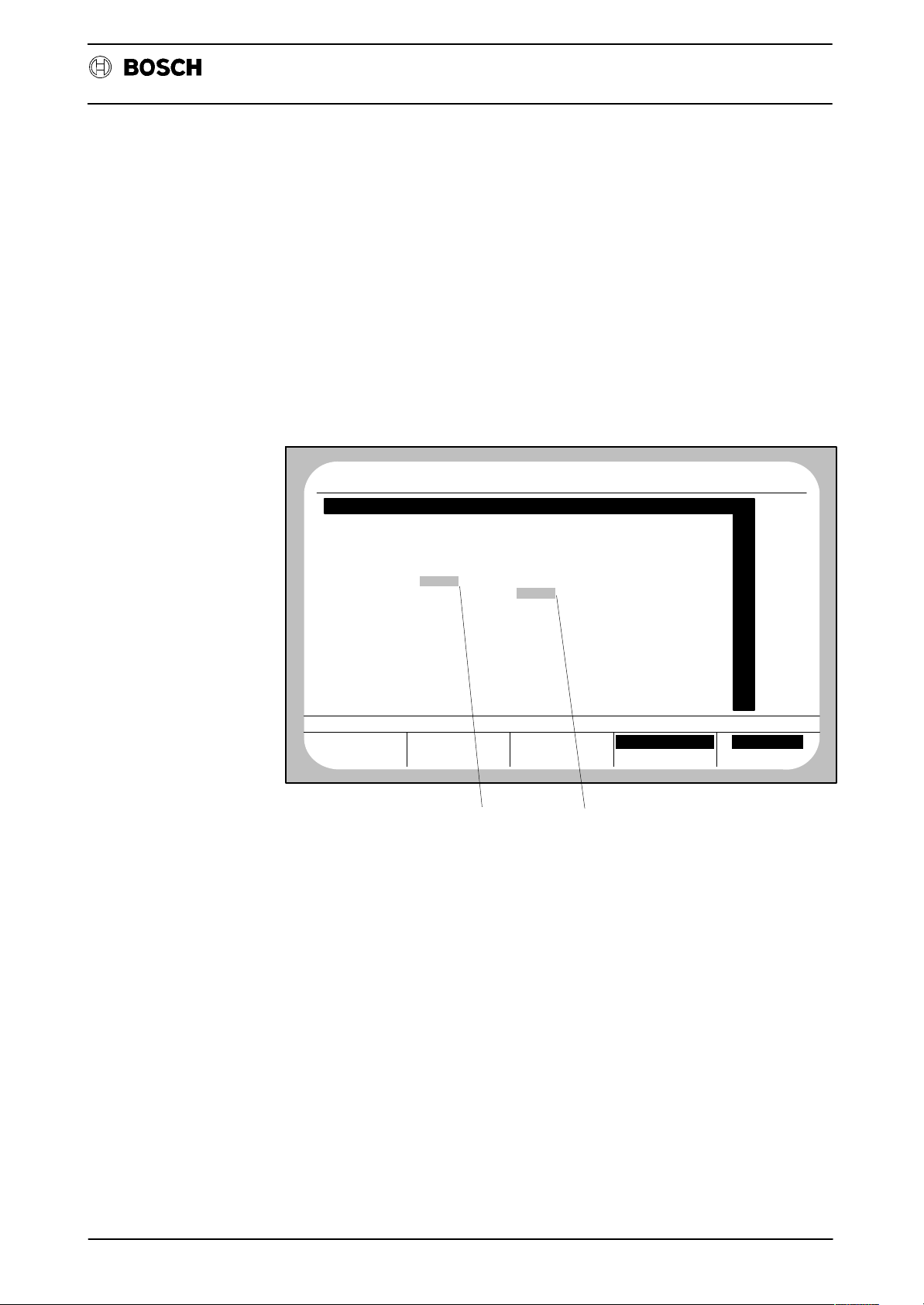

Example:

Y

Y

Y

X

No expansion Y−axis expanded by

a factor of 2

X

X−axis expanded by

a factor of 2

X

Note:

If the function EXPANSION is active for an axis, the text ”AXIS” with the corresponding expansion factor appears on the display under the column ”MAGNIFI.

FACTOR” (refer to softkey DISPLAY) in addition to ”DISPLAY” and ”MAGNIF.”.

D23 – 36

Page 42

Flexible Automation

TRIGGER

D23 Contour display

CC 220 / 320

Diagnosis

MOVE

JOG BUTTON

PROGR. NO.

BLOCK NO.

Definition of trigger condition. When the softkey START RECORDING is pressed,

recording is delayed until the trigger event defined here occurs. The active trigger

condition is indicated by inverted display of the corresponding softkey.

START

RECORDING

After operation of START RECORDING, recording is started when the trigger condition occurs.

The message ”RECORDING” appears under the line ”CONTOUR DISPLAY”. The

status ”WAITING” is displayed here when recording has been completed.

DISPLAY

The contour diagram can be called after the end of a recording by pressing the softkey DISPLAY.

The set and actual contours are shown (set contour: green; actual contour: red).

Two cross–hairs can be moved simultaneously along the contour with the cursor

keys

tion and

. results in cross–hair movement opposite to the machining direc-

in movement in machining direction.

The values for axis position and axis speed (referred to the contour locations

marked by the cross–hairs) are displayed on the left of the monitor.

The ”movement speed” of the cross–hairs can be preselected with the softkey

<<

<

(see next monitor display). The active mode is shown inverted on the softkey:

<< Fast movement (step distance = 10 sampling steps)

< Slow movement (step distance = 1 sampling step).

D23 – 37

Page 43

Flexible Automation

D23 Contour display

CC 220 / 320

Diagnosis

MAGNIFI. FACTOR

DISPLAY

MAGNIF.

CURSOR VALUE

COMMAND−POS.

X 47.883

47.883Y

ACTUAL−POS.

X 48.618

49.110Y

COMMAND−SPEED

X −0.708

−0.708Y

ACTUAL−SPEED

X −0.243

−0.531Y

1.00

Y

X

<<

<

The whole display or part of it can be magnified with the MAGNIFIER key in order

to examine certain contour locations.

A frame appears on the screen after operation of the MAGNIFIER key . In addition,

the following softkey bar is offered:

MAGNIFI. FACTOR

DISPLAY

MAGNIF.

CURSOR VALUE

COMMAND−POS.

X 47.883

47.883Y

ACTUAL−POS.

X 48.618

49.110Y

COMMAND−SPEED

X −0.708

−0.708Y

ACTUAL−SPEED

X −0.243

−0.531Y

1.00

10.00

Y

X

ON OFF + −

ON

<<

<

Magnification of the displayed frame content to the complete display area of the

monitor. The cross–hairs stay in their current position and may thus not be visible

initially after magnification.

OFF

Deactivation of the magnifier function. The graphic display is built up again without

magnification. The cross–hairs stay in their current positions.

D23 – 38

Page 44

Flexible Automation

D23 Contour display

+ –

Magnification or reduction in size of the displayed magnifier frame.

The step distance by which the frame is magnified or reduced each time the soft-

keys ”+” or ”–” are pressed can be set by means of the softkey <<< .

The frame can be moved arbitrarily with the cursor keys while the magnifier frame

is displayed on the monitor.

The step width by which the frame is moved can be adjusted by way of softkey

<<

<

.

Example: Magnified display of the previously marked screen section.

Y

MAGNIFI. FACTOR

DISPLAY

MAGNIF.

CURSOR VALUE

COMMAND−POS.

X 47.883

47.883Y

ACTUAL−POS.

X 48.618

49.110Y

COMMAND−SPEED

X −0.708

−0.708Y

ACTUAL−SPEED

X −0.243

−0.531Y

10.00

10.00

Diagnosis

X

CC 220 / 320

ON OFF + −

<<

<

Note:

‘ It is possible to perform magnification several times successively. However,

when the displayed values under the column ”MAGNIFI. FACTOR” are re-

placed by an asterisk, magnification should be stopped.

D23 – 39

Page 45

Flexible Automation

D23 Contour display

CC 220 / 320

Diagnosis

D23 – 40

Page 46

Flexible Automation

D24 – Axis optimization

General

D24 Axis optimization

The servo loops of the control must be adapted to the drives used. The diagnostic

program D24 offers the following functions for this purpose:

‘ Definition of a step function (speed) for each applied axis.

‘ Graphic representation of the axis reaction to the step function (as speed

characteristic) and numeric display of the determined servo loop parameters.

‘ Display of position, lag, offset and required lag of all axes.

‘ Modification of the active required closed–loop gain.

‘ Offset adjustment of one axis.

‘ Acceptance of the optimized closed–loop gain and offset values in the ma-

chine parameters.

Diagnosis

CC 220 / 320

The axis reaction is always measured by recording of 160 actual axis position values. The time between 2 sampling operations corresponds to the value entered in

machine parameter P9901. The recording time is thus 1.6 s if P9901 = 10 ms.

User interface/softkey assignment

The following monitor display appears after selection of D24:

No CP0

AXIS OPTIMIZATION

WAITING

DISPLAY AXIS:

TIME SCALE (SEC):

TRAVEL RANGE (MM):

TARGET VALUE (M/MIN):

SERVO LOOP WITH SLOPE

ACCELERATE

DISPLAY

ACT

ADJUSTMENTS

STARTING

VALUES

NC0

WAIT

AXIS OPTIMIZATION STATUS

X

0.50

100

1.00

MACHINE

PARAMETER

SELECTION

AXIS

DIAGNOSTIC

20.2 17:2PROGRAM

START

RECORDING

AXIS

SELECTION

Selection of the machine axis which it is wished to optimize by input of the axis number.

D24 – 41

Page 47

Flexible Automation

D24 Axis optimization

STARTING

VALUES

CC 220 / 320

Diagnosis

SERVO O/P

SERVO LOOP

SERVO O/P

SERVO LOOP

DECELERATE/

ACCELERATE

TARGET

VALUE

TRAVEL

RANGE

Selection of the following operating modes is possible by repeated operation of this

softkey:

‘ SERVO LOOP WITH SLOPE: The axis accelerates to the speed en-

tered on the softkey TARGET VALUE

with a slope. The servo loop is closed

during this operation (refer to machine

parameter P1002 for details of slope).

‘ SERVO LOOP WITHOUT SLOPE: The axis accelerates without slope to

the speed entered under the softkey

TARGET VALUE. The servo loop is

closed during this operation (refer to

machine parameter P1002 for details of

slope).

‘ SERVO OUTPUT: The servo loop is open. The axis tra-

verses at the speed which was entered

under the softkey TARGET VALUE.

The measuring system is used only for

speed measurement.

DECELERATE

ACCELERATE

Selection of acceleration or deceleration.

TARGET

VALUE

It is possible to define the desired axis speed in m/min. here. 10 % of the maximum

speed (refer to machine parameter P501) is stored as a default value for the modes

SERVO LOOP with/without SLOPE. The entered value is interpreted in V in

SERVO OUTPUT mode (default value:

1.5 V).

TRAVEL

RANGE

Input of the maximum distance which may be traversed for a single measurement

(corresponds to an incremental value as from the starting position!). If the limit

value entered here should be exceeded during the measurement, the axis will stop

and a corresponding message is displayed.

Please note the maximum traversing range of your machine if you perform

several successive measurements!

D24 – 42

Page 48

Flexible Automation

D24 Axis optimization

MACHINE

PARAMETER

The following display appears:

CC 220 / 320

Diagnosis

No CP0

PROGRAM

POSITION LAG OFFSET REQIRED LAG

X

0.000

Y

0.000

Z

0.000

0.000

OFFSET−ADJ

AUTO

ACT

X

Y

Z

OFFSET−ADJ

MANUAL

0.000

0.000

0.000

0.000

NC0

STOP

X

Y

Z

REQUIRED

0.002

0.000

0.000

0.000

LAG

X

Y

Z

DIAGNOSTIC

2000.000

2000.000

10000.000

10000.000

ACTIVATE

Offset and required lag values of all axes can be changed on this operating level.

Select the axis where you wish to change the values with the cursor keys

.

SERVO

SERVO

OFFSET–ADJ

AUTO

OFFSET–ADJ

MANUAL

Automatic or manual offset adjustment. The lag should set itself to zero when

the offset has been entered or automatically adjusted. The changed offset value

is transferred directly to the axis processor and is thus active. The machine parameter record is not yet changed at this point in time. Active offset values remain active

until they are overwritten by other offset values or until the control is reset.

REQUIRED

LAG

Input of a new required lag value. This input must be made with care in order to

exclude incorrect drive response.

The required lag is calculated as follows:

Required lag = max. axis speed (P501)/required closed loop gain (P1001).

If the required lag is changed by means of this softkey, the new value becomes active for the corresponding axis when the ENTER key is pressed. For this purpose,

the CNC adapts the currently active required closed loop gain in accordance with

the above relationship (the maximum axis speed remains constant).

The entered value remains active until the control is reset or until a different value

is entered.

The CNC modifies machine parameter P1001 correspondingly if the required lag

is changed by means of the softkey REQUIRED LAG and this value then transferred to the machine parameter record (by softkey ACTIVATE). P501 remains

constant. The new values are then active after each control run–up.

D24 – 43

Page 49

Flexible Automation

MP

D24 Axis optimization

ACTIVATE

All currently active closed loop gain and offset values are immediately transferred

to the machine parameter record when the softkey ACTIVATE is pressed. The

READY 2 signal is cancelled and a new control run–up takes place.

Caution:

The new values are not transferred to the file L444, if this file should exist. If you

wish the file L444 to contain the modified values, you must first delete L444 after

transfer and then regenerate it (with/without texts).

Diagnosis

CC 220 / 320

D24 – 44

Page 50

Flexible Automation

MOVE

D24 Axis optimization

START

RECORDING

When this softkey is pressed, the text under AXIS OPTIMIZATION changes from

”WAITING” to ”RECORDING”. The instruction ”ACTIVATE JOG BUTTON” ap-

pears in the message line.

The traversing movement starts after operation of the jog button (also without

approached reference point or active jog mode!)

DISPLAY

The step response of the corresponding axis can be displayed as a graph after

completion of a recording by pressing the softkey DISPLAY:

Diagnosis

CC 220 / 320

ABSOLUTE VALUE

(M/MIN)

XI

1.00

CHARACTERISTIC

DELAY TIME

0.000 S

TU

REACTION TIME

TA 0.136

OVERSHOOT

UE 44.600

CHAR.FREQ.

WO 68.837

DAMPING

DA 0.320

I.S.E.

3.7

KV

8.867

S

X

1/S

XI

T

One scale division of the time axis (T) always corresponds to 50 sampling steps.

Consequently, the corresponding time interval of a scale division is nt = 50*P9901

(the time interval of a scale divisions is also displayed numerically in the start

screen of D24 under the column ADJUSTMENTS as ”TIME SCALE (SEC):”).

One scale division of the absicissa (XI) always corresponds to 10 % of the currently

set target value.

In addition to the graph, the CNC also displays the internally calculated characteristic servo loop values on the left side of the screen:

XI: Currently active target value

TU: Delay time

TA: Reaction time

UE: Overshoot (in % of XI)

WO: Characteristic frequency (characterized by envelope curve A

in following figure)

DA: Damping (characterized by n1/n2 in the following figure)

I.S.E.: Quadratic control area

KV

: Actual closed loop gain factor

act

= measured speed/measured lag (at last sampling step).

KV

act

D24 – 45

Page 51

Flexible Automation

D24 Axis optimization

Notes:

‘ If the CNC cannot calculate characteristic values which are sufficiently accu-

rate, question marks are displayed instead of the numbers.

‘ Range transgression of a calculated number (numeric value is greater than

the display range) is indicated by the CNC by ”*****”.

Interrelationships of the servo loop characteristics:

Diagnosis

CC 220 / 320

D1

V

D2

TU TA

D1 Magnitude of the 1st overshoot

D2 Magnitude of the 2nd overshoot

WP Reversing point

A Envelope curve

Setpoint speed

V

Set

A

V

Set

WP

TU Delay time

TA Reaction time

5%−

limit

t

Optimization instructions

While the setpoint speed should be reached as quickly as possible for pure positioning operations (thus accepting overshoot), a compromise must be reached between fast attainment of the setpoint speed and the minimum possible overshoot

(contour violation by overshoot) in the case of machining operations (tool engaged).

D24 – 46

Page 52

Flexible Automation

D25 – Lead screw error compensation

General

D25 Lead screw error compensation

The lead screw error compensation function permits compensation of the mechanical inaccuracies of drive spindles or rack drives. It is possible to determine and

compensate both linearity errors as well as reversing backlash.

In order to permit compensation, an error curve is recorded for each axis traversing

direction for each machine axis to be compensated. The actual axis position is

measured exactly with an external device for this purpose. The established compensation data is entered in the files L101–L108 using this diagnostic program. After activation of the function (refer to the section ”General information” at the end

of this chapter), the control corrects the corresponding machine positions automatically.

Note:

Diagnosis

CC 220 / 320

The machine parameter P1509 (reversing backlash) is no longer active if the lead

screw error compensation is active.

User interface/softkey assignment

The following display is an example of the display which will appear on the screen

after selection of D25:

No CP0

AXIS LEAD SCREW ERROR POSITION

X

Y

Z

ACT

NC0

WAIT

0 INCREMENTS

INCREMENTS

0

INCREMENTS

0

DIAGNOSTIC

14.10 8:49PROGRAM

5

INCREMENTS

−

2

4

INCREMENTS

INCREMENTS

EDIT DATA IN PRERUN DATA OUT MANAGE

DATA IN DATA OUT

These keys are used to read the compensation files (L101–L108) in or out via the

standard interfaces of the CNC.

Please refer to the operating manual for further information on reading data in/out.

D25 – 47

Page 53

Flexible Automation

D25 Lead screw error compensation

MANAGE

Deletion of the displayed L files.

All compensation files (L101–L108) are deleted (if present) by the softkey DELETE

ALL. Other files are not deleted by this softkey.

Diagnosis

CC 220 / 320

DATA

It is possible to selectively delete individual files by means of the softkey DELETE